Ammonia synthesis technology for improving ammonia separation effect through temperature swing adsorption

A technology of temperature swing adsorption and ammonia separation, which is applied in ammonia preparation/separation, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of increased power consumption of ice machines, reduce consumption, reduce operating pressure, and reduce compression work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

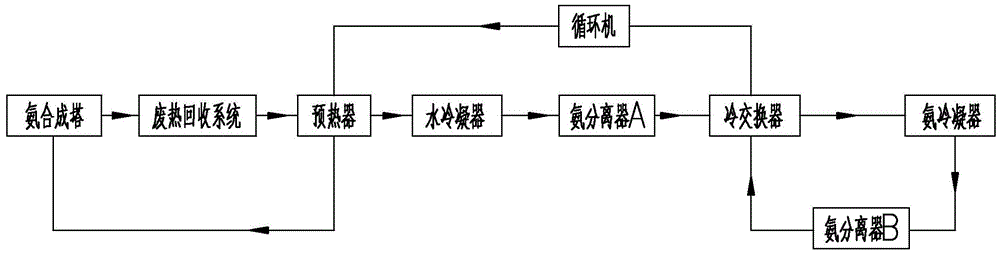

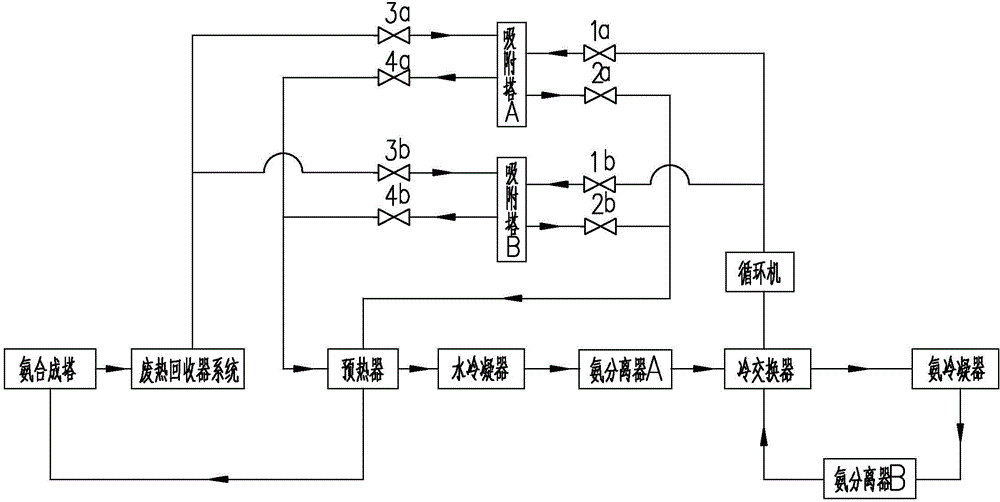

[0014] Such as figure 2 Shown, the temperature swing adsorption ammonia synthesis process of the present invention is as follows:

[0015] The synthesis gas from the ammonia synthesis tower recovers the reaction heat through the waste heat recovery system. At least two sets of adsorption and desorption towers are connected in parallel at the outlet of the waste heat recovery device. This embodiment is the parallel connection of adsorption and desorption tower A and adsorption and desorption tower B. The synthesis gas enters the inlet of the desorption end of the adsorption and desorption tower A after passing through the switching valve 3a, and the synthesis gas with desorbed ammonia at the outlet of the desorption end of the adsorption and desorption tower A passes through the switching valve 4a and enters the preheater and the water condenser to cool down in turn through the pipeline , and then enter the ammonia separator A to separate the liquid ammonia, the synthetic gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com