Multi-direction sequential combined core-pulling device for single slide block of injection mould

A technology for injection molds and core-pulling devices, which is applied in the field of single-slider multi-directional sequentially combined core-pulling devices for injection molds, and can solve problems such as prone to failure, increased mold costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

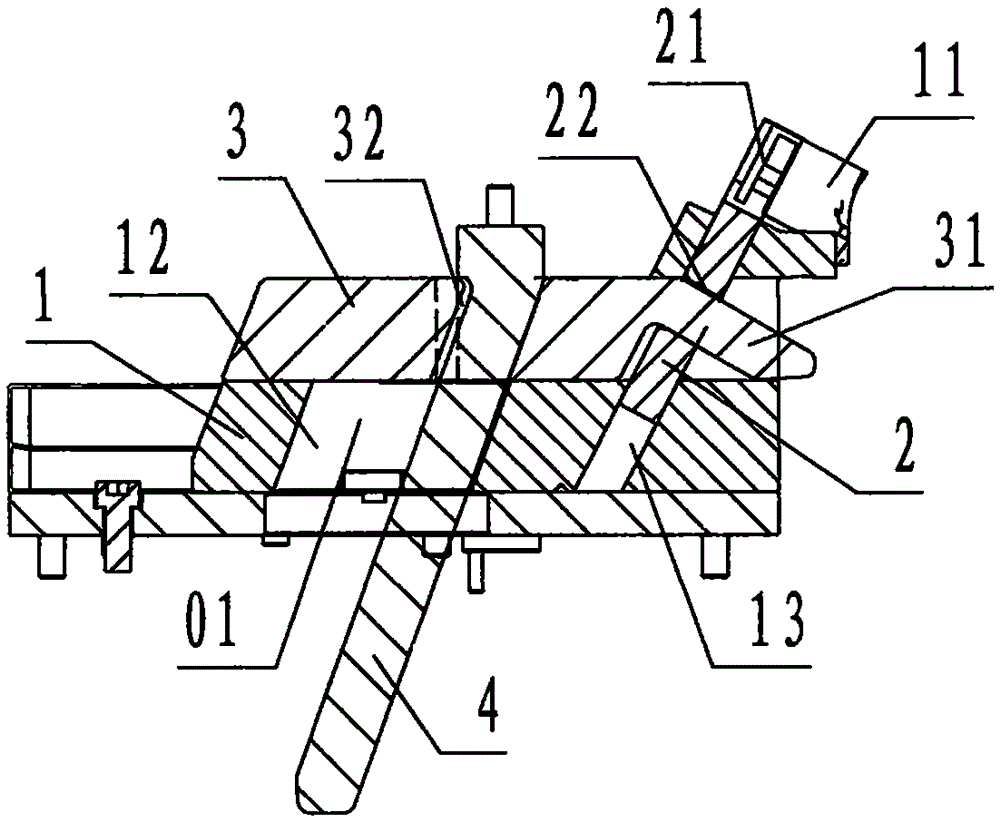

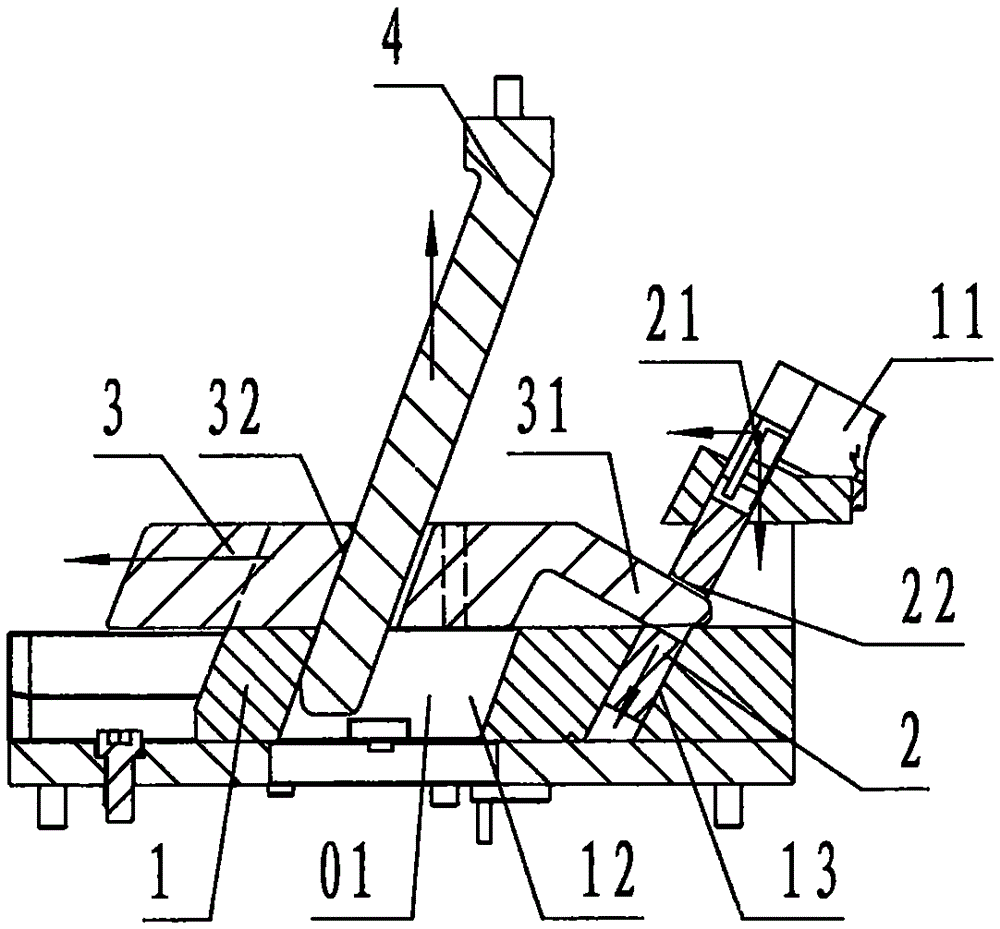

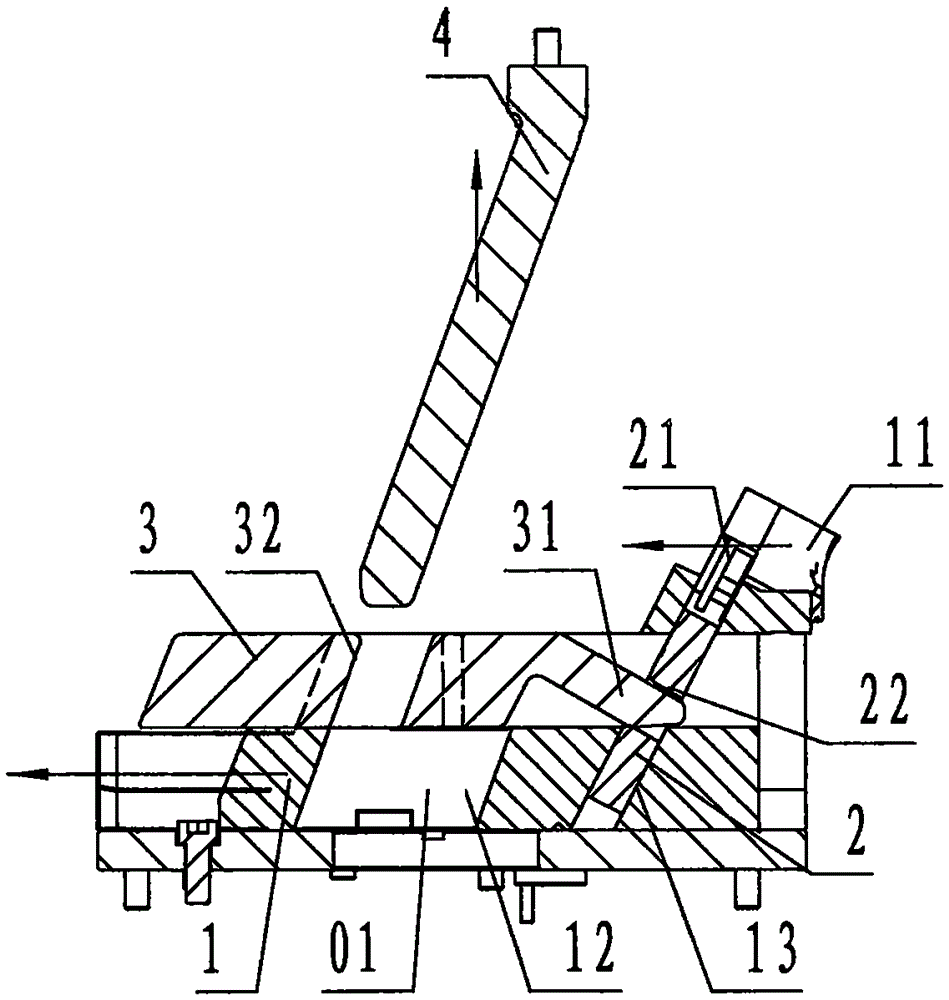

[0023] see Figure 1 ~ Figure 4 , an injection mold single-slider multi-direction combined core-pulling device of the present invention includes a transverse sliding block 1, an oblique sliding block 2, an oblique-pulling drive block 3, and a transverse-pulling and inclined guide column 4, wherein: the said The horizontal slider 1 is a rectangular block-shaped steel member. The left part of the horizontal slider 1 is provided with a through hole sloping from top to bottom to the left, which is called A inclined guide hole 12, and the right part of the horizontal slider 1 is provided with a The through hole inclined from top to bottom to the left is called the B inclined guide hole 13. The right side of the lateral slider 1 is provided with a horizontal core 11 that protrudes upward. The upper and right sides of the horizontal core 11 are provided with convex shapes corresponding to the product The concave surface corresponding to the surface;

[0024] The oblique sliding bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com