Engine heat pump

An engine and heat pump technology, applied in compressors, refrigerators, compressors, etc., can solve problems such as increasing power consumption, and achieve the effect of reducing total compression work, ensuring performance, and operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

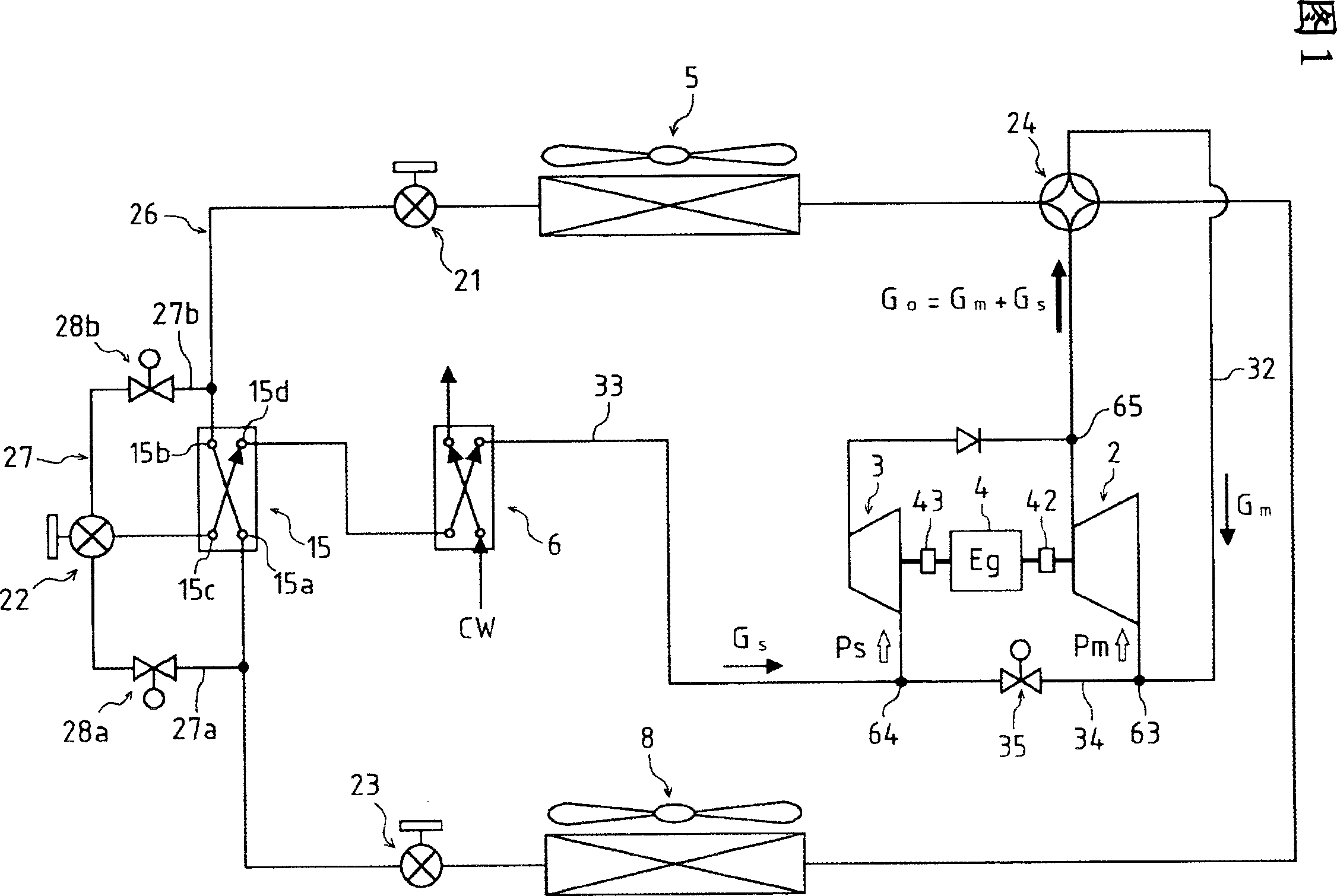

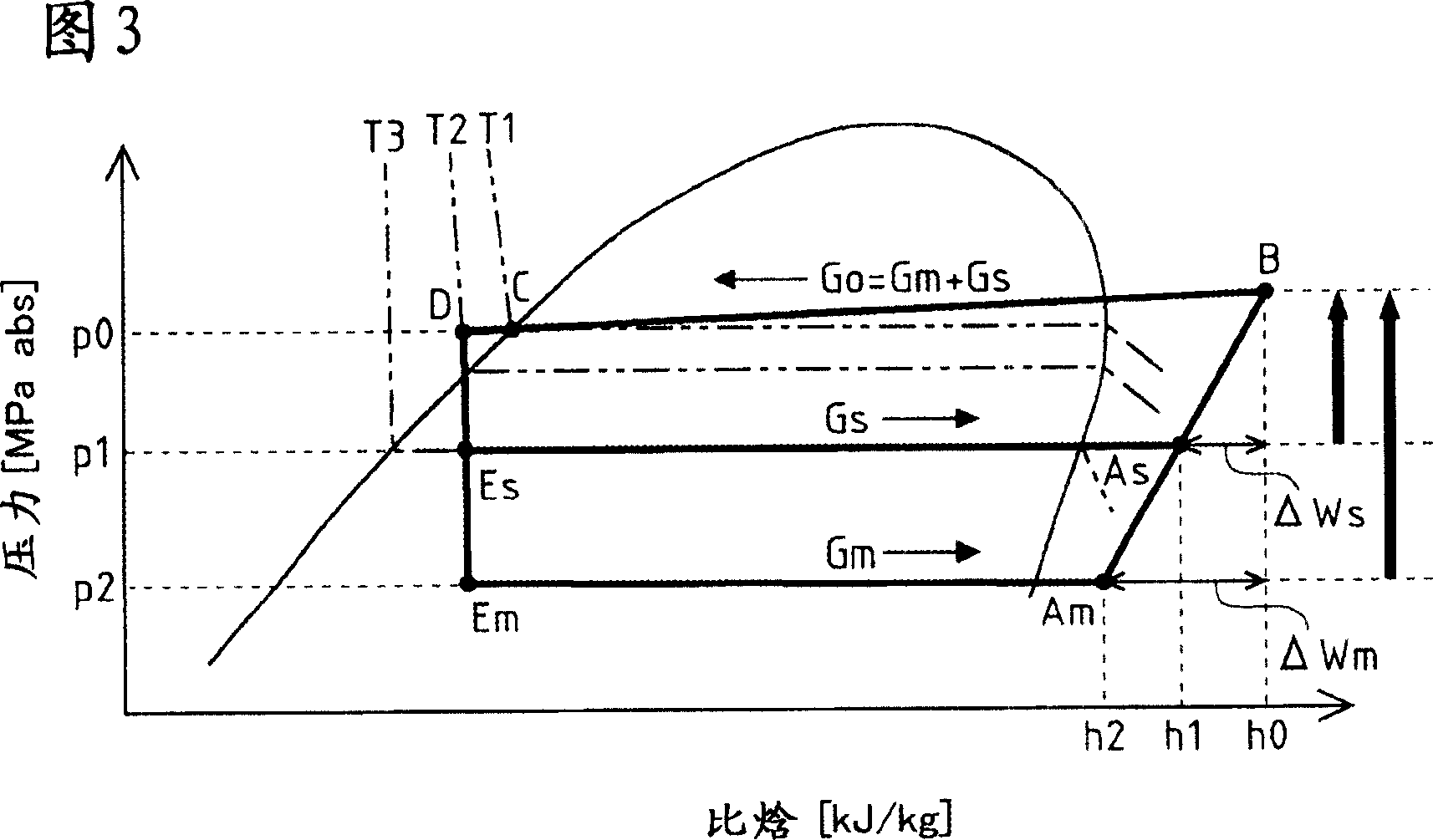

[0031] First, the refrigerant circuit structure and refrigerant cycle of the engine heat pump according to the present invention will be described with reference to FIG. 1 .

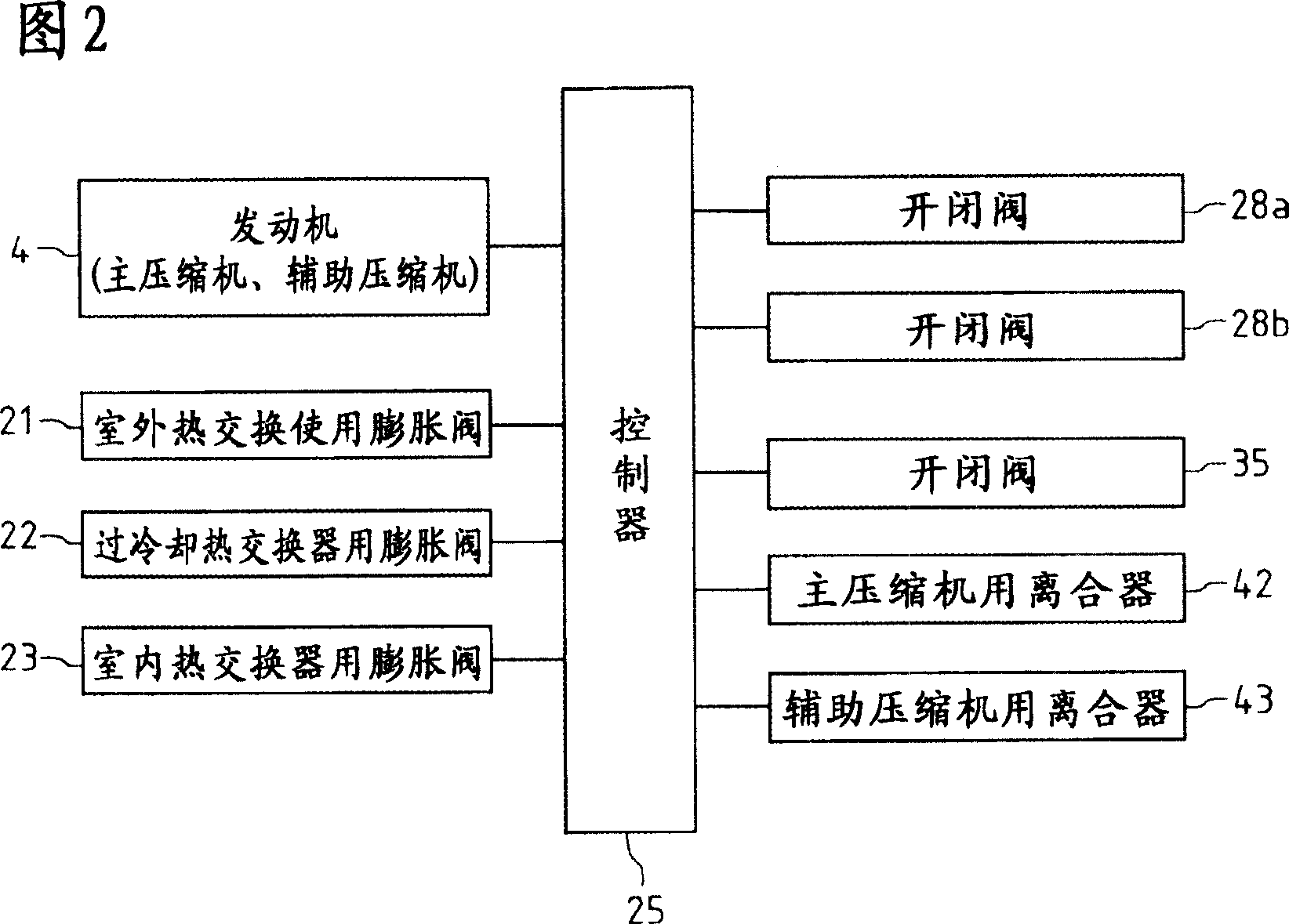

[0032] The engine heat pump according to the present invention includes: a main compressor 2 driven by an engine 4, an auxiliary compressor 3, an indoor heat exchanger 8, an outdoor heat exchanger 5, an expansion valve 23 for the indoor heat exchanger, and an expansion valve for the outdoor heat exchanger 21, and the supercooling heat exchanger 15, the supercooling heat exchanger 15 is arranged in the main path 26 as the liquid refrigerant passing path among the connecting paths between the indoor heat exchanger 8 and the outdoor heat exchanger 5, and utilizes The liquid refrigerant for subcooling branched into the branch path 27 (27a, 27b) subcools the liquid refrigerant before branching. The engine heat pump utilizes the refrigerant cycle constituted by the above-mentioned parts. In addition, the subco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com