Secondary core-pulling and ejection demoulding device by asynchronous inclined downward ejection

A secondary core-pulling and demoulding device technology, which is applied in the field of ejection and demoulding mechanisms, can solve the problems of large mold volume, hindering the upward oblique movement of oblique core-pulling blocks, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

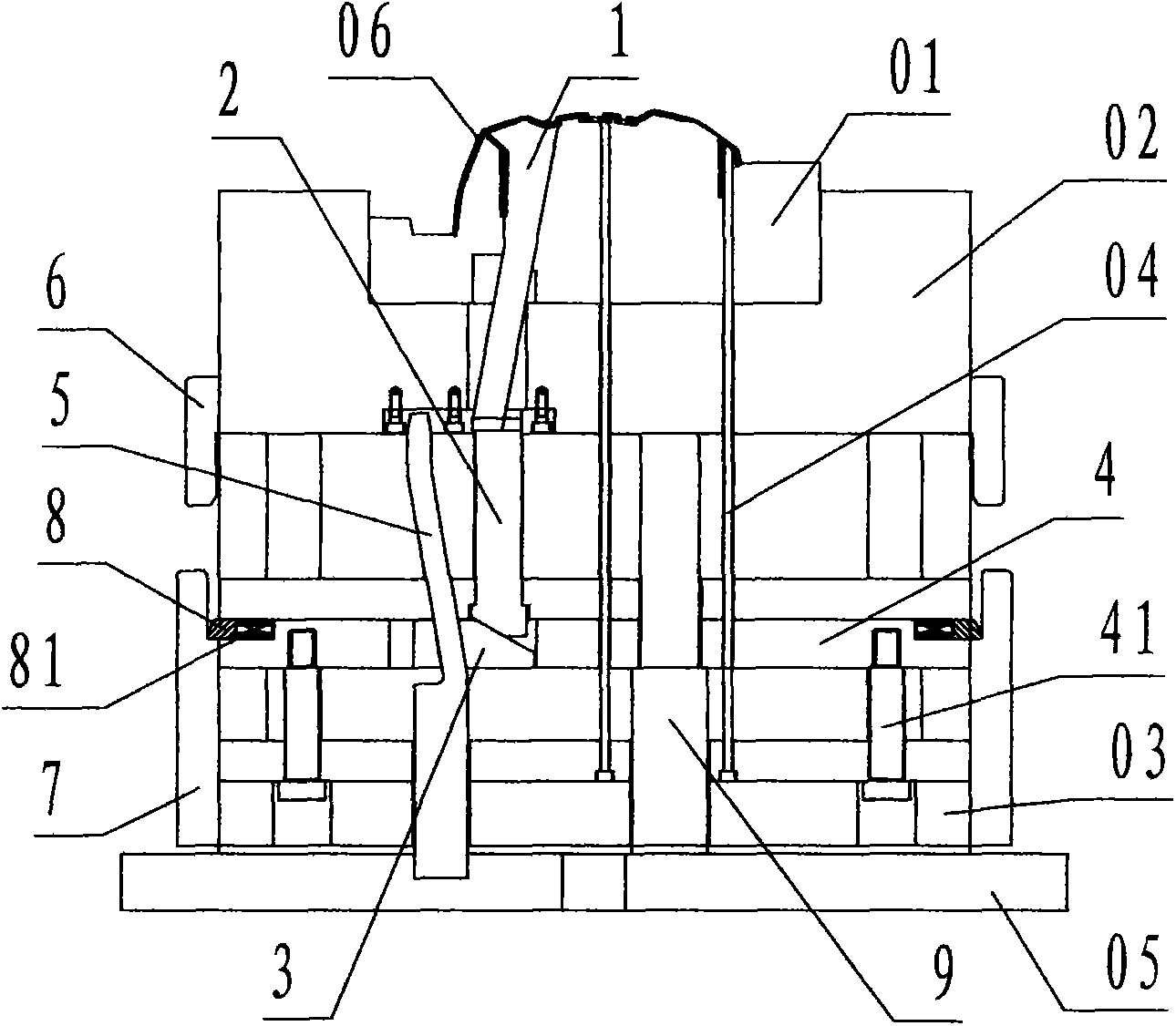

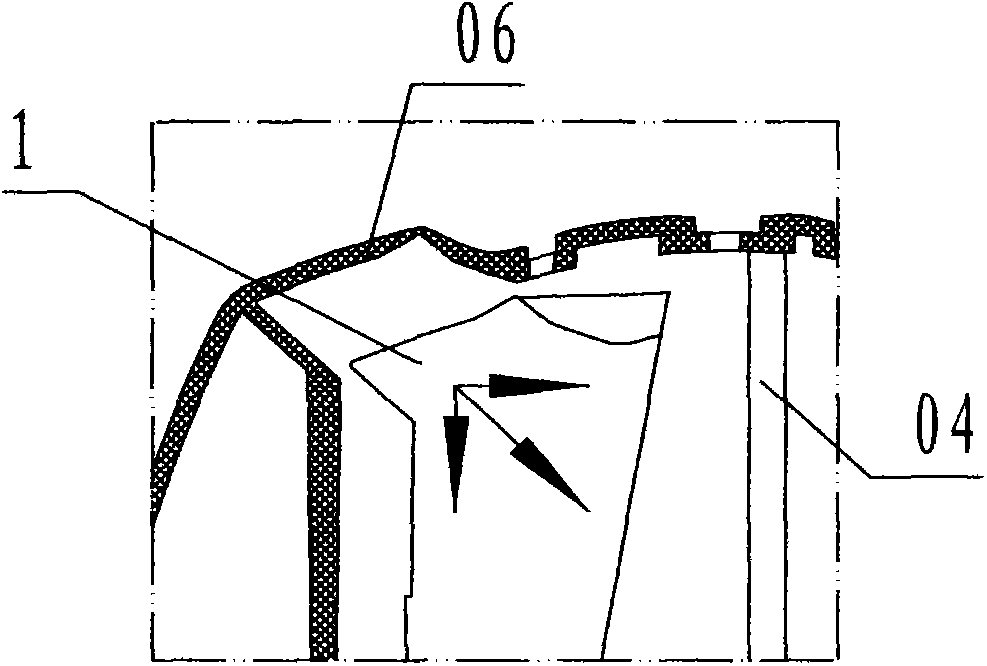

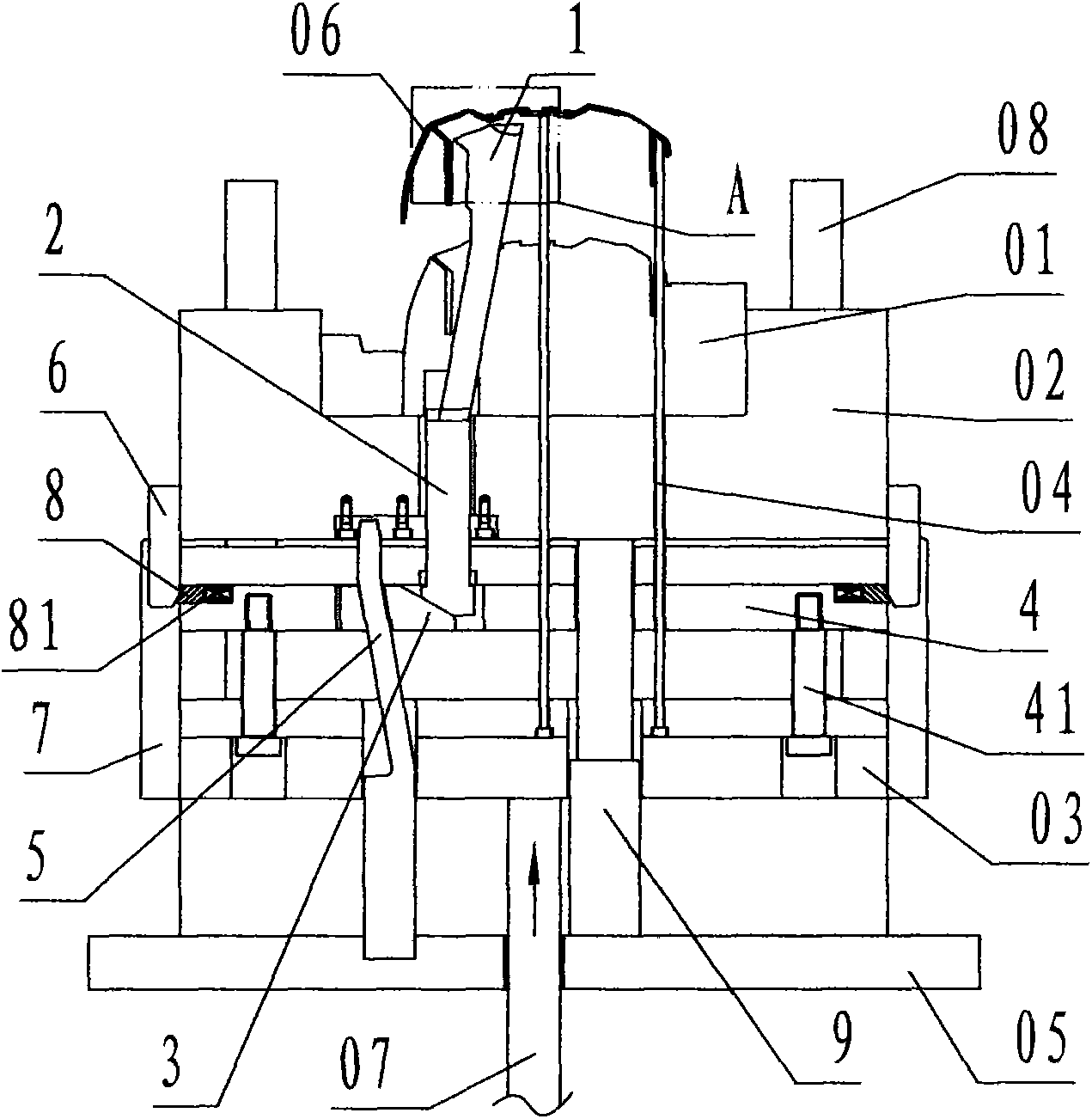

[0024] refer to Figure 1 ~ Figure 4, a secondary core-pulling ejector ejector with an asynchronous inclined roof inclined downwards according to the present invention, comprising an inclined top core-pulling block 1, a longitudinal slider 2, a horizontal slider 3, a horizontal slider carrier plate 4, a dial Moving rod 5, unlocking block 6, lock hook block 7, deadbolt block 8, limit guide post 9, wherein: the inclined top core-pulling block 1 is a long rod-shaped block-shaped steel member in the up and down direction, and the inclined top The top of the core-pulling block 1 is provided with a profile that matches the vertical and horizontal bidirectional structure of the product 06, and the bottom of the inclined-top core-pulling block 1 is provided with a horizontal T-shaped slide rail called a smooth rail;

[0025] The longitudinal slider 2 is a long rod-shaped block-shaped steel member in the up and down direction, and the upper surface of the longitudinal slider 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com