Under-cut demolding device for straightly pulling and transversely extracting injection mold

A technology for injection molds and demoulding devices, applied in the field of undercut core-pulling and demoulding devices, which can solve the problems of increased mold size, increased operating costs, and cramped internal space of the mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

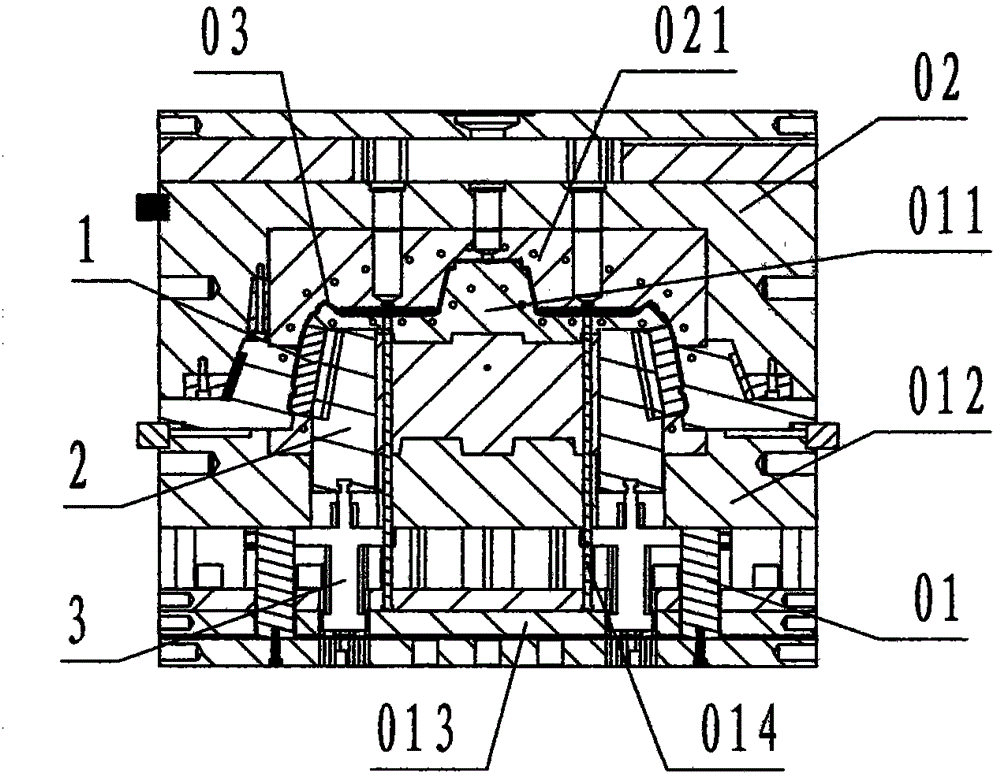

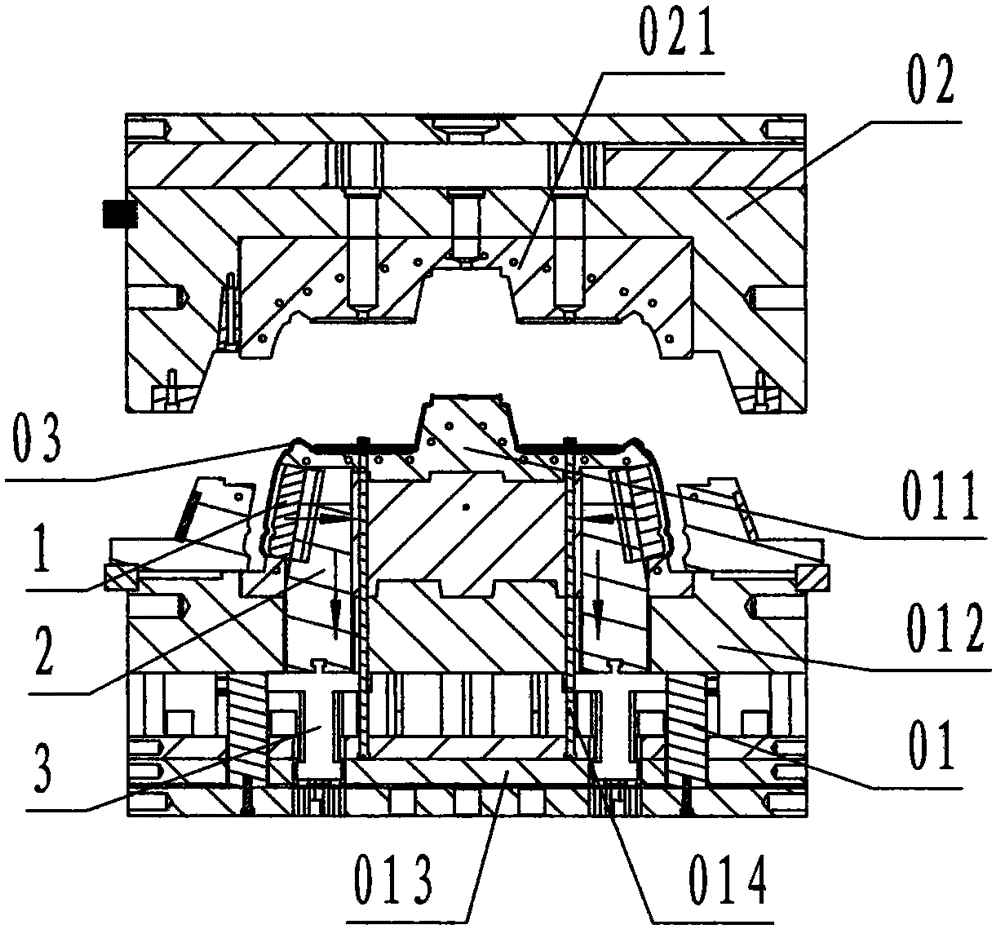

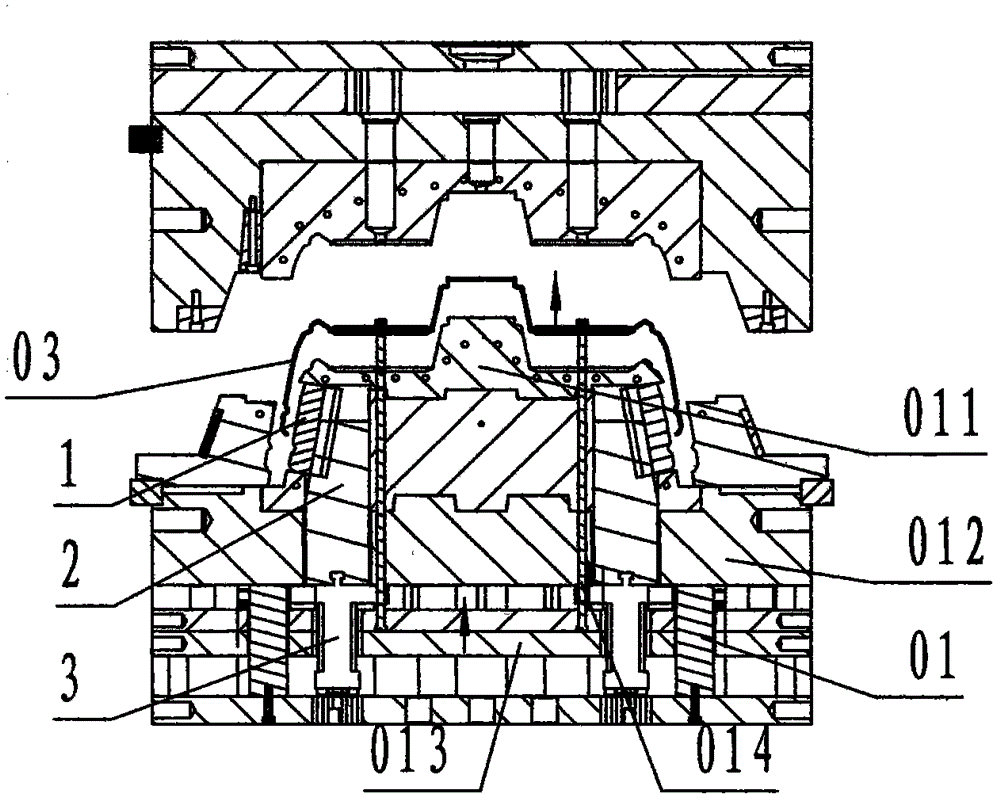

[0018] refer to Figure 1 ~ Figure 3 , an injection mold straight-pull, horizontal-draw, reverse buckle stripping device of the present invention comprises a buckle core block 1, a straight pull slider 2, and an oil cylinder 3, wherein: the buckle core block 1 is a rectangular block of steel Quality components; the centrifugal side of the inverted core block 1 is provided with a profile corresponding to the internal inverted surface of the product, and the centripetal side of the inverted core block 1 is provided with a T-shaped inclined slide rail inclined from bottom to top. ;

[0019] The straight-pull slider 2 is a rectangular block-shaped steel component; the upper part of the centrifugal side of the straight-pull slider 2 is provided with an inclined chute correspondingly slidingly matched with the inclined slide rail of the inverted core block 1;

[0020] The oil cylinder 3 is a hydraulically telescopic actuator composed of a cylinder body and a piston rod;

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com