Patents

Literature

52 results about "Tesla turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

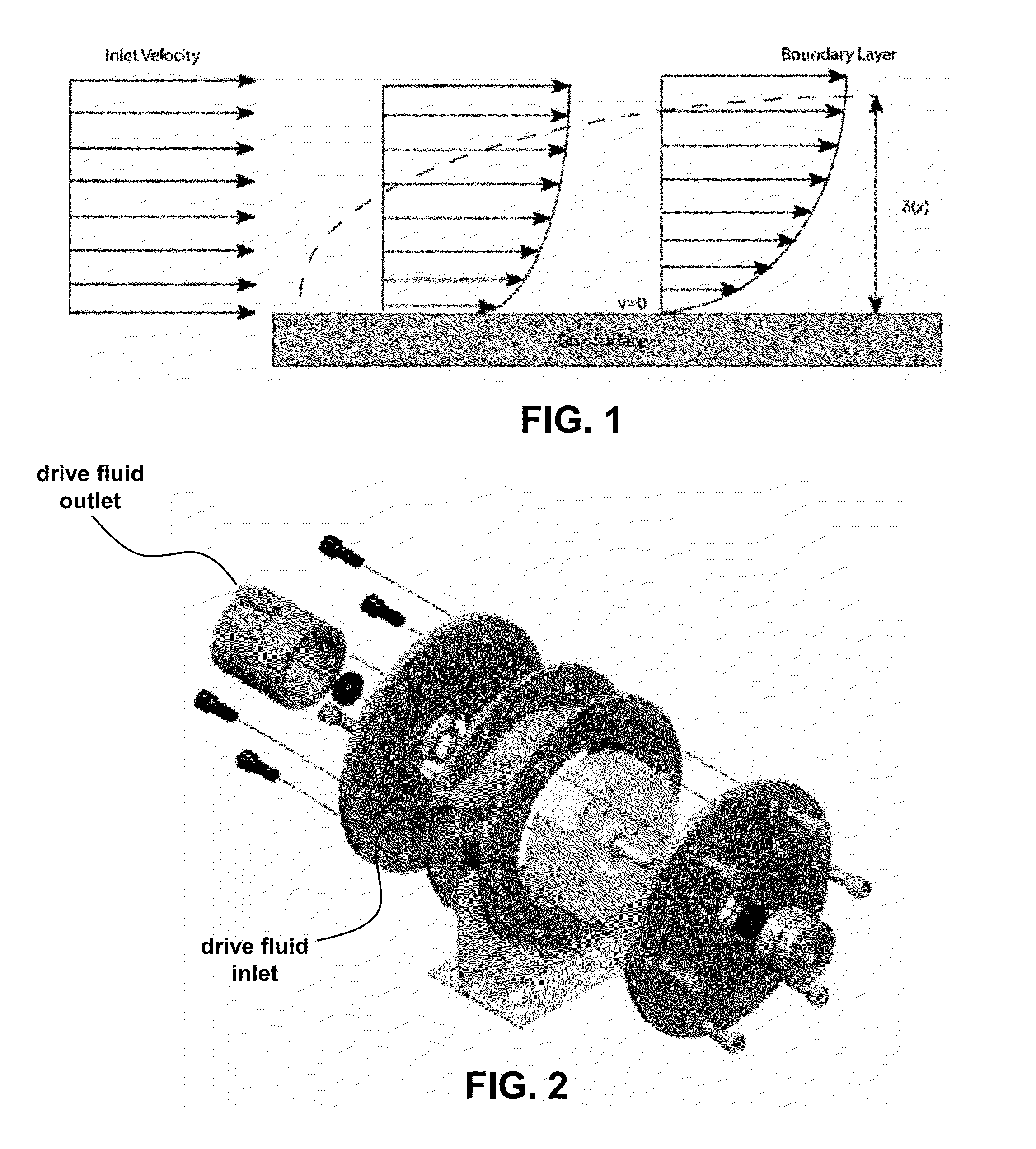

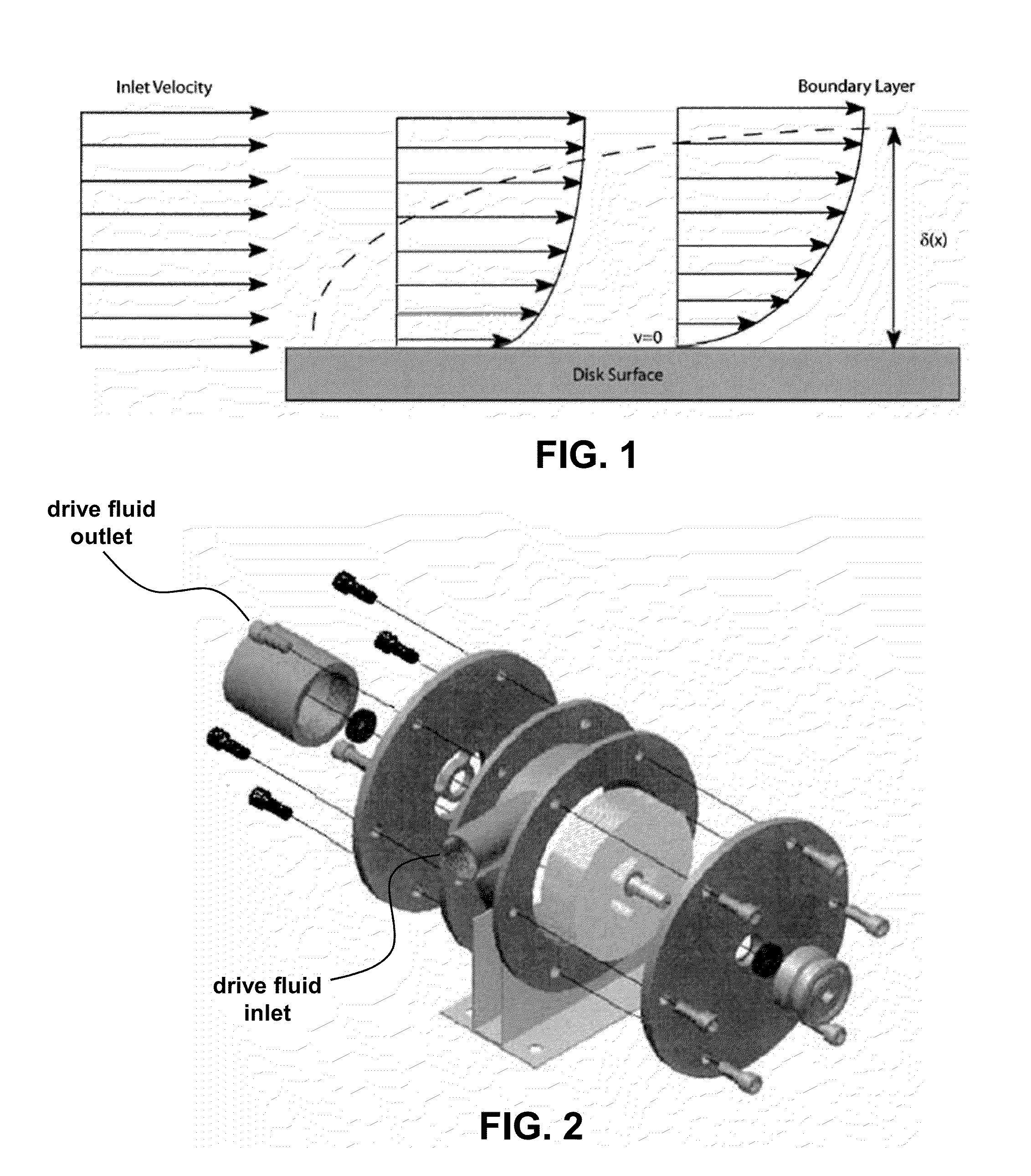

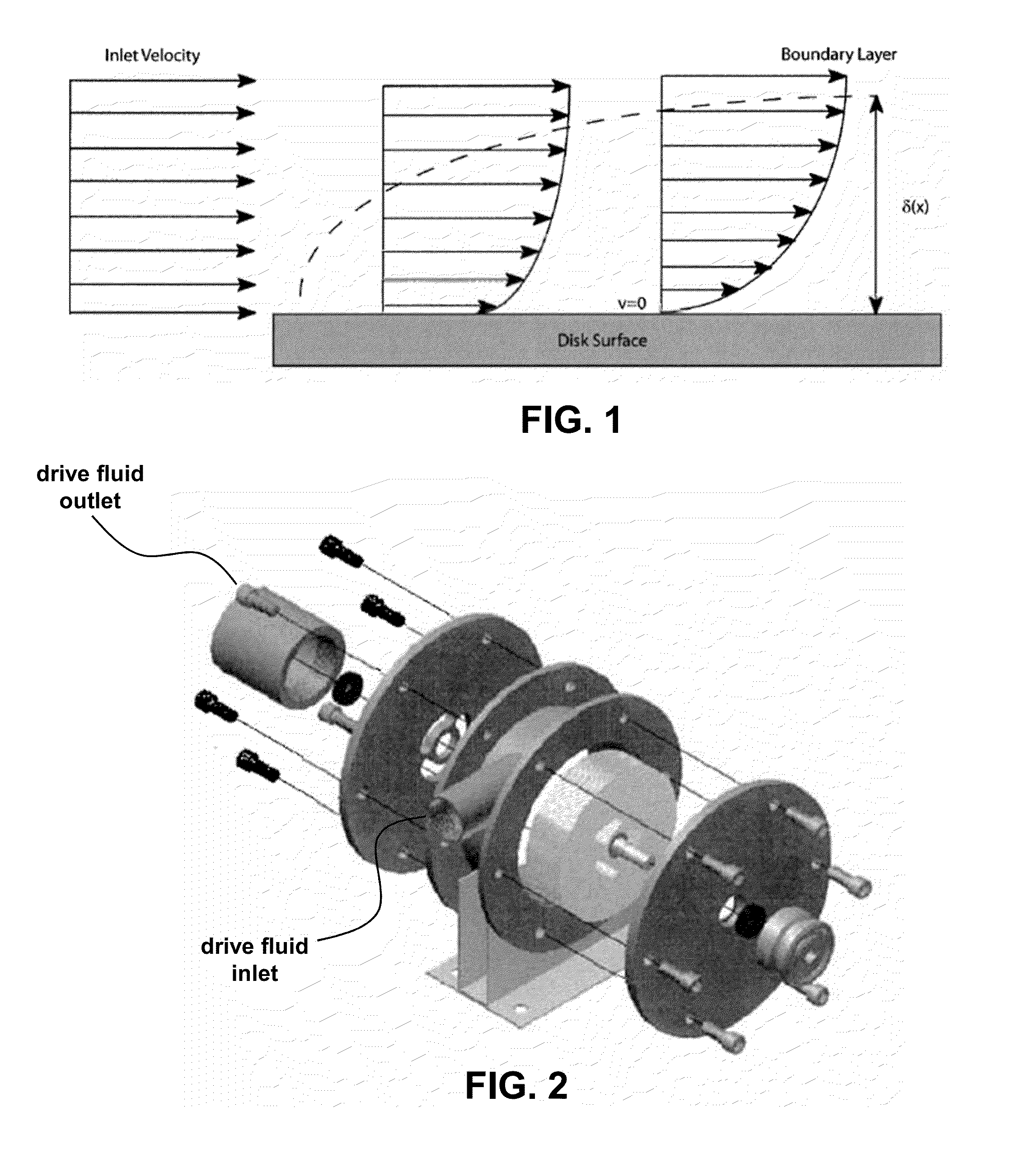

The Tesla turbine is a bladeless centripetal flow turbine patented by Nikola Tesla in 1913. It is referred to as a bladeless turbine. The Tesla turbine is also known as the boundary-layer turbine, cohesion-type turbine, and Prandtl-layer turbine (after Ludwig Prandtl) because it uses the boundary-layer effect and not a fluid impinging upon the blades as in a conventional turbine. Bioengineering researchers have referred to it as a multiple-disk centrifugal pump. One of Tesla's desires for implementation of this turbine was for geothermal power, which was described in Our Future Motive Power.

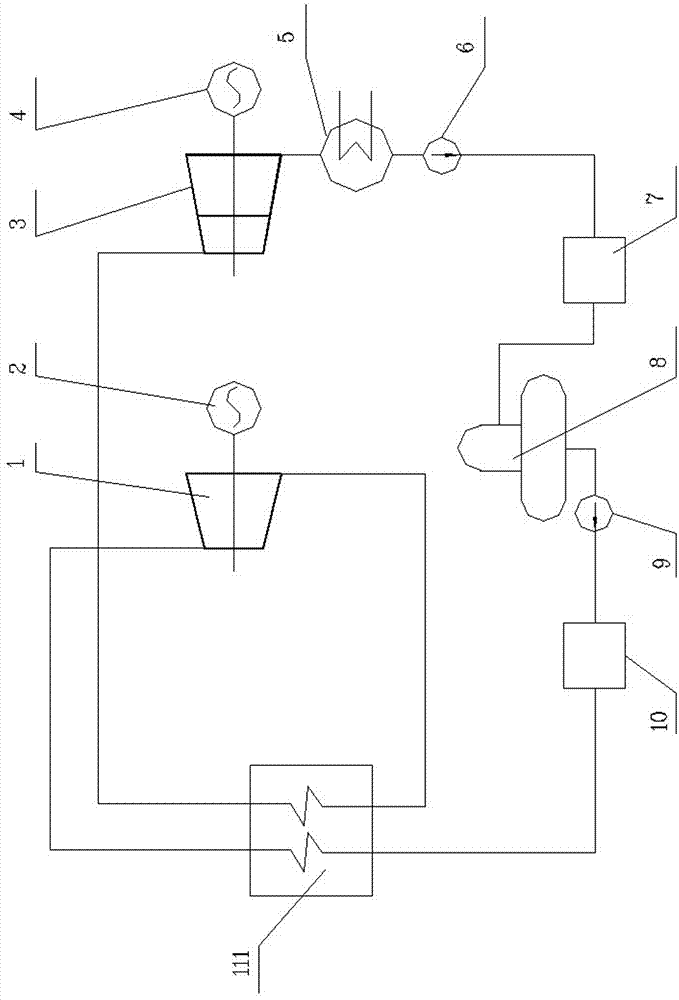

Isothermal power system

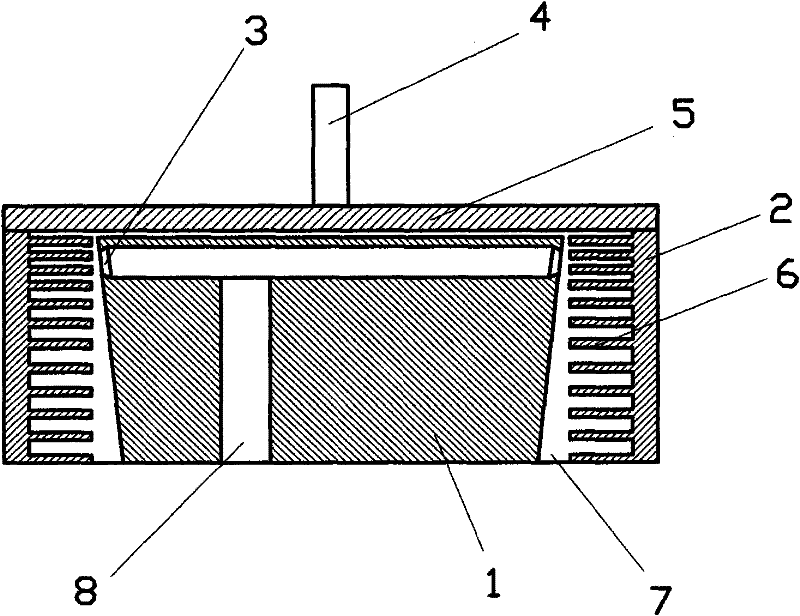

InactiveUS20090260361A1Increase in sizeMore energySteam engine plantsPlate heat exchangerCounter flow

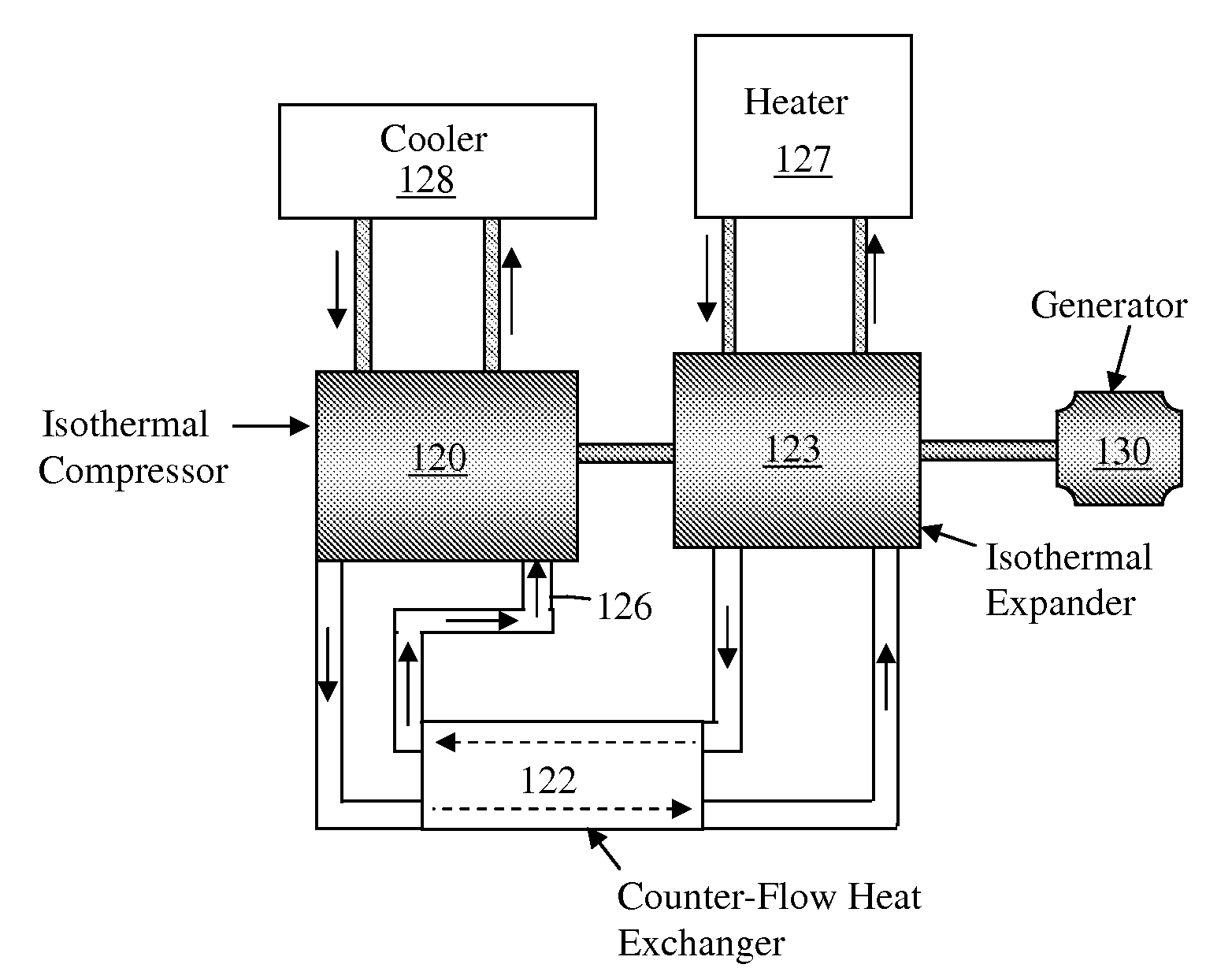

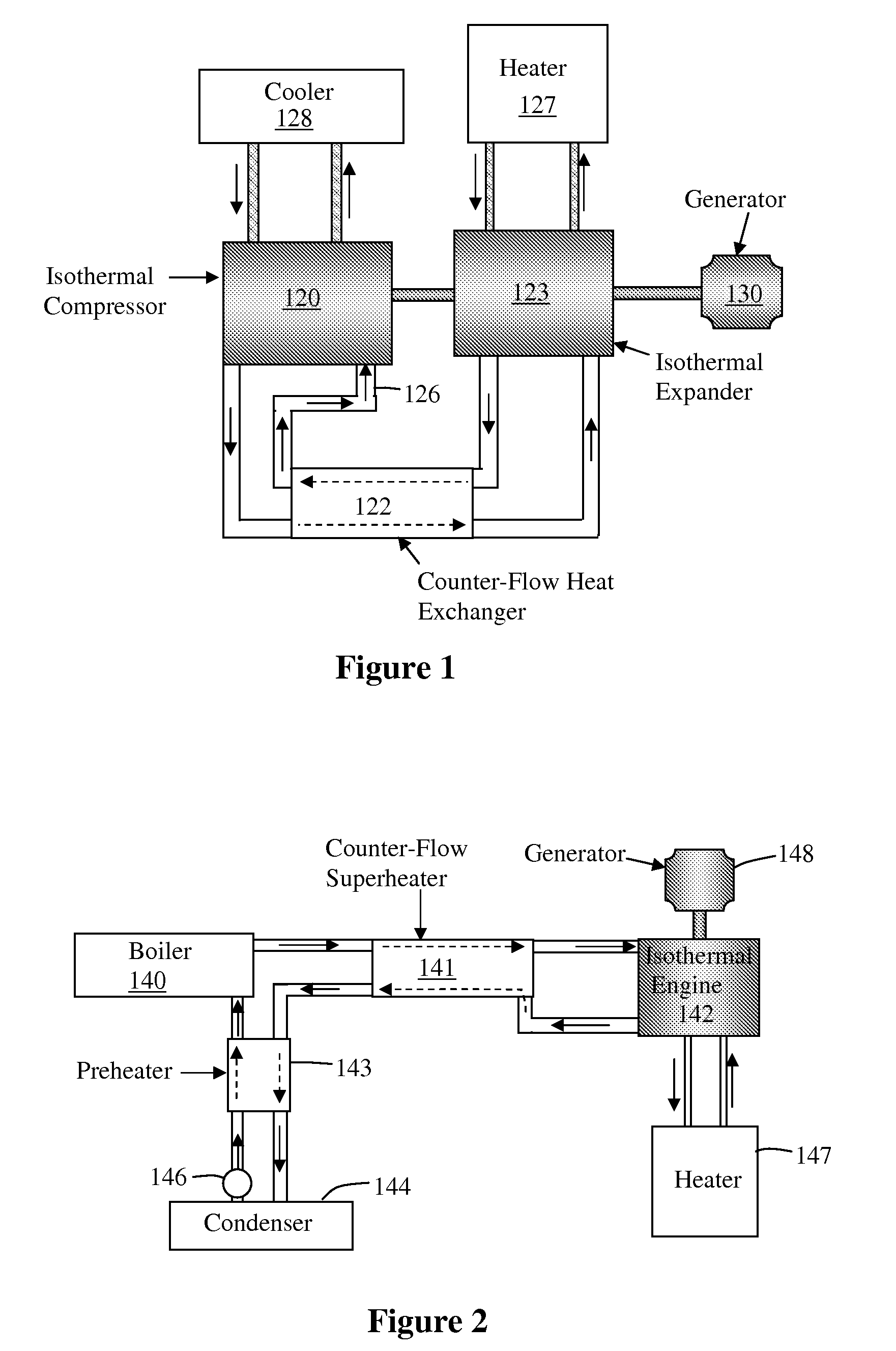

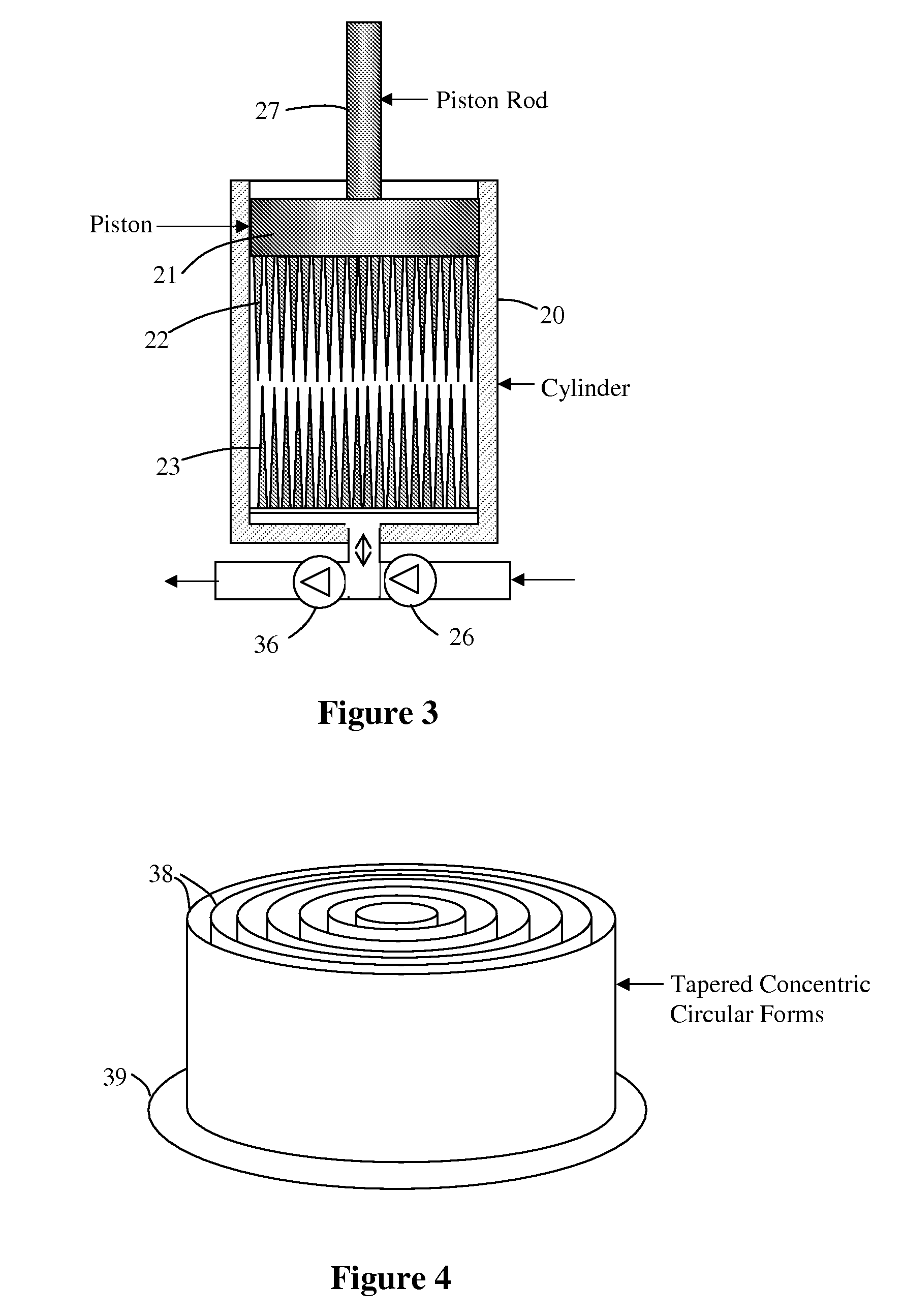

This invention provides means for producing power by using isothermal compressors and isothermal expanders. One embodiment has an isothermal compressor that compresses air (or other gas), passes the air through a counter-flow heat exchanger, which heats the air, uses the heated air to drive an isothermal expander for power generation, and passes the expander exhaust back through the counter-flow heat exchanger to heat the input air to the expander. Another embodiment has a boiler that produces vapor that flows through a counter-flow heat exchanger to superheat the vapor. The vapor then flows through an isothermal expander for power generation. The exhaust from the isothermal expander flows back through the counter-flow heat exchanger to supply heat to super heat the vapor coming from the boiler. The description presents several devices that can perform at near isothermal conditions, including a modified Tesla turbine.

Owner:PRUEITT MELVIN L

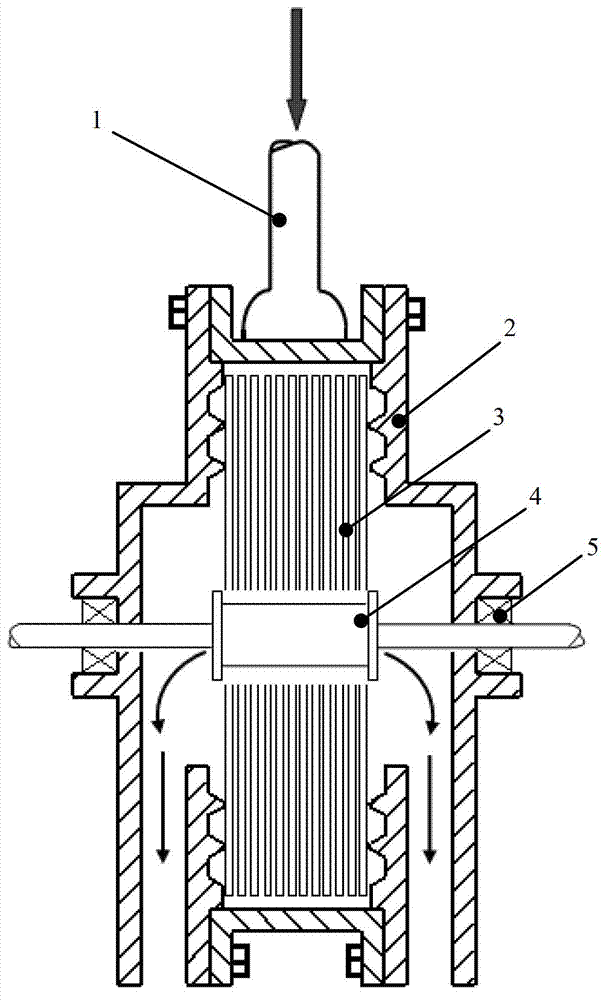

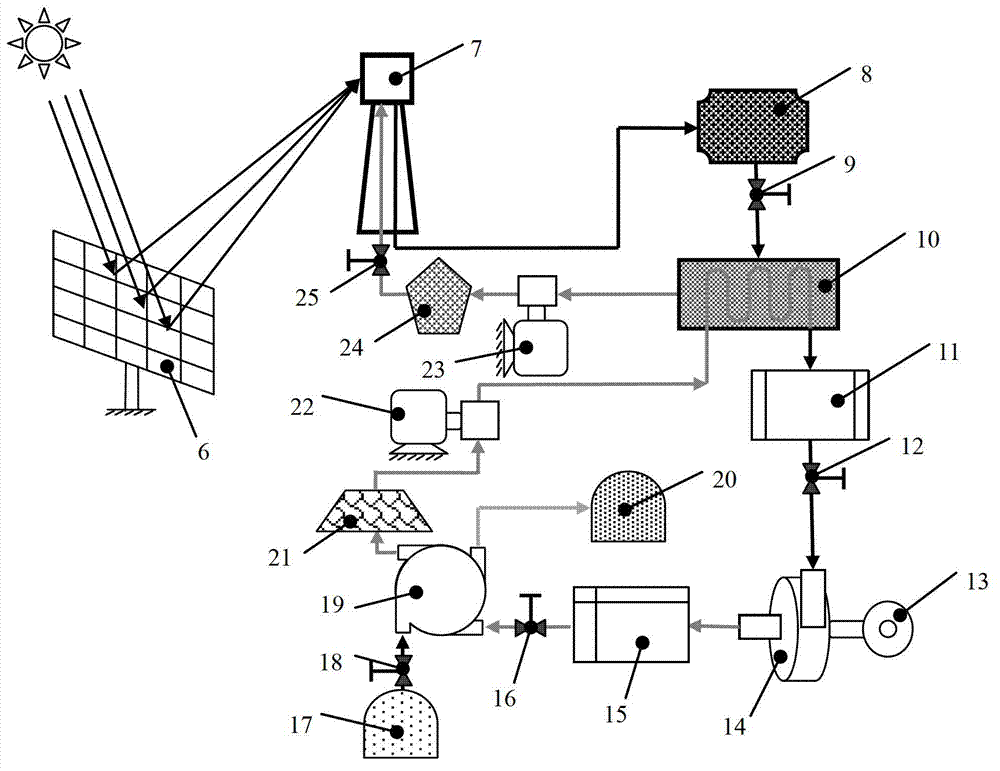

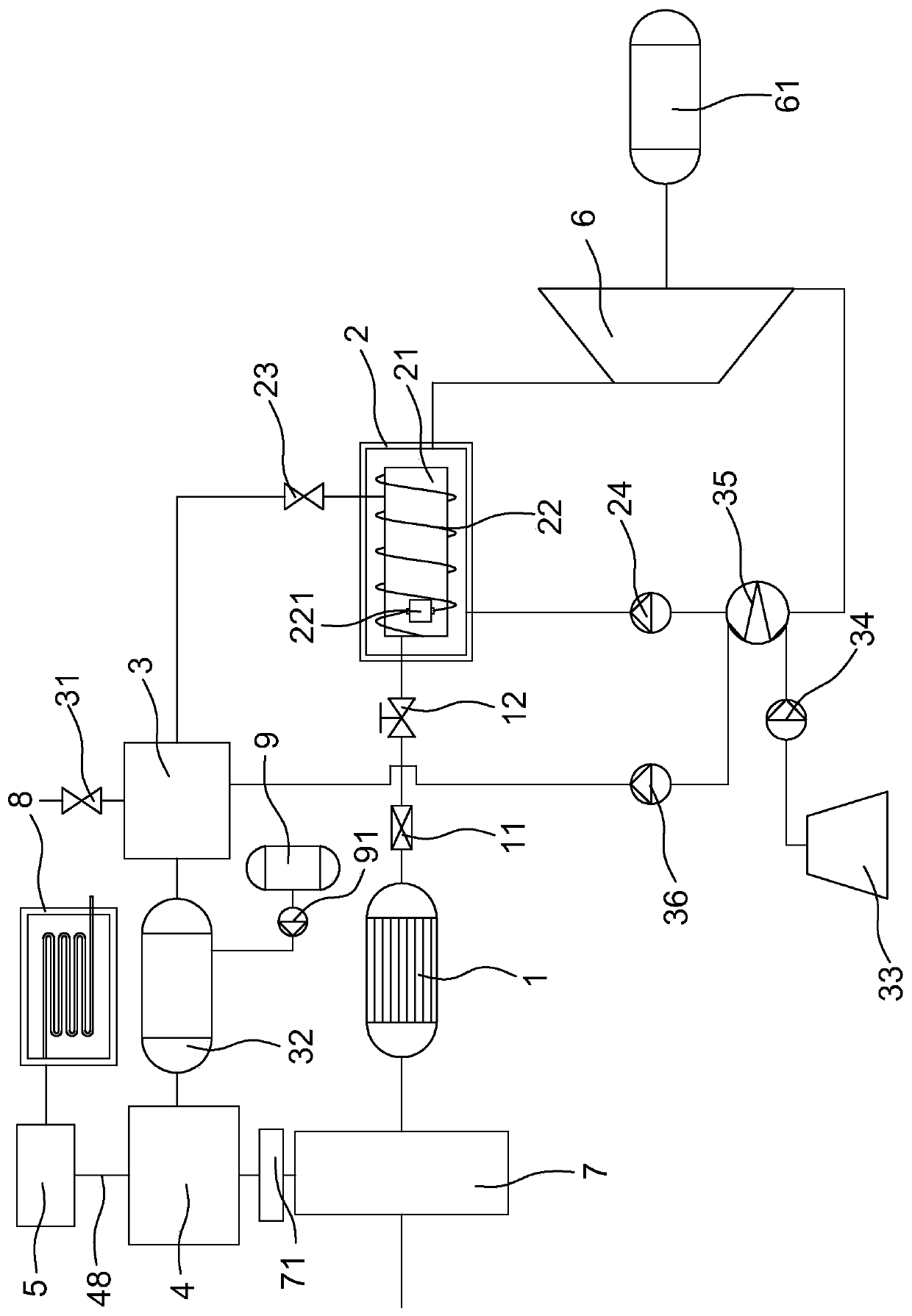

Tower type Tesla turbine solar power generation device

InactiveCN102817799ALow heat utilizationImprove photoelectric conversion efficiencyFrom solar energySolar heat devicesEngineeringSolar power

The invention provides a tower type Tesla turbine solar power generation device. The device comprises a solar energy receiving assembly, a heat transfer working medium circulation assembly, a low boiling point power generating working medium circulation assembly, a cooling working medium circulation assembly and a Tesla turbine power generating assembly. Compared with traditional steam turbine tower type solar thermal power generation systems, the device has the advantages that a Tesla turbine is composed of a simple disk and a turbine casing only, and complex blades which are difficult to design and machine are not required, so that the device is simple in structure, convenient to machine and low in usage and maintenance cost; besides, the heat utilization efficiency of steam turbines is only around 30%, a lot of energy of a heat working medium is lost from tails of steam turbines, the photoelectric conversion efficiency of solar thermal power generation systems is low, the heat utilization efficiency of the Tesla turbine of the device can exceed 90%, so that the photoelectric conversion efficiency of existing solar thermal power generation systems can be greatly improved; and the device can not only generate electricity but also provide hot water required by life for residents.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

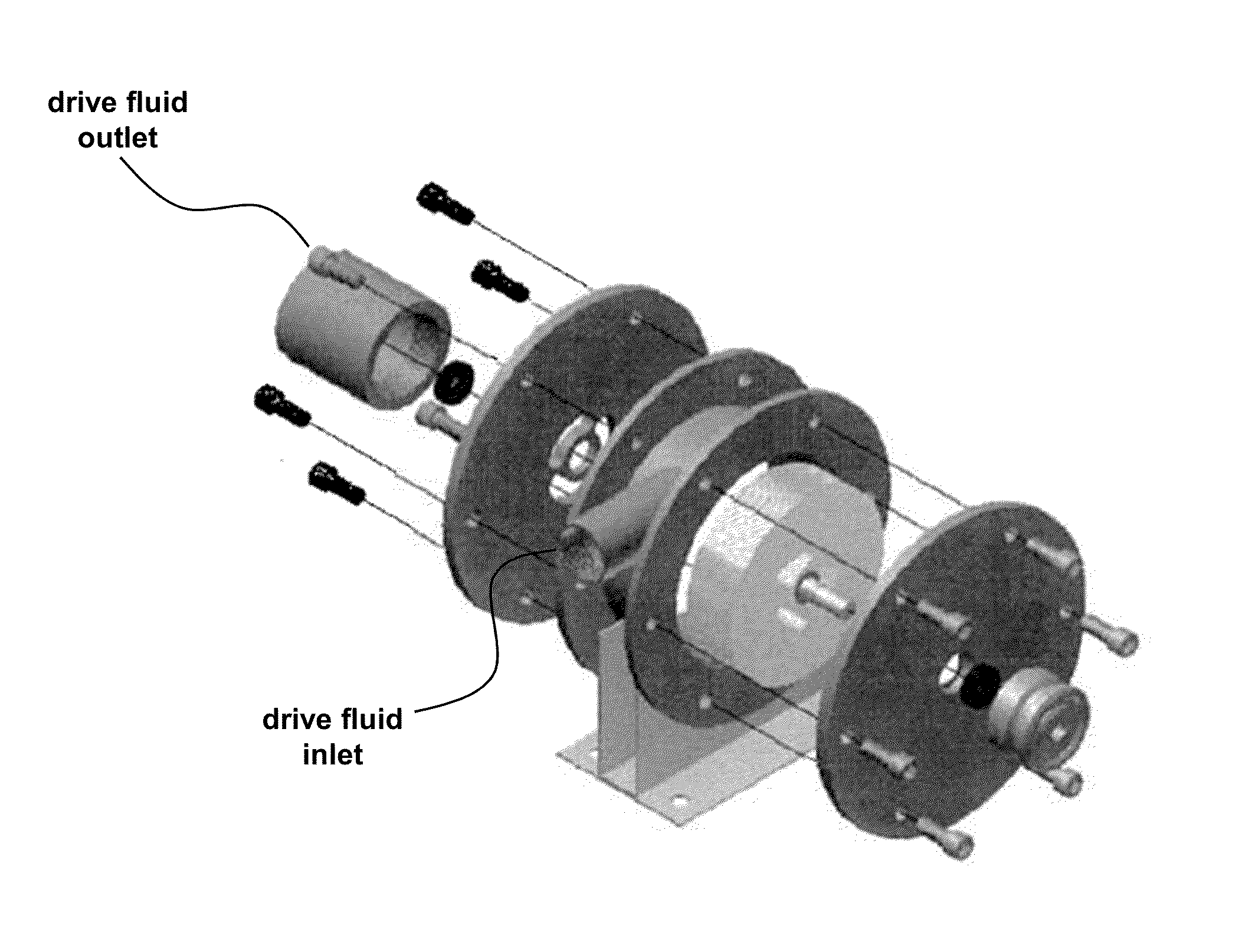

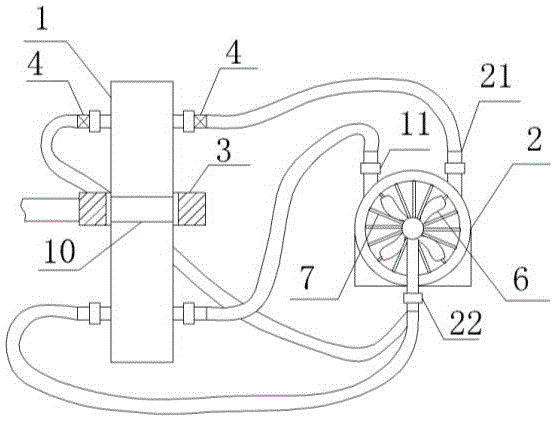

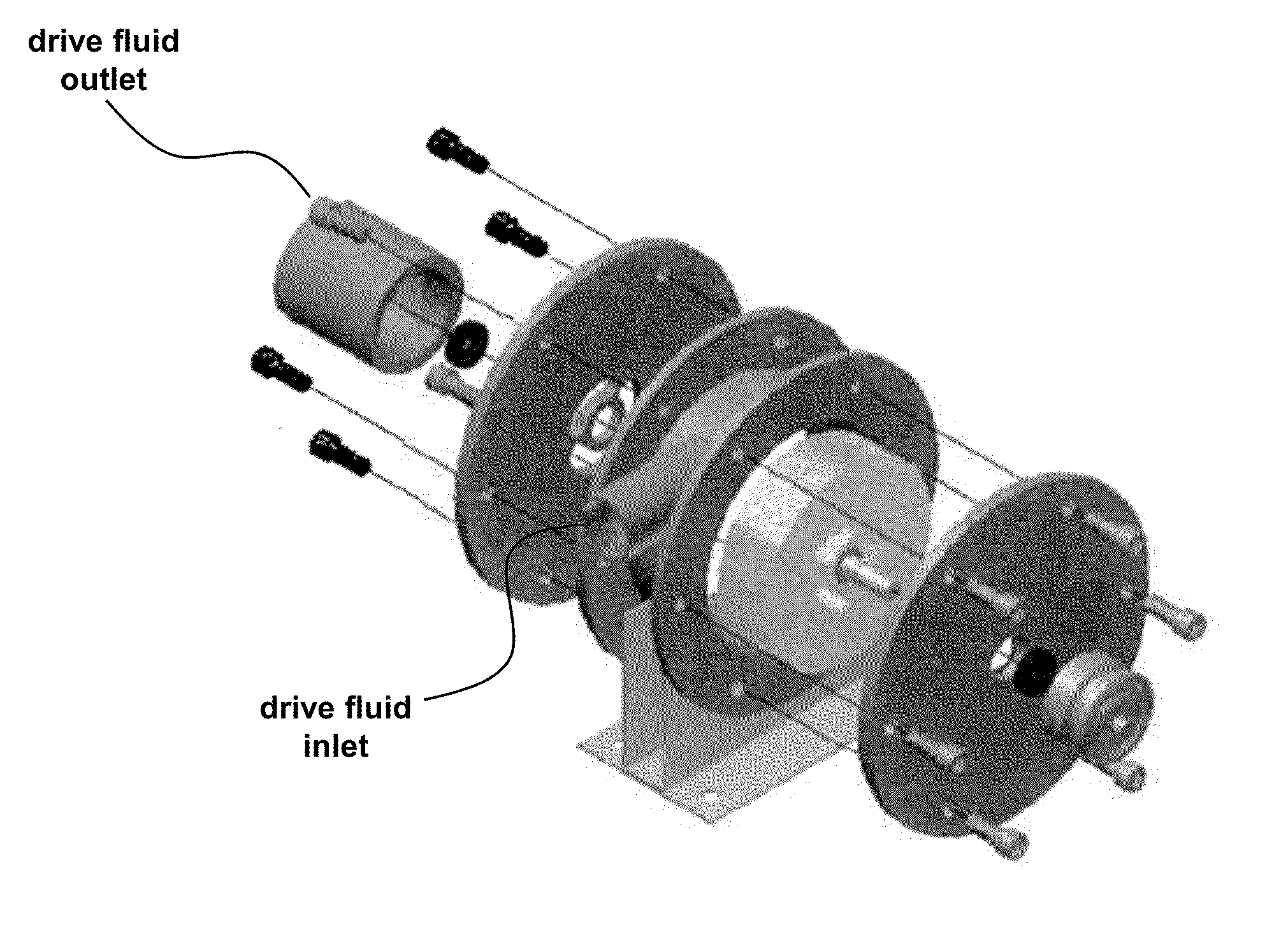

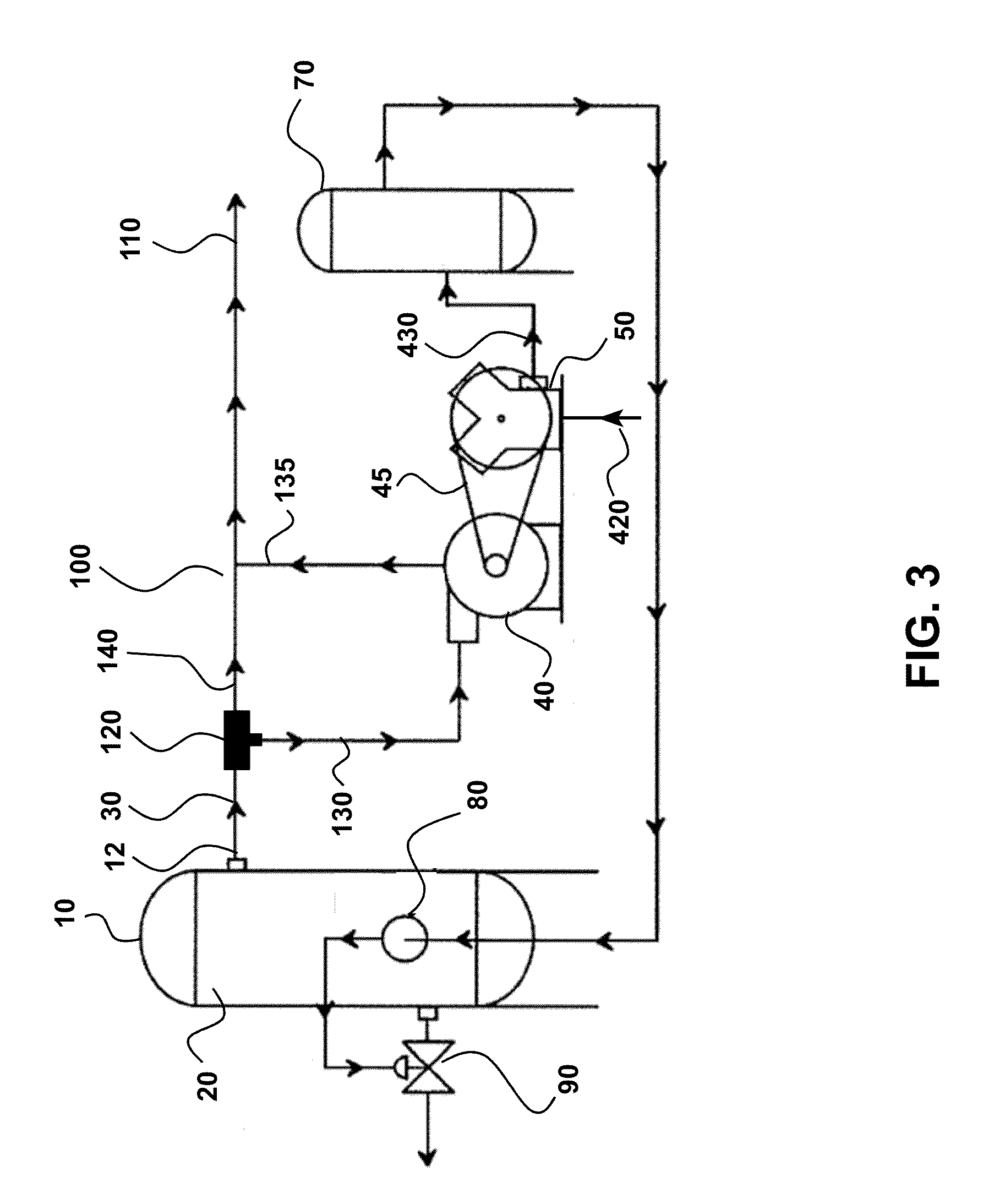

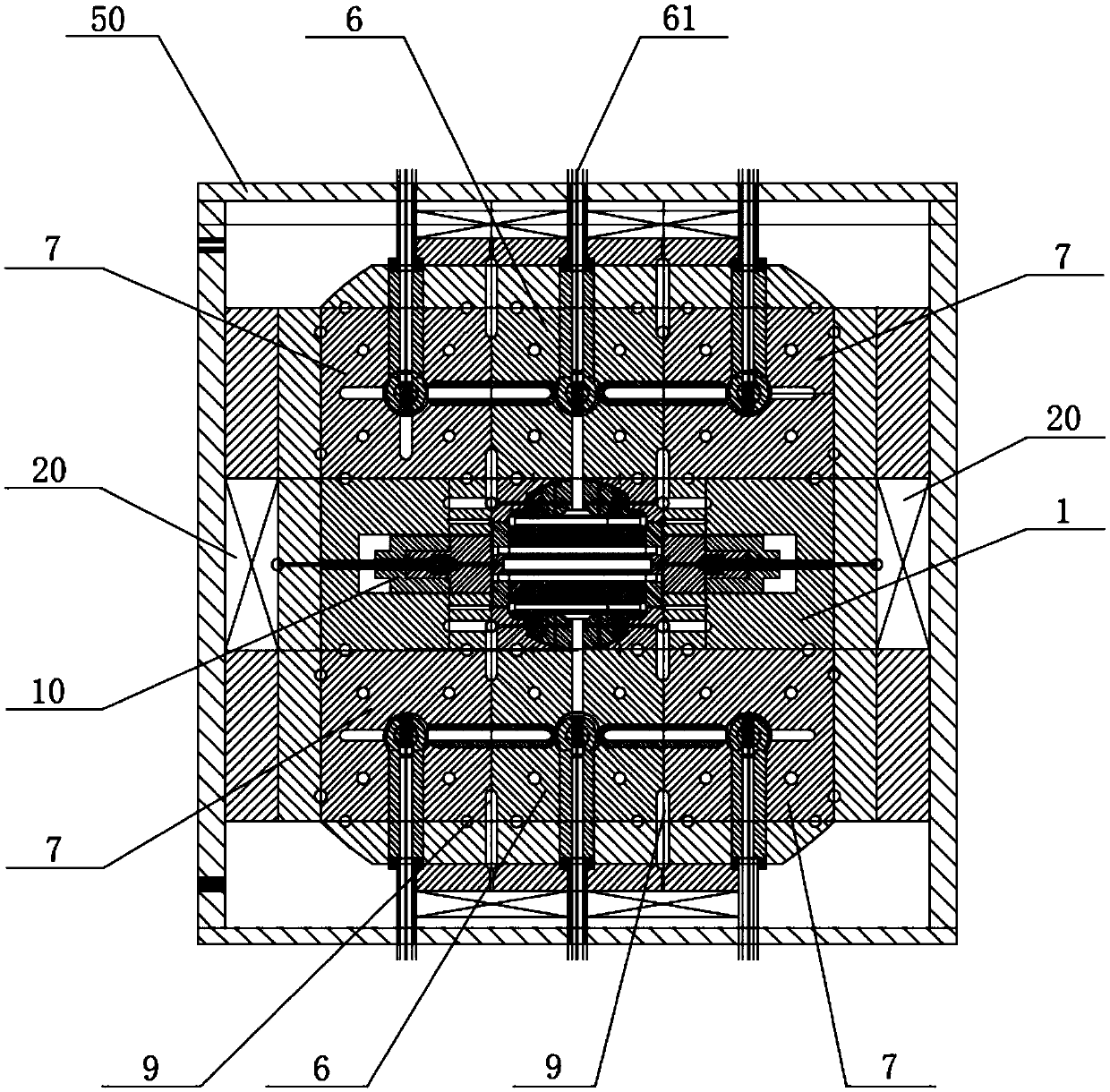

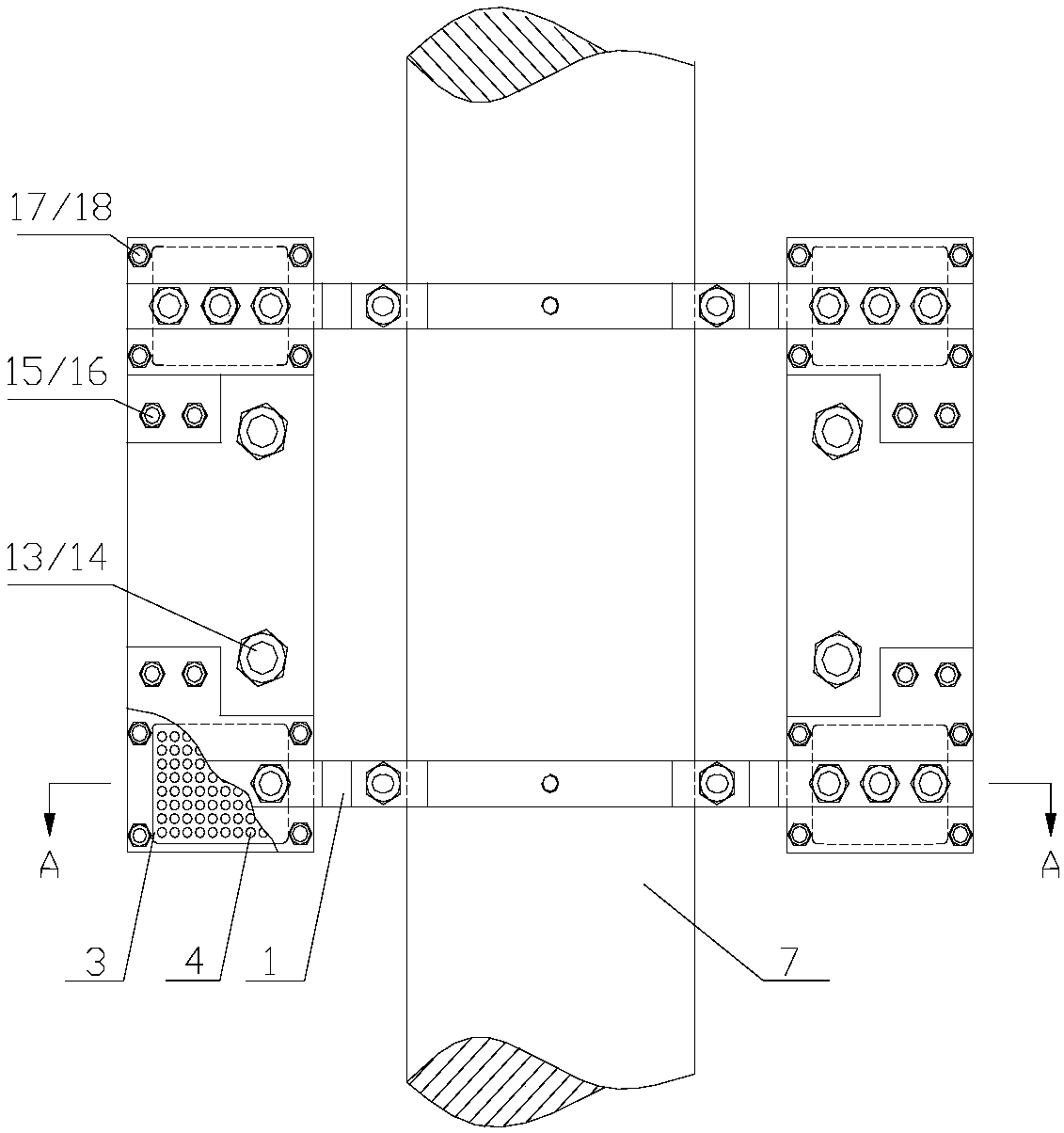

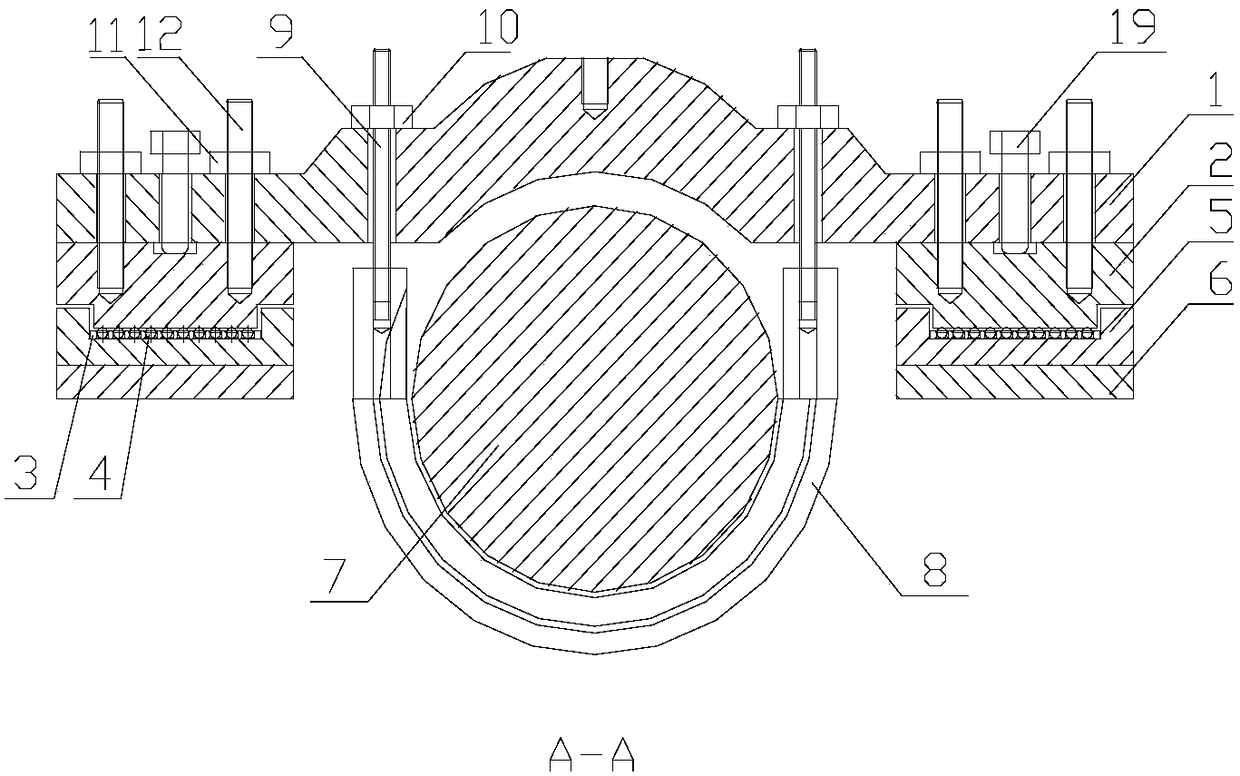

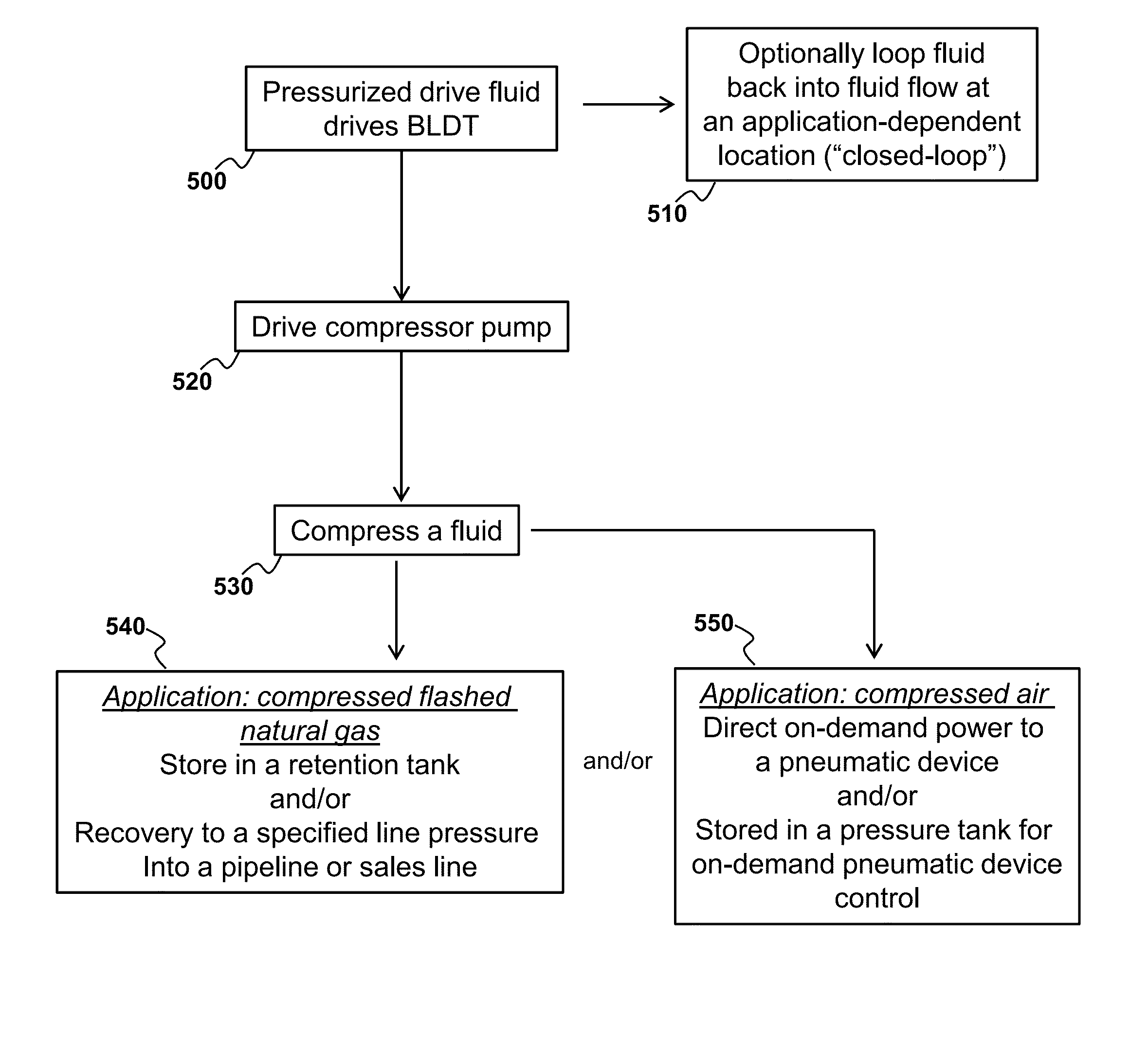

Boundary Layer Disk Turbine Systems for Hydrocarbon Recovery

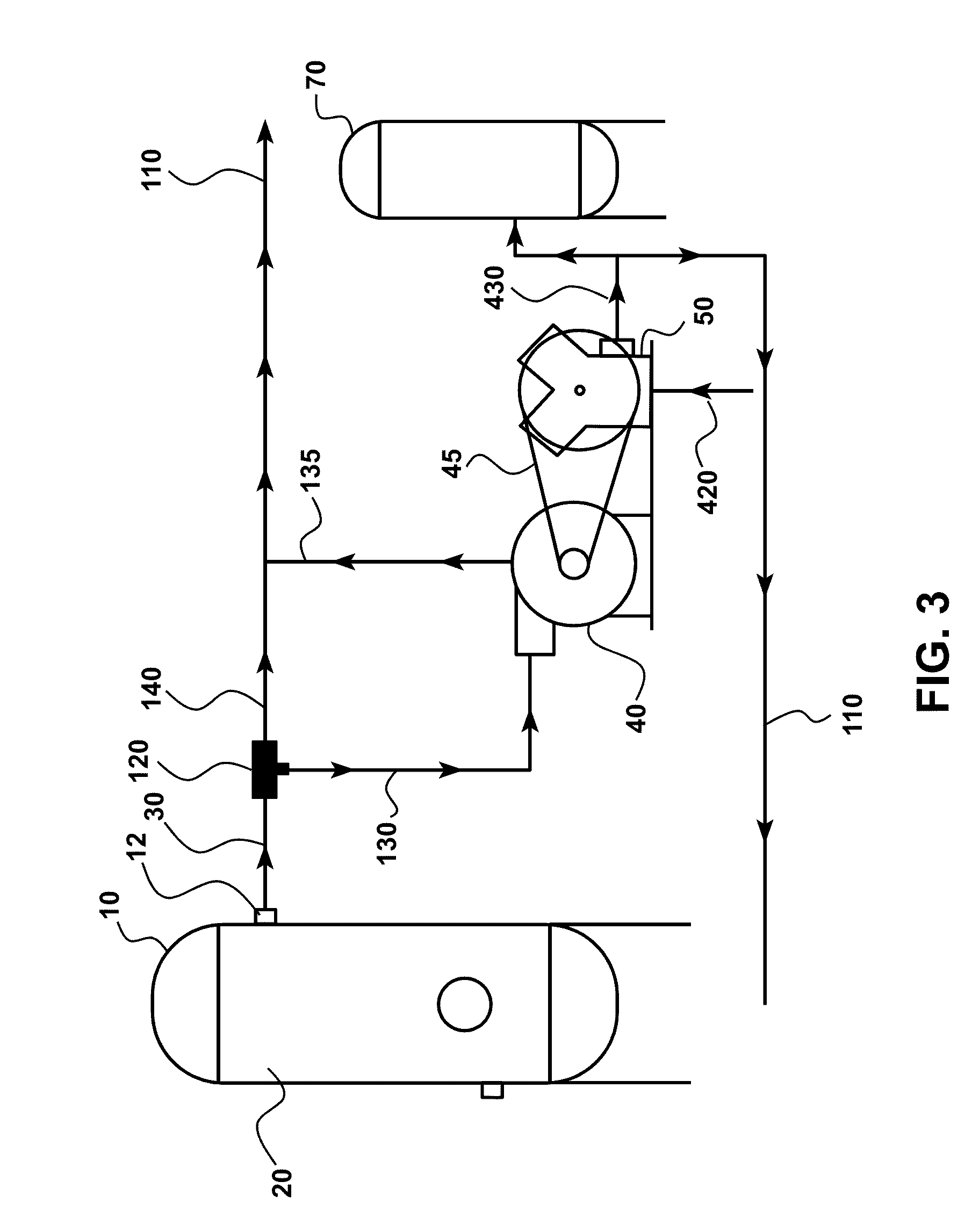

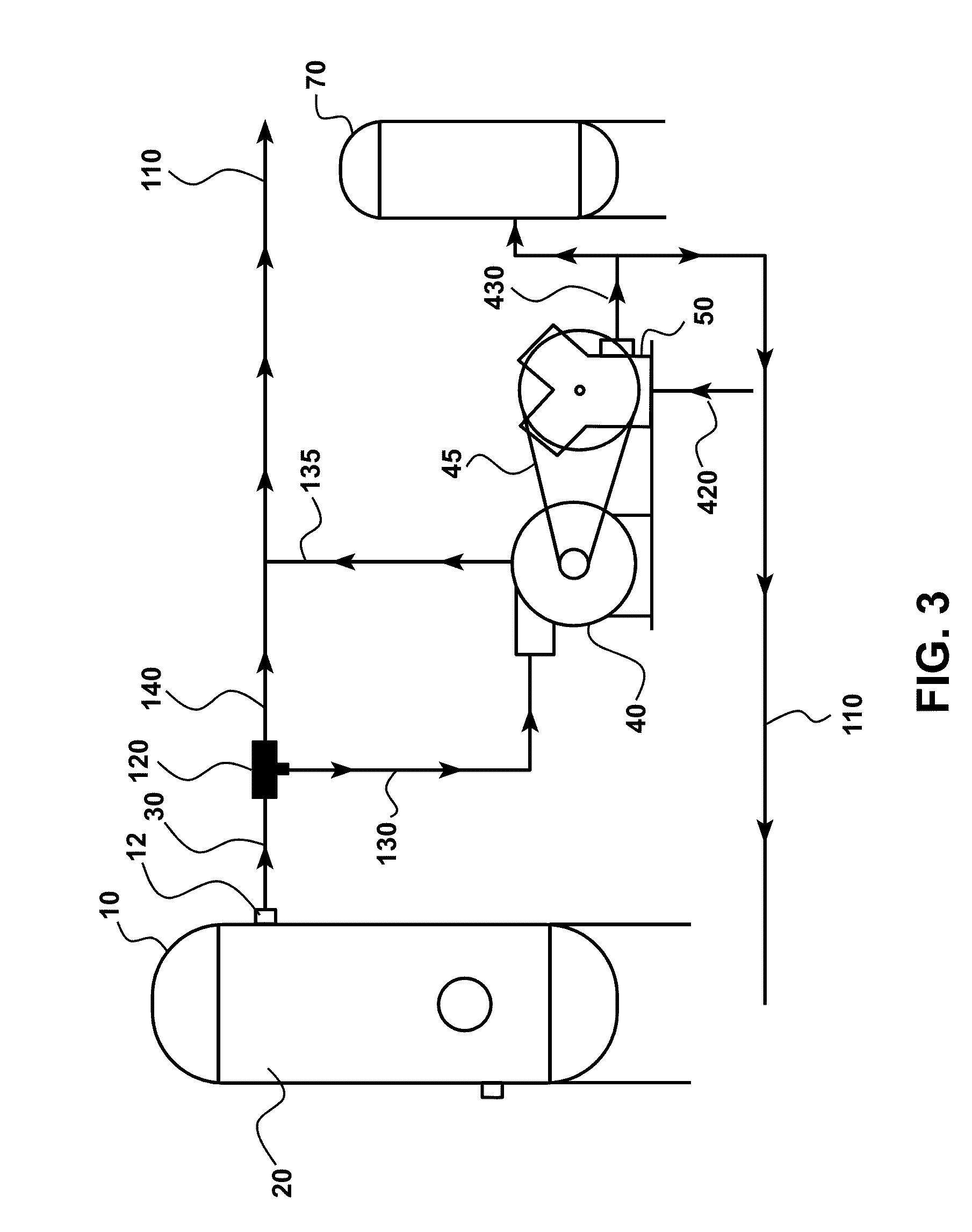

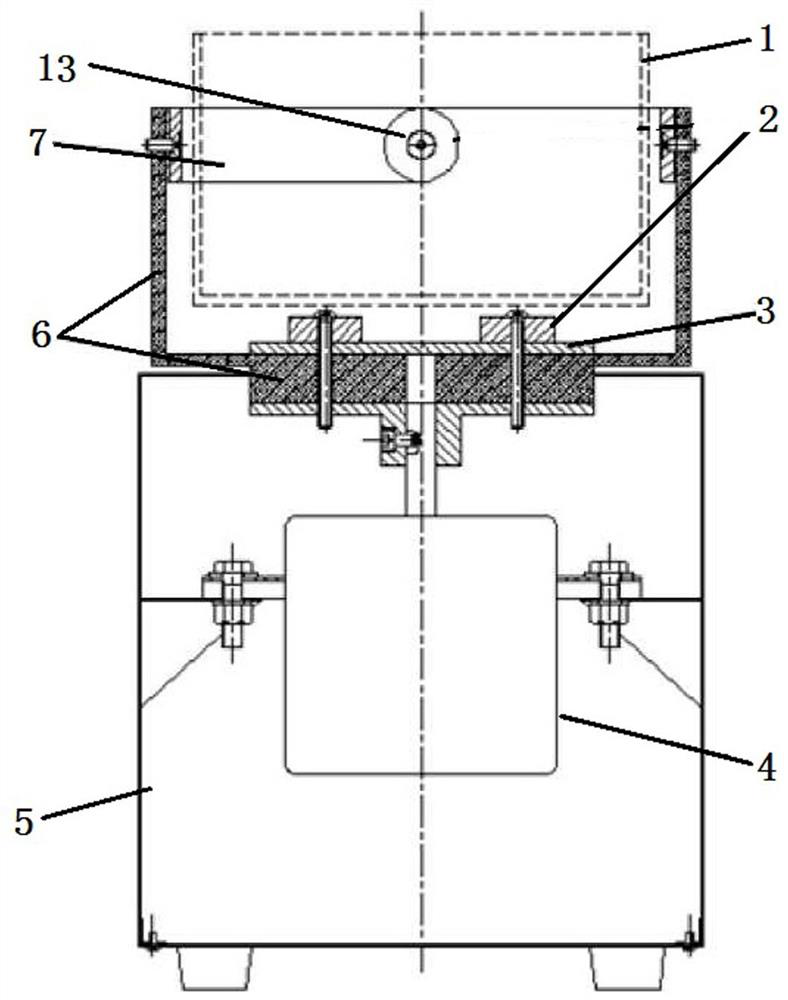

InactiveUS20130068314A1Easy to driveGuaranteed uptimeFluid couplingsPipeline systemsCompressed fluidProcess engineering

Provided are various devices and processes that harness the inherent kinetic energy of a flowing pressurized fluid to drive a compressor to compress a fluid without any need for electrical or chemical energy. The flowing fluid flows over a boundary layer disk turbine, or Tesla turbine, which is mechanically coupled to a compressor that compresses a fluid. The flowing fluid may be a natural gas from a hydrocarbon recovery operation. The compressed fluid may be a vapor gas from a hydrocarbon production, processing, or storage facility. Harnessing the kinetic energy of the flowing fluid increases economic efficiency of the process, while also avoiding unwanted emissions adverse to the environment and public health.

Owner:TRI POINT OIL & GAS PRODN SYST LLC

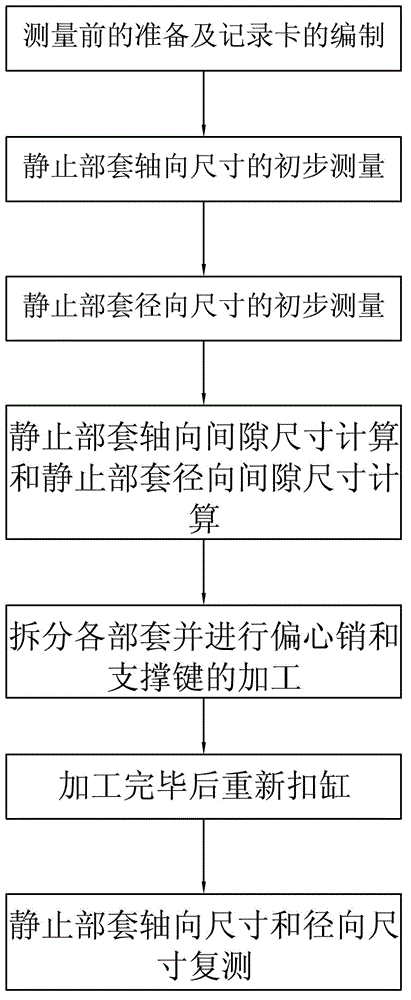

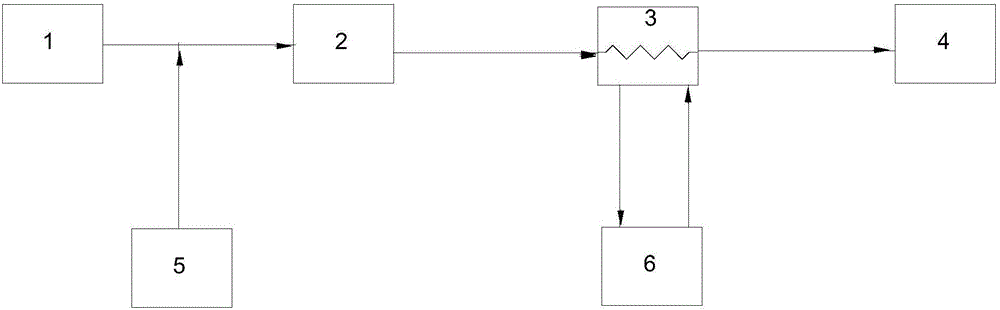

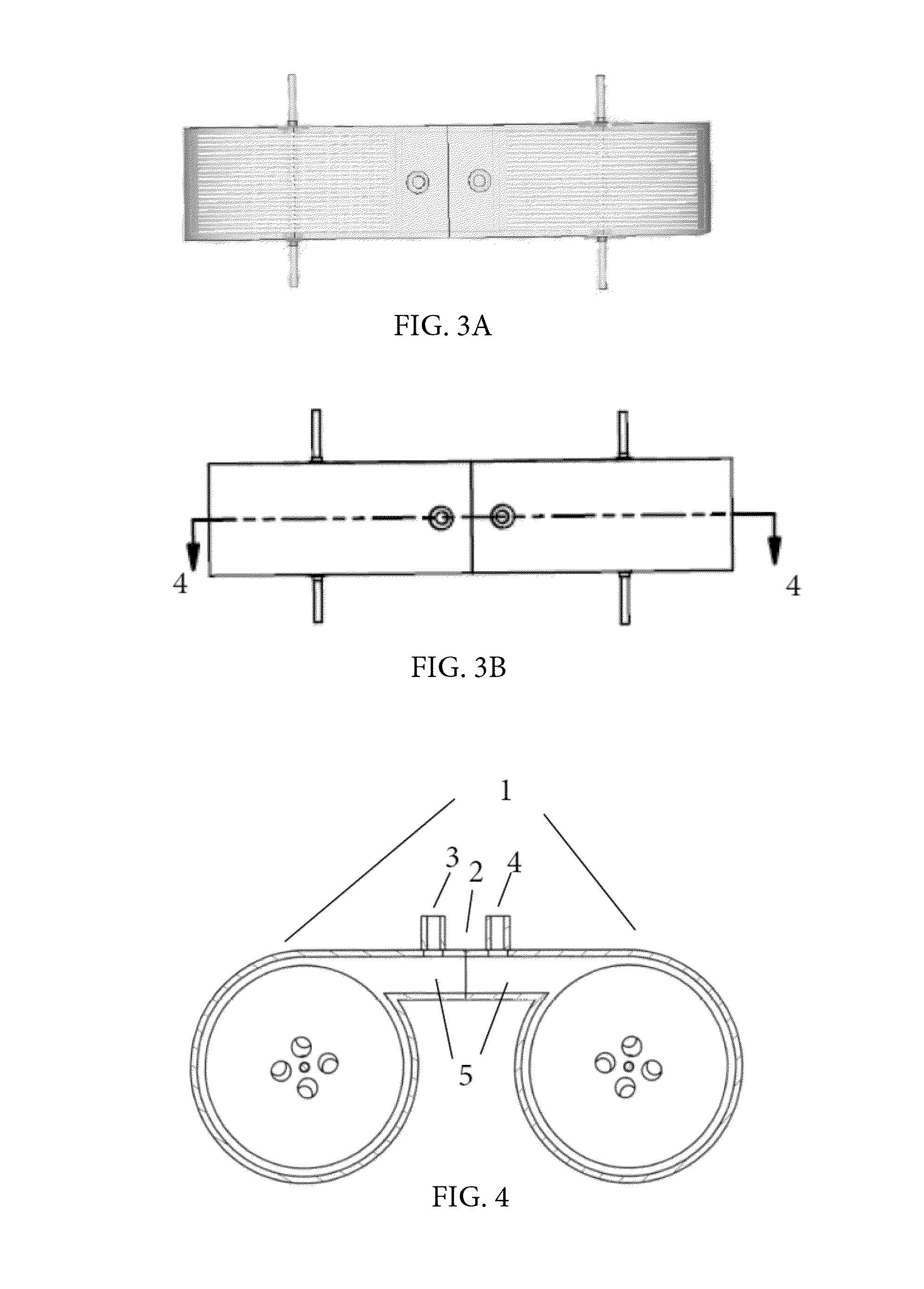

Rotor-free through-flow measurement method for steam turbine

ActiveCN102944182AShorten delivery timeShorten assembly cycleUsing optical meansUltimate tensile strengthTesla turbine

The invention discloses a rotor-free through-flow measurement method for a steam turbine, and relates to a through-flow measurement method, in particular to a rotor-free through-flow measurement method for a steam turbine. The invention solves the problems in the prior art, such as complicated operation, low safety and high labor intensity. Specifically, the method comprises the following steps: doing preparation before measurement and making record cards, performing primary measurement of the axial dimension of a static part sleeve, performing primary measurement of the radial dimension of the static part sleeve, calculating the axial clearance of the static part sleeve and the radial clearance of the static part sleeve, dismounting each part sleeve and machining an eccentric pin and a support key, re-mounting a cylinder after completing the machining, and measuring the axial dimension and radial dimension of the static part sleeve again. The rotor-free through-flow measurement method is used for measuring the through-flow clearance of the static part sleeve of the steam turbine.

Owner:HARBIN TURBINE +1

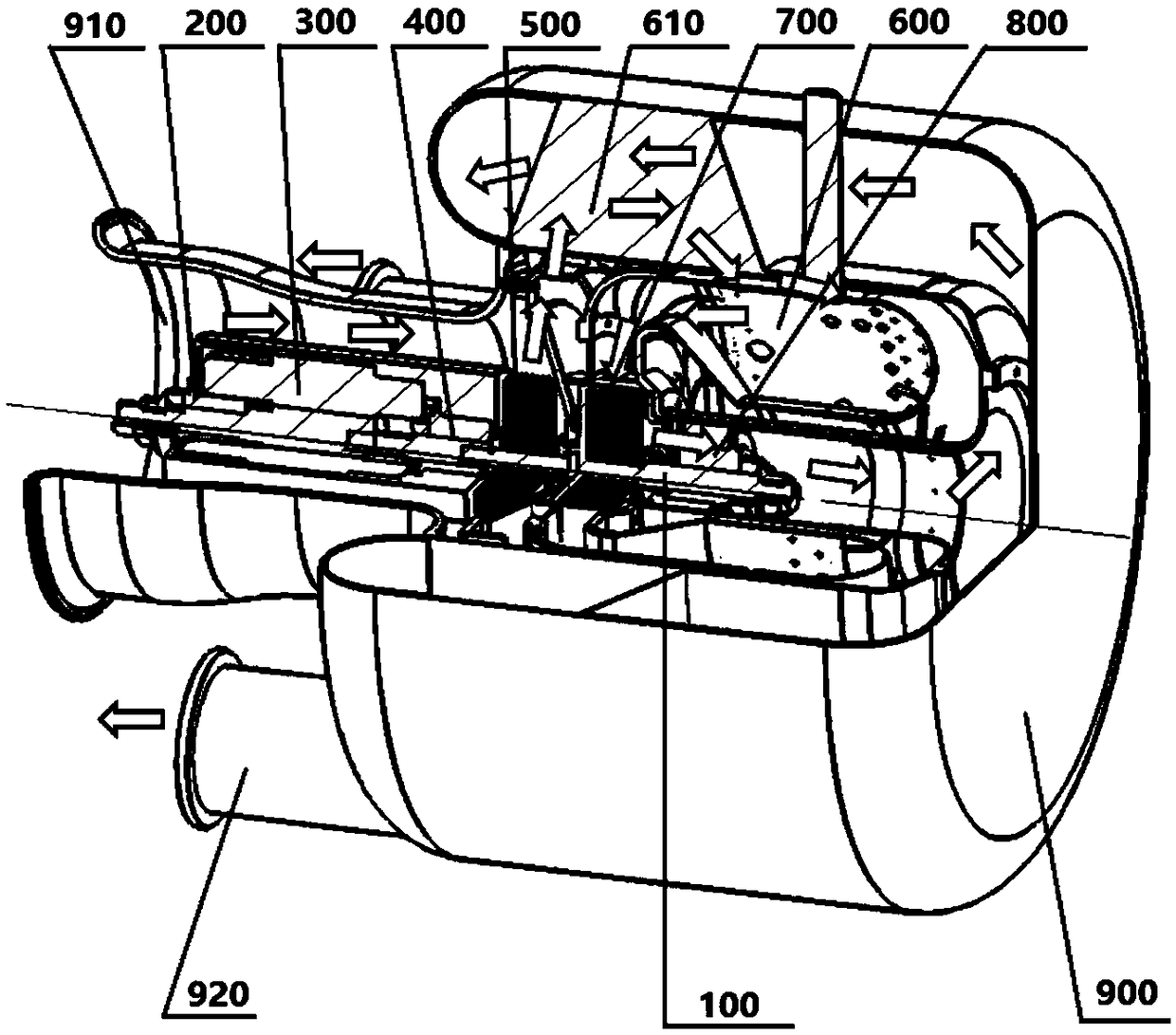

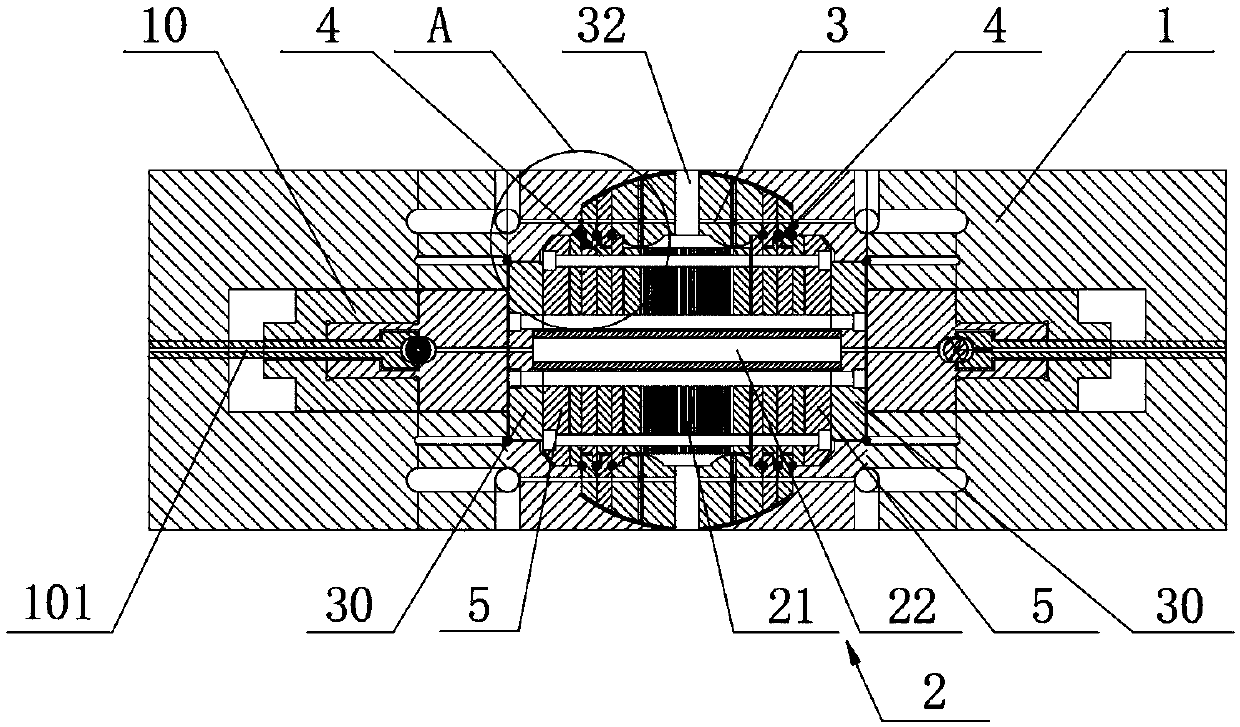

Gas turbine generator and control method

PendingCN109162811AImprove efficiencyIncrease profitTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustion chamberGas compressor

The invention relates to a gas turbine generator. The gas turbine generator comprises a rotating shaft, a first radial bearing, a motor, a second radial bearing, a Tesla compressor, a combustion chamber, a Tesla turbine and a third radial bearing; the rotating shaft sequentially passes through the first radial bearing, the motor, the second radial bearing, the Tesla compressor, the Tesla turbine and the third radial bearing; a gas inlet of the Tesla compressor is communicated with the outside; an exhaust outlet is communicated with a gas inlet of the combustion chamber; an exhaust outlet of the combustion chamber is communicated with a gas inlet of the Tesla turbine; an exhaust outlet of the Tesla turbine is communicated with the outside; and the first radial bearing, the second radial bearing and the third radial bearing are non-contact bearings. The equipment adopts the Tesla compressor and the Tesla turbine, and a rotor system is supported by the non-contact bearings, so that the integrated efficiency of the gas turbine generator is improved.

Owner:刘慕华

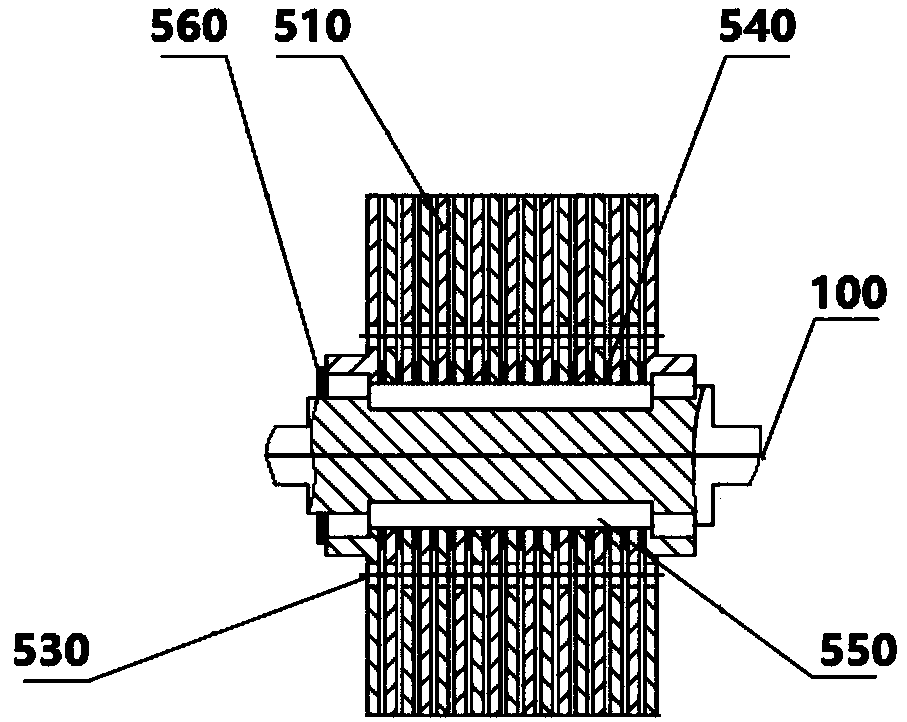

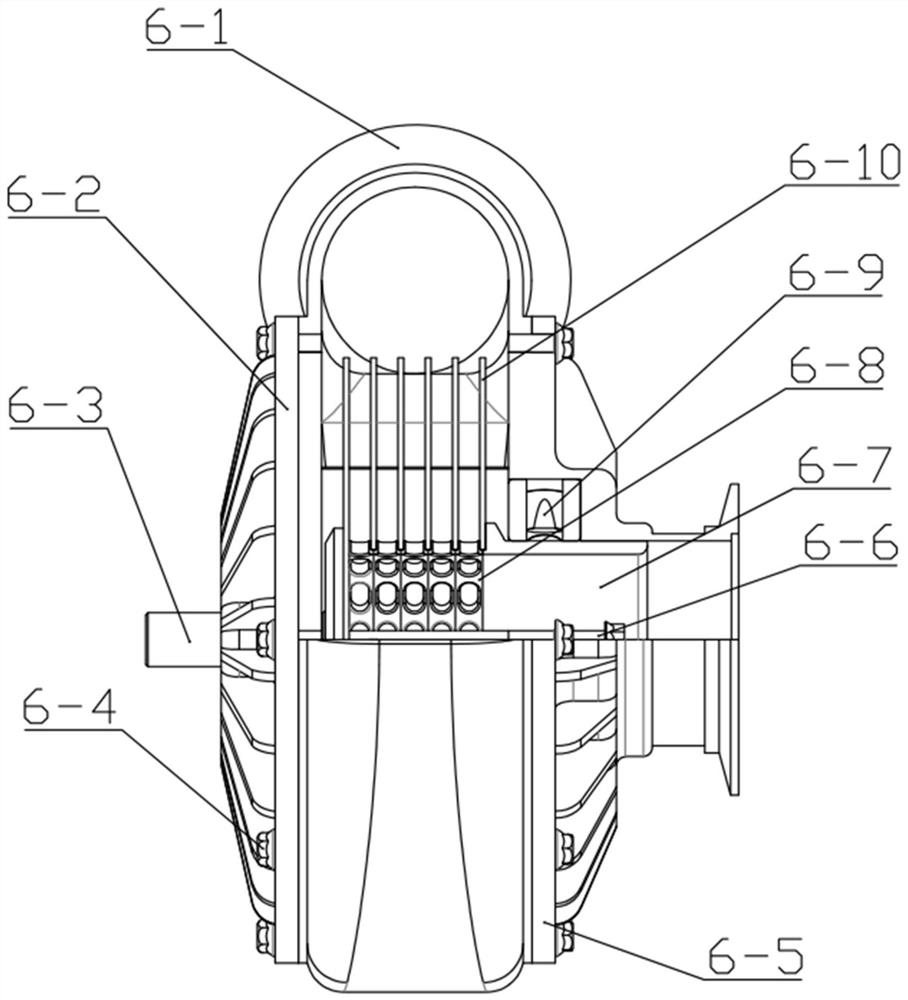

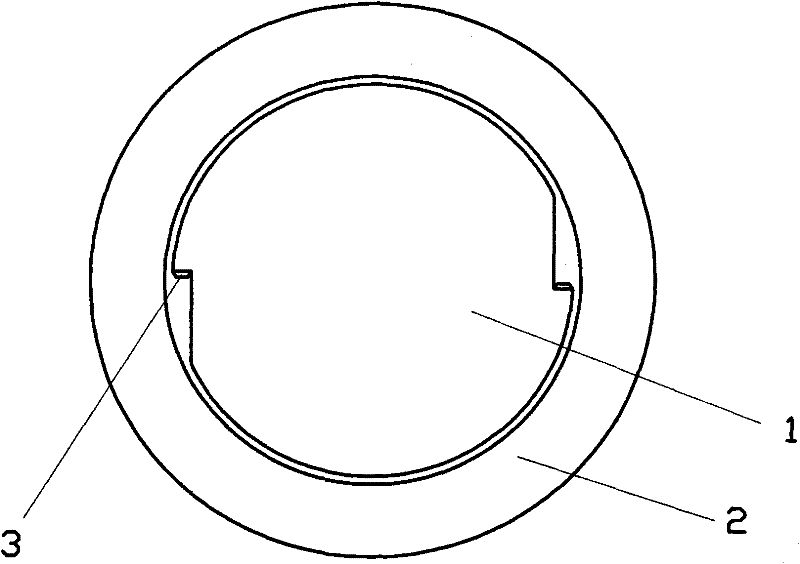

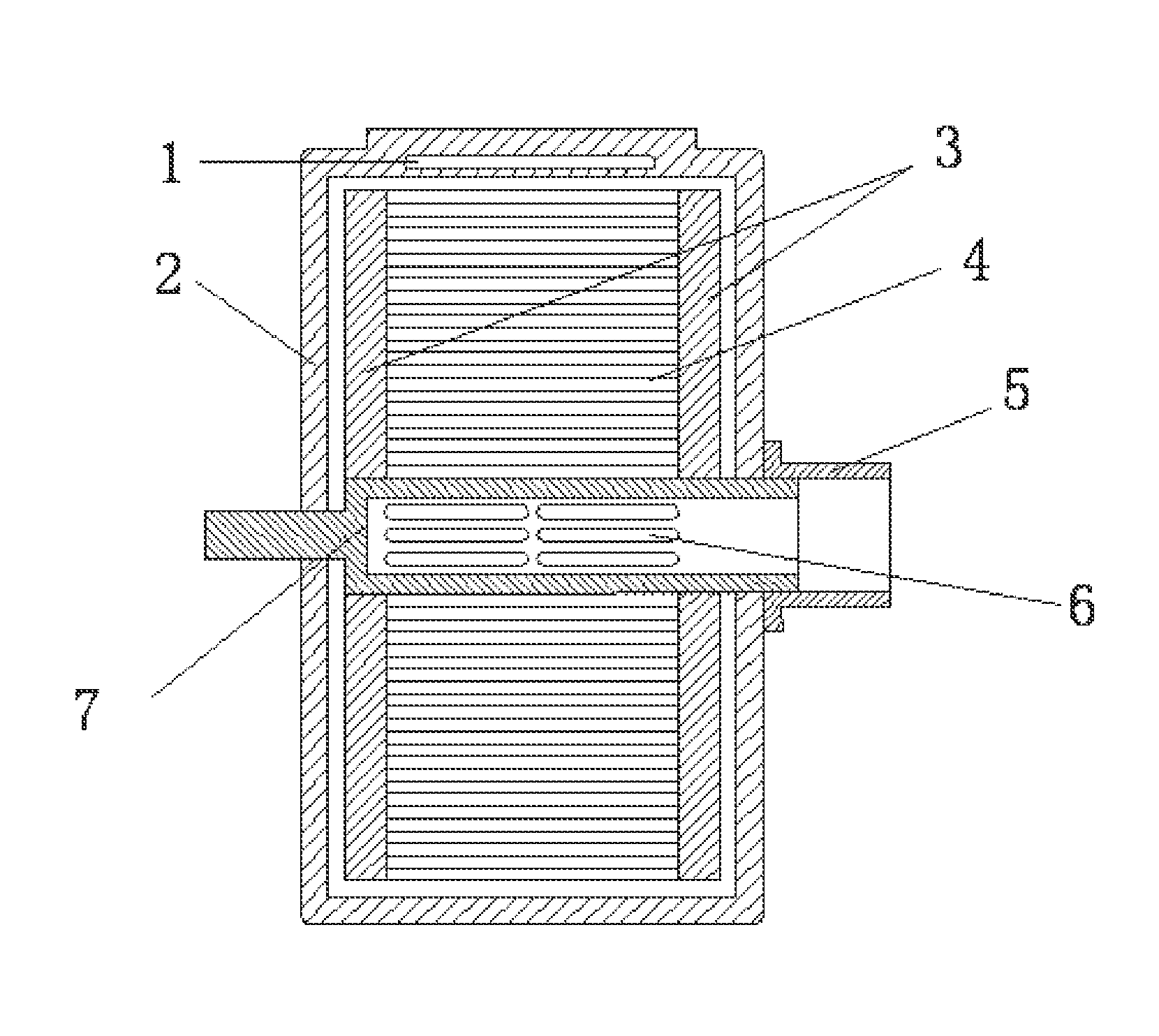

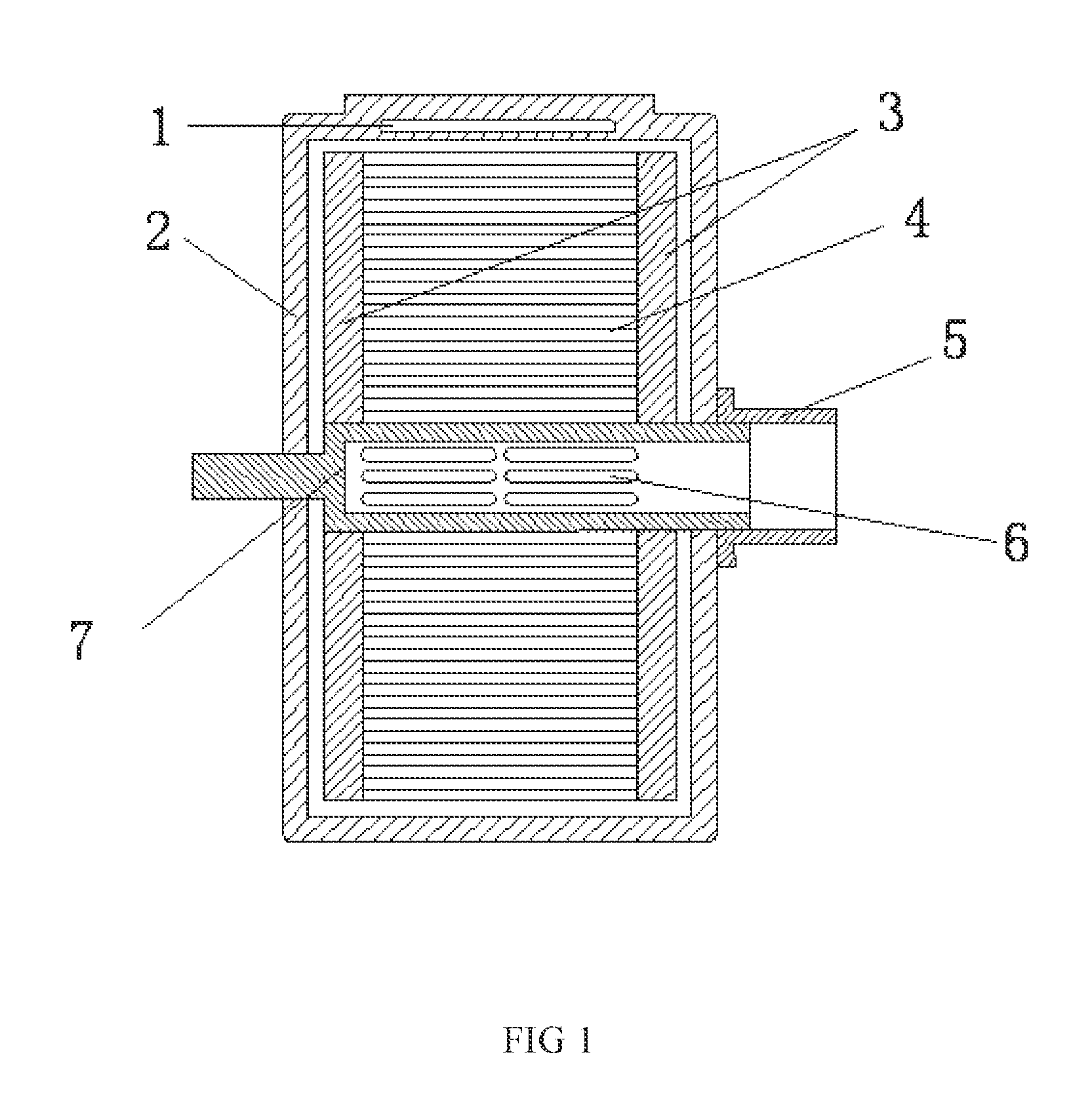

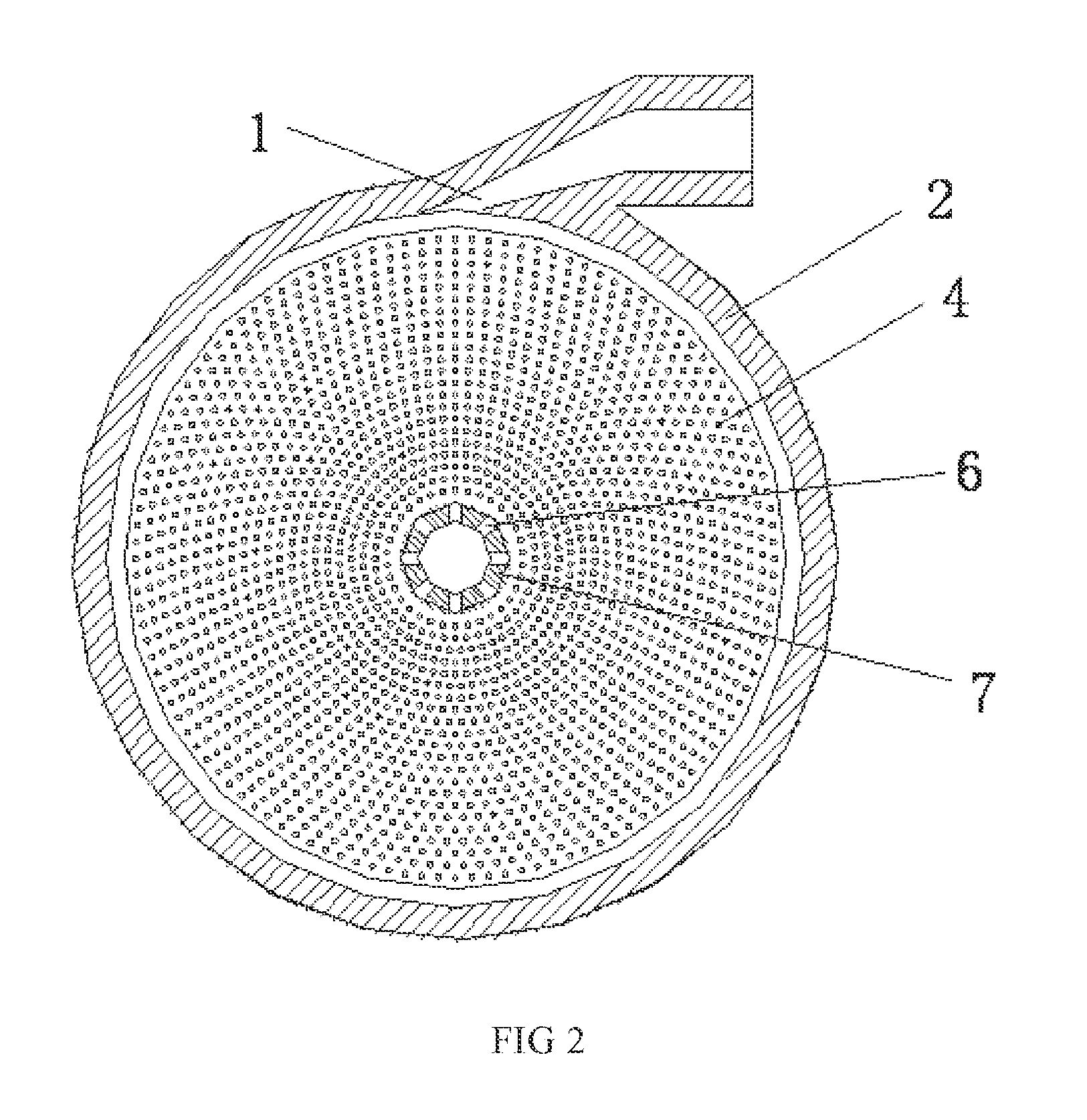

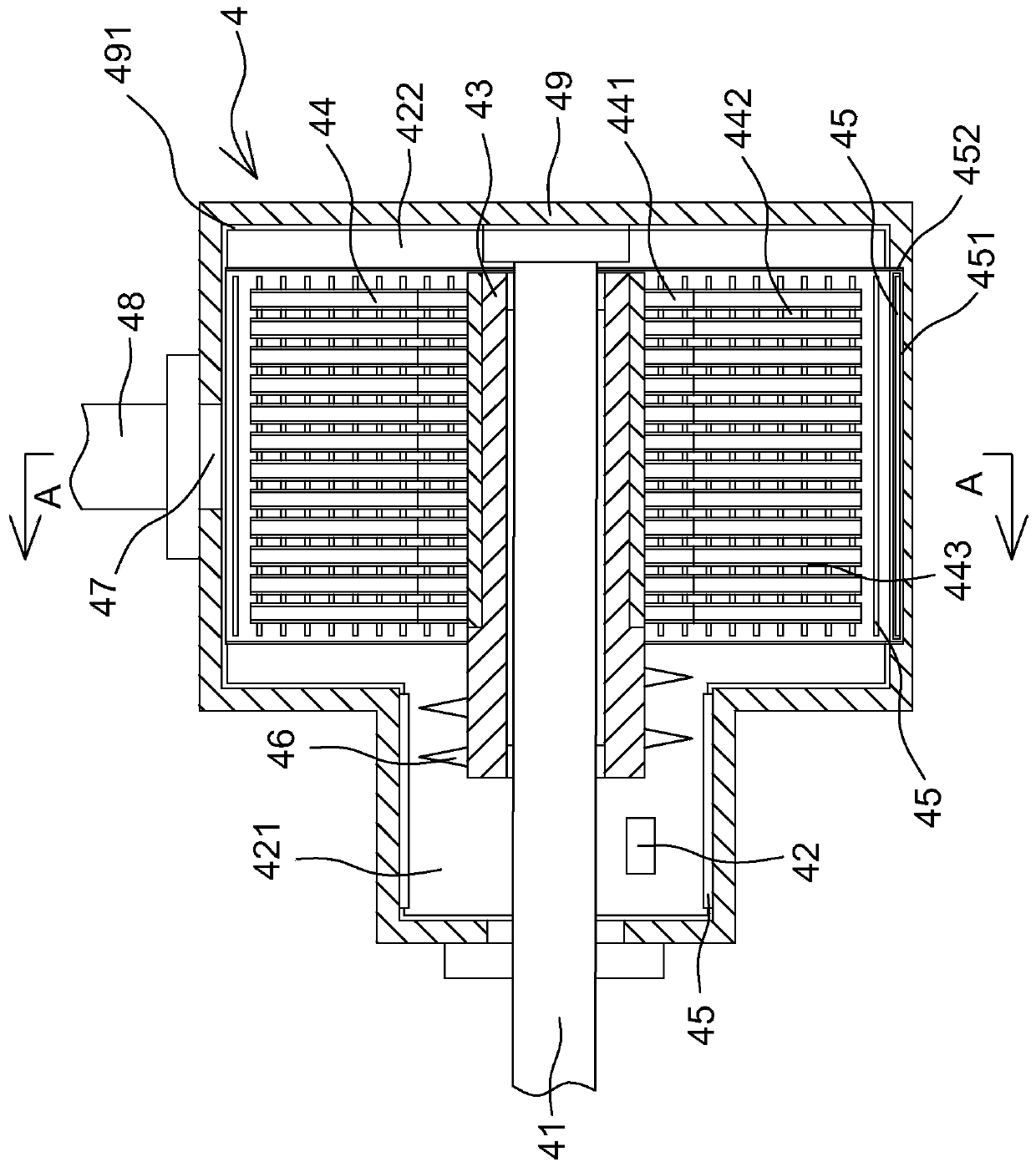

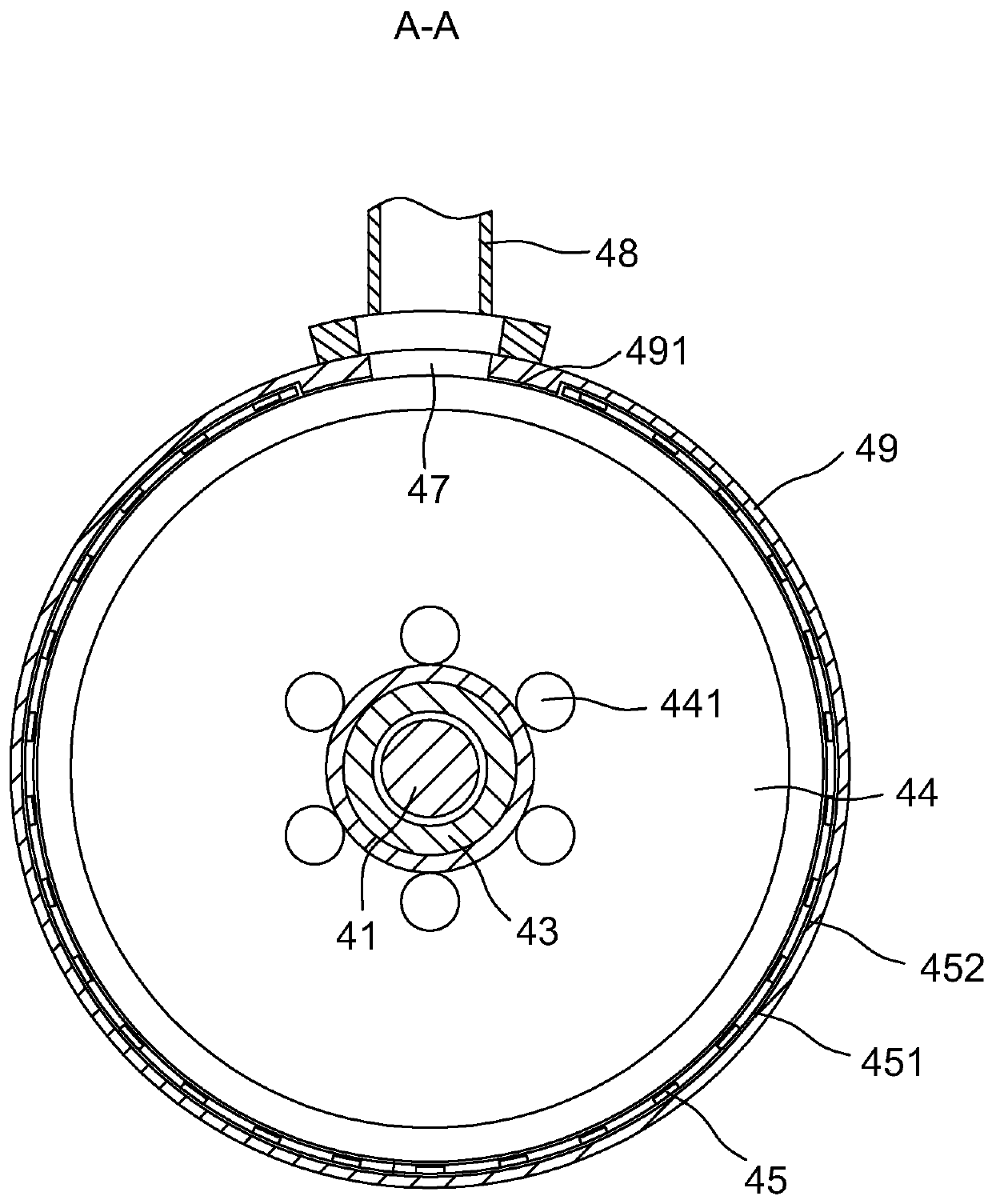

Annular Tesla turbine

InactiveCN103306738ASmall sizeIncrease powerBlade accessoriesNon-positive displacement enginesCircular discTesla turbine

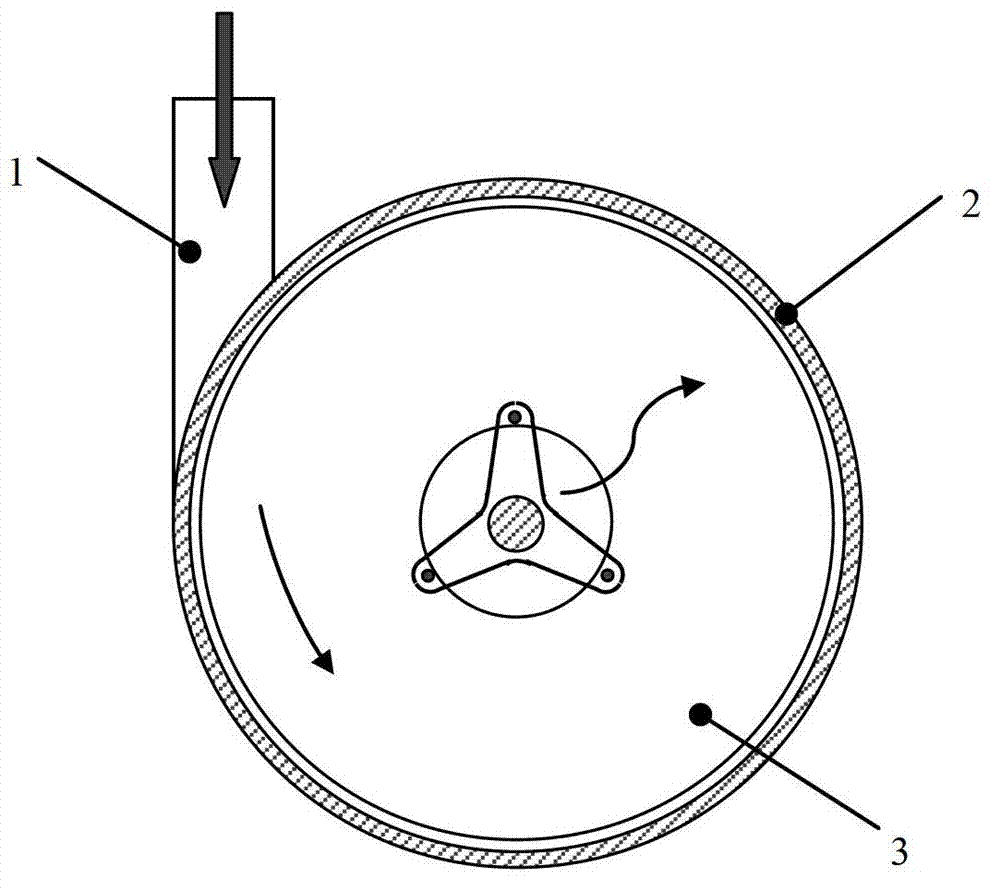

The invention provides an annular Tesla turbine which is characterized in that a rotor is in a ring shape, a stator is cylindrical and is arranged in the rotor, airflow rings are fully distributed inside the rotor, the space between the airflow rings adjacent to a nozzle is smaller, the space between the airflow rings far away from the nozzle is larger, and the nozzle is used for spraying air to the rotor along the tangential direction of the ring of the rotor. Since the airflow rings fully distributed inside the ring can be used for greatly increasing the contact area between the ring of the rotor and airflow; according to a boundary layer effect, the ring of the rotor can be driven to rotate by the airflow, so that the rotation of the rotor is realized; the airflow rings inside the ring of the rotor of the annular Tesla turbine are used for replacing the thin disc of a traditional Tesla turbine, the airflow rings and the ring of the rotor can be manufactured into a whole, or the airflow rings are supported and fixed on the ring, so that the airflow rings have rigidity better than that of the thin disc and have less possibility of deformation, and thus the rotor with a greater diameter and less possibility of deformation can be manufactured; and the power is increased, the efficiency is improved, and the operation is stable and reliable.

Owner:时剑

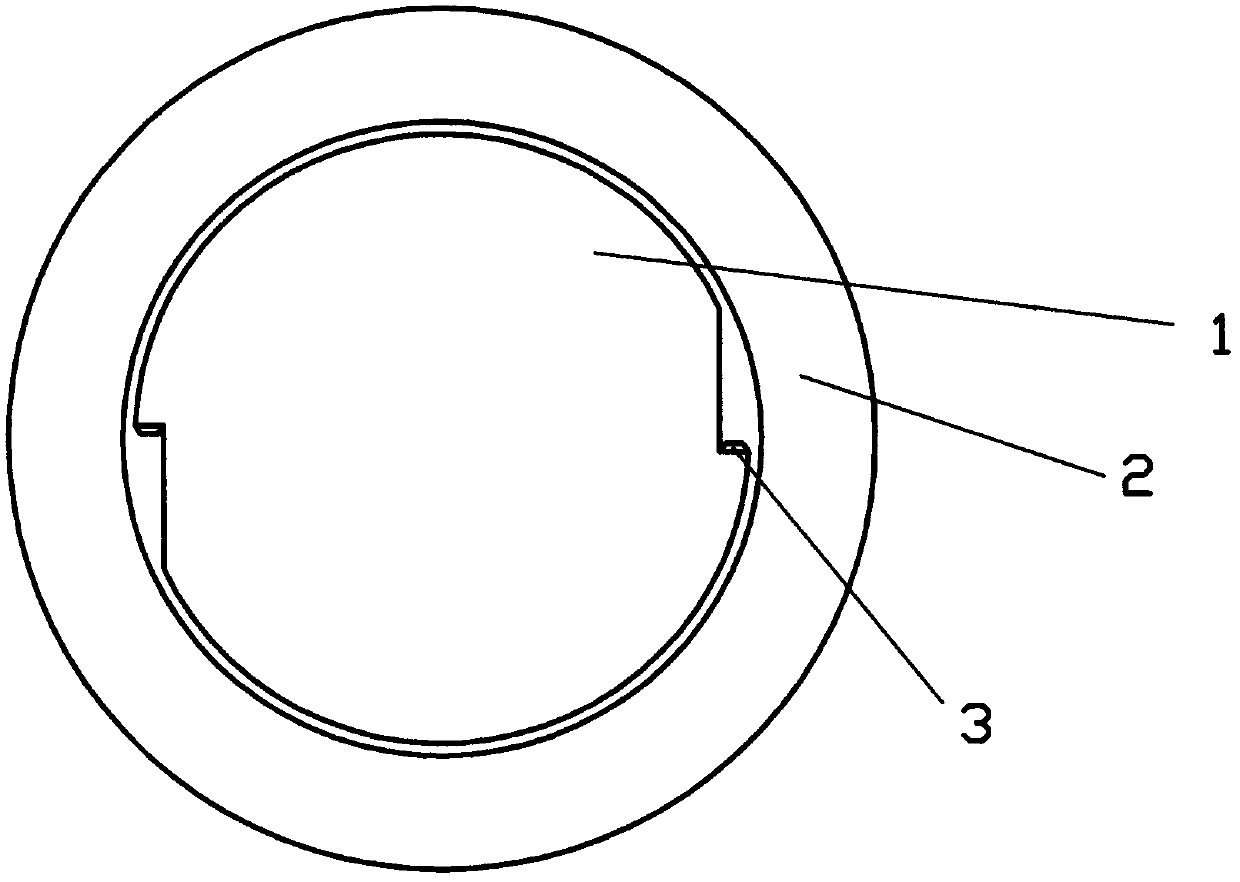

Annular tesla turbine

InactiveCN102373958ASmall sizeGuaranteed uptimeBlade accessoriesNon-positive displacement enginesSpray nozzleEngineering

The invention relates to an annular tesla turbine, which is characterized in that a rotor is made into a circular ring; annular slices are uniformly distributed on the inner side of the ring; a nozzle stretches into the inner side of the circular ring and jets air for the circular ring along a tangential direction of the circular ring; a vortex is formed by airflow under the guidance action of the inner side of the circular ring; and due to the annular slices uniformly distributed on the inner side of the circular ring, a contact surface of the circular ring and the airflow is greatly increased, so the circular ring is driven by the airflow to be rotated together according to a boundary layer effect, and thus the rotation of the rotor is realized. According to the annular tesla turbine, the annular slices on the inner side of the circular ring replace a thin disk of a conventional tesla turbine, and the annular slices and the circular ring can be made into a whole, or the annular slices are supported and fixed on the ring, so that the stiffness of the annular slices is better than that of the thin disk, the annular slices are not easy to deform, the rotor can have larger diameter and is not easy to deform, and thus the power is increased and the operation is more stable and reliable.

Owner:时剑

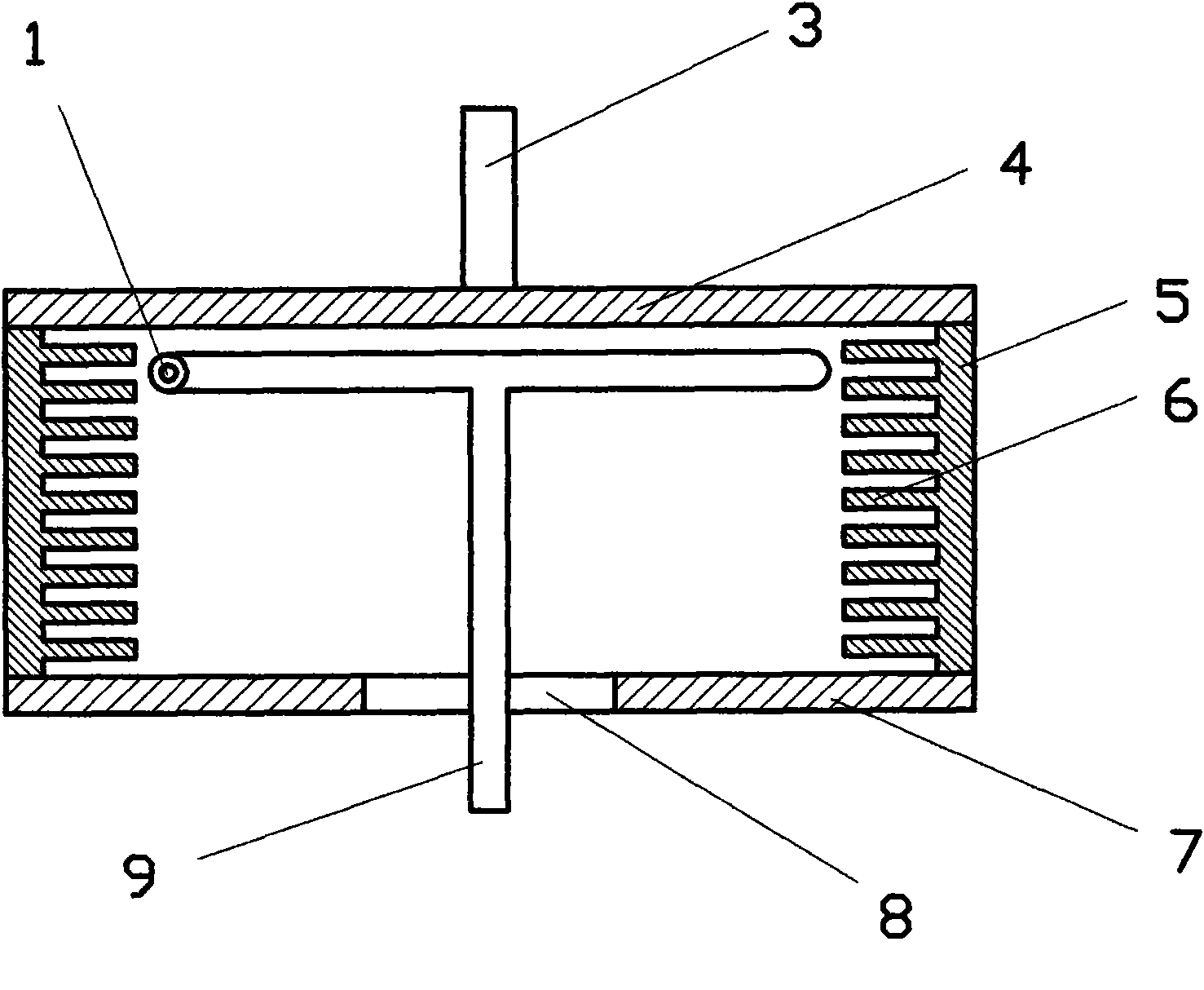

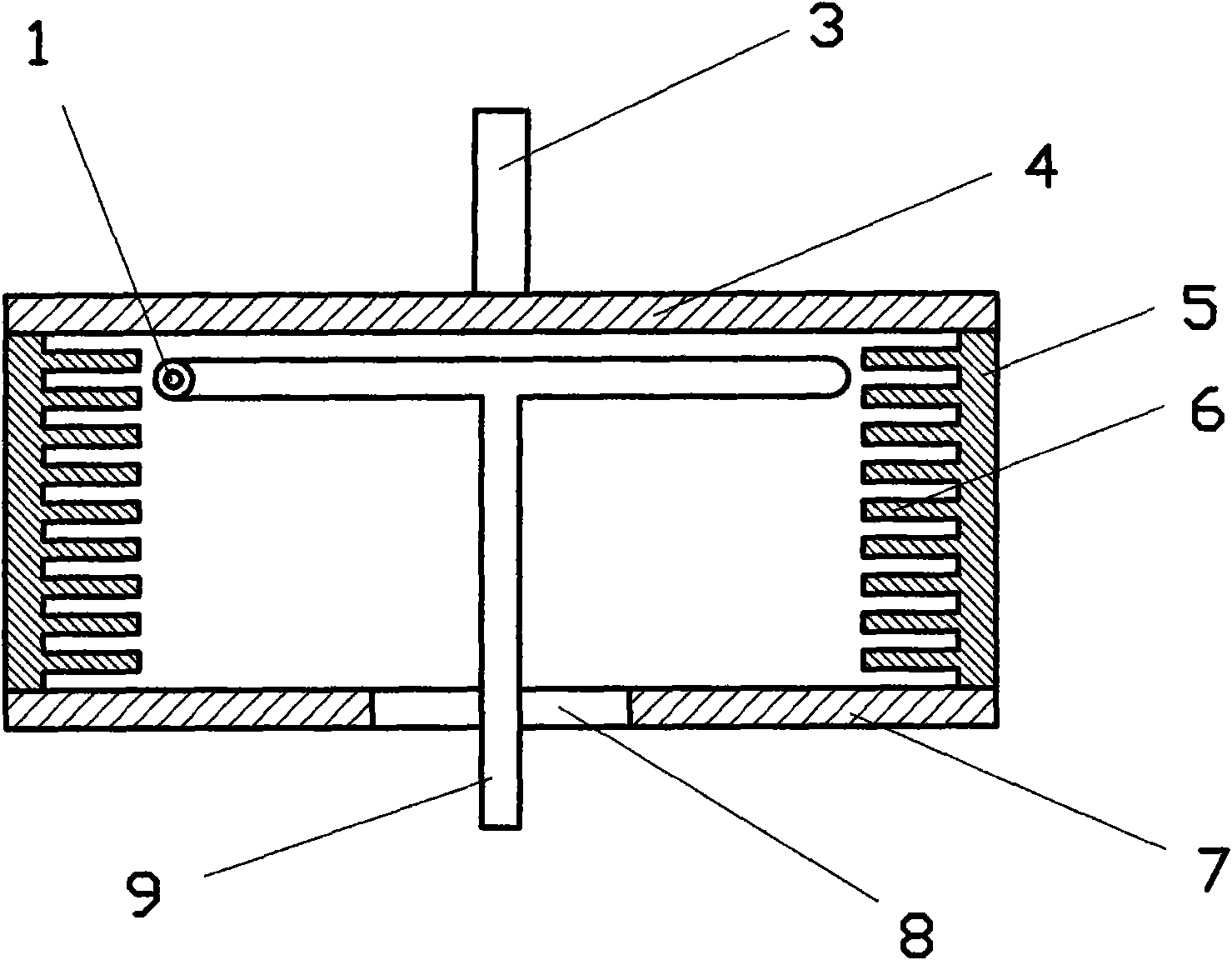

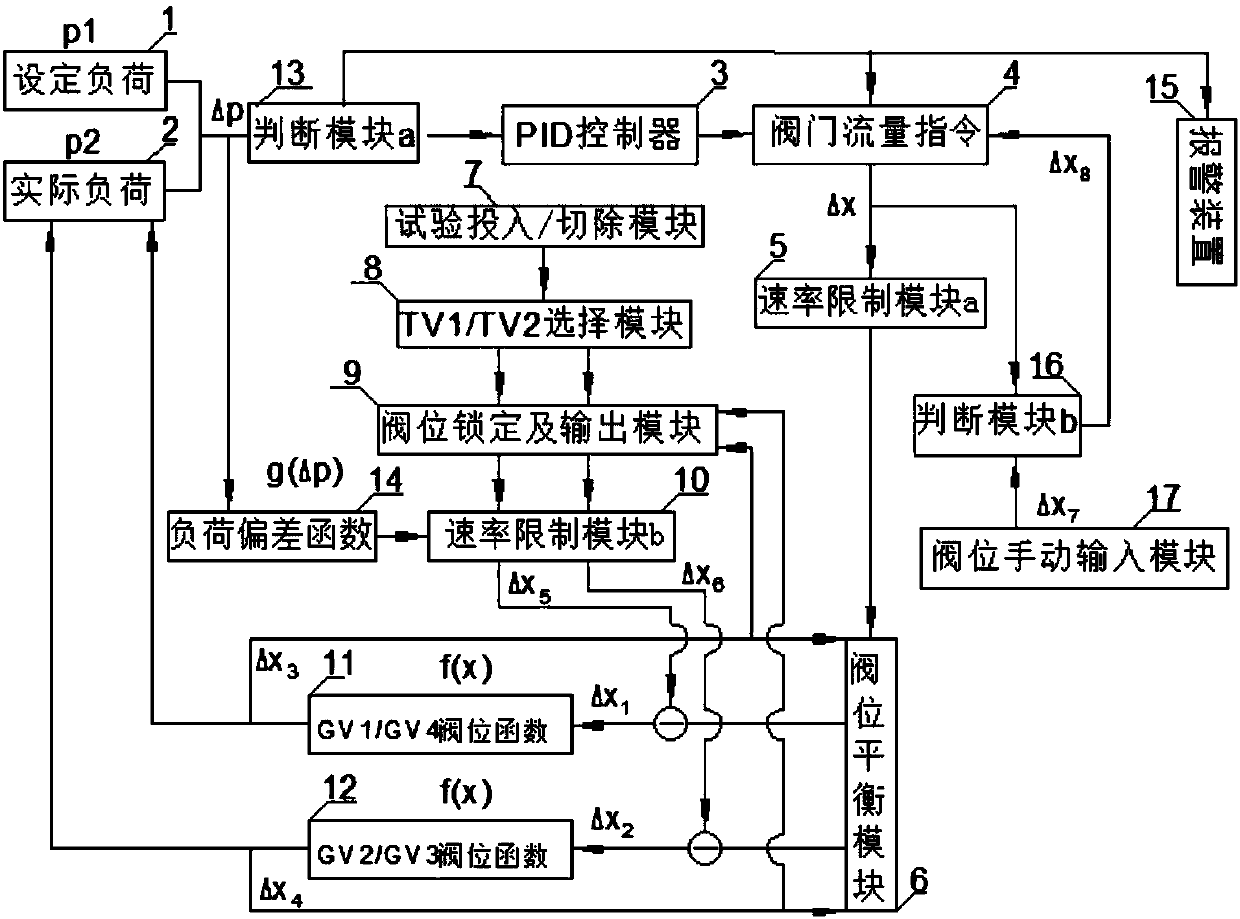

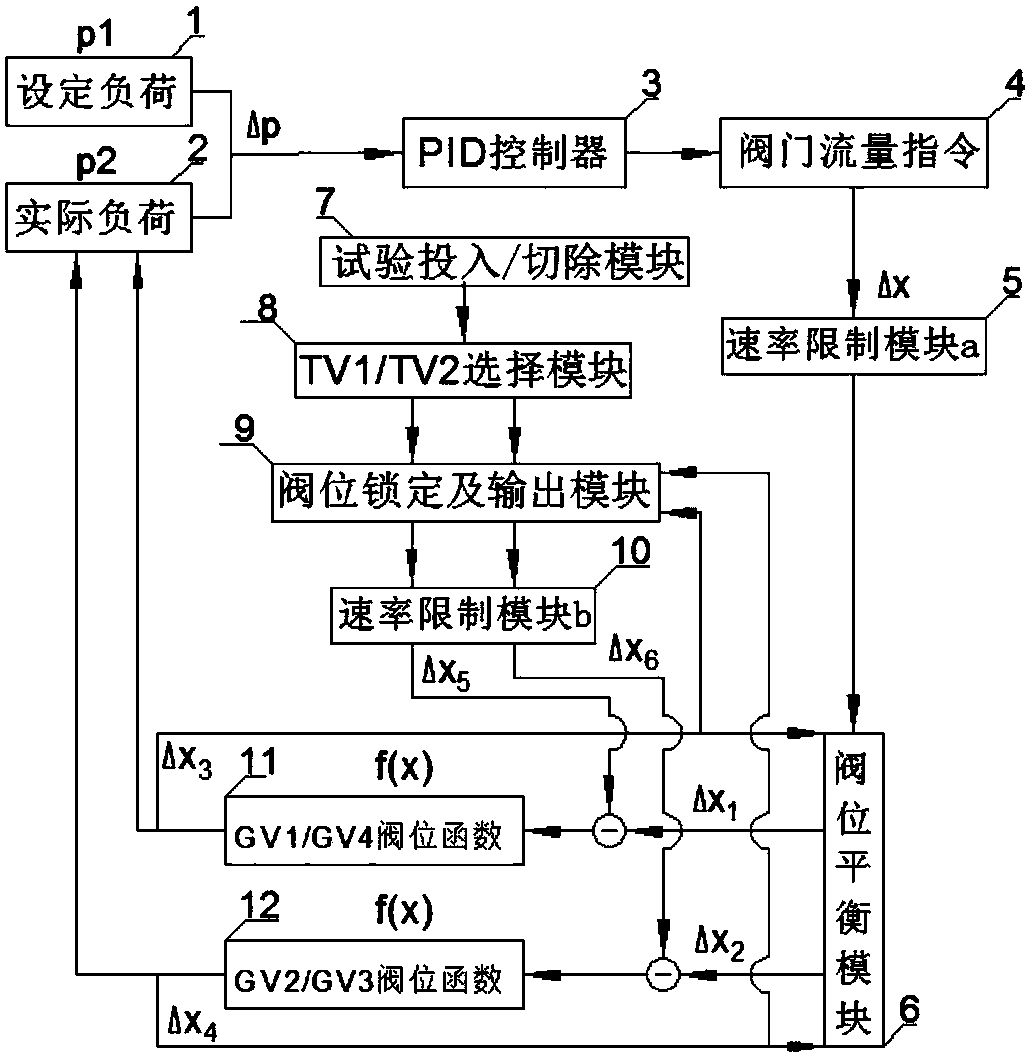

Method for prevention of generation of power oscillation in main stop valve full-stroke test of steam turbine

The present invention discloses a method for prevention of generation of power oscillation in a process of a main stop valve full-stroke test of a steam-turbine generation steam turbine. On the basisof the prior art, a determination module a and an alarm device are added to achieve removal of a power control loop, effectively prevent a unit from generating power fluctuation and power oscillationad emit an acousto-optic alarm after a steam turbine set is large in load deviation; a load deviation function is added to achieve that a high-pressure control valve can be switched on and off at variable speeds and reduce a small steam turbine load fluctuation amplitude; and a determination module b and a valve location manual input module are added to achieve a unit valve location maintenance function and a manual input valve location value function and effectively prevent the unit to generate power fluctuation and power oscillation. The method for prevention of generation of power oscillation in a main stop valve full-stroke test of a steam turbine provides a great guarantee for normal and smooth performing of the main stop valve full-stroke test of the steam turbine, and effectively reduces operators' burden.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

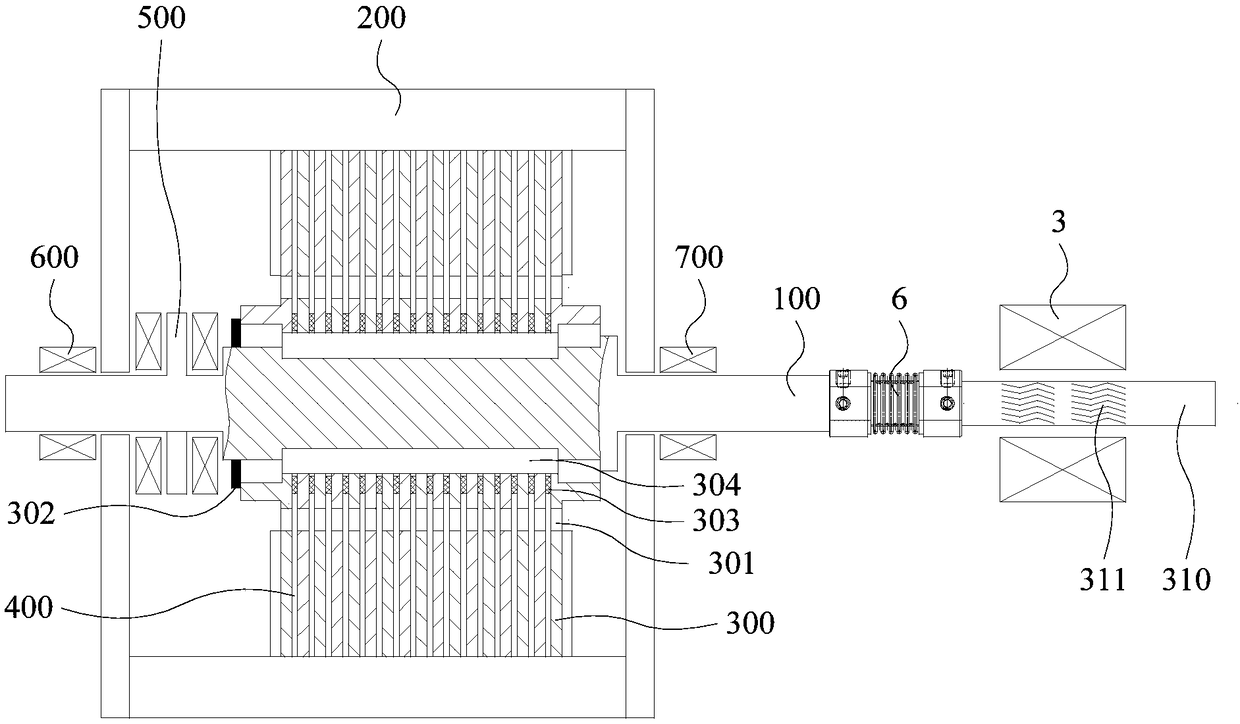

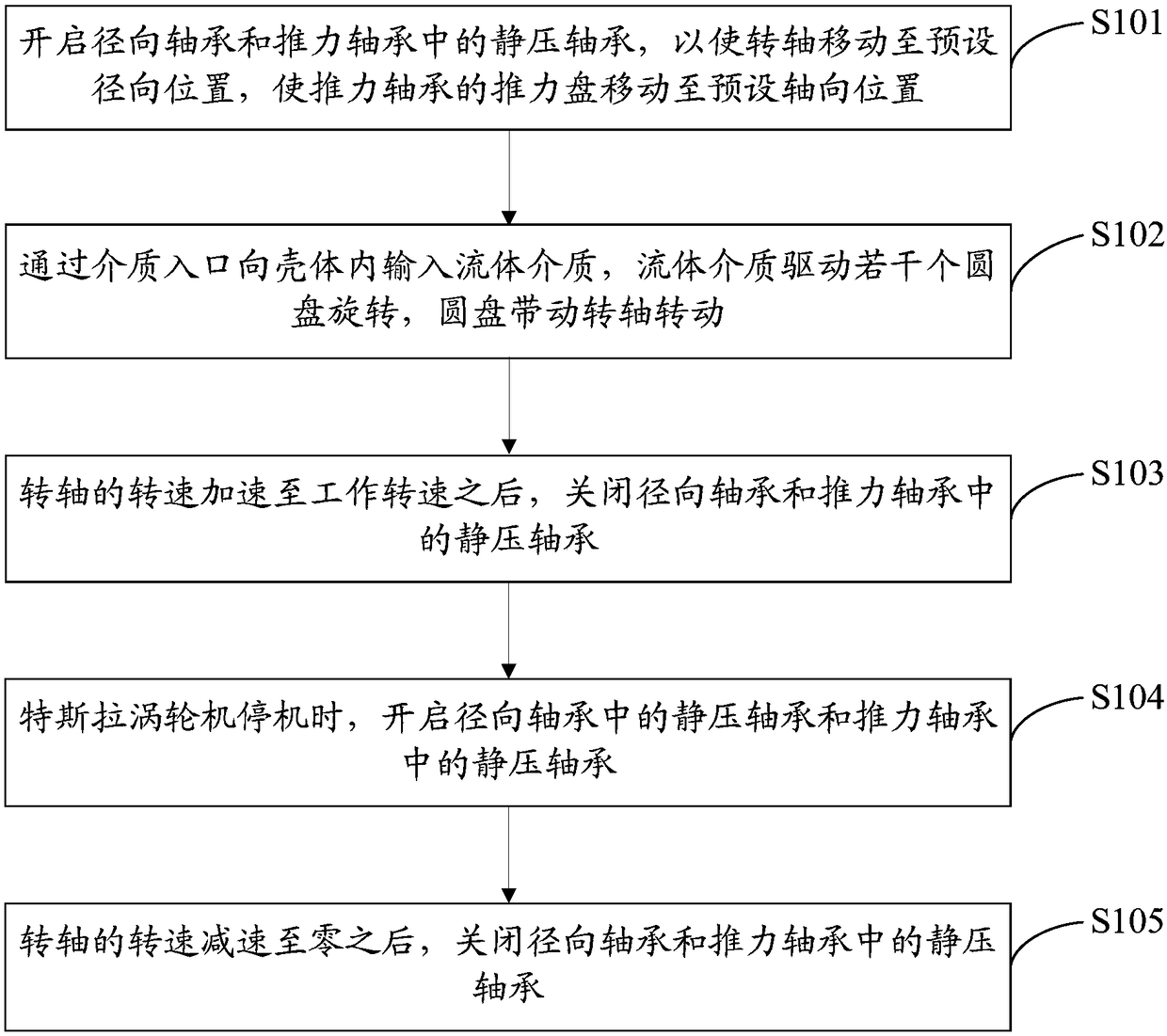

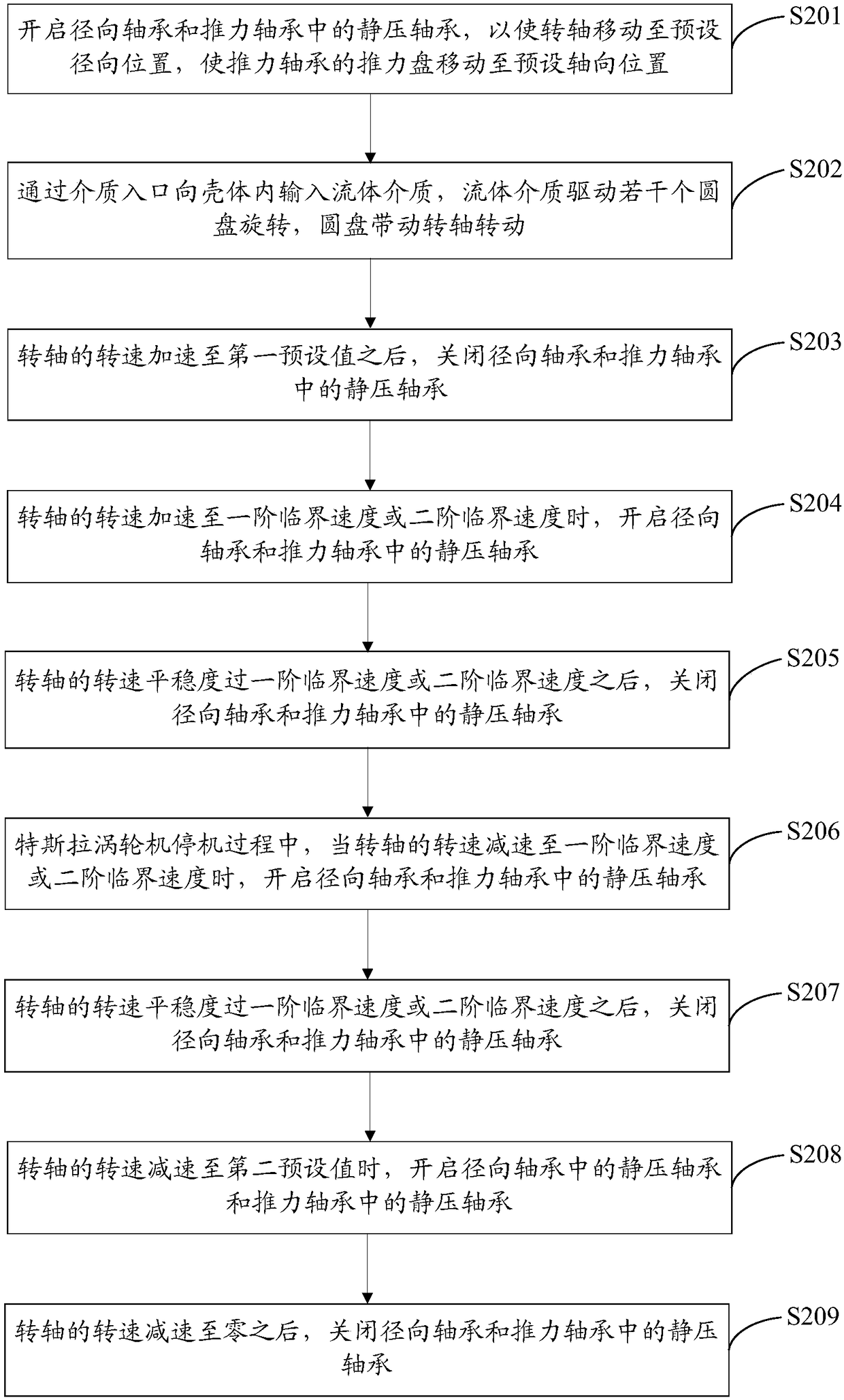

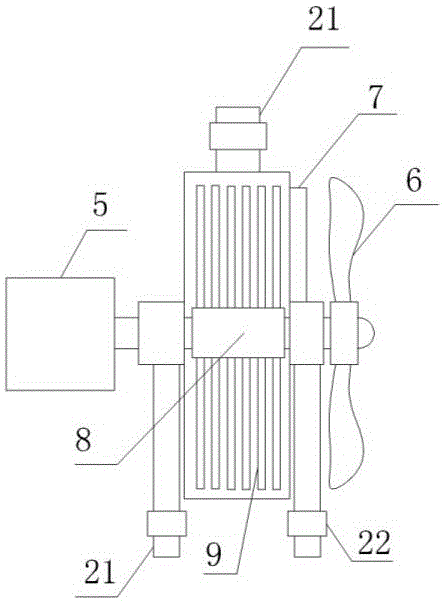

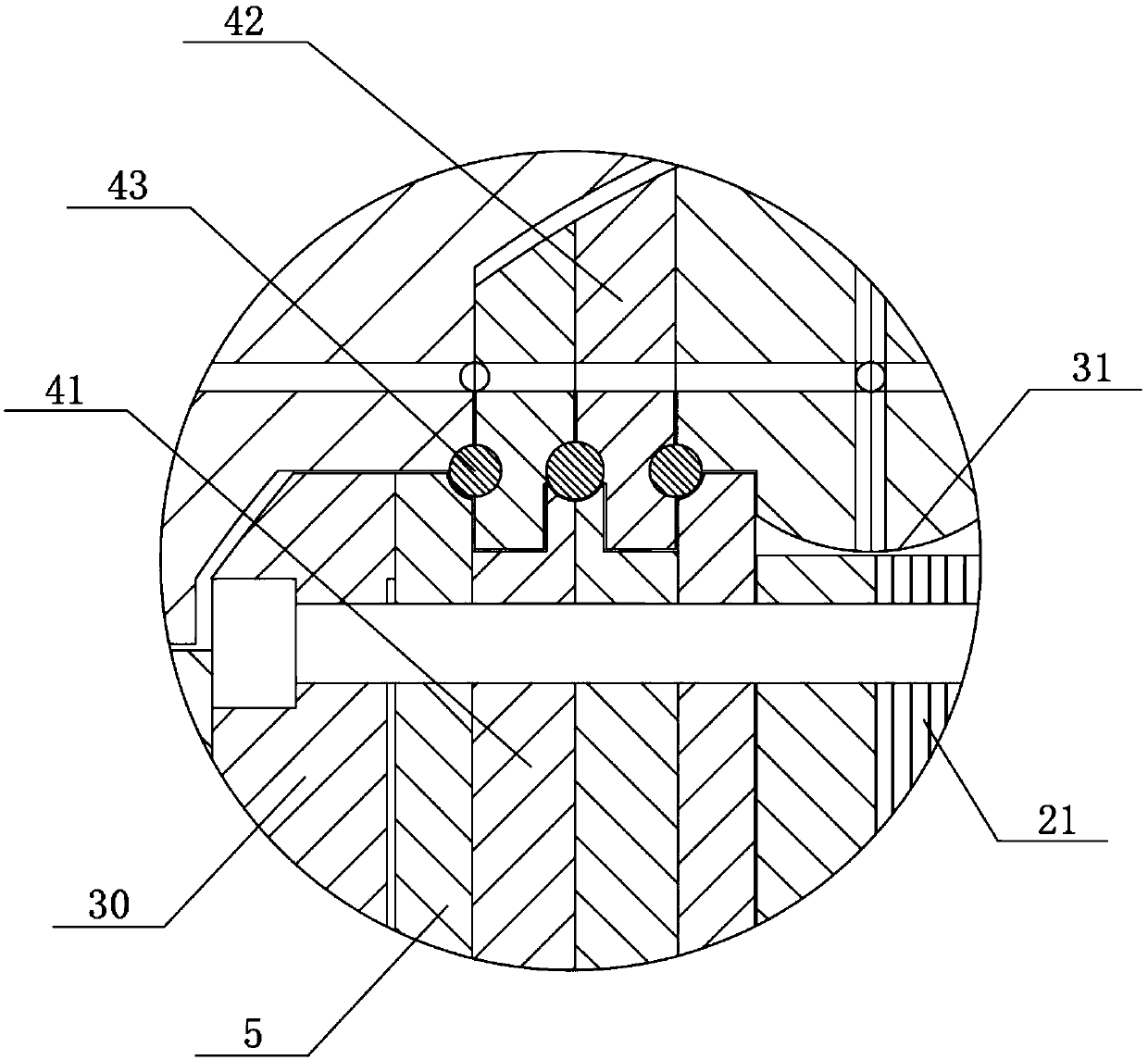

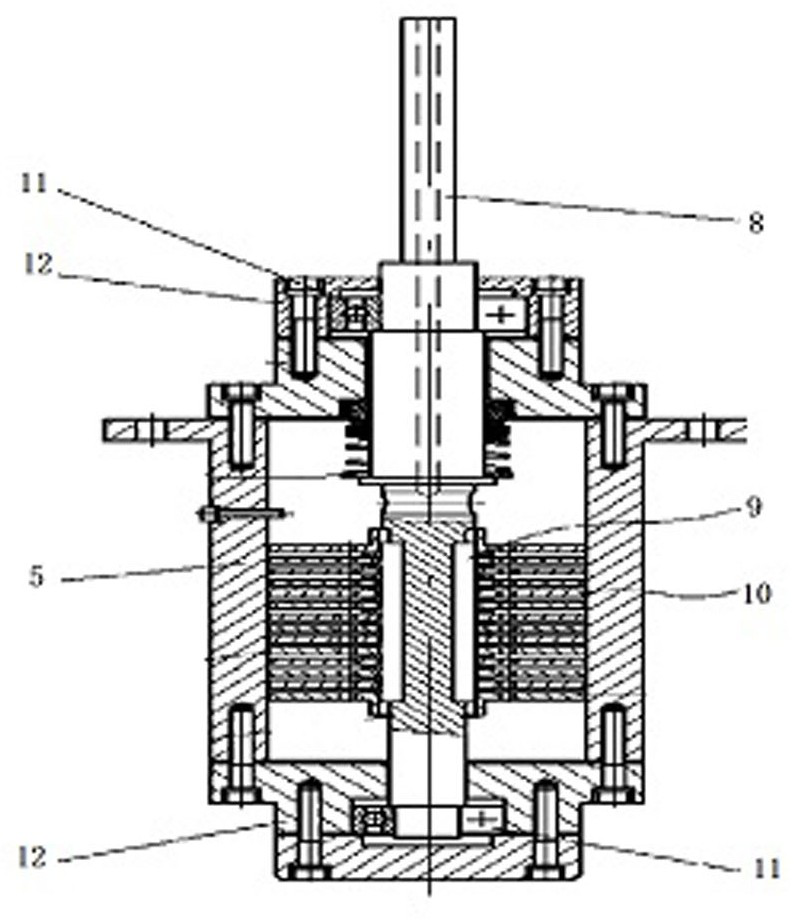

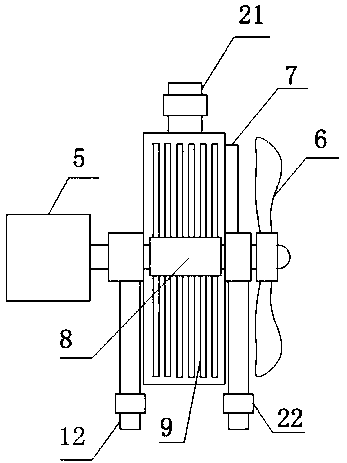

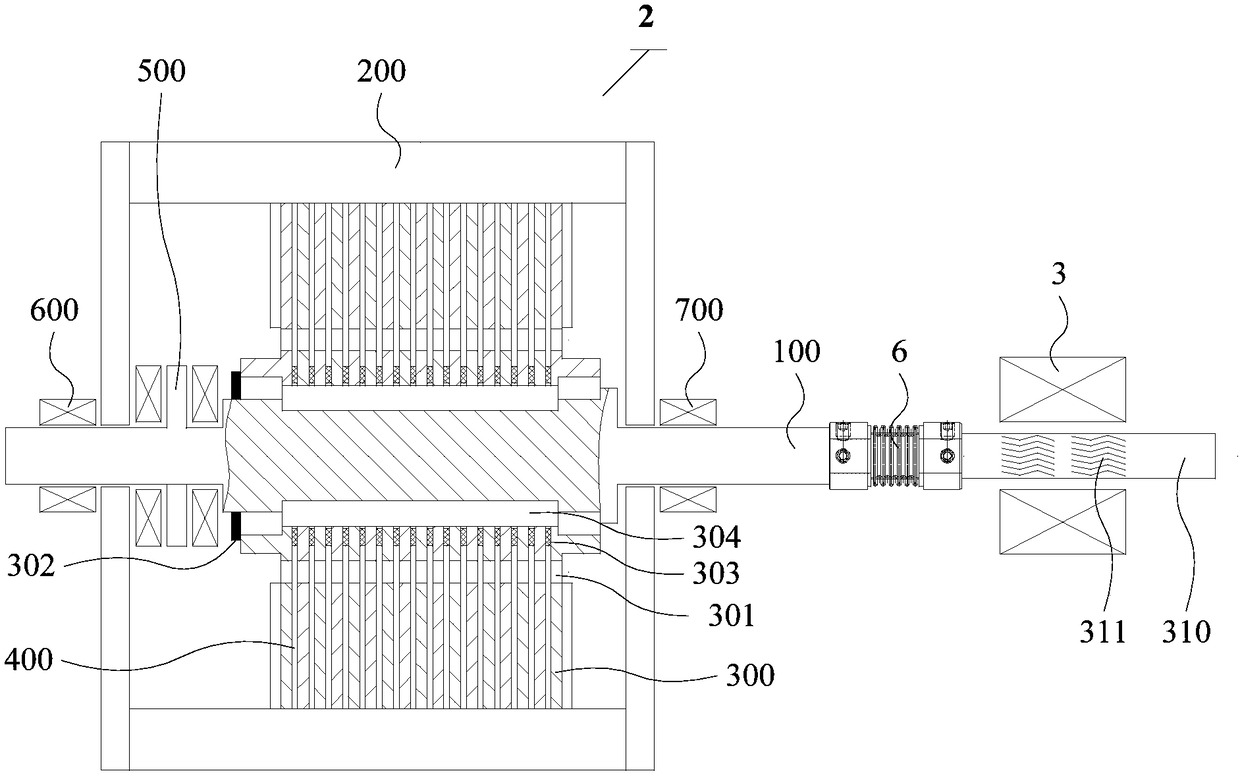

Tesla turbine and control method

PendingCN108868890AImprove dynamic performanceImprove stabilitySafety/regulatory devicesNon-positive displacement enginesThrust bearingTesla turbine

The invention provides a tesla turbine and a control method. The tesla turbine comprises a rotating shaft, a shell, a plurality of discs, a thrust bearing and at least two radial bearings; the shell is arranged on the rotating shaft, and a medium inlet and a medium outlet are formed in the shell; the plurality of discs are arranged in the shell, the plurality of discs are fixedly connected to therotating shaft, a gap is formed between every two adjacent disks of the plurality of disks, and at least one exhaust hole is formed in each of the plurality of disks; and the thrust bearing and at least two radial bearings are arranged on the rotating shaft, and the thrust bearing and the at least two radial bearings are non-contact bearings. According to the tesla turbine, non-contact thrust bearings of the thrust bearing and the radial bearings are adopted, the power loss of the tesla turbine on the bearings is reduced, so that the efficiency of the tesla turbine is improved.

Owner:靳普

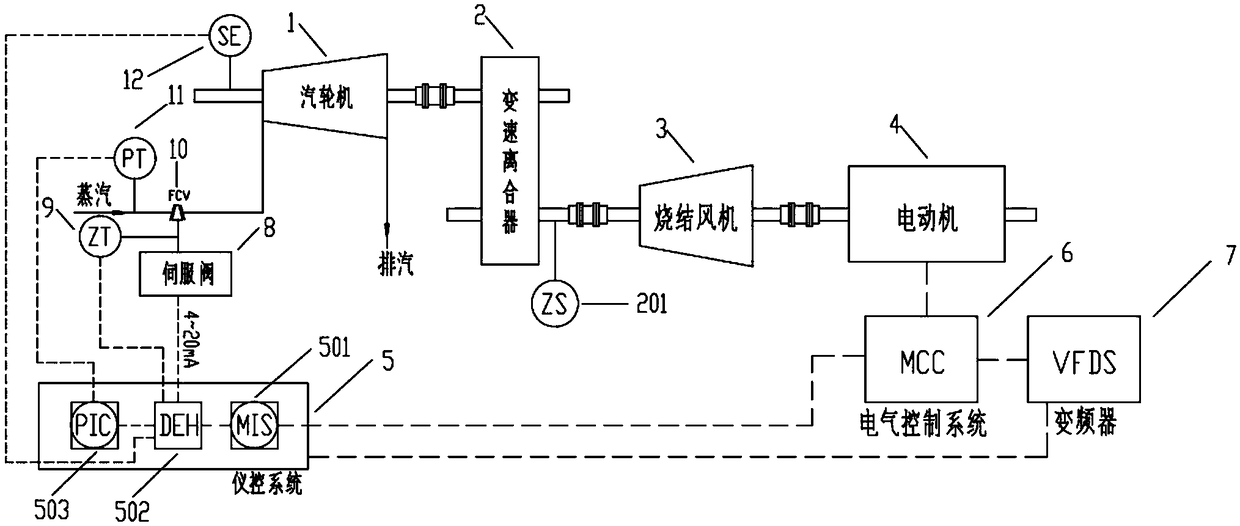

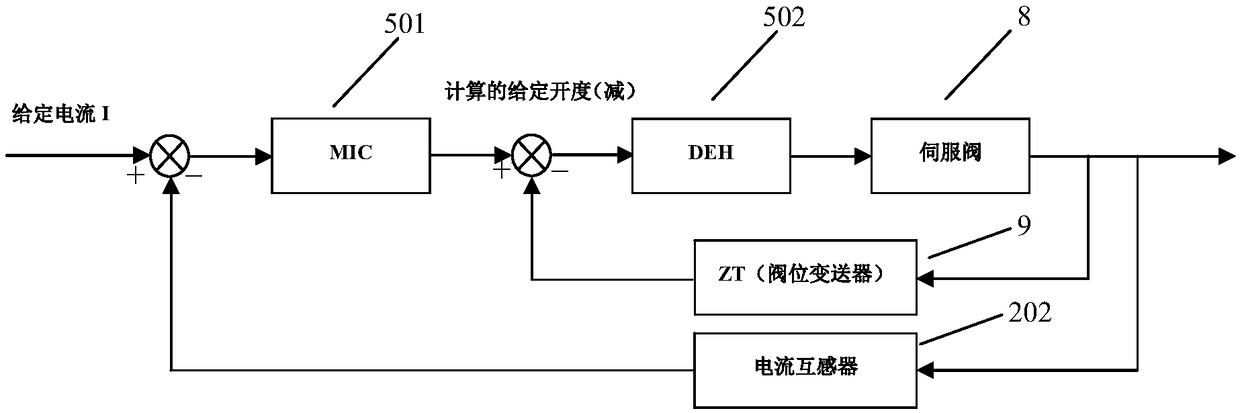

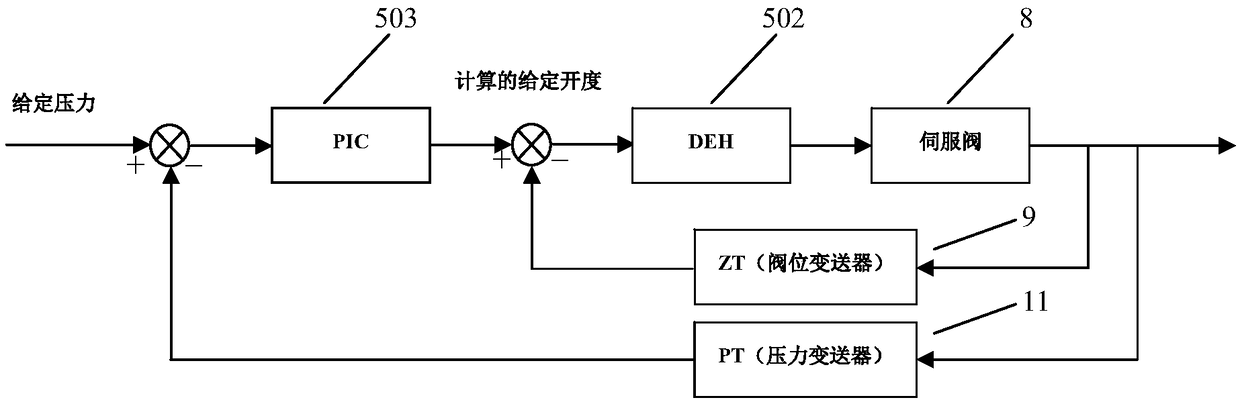

Method for load control of steam turbine in frequency-variable rotating speed reducing process of SHRT (sinter blower residual heat recovery turbine) set

ActiveCN109268079AEnsure safetyResolve downtimeMachines/enginesSafety/regulatory devicesFrequency changerPower flow

The invention discloses a method for load control of a steam turbine in a frequency-variable rotating speed reducing process of an SHRT (sinter blower residual heat recovery turbine) set. The method includes: step 1, starting the steam turbine, and detecting regulating steam port openness when the steam turbine is in a maximum non-load speed; step 2, performing rotating speed reducing control of the set, to be more specific, 1) when rotating speed reducing operation of the set is needed, setting VFDS frequency or rotating speed by operating personnel; sending a 'preparing for rotating speed reduction' signal to an instrument control system by VFDS, judging whether the set meets speed regulating conditions or not by the instrument control system, and if yes, feeding a 'permission of rotating speed reduction' signal to VFDS7, and executing the step 2); 2) reducing the rotating speed of a motor to a target rotating speed S1 under the control of VFDS, and in a rotating speed reducing process, reducing output power of the steam turbine to guarantee that current of the motor is constantly set current II. The method is free of human intervention, and the problem of frequency converter failure shutdown caused by current fluctuation of the motor in the rotating speed reducing process is effectively solved; in addition, enormous economic benefits can be created for enterprises by the SHRT set.

Owner:XIAN SHAANGU POWER

Intermediate reheating small-capacity split axle type steam-turbine generator set

An intermediate reheating small-capacity split axle type steam-turbine generator set comprises a reheating boiler with the evaporation capacity of 410t / h-120t / h and two double-circulation communicated steam turbines with the capacity of 120MW-15MW, wherein each steam turbine is provided with a matched generator. The mature high parameter backpressure steam turbine and medium and low-pressure parameter steam turbine technologies are utilized, the existing small-capacity single-axle type steam turbine is split into double-axle steam turbines, one set of high parameter steam turbine is changed into a high parameter backpressure turbine and a medium and low-pressure parameter rear turbine, and at the same time, a set of large-capacity generator is changed into two small-capacity generators. After change, the two steam turbines are separately arranged, the problem that pipelines cannot be arranged caused by adopting a reheating technology by a small-capacity unit is systematically solved; after axle splitting, generating shaft systems of the two steam turbines both become short, the stability of the shaft systems is favorably increased; after cylinder splitting, the power of each steam turbine becomes small, and the axial unbalanced force borne by a thrust bearing is favorably reduced.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

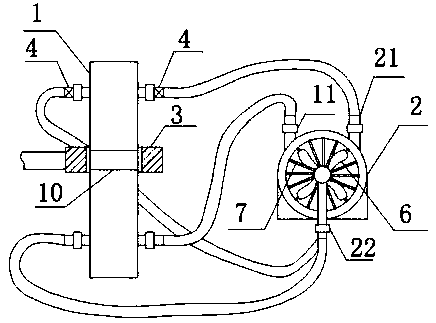

Automobile damping device

The invention provides an automobile damping device, belongs to the technical field of damping, and solves the problems that performances of a damper cannot be flexibly regulated and temperature of an oil liquid rises quickly during frequent vibration. The automobile damping device comprises a piston hydraulic damper, wherein the bottom of a cavity of the piston hydraulic damper communicates with a liquid inlet end opening of a Tesla turbine; the upper part of the cavity of the piton hydraulic damper communicates with a liquid outlet end opening of the Tesla turbine; one end of a turbine shaft of the Tesla turbine is connected to a motor; and fan blades are arranged on a turbine shaft at the other end. According to the automobile damping device provided by the invention, the damper is combined with the Tesla turbine, so that regulation on damping force of the damper can be realized through rotation of the motor; and the fan blades are arranged on the Tesla turbine, so that the oil liquid can be cooled by utilizing vibrating energy of the damper.

Owner:JIAXING UNIV

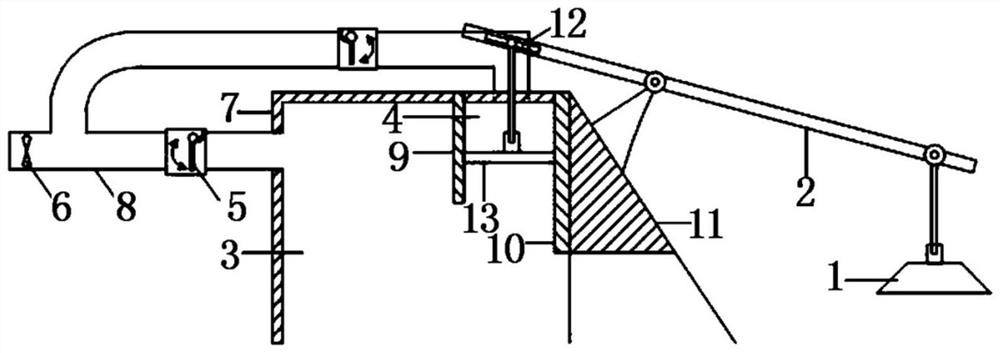

Oscillation water column type wave energy power generation device combined with Tesla turbine

PendingCN112211771AImprove conversion efficiencySolve efficiency problemsEngine componentsNon-positive displacement enginesEngineeringTesla turbine

The invention discloses an oscillation water column type wave energy power generation device combined with a Tesla turbine, comprising a wave absorption device, an energy conversion device and an output device. The wave absorption device comprises a floater for absorbing wave energy, a main air chamber and a piston; the energy conversion device comprises a lever, an oscillation air chamber and anair conveying pipeline; the energy conversion device converts the wave energy absorbed by the wave absorption device into kinetic energy of air; the output device comprises the Tesla turbine and a power generator; and the output device converts the kinetic energy of the air into mechanical energy of the Tesla turbine, then the power generator is driven to rotate to generate power, and bidirectional compression and air suction in a wave energy air chamber are implemented. The device is suitable for wave energy resource areas, can greatly enhance the wind power passing through a turbine to improve the power generation efficiency, overcomes the defects that an existing wave energy device is low in power generation efficiency and complex in structure, effectively utilizes reciprocating airflowgenerated by waves in the air chamber, lowers the requirement for the structural design of an air turbine, and is simple in form and convenient to install and transfer.

Owner:SHANGHAI OCEAN UNIV

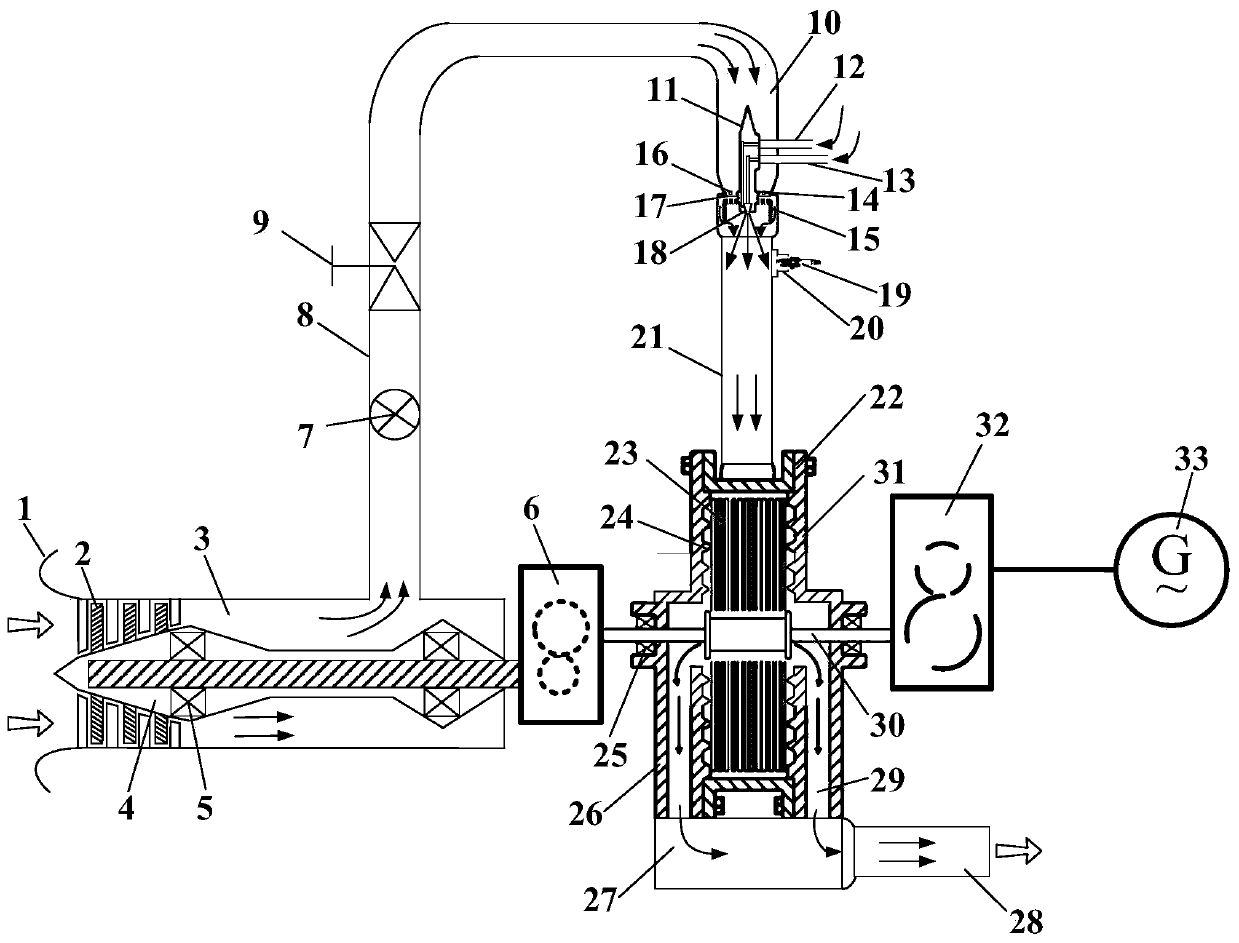

Gas turbine power generation device acting through pulse detonation fuel gas viscous force

ActiveCN111577459AIncrease output generating powerImprove cycle thermal efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberGas compressor

The invention discloses a gas turbine power generation device acting through pulse detonation fuel gas viscous force. The gas turbine power generation device comprises a gas inlet channel, a gas compressor and the like. The gas inlet channel is located at the forefront end of a gas turbine, the gas compressor is connected with the gas inlet channel, and a gas storage chamber is arranged on the downstream portion of the gas compressor. An exhaust pipe of the gas compressor is connected with the gas storage chamber and a combustion chamber gas inlet channel. A combustion chamber gas inlet cone is arranged in the combustion chamber gas inlet channel, and a combustion chamber pneumatic valve is mounted on the combustion chamber gas inlet cone. A pulse detonation combustion chamber is connectedwith the combustion chamber gas inlet channel, a spark plug is arranged on the head of the pulse detonation combustion chamber, and a telsa turbine is arranged at an outlet of the pulse detonation combustion chamber. A gas collection cavity is arranged on the side of the telsa turbine. The exhaust pipe is connected with the gas collection cavity. The left end of a gas compressor transmission is connected with a gas compressor rotor, and the right end of the gas compressor transmission is connected with a turbine rotor. The left end of a generator transmission is connected with the turbine rotor, and the right end of the generator transmission is connected with a generator. According to the gas turbine power generation device, the problems happening after the pulse detonation combustion chamber replaces an isobaric combustion chamber in a ground gas turbine and other power generation power devices are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

System and method for carrying out steam turbine running by virtue of non-nuclear steam

ActiveCN105937413AShorten the timeReduced turnaround timeMachines/enginesEngine startersNuclear powerEngineering

The invention discloses a system and a method for carrying out steam turbine running by virtue of non-nuclear steam. The system comprises an isolation door for the outlet of a water feeding pump, a high-pressure heater bypass tube, an evaporator, a main steam door, an external steam inflation valve group and a pressure container. According to the method, a time needed for heating external steam to steam under running parameters by virtue of the heat generated by rotation of a main pump (main nuclear fan) is shorter (relative to a time needed for heating water to water under the running parameters), thus the running time is greatly shortened, and the test run construction period is shortened; and the external steam can be continuously supplied if the pressure of the external steam is greater than the minimum pressure needed for the running, the heat is generated by the rotation of the main pump (main nuclear fan) to further heat the steam to achieve running requirements. Therefore, the steam under the running parameters can be continuously supplied, thus continuous running of a steam turbine after achieving a constant speed is ensured, most of tests on the steam turbine in the constant-speed state are completed, the occupied time of a conventional island test on a nuclear power station after charging is reduced, and then the test run construction period of a nuclear power unit is shortened.

Owner:XIAN THERMAL POWER RES INST CO LTD

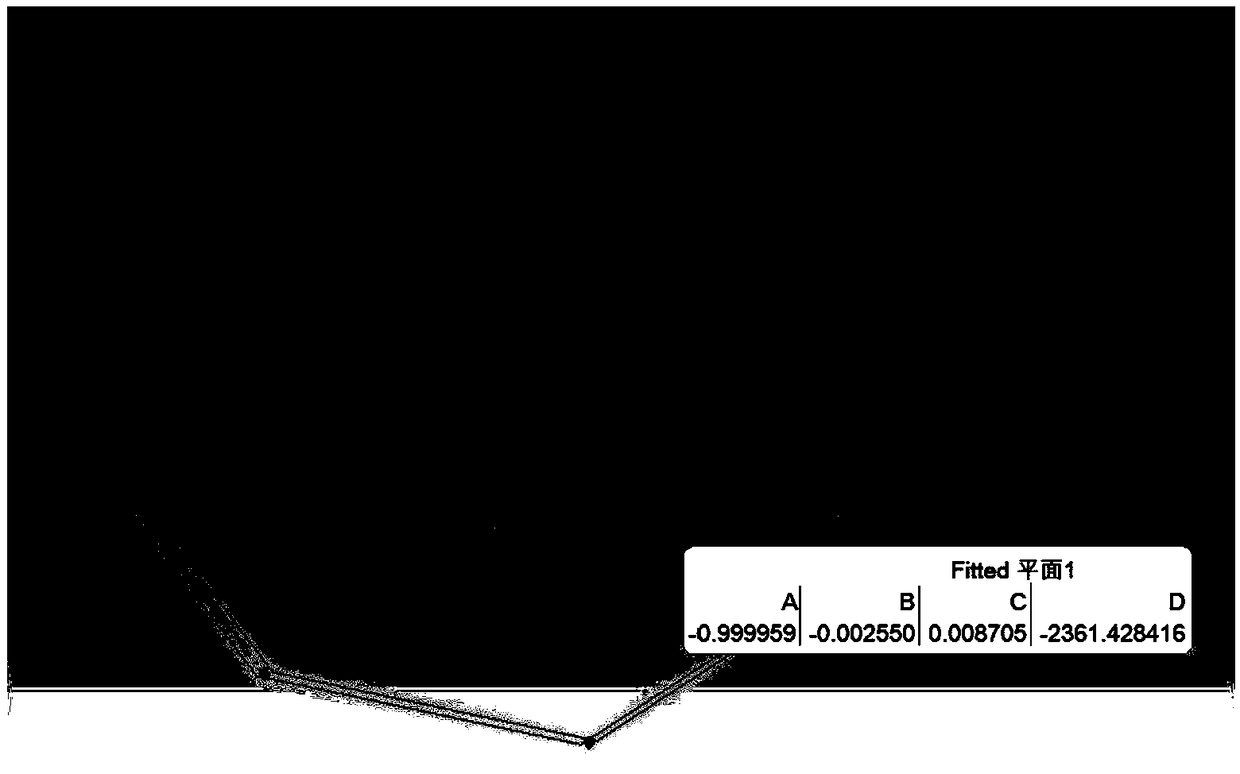

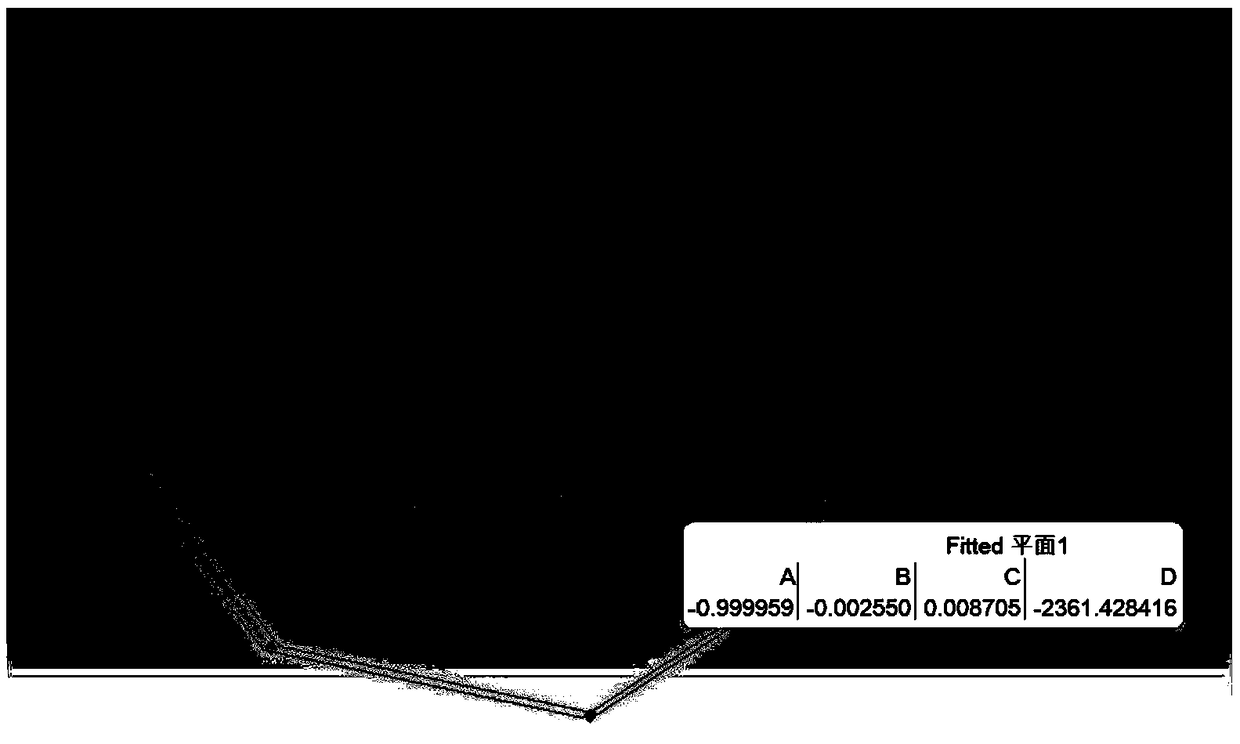

Steam turbine full cylinder state flow clearance detection method

InactiveCN108709511AHigh measurement accuracyShorten delivery timeUsing optical meansElement analysisEngineering

The invention provides a steam turbine full cylinder state flow clearance detection method, relates to a flow clearance detection method, and aims at solving the problems that the accuracy of presentsmall steam turbine flow clearance measurement is low and multiple times of assembling, disassembling, detection and other repetitive work require to be performed in measurement. The method comprisesthe steps that step one, the separating plate inner circle of each shaft segment and the separating plate inner circle of each of each rotor blade are measured under the split and combining state of each separating plate; step two, each circular arc having the flow clearance requirement of the upper and lower cylinders is measured by using the target sphere under the cylinder disassembling state;step three, the measured data are processed by using the SpatialAnalyzer software and the center of circle and the diameter are extracted; step four, a steam turbine three-dimensional design model isestablished, finite element analysis is performed under the full cylinder and half cylinder state and the compensation value is calculated; and step five, a steam turbine flow clearance calculation model is established and the flow clearance under the full cylinder state is calculated. The steam turbine full cylinder state flow clearance detection method is used for the field of steam turbine digital detection.

Owner:HARBIN INST OF TECH

Boundary Layer Disk Turbine Systems for Controlling Pneumatic Devices

InactiveUS20130071259A1Lower requirementEasy to driveFlexible member pumpsPump controlCompressed fluidProcess engineering

Provided are various devices and processes that harness the inherent kinetic energy of a flowing pressurized fluid to drive a compressor to compress a fluid without any need for electrical or chemical energy. The flowing drive fluid flows over a boundary layer disk turbine, or Tesla turbine, which is mechanically coupled to a compressor that compresses a fluid. The flowing fluid may be a natural gas from a hydrocarbon recovery operation. The compressed fluid may be air that is used to power a pneumatic device in an industrial process. Harnessing the kinetic energy of the flowing fluid increases economic efficiency of the process, while also avoiding unwanted emissions adverse to the environment and public health.

Owner:LEED FABTION SERVICES

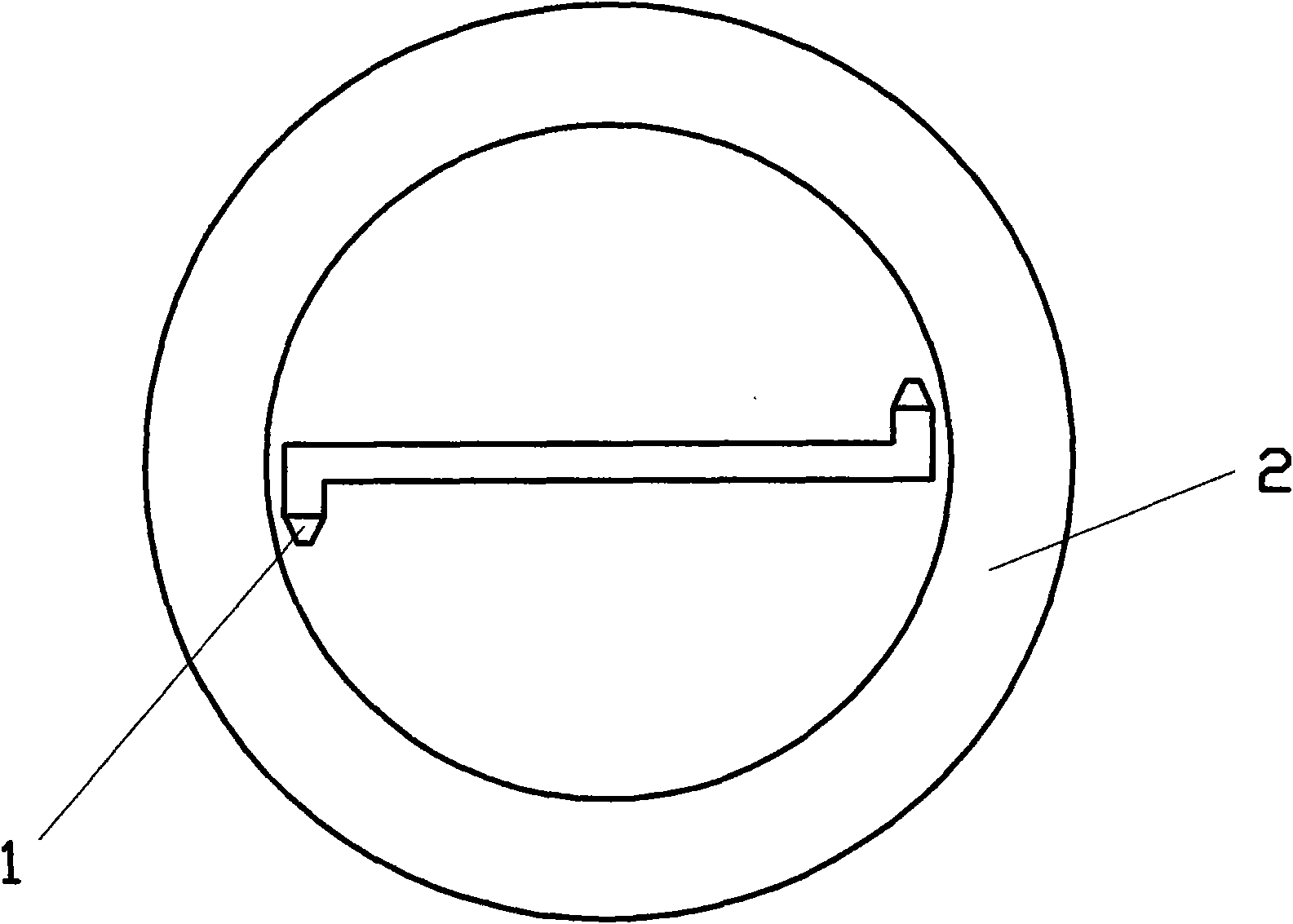

Annular Tesla turbine

The invention provides an annular Tesla turbine. A rotor of the ring-shaped Tesla turbine is made into a circular ring; a stator is arranged inside the rotor; the stator has bigger diameter at one end and smaller diameter at the other end; the bigger end of the stator is provided with a spray nozzle; the smaller end of the stator and the rotor have a bigger gap to form an exhaust port; annular thin sheets are fully distributed at the internal side of the rotor; the annular thin sheets close to the spray nozzle have small gaps and the annular thin sheets close to the exhaust port have big gaps; the spray nozzle injects the air toward the rotor along the tangent line direction of the circular ring; an airflow can form a vortex flow under the guide action of the internal side of the circular ring and drive the circular ring to rotate together, so that the rotation of the rotor is realized. The annular Tesla turbine disclosed by the invention can replace a thin circular tray of the traditional Tesla turbine by using the annular thin sheets at the internal side of the circular ring; the annular thin sheets can be integrated with the circular ring into a whole or are supported and fixed from the ring, the rigidity of the annular thin sheets is better than that of the thin circular tray, and the thin sheets are not easy to deform, so that the diameter of the rotor can be bigger and rotor are not easy to deform, accordingly, the power is increased, the efficiency is improved and the operation process is stable and reliable.

Owner:时剑

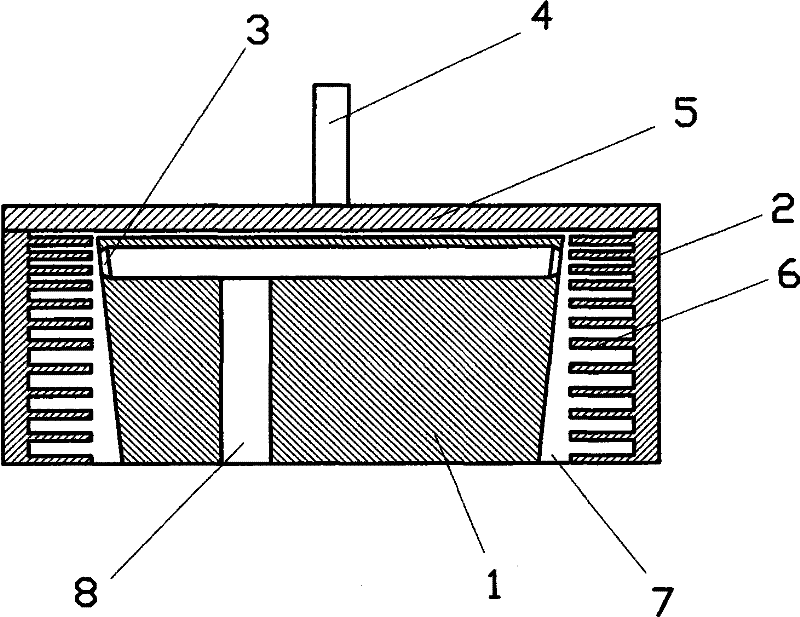

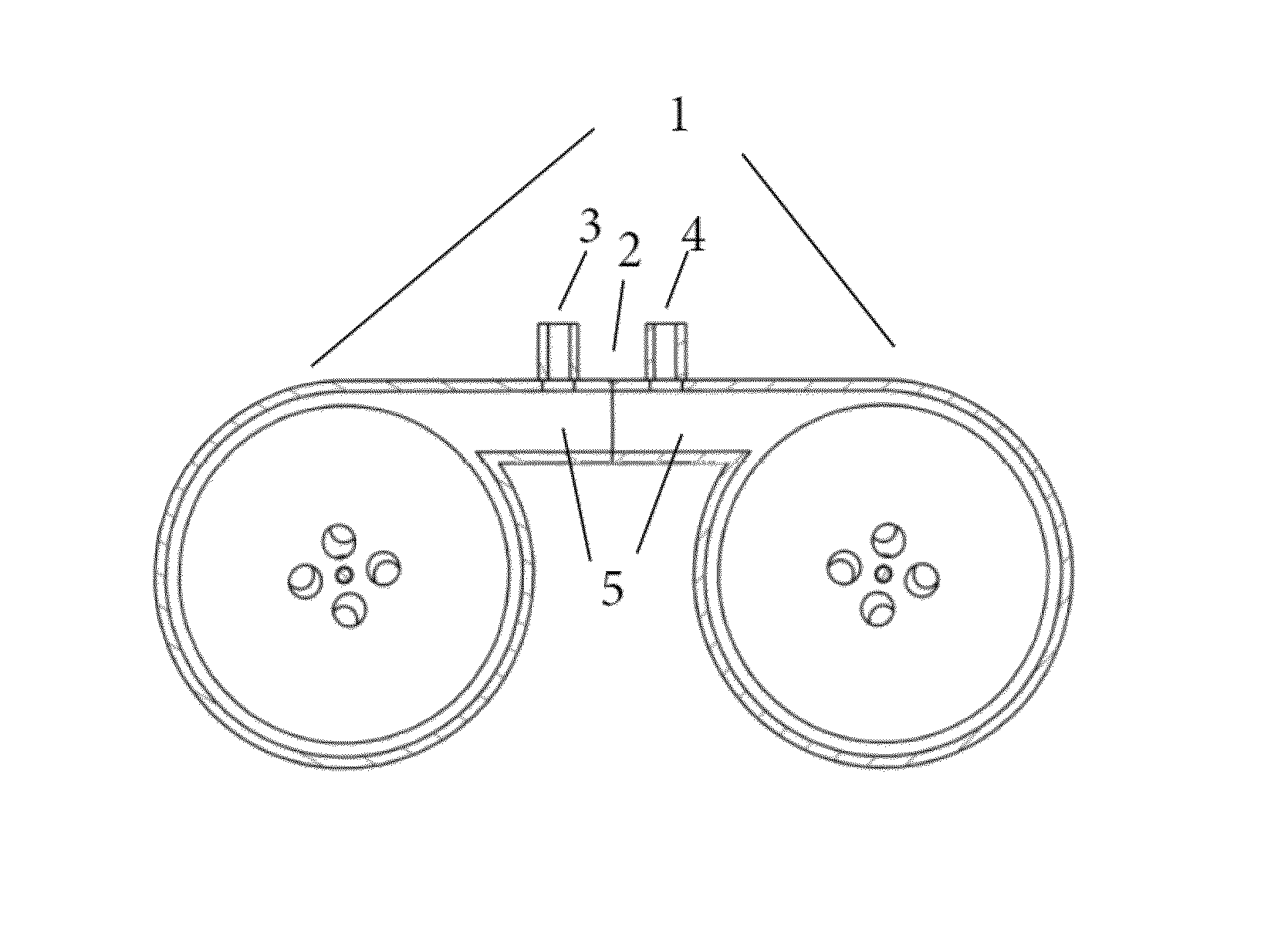

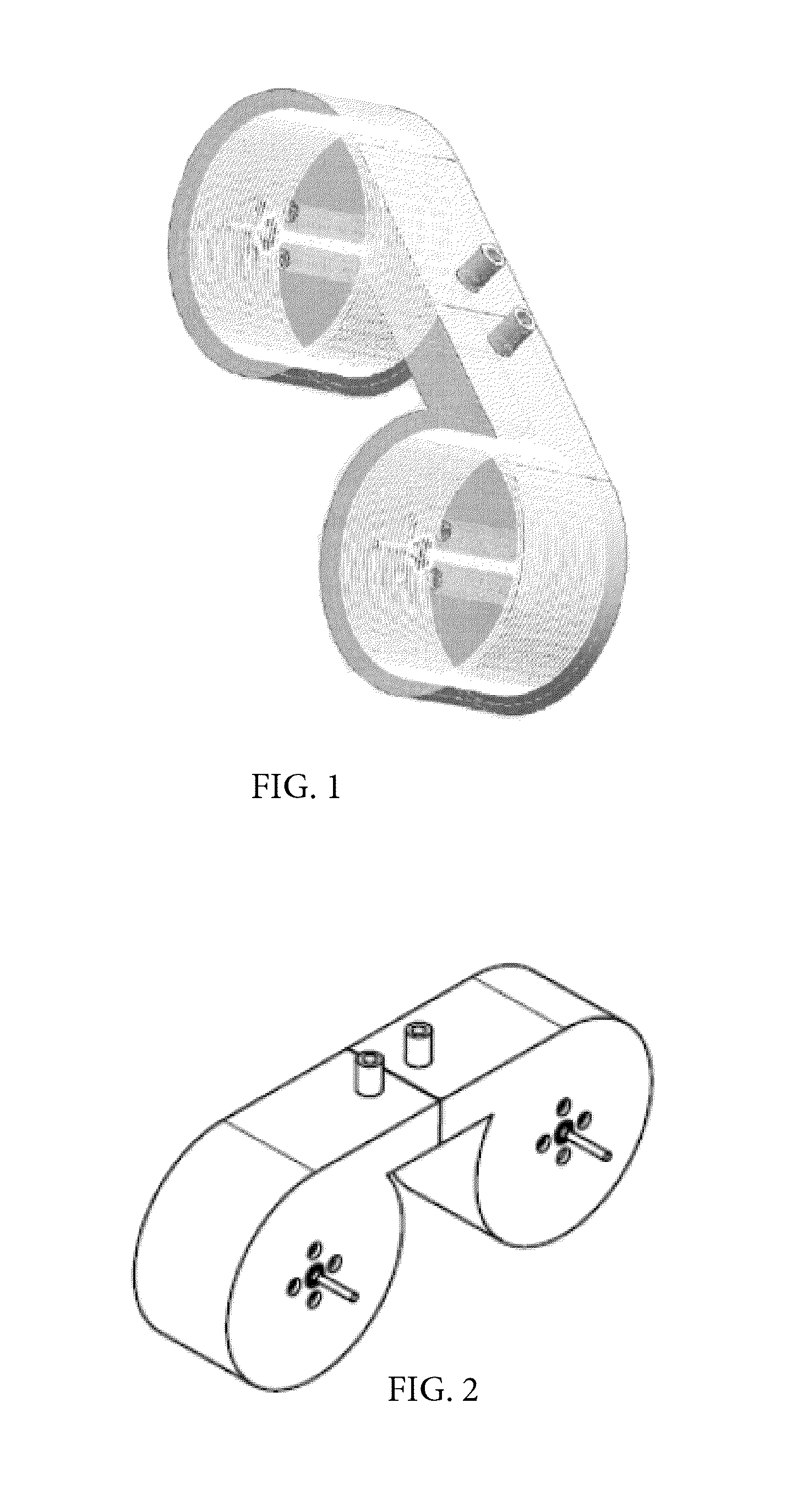

The tesla twin turbines combustion engine module

InactiveUS20140196432A1Simple designSimplify manufacturabilityGas turbine plantsNon-positive displacement enginesEnergy transferCircular disc

A new type of engine module is described based on the Tesla turbine. Our Tesla Twin Turbines Combustion Engine Module comprises of two Tesla turbines welded together, forming a combustion chamber in between. The combustion chamber includes an air-fuel mixture inlet and an ignition inlet. Fuel-air mixture is injected through the air-fuel inlet into the combustion chamber which is ignited by an ignition device. The high temperature combustion gas flow in opposite directions across 2 stacks of evenly spaced smooth parallel discs, transferring energy into rotating the discs via the mechanism of boundary layer laminar flow interaction. The pair of rotating stacks of discs rotates a pair of rods. The gas exits through exhaust holes or openings adjacent to the pair of rods. The rotating rods can be used to drive generators or do useful works.

Owner:LAM VINH MINH GLISTTENMEER +3

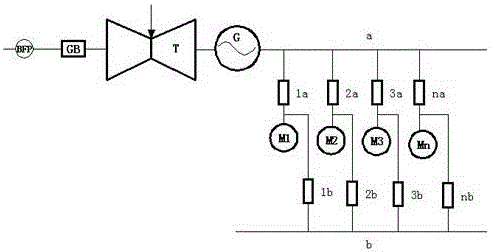

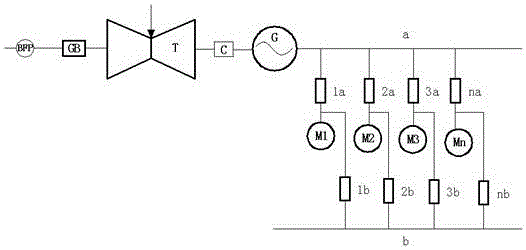

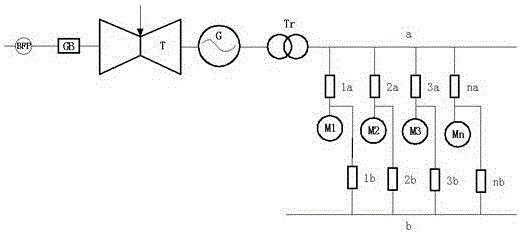

Generalized frequency conversion system used for steam turbine generator unit

InactiveCN105703676AReduce manufacturing costIncrease speedElectric generator controlFrequency changerFrequency conversion

The invention discloses a generalized frequency conversion system for a steam turbine generator set, which at least includes a steam turbine with adjustable speed, a feed water pump, a generator, a speed-increasing gearbox, a frequency conversion bus and auxiliary machines connected thereto; Change, correspondingly adjust (change) the steam parameters and extraction steam entering the steam turbine, so that the speed of the steam turbine changes accordingly, so that on the one hand, the speed of the feed pump is changed through the speed-increasing gearbox, and on the other hand, the frequency of the alternating current output by the generator is changed. The invention does not need additional frequency converters of other types, and the system is simple, reliable, low in cost and high in efficiency.

Owner:冯伟忠

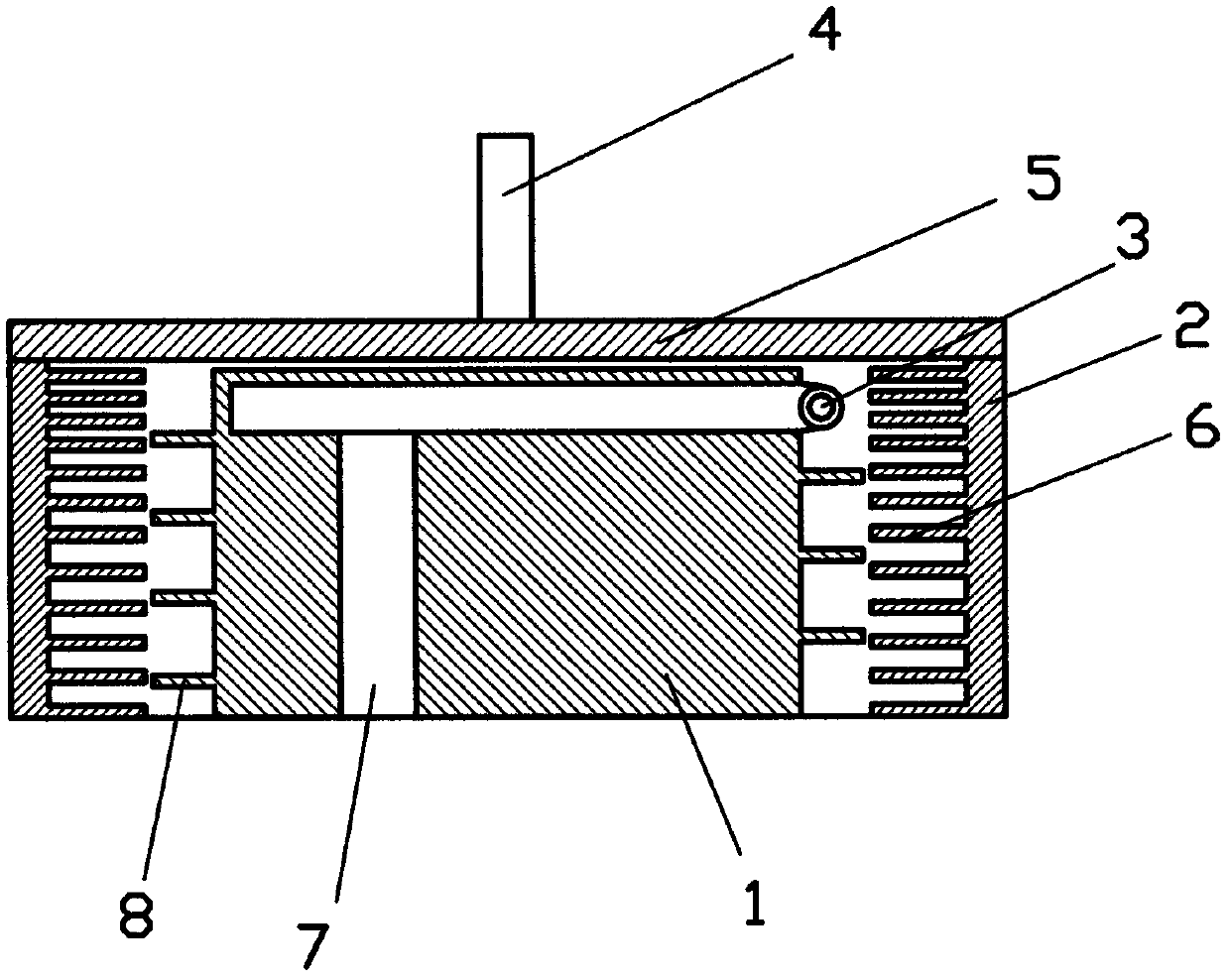

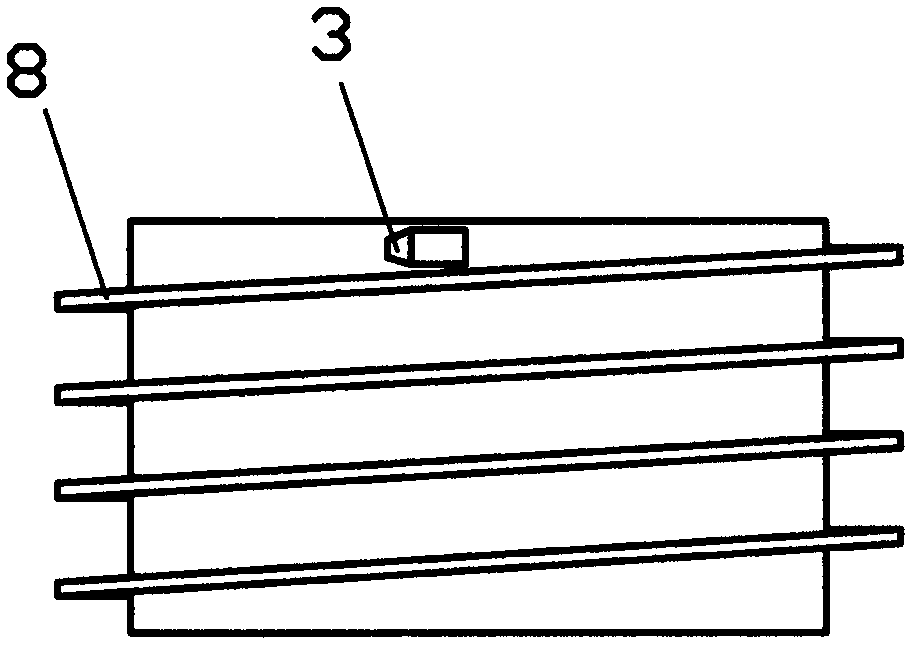

Filamentous turbine

ActiveUS9260967B2Increase contact areaImprove rigidityWorking fluid for enginesNon-positive displacement enginesTesla turbineNozzle

A kind of filamentous turbine comprises a shell body and a rotor, the shell body is provided with a nozzle, the nozzle is used to eject gas into the shell body, the rotor which is arranged in the shell body comprises a rotor shaft, two fixing disks and a filamentous structure, the two fixing disks are mounted to the rotor shaft, the filamentous structure is mounted between the two fixing disk. The filamentous structure for this kind of filamentous turbine replaces the thin and circular disk of the traditional Tesla turbine, and the filamentous structure provides good integral rigidity and is not easy to deform, so that the rotor can be made larger in diameter, and the filamentous structure facilitates to reduce the machine noise.

Owner:SHI JIAN

Ship tail gas treatment system

PendingCN110541747AAdequate contact timeFully irradiatedGas treatmentInternal combustion piston enginesUltravioletSulfide

The invention relates to the field of ship tail gas emission control and relates to a ship tail gas treatment system. The ship tail gas treatment system comprises a tail gas waste heat recycling unitand a tail gas treatment unit; the tail gas waste heat recycling unit comprises a filter and an evaporator; the tail gas treatment unit comprises a washing agent reactor and a tail gas processor; thewashing agent reactor is connected with the evaporator; the tail gas processor comprises a shell which is provided with a flow-in hole and a flow-out hole; the flow-in hole is connected with the washing agent reactor and an oxygen supplying element; the shell is provided with a rotating shaft which is provided with a Tesla turbine rotating assembly; the Tesla turbine rotating assembly comprises aplurality of wafers; a photocatalyst layer is arranged on the outer side face of each wafer; a plurality of ultraviolet lamps are arranged in the shell; and the rotating shaft is provided with a driving mechanism driving the rotating shaft to rotate. The ship tail gas treatment system has the advantages that in the process of recycling the ship tail gas waste heat, sulfide and nitrated compound inship tail gas can be effectively recycled.

Owner:ZHEJIANG OCEAN UNIV

Supercritical fluid power device

PendingCN109595073AImprove solubilityGood flow transport propertiesGas turbine plantsNon-positive displacement enginesCircular discTesla turbine

The invention belongs to the technical field of energy power, and discloses a supercritical fluid power device. The supercritical fluid power device comprises a turbine chamber, a Tesla turbine, an input part annularly arranged outside the Tesla turbine in the circumferential direction, and two bearing assemblies symmetrically arranged on the two sides of a disc of the Tesla turbine. Each bearingassembly comprises a plurality of first bearing sheets sleeving a shaft and a plurality of second bearing sheets, wherein a gap is formed between one of the two first bearing sheets on the outermost side and the input part, and a gap is formed between the other one of the two first bearing sheets on the outermost side and the turbine chamber; the second bearing sheets correspondingly sleeve the outer sides of the middle first bearing sheets, balls are arranged between the two sides of each second bearing sheet and the first bearing sheet adjacent to the second bearing sheet, the balls abut against the second bearing sheets, gaps are formed between the balls and the first bearing sheets, and gaps are formed between the second bearing sheets and the first bearing sheets. According to the supercritical fluid power device, the bearing abrasion probability is close to zero, and the service life of the whole device is prolonged.

Owner:天津市远大实创科技有限公司

Tool and method for measuring throw of steam turbine generating set hanger

PendingCN108267069AHigh measurement accuracyReduce processing timeAngles/taper measurementsHydro energy generationFree stateEngineering

The invention belongs to the technical field of steam turbine generating set researching, and particularly relates to a tool and a method for measuring throw of a steam turbine generating set hanger.According to the tool and the method of the invention, a rotor is lifted through dragging a floating bearing by an adjusting screw. Through protection of the floating bearing, a bearing bush of a bearing seat is turned to outside. After the bearing bush is turned to outside, the rotor falls to an original position through the adjusting screw. Hereon, a force which is bear by the rotor is distributed to four ball pressing plates through two supporting frames in front of and behind the rotor. The ball pressing plates are arranged on balls of a ball bracket and can freely slide in a planar direction for simulating a no-resistance free state of the rotor. A bearing bush turning process and a measuring process are carried out through protection of the two floating bearings. The tool and the method settle technical problems of high measurement error and low operation safety in prior art. Furthermore the tool and the method have advantages of remarkably improving measuring precision, reducingtime in an operation step and measurement, and ensuring safety of equipment and an operator.

Owner:JIANGSU NUCLEAR POWER CORP

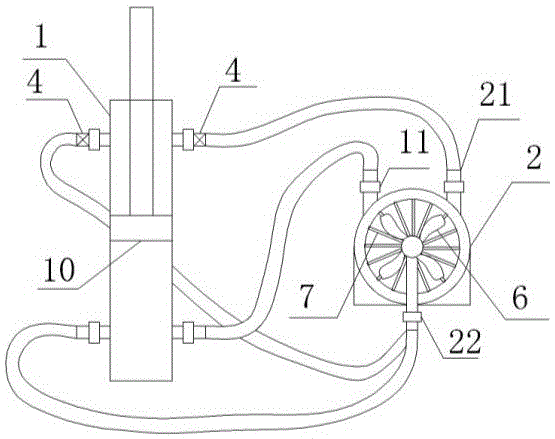

Boundary layer disk turbine systems for hydrocarbon recovery

InactiveUS9410426B2Easy to driveGuaranteed uptimeFluid couplingsPipeline systemsCompressed fluidProcess engineering

Provided are various devices and processes that harness the inherent kinetic energy of a flowing pressurized fluid to drive a compressor to compress a fluid without any need for electrical or chemical energy. The flowing fluid flows over a boundary layer disk turbine, or Tesla turbine, which is mechanically coupled to a compressor that compresses a fluid. The flowing fluid may be a natural gas from a hydrocarbon recovery operation. The compressed fluid may be a vapor gas from a hydrocarbon production, processing, or storage facility. Harnessing the kinetic energy of the flowing fluid increases economic efficiency of the process, while also avoiding unwanted emissions adverse to the environment and public health.

Owner:TRI POINT OIL & GAS PRODN SYST LLC

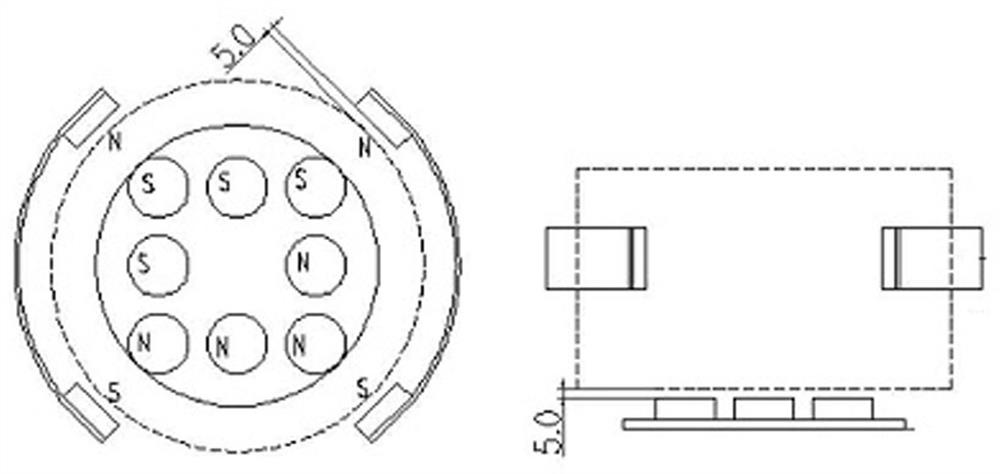

Ultra-high-speed rotating cylinder type permanent magnet polishing device

PendingCN111906679AImprove polishing efficiencyIncrease distribution densityEdge grinding machinesPolishing machinesUltra high speedMetal sheet

The invention belongs to the technical field of magnetic grinding and polishing, and particularly relates to an ultra-high-speed rotating cylinder type permanent magnet polishing device. The ultra-high-speed rotating cylinder type permanent magnet polishing device is characterized by comprising a casing, a Tesla turbine, a container, a non-magnetic cylinder, a group of permanent magnets I and a group of permanent magnets II, wherein the Tesla turbine is arranged in the casing; the container is arranged at the upper part of the casing through a fixing frame; the non-magnetic cylinder is connected with an output shaft of the Tesla turbine; the group of permanent magnets I are fixed to the bottom of the non-magnetic cylinder through a magnetic metal plate; the group of permanent magnets II are fixed to the periphery of the non-magnetic cylinder through a magnetic conductive metal sheet; and the container is arranged inside the non-magnetic cylinder. Permanent magnet arrangement polishingand grinding machining is used; a still magnetic steel needle in the container is magnetized; along with the ultra-high speed rotation of the cylinder driven by the Tesla turbine, a generated rotatingmagnetic field is used for driving the steel needle to polish the surface of a workpiece; the Tesla turbine can exceed the upper limit of the speed of a used motor and reaches tens of thousands of revolutions per minute; and when the rotating speed is higher, the polishing efficiency of the cylinder type permanent magnet polishing device is higher.

Owner:UNIV OF SCI & TECH LIAONING

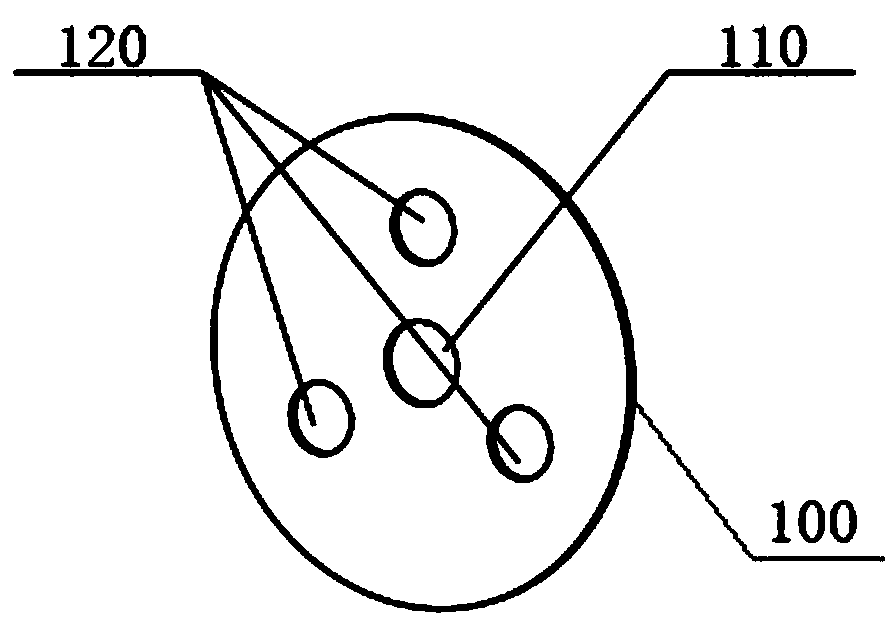

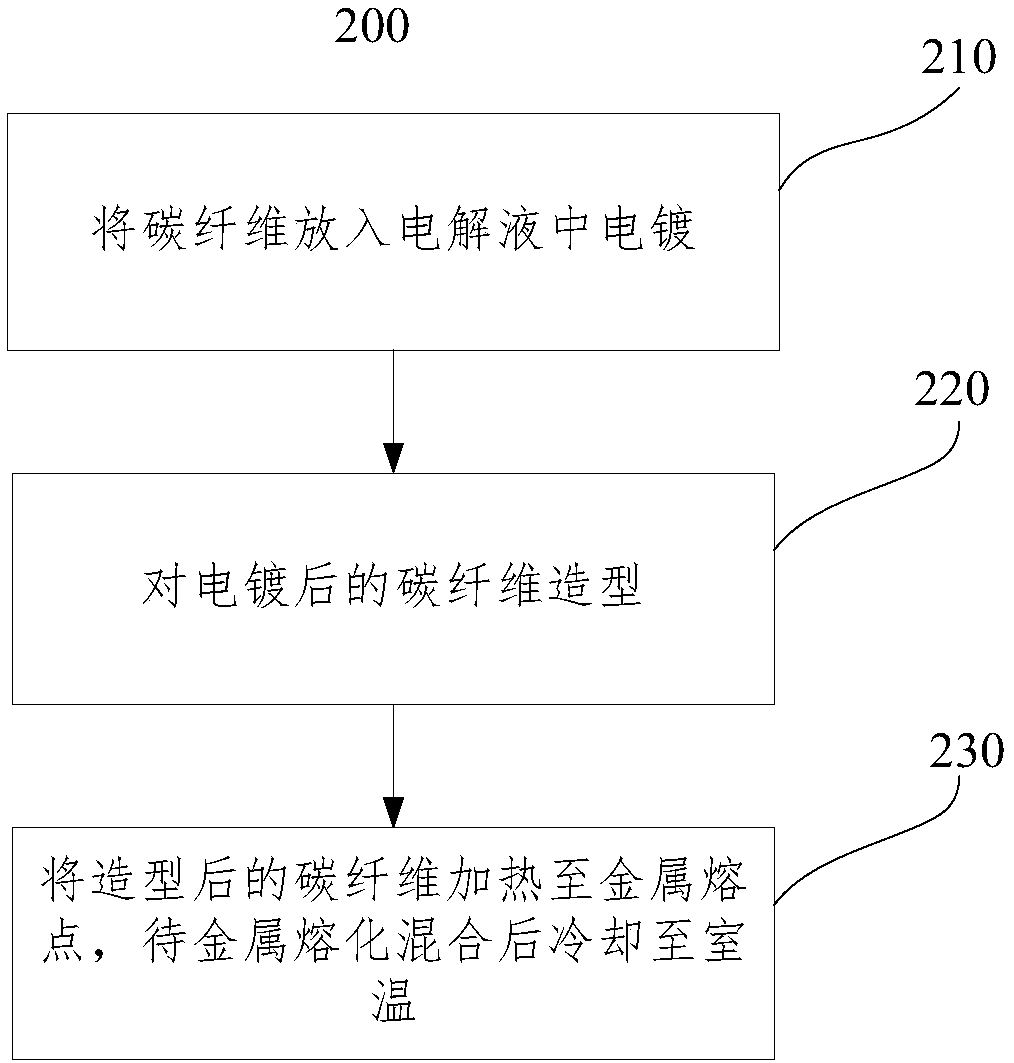

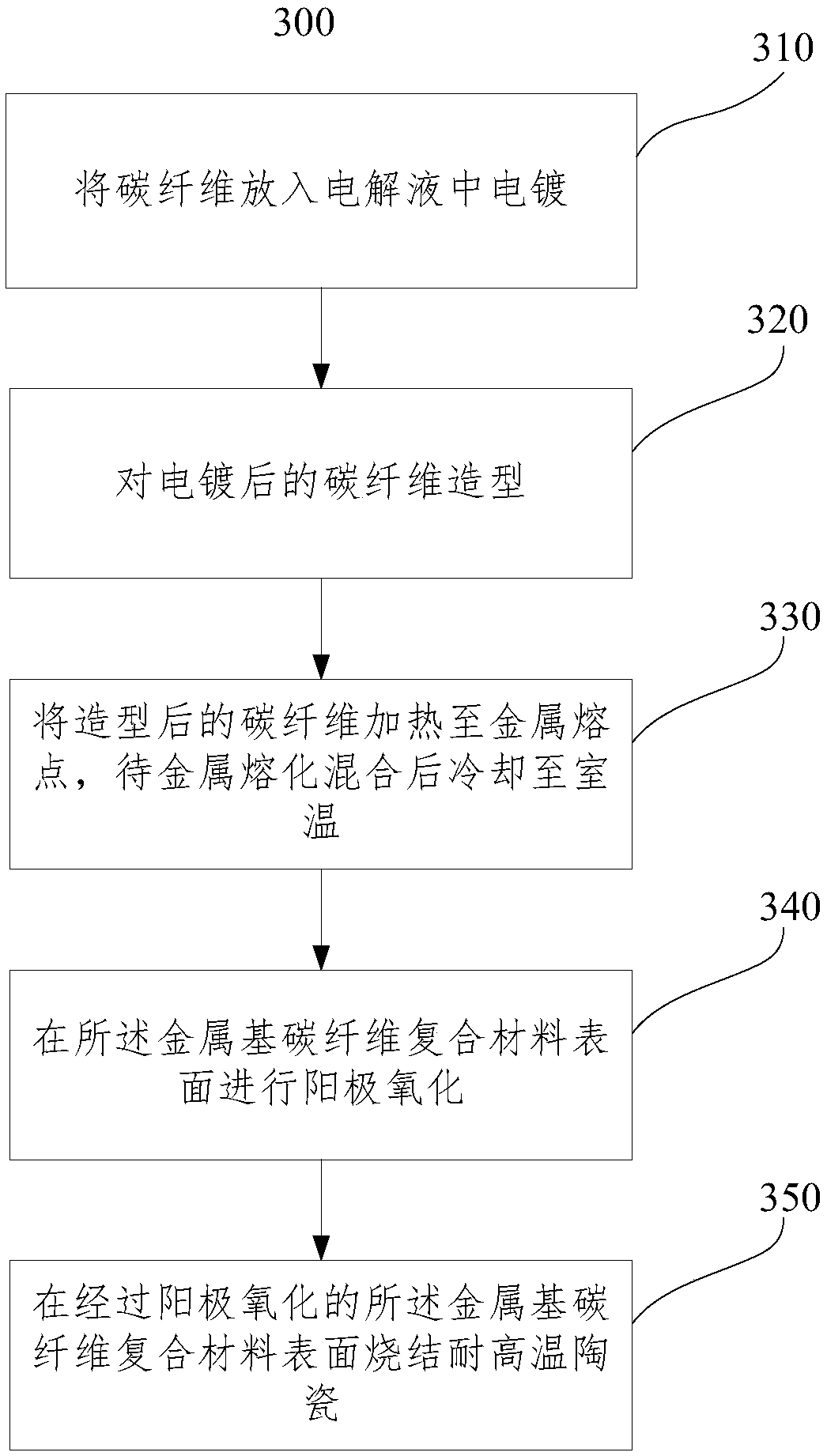

Tesla turbine disk and production method thereof

ActiveCN109020591AEffective combinationHigh bonding strengthBlade accessoriesMachines/enginesFiberTesla turbine

The invention discloses a Tesla turbine disk and a production method thereof. The production method comprises the following steps: electroplating carbon fibers in an electroplating bath provided witha metal electrolyte; winding the electroplated carbon fibers around a spindle to form disc-shaped carbon fibers; heating the disc-shaped carbon fibers and the spindle to the melting point of the metalin order to melt and adhere the metal, and cooling the molten metal to room temperature in order to prepare a metal-based carbon fiber composite material for the Tesla turbine disk; removing the spindle, and processing vent holes in the metal-based carbon fiber composite material for the Tesla turbine disk in a machining manner; anodizing the surface of the metal-based carbon fiber composite material; sintering ceramic on the anodized surface of the metal-based carbon fiber composite material to obtain a ceramic material for the Tesla turbine disk; and polishing the ceramic material by usinga diamond grinding solution to produce the Tesla turbine disk. The Tesla turbine disk produced by the method has the advantages of extremely high hardness, extremely high compressive strength and goodheat resistance.

Owner:靳普

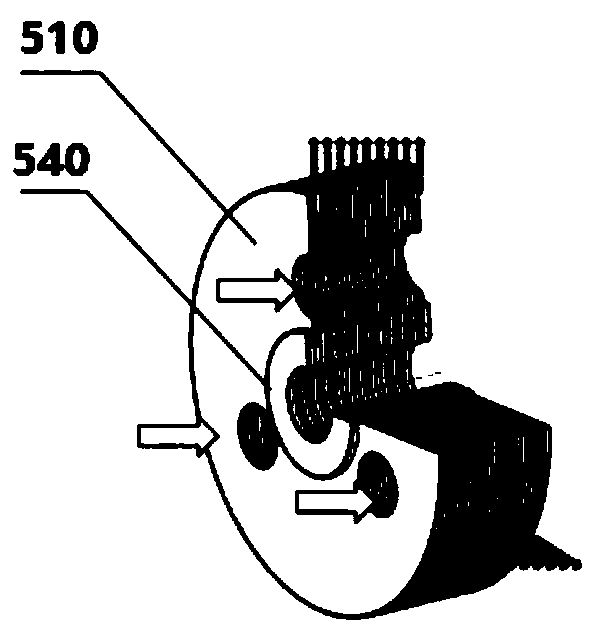

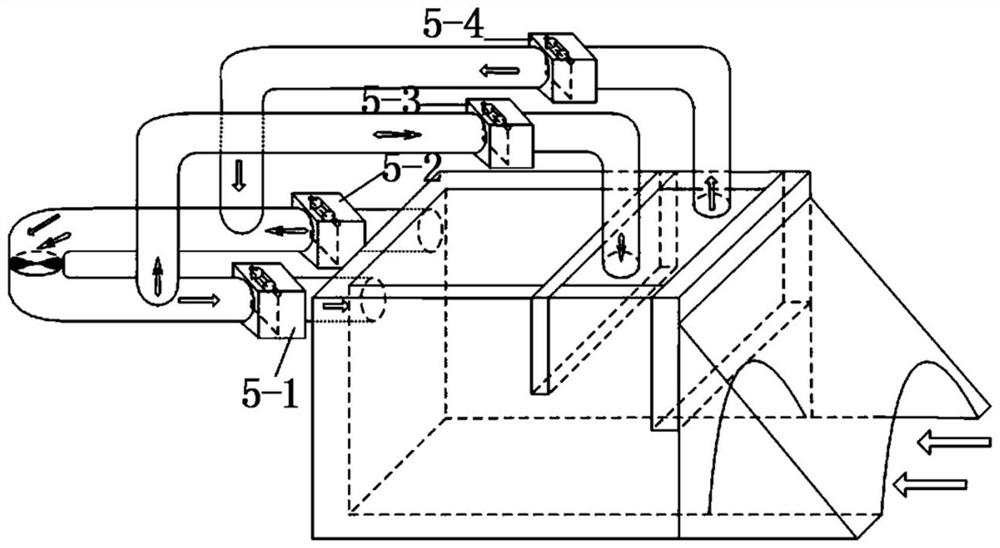

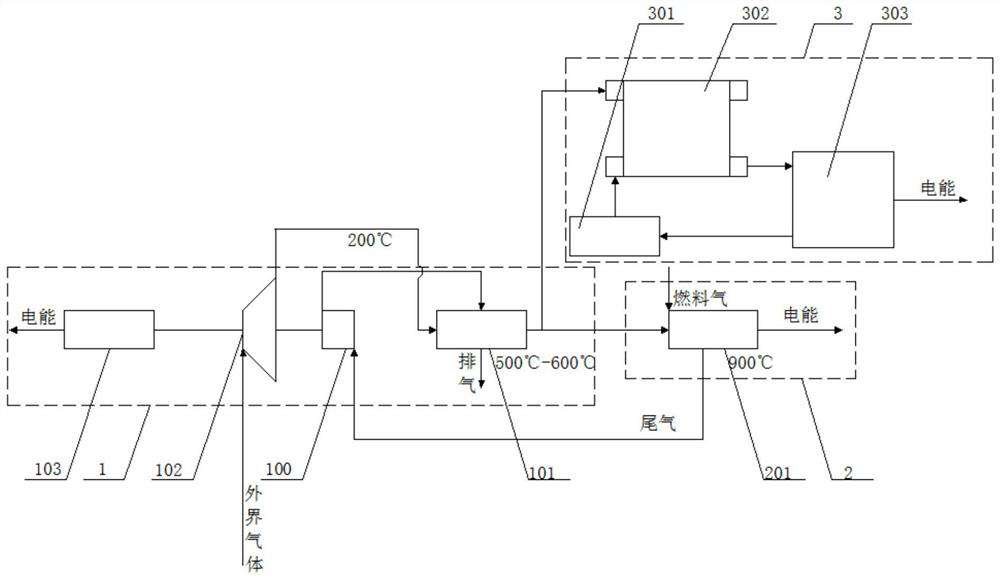

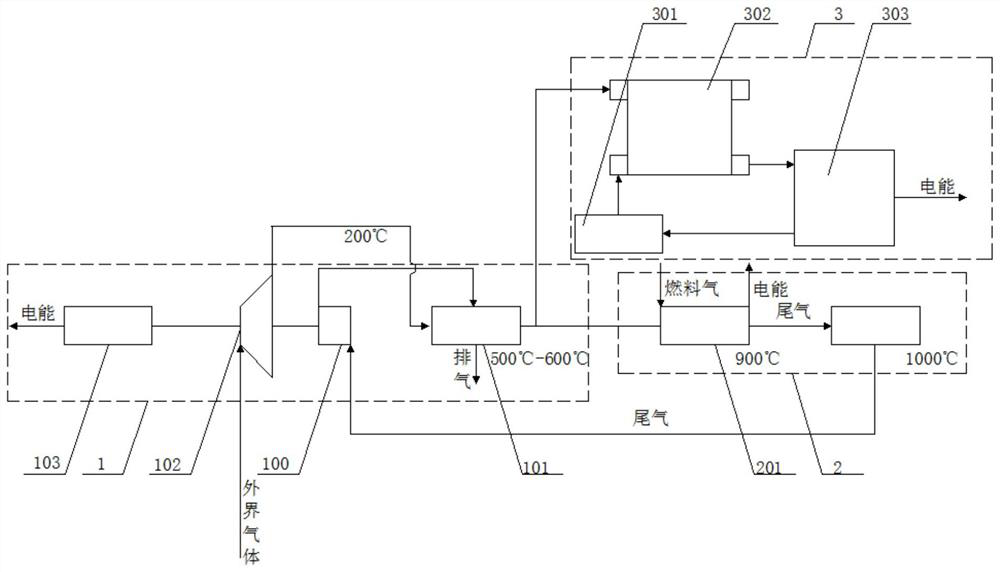

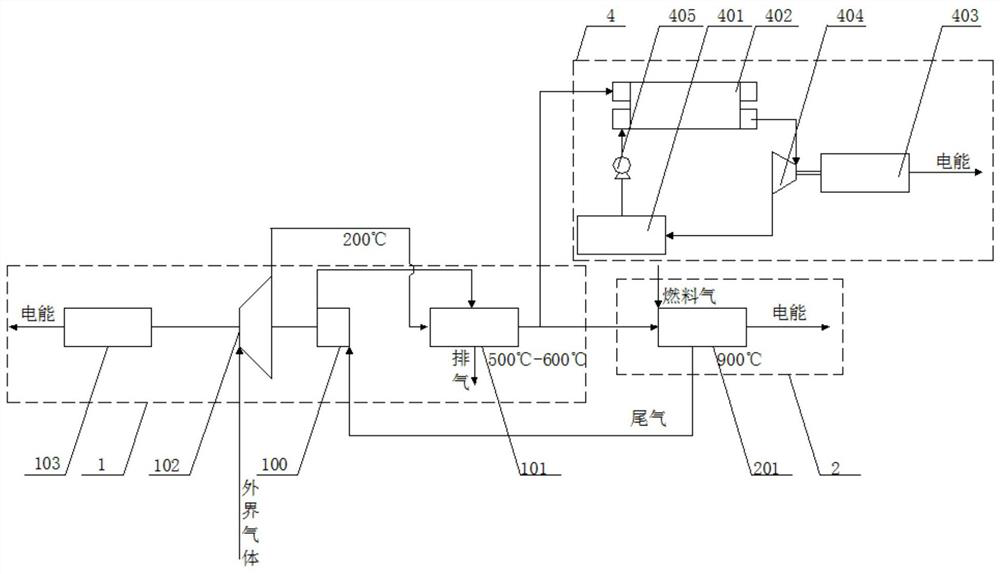

Micro gas turbine combined cycle system with multi-stage Tesla turbine

PendingCN112502801ALow calorific valueSolve the technical problem that less heat cannot be recovered efficientlySolar heating energyFuel cell heat exchangeFuel cellsMicro gas turbine

The invention relates to a micro gas turbine combined cycle system with a multi-stage Tesla turbine. The micro gas turbine combined cycle system with the multi-stage Tesla turbine comprises a micro gas turbine with the multi-stage Tesla turbine, and further comprises at least one of a fuel cell system, a steam power generation system and a solar receiver. The cycle system can further recycle energy carried in exhaust gas of a heat regenerator, so that the efficiency of the whole micro gas turbine is improved, and the recovery problem of SOFC power generation waste heat and exhaust gas waste heat of the heat regenerator can be solved at the same time; heat generated in all links in the system is recycled, so that the power generation and recovery efficiency of the whole system can be improved; meanwhile, integrated arrangement can be achieved, so that the occupied space is small; in addition, efficient utilization of solar energy is achieved through tracking of the solar energy so as toimprove the power generation efficiency of the system; and in addition, the cycle system can solve the problems that an existing Tesla turbine is low in pressure drop ratio, prone to causing pressureloss and low in system efficiency.

Owner:靳普

A kind of damping device for automobile

The invention provides an automobile damping device, belongs to the technical field of damping, and solves the problems that performances of a damper cannot be flexibly regulated and temperature of an oil liquid rises quickly during frequent vibration. The automobile damping device comprises a piston hydraulic damper, wherein the bottom of a cavity of the piston hydraulic damper communicates with a liquid inlet end opening of a Tesla turbine; the upper part of the cavity of the piton hydraulic damper communicates with a liquid outlet end opening of the Tesla turbine; one end of a turbine shaft of the Tesla turbine is connected to a motor; and fan blades are arranged on a turbine shaft at the other end. According to the automobile damping device provided by the invention, the damper is combined with the Tesla turbine, so that regulation on damping force of the damper can be realized through rotation of the motor; and the fan blades are arranged on the Tesla turbine, so that the oil liquid can be cooled by utilizing vibrating energy of the damper.

Owner:JIAXING UNIV

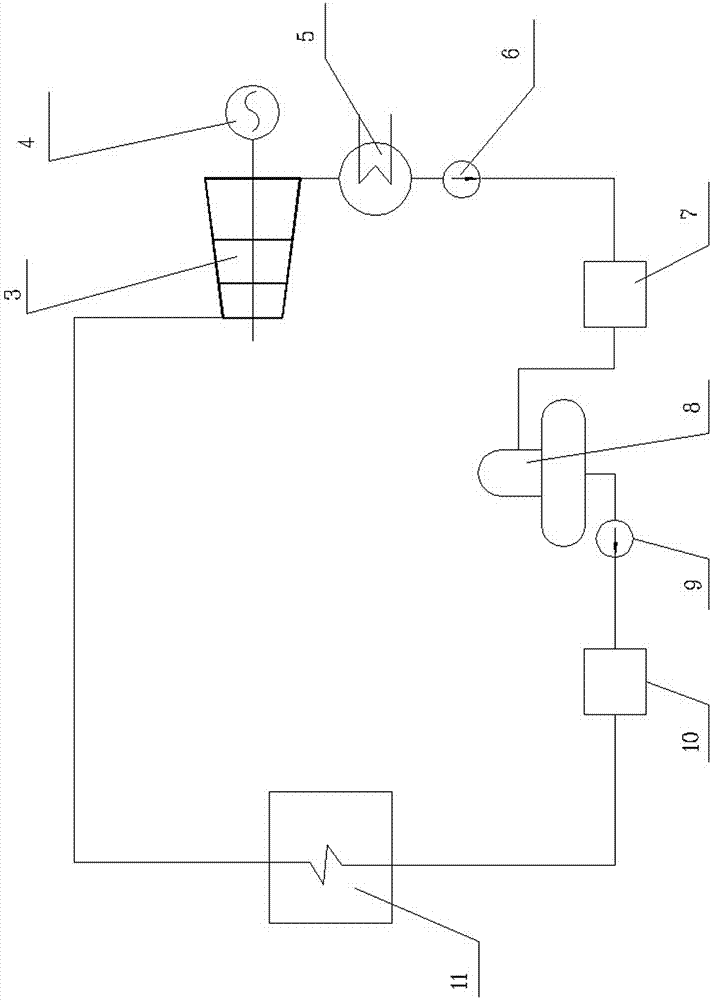

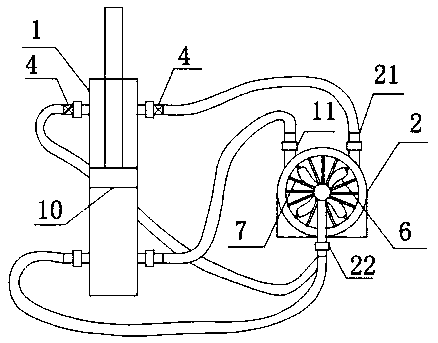

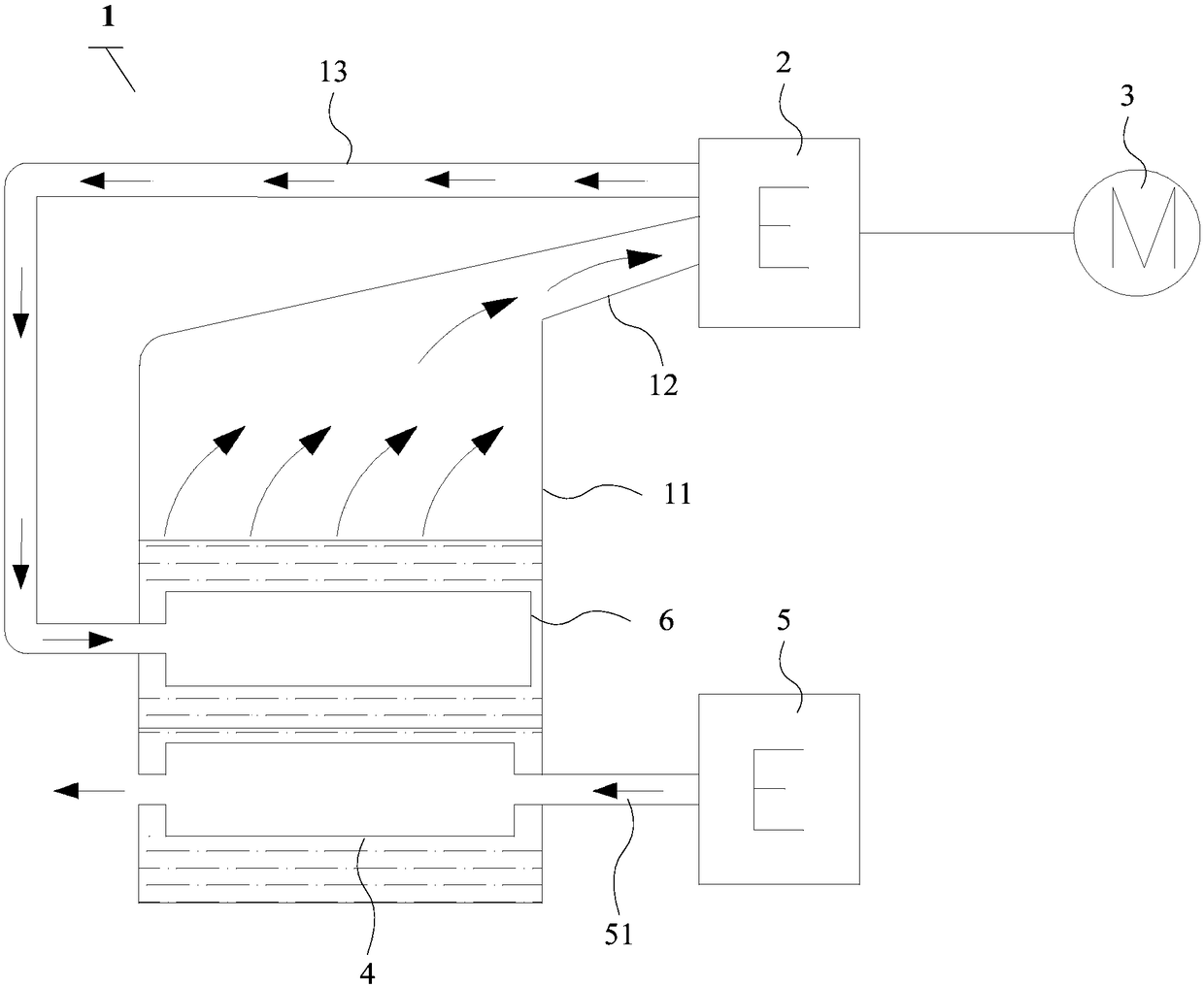

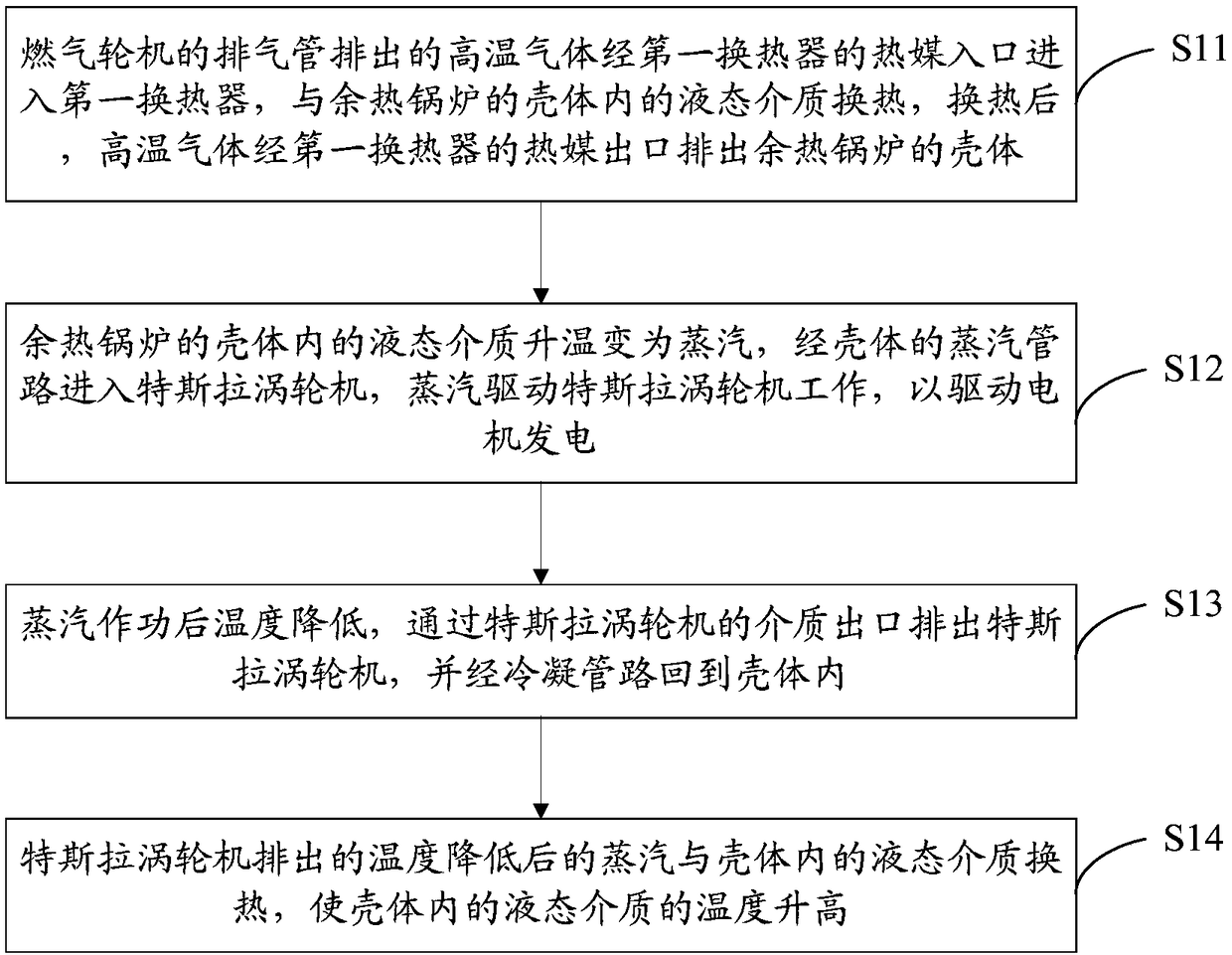

Power generation system and control method thereof

PendingCN108868911AImprove efficiencyImproved dynamic performance and stabilityBearing assemblyEngine componentsLiquid mediumEngineering

The invention provides a power generation system and a control method thereof. The power generation system comprises a waste heat boiler, a Tesla turbine and a motor, wherein the Tesla engine is connected with the motor, the Tesla turbine is used for driving the motor to work, and the Tesla turbine is provided with a medium inlet and a medium outlet; the waste heat boiler comprises a shell body, aliquid medium is filled in the shell body, at least one heat exchanger used for converting the liquid medium into a vapor state medium is further arranged inside the shell body, and the heat exchanger is immersed in the liquid medium; and a steam pipeline and a condensation pipeline are arranged on the shell body, wherein the steam pipeline communicating with the medium inlet is arranged on the shell body, and the condensation pipeline communicates with the medium outlet; and the at least one heat exchanger comprises a first heat exchanger, a heat medium inlet of the first heat exchanger communicates with an exhaust pipe of a gas turbine, and the heat medium outlet of the first heat exchanger is located outside the shell body. According to the system and the method, the high-efficiency Tesla turbine is used as a steam turbine, so that the efficiency of the fuel gas and steam combined cycle power generation system is improved.

Owner:刘慕华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com