Gas turbine power generation device acting through pulse detonation fuel gas viscous force

A technology of pulse detonation and gas turbines, which is applied in the direction of gas turbine devices, deflagration combustion chambers, machines/engines, etc., and can solve the problems of low energy conversion efficiency of pulse detonation gas, influence of detonation combustion wave pressure back transmission, and detonation gas energy. Low conversion efficiency and other issues, to achieve the effect of improving cycle thermal efficiency, fast flame propagation speed, and reducing the number of stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

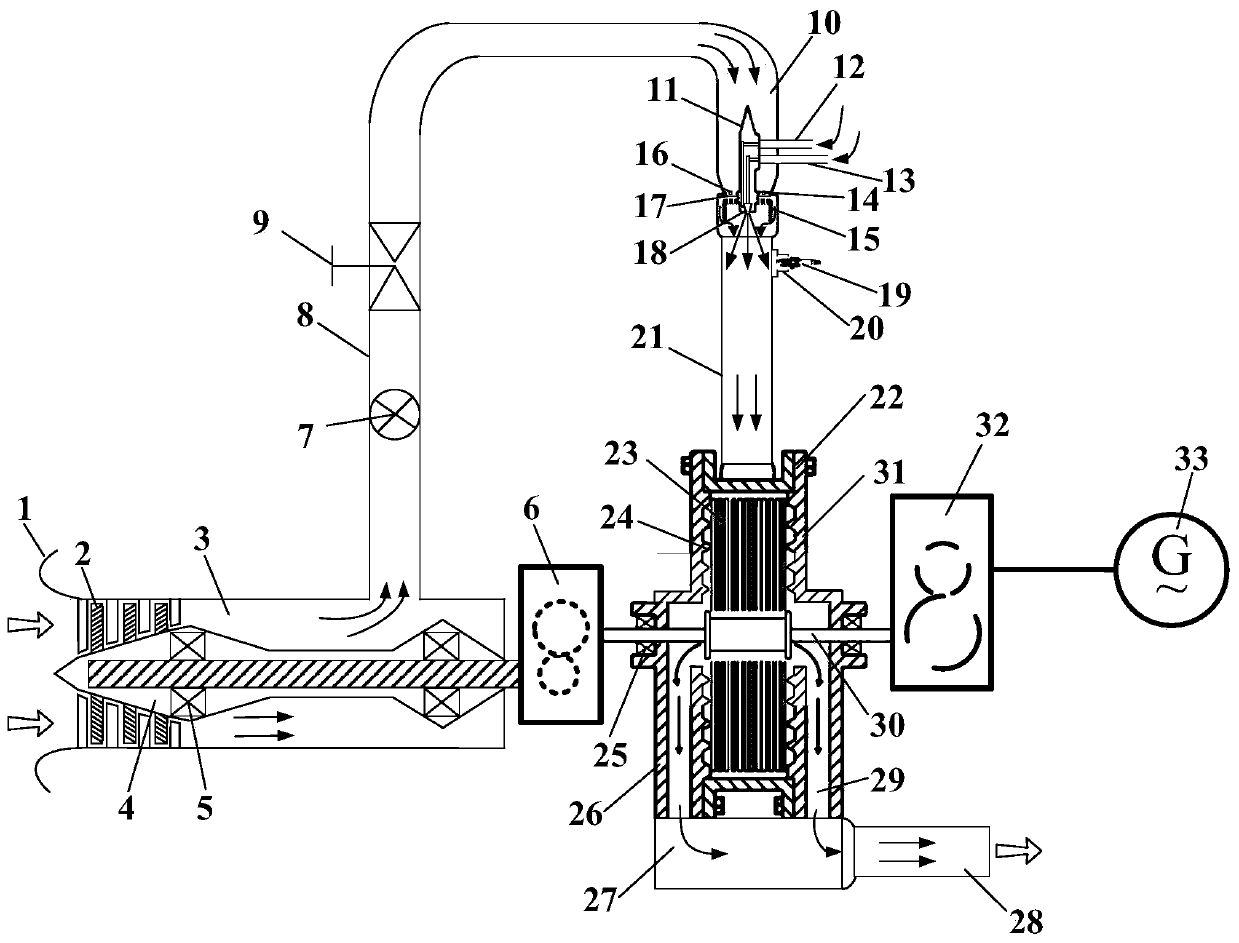

[0025] See figure 1 As shown, the gas turbine involved in this embodiment has a compressor rotor 4, an intake duct 1, a compressor 2, and a gas storage chamber 3 and a compressor exhaust pipe 8 that are annularly mounted on the outside of the rotor 4, rotating around a rotating shaft. , Combustion chamber inlet 10, combustion chamber inlet cone 11, combustion chamber pneumatic valve 14, pulse detonation combustion chamber 21, Tesla turbine 22 and exhaust pipe 28, and form such figure 1 The middle arrow shows the gas flow path through them.

[0026] In the direction of the gas turbine's airflow, the inlet port 1 is placed at the forefront of the gas turbine, and the compressor 2 is connected to the inlet port 1. As knock combustion has the advantage of self-supercharging, the number of compressor stages in this example only needs to be 2 to 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com