Power generation system and control method thereof

A power generation system, Tesla turbine technology, applied in engine components, machines/engines, steam engine devices, etc., can solve the problem that the efficiency of gas-steam combined cycle power generation system cannot be further improved, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

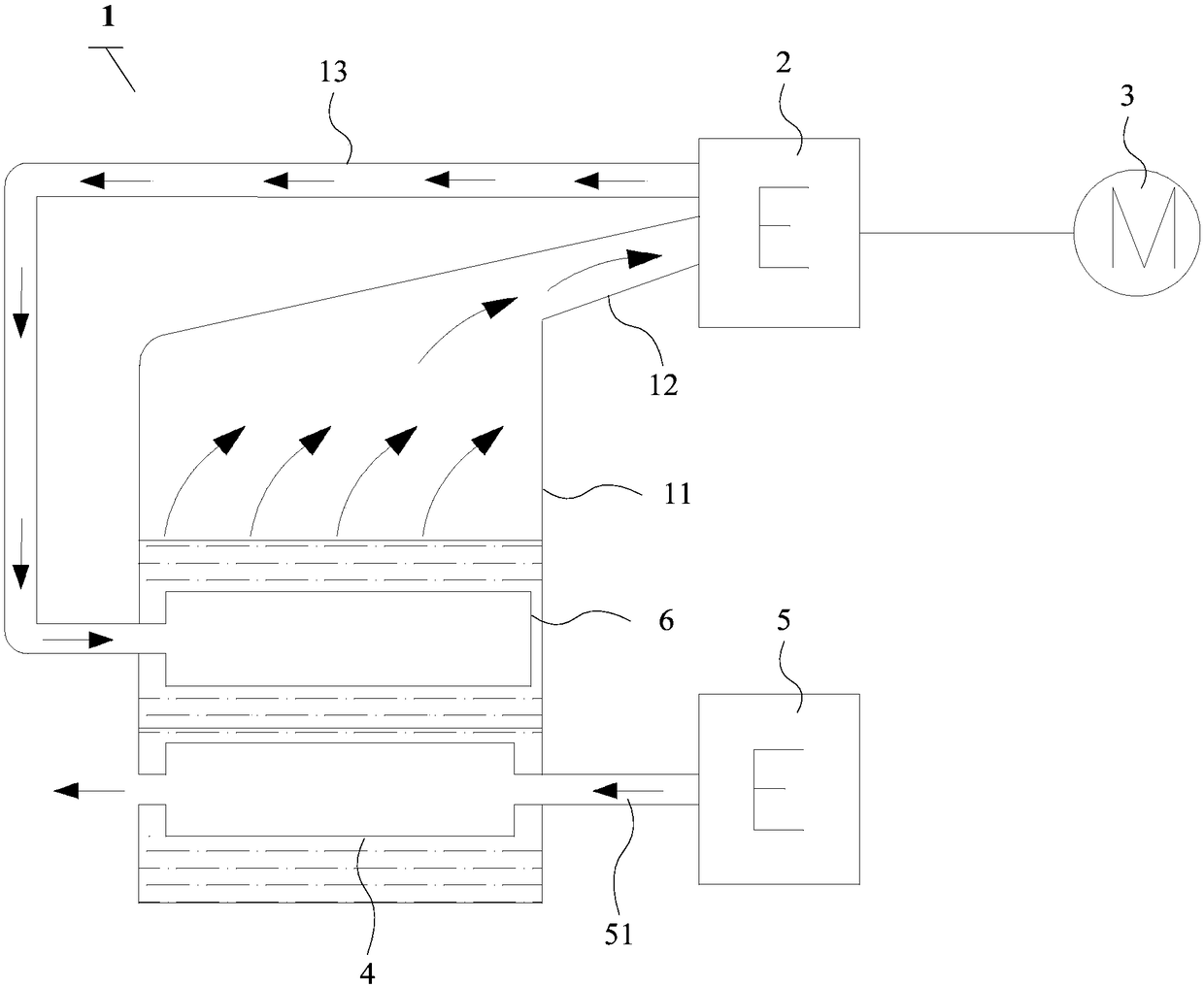

[0098] Such as Figure 1 to Figure 2 As shown, a power generation system includes:

[0099] Waste heat boiler 1, Tesla turbine 2 and motor 3;

[0100] The Tesla turbine 2 is connected to the motor 3, and the Tesla turbine 2 is used to drive the motor 3 to work;

[0101] The Tesla turbine 2 is provided with a medium inlet and a medium outlet;

[0102] The waste heat boiler 1 includes a shell 11, which is filled with a liquid medium, and at least one heat exchanger for converting the liquid medium into a vapor medium is arranged inside the shell 11, and the heat exchanger is immersed in the liquid medium; The casing 11 is provided with a steam pipeline 12 communicating with the medium inlet, and a condensation pipeline 13 communicating with the medium outlet;

[0103] The heat exchanger includes a first heat exchanger 4 , the heat medium inlet of the first heat exchanger 4 communicates with the exhaust pipe 51 of the gas turbine 5 , and the heat medium outlet of the first hea...

Embodiment 2

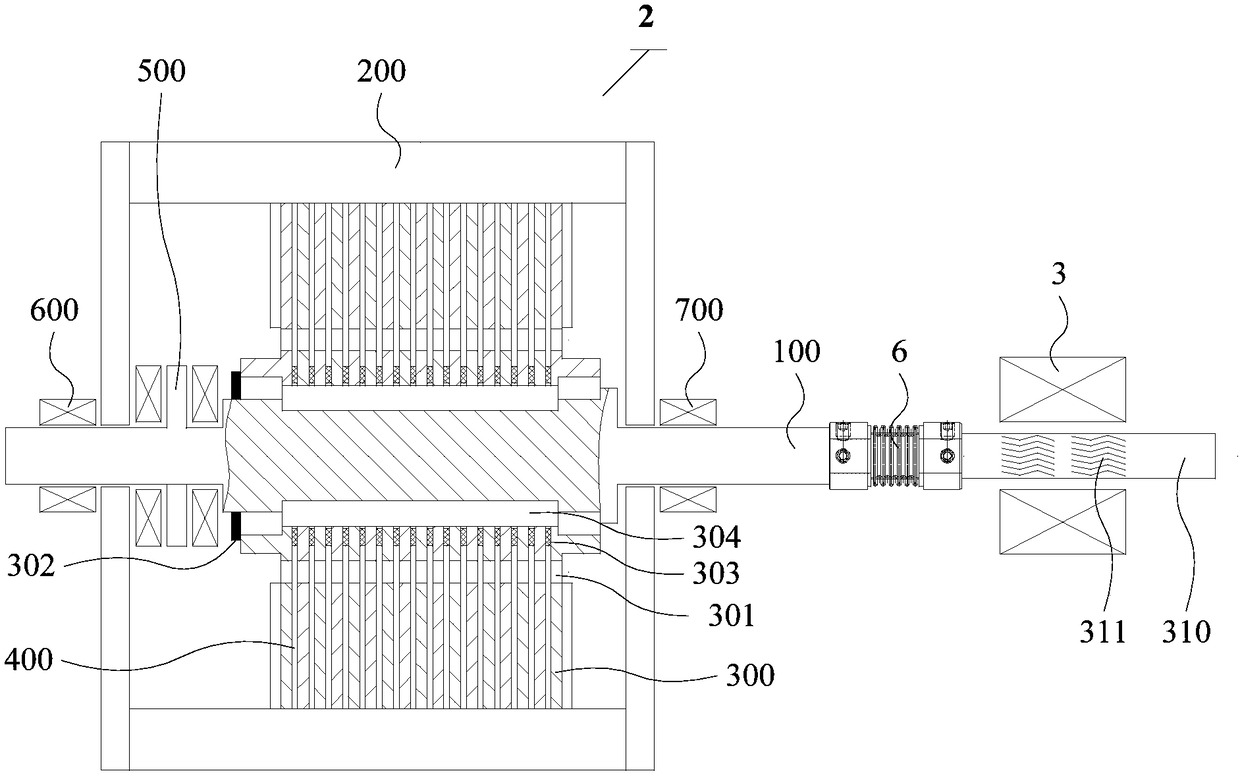

[0124] Such as image 3 As shown, a Tesla turbine 2 comprising:

[0125] Shaft 100;

[0126] A housing 200 disposed on the rotating shaft 100, the housing 200 is provided with a medium inlet (not shown in the figure) and a medium outlet (not shown in the figure);

[0127] Several disks 300 are arranged in the housing 200, and several disks 300 are fixedly connected to the rotating shaft 100. A gap 400 is provided between every two adjacent disks 300 among the several disks 300. Each of the disks 300 is provided with at least one exhaust hole 301;

[0128] And, the thrust bearing 500 and at least two radial bearings disposed on the rotating shaft 100 are non-contact bearings.

[0129] In the embodiment of the present invention, the working principle of the Tesla turbine is as follows: the high-speed fluid medium enters the interior of the housing 200 through the medium inlet provided on the housing 200, and the fluid medium enters the gap between adjacent discs 300 through t...

Embodiment 3

[0186] Such as Figure 6 to Figure 9 As shown, the tubular heat exchanger consists of:

[0187] The first pipe body 10, the second pipe body 20 and the heat exchange element 30, the outer diameter of the first pipe body 10 is smaller than the inner diameter of the second pipe body 20, and the second pipe body 20 is sleeved outside the first pipe body 10;

[0188] A plurality of heat exchange elements 30 are attached and connected between the inner wall of the first pipe body 10 and the outer wall of the first pipe body 10 and the inner wall of the second pipe body 20 , and any two adjacent heat exchange elements 30 There are gaps between them;

[0189] The space between the outer tube wall of the first tube body 10 and the tube inner wall of the second tube body 20 forms a refrigerant channel, and the space surrounded by the first tube body 10 forms a heat medium channel.

[0190] When the tubular heat exchanger of the embodiment of the present invention is applied to a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com