Nutritional healthcare ice cream containing vegetable protein, and making method thereof

A technology of plant protein and production method, applied in frozen sweets, food science, application, etc., can solve problems such as excessive intake of cholesterol and fat, overnutrition, obesity, etc., achieve lower serum cholesterol, high sweetness, and delay aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

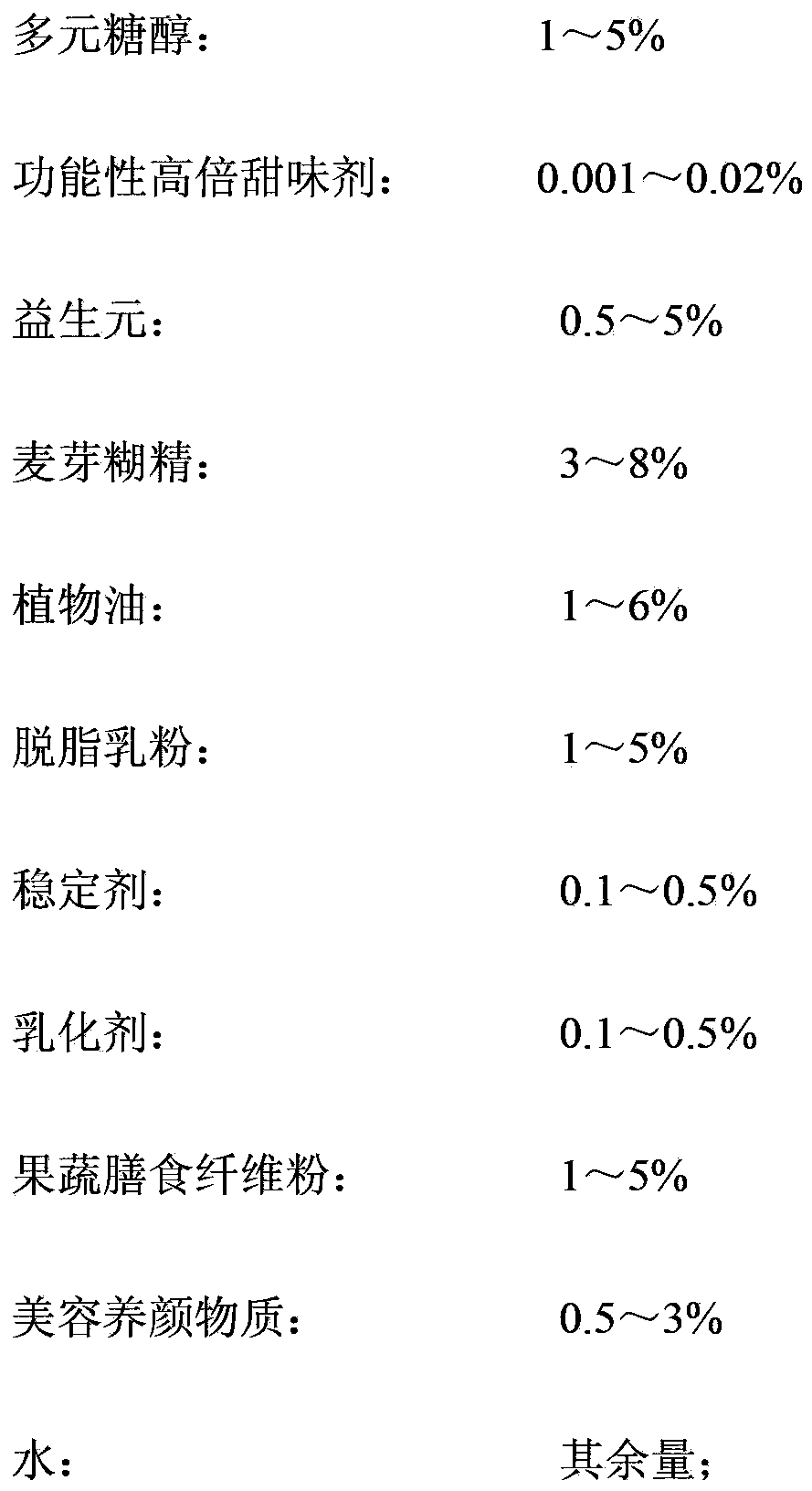

[0033] A kind of preparation method of vegetable protein nutritional health type ice cream, its component and mass percentage are:

[0034]

[0035]

[0036] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0037] 1) Pre-homogenization: After mixing 2kg of soybean protein, 4kg of soybean oil and 20kg of water, homogenize under a pressure of 150bar to obtain a soybean protein emulsion;

[0038] 2) Sterilization: Stir and mix the soybean protein emulsion prepared in step 1) and the remaining raw materials evenly, then sterilize in a sterilization tank at 90°C for 15 minutes,

[0039] 3) Homogenization: control the temperature to drop to 60°C after sterilization, and homogenize at 100bar for 7 minutes;

[0040] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at this temperature for 2 hours;...

Embodiment 2

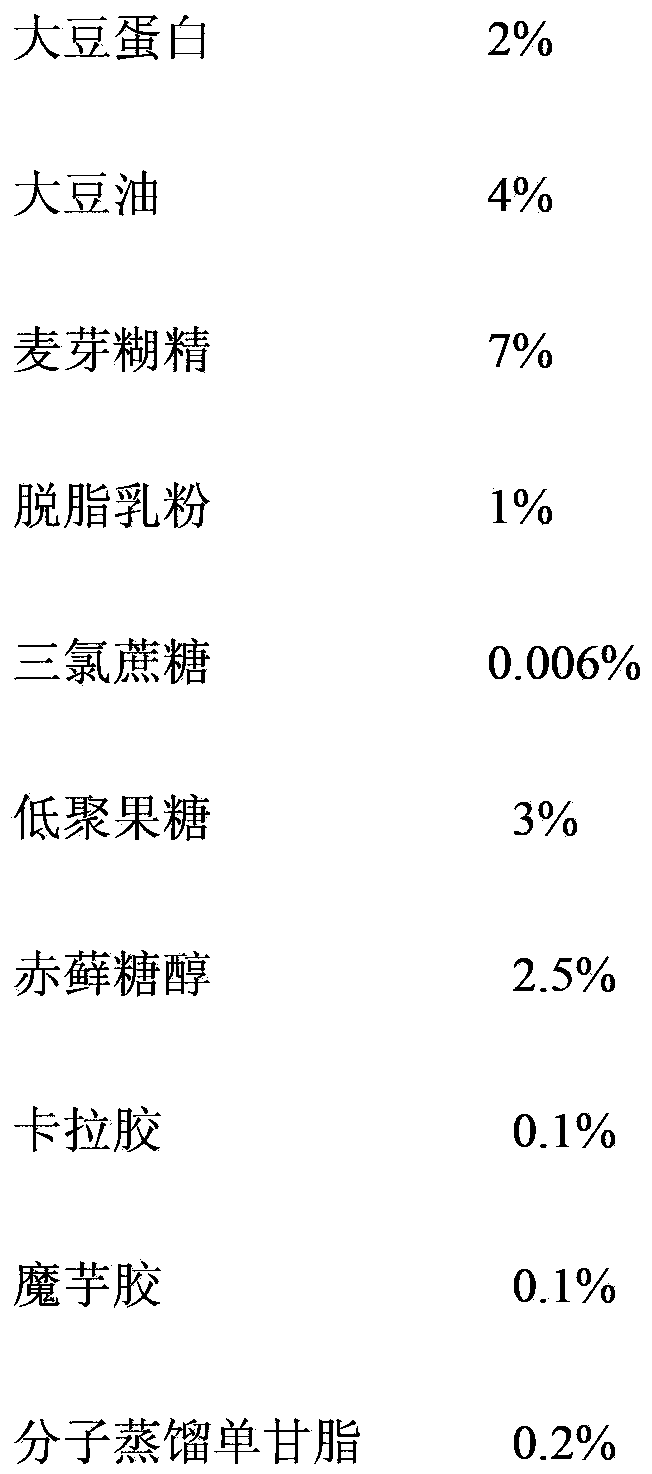

[0044] A kind of preparation method of plant protein nutrition and health type ice cream, its component and weight percentage are:

[0045]

[0046]

[0047] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0048] 1) Pre-homogenization: After mixing 5kg of soybean protein, 6kg of corn germ oil, and 50kg of water, homogenize under a homogenization pressure of 250bar to obtain soybean protein emulsion;

[0049] 2) Sterilization: After the soybean protein emulsion prepared in step 1) is fully stirred and mixed with the remaining raw materials, sterilize in a sterilization tank at 75°C for 30 minutes;

[0050] 3) Homogenization: control the temperature to drop to 65°C after sterilization, and homogenize at 250bar for 10 minutes;

[0051] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at thi...

Embodiment 3

[0055]

[0056] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0057] 1) Pre-homogenization: Mix 1 kg of peanut protein, 1 kg of olive oil, 1 kg of sunflower oil, and 10 kg of water, and then homogenize at 200 bar to obtain a peanut protein emulsion;

[0058] 2) Sterilization: Stir and mix the peanut protein emulsion prepared in step 1) and the remaining components evenly, then sterilize in a sterilization tank at 80°C for 25 minutes;

[0059] 3) Homogenization: control the temperature to drop to 65°C after sterilization, and homogenize at 200bar for 8 minutes;

[0060] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at this temperature for 12 hours;

[0061] 5) Freezing: Use a continuous freezer to freeze the aged liquid in step 4), and stop freezing when the expansion rate reaches 85%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com