Patents

Literature

83results about How to "Achieve picking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

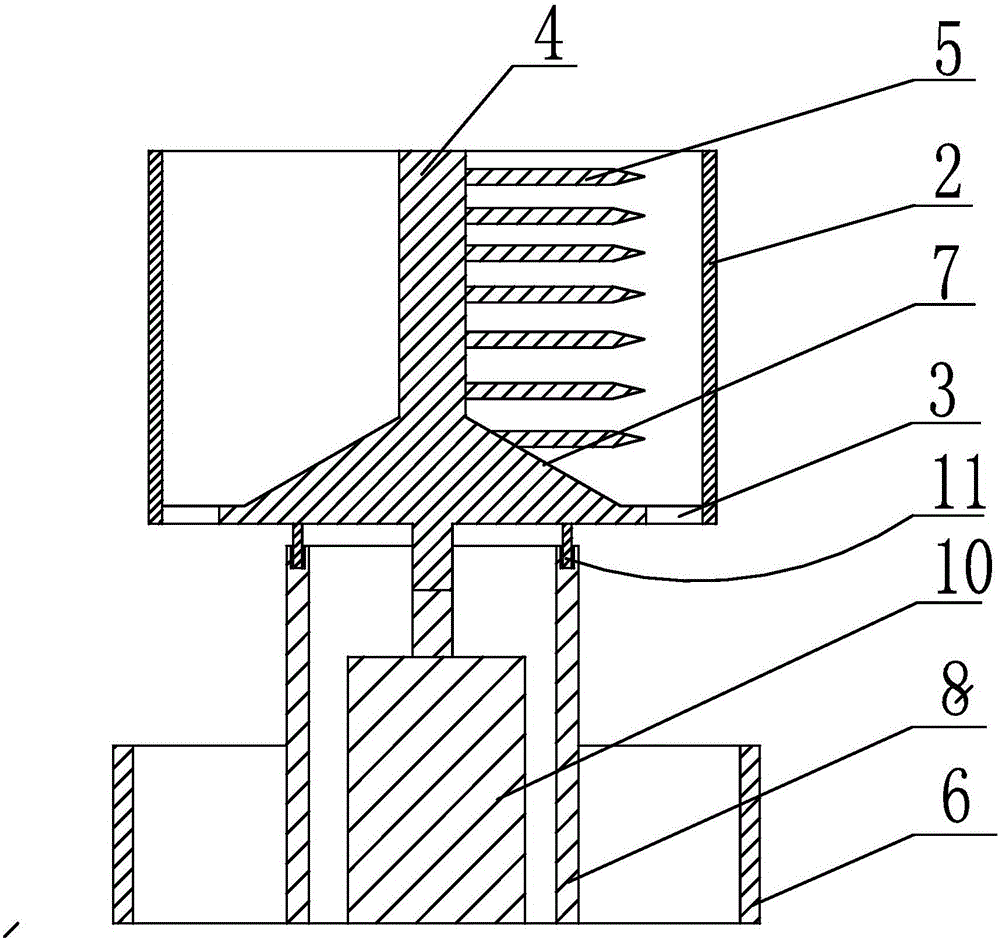

Twist-off picking paw mechanism and picking method thereof

InactiveCN101878699AAccurate and stable gripGuaranteed stabilityPicking devicesEngineeringDrive wheel

Owner:CHINA AGRI UNIV

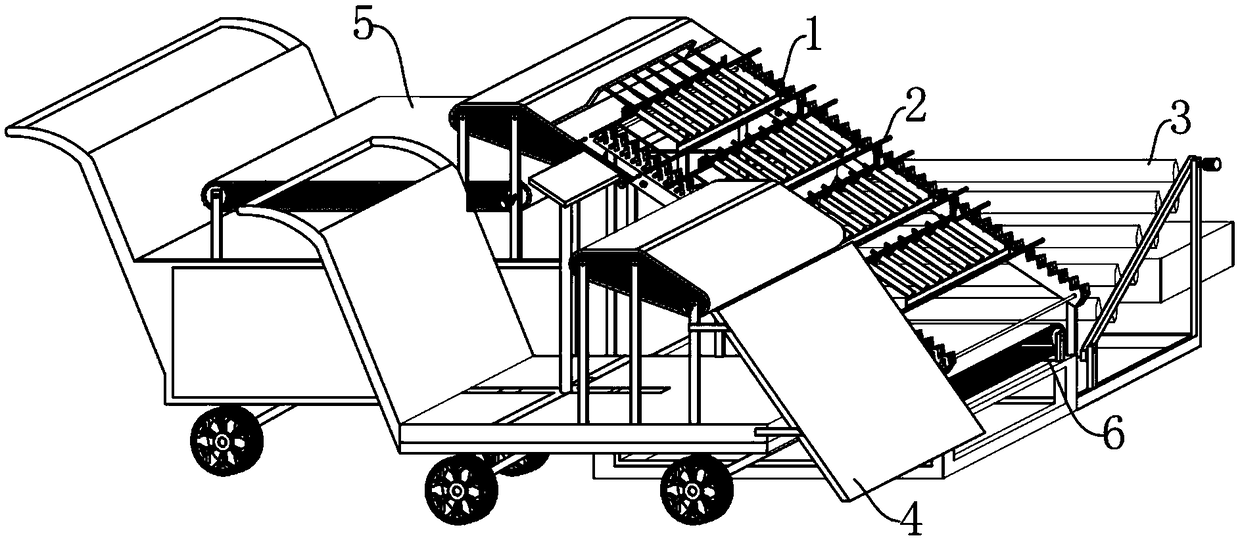

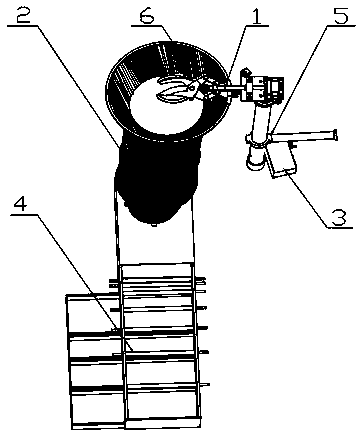

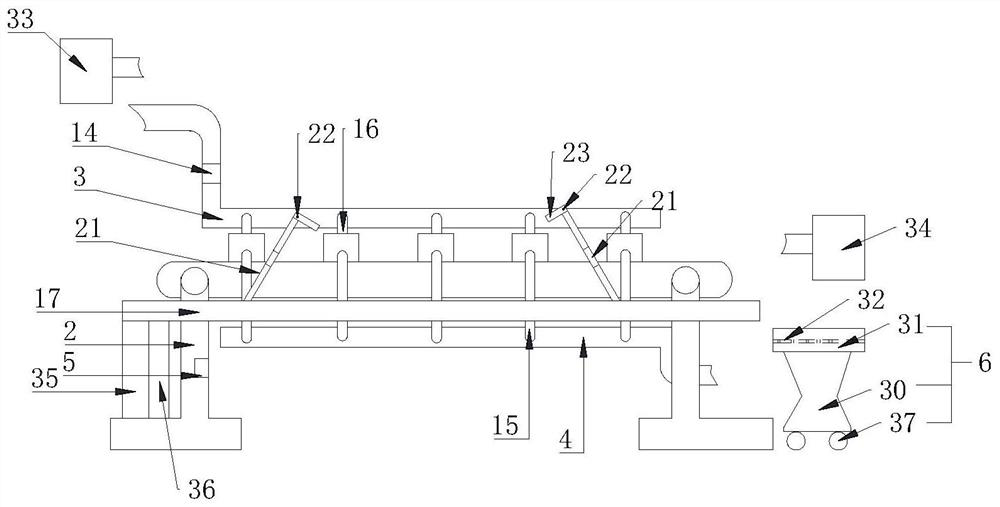

Mushroom planting picking automatic integrated machine

ActiveCN109463203AFast degradationGuaranteed sealed sterile conditionsCultivating equipmentsMushroom cultivationAgricultural engineeringMushroom

The invention discloses a mushroom planting picking automatic integrated machine. The machine comprises a planting frame supporting moving device, a planting picking device, a mushroom collecting conveying mechanism, a mushroom collecting device, a mushroom stick recovery device and a planting frame recovery device, the planting picking device is arranged on the planting frame supporting moving device, the mushroom collecting conveying mechanism is arranged on the planting frame supporting moving device, the mushroom collecting device is arranged at the rear end of the mushroom collecting conveying mechanism, the mushroom stick recovery device is arranged on the left side of the planting frame supporting moving device, and the planting frame recovery device is arranged in front of the planting frame supporting moving device; the planting picking device comprises a mushroom stick mechanism and a planting picking frame, and the mushroom stick mechanism is arranged on the planting pickingframe. The machine belongs to the technical field of edible fungus equipment, and particularly provides the mushroom planting picking integrated machine which has the advantages that the practicability is high, the operation is simple, the integrated machine saves energy and is environmental friendly, the efficiency is improved, the labor intensity is reduced, and the mechanical picking and planting of mushrooms is achieved.

Owner:重庆市鸦地坝农业开发有限公司

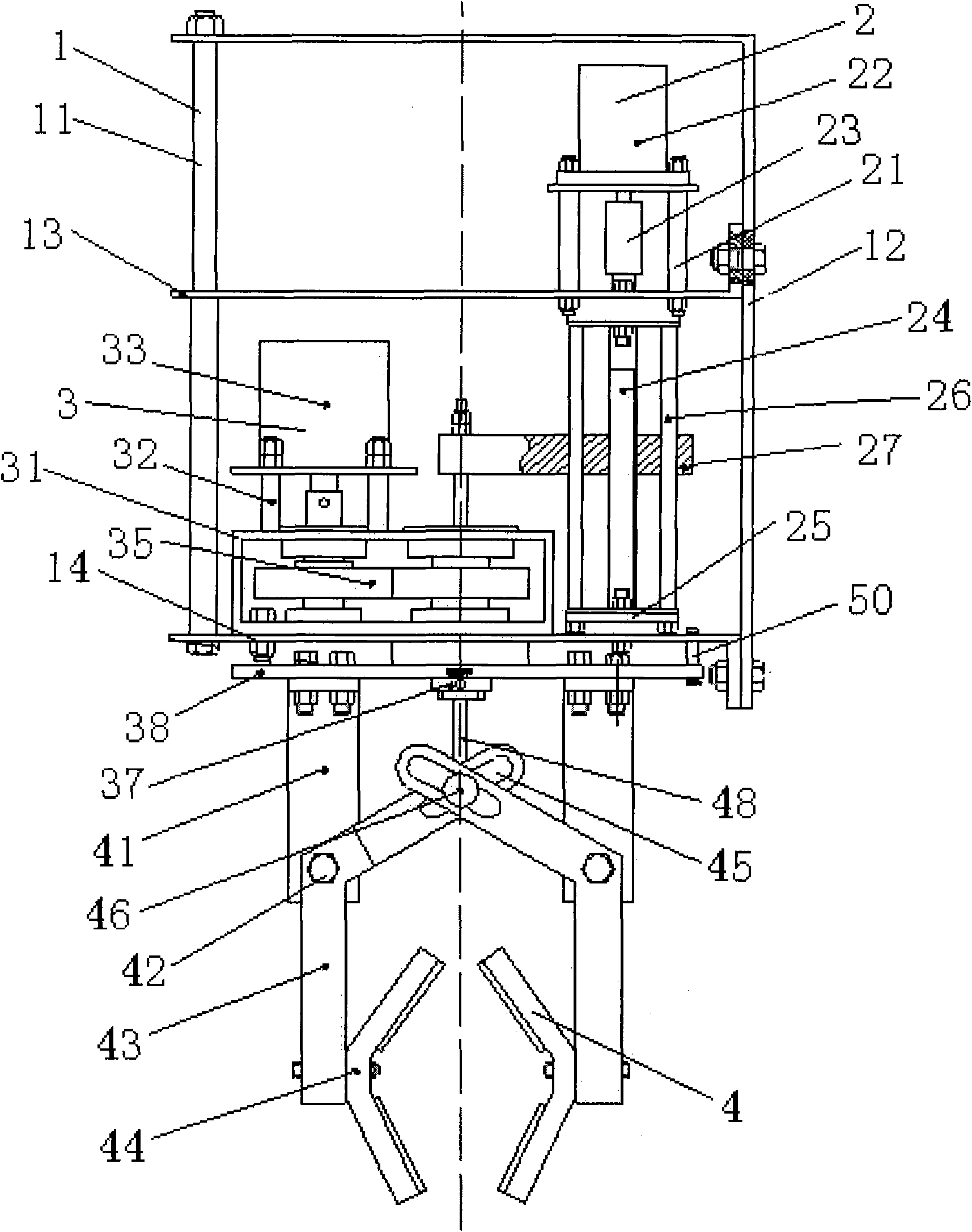

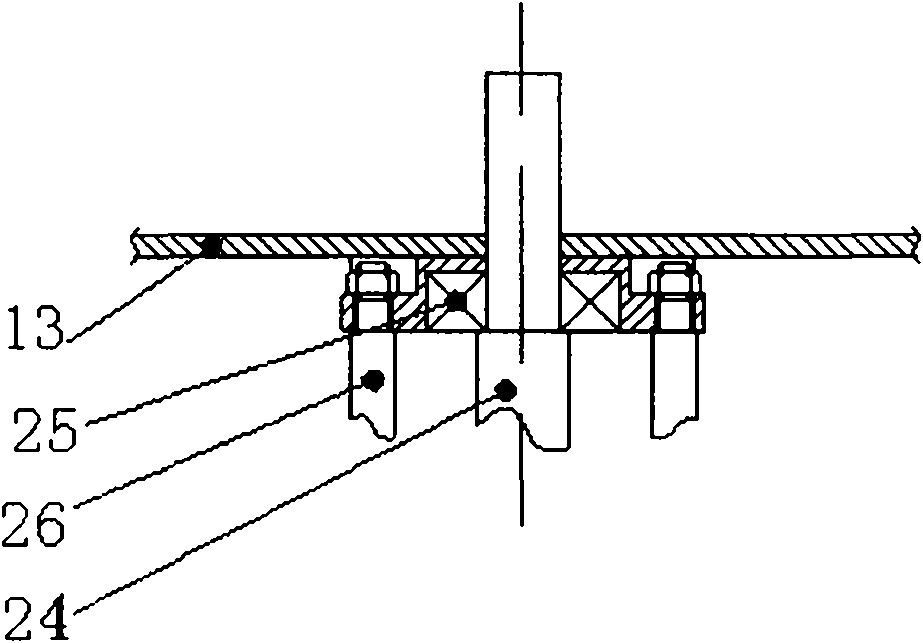

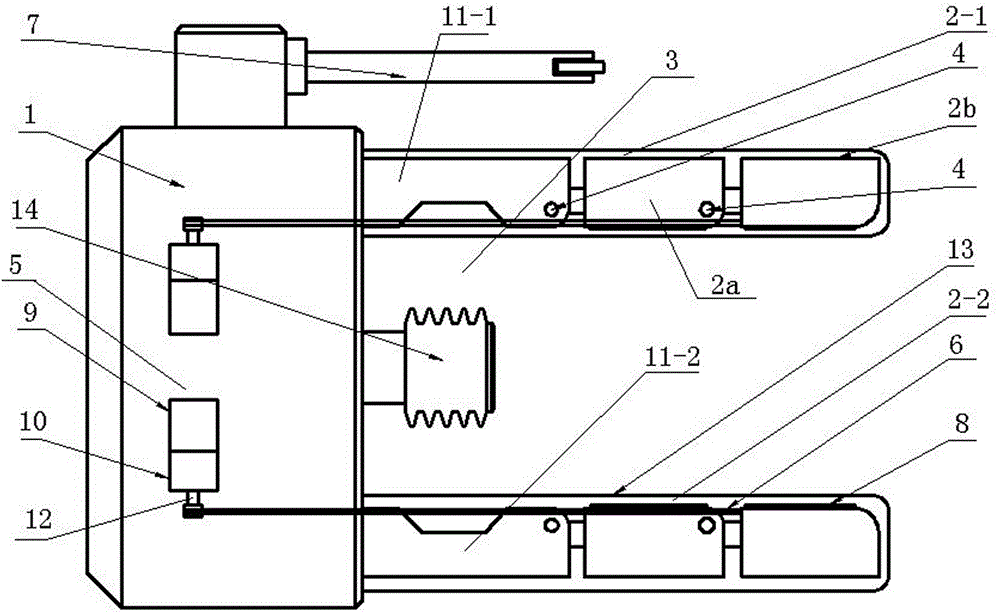

Multi-manipulator truss tomato picking robot and picking method thereof

The invention relates to a multi-manipulator truss tomato picking robot and a picking method thereof. The truss tomato picking robot comprises a movable platform car, mechanical arms, end executors, visual identification devices and a control module, wherein the mechanical arms which are arranged in the travelling direction of the movable platform car at equal intervals are vertically fixedly connected to the plane of the top of a lifting mechanism; each end executor comprises an electric clamping jaw, rockers, a first connecting rod, a main clamping body, a second connecting rod, a cutter blade and an auxiliary clamping body; every two rockers, the corresponding first connecting rod, the corresponding second connecting rod and two gears which are arranged in the electric clamping jaw and mutually meshed form a five-link mechanism, and enveloping of truss tomatoes is achieved. The structure is simple, the operation is convenient, the cost is low, the picking efficiency and the success rate are high, whole-bunch harvesting of the truss tomatoes is achieved without damaging the truss tomatoes, and the damage rate of the truss tomatoes and main stems is reduced.

Owner:SUZHOU AGRIBOT AUTOMATION TECH

Cotton picking robot

InactiveCN107182448AGuarantee the effect of picking cottonAchieve scaleManipulatorPicking devicesMachine visionEngineering

The invention relates to a cotton picking robot, and belongs to the technical field of agricultural machinery. According to the robot, the whole unmanned picking process of cotton is achieved, and the functions comprise automatic moving and machine vision guiding cotton picking. The robot comprises an automatic mobile platform, a vision cotton picking head and a cotton collection bin. The automatic mobile platform conducts path planning and real-time guiding according to GPS information, real-time path and posture adjustment is conducted according to vision and an automatic row-controlled sensor, mobile platform posture and speed tracking is conducted according to an angular acceleration sensor and acceleration sensor information, when picking tasks are completed or a failure occurs or the electric quantity and cotton picking weight reach a limiting value, returning is conducted. The vision cotton picking head conducts visual identification on the cotton mature degree and the spacial position through a machine, and a cotton picking spindle unscrews the cotton off in a rotating stretching mode and then retracts into a picking box, and the cotton is scraped off through a cotton brushing pad. The picked cotton is conveyed to the cotton collection bin installed on the automatic mobile platform through wind power.

Owner:庞川

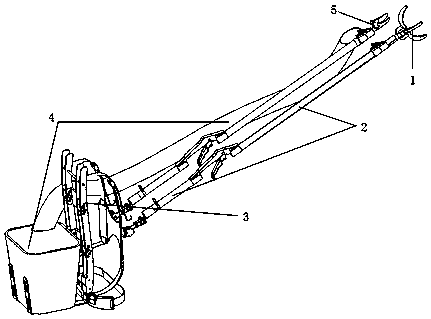

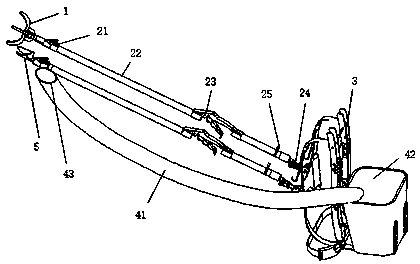

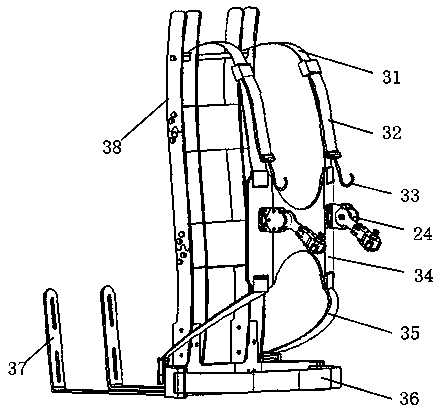

Wearable fruit picking assistance device

The invention provides a wearable fruit picking assistance device. The wearable fruit picking assistance device comprises a secondary telescopic execution arm device, an S-shaped wearable device and aleft tail end shear device, wherein the secondary telescopic execution arm device comprises a left mechanical arm, a right mechanical arm, a right tail end grabbing device and a fruit collecting device, the left mechanical arm and the right mechanical arm are completely identical in structure, each left mechanical arm comprises a connecting rod, a control handle, a secondary telescopic rod, an internal telescoping mechanism and a locking mechanism, the left tail end shear device and a right tail end shear device are installed on corresponding locking mechanisms, control handles of the left tail end shear device and the right tail end shear device are respectively controlled to work and pick fruits, and after cutting is completed, an operator turns the right tail end shear device and loosens the corresponding control handle to make fruits slip into a pack basket from a sliding channel.

Owner:HENAN UNIV OF SCI & TECH

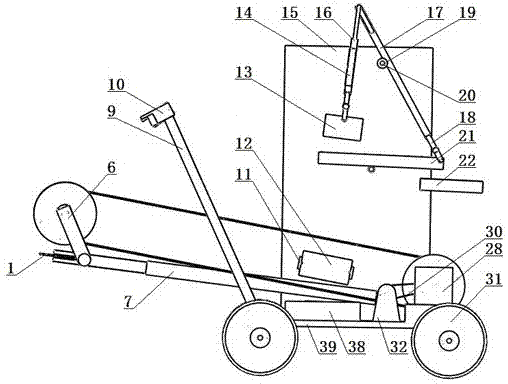

Fruit picking, sorting and boxing vehicle

InactiveCN107318379AAvoid lostImprove picking efficiencyLoadersPicking devicesAgricultural engineeringUltimate tensile strength

The invention discloses a fruit picking, sorting and boxing vehicle, which includes a picking device, a sorting device, a steering device and a chassis, the picking device, and the sorting device. The picking device includes a steering motor, and a steering motor is installed on the steering motor. A steering bracket is nested on the steering shaft, the steering bracket is connected to the support frame through the first rotating shaft, the first hydraulic rod is installed on the upper right of the steering bracket, the right end of the first hydraulic rod is connected with the left lower end of the support frame, and the rear end of the support rod Connected with the picking platform through the second rotating shaft, a second hydraulic rod is installed on the upper right of the support frame, the end of the second hydraulic rod is connected with the lower left side of the picking platform, and picking shears are installed on the right end of the picking platform, which reduces the burden on the fruit grower during the fruit picking process. The labor intensity and production cost can avoid the loss caused by lack of personnel when picking fruit, and improve the efficiency of fruit picking. It has good development prospects and application value in the fruit industry.

Owner:何天行

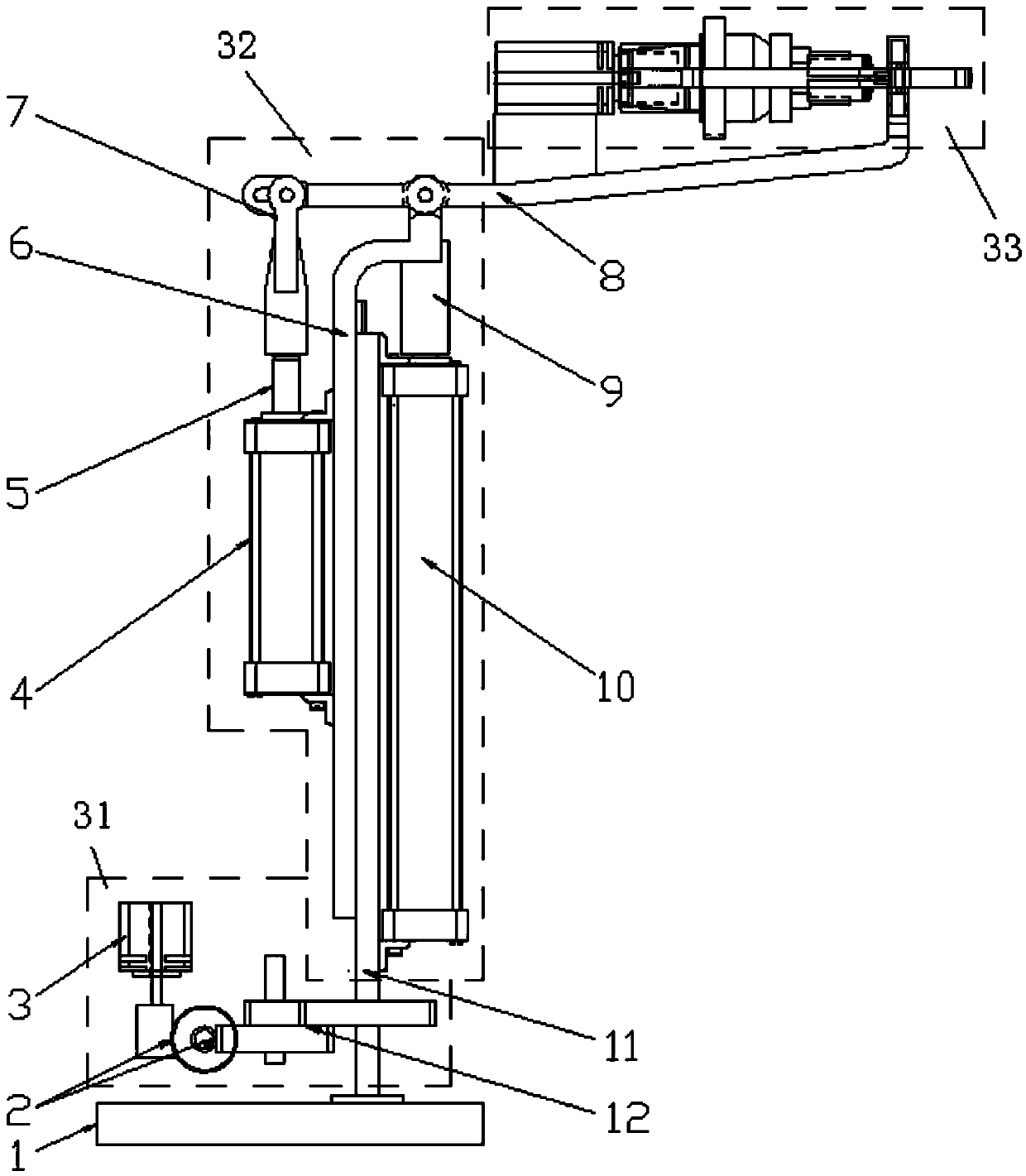

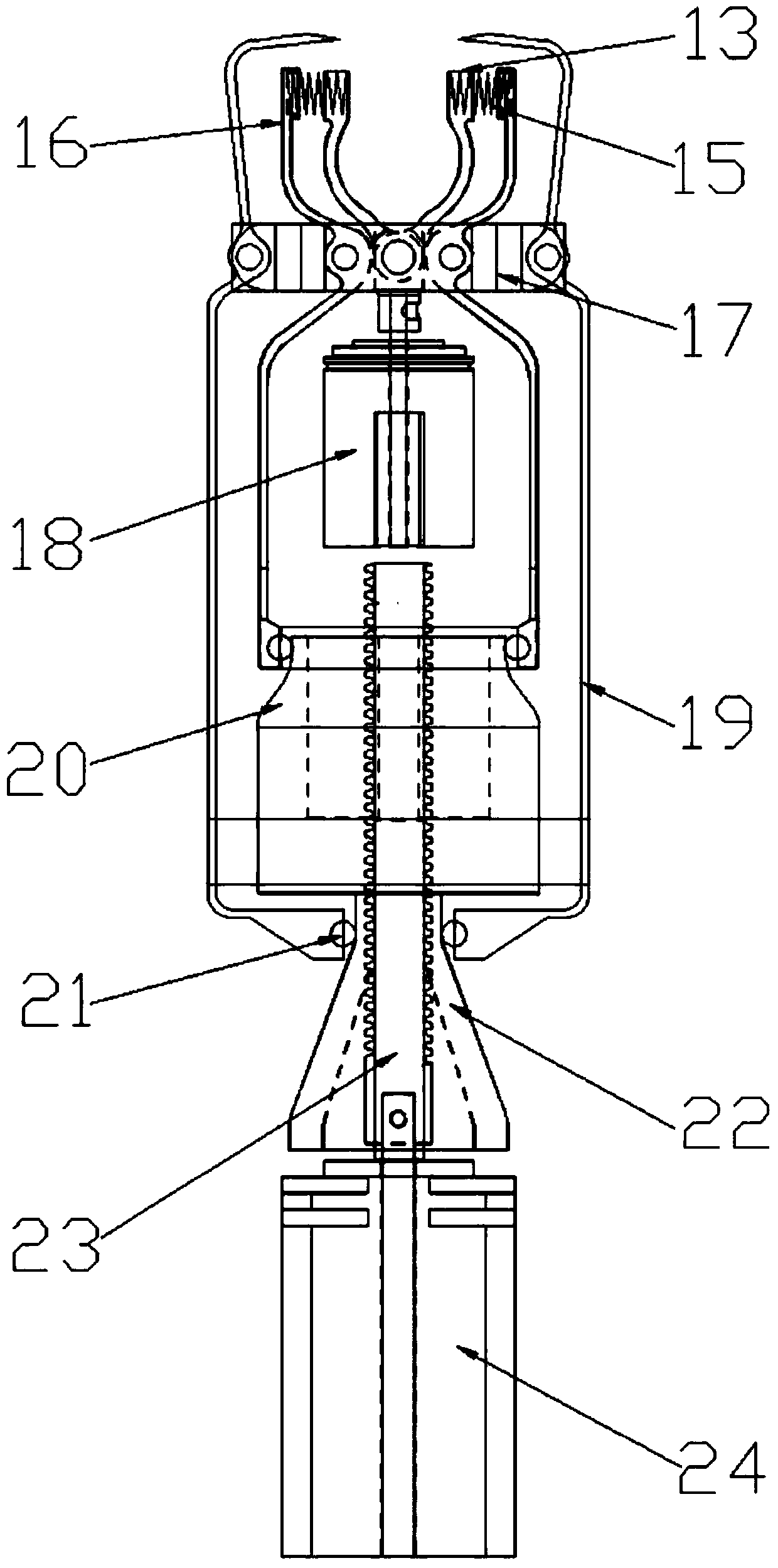

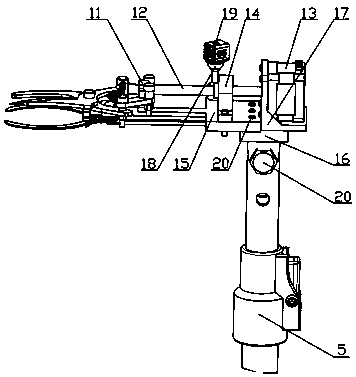

Coconut picking machine

InactiveCN103430701AImprove securityAvoid the dangers of cutting and pickingPicking devicesEngineeringSliding contact

The invention discloses a coconut picking machine. The coconut picking machine mainly comprises picking tongs which are connected with the upper end of a swing arm assembly through a machine head connecting rod. The picking tongs comprise a stepping motor, a servo motor, a lead screw, a conical sliding sleeve, a cylindrical step sliding sleeve, an inner hand grab, an outer hand grab and a bearing. One end of the lead screw is connected with a rotating shaft of the stepping motor, and the other end of the lead screw is connected with the servo motor. The conical sliding sleeve and the cylindrical step sliding sleeve are arranged in the middle of the lead screw in a sleeved mode and are in thread fit with the lead screw. The front grab portion of the outer hand grab is movably connected with an outer ring of the bearing, and the back end portion of the outer hand grab is in sliding contact with the conical surface of the conical sliding sleeve through a roll ball. The front grab portion of the inner hand grab is movably connected with an inner ring of the bearing, the back end portion of the inner hand grab is in sliding contact with an inner cambered surface of the cylindrical step sliding sleeve, and a rotating shaft of the servo motor is fixedly connected with the inner hand grab. Manual picking is replaced by the coconut picking machine, the picking labor intensity is reduced, the picking efficiency is improved, and the safety of the picking operation is improved.

Owner:SOUTH CHINA UNIV OF TECH

Automatic sorting robot for edible rose petals in flower field

InactiveCN103688662AAchieve pickingAutomate sortingSortingPicking devicesDrive shaftTransmission belt

The invention relates to an automatic sorting robot for edible rose petals in a flower field, and belongs to the technical field of agricultural product processing machinery. The automatic sorting robot comprises a picking portion, a sorting portion and a vision portion, the picking portion comprises a rotating blade, a front roller I, a front roller II, a conveying belt I, a conveying belt II, a front arm support, a middle shaft, a middle shaft gear, a rear roller I, a rear roller II, a rear roller shaft, a motor, a motor rotating shaft, a transmission belt, a support II, a fixed shaft, a driven bearing, a driving shaft, a driving gear and a driving bearing, the sorting portion comprises a gripper guide rail, a gripper, a manipulator, a manipulator guide rail, a support I, a manipulator front arm, a manipulator rear arm, a carrier plate frame, a manipulator bearing, a manipulator fixed shaft, a front petal carrier plate, a rear petal carrier plate, a carrier plate bearing, a carrier plate fixed shaft and a receptacle recycling box, and the vision portion comprises a camera support and a CCD (charge coupled device) camera. Labor intensity can be effectively reduced, and productivity is liberated, so that roses are automatically picked, and the petals are automatically sorted.

Owner:KUNMING UNIV OF SCI & TECH

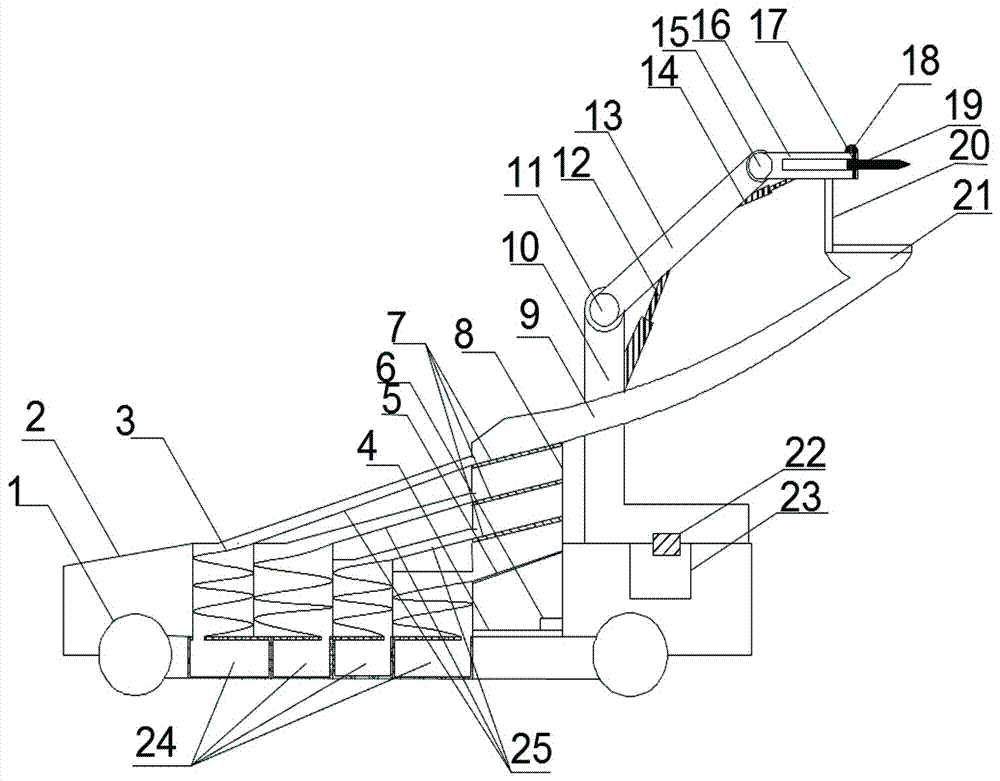

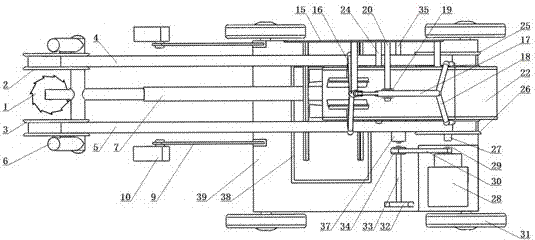

Backpack type small berry picking machine

A backpack type small berry picking machine comprises a back frame, a miniature gasoline engine, a centrifugal type clutch, a steel wire flexible shaft, a secondary gear drive mechanism, an eccentric vibration mechanism, a housing, a front annular handle, a rear handle, and branch vibrators; the miniature gasoline engine is arranged on the back frame through a vibration isolation rubber pad; an output shaft of the miniature gasoline engine is connected with an input end of the steel wire flexible shaft through the centrifugal type clutch; a square joint of the output end of the steel wire flexible shaft is connected with a square interface of an axle drive bevel pinion of the secondary gear drive mechanism; the eccentric vibration mechanism comprises an upper crank, a lower crank, an eccentric adjustable camshaft, a dual-face guide rail, an upper reciprocating oscillating lever and a lower reciprocating oscillating lever; the branch vibrators are respectively fixed on the front ends of the upper and lower reciprocating oscillating levers; the front portion and rear portion of the housing are respectively provided with a front annular handle and a rear handle; the rear handle is provided with a speed regulator; the speed can be regulated so as to allow the small berry branches to generate different frequency vibrations, and the vibration force can separate the small berries from the branches.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

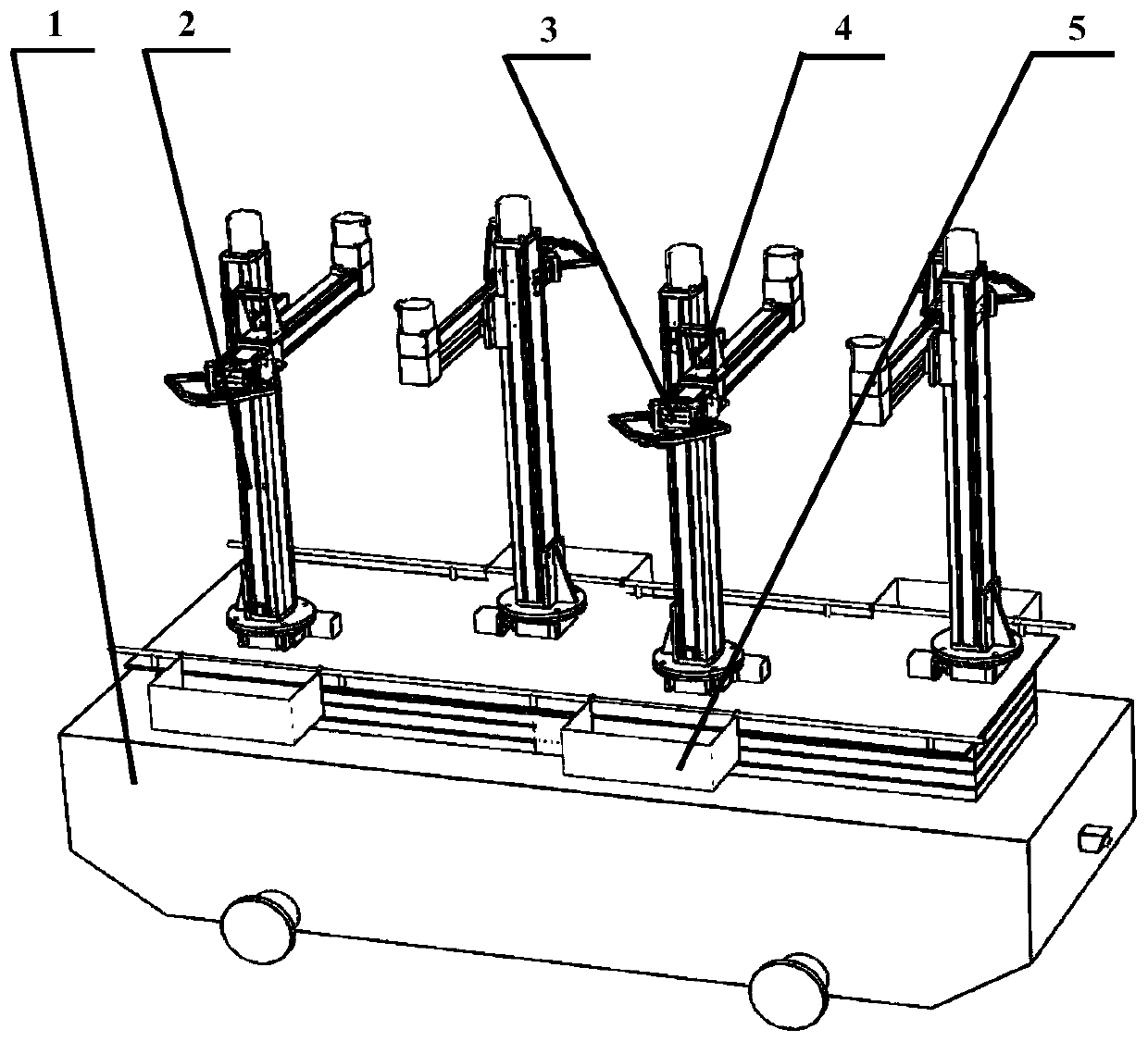

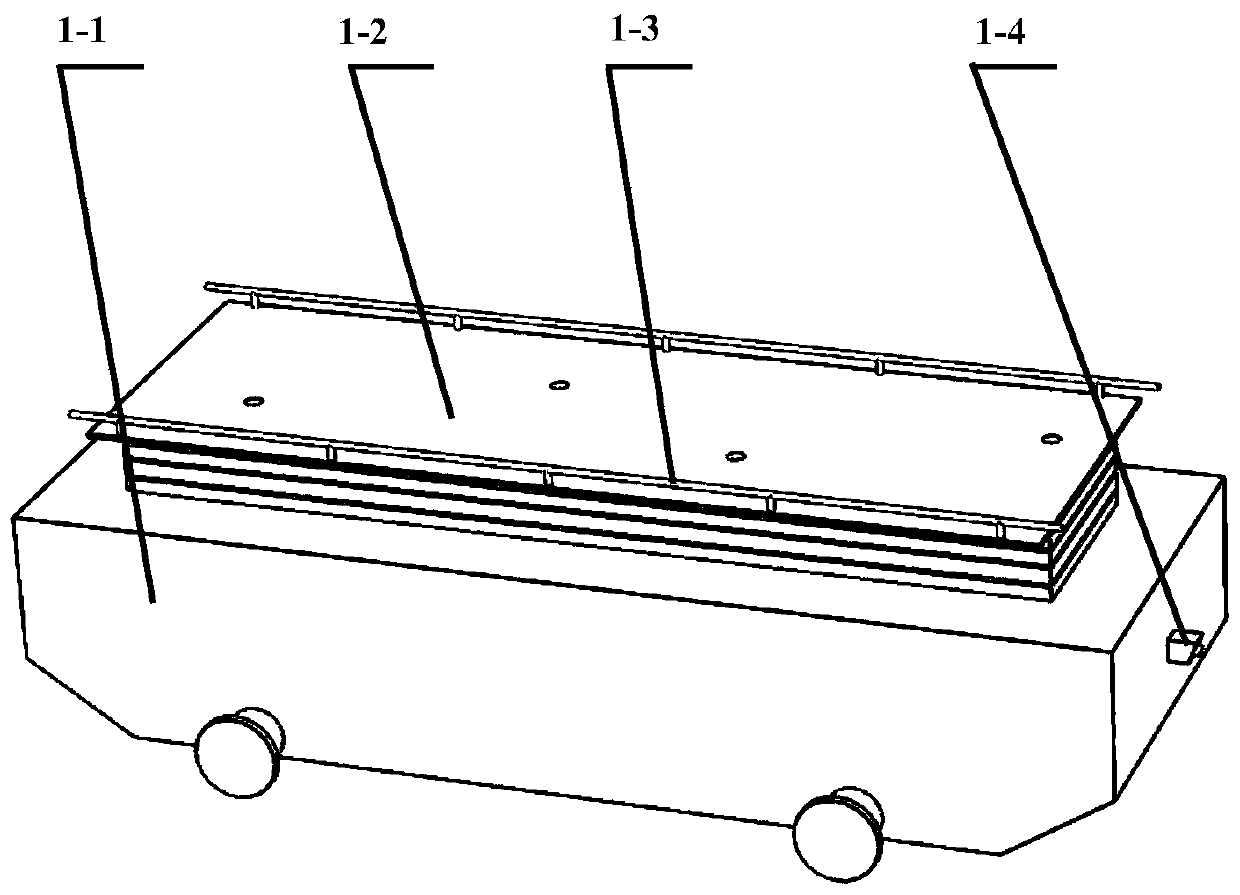

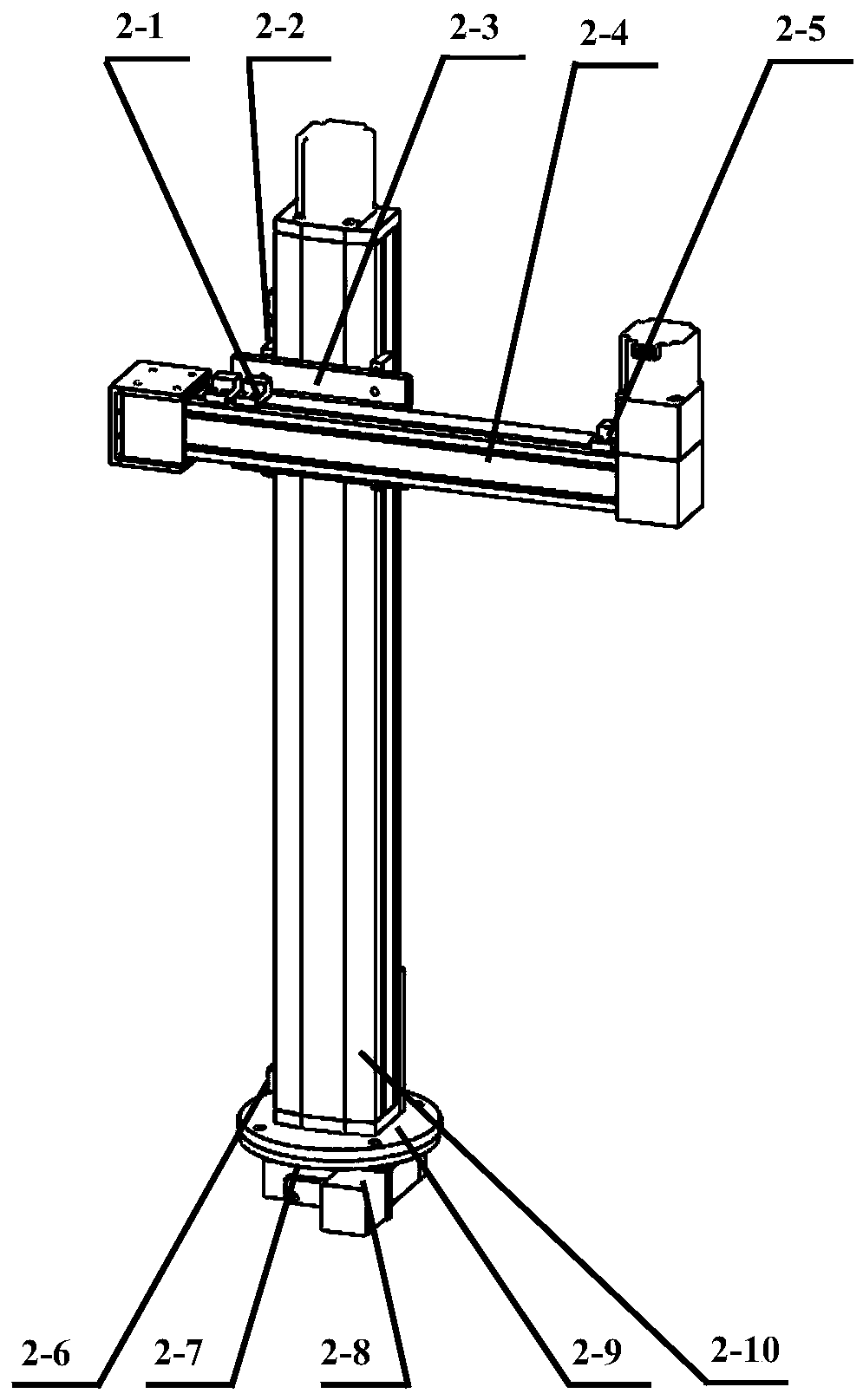

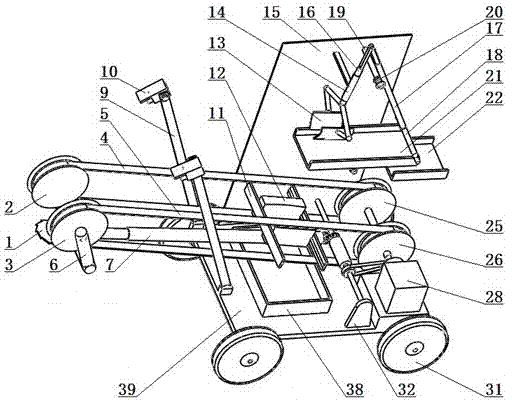

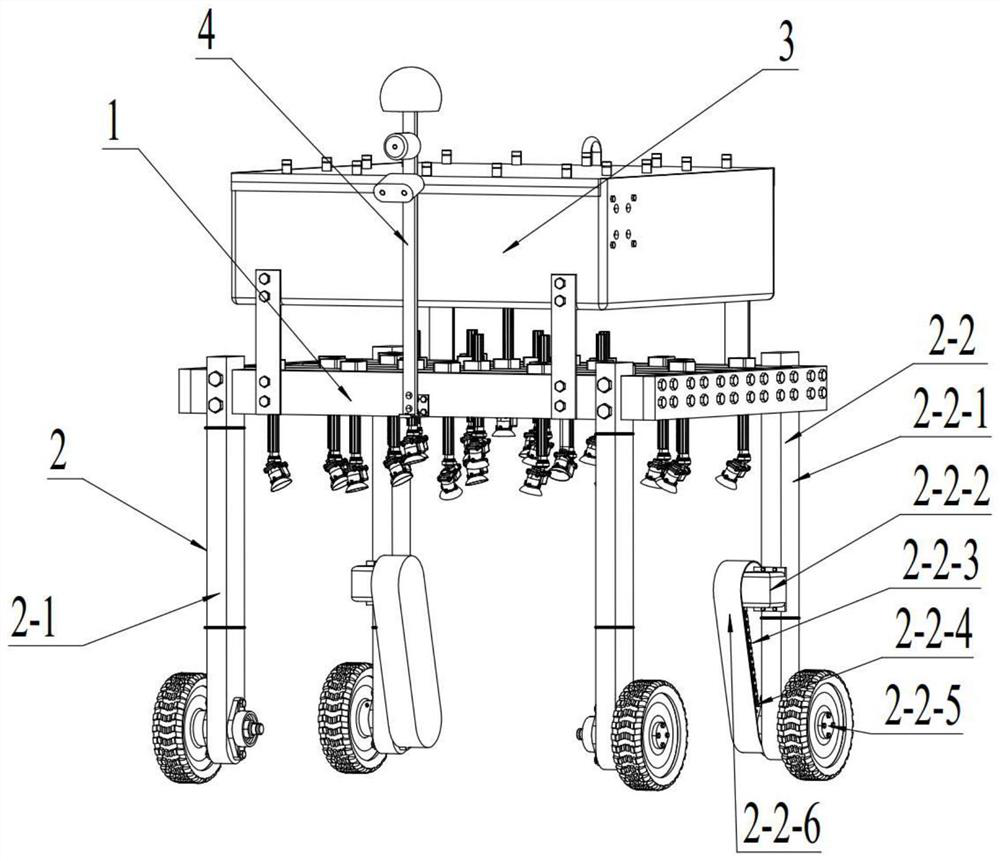

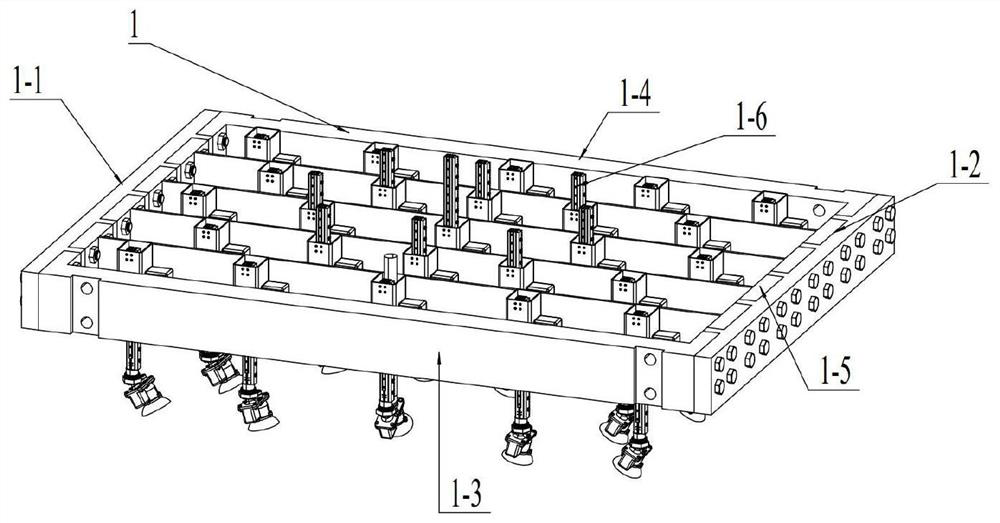

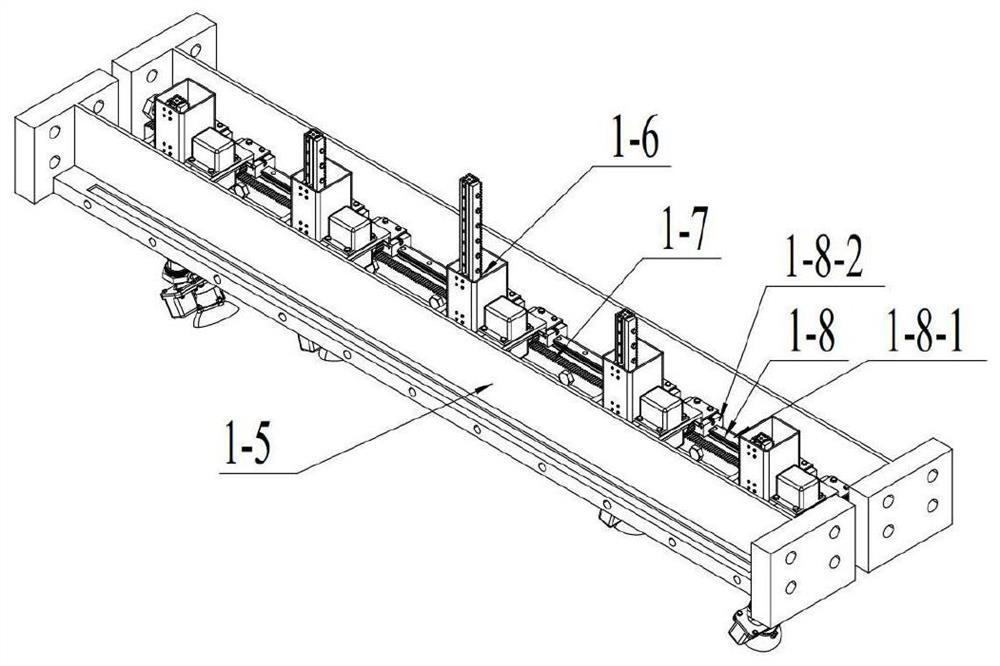

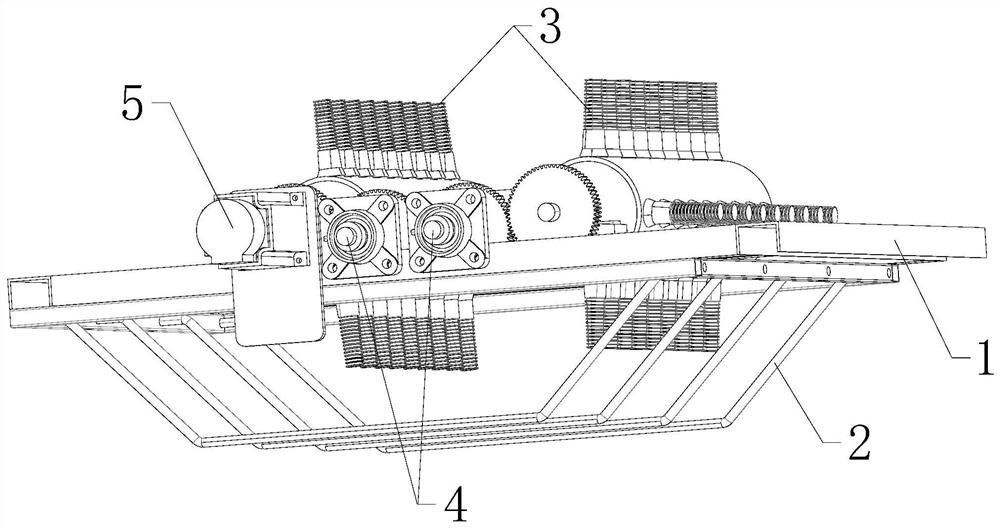

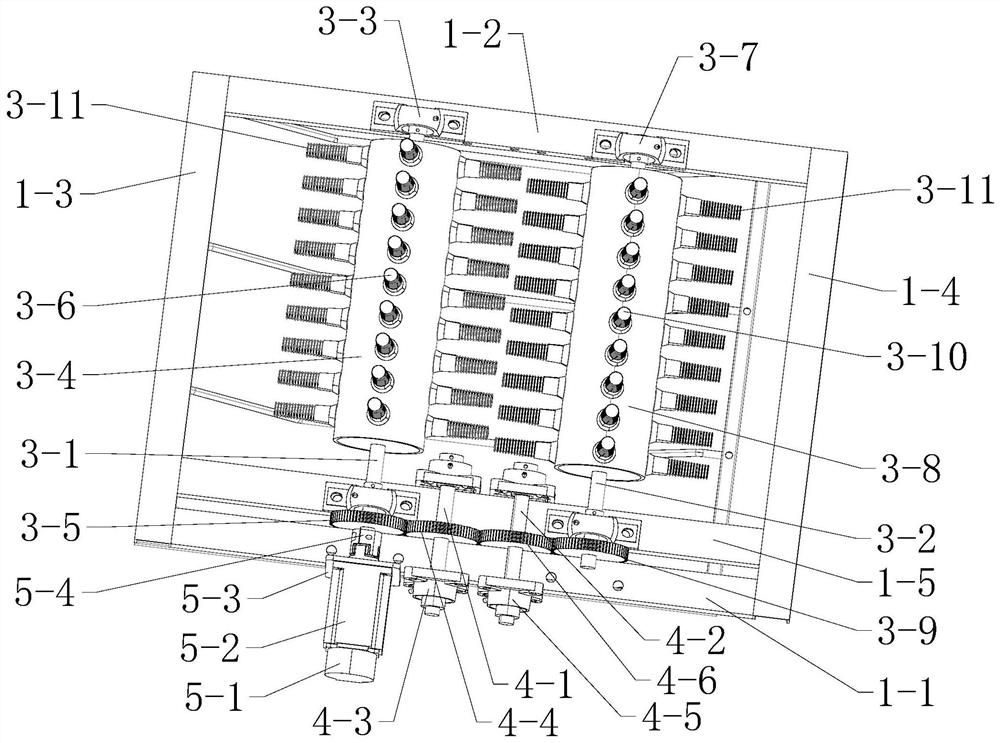

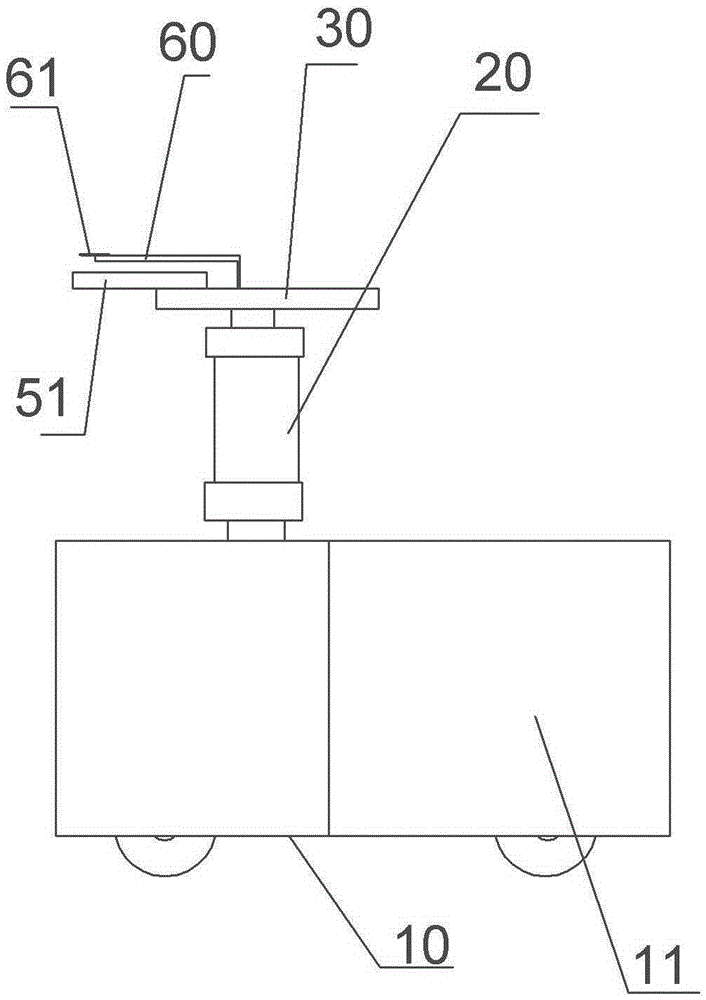

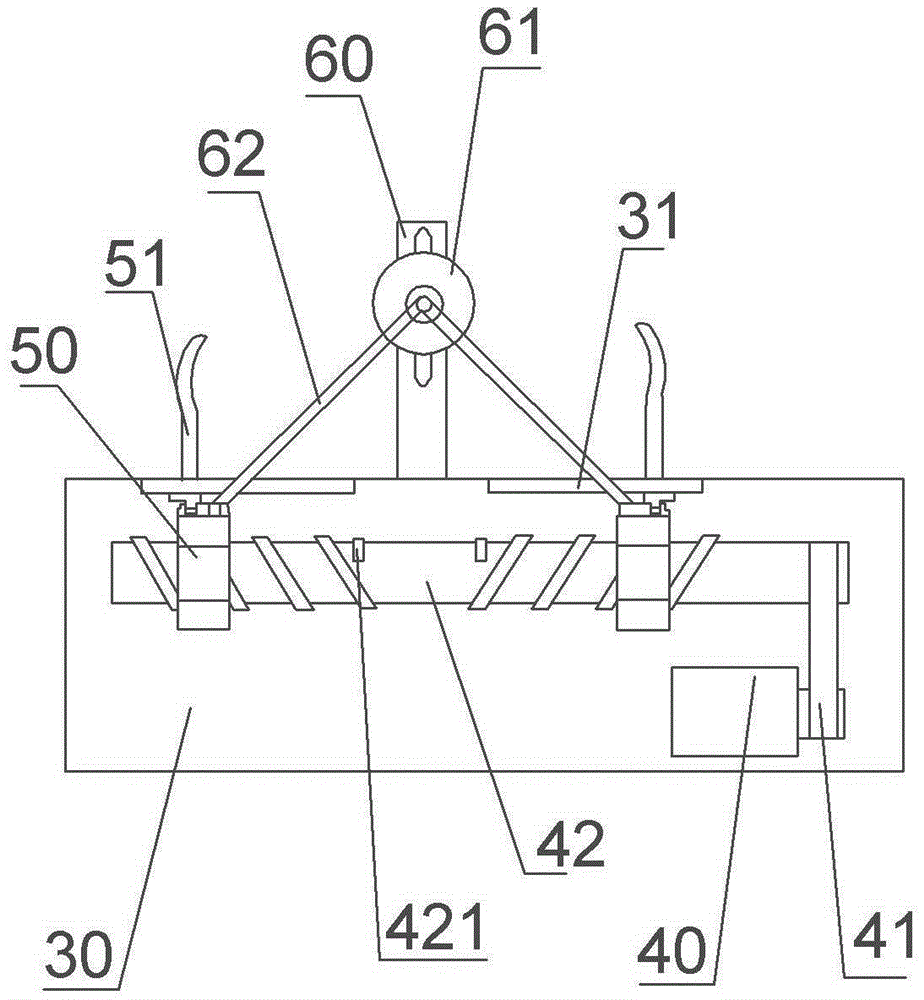

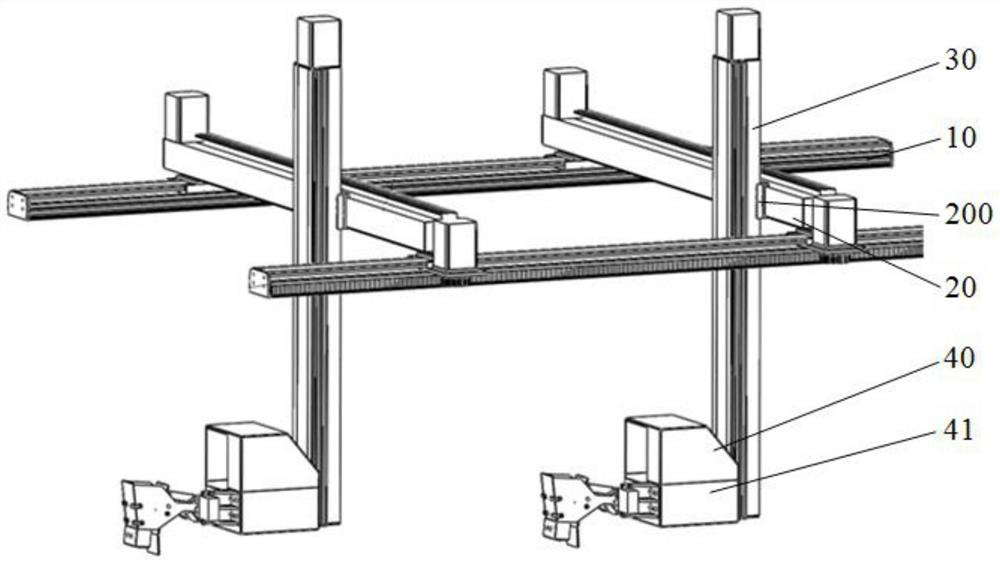

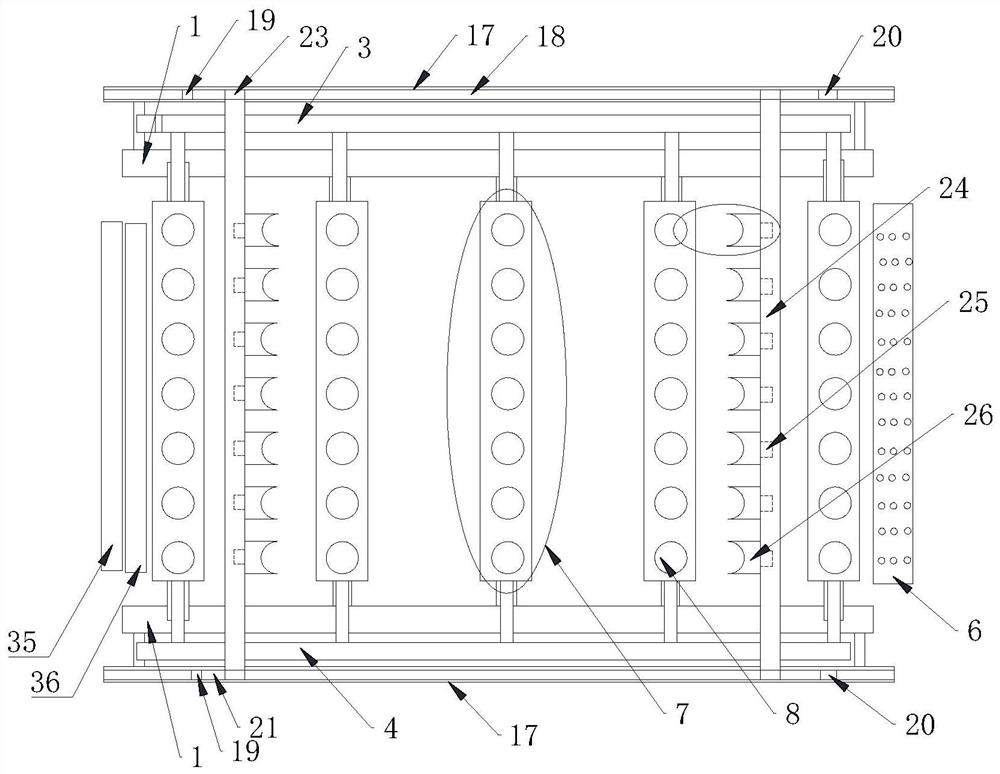

Self-propelled full-coverage multi-target safflower filament picking robot

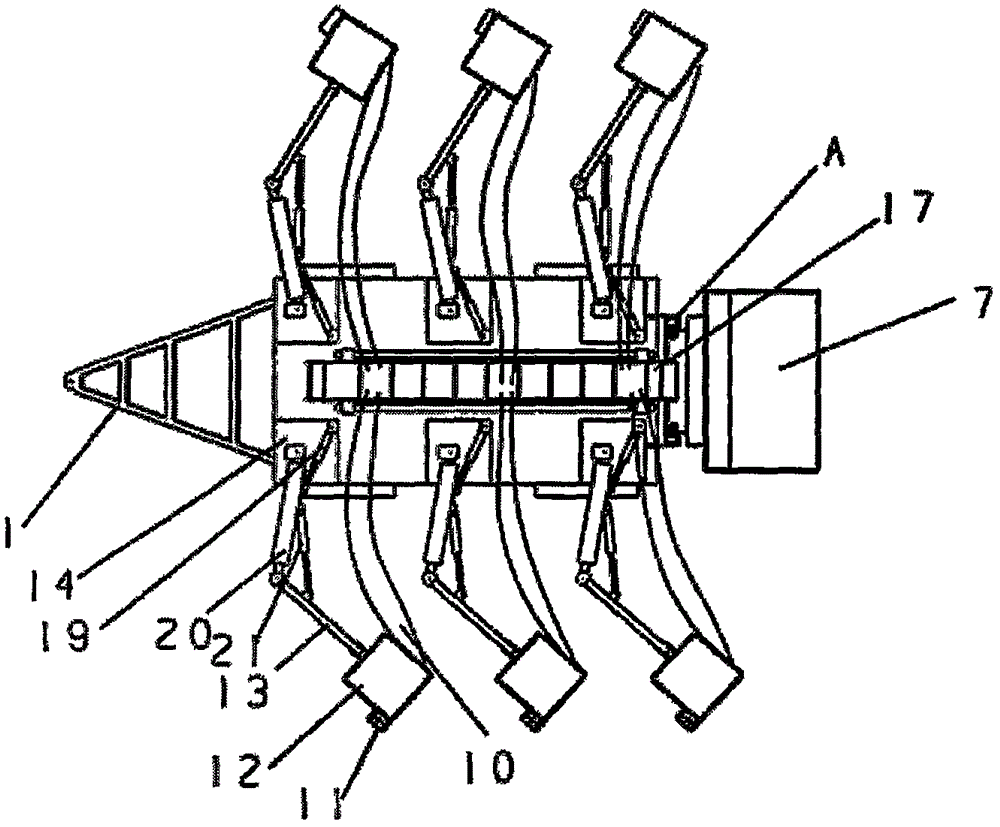

The invention relates to a self-propelled full-coverage multi-target safflower filament picking robot. The robot comprises a picking manipulator guide frame, walking devices, a filament collecting system and a multi-information fusion filament positioning, navigation and recognition system; the four walking devices with adjustable height are fixedly connected to the four corners of the horizontally-arranged rectangular picking manipulator guide frame respectively; the filament collecting system is fixedly connected above the picking manipulator guide frame; the multi-information fusion filament positioning, navigation and recognition system is fixedly connected to the front end of the picking manipulator guide frame to realize accurate recognition and positioning of safflower plants; and the picking manipulator guide frame comprises a left supporting frame, a right supporting frame, a front supporting frame, a rear supporting frame, a guide rail supporting frame, a picking manipulatorsingle body, a horizontal moving rack and horizontal moving guide rails. According to the robot, safflower fruit balls are divided into regions in a gridding mode, the whole safflower is picked in a covering mode, missing picking of filaments is avoided, and therefore the missing picking rate of the safflower picking robot is reduced, and the purpose of improving the picking efficiency of the robot is achieved.

Owner:XINJIANG AGRI UNIV

Mushroom automatic picking detection control method

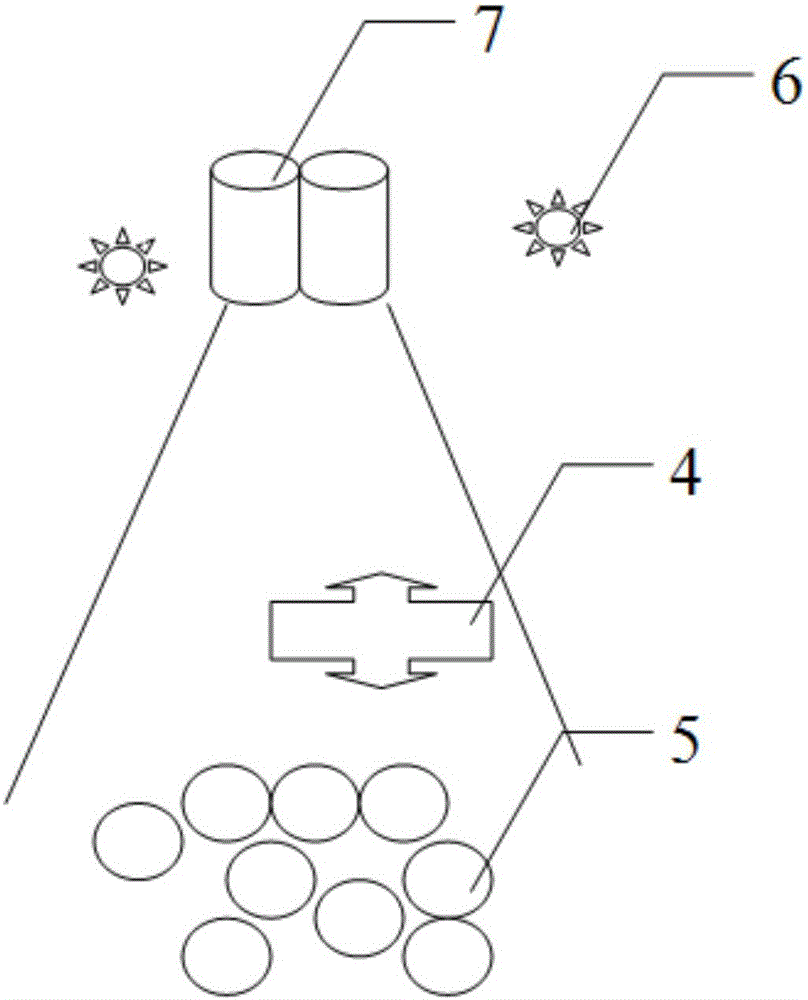

InactiveCN105865345AAutomatic picking detection control method is easy to realizeRealization of automatic picking detection control methodUsing optical meansPicking devicesMushroomAutomatic testing

The invention discloses a mushroom automatic picking detection control method. A mushroom picking system is used, and comprises a mushroom picking device, a first camera and a second camera. The mushroom automatic picking detection control method has the advantages that the realization is easy; the efficiency is high; the position of a mushroom can be conveniently and fast detected by the two cameras; the automatic detection and picking of the mushroom can be conveniently and fast realized; the mushroom picking regions are divided into a detection region and a picking region; the detection and the picking are separated and are not mutually influenced; the mushroom collection efficiency can be greatly improved.

Owner:NANJING DASHU INTELLIGENT SCI & TECH CO LTD

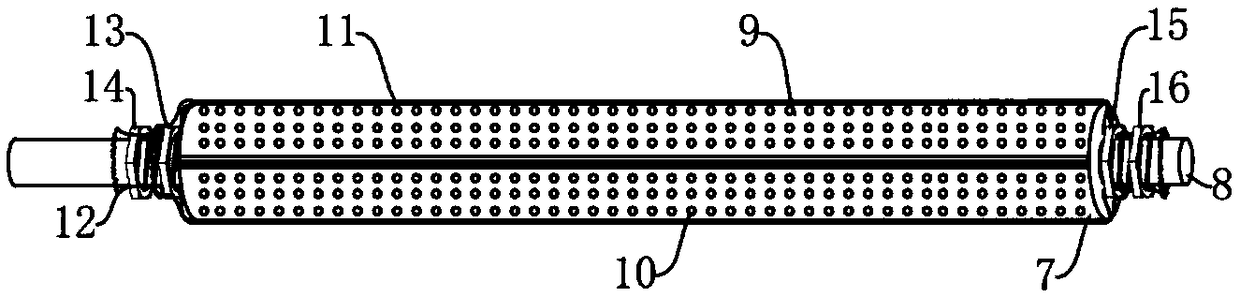

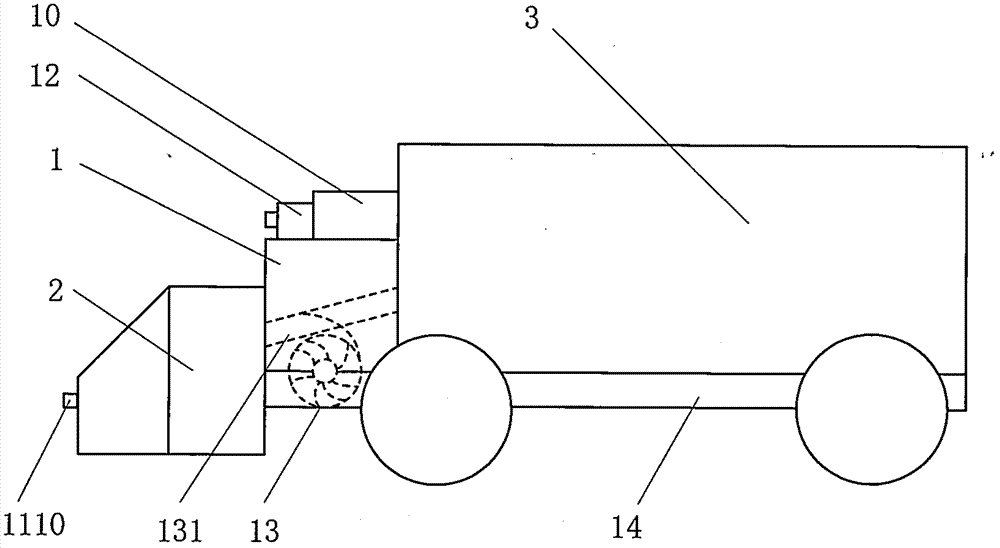

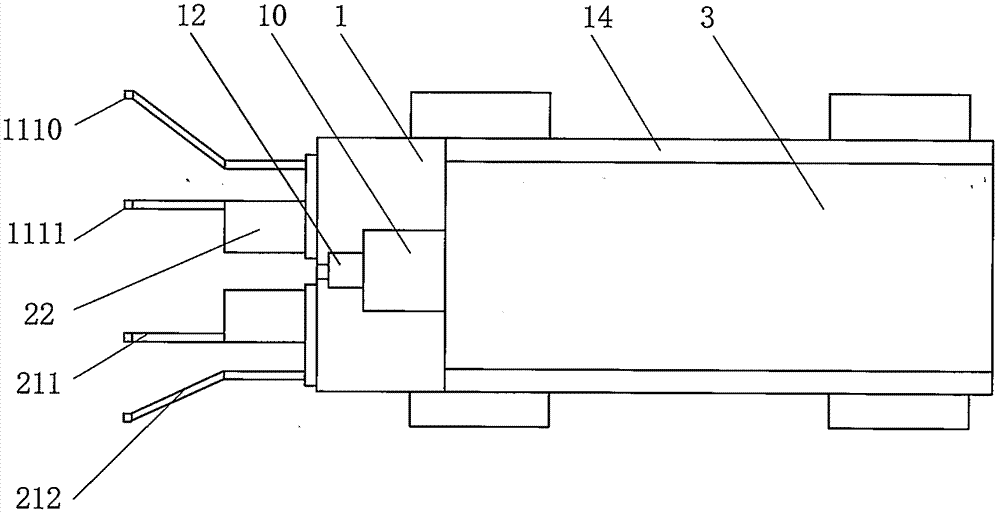

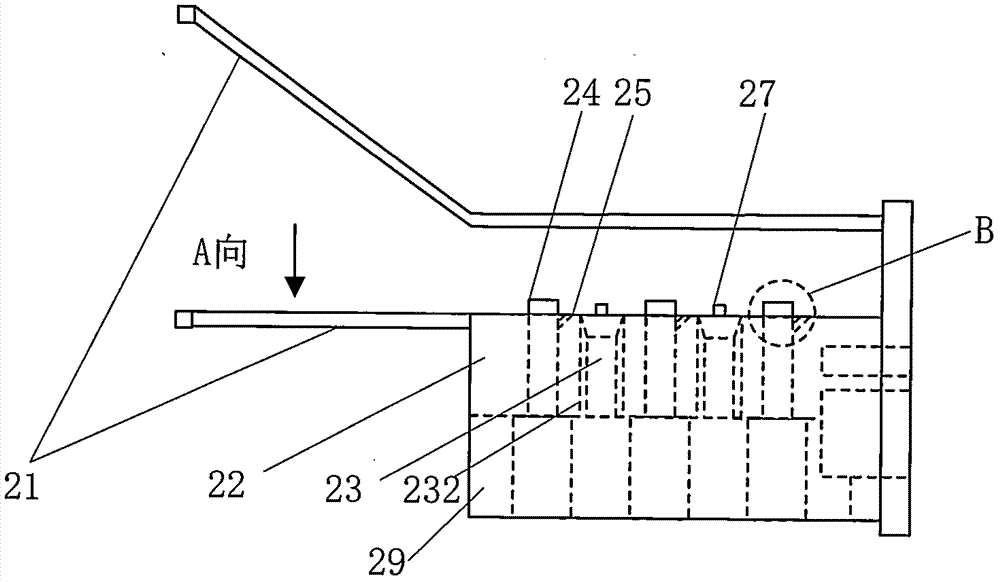

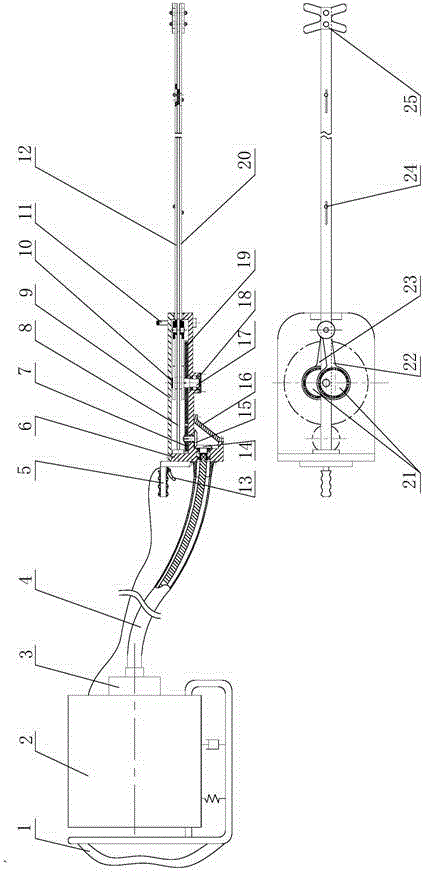

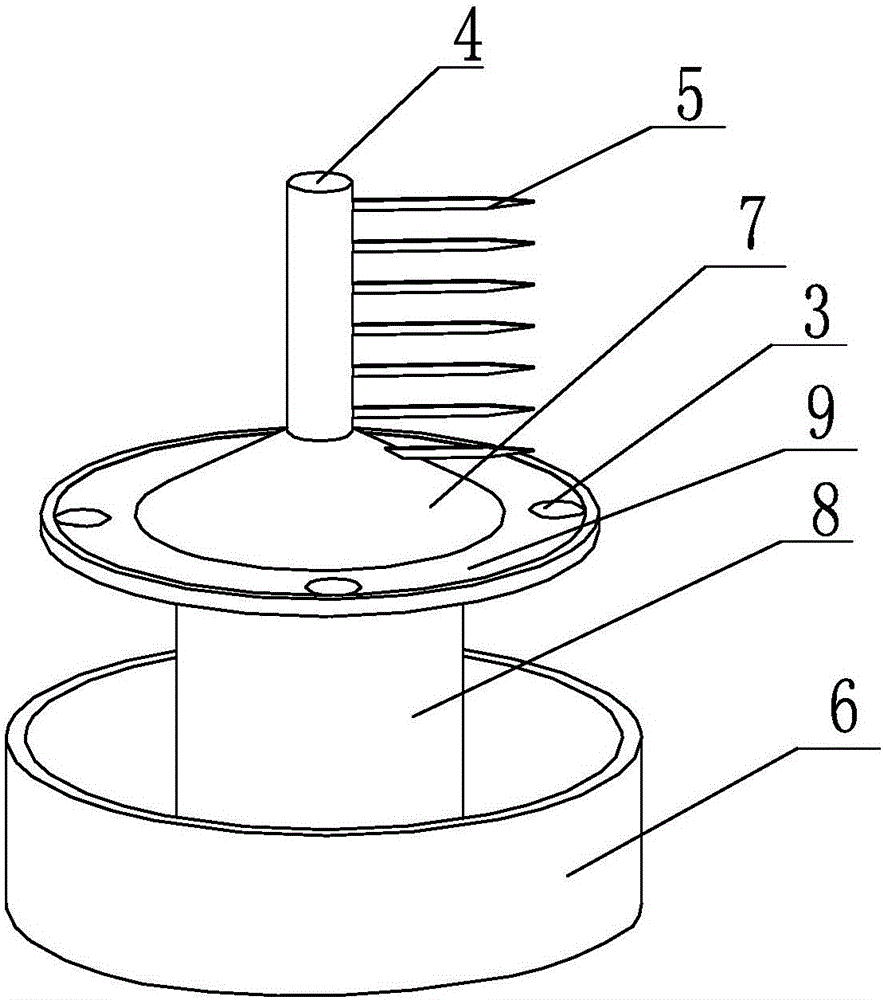

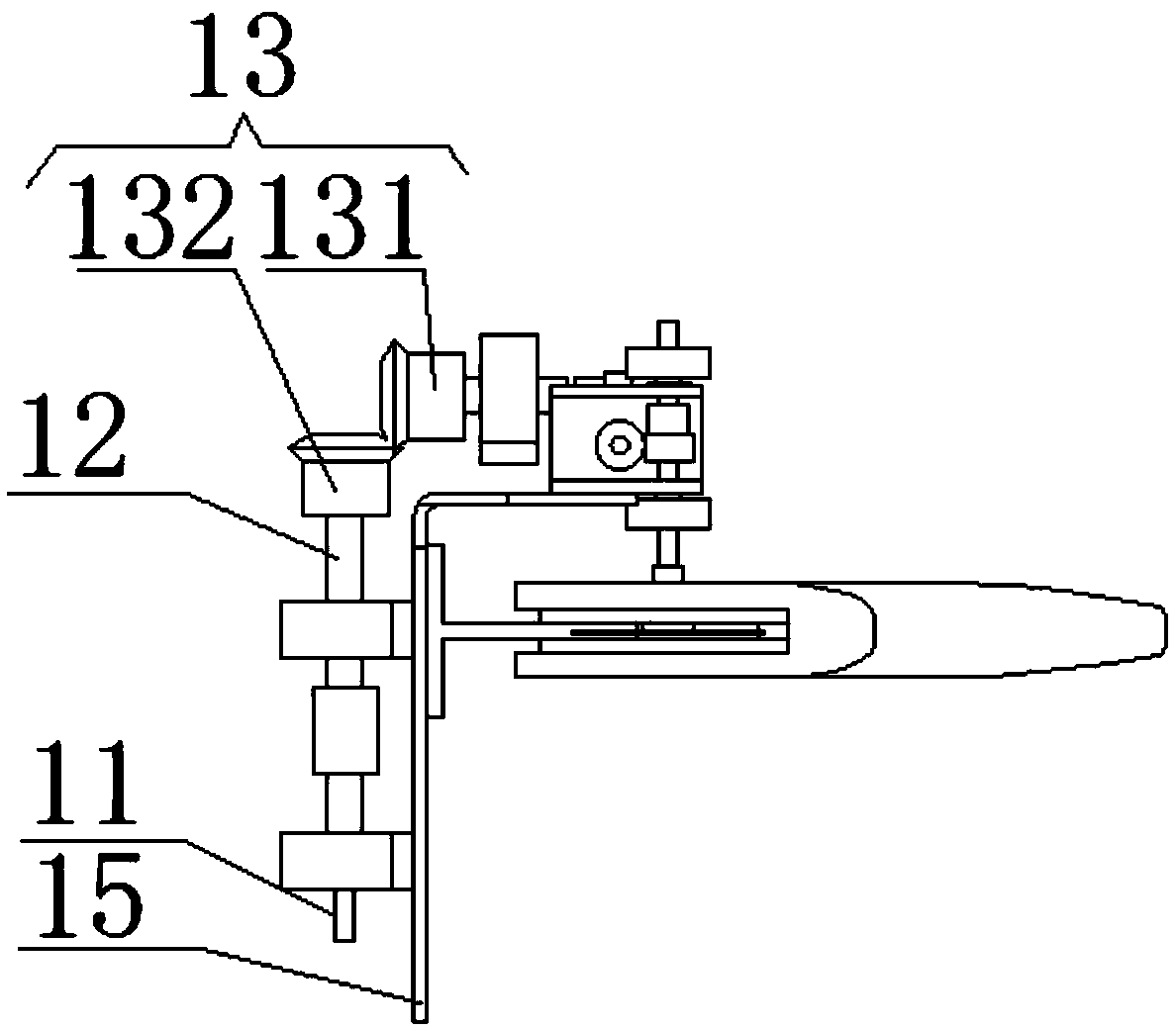

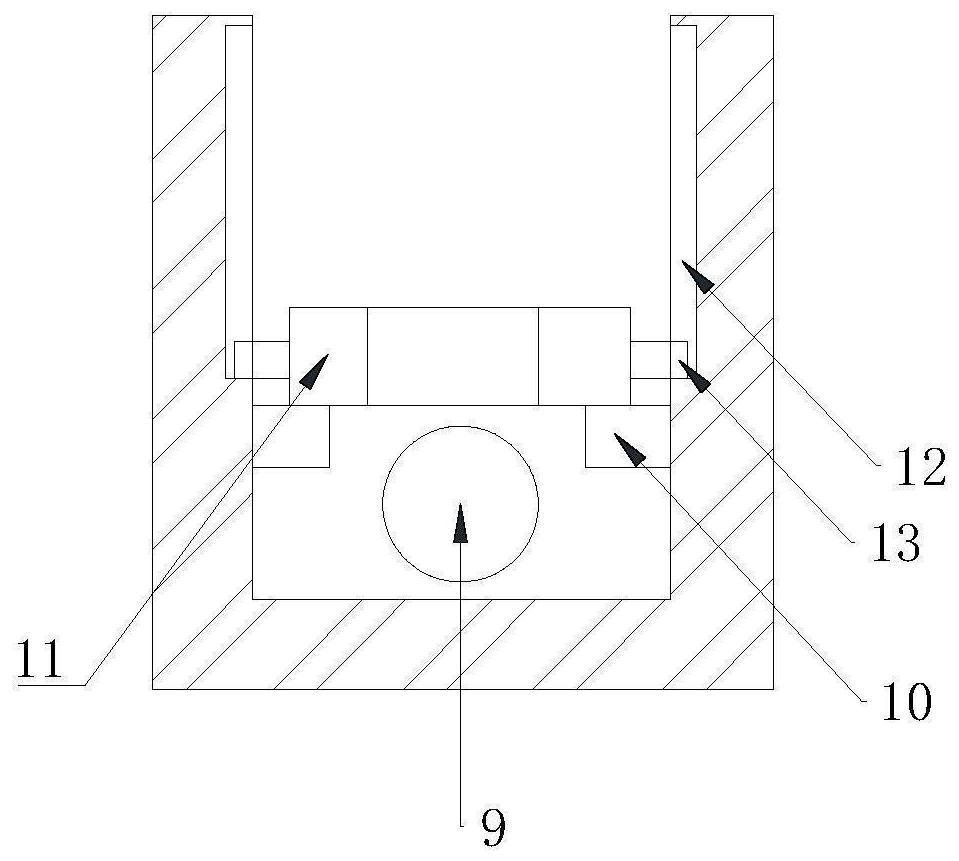

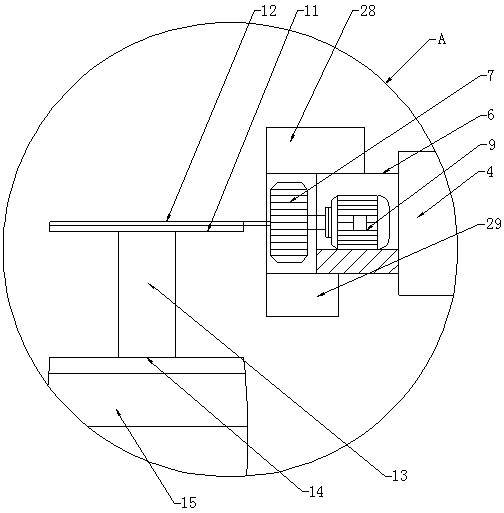

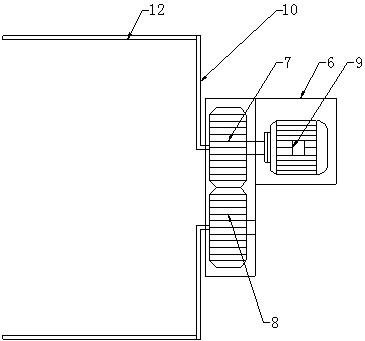

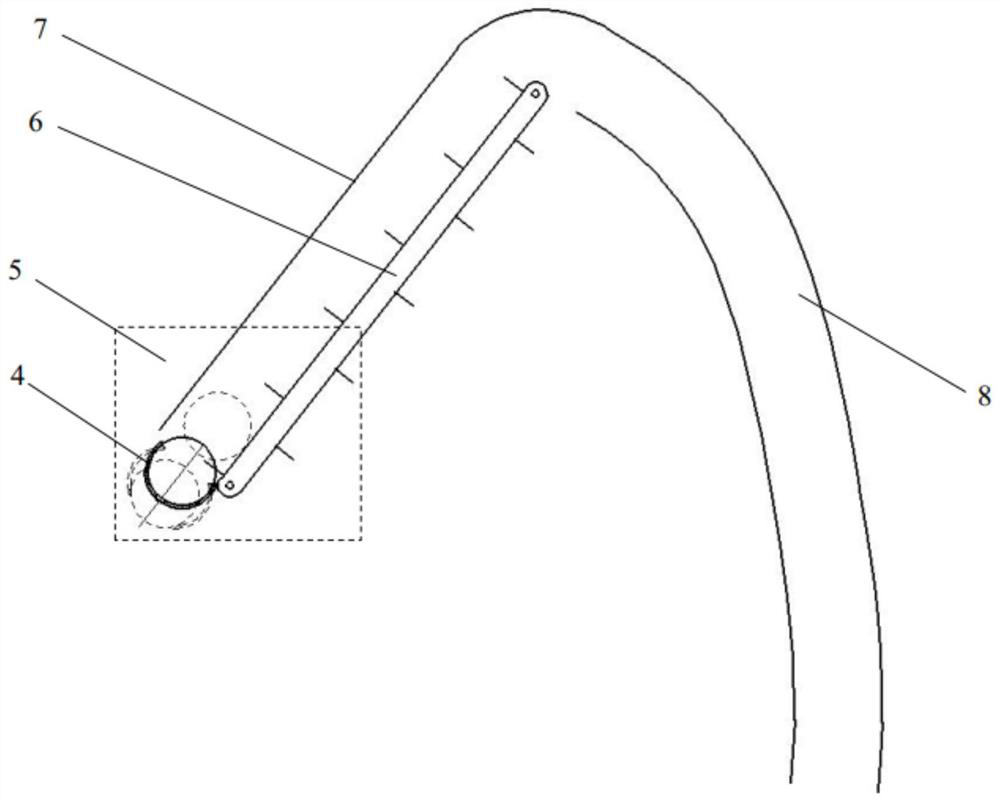

Handheld vibratory matrimony vine harvester

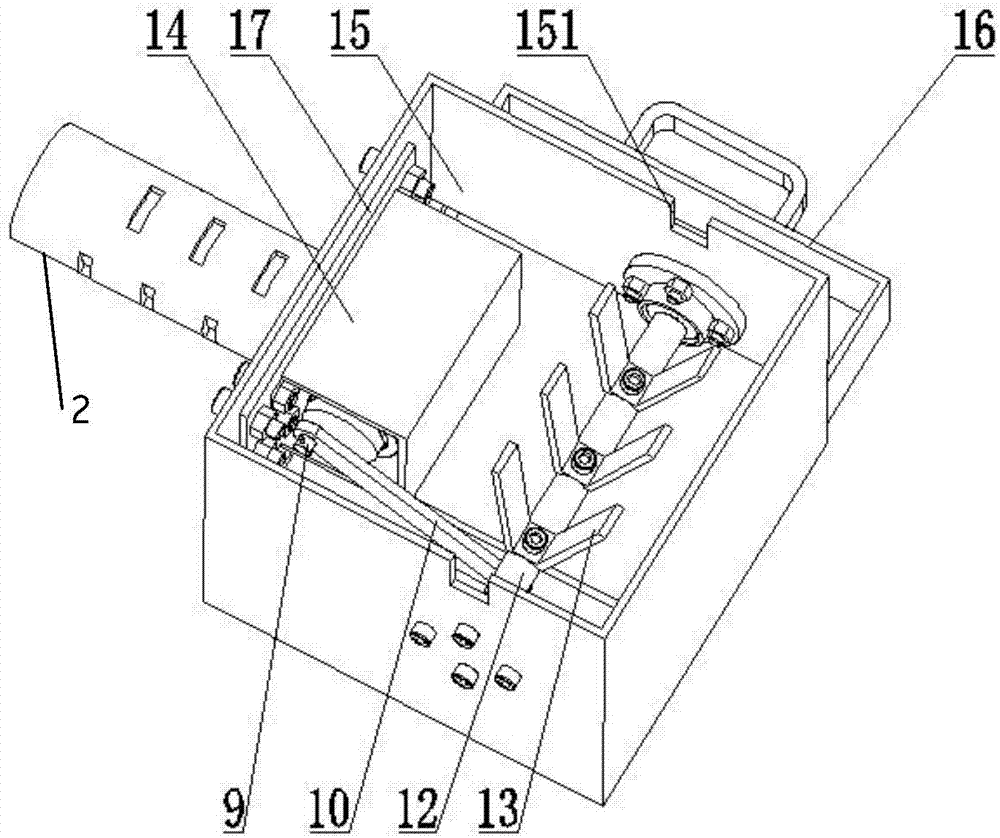

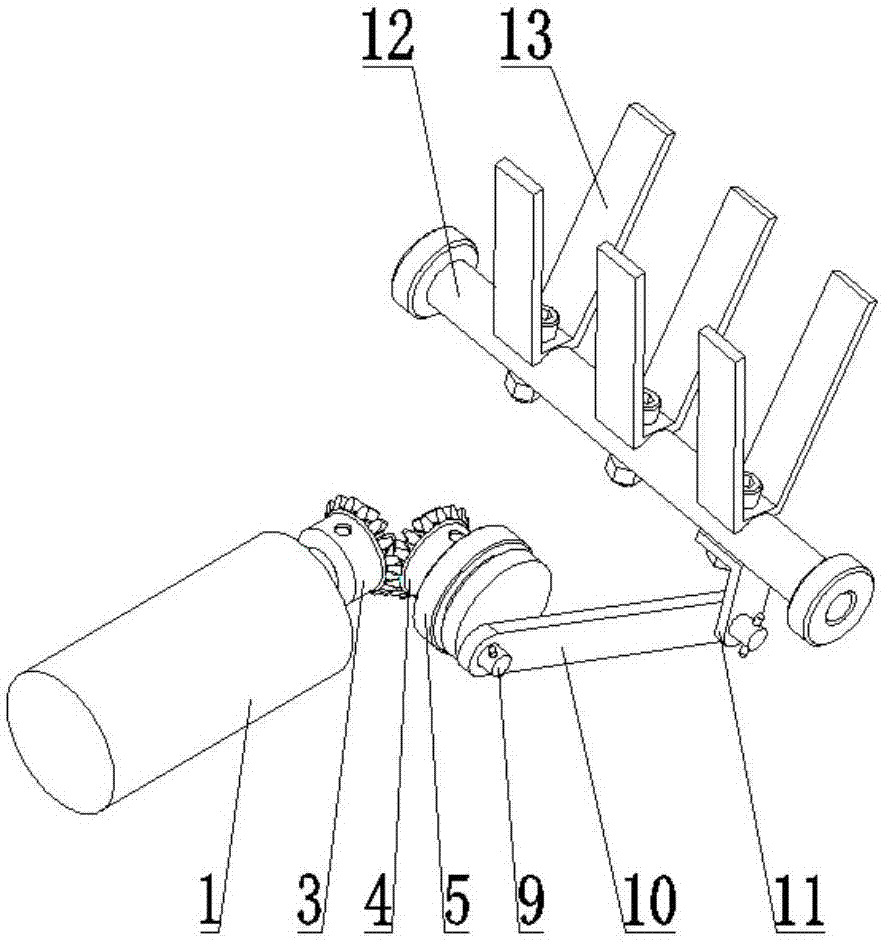

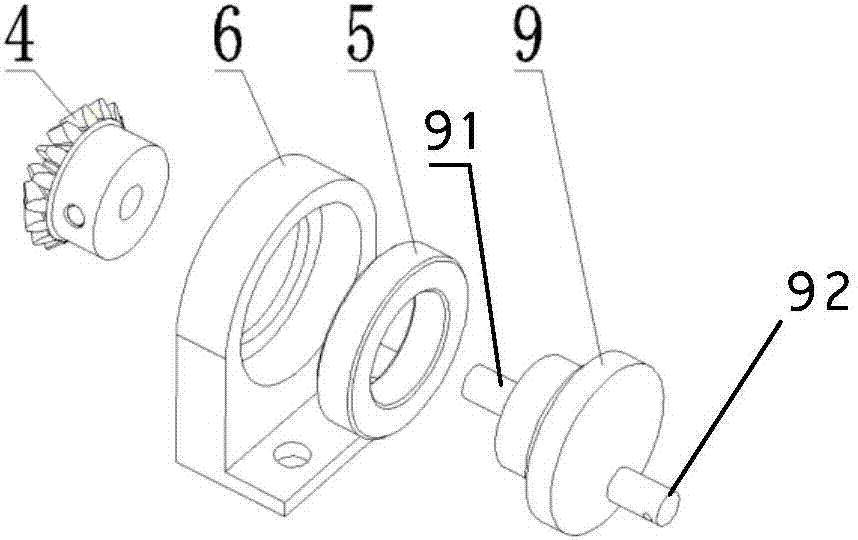

ActiveCN107360796AAchieve pickingRealize the integration of harvestingPicking devicesHuman bodyEngineering

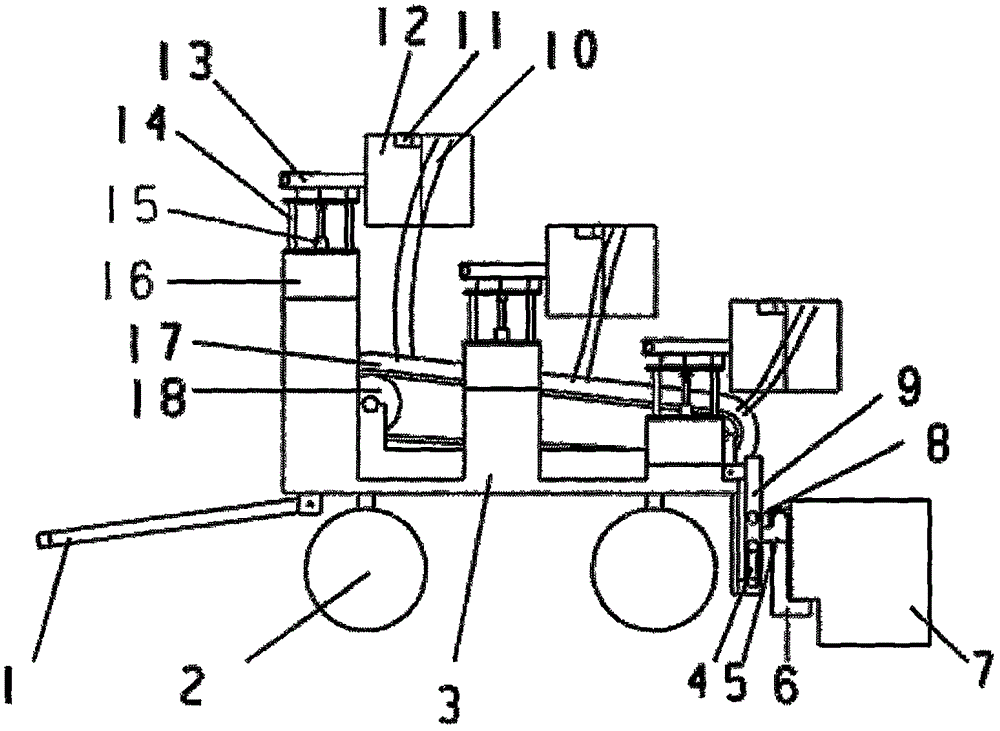

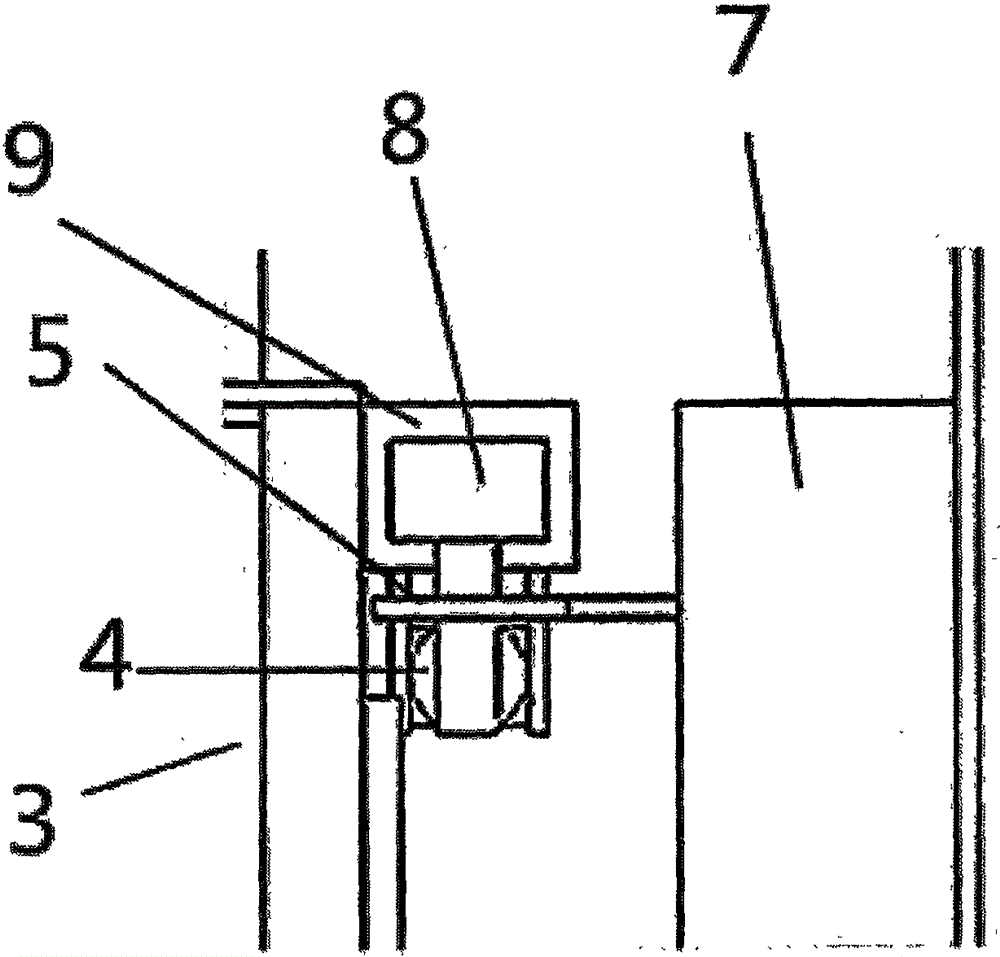

The invention relates to the field of agricultural machinery, in particular to a handheld vibratory matrimony vine harvester. The harvester comprises a direct current motor (1), a motor protecting shell (2), a first bevel gear (3), a second bevel gear (4), a second bearing (5), a second bearing base (6), an eccentric wheel with a shaft (9), a straight connecting rod (10), an L-shaped connecting rod (11), a rotating shaft (12), a flap finger (13), a protective cover (14), an installation box (15), a collecting box (16) and an installation plate (17). A crank rocker mechanism of the harvester can drive the flap finger to constantly flap matrimony vine branches to produce a certain amplitude of vibration, and therefore matrimony vine fruits are separated from the branches under the action of inertia force to achieve picking. In the process of harvesting, the vibration direction of the matrimony vine branches is as the same as the direction of picking staff' arms, which can reduce the impact of the vibratory force of the harvester on human bodies. The harvester has the advantages of a simple structure, convenient operation, low costs and a long service life, and meanwhile guarantees high picking efficiency.

Owner:CHINA AGRI UNIV

Electric portable fruit picking device

InactiveCN108848911AAchieve pickingTo achieve the purpose of collectionPicking devicesMicrocontrollerGear wheel

The invention discloses an electric portable fruit picking device which comprises a driving device, a picking device, a conveying device, a collecting device and a grabbing device. The driving devicemainly comprises a lithium battery, a driving board, a microcontroller, a battery frame and the like; the picking device mainly comprises a telescopic rod, bent scissors, scissors link rods, a steppermotor, a nut push plate, a motor square frame and a miniature camera; the conveying device mainly comprises a long net sleeve, an aluminum closure ring, a cushion net and a closing rope; the collecting device mainly comprises a feed inlet, discharge outlets, rollers and sponge mats; the grabbing device mainly comprises grabbing jaws, grabbing link rods, incomplete gears, bevel gears and a bevel gear shaft. The electric portable fruit picking device has the advantages that fruits can be grabbed, positioned and then picked by the semi-automatic electric portable fruit picking device; the electric portable fruit picking device has cutter rotary cutting control, fruit and branch separating, conveying and sorting functions, and accordingly the fruits can be ultimately picked and collected by the electric portable fruit picking device.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flexible contra-rotating pineapple harvesting device

The invention relates to a flexible contra-rotating pineapple harvesting device. The flexible contra-rotating pineapple harvesting device comprises a rack, a leaf pressing frame, a harvesting mechanism, a transmission mechanism and a driving mechanism; the leaf pressing frame is fixedly connected to the bottom of the rack; the harvesting mechanism comprises a first transmission shaft and a second transmission shaft, the first transmission shaft is sleeved with a first roller and a first gear, a plurality of first flexible rods are arranged on the side wall of the first roller, the second transmission shaft is sleeved with a second roller and a fourth gear, and a plurality of second flexible rods are arranged on the side wall of the second roller; the transmission mechanism comprises a first mandrel and a second mandrel, the first mandrel is sleeved with a second gear, the second mandrel is sleeved with a third gear, and the first gear, the second gear, the third gear and the fourth gear are sequentially in meshing transmission; the driving mechanism comprises a motor which is connected with a speed reducer, and the speed reducer is connected with the first transmission shaft through a coupler. The first roller and the second roller rotate oppositely, the first flexible rods and the second flexible rods are driven to rotate oppositely, and pineapples are separated from plants.

Owner:SOUTH CHINA AGRI UNIV

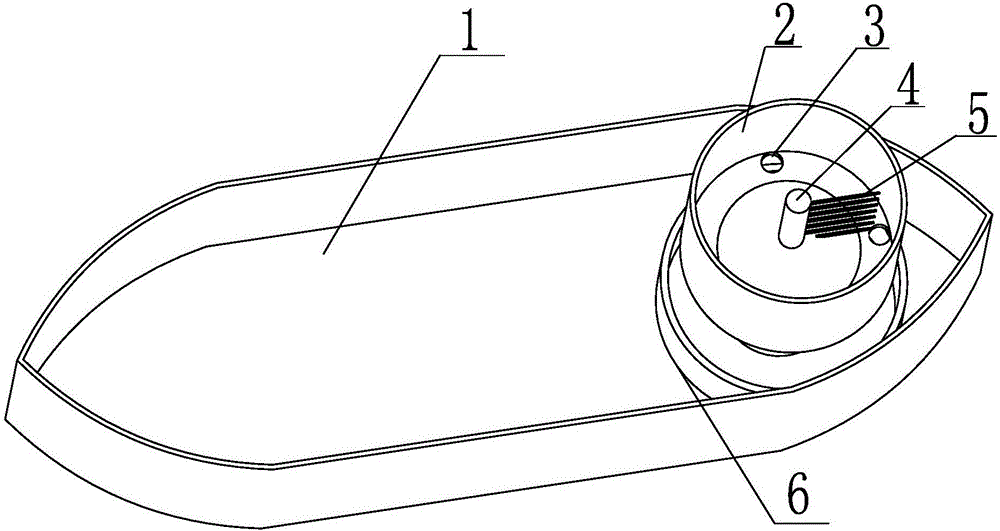

Automatic lotus seedpod threshing and picking boat

ActiveCN106068950ASolve the problem of frequent dockingAchieve pickingWaterborne vesselsThreshersCouplingEngineering

The invention discloses an automatic lotus seedpod threshing and picking boat. The automatic lotus seedpod threshing and picking boat comprises a boat body and a threshing mechanism connected with the bottom of the boat body through screws; the boat body is a common boat body driven by an engine; the threshing mechanism comprises a box, a seed feeding hole, a shaft coupling, a stirring rod, a seed storage box, a trapezoidal cylinder, a supporting pillar, a box bottom, a motor and a sliding block; the seed storage box, the motor and the supporting pillar are all fixedly connected with the bottom of the boat body, a guide rail is arranged at the upper end of the supporting pillar, the sliding block is connected with the guide rail arranged at the upper end of the supporting pillar in a sliding fit mode, the upper end of the sliding block is fixedly connected with the box bottom, the box and the box bottom are connected through screws to form a storage box used for containing picked lotus seedpods, the seed storage box is used for containing unshelled lotus seeds. The automatic lotus seedpod threshing and picking boat can achieve the function of continuous lotus seedpod picking, and lotus seed collection efficiency is improved.

Owner:合肥曌云科技有限公司

Watermelon picking equipment

The invention discloses watermelon picking equipment. The watermelon picking equipment comprises a vehicle body, a controller, a travel switch and a watermelon collecting box, wherein the watermelon collecting box is positioned on the vehicle body; a cylinder is further arranged on the vehicle body; a cylinder piston rod is connected with a worktable; and a motor, a transmission belt, a clamping mechanism and a cutting mechanism are arranged on the worktable. The clamping mechanism comprises a bidirectional lead screw and a clamping plate, and nuts are respectively arranged at two ends of the bidirectional lead screw and are connected with the clamping plate; the cutting mechanism comprises a cutter, a cutter rest and connecting rods, a guide track is arranged on the cutter rest, the cutter is slidably connected with the cutter rest through the guide track, and the cutter is respectively connected with the two nuts through the connecting rods; and the travel switch is positioned on the bidirectional lead screw, and the travel switch and the motor are connected with the controller respectively. The watermelon picking equipment uses a single power source and is simple in structure, clamping and cutting are matched with each other, the time is saved, and the work efficiency is improved.

Owner:CHONGQING FENGZHINONG AGRI DEV CO LTD

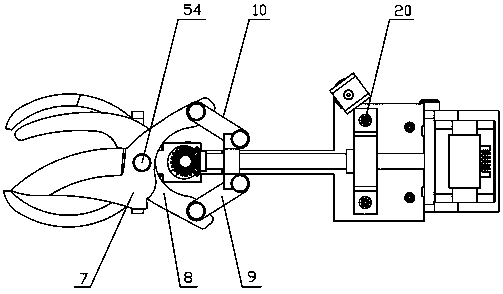

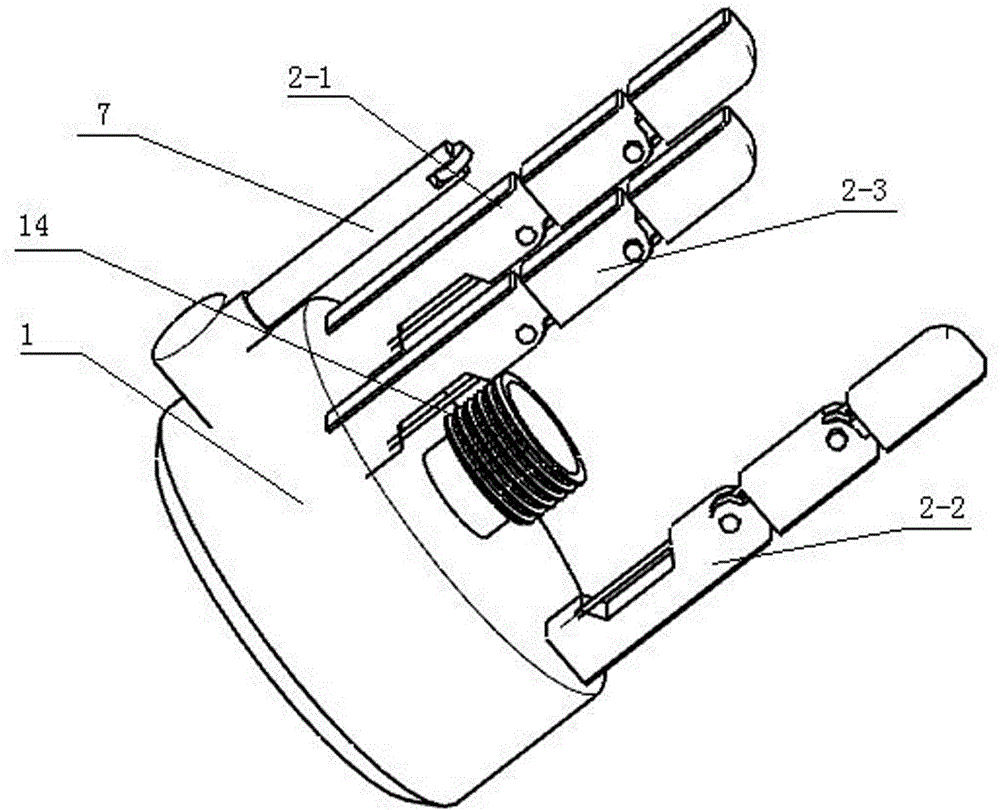

End effector structure of garden stuff picking robot

InactiveCN108098801AAchieve pickingGuaranteed pinch stabilityGripping headsPicking devicesKnuckleEngineering

The invention provides an end effector structure of a garden stuff picking robot. On the promise that garden stuff picking is met and the stability of garden stuff holding is guaranteed, the end effector structure of the garden stuff picking robot is simple in structure, the control difficulty is relatively small, the using cost and the manufacturing cost are relatively low, the adaptation is relatively high, and the end effector structure is suitable for being applied and popularized. The end effector structure comprises a drive box and is characterized in that the drive box is provided withat least three movable knuckles, the movable knuckles are circumferentially distributed to form a storage cavity, the movable knuckles are connected with the drive box through torsional springs or tension springs, the drive box is provided with drive devices corresponding to the movable knuckles, and the drive devices are connected with the movable knuckles through key ropes.

Owner:CHANGSHA ZHIWEI ELECTRONICS TECH CO LTD

Citrus gonggan picking device and method for same

The invention relates to the field of fruit picking and specifically relates to a Citrus gonggan picking device and a method for the same, wherein the device is powered by a storage battery inside the device; a camera recognizes directions and determines positions of Citrus gonggan; a first mobile arm is coordinated with a second mobile arm; the Citrus gonggan is picked off by a picking head; and the Citrus gonggan is then conveyed along a slide conveying pipe and then stored in a storage cabin. The device provided by the invention picks off the Citrus gonggan through intelligent control of the mobile arms, so that manual picking of the Citrus gonggan can be replaced, and labor force is relieved; and a buffer layer is disposed inside the storage cabin, so that the Citrus gonggan can be collected during the picking, and picking processes are optimized and simplified greatly.

Owner:ZHONGSHAN CHENGHAO FRUIT PLANTING SPECIALIZED COOP

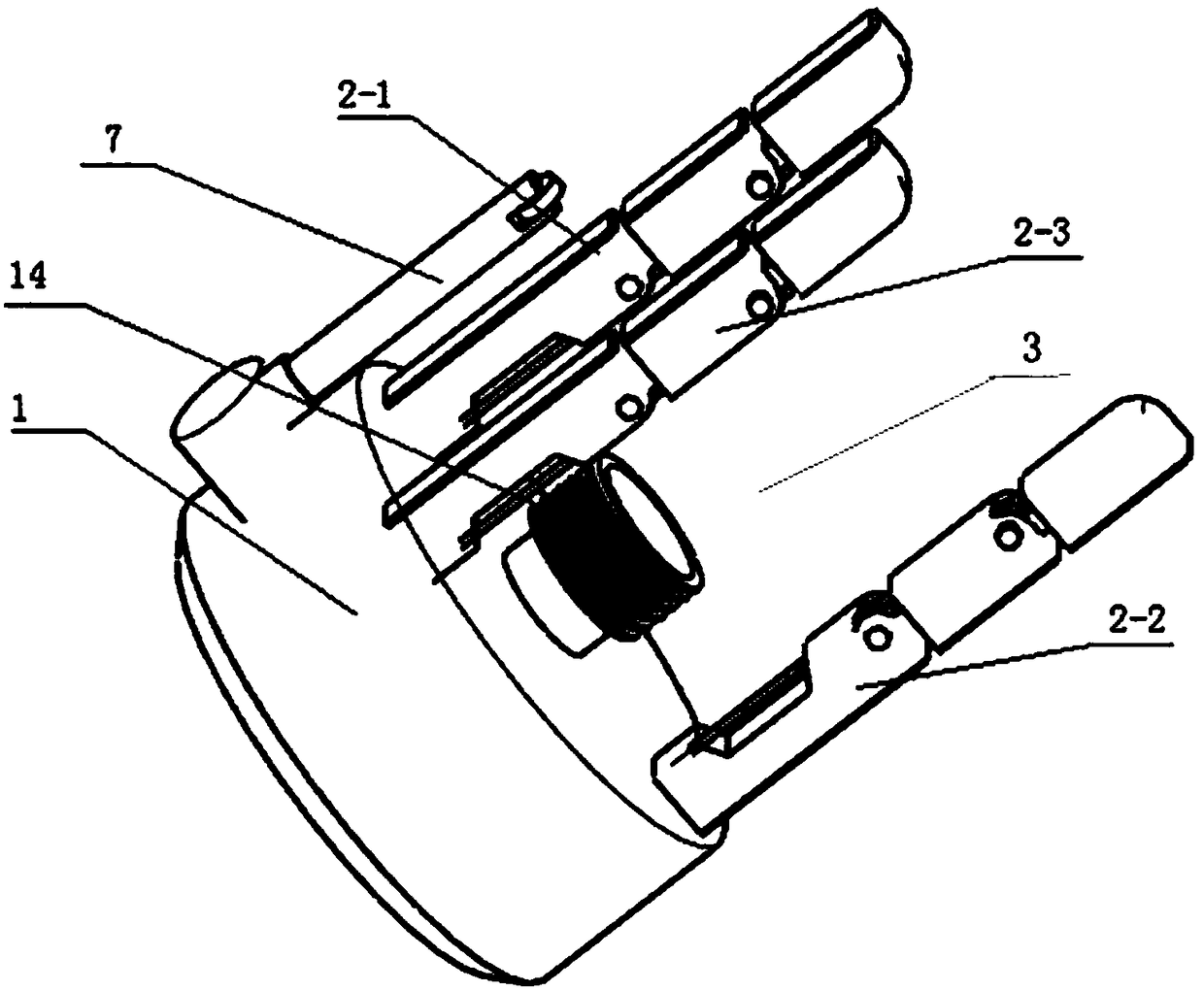

End effector structure of fruit and vegetable picking robot

The invention provides an end effector structure of a fruit and vegetable picking robot. On the premise of meeting the fruit and vegetable picking requirements and guaranteeing fruit and vegetable picking stability, the end effector structure is simple in structure, small in control difficulty, low in use and manufacturing cost, high in adaptability and suitable for popularization and application. The end effector structure comprises a driving box. The end effector structure is characterized in that the driving box is provided with at least three movable knuckles, the movable knuckles are circumferentially arranged to form an accommodating cavity and are connected with the driving box respectively through torsional springs or tension springs, the driving box is provided with a driving device corresponding to the movable knuckles, and the driving device is connected with the movable knuckles through key ropes.

Owner:JIANGNAN UNIV

Split orchard picking platform

The invention discloses a split orchard picking platform which mainly comprises a traction frame, a machine frame, traveling wheels, six split picking platforms, controllers, telescopic pipes, a conveying device, a lifting mechanism at the rear part of the machine frame and a fruit box, wherein the six split picking platforms are connected to the upper part of the machine frame, and are symmetrically distributed on the left and right sides of the machine frame respectively; the traveling wheels are connected below the machine frame; the traction frame is hinged to the front of the machine frame; each controller is mounted on one side of the corresponding split picking platform; the two ends of the telescopic pipes are connected with the picking platforms and the conveying device respectively; the conveying device is positioned above the middle part of the machine frame, and is driven by a hydraulic motor; the lifting mechanism at the rear part is mounted at the rear part of the machine frame; the fruit box is connected with the lifting mechanism, and is positioned behind the machine frame. The split orchard picking platform can be adapted to orchard field management under the condition of different row spacings, picking heights and crown shapes, and is particularly suitable for large-area orchard management and fruit picking, and the labor intensity of a worker can be greatly reduced.

Owner:NORTHWEST A & F UNIV

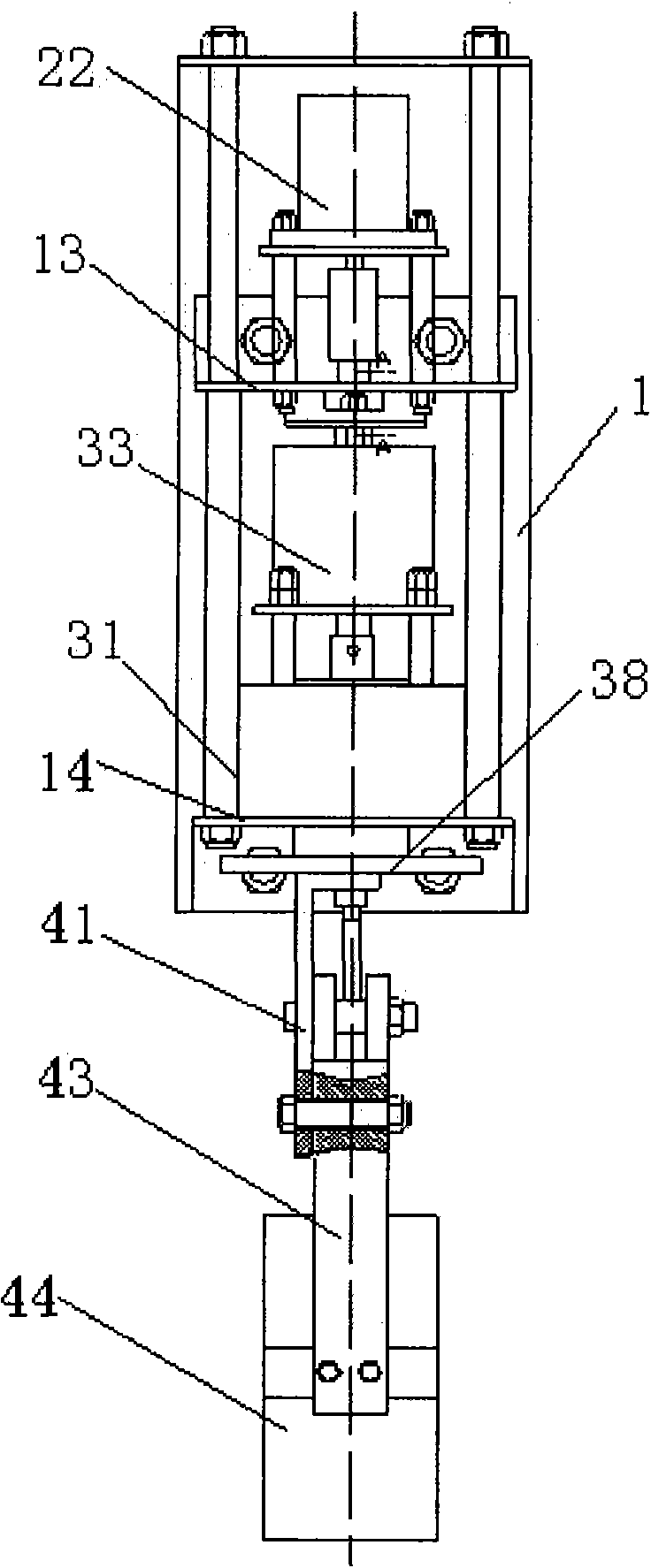

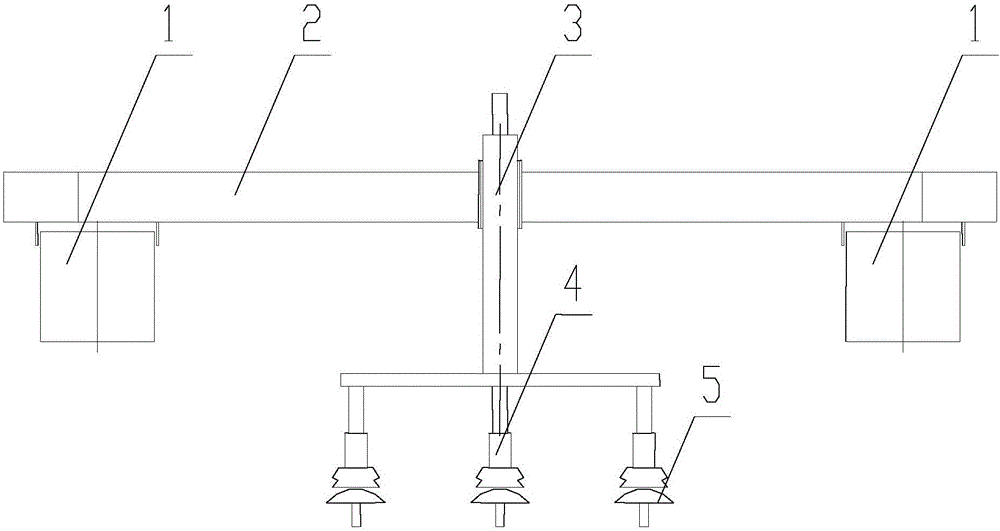

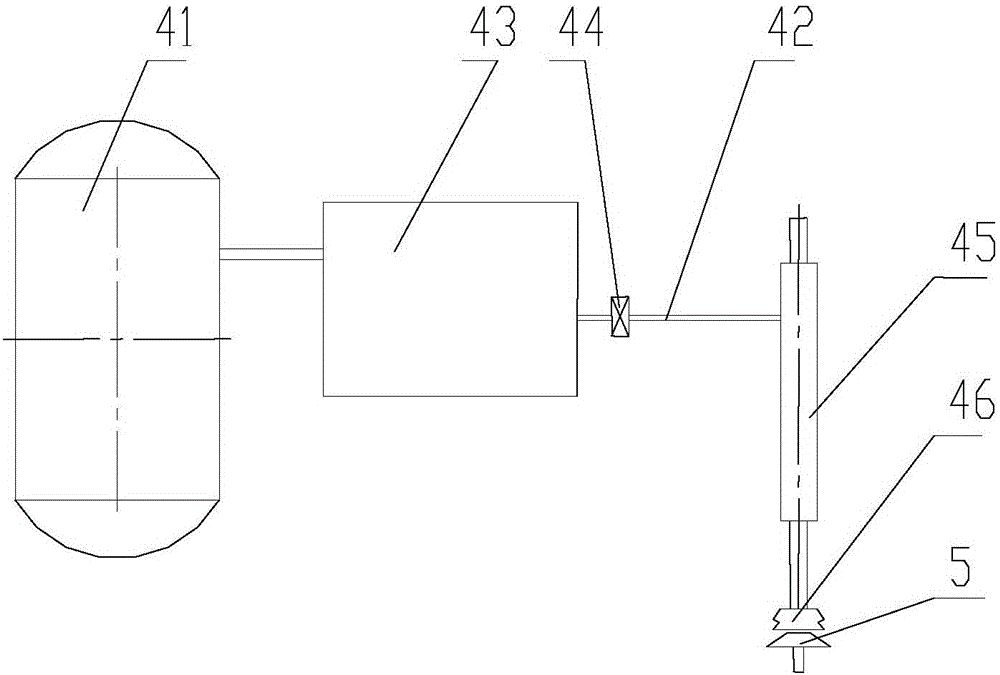

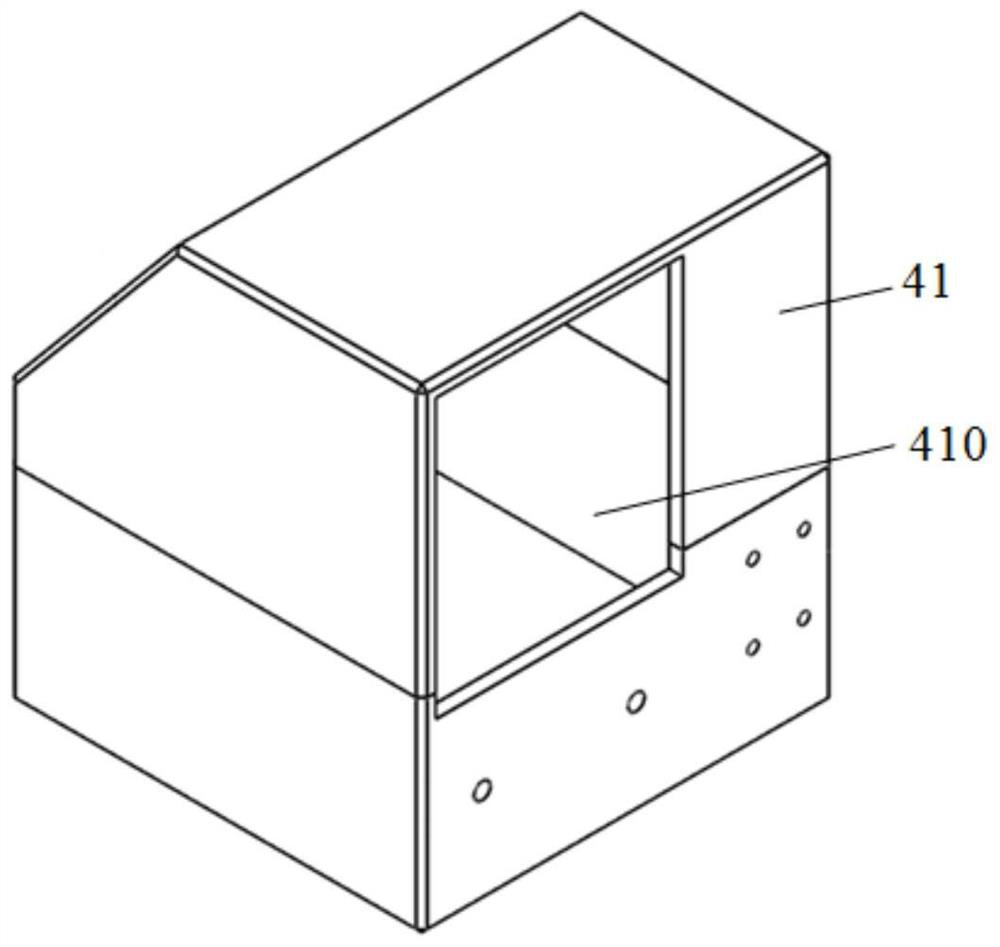

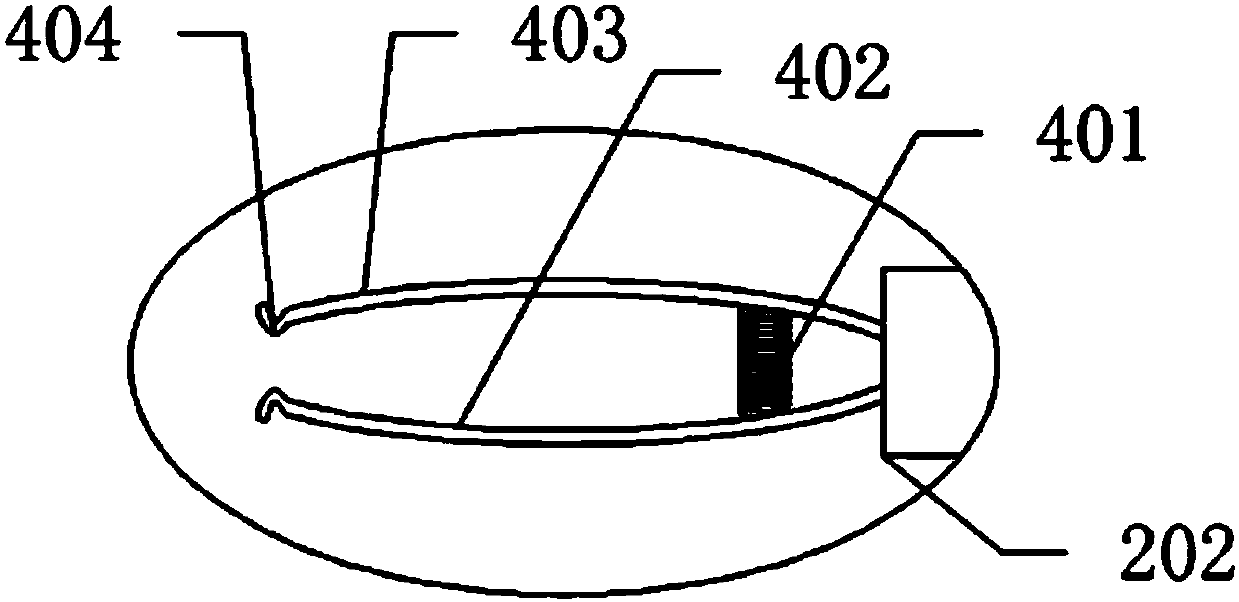

Double-mechanical-arm tea leaf picking robot based on machine vision

ActiveCN114731840AEffectively achieve pickingAchieve pickingImage enhancementImage analysisMachine visionDrive shaft

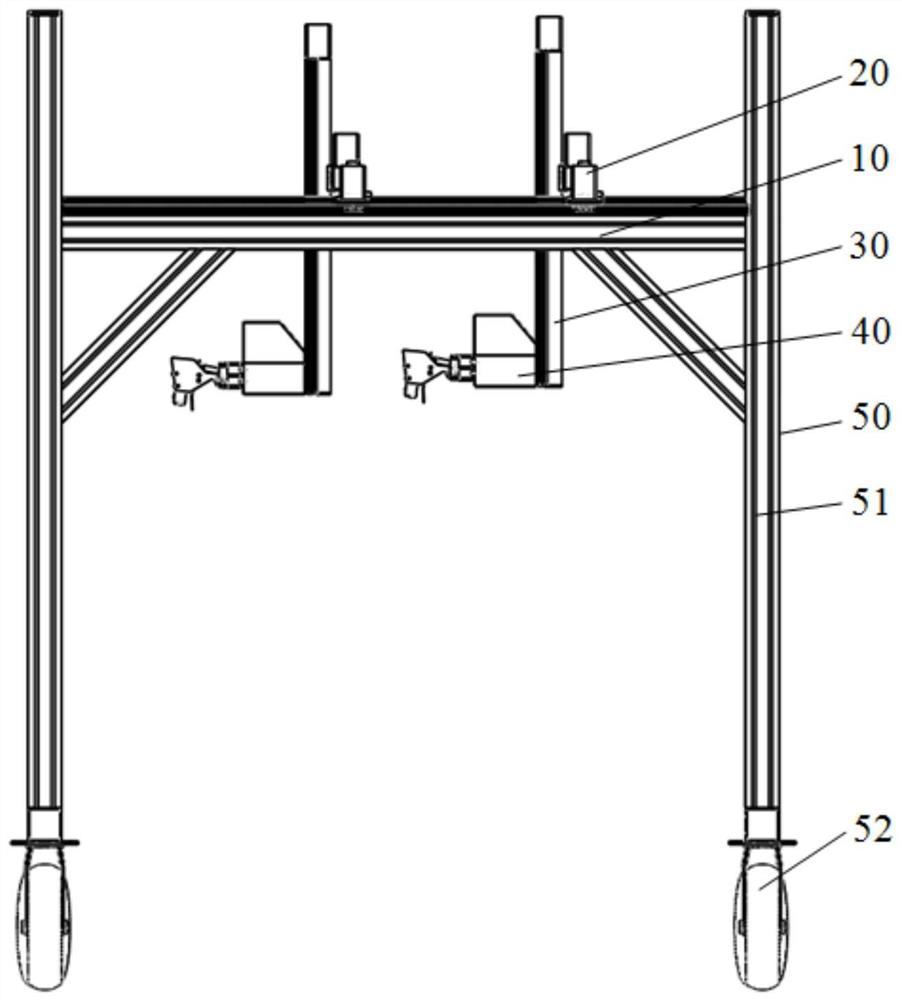

The invention provides a double-mechanical-arm tea leaf picking robot based on machine vision. The double-mechanical-arm tea leaf picking robot comprises a transverse guide rail module (10), a longitudinal guide rail module (20), a vertical guide rail module (30), a tail end execution assembly (40) and a visual recognition mechanism. The end execution assembly (40) comprises a collection box (41), a mounting seat (42), a driving assembly (43), a first connecting rod (44), a guide plate (45), a knife rest box (46), a knife rest seat (47) and a blade (48); the driving assembly (43) comprises a steering engine support (431), a steering engine (432), a transmission shaft (433) and a second connecting rod (434). The picking robot can automatically detect and position tea leaves, and meanwhile, the picking robot is matched with the tail end execution assembly to shear and collect the tea leaves; compared with traditional manual collection, the picking robot is high in positioning precision, good in picking consistency and high in picking efficiency.

Owner:ZHONGKAI UNIV OF AGRI & ENG

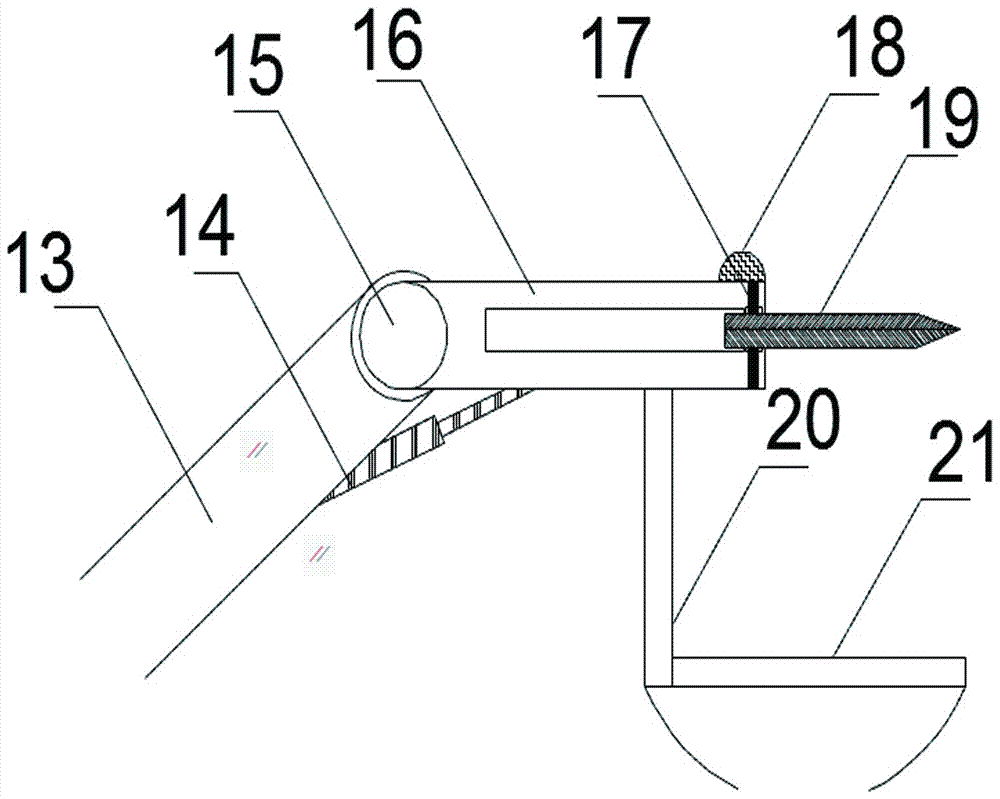

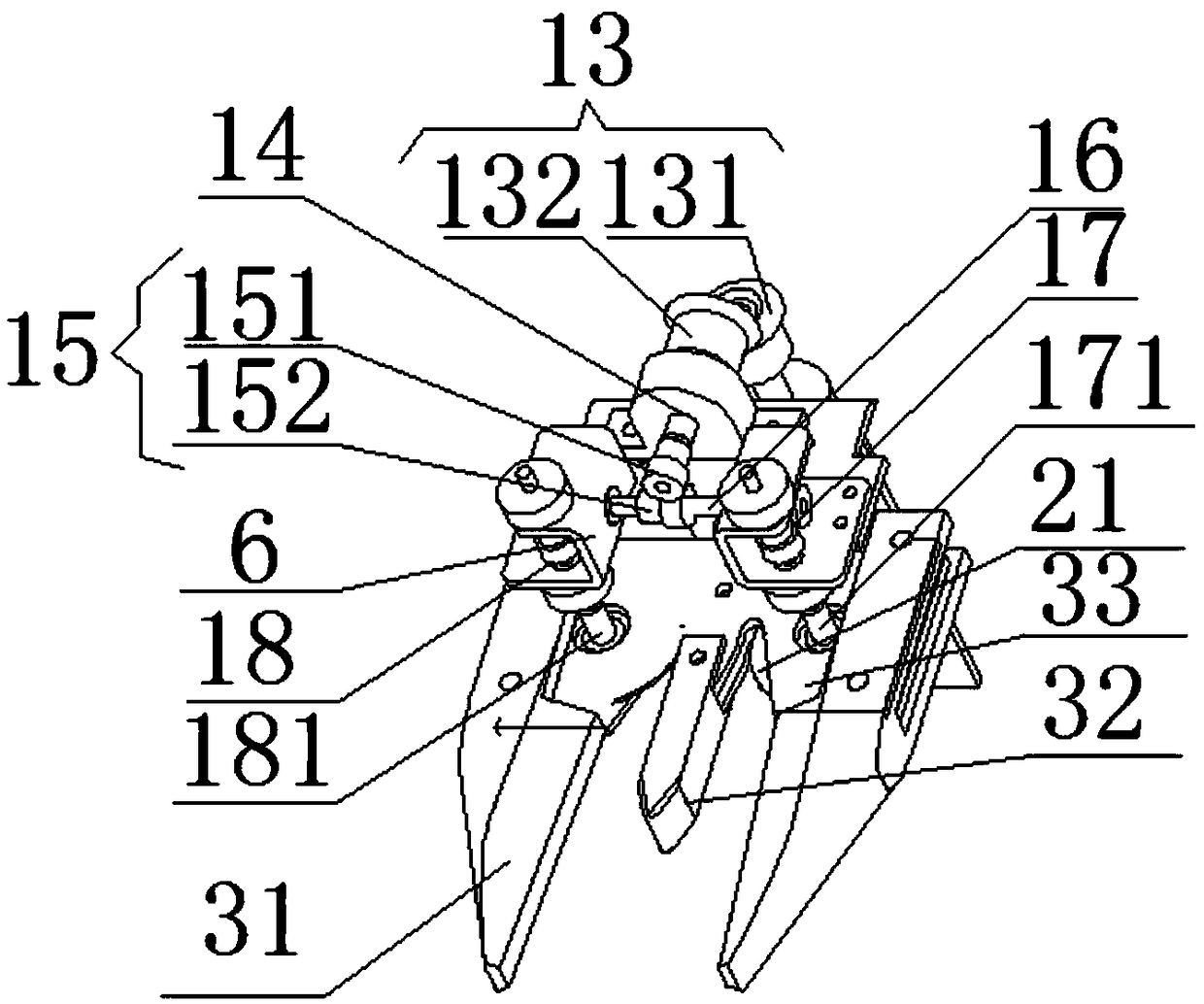

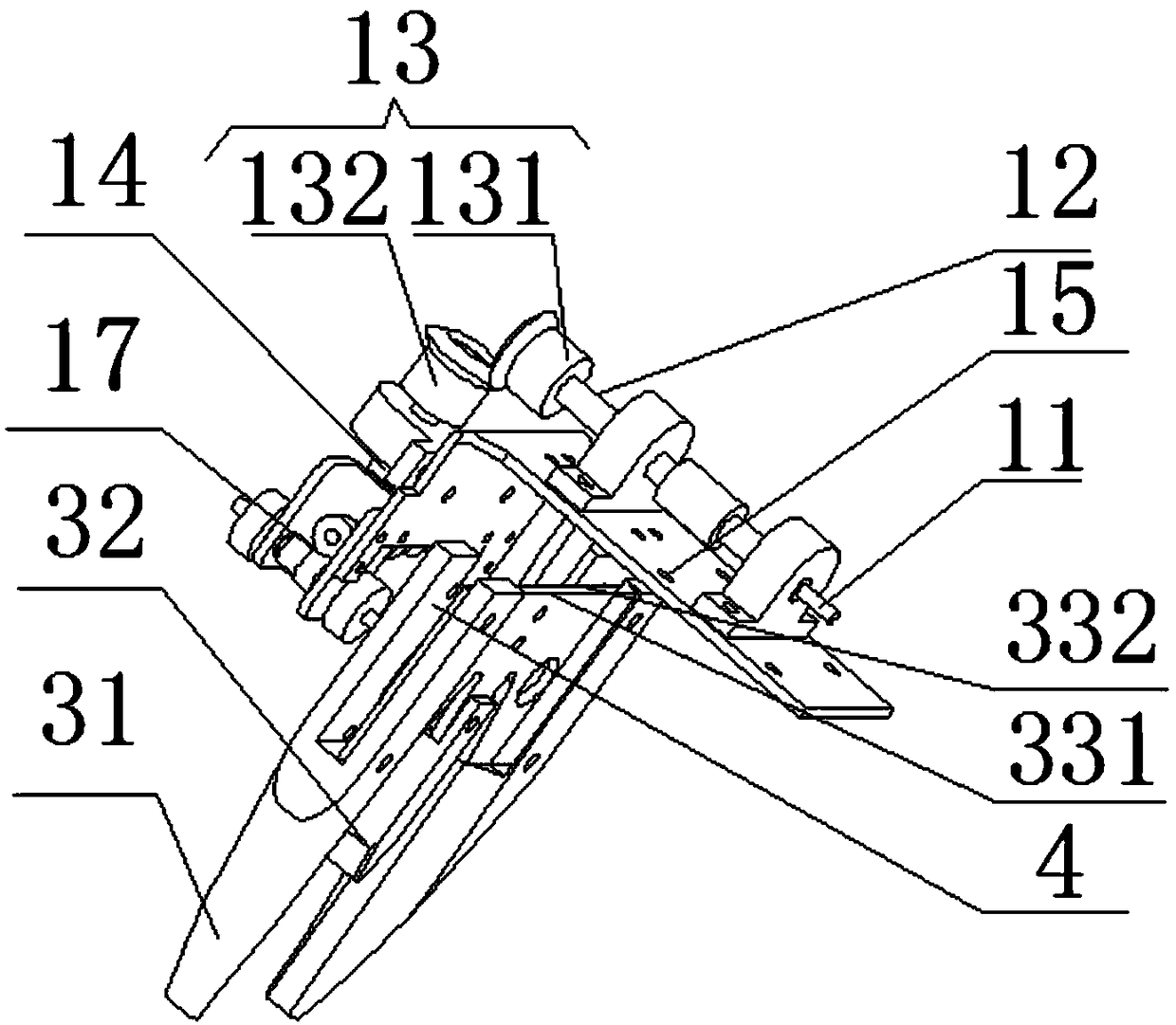

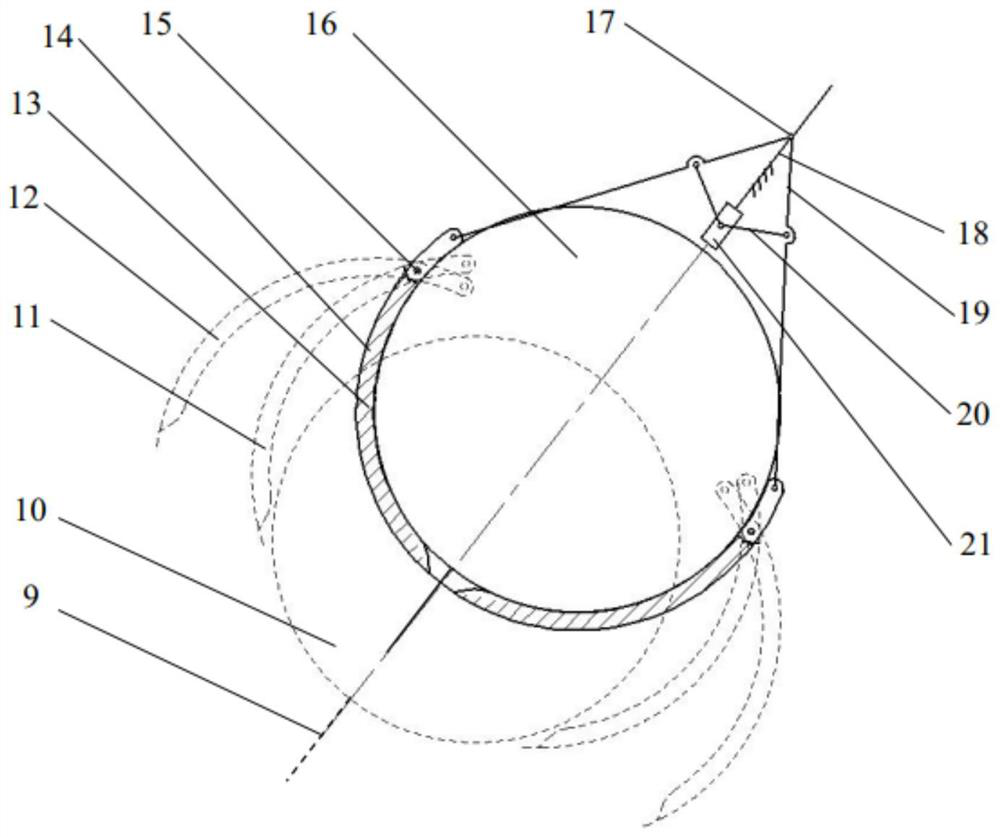

Human-assisted end-effector for citrus picking

The invention relates to the field of fruit picking machines, in particular to a human-assisted end-effector for citrus picking. The end effector includes a transmission mechanism, a cutting mechanismand a grab mechanism; the transmission mechanism comprises a first spindle, a second spindle, a straight bevel gear pair, a third spindle, a fourth spindle and three pairs of staggered helical gear pairs, and the cutting mechanism comprises a circular saw blade. The circular saw blade is rotatably connected with a first output shaft connected with the tail end of the second helical gear pair anda second output shaft connected with the tail end of the third helical gear pair; the grab mechanism includes a large grabbing claw, a small grabbing claw and a clamping plate, and the clamping plateis fixedly connected with the large grabbing claw and the small grabbing claw through bolts; citrus fruit stalks are teased to the circular saw blade through three mechanical claws, a motor can serveas a power source, power is transmitted to the circular saw blade through a rotating shaft, a pair of straight bevel gears and the three pairs of staggered gears, and the citrus fruit stalks are cut through rotation of the circular saw blade.

Owner:NANCHANG UNIV

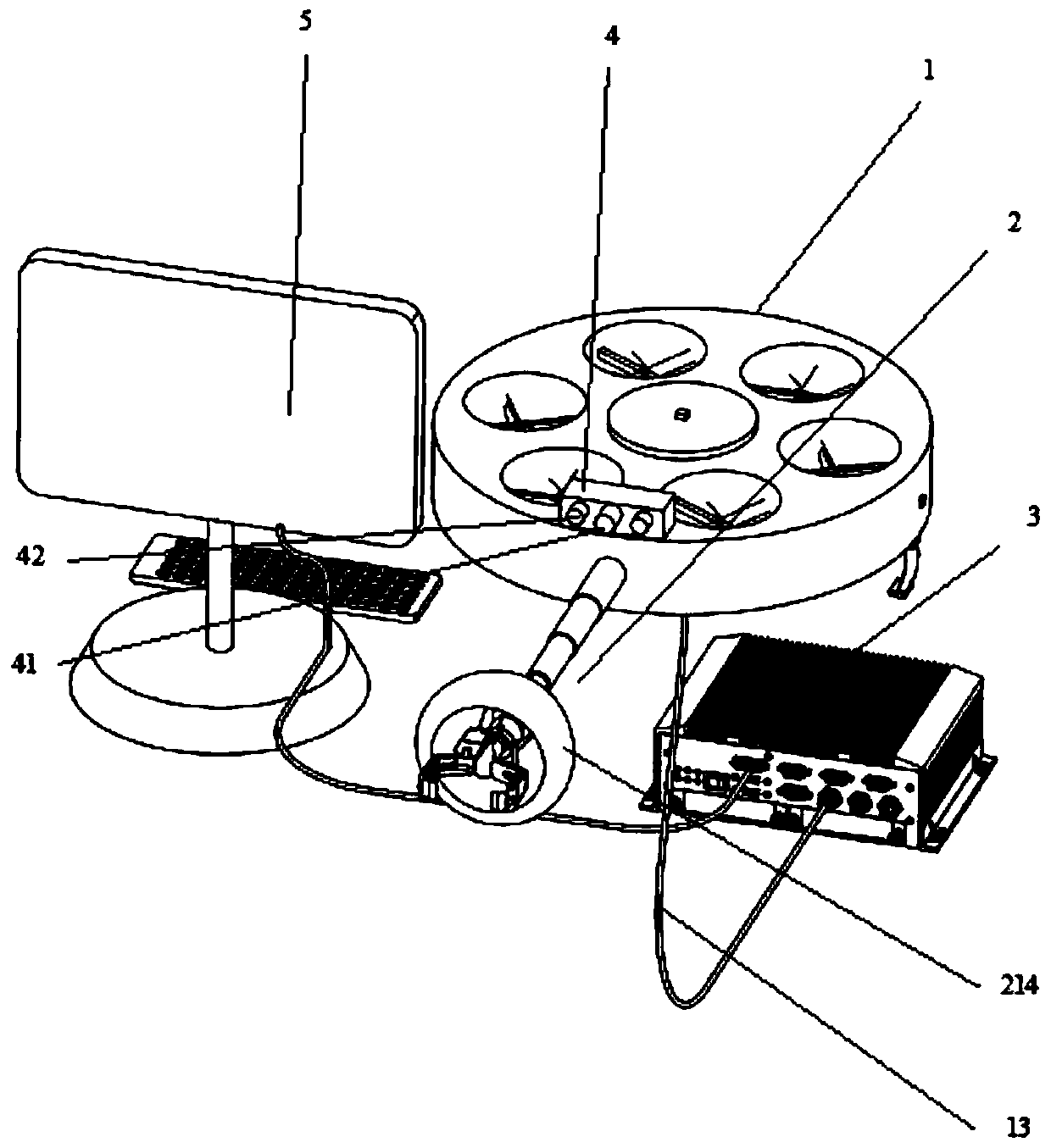

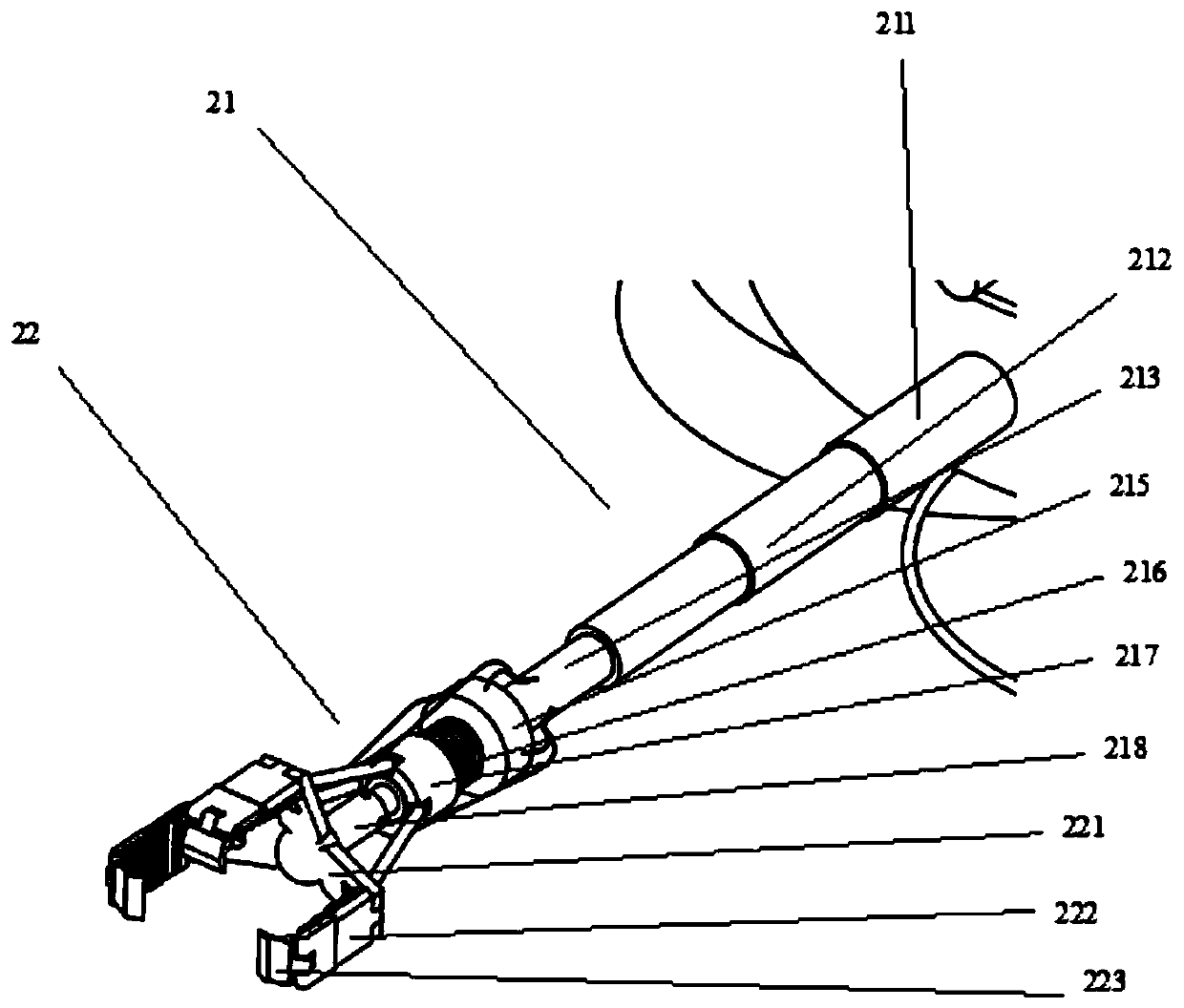

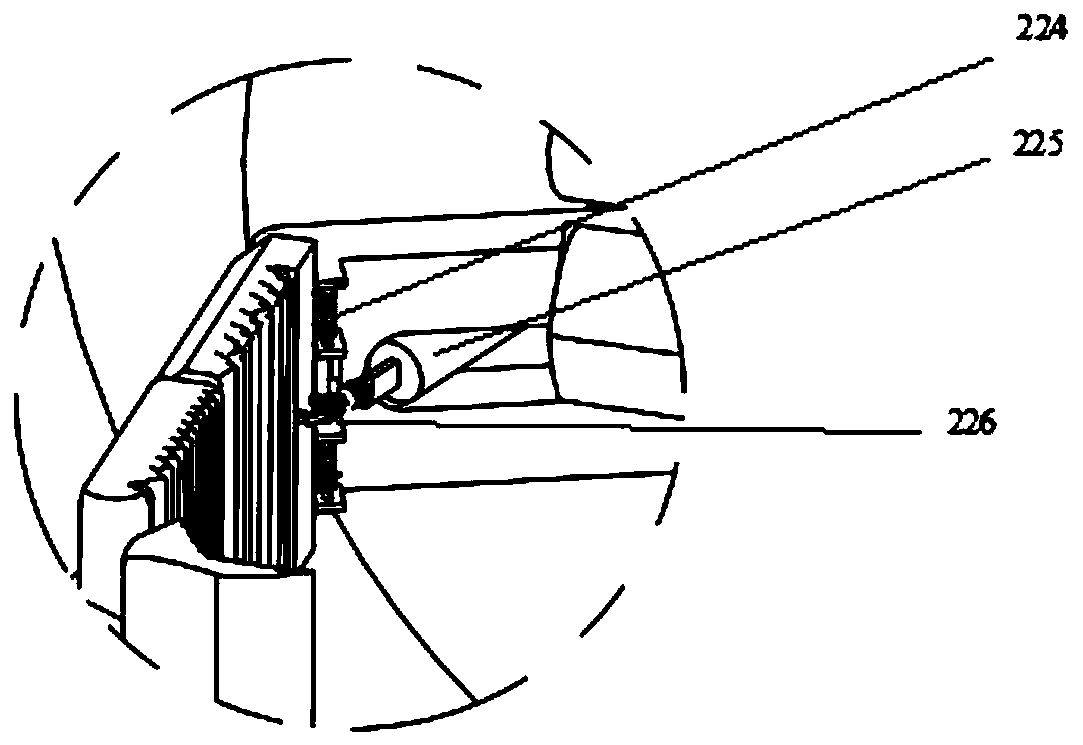

Four-degree-of-freedom multi-eye visual rotary flight type picking robot and picking method thereof

PendingCN111587665ARealize integrated designAchieve pickingAircraft componentsPicking devicesData transmissionAutomotive engineering

The invention discloses a four-degree-of-freedom multi-eye visual rotary flight type picking robot and a picking method thereof. The picking robot comprises an unmanned aerial vehicle, a picking mechanism and a multi-eye visual device, wherein the picking mechanism comprises a telescopic rod and a picking mechanical hand, and the picking mechanism and the multi-eye visual device are mounted on theunmanned aerial vehicle; and the unmanned aerial vehicle communicates with an industrial control computer and a computer through a cable or wireless manner for data transmission and system control. Integrated design of the unmanned aerial vehicle and the picking mechanism is realized, the four-degree-of-freedom multi-eye visual rotary flight type picking robot is a four-degree-of-freedom pickingrobot, multiple-oriented picking can be realized, the picking range is extended, and the picking efficiency is improved; and the designed picking mechanical hand can dynamically change free expandingand contracting of middle finger joints of three fingers according to the size of fruits, the holding capacity of the mechanical hand on the fruits is improved, and the applicability is high.

Owner:SOUTH CHINA AGRI UNIV +1

Automatic soilless culture production line

ActiveCN113940268AHelps fixHelps fix soilless cultivationHarvestersAgriculture gas emission reductionAgricultural scienceElectric machine

The invention discloses an automatic soilless culture production line, and belongs to the technical field of soilless culture. The automatic soilless culture production line is characterized by comprising a conveyor belt group, supporting frames and a plurality of soilless culture devices, wherein, each soilless culture device comprises a plurality of culture grooves; vegetable fixing discs are arranged on the inner walls of the culture grooves; two sliding grooves are formed in the inner wall of each culture groove, first stepping motors are arranged in the sliding grooves, and the first stepping motors are fixedly connected with the vegetable fixing discs; supporting transverse plates are fixedly connected to the outer sides of the two supporting frames correspondingly, and strip-shaped grooves are formed in the two supporting transverse plates correspondingly; second stepping motors and third stepping motors are installed in the strip-shaped grooves, the second stepping motors and the third stepping motors are connected with electric telescopic rods, rotating motors are arranged at the ends of the electric telescopic rods, and the rotating motors are connected with rotating parts; and a transverse part is fixedly connected between every two rotating parts, a plurality of sliding motors are arranged in the transverse parts, and the sliding motors are connected with picking blades. The automatic soilless culture production line is mainly used for automatically planting and picking vegetables, and the working efficiency and the automation degree are effectively improved.

Owner:SOUTH CHINA AGRI UNIV

Automatic pomegranate picking equipment and use method

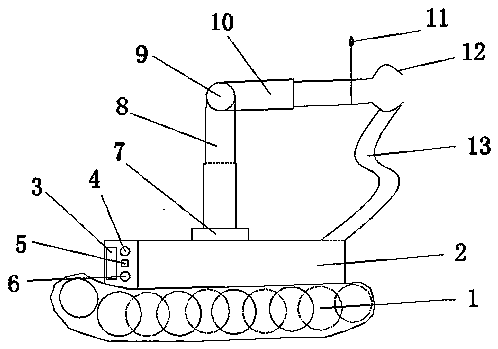

PendingCN113767755AAchieve pickingSmooth feedingNon-rotating vibration suppressionElectromagnetic wave reradiationGear wheelAgricultural engineering

The invention discloses automatic pomegranate picking equipment and a use method. The automatic pomegranate picking equipment comprises a tracked vehicle, wherein a rotating base is arranged on the upper side of the tracked vehicle, a first electric telescopic rod is arranged on the upper side of the rotating base, a second electric telescopic rod is vertically fixed to the upper end of the first electric telescopic rod, a shell is fixed to the end of the second electric telescopic rod, a driving gear is arranged in the shell and meshed with a driven gear, a driving motor is connected to the right side of the driving gear, L-shaped rods are connected to the left sides of the driving gear and the driven gear, tool rests are perpendicularly fixed to the L-shaped rods, strip-shaped blades are fixed to the upper sides of the tool rests, spring discharging pipes are connected to the lower sides of the strip-shaped blades, a turnover basket is further arranged on the upper side of the tracked vehicle, a strip-shaped plate is arranged above the turnover basket, a through hole is formed in the middle of the strip-shaped plate, and a buffering protection assembly is arranged on the lower side of the through hole. According to the automatic pomegranate picking equipment and the use method, automatic picking of pomegranates can be achieved, operation is convenient and fast, the structure is simple, the picking efficiency of the pomegranates is improved, and the picked pomegranates are better in appearance.

Owner:河南丹圣源农业开发有限公司 +4

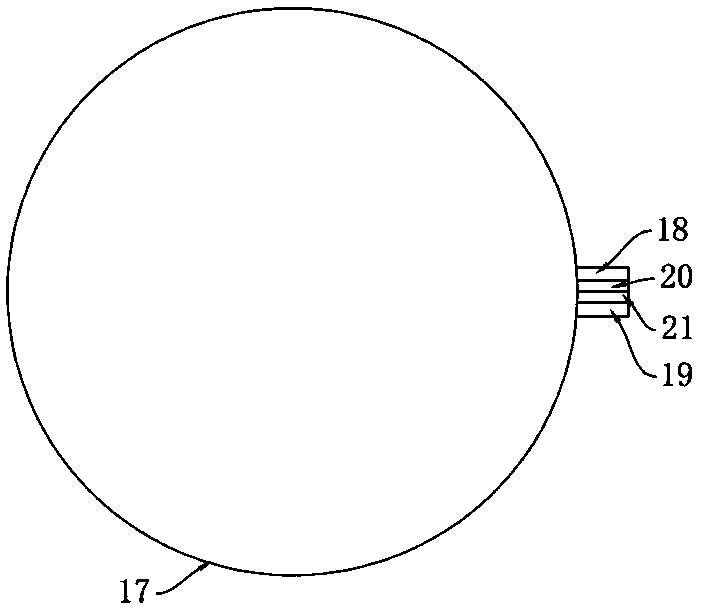

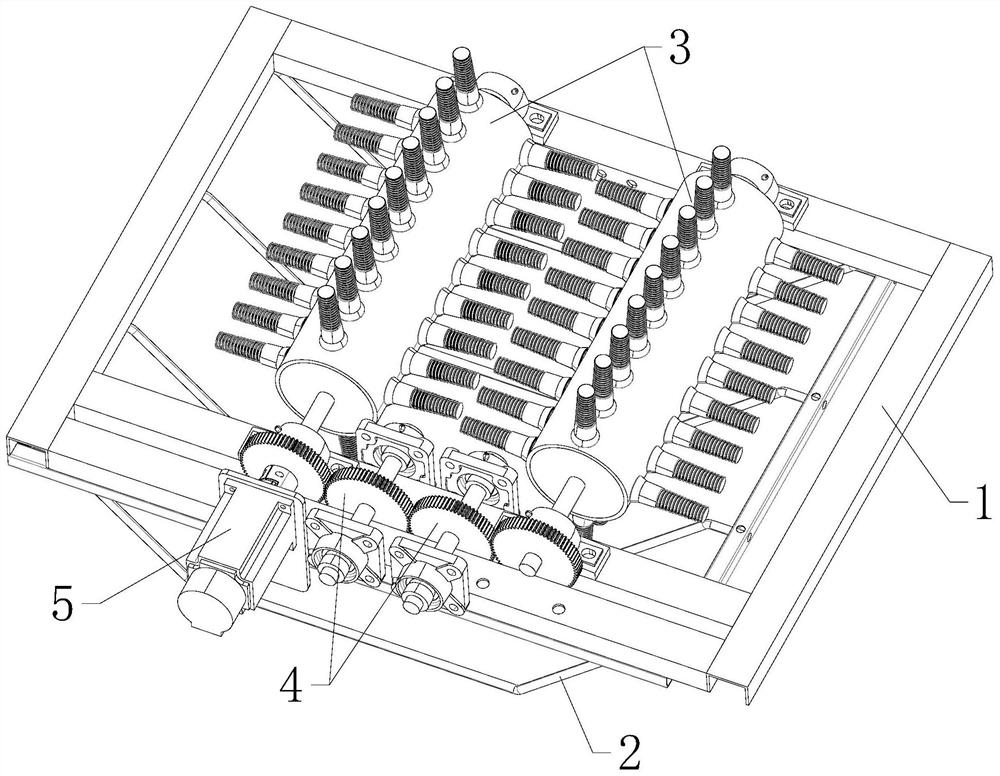

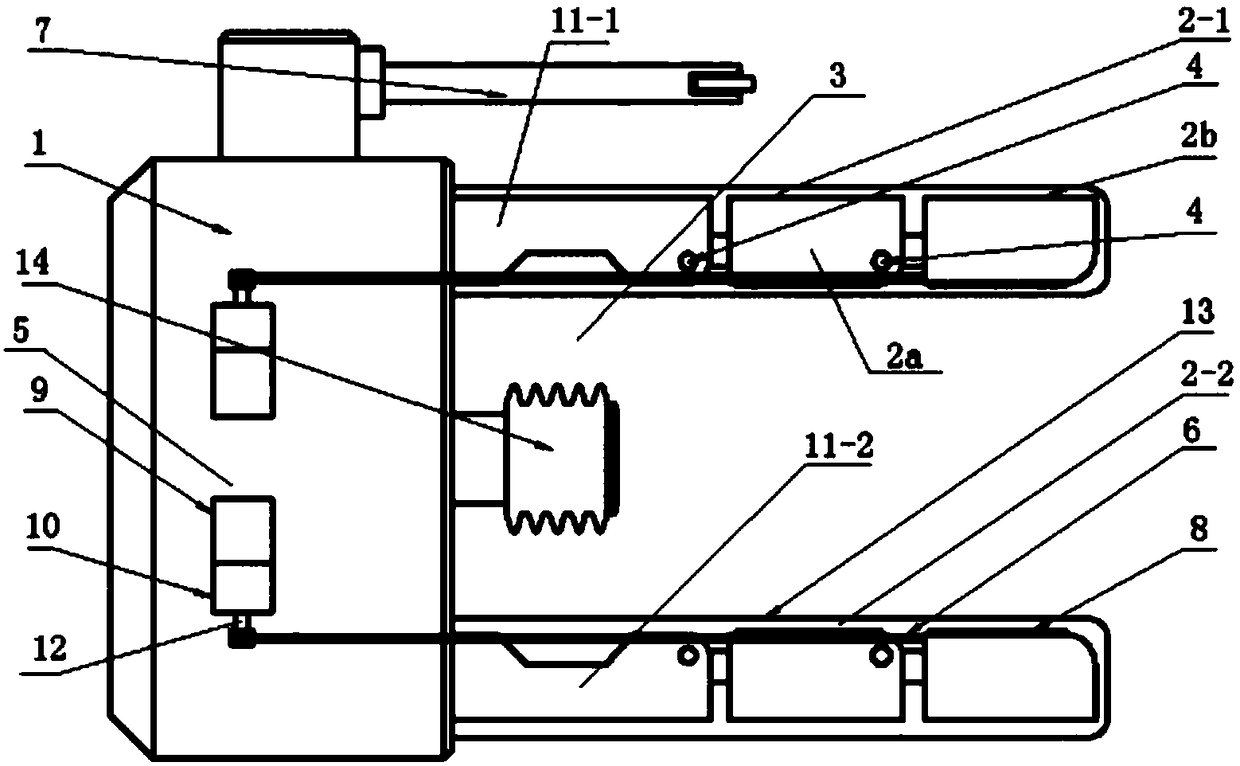

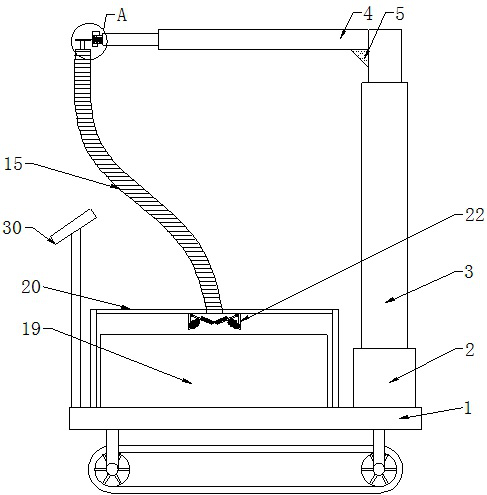

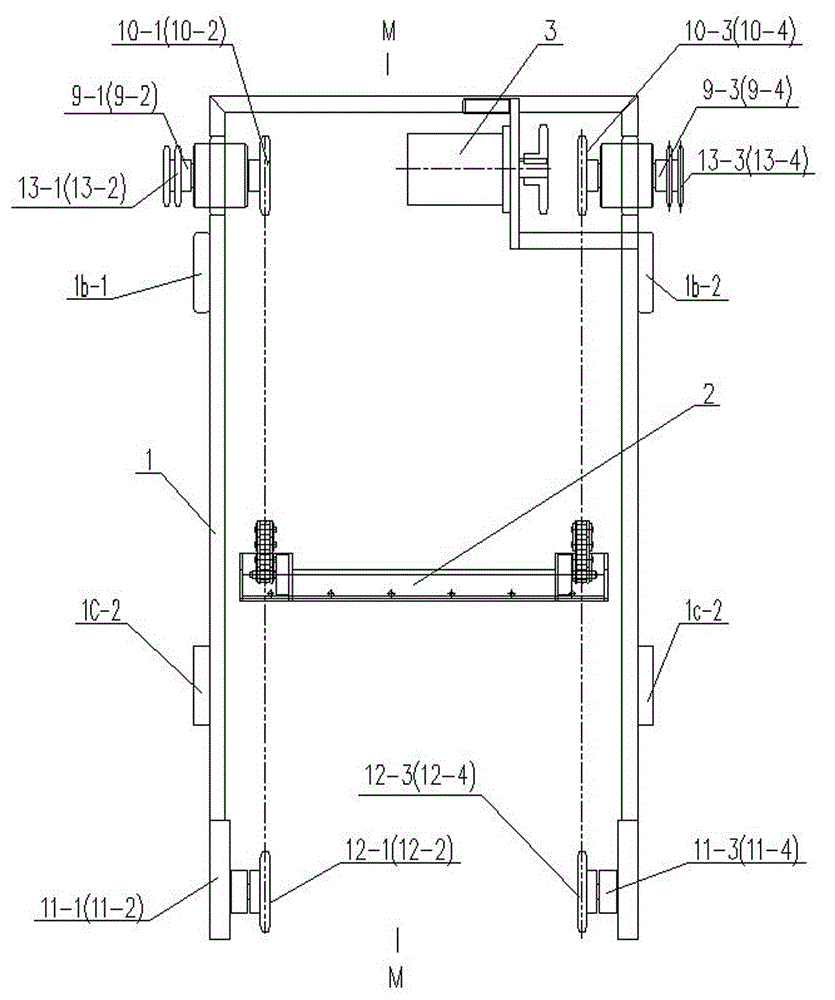

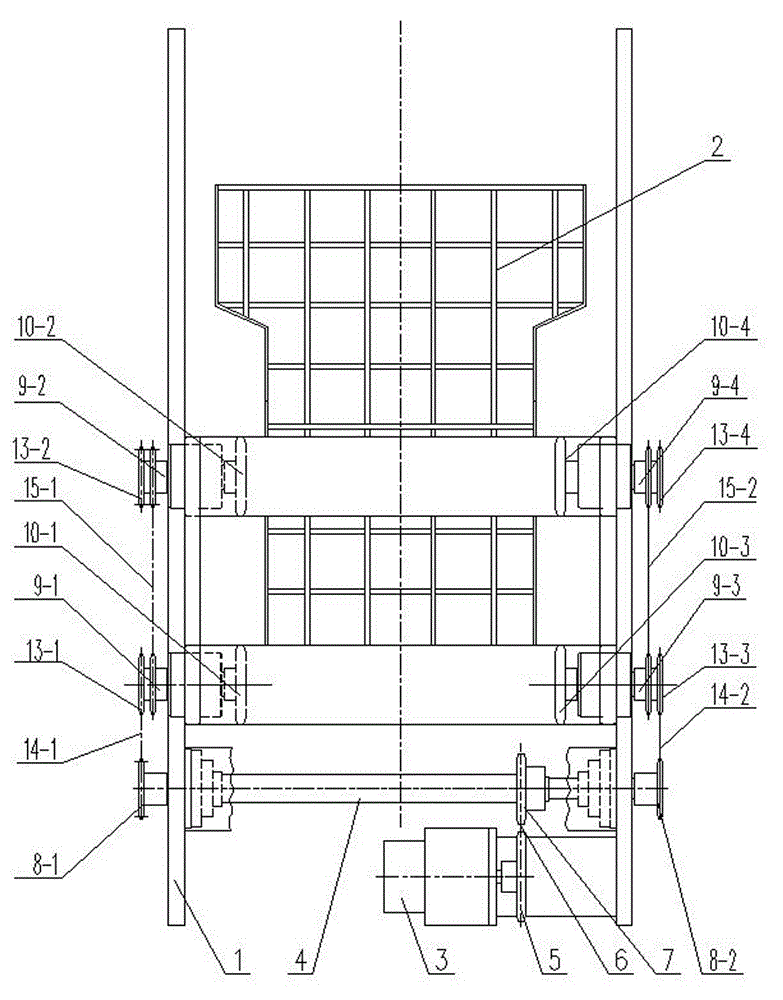

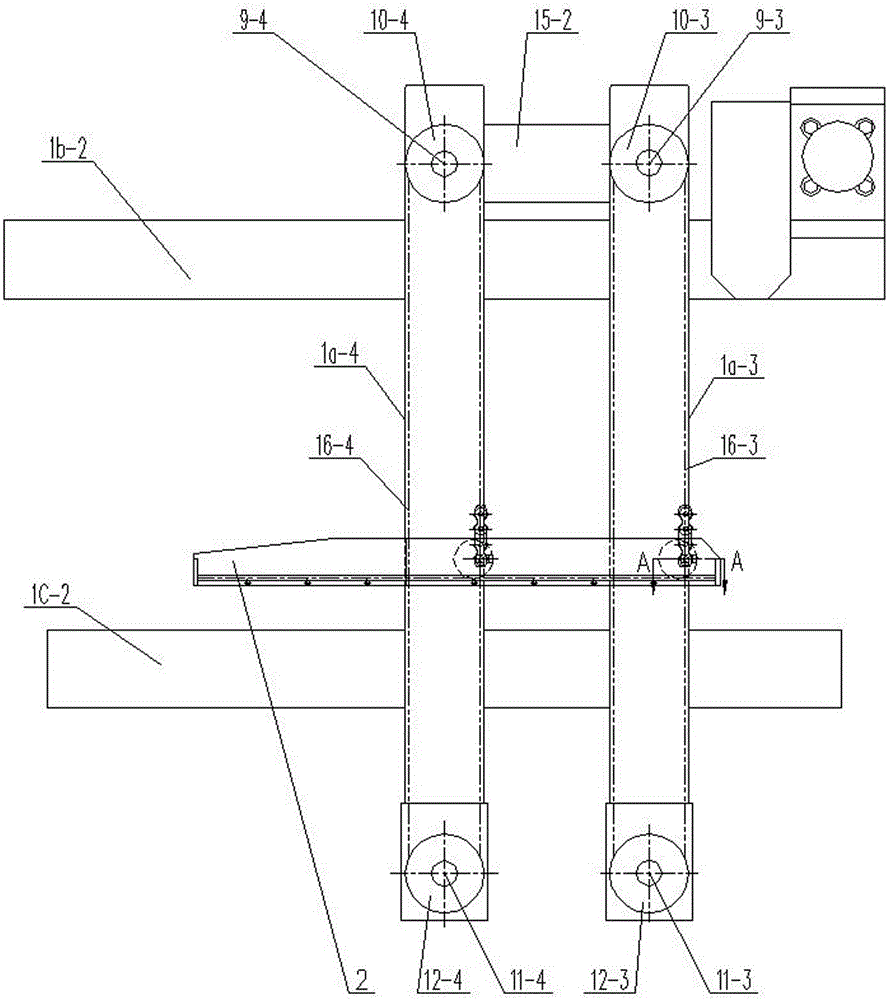

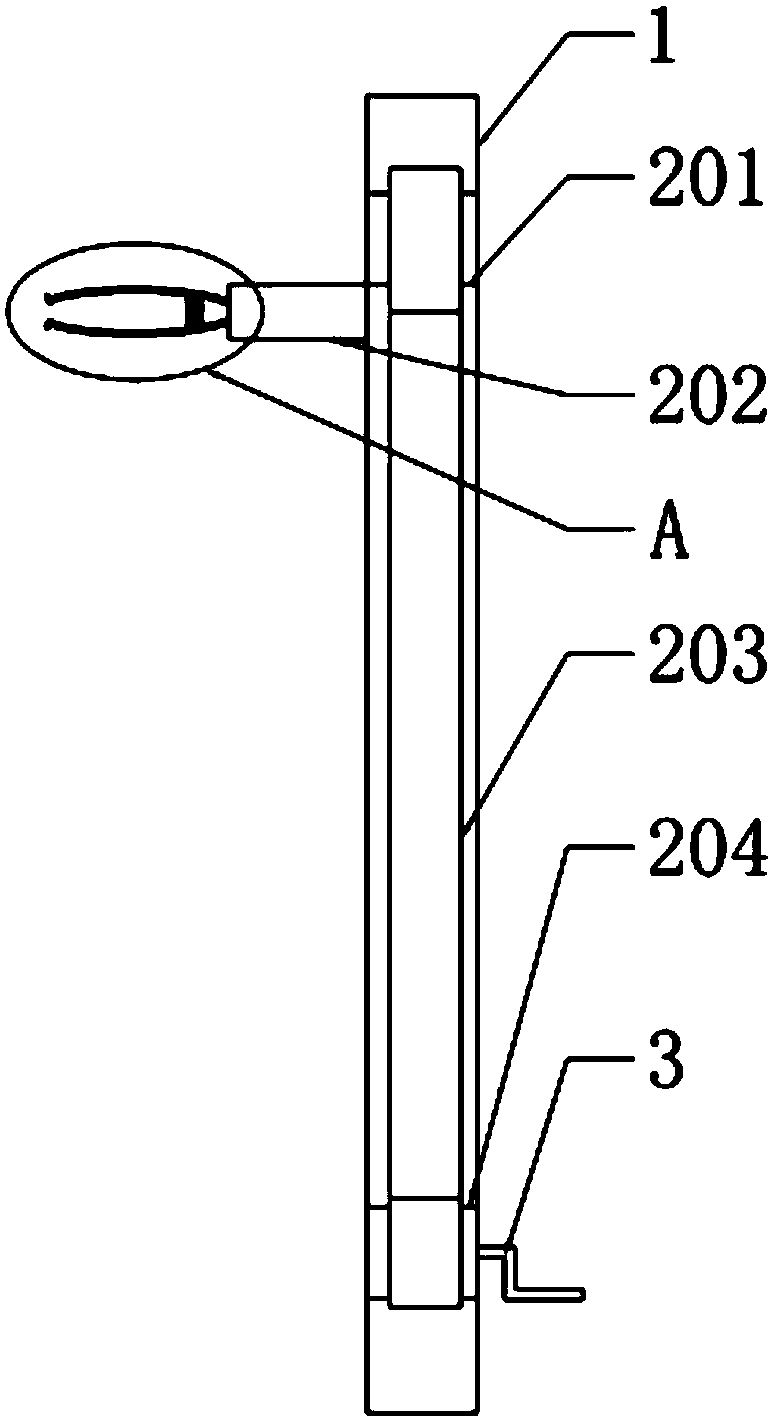

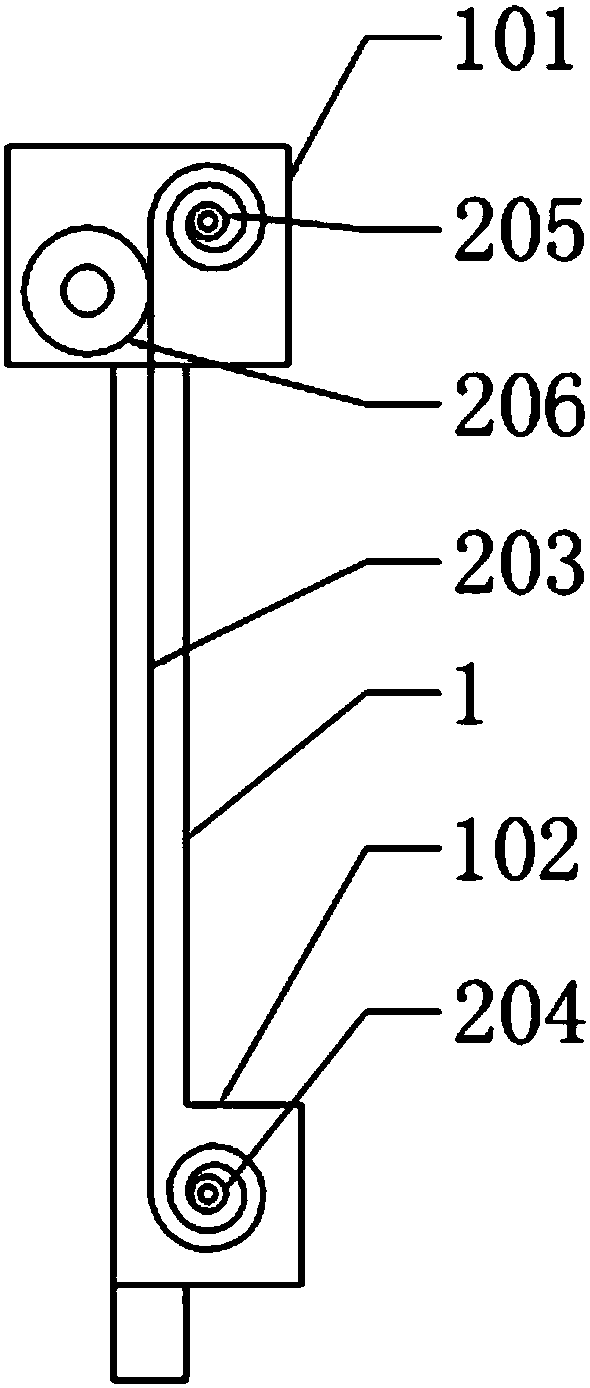

Device for picking tobacco leaf from top to bottom of tobacco plant

The invention relates to a device for picking tobacco leaves from the top to the bottom of a tobacco plant. The device comprises a gantry hanger (1), a grid-type horizontal leaf falling framework (2) which is arranged in the hanger, a chain wheel system which drives the leaf falling framework to move up and down, and a driving device (3) which is used for driving the chain wheel system to move forwards and reversely. The leaf falling framework (2) is respectively connected with the chain wheel system through four connecting bases (18). The four connecting bases are respectively and fixedly connected with the frame of the leaf falling framework (2). A chain system drives the horizontal leaf falling framework (2) to move up and down, so as to take down and pick the tobacco leaves during downward movement. The device for picking tobacco leaves from the top to the bottom of the tobacco plant has the advantages of simple structure, lower production cost, high picking efficiency and high full picking rate.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

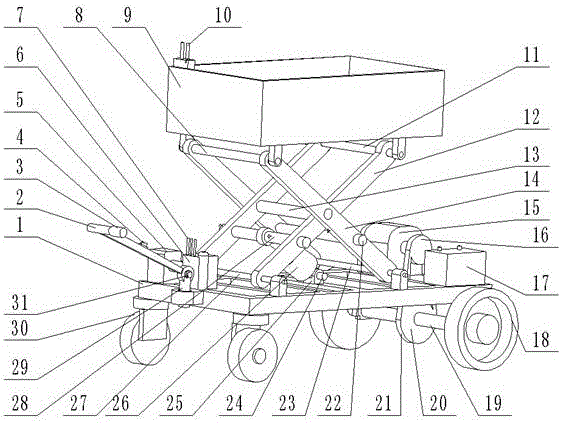

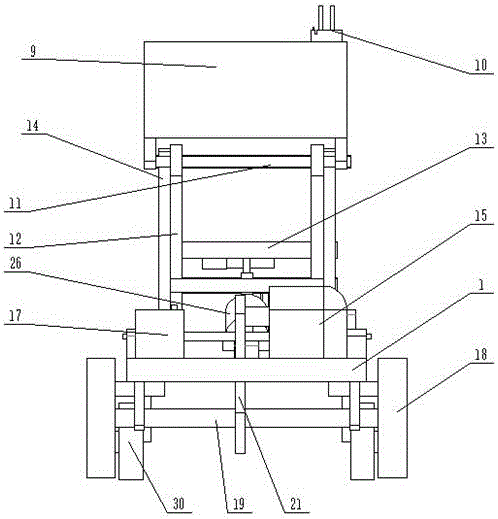

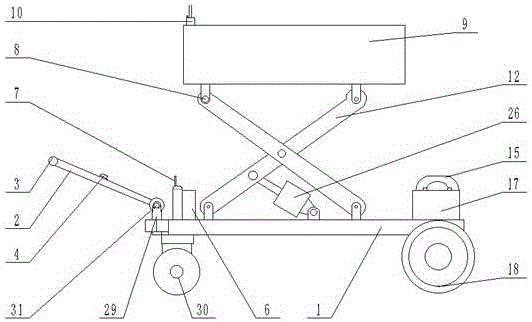

Special jack device for orchard

The invention relates to a special jack device for an orchard, and belongs to the technical field of agricultural machinery. The jack device comprises a running unit and a jack unit, wherein the running unit comprises a frame, a pull rod, a driving motor, a driving motor belt wheel, a driving wheel, a rear-wheel driving belt wheel, a belt and universal wheels, the pull rod is arranged on the frame, the driving motor is connected with the driving motor belt wheel which is connected with the rear-wheel driving belt wheel, and the rear-wheel driving belt wheel is connected with the driving wheel; the jack unit comprises a jack box, a hydraulic operating rod, a hydraulic cylinder and a lifting mechanism. The problems that the aloft fruits are difficult to pick, it is not safe for people to work with one hand at heights and the picking efficiency is low at heights are solved, the jack height consistency can be ensured, so that it is beneficial for better completing the jack work, and the aloft fruits in the orchard can be picked in safety. The jack device is reasonable in structure design, reliable in operation, high in universality degree, can improve greatly the working efficiency on crops and reduce labor intensity and production cost.

Owner:KUNMING UNIV OF SCI & TECH

Fruit picking robot end actuator and harvesting method

PendingCN111247962AAchieve pickingSimple structurePicking devicesRenewable energy machinesAgricultural engineeringControl theory

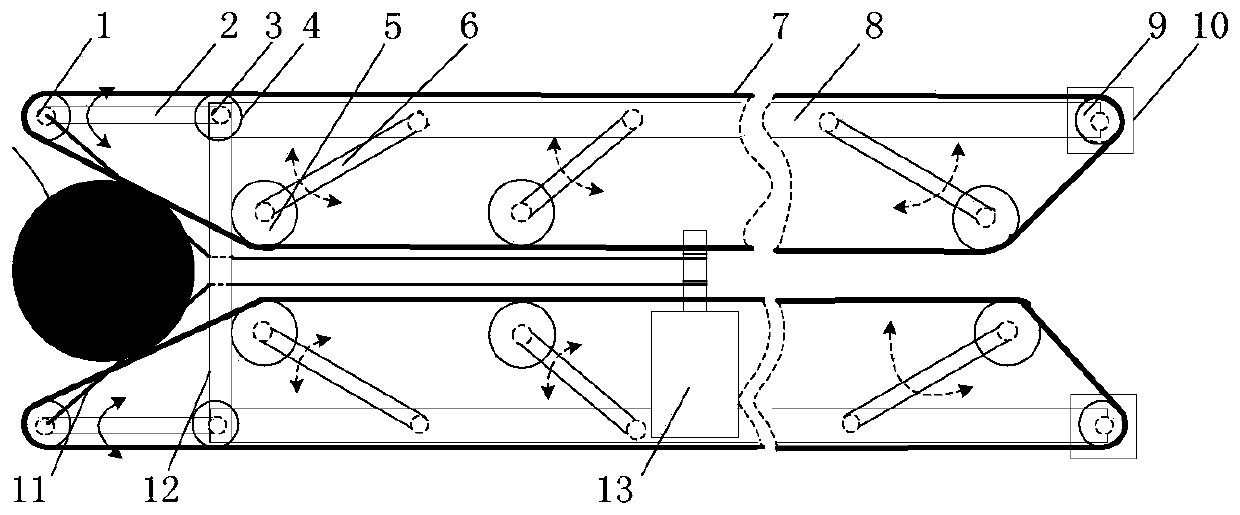

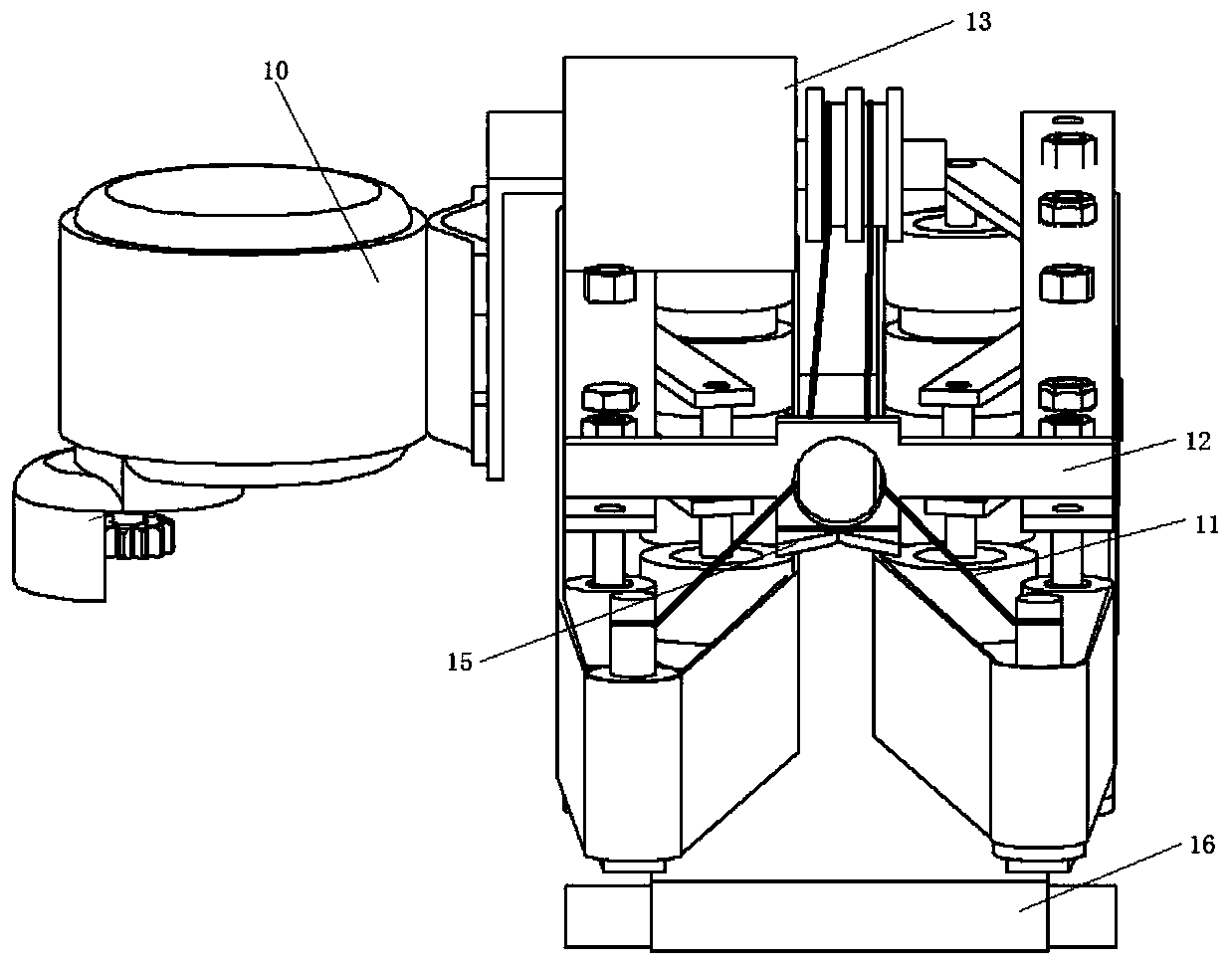

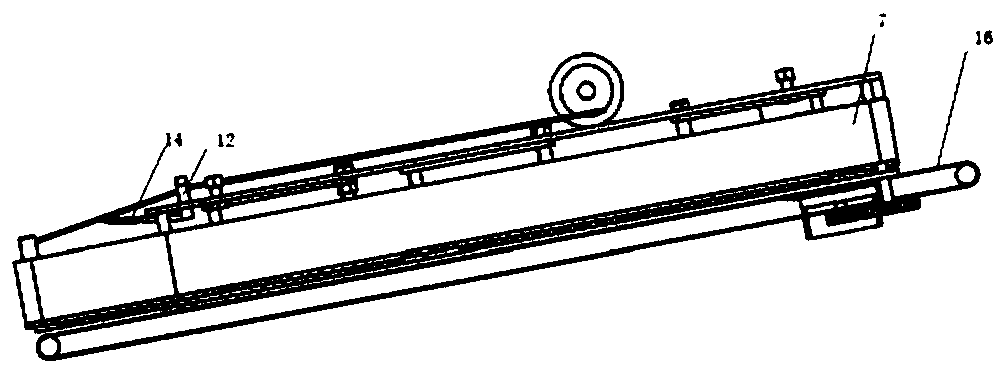

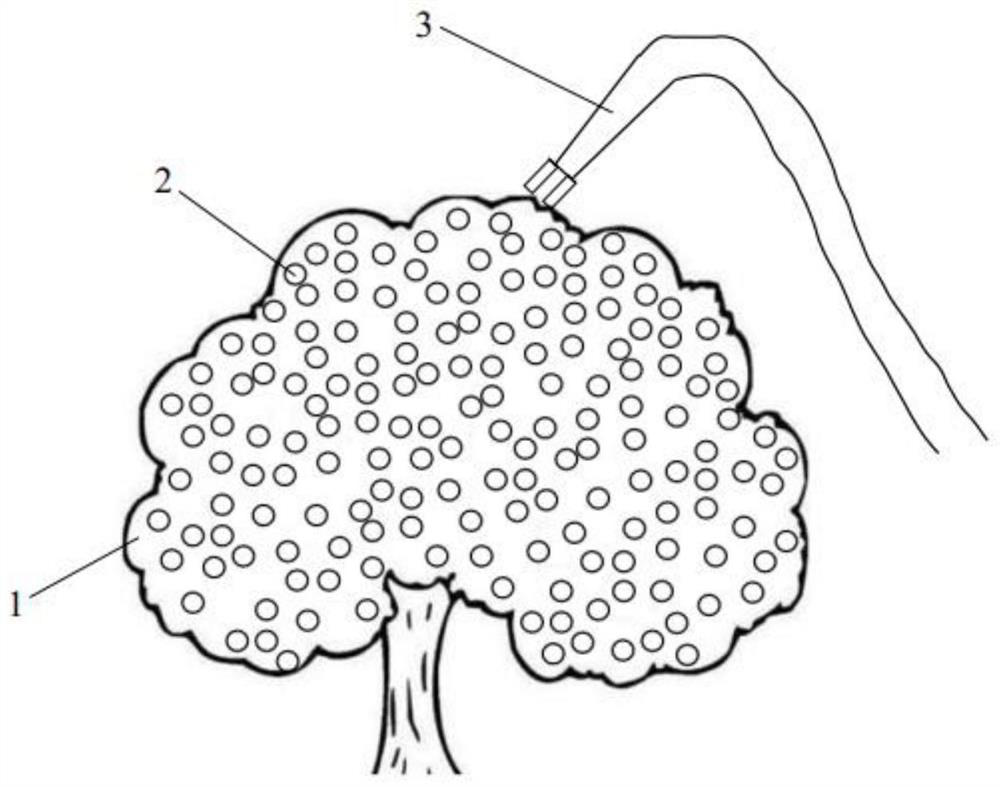

The invention relates to a fruit picking robot end actuator and a harvesting method. The fruit picking robot end actuator comprises a rack, a flexible belt, supporting wheels, a guiding mechanism, a clamping adjusting mechanism, a floating adjusting mechanism, a driving mechanism and a lower conveying belt, and a symmetrical clamping conveying action mode is adopted. A flexible material is attached to the surface of the flexible belt and used for clamping and picking fruits and conveying the fruits; the supporting wheels are used for supporting the flexible belt and keeping the flexible belt in a tensioned state; the guiding mechanism is used for guiding the feeding of the fruits and completing the cutting of fruit stems; the floating adjusting mechanism can adjust the rotating angle according to the sizes of the fruits and change the opening size of the end actuator; the clamping adjusting mechanism is used for changing the clamping force and completing the clamping and picking of thefruits; and the lower conveying belt is used for changing the fruit picking stress direction during feeding and meanwhile plays a role in supporting the fruits. The fruit picking robot end actuator integrates fruit picking and conveying and has the advantages of being simple in structure, capable of reducing the harvesting process and high in harvesting efficiency.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Robot picking and recovering system for mandarin orange fruits and operation method

ActiveCN112470708ASolving Recycling ProblemsAchieve pickingGripping headsPicking devicesAgricultural engineeringAgricultural robot

The invention provides a robot picking and recovering system for mandarin orange fruits and an operation method, and belongs to the field of agricultural robots. The robot picking and recovering system is composed of an end executor and a fruit conveying device, wherein the end executor is of a two-hemispherical-surface finger structure with short blades arranged at fingertips, and by control forhemispherical-surface finger clamping and bouncing actions and cooperation of the hemispherical-surface finger clamping and bouncing actions with a scraper conveyor and a conveying hose of the fruit conveying device, the robot can realize picking and recovering with short reserved stems in all directions of the crown of the closed mandarin orange. The recovery problem of downward fruit picking ofthe robot is solved, and the structure is simple and reliable.

Owner:JIANGSU UNIV

Spina gleditsiae picking device

The invention discloses a spina gleditsiae picking device and belongs to the field of crop picking equipment. The device comprises a cutting mechanism, a lower mechanism and a hollow sleeve; the powermechanism comprises a drive wheel, a driven wheel, a driven gear, a coiling tape and a spring ring, a rocking handle is fixedly connected onto the drive wheel, and the drive wheel is rotatably connected to the lower end of the hollow sleeve; the driven wheel is rotatably connected to the upper end of the hollow sleeve, and the spring ring is fixedly connected onto the driven wheel in a sleeving mode; one end of the coiling tape is connected onto the driver wheel in a surrounding mode, and the other end of the coiling tape is connected to the surface of the spring ring in a surrounding mode; arack is arranged on the surface of the coiling tape, and the driven rack is meshed with the rack; a connection shaft is connected to the driven gear; the cutting mechanism comprises an upper clampingplate and a lower clamping plate. According to the embodiment, a person who can climb trees does not need to be designated to operate the device in the operation device, spina gleditsiae can be picked on the ground, the hidden safety dangers which exist when people climb tree trunks are avoided, meanwhile, through arrangement of the hollow sleeve, the distance between the human body and the spinagleditsiae is increased, and the risk is lowered that people are stabbed by the spina gleditsiae.

Owner:贵州湄潭百卉中药工程技术研究开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com