Core pulling device of cylindrical core with backoff structures uniformly distributed on cylindrical surface

A core-pulling device and cylindrical technology, applied in the field of core-pulling devices, can solve the problems of large internal volume, complex structure and high cost of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

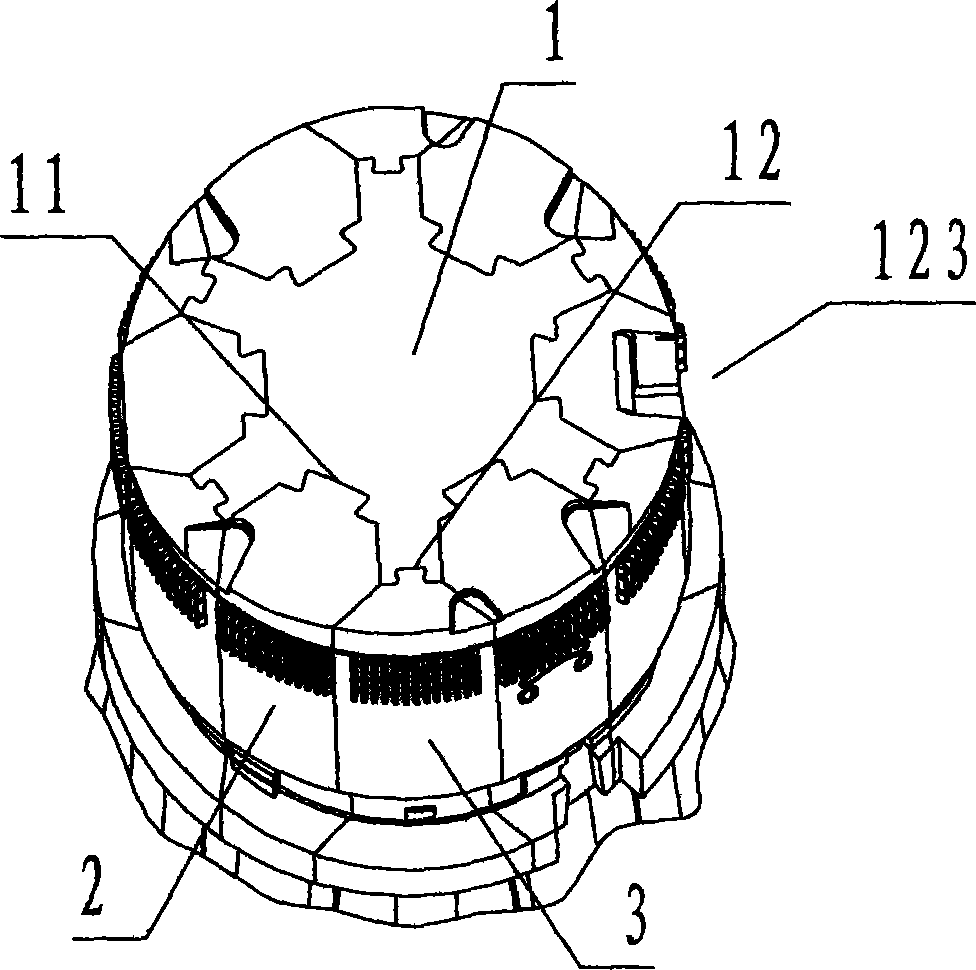

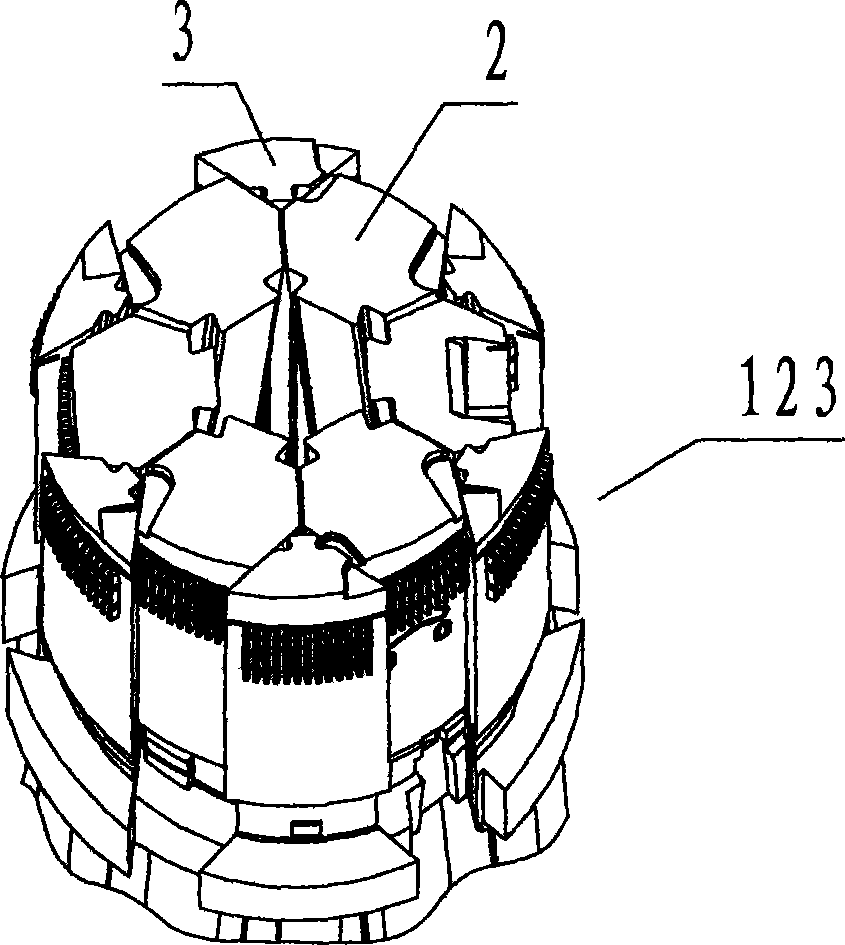

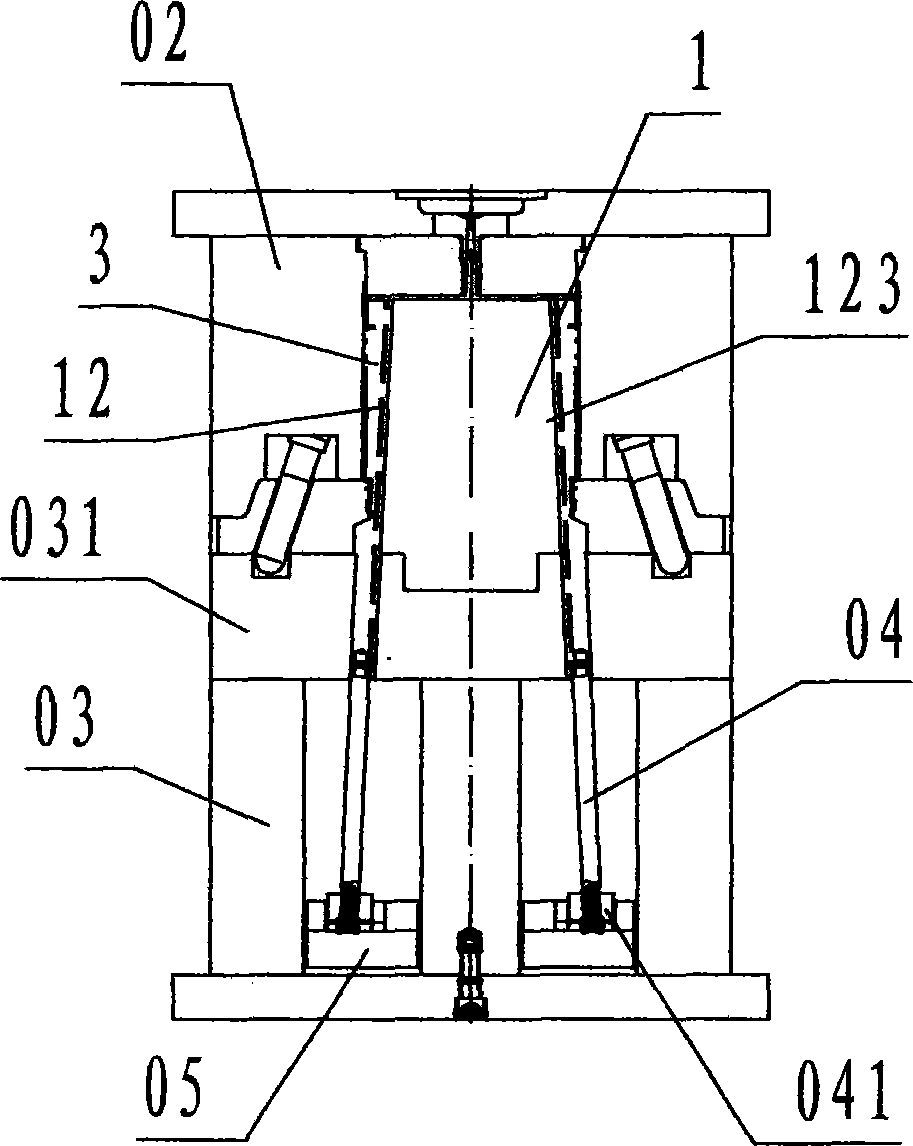

[0020] refer to Figure 1 to Figure 6 , a core-pulling device for a cylindrical core evenly distributed on the cylindrical surface of the present invention, including a core column 1, an A slider 2, and a B slider 3, wherein: the core column 1 is small at the top and large at the bottom, six Pyramid-shaped columnar steel member, the cylinder surface of the core column 1 is evenly equipped with six ribs protruding outward, up and down, and projected radially in the top view. The formed groove is called a chute, the top of the rib is provided with a dovetail-shaped chute called B chute 12, and the bottom of the chute is provided with a dovetail-shaped chute called A chute 11 , the cone angle of the A chute 11 is greater than the cone angle of the B chute 12;

[0021] The A slider 2 is a long strip in the up and down direction, and a hexagonal block steel member in a top view projection. One side of the A slider 2 is a 1 / 12 cylindrical arc surface called the A centrifugal surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com