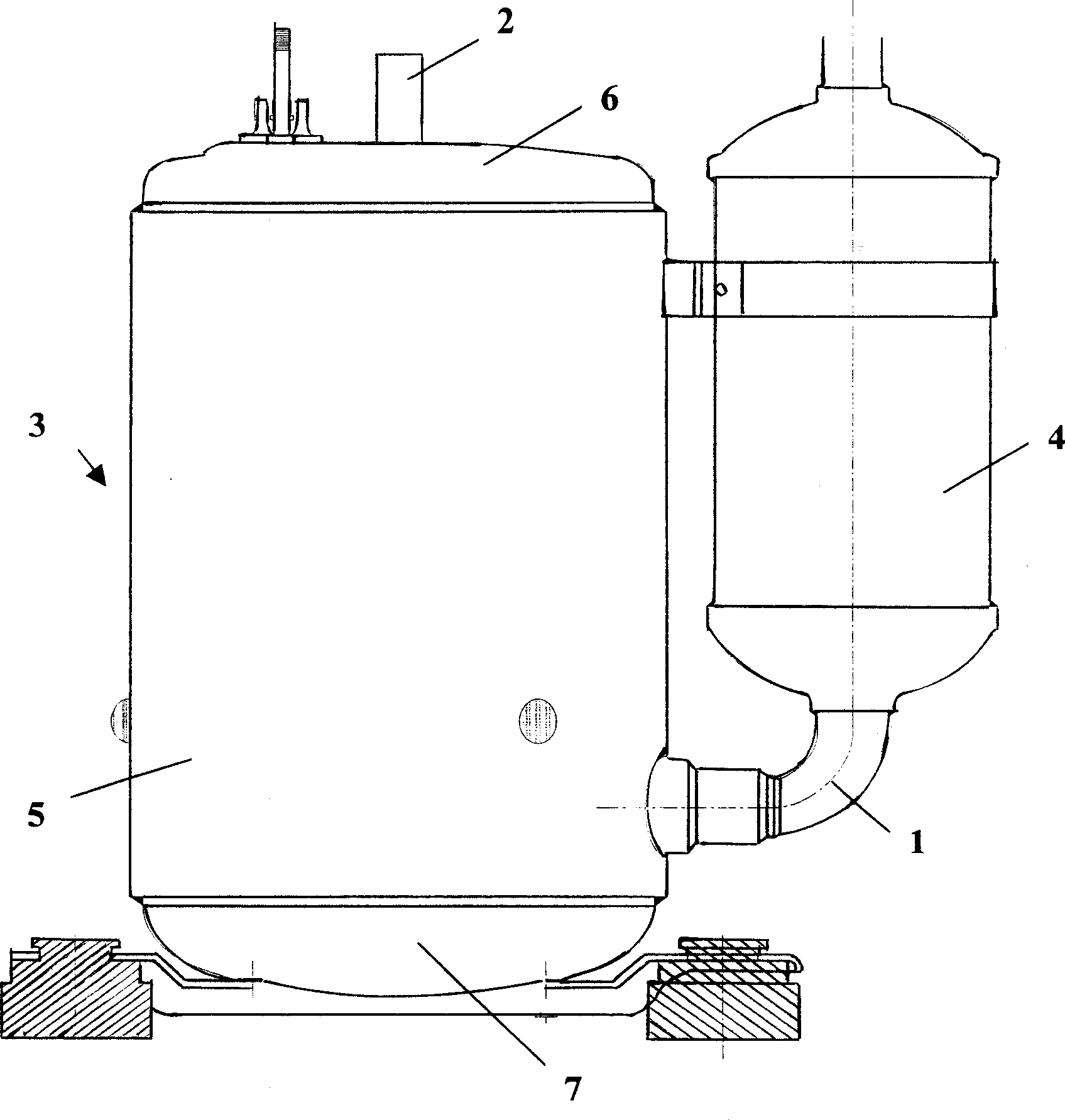

Top cover of compressor

A compressor and discharge pipe technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of reducing the refrigeration capacity and inflow of the compressor, improve the refrigeration capacity and reduce impurities entering the circulation pipeline the dangerous effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

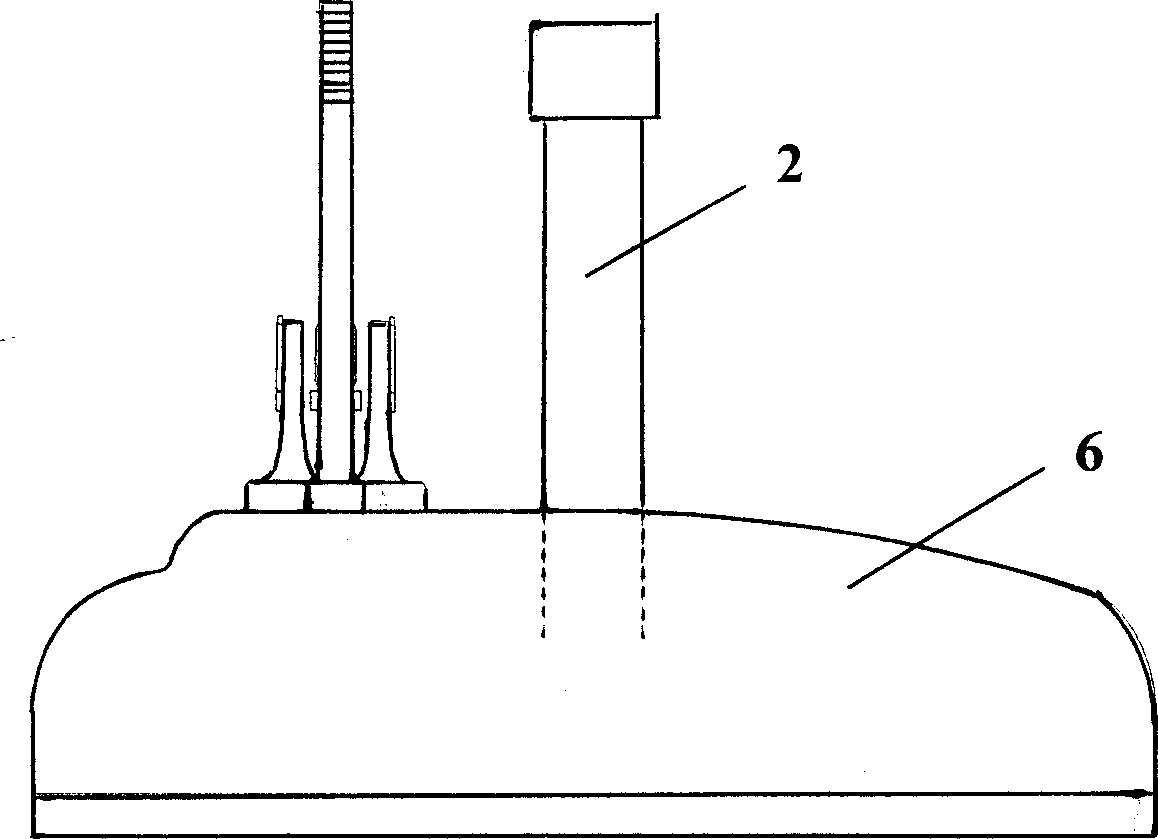

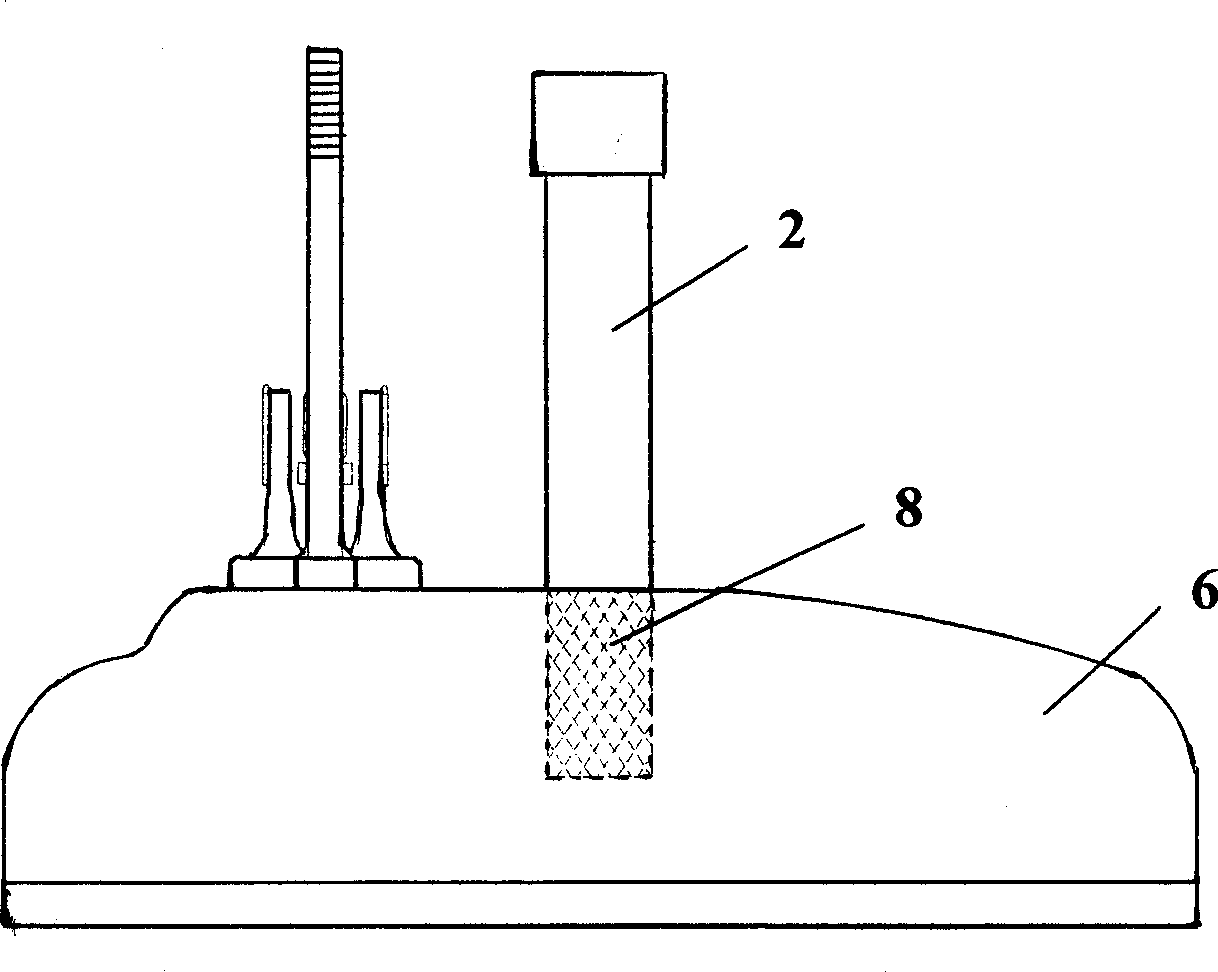

[0011] Such as image 3 As shown, a discharge pipe 2 is vertically provided at the center of the upper cover 6 of the compressor provided by the present invention, and a filter device 8 capable of filtering impurities in the refrigerant and lubricating oil is provided at the lower end of the discharge pipe 2 . The filtering device 8 is a mesh screen. When the compressor provided by the present invention is in operation, the refrigerant sucked into the airtight casing 3 through the suction pipe 1 can be compressed in the compression mechanical part set inside it to become a high temperature and high pressure state, and compressed by the compression mechanical part to high temperature and high pressure The gaseous refrigerant can be discharged into the circulation system together with the lubricating oil inside the compressor from the discharge pipe 2 arranged in the center of the upper cover 6. Since the lower end of the discharge pipe 2 is provided with a filter device 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com