Dished wire distributing wheel for circular weaving machine

A technology of splitting wheel and circular loom, which is applied to circular looms, looms, textiles, etc., can solve the problems that affect the normal operation of the shuttle running mechanism as a whole circular loom, and achieve the effect of stable and reliable operation and compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

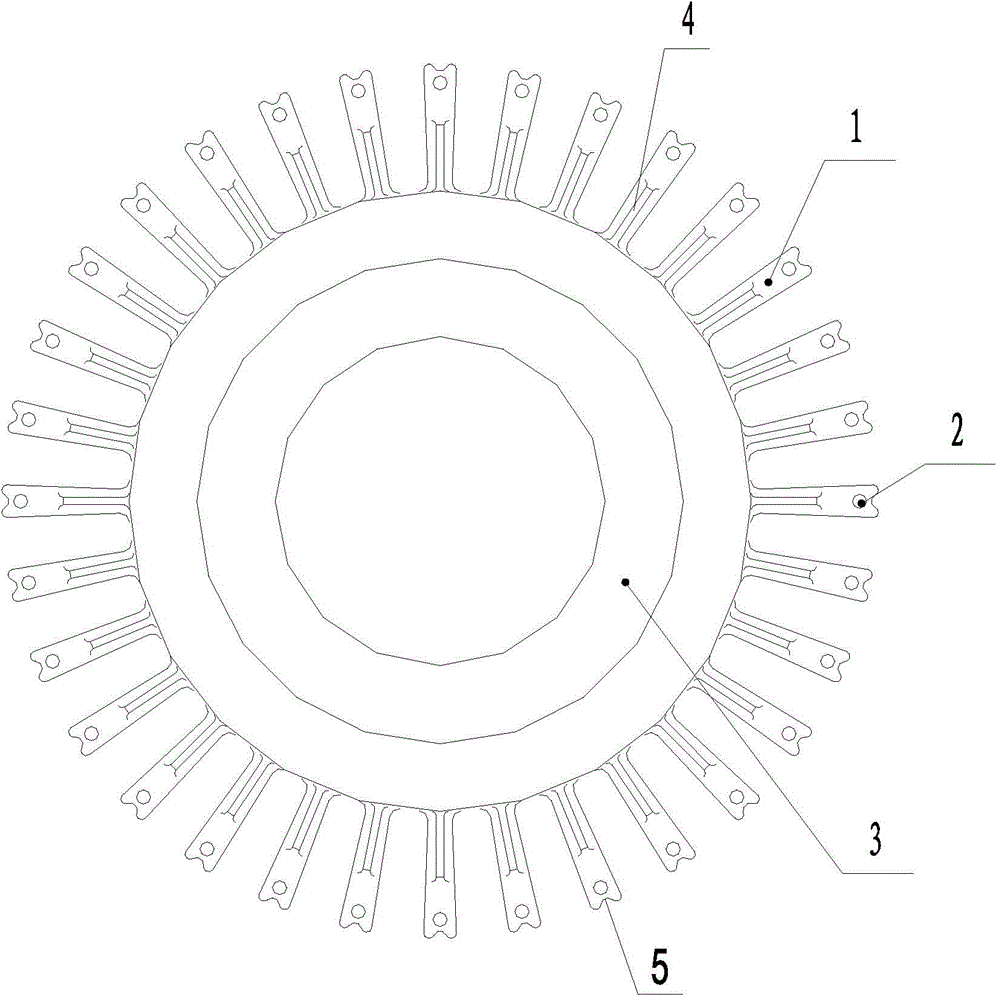

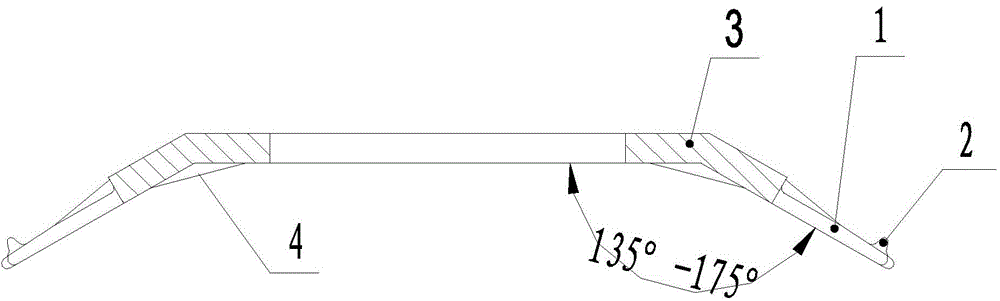

[0016] like figure 1 and figure 2 As shown, the dish-shaped wire splitting wheel of the circular loom includes a wheel body 3 and a wire splitting branch 1, the wheel body 3 is set as a ring, the center of the wheel body 3 is provided with a central hole, and the outer circumference of the wheel body 3 is provided with Several branching branches 1 form an angle between the branching branch 1 and the wheel body 3 after being bent, and the included angle is greater than 90 degrees and less than 180 degrees.

[0017] In this embodiment, the included angles between all branching branches 1 of the outer circumference of the wheel body 3 and the wheel body 3 are equal, and the preferred value of the included angle is 135 degrees to 175 degrees. The thread branching branch 1 forms a tapered surface, so that the thread branching wheel is in a dish shape as a whole. In this embodiment, the end of the branch branch 1 is provided with a conical positioning tooth 2 , a reinforcing rib ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com