Patents

Literature

45results about How to "Stable and reliable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

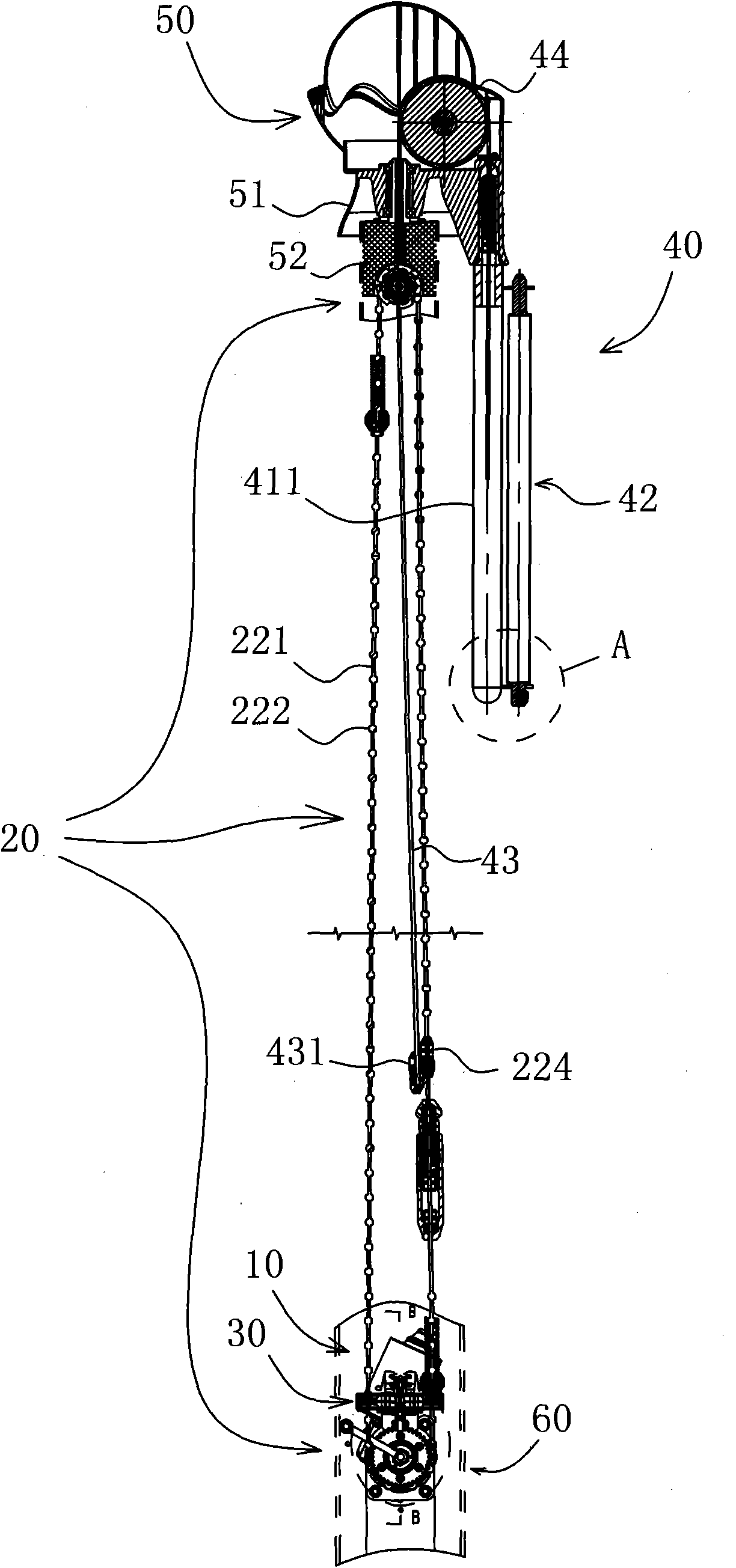

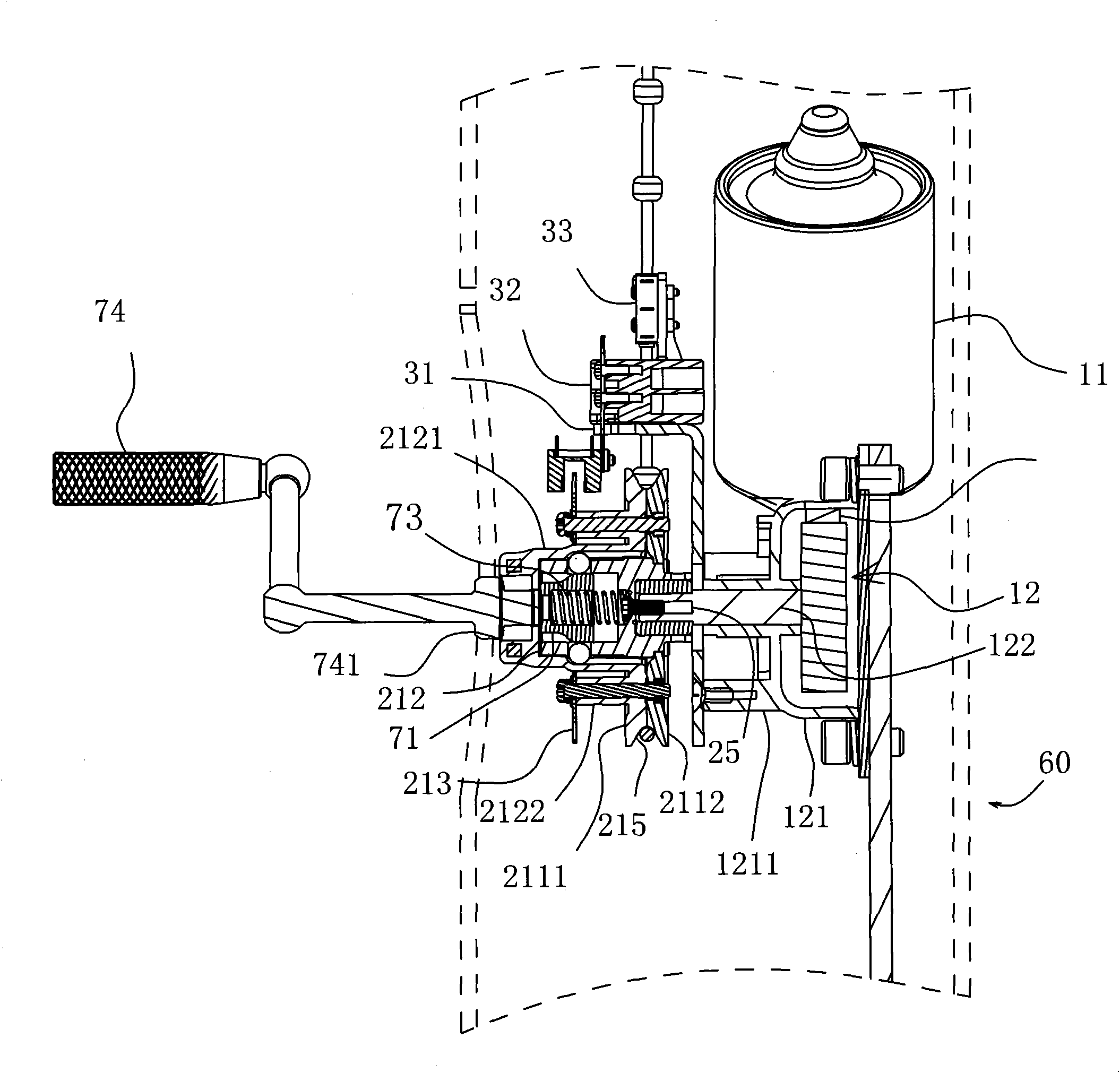

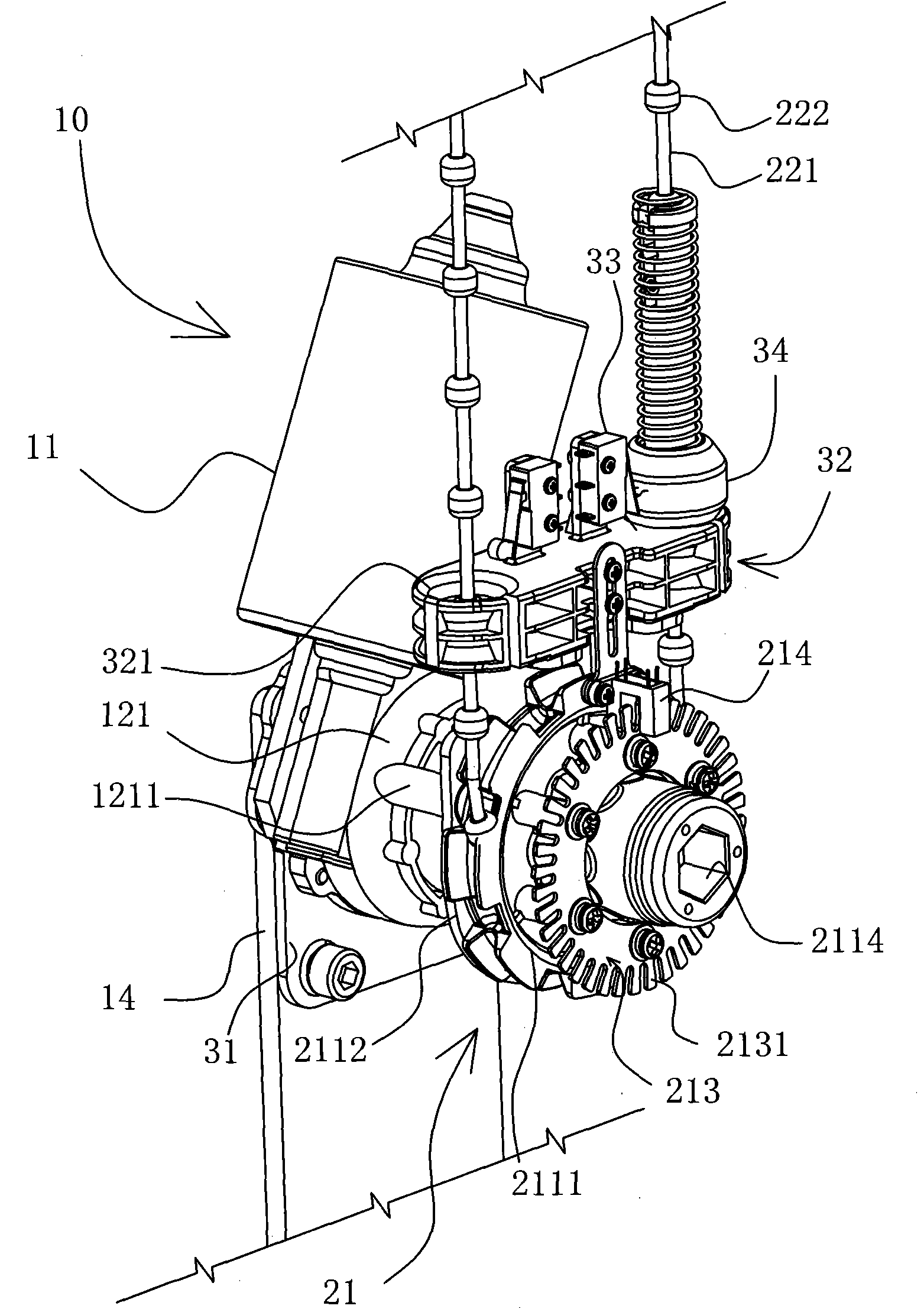

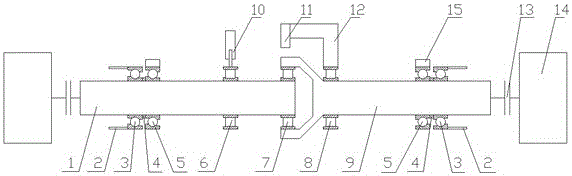

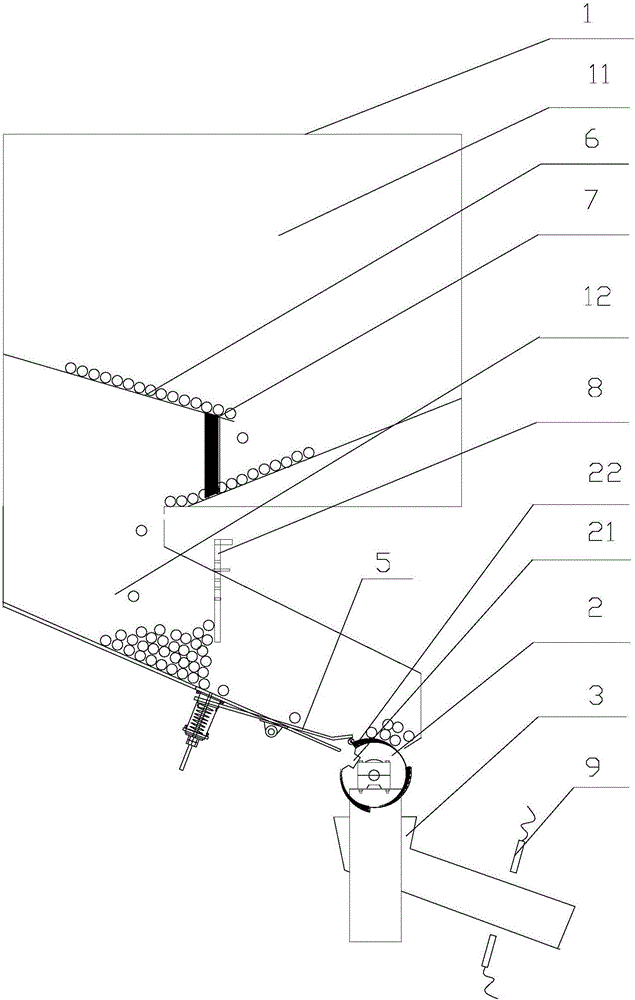

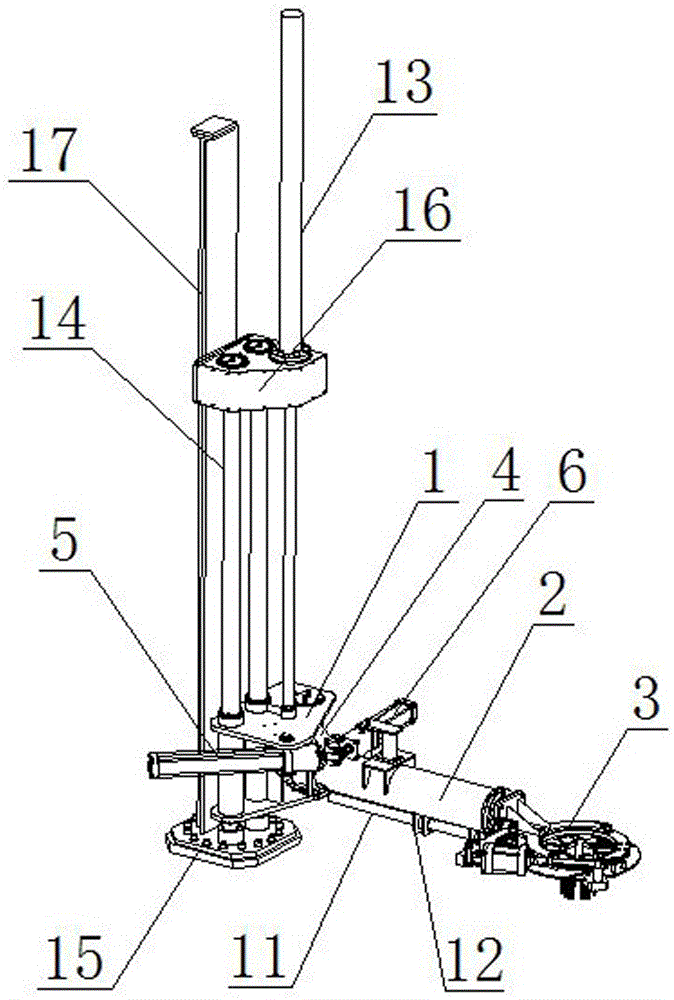

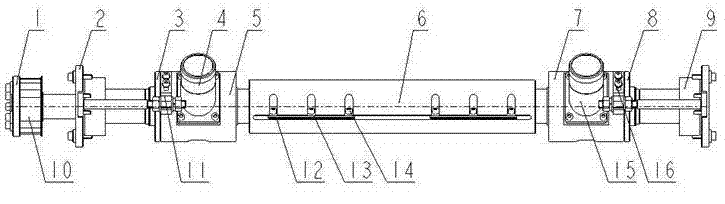

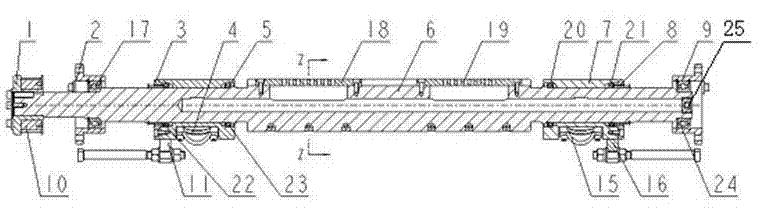

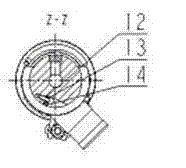

Flag hoisting and lowering mechanism of flag pole

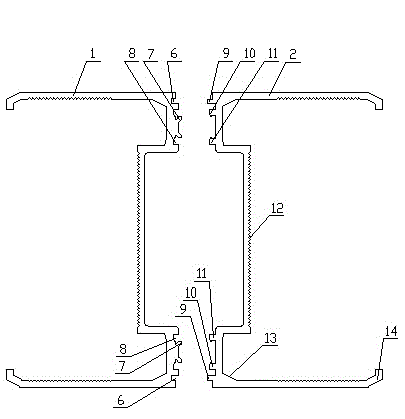

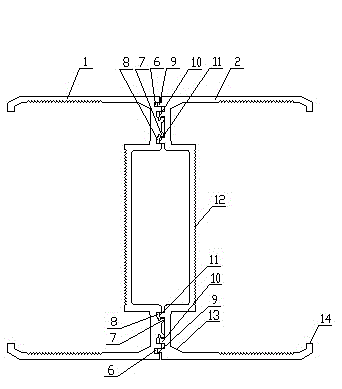

The invention discloses a flag hoisting and lowering mechanism of a flag pole, which comprises a driving mechanism, a transmission mechanism, a flag hoisting and lowering in-place positioning mechanism, a flag hanging component and a crown component, wherein the driving mechanism is arranged on the lower part of the flag pole; the transmission mechanism is connected with the driving mechanism, comprises a driving wheel component, a driven wheel and a chain bead type steel wire rope movably connected with the driving wheel component and the driven wheel, and is connected with the flag hanging component through a flag hoisting and lowering steel wire rope fixedly connected with the chain bead type steel wire; the flag hoisting and lowering in-place positioning mechanism is arranged on the upper part of the driving wheel component; the flag hanging component is arranged on the outer side of the top part of the flag pole; and the crown component is arranged on the top part of the flag pole and makes the flag hanging component rotate in a range of 360 DEG C. The driving mechanism drives the chain bead type steel wire rope to move up and down, and the chain bead type steel wire rope drives the flag hoisting and lowering steel wire to move upwards or downwards to ensure that the flag hanging component moves downwards or upwards to realize flag hoisting and lowering; and when a flag is hoisted and lowered in place, the position of the flag is limited by a limiting mechanism. The flag hoisting and lowering mechanism has the characteristics that the running is smooth and reliable, transmission and flag hoisting and lowering ropes have no distortion and twisting, the flag can rotate automatically along with the wind direction, the flag can be hoisted manually when an abnormal condition appears, and the like.

Owner:HONGMEN ADVANCED TECH CORP

Hydraulic control system for hydraulic boarding ladder

InactiveCN102092463AStable and reliable operationImprove securityCargo handling apparatusServomotorsPistonMoment of inertia

The invention relates to a hydraulic control system for a hydraulic boarding ladder. In the system, a ladder is connected to a rotary substrate through a rotary axis, and is connected with the piston of a lifting hydraulic cylinder; the lifting hydraulic cylinder is rotatably connected to the top surface of the rotary substrate through a pivot; a fuel tank and a pumping station are arranged in the rotary substrate; a rotary gear is fixed on the rotary substrate; and pinions are arranged on the output shafts of two hydraulic motors, are engaged with the rotary gear. The system is divided into a main rotary control part and a variable amplitude hydro-cylinder control part. The hydraulic control system has the advantages that the up-down left-right floating of the boarding ladder is realized by adopting a balance loop, and the problem of excessive rotation inertia is solved by adopting a proportional electromagnetic valve, wherein the proportional valve is utilized to control small current start when the system is started, after a certain speed is achieved, normal current is started to ensure that the ladder rotates smoothly, and the system is stopped slowly by controlling the proportional valve when the system is stopped, so the operation is smooth and reliable.

Owner:JIANGNAN UNIV

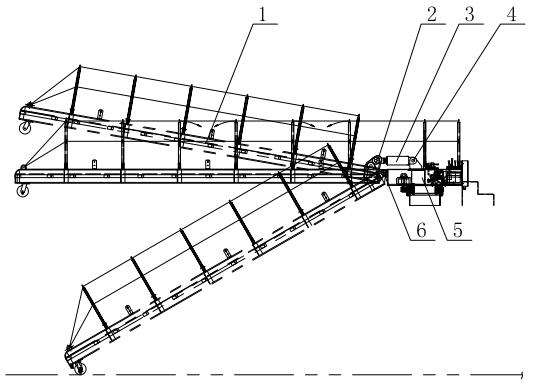

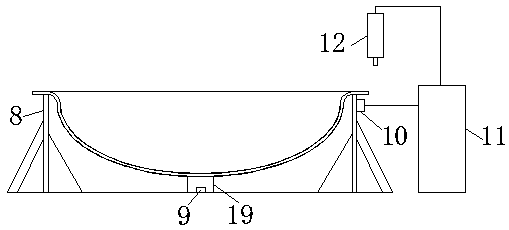

Hydraulic boarding ladder

InactiveCN102001421AStable and reliable operationImprove securityCargo handling apparatusPassenger handling apparatusPistonFuel tank

The invention relates to a hydraulic boarding ladder. The ladder is connected to a rotating base by a rotating axis and simultaneously connected with the piston of an elevating hydraulic cylinder, and the elevating hydraulic cylinder is rotatably connected with the top surface of the rotating base by a pivot. Fuel tanks and a pump station are arranged in the rotating base, a rotating gear is fixed on the rotating base, pinion gears are arranged on the output shafts of two hydraulic motors, and the pinion gears are engaged with the rotating gear. In the invention, one pair of fuel tanks are connected with the main part of the boarding ladder, the boarding ladder is driven by the contraction and expansion of the fuel tanks to rise and fall, and the maximum rising and falling angle is + / -30 degrees; and the boarding ladder is driven by the clockwise and anticlockwise rotation of one pair of rotating motors to swing left and right, torsion is by transmitted by one pair of pinion gears and the rotating gear fixed on a base frame, and the swinging angle is about + / -180 degrees.

Owner:JIANGNAN UNIV

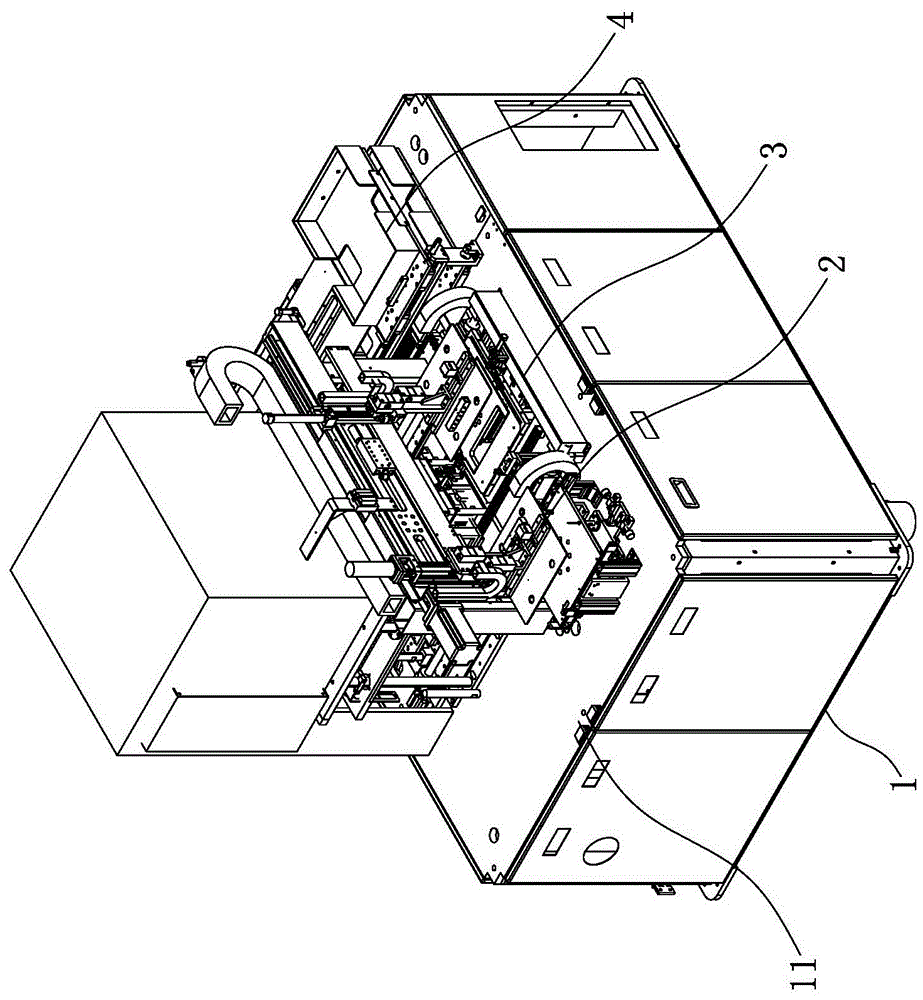

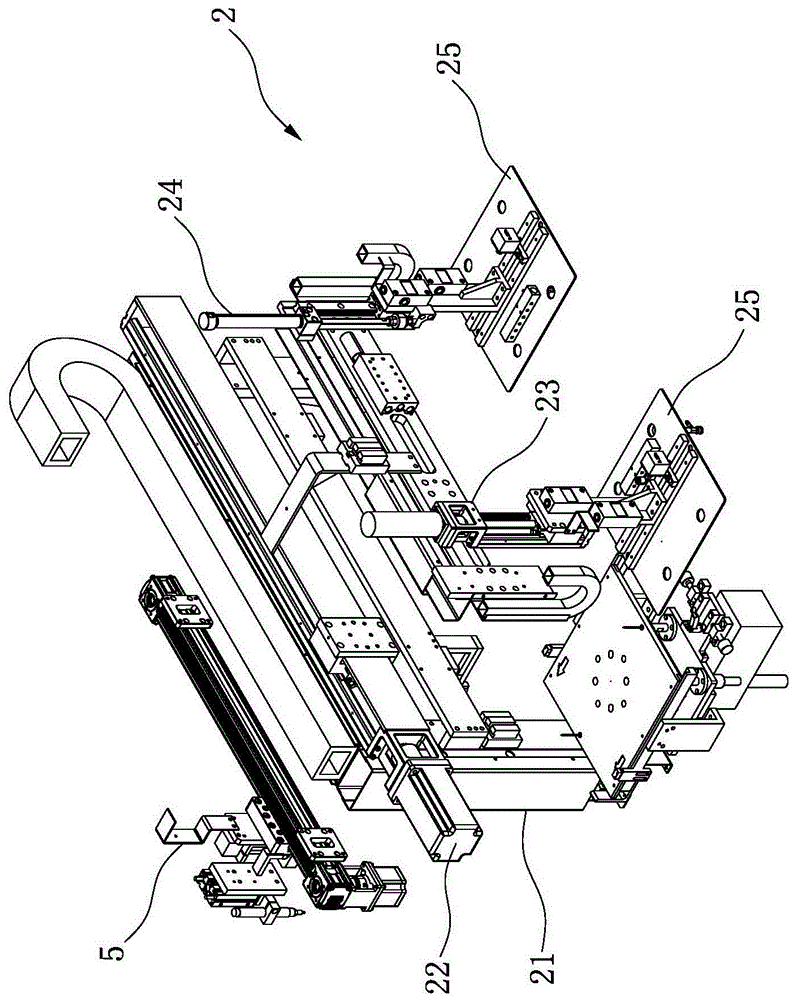

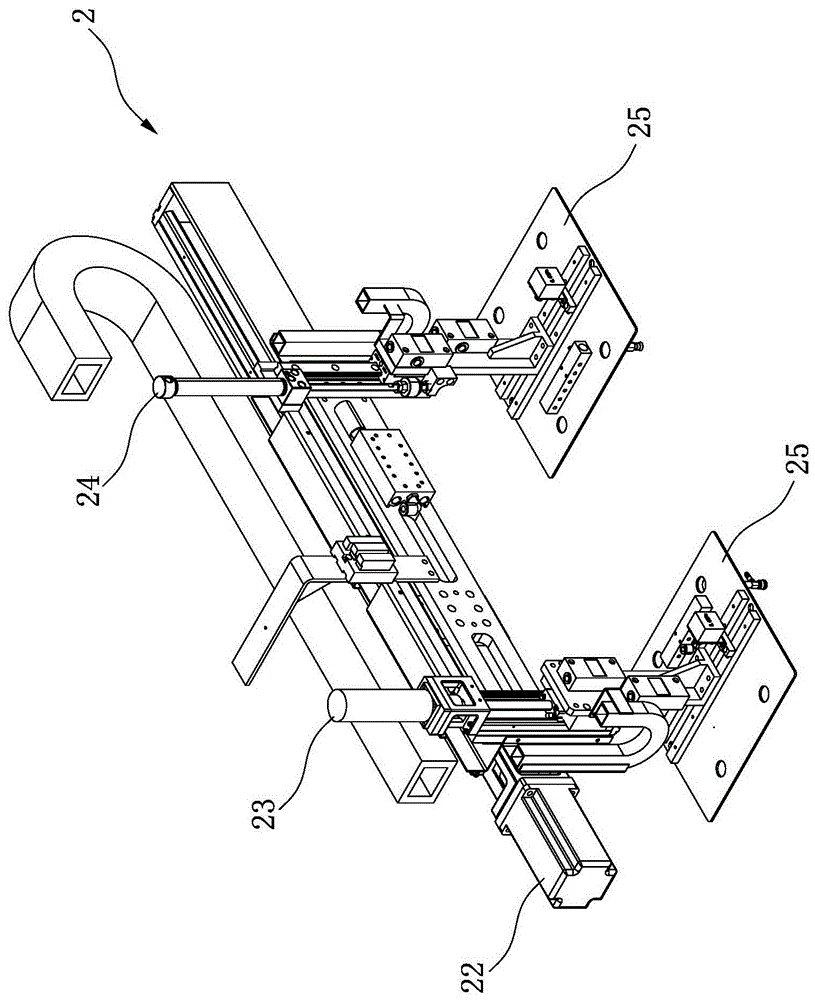

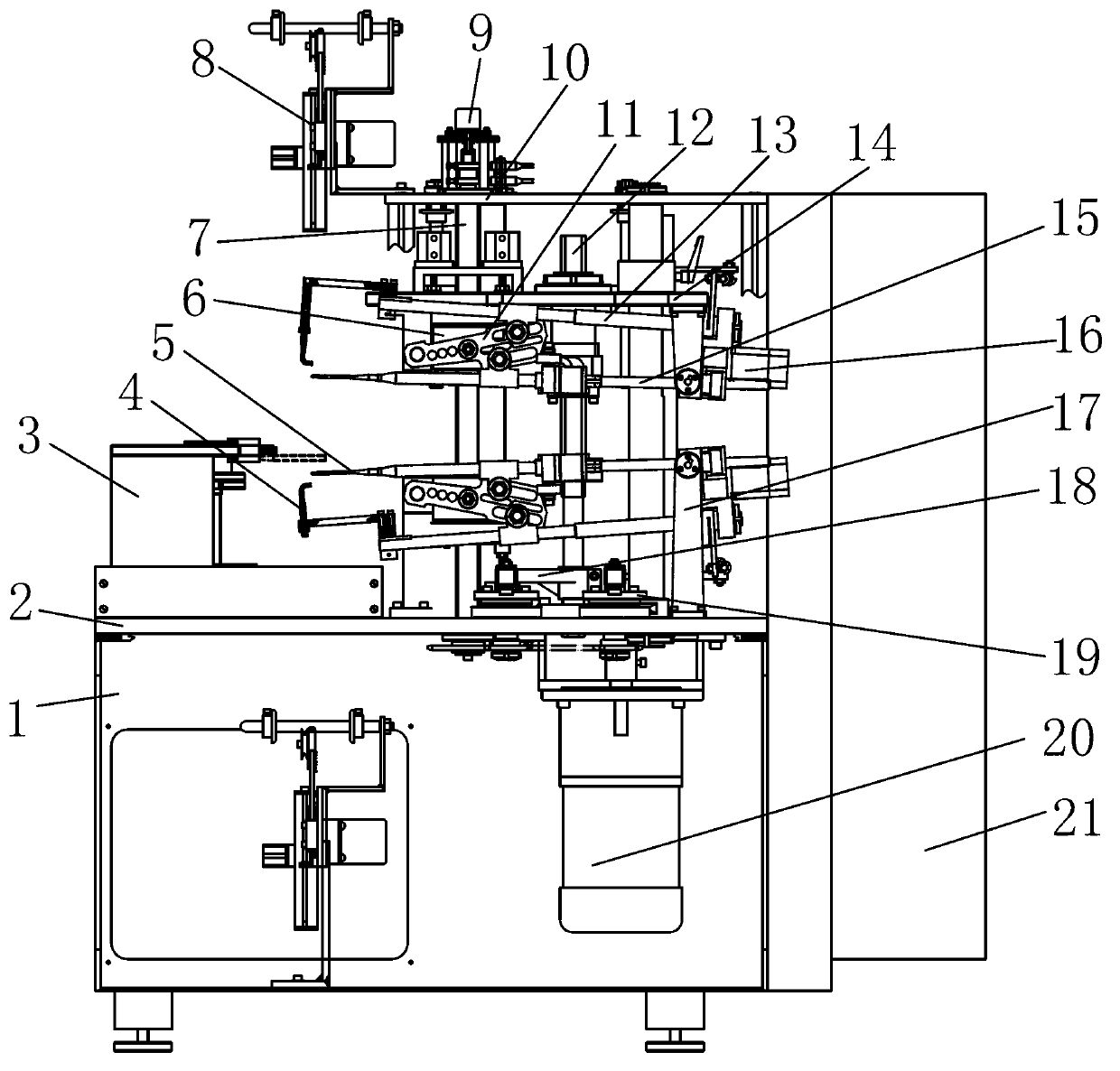

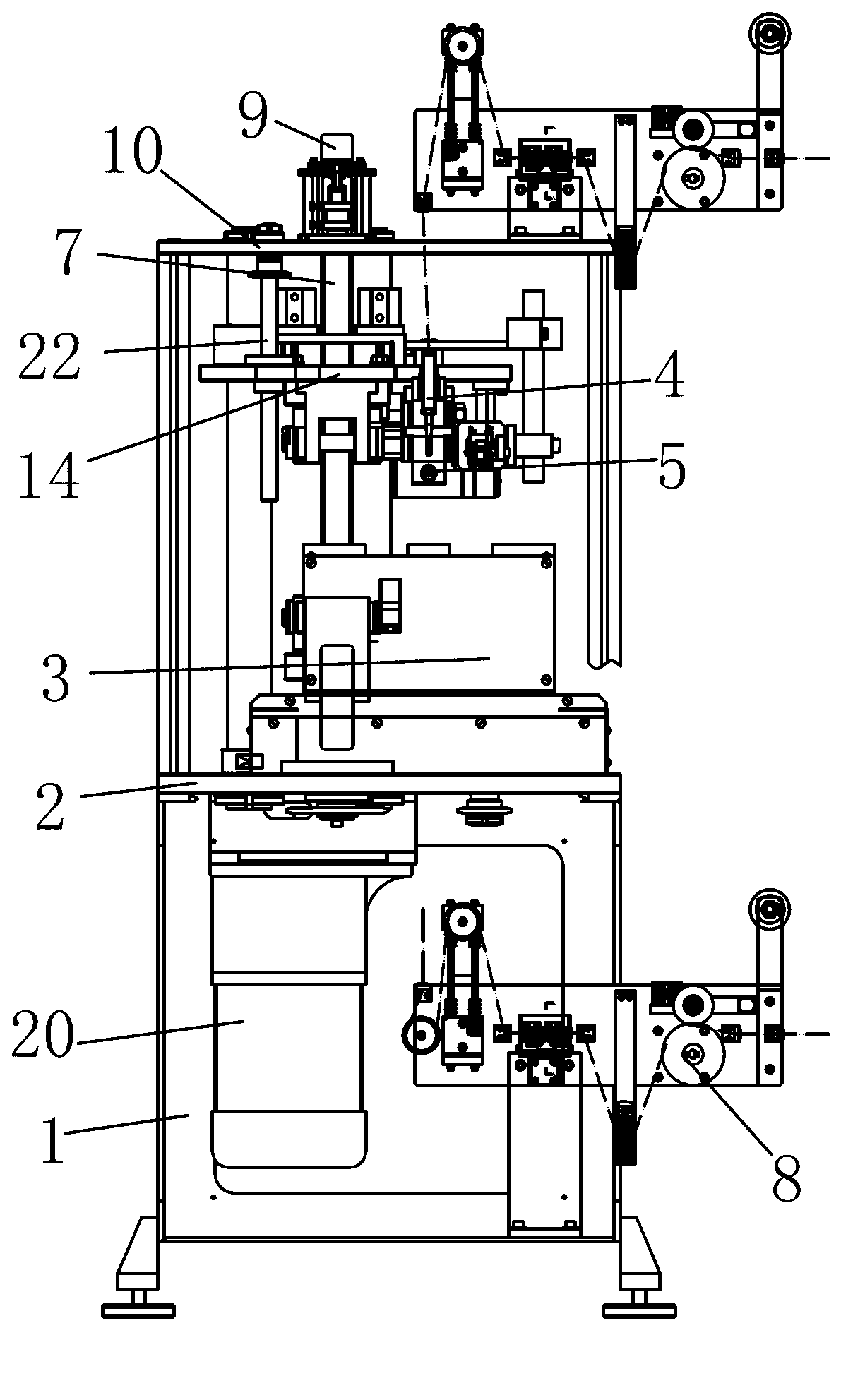

Automatic feeder of integrated matching electric measurement machine equipment

ActiveCN105792628ASimple and reasonable structureStable and reliable operationElectrical componentsManipulatorElectricity

The invention discloses an automatic feeder of integrated matching electric measurement machine equipment. The feeder comprises a rack, a material loading and blanking carrying mechanism, a feeding carrying mechanism, a blanking mechanism and a mark punching mechanism. The material loading and blanking carrying mechanism, the feeding carrying mechanism, the blanking mechanism and the mark punching mechanism are installed on a work platform of the rack. Through organic linking of the material loading and blanking carrying mechanism, the feeding carrying mechanism, the blanking mechanism and the mark punching mechanism, rapid product counterpoint placement detection is realized; aiming at a sub-quality product, the mark punching mechanism automatically make a mark and a visual system automatically examine and identify a mark symbol. A placement position is accurate and reliable. Because of a fool-proof function, the sub-quality product can be fully guaranteed to be marked successfully. Two groups of carrying assembly mechanisms are adopted to realize synchronization work of a material loading manipulator and an electric measurement feeding carrying manipulator. Production efficiency is greatly increased, labor force cost is saved and product quality is guaranteed.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

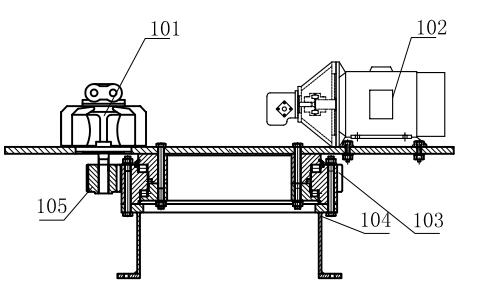

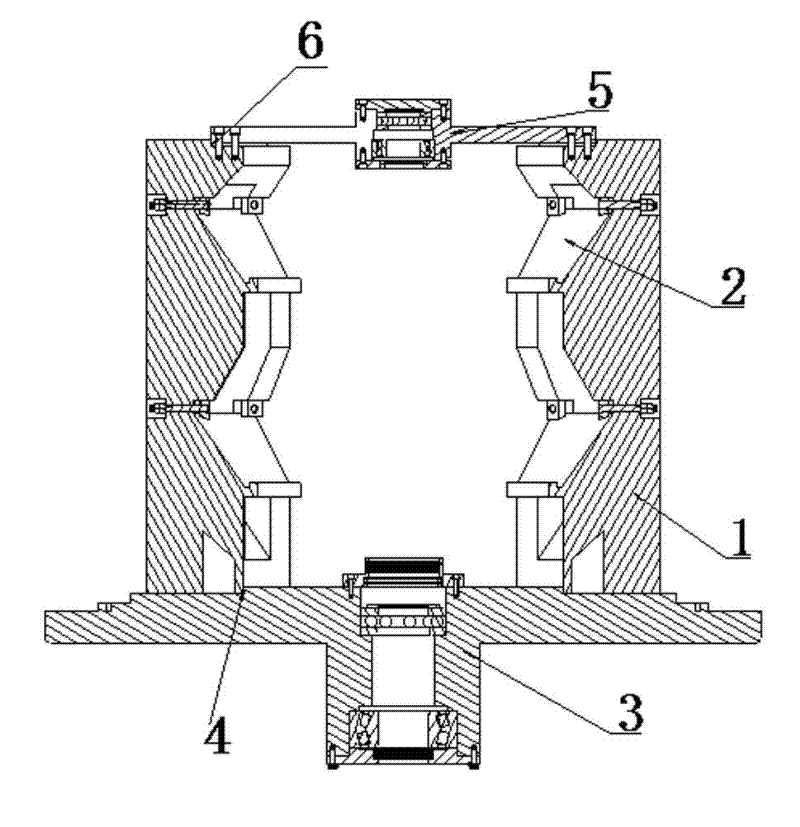

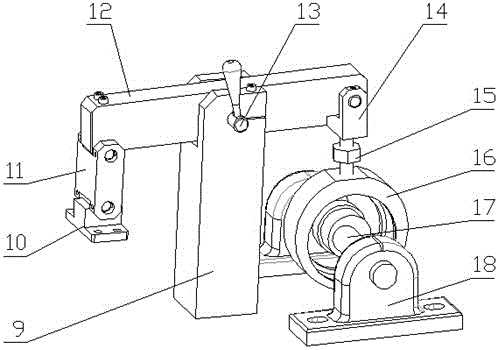

Testing method of simultaneous rotation of inner and outer rings of cylindrical roller bearing

ActiveCN106644478AStable and reliable operationReliable structureMachine bearings testingEngineeringRoller bearing

The invention discloses a testing method of simultaneous rotation of inner and outer rings of a cylindrical roller bearing; the testing device comprises a substrate, an inner ring revolving system arranged at the upper part to drive a testing bearing to rotate and an outer ring revolving system; the outer ring revolving system comprises an outer ring main shaft, an accompanied testing bearing, an axial force applying bearing and a supporting bearing are sleeved on the outer ring main shaft; the inner ring revolving system comprises an inner ring main shaft, and an axial force applying bearing, the supporting bearing and a radial loading bearing are sleeved on the inner ring main shaft; outsides of two axial force applying bearings are provided with axial force applying devices; the upper part of the radial loading bearing is provided with a radial loading device; the upper part of the accompanied testing bearing is provided with a sensor unit; the testing device further comprises a lubricating system and a measuring and control device; the axial force applying device, the radial loading device and the lubricating system are connected with the measuring and control device. The invention provides a testing method of the simultaneous rotation of inner and outer rings of the cylindrical roller bearing; the method applies the method of rotating the inner and outer rings at the same time, and thus the testing rotate speed can be effectively improved.

Owner:HENAN UNIV OF SCI & TECH

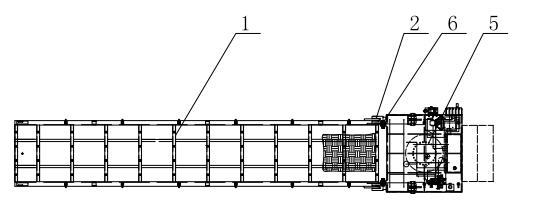

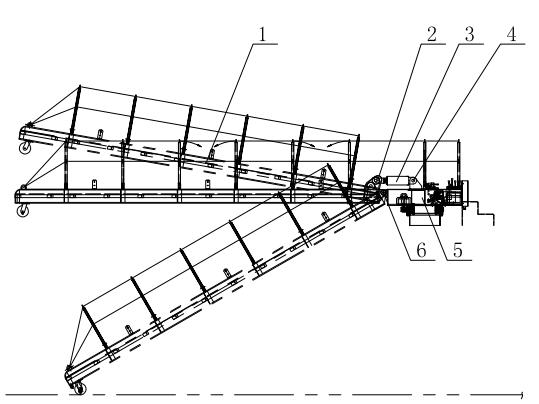

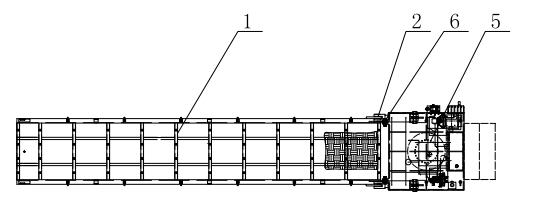

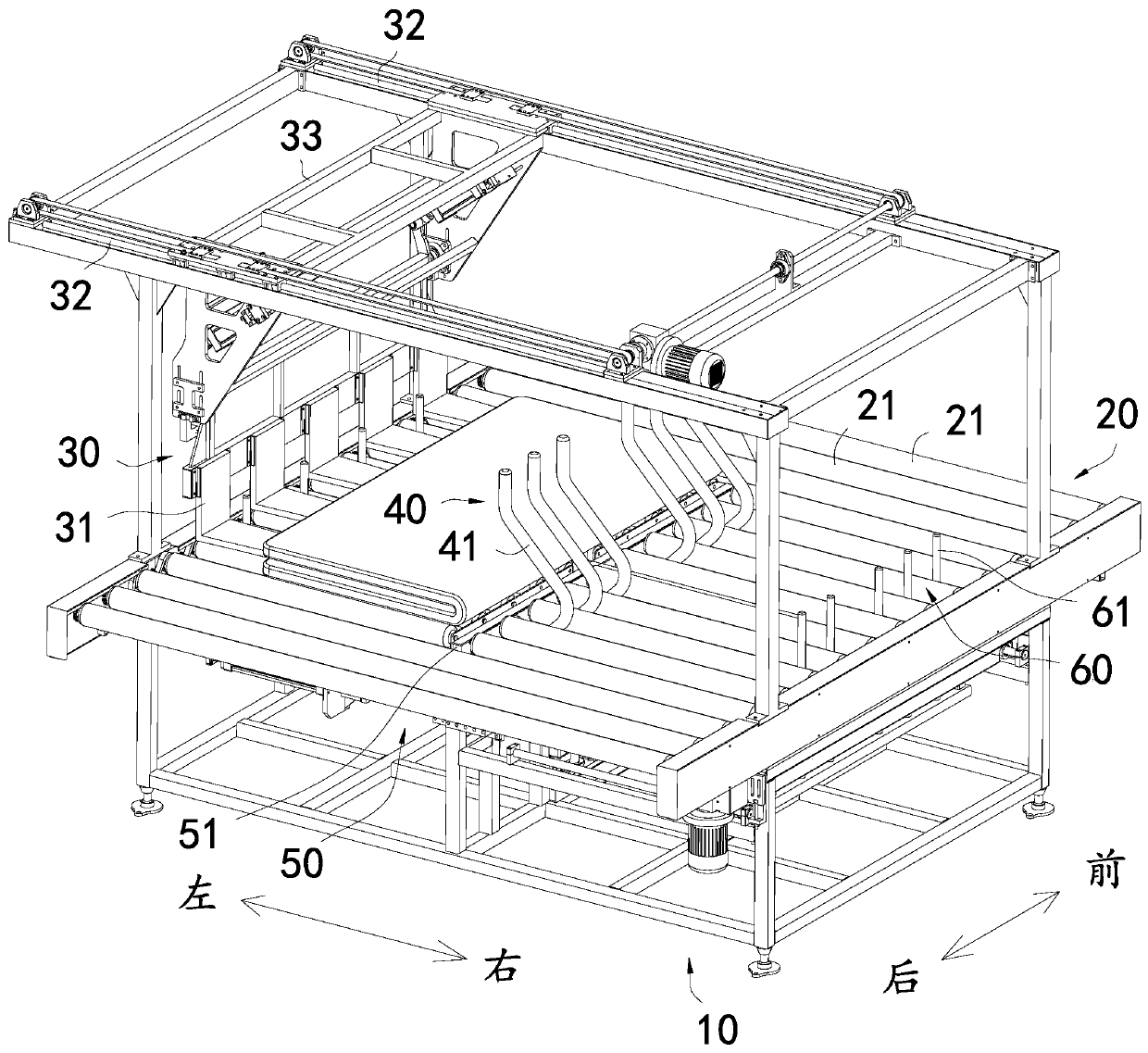

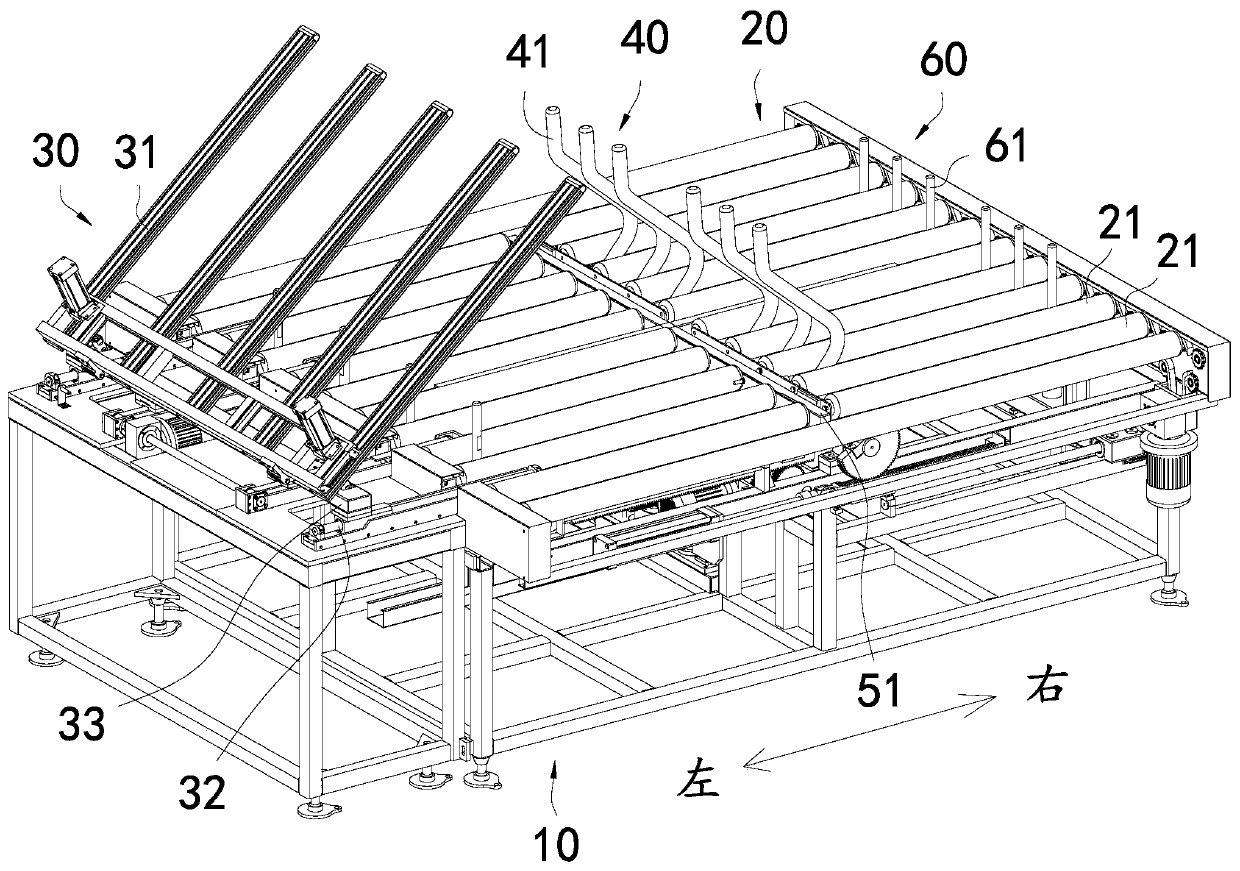

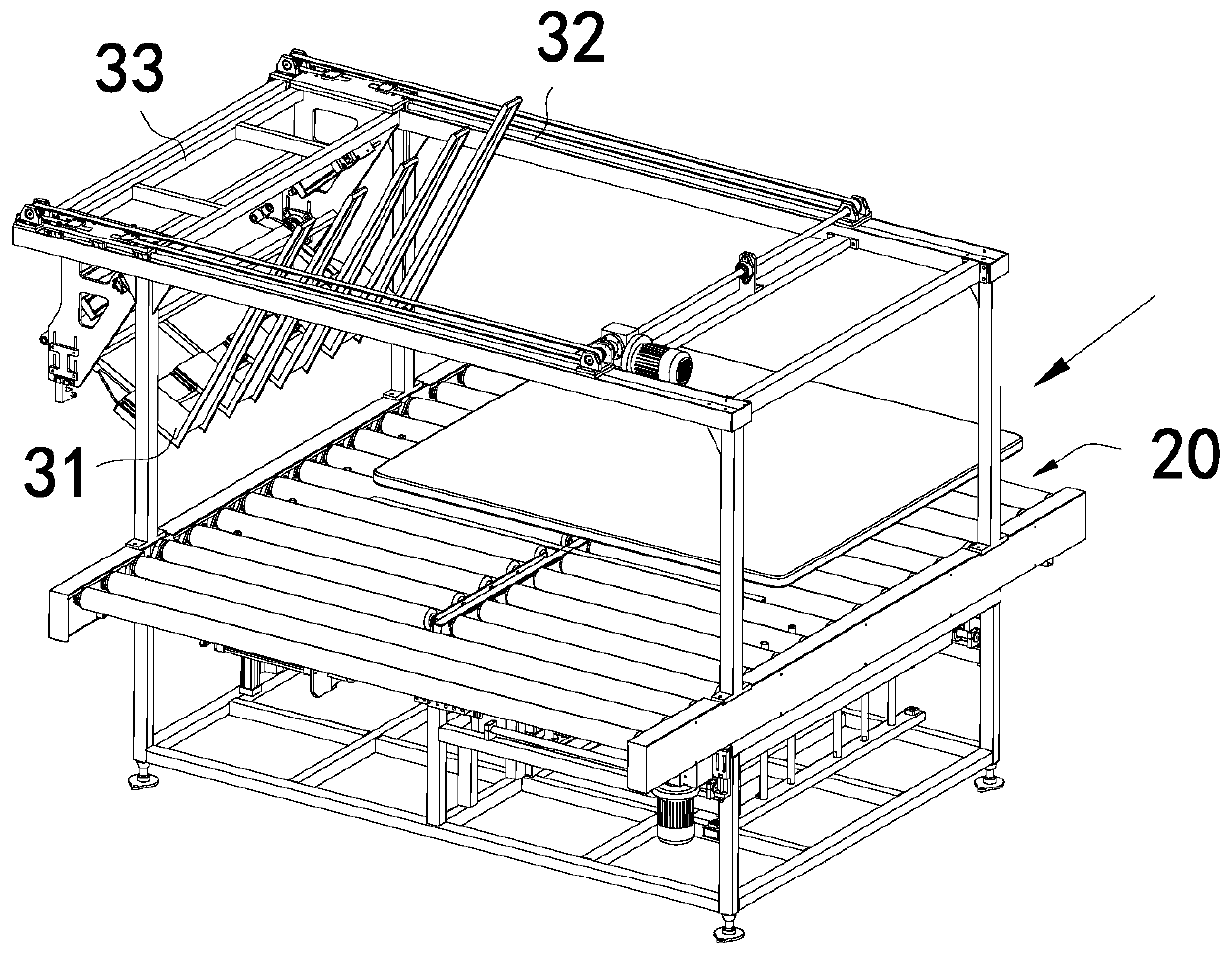

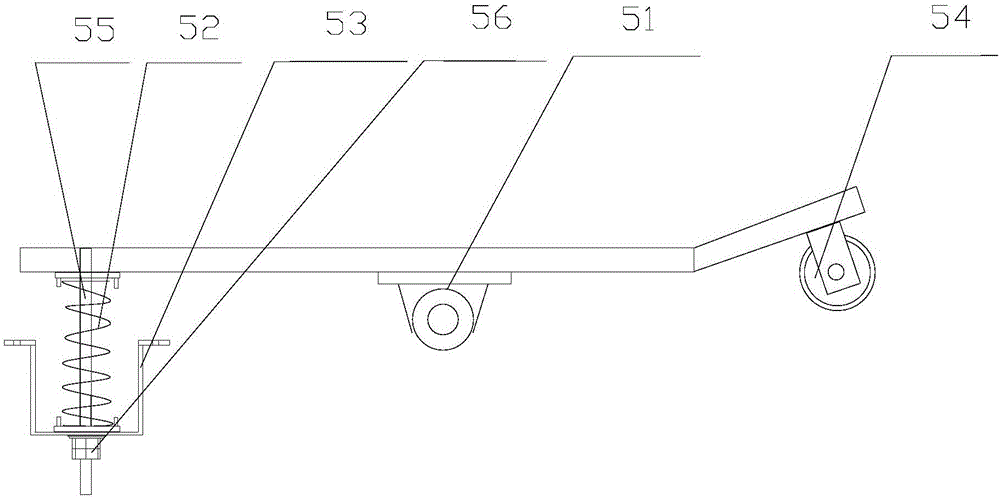

Soft cushion conveying device and method and soft cushion rolling, pressing and packaging device and method

ActiveCN110053837ASimple and fast folding actionStable and reliable operationWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

The invention discloses a soft cushion conveying device and method and a soft cushion rolling, pressing and packaging device and method. The soft cushion conveying device comprises a machine frame, aconveying platform, an abutting pressing mechanism and a folding mechanism. At least one gap area is arranged on the conveying platform. The abutting pressing mechanism can move in a reciprocating manner so as to be in contact with at least one part of a soft cushion located on the conveying platform in an abutting pressing mode. The folding mechanism comprises at least one folding member which can move back and forth and penetrate through the gap area. The folding member can extend out of the gap area and abut against the soft cushion located on the conveying platform in a contact mode, so that the soft cushion can be turned and folded. The soft cushion is conveyed to the conveying platform, and is folded in a turning mode through the joint efforts of the abutting pressing mechanism and the folding mechanism. The folding action is simple and rapid. The soft cushion is directly conveyed to the next working procedure through the conveying platform after being folded, and does not need to be additionally adjusted. For example, the soft cushion does not need to be additionally turned over. The operation is stable and reliable.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

Penetrating type worm wheel

InactiveCN105201559AIncrease powerStable and reliable operationNon-positive displacement enginesAirflowTesla turbine

A penetrating type worm wheel comprises a nozzle, a shell and a disc-shaped blade. Small holes are densely distributed in the whole disc-shaped blade, or the disc-shaped blade is directly made of porous materials, and therefore airflow can freely penetrate through the disc-shaped blade. Therefore, when airflow flushes the disc face or gas pressures on the two sides of the disc-shaped blade are different, penetration can happen, and the viscous force of airflow on the disc face is greatly enhanced. Compared with a smooth disc of a Tesla worm wheel, the number of blades can be small, the thickness can be large, the rigidity of the penetrating type worm wheel is better than that of the thin disc of the Tesla worm wheel, the size of the worm wheel can be large, the worm wheel cannot deform, and therefore power is increased, and running is more stable and reliable.

Owner:时剑

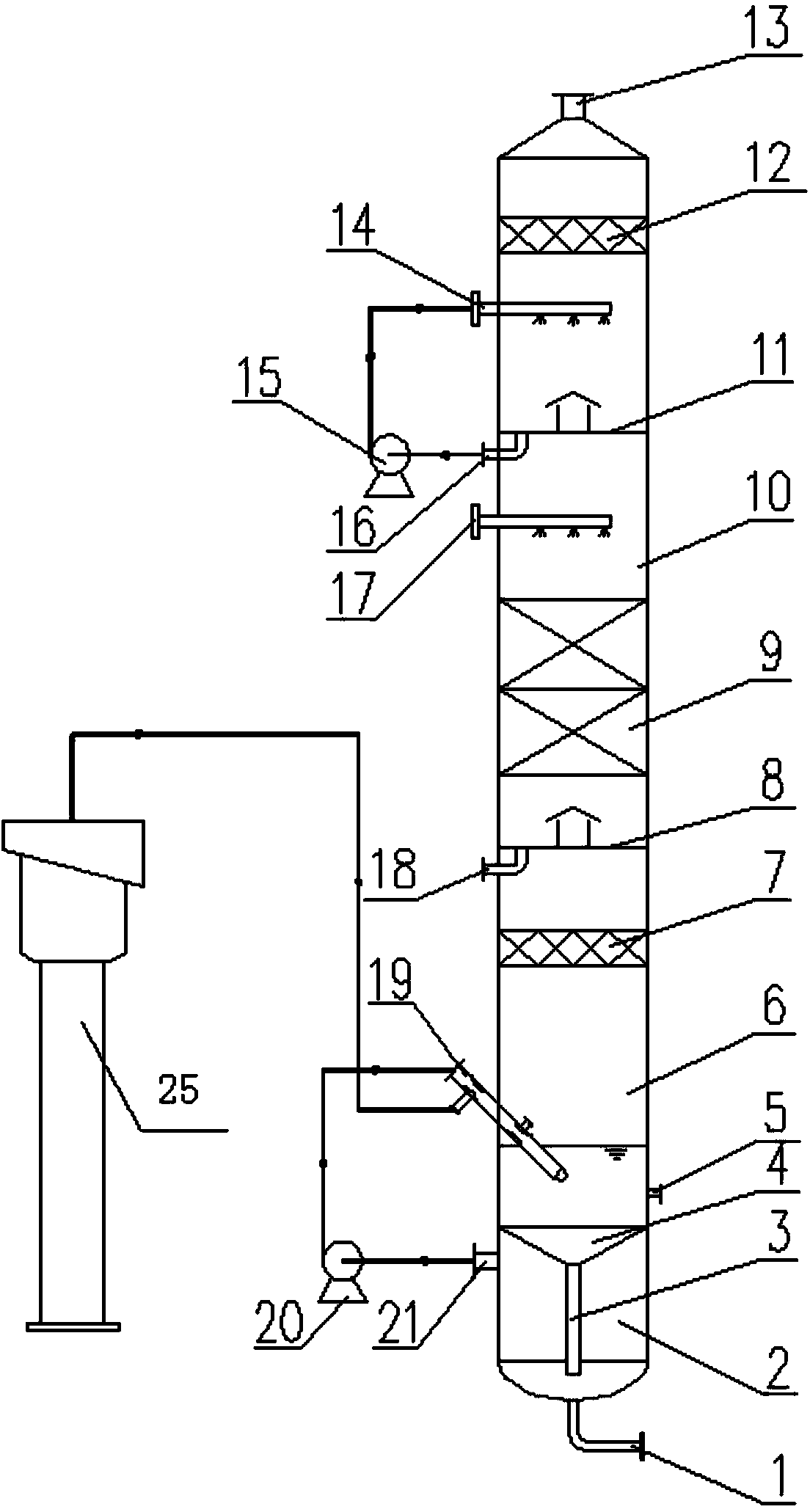

Regenerated tail gas purification combined tower

ActiveCN103831003ASimple operation and maintenanceStable and reliable operationDispersed particle separationAir quality improvementAmmonium sulfateChemistry

The invention discloses a regenerated tail gas purification combined tower which comprises a regenerated tower tail gas acid gas removal device and a vertical tower, wherein the vertical tower is connected with the regenerated tower tail gas acid gas removal device through a secondary ejector; the vertical tower is divided into a crystallization section, a deamination section and an acid gas removal section; the acid gas removal section is arranged on the upper part of the deamination section and is connected with the deamination section through a first liquid interrupt disc; the crystallization section is arranged on the lower part of the deamination section; the deamination section is connected with the crystallization section through a conical seal head. Compared with the prior art, the regenerated tail gas purification combined tower has the beneficial effects that ammonia and acid gases entrained in the tail gas can be effectively absorbed, and the equipment is simple to operate and maintain and stable and reliable to operate. The purification process is simplified, the floor space is saved, the regenerated tail gas is injected by utilizing circulating mother liquor, the resistance of the regenerated tail gas is reduced, and the energy consumption is reduced. The ammonia in the tail gas can directly form ammonium sulfate crystals, the combined tower is independent from a coke oven gas ammonia recovery device, and the investment is saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

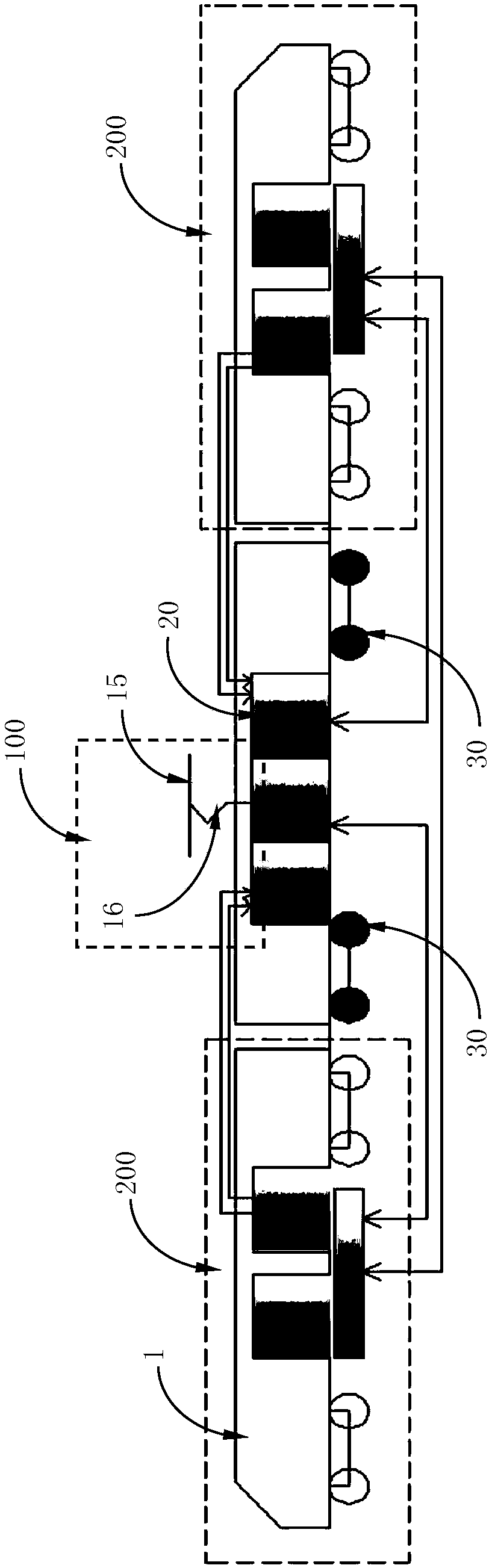

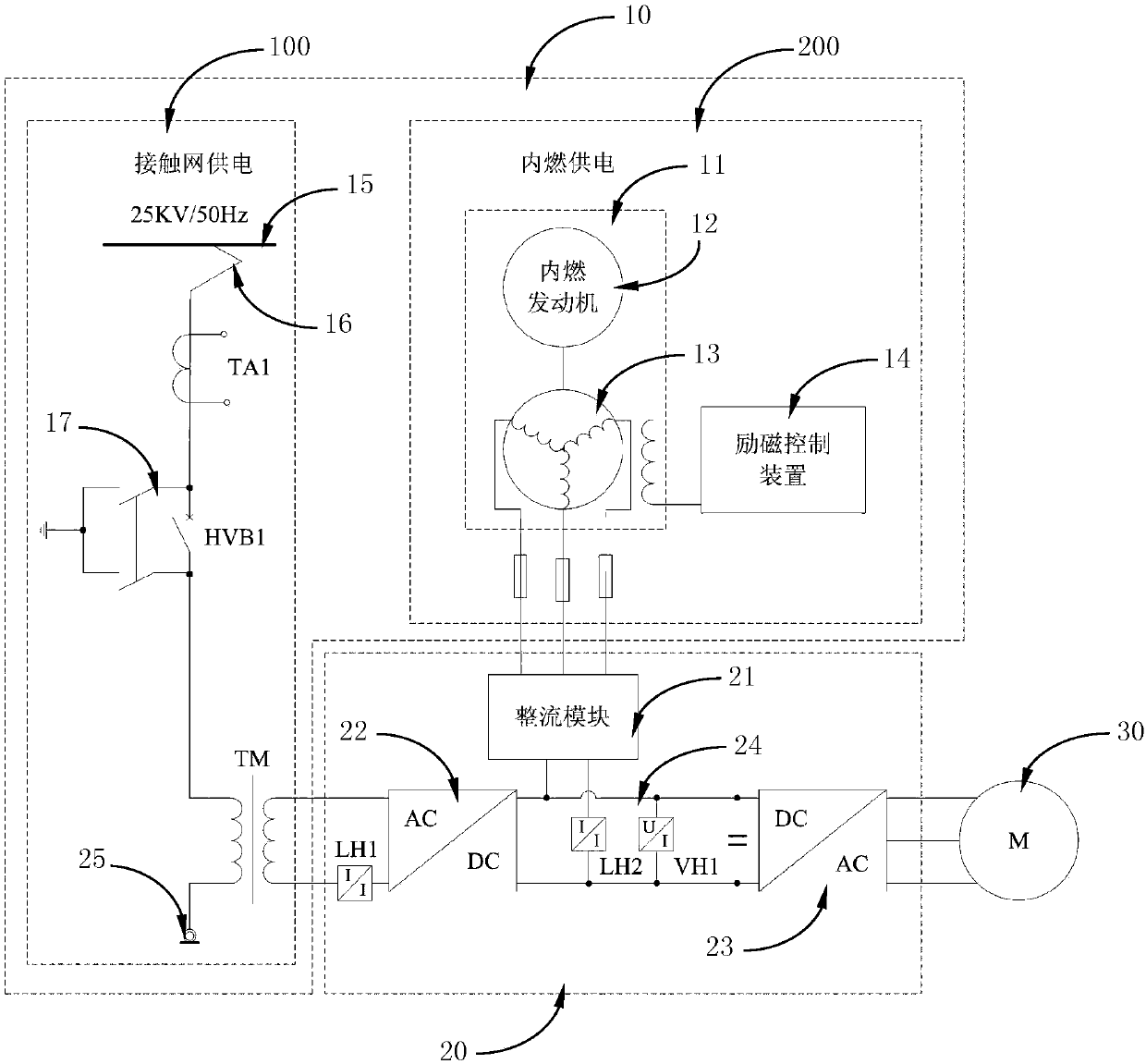

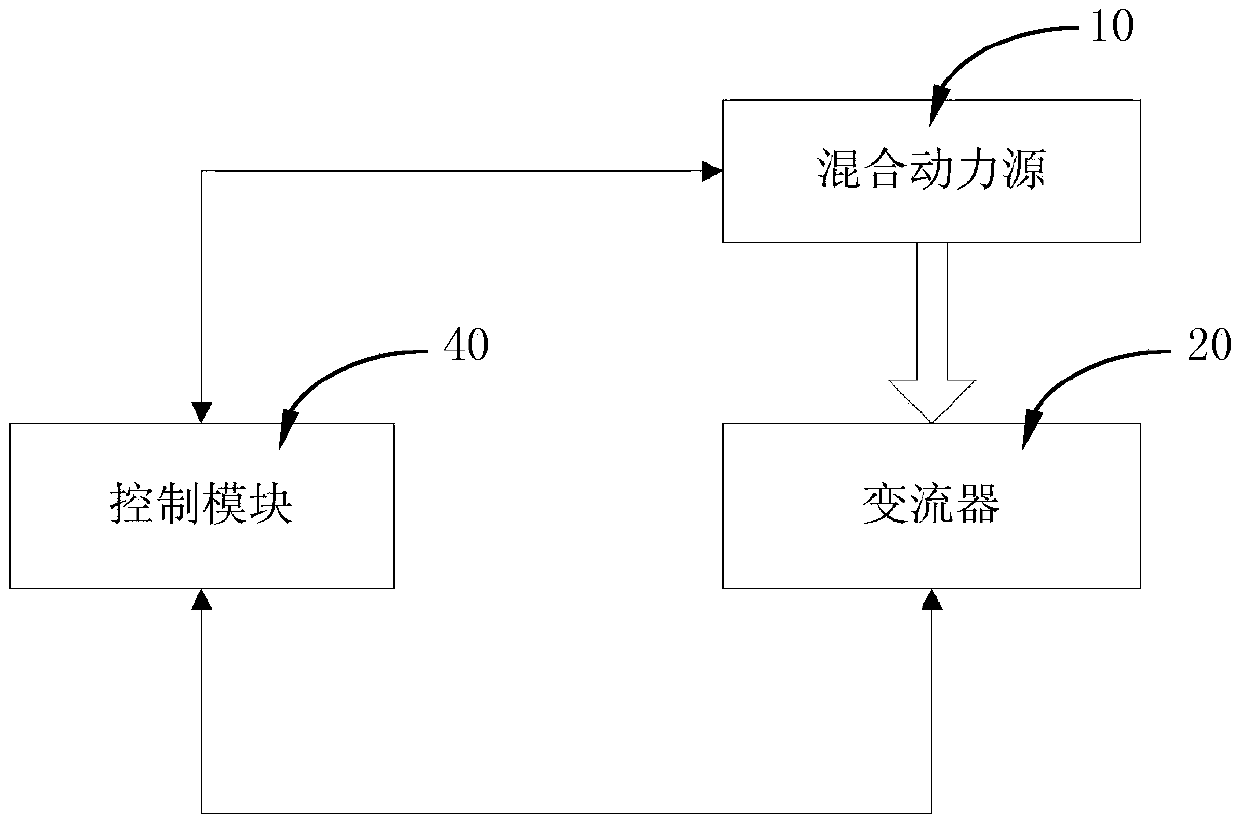

Switching control method for hybrid power sources of railway engineering machinery

ActiveCN107618379AReduce points of failureReduce workloadPropulsion using engine-driven generatorsElectric motor propulsion transmissionElectricityCombustion

The invention discloses a switching control method for hybrid power sources of railway engineering machinery. The hybrid power sources comprise a catenary power supply module and an internal combustion power supply module, electrical power from the catenary power supply module or the internal combustion power supply module is converted and processed by a converter and then converted into electricpower required by a traction motor. When a catenary is electrically connected and power is continuously supplied to the catenary, the power is supplied to the traction motor through the catenary powersupply module. When the catenary is not electrically connected or power cannot be continuously supplied to the catenary, the power is supplied to the traction motor through the internal combustion power supply module. When the two power supply modules need to be switched, the catenary power supply module and the internal combustion power supply module supply the power to the traction motor at thesame time during switching, and the replaced power supply module stops supplying the power when switching is finished. The switching control method for the hybrid power sources of the railway engineering machinery can achieve the technical purpose that when the two power sources are switched, it is ensured that an operating mechanism can run continuously without impact.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Groove type automatic ball feeder for ball mill

The invention belongs to the technical field of ball feeding equipment for a ball mill and particularly relates to a groove type automatic ball feeder for the ball mill. The ball feeder comprises a ball storage bin, a ball conveying assembly and a funnel. The ball storage bin comprises a bin body and a buffering ball channel, and an outlet is formed in the buffering ball channel. The ball conveying assembly comprises a ball conveying wheel and a driving assembly, the ball conveying wheel is arranged on the outlet, a rotating shaft penetrates through the middle of the ball conveying wheel, and a plurality of parallel ball conveying channels are arranged on the surface of a wheel body. Each ball conveying channel is provided with a groove and a protrusion, wherein the groove is formed in the front end of the protrusion, the portion from the front end to the tail end of the upper surface of the protrusion is an arc face, the arc face is along the circumference where the ball conveying channels are located, and finally makes contact with the surface of the wheel body. The driving assembly is connected to the rotating shaft, the distance from the surface of the ball conveying ball to the edge of the outlet is smaller than the diameter of steel balls, and each groove contains one steel ball each time. The funnel comprises an inlet end located under the ball conveying wheel, and the funnel conveys the steel balls to the ball mill. The advantages that the grooves are high in ball grasping strength and stable and reliable in operation are used, and accordingly the aim of automatically adding balls is achieved.

Owner:BENGANG STEEL PLATES

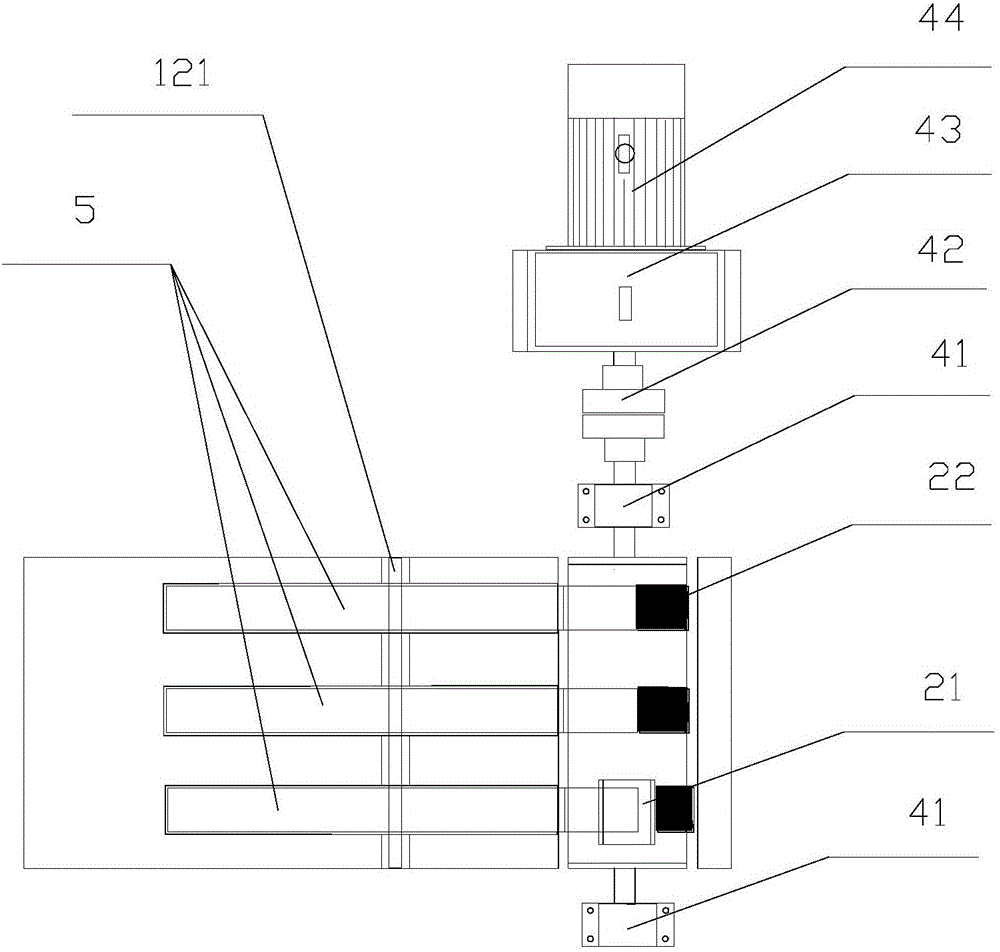

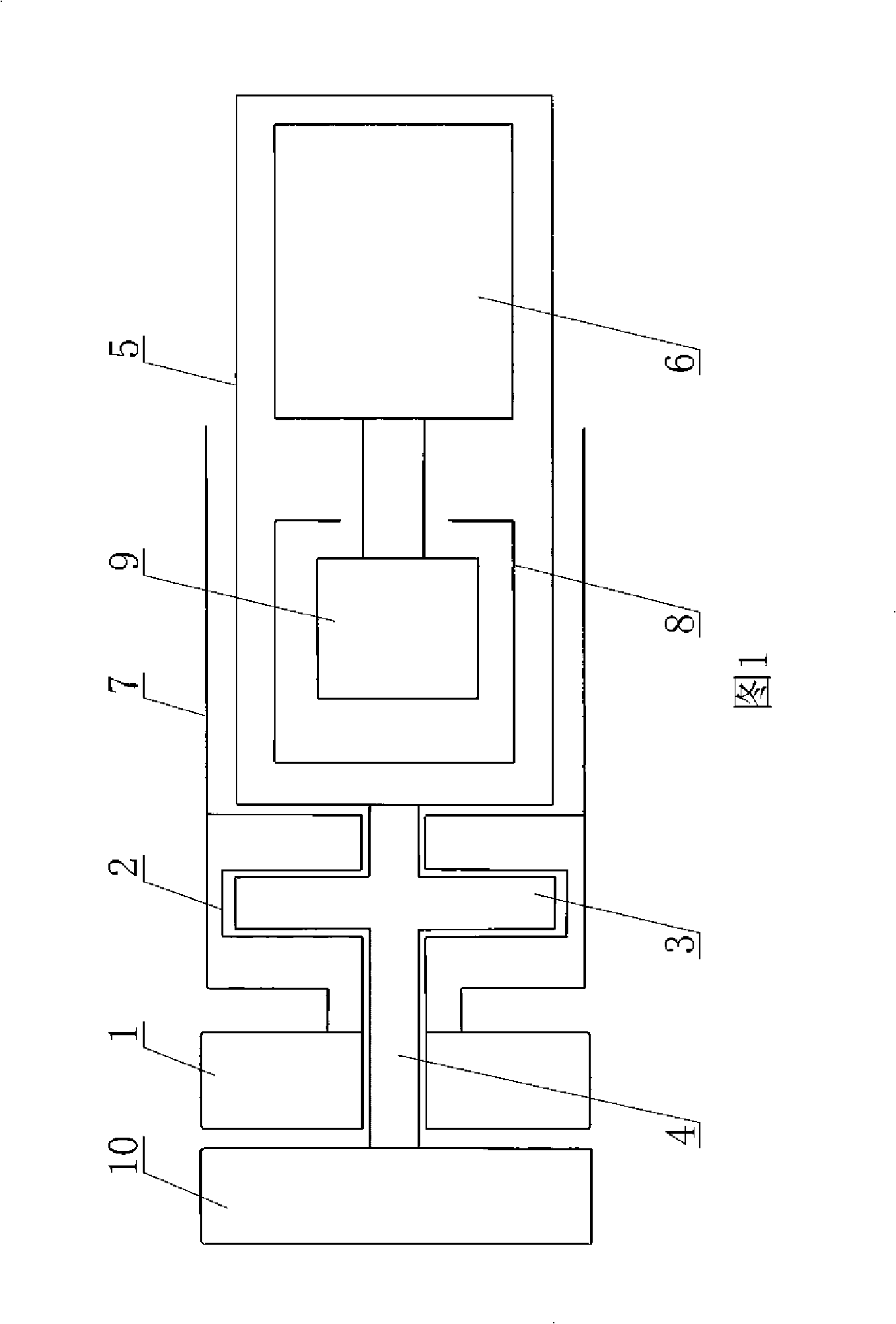

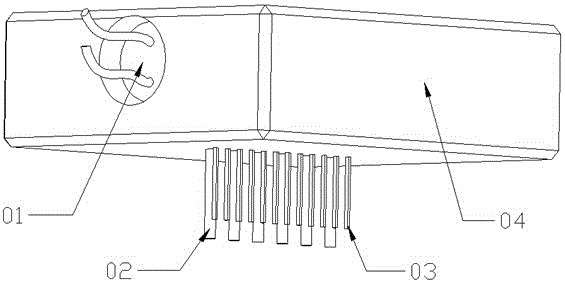

Two-sided wire binding machine

InactiveCN103107654AStable and reliable operationImprove efficiencyManufacturing dynamo-electric machinesStatorSprocket

The invention discloses a two-sided wire binding machine which comprises a machine body, a stator dividing device, wire laying mechanisms and a bearded needle nozzle mechanism. The machine body comprises a machine seat, a bottom plate, an intermediate plate, a top plate and an electrical box arranged on two sides of the machine seat, a sliding rod is arranged at the upper end of the machine seat, the bottom plate is arranged on the top portion of the machine seat, a gear motor and a tensioner sprocket are fixed below the bottom plate, a guide shaft and a support shaft are arranged between the bottom plate and the top plate, two parallel ball screw rods are arranged below the top plate, and the intermediate plate is arranged on the ball screw rods. The wire laying mechanisms are respectively arranged on the bottom portion of the machine seat and the top portion of the top plate. The stator dividing device is arranged on the sliding rod, and an air cylinder is arranged between the stator dividing device and the machine seat. The bearded needle nozzle mechanism is symmetrically arranged on the machine body. Through the mentioned mode, the two-sided wire binding machine can carry out binding to the upper wire coil and the lower wire coil of the stator of an electric motor, running is stable and reliable, efficiency is high, operation difficulty is reduced, and processing cost is reduced.

Owner:NIDE MECHANICAL EQUIP

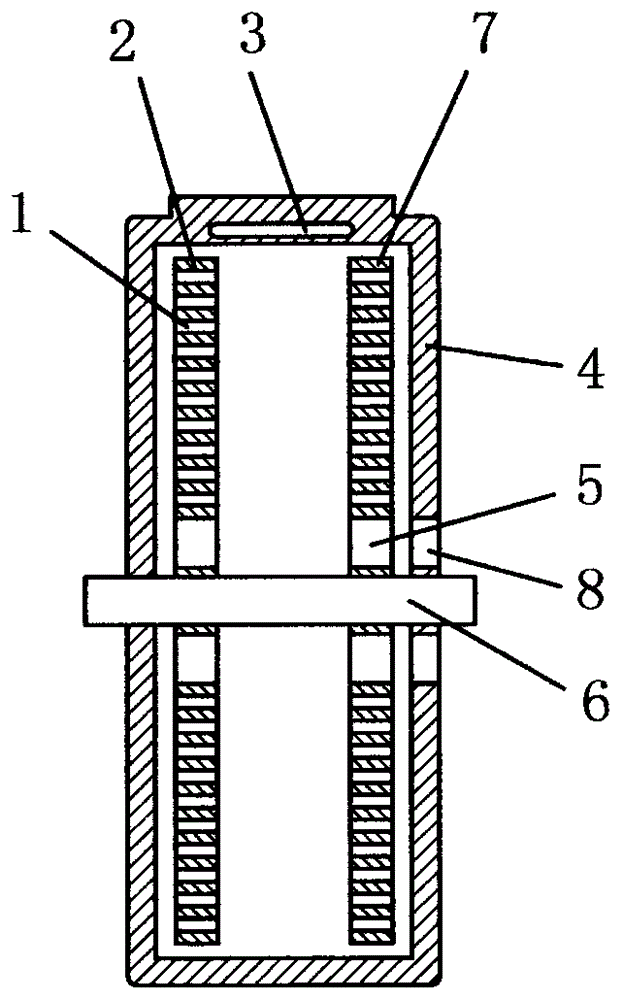

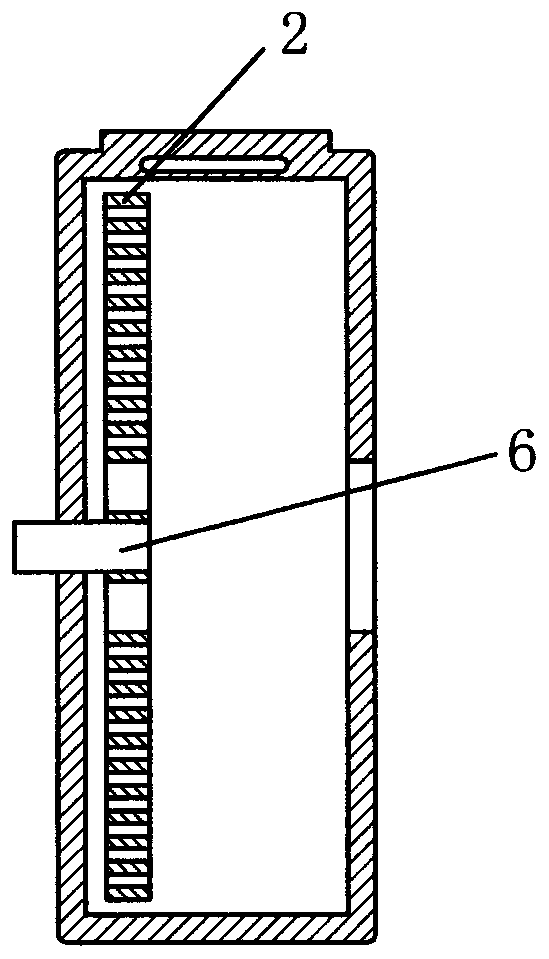

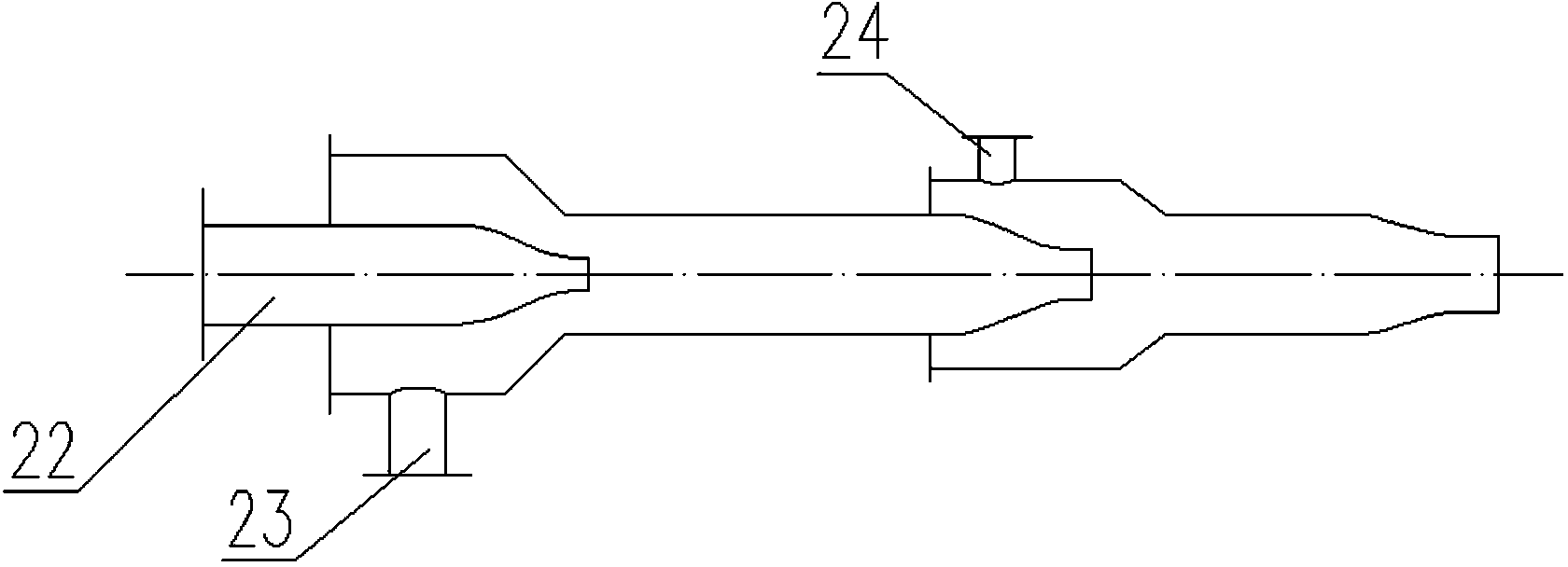

Down-hole slurry generator

InactiveCN101251077AExtend product lifeStable and reliable operationDynamo-electric gearsMachines/enginesStatorElectricity

The invention relates to an underground mud generator, the main structure of which is as follows: a turbine is connected to an outer magnetic rotor of a magnetic coupling through a cushion double wall sleeve; an annular groove is arranged in the middle part of the inside wall of the cushion double wall sleeve; a buffer plunger is contained in the annular groove; one of the buffer plunger and the cushion double wall sleeve is a magnet; the center of the buffer plunger is connected to two ends of a stator plunger rod; one end of the stator plunger rod is connected to a seal housing of the generator, while the other end passes through the center of the turbine and is connected to a supporter; an inner magnetic rotor of the magnetic coupling is positioned in an outer magnetic rotor drum of the magnetic coupling, and the both are isolated by the seal housing; the inner magnetic rotor is provided with a necking cavity; one end of a suspended shaft is arranged in the necking cavity, while the other end is connected to the rotor of the generator body; and the seal housing encloses the generator body, the inner magnetic rotor of the magnetic coupling and the suspended shaft. The underground mud generator has the advantages of no-sealing, zero leakage and shock proof, and supplies steady electricity for logging-while-drilling instruments underground in a high temperature and high pressure environment.

Owner:BEIJING TIANXING JINGZUAN TECH DEV

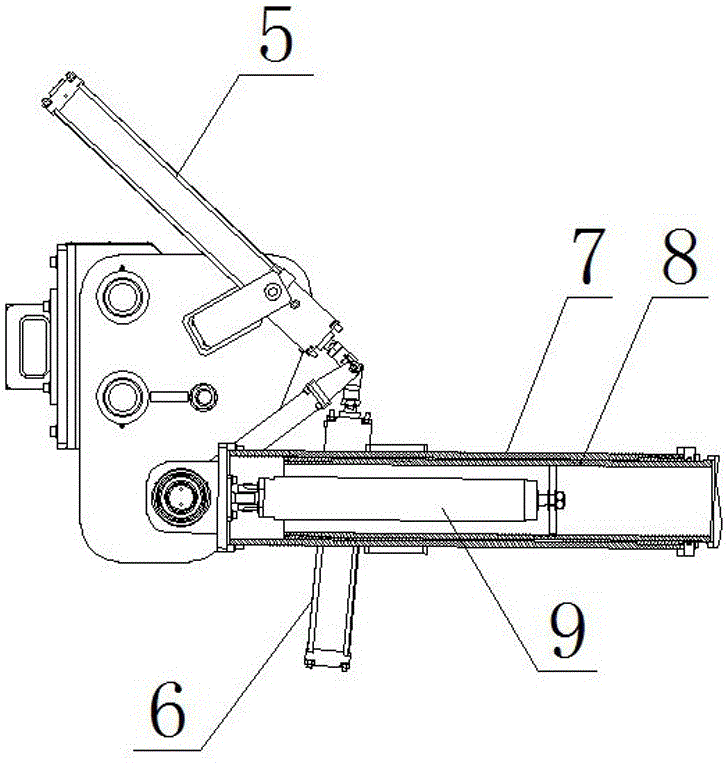

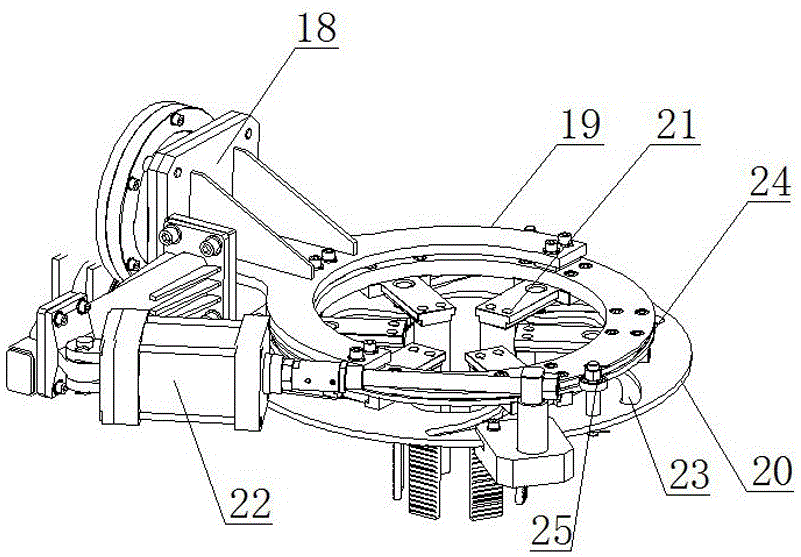

Four-station vulcanizing machine release telescopic manipulator

ActiveCN106346655AGuaranteed length change telescopingExtended service lifeTyresArmsManipulatorIndustrial engineering

The invention discloses a four-station vulcanizing machine release telescopic manipulator which comprises a vertical lifting mechanism, a lifting slide block, a telescopic mechanism, a claw disc, a swing arm, a first cylinder and a second cylinder, wherein the lifting slide block is arranged on the vertical lifting mechanism and is driven to lift along the vertical direction by the vertical lifting mechanism; one end of the telescopic mechanism is rotationally arranged on the lifting slide block; the claw disc is arranged at the other end of the telescopic mechanism; the first cylinder is hinged on the lifting slide block; one end of the swing arm is hinged on the lifting slide block; one end of the first cylinder is hinged with the other end of the swing arm; the second cylinder is hinged on the telescopic mechanism; and one end of the second cylinder is hinged to the other end of the swing arm. According to the invention, large-angle swing of a gripper is realized by matching the two cylinders, and due to the telescopic boom structure, length change and telescoping of the gripper can be guaranteed, and the manipulator is reliable in operation and long in service life.

Owner:NANTONG RAINBOW HEAVY MACHINERIES

Small folding suction roller device for handkerchief paper folding machine

InactiveCN102241162ASimple structureStable and reliable operationPaper-makingBox making operationsFlangePulley

The invention discloses a small folding suction roller device for a handkerchief paper folding machine. The device comprises a suction roller, wherein one end of the suction roller is fixedly provided with a cover plate and a belt pulley; the rest part of the suction roller has a symmetrical structure; the suction roller is connected with a folding machine tank body through flanges at the two ends; the flanges are connected with the suction roller through bearings; pipe joints are connected with air distribution sleeves through screws; the two ends of the suction roller are provided with radial square holes which are communicated with the air distribution sleeves at the two ends respectively; the air distribution sleeves are fixed on the folding machine tank body through fixing blocks; the inner parts of the air distribution sleeves are connected with the suction roller through bearings; two suction bars are arranged in the middle of the suction roller and are fixed through screws; and two folding knives are arranged in a mounting groove in the middle of the suction roller through screws. In the device, two shafts on the two sides of the conventional structural suction roller and the suction roller are combined into a whole, and the surface of the roller, the matching surfaces of the roller and the air distribution sleeves and the mounting surfaces of all the bearings are integrally machined, so that the coaxiality of the suction roller is ensured. The device has a simple structure and is operated stably and reliably.

Owner:CHANGDE TOBACCO MACHINERY

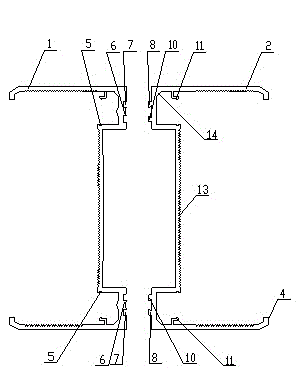

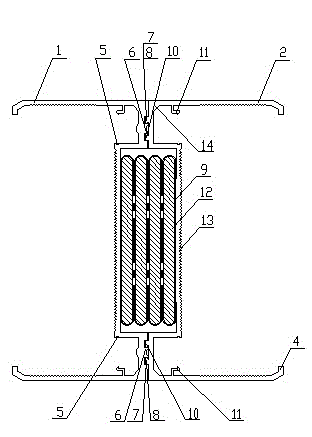

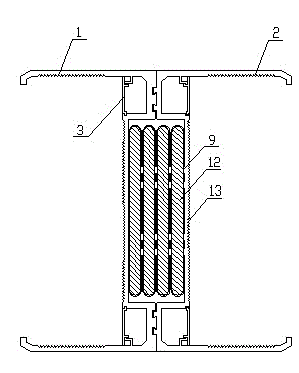

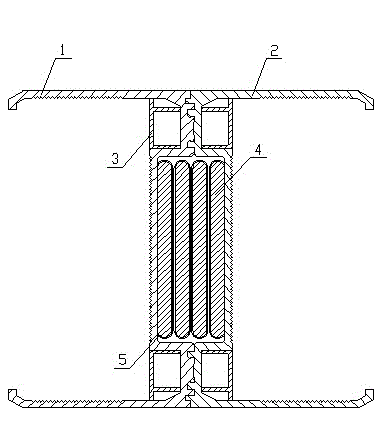

Compact busway

ActiveCN102751682APrecise calculation of deformation parametersClose contactCooling bus-bar installationsPartially enclosed bus-bar installationsBusbarEngineering

The invention relates to a compact busway. The busway comprises a left one-piece side cover plate, a right one-piece side cover plate, reinforcing rib seal plates, a busbar and an insulating layer, wherein the busbar is put between the left one-piece side cover plate and the right one-piece side cover plate after wrapping the insulating layer; the left and right one-piece side cover plates are laminated and riveted by special riveting equipment to form a whole compact busway; and the reinforcing rib seal plates are fixed on the upper and lower necks of the whole compact busway formed by the left and right one-piece side cover plates. The busway is simple in structure, achieves minimum part quantity, is simplified in production process and simple in assembly procedures, is convenient to transport and install and is reliable in operation effect and excellent in heat dissipation.

Owner:江苏华鹏电力设备股份有限公司

Biological sewage treating process by means of fiber membrane fixed organism

InactiveCN101066799APromote formationPromote regenerationSustainable biological treatmentBiological water/sewage treatmentFiberSludge

The biological sewage treating process by means of fiber membrane fixed organism includes the following steps: 1. weaving fibrous biological membrane carrier with Dacron filament and attaching active microbial sludge for sewage treatment to the surface of the fiber; and 2. setting the fibrous biological membrane carrier in anaerobic or aerobic reactor, and soaking the carrier in industrial sewage over aerator and basic device so that the ascending bubble can provide organism with sufficient oxygen. The present invention has high sewage treating efficiency, stable performance, low power consumption, long service life and other advantages.

Owner:普罗生物技术(上海)有限公司

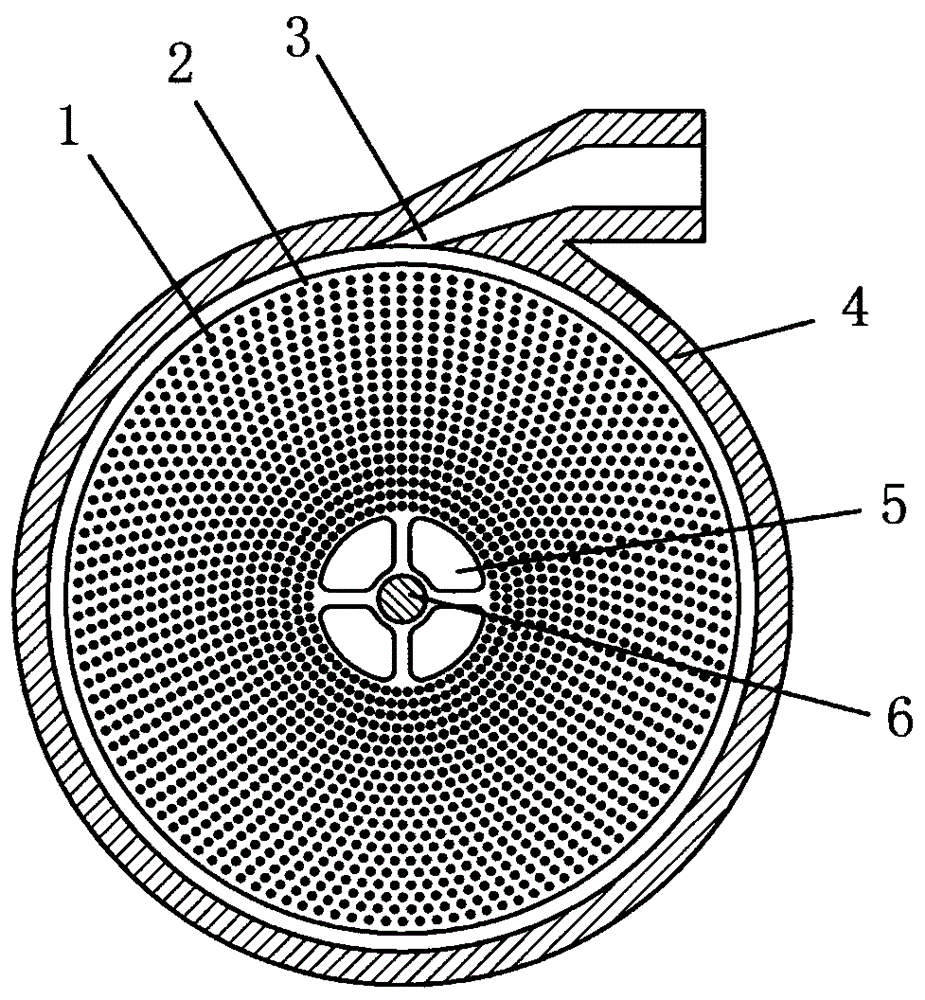

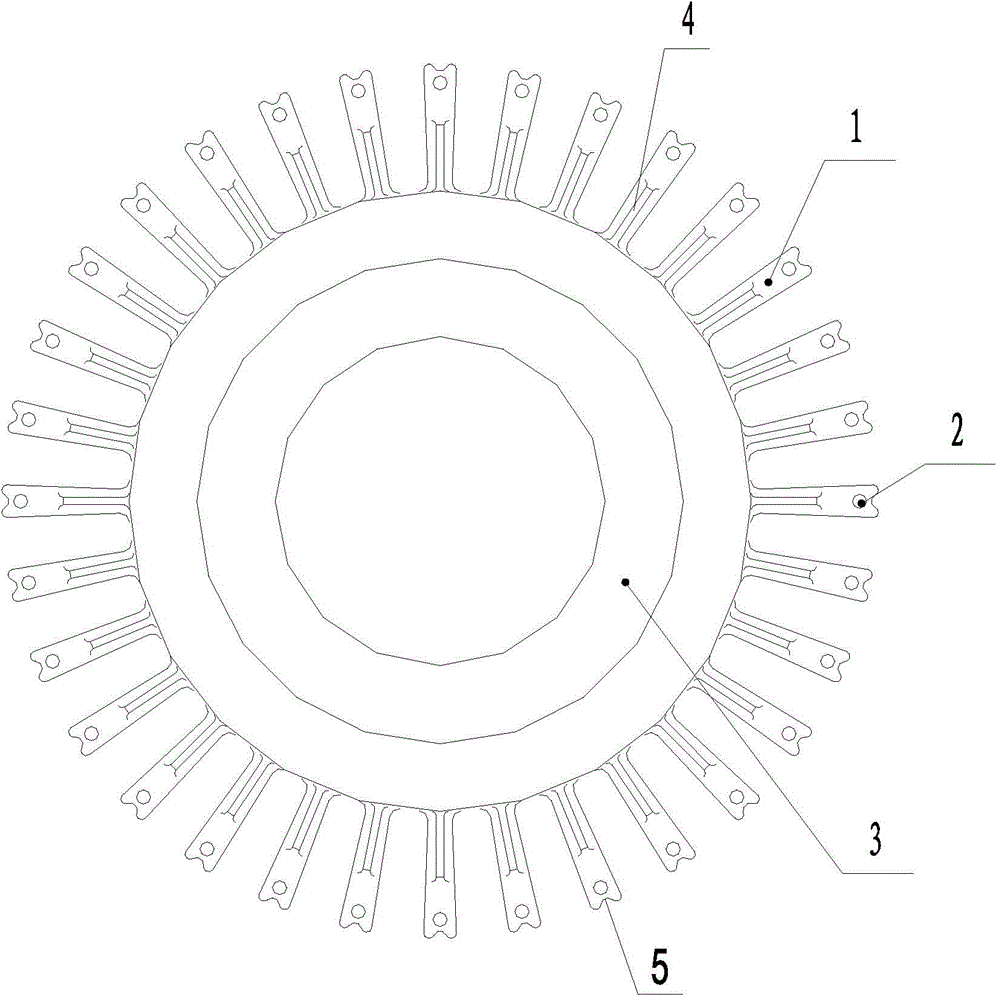

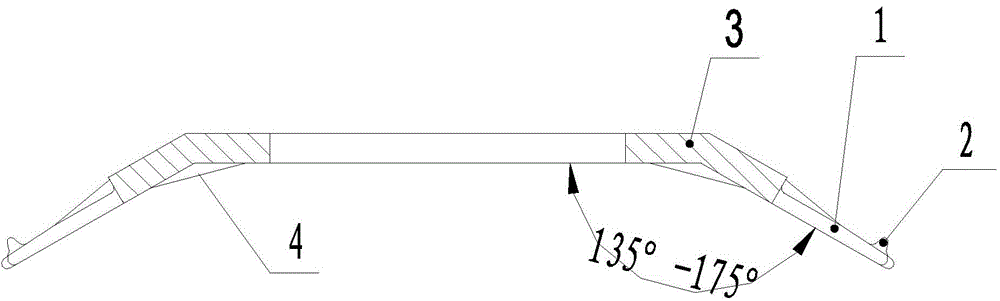

Dished wire distributing wheel for circular weaving machine

InactiveCN104652021AThe overall structure is compactStable and reliable operationCircular loomsNeedle guideEngineering

The invention relates to a dished wire distributing wheel for a circular weaving machine. The dished wire distribution wheel comprises an annular wheel body and a plurality of wire distributing forks. The wheel body is provided with a center hole, the wire distributing forks are arranged on the external circumference of the wheel body, included angles are formed among the bent wire distributing forks and the wheel body and range from 135 degrees to 175 degrees, the ends of the wire distributing forks are provided with grooves and conical positioning teeth, and reinforcing ribs are arranged among the wire distributing forks and the wheel body. Compared with the prior art, the included angles are formed among the bent wire distributing forks and the wheel body, the dished wire distributing wheel is formed and used for running a shuttle, and the wire distributing forks of the wire distributing wheel and a guide rail below a needle guide disk cannot be interfered by the aid of the circular weaving machine with a rail mechanism, so that the circular weaving machine is more compact in integrated structure and more stable and more reliable to run.

Owner:朱根山

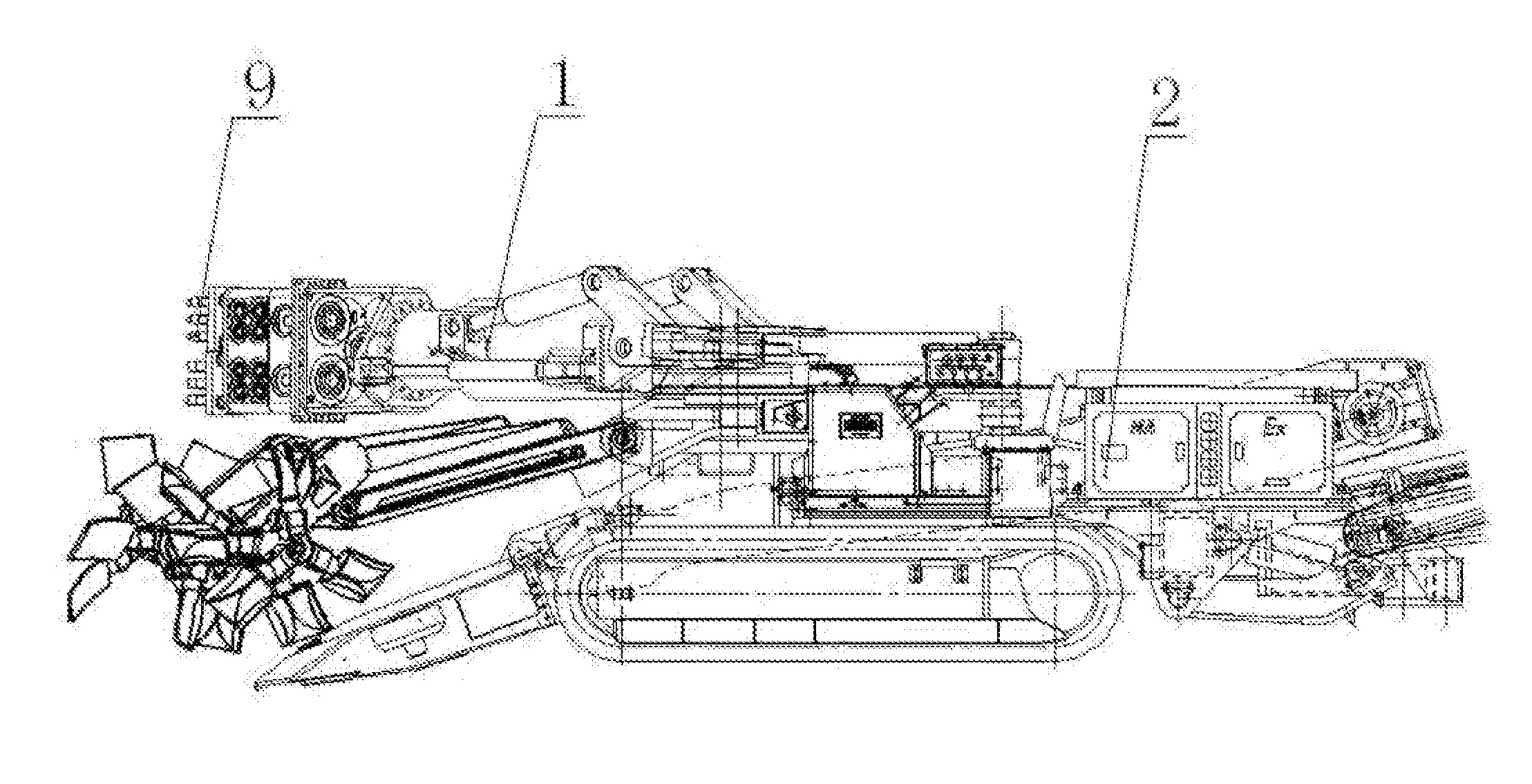

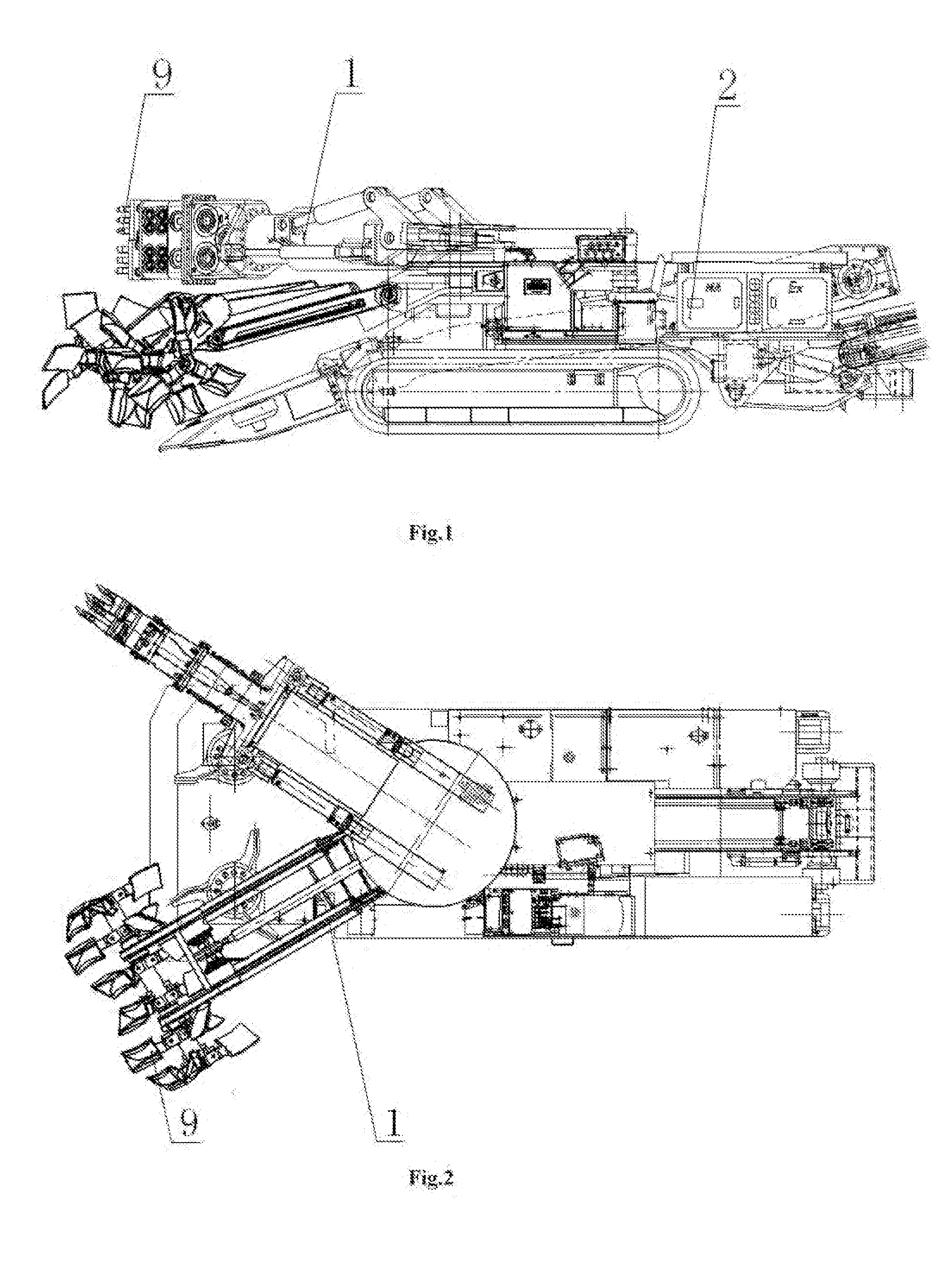

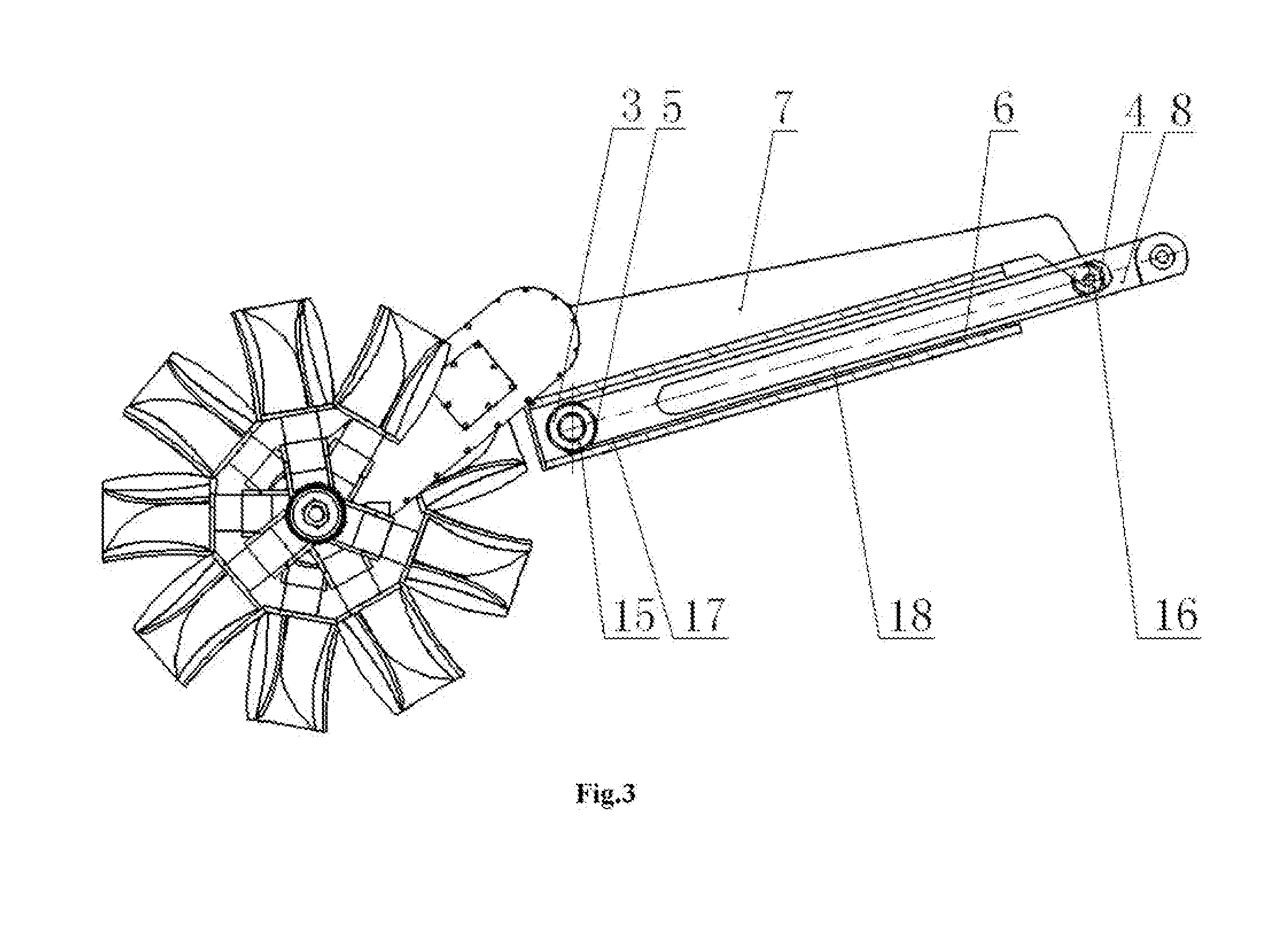

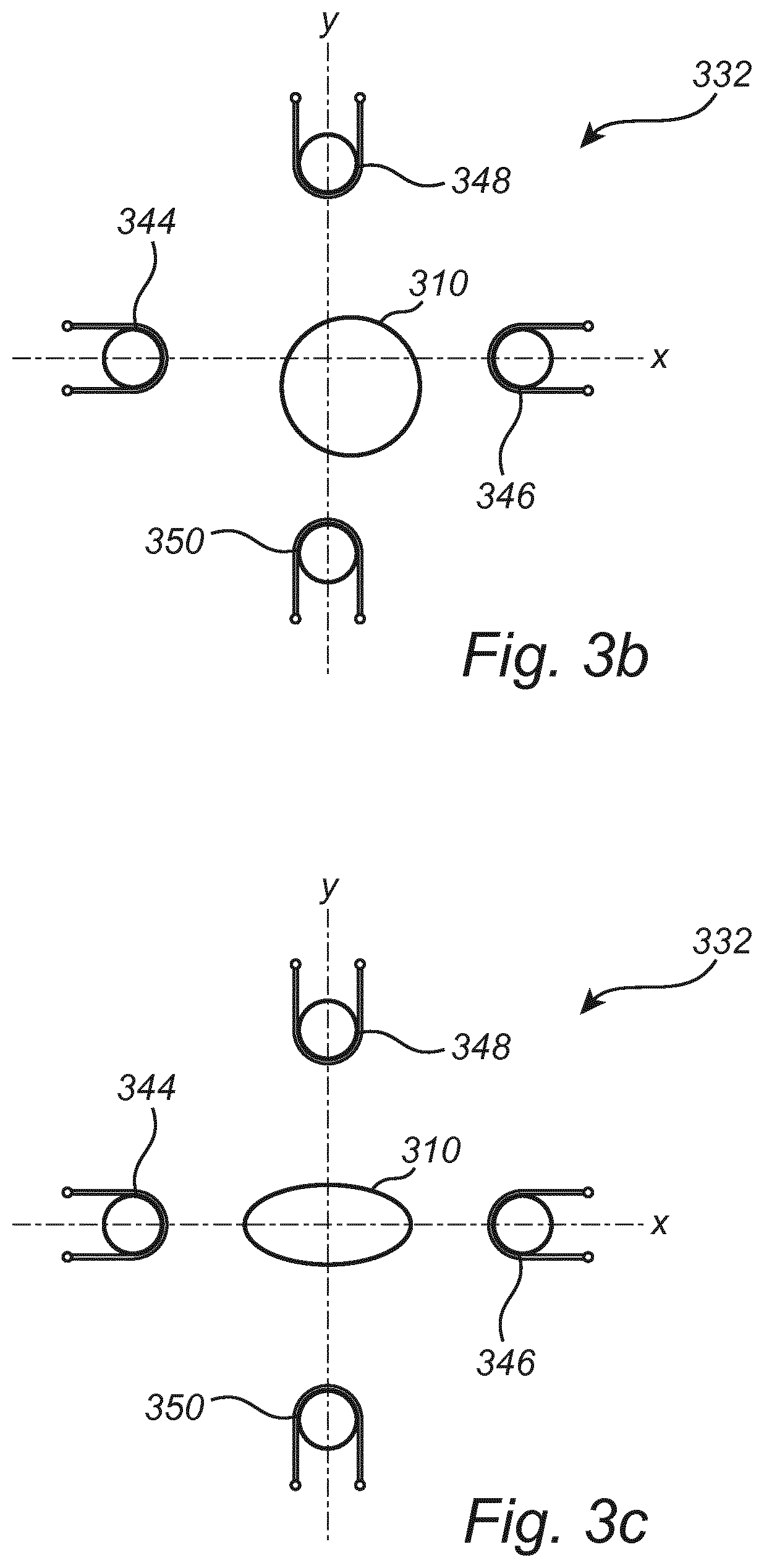

Method for arranging rolling-friction stretching and retraction based rolling stroke sections of a rocker arm in parallel, and an excavator or loader comprising a rocker arm having rolling stroke sections arranged in parallel

InactiveUS20150315909A1Improve work efficiencyStable and reliable operationMechanical machines/dredgersDriving meansRocker armExcavator

Owner:LIU SUHUA

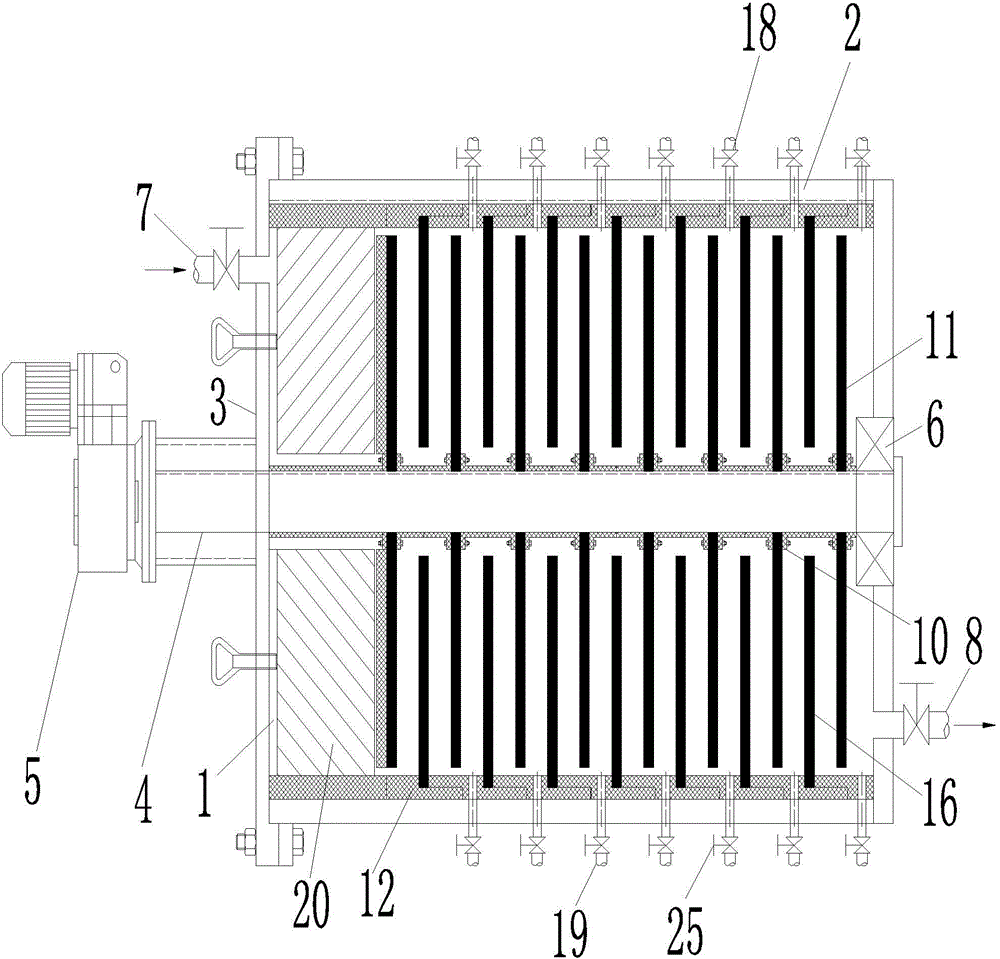

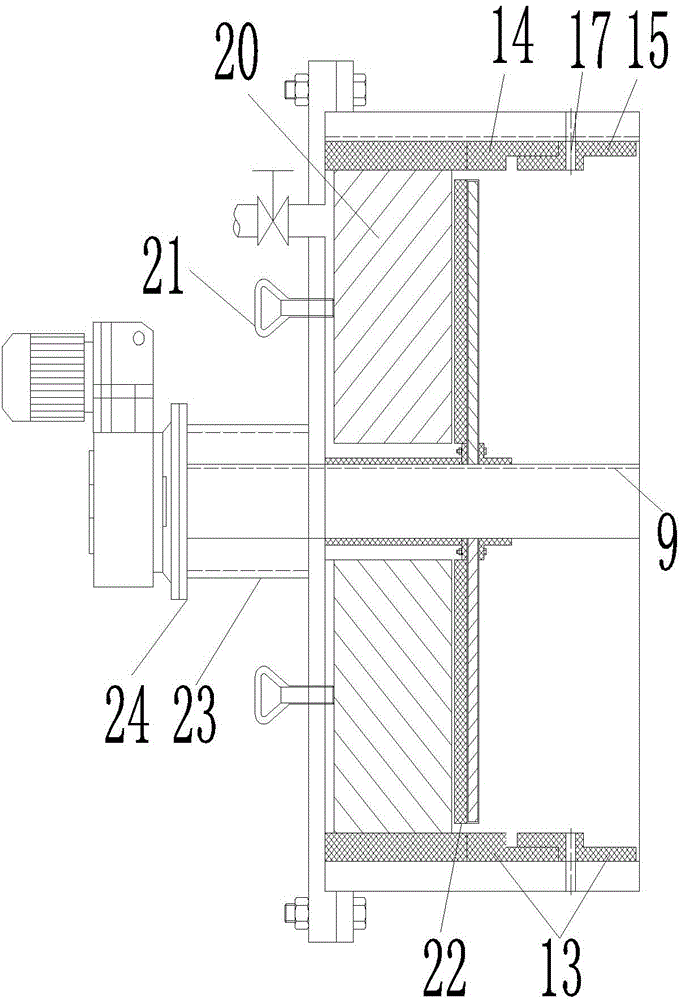

High efficiency autocontrol electro-fenton decontamination equipment

ActiveCN105836850AReasonable structural designStable and reliable operationWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationEngineeringAnode

The invention relates to high efficiency autocontrol electro-fenton decontamination equipment, which comprises a cylindrical shell with one end provided with a mounting hole. A central main shaft is horizontally disposed at the middle part of the shell, a central main shaft end outside the shell is provided with a drive unit, a water inlet is arranged at the upper part of a cover plate, a shell side wall below a ceramic bearing shell is provided with a water outlet, pole plate bases are provided with Ti positive pole plates, an annular PE support piece is disposed close to the cylindrical inner wall of the shell in the shell, graphite negative pole plates are plugged at joints of right-angle type connecting pieces and Z shaped connecting pieces, a sacrificial anode is arranged in the shell at the mounting hole, an adjusting knob is disposed on the cover plate corresponding to the middle part of the sacrificial anode, and a nylon interlayer is arranged on the Ti positive pole plate close to the sacrificial anode. The equipment provided by the invention has the advantages of good decontamination effect, reasonable structure arrangement, convenient installation and disassembly, high efficiency autocontrol, and wide use range.

Owner:YIXING LINGTAI ENVIRONMENTAL PROTECTION

Supporting bracket of interlayer box body of lining plate mounting bearing seat of vertical type mill

InactiveCN102228847ACompact structureStable and reliable operationGrain treatmentsEngineeringFront edge

The invention relates to a supporting bracket of an interlayer box body of a lining plate mounting bearing seat of a vertical type mill. The support bracket comprises a blocking interlayer box body, wherein the inner side of the blocking interlayer box body is provided with a lining plate mounting bracket, an interlayer is an interlayer space communicated with a fine powder outlet, a coarse powder outlet and an air inlet which are mutually separated, the bottom end of the blocking interlayer box body is arranged on a positioning front edge on the upper end face of a lower bearing seat, and the top end of the blocking interlayer box body is provided with a positioning front edge and embedded and fixed with the bottom surface of an upper bearing seat through the positioning front edge. One set of mechanism is shared in mounting a lining plate and supporting the upper bearing seat and the lower bearing seat of a mounting main shaft, thus the supporting bracket has the advantages of simple and compact structure, stable and reliable operation, convenience for mounting and maintaining, small equipment volume, low manufacture cost and small vibration noise.

Owner:XIANGTAN XIANGKE MECHANICAL & ELECTRICAL EQUIP

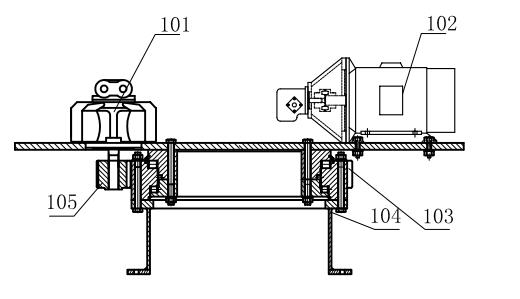

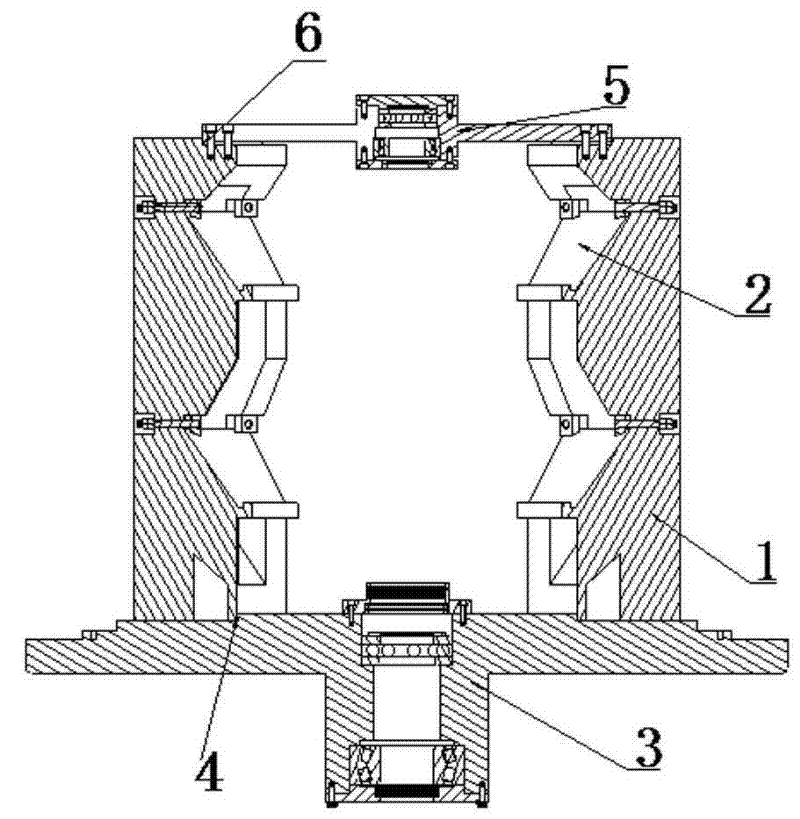

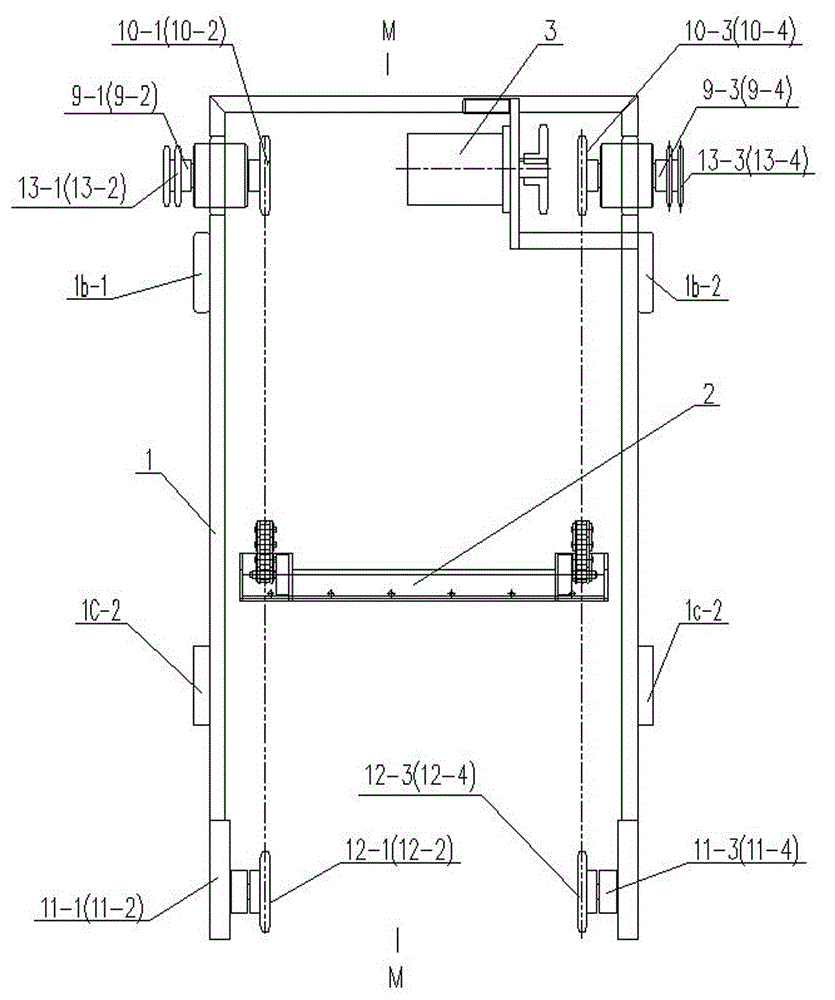

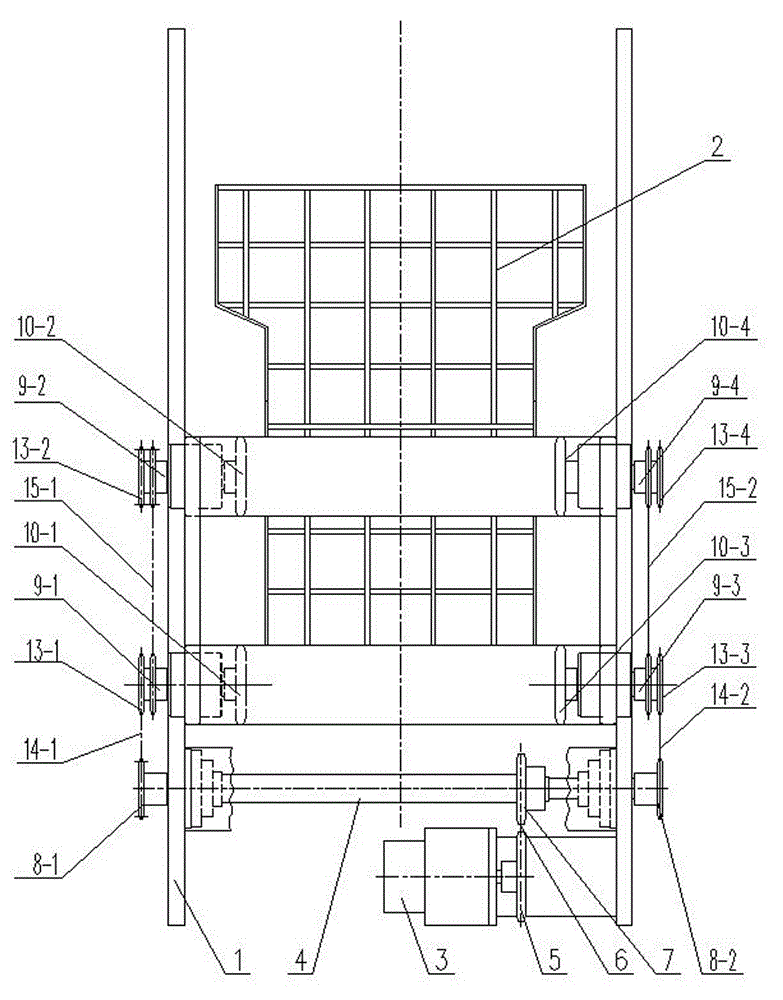

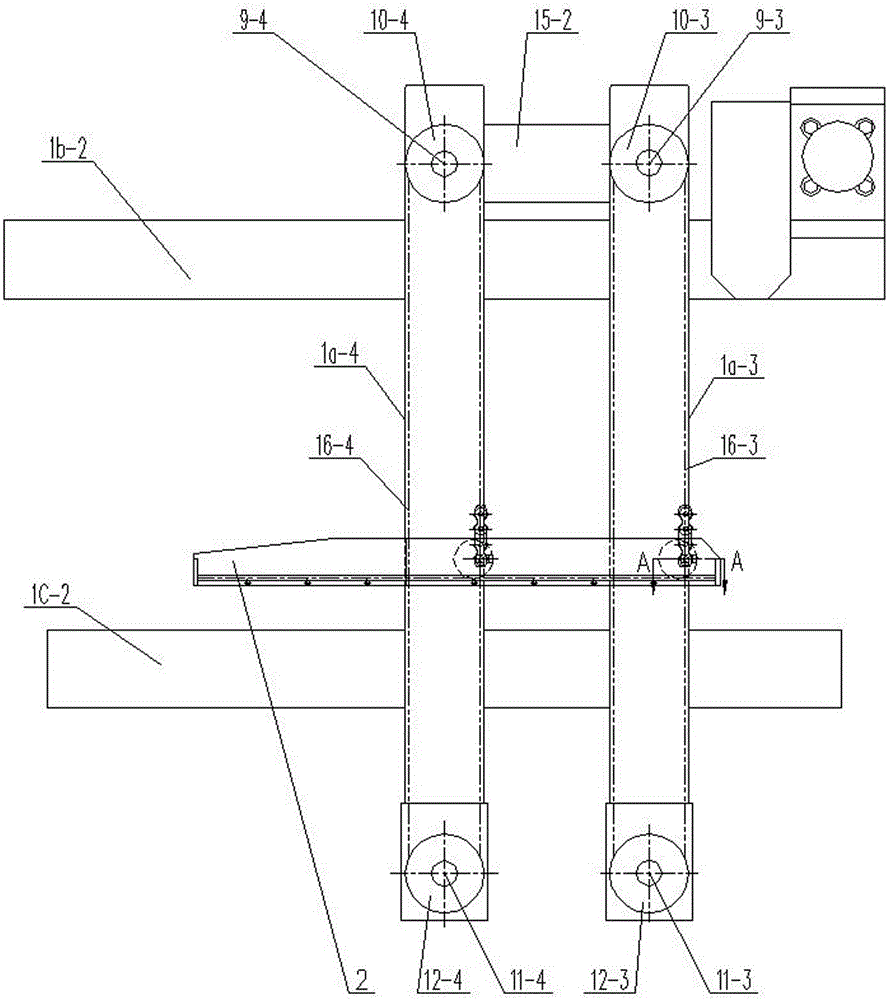

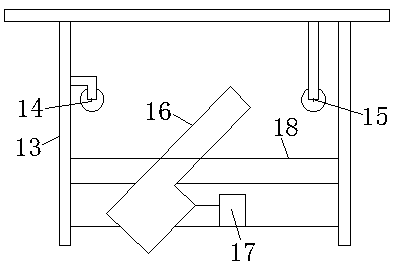

Device for picking tobacco leaf from top to bottom of tobacco plant

The invention relates to a device for picking tobacco leaves from the top to the bottom of a tobacco plant. The device comprises a gantry hanger (1), a grid-type horizontal leaf falling framework (2) which is arranged in the hanger, a chain wheel system which drives the leaf falling framework to move up and down, and a driving device (3) which is used for driving the chain wheel system to move forwards and reversely. The leaf falling framework (2) is respectively connected with the chain wheel system through four connecting bases (18). The four connecting bases are respectively and fixedly connected with the frame of the leaf falling framework (2). A chain system drives the horizontal leaf falling framework (2) to move up and down, so as to take down and pick the tobacco leaves during downward movement. The device for picking tobacco leaves from the top to the bottom of the tobacco plant has the advantages of simple structure, lower production cost, high picking efficiency and high full picking rate.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

Intensive bus duct

ActiveCN102751685APrecise calculation of deformation parametersClose contactCooling bus-bar installationsPartially enclosed bus-bar installationsInsulation layerEmbedded system

The invention relates to an intensive bus duct which comprises a left connecting body side cover plate, a right connecting body side cover plate, reinforcing rib seal plates, a bus bar and an insulation layer; the bus bar is coated with the insulation layer and then is arranged between the left connecting body side cover plate and the right connecting body side cover plate; the left connecting body side cover plate and the right connecting body side cover plate are formed into the whole intensive bus duct by rolling and riveting through special riveting equipment; and the reinforcing rib seal plates are fixedly arranged on the upper neck and the lower neck of the whole intensive bus duct formed by the left connecting body side cover plate and the right connecting body side cover plate. According to the intensive bus duct, the product structure is simple, the number of parts is minimized, the production process is simplified, assembly procedures are simple, the transportation and the installation are convenient, the operation effect is reliable, and the heat dissipation performance is excellent.

Owner:江苏华鹏电力设备股份有限公司

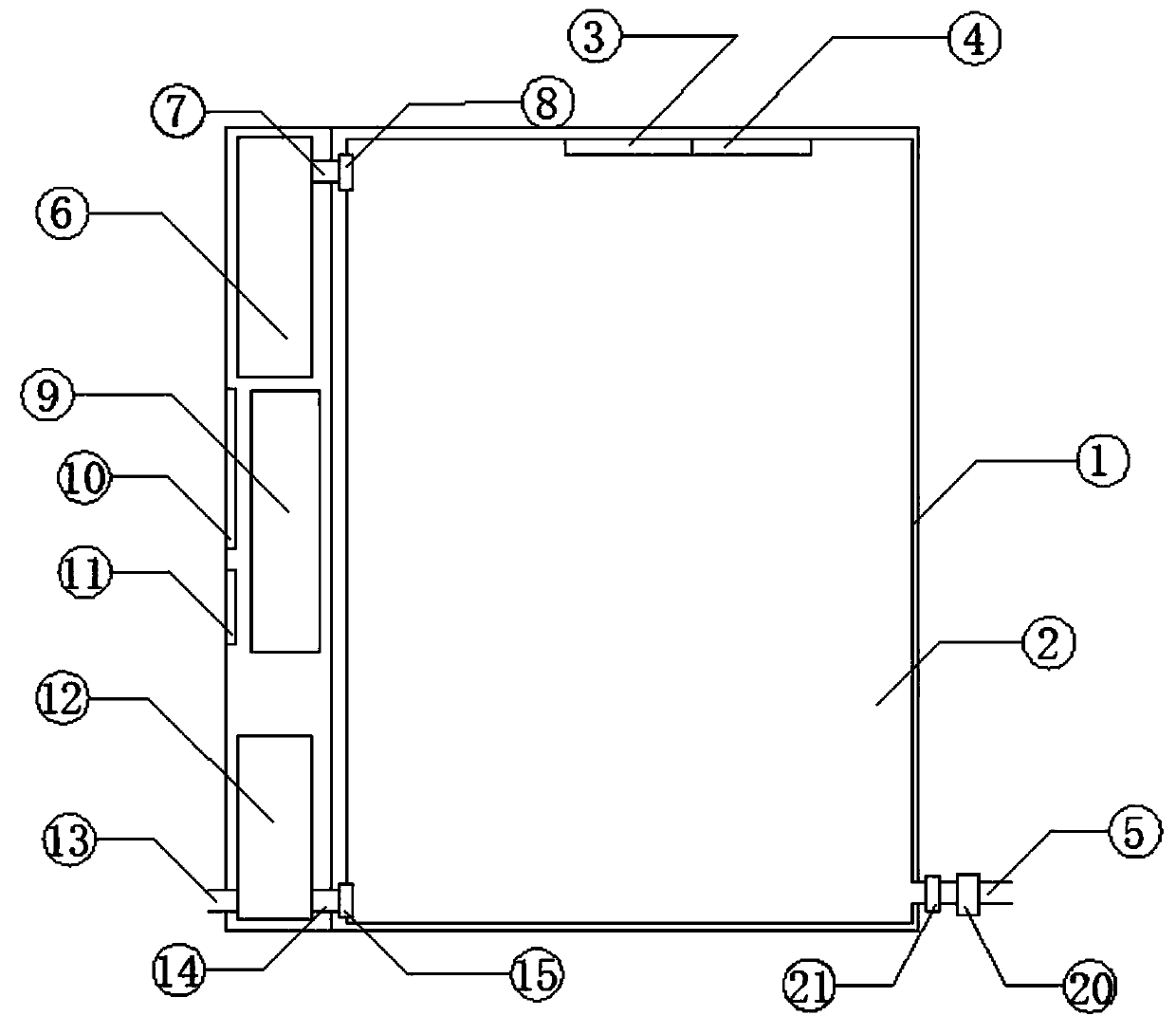

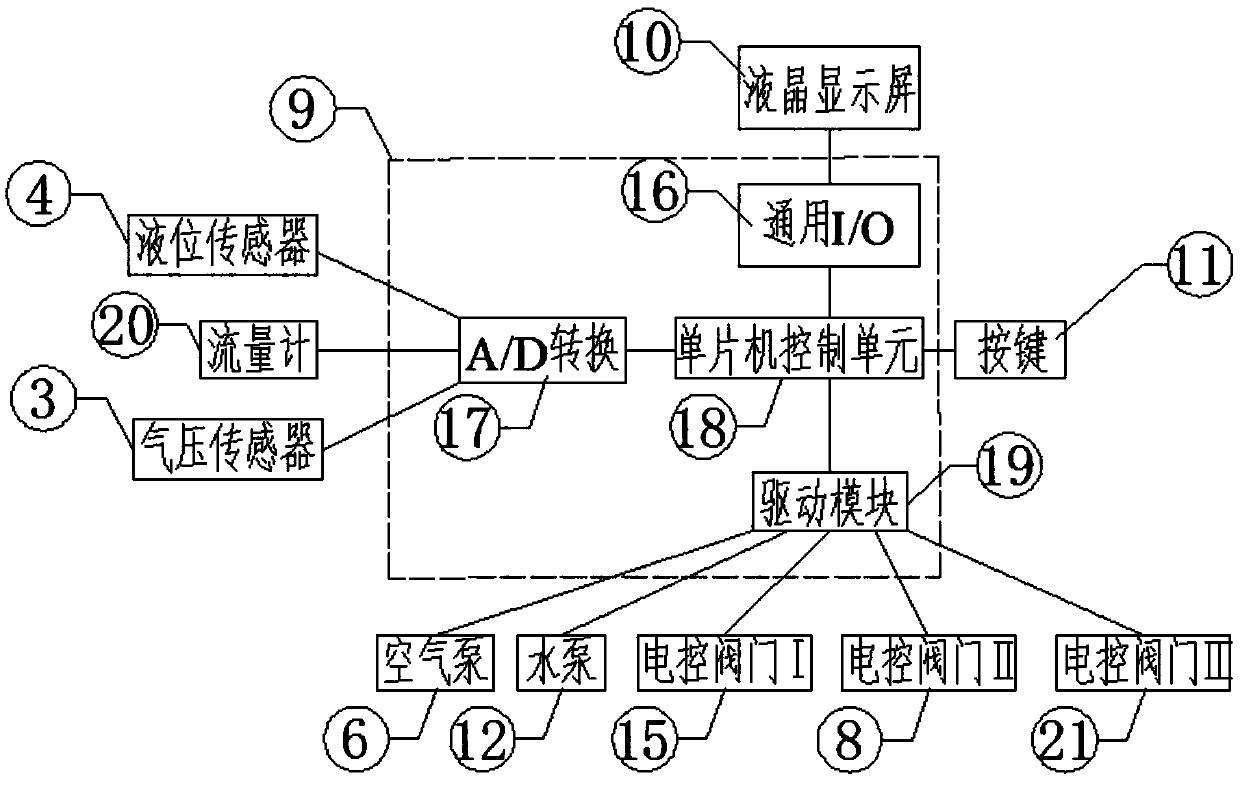

Full-automatic controllable waterhead constant-flow water supply device

PendingCN107630489ACreate novel structuresCreate a reasonable structureService pipe systemsPump controlInstabilityAir pump

The invention discloses a full-automatic controllable waterhead constant-flow water supply device, and belongs to civil engineering experimental apparatuses. Through cooperation of a circuit assembly,an air pump, a water pump, a plurality of electric control gates and all kinds of sensors, the device achieves flexible setting and a corresponding capability of stabilizing waterhead and prevents the defects that the waterhead is supplied unstably by traditional Mariotte bottles and the traditional Mariotte bottles cannot be used in a high temperature environment; the device is novel, reasonableand simple in structure, easy and convenient to operate, low in labor intensity, high in precision, stable and reliable during operation and running and capable of achieving automated operation, reducing operator number and ensuring the stable waterhead required by mating experiments.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

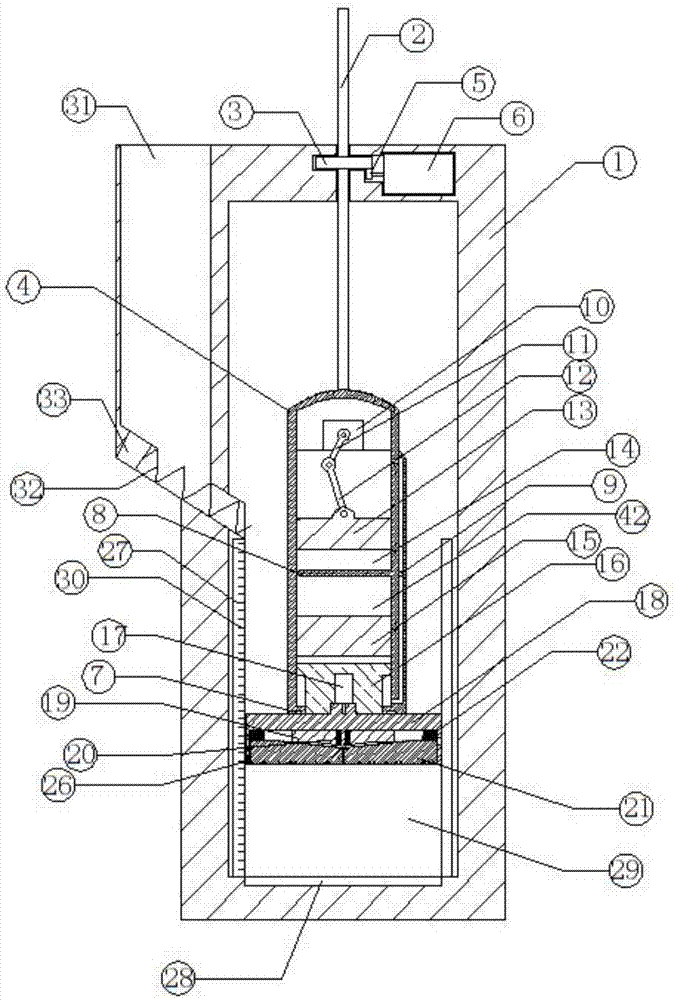

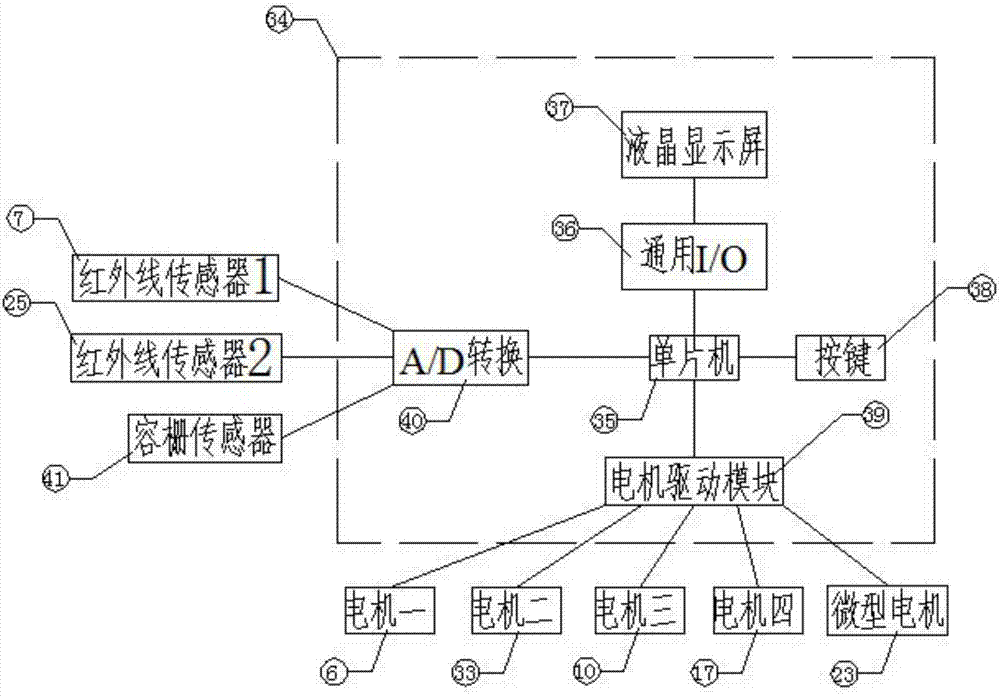

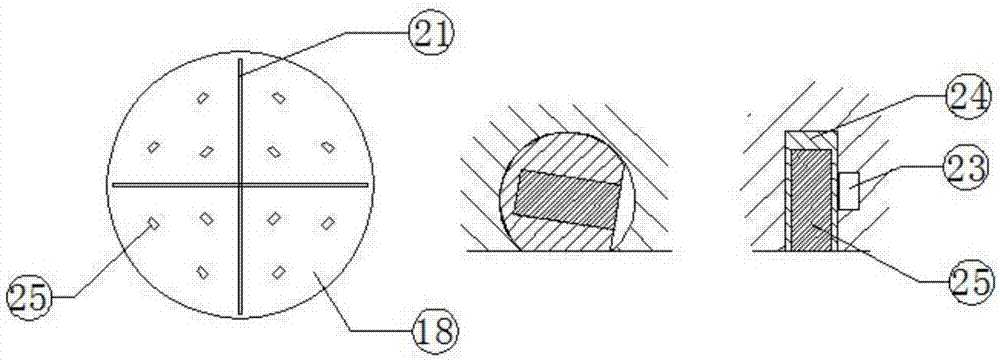

Full automatic soil saturation device

ActiveCN106908296ACreate novel structuresCreate a reasonable structureClimate change adaptationPreparing sample for investigationSoil scienceAgricultural engineering

A full automatic soil saturation device belongs to civil engineering experimental instruments; the full automatic soil saturation device is matched with a plurality of motors and all kinds of a plurality of sensors by a circuit assembly to realize automatic filling and piecewise compaction functions, by a rotary build-in blade, each stage of soil material compaction surface can be polished, the combination is more natural and more uniform; the full automatic soil saturation device is novel, reasonable and simple in structure, can realize automated operation, operation is simple and convenient, operating staff can be saved, labor intensity is low, soil sample preparation precision is high, and operation is stable and reliable.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

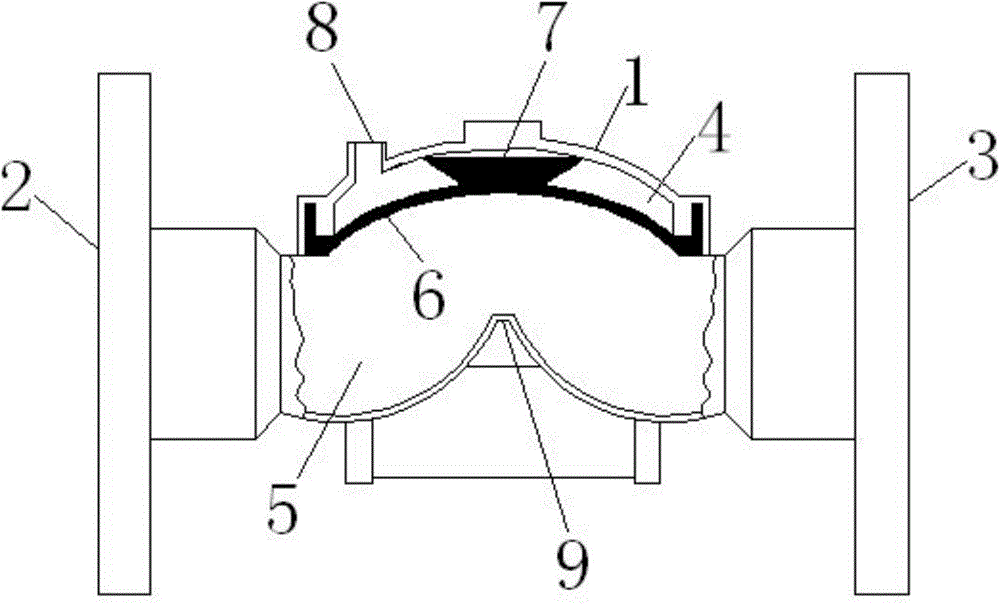

Novel V-type diaphragm valve

InactiveCN105485369AThe overall structure is simpleStable and reliable operationDiaphragm valvesEngine diaphragmsCorrosionEngineering

The invention relates to a novel V-type diaphragm valve. The novel V-type diaphragm valve comprises a diaphragm valve body, wherein one end, in a horizontal direction, of the diaphragm valve body is a water inlet, and the other end of the diaphragm valve body is a water outlet; the middle part of the diaphragm valve body is provided with a control cavity; a running water channel is arranged below the control cavity; a rubber diaphragm is arranged in the control cavity; a spring is arranged between the rubber diaphragm and a position above the control cavity; a hydraulic or gas pressure control opening is formed in the upper part of the control cavity; a waterproof lug boss is arranged at the inner side of the lower part of the control cavity; and the two ends of the rubber diaphragm are arranged within the wall of the diaphragm valve body. The novel V-type diaphragm valve is simple in structure, is good in corrosion resistance, is stable and reliable to operate, is low in manufacturing cost and is less in daily maintenance quantity.

Owner:江苏开能华宇环保设备有限公司

Angle steel flange machine for fence

InactiveCN110856966ALow elastic shock absorption effectGood elastic shock absorptionNon-rotating vibration suppressionMachineEnergy consumption

The invention discloses an angle steel flange machine for a fence. The angle steel flange machine comprises a machine base, a movable pressing wheel, a fixed pressing wheel, a speed reducer, a variable-speed motor, a first-stage coupler and a second-stage coupler. The movable pressing wheel is arranged at one end of the machine base, the movable pressing wheel is arranged at the upper end of the machine base, the fixed pressing wheel is arranged on one side of the movable pressing wheel, the movable pressing wheel and the fixed pressing wheel are in transmission connection, a buffer anti-skidlayer is pasted at the bottom end of the machine base, the first-stage coupler is arranged at the other end of the machine base, and the first-stage coupler and the speed reducer are in transmission connection. The faults are fewer, and the angle steel flange machine is high in mechanical efficiency, long in service life, reliable and stable in operation, low in noise, convenient to dismount and mount, easy to maintain, high in bearing capacity, low in energy consumption and good in economical efficiency. The buffer anti-skid layer is pasted at the bottom end of the machine base, the buffer anti-skid layer is of an integrally-formed structure formed by injection molding of polyurethane rubber, the anti-skid performance of the polyurethane rubber is extremely good, the elastic damping effect is good, the overall fixity of the structure can be effectively guaranteed, and the machine base can be effectively prevented from moving.

Owner:刘浩荫

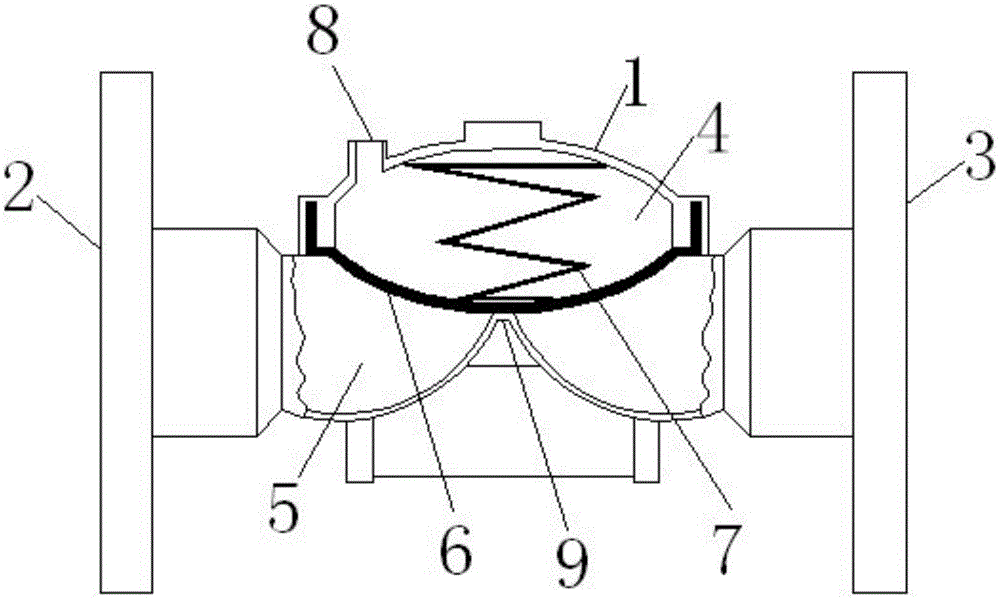

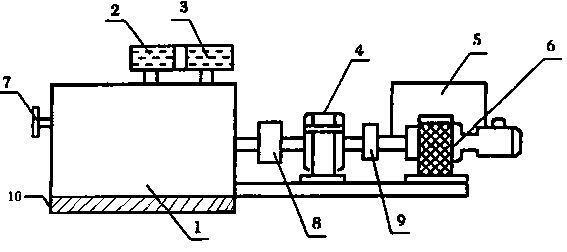

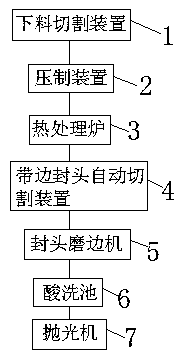

Band edge sealing head production system

PendingCN107756048AStable and reliable operationAutomate operationOther manufacturing equipments/toolsSensor holderEngineering

The invention relates to a band edge sealing head production system. The band edge sealing head production system sequentially comprises a feeding and cutting device, a pressing device, a heat treatment furnace, a band edge sealing head automatic cutting device, a sealing head edge grinding machine, an acid pickling pond and a polishing machine. The band edge sealing head automatic cutting devicecomprises a cutting support, a telescopic supporting table is arranged in the middle of the bottom face of the cutting support, and a workpiece locating inductor is arranged on the upper portion of the cutting support. The band edge sealing head production system achieves automatic operation and is stable and reliable in operation and high in work efficiency.

Owner:宜兴市九洲封头锻造有限公司

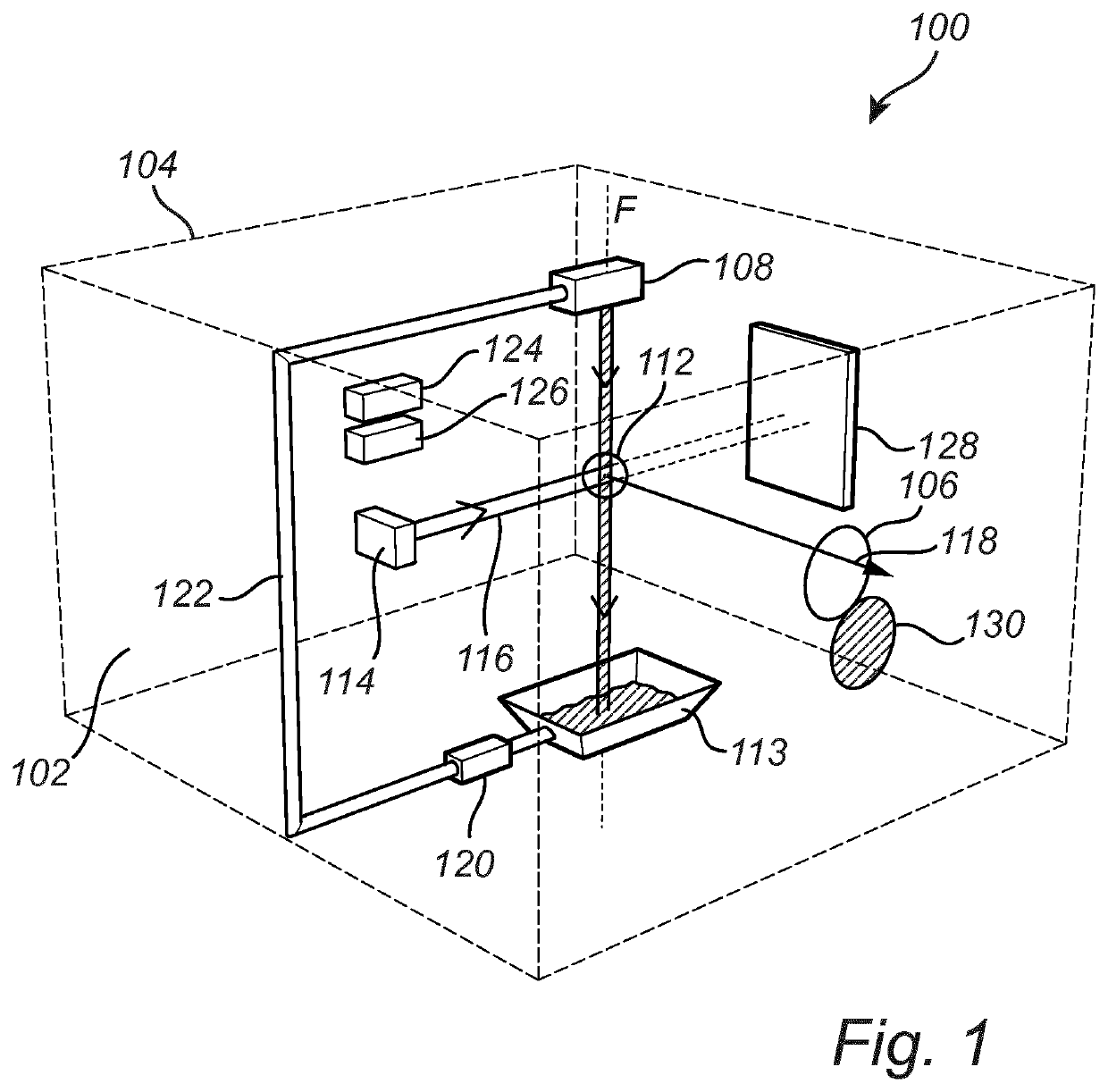

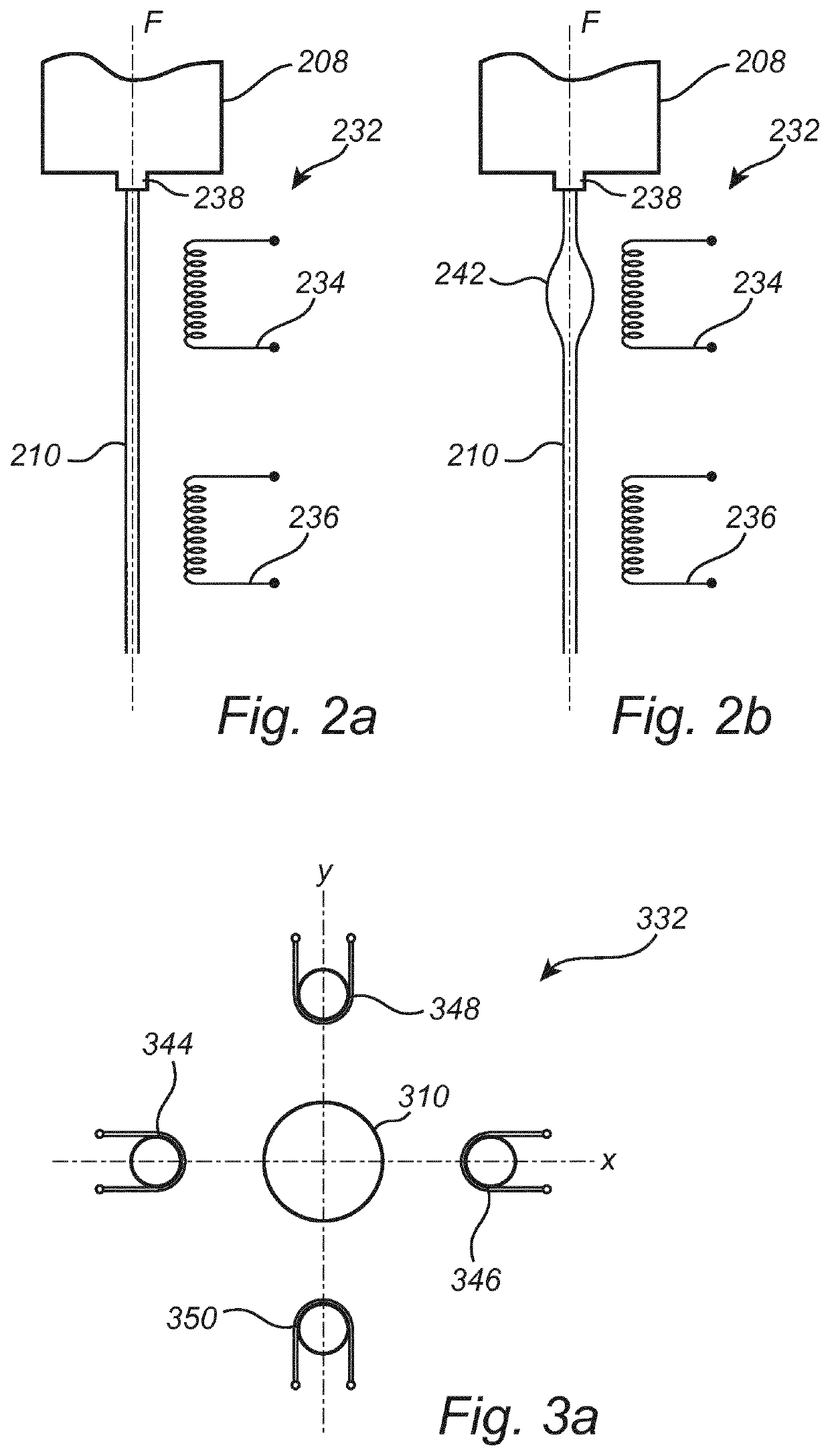

A method for protecting an x-ray source and an x-ray source

ActiveUS20200367351A1Stable and reliable operationLower performance requirementsX-ray tube with very high currentX-ray apparatusLiquid jetQuantum electrodynamics

A method for protecting an X-ray source including: a liquid jet generator configured to form a liquid jet moving along a flow axis; an electron source configured to provide an electron beam interacting with the liquid jet to generate X-ray radiation; the method including: generating the liquid jet: monitoring a quality measure indicating a performance of the liquid jet; identifying, based on the quality measure, a malperformance of the liquid jet; and if said malperformance is identified, causing the X-ray source to enter a safe mode for protecting the X ray source. Further, to corresponding devices.

Owner:EXCILLUM

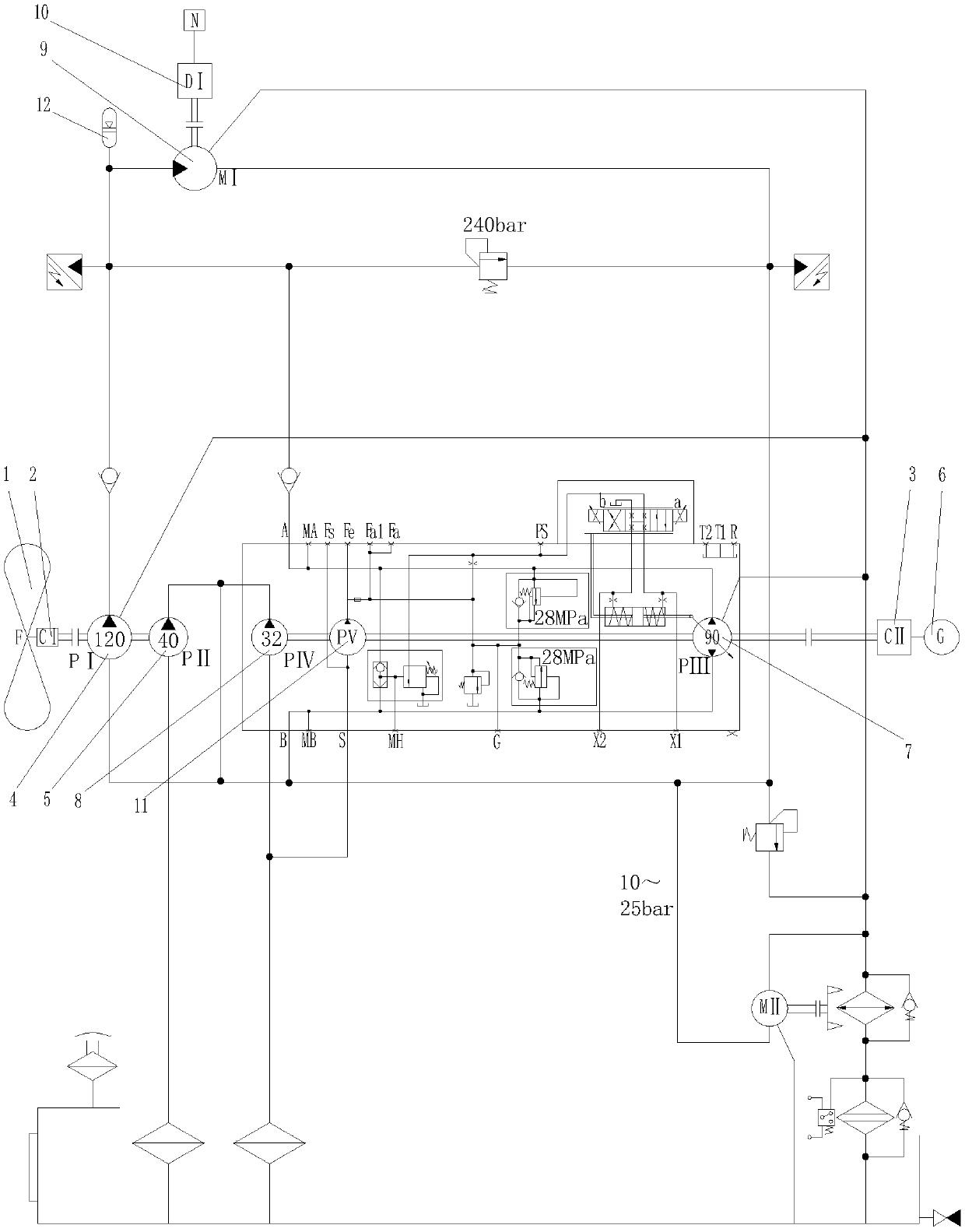

Hydraulic system generating electricity by comprehensively utilizing bioenergy and wind energy

InactiveCN108679189AReasonable structureEconomical and reliable operationEnergy industryWind motor combinationsElectricityHydraulic motor

The hydraulic system generating electricity by comprehensively utilizing bioenergy and wind energy is a closed hydraulic system and comprises a large windmill F, a speed increasing gearbox CI, a speedreduction gearbox CII, a first hydraulic pump PI, a second hydraulic pump PII, a biomass turbine G, a third hydraulic pump PIII, a fourth hydraulic pump PIV, a hydraulic motor MI, a generator DI, a fifth hydraulic pump PV, an incremental encoder, a PLC controller, a hydraulic oil tank, a filter, an energy accumulator and corresponding connectors. The first hydraulic pump PI and the third hydraulic pump PIII together supply oil to the hydraulic motor MI so as to drive the hydraulic motor MI to drive the generator set DI to generate electricity. During operation, the rotational speed of the generator DI is detected by the PLC controller in real time through the incremental encoder, and the displacement of the third hydraulic pump PIII is adjusted by the PLC controller in real time accordingto the detected rotational speed of the generator DI, so that the randomness and uncertainty when the large windmill F drives the first hydraulic pump PI to provide flow are offset.

Owner:INI HYDRAULIC

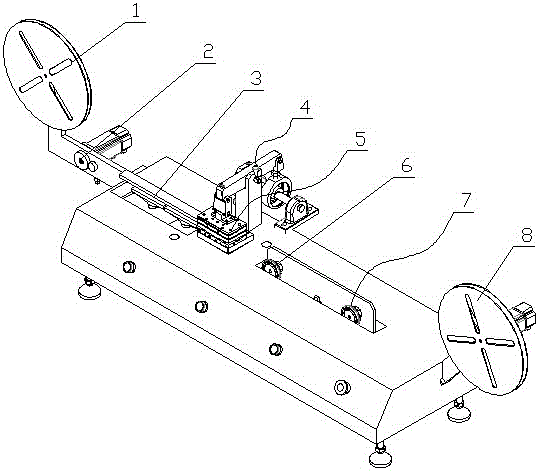

Molding device for high-precision plastic carrier tape product

PendingCN107433711AEasy to stretch and formOvercome molding inconsistenciesBeltsManufactured materialMechanical engineering

The invention discloses a molding device for a high-precision plastic carrier tape product. A feeding mechanism, an actuating mechanism and a constant-speed drawing mechanism are arranged sequentially between a raw material tray and a material collecting tray, wherein heating blocks are arranged between the feeding mechanism and the actuating mechanism; one end of the actuating mechanism is fixed on a worktable, and the lower part of the other end of the actuating mechanism is connected with a mold; the actuating mechanism comprises a support upright column, a rocker link, a mold hoisting device and a travel adjusting device; the mold comprises an upper mold assembly and a lower mold assembly; the upper mold assembly comprises a face plate, an upper mold seat and an upper mold unloading plate; the lower mold assembly comprises a cavity plate, a lower mold unloading block and a lower mold unloading block fixing plate; an unloading fixing plate ejection pin is arranged on the lower mold unloading block fixing plate; and an unloading plate jacking spring is arranged at the lower part of the lower mold unloading block fixing plate and fixed on an equipment bottom plate at the lower part of the worktable. The molding device for the high-precision plastic carrier tape product is simple in structure, easy to operate and stable in quality, raw materials are uniformly heated and is good in molding consistency, so that stretching sinking of edge lines is avoided.

Owner:苏州英士力精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com