Method for arranging rolling-friction stretching and retraction based rolling stroke sections of a rocker arm in parallel, and an excavator or loader comprising a rocker arm having rolling stroke sections arranged in parallel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Embodiment 1

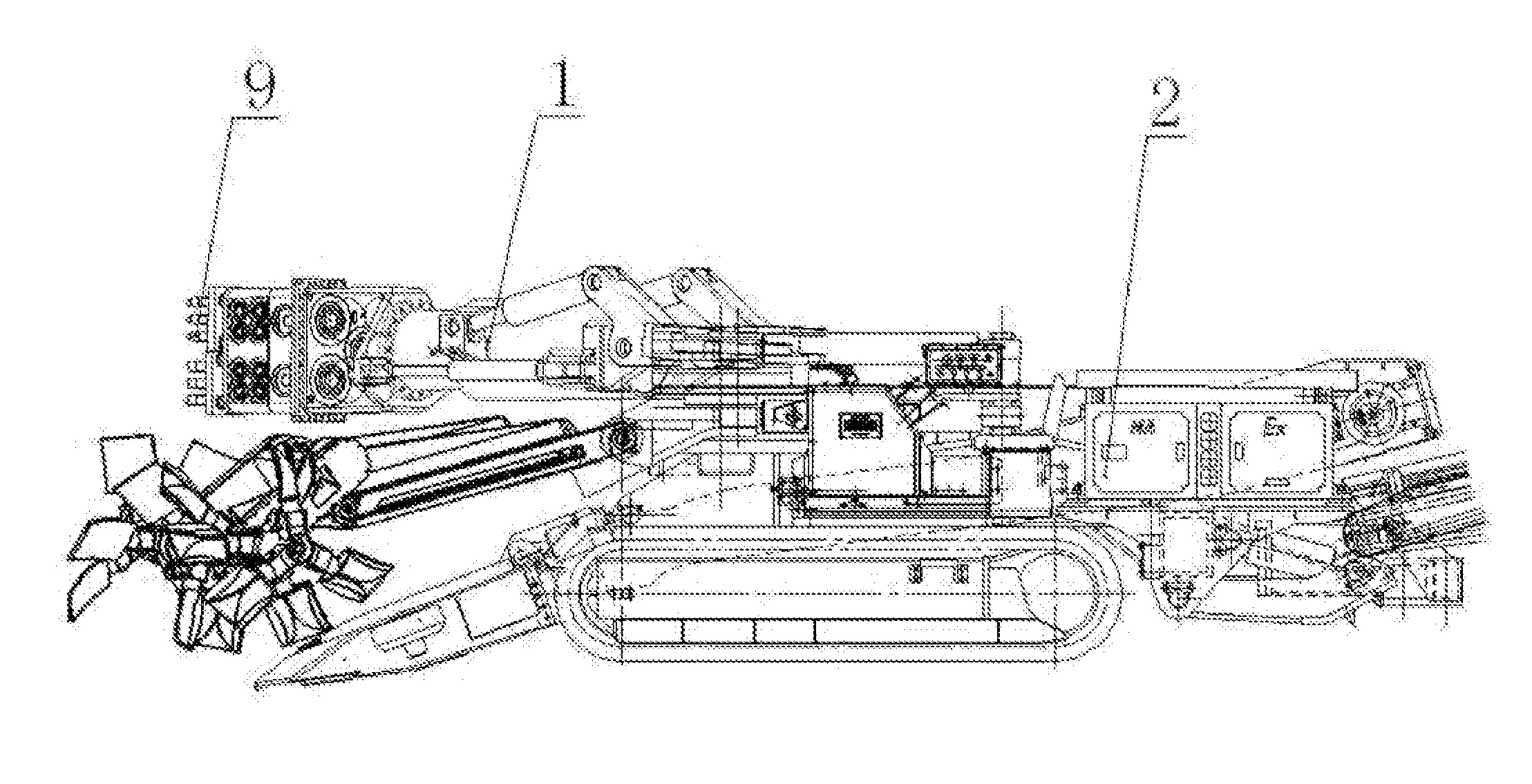

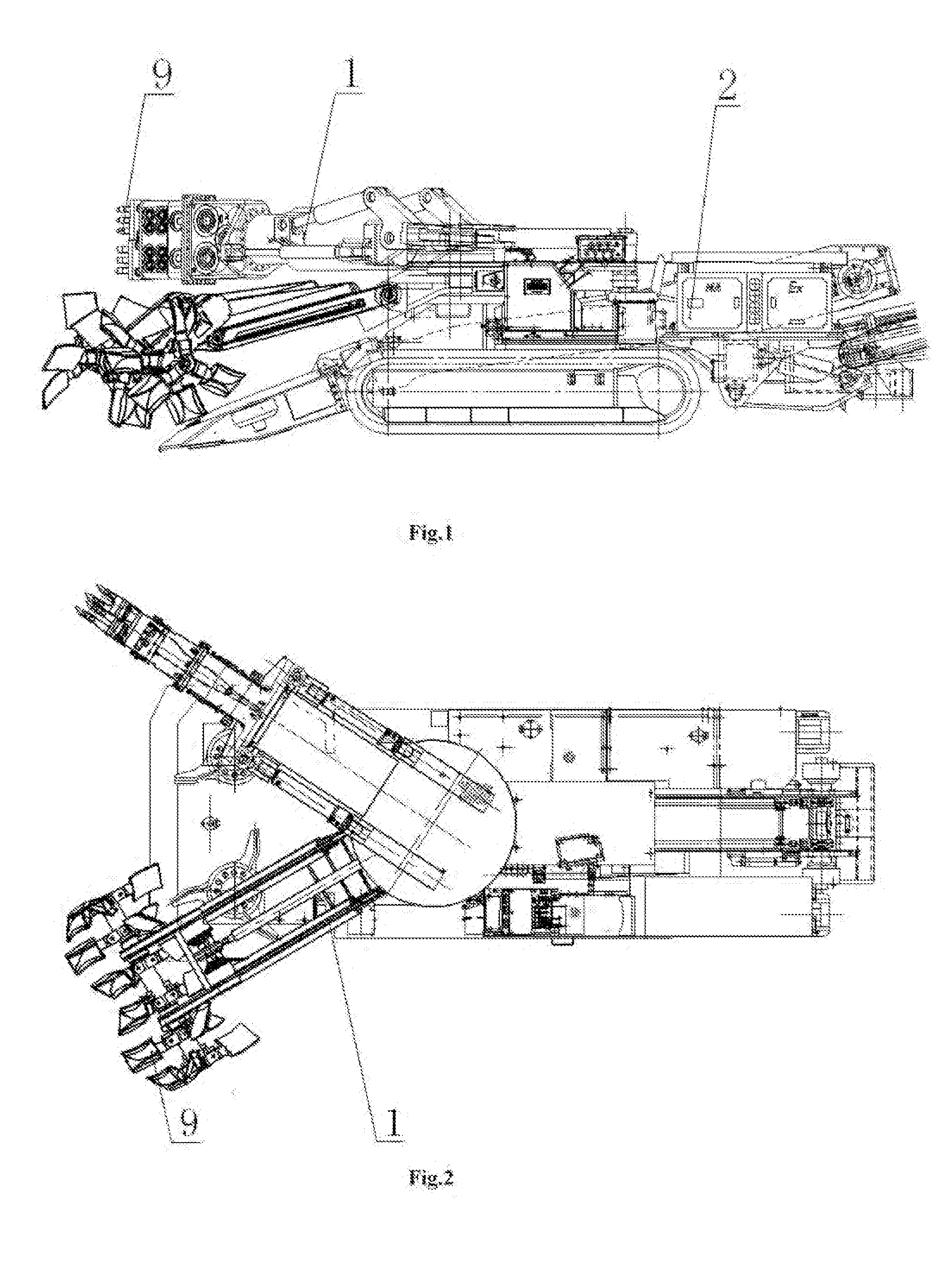

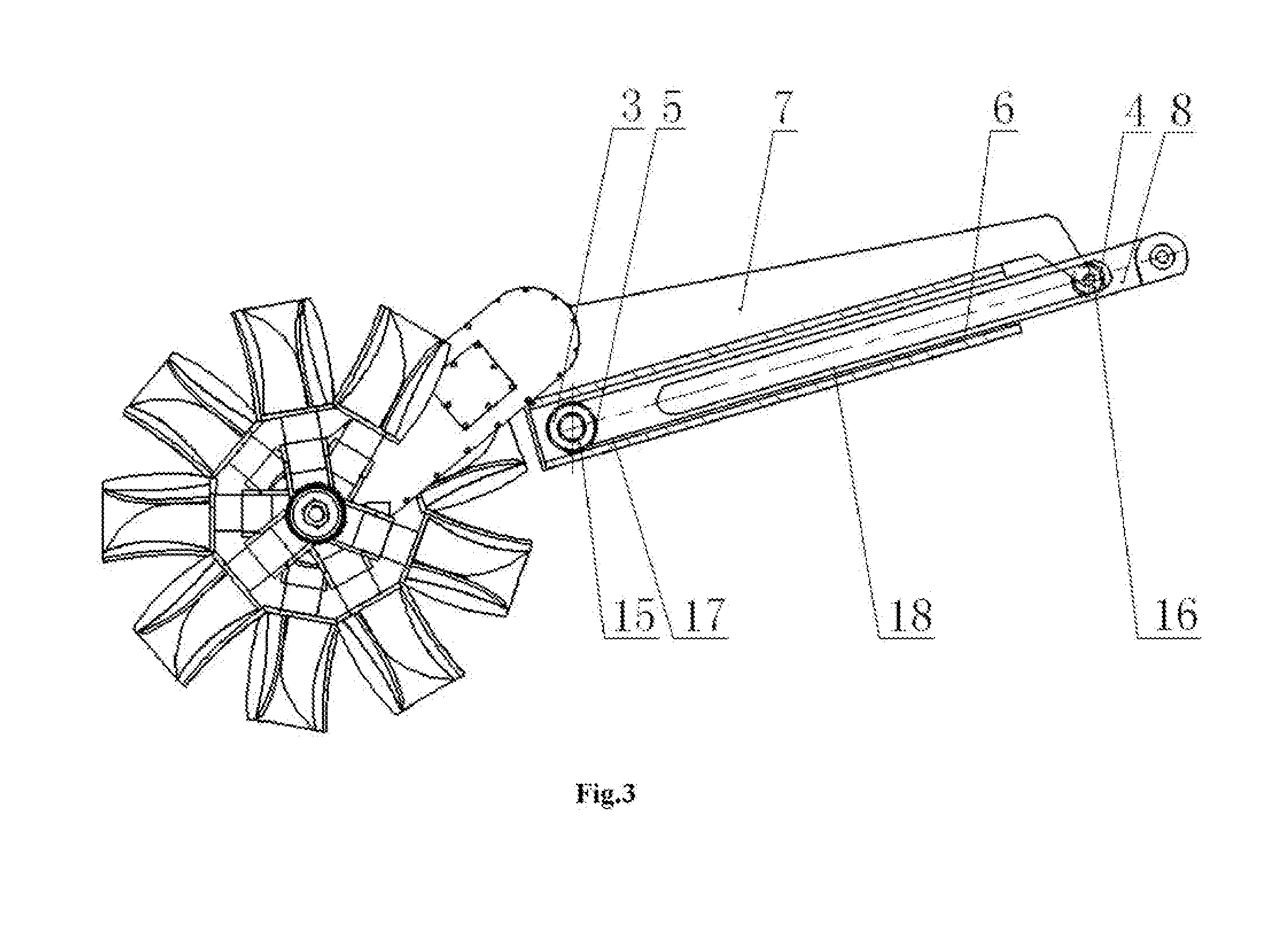

[0097]An excavator or loader comprising a rocker arm having rolling stroke sections arranged in parallel, as shown in FIGS. 1-3, is characterized in that: the excavator or loader having rolling stroke sections arranged in parallel comprises a rocker arm 1, a machine body 2, a work head 9, etc.; the rocker arm 1 is mainly composed of a front roller 3, a rear roller 4, a front roller rollaway 5, a rear roller rollaway 6, a telescopic arm 7, a telescopic support arm 8, etc.; the front roller rollaway 5 is disposed on the telescopic arm 7; the rear roller rollaway 6 is disposed on the telescopic support arm 8; the front roller 3 is disposed on the telescopic support arm 8; the rear roller 4 is disposed on the telescopic arm 7; the front roller rollaway 5 and the rear roller rollaway 6 are arranged in parallel; the front roller 3 rolls in the front roller rollaway 5, and the rear roller 4 rolls in the rear roller rollaway 6; the front roller 3 coordinates with the rear roller...

Example

Embodiment 2

[0114]As shown in FIG. 4 and FIG. 5, the excavator or loader comprising a rocker arm having rolling stroke sections arranged in parallel shown in embodiment 2 is different from that in embodiment 1 in that: the work head 9 comprises a rolling harrow 11, or a reciprocating impact head 10, or a bucket, or a scraper box, or a cutting drum, or a crushing head, or a combination of the reciprocating impact head 10 and the bucket, or a combination of the rolling harrow 11 and the scraper box, or a combination of the rolling harrow 11 and the reciprocating impact head 10, or the like.

[0115]The others are the same as those in embodiment 1.

Example

Embodiment 3

[0116]As shown in FIG. 6 and FIG. 7, the excavator or loader comprising a rocker arm having rolling stroke sections arranged in parallel shown in embodiment 3 is different from that in embodiment 1 in that: the rocker arm 1 comprises a rolling harrow rocker arm 12, or a reciprocating impact head rocker arm 13, or an excavating / loading rocker arm 14, or a combination of the rolling harrow rocker arm 12 and the reciprocating impact head rocker arm 12, or a combination of the reciprocating impact head rocker arm 13 and the scraper box rocker arm, or the like.

[0117]The others are the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com