Automatic sorting robot for edible rose petals in flower field

A rose and robot technology is applied in the field of automatic sorting robots for edible rose petals in flower fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

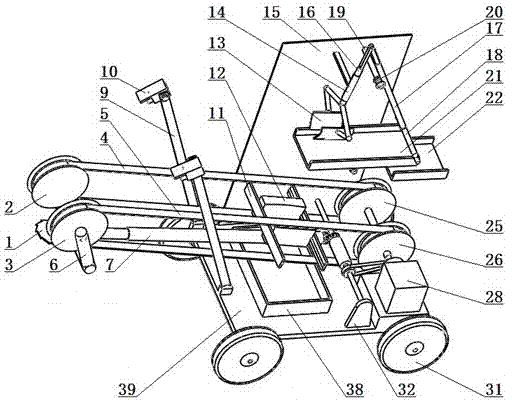

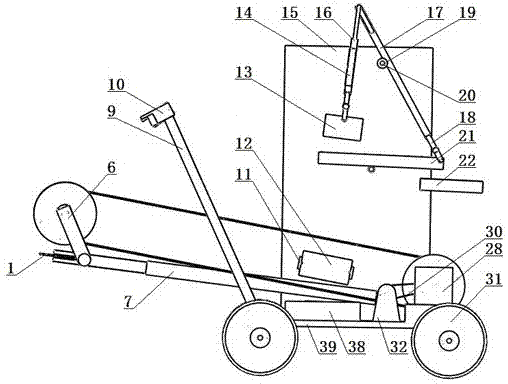

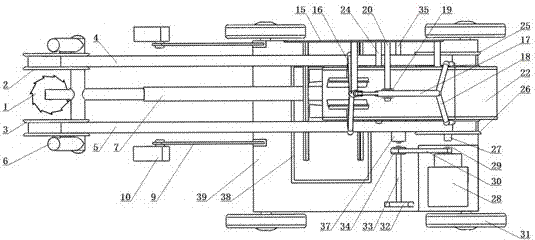

[0020] Embodiment 1: as Figure 1-5 As shown, an automatic sorting robot for edible rose petals in a flower field includes a picking part, a sorting part, a visual part, a wheel 31, and a base 39; the picking part includes a rotary blade 1, a front roller I2, a front roller II3, and a conveyor belt Ⅰ4, conveyor belt Ⅱ5, forearm bracket 6, center shaft 7, center shaft gear 8, rear roller Ⅰ25, rear roller Ⅱ26, rear roller shaft 27, motor 28, motor shaft 29, transmission belt 30, bracket Ⅱ32, fixed shaft 33, driven Bearing 34, driving shaft 35, driving gear 36, driving bearing 37, the sorting part includes gripper guide rail 11, gripper 12, manipulator 13, manipulator guide rail 14, support I 15, manipulator forearm 16, manipulator rear arm 17, loading Plate frame 18, manipulator bearing 19, manipulator fixed axis 20, petal front carrier plate 21, petal rear carrier plate 22, carrier plate bearing 23, carrier plate fixed axis 24, receptacle recovery box 38, visual part includes ca...

Embodiment 2

[0021] Embodiment 2: as Figure 1-5 As shown, an automatic sorting robot for edible rose petals in a flower field includes a picking part, a sorting part, a visual part, a wheel 31, and a base 39; the picking part includes a rotary blade 1, a front roller I2, a front roller II3, and a conveyor belt Ⅰ4, conveyor belt Ⅱ5, forearm bracket 6, center shaft 7, center shaft gear 8, rear roller Ⅰ25, rear roller Ⅱ26, rear roller shaft 27, motor 28, motor shaft 29, transmission belt 30, bracket Ⅱ32, fixed shaft 33, driven Bearing 34, driving shaft 35, driving gear 36, driving bearing 37, the sorting part includes gripper guide rail 11, gripper 12, manipulator 13, manipulator guide rail 14, support I 15, manipulator forearm 16, manipulator rear arm 17, loading Plate frame 18, manipulator bearing 19, manipulator fixed axis 20, petal front carrier plate 21, petal rear carrier plate 22, carrier plate bearing 23, carrier plate fixed axis 24, receptacle recovery box 38, visual part includes ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com