Patents

Literature

105results about How to "Save compression work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

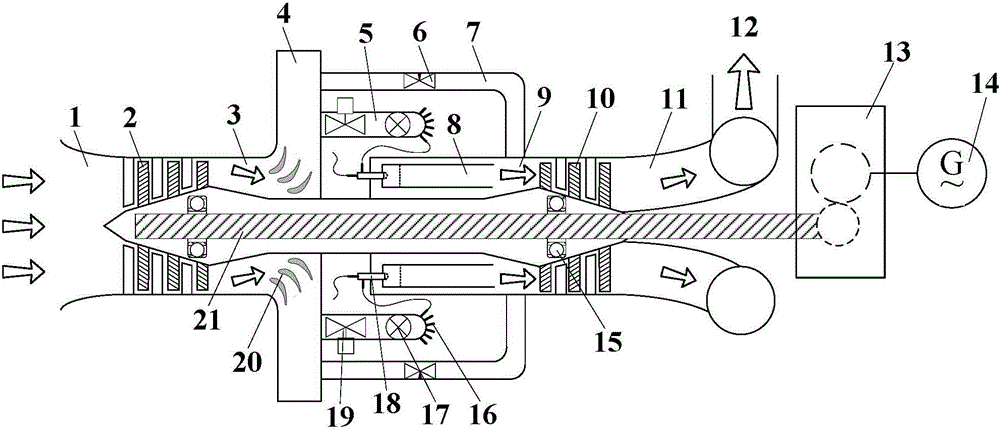

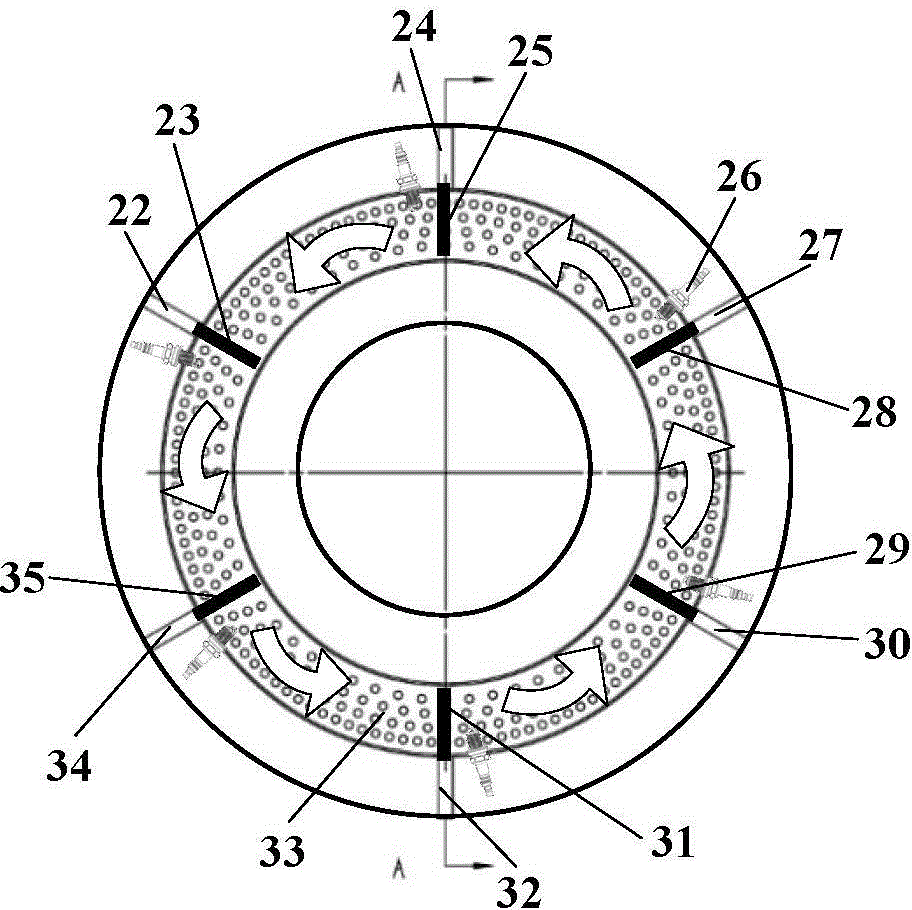

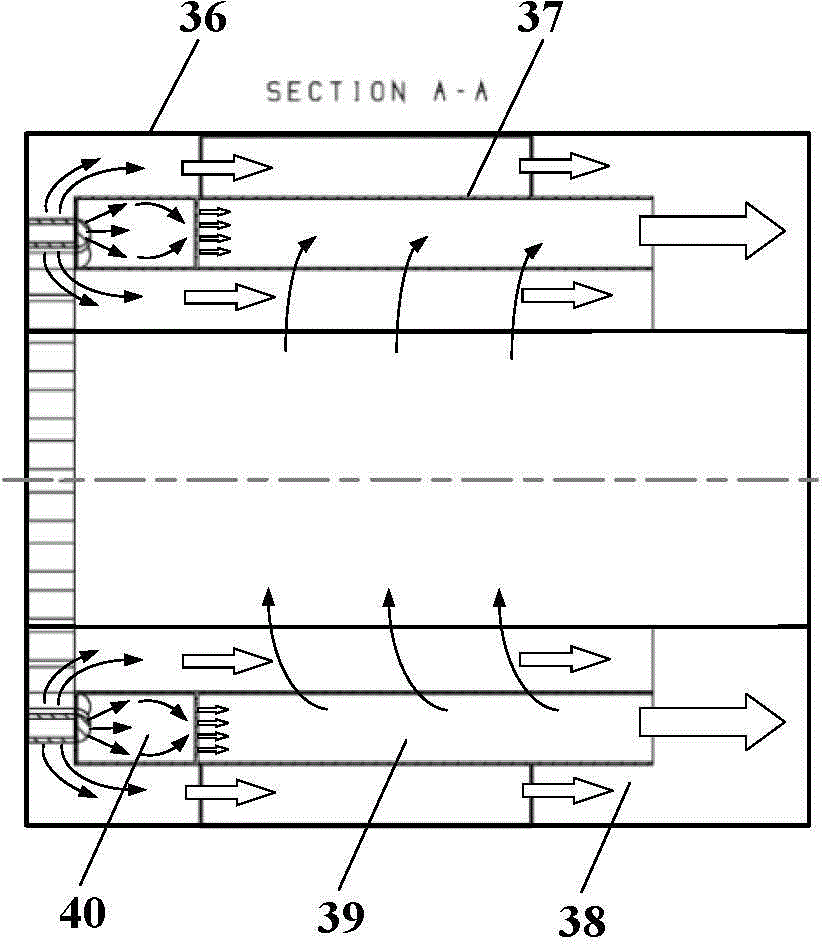

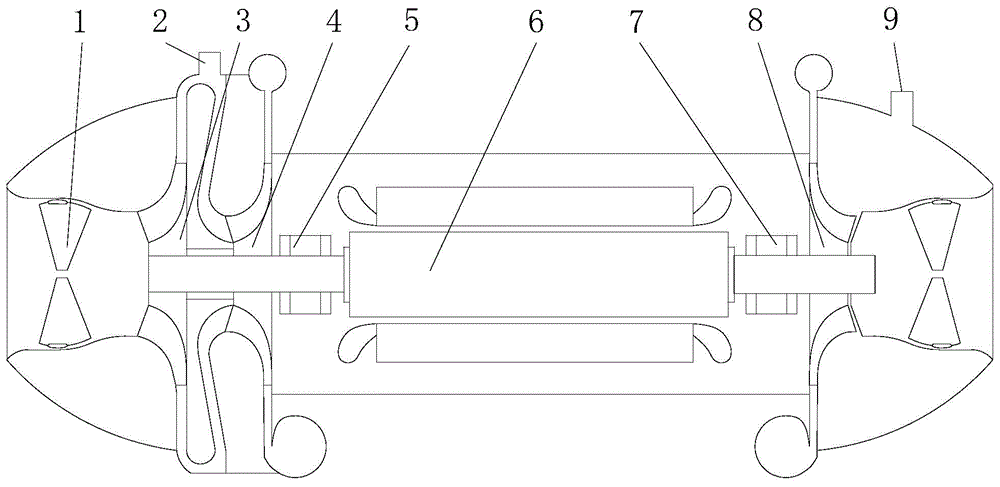

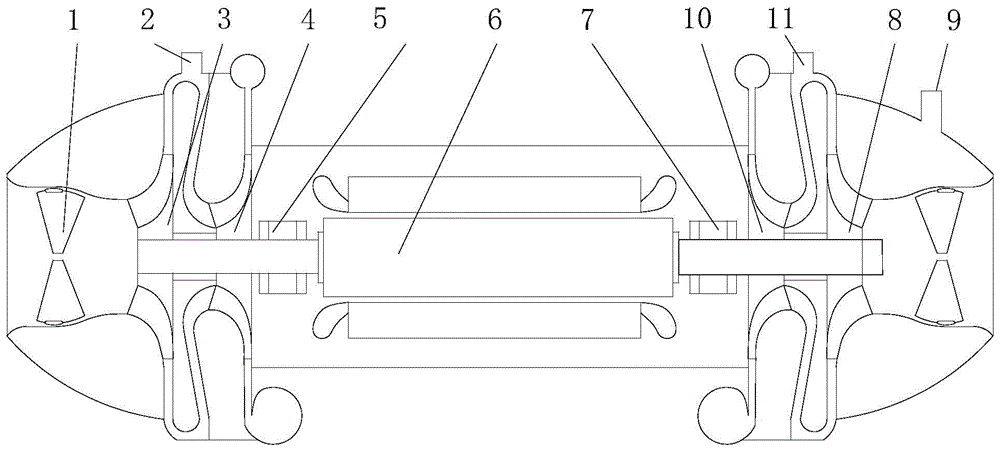

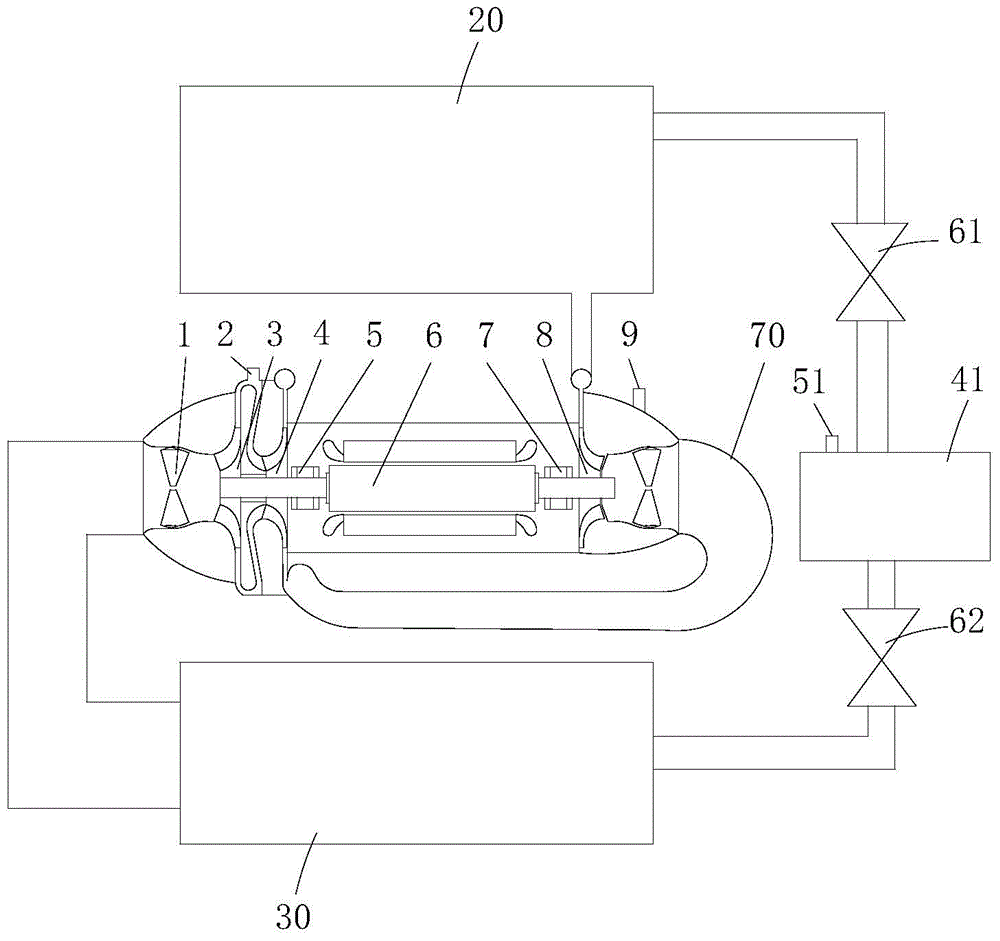

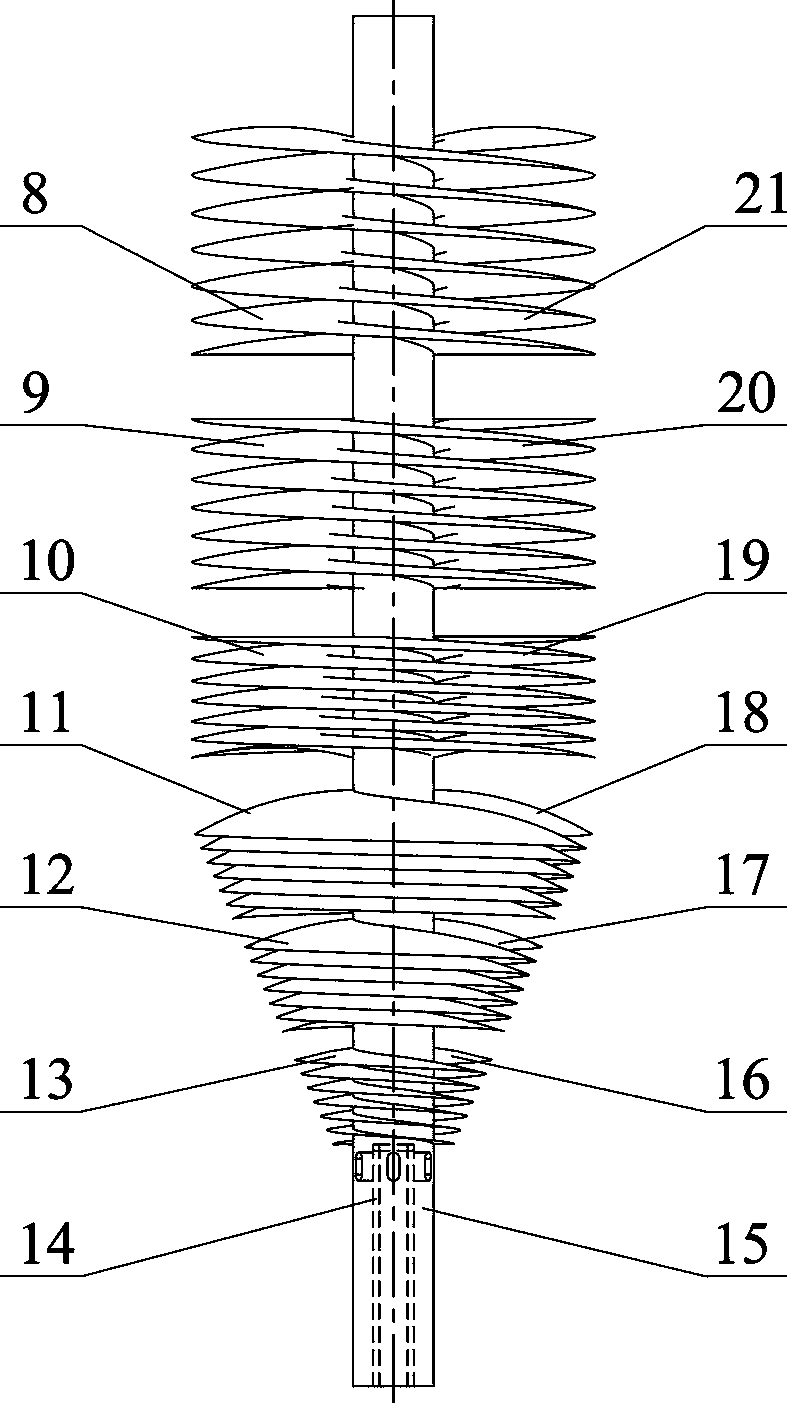

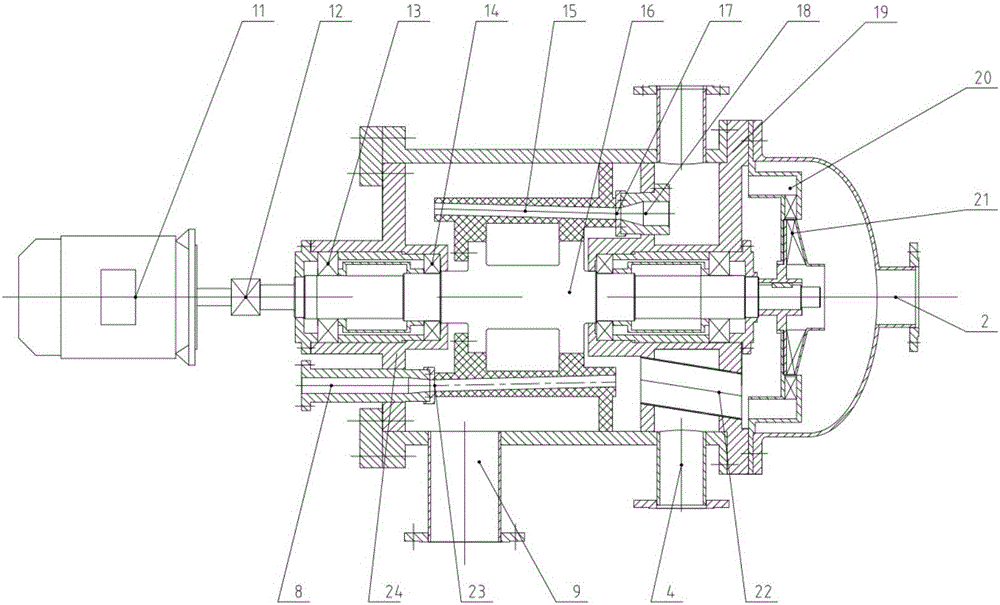

Rotary knocking gas turbine

InactiveCN104153884AImprove cycle thermal efficiencyLower Burn Control SystemGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

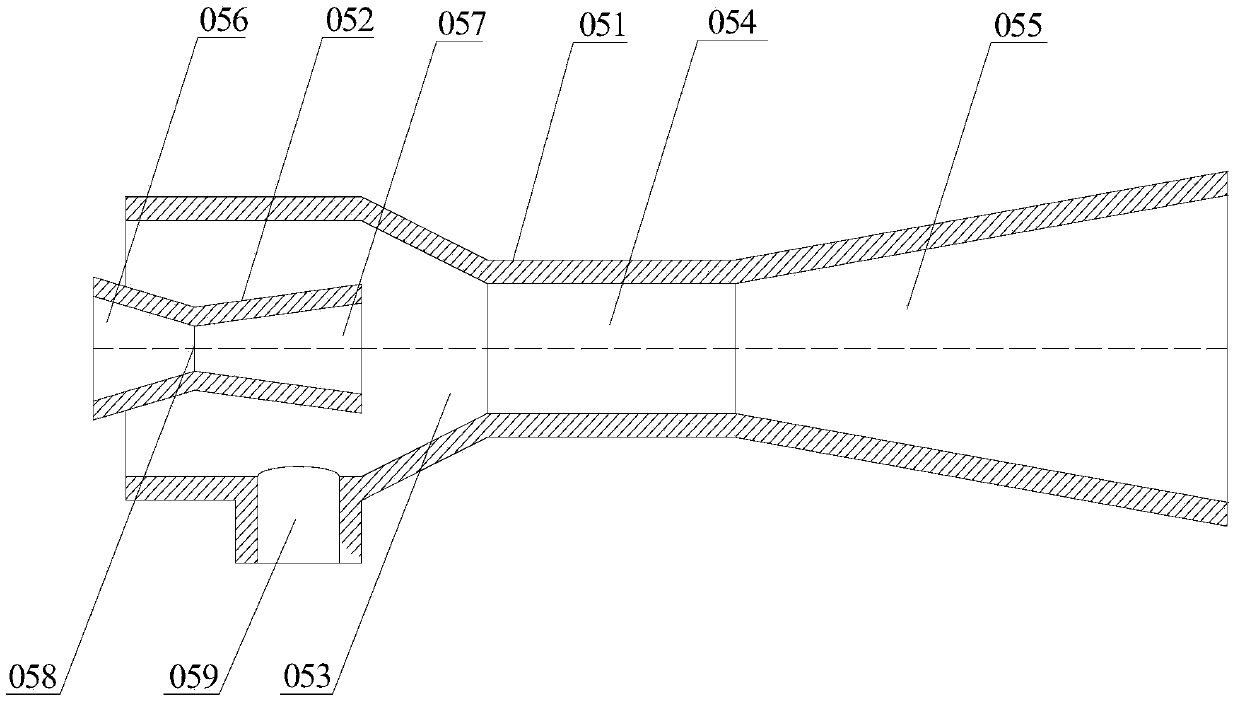

The invention discloses a rotary knocking gas turbine. The rotary knocking gas turbine comprises a gas inlet passage, a diffusion section and a gas storage chamber which are connected in sequence from left to right, wherein a gas compressor is arranged at the downstream of the gas inlet passage; a rotary knocking combustion chamber is positioned at the right end of the gas storage chamber, the right end of the rotary knocking combustion chamber is connected with a mixing chamber, a turbine and an exhaust pipe in sequence, a plurality of nozzles are annularly arranged on the left end face of the rotary knocking combustion chamber at equal intervals, and six ignition plugs are uniformly arranged on the circumference of the rotary knocking combustion chamber; an air passage and a combustion passage are arranged on each nozzle, the gas storage chamber is communicated with the rotary knocking combustion chamber through a gas supply passage and the air passages of the nozzles, and the mixing chamber is communicated with the gas storage chamber through a gas escape bypass; a rotor is arranged between the gas compressor and the turbine, the gas compressor of a rotating component of the gas turbine and the turbine are connected with a casing of a static bearing component of the gas turbine through two bearings, and one end of the rotor is led out from the gas exhaust pipe. When the rotary knocking gas turbine is used, the leading-out end of the rotor is connected with a generator assembly through a speed changer.

Owner:XIAN THERMAL POWER RES INST CO LTD

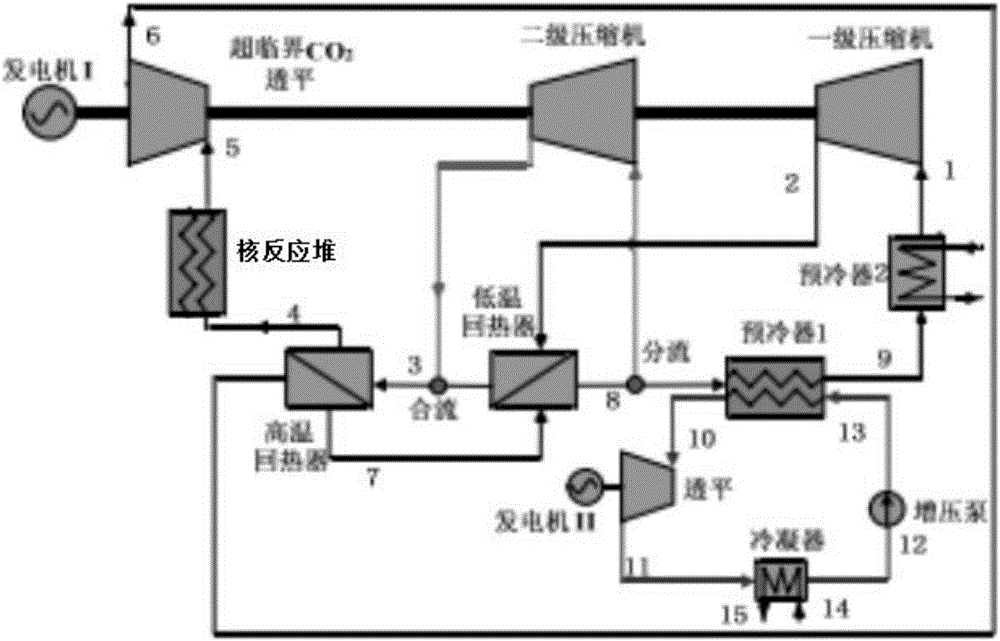

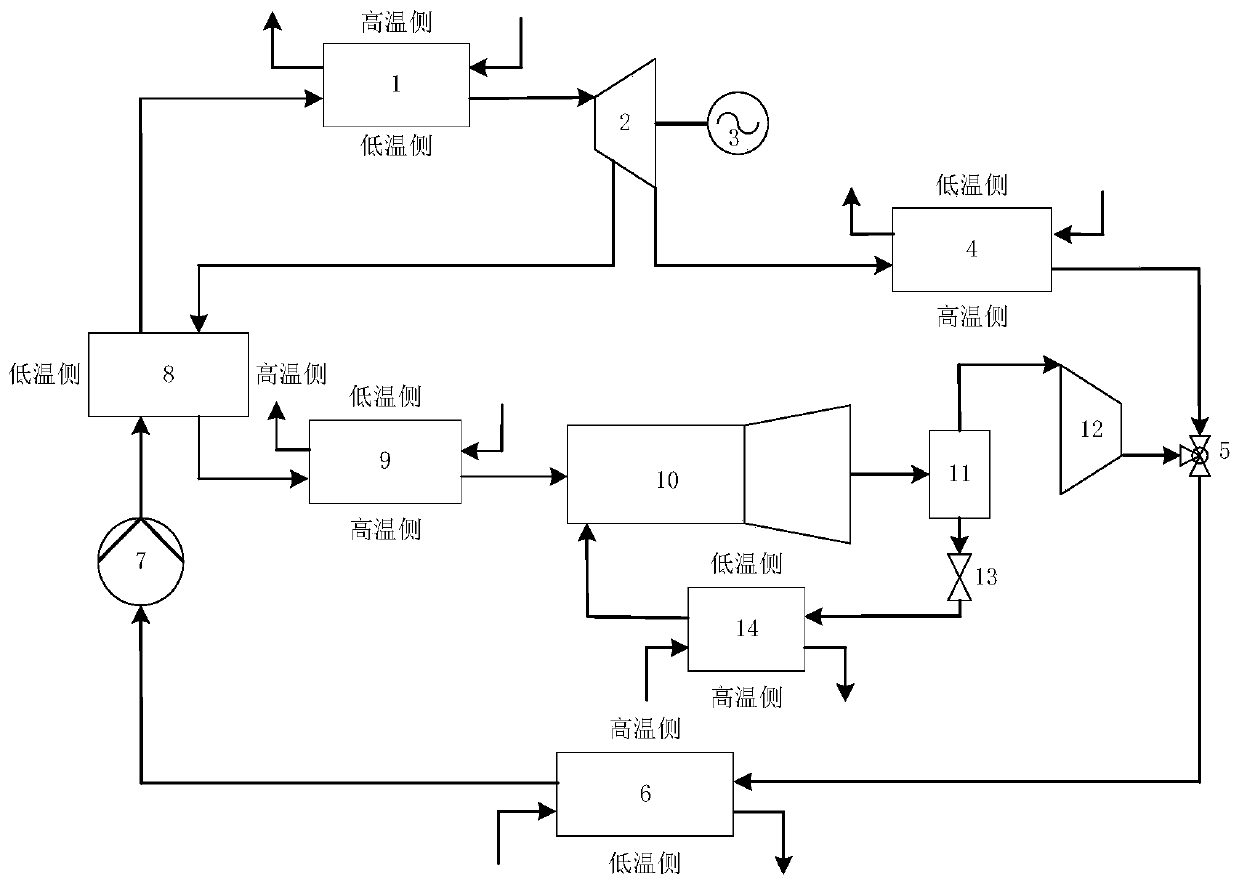

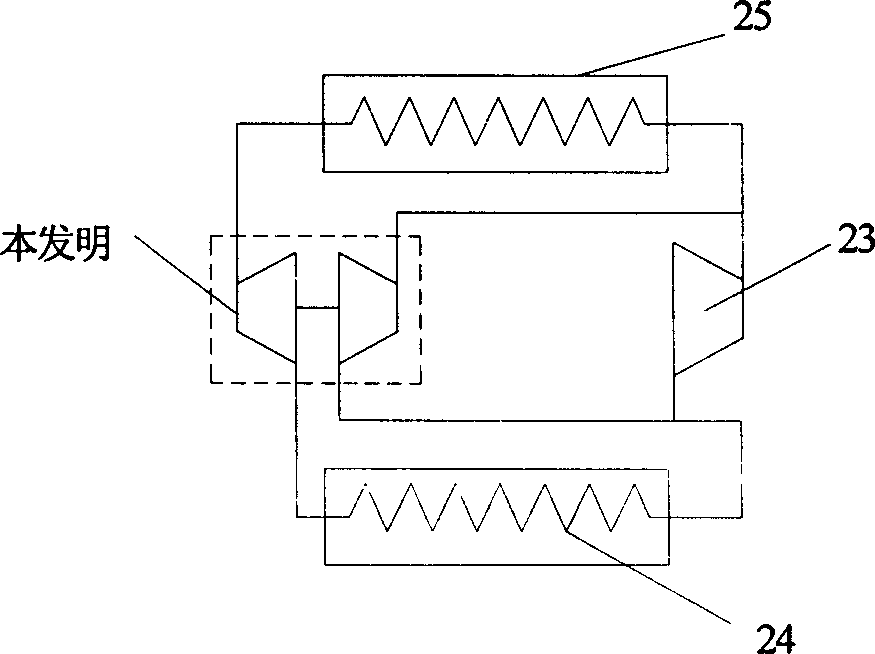

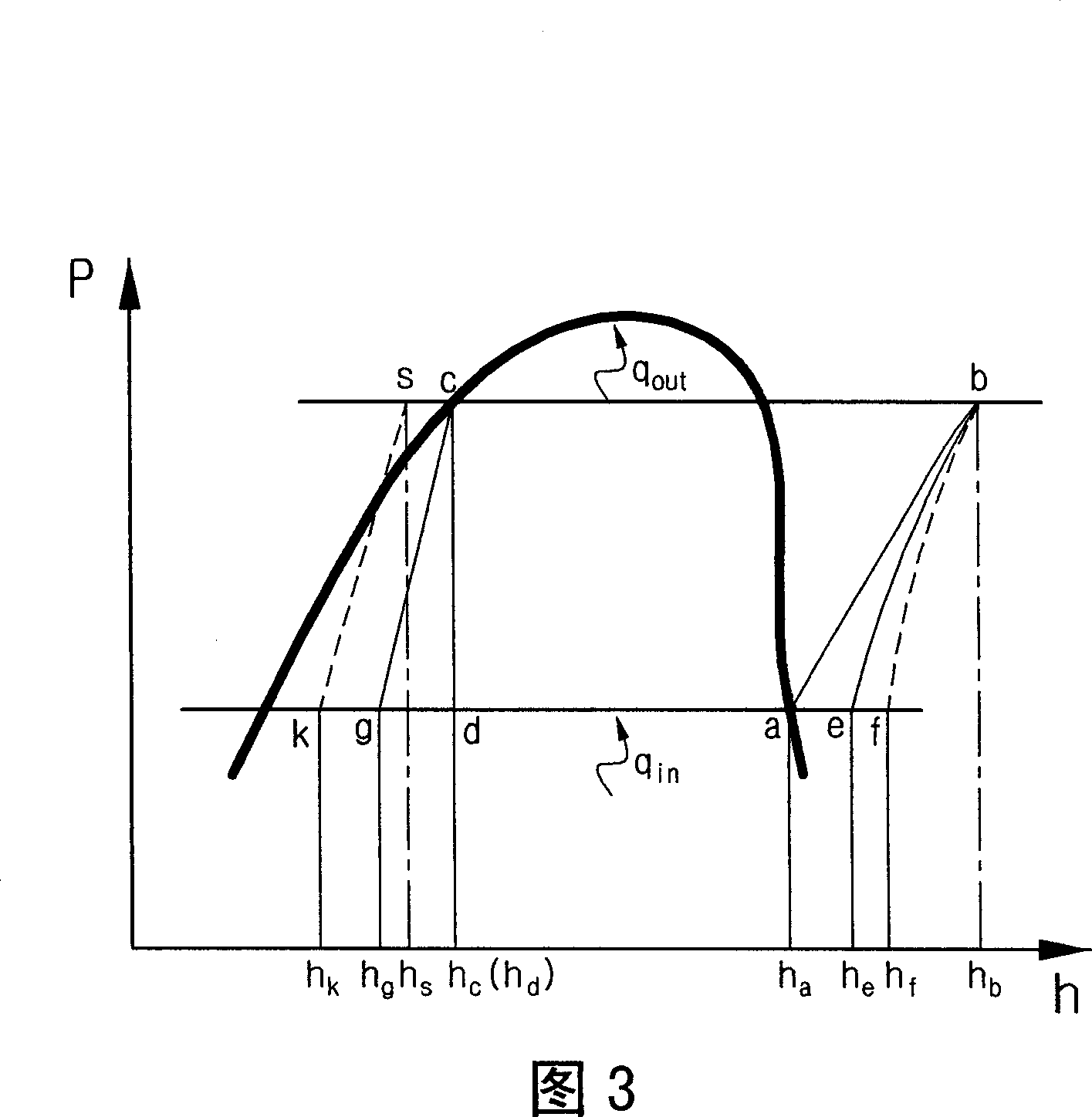

Nuclear electricity generation system based on Brayton cycle of supercritical carbon dioxide

InactiveCN106098122ASave compression workNuclear energy generationCooling arrangementBrayton cycleNuclear reactor

The invention specifically relates to a nuclear electricity generation system based on the Brayton cycle of supercritical carbon dioxide, belonging to the field of energy conservation and environmental protection. The nuclear electricity generation system based on the Brayton cycle of supercritical carbon dioxide comprises the Brayton recompression cycle of supercritical carbon dioxide and the Rankine cycle of transcritical carbon oxide, wherein the Brayton recompression cycle of supercritical carbon dioxide comprises seven parts, i.e., a nuclear reactor, a turbine, two compressors, a low-temperature heat regenerator, a high-temperature heat regenerator and a precooler. Under the condition of operation, the nuclear electricity generation system can reduce compression work and the like by using the properties of the actual gas of the system; and the cycles with CO2 as a working medium have efficiency equivalent to helium cycles without high temperatures.

Owner:HARBIN ENG UNIV

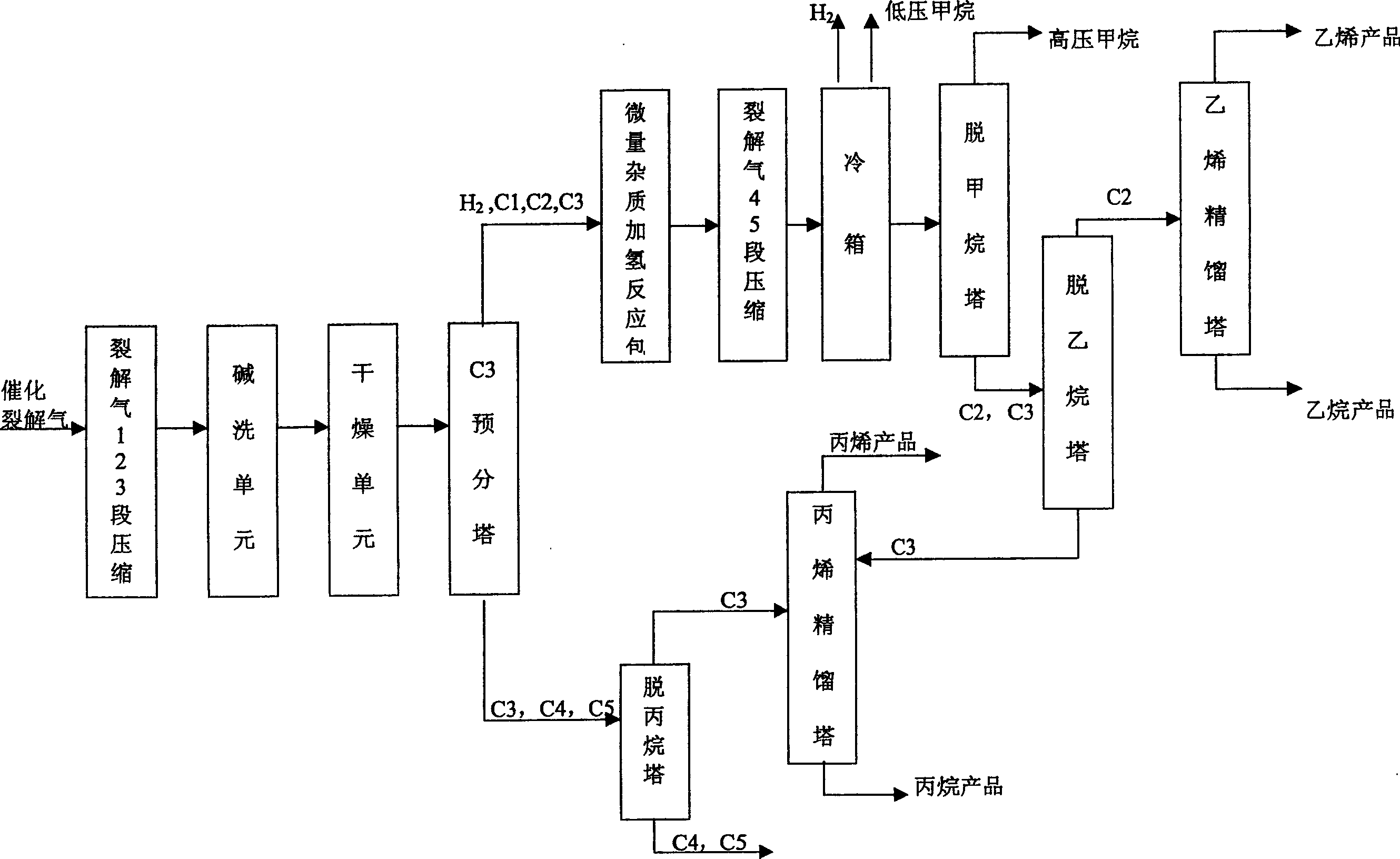

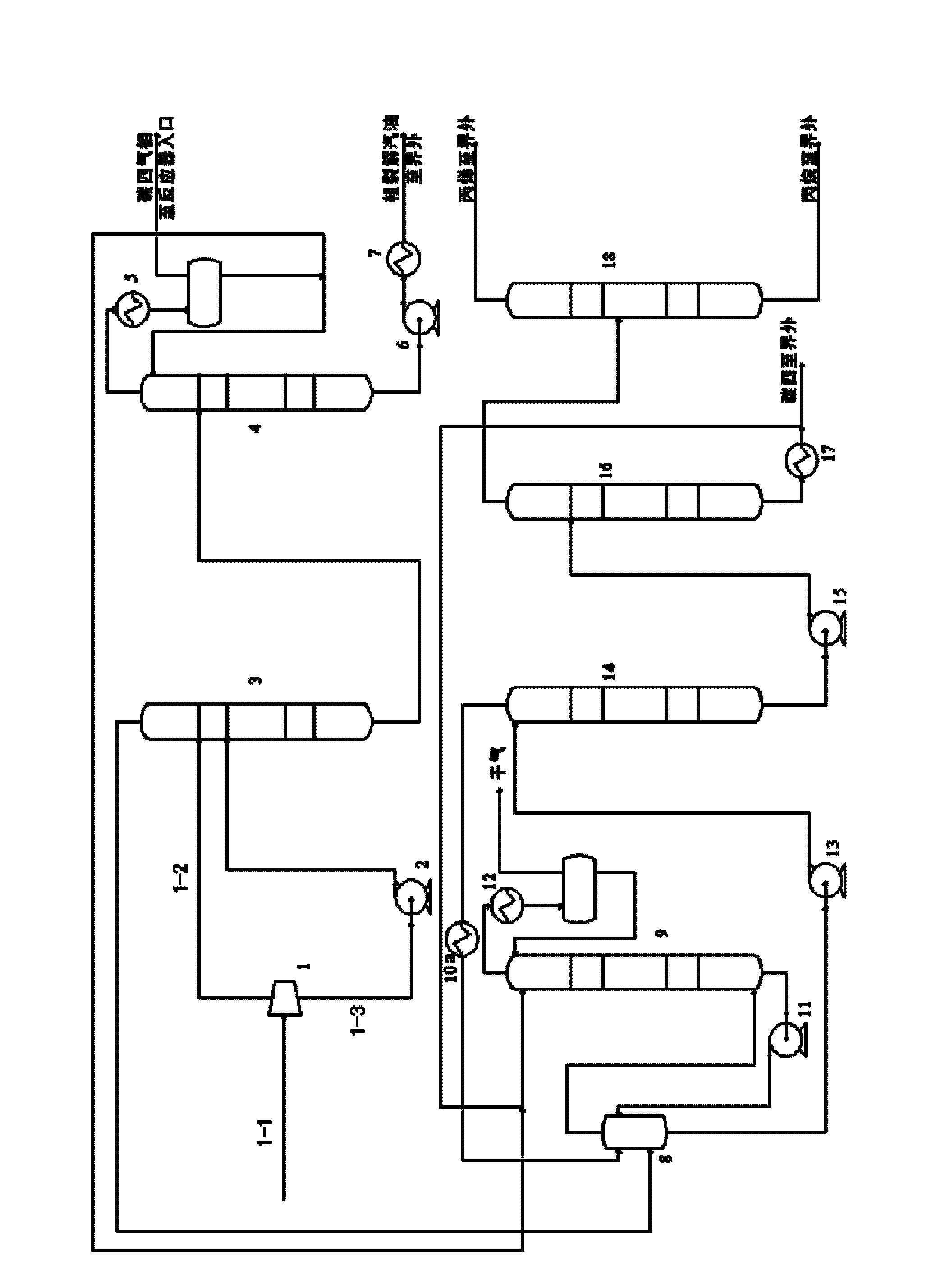

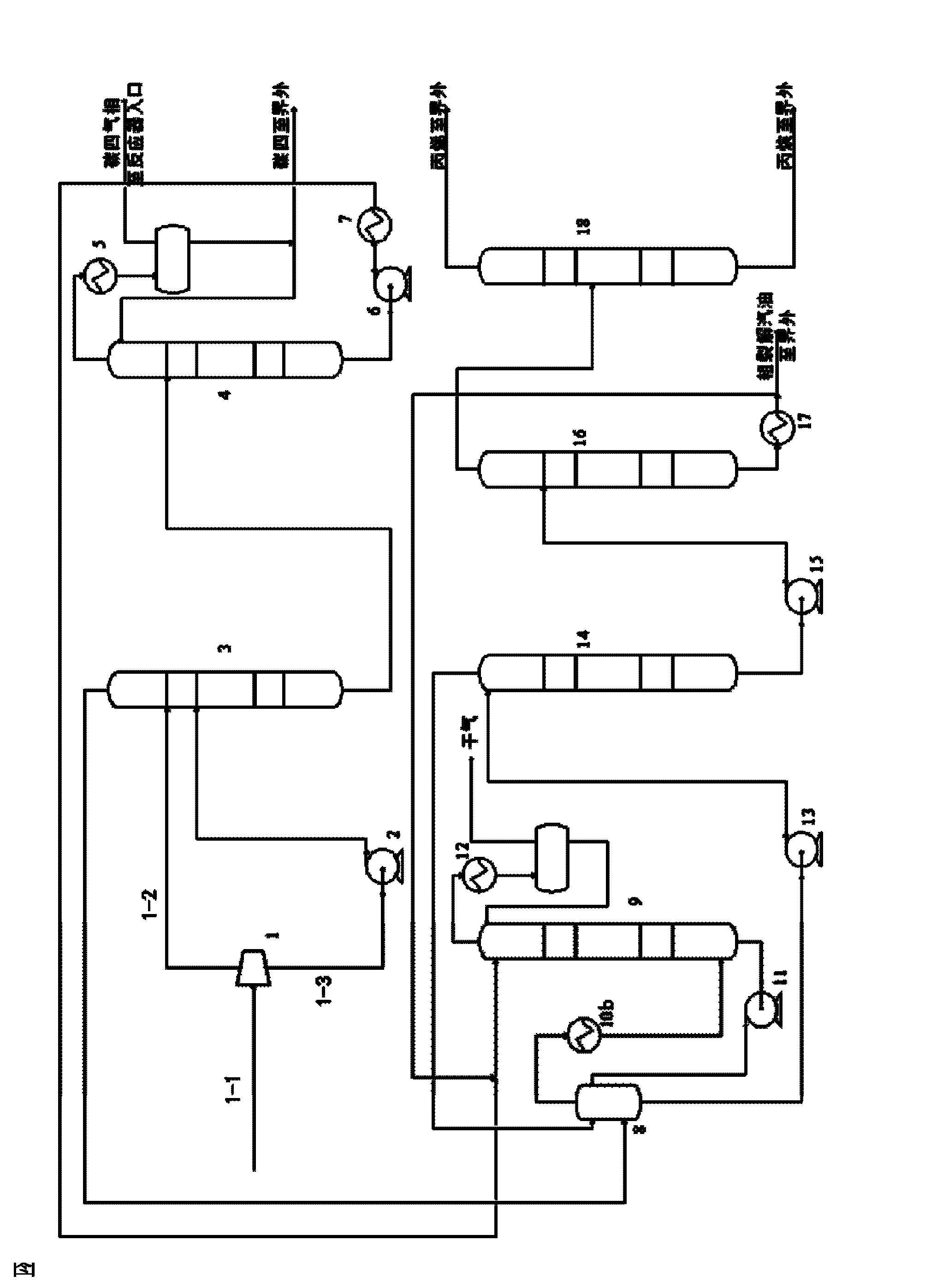

Method for separating catalytic splitting gas of enriching propylene and propane

ActiveCN1660722ALess investmentReduce energy consumptionDistillation purification/separationPetroleumPropane

A separation process for the propene and propane enriched catalytic cracked gasincludes compressing to 10-14 atm, alkali washing, removing acidic gas, drying and C3 prefractionating in a fractional tower to obtain H2, methane, ethane, ethane and propene components from tower top and the propene, propane and C4 components from tower bottom.

Owner:SINOPEC SHANGHAI ENG

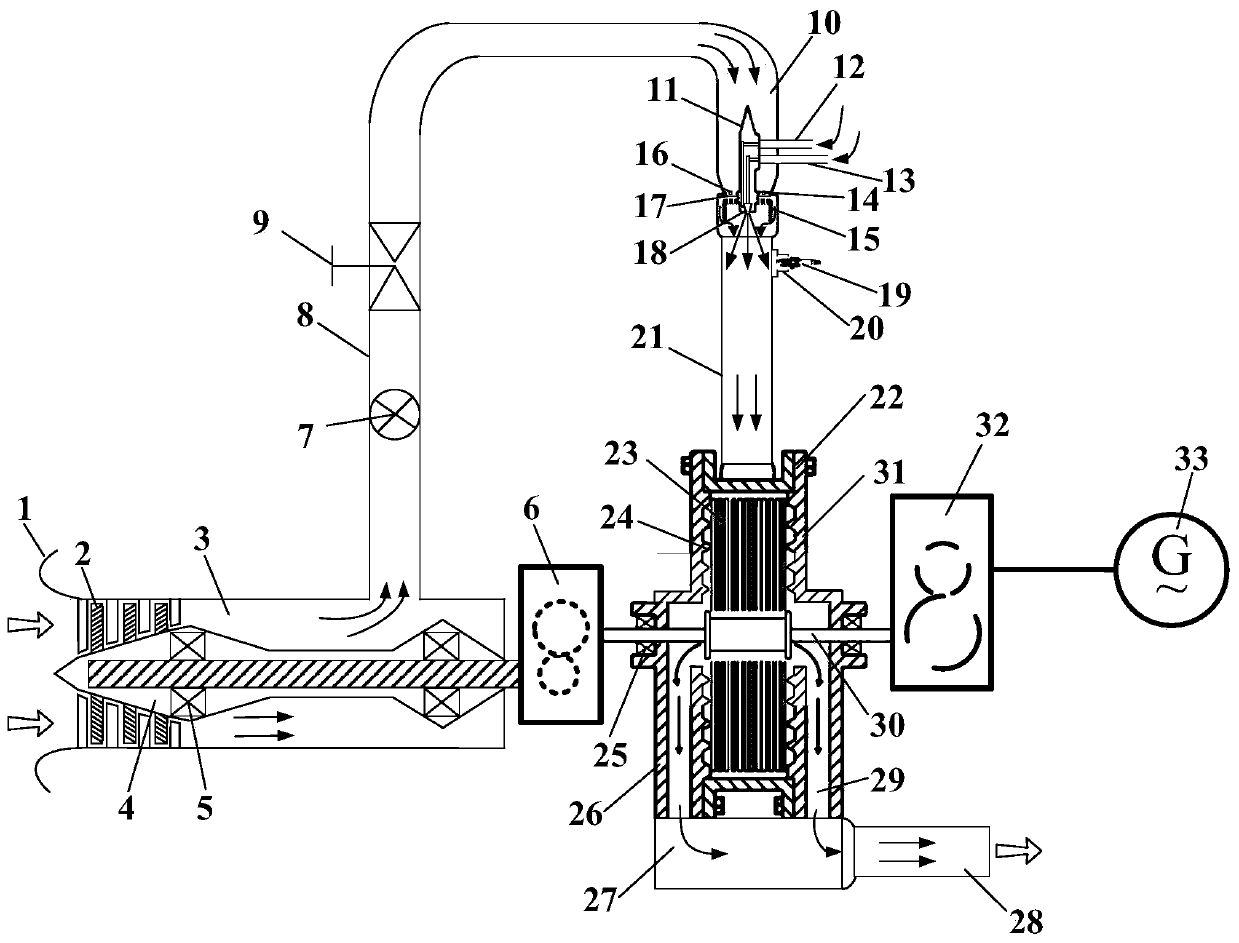

Supercritical/trans-critical carbon dioxide combined cycle power generation system for internal combustion engine waste-heat utilization

ActiveCN108868930ASave compression workIncrease net power outputInternal combustion piston enginesExhaust apparatusBrayton cycleExternal combustion engine

The invention discloses a supercritical / trans-critical carbon dioxide combined cycle power generation system for internal combustion engine waste-heat utilization. After carbon dioxide enters a working medium pump from a condenser, the carbon dioxide is compressed into supercritical gas, then the compressed carbon dioxide gas is divided into two branches in an outlet of the working medium pump, wherein one branch is used as the working medium for a trans-critical carbon dioxide Rankine cycle system, and the another branch is used as the working medium of a supercritical carbon dioxide recompression Breton cycle system. The supercritical / trans-critical carbon dioxide combined cycle power generation system uses the waste heat of internal combustion engine exhaust gas as a heat source, and sequentially recycles the high quality waste heat of the internal combustion engine exhaust gas by supercritical carbon dioxide recompression Breton cycle, and recycles the low quality waste heat of theinternal combustion engine exhaust gas by trans-critical carbon dioxide Rankine cycle, and converts the waste heat energy of a power device into electric energy, has the characteristics of high thermal efficiency, compact structure, low maintenance cost and the like, and can significantly improve the economy of the power device.

Owner:JIANGSU UNIV OF SCI & TECH

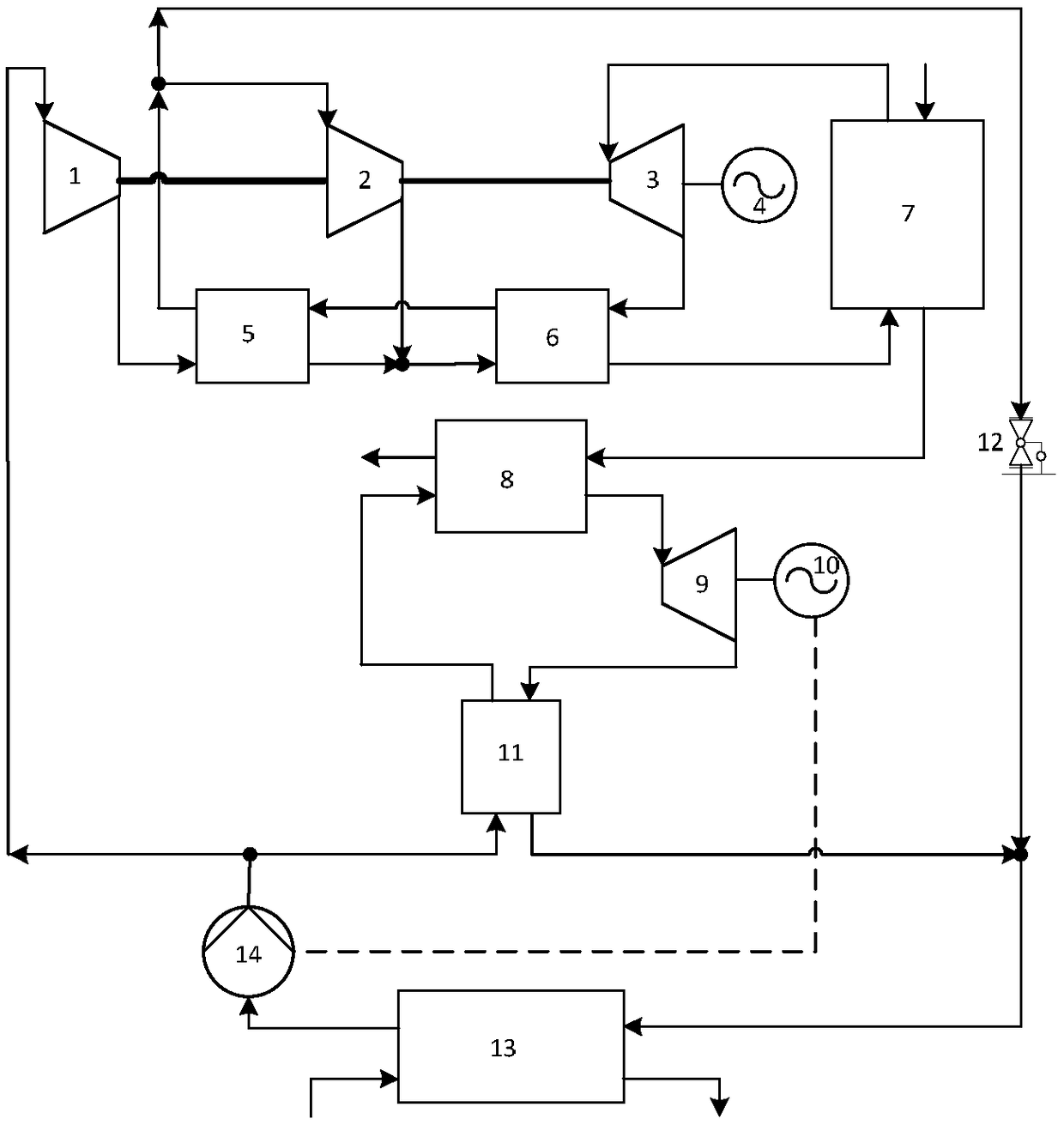

Energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for low-grade heat source

ActiveCN110887278ASave compression workIncrease net output powerCompression machinesFluid circulation arrangementGas compressorCogeneration

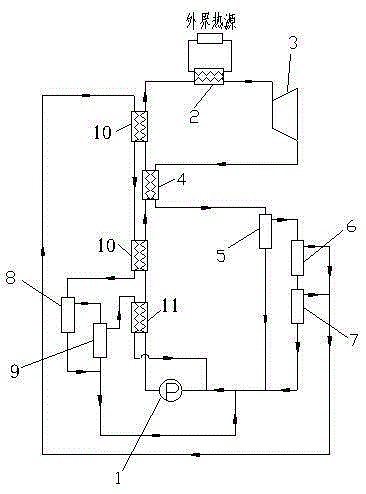

The invention discloses an energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for a low-grade heat source. The energy self-supplying type carbon dioxide coldand hot electricity co-generation system comprises a transcritical carbon dioxide reheat Rankine dynamic cycle system and a transcritical carbon dioxide injection refrigeration cycle system; the energy self-supplying type carbon dioxide cold and hot electricity co-generation system integrates reheat Rankine dynamic cycle and injection refrigeration cycle, adopts carbon dioxide as a single workingmedium, converts low-grade heat energy to useful work through a extraction turbine of the transcritical carbon dioxide reheat Rankine dynamic cycle system and supplies the heat energy to users by using a water heater. The transcritical carbon dioxide injection refrigeration cycle system utilizes high-pressure exhaust waste heat of the extraction turbine to drive an injector to output cold energy to the users. Through reasonable arrangement of the system, the system can output more electric energy. By adoption of a working medium pump and a low-pressure-ratio gas compressor, the energy self-supplying type carbon dioxide cold and hot electricity co-generation system reduces compression power efficiently during the system operation and improves net electric generation and conversion efficiency of the low-grade heat energy of the system.

Owner:北京绿卡科技有限公司

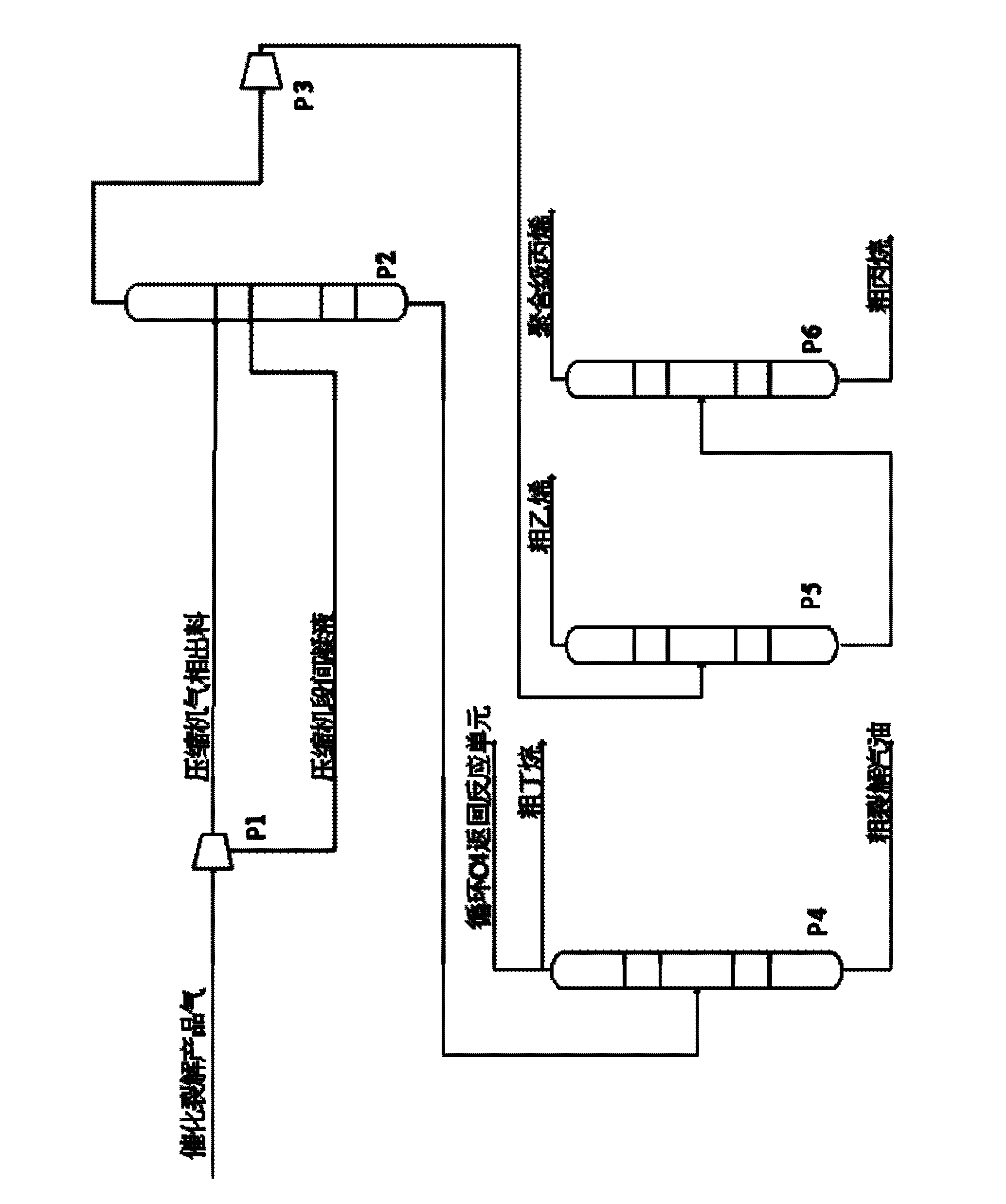

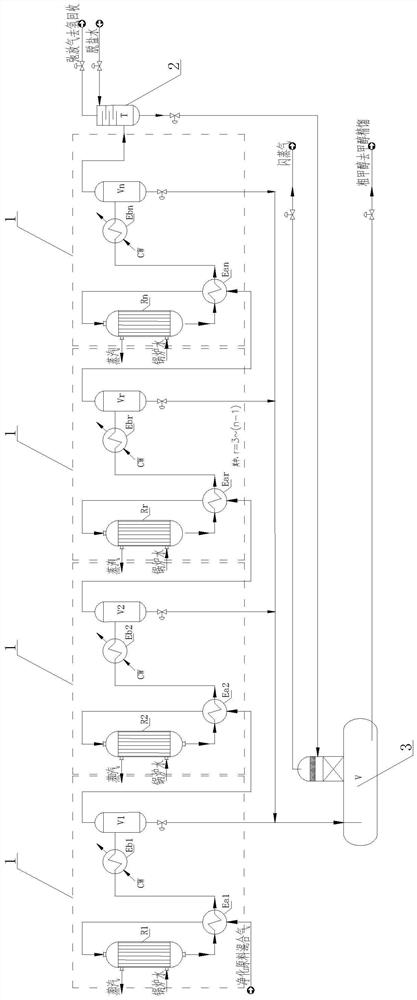

System and method for preparing polymer-grade propylene through absorption and separation of catalytic cracking product gas

ActiveCN103159581AReduce energy consumptionReduce usageLiquid hydrocarbon mixture recoveryHydrocarbonsDesorptionProcess engineering

The invention provides a system and a method for preparing polymer-grade propylene through absorption and separation of catalytic cracking product gas. A debutanizing tower, an absorption tower, and a desorption tower are sequentially arranged between a pre depropanizing tower and a post depropanizing tower. A propylene tower is arranged behind the post depropanizing tower. A gas enrichment balancing tank is arranged between the absorption tower and the desorption tower. Through the pre depropanizing tower, catalytic cracking product gas is separated into C3 and lighter components and C4 and heavier components. The C4 and heavier components are processed by using the debutanizing tower, such that C4 component or C5 and heavier components are obtained. The obtained component is adopted as an absorption agent, and is used for absorbing the C3 and lighter components of the pre depropanizing tower top gas in the absorption tower. With the desorption tower, C3 component and C2 and lighter components are separated through desorption. The tower kettle liquid of the desorption tower is delivered to the post depropanizing tower. Post depropanizing tower top gas is subjected to propane-propylene separation in the propylene tower, such that the polymer-grade propylene product is obtained at the top of the propylene tower. With the system and method provided by the invention, an oil absorption method is adopted; the application of low-temperature cold energy is avoided; energy consumption is reduced; and equipment investment is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

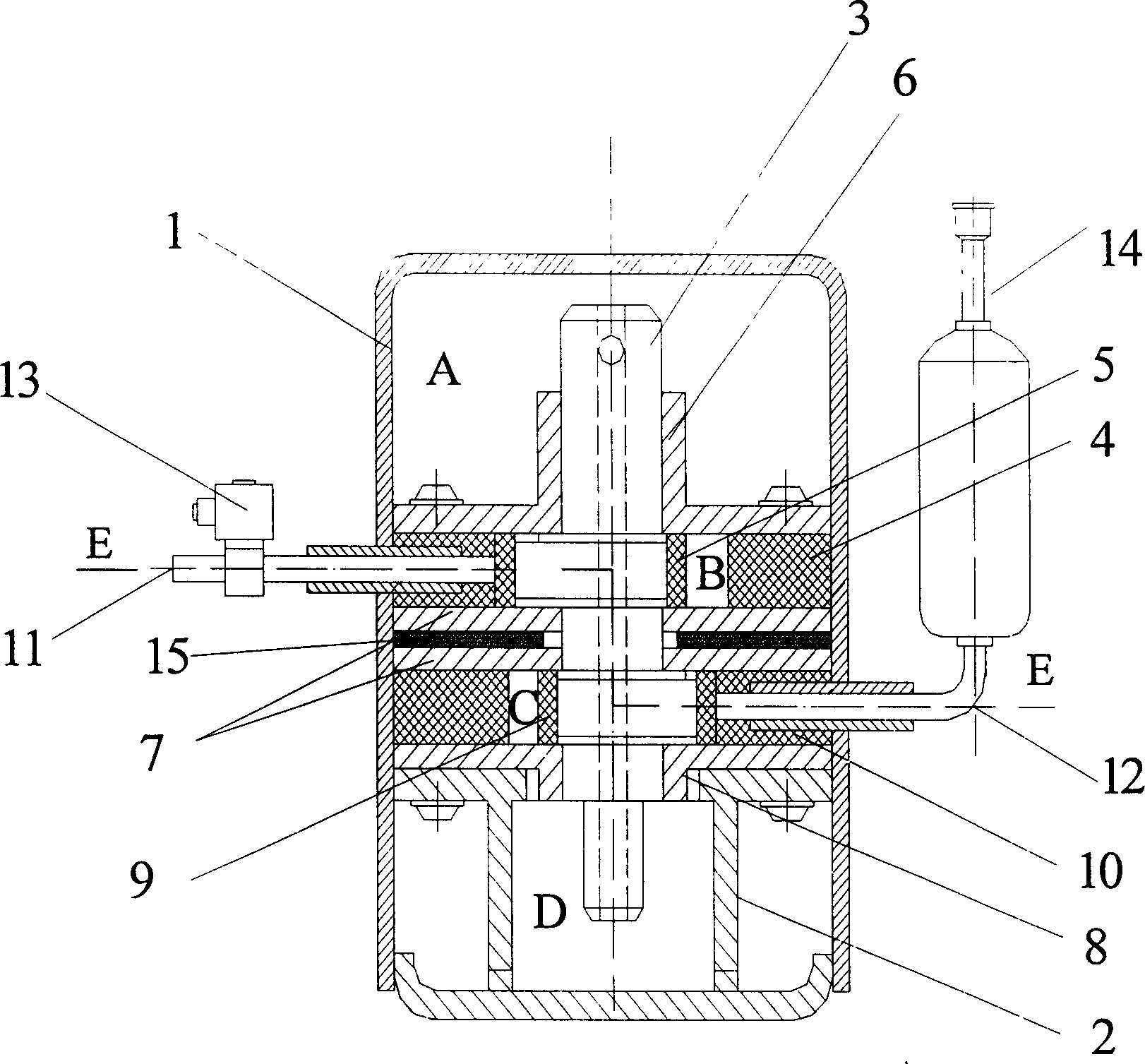

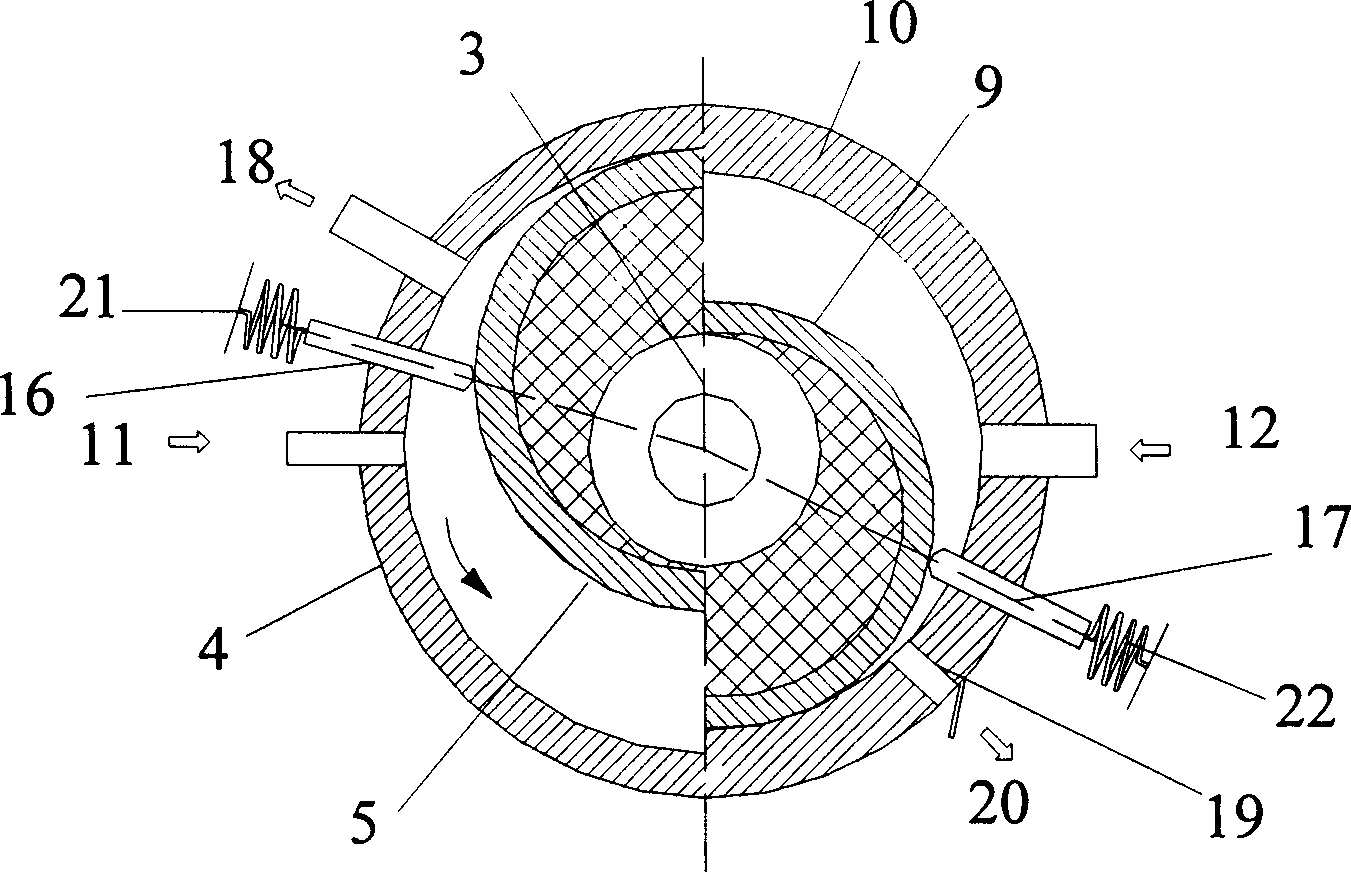

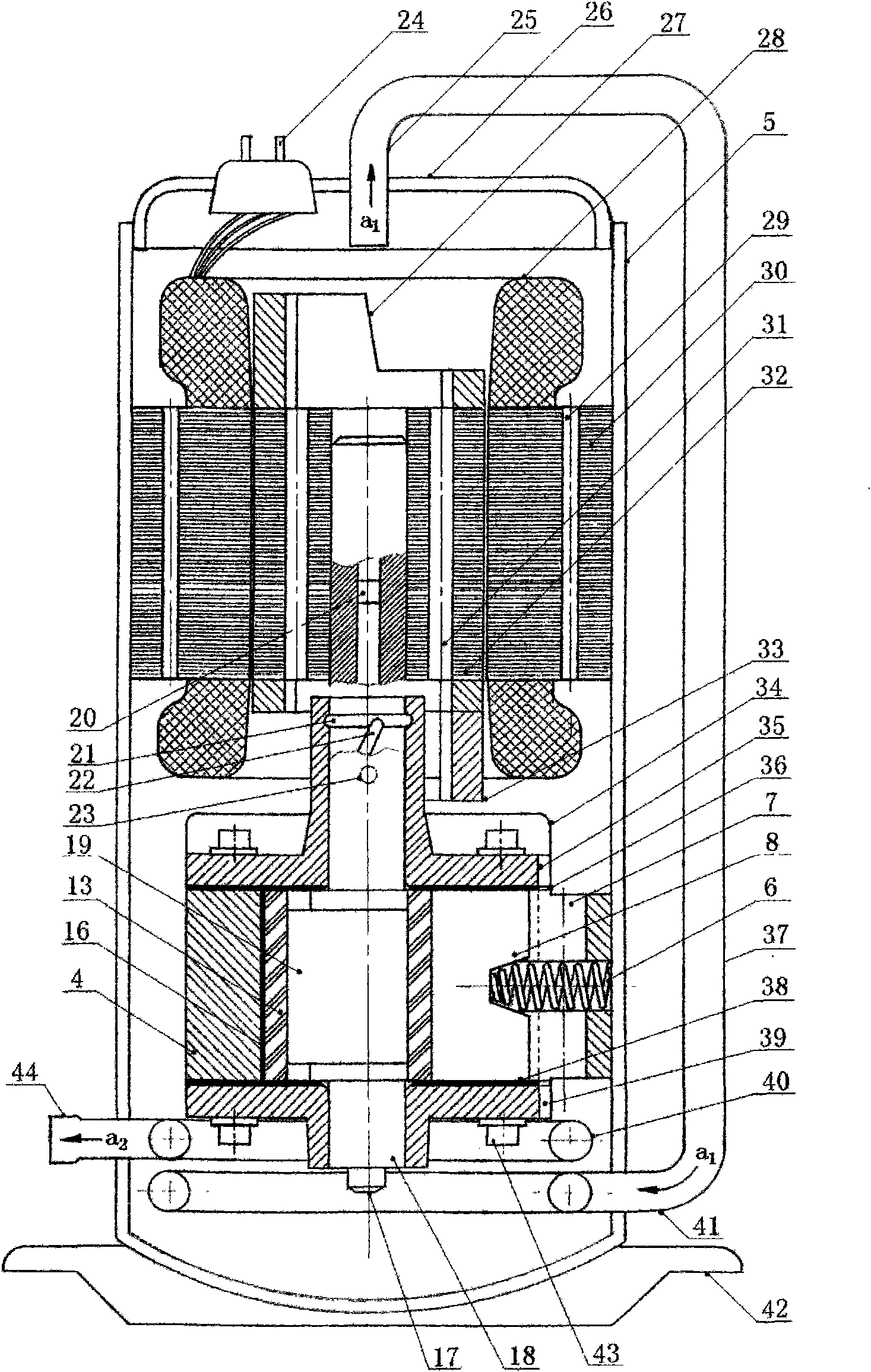

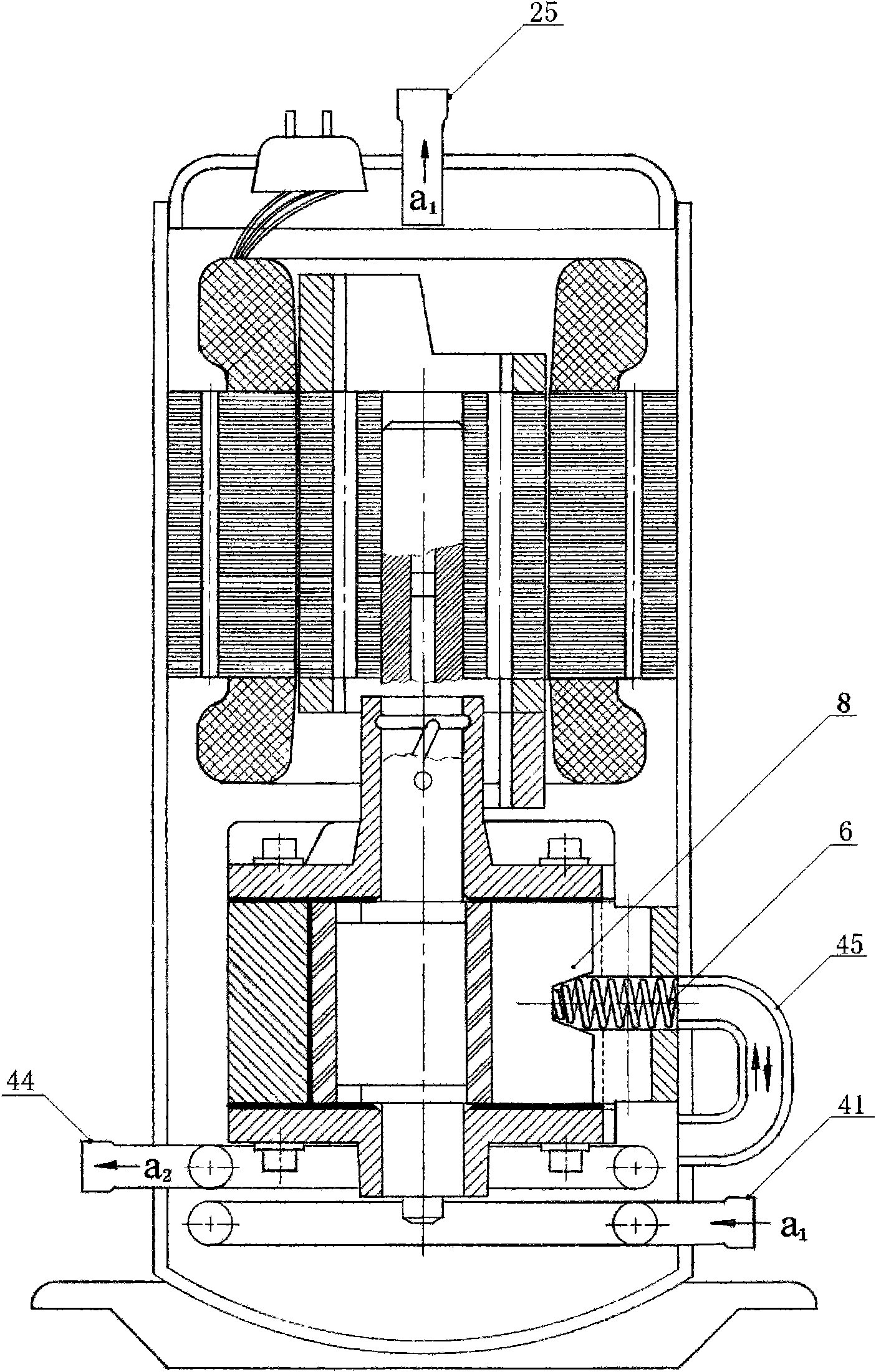

Carbon dioxide transcrisis refrigeration circulation rotor type expansion energy-saving device

InactiveCN1419089AReduce lossesSave compression workEnergy recovery in ventilation and heatingEngine of arcuate-engagement typeLiquid pressureCarbon dioxide

The carbon dioxide transcritical refrigeration circualting rotor type expansion energy-saving device is formed from cylinder body, rolling piston, eccentric wheel shaft, base seat and electromagnetic valve. The internal cavity of expansion energy-saving device can be divided into two high-pressure cavities and two low-pressure cavities by means of main and secondary bearings and partion board. After the carbon dioxide is come into the expasion cylinder, it can driven eccentric wheel shaft to make it rotate and make expansion cylinder produce volume change to lower liquid pressure and output mechanical power. According to the rotating angle of eccentric wheel shaft its circuit control system can output signal to control opening and closing of the electromagentic valve to control suction time of the expansion energy-saving device to make it circularly apply work.

Owner:TIANJIN UNIV

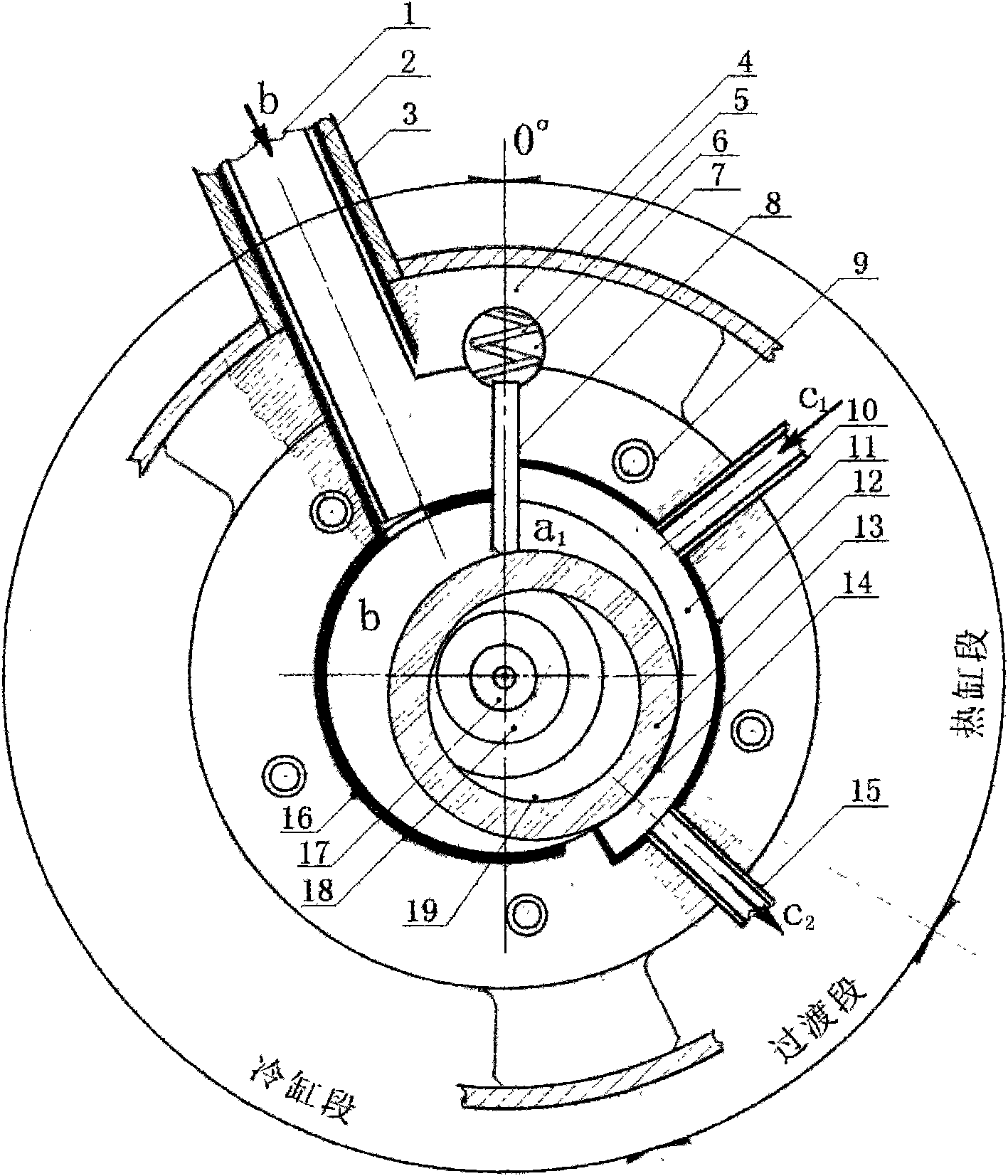

Cooling cylinder compression cycle of rotor-type compressor

InactiveCN101576083ALower subcooling temperatureReduce condensation loadRotary piston pumpsRotary piston liquid enginesRefrigeration compressorSuction force

The invention relates to a cycling system for improving the efficiency of a cooling compressor, cooling cylinder compression cycle for short. The cooling cylinder compression cycle of a rotor-type compressor is mainly realized in four aspects: a. cooling cylinder compression, i.e. performing low-temperature cooling to a compression strong-heat-release cylinder wall surface (defined as a heat cylinder and others are cooling cylinders), coating heat insulating ceramic on the surfaces of a tongue piece and a rolling rotor, pushing compression heat release to a cooled heat cylinder, and increasing the area of the heat cylinder or reduce the rotational speed so as to fully discharge the compression heat release and prevent the discharged gas from overheating and then to reduce the compression net work and the condensation load; b. cooling cylinder gas suction, i.e. performing the isolation of gas phase from heat insulation to high-pressure gas discharge, the cooling and heat cylinders, upper and lower covers and a gas suction pipe, and ensuring the low-temperature characteristic of a gas suction chamber by means of continuous gas suction and heat cylinder cooling so as to obtain greater cold energy; c. oil way improvement, i.e. increasing the gas-suction force; and d. recovery gas discharge overheating and motor heat releasing, for purposes of heating and compensating absorptive lubricant, wherein an absorbent has low partial pressure and strong absorption capability on the surfaces of the cooling cylinders so that the cold energy is further increased and the compression work is further reduced.

Owner:童夏民

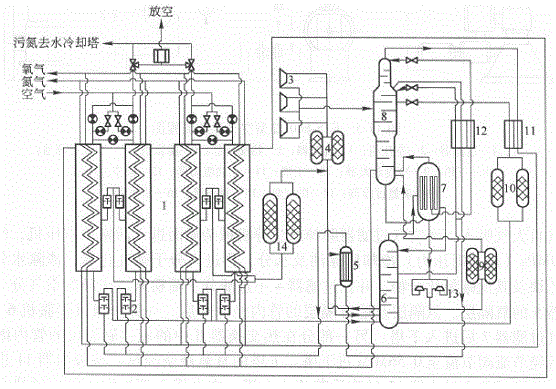

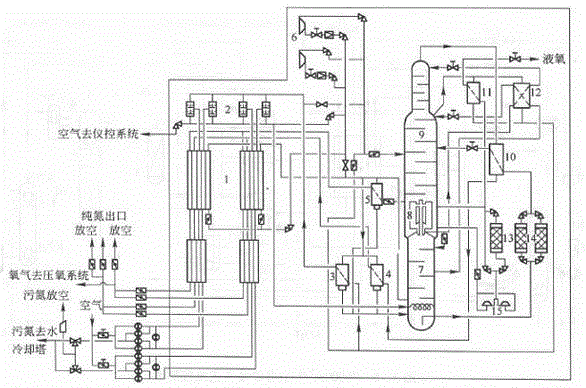

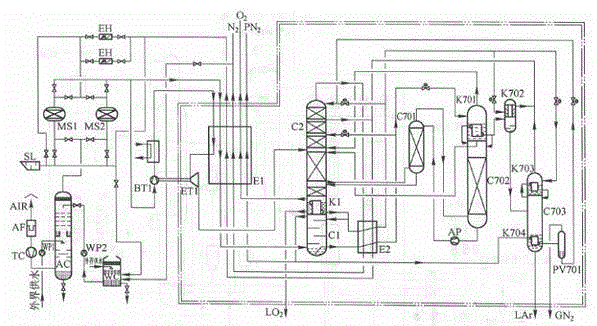

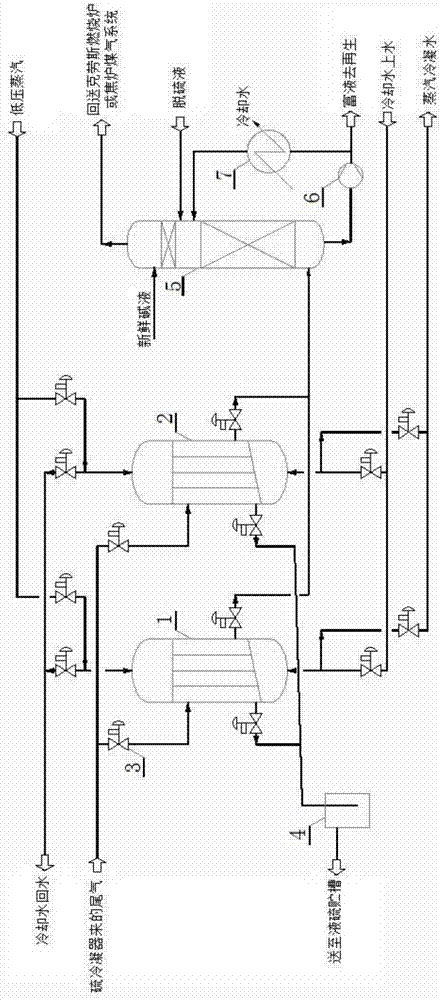

Air separation device for preparing oxygen and nitrogen through isobaric separation

ActiveCN103148676AAchieve isobaric separationImprove energy savingSolidificationLiquefactionThermal energyPower cycle

The invention relates to an air separation device for preparing oxygen and nitrogen through isobaric separation. In the air separation device, a Rankine cycle system with a similar thermal energy power cycle device at a low-temperature end is adopted, a liquid nitrogen washing process is adopted, and cold is replenished to the air separation device through a liquid nitrogen washing cold-replenishing system, so that nitrogen and oxygen can be prepared by performing isobaric separation on the air. Compared with the conventional advanced unit, the air separation device has the advantages that on the premise of the same refrigerating capacity, energy is saved by over 30 percent compared with the traditional advanced unit, equipment and materials are saved, and operation and adjustment are performed flexibly and conveniently; and meanwhile, multiple pressure grades and multi-gas supply can be realized conveniently through the air separation device, so that low-energy-consumption concentrated air supplying can be realized, the conventional air separation technology and theory are broken through, and remarkable economic, social and environmental protection benefits are achieved.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

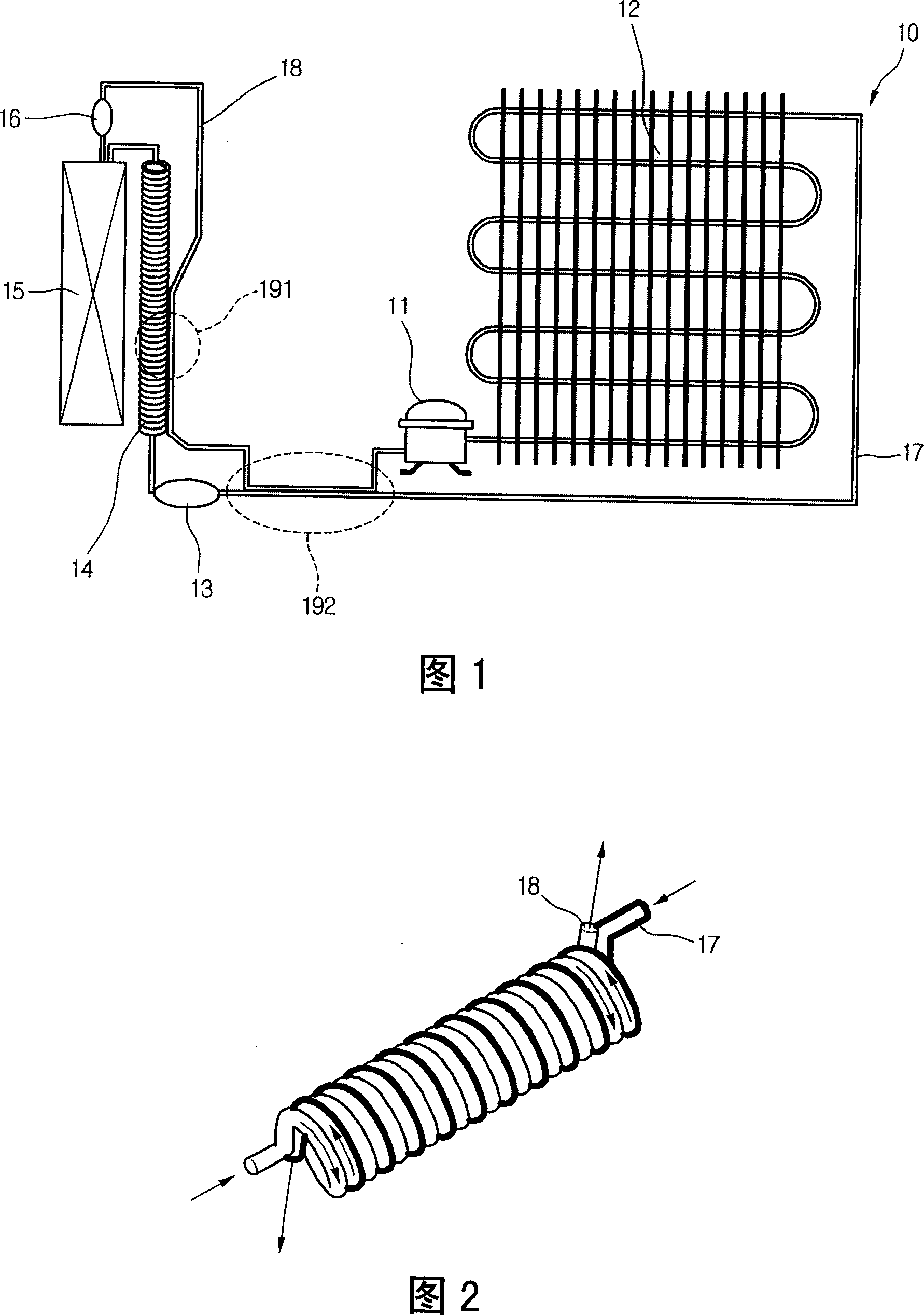

Refrigerator

InactiveCN1995877ASave compression workImprove COPMechanical apparatusCompression machines with non-reversible cycleCooling chamberEngineering

There is provided a refrigerator. The refrigerator includes a compressor for compressing a refrigerant, a condenser for heat-exchanging the compressed refrigerant with ambient air, an expansion member for expanding the heat-exchanged refrigerant, a condensing pipe interconnecting the condenser and the expansion member, a vaporizer for heat-exchanging the expanded refrigerant with a cooling air in a freezing or cooling chamber, and a suction pipe interconnecting the vaporizer and the compressor and associated with the condensing pipe to allow a heat exchange between the suction pipe and the condensing pipe.

Owner:LG ELECTRONICS INC

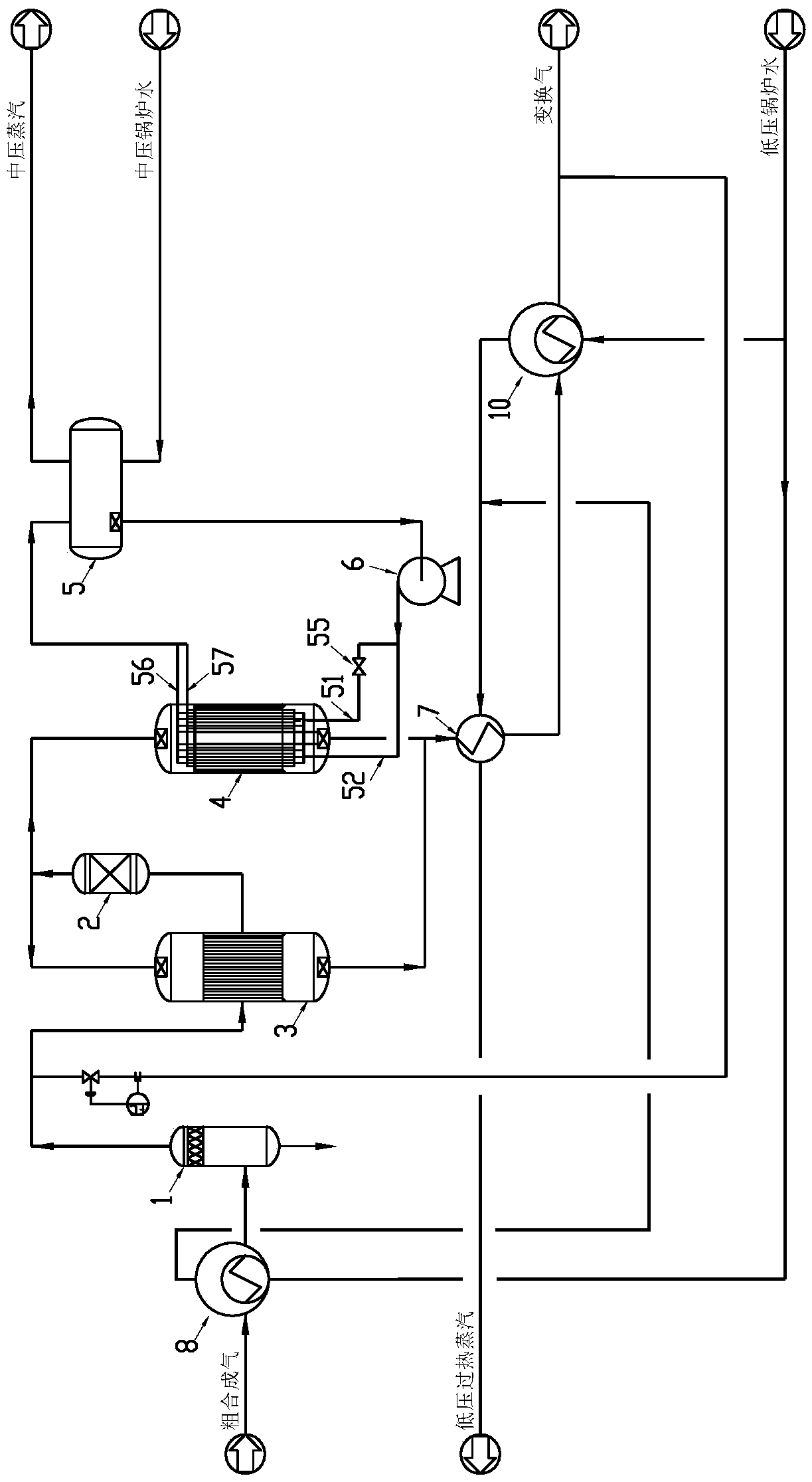

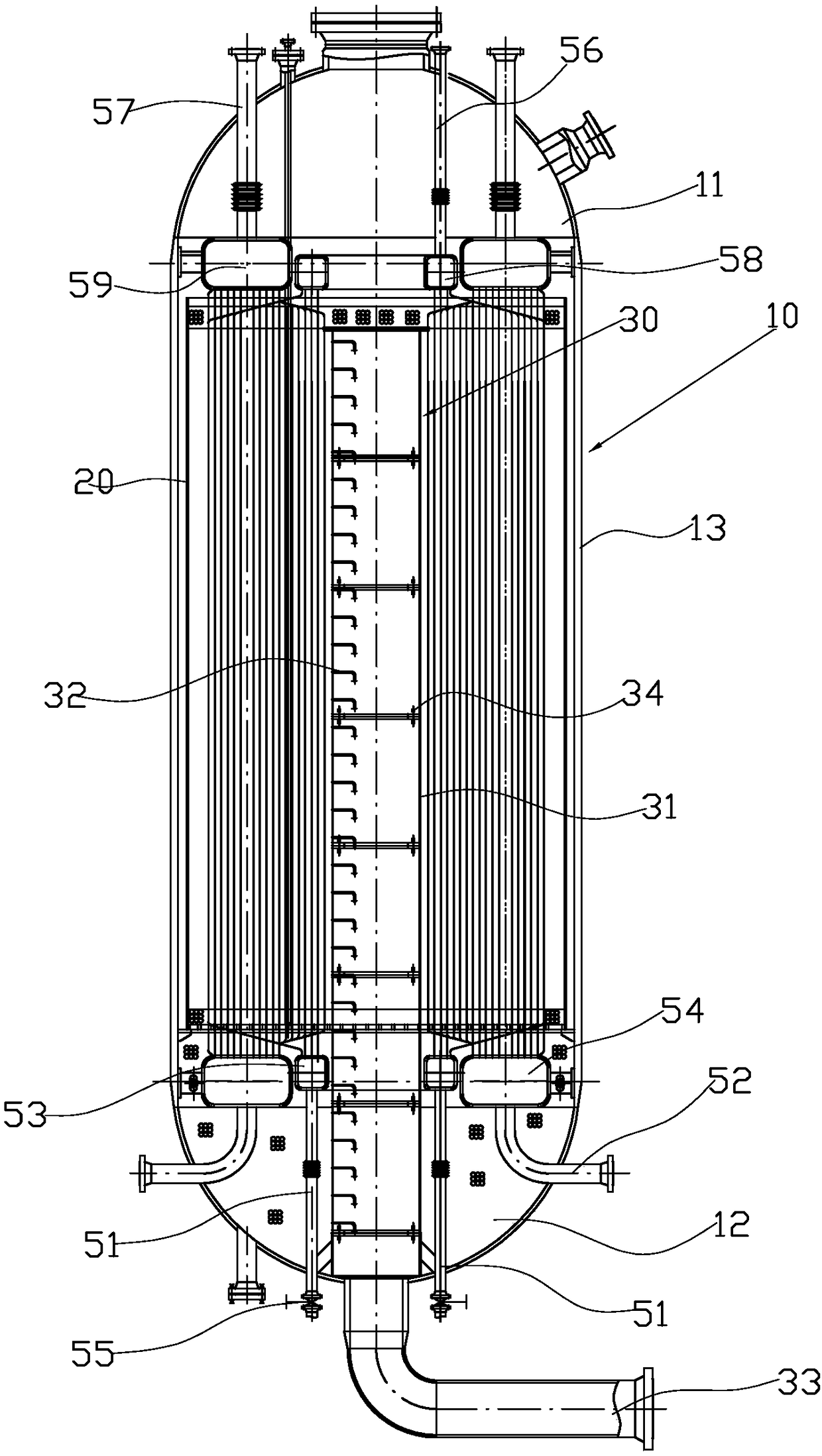

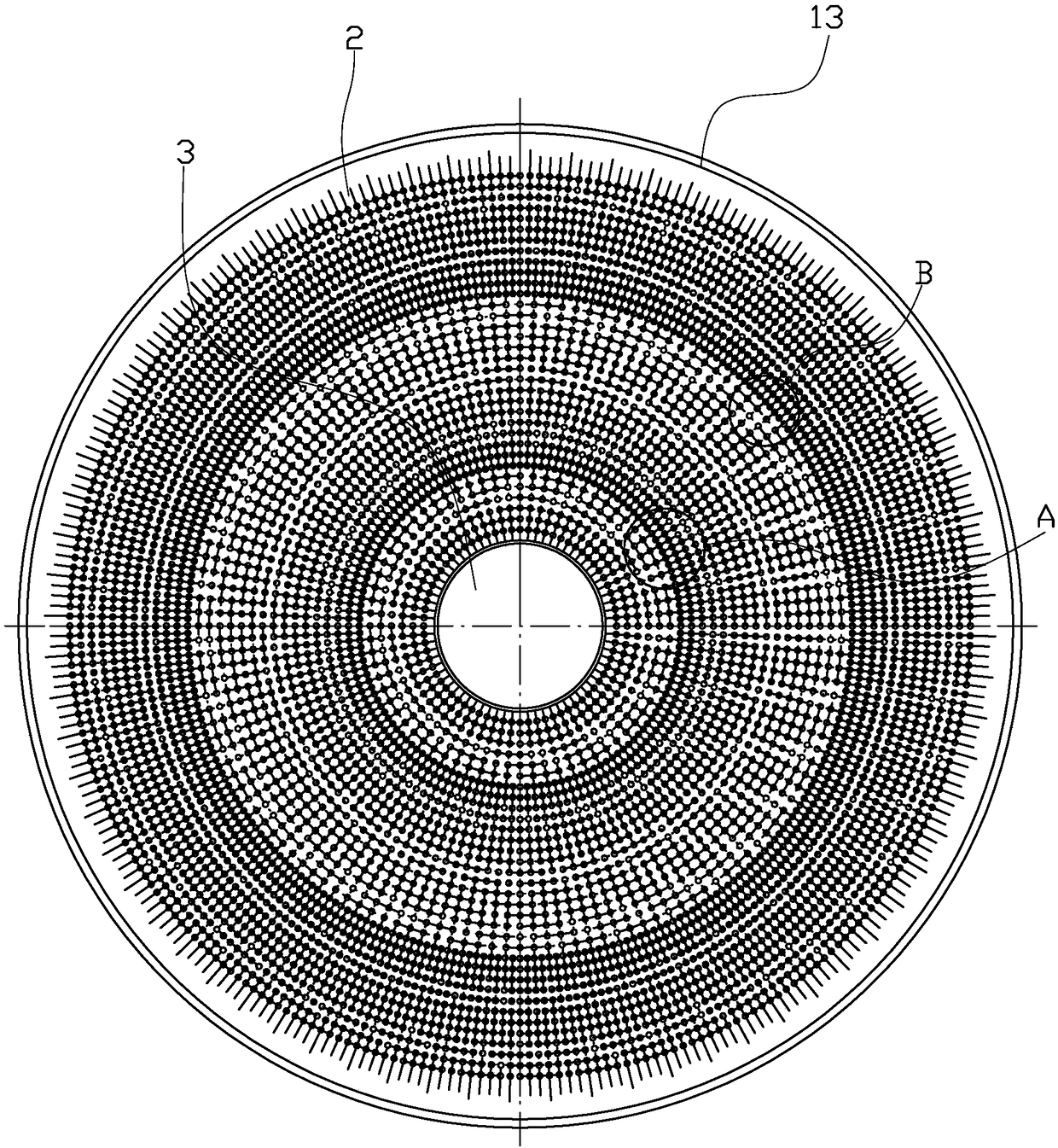

CO shift process matched with synthesis of methanol

The invention relates to a CO shift process matched with synthesis of methanol. The CO shift process is characterized by comprising the following steps: raw gas firstly enters a low-pressure steam generator for cooling and is subjected to liquid separation to adjust water-gas ratio; the raw gas subjected to liquid separation is divided into two paths, wherein one path accounts for 45 to 55 percentto serve as non-transforming gas, and the rest is used as a second path, is subjected to temperature improvement and detoxification in sequence, is divided again and then enters a gas-cooled converter and an isothermal transformation furnace which are arranged in parallel for isothermal transformation respectively; heat is recovered, subsequently the transformed gas is mixed with the first path of non-transforming gas to serve as synthesis gas; the mole ratio of H2 to CO in the synthesis gas is controlled at 2.1 to 2.3. According to the CO shift process disclosed by the invention, byproductsof medium pressure saturated steam and low pressure overheat stream are generated; the gas-cooled converter uses the transforming gas as a refrigerant; by multiple times of dividing conversions, the CO shift process has the advantages of short flow, small size of the converter, no over-temperature risk, adjustable heat exchange area of the used isothermal transformation furnace, small pressure fluctuation of the byproduct medium pressure steam and more stable system operation.

Owner:SINOPEC NINGBO ENG +2

Multistage centrifugal compressor and air conditioning unit

InactiveCN104421188AMeet the requirements of external dimensionsImprove airflowCompressorPump componentsEngineeringAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC

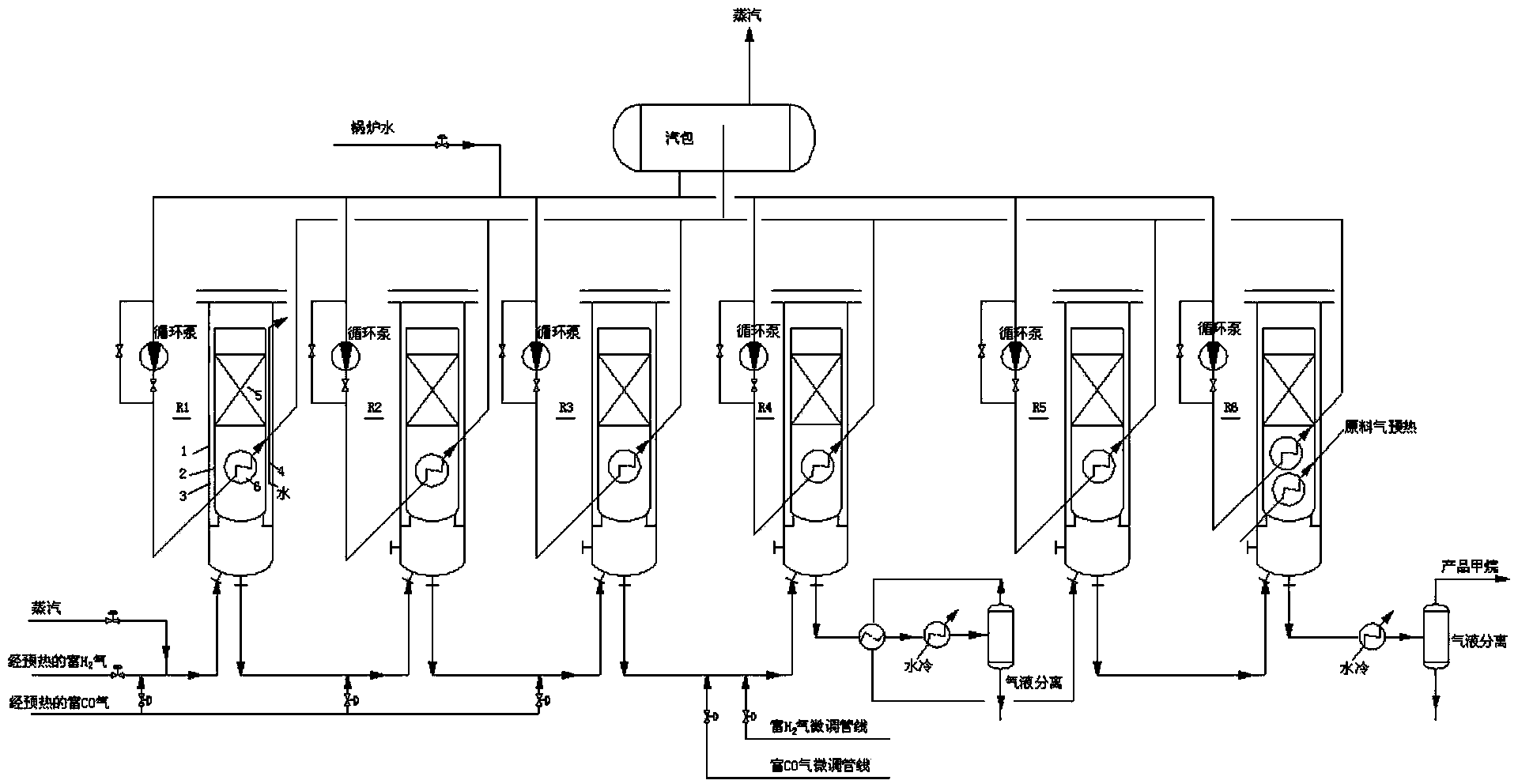

Circulation-free methanation system

The invention discloses a circulation-free methanation system which comprises a gas distribution methanation stage and a supplementation methanation stage, wherein in the gas distribution methanation stage, 1 to 3 stages of serially connected high-temperature reactors are adopted; in the supplementation methanation stage, 2 to 3 stages of serially connected low and medium-temperature reactors are adopted; the final-stage reactor in the gas distribution methanation stage is connected in series with the head-stage reactor in the supplementation methanation stage; technical gas discharged by the former stage of the reactor is used as part of or all the synthesized gas of the next stage of the reactor; technical gas discharged by the final-stage reactor is subjected to cooling separation to obtain a final methane product. The technical system is simple, and the reaction is steady, safe and reliable; the running cost and the manufacturing cost are low.

Owner:BEIJING HUAFU ENG +2

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

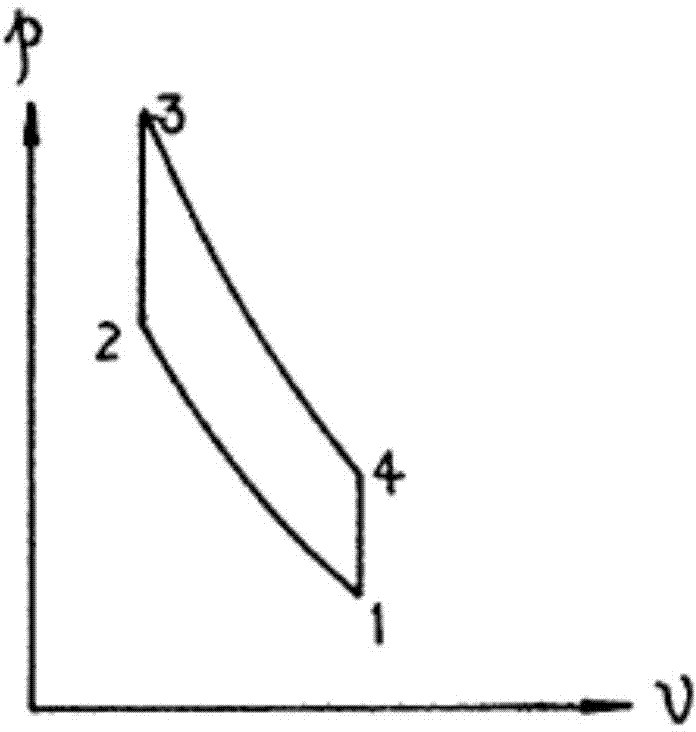

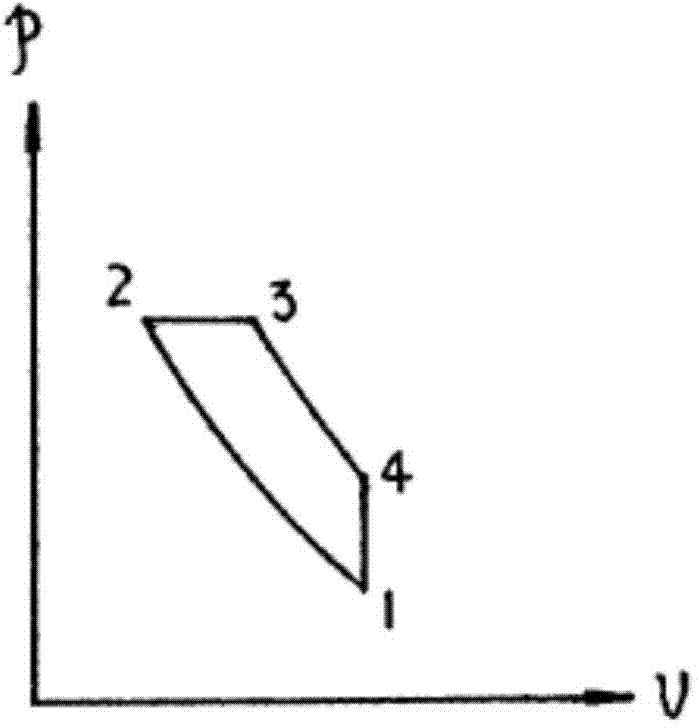

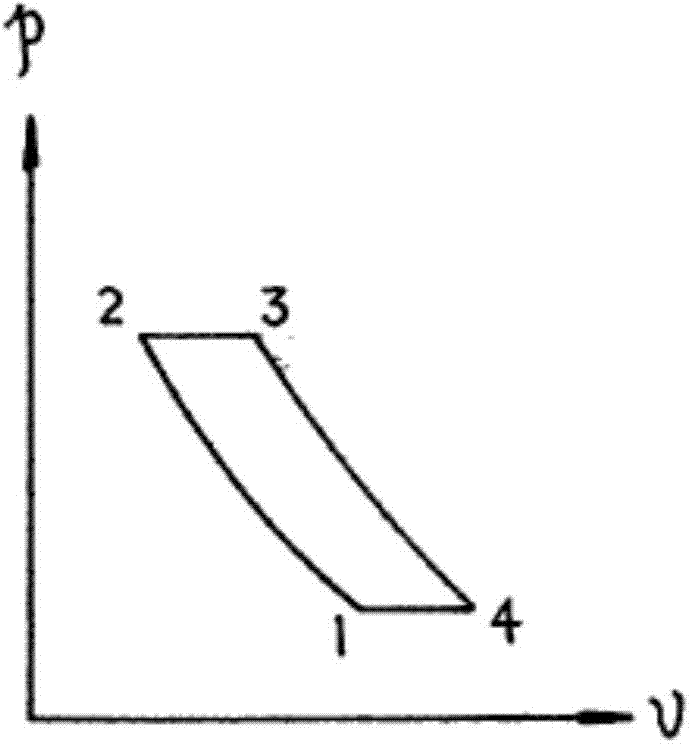

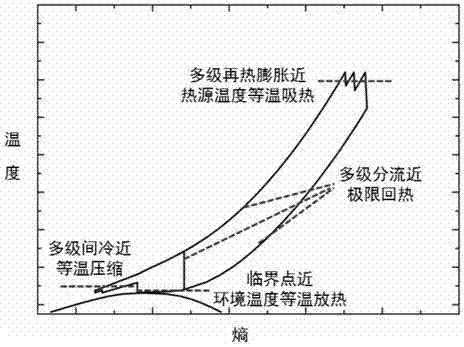

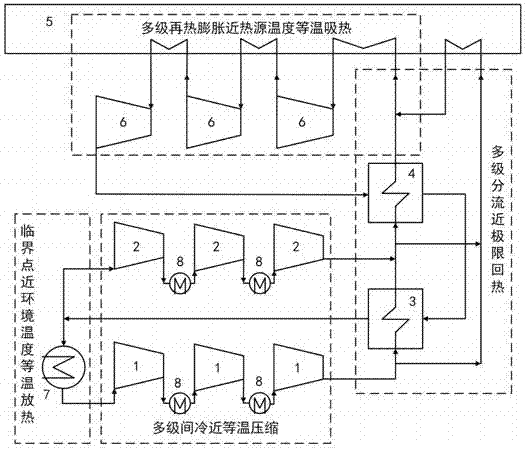

Supercritical carbon dioxide generalized generality Carnot cycle system

ActiveCN107401431AImprove heat transfer efficiencyReduce lossesSteam engine plantsChemistryIrreversible loss

The invention provides a supercritical carbon dioxide generalized generality Carnot cycle system. By adoption of the supercritical carbon dioxide generalized generality Carnot cycle system, higher cyclic power generation efficiency can be achieved at a lower heat absorption temperature. According to the supercritical carbon dioxide generalized generality Carnot cycle system, supercritical carbon dioxide is used as a working medium, an approximately-isothermic compression process is achieved through the measures such as multi-stage indirect cooling, and thus compression power is reduced; the heat capacity difference between a cold side and a heat side is balanced through the measures such as multi-stage distribution, so that an extreme backheating process, approximately with a zero temperature difference, of fluid on the cold side and the heat side is achieved in the whole backheating process, and the irreversible loss, caused by a large temperature difference, of available energy is reduced; an isothermic heat absorption process approximate to the temperature of a high-temperature heat source is achieved through multi-stage reheating and an expansion measure, so that the average heat absorption temperature is increased; and since a precooler operates near the critical point of the carbon dioxide, both specific heat and the density are large, the whole heat release process is approximate to isothermic heat release, and the irreversible loss of available energy at the cold end is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Claus tail gas condensing treatment process

The invention relates to a Claus tail gas condensing treatment process, which comprises the steps that Claus tail gas coming from a Claus process sulfur condenser enters a heat exchanger I, gaseous sulfur is condensed and removed; the gaseous sulfur-removed Claus tail gas is sent to a desulfurizing absorption tower and is sprayed by adopting a doctor solution coming from a gas purification device, rich liquor is returned to the gas purification device for regeneration, and regenerated acid gas is used as a raw material for a Claus process; the upper part of the desulfurizing absorption tower is provided with an alkali washing section, and alkali liquor is a replenishing solution coming from a desulfurizing unit of the gas purification device; after the removal of H2S, the Claus tail gas is sent to a coke oven gas system or is returned to a returned gas system; the heat exchanger I and a heat exchanger II work in a cyclic alternating pattern, and the continuous condensing of the gaseous sulfur in the Claus tail gas is realized. The Claus tail gas condensing treatment process has the remarkable advantages of small investment, low operating cost, energy conservation, greenness, environmental protection and the like.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Technology for producing hydrogen from coke oven gas through deep deoxygenation and dehydration

ActiveCN106698343ASave compression workHydrogen separation by selective and reversible uptakeSpecific gas purification/separationCoke ovenTower

The invention relates to a technology for producing hydrogen from coke oven gas. The feed gas contains 45-55% of hydrogen. The technology comprises the following steps: removing most of carbon dioxide, C<2+> and methane through first-stage pressure swing adsorption so that the concentration of hydrogen-rich gas is 93-96% and the hydrogen yield is greater than 97%; compressing the hydrogen-rich gas to 0.8-2.8MPa, wherein the compressed exit gas is not cooled (interstage cooling is needed); at 80-110 DEG C, catalyzing oxygen in a deoxygenation tower and generating carbon dioxide with carbon monoxide or catalyzing oxygen and generating water with hydrogen; removing oxygen to below 1ppm and cooling the deoxygenated gas to below 40 DEG C; removing non-hydrogen gas through second-stage pressure swing adsorption; and purifying the hydrogen to 99-99.99999% as required.

Owner:杨皓

Waste heat utilization method for flue-gas acid making process

The invention discloses a waste heat utilization method for a flue-gas acid making process. Half of SO2 flue gas is mixed with air, the mixture is heated by a first heat exchanger and a fore heat exchanger and then enters a fore bed layer of a sulfur dioxide converter, exit gas is subjected to heat exchange with the fore heat exchanger and then is mixed with the other half of SO2 flue gas, and then, the mixture enters a first-segment bed layer; exit gas of the first-segment bed layer is subjected to heat exchange with a first steam superheater and then enters a second-segment bed layer; exit gas of the second-segment bed layer is subjected to heat exchange with a third heat exchanger and then enters a third-segment bed layer; exit gas of the third-segment bed layer is subjected to heat exchange with a second steam superheater, then, one part of the exit gas is subjected to heat exchange with the first heat exchanger, and the other part of the exit gas is subjected to heat exchange with a second heat exchanger and then enters a high-temperature absorption tower; exit gas of the tower is heated by a fourth heat exchanger and the third heat exchanger and then enters a fourth-segment bed layer; exit gas of the fourth-segment bed layer is subjected to heat exchange with a third steam superheater and the fourth heat exchanger and then enters a final absorption tower. According to the method, the process adaptability is extensive, the operation is convenient, the running is reliable, and the waste heat utilization ratio is high.

Owner:CHIFENG YUNTONG NONFERROUS METALS

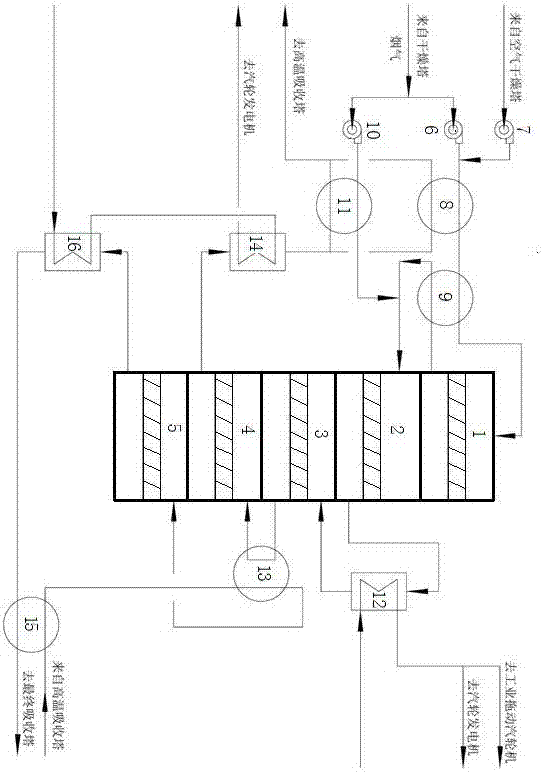

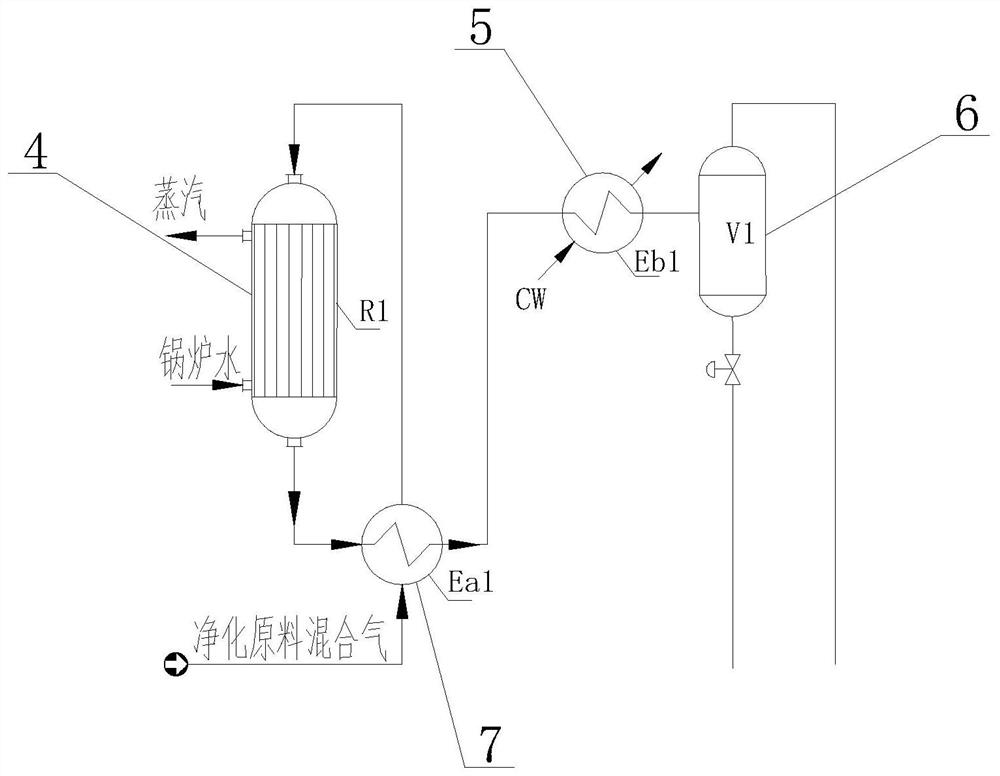

System and process for preparing methanol through hydrogenation of carbon dioxide

PendingCN113045383AAchieve cycle-freeSave compression workOrganic compound preparationHydroxy compound separation/purificationMethanol waterProcess engineering

The invention discloses a system for preparing methanol through hydrogenation of carbon dioxide, wherein the system comprises at least three stages of methanol preparation units connected in series, and each methanol preparation unit comprises an in-tower preheater, a methanol synthesis tower, a methanol water cooler and a methanol separator; a raw material gas inlet of the in-tower preheater is communicated with a purified raw material mixed gas pipe, and a raw material gas outlet of the in-tower preheater is communicated with a gas inlet of the methanol synthesis tower; a gas outlet of the methanol synthesis tower is communicated with a high-temperature gas inlet of the in-tower preheater, a high-temperature gas outlet of the in-tower preheater is communicated with a feed port of the methanol water cooler, and a discharge port of the methanol water cooler is communicated with a feed port of the methanol separator; a gas outlet of the methanol separator of the previous-stage methanol preparation unit is communicated with a raw material gas inlet of the in-tower preheater of the next-stage methanol preparation unit; and the gas outlet of the methanol separator of the last-stage methanol preparation unit is communicated with the gas inlet of the methanol water washing tower. A recycle gas compressor is omitted, non-circulation of methanol preparation through hydrogenation of carbon dioxide is realized, and the compression work is saved.

Owner:华电水务工程有限公司

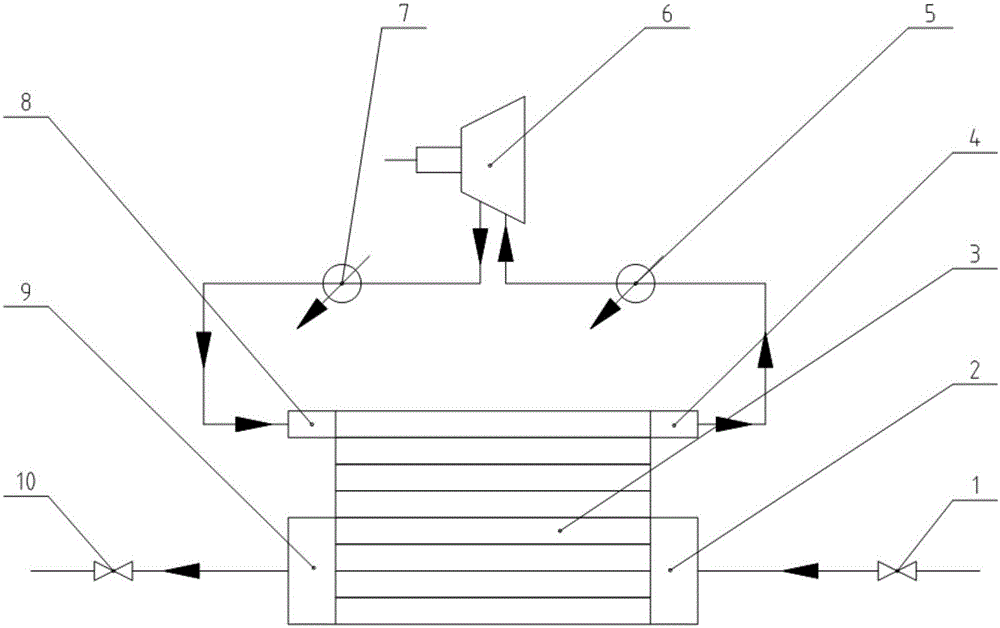

Supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery

PendingCN109322743ARealize full captureThe actual compression work decreasesCarbon compoundsEnergy inputCyclic processExothermic process

The invention provides a supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery. The supercritical carbon dioxide power generation system comprises anair separation device, a combustor, a carbon dioxide turbine, a heat regenerator, a water separator, a first carbon dioxide pressurization device, a carbon dioxide recovery device, a waste-heat-recovery heat exchanger, a Kalina turbine, a Kalina heat regenerator, a first mixer, an ammonia separator, a second mixer, a high-pressure condenser and a gas-liquid separator. According to the supercritical carbon dioxide power generation system, natural gas is taken as fuel, and the full capture of carbon dioxide is achieved by adopting an oxygen-enriched combustion method; in the carbon dioxide turbine, carbon dioxide expands to the subcritical state and achieves a higher expansion ratio than that the supercritical carbon dioxide Brayton cycle, so that the carbon dioxide turbine can do more workand the cycle efficiency can be improved; and during the bottom cycle, waste heat of the supercritical carbon dioxide cycle is recovered by adopting the Kalina cycle, and the concentration of a working medium changes in the working medium phase-change non-isothermal process and cycle process, so that the vaporization process and the heat-source heat release process can be matched well, the irreversible loss in the heat exchange process can be reduced, and the waste heat utilization efficiency can be improved.

Owner:HUANENG CLEAN ENERGY RES INST

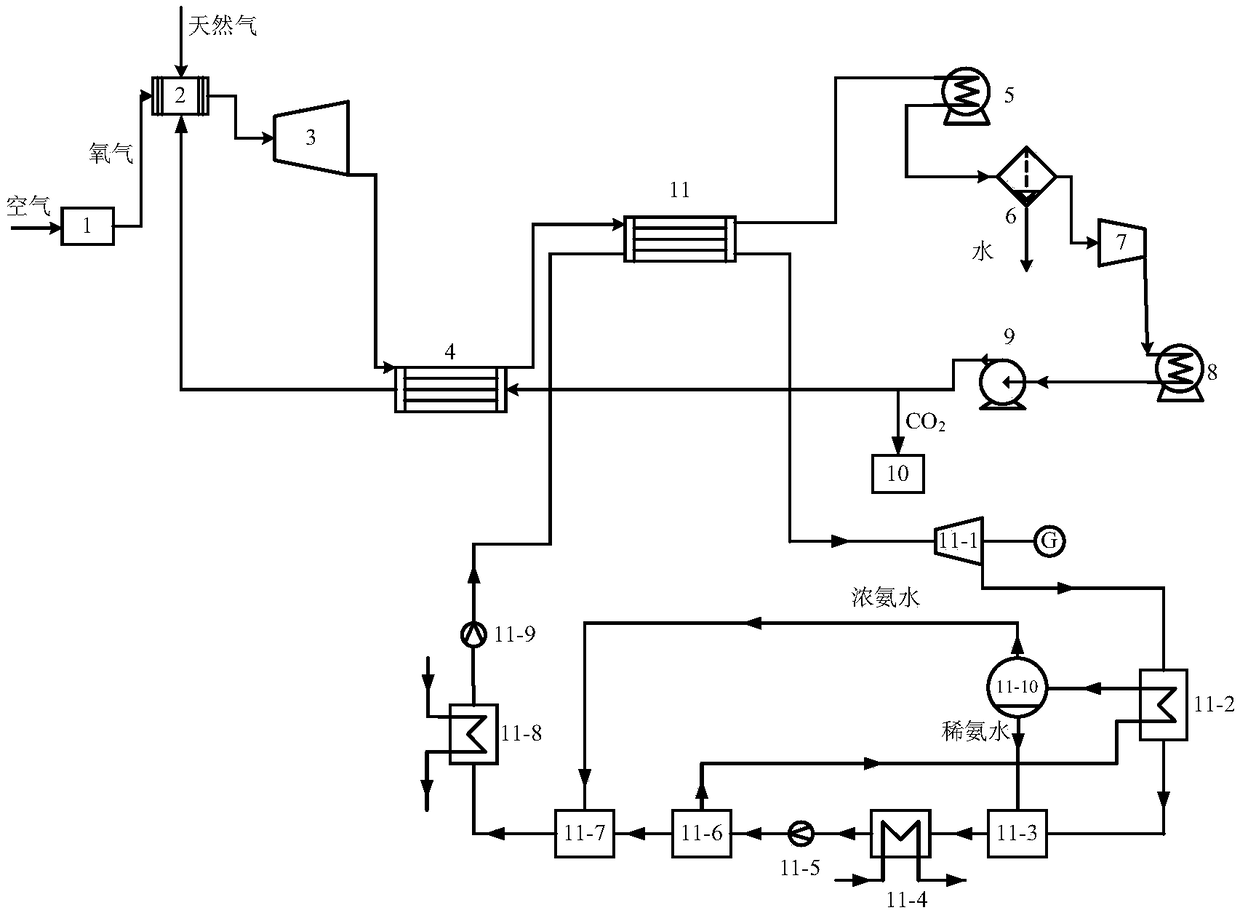

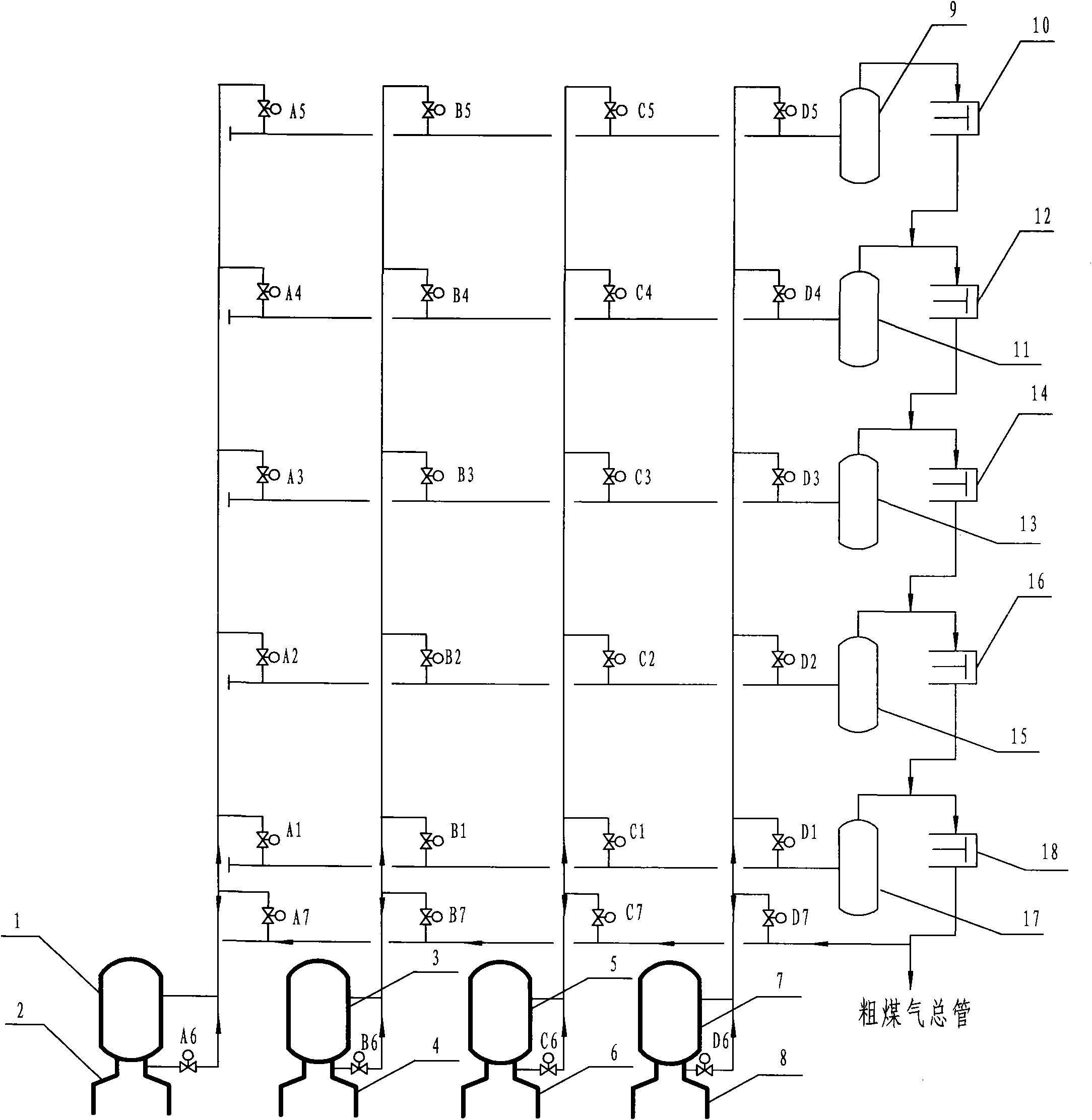

Grading pressurization and depressurization method of pressure gasification furnace coal lock

InactiveCN101781580AReduce the amount of dustExtended service lifeChemical industryCombustible gas productionProduct gasProcess engineering

The invention belongs to the technical field of coal gasification, which discloses a grading pressurization and depressurization method of a pressure gasification furnace coal lock. The coal lock is provided with a gas pipeline; a plurality of sequencing valves are installed on the gas pipeline in parallel; one sequencing valve is arranged between the gas pipeline and a gasification furnace; the sequencing valve groups can be utilized to carry out grading pressurization and depressurization on the coal lock; gas for pressurization is the gas produced by depressurization, compressed gas can be reduced to the utmost, and gas can be compressed at higher pressure as much as possible so as to reduce compression work, thus obtaining the purpose of energy saving. The invention is suitable for parallel operation of multiple, dozens of and even hundreds of gasification furnaces.

Owner:刘宏建

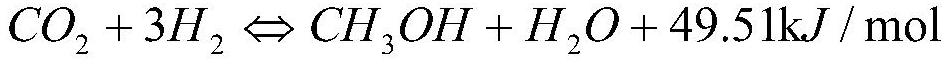

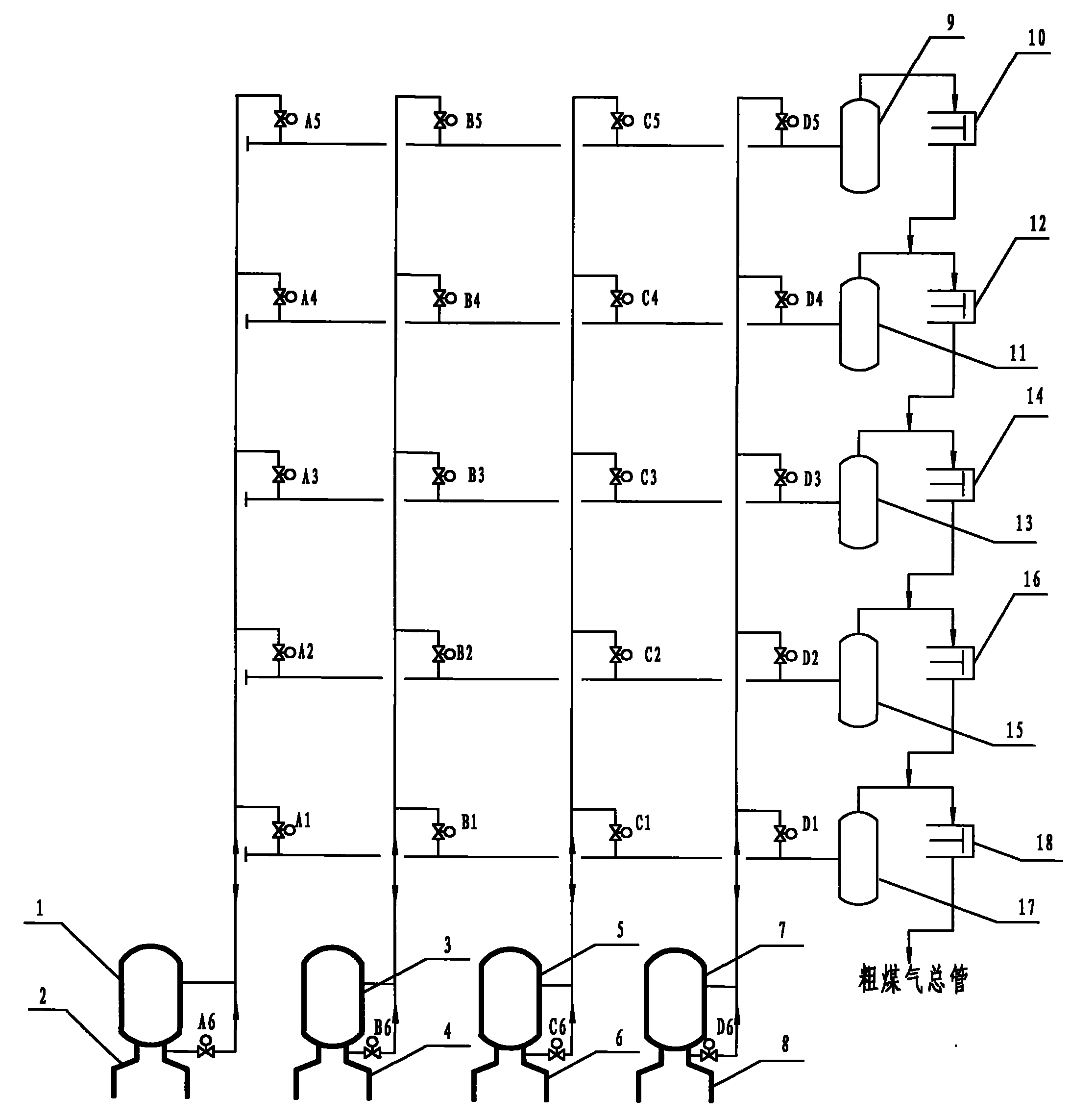

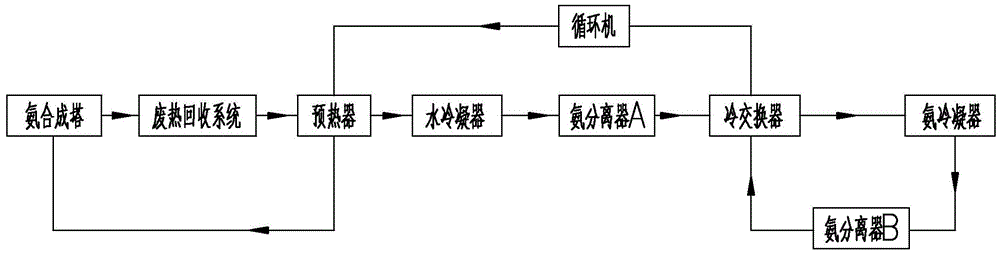

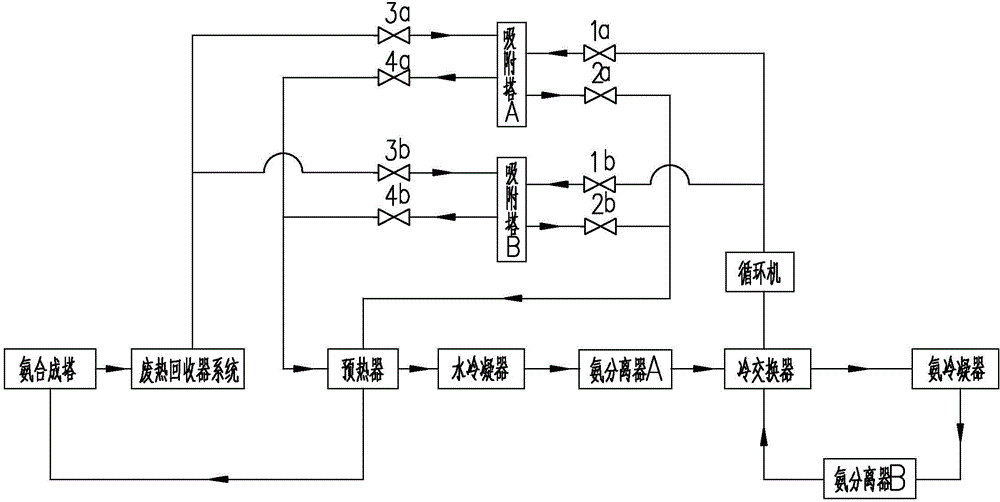

Ammonia synthesis technology for improving ammonia separation effect through temperature swing adsorption

InactiveCN103818929AReduce energy consumptionSimple reaction conditionsEnergy inputAmmonia preparation/separationSyngasDesorption

The invention discloses an ammonia synthesis technology for improving ammonia separation effects through temperature swing adsorption. Synthetic gas is connected to the inlet of a desorption end of an adsorption and desorption tower, synthetic gas at the outlet of the desorption end of the adsorption and desorption tower is successively cooled through a preheater and a water condenser and then enters an ammonia separator; circulation gas is connected to an inlet of the adsorption end of the adsorption and desorption tower; the circulation gas at the outlet of the adsorption end of the adsorption and desorption tower enters the preheater for being preheated, and the preheated circulation gas enters an ammonia synthesis tower. Only two adsorption and desorption towers and transfer valves, which can be mutually replaced for regeneration adsorption, are added, and the aims of greatly increasing one-way ammonia synthesis rate and reducing the energy consumption of an ice machine can be realized. Under the conditions of lower temperature and less NH3 partial pressure, NH3 in the circulation gas in the ammonia converter is adsorbed, so that the absorbed NH3 reaches a less in-tower ammonia content, and the out-tower synthetic gas desorbs the absorbed NH3; the desorbed NH3 is gathered in the out-tower gas, so as to increase the total ammonia partial pressure of the synthesis cycle gas. After water cooling, condensation and separation are carried out, so as to increase one-time one way synthetic ratio and an ammonia net value, and increase the ammonia yield and improve the reaction condition of the synthesis tower.

Owner:刘金成

Air conditioning system

InactiveCN104214837AIncrease outlet pressureReduce lossesSpace heating and ventilation detailsFluid circulation arrangementEngineeringAir conditioning

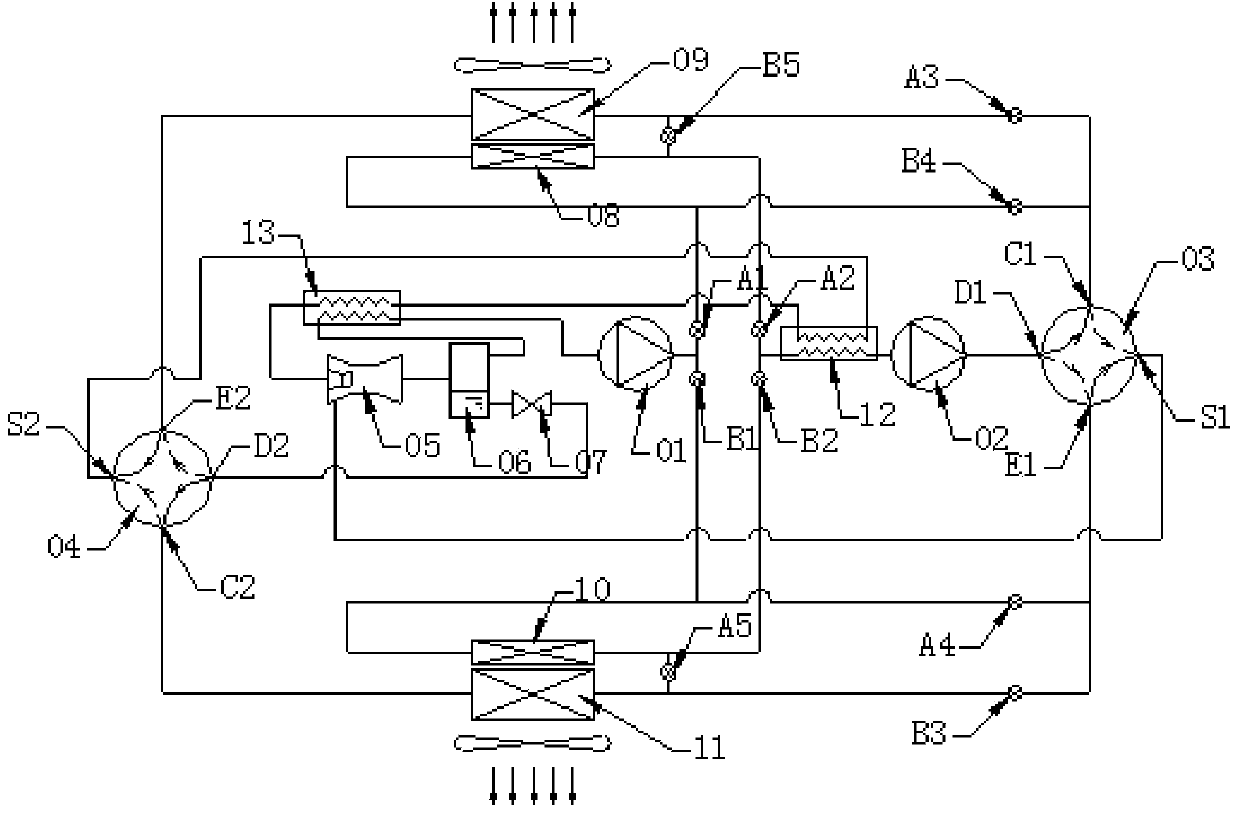

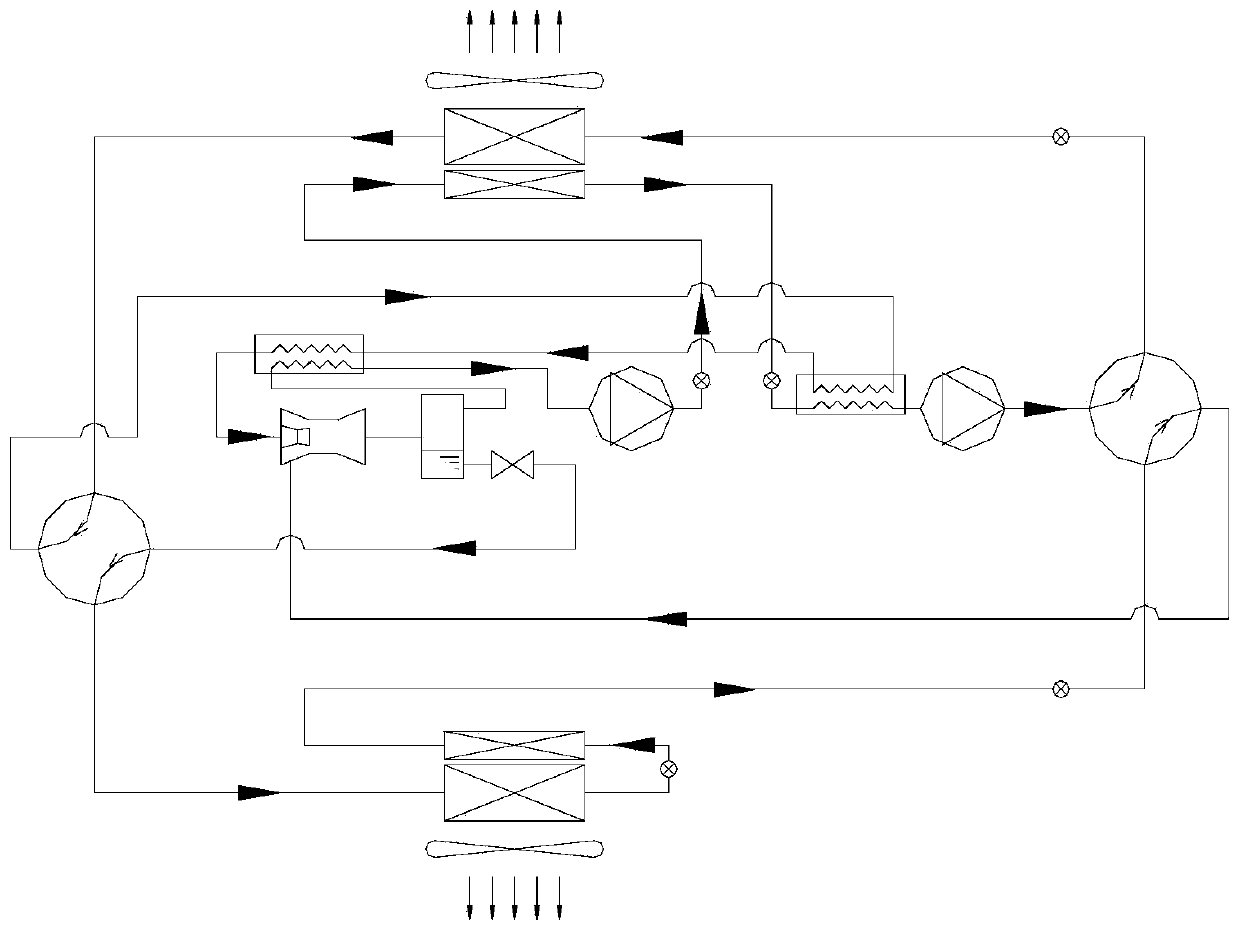

The invention discloses an air conditioning system, which comprises a compressor device, an outdoor heat exchange device, an indoor heat exchange device, a first valve device, a second valve device, an air-liquid separating device, an expansion valve device and a jetting device, wherein the first valve device comprises an opening C1, an opening D1, an opening E1 and an opening S1, the second valve device comprises an opening C2, an opening D2, an opening E2 and an opening S2, an exhaust opening of the compressor device is communicated with the opening D1, a first opening of the outdoor heat exchange device is connected with the opening C1 in a switchable manner, a second opening of the outdoor heat exchange device is connected with the opening E2, a first outlet of the air-liquid separating device is connected with the expansion valve device, a second outlet of the air-liquid separating device is connected with an inlet of the compressor device, the expansion valve device is connected with the opening D2, a first opening of the indoor heat exchange device is connected with the opening C2, and a second opening of the indoor heat exchange device is connected with the opening E1. The air conditioning system provided by the invention has the advantages that carbon dioxide can be used as a refrigerant, and in addition, the available energy loss is less.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient thermodynamic cycle system utilizing vortex tubes

ActiveCN105401988ASave compression workIncrease net efficiencyCompression machinesSteam regenerationThermodynamic cycleCooling Units

An efficient thermodynamic cycle system utilizing vortex tubes is mainly composed of a work medium pump, a heat exchanger, an expanding machine and a vortex tube flow dividing and cooling unit. The vortex tube flow dividing and cooling unit is formed by combining the multiple vortex tubes. Liquid working media separated from the vortex tubes directly enter a working medium pump inlet. Gaseous working media enter the heat exchanger to exchange heat with low-temperature working media on the high-pressure side of the cycle system. The cooled working media enter the vortex tubes again to be subjected to flow dividing and cooling; liquid working media enter the working medium pump inlet; and gaseous working media enter the heat exchanger to exchange heat with low-temperature working media on the high-pressure side of the cycle system again. Due to flow dividing and cooling of the multi-stage vortex tubes and many times of heat exchange with the low-temperature working media, most of the working media enter the working medium pump inlet in the form of liquid, only an extremely small part of working media are not liquefied, the proportion of the working media entering the working medium pump inlet to the non-liquefied working media is proper, and it can be guaranteed that all the working media on the working medium pump inlet are liquid working media by combining the working media entering the working medium pump inlet and the non-liquefied working media. A liquid working medium pump is used for pressurizing working media, power consumption of the pump is reduced, heat in the cycle system is recycled, and thermal efficiency is high.

Owner:DEZHOU GAOKELI HYDRAULIC

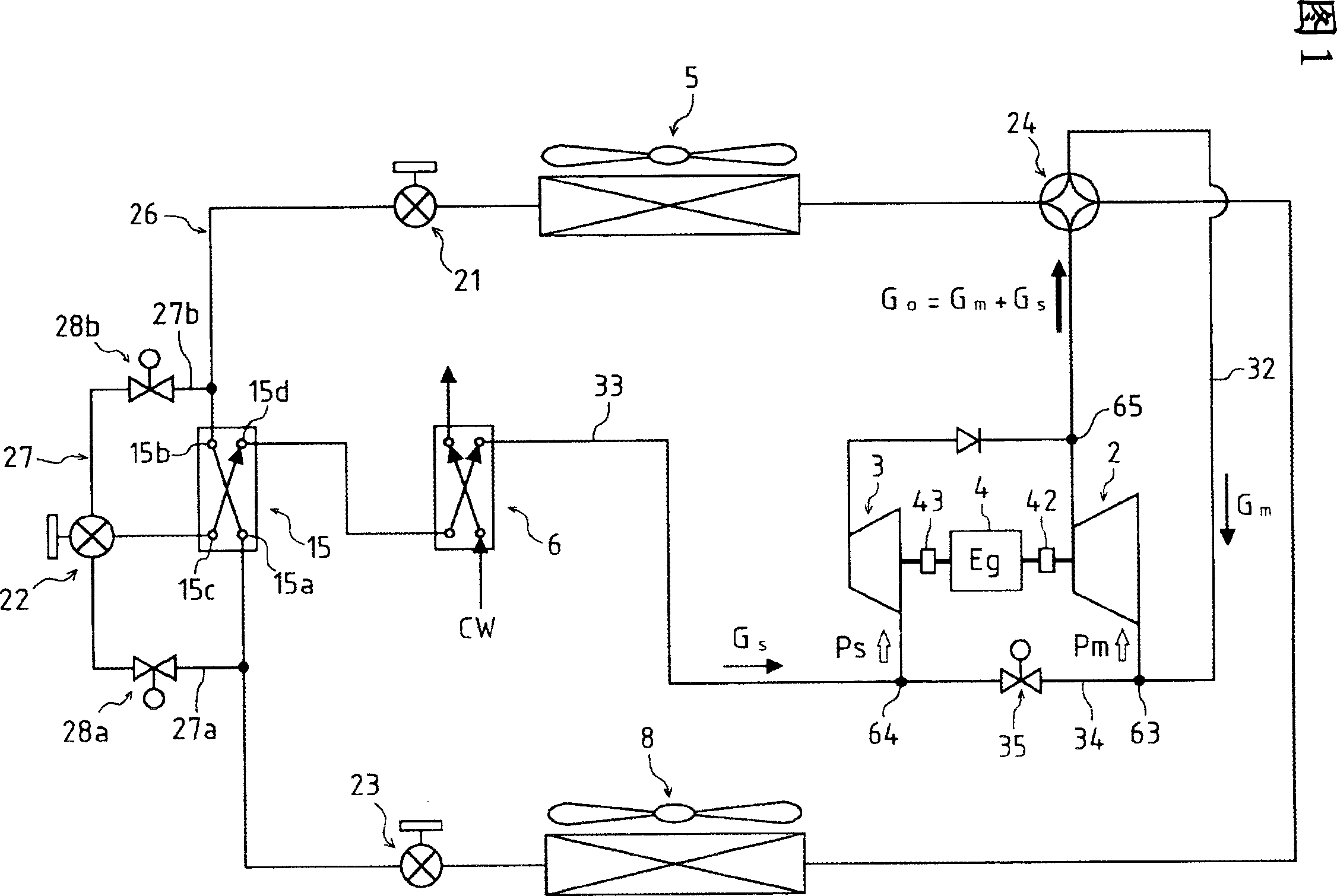

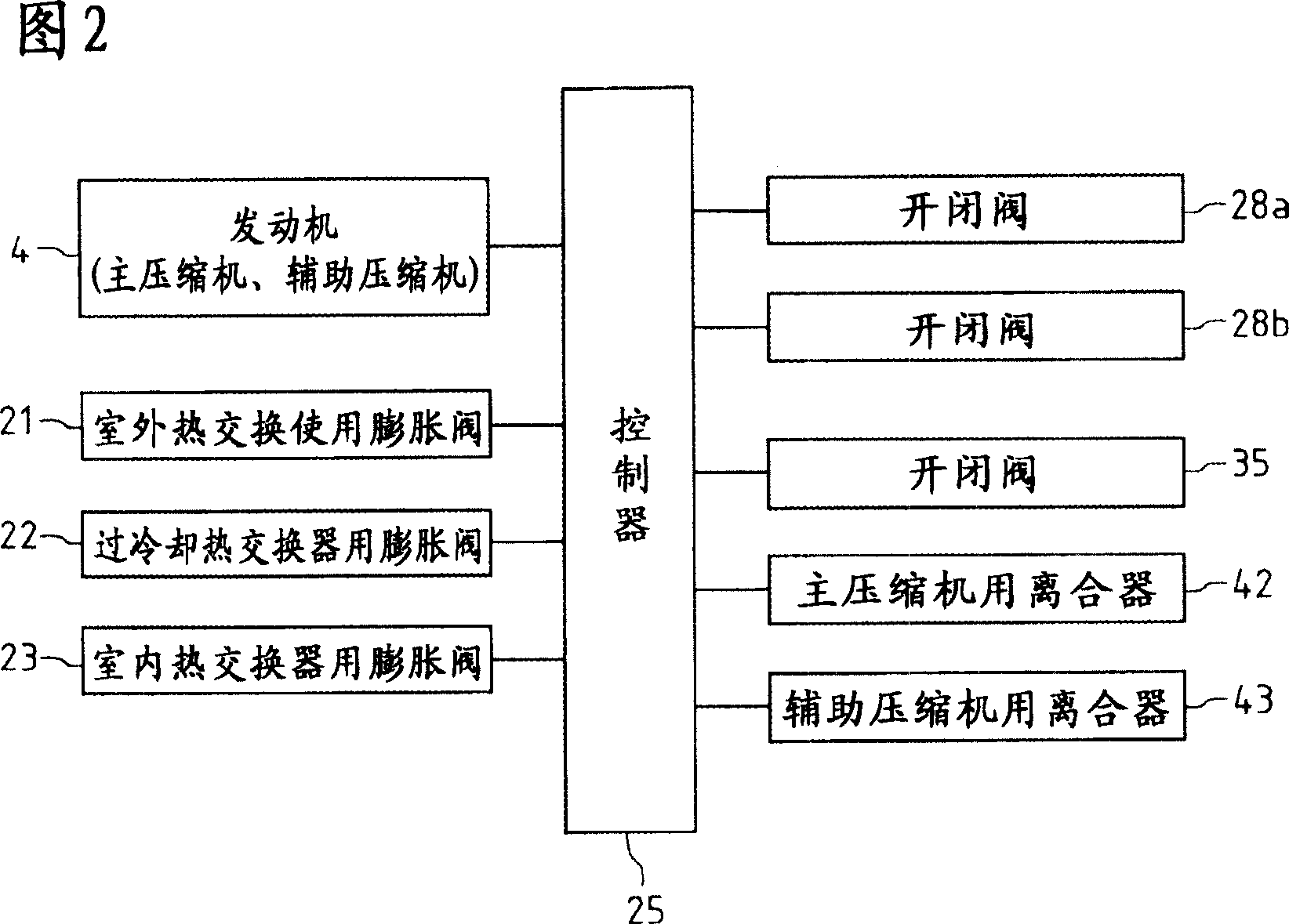

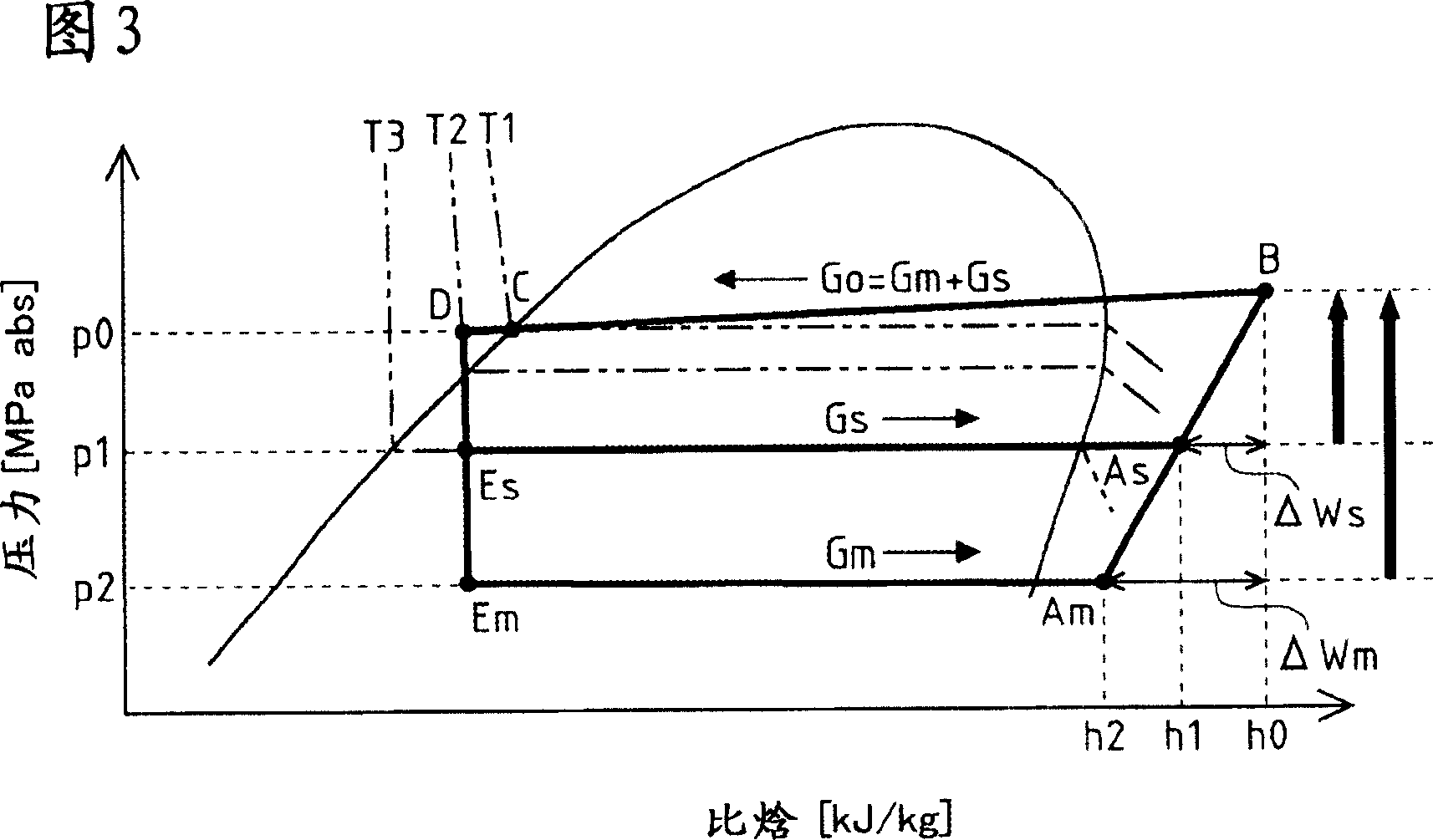

Engine heat pump

InactiveCN1957211AImprove cooling capacityGuaranteed performanceCompressorCompression machines with non-reversible cycleRefrigerantEngineering

An object of the invention is to provide an engine heat pump whose compression work is reduced without increase of consumed electric power, thereby improving its driving efficiency (energy efficiency). An engine heat pump comprises: an engine (4); a main compressor (2) driven by the engine (4); a sub compressor (3); an indoor heat exchanger (8); an outdoor heat exchanger (5); an expansion valve (23) for the indoor heat exchanger; an expansion valve (21) for the outdoor heat exchanger; and a supercooling heat exchanger (15) disposed on a liquid refrigerant passage (main passage 26) of a connection passage between the indoor heat exchanger (8) and the outdoor heat exchanger (5). In the supercooling heat exchanger (15), a supercooling liquid refrigerant branched into a branching passage (27(27a, 27b)) supercools a liquid refrigerant before being branched. The sub compressor (3) is driven by the engine (4) so as to compress the supercooling liquid refrigerant. A ratio (R) of a capacity of the sub compressor (3) to a total capacity of the main compressor (2) and the sub compressor (3) ranges between 20% and 29%.

Owner:YANMAR CO LTD

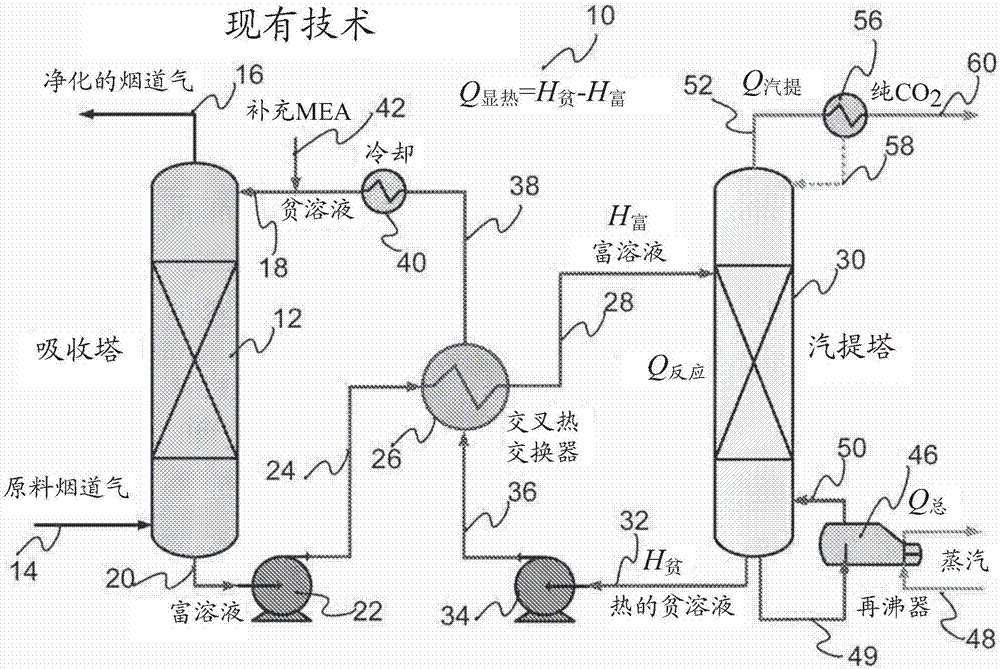

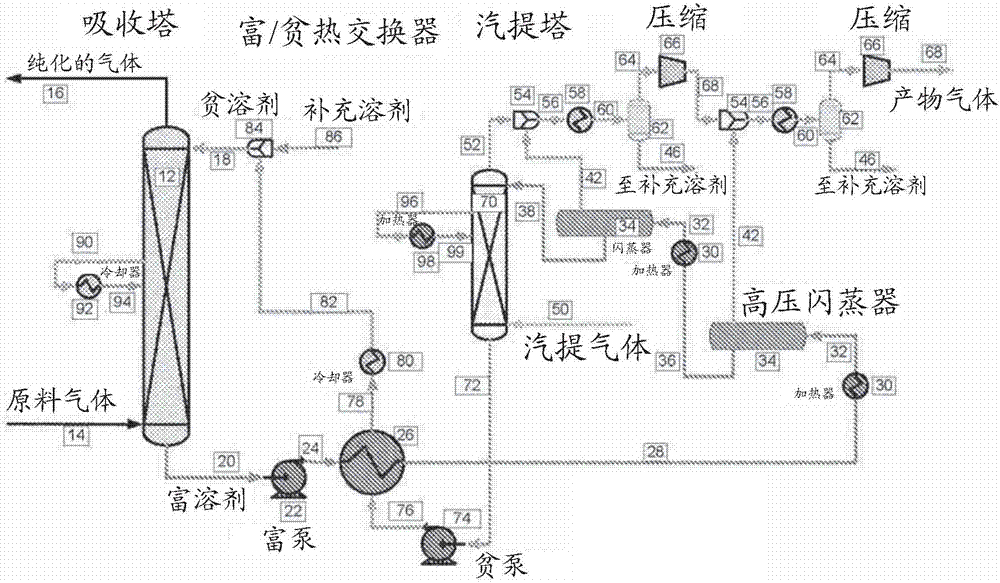

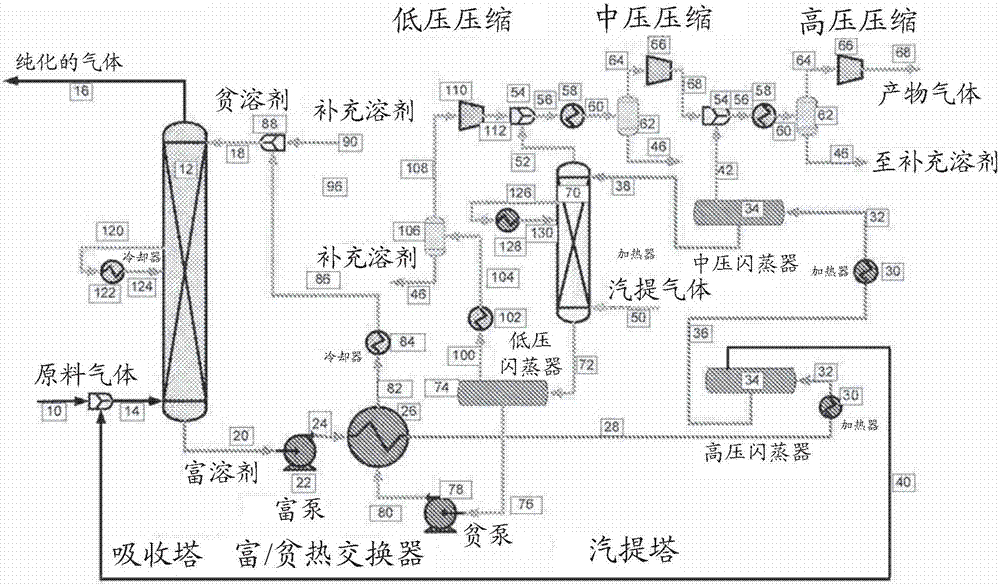

A process for separating a product gas from gaseous mixture

InactiveCN107148398ALower energy requirementsSave compression workProductsGas treatmentHigh pressureChemistry

A gas pressurized separation system strips a product gas from a stream yielding a high pressure gaseous effluent containing the product gas such as may be used to capture CO2 from coal fired post combustion flue gas capture and to purify natural gas, syngas and EOR recycle gas. The system comprises a gas pressurized stripping column allowing flow of one or more raw streams in a first direction and allowing flow of one or more high pressure gas streams in a second direction, to strip the product gas into the high pressure gas stream and yield a high pressure gaseous effluent that contains the product gas. The process can further comprise a final separation process to further purify the product gas from the GPS column. For CO2 product, a preferred energy efficient final separation process, compound compression and refrigeration process, is also introduced.

Owner:CARBON CAPTURE SCI

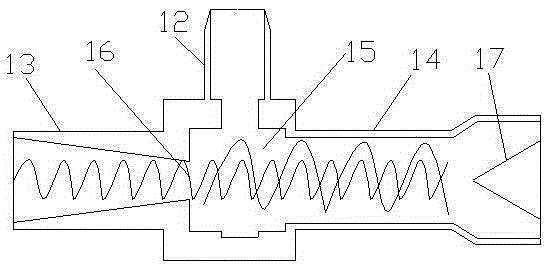

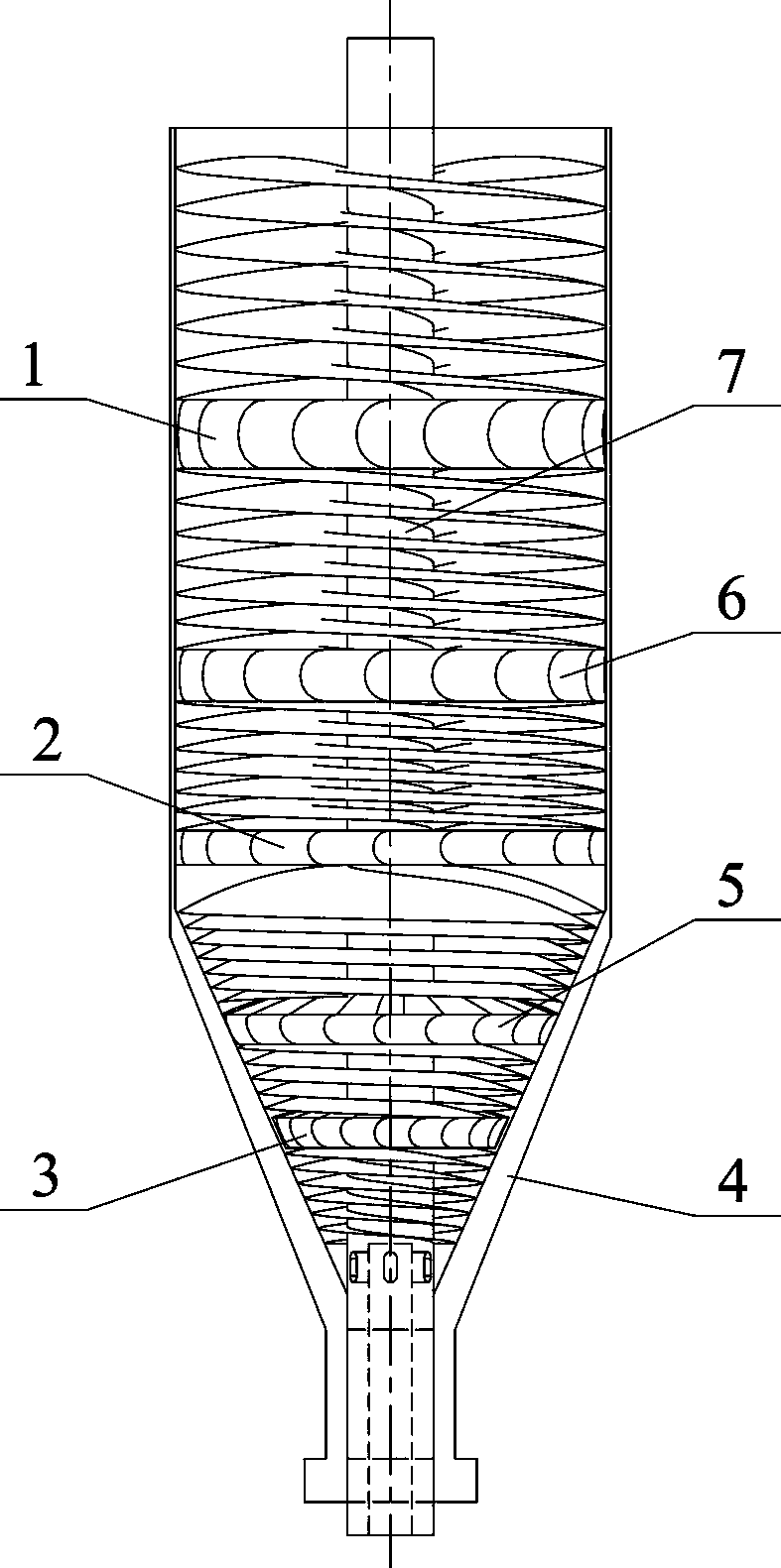

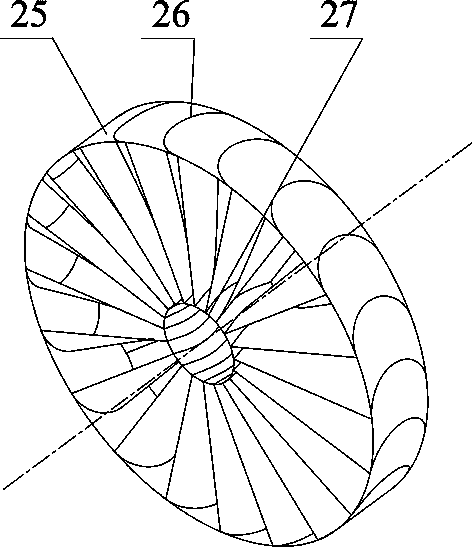

Variable pitch spiral compression machine head of spiral compression-expansion refrigerator

InactiveCN103423160AMiniaturizationFlexible designRotary piston pumpsRotary piston liquid enginesStatic compressionMiniaturization

A variable pitch spiral compression machine head mainly comprises a dynamic spiral rotor with multistage vanes, multistage axial static diffuser rings and a static compression cover. By means of the method that the spiral ascent angle and the pitch of a spiral compression vane are adjusted stage by stage, the distance between adjacent spiral vanes and the passage section area are changed. By means of the multistage compression method that the spiral vanes rotating at a high speed press in a centrifugal mode stage by stage and the method that the multistage diffuser rings are arranged axially and diffuse pressure axially, the process that gas is pressed in a centrifugal mode and pressurized stage by stage is achieved. A high pressure ratio can be generated, high pressure can be borne, the diameter of a cylinder of a compressor is reduced, and miniaturization of the compressor is facilitated. The number of the spiral vanes of the compressor, the diameter of a base circle, the number of compression stages, the pitch of the spiral vanes and other important design parameters can be determined according to compressible performance of actual gas and the pressure ratio of the gas, and the compressor can be designed flexibly. By means of the long cylindrical compression machine head, the heat conductive area of the cylinder is increased, the compression process is close to the constant-temperature compression process, and compression work is reduced.

Owner:张周卫

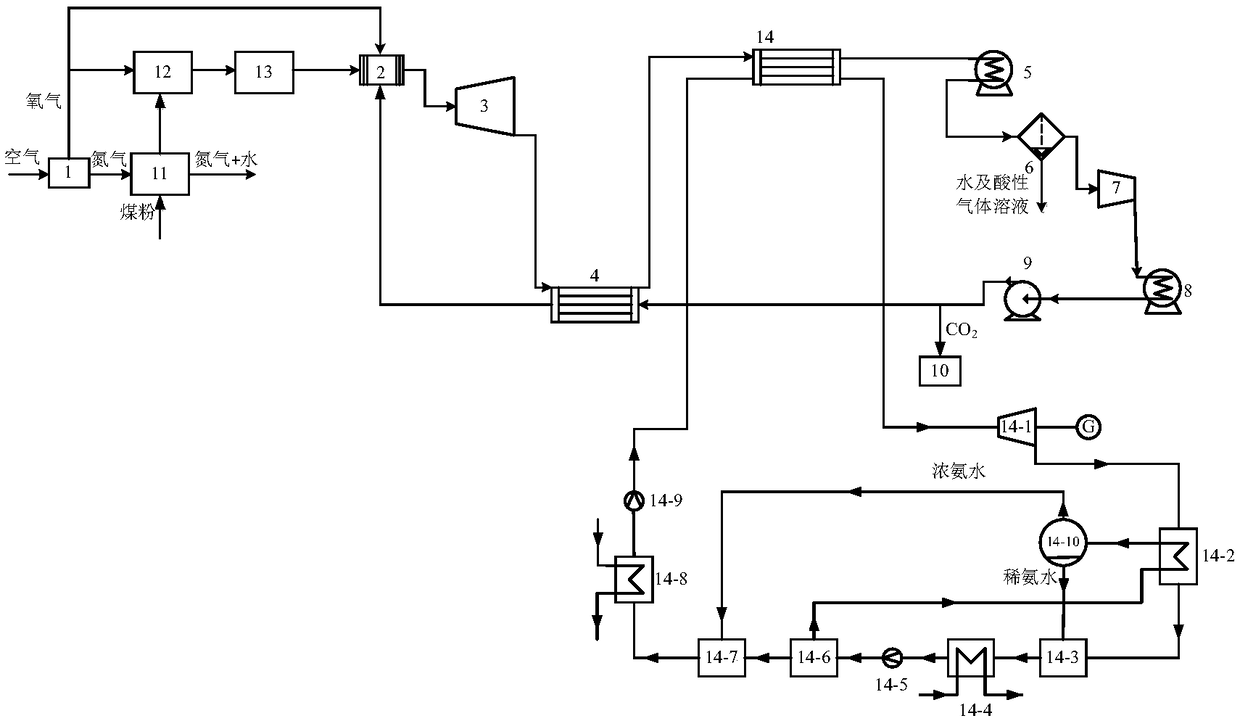

Coal gasification supercritical carbon dioxide power generation system and method capable of realizing waste heat recovery

PendingCN109322744ARealize full captureContribute a lotCarbon compoundsEnergy inputBrayton cycleIrreversible loss

The invention provides a coal gasification supercritical carbon dioxide power generation system and method capable of realizing waste heat recovery. The system comprises an air separating device, a burner, a carbon dioxide turbine, a heat regenerator, a water separator, a first carbon dioxide supercharging device, a carbon dioxide recovery device, a waste heat recovery device, a coal gasificationdevice, a Kalina turbine, a Kalina heat regenerator, a first mixer, an ammonia separator, a second mixer, a high-pressure condenser and a gas-liquid separator. According to the system, coal gas is used as fuel, and total capture of carbon dioxide is realized through oxygen-enriched combustion; the carbon dioxide expands to the subcritical state in the turbine, and the expansion ratio is higher than that of supercritical carbon dioxide Brayton cycle, so that the turbine works more, and the cycle efficiency is improved; supercritical carbon dioxide cycle waste heat is recovered through Kalina cycle during bottom cycle, by the aid of change of the working medium concentration in the non-isothermal process and the cyclic process of the working medium phase change, the gasification process andthe heat release process of a heat source are well matched, the irreversible loss of the heat exchange process is reduced, and the waste heat utilization efficiency is improved.

Owner:HUANENG CLEAN ENERGY RES INST

Oblique flow re-pressurizing expansion refrigeration device and method

ActiveCN106595114ASolve drainage problemsImprove cooling efficiencyCompression machinesThermal energyEngineering

The invention belongs to the technical field of gas expansion refrigeration and relates to an oblique flow re-pressurizing expansion refrigeration device and method. The oblique flow re-pressurizing expansion refrigeration device and method overcome the thermodynamics defect that traditional gas wave refrigerating machine pressure energy is changed into thermal energy, a double-opening pressure exchange gas wave machine serves as an expansion machine to form a refrigerating process with a compressor, one time of compression pressurizing is performed on refrigerating raw material gas in a double-opening oscillation pipe channel by means of the pressure exchange characteristic of a double-opening oscillation pipe, the high-pressure refrigerating gas pressure energy is directly recycled efficiently, and therefore the subsequent power consumption of the compressor is lowered, and the system refrigerating efficiency is improved. The oblique passageway design with the rotating radius changing is adopted for the double-opening oscillation pipe channel of the oblique flow re-pressurizing expansion refrigeration device and method, condensate drops in the oscillation pipe channel are thrown out of a cold end port by means of the rotation centrifugal force of a rotating drum, and the refrigerating efficiency is further improved. The oblique flow re-pressurizing expansion refrigeration device and method can be widely used for low temperature cold gas source supply, natural gas low temperature dehydration, petroleum gas light hydrocarbon recycling and other fields.

Owner:CHINA UNITED COALBED METHANE +1

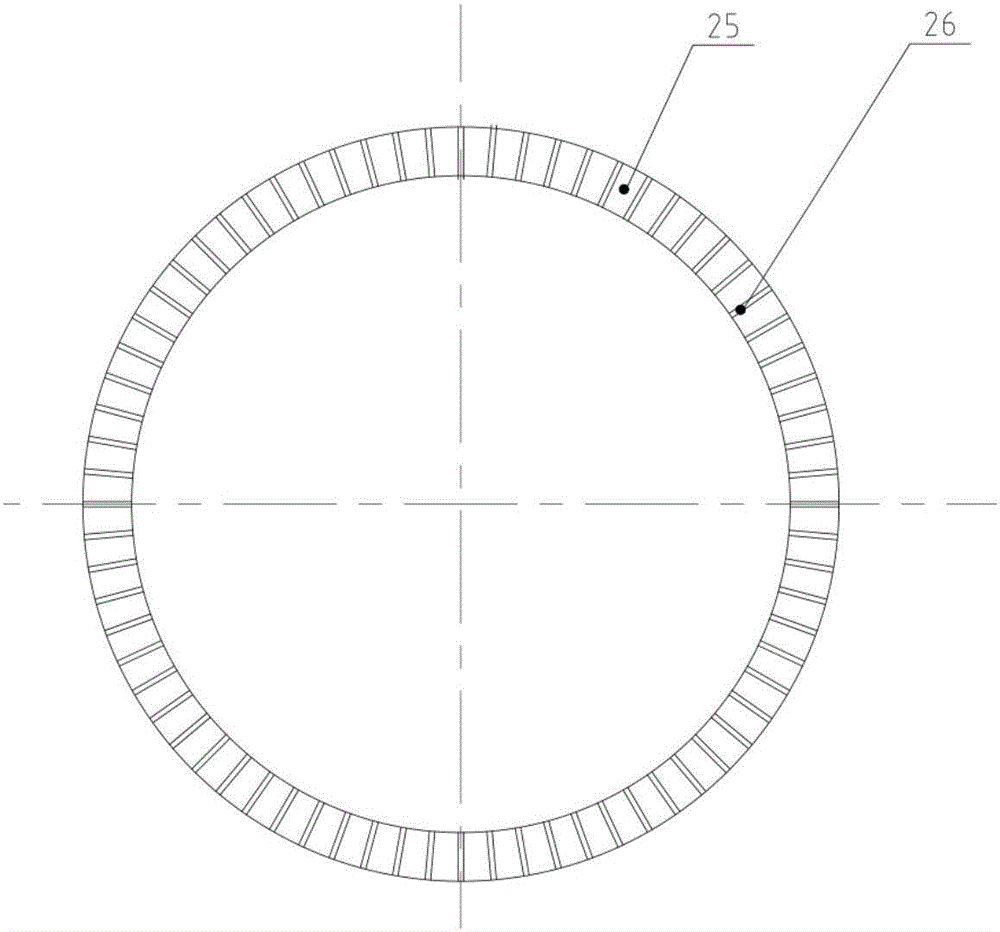

Gas turbine power generation device acting through pulse detonation fuel gas viscous force

ActiveCN111577459AIncrease output generating powerImprove cycle thermal efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberGas compressor

The invention discloses a gas turbine power generation device acting through pulse detonation fuel gas viscous force. The gas turbine power generation device comprises a gas inlet channel, a gas compressor and the like. The gas inlet channel is located at the forefront end of a gas turbine, the gas compressor is connected with the gas inlet channel, and a gas storage chamber is arranged on the downstream portion of the gas compressor. An exhaust pipe of the gas compressor is connected with the gas storage chamber and a combustion chamber gas inlet channel. A combustion chamber gas inlet cone is arranged in the combustion chamber gas inlet channel, and a combustion chamber pneumatic valve is mounted on the combustion chamber gas inlet cone. A pulse detonation combustion chamber is connectedwith the combustion chamber gas inlet channel, a spark plug is arranged on the head of the pulse detonation combustion chamber, and a telsa turbine is arranged at an outlet of the pulse detonation combustion chamber. A gas collection cavity is arranged on the side of the telsa turbine. The exhaust pipe is connected with the gas collection cavity. The left end of a gas compressor transmission is connected with a gas compressor rotor, and the right end of the gas compressor transmission is connected with a turbine rotor. The left end of a generator transmission is connected with the turbine rotor, and the right end of the generator transmission is connected with a generator. According to the gas turbine power generation device, the problems happening after the pulse detonation combustion chamber replaces an isobaric combustion chamber in a ground gas turbine and other power generation power devices are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com