Patents

Literature

239results about How to "Small body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

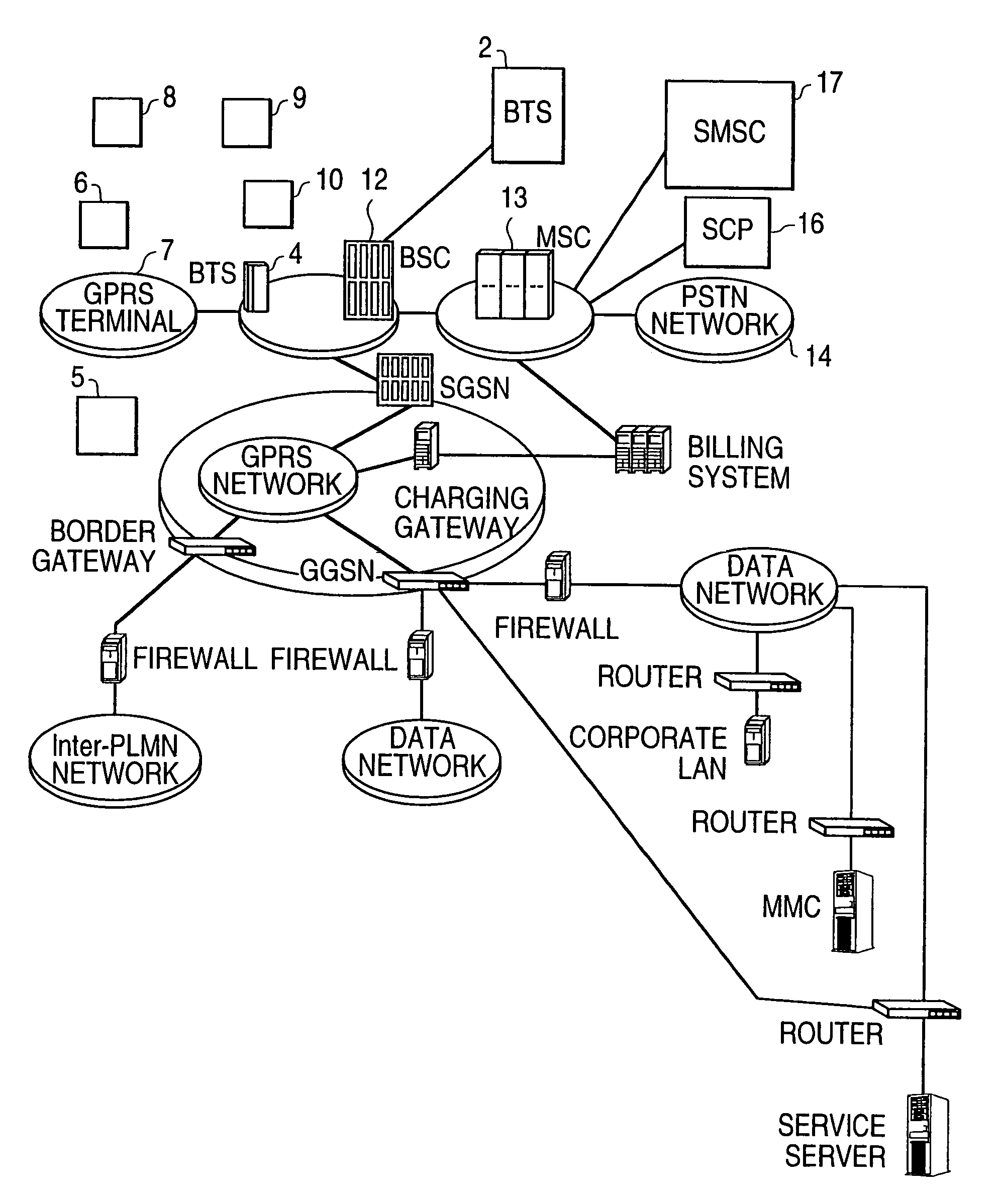

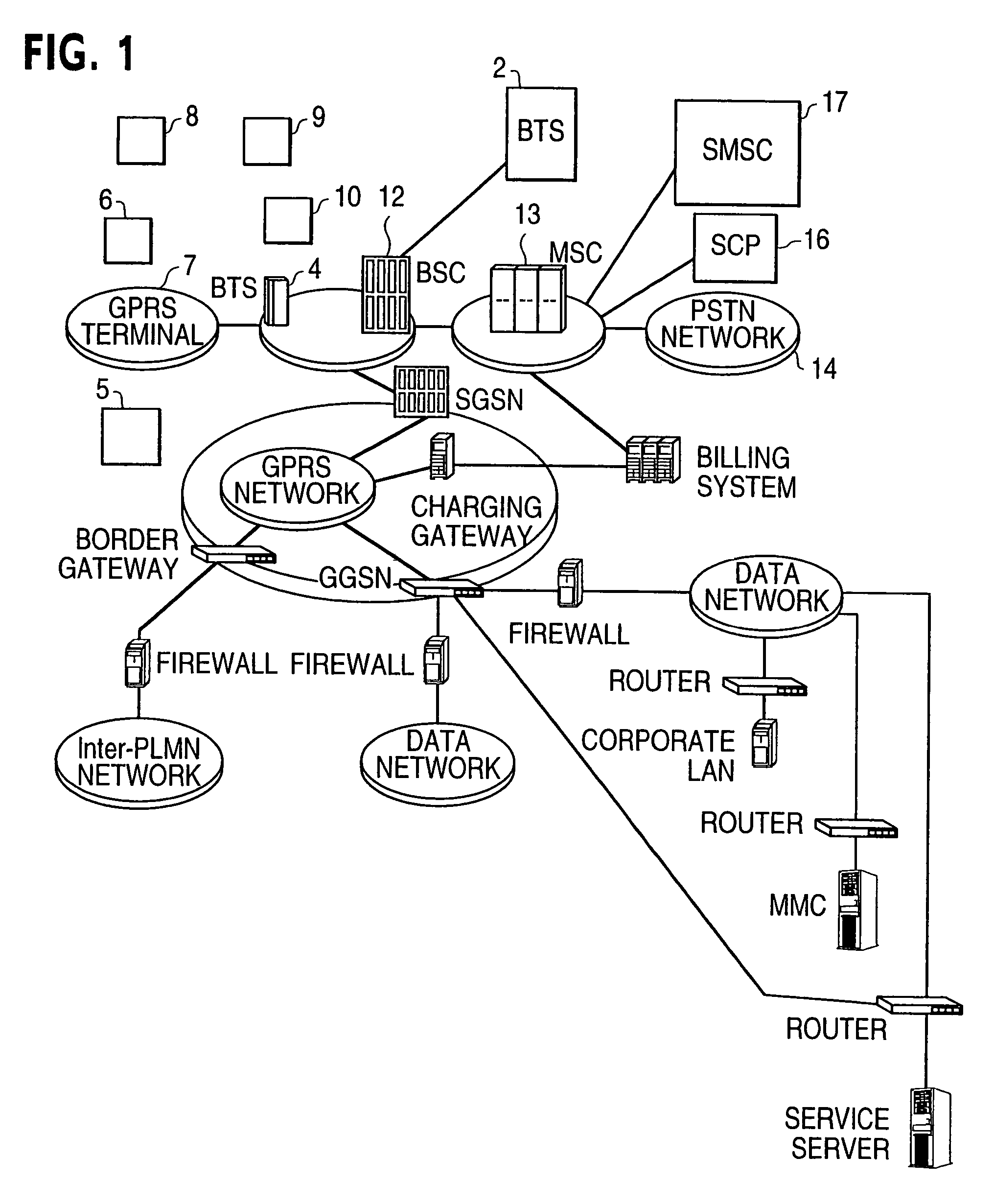

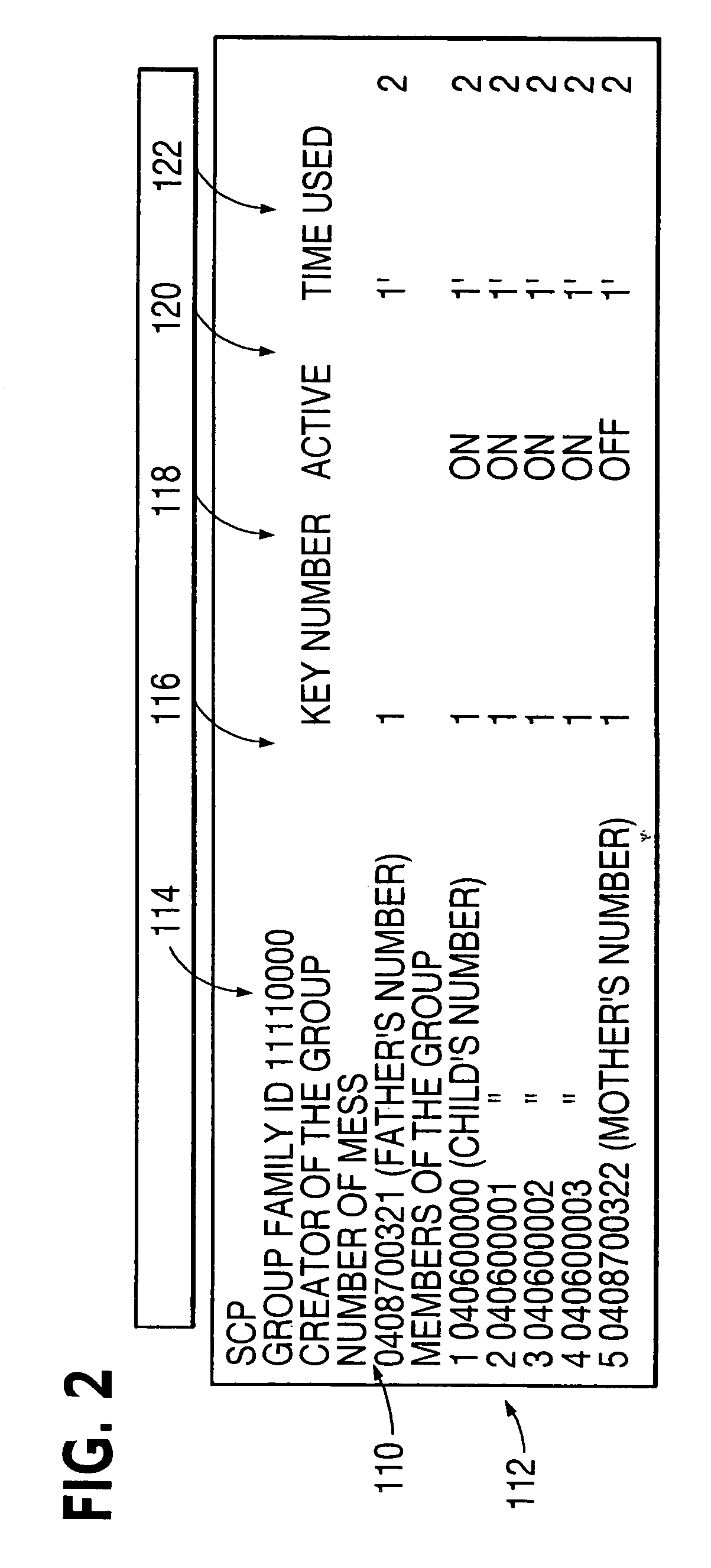

Group communication device and method

InactiveUS7046993B2Easy to useLow production costFrequency-division multiplex detailsSpecial service for subscribersTelecommunications networkCommunication device

A method for voice based communication between a number of mobile terminals of a telecommunication network, the method comprising the steps of creating a group of said number of terminals and storing group information in each of the number of terminals, recording a voice message in one of the terminals of the group, dispatching the voice message to the terminals of the group from the one of the terminals, and receiving the voice message at at least all other terminals of the group. The step of creating a group of terminals further comprises the steps of coupling together a number of mobile terminals, initiating a group creation command from at least one of the terminals, sending predetermined information from terminal to terminal to each terminal of the number of terminals for forming a group information, and transmitting the group information to all of the terminals thus forming a group of the terminals.

Owner:NOKIA CORP

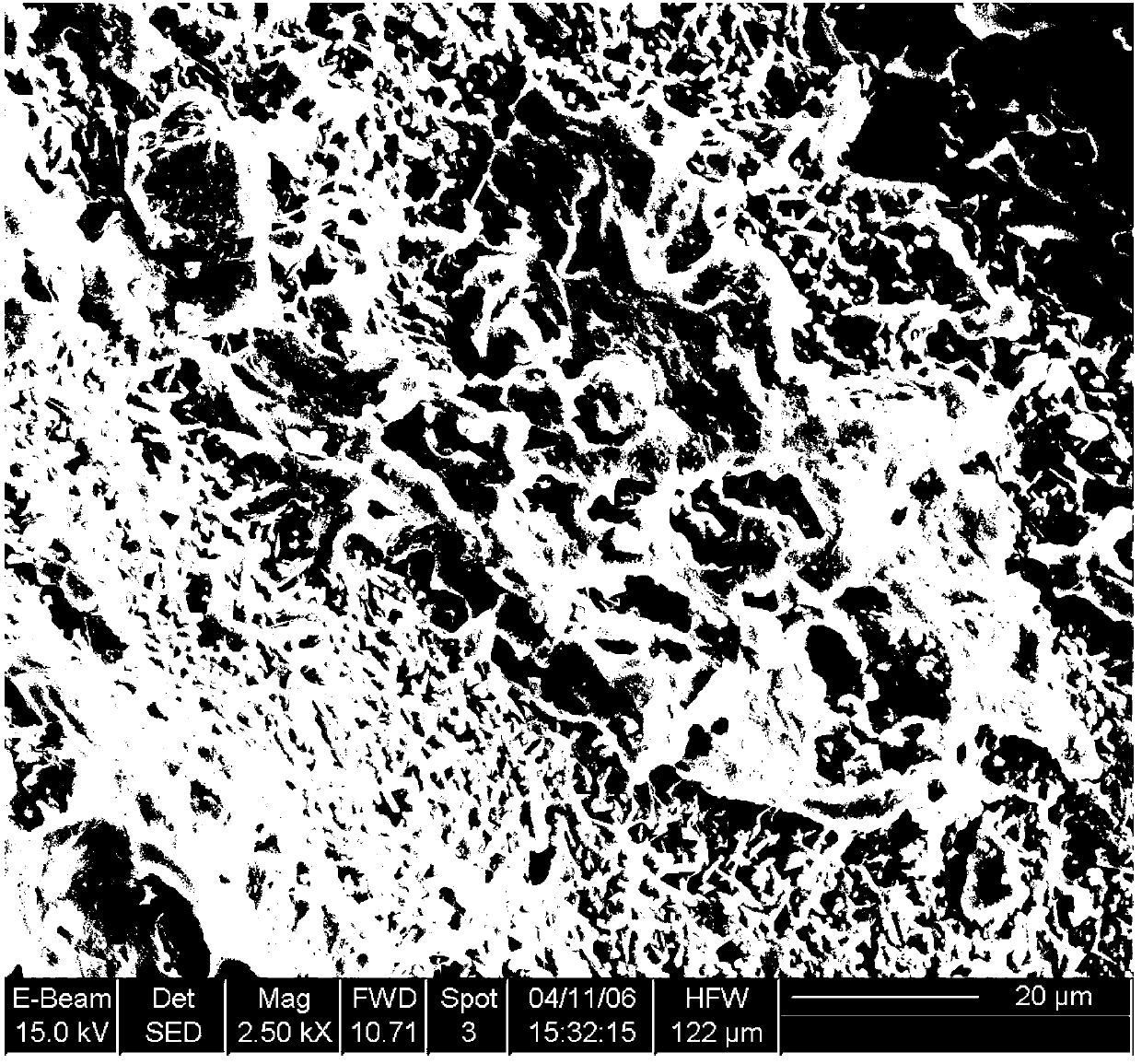

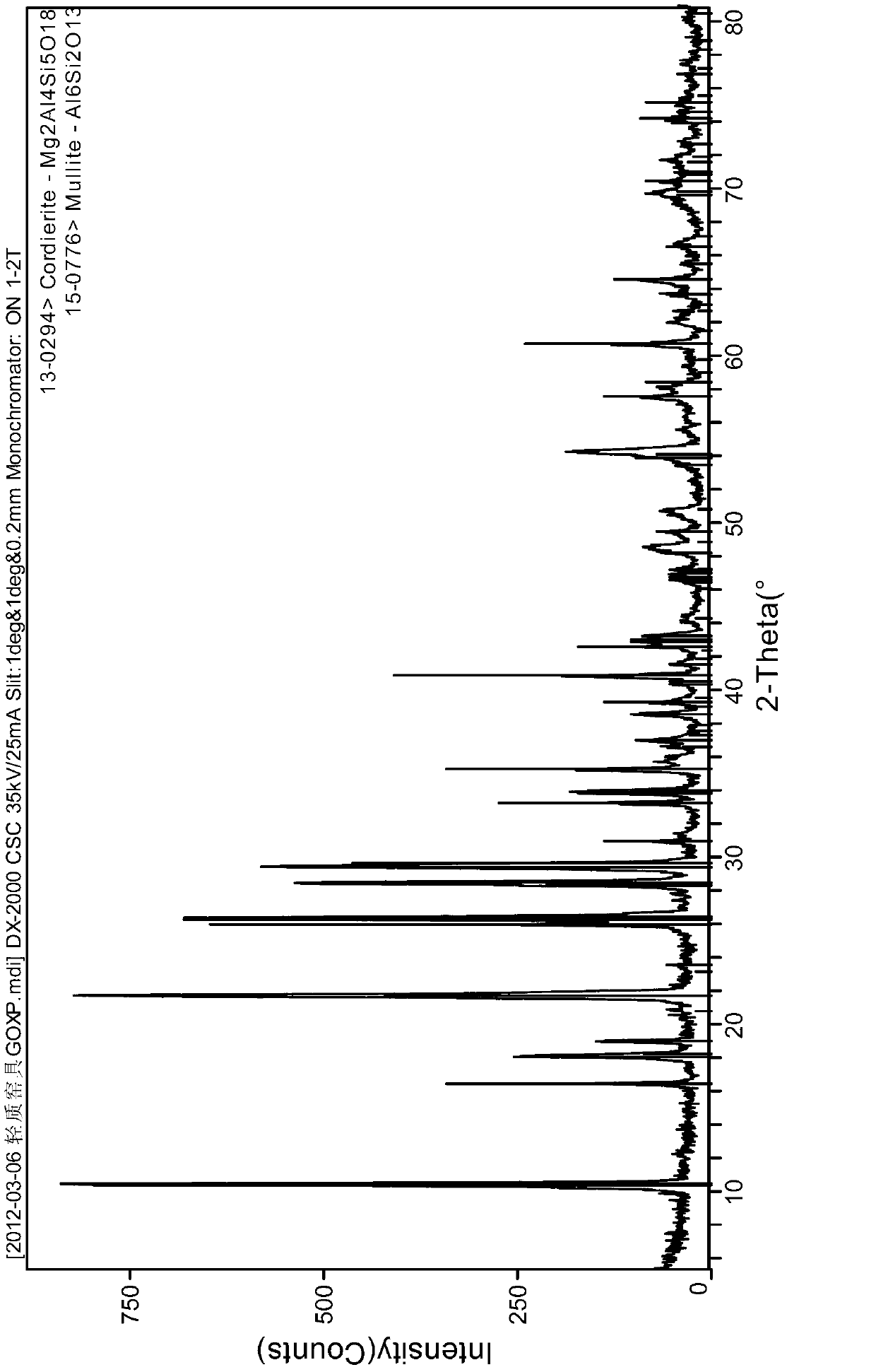

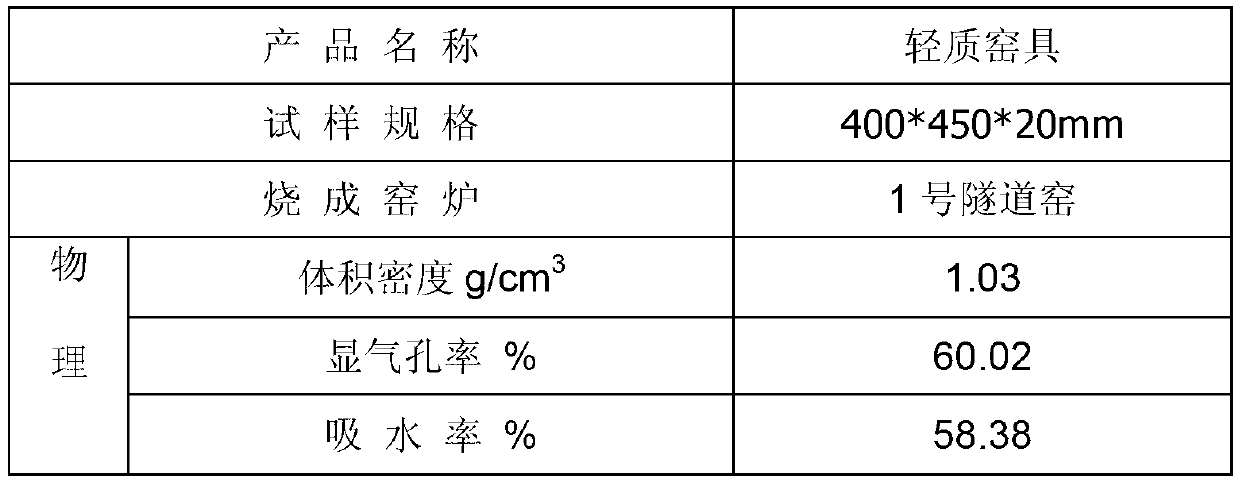

Energy-saving light cordierite-mullite kiln furnace material, kiln furnace and preparation method of material

The invention relates to an energy-saving light cordierite-mullite kiln furnace material, a kiln furnace and a preparation method of the material, and belongs to the field of kiln furnace materials. The preparation method of the kiln furnace material comprises the following steps of: preparing kiln furnace material solid by using floating beads, aquamarine and mullite as aggregates, using magnesium powder, steatite, alumina and clay as substrate materials and adding additives yellow dextrin and wood powder; adding water to the solid for stirring to obtain a mixture, wherein the floating balls are very small in volume density, and are light and hollow materials, so that the product is high in porosity and small in volume density. Besides, the wood powder is evaporated by being fired at high temperature to form more gap structures, so that the volume density of the product is further reduced, and the material is light and energy-saving. During the whole proportioning process, the final material composition is consistent with that of the cordierite-mullite kiln furnace material, and the firing temperature is also kept consistent, so that the product performances are kept to be excellent and not lower than those of the cordierite-mullite material.

Owner:天津创导热材料有限公司

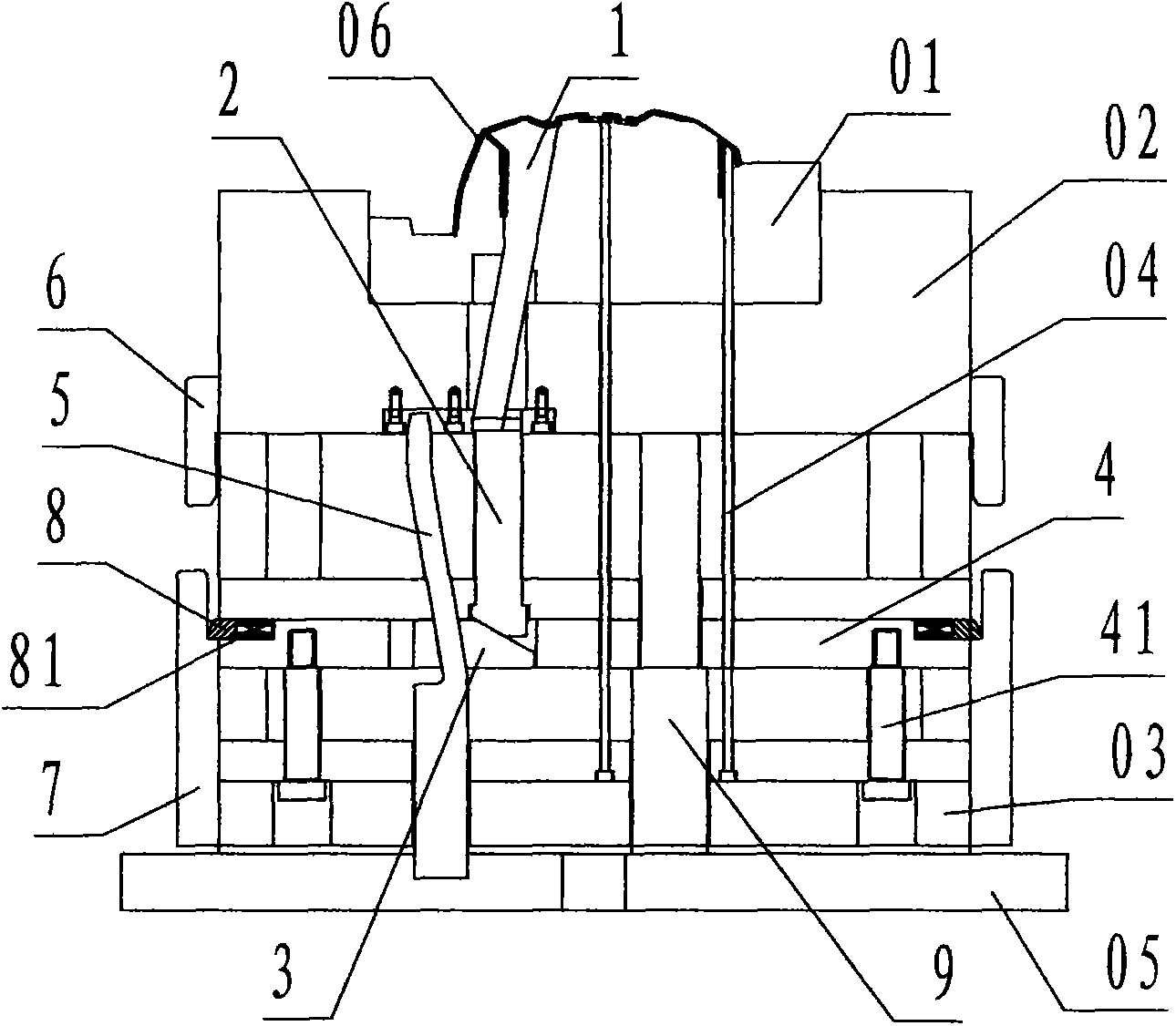

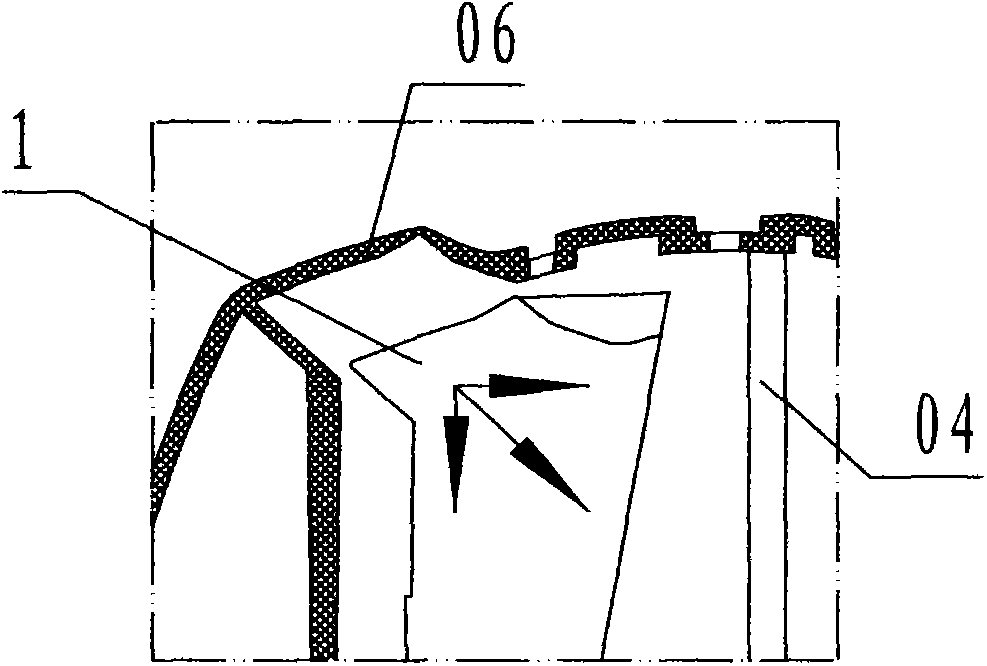

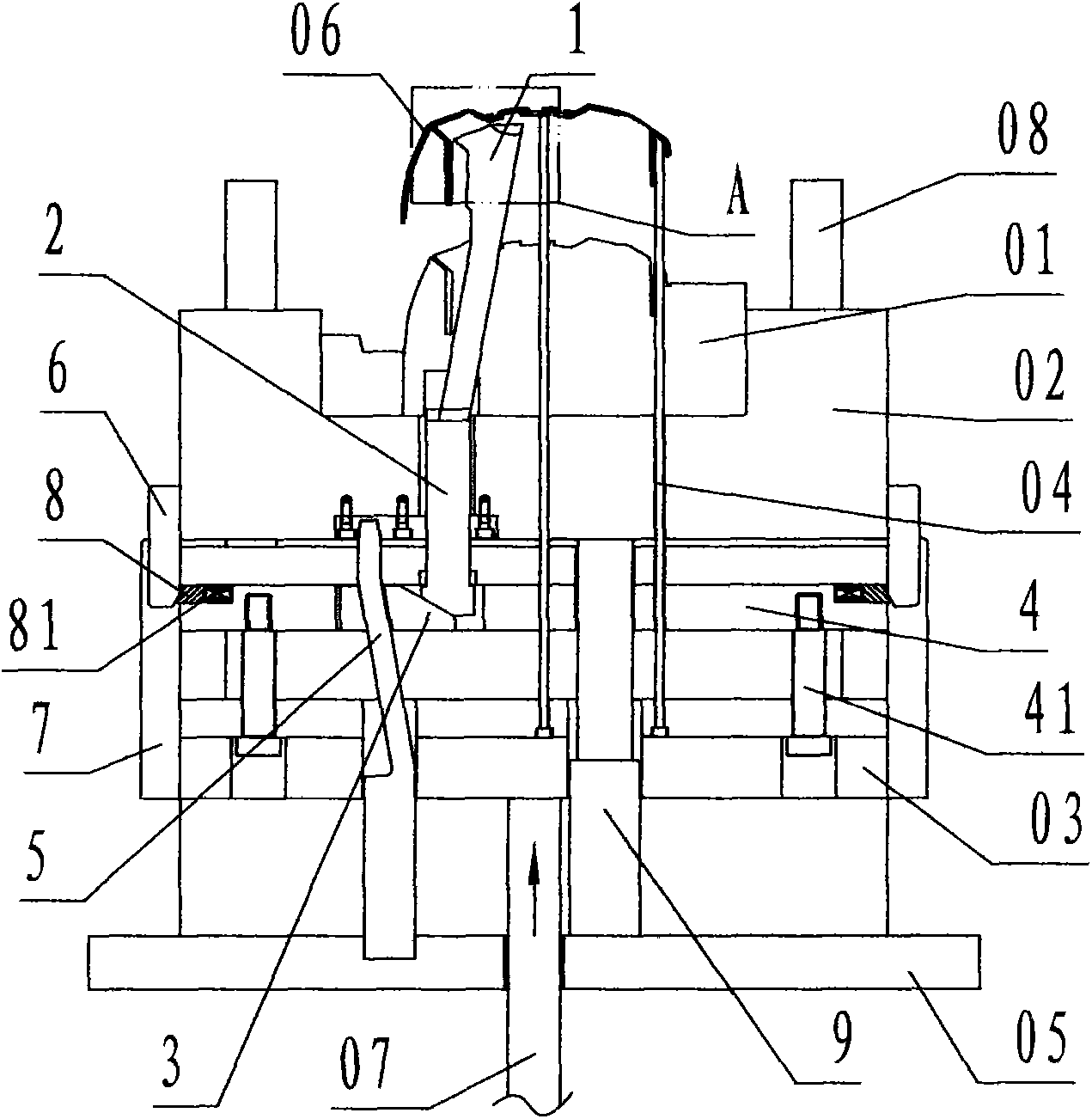

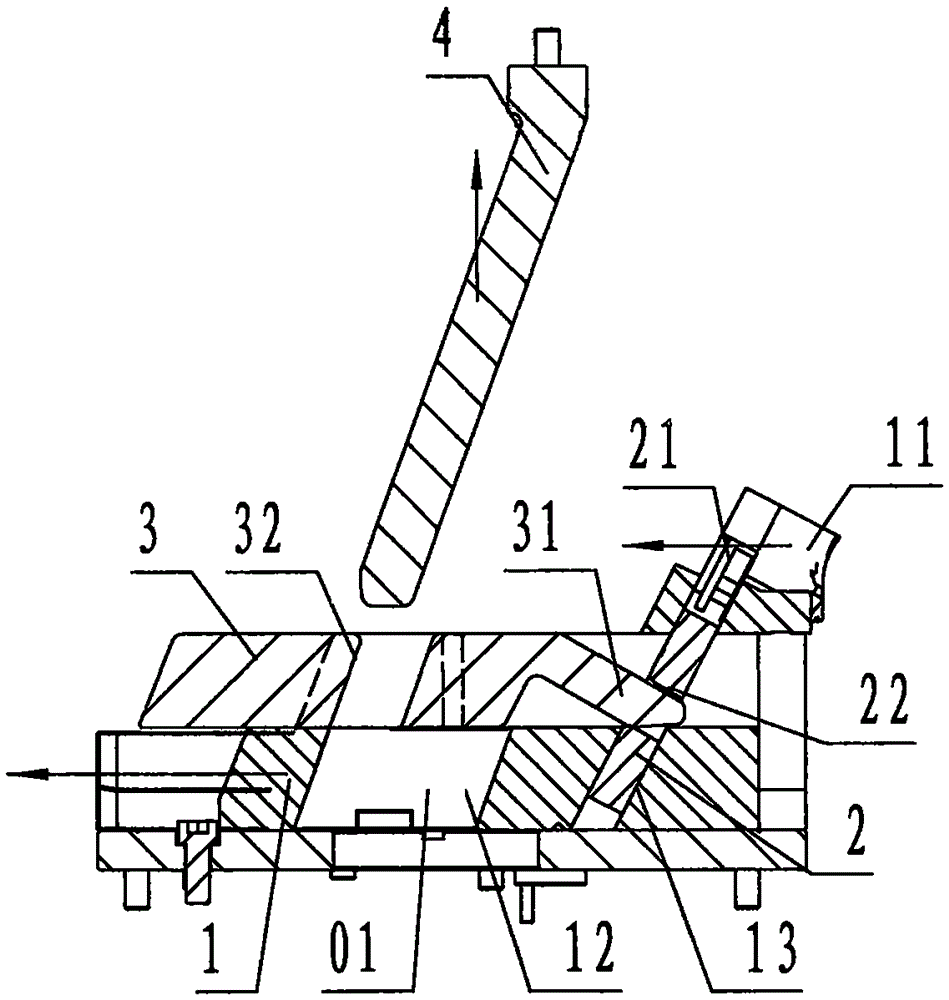

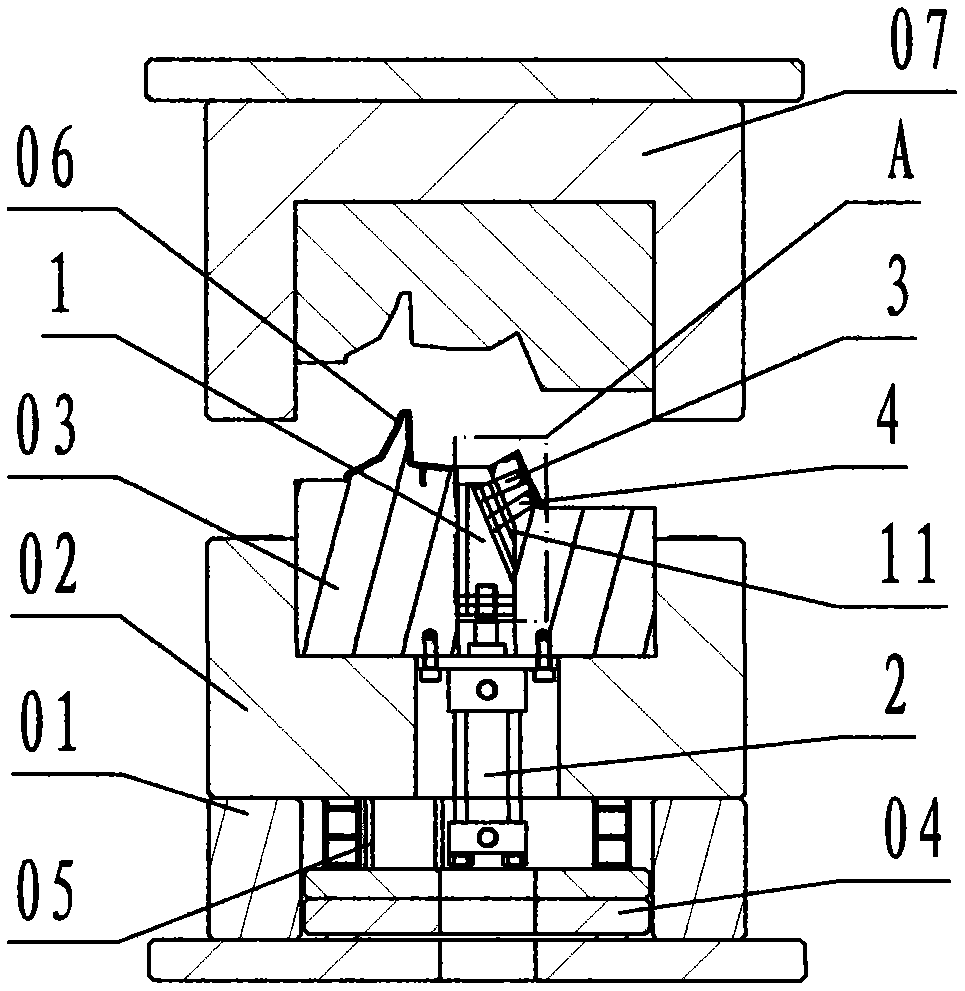

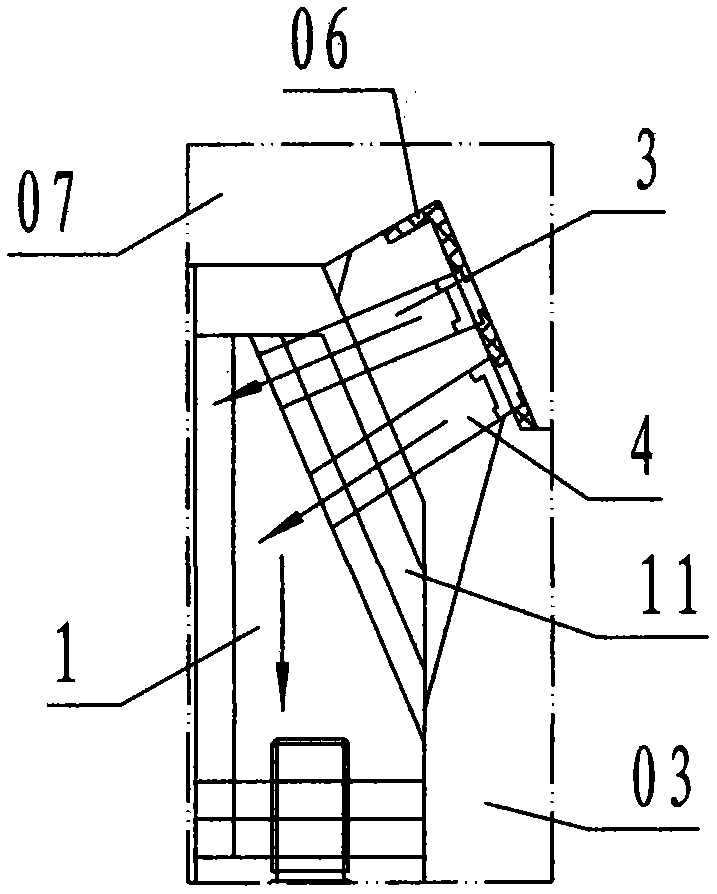

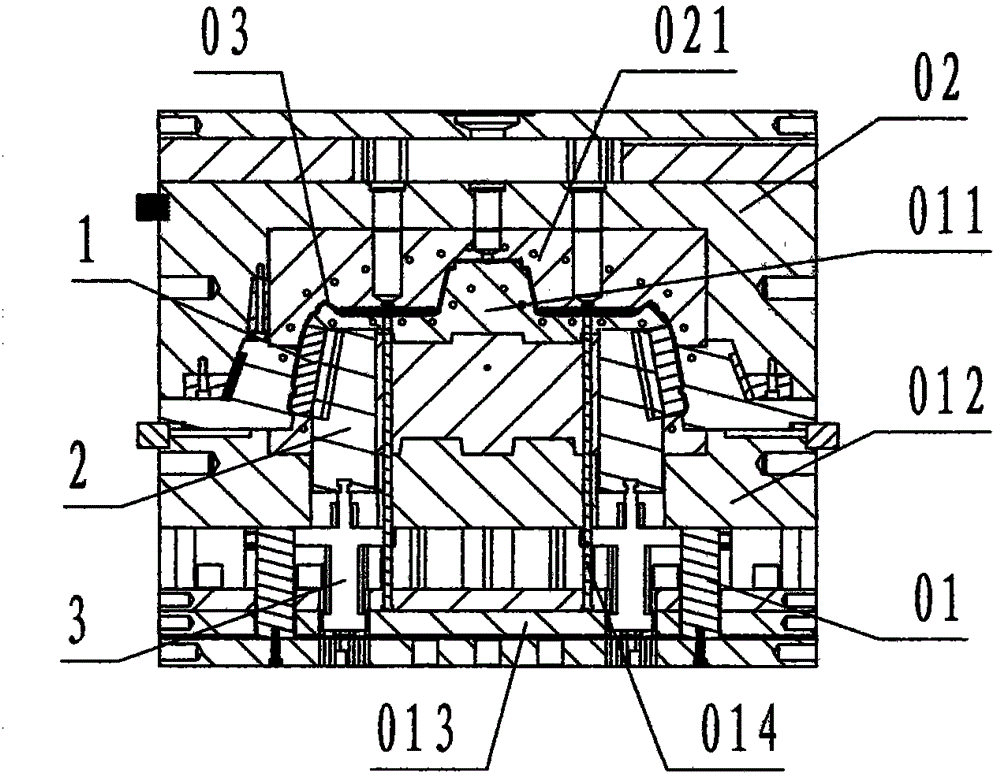

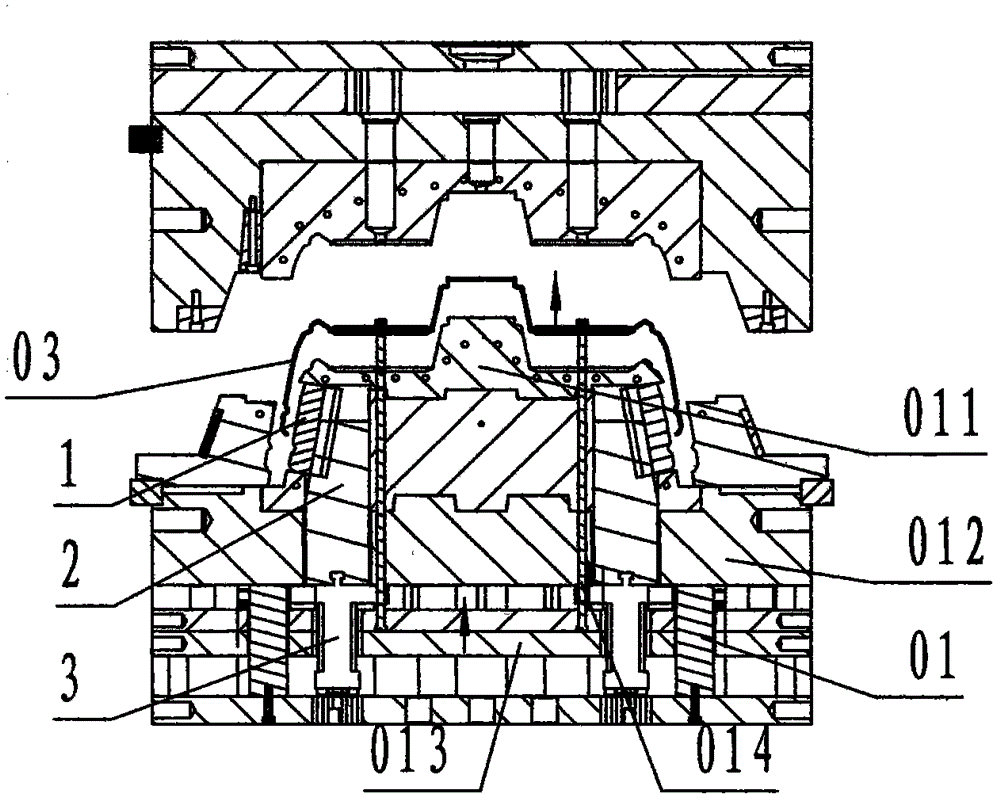

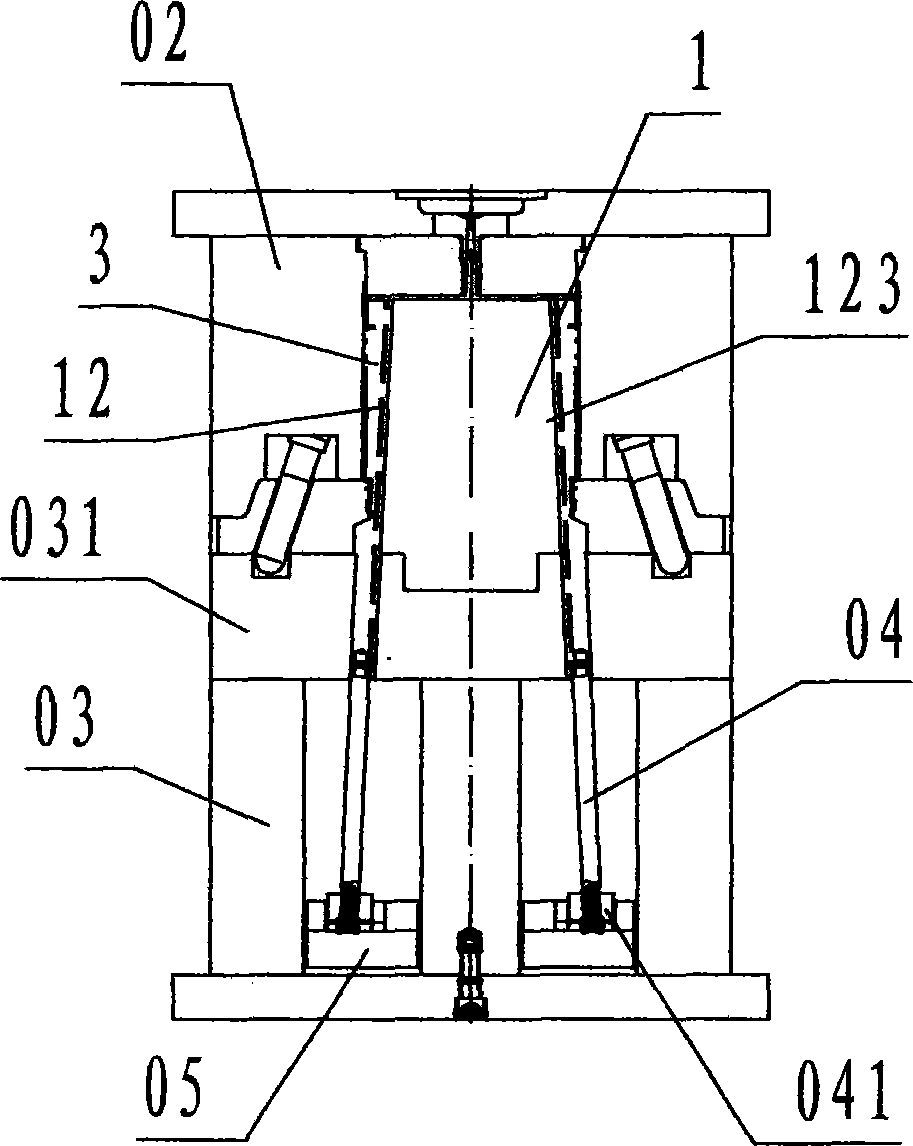

Secondary core-pulling and ejection demoulding device by asynchronous inclined downward ejection

The invention discloses a secondary core-pulling and ejection demoulding device by asynchronous inclined downward ejection. The device provided by the invention comprises an inclined ejection core block (1), a vertical slide block (2), a transverse slide block (3), a transverse slide block support plate (4), a poke rod (5), a deblocking block (6), a latch hook block (7), a spring bolt block (8) and a limit guide pillar (9). By the adoption of the device composed of the above members, the technical scheme of bidirectional backoff core-pulling demoulding is realized by a asynchronous inclined downward ejection mode, problems and insufficiencies of complex structure, large size and high cost existing in the prior art are overcome, and structure simplification, size reduction and cost reduction purposes of an injection mould which requires vertical and horizontal bidirectional backoff core-pulling are achieved.

Owner:NINGBO SHUANGLIN MOULD CO LTD

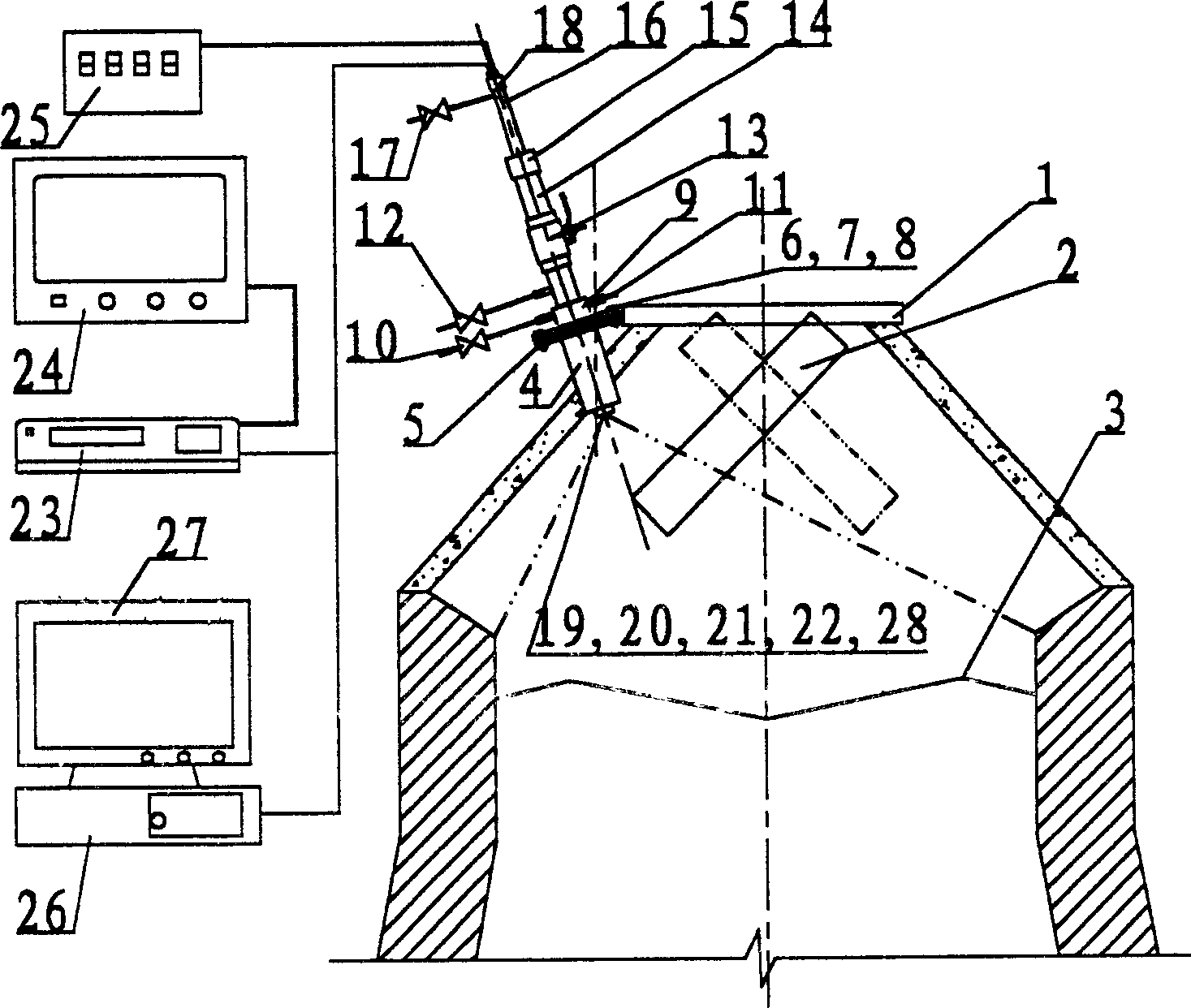

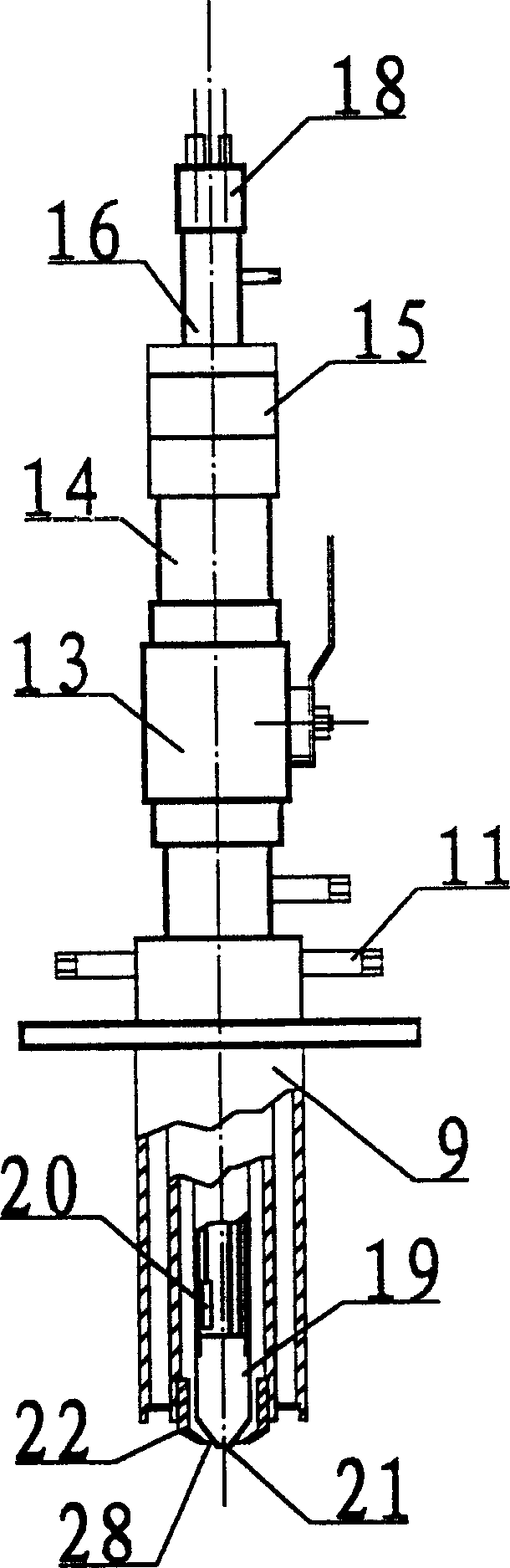

Image processing method for processing image of plug in type stove camera

InactiveCN1505387ASmall apertureReduce dosageTelevision system detailsFurnace componentsImaging processingDigital thermometers

The invention provides an image process method for image generated by plug-type camera in stove, especially monitors the work state of fuel in the stove in process of puddling high furnace, and uses computer to process the image in order to describe the air and temperature distribution state of fuel, monitor the work state of chute and big clock and the material flow state, and monitor the abnormal state of tube and material collapsing in stove. The camera is made up of the body, camera, monitor, digital thermometer, computer and color monitor. The advantages lie in: it uses micro-camera without moving part to acquire the infrared image in stove, and uses the computer to process the image.

Owner:UNIV OF SCI & TECH BEIJING +1

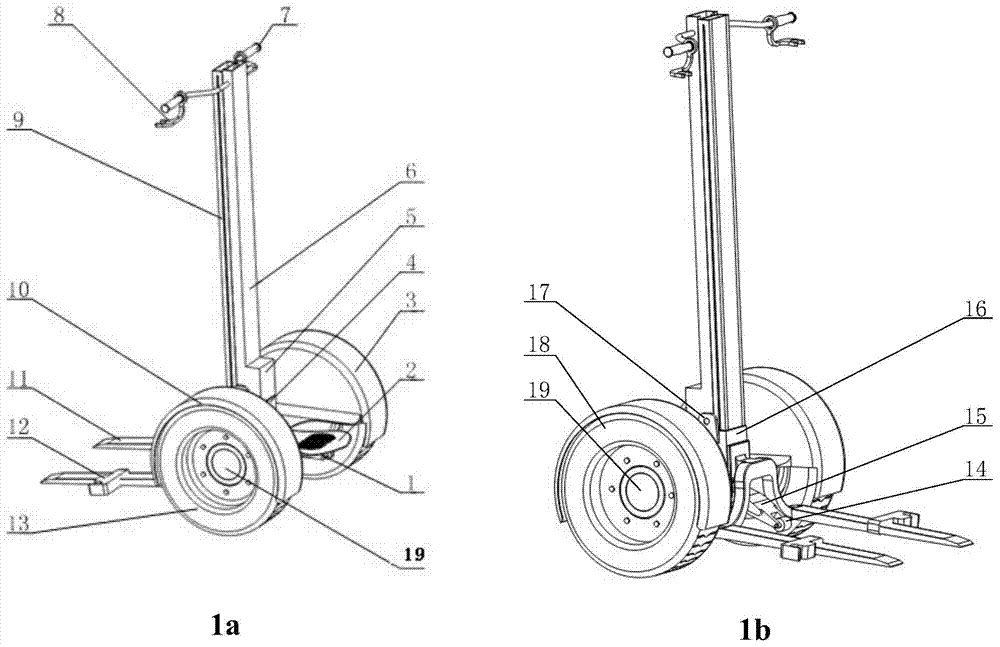

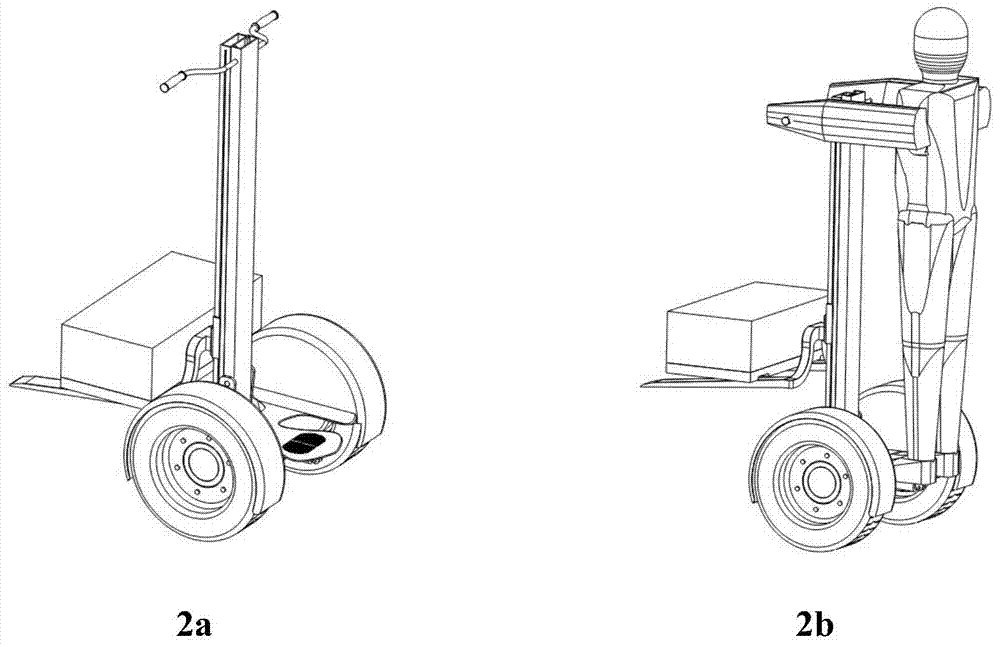

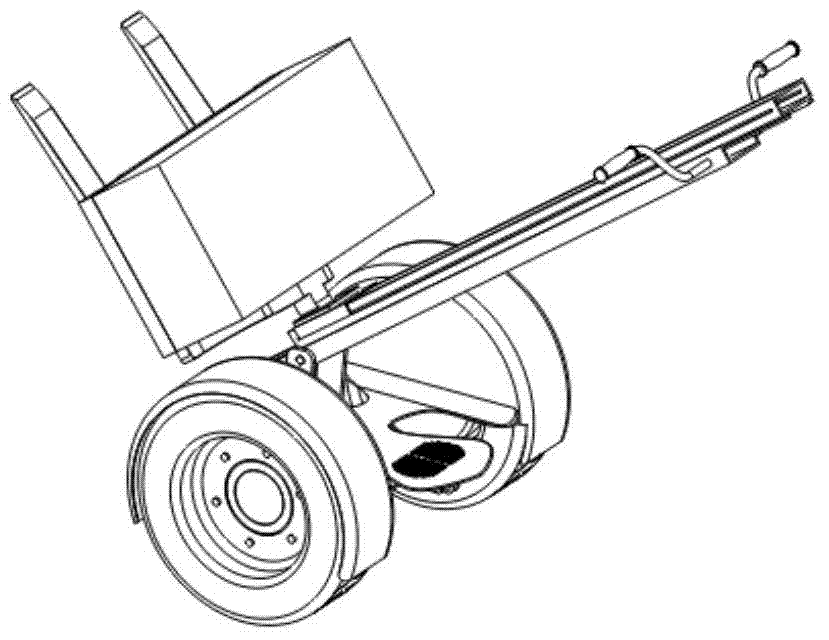

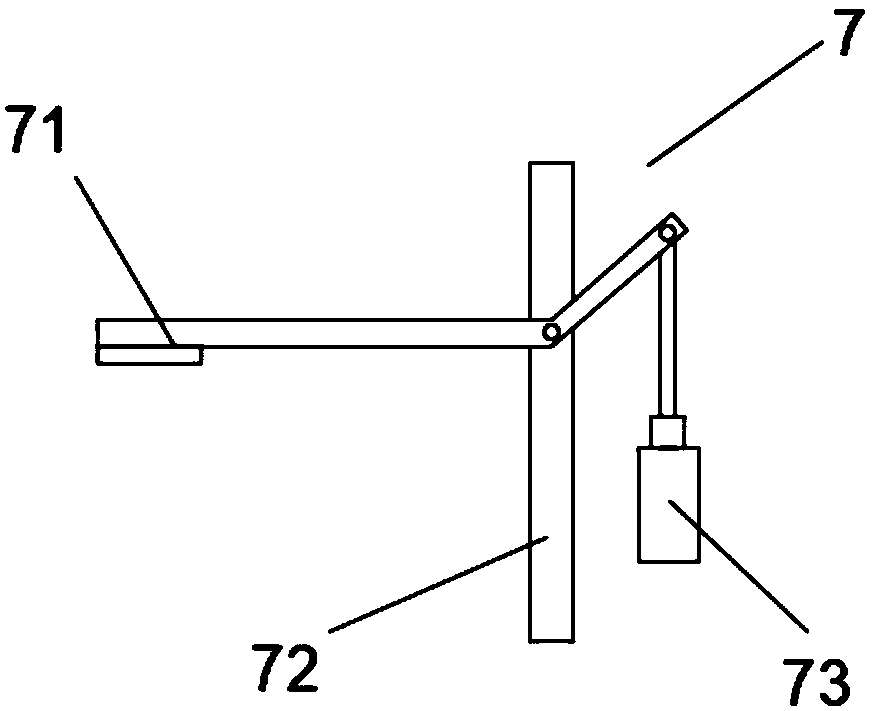

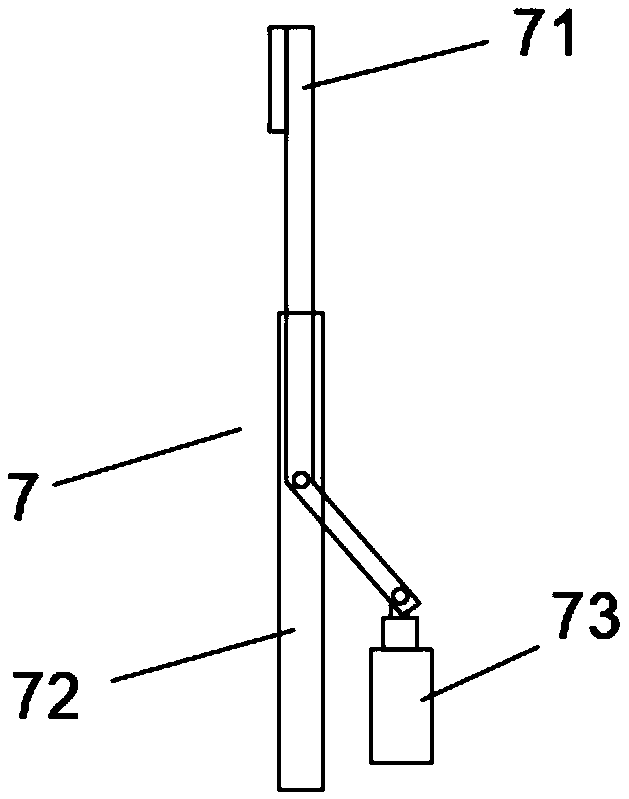

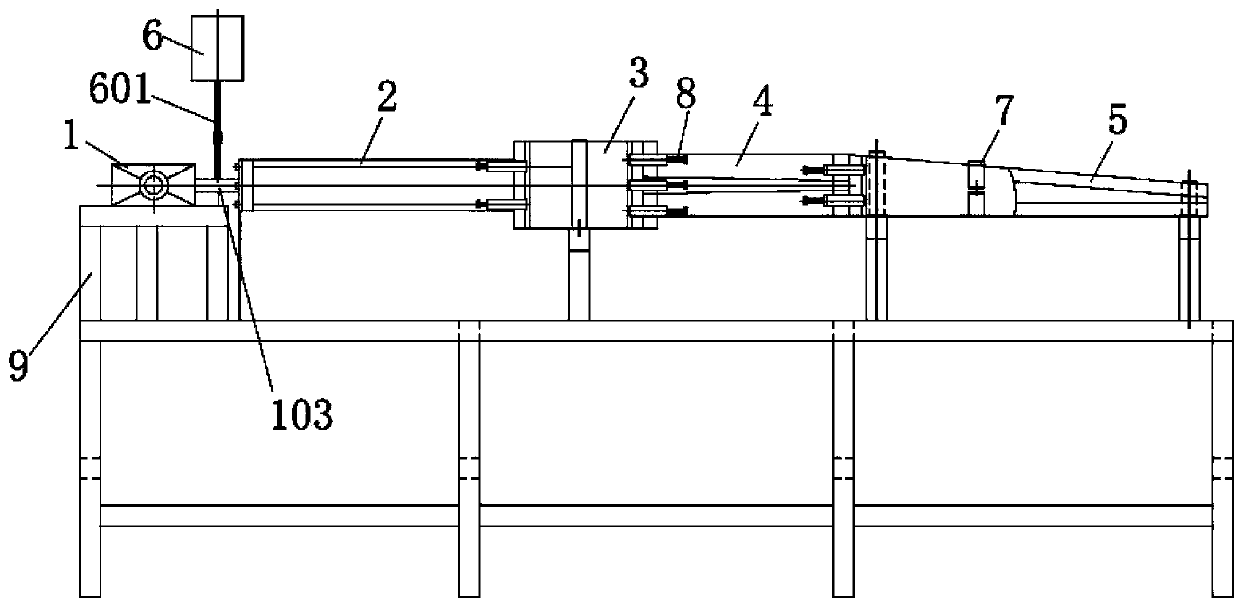

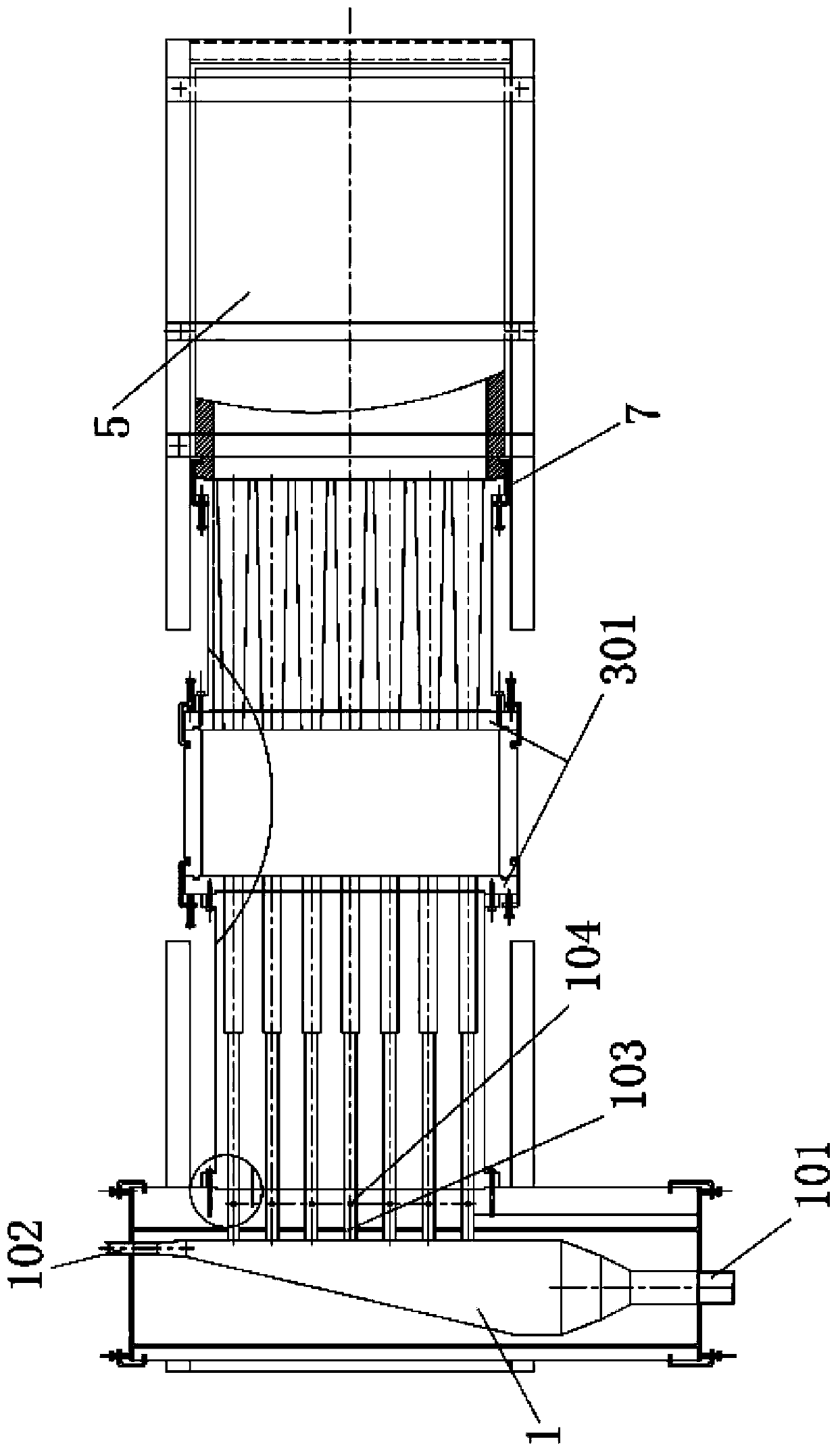

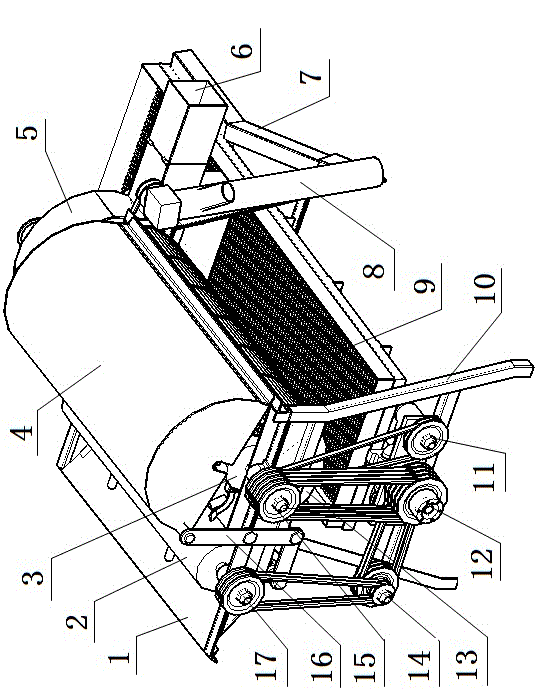

Self-balance multifunctional carrier

InactiveCN104709847AImprove the efficiency of loading and unloading guaranteeSmall bodyLifting devicesLithiumGyroscope

The invention discloses a self-balance multifunctional carrier which comprises a vehicle body, a lifting motor, a wheel drive motor, a motor controller, a winch, a pulley mechanism, a hinge type two-stage lifting portal, a fork, driving wheels, balance supporting legs, a lithium ion storage battery set, an attitude-control gyroscope, a dip angle sensor, a mechanical electric accessory and the like. The self-balance off-road multifunctional carrier has an off-road wheelbarrow work mode and a manual forklift work mode, people can get on and off the carrier by themselves by means of the design of the two-stage lifting portal, people can drive the carrier in the manual forklift mode and a self-balance mode when road environments are good, and the carrier can be assisted and pushed by hands to drive in the off-road wheelbarrow mode when the road environments are bad. The self-balance driving technology and the goods gravity self-adjustment technology are adopted, and flexible switching between the two modes is achieved through the portal toppling structure. The carrier has the advantages that a vehicle body is light, work is flexible, functions are diverse and adaptability is high, and goods loading, unloading and transporting efficiency in field environments can be effectively improved.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Fluorescent temperature sensor probe and manufacturing method thereof

InactiveCN101701855AReduce sizeHigh sensitivityThermometers using physical/chemical changesFluorescenceReflective layer

The invention relates to a fluorescent temperature sensor probe which is characterized in that the top of exciting light waveguide is stuck with fluorescent mixture to form the sensor probe which is connected with a reflecting layer. The fluorescent temperature sensor probe has the advantages of tiny body form of the sensor probe, high sensitivity, stable signal, good reliability as well as simple and convenient manufacturing.

Owner:NANCHANG HANGKONG UNIVERSITY

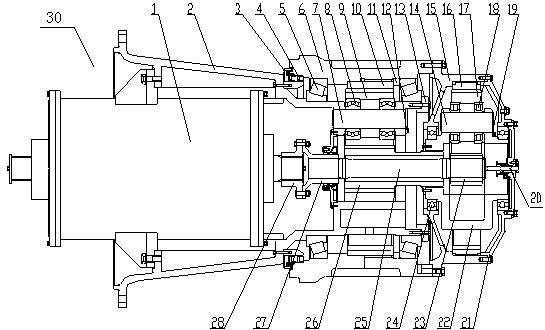

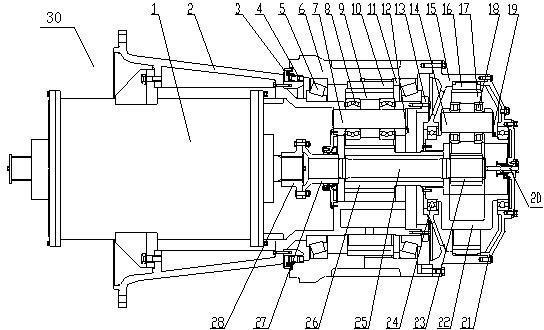

Hub reduction device for mining dump truck with electric wheels

ActiveCN102343809AReasonable structureReduce the size of the vehicleAxle unitsControl devicesTruckDrive motor

The invention discloses a hub reduction device for a mining dump truck with electric wheels and belongs to the technical field of hub reduction of engineering machinery vehicles. The hub reduction device comprises a main body, a driving motor, a secondary planet carrier, a retainer ring I, a sealing ring, a bearing I, a hub, a secondary planet shaft, a bearing II, a secondary planet wheel, a secondary annular gear, a spacing ring, an axle baffle I, a retainer ring II, a primary planet wheel shaft, an end cover, a primary annular gear, a primary planet wheel, a bearing III, an axle baffle II, a respirator, an outer end cover, a primary planet carrier, a primary sun wheel, a bearing IV, a half shaft, a connecting shaft, a half shaft flange and a motor shaft flange. The hub reduction device has the beneficial effects that construction is reasonable, mechanism of the whole mining dump truck is reduced, use ratio of space is high, safety and reliability are supplied, service life is prolonged, power consumption of the whole mining dump truck is reduced and use cost is lowered.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

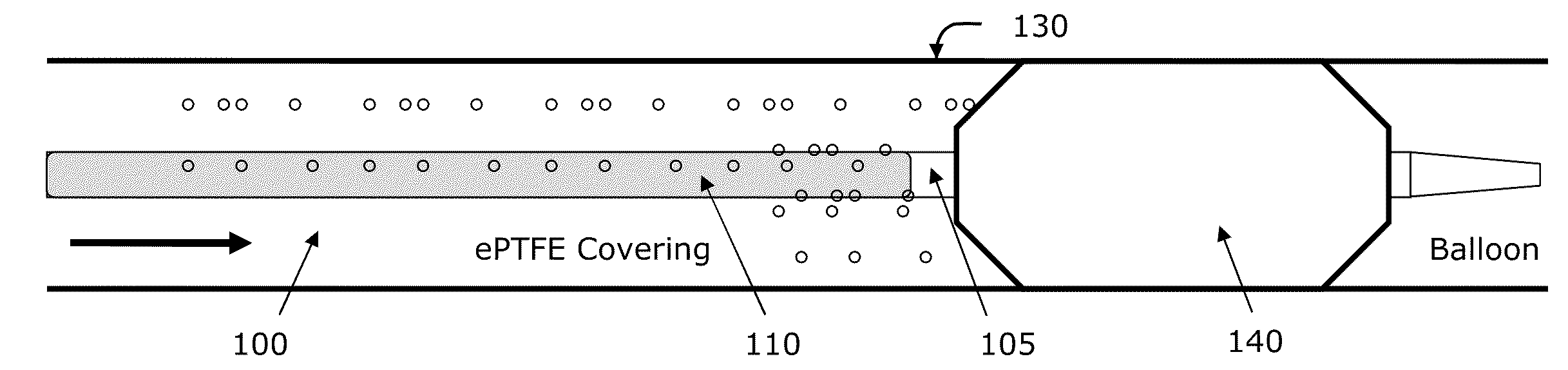

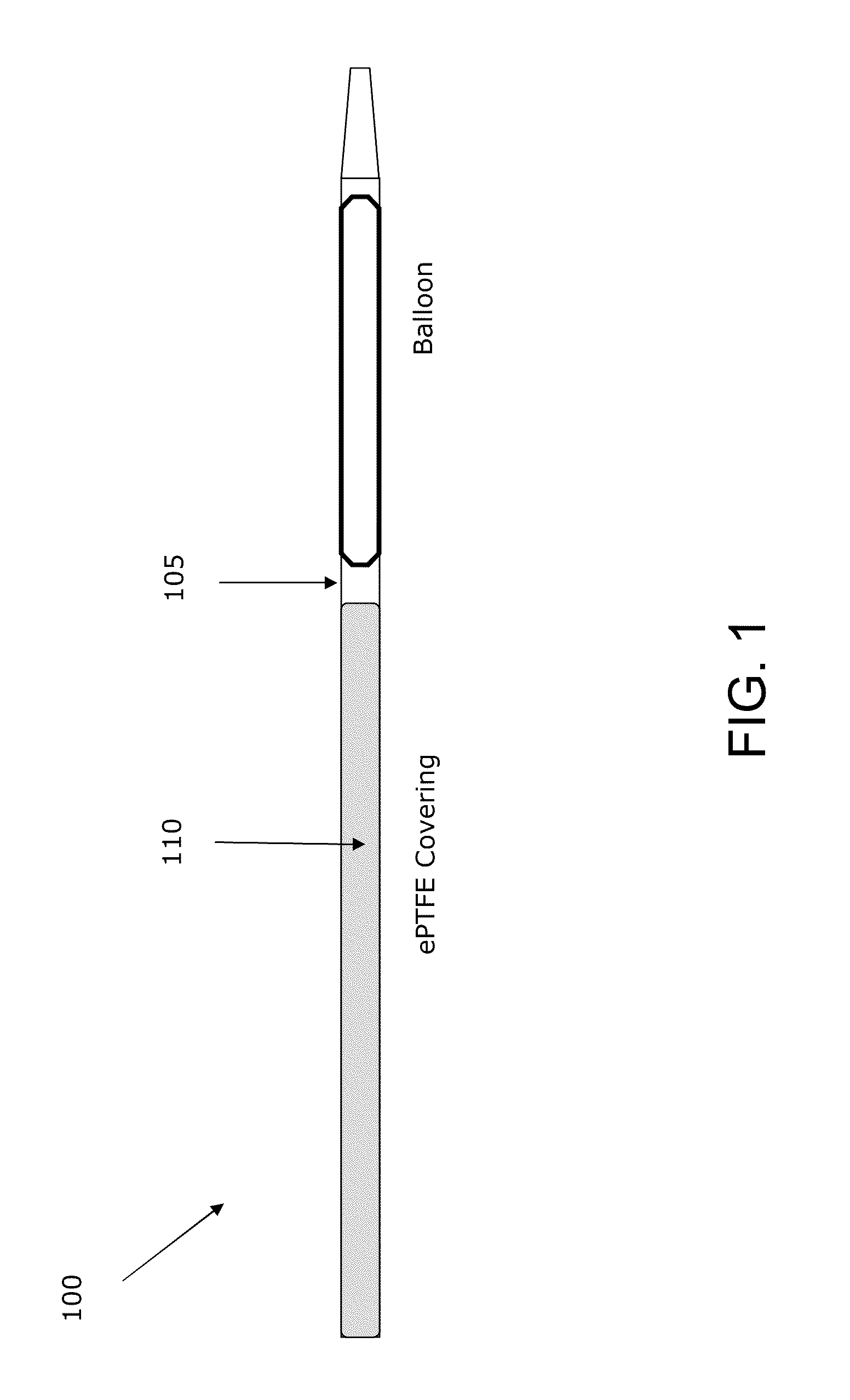

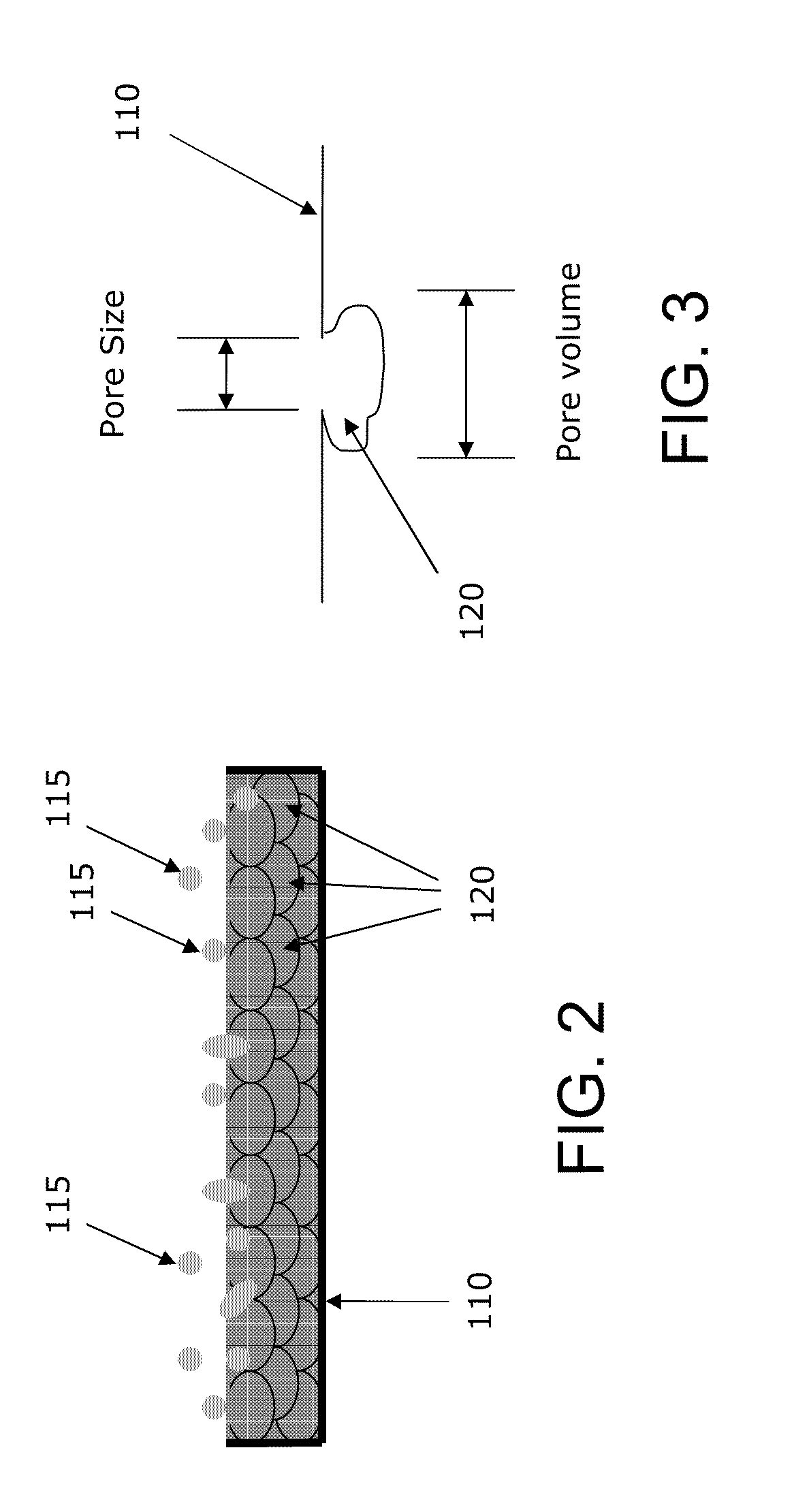

Method and apparatus for delivering oxygen and/or other gases and/or pharmacological agents to tissue

A system comprising:a hollow tube having a distal end, a proximal end, and a lumen extending between the distal end and the proximal end;at least a portion of the tube comprising a porous membrane; anda pharmacological agent incorporated in the porous membrane;wherein the porous membrane has a porosity such that: (i) the pharmacological agent is effectively incorporated into the porous membrane; and(ii) when the porous membrane is positioned in blood, the pharmacological agent elutes out of the porous membrane at a rate which matches the desired rate of dosage for the pharmacological agent.

Owner:OXIRA MEDICAL

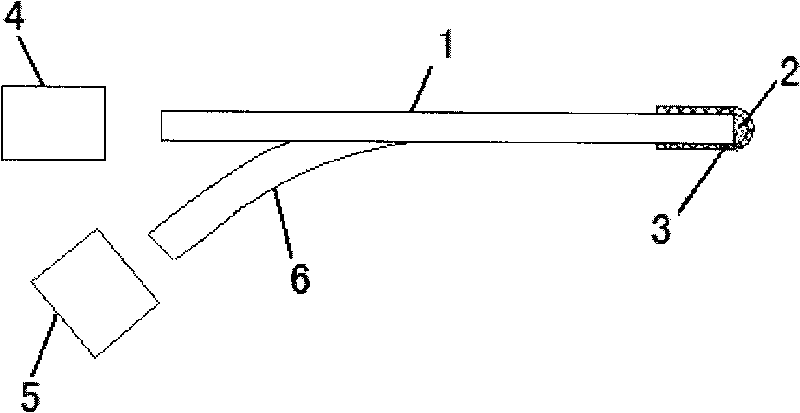

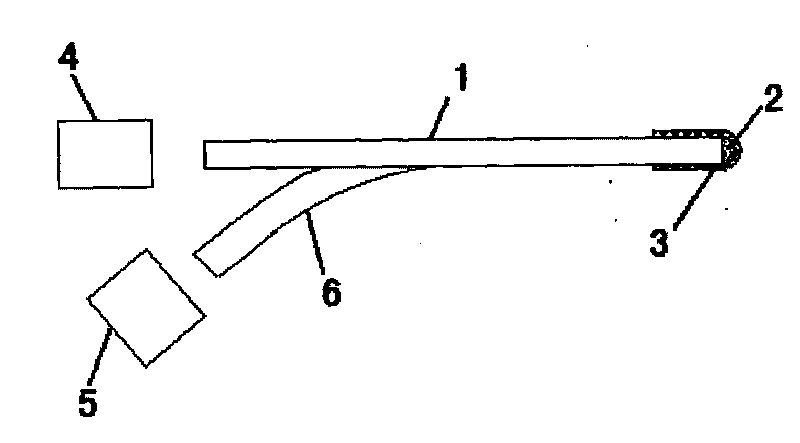

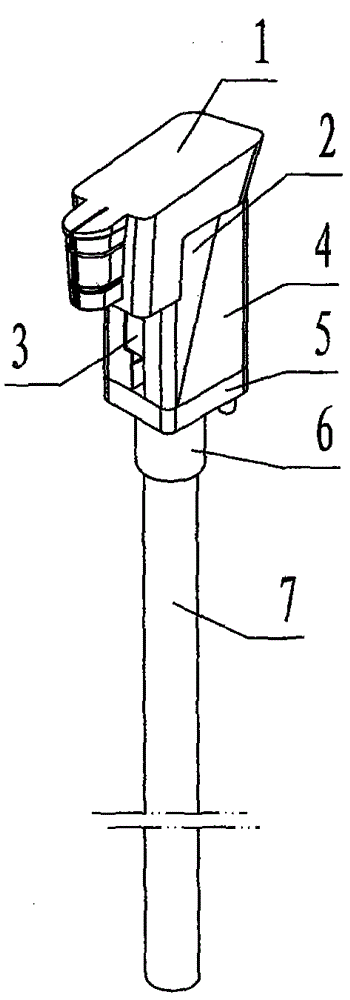

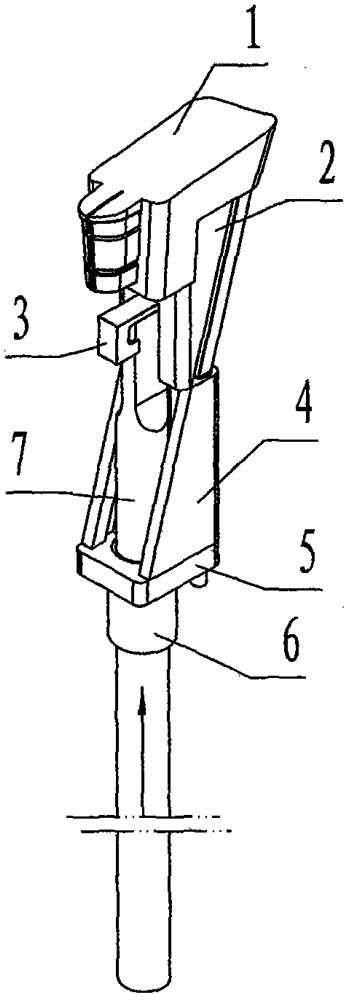

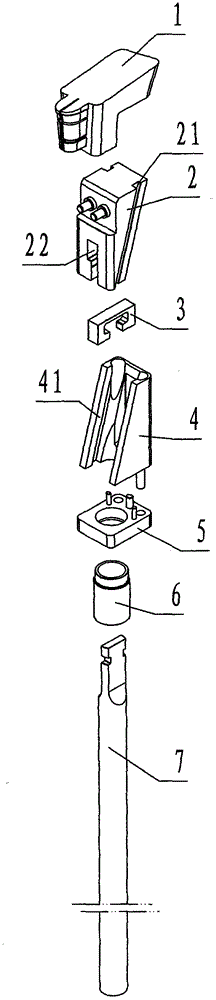

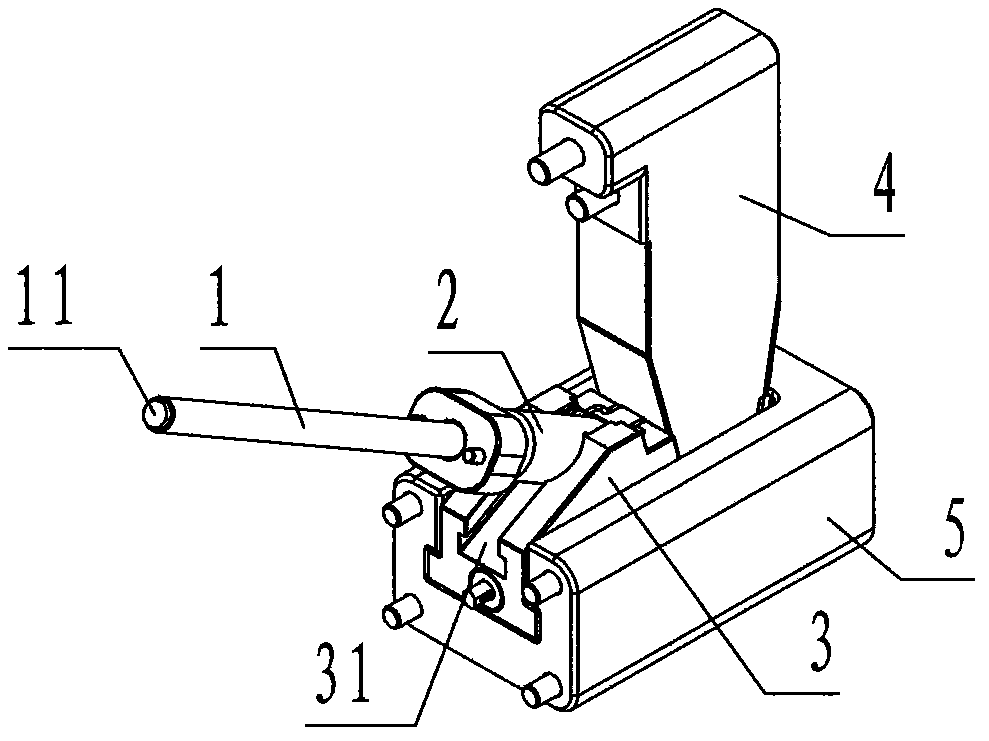

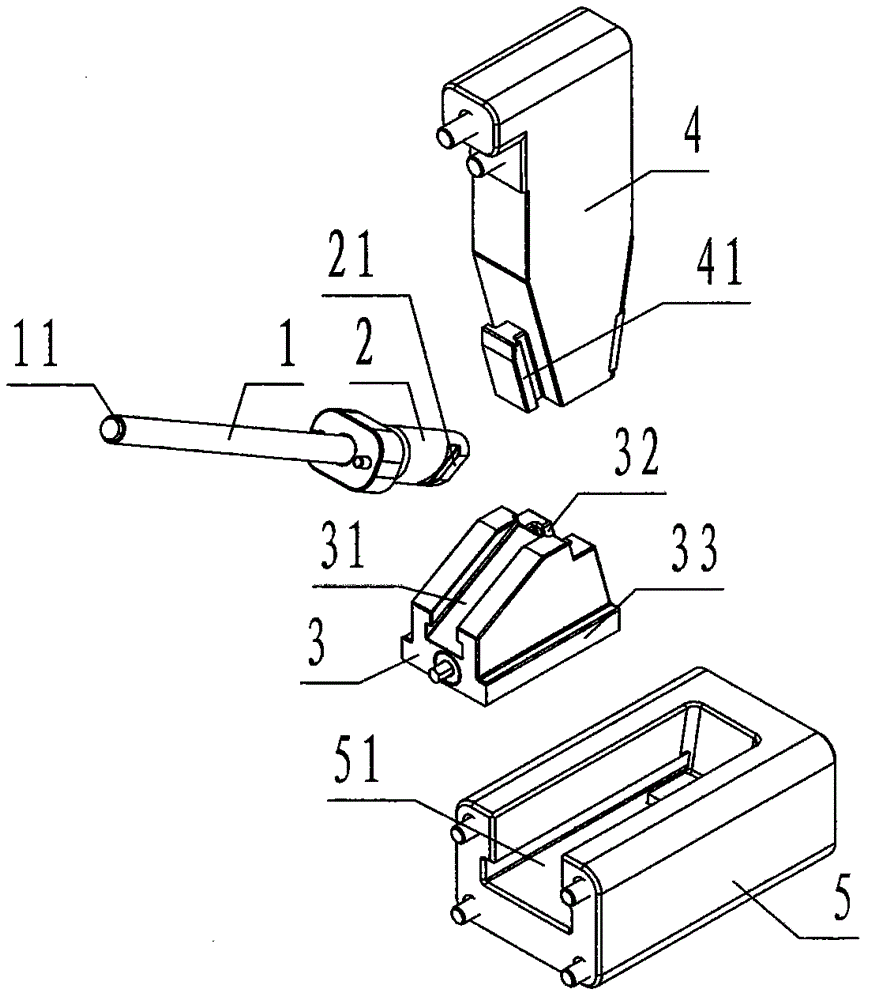

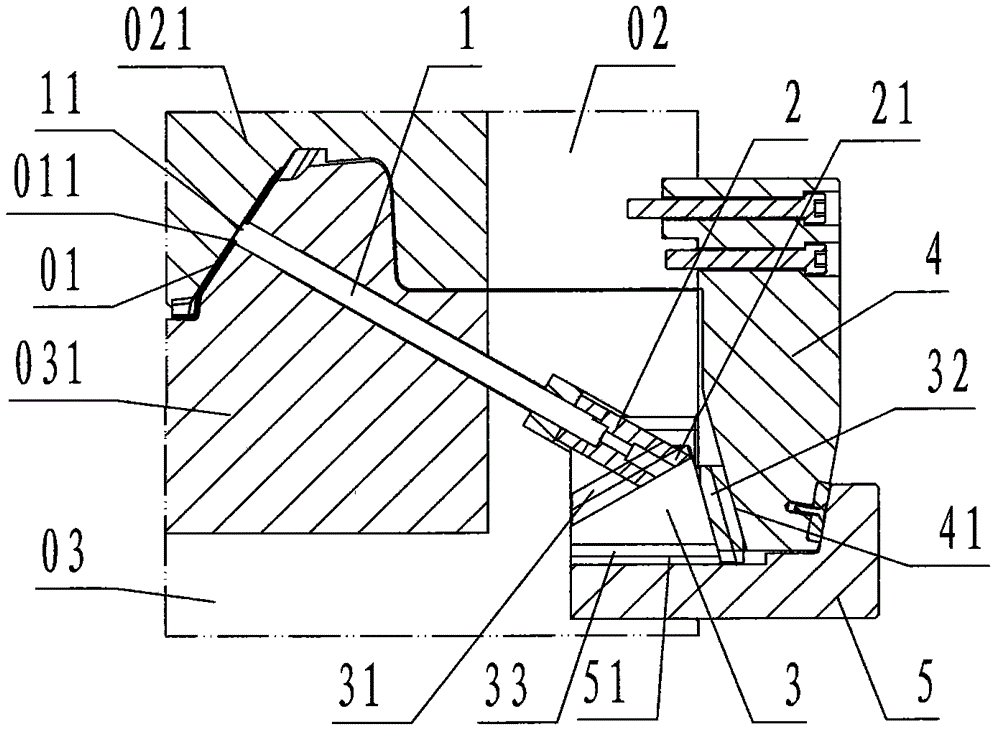

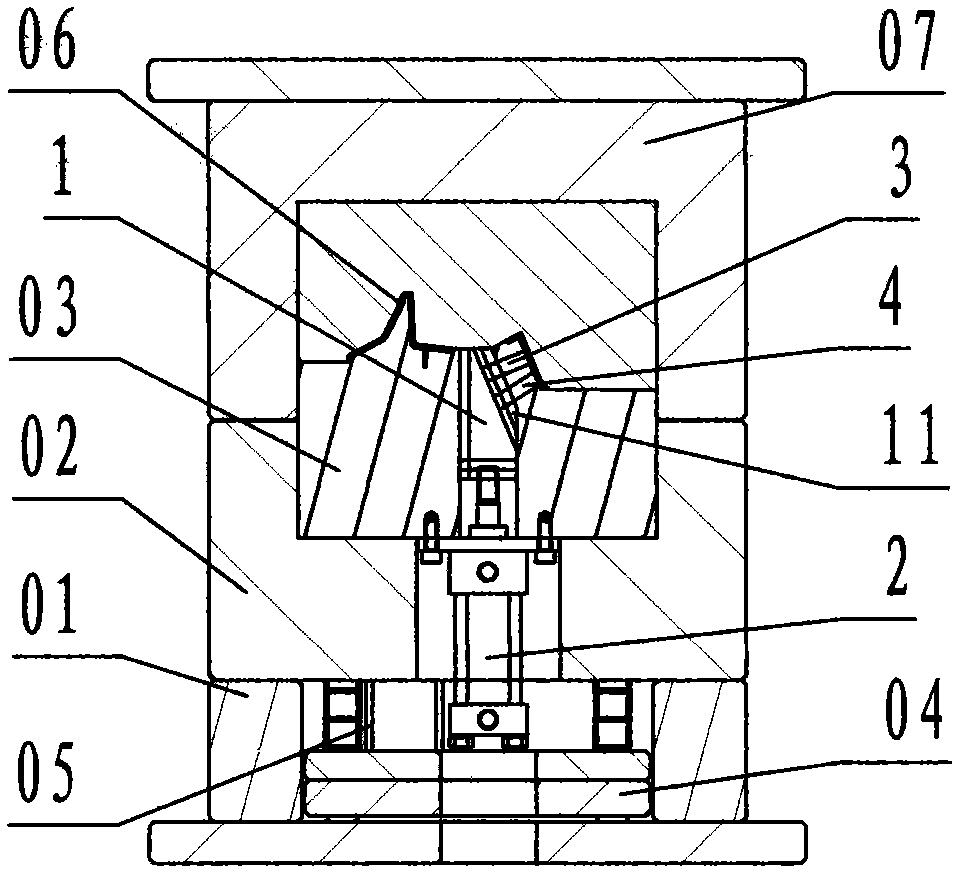

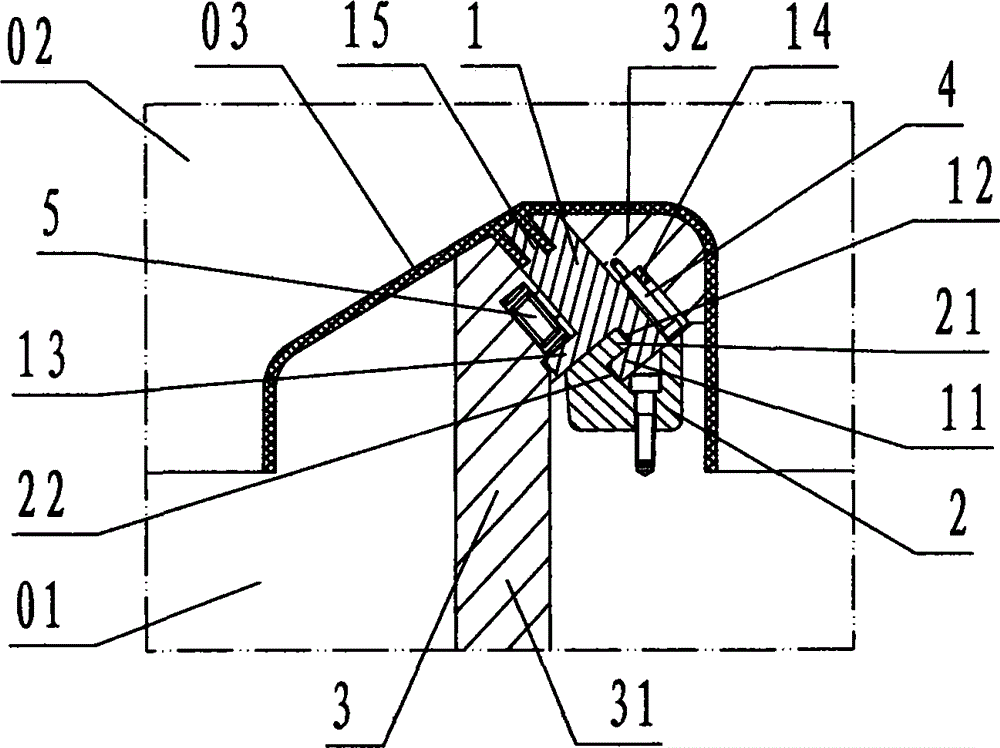

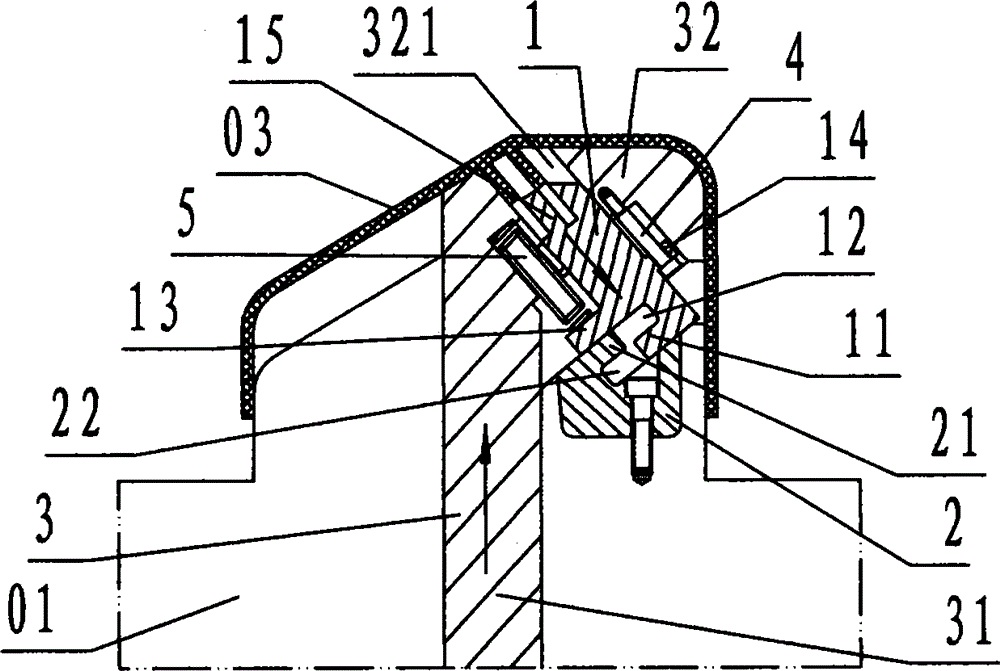

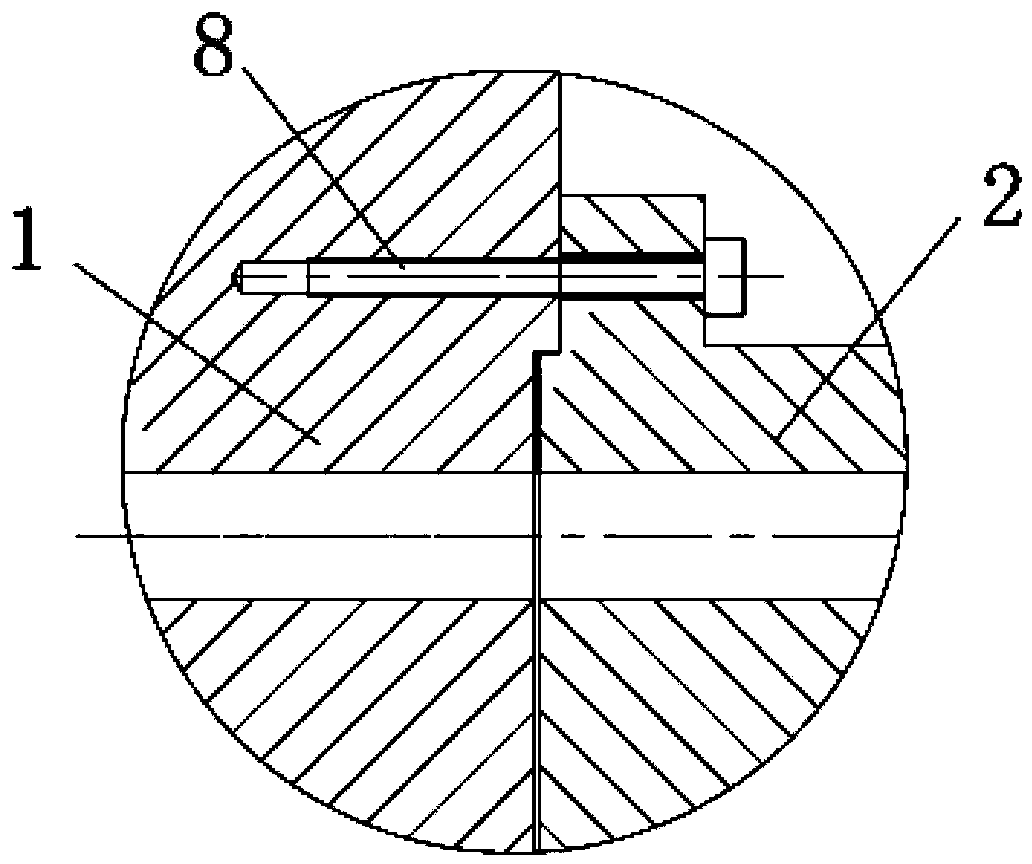

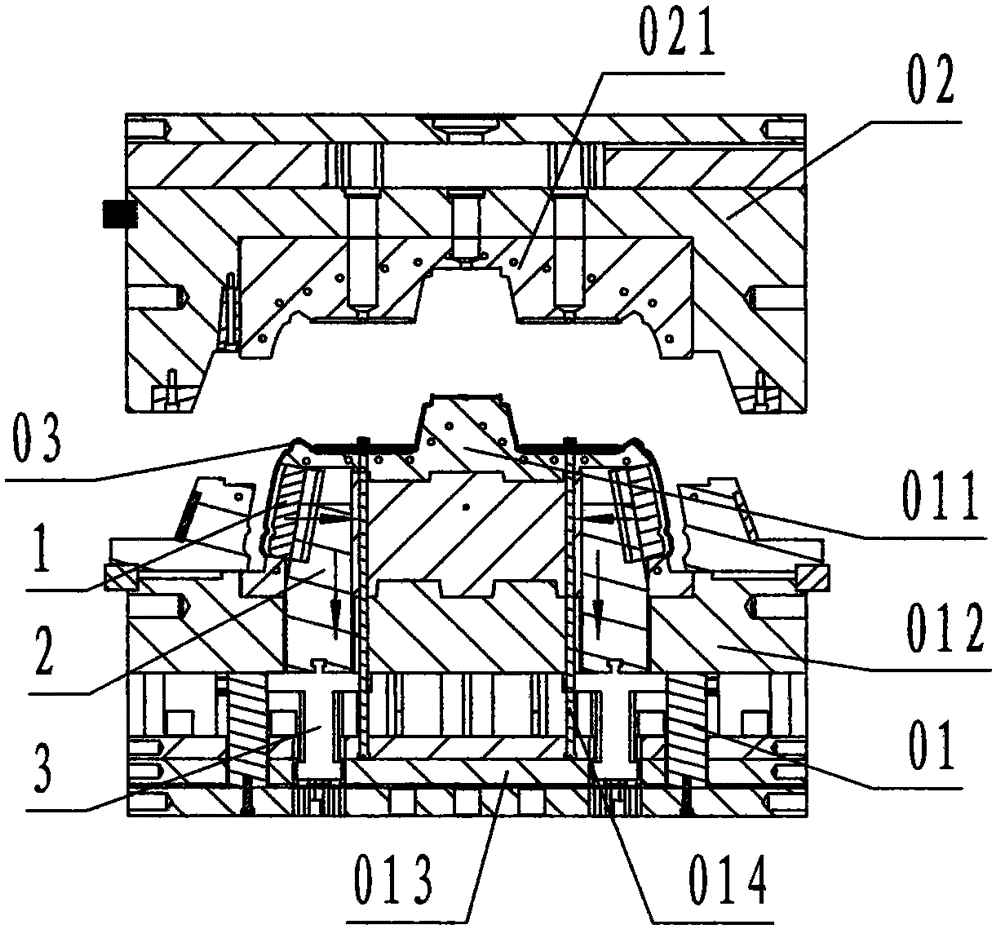

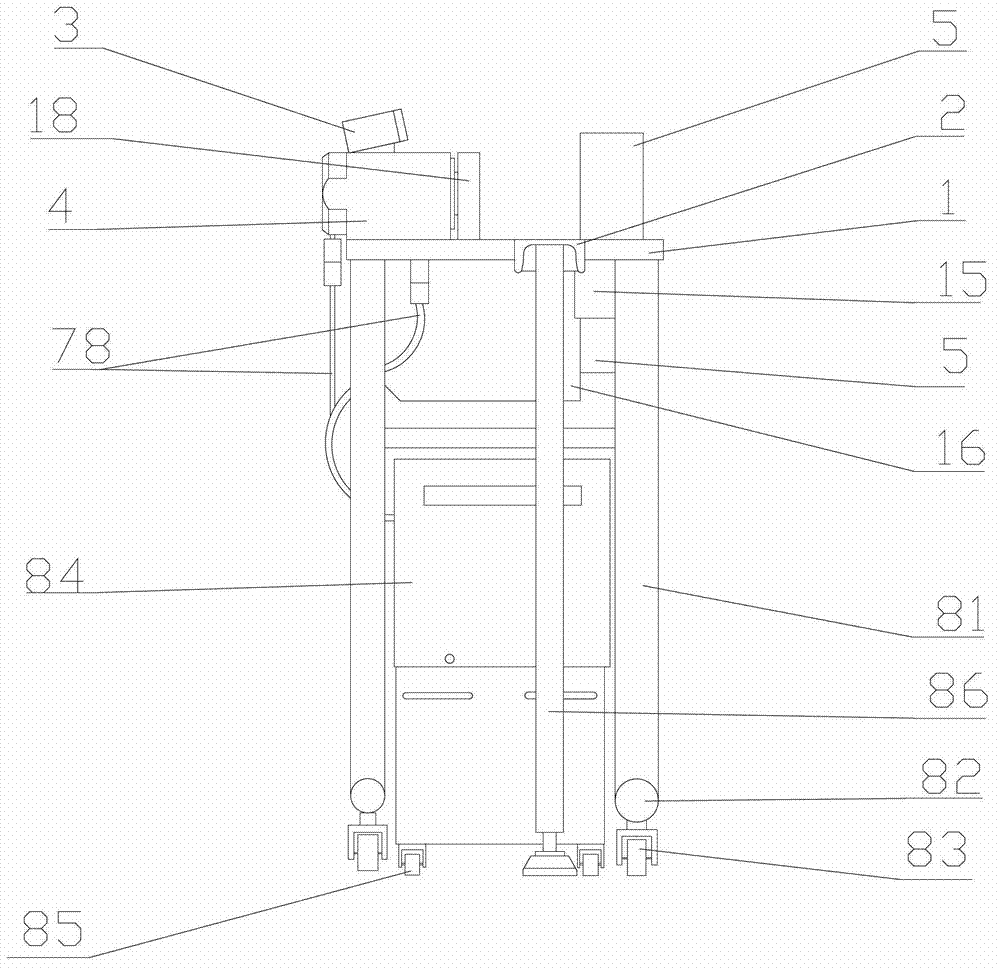

Straight ejecting and inclined pulling demolding device of deep reversed buckle in injection mold

The invention discloses a straight ejecting and inclined pulling demolding device of a deep reversed buckle in an injection mold. The device comprises a core pulling block (1), an inclined slide block (2), a transverse slide block (3), an inclined slide base (4), a base plate (5), a guide sleeve (6) and a straight ejecting rod (7). The inclined slide block is provided with an inclined chute and a transverse chute; the inclined slide base is provided with an inclined slide rail; the core pulling block is positioned on the upper surface of the inclined slide block; the transverse slide block is positioned in the transverse chute; the guide sleeve is connected below the inclined slide base by the base plate; the inclined slide block is connected with the inclined slide base by a inclined chute rail; the upper part of the straight ejecting rod penetrates through the guide sleeve to be connected with the transverse slide block; the core pulling block, the inclined slide block, the inclined slide base, the base plate and the guide sleeve are positioned in an accommodating tank of a molding core; the core pulling block and the inclined slide block are in sliding contact with the molding core; the inclined slide base and the guide sleeve are fixedly connected with the molding core by the base plate; the lower end of the straight ejecting rod is fixedly connected with a top plate; and in working, the straight ejecting rod drives the inclined slide block and the core pulling block to upwards move by the transverse slide block, and the inclined slide block and the core pulling block move from left to right to be pulled out from the deep reversed buckle in a product while upwards moving, so that the injection mold provided with the deep reversed buckle achieves the purposes of shortening of an ejecting travel, body reduction and cost reduction.

Owner:柳州双林汽车部件科技有限公司

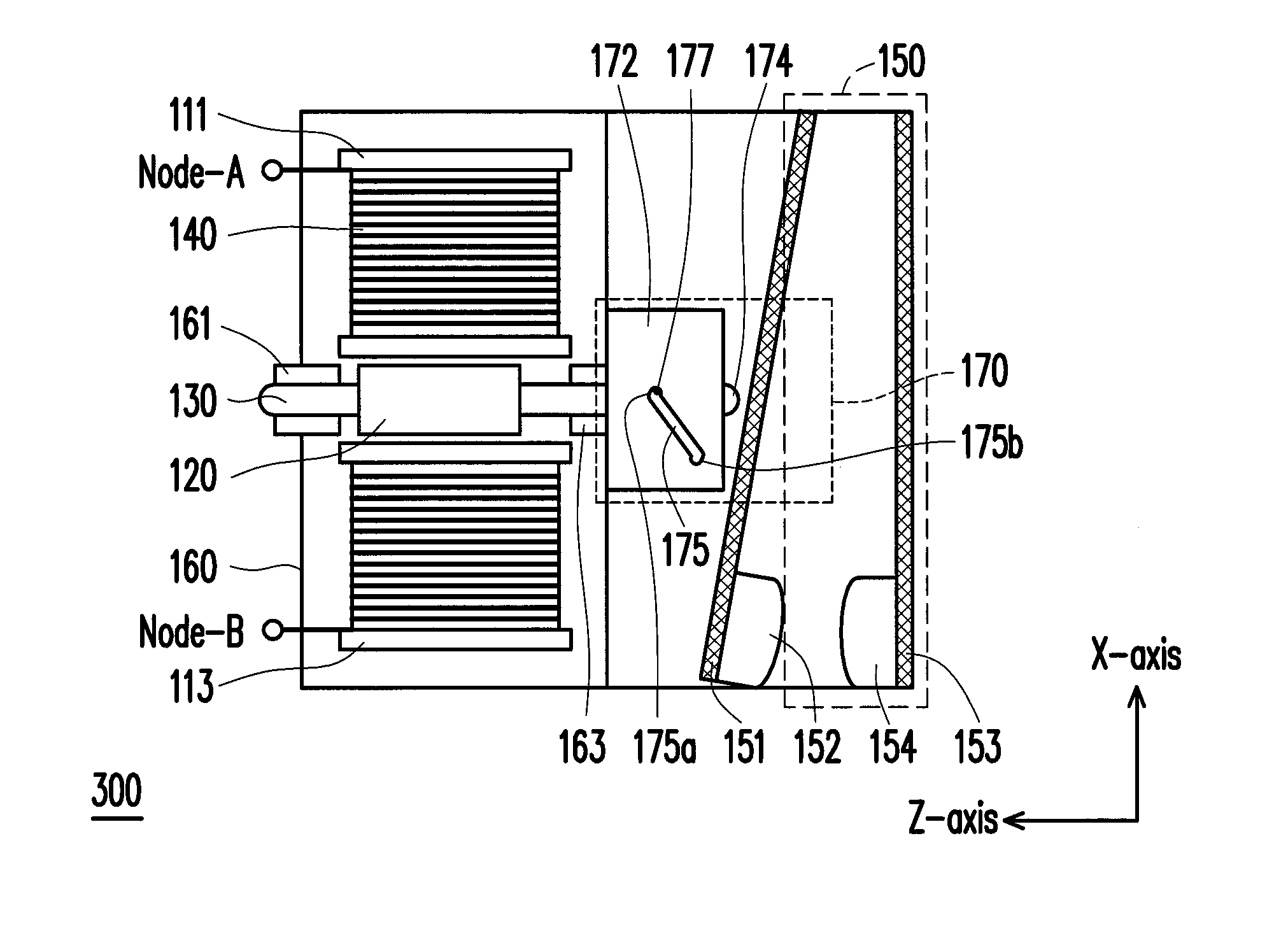

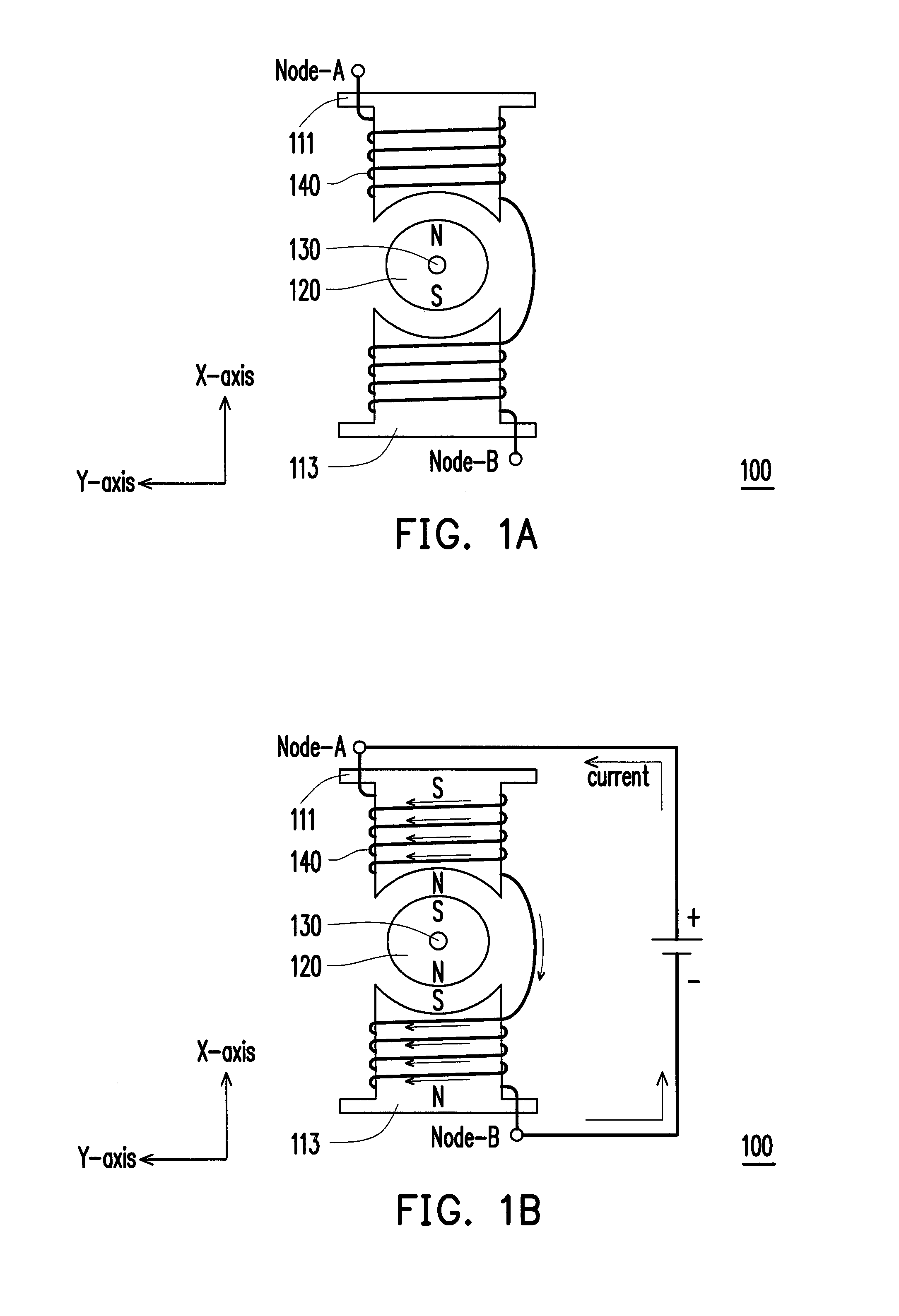

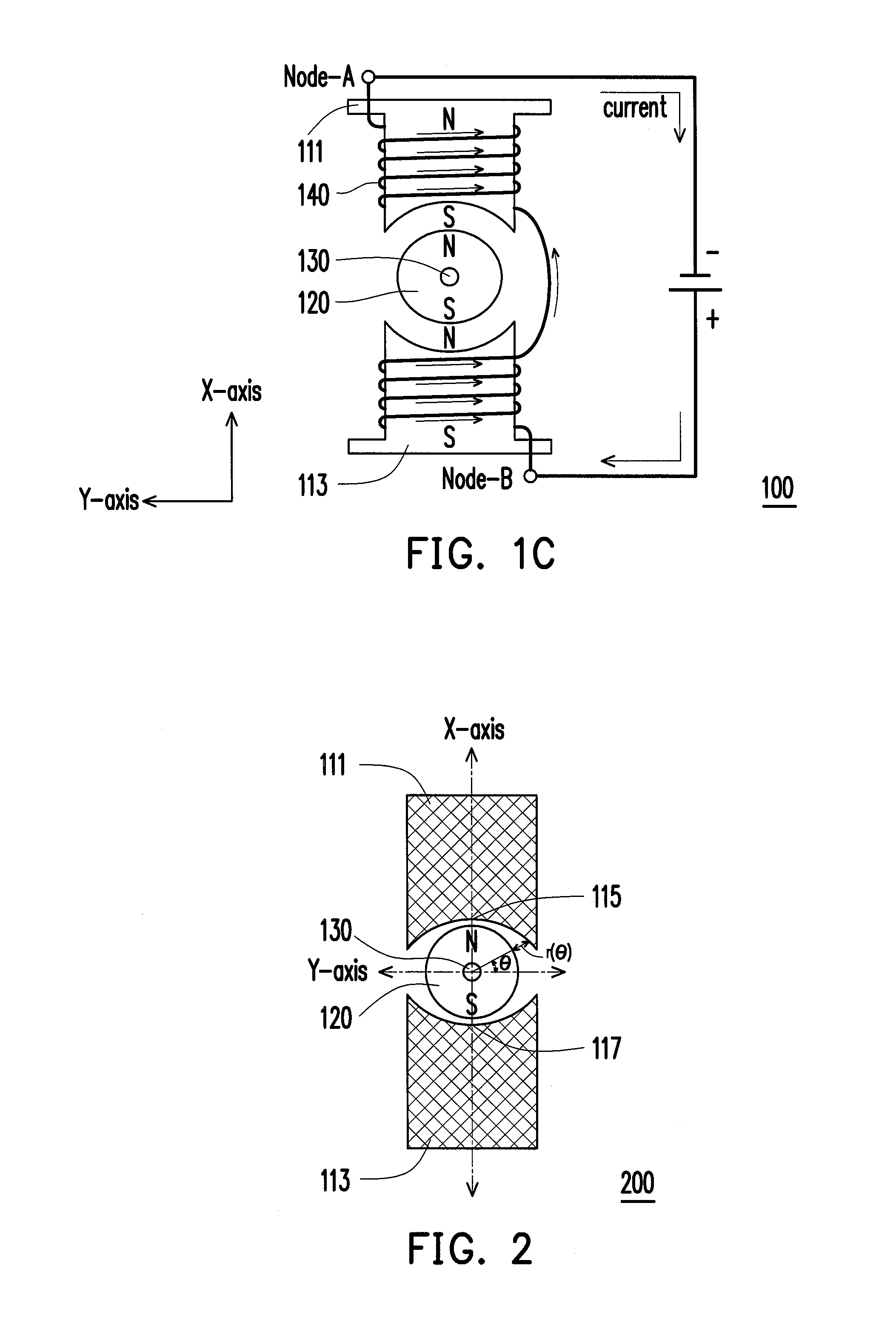

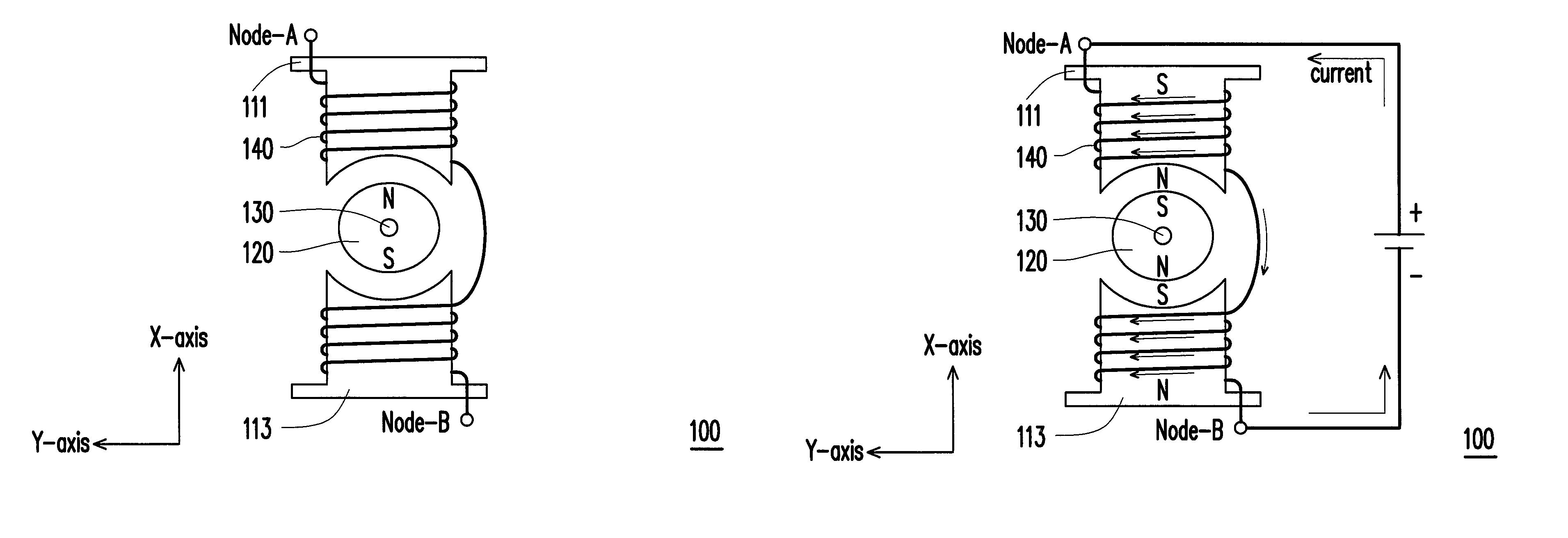

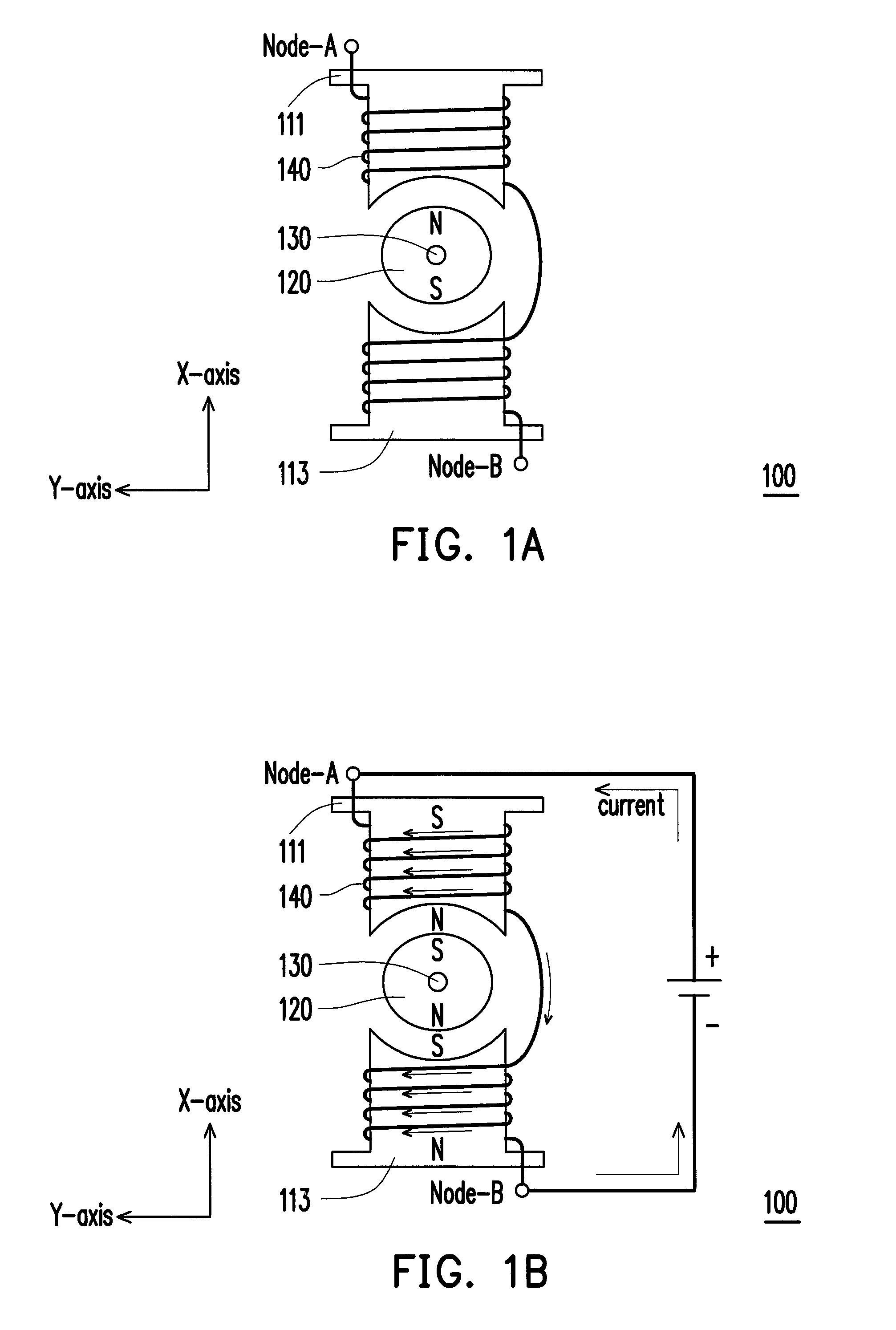

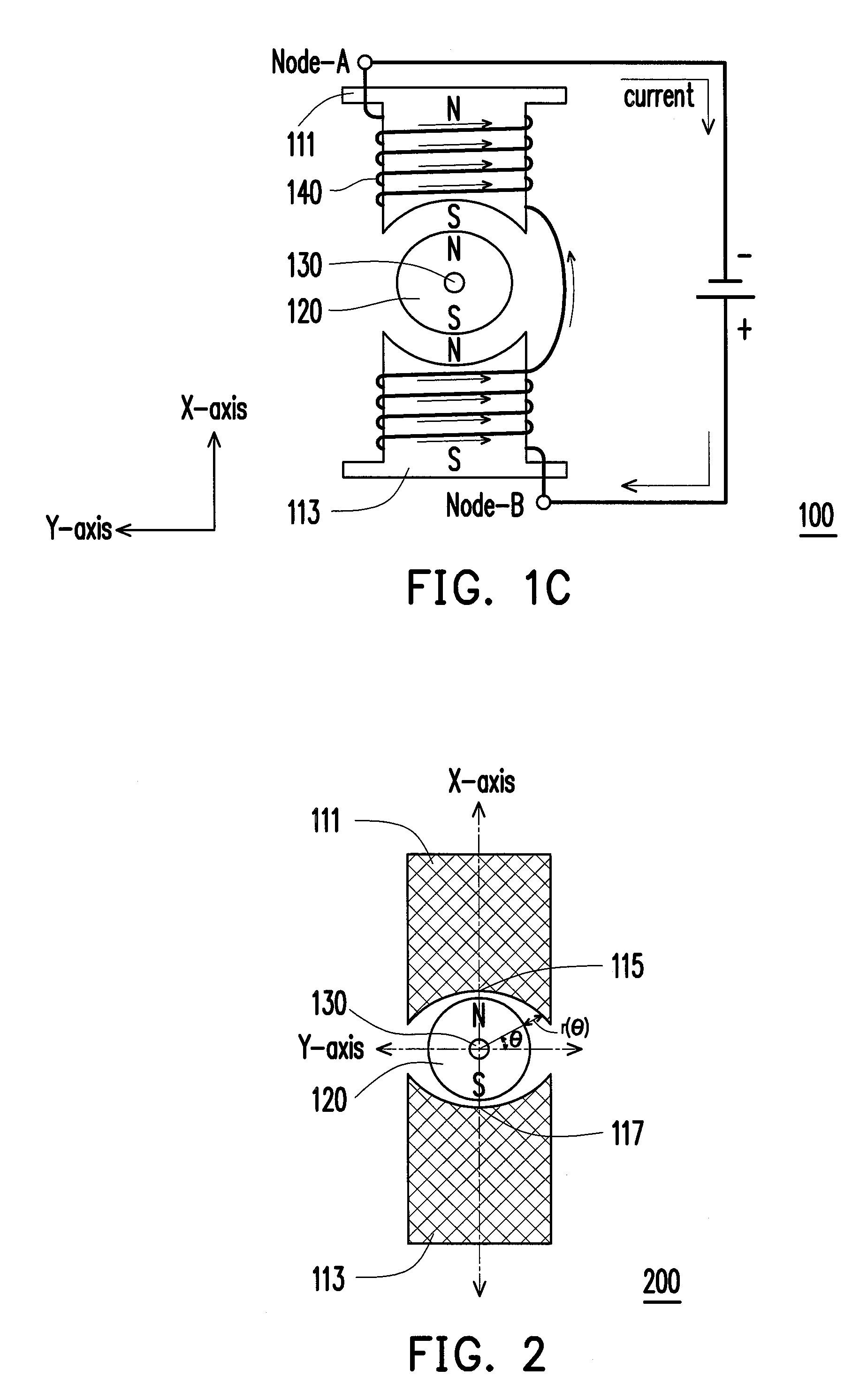

Bistable switching method and latching relay using the same

ActiveUS20120049987A1Increased power consumptionStable stateElectromagnetic relay detailsPolarised relaysEngineeringHIT device

A bistable switching method and a latching relay using the same are provided. The latching relay includes a rotor shaft, a cylindrical permanent magnet, a first permeability material, a second permeability material, a coil, a hitting device and a contact unit. The method includes the following steps. While the coil is applied first direction currents, the rotor shaft rotates and to make the contact unit from the open state to the closed state or the contact unit keeps the closed state. After the first direction currents are turned off, the contact unit still remains in the closed state. Otherwise, while the coil is applied second direction currents, the rotor shaft rotates and to make the contact unit from the closed state to the open state or the contact unit keeps the open state. After the second direction currents are turned off, the contact unit still remains in the open state.

Owner:LIANG CHIH CHUAN

Composite microbial preparation for treating domestic sewage and preparation method thereof

The invention belongs to the field of microbial preparations, and in particular relates to a composite microbial preparation for treating domestic sewage and a preparation method thereof. The composite microbial preparation for treating the domestic sewage comprises rhodopseudomonas palustris ACCC10649, saccharomyces cerevisiae ACCC20251, lactobacillus acidophilus ACCC11073, bacillus subtilis ACCC10619, pseudomonas nitroreducens ACCC04184, acinetobacter lwoffii ACCC01091 and candida tropicalis ACCC20004. According to the composite microbial preparation for treating the domestic sewage and the preparation method thereof, which are provided by the invention, organic matters in the sewage are converted into simple inorganic matters through decomposition of microorganisms, so that the sewage is treated effectively.

Owner:深圳科鹏境美环保科技有限公司

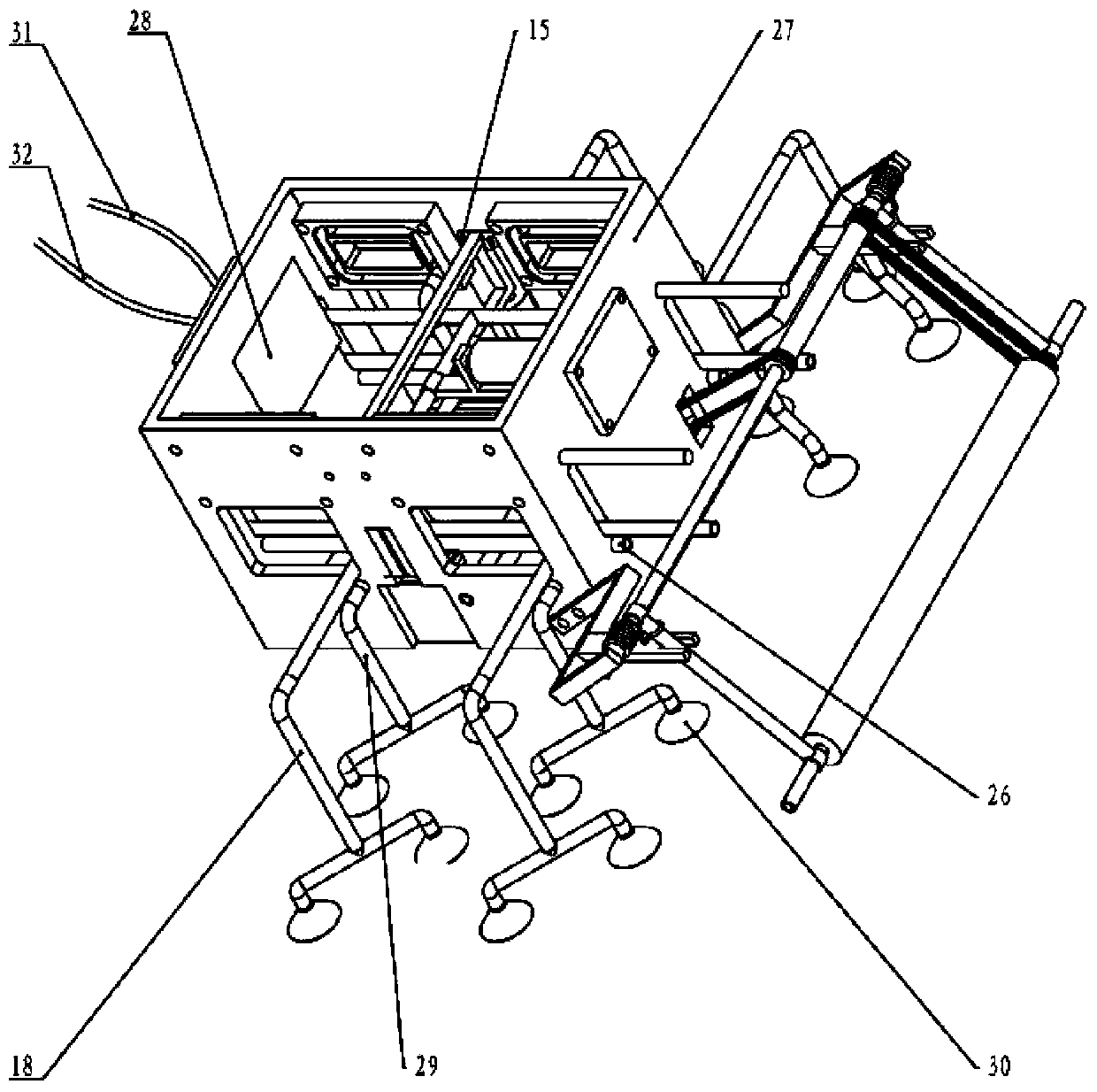

Surface cleaner for high-rise buildings

InactiveCN103462566AImprove structural strengthSmall bodyCarpet cleanersFloor cleanersEngineeringHigh rise

The invention discloses a surface cleaner for high-rise buildings. The surface cleaner powered by compressed air has the function of adsorbing to the surface of a high-rise building during operating, the function of having a cleaning mechanism, and the function of being controlled to move on the surface of the building through a control unit. When performing the third function, the surface cleaner can move up and down in the vertical direction and move horizontally according to the principle: each motion is decomposed of movements in spatial three orthogonal directions, and the movements are achieved through three orthogonal cylinders respectively under control of simple programs. A body of the surface cleaner is light in weight; production process of the surface cleaner is simple; structural strength of the surface cleaner is high; multiple surface cleaners can be used simultaneously for efficient automatic cleaning with no manual intervention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bistable switching method and latching relay using the same

ActiveUS8476996B2Increased power consumptionStable stateElectromagnetic relay detailsPolarised relaysHIT deviceClosed state

A bistable switching method and a latching relay using the same are provided. The latching relay includes a rotor shaft, a cylindrical permanent magnet, a first permeability material, a second permeability material, a coil, a hitting device and a contact unit. The method includes the following steps. While the coil is applied first direction currents, the rotor shaft rotates and to make the contact unit from the open state to the closed state or the contact unit keeps the closed state. After the first direction currents are turned off, the contact unit still remains in the closed state. Otherwise, while the coil is applied second direction currents, the rotor shaft rotates and to make the contact unit from the closed state to the open state or the contact unit keeps the open state. After the second direction currents are turned off, the contact unit still remains in the open state.

Owner:LIANG CHIH CHUAN

Externalinclined core pulling device of injection mold

Owner:NINGBO SHUANGLIN MOULD CO LTD

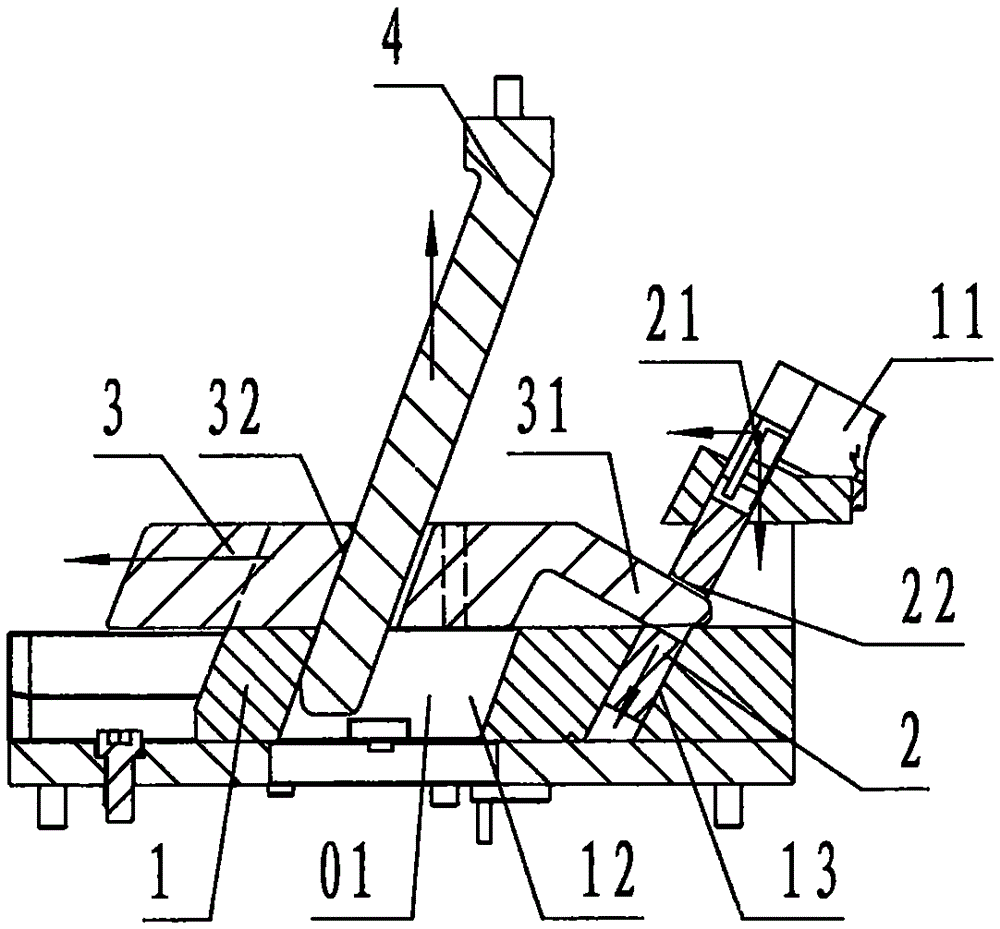

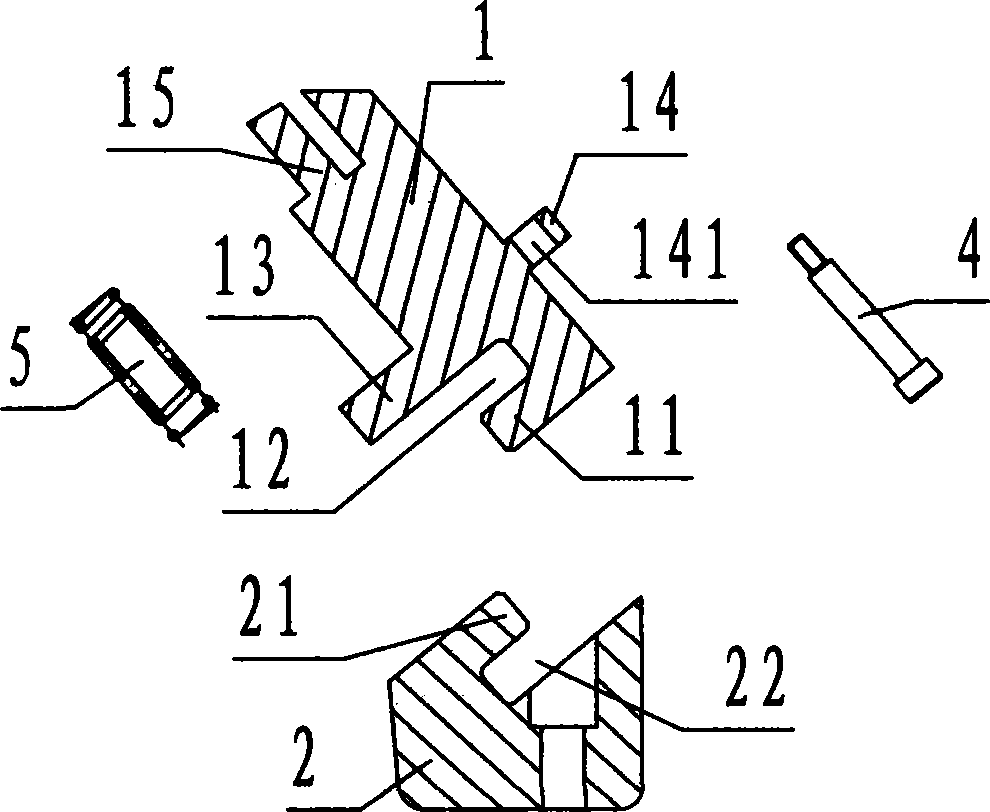

Multi-direction sequential combined core-pulling device for single slide block of injection mould

The invention discloses a multi-direction sequential combined core-pulling device for a single slide block of an injection mould. The multi-direction sequential combined core-pulling device comprises a transverse slide block (1), an inclined slide block (2), an inclined pulling drive block (3) and a transverse pulling inclined guide post (4). The transverse slide block is provided with an inclined guide hole A, an inclined guide hole B and a transverse pulling core; the inclined slide block is provided with an inclined pulling core and a pulling hole; the inclined pulling drive block is provided with an inclined pulling finger and an inclined guide hole C; the length, in the left-right direction, of the inclined guide hole A is greater than that of the inclined guide hole C, and the difference between the length, in the left-right direction, of the inclined guide hole A and the length, in the left-right direction, of the inclined guide hole C is defined as delay spacing; the transverse pulling inclined guide post is fixedly connected to a fixed mould, and the transverse slide block is in sliding connection to a movable mould; during mould closing, the delay spacing is positioned on the left part of the inclined guide hole A; by adopting the technical scheme that the transverse pulling inclined guide post firstly drives the inclined pulling drive block to drive the inclined slide block for pulling out the inclined pulling core in an inclined mode via the inclined pulling finger, then, when the delay spacing is moved to the right part of the inclined guide hole A, the transverse pulling inclined guide post drives the inclined pulling drive block and the transverse slide block to synchronously move for pulling out the transverse pulling core, so that the injection mould with narrow multi-direction sequential core-pulling achieves the purposes of simplifying the structure, reducing the body, reducing the cost and reducing faults.

Owner:NINGBO SHUANGLIN MOULD CO LTD

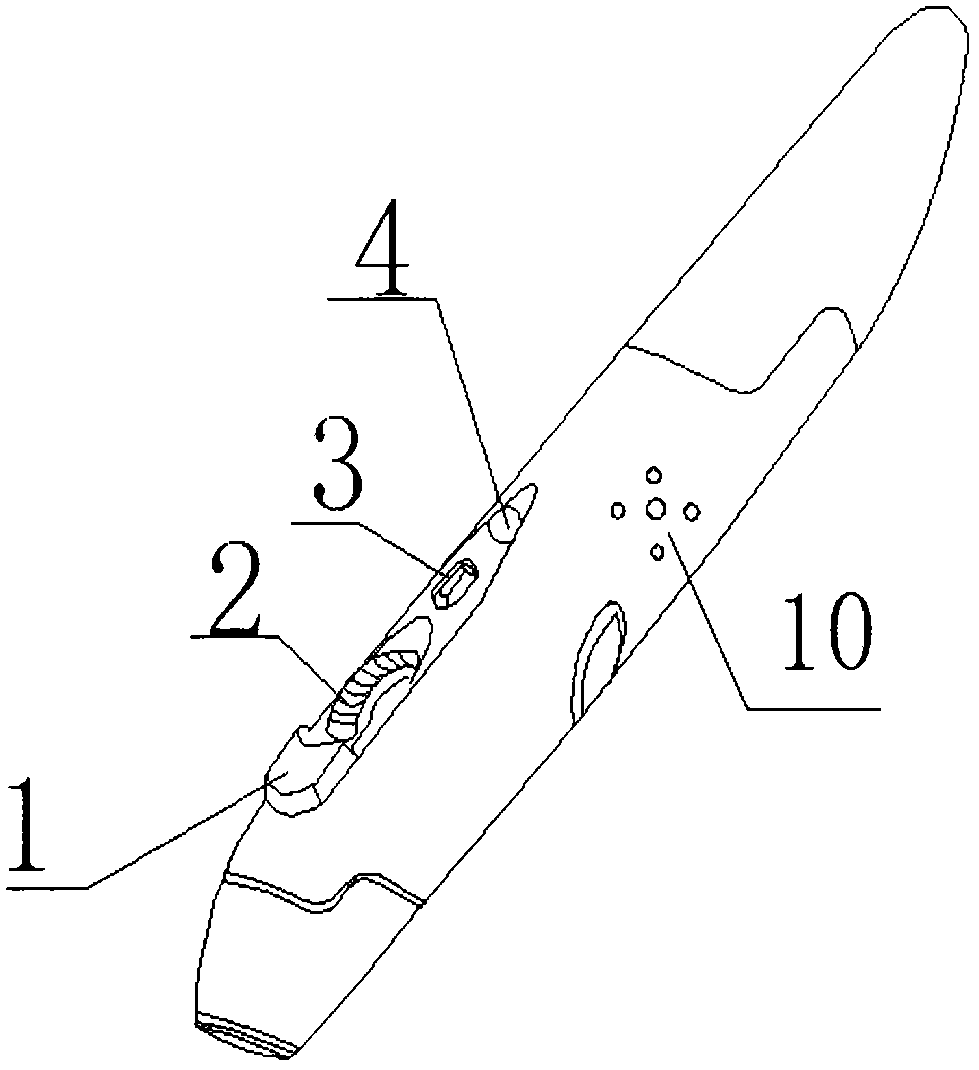

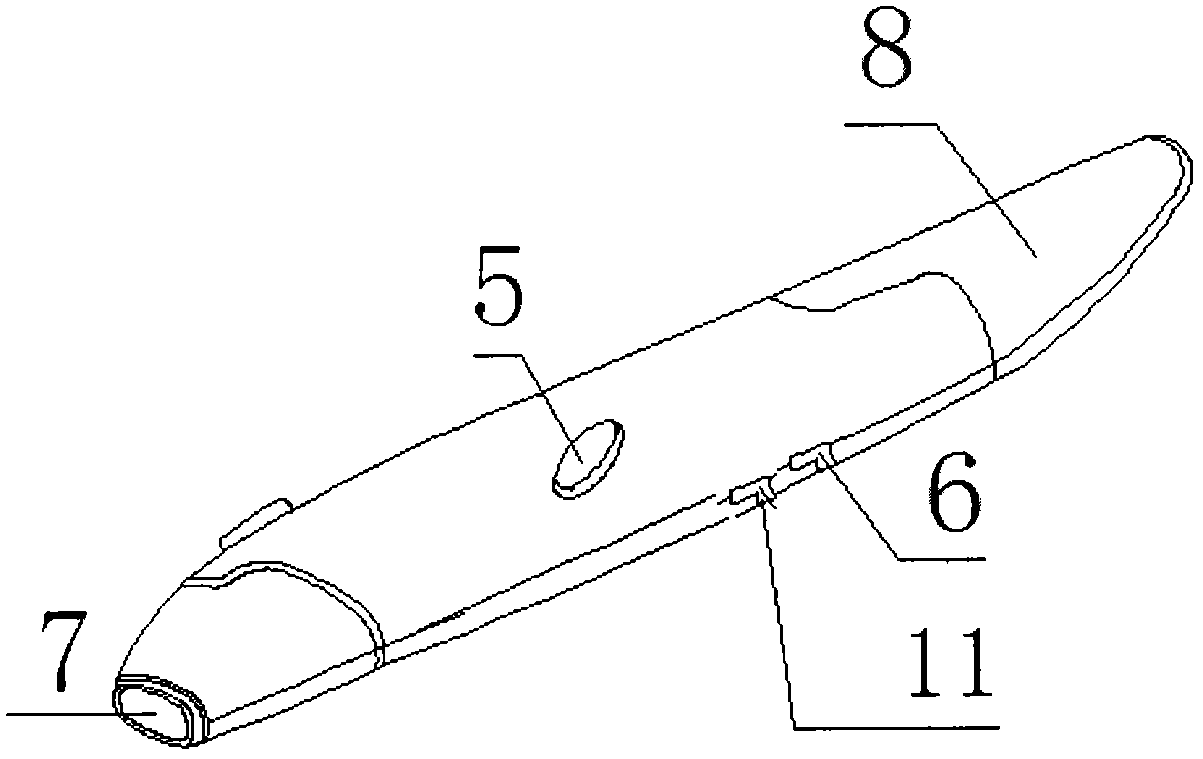

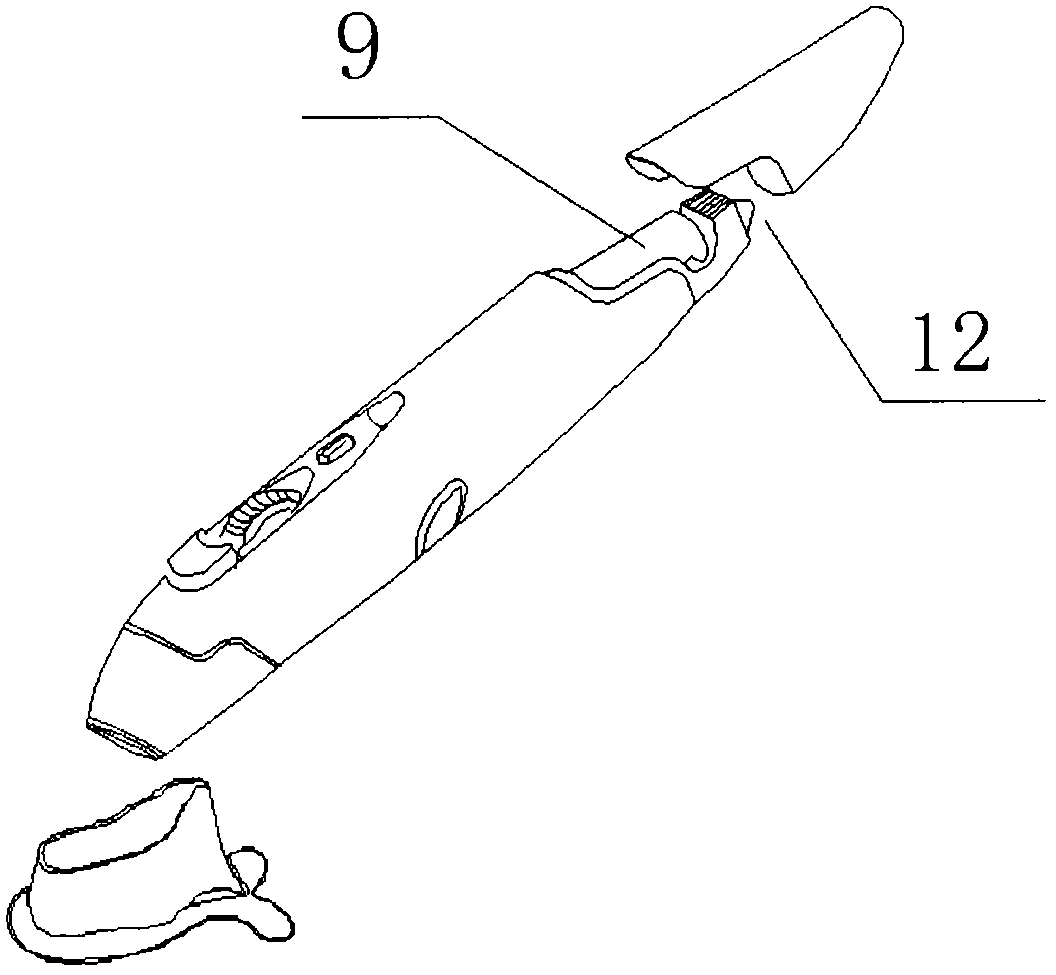

Novel multifunctional pen type mouse

InactiveCN104375675AEasy to graspConvenient and quick to useInput/output processes for data processingLow voltageRed laser

A novel multifunctional pen type mouse comprises a left mouse key, a page turning rolling wheel, a speed switching key, a low-voltage alarm light, a right mouse key, a power switch, an optical sensor, a battery cover, a battery bin, a recording hole, a recording switch and a laser indicator, wherein the left mouse key is arranged at the front end of the upper end face of a mouse body, the page turning rolling wheel is embedded in the mouse body and arranged between the left mouse key and the speed switching key, the right mouse key is installed on the right side face of the mouse body, the optical sensor is arranged at the bottommost end of the mouse body, the laser indicator is located above the battery bin and below the battery cover, the recording switch is arranged in the middle of the rear end face of the mouse body and below the power switch, a FLASH internal storage is further arranged inside the mouse body and used for storing recorded content, and a red light-emitting diode is adopted for the laser indicator to generate red lasers. The novel multifunctional pen type mouse is fashionable in appearance, small in size, convenient to carry, and capable of being applied to various occasions such business conferences, PPT showing in work, speeches, teaching, legal recording for evidence obtaining and the like.

Owner:GANSU AGRI UNIV

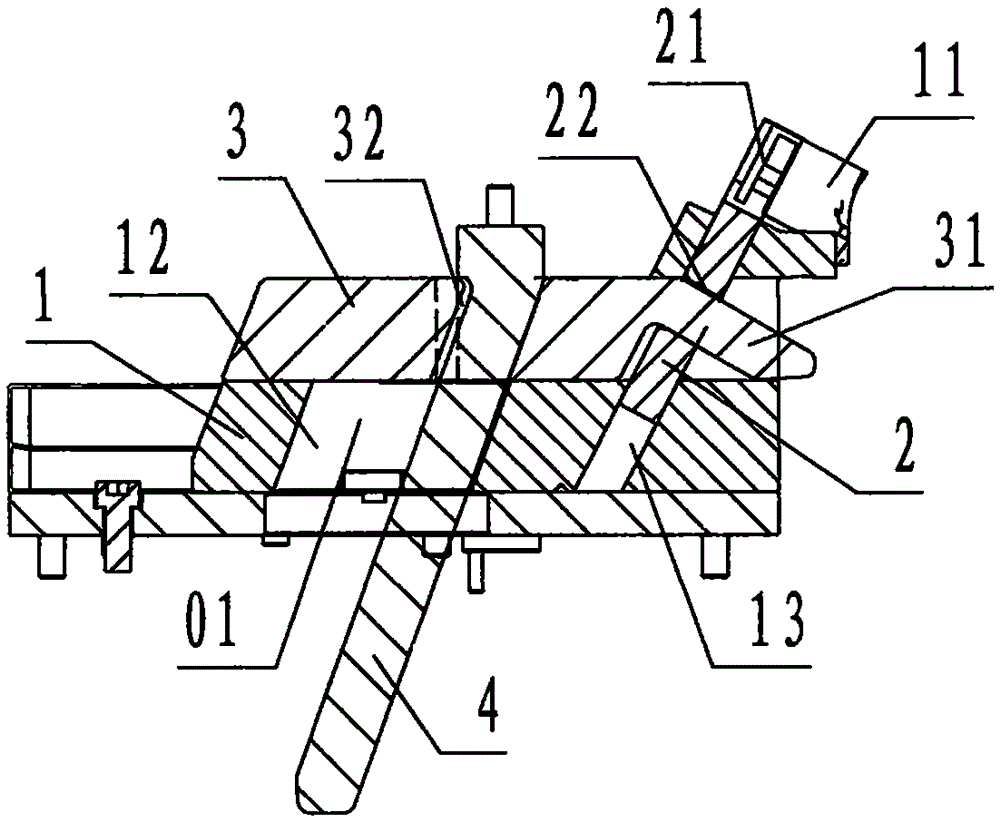

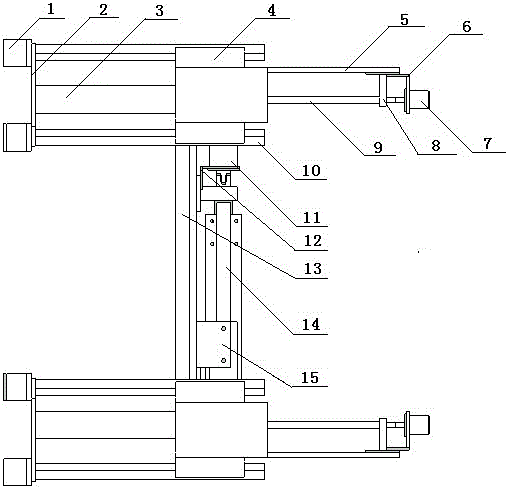

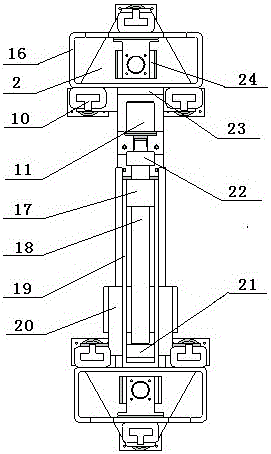

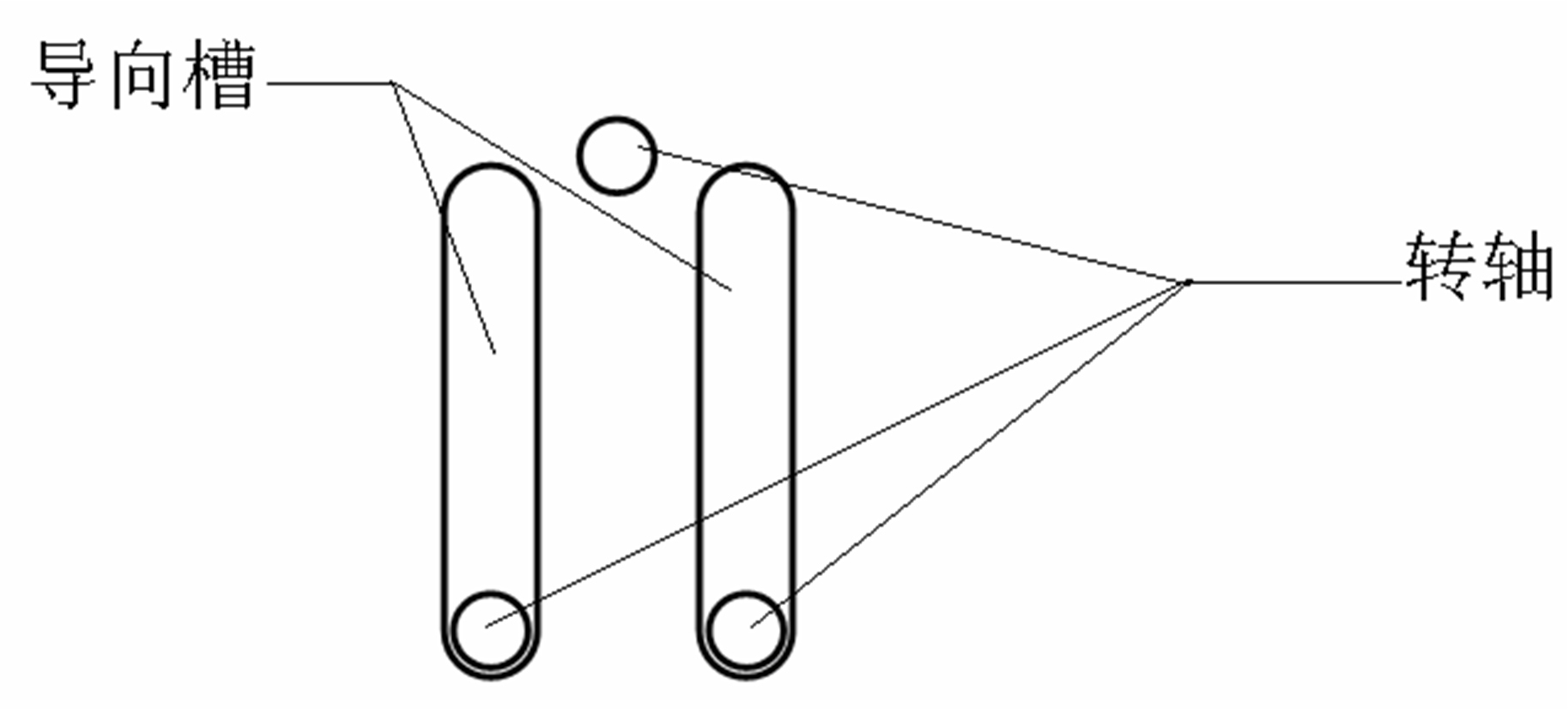

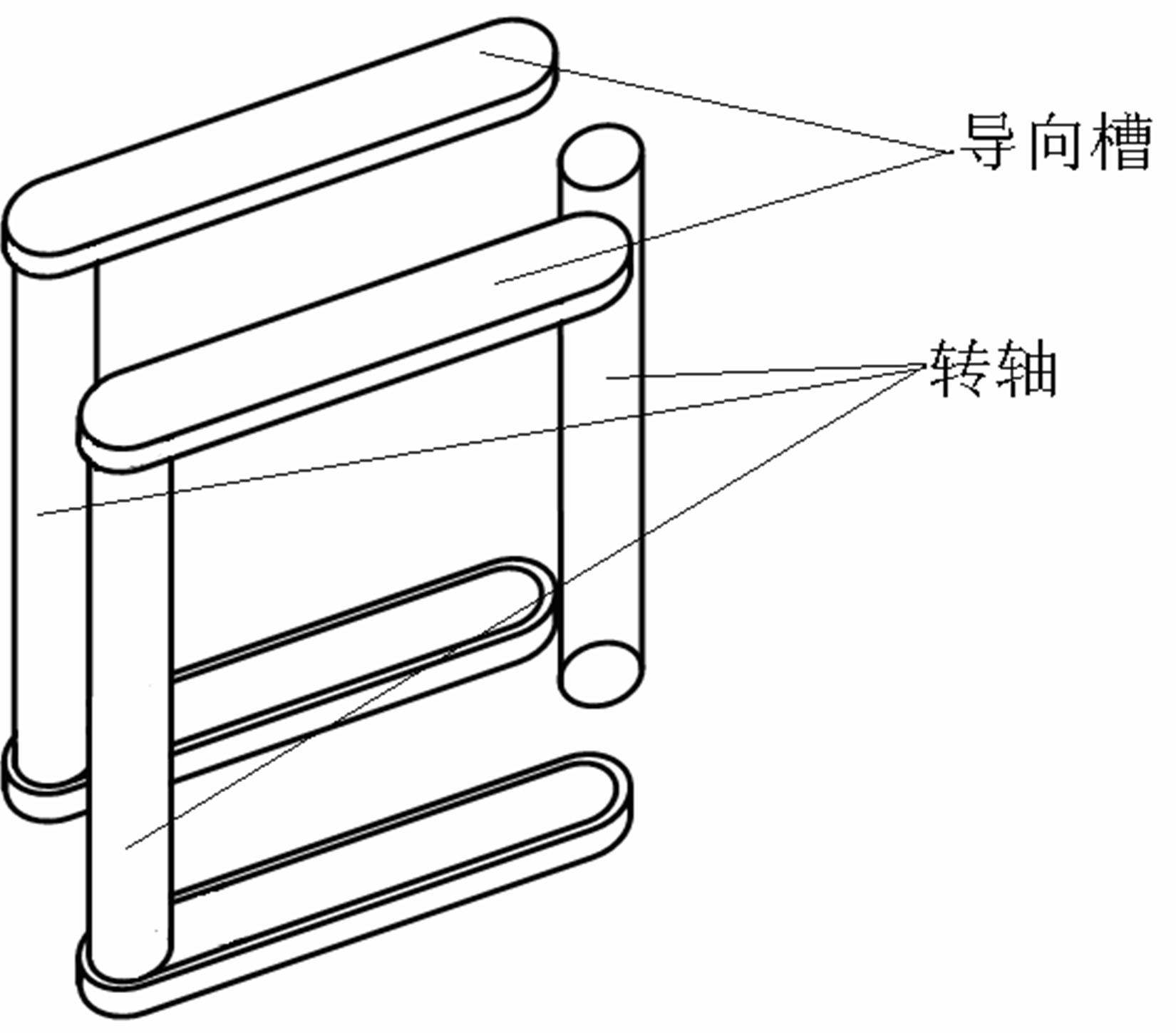

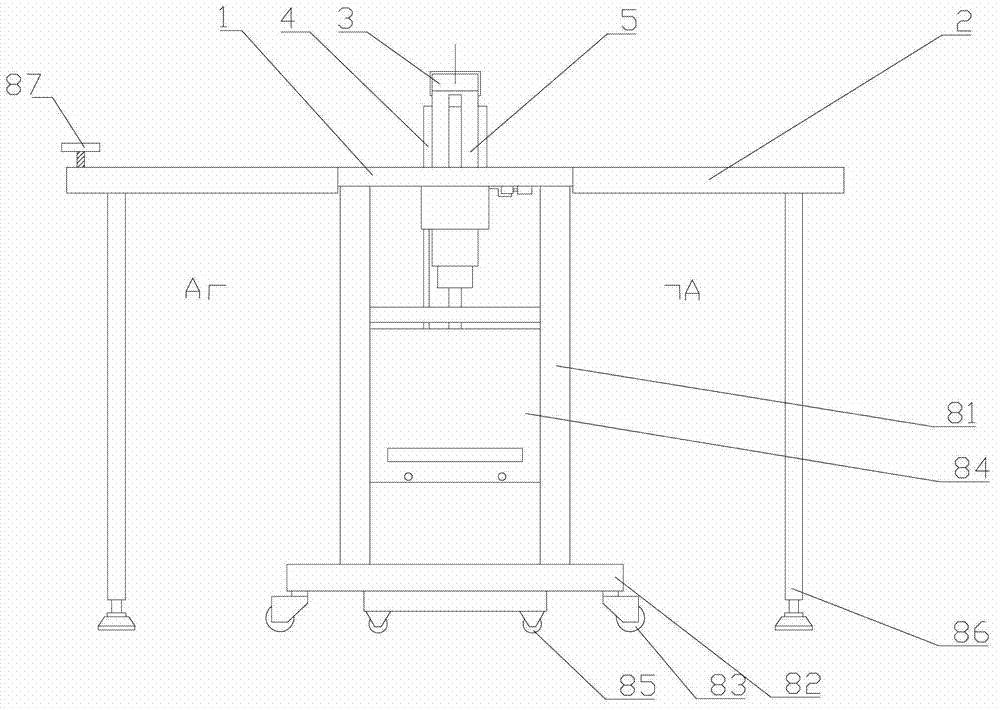

Straight-ejection inclined core-pulling device for multiple parallel linked core blocks for injection mold

The invention discloses a straight-ejection inclined core-pulling device for multiple parallel linked core blocks for an injection mold. The device comprises a straight-ejection inclined rail sliding block (1), an oil cylinder (2), an inclined pulling core block A (3) and a inclined pulling core block B (4), wherein the right side of the straight-ejection core block-pulling sliding block is provided with a bevel sliding rail; the right sides of the inclined pulling core block A and the inclined pulling core block B are provided with core-pulling profiles, the left sides of the inclined pulling core block A and the inclined pulling core block B are provided with a sliding chute A and a sliding chute, respectively, and the pressure angles of the sliding chute A and the sliding chute B are different; the inclined pulling core block A and the inclined pulling core block B are parallel, have different inclined pulling angels and are respectively slidingly connected with the bevel sliding rail of the straight-ejection inclined rail sliding block through the sliding chute A and the sliding chute B; a cylinder body of the oil cylinder is fixedly and vertically connected with a movable mold support plate along an up-down direction, the lower surface of the straight-ejection inclined rail sliding block is fixedly connected with a piston rod of the oil cylinder; when the core-pulling is performed, the oil cylinder drives the straight-ejection inclined rail sliding block to vertically move downward, and the inclined pulling core block A and the inclined pulling core block B are respectively demolded from respective core-pulling axes synchronously. By adopting the technical scheme, the parallel multi-core block mold achieves the aim of simplifying structure, reducing the size and reducing cost.

Owner:宁波宇升模塑有限公司

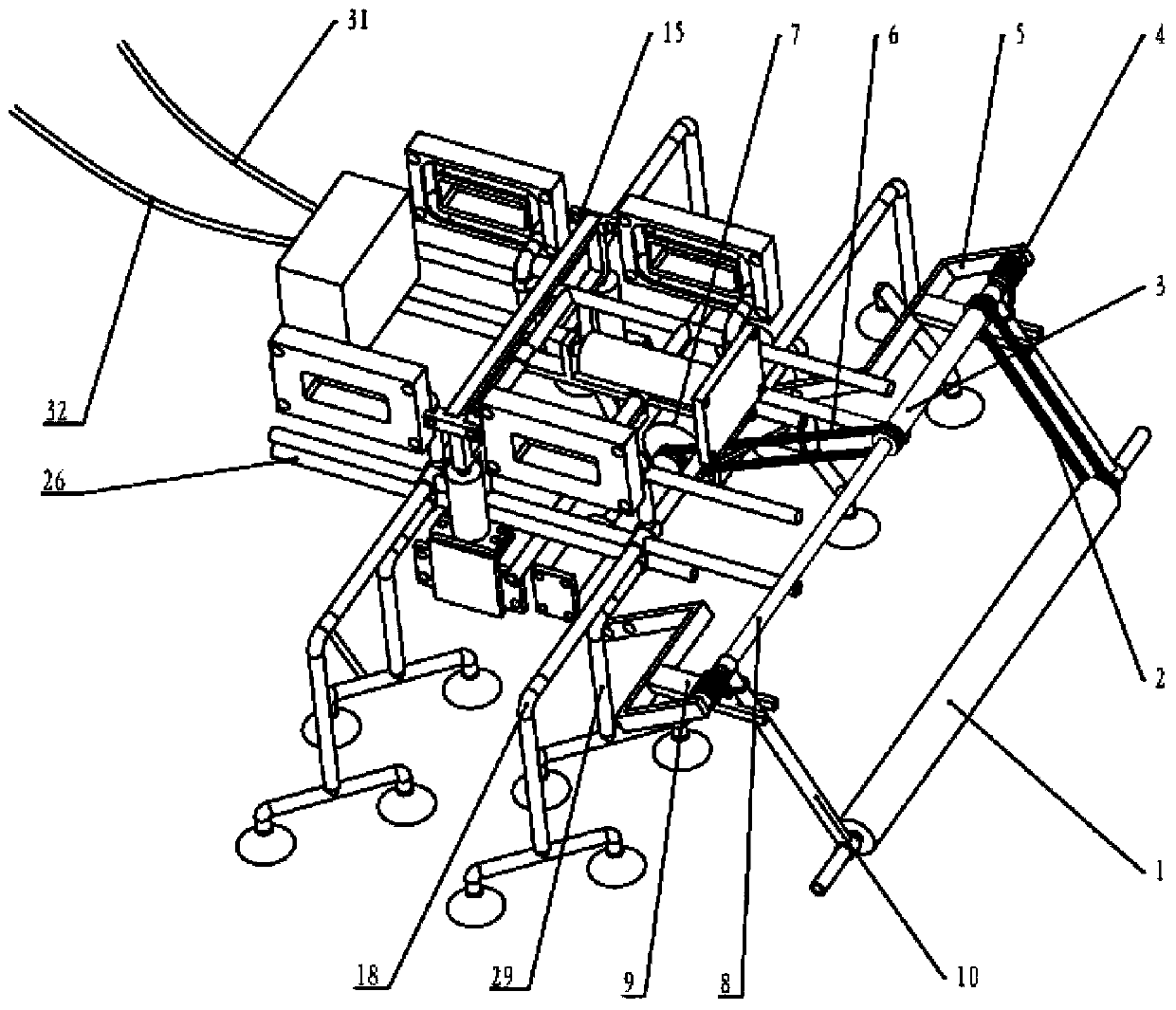

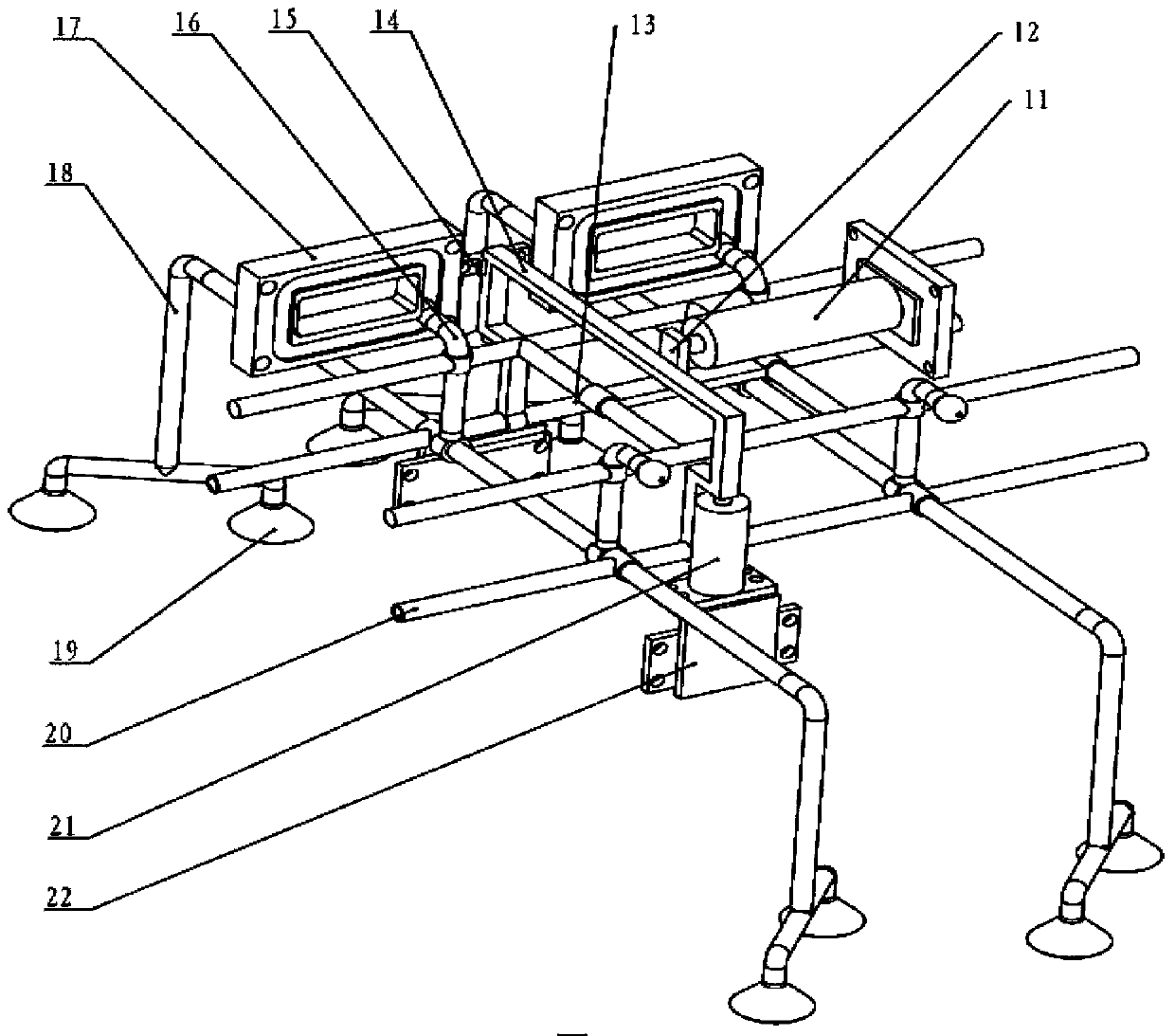

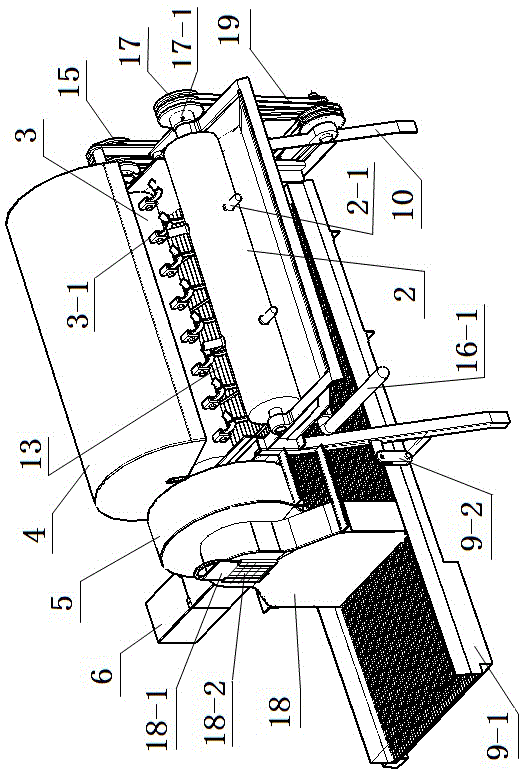

Offshore platform dry type pile leg inner wall crawling robot

ActiveCN106428277AAchieve scaleReal-time adjustment of acquisition densityVehiclesEngineeringControl theory

The invention relates to a pure power-driven crawling robot. The overall robot is composed of an upper leg group, a lower leg group, electromagnetic suction cup, a body, motors, screw nuts and other mechanisms. Extensible movement of the robot mechanism is achieved through the motors and the screw nuts, and guiding and supporting are achieved through a guiding rail mechanism. Vertical reciprocating crawling of the robot is achieved through cooperation of extension and absorption the leg groups and extension of the body. The overall robot can freely crawl in a semicircular columnar space in a dry type pile leg and step over a flange obstacle in the joint in the middle of the pile leg through a mode of step size changing. According to the robot, a pile leg inner wall defect detecting device or an operating device can be carried, human operation can be replaced, safety of the pile leg and even a platform system is improved, and overhauling cost is saved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Straightly-jacking and obliquely-drawing device for injection mould

Owner:NINGBO YUEFEI MOLD

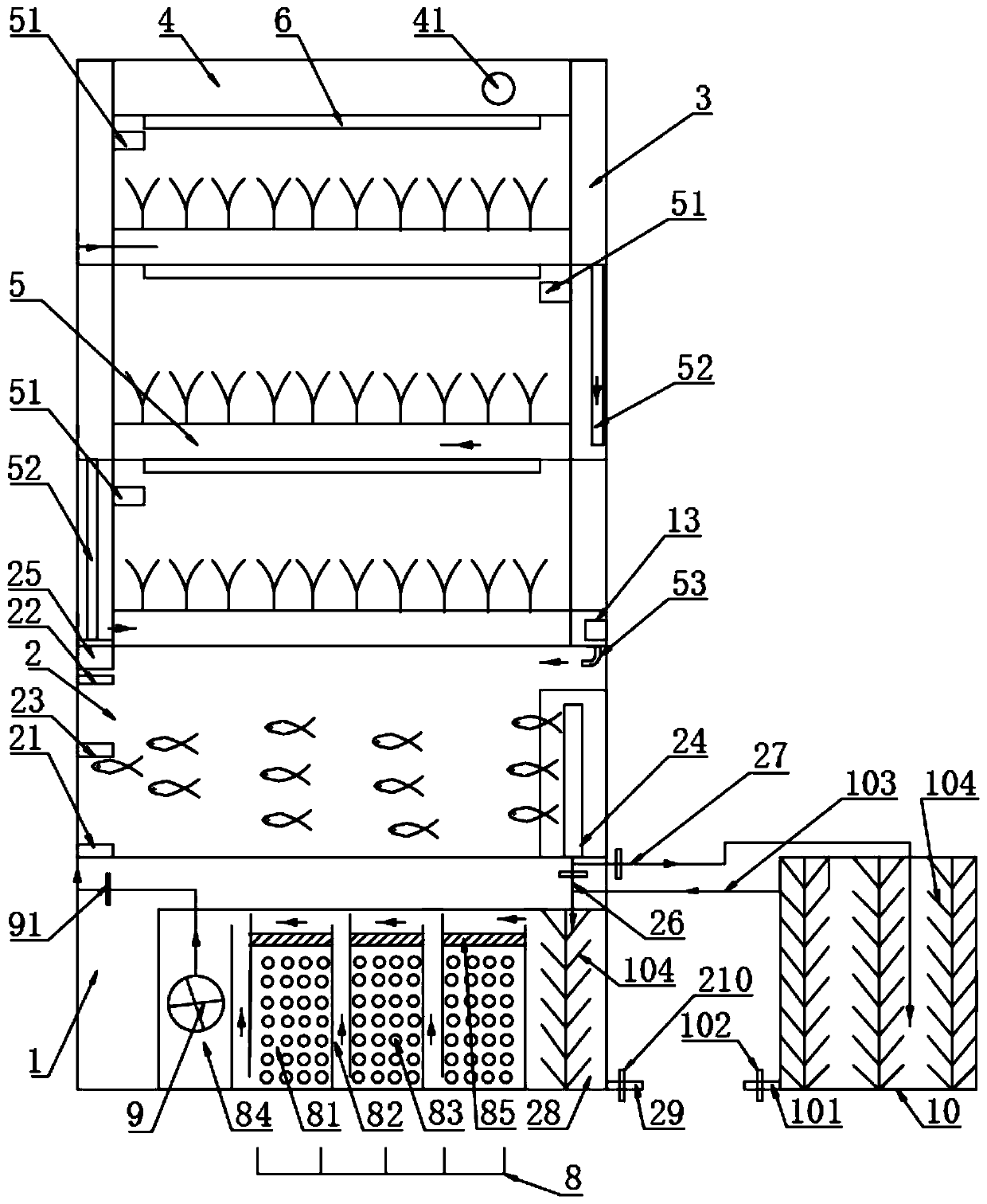

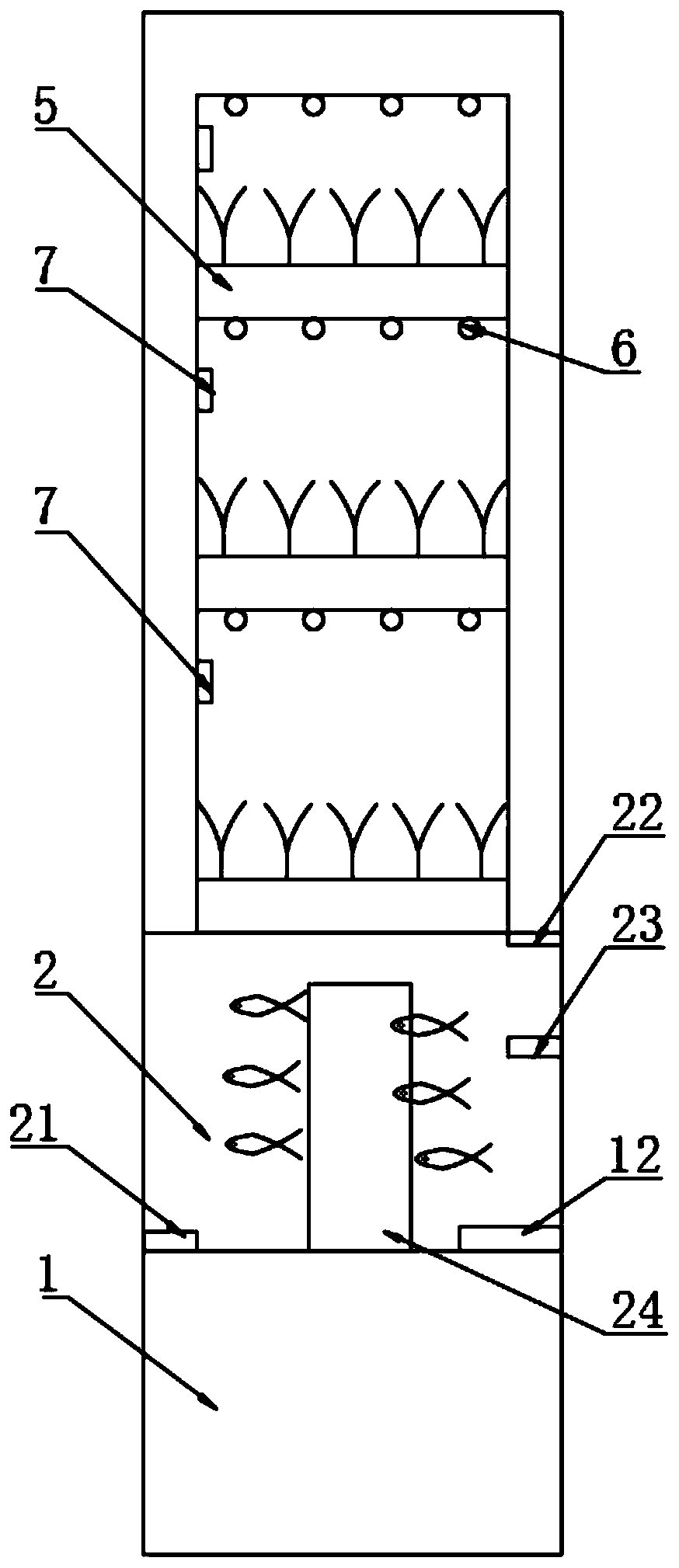

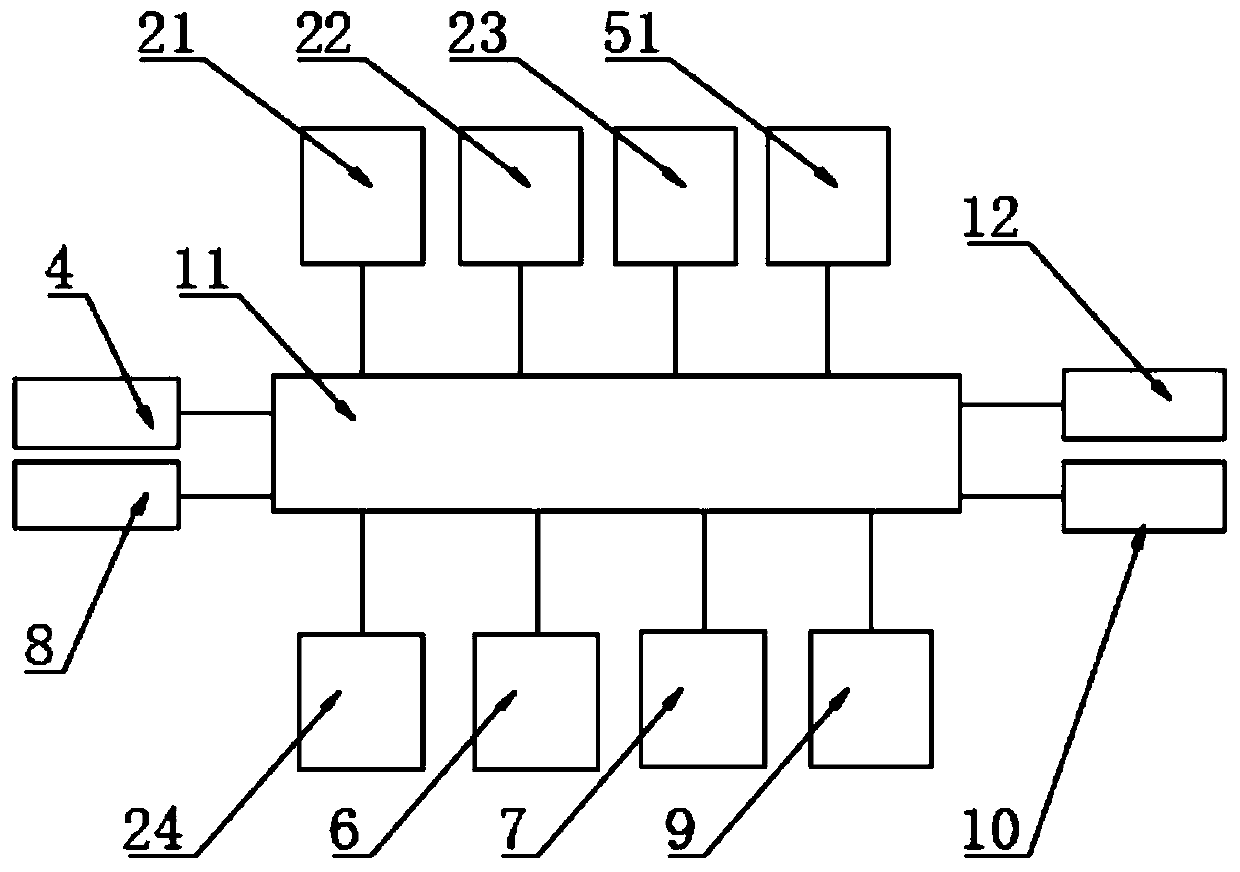

Intelligent aquaponics cultivation equipment

InactiveCN110810308ABeautiful shapeSimple structurePisciculture and aquariaAgriculture gas emission reductionAquaponicsAgricultural science

The invention relates to intelligent aquaponics cultivation equipment and belongs to the field of aquaponics cultivation. The intelligent aquaponics cultivation equipment comprises a rack, a fish tankand a storage cabinet which are sequentially connected from top to bottom and is characterized in that the top end of the rack is provided with a display screen, the interior of the rack is separatedinto multiple layers, the top of each layer is provided with a light-supplementing lamp, the bottom of each layer is provided with a planting tank, a filter communicated with the fish tank is arranged in the storage cabinet, one end of the filter is communicated with the fish tank, the other end of the filter is provided with a water pump, the water pump is communicated with the planting tanks through water pipes, the planting tank is communicated with the fish tank, and the fish tank, the display screen, the planting tanks, the light-supplementing lamps, the filter and the water pump are electrically connected with a PLC. The intelligent aquaponics cultivation equipment is simple in structure, convenient to operate, capable of effectively solving many inconveniences in aquaponics cultivation by the PLC, the fish tank, the planting tanks, the light-supplementing lamps, fans, the filter, the water pump and a fermentation tank, relatively small in size, capable of being movably placed at home and in offices, hotels and supermarkets and capable of beautifying the environment and producing organic vegetables and fish for people.

Owner:烟台宏远光电科技有限公司

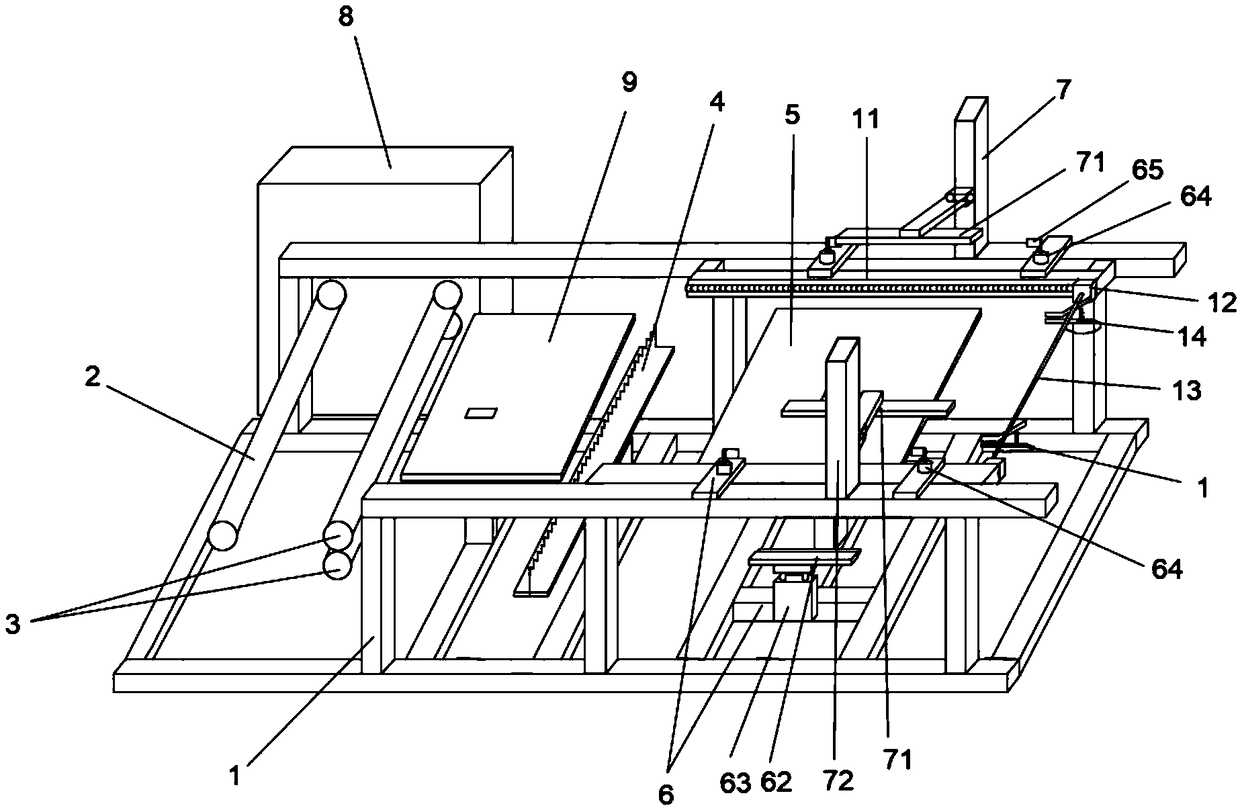

Novel film lamination device for packaging boards

The invention discloses a novel film lamination device for packaging boards. The novel film lamination device comprises a stander, wherein a fixed roll, a rubber covering roll, a cutter assembly, a film laminating table surface and a side brushing mechanism are sequentially arranged from one end to the other end of the stander in the length direction; a compression mechanism for fixing a to-be-film-laminated packaging board to the film laminating table surface is arranged on at least one side, located in the width direction of the stander, of the film laminating table surface, and after the stress of the compression mechanism to the packaging board is relieved, a mounting space for taking away the film-laminated packaging board and putting the next packaging board to the film laminating table surface is formed. According to the novel film lamination device, the operation of a worker is facilitated, the length of the whole film lamination device is shortened, and the film lamination device is convenient to move, so that the occupied space of equipment is reduced, meanwhile, the production cost is lowered, and the operation safety is improved.

Owner:SUZHOU BAOTEYUAN ELECTRONICS TECH CO LTD

Hydraulic power experimental flow box capable of being used for flow field measurement and visualization research

The invention discloses a hydraulic power experimental flow box capable of being used for flow field measurement and a visualization research. The hydraulic power experimental flow box comprises a visualization conical pulp distribution device, a visualization step diffuser, a visualization setting chamber, a visualization turbulence generator, a visualization lip chamber and a dilution water supply system, wherein the visualization conical pulp distribution device, the visualization step diffuser, the visualization setting chamber, the visualization turbulence generator and the visualization lip chamber are connected in sequence to form a box body structure; every adjacent two of the visualization conical pulp distribution device, the visualization step diffuser, the visualization setting chamber, the visualization turbulence generator and the visualization lip chamber are sealed through a concave-convex surface or a tongue-and-groove; meanwhile, a dilution water injection port is arranged on the visualization conical pulp distribution device, and the dilution water supply system is connected with the dilution water injection port through a dilution water pipe. The hydraulic power experimental flow box enables the flow field measurement and the visualization research of the flow box to be conducted conveniently, can effectively realize sealing between nonmetal and nonmetal, and is quite convenient to dismount.

Owner:SOUTH CHINA UNIV OF TECH

Heating method with heat stored in electromagnetic induction heating mode and heat released slowly

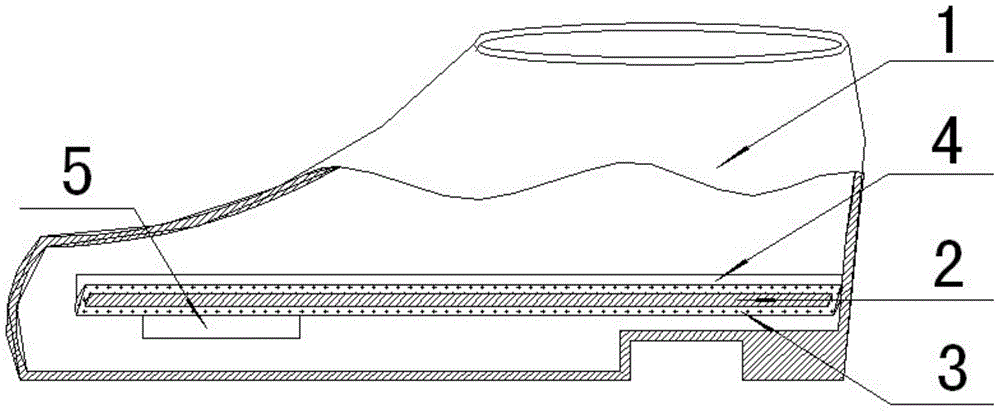

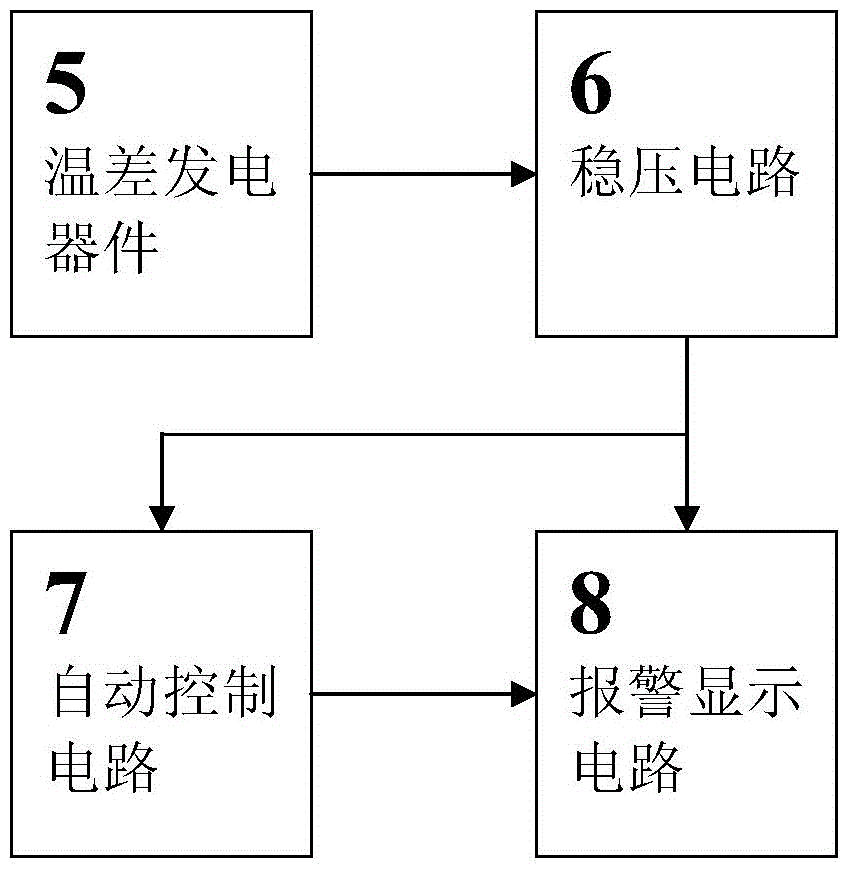

InactiveCN103561494AShort heating timeSave charging timeGlovesFootwearThermal energyAutomatic control

The invention discloses a heating method with heat stored in an electromagnetic induction heating mode and heat released slowly. Electromagnetic induction is adopted to carry out heating directly, temperature difference power generation appliances output electric energy through the temperature difference effect, temperature adjustment through high thermal expansion materials is adopted, and therefore thermal energy conversion and automatic control of electrically-warmed shoes or electrically-warmed gloves are achieved. According to the heating method with heat stored in the electromagnetic induction mode and heat released slowly, non-contact type heaters such as induction cookers or matched special electromagnetic induction heaters are adopted to carry out direct heating on the electrically-warmed shoes or the electrically-warmed gloves, the temperature difference power generation appliances generate electric energy to start a control circuit to display the heat storage capacity and the heating usage time, and gives out an alarm under the overheating and needed heat storage conditions. The heating method with heat stored in the electromagnetic induction heating mode and heat released slowly is exquisite in design, simple in structure, stable in performance and convenient to use, due to the fact that no power lines, batteries or power generators are arranged, and the whole heating appliances are all packaged into a whole, heat preservation performance is better, and heat storage and heat release time is longer; when heating is conducted, the heating appliances can be moved to any place, so that the heating method with heat stored in the electromagnetic induction heating mode and heat released slowly can be widely applied to the field of daily-used heating articles such as shoes of any models and gloves of any models.

Owner:顾晓烨

Wheat-threshing and cornstalk-cutting machine

InactiveCN104969728AEasy to bagWon't fly backMowersThreshersAgricultural engineeringAgricultural machinery

The invention relates to a grain-threshing and stalk-cutting machine in agricultural machinery, specifically to a wheat-threshing and cornstalk-cutting machine. A conventional wheat-threshing machine can only smash and thresh sundried wheat and has the disadvantages of single function, complex and cumbersome structure, and largely-required power. The wheat-threshing and cornstalk-cutting machine provided by the invention comprises a frame, and a feeding table, a smashing-threshing cabin, a vibration screen mechanism, an air exhausting mechanism and a packing auger conveyer which are arranged on the frame, wherein the feeding table is arranged in the front and upper part of the smashing-threshing cabin; the lower part of the smashing-threshing cabin is provided wtih the vibration screen mechanism; the air exhausting mechanism is arranged above the rear half part of the vibration screen mechanism and at the left side of the smashing-threshing cabin; and the rear part of the smashing-threshing cabin is provided with the packing auger conveyer. The wheat-threshing and cornstalk-cutting machine provided by the invention has the advantages of compact structure, light weight, low cost, small equipped power, clean separation of grain and stalk powder, convenient bagging of grain, no air pollution, timely halt and rescue treatment, no need of wheat sundrying treatment and capablities of cutting and smashing cornstalks.

Owner:穆合塔尔·图尔荪

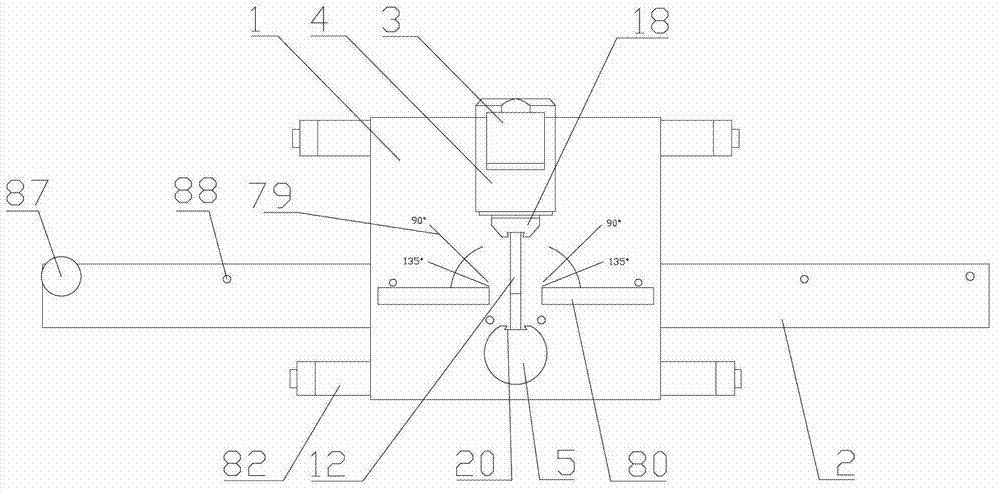

Under-cut demolding device for straightly pulling and transversely extracting injection mold

The invention discloses an under-cut demolding device for straightly pulling and transversely extracting an injection mold. The demolding device comprises two under-cut core blocks (1), two straight-pulling slide blocks (2) and an oil cylinder (2). The technical scheme is adopted as follows: a molded surface is arranged on the centrifugal side surface of each under-cut core block; an inclined slide rail is arranged on the centripetal side surface of each under-cut core block; an inclined slide groove corresponding to the inclined slide rail is formed in the centrifugal side surface of each straight-pulling slide block; the two straight-pulling slide blocks are respectively arranged in vertical mounting grooves formed in the left side surface and the right side surface of a mold core; the lower surfaces of the straight-pulling slide blocks are connected with a piston rod of the oil cylinder; a cylinder body of the oil cylinder is fixedly connected with a movable mold support plate; the two under-cut core blocks are arranged in horizontal mounting grooves in the left side surface and the two side surface of the mold core, and are in sliding fastened connection with the straight-pulling slide blocks through inclined slide rail grooves; the oil cylinder pulls the straight-pulling slide blocks downwards during working; the straight-pulling slide blocks drive the under-cut core blocks to transversely move along the horizontal mounting grooves through the inclined slide rail grooves in a centripetal manner, so that the under-cut core blocks are transversely extracted from an under-cut structure in a product; and then the product is pushed out from a top plate and a top rod upwards, and thus, due to the injection mold with a plurality of under-cut demolding devices, the shape is reduced, and the cost is lowered.

Owner:NINGBO YUSHENG MOLD & PLASTICS

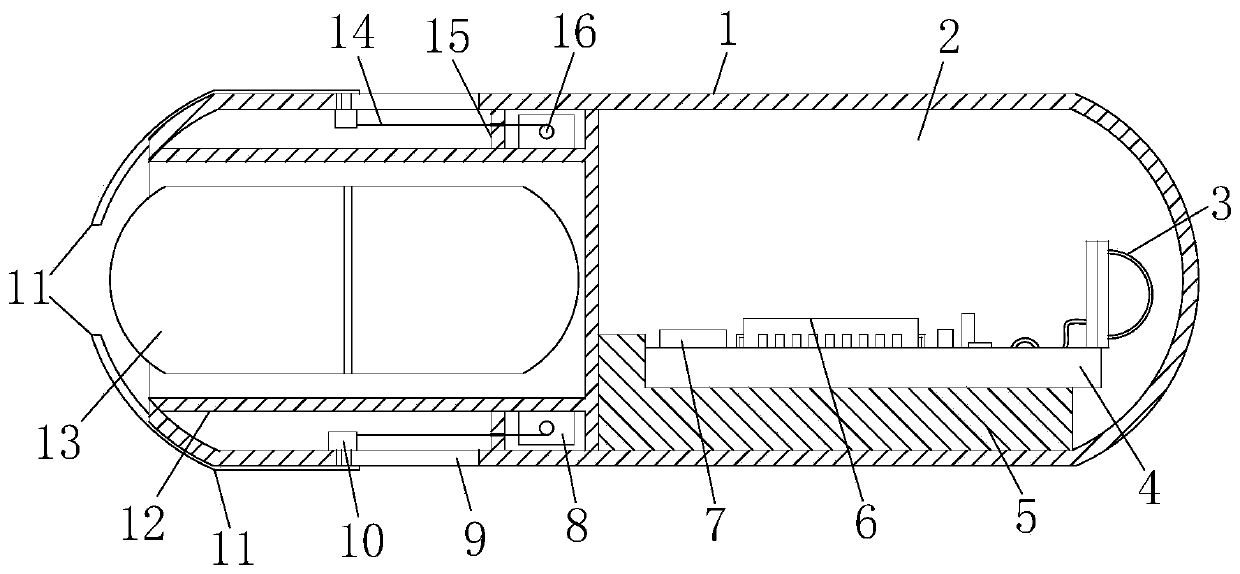

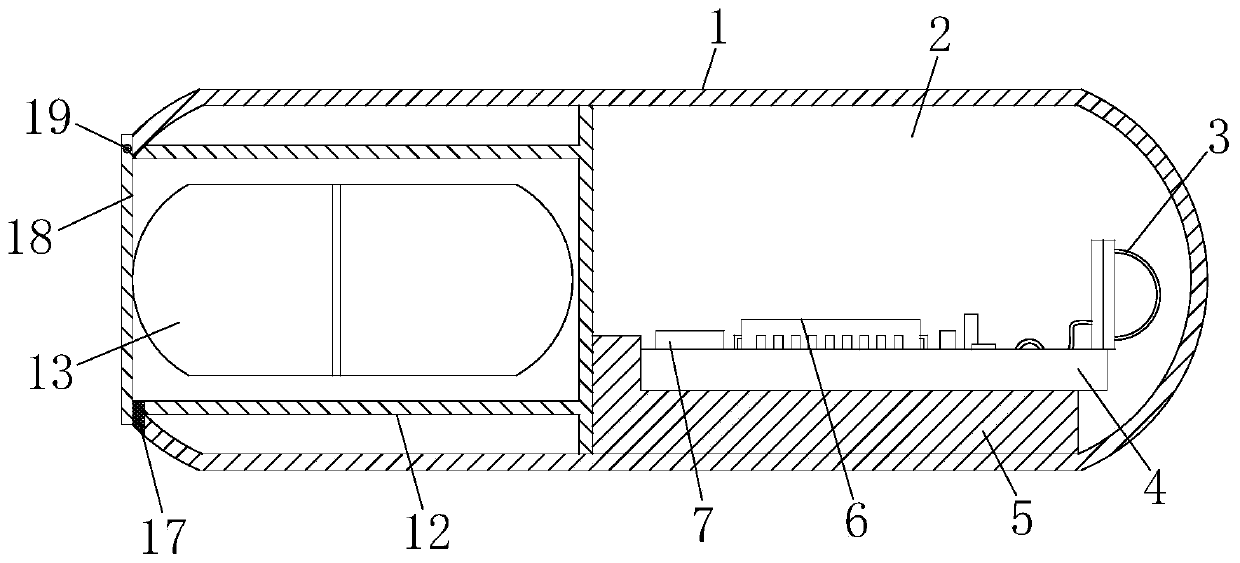

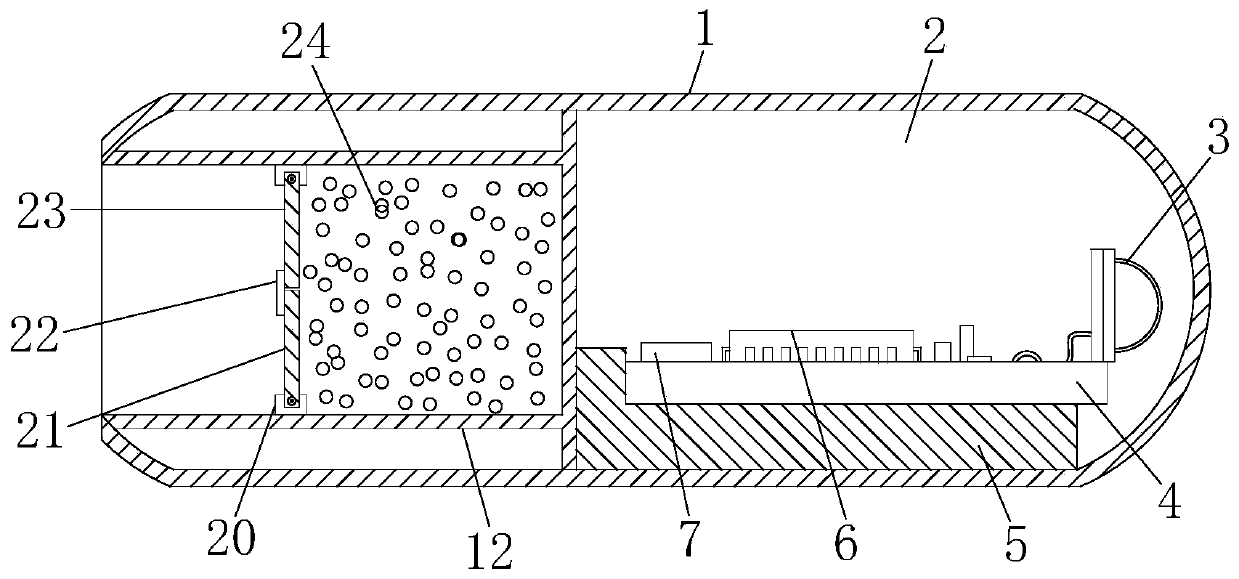

Target medicine transporting field control micro nanometer robot

InactiveCN110393848APrecision therapyConvenient treatmentMicromanipulatorMedical devicesDiseaseKinematics

The invention discloses a target medicine transporting field control micro nanometer robot. The target medicine transporting field control micro nanometer robot comprises a micro nanometer robot housing, wherein a sealing cavity is formed in a position at the inner right side of the micro nanometer robot housing; a control main board is arranged in the sealing cavity; a processor and a battery aremounted on the control main board; a camera is mounted at a position at the right end of the control main board; a partition board is arranged at a position on the left side in the micro nanometer robot housing; capsule medicines are arranged in the partition board; a fixed seat is arranged at a position at the bottom in the sealing cavity; barrier chips are respectively arranged at positions ofthe upper side and the lower side of the upper left side of the micro nanometer robot housing; and micro motors are respectively mounted at positions adjacent to the right end of the upper side and the lower side of the partition board on the inner left side of the micro nanometer robot housing. According to the target medicine transporting field control micro nanometer robot disclosed by the invention, the micro nanometer robot carries target medicines to enter the human body, and a conventional magnetism guiding transfer technology is adopted to guide the kinematic trajectory of the robot inthe human body; and when the diseased region is found, the target medicines are directly released, so that accurate treatment is realized, the medicine effect of the medicines is sufficiently utilized to treat the diseased region, the treatment of the disease is facilitated, and besides, the accuracy is high.

Owner:NANJING YUSHENG ROBOT CO LTD

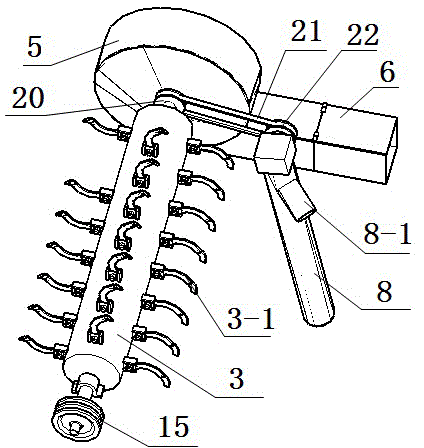

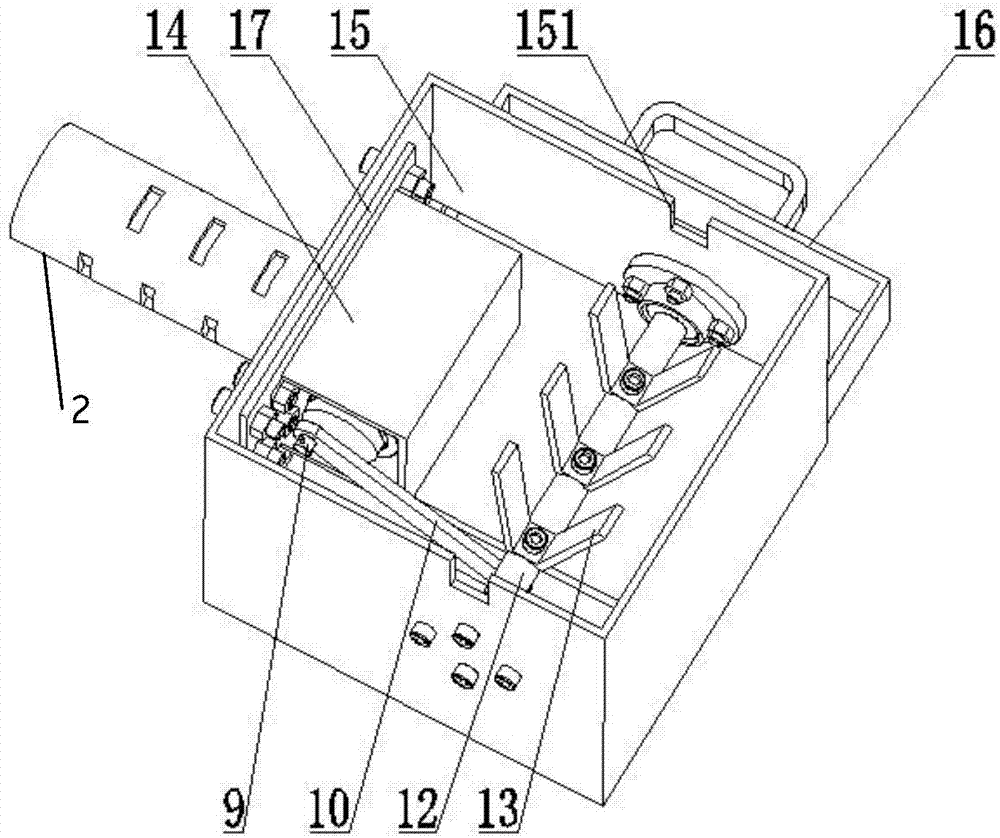

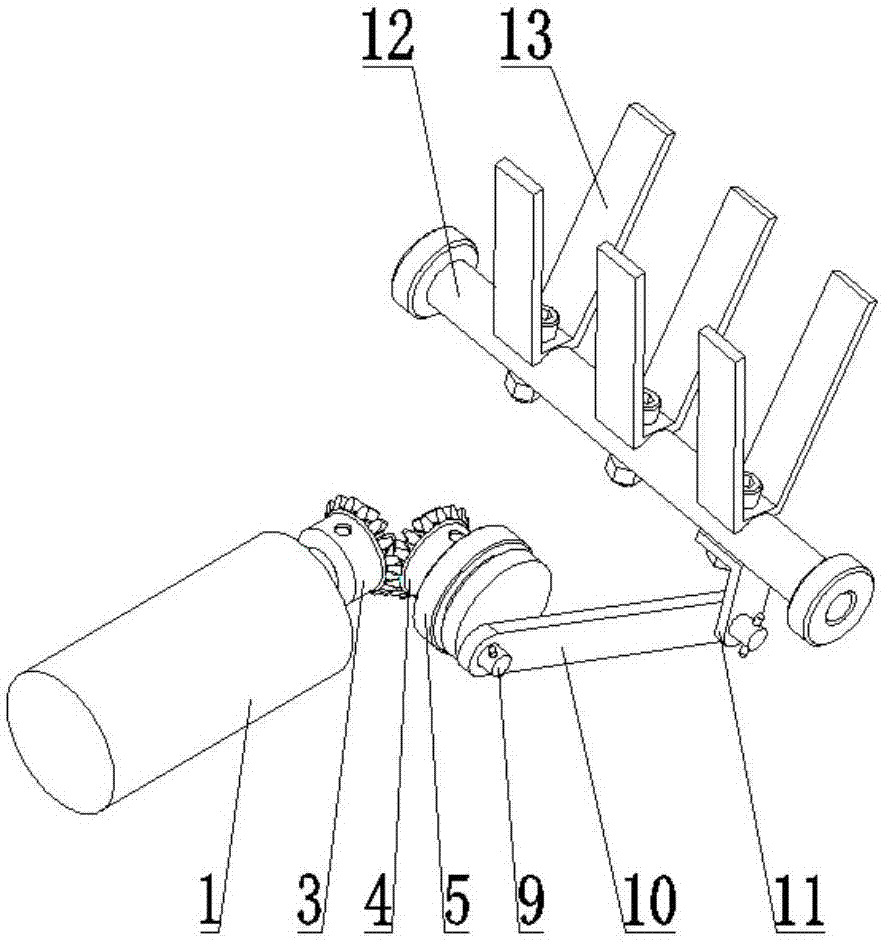

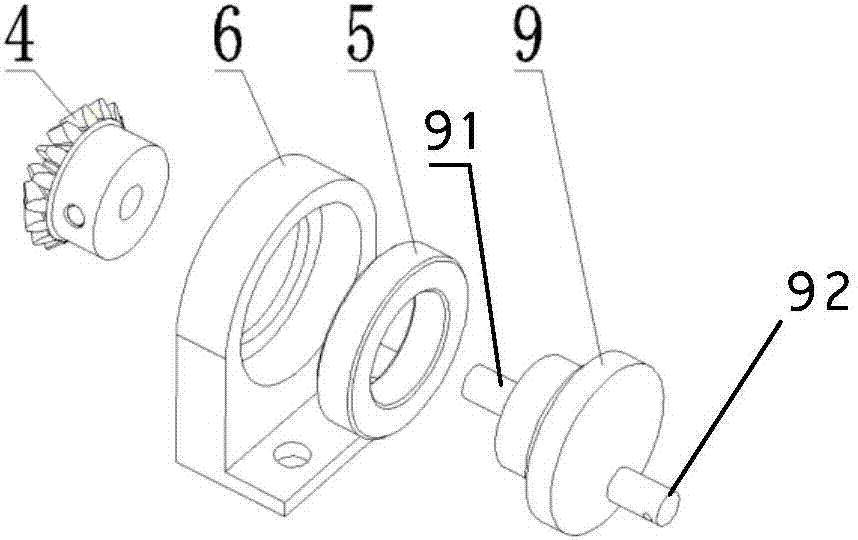

Handheld vibratory matrimony vine harvester

ActiveCN107360796AAchieve pickingRealize the integration of harvestingPicking devicesHuman bodyEngineering

The invention relates to the field of agricultural machinery, in particular to a handheld vibratory matrimony vine harvester. The harvester comprises a direct current motor (1), a motor protecting shell (2), a first bevel gear (3), a second bevel gear (4), a second bearing (5), a second bearing base (6), an eccentric wheel with a shaft (9), a straight connecting rod (10), an L-shaped connecting rod (11), a rotating shaft (12), a flap finger (13), a protective cover (14), an installation box (15), a collecting box (16) and an installation plate (17). A crank rocker mechanism of the harvester can drive the flap finger to constantly flap matrimony vine branches to produce a certain amplitude of vibration, and therefore matrimony vine fruits are separated from the branches under the action of inertia force to achieve picking. In the process of harvesting, the vibration direction of the matrimony vine branches is as the same as the direction of picking staff' arms, which can reduce the impact of the vibratory force of the harvester on human bodies. The harvester has the advantages of a simple structure, convenient operation, low costs and a long service life, and meanwhile guarantees high picking efficiency.

Owner:CHINA AGRI UNIV

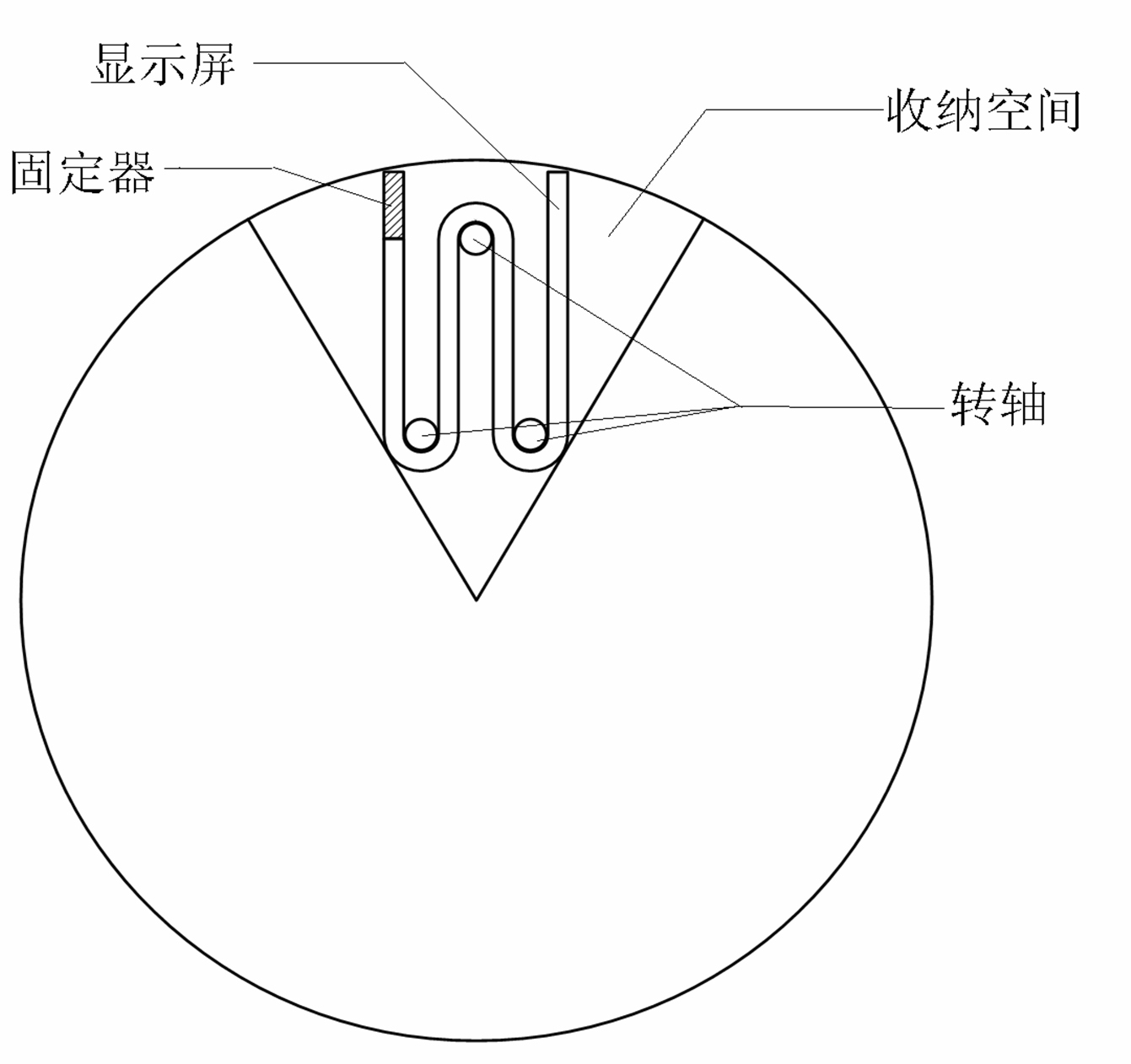

Mobile phone

ActiveCN102104643ASmall footprintSmall bodyCurrent supply arrangementsTelephone set constructionsMobile phoneComputer science

The invention discloses a mobile phone. The mobile phone comprises a body. The mobile phone is characterized in that the mobile phone also comprises a plurality of expansible display screens, a bearing device fixed in the body and connected with the display screens and a driving device driving the display screens to expand out of the body after being started, wherein display screen extending holes corresponding to the display screens are arranged on the body; and the body is provided with one or more containing space for containing the display screens in the retraction states. The mobile phone will bring the users a brand-new feeling. The mobile phone has the following advantages: the mobile phone adopts compact design; the display screens are internally arranged; the space occupied for storage is reduced; and the whole body is smaller, can be easily put in the bag and is convenient to carry.

Owner:ZTE CORP

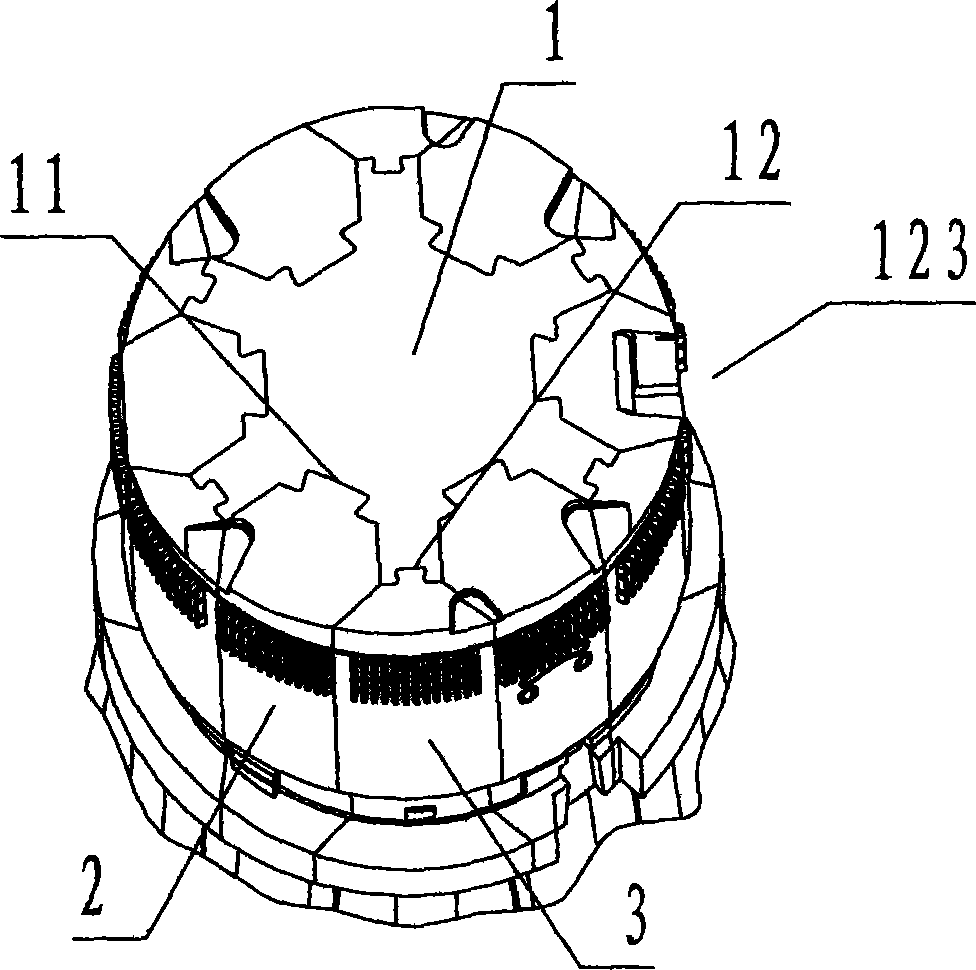

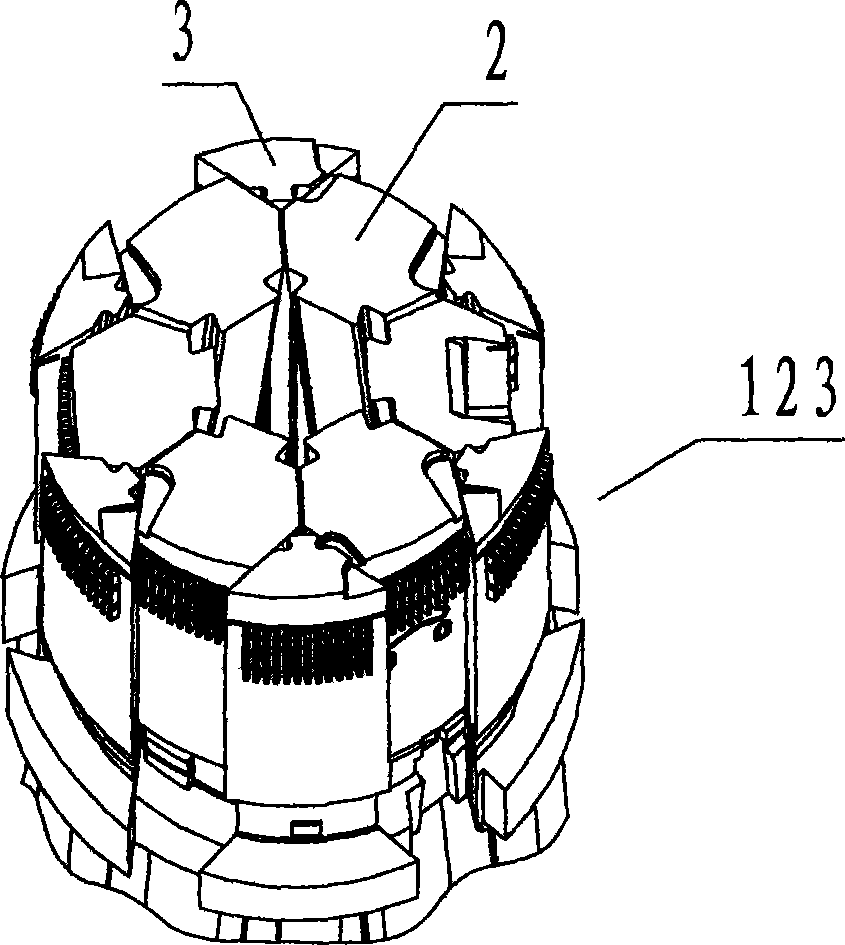

Core pulling device of cylindrical core with backoff structures uniformly distributed on cylindrical surface

Owner:宁波和鑫光电科技有限公司

Small light numerically-controlled bus processing machine

The invention relates to a small light numerically-controlled bus processing machine. The small light numerically-controlled bus processing machine comprises a platen, supporting plates, a grating controller, an oil cylinder, a pressure head, an upright column, a shearing mold, a punching mold and a bending mold, wherein an oil cylinder insertion hole, a guide groove and an upright column fixing hole are formed in the platen respectively, the oil cylinder is inserted in the oil cylinder insertion hole and fixed on the platen, and the upright column is fixed on the platen; a strengthening plate is connected with the lower wall surface of the platen, the upright column and a strengthening sleeve; a falling object chute is formed in the strengthening plate, a section of the guide groove is correspondingly formed above the falling object chute, the pressure head is arranged at the front end of a piston rod of the oil cylinder, a first dovetail groove is formed in the pressure head, a second dovetail groove is formed in the upright column, and the supporting plates are positioned on two sides of the platen; a grating scale is connected below the pressure head, and arranged on the lower bottom surface of the platen; and a shearing stripping groove penetrating a middle shaft of the upright column and the whole upright column is formed in the side surface of the upright column, and an opening on one side of the shearing stripping groove is positioned in the second dovetail groove. The small light numerically-controlled bus processing machine has the advantages of functional diversity, simplicity, light weight, small size and the like.

Owner:陈伟民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com