Intermediate reheating small-capacity split axle type steam-turbine generator set

A steam turbine generator set, steam turbine technology, applied in the direction of steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of low power generation efficiency of small-capacity steam turbine generator sets, improve energy utilization, increase project cost, and improve reliability. The effect of sexual assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

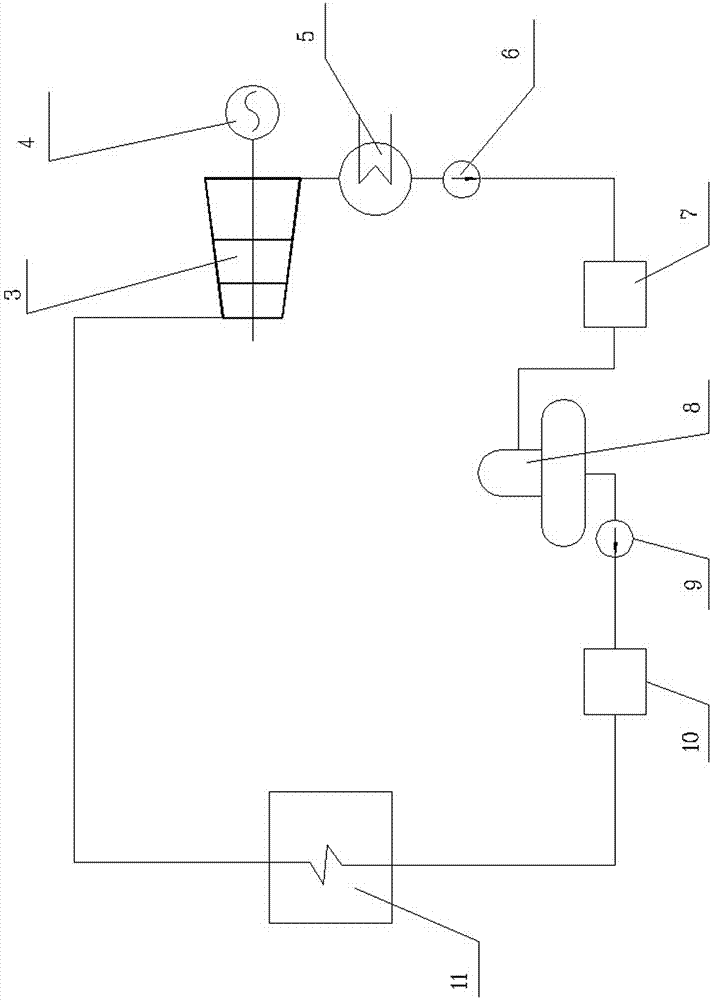

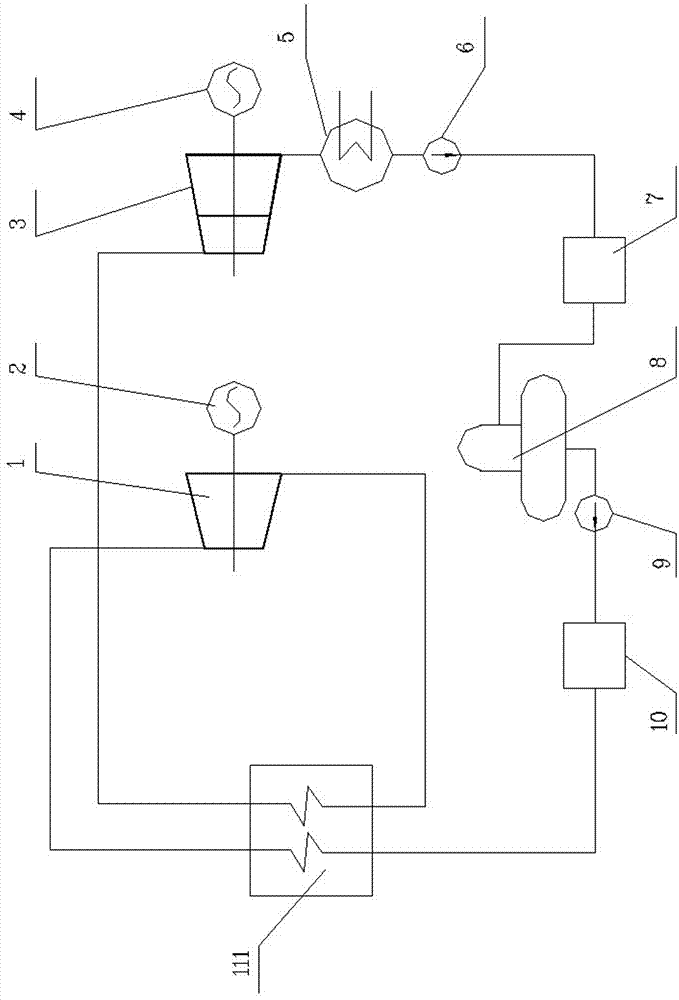

[0016] Such as figure 2 As shown, a small-capacity split-shaft turbo-generator set with intermediate reheating includes a reheating boiler with an evaporation capacity of 410t / h-120t / h, two steam turbines with a capacity of 120MW-15MW connected in double circulation, each The steam turbine is configured with a matching generator.

[0017] The first cycle of the two-cycle communication is: the high-pressure steam of the reheating boiler enters the high-pressure steam turbine, and the exhaust steam of the high-pressure steam enters the reheating boiler cycle; , into the medium and low pressure steam turbine, the medium and low pressure steam turbine is a condensing steam turbine, the medium and low pressure steam turbine exhausts to the condenser, and the condensed water or make-up water in the condenser is treated, enters the reheat boiler to generate high pressure steam and enters the first cycle .

[0018] The high pressure steam turbine is a high back pressure steam turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com