Wind wheel of pipe blade cone connected wind driven generator

A technology for wind turbines and rotors, applied in wind turbines, wind turbine combinations, wind power generation, etc., can solve the problems of increasing blade mass, lengthening blade length, unable to lock or completely lock airflow, etc., to increase output power generation, The effect of increasing the torque and increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

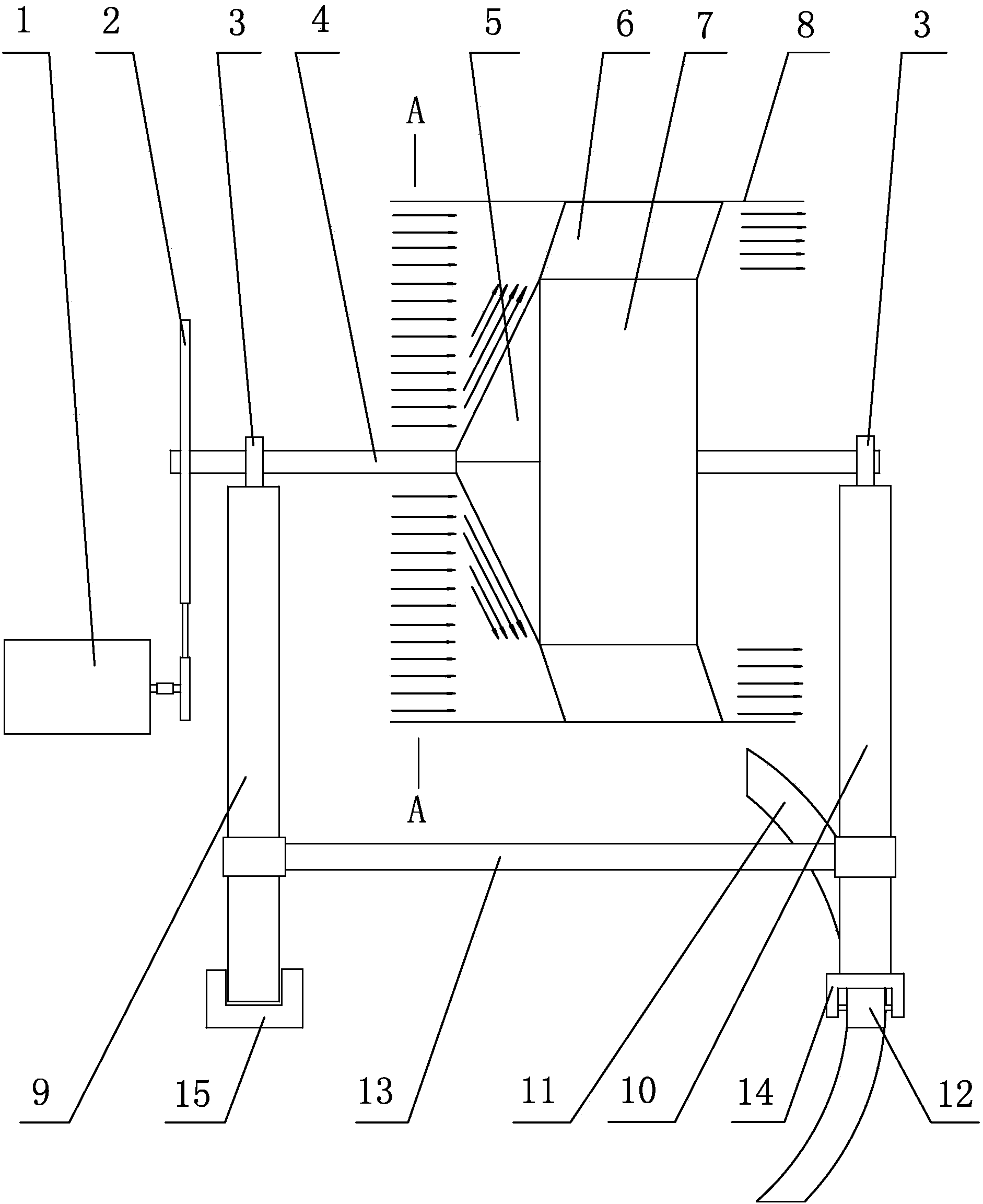

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

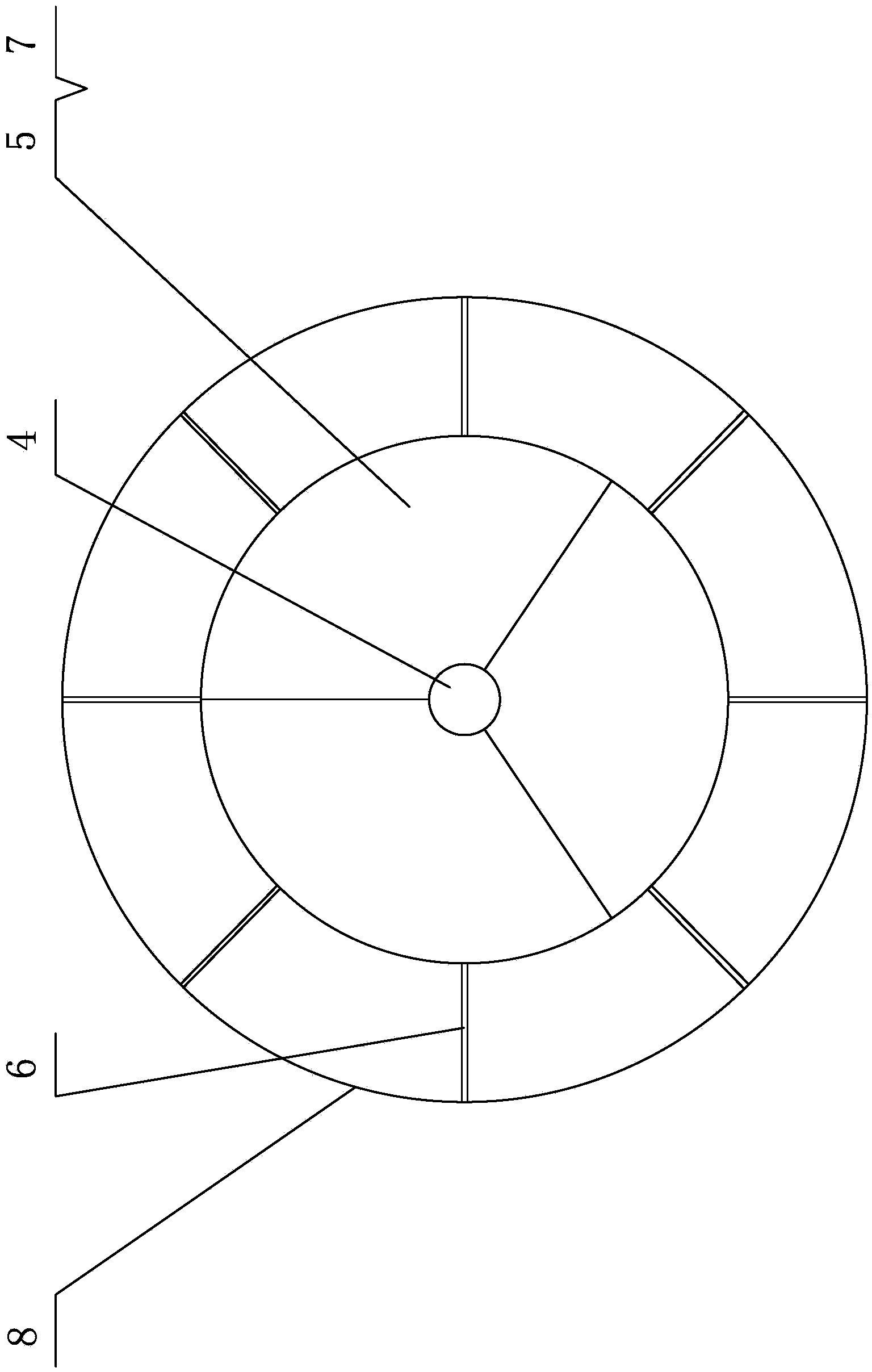

[0025] The wind wheel of the tube-blade-cone conjoined wind power generator of the present invention is mainly composed of a wind wheel shaft 4 , blades 6 , a wind wheel hub 7 and an air duct 8 .

[0026] The wind wheel hub 7 (cylindrical body) is coaxially installed on the wind wheel shaft 4, the air duct 8 is coaxially sleeved outside the wind wheel hub 7, and the blades 6 are evenly distributed around the circumference (at least four light and thin blades 6) It is arranged in the annular cavity formed between the air duct 8 and the wind wheel hub 7; the windward end of the wind wheel hub 7 is set to be tapered to form a tapered wind guide surface 5 (guiding the airflow to the blade 6), and the tapered Wind guide surface 5 is preferably conical surface and triangular conical surface, such as figure 1 , figure 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com