Method for separating catalytic splitting gas of enriching propylene and propane

A technology of catalytic cracking and separation method, which is applied in the field of separation of catalytic cracking gas, which can solve the problems of complex process and separation process that cannot be completed at one time, and achieve the effects of saving compression work, saving investment and energy consumption of processing, and reducing compression work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

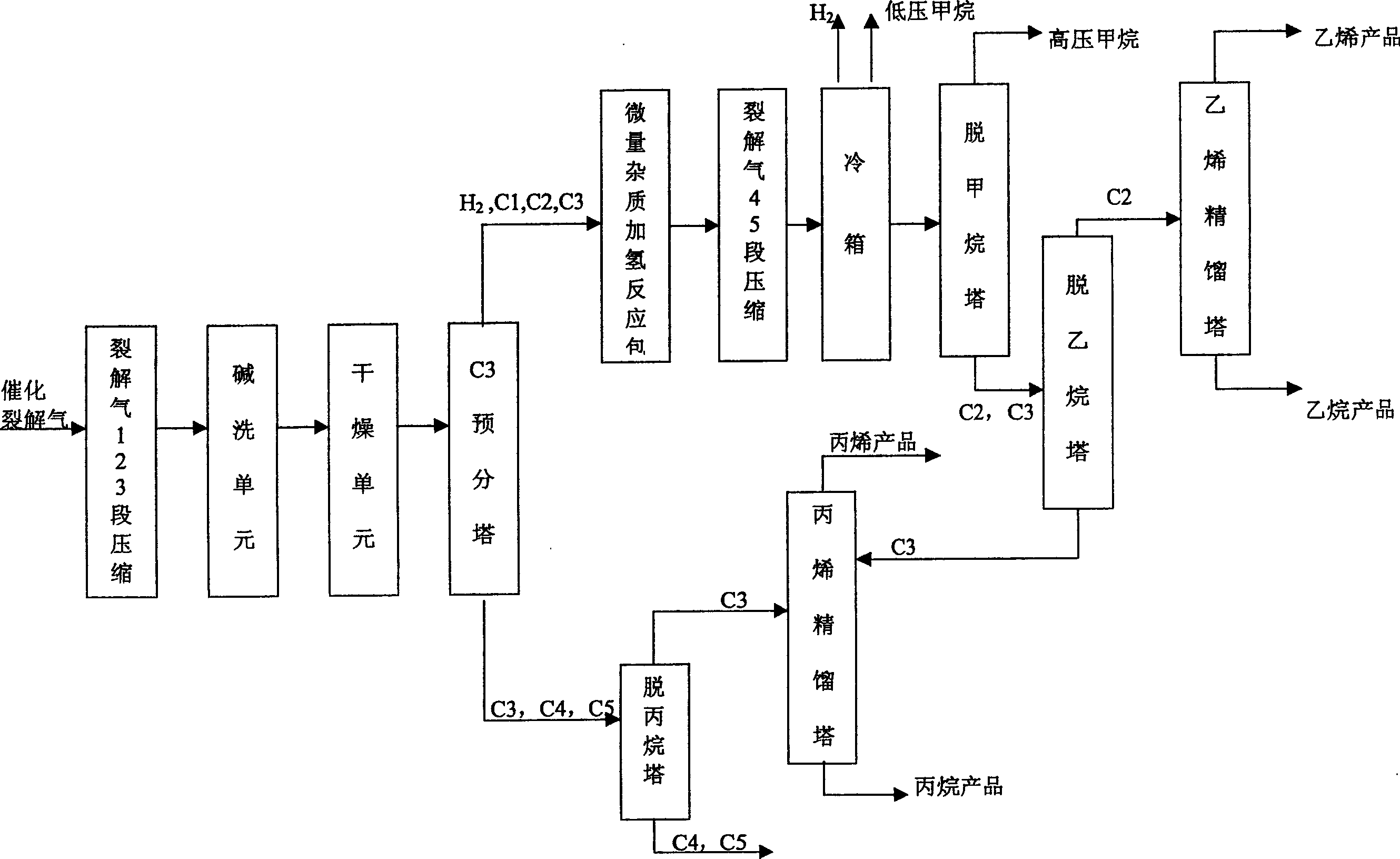

[0017] Embodiment 1: With reference to the accompanying drawings, the present invention uses the separation of the catalytic cracking gas rich in propylene and propane combined with No. 1 ethylene plant and SHMP catalytic cracking new technology in Shanghai Petrochemical Co., Ltd. The SHMP catalytic cracking gas enters the C-201 system of the cracking gas compressor. When the catalytic cracking gas is compressed to 12 atm by the 1st, 2nd, and 3rd stage compressors, it enters the alkaline cleaning unit for alkaline cleaning. The alkaline cleaning unit is the alkaline washing tower T-201. Remove the acid gas, and then enter the drying unit for drying. The drying unit is the inlet tank V-204 of the dryer, and C is added after the drying unit. 3 Pre-separation tower (T-1201), C 3 The pre-fractionation tower is a general distillation tower, the temperature of the tower bottom is 43°C, the temperature of the top of the tower is -26°C, the operating pressure of the bottom of the towe...

Embodiment 2

[0018] Embodiment 2, catalytic cracking gas is compressed to 13atm by 1, 2, 3 stage compressors, C 3 The temperature at the top of the pre-separation tower is -32°C, the operating pressure at the bottom of the tower is 12.3 atm, and the operating pressure at the top of the tower is 12.8 atm. After compression in stages 4 and 5, the pressure is increased to 38.5 atm. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com