Penetrating type worm wheel

A penetrating, turbine technology, applied in the field of steam turbines, can solve the problems of large vibration, large eddy current between disks, insufficient rigidity, etc., and achieve the effect of increased power and stable and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

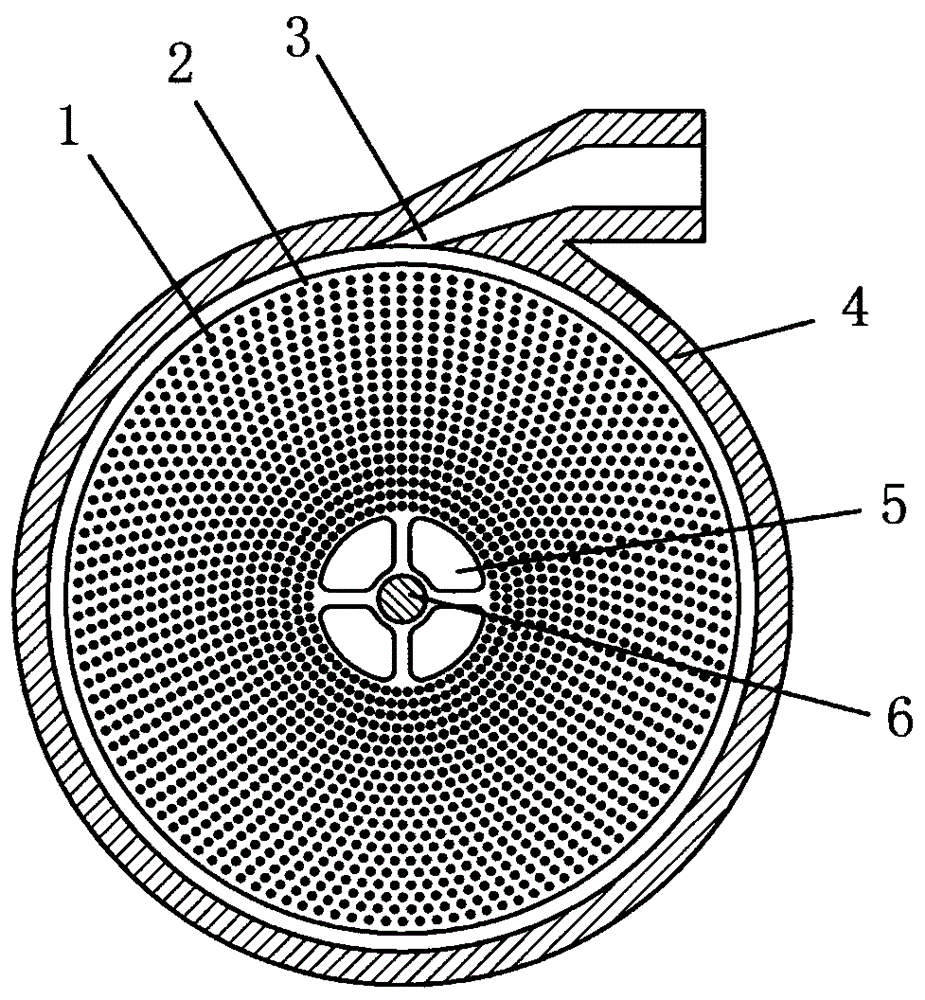

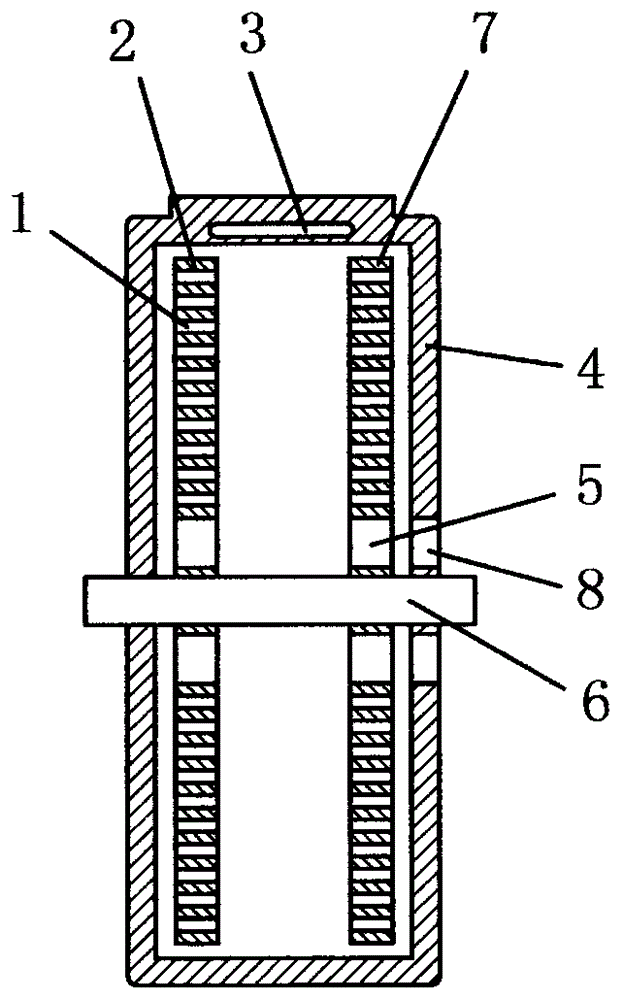

[0010] exist figure 1 with figure 2 Among them, there is a nozzle (3) on the casing (4), and there is a rotor inside the casing (4). The rotor is composed of a disc-shaped blade (2) and a disc-shaped blade (7) fixed on the rotor shaft (6). The air vents (1) are densely covered with the disc-shaped blades, and the center of the disk-shaped blades has an air vent (5), and the vent (5) is directly facing the exhaust port (8) on the housing (4).

[0011] When working, the gas is sprayed into the housing (4) from the nozzle (3), and the air flow will form a vortex between the disc-shaped blades (2) and the disc-shaped blades (7) under the guidance of the inner side of the housing (4), The vortex drives the disk-shaped blade (2) and the disk-shaped blade (7) to rotate together, so as to realize the rotation of the rotor, and the exhaust gas after work is passed from the exhaust hole (5) in the center of the disk-shaped blade to the exhaust port (8) discharge.

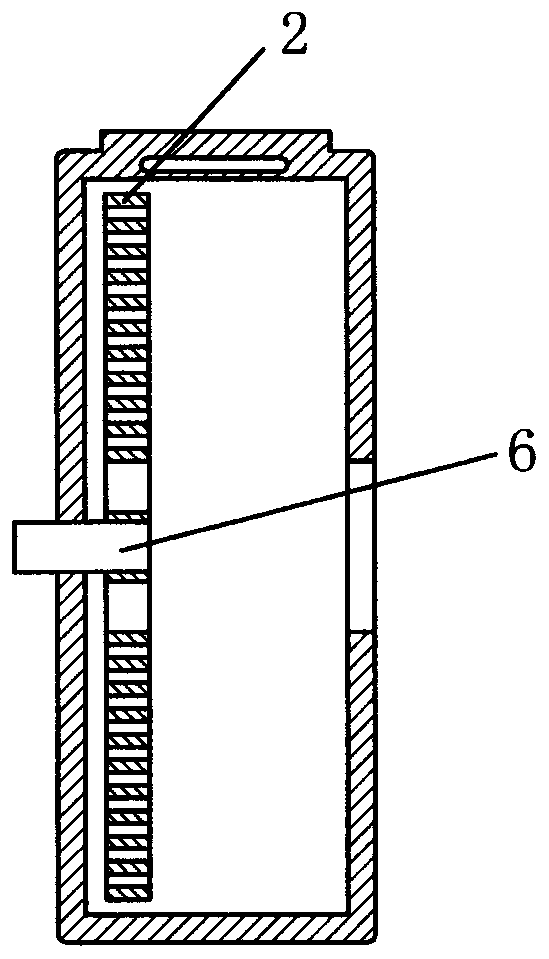

[0012] image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com