Waste modulator tube treatment recovery system and technology

A recycling system and lamp technology, applied in lamp tube/lamp material recycling, electronic waste recycling, defective lamp tube/lamp repair/regeneration, etc., can solve the problem that fluorescent powder and mercury vapor cannot be reused, and waste can not be sorted Recycling, low efficiency and other issues, to achieve stable and reliable performance, improve efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

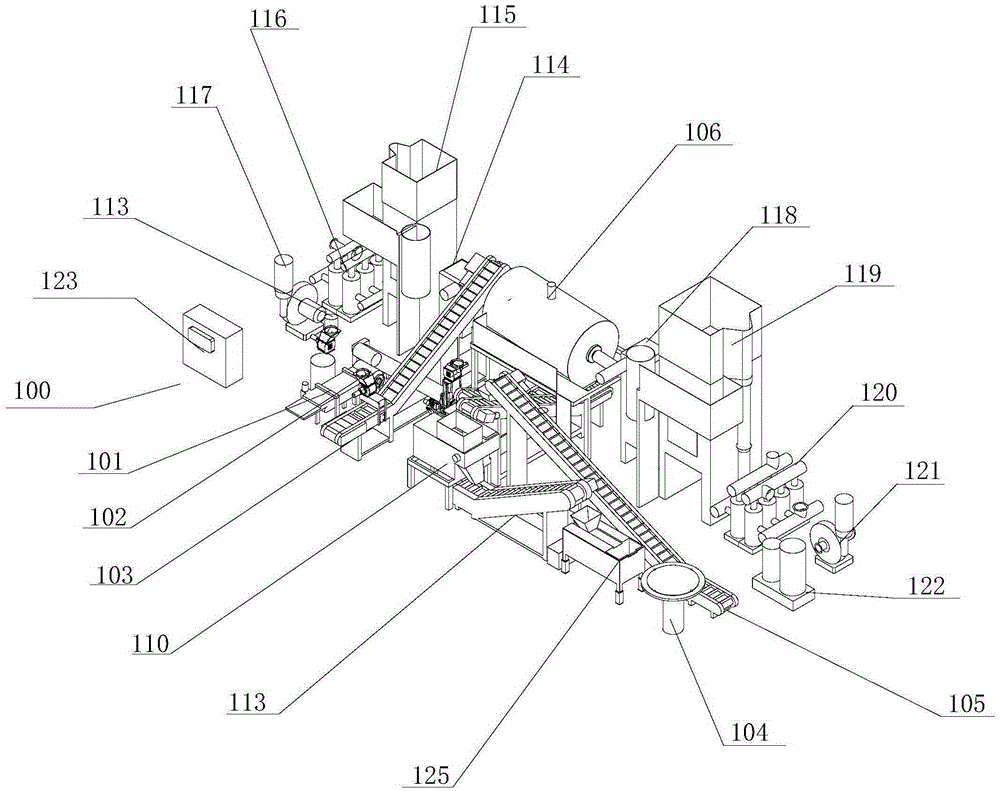

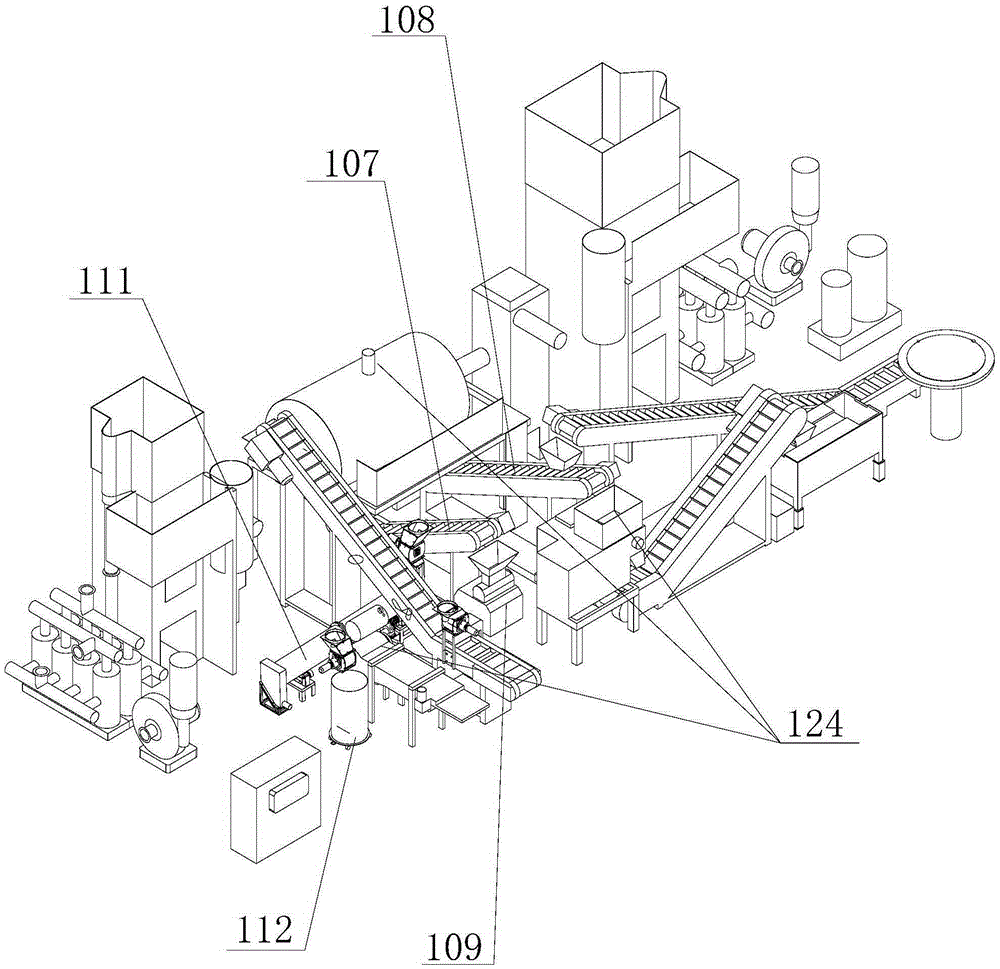

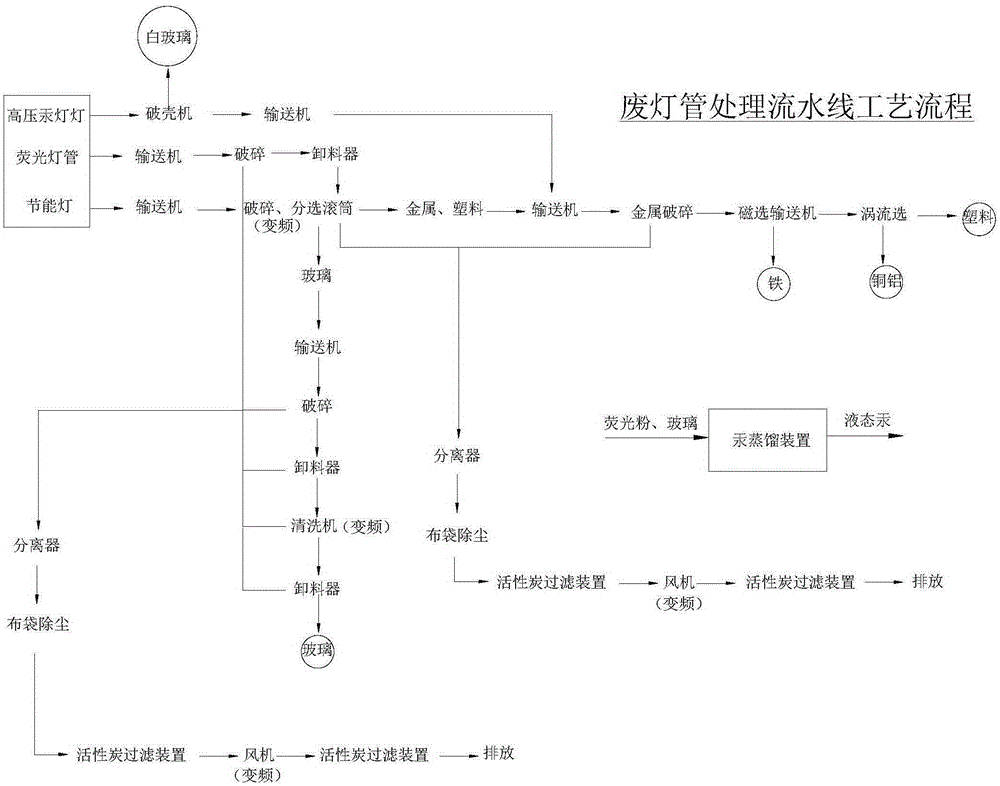

[0047] See figure 1 with figure 2 , Which shows a schematic diagram of the waste lamp tube processing and recycling system 100 provided by the present invention. It can be seen from the figure that the entire recycling system mainly consists of three feeding units, a crushing and sorting unit, a metal crushing unit, a non-ferrous metal sorting unit, a cleaning unit, two sets of hazardous material recovery units and a control cabinet.

[0048] Among them, the three types of feeding units include a first feeding unit, a second feeding unit, and a third feeding unit.

[0049] The first feeding unit is used for conveying fluorescent tubes, and preliminarily crushing the fluorescent tubes, and transporting the crushed fluorescent tubes to the crushing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com