Patents

Literature

54results about How to "Conducive to waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

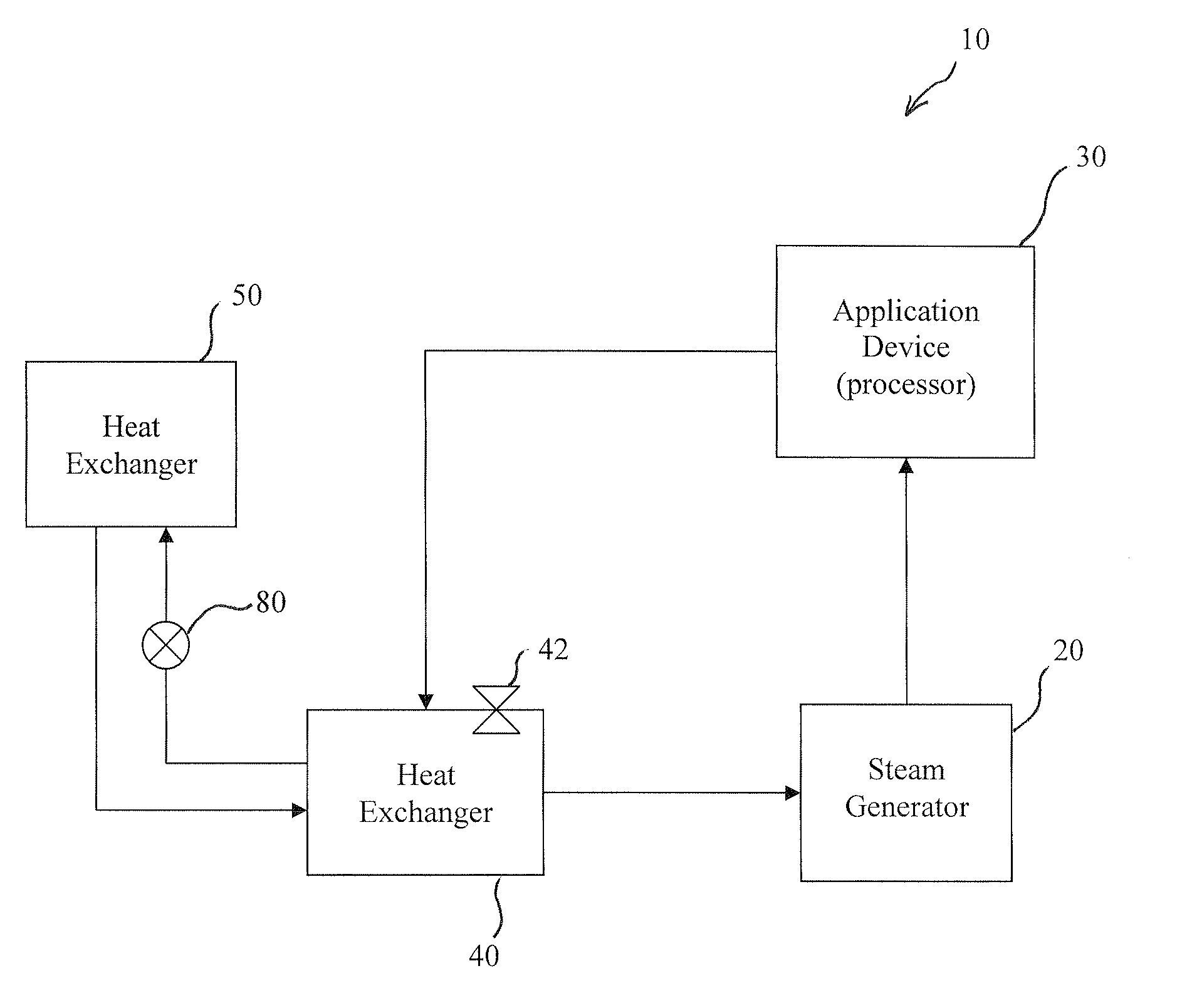

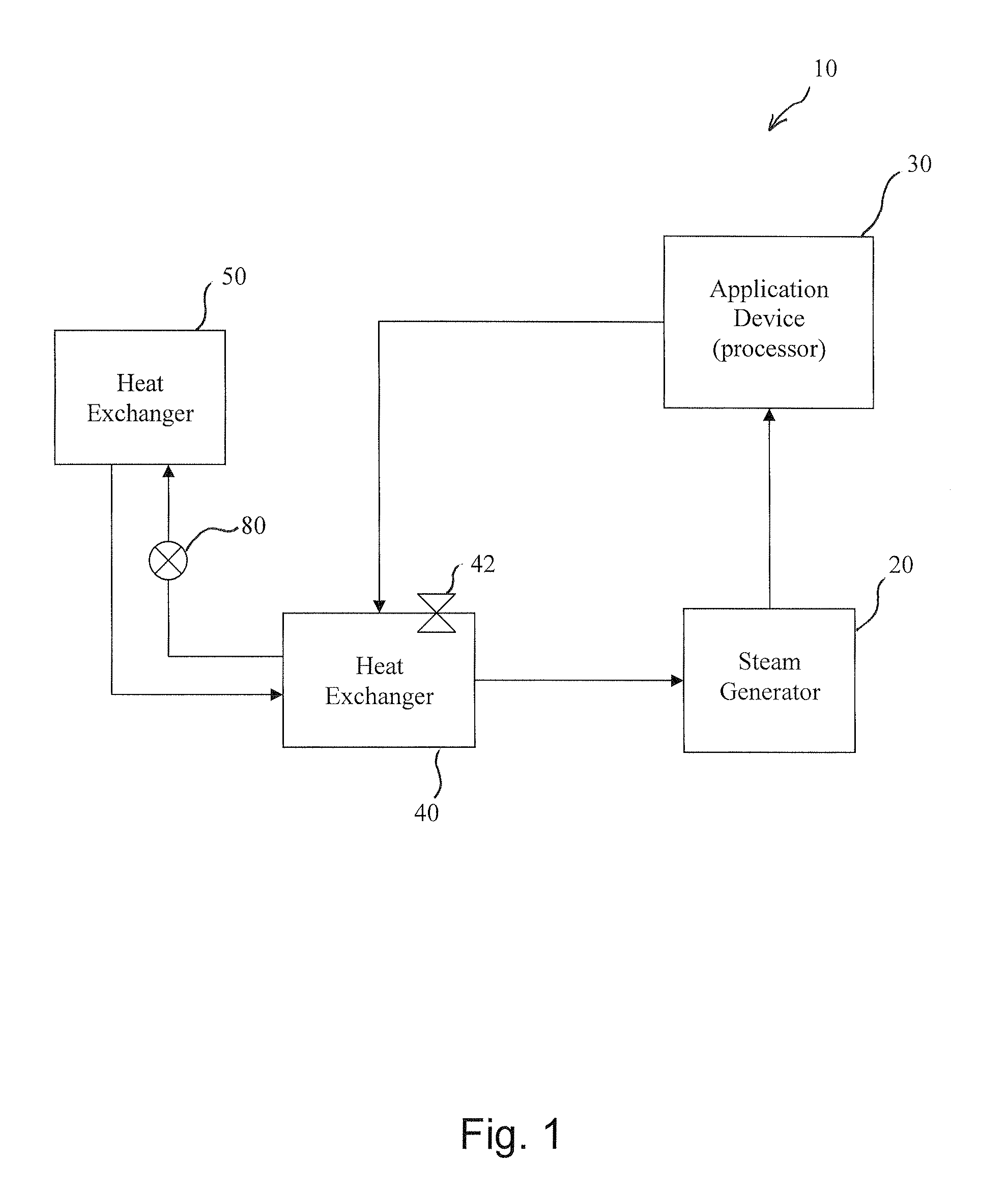

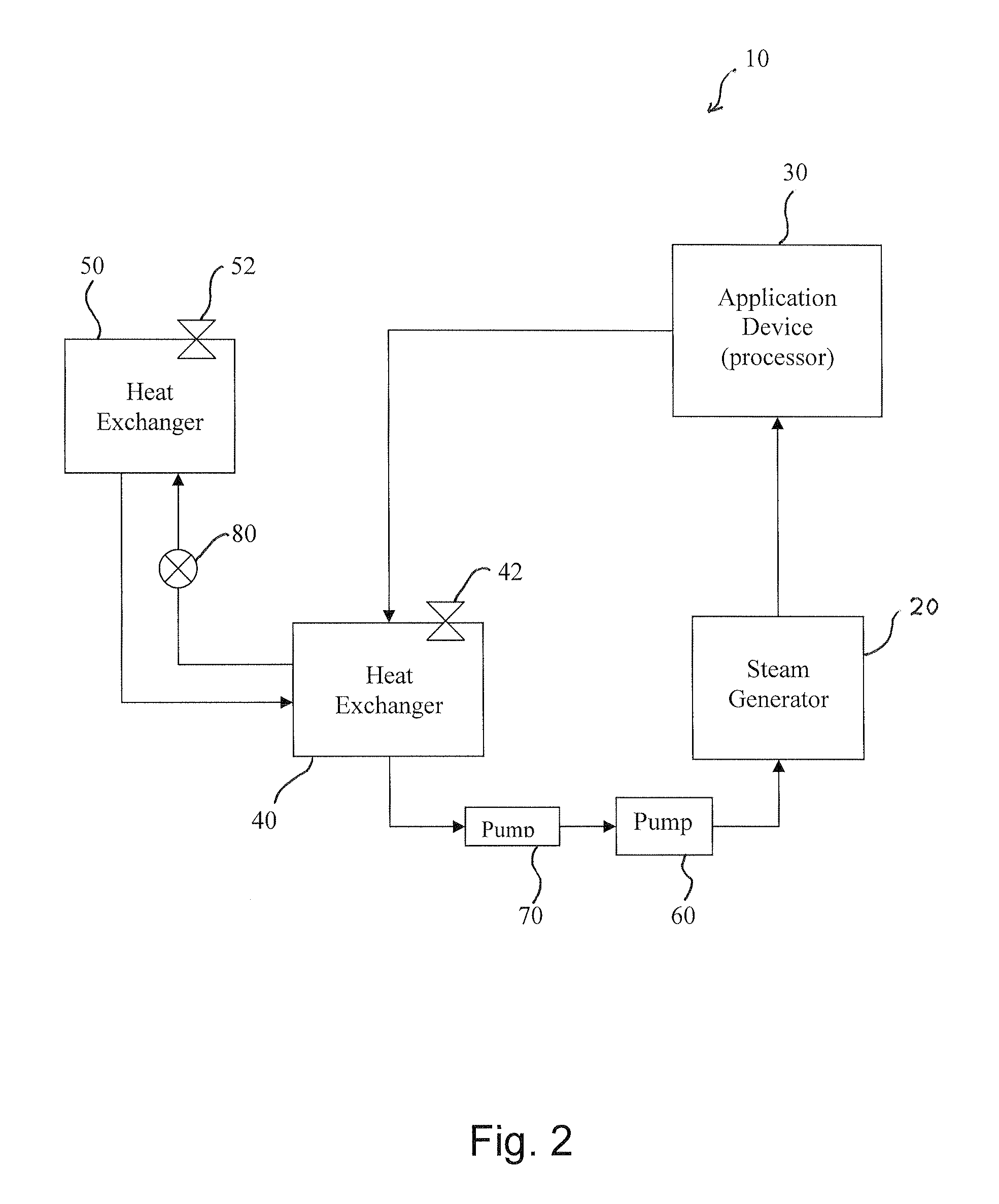

Waste Heat Recovery System and Method Thereof

InactiveUS20110083620A1Facilitate waste heat recoveryConducive to waste heat recoverySteam/vapor condensersSteam separation arrangementsRelief valveInternal pressure

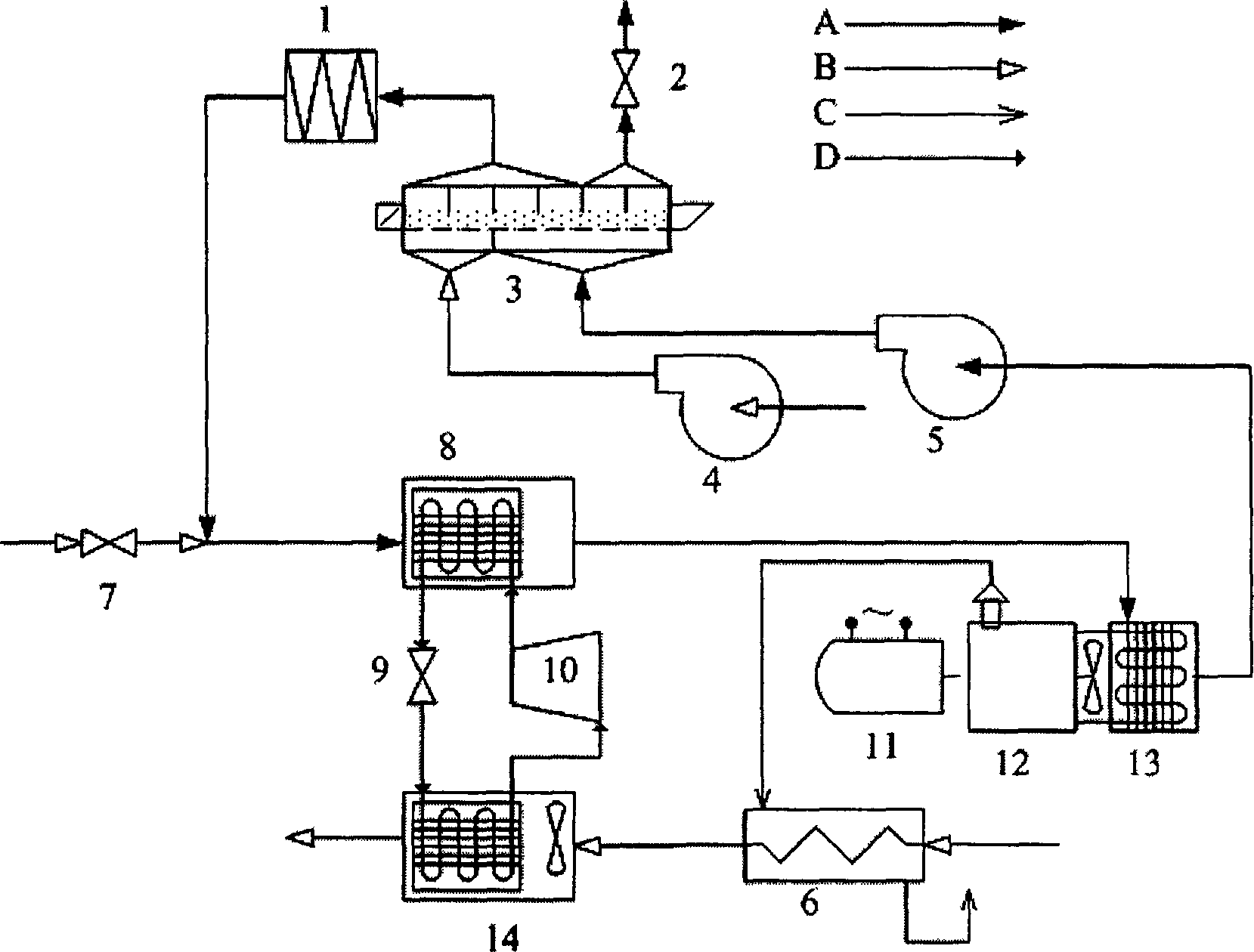

A waste heat recovery system comprises a steam generator, a processor, a first heat exchanger, and a second heat exchanger. The steam generator generates an original steam using water. The first heat exchanger condensates the first steam and emit water and a second steam from the processor. The second heat exchanger condensates the second steam from the first heat exchanger. The second heat exchanger condensates the second steam from the first heat exchanger leaving water only. The water from the first heat exchanger and the second heat exchanger may be guided into the steam generator or into the first heat exchanger. The second heat exchanger comprises one or more pressure relief valve. The pressure relief valve operates when inner pressure of the second heat exchanger exceeds above a predetermined value.

Owner:YOON YONG K

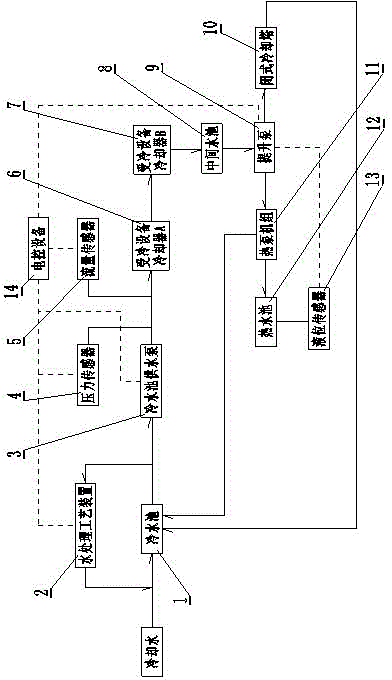

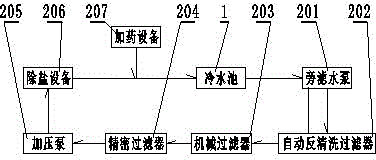

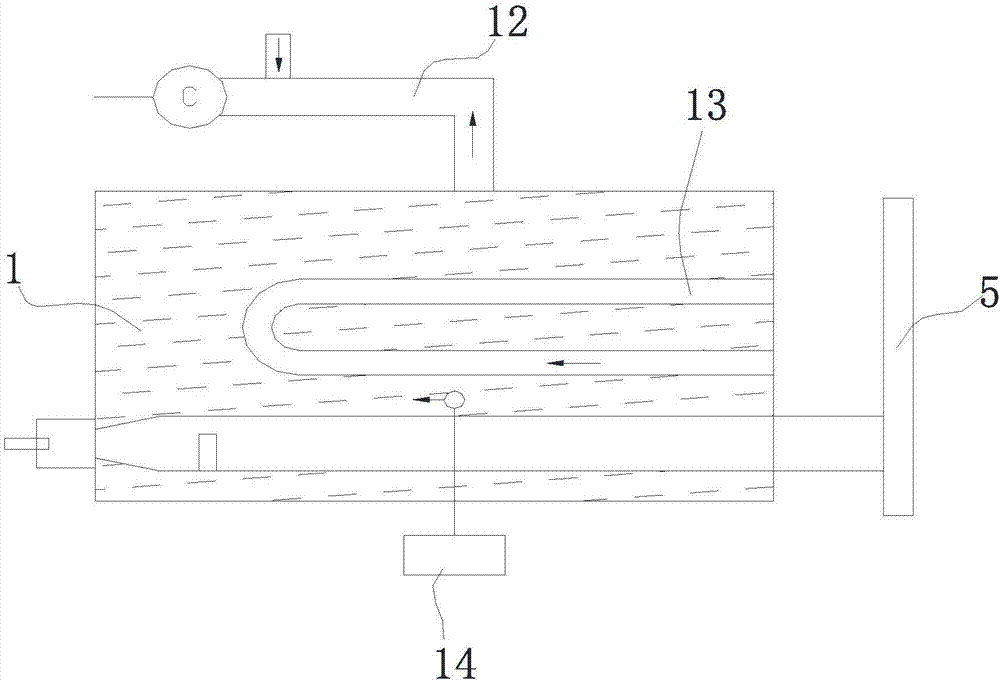

Energy-saving recycling combination system for industrial circulating cooling water

InactiveCN104478137AIncrease profitIncrease return water temperatureLighting and heating apparatusTreatment involving filtrationCooling towerWater quality

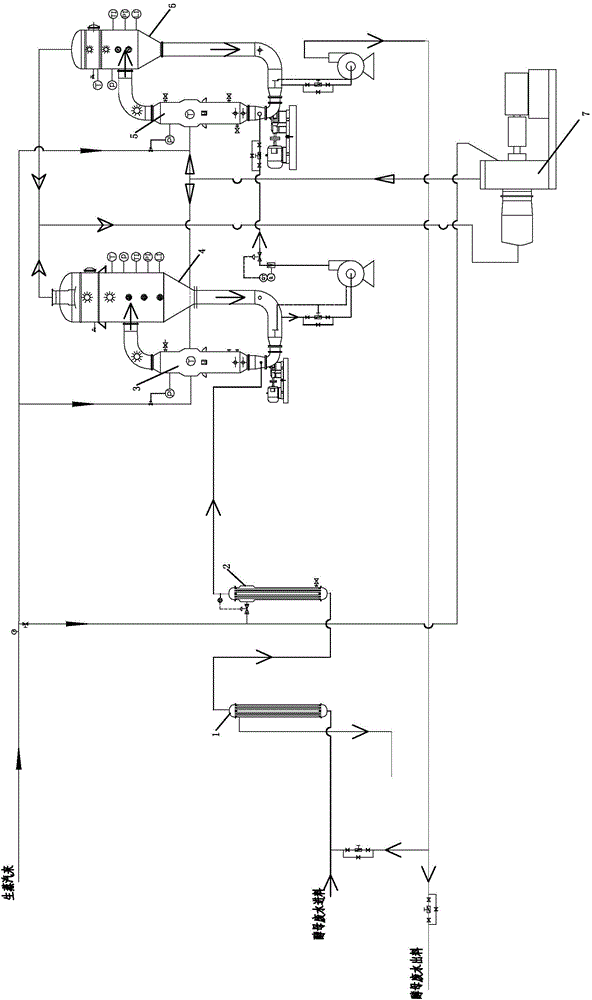

The invention discloses an energy-saving recycling combination system for industrial circulating cooling water. The system comprises two circulating cooling water systems, namely, a sealed-type circulating cooling water system and an open-type circulating cooling water system and specifically comprises a cold water tank, a water treatment process device, a cooling water supply pump, a pressure sensor, a flow sensor, a cooled device, an intermediate water tank, a lift pump, a cooling tower, a heat pump set, a hot water tank, a liquid-level sensor and an electronically controlled device and is an energy-saving and water-saving optimized combination system for industrial circulating cooling water. Serial-type water supply is adopted in the sealed-type circulating cooling water system, parallel-type water supply is adopted in the open-type circulating cooling water system, the utilization rate of the cooling water is increased to a maximize extent and the water supply amount of the cooling water is decreased. Since the system is provided with the water treatment process device, the water quality of the circulating water is improved, the sewage discharge capacity is decreased and the concentration multiple of the circulating water is increased. By arranging the heat pump set in the system, the low-temperature waste heat of the return water of the cooling water is effectively recovered, the evaporation amount is reduced and the effective utilization of the heat source is achieved and the system has important practical values.

Owner:CHINA FIRST HEAVY IND

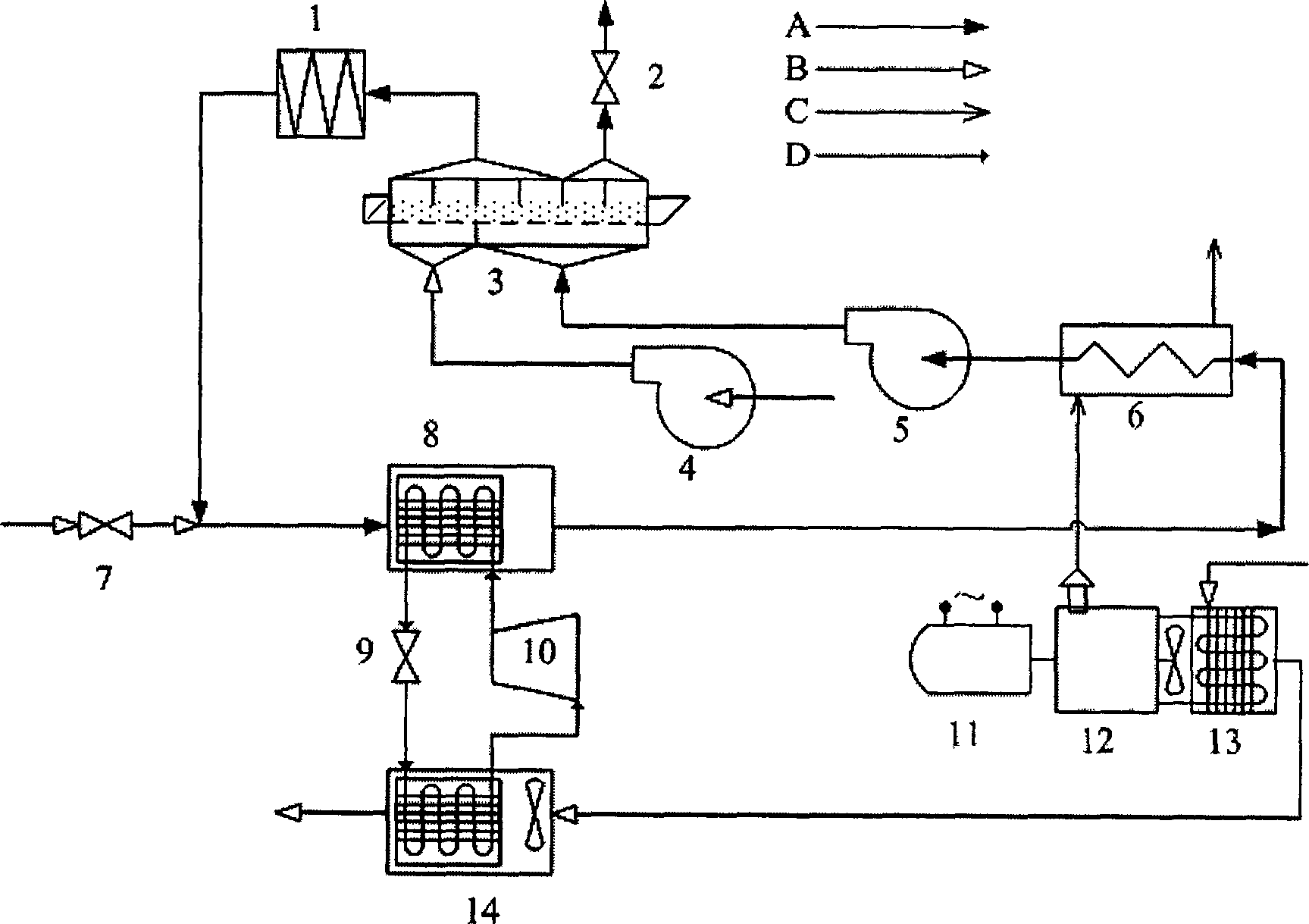

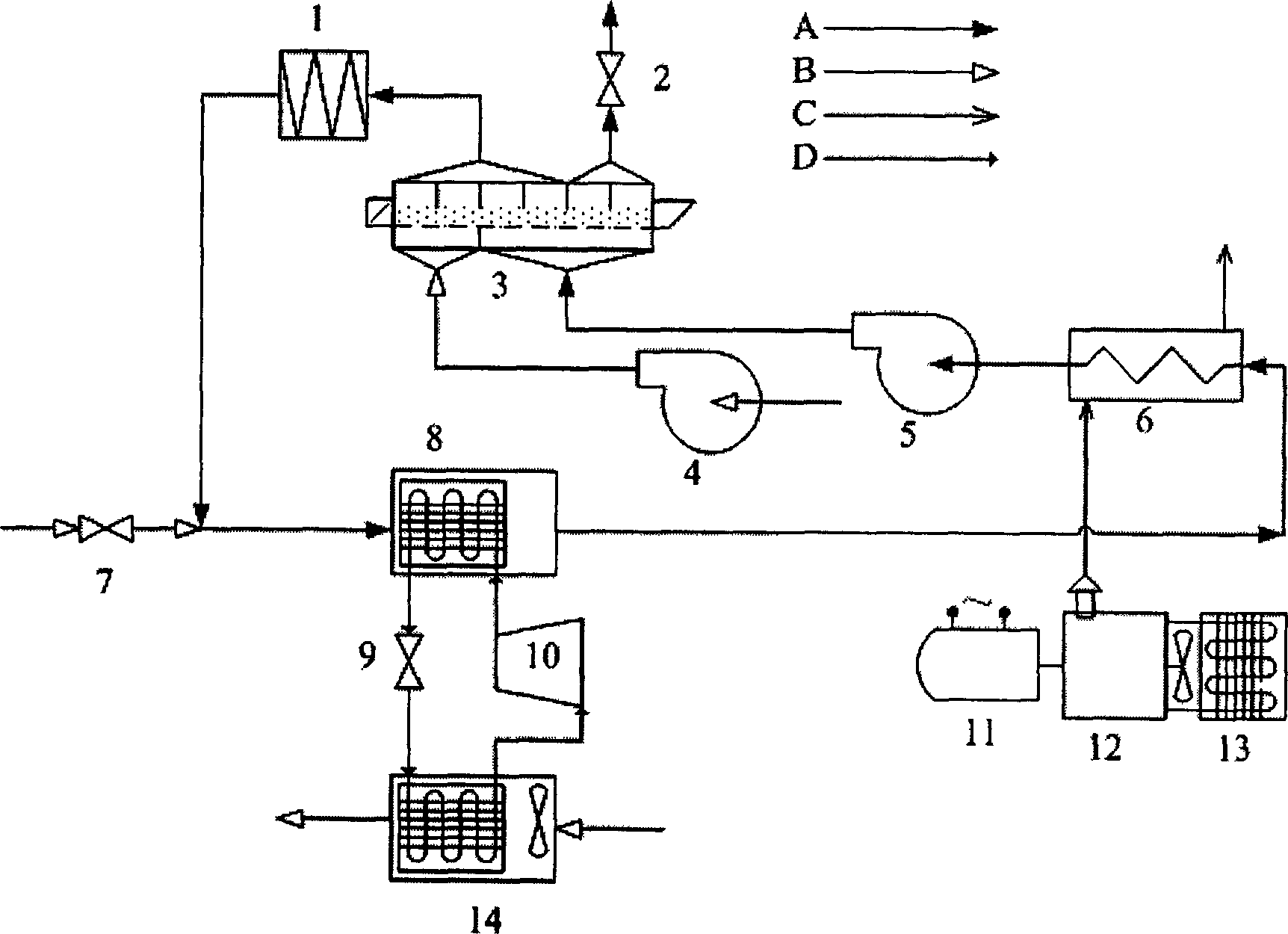

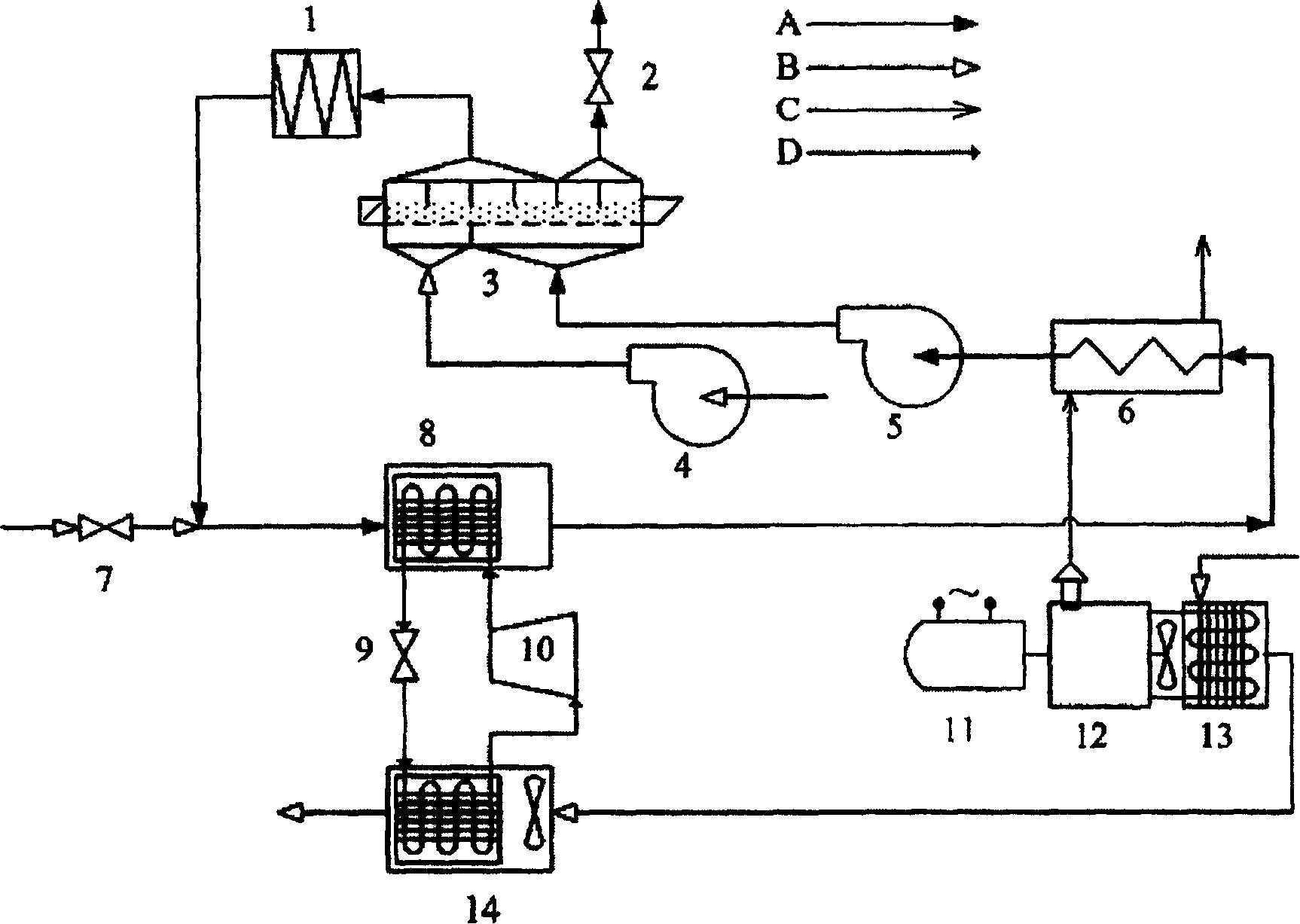

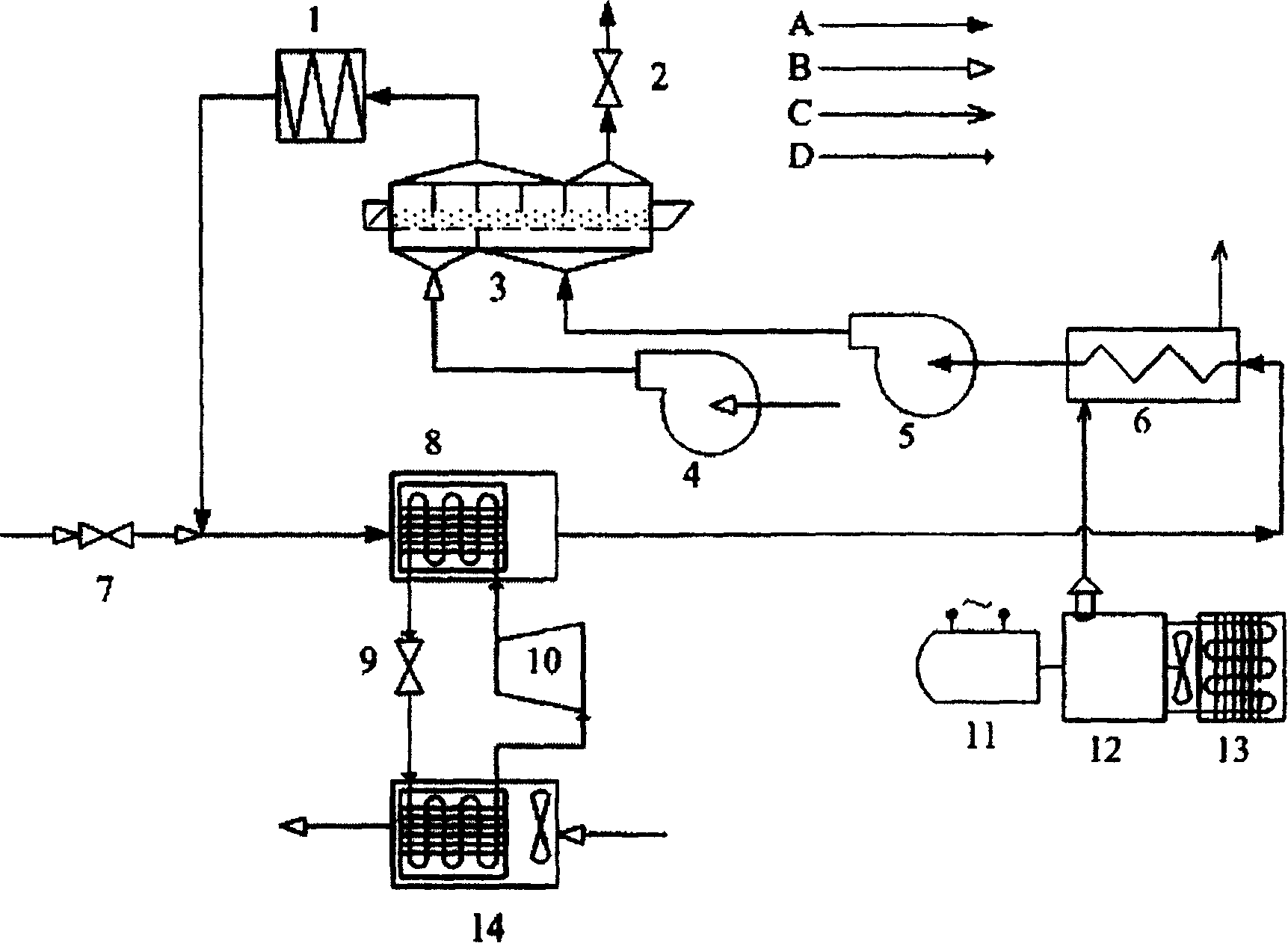

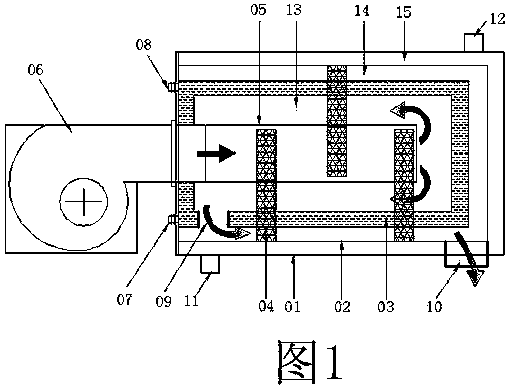

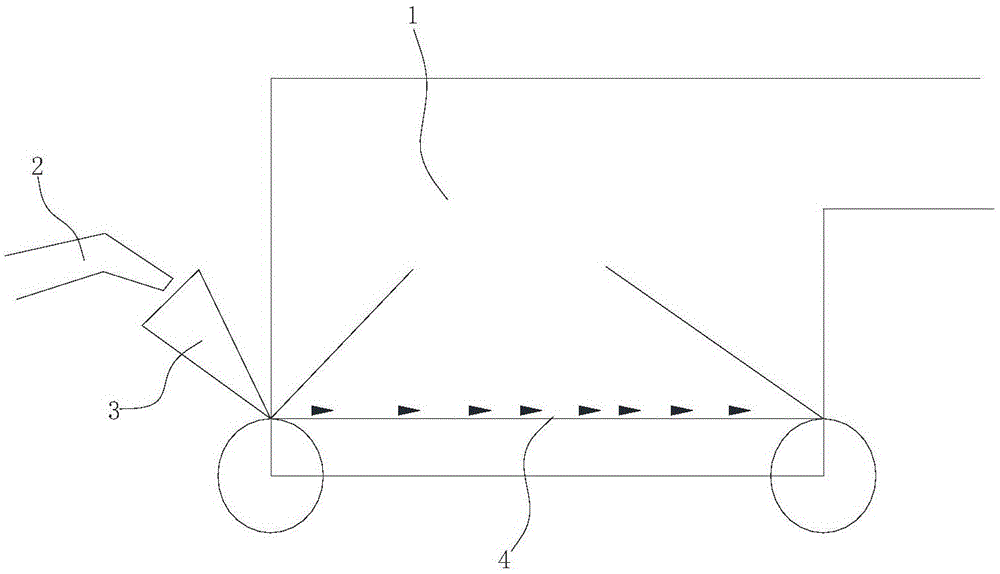

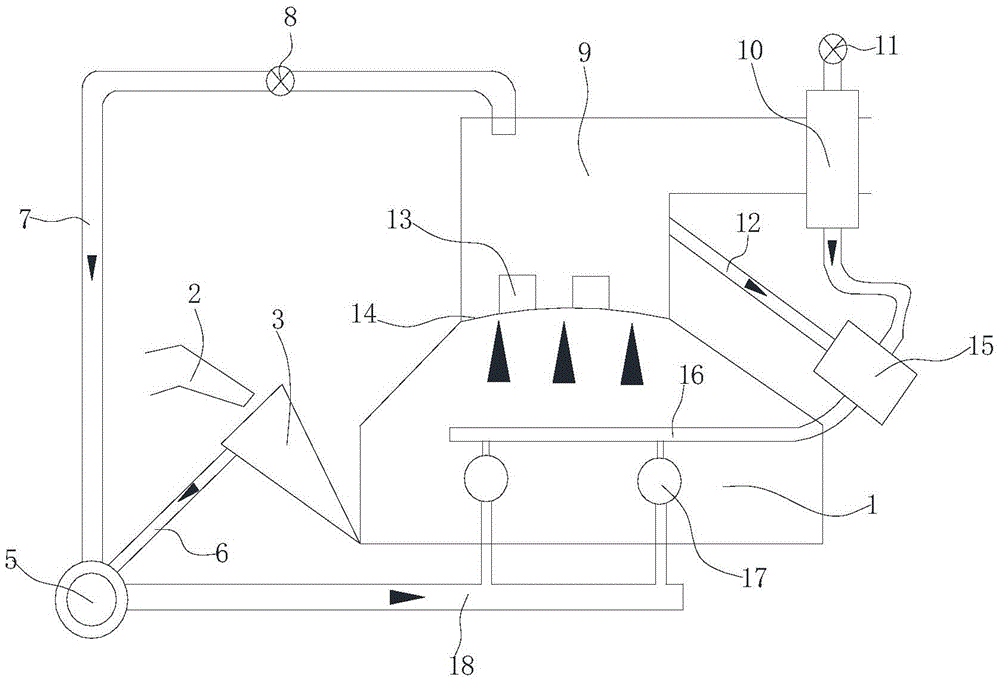

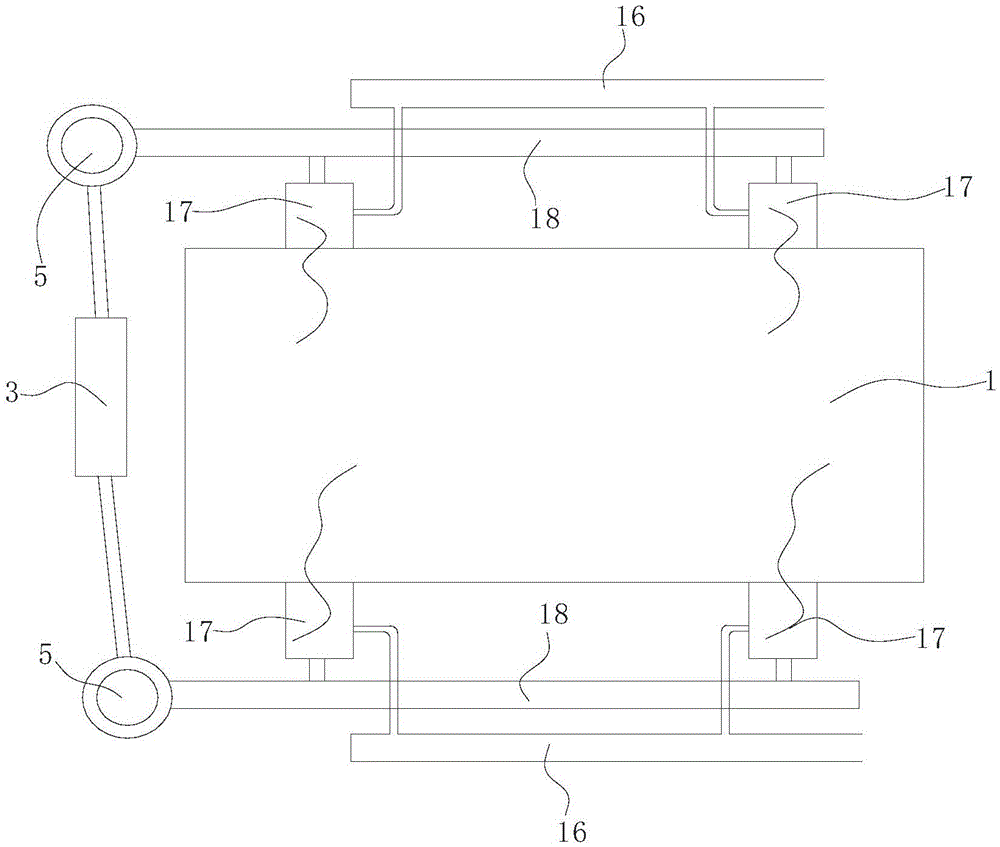

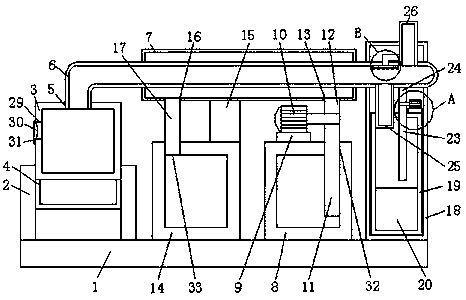

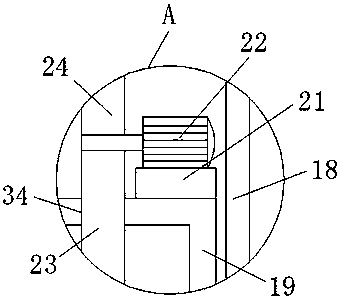

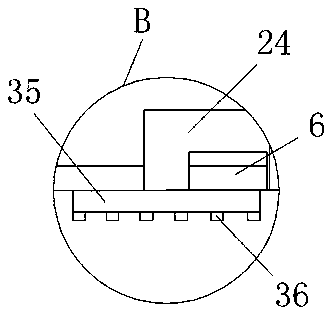

Internal combustion engine driving heat pump fluidized bed drying device capable of recovering used heat

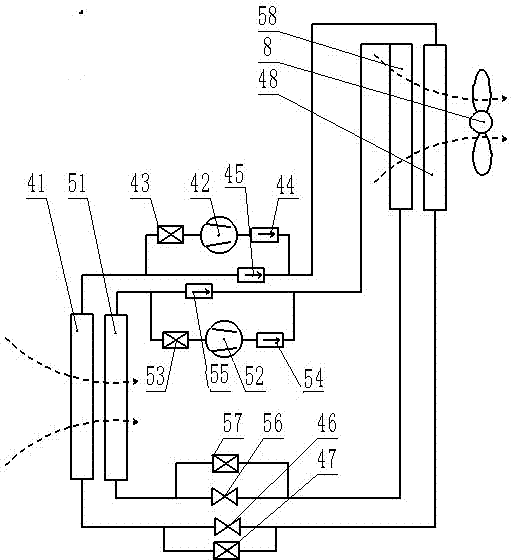

ActiveCN1719170AImprove drying efficiencyIncrease temperatureDrying solid materials with heatHearth type furnacesFluidized bed dryingExternal combustion engine

The present invention provides an internal combustion engine driven heat pump fluidized-bed drying equipment capable of recovering waste heat, belonging to the field of fluidized-bed drying technology. The heat pump condenser, heat-pump expansion valve, heat-pump evaporator and heat-pump compressor are successively connected and formed into the heat pump system. Said equipment also includes the following components: circulating fan, fluidized-bed drying chamber, cooling fan, dust collector and air pipe, etc.

Owner:汉广中药科技(天津)有限公司

Yeast wastewater zero discharge treatment method

ActiveCN104787823AAvoid entrainmentSolve the phenomenon of reducing separation efficiencyWater/sewage treatment by heatingWater treatment multistage treatmentsYeastGas phase

The invention discloses a yeast wastewater zero discharge treatment method, and belongs to the field of yeast wastewater treatment. The method solves the technical problems of high operating cost and drywall phenomenon in the existing multi-stage film fall evaporator yeast wastewater concentration. The method comprises the following steps: firstly, preheating yeast wastewater for two times to 90 DEG C; secondly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 30 percent; thirdly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 50 percent, and ensuring that a discharged material part returns a material inlet part; then adopting conventional centrifugation and spray drying methods to obtain organic fertilizer and feed additives; discharging condensate water after the condensate water is subjected to biochemical treatment and meet wastewater standard. The method effectively controls the concentration of materials in all links, and avoids the drywall phenomenon of heating tubes. According to the method, evaporated and separated gas phase is reused, so that the production cost is reduced.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD

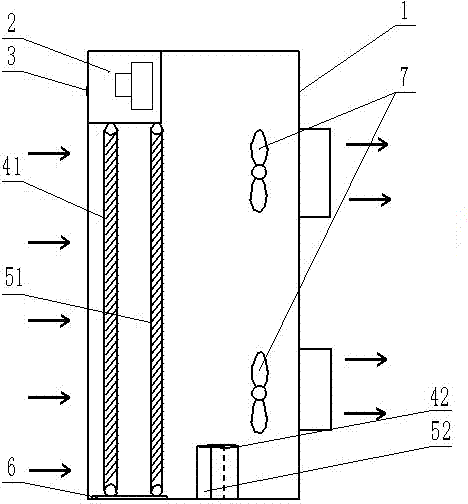

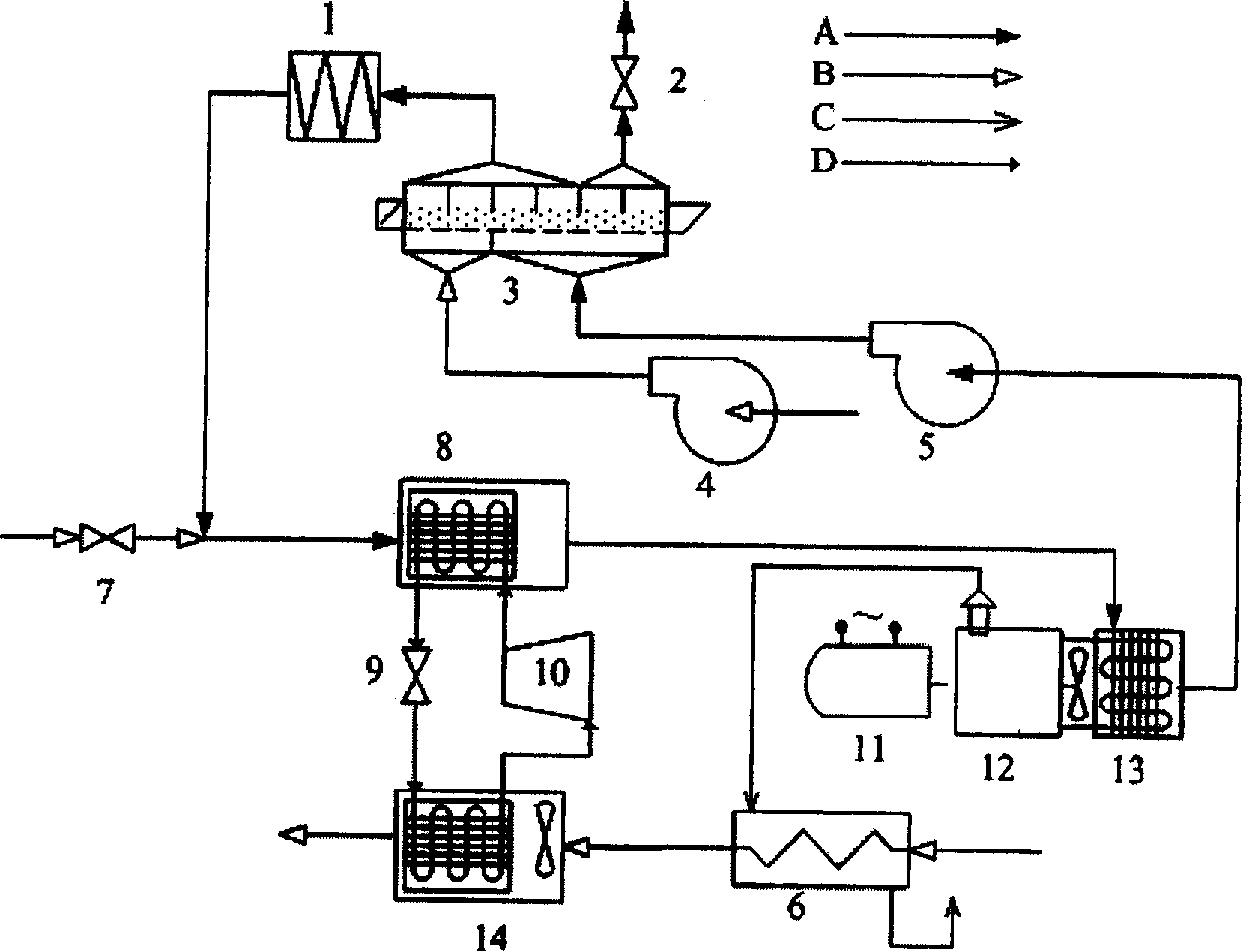

Novel energy-saving air conditioner for computer room

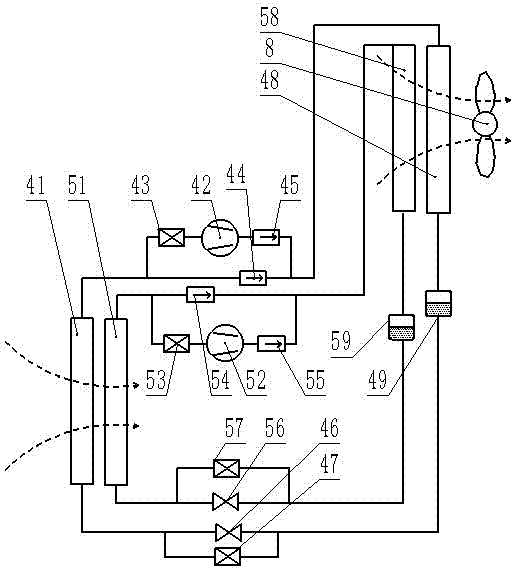

InactiveCN103884068AImprove heat transfer efficiencyImprove cooling efficiencySpace heating and ventilation safety systemsLighting and heating apparatusCold airControl system

The invention discloses a novel energy-saving air conditioner for a computer room. The novel energy-saving air conditioner for the computer room comprises an indoor machine box located in the room, and a control system placing area, a control panel displayer, two sets of air conditioner parts, a water pan, an indoor unit fan, a condenser A, a condenser B and a condenser fan are arranged in the indoor machine box, wherein the condenser A, the condenser B and the condenser fan are arranged out of the room. Hot air in the room enters an air inlet duct area through air inlets formed in the rear wall of the indoor machine box and the top of the indoor machine box under the pumping pressure of the indoor unit fan, is cooled through an evaporator A and an evaporator B and then enters an exhaust duct, and cold air in the exhaust duct is sent into the room through an air outlet in the bottom of the indoor machine box. The novel energy-saving air conditioner for the computer room is simple in structure and relatively low in product manufacturing cost; when the novel energy-saving air conditioner for the computer room is used, the reliability is high, the refrigeration effect is good, and vigorous promotion and application can be performed easily.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

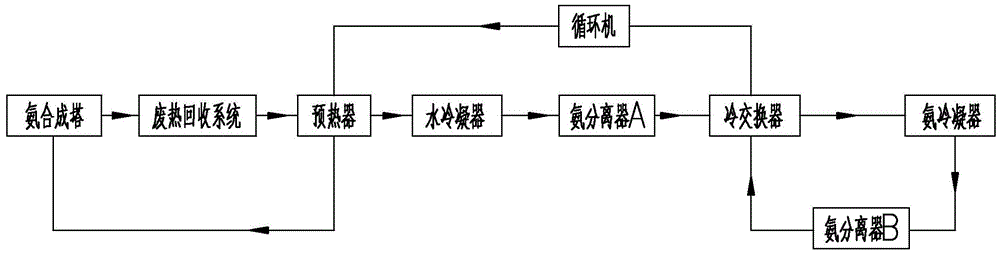

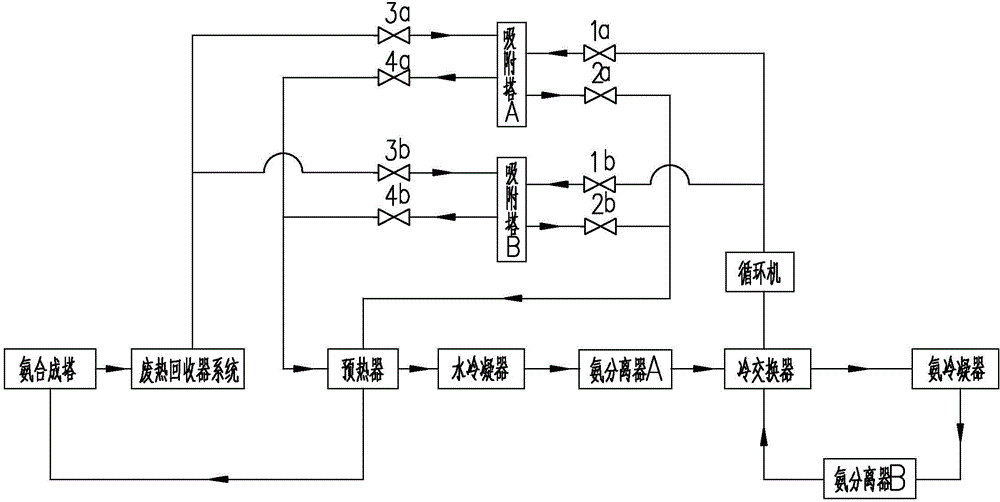

Ammonia synthesis technology for improving ammonia separation effect through temperature swing adsorption

InactiveCN103818929AReduce energy consumptionSimple reaction conditionsEnergy inputAmmonia preparation/separationSyngasDesorption

The invention discloses an ammonia synthesis technology for improving ammonia separation effects through temperature swing adsorption. Synthetic gas is connected to the inlet of a desorption end of an adsorption and desorption tower, synthetic gas at the outlet of the desorption end of the adsorption and desorption tower is successively cooled through a preheater and a water condenser and then enters an ammonia separator; circulation gas is connected to an inlet of the adsorption end of the adsorption and desorption tower; the circulation gas at the outlet of the adsorption end of the adsorption and desorption tower enters the preheater for being preheated, and the preheated circulation gas enters an ammonia synthesis tower. Only two adsorption and desorption towers and transfer valves, which can be mutually replaced for regeneration adsorption, are added, and the aims of greatly increasing one-way ammonia synthesis rate and reducing the energy consumption of an ice machine can be realized. Under the conditions of lower temperature and less NH3 partial pressure, NH3 in the circulation gas in the ammonia converter is adsorbed, so that the absorbed NH3 reaches a less in-tower ammonia content, and the out-tower synthetic gas desorbs the absorbed NH3; the desorbed NH3 is gathered in the out-tower gas, so as to increase the total ammonia partial pressure of the synthesis cycle gas. After water cooling, condensation and separation are carried out, so as to increase one-time one way synthetic ratio and an ammonia net value, and increase the ammonia yield and improve the reaction condition of the synthesis tower.

Owner:刘金成

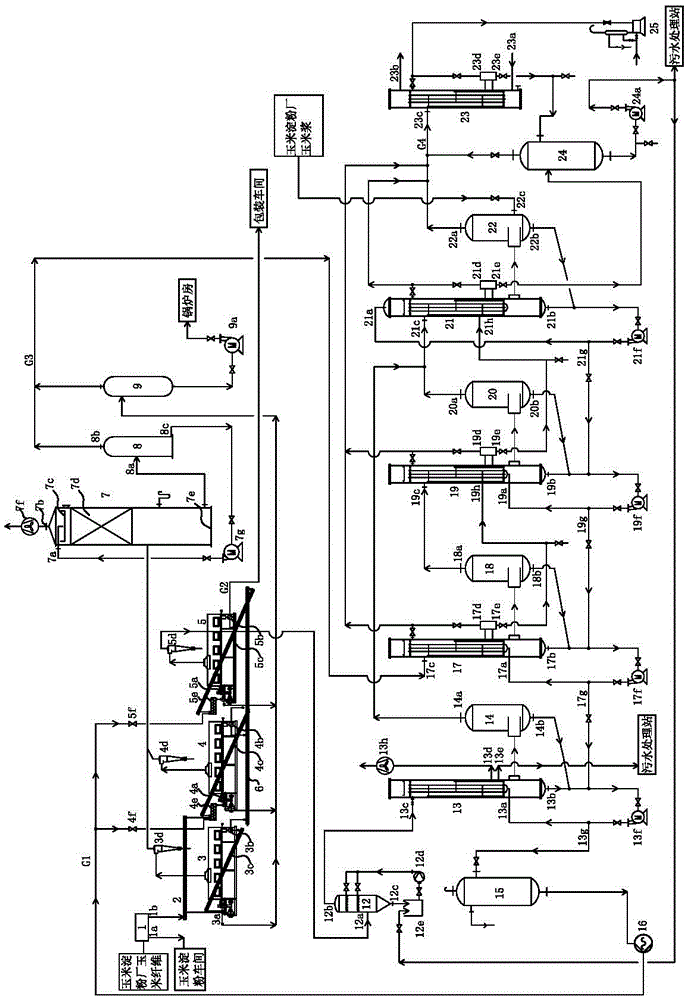

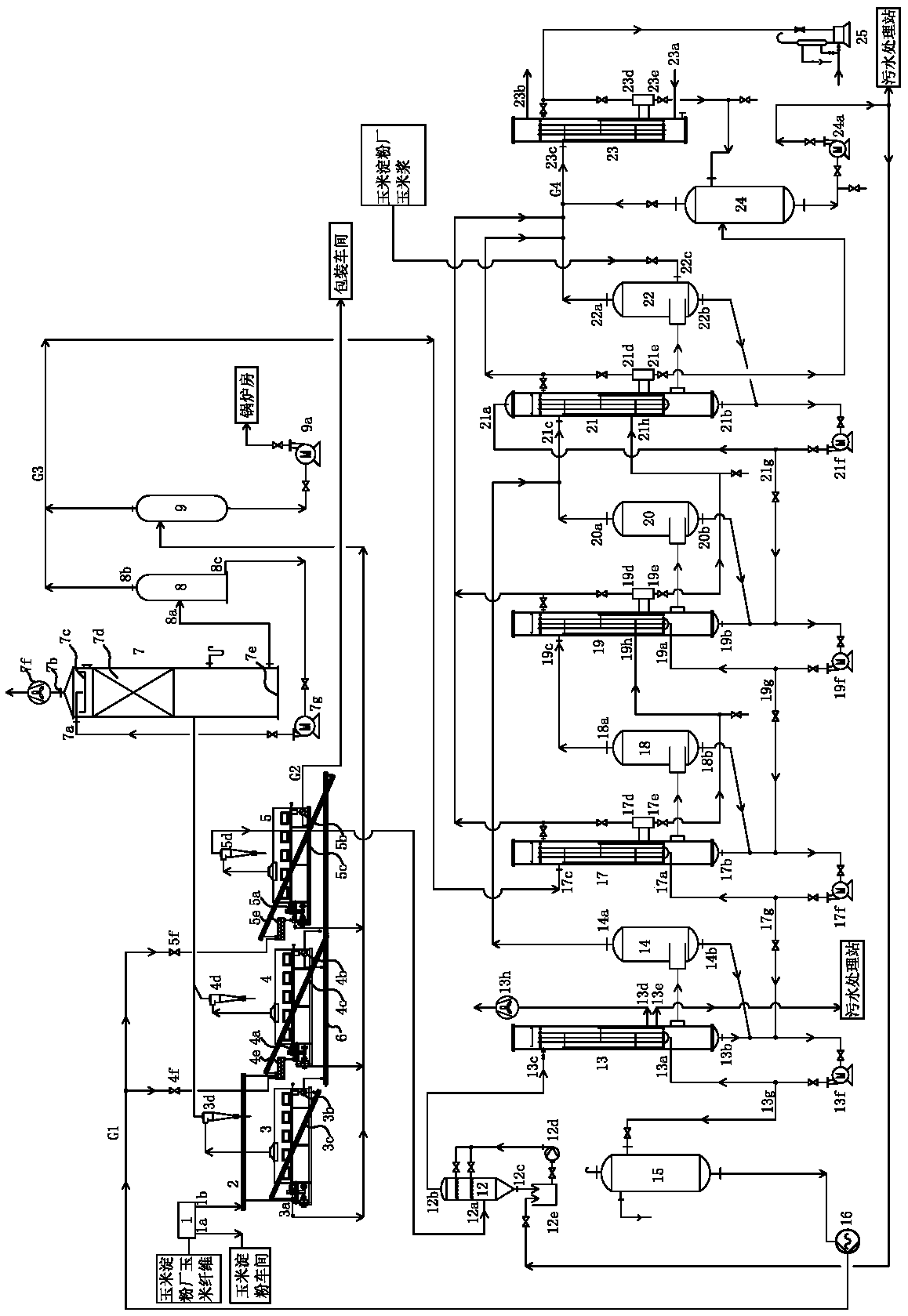

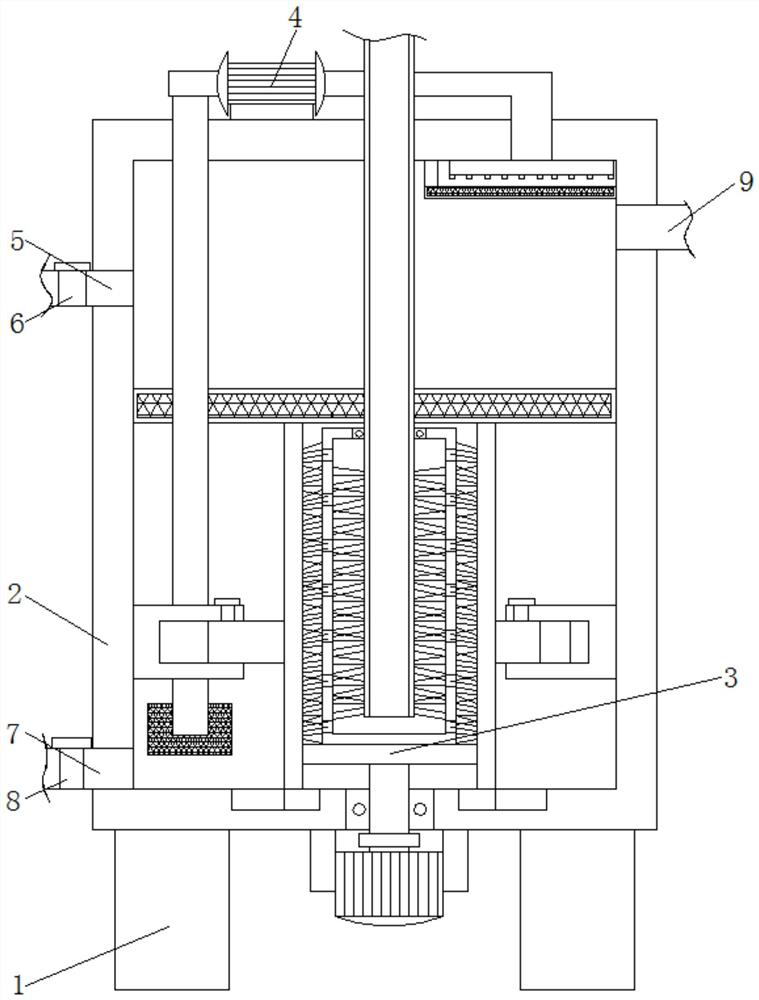

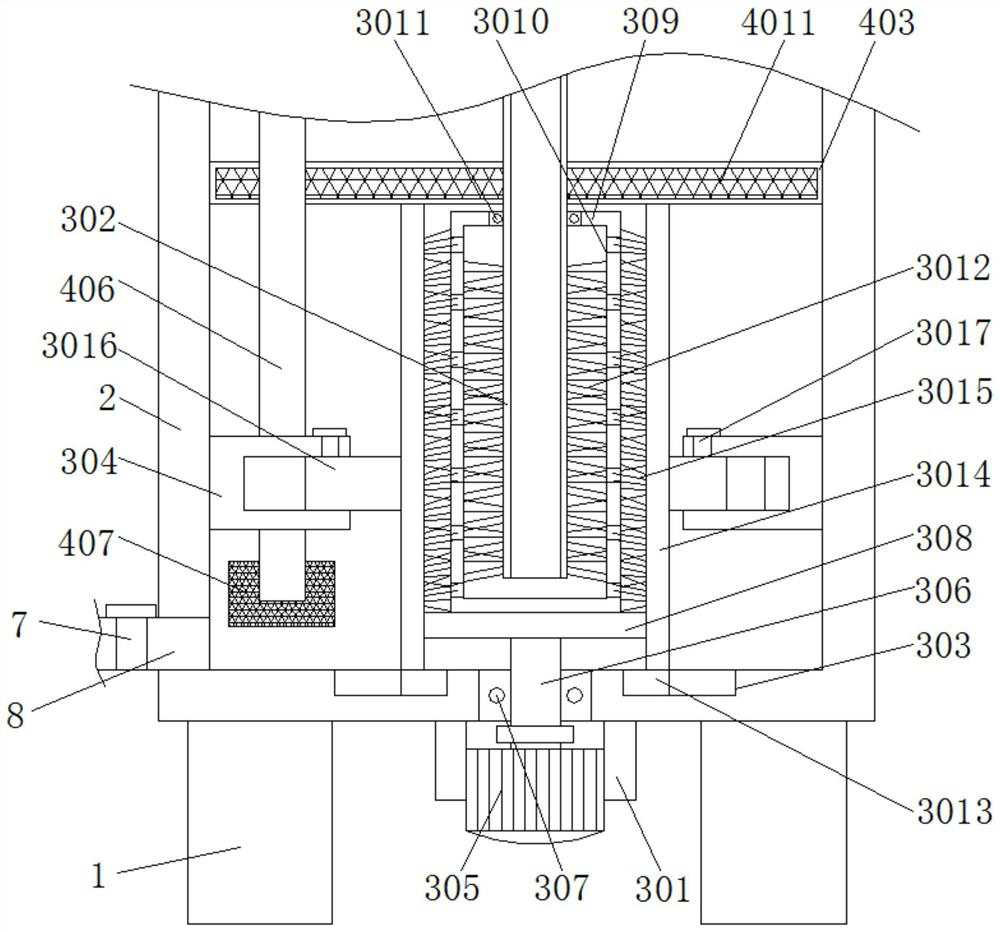

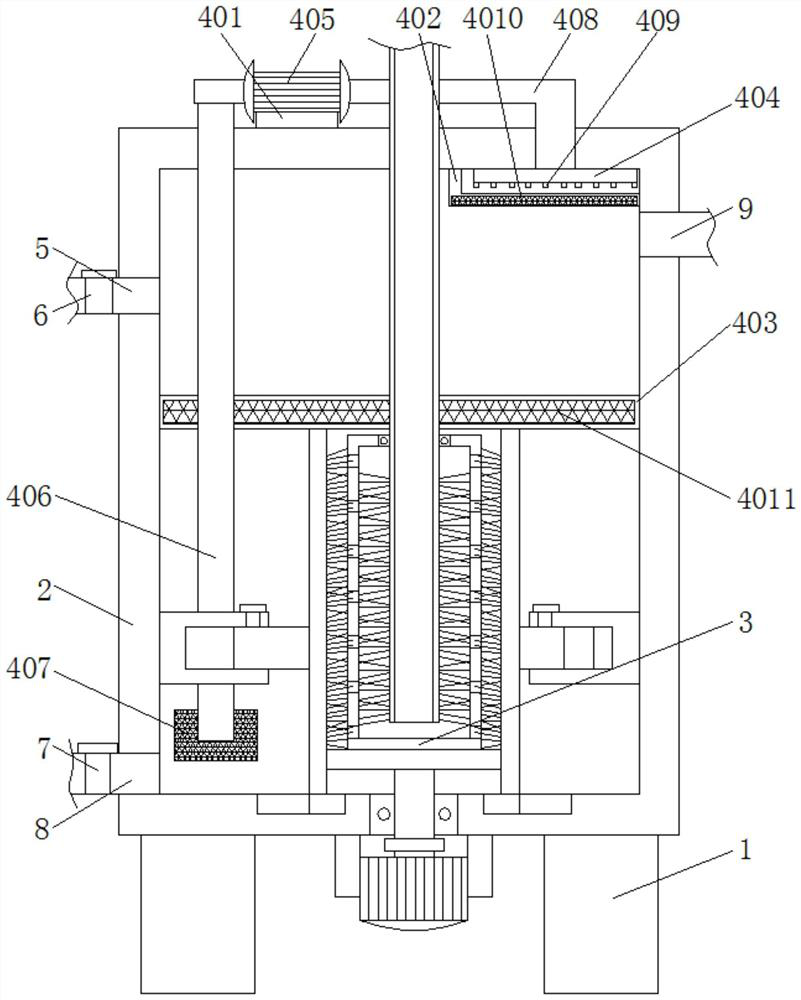

Production technology of corn pulp addition fibers

ActiveCN106387369AReduce consumptionImprove qualityFood processingAnimal feeding stuffFiberCooling tower

The invention relates to a production technology of corn pulp addition fibers. The production technology sequentially comprises the following steps of separating corn fibers in a corn starch plant into dehydrated corn fibers and dehydrated fluid, conveying the dehydrated corn fibers into a first pipe bundle drier for first-stage drying, and controlling a product return ratio; after the first-stage drying, performing primary pulp addition with thick corn pulp, performing uniform mixing to obtain a first mixture, conveying the first mixture into a second pipe bundle drier for second-stage drying, and controlling a product return ratio; after the second-stage drying, performing secondary pulp addition with thick corn pulp, performing uniform mixing to obtain a second mixture, conveying the second mixture into a third pipe bundle drier for third-stage drying, and controlling a product return ratio; enabling discharged corn fibers after the third-stage drying, namely corn pulp addition fibers to enter a multi-stage countercurrent cooling tower for cooling; and respectively performing dust removal and residual heat recover on the high-quality tail gas of the first pipe bundle drier, the high-quality tail gas of the second pipe bundle drier, and the low-quality tail gas of the third pipe bundle drier, and gradually concentrating thin corn pulp into the thick corn pulp through recovered heat. The production technology of the corn pulp addition fibers disclosed by the invention is low in steam consumption and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

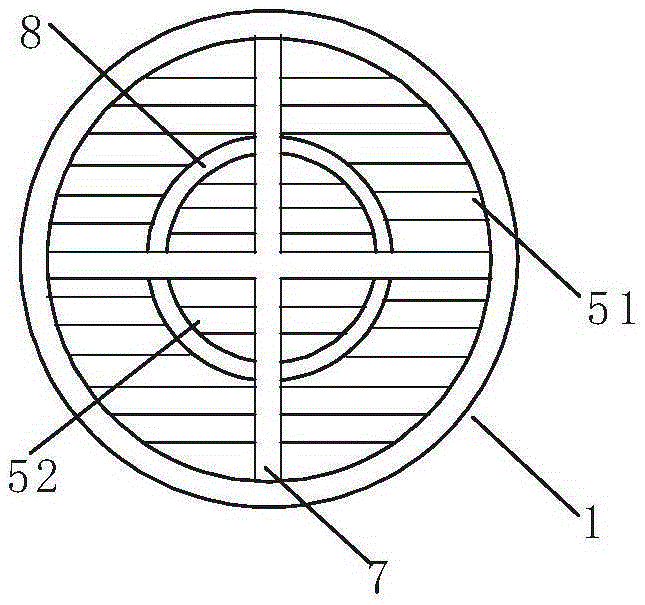

Energy-saving and environment-friendly combustion system using flue gas for supporting combustion for industrial furnace

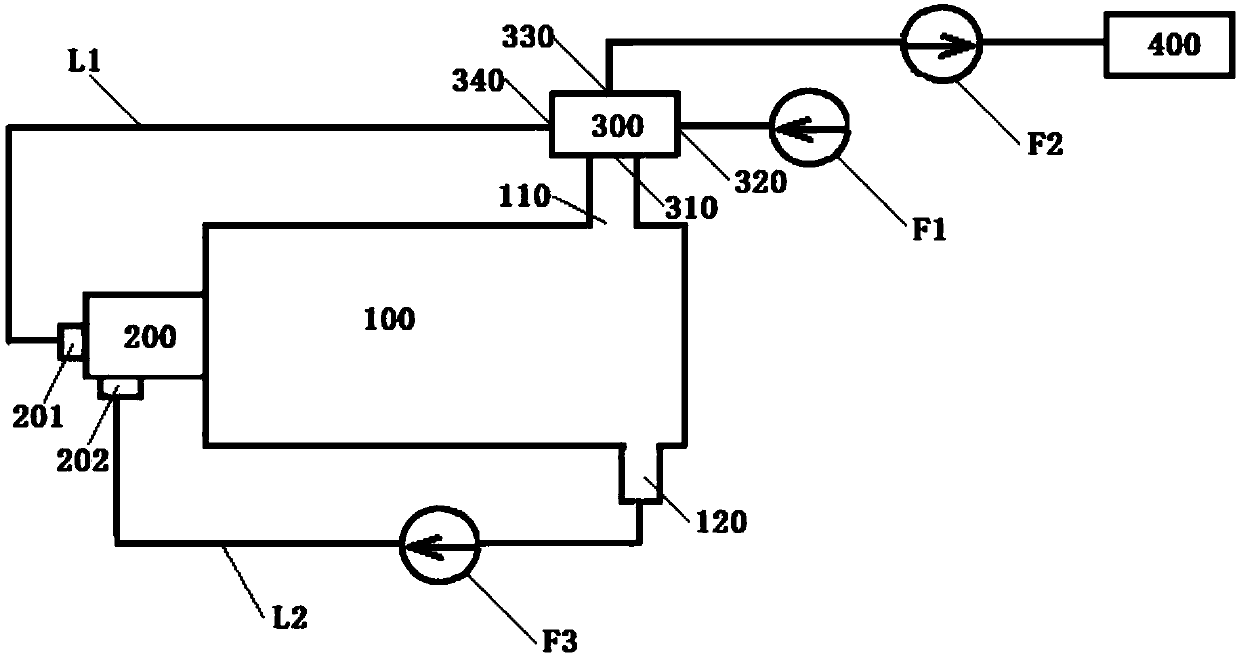

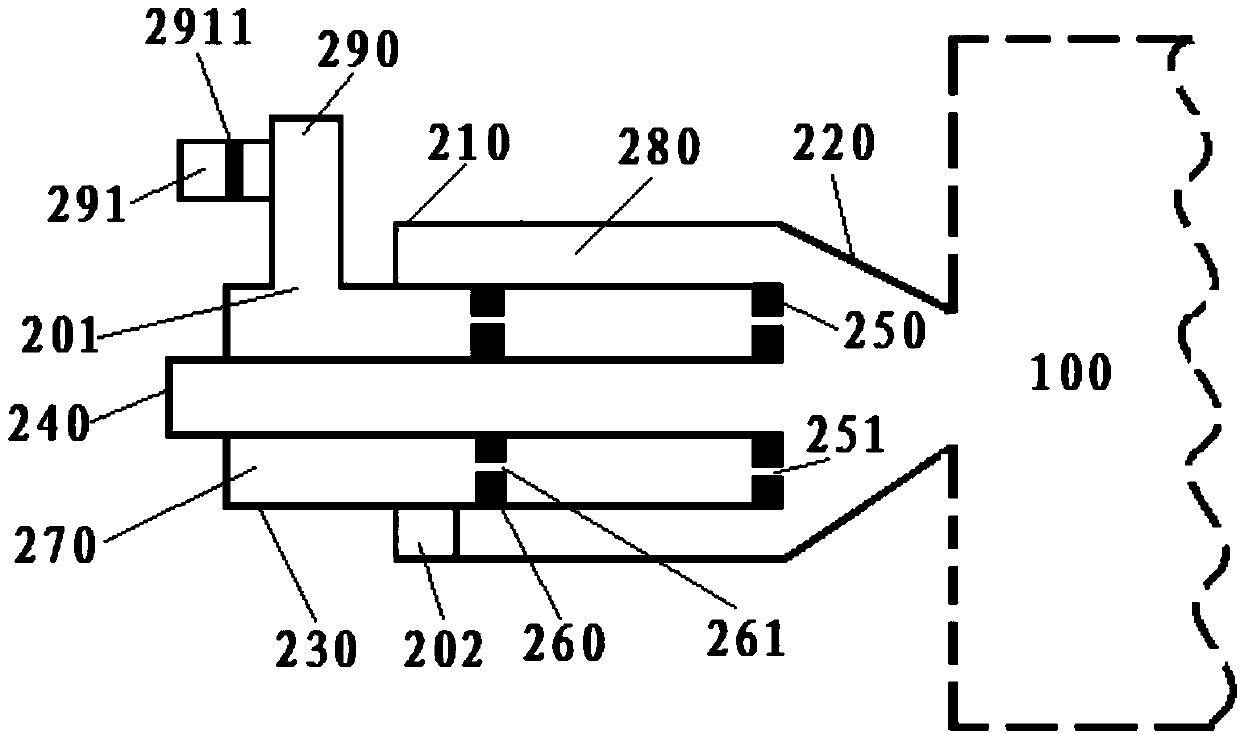

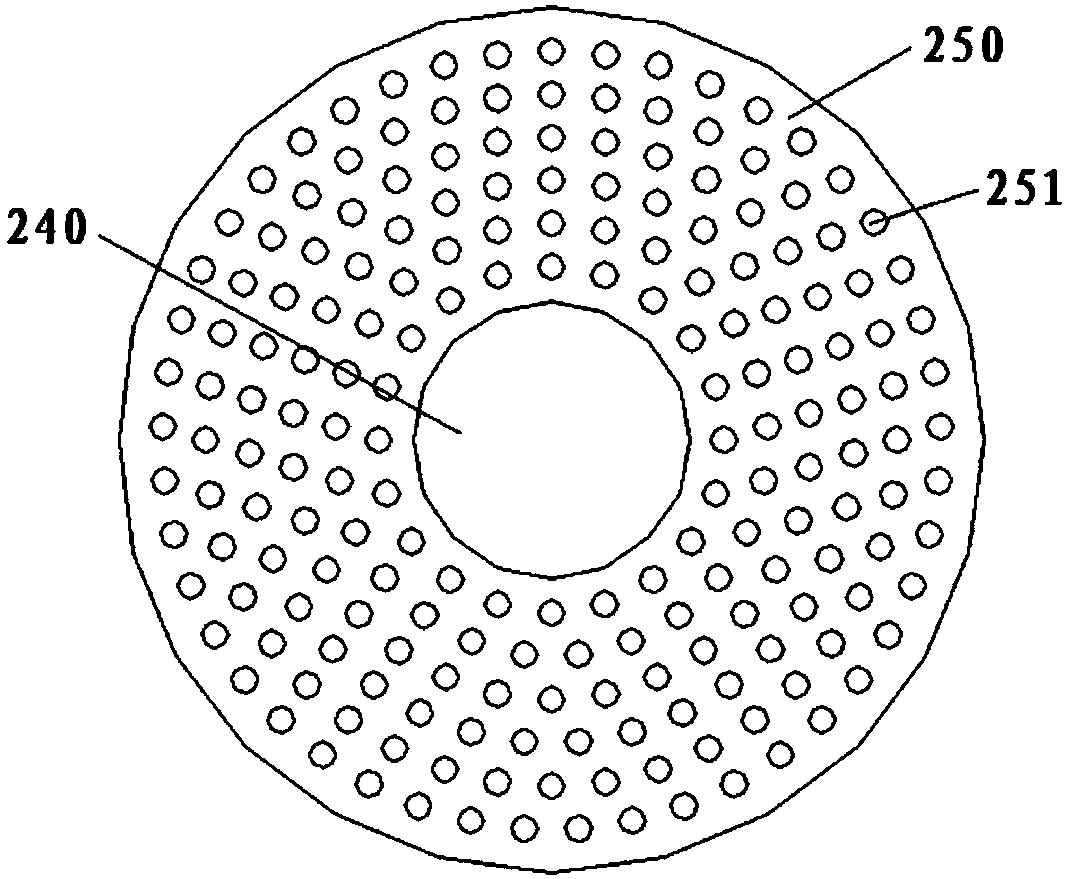

PendingCN107677137ABurn fullyPromote combustionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion systemCold air

The invention discloses an energy-saving and environment-friendly combustion system using flue gas for supporting combustion for an industrial furnace. The energy-saving and environment-friendly combustion system comprises a furnace body, a combustor and a heat exchanger, wherein the furnace body is provided with a first flue and a second flue; the combustor is provided with a first inlet and a second inlet; the heat exchanger is provided with a high-temperature flue gas inlet, a cold air inlet, a low-temperature flue gas inlet and a hot air inlet, the high-temperature flue gas inlet is connected with the first flue, the low-temperature flue gas inlet is connected with a chimney, the cold air inlet is connected with a first fan, the hot air inlet is connected with the first inlet of the combustor, and the second flue is connected with the second inlet; and the combustor comprises a central pipe, an inner barrel arranged outside the central pipe in a sleeving manner, an outer barrel arranged outside the inner barrel in a sleeving manner, and a circular-table-shaped mixing cavity connected between the outer barrel and the furnace body, the first inlet communicates with a first annular space formed between the outer wall of the central pipe and the inner wall of the inner barrel, and the second inlet communicates with a second annular space formed between the outer wall of the inner barrel and the inner wall of the outer barrel.

Owner:GUANGDONG UNIV OF TECH

Multifunctional energy-saving combustion system

PendingCN107490002AFully warmed upGood for low-oxygen combustionBurnersLiquid fuel feeder/distributionCombustion systemNitrogen oxides

The invention discloses a multifunctional energy-saving combustion system. The multifunctional energy-saving combustion system comprises a furnace body, an injector burner, a heat exchanger and a fuel vaporization device. The injector burner is installed on one side of the furnace body and connected with the furnace body. The injector burner communicates with an inner cavity of the furnace body. A smoke exhausting pipe is arranged on the furnace body. The smoke exhausting pipe is connected with the heat exchanger. The fuel vaporization device is connected with a suction inlet of the injector burner through a conveying pipe. A combustion-supporting duct is arranged and connected with an air inlet of the injector burner through the heat exchanger. The combustion-supporting duct is provided with a branch pipeline and is connected with the fuel vaporization device. The multifunctional energy-saving combustion system has the beneficial effects that sufficient combustion is achieved to release the highest heat value, high temperature and low oxygen combustion can be achieved, nitrogen oxide emission is effectively reduced, the combustion efficiency is increased, full combustion is achieved under the high temperature and a low oxygen state, and emission of over 50% of nitrogen oxide can be reduced.

Owner:北京中能天诚石油工程技术有限公司

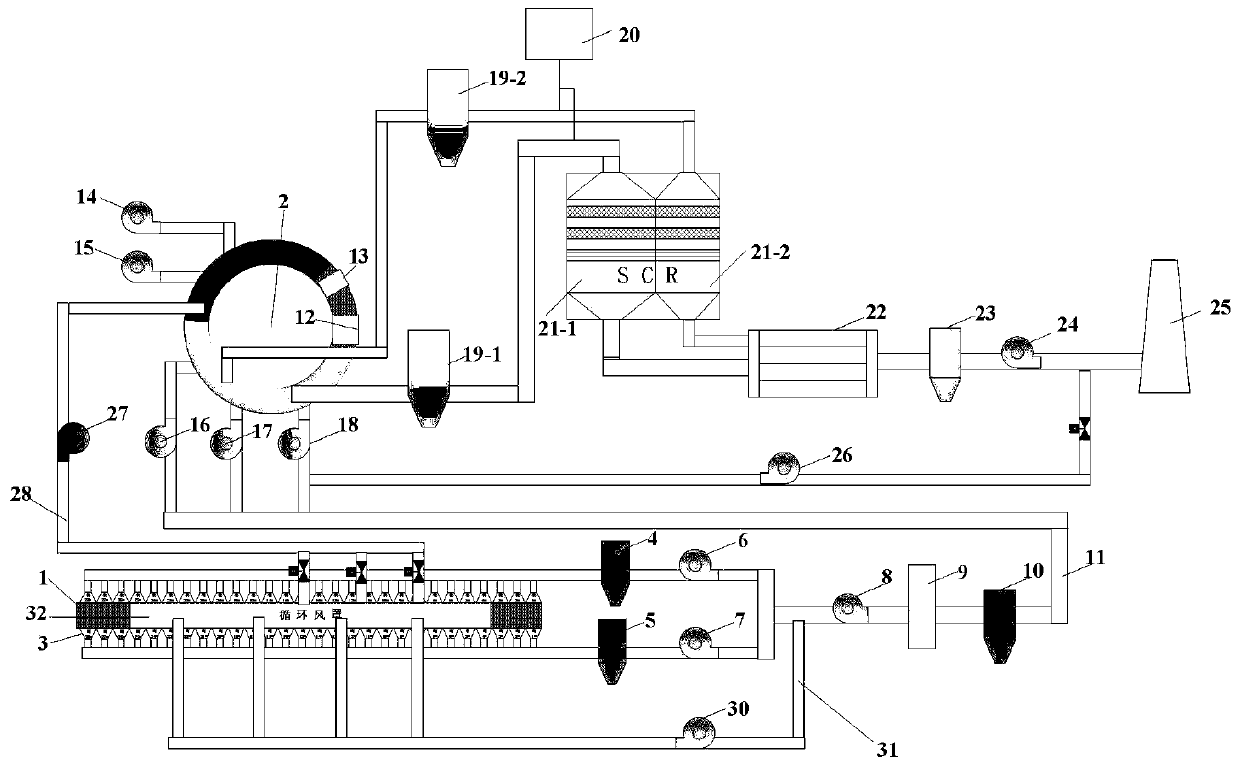

Sintering flue gas desulfurization and denitrification process

ActiveCN111203083AGuaranteed heat exchange effectLess quantityCombination devicesGas treatmentWaste heat recovery unitThermodynamics

The invention discloses a sintering flue gas desulfurization and denitrification process, belongs to the field of metallurgical industry, and solves the problems of large investment and high operationcost of the sintering flue gas desulfurization and denitrification process in the prior art. The method comprises the following steps that sintering flue gas of a sintering machine is divided into flue gas needing desulfurization and denitrification and circulating flue gas through a flue gas circulation process; flue gas to be desulfurized and denitrified is desulfurized after being desulfurizedand pressurized, and the desulfurized flue gas is subjected to dust removal; the dedusted flue gas is blown into the high-temperature section material layer of the circular cooler from an air blowerat the high-temperature section of the circular cooler to exchange heat with hot sinter for heating; the flue gas subjected to heat exchange and temperature rise is subjected to coarse dust removal and then enters a denitration reactor for denitration; the denitrated flue gas enters a waste heat recovery unit to be cooled, and the cooled flue gas is subjected to dust removal firstly and then is led out by an induced draft fan; and the led-out flue gas is directly discharged from a chimney. The process is low in cost, energy-saving and suitable for desulfurization and denitrification treatmentof sintering flue gas.

Owner:CENT IRON & STEEL RES INST +1

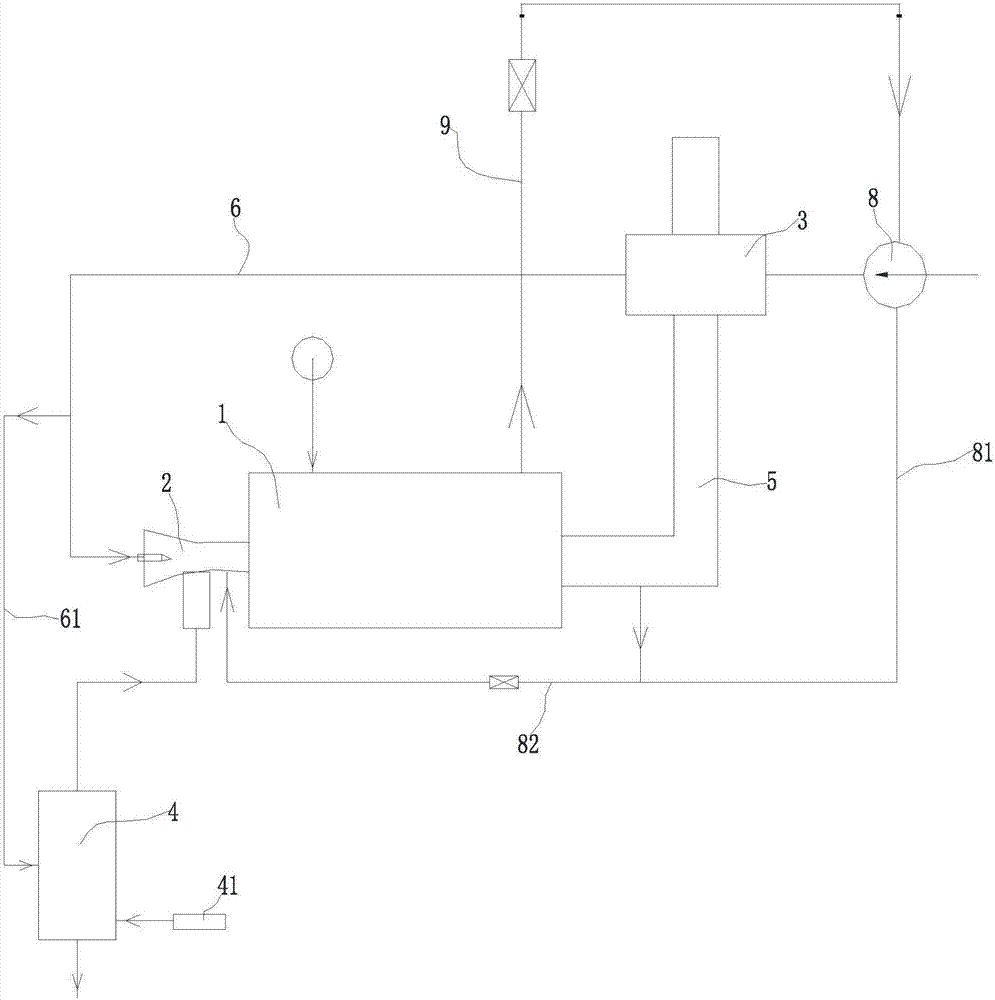

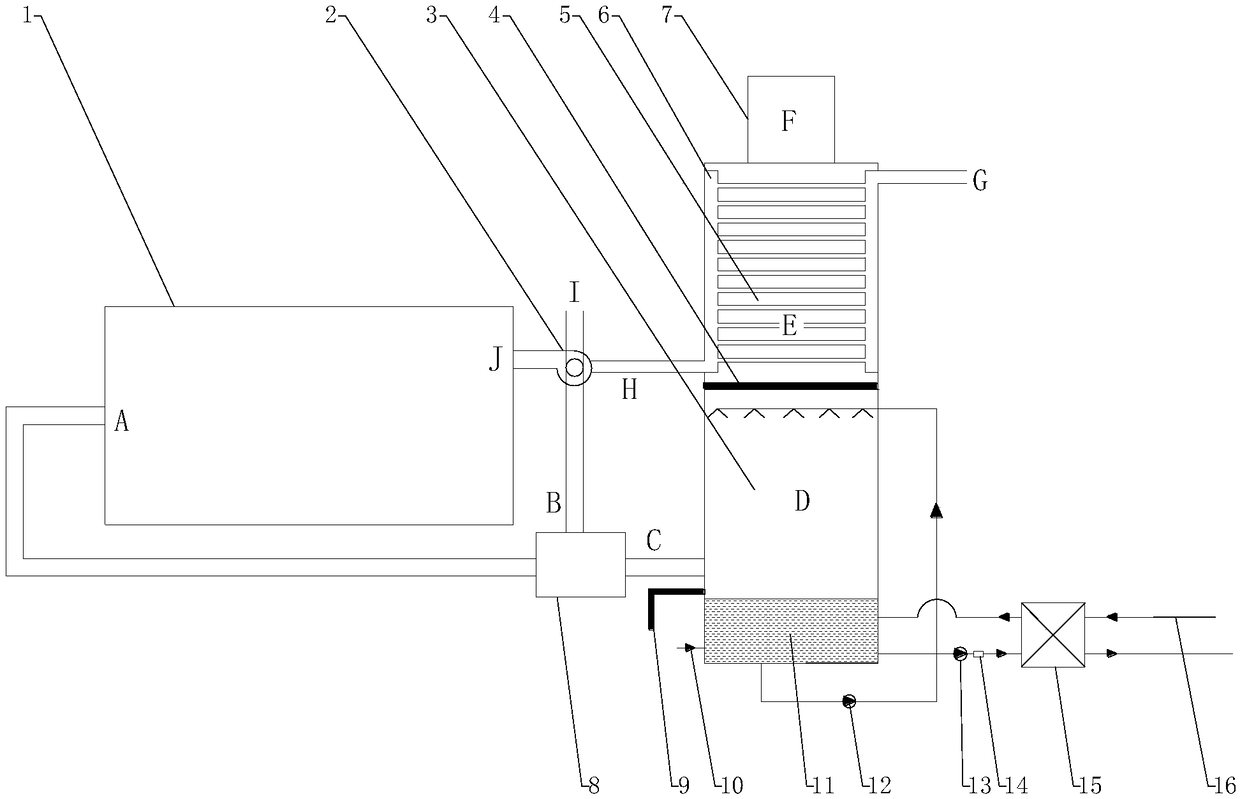

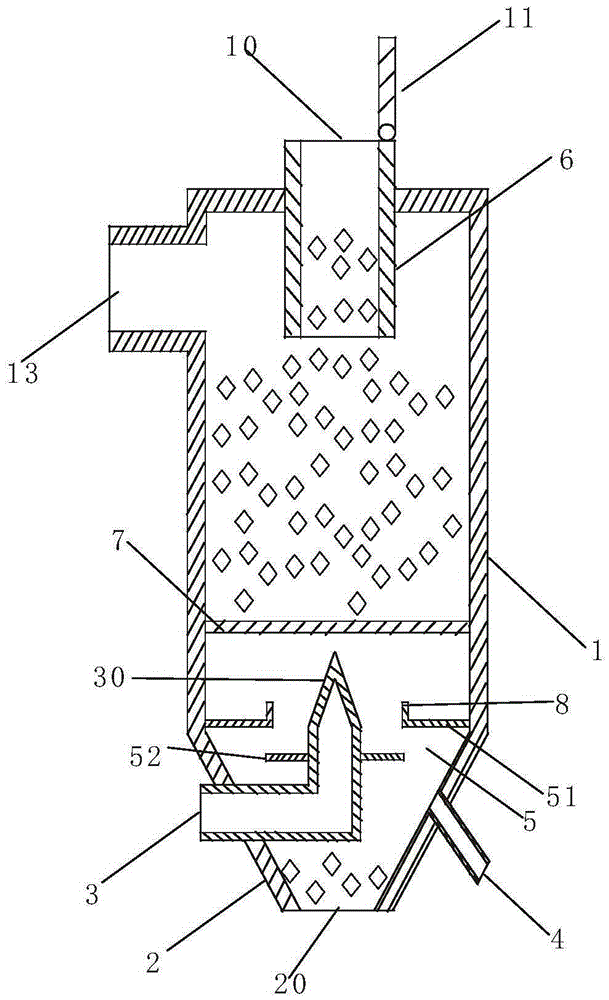

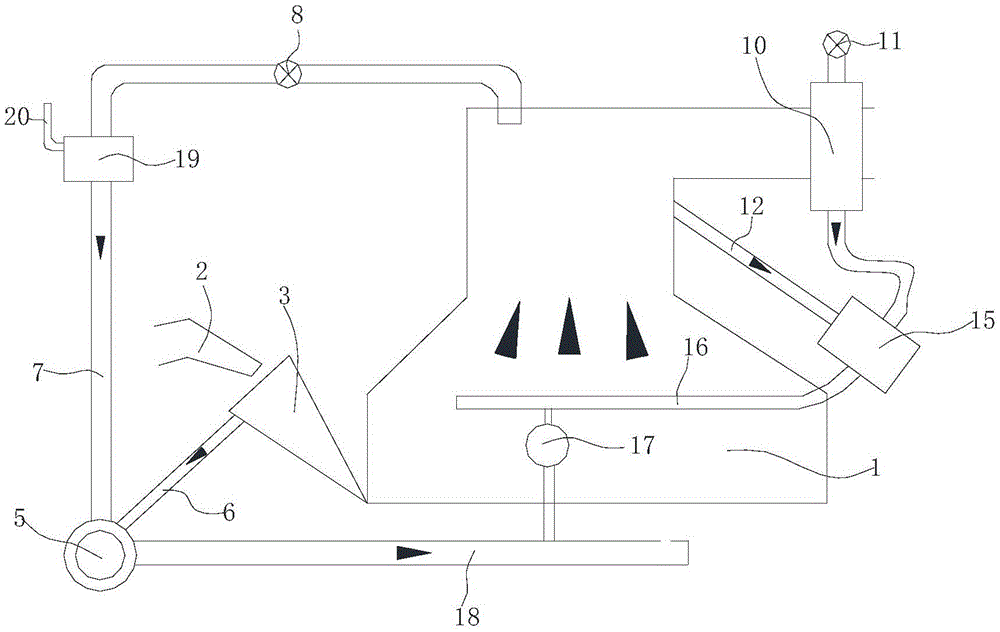

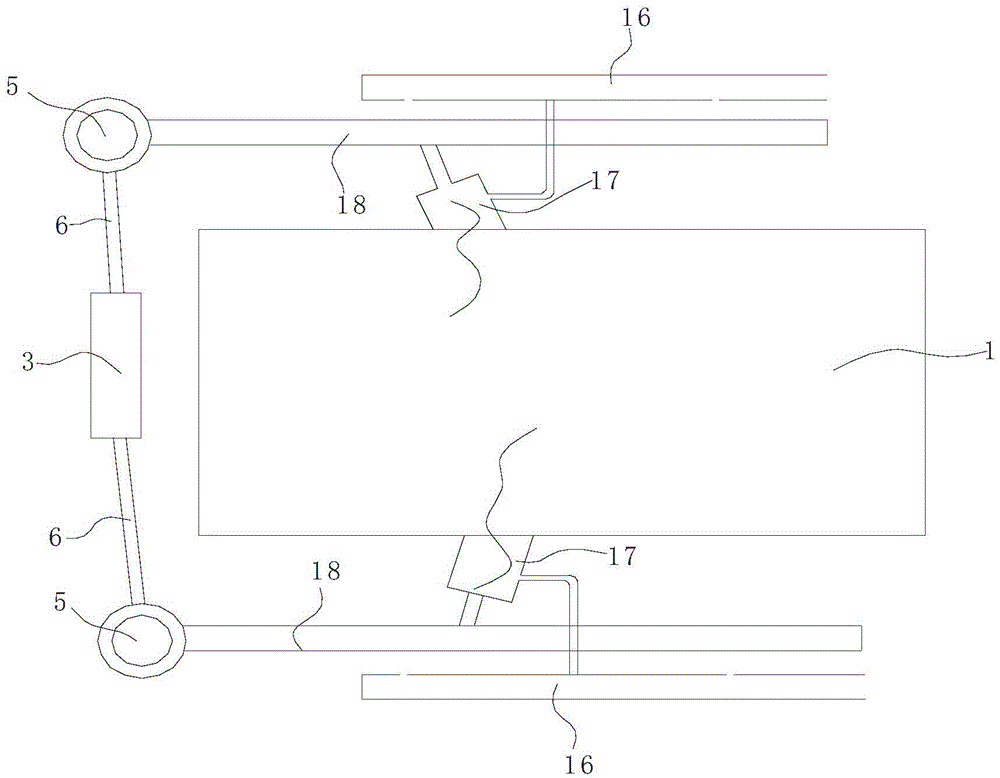

Gas boiler waste heat recovery and purification system based on membrane humidification

ActiveCN109268821ALower combustion temperatureAchieve depthIndirect carbon-dioxide mitigationCombustion apparatusLiquid storage tankHeat transfer

The invention discloses a gas boiler waste heat recovery and purification system based on membrane humidification, which belongs to the technical field of flue gas waste heat recovery and purification. The system comprises a membrane type spray heat and mass transfer tower 7 and a flue gas recirculation device 2. The flue gas recirculation device 2 is respectively connected with a boiler 1 and themembrane type spray heat and mass transfer tower 7, after flue gas A passes through a fan 8, recirculation flue gas B is supplied to a draught fan, the recirculation flue gas B, and fuel gas I and high-temperature high-humidity combustion air H are introduced into the boiler 1 after mixed to supply gas J for the boiler so as to reduce NOx; the membrane type spray heat and mass transfer tower 7 isvertically divided into a liquid storage tank 11, a flue gas-medium circulating water heat transfer segment 3 and a flue gas-air heat and mass transfer segment 5 from bottom to top so as to be used for recycling the total heat of the flue gas. The system realizes the recycle of the total heat of flue gas waste heat, improves the heat efficiency of the boiler, and reduces the NOx emission of the boiler through the humidification of combustion air and the recirculation of the flue gas.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

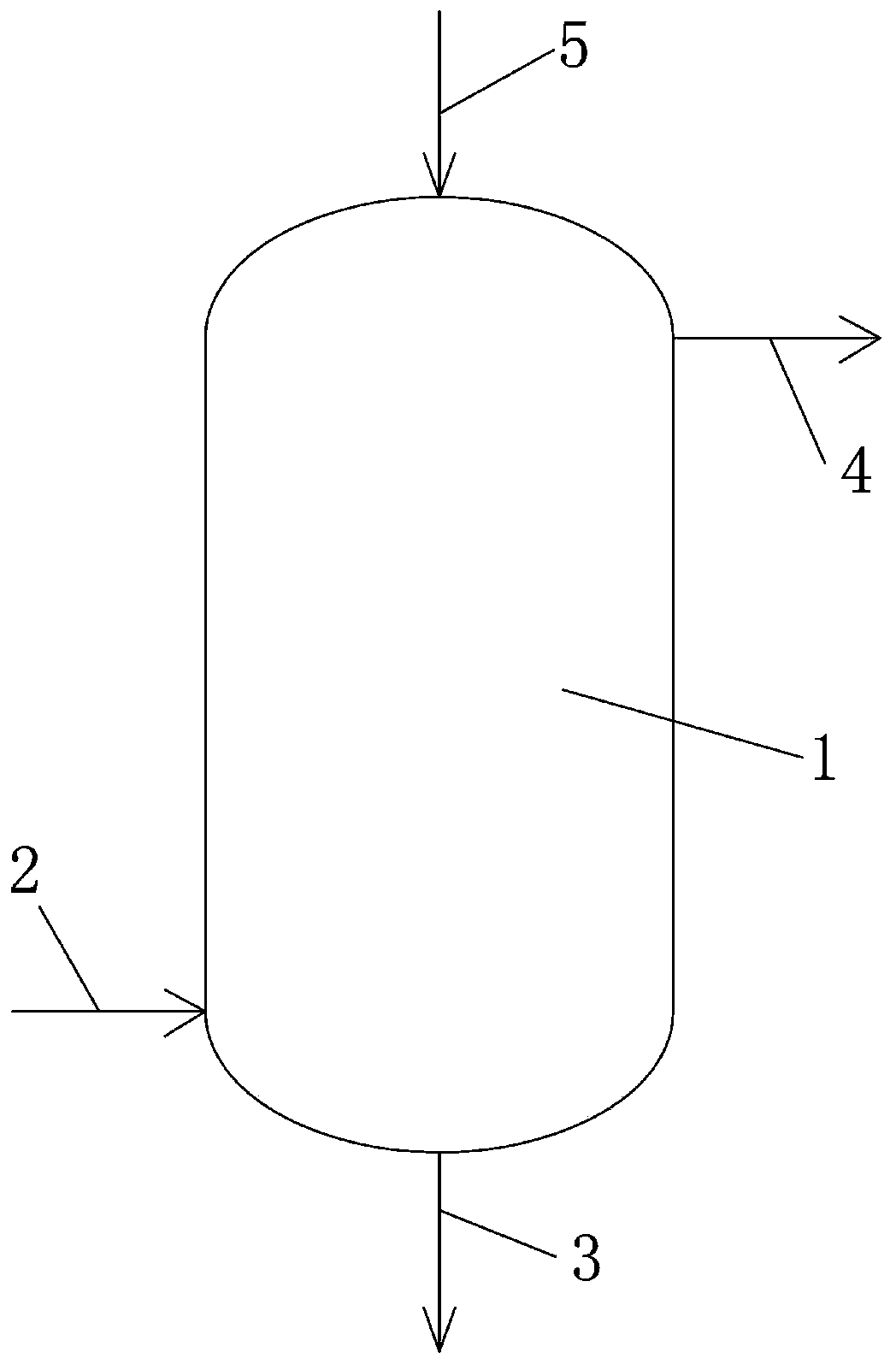

Dry desulfurization agent for ships, preparation method thereof, and ship dry desulfurization process

InactiveCN110711477AWith dust removal functionImprove desulfurization efficiencyGas treatmentDispersed particle separationCombustionFlue gas

The invention discloses a dry desulfurization agent for ships, a preparation method thereof, and a ship dry desulfurization process, and belongs to the technical field of ship dry desulfurization. Thepreparation method comprises the following steps: mixing a component A and a component B according to a certain ratio; uniformly mixing the component A and the component B, adding water accounting for 20-60% of the total amount of the component A and the component B, uniformly mixing all the components, carrying out extrusion molding to from strips, activating the molded product at 60-120 DEG C for 2-12 hours, and drying the molded product at 120-200 DEG C for 2-12 hours to obtain the dry desulfurization agent for ships. Ship flue gas is fed from the bottom of a moving bed dry desulfurizationreactor, the ship flue gas is desulfurized by a dry desulfurization agent in the moving bed dry desulfurization reactor, and the desulfurized ship flue gas enters a chimney or a heat exchange systemfrom the upper part of the moving bed dry desulfurization reactor to take heat again. A moving bed process is adopted, a certain dust removal function is achieved, dust generated by heavy oil combustion can be effectively eliminated, an existing flue gas system of a ship is slightly changed, the desulfurization efficiency is high and is 90% or above, stability is achieved, and the influence of external factors is small.

Owner:董红彭

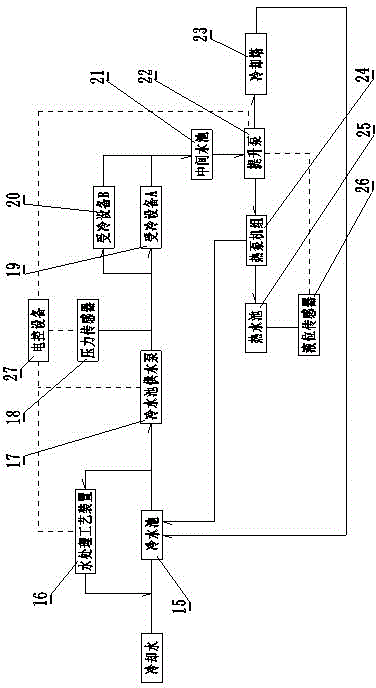

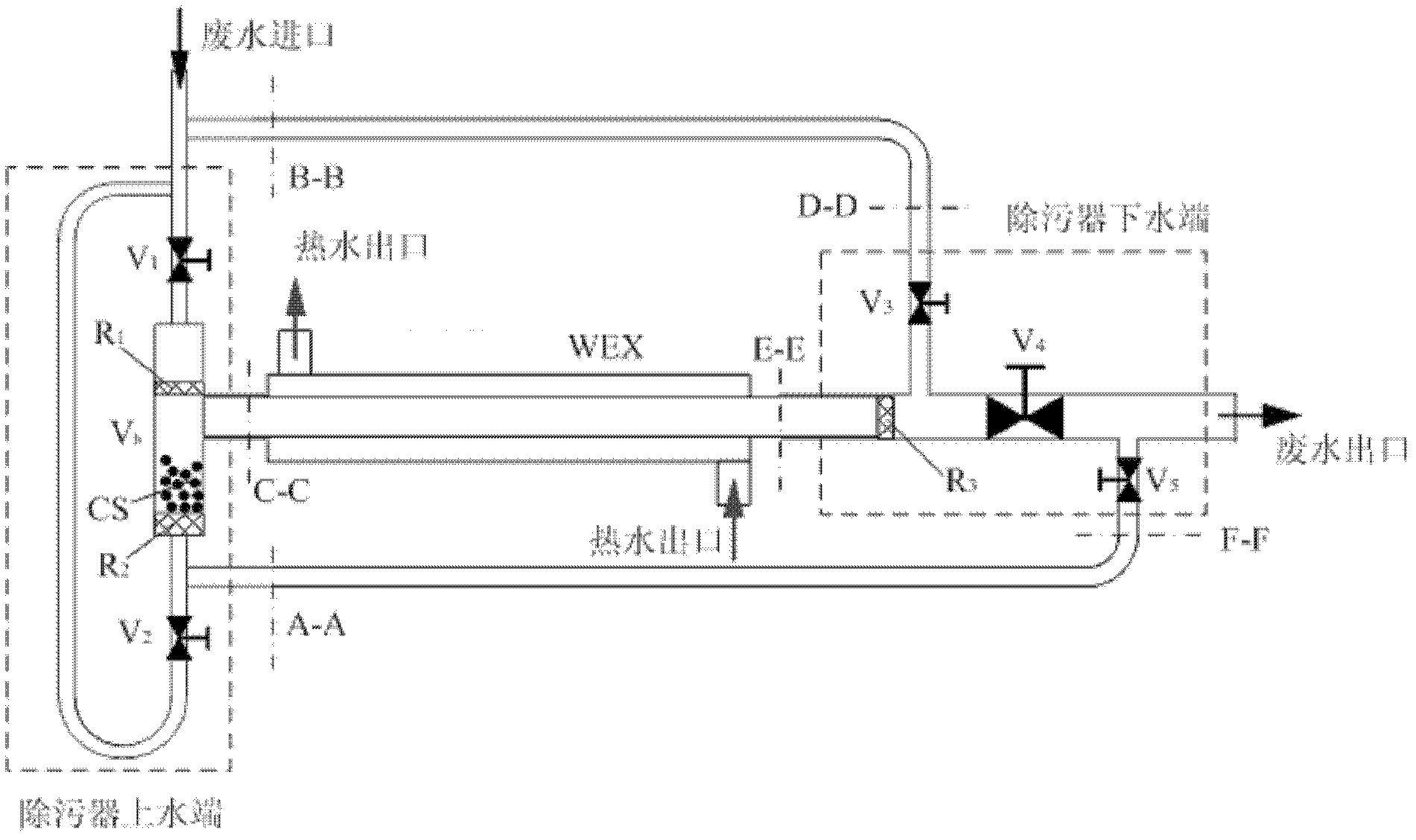

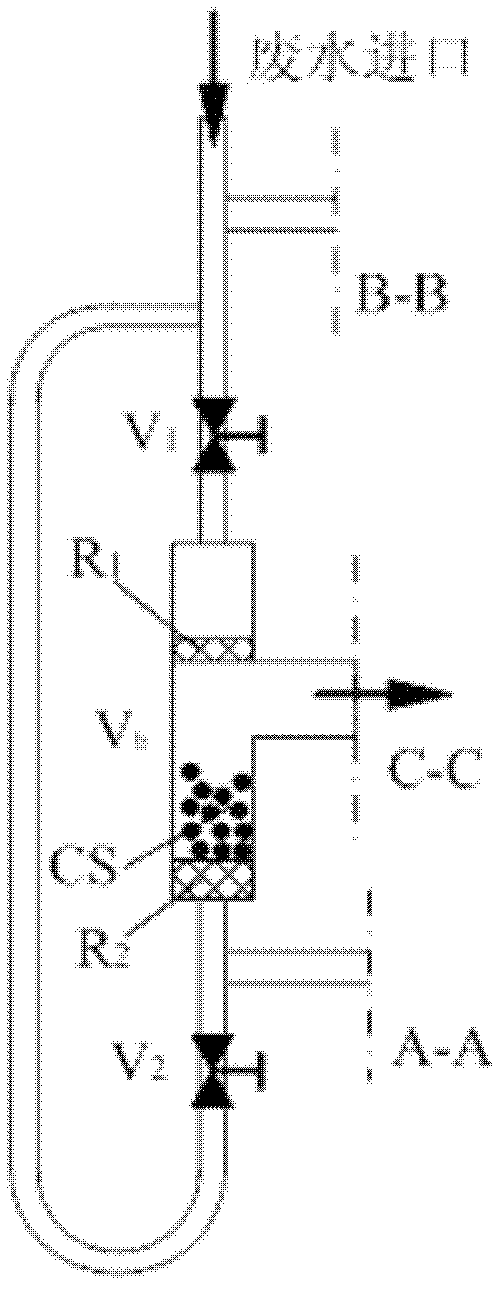

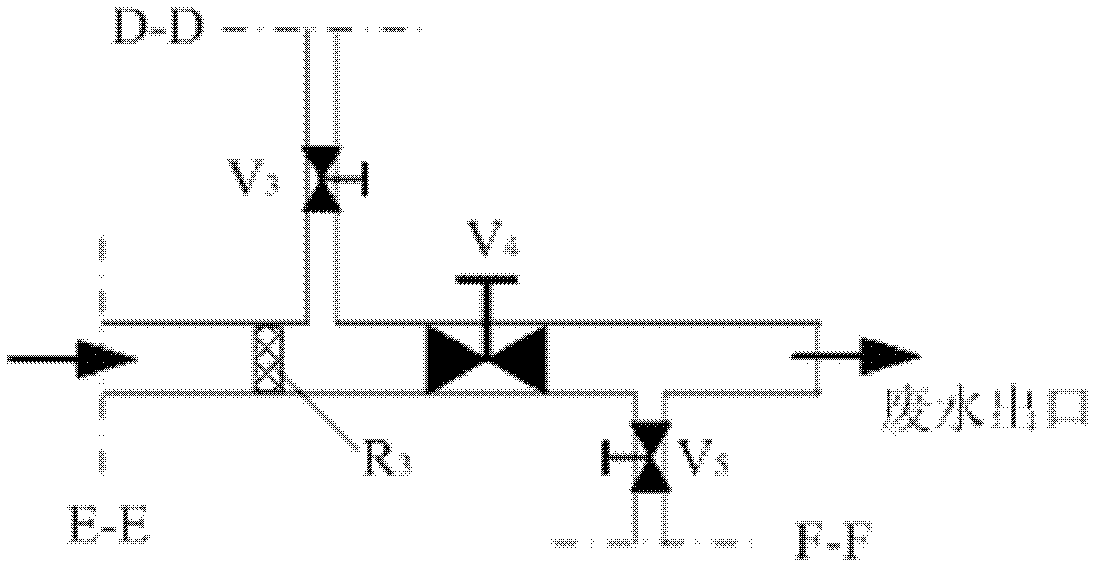

Decontamination system for wastewater heat exchanger

InactiveCN102564214AExtended service lifeImprove heat transfer effectNon-rotary device cleaningEngineeringReciprocating motion

The invention discloses a decontamination system for a wastewater heat exchanger, belonging to the technical field of energy utilization. A bypass pipeline at a wastewater inlet side of an upper water end of a system cleaner is communicated with a bypass pipeline at a wastewater inlet side of a lower water end of the cleaner, and a valve is mounted between the communicated pipelines. A bypass pipeline at a lower water side of the upper water end of the cleaner is communicated with a bypass pipeline at the lower water side of the lower water end of the cleaner, and a valve is mounted between the communicated pipelines. A bypass pipeline in the middle of the upper water end of the cleaner is communicated with a bypass pipeline in the middle of the lower water end of the cleaner, and a wastewater heat exchanger, a third filter and a valve are mounted between the communicated pipelines. According to the system disclosed by the invention, a decontaminating ball is driven by pushing of wastewater to do reciprocating motions in a wastewater channel in a pipe of the heat exchanger by opening the valves to realize relative pipeline switching, so as to remove a dirt layer on the inner wall of the pipe by colliding and rubbing the dirt layer on the inner wall of the pipe. Therefore, the dirt heat resistance of the heat exchanger is reduced to improve the heat exchange property of the wastewater heat exchanger.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Internal combustion engine driving heat pump fluidized bed drying device capable of recovering used heat

ActiveCN100392335CImprove drying efficiencyIncrease temperatureDrying solid materials with heatHearth type furnacesFluidized bed dryingExternal combustion engine

The present invention provides an internal combustion engine driven heat pump fluidized-bed drying equipment capable of recovering waste heat, belonging to the field of fluidized-bed drying technology. The heat pump condenser, heat-pump expansion valve, heat-pump evaporator and heat-pump compressor are successively connected and formed into the heat pump system. Said equipment also includes the following components: circulating fan, fluidized-bed drying chamber, cooling fan, dust collector and air pipe, etc.

Owner:汉广中药科技(天津)有限公司

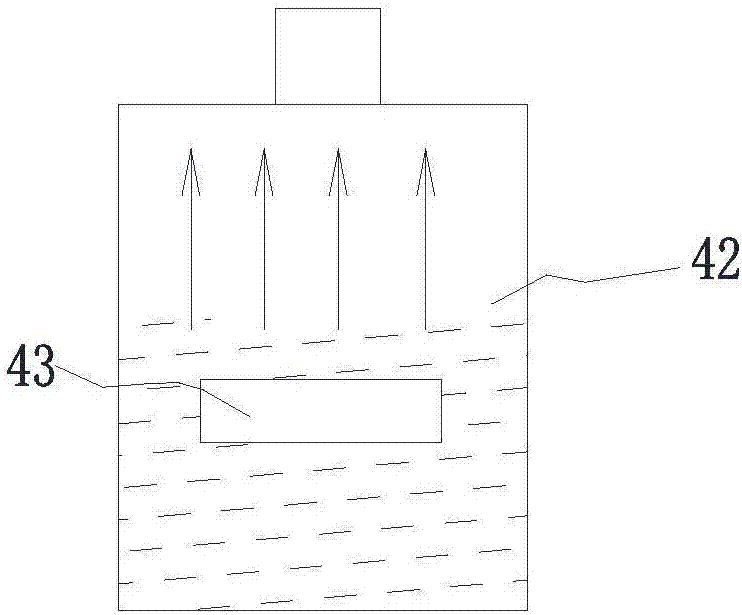

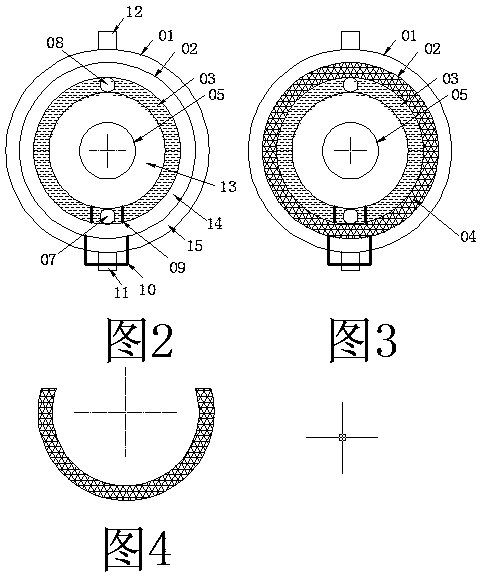

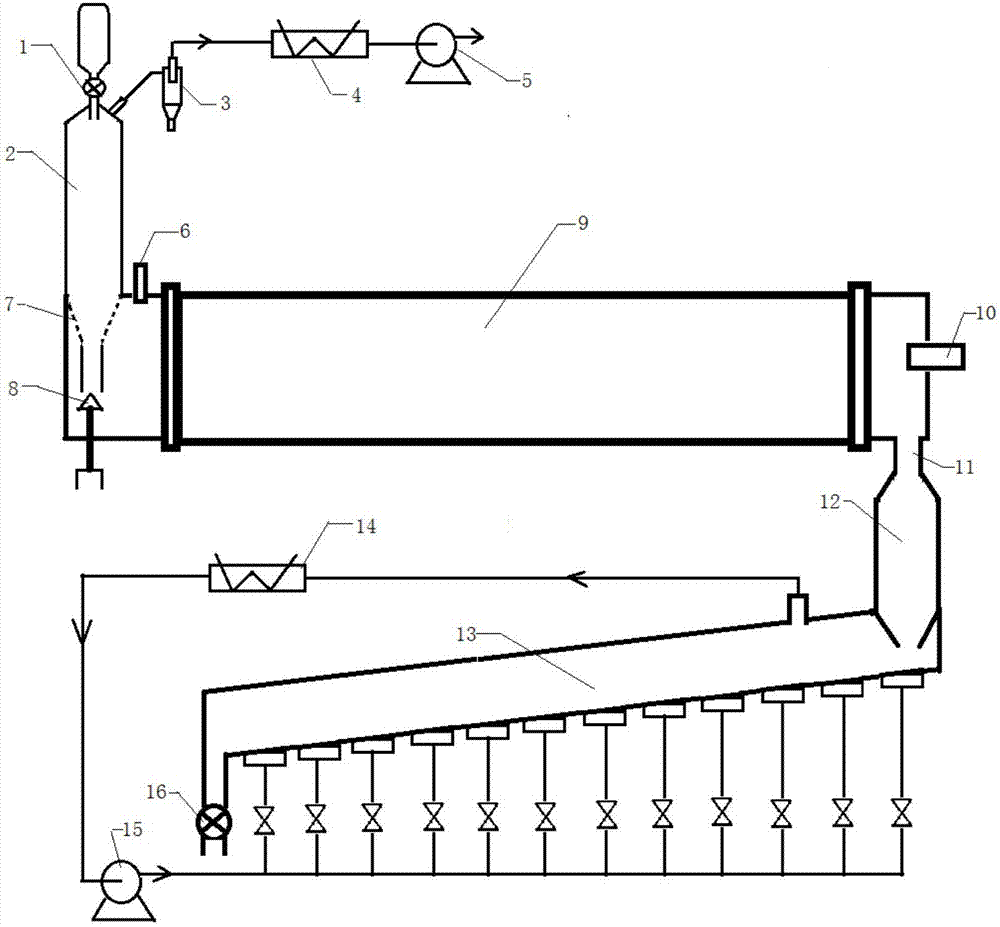

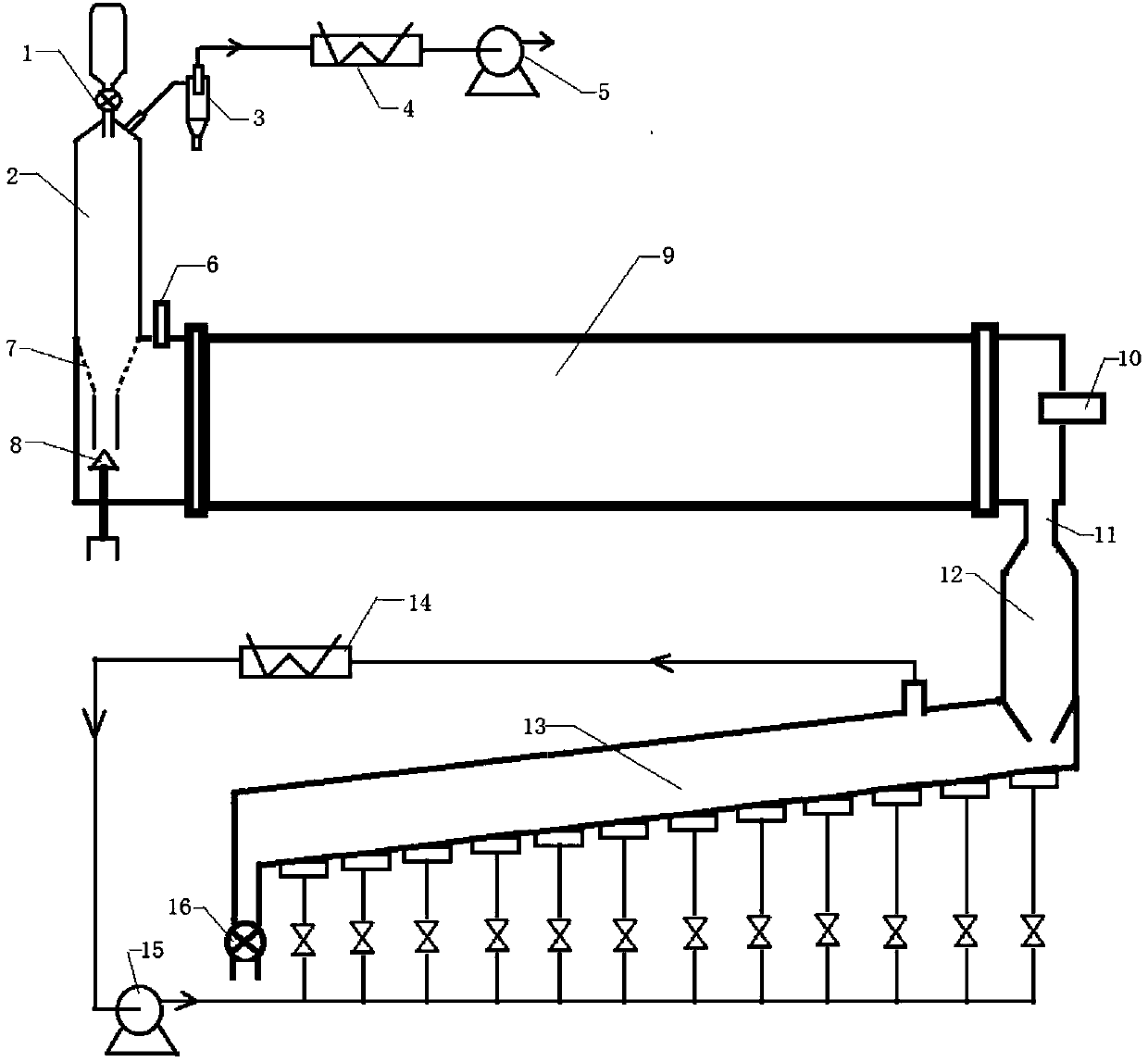

System for evaporation and concentration by using waste heat of dryer

ActiveCN106110685AImprove qualityQuality improvementEvaporators with heating coilsDrying solid materialsEvaporationTower

The invention relates to a system for evaporation and concentration by using waste heat of a dryer. The system comprises a first tube bank dryer, a second tube bank dryer and a third tube bank dryer which successively heat materials in series, the exhaust gas outlets of the tube bank dryers are respectively connected with the air inlets of a first cyclone dust collector, a second cyclone dust collector and a third cyclone dust collector, the air outlets of the first cyclone dust collector and the second cyclone dust collector are connected with the air inlet of a waste heat absorption tower, the air outlet in the top of the waste heat absorption tower is connected with the inlet of an absorption tower exhaust fan, a filler layer is arranged at the upper part of an inner cavity of the waste heat absorption tower, a liquid distributing tray is arranged above the filler layer, a water collecting tray is arranged at the bottom of the waste heat absorption tower, the drainage outlet in the bottom of the water collecting tray is connected with the inlet in the middle of a waste heat flash tank, the waste heat flash tank steam outlet in the top of the waste heat flash tank is connected with a flash steam pipe, the bottom of the waste heat flash tank is connected with the inlet of an absorption tower circulating pump, and the outlet of the absorption tower circulating pump is connected with a water replenishing pipe in the center of the liquid distributing tray. The system for the evaporation and concentration by using the waste heat of the dryer disclosed by the invention is high in utilization rate of the waste heat and good in concentration effect.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

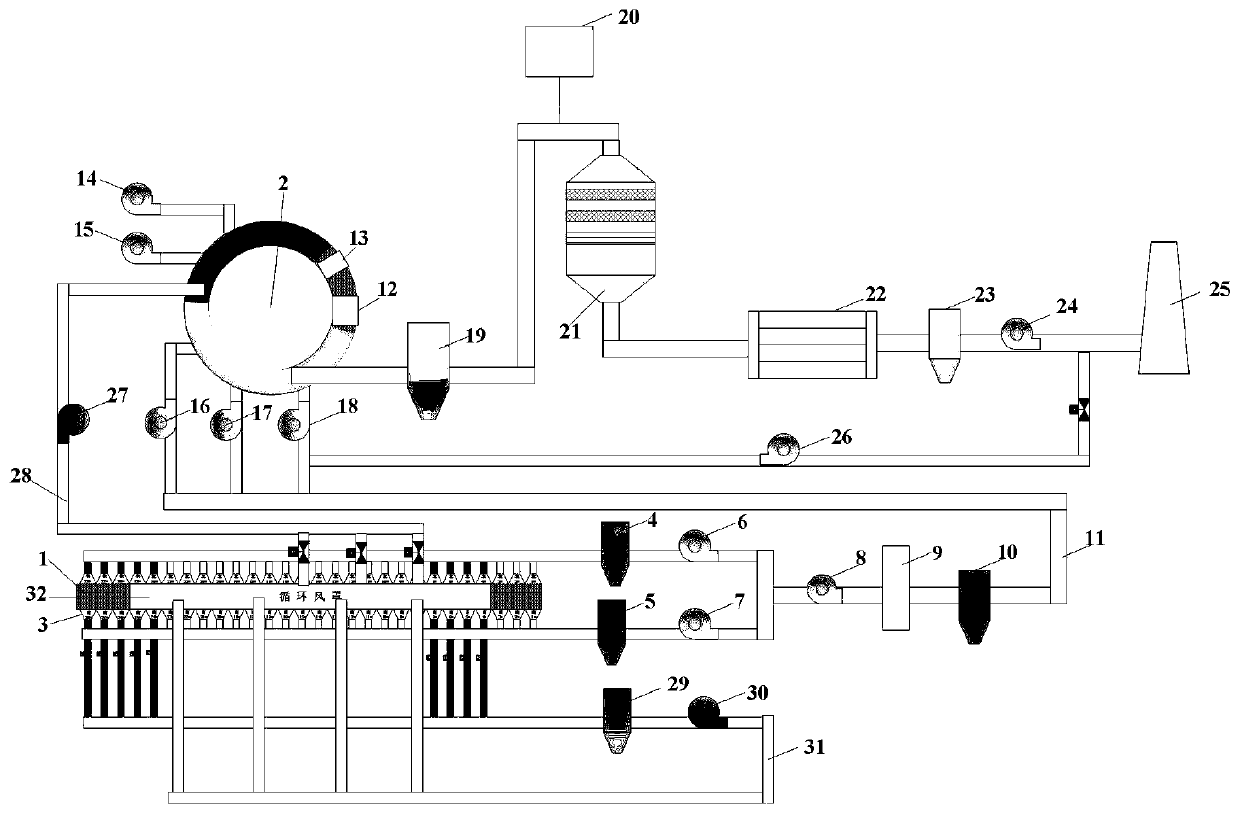

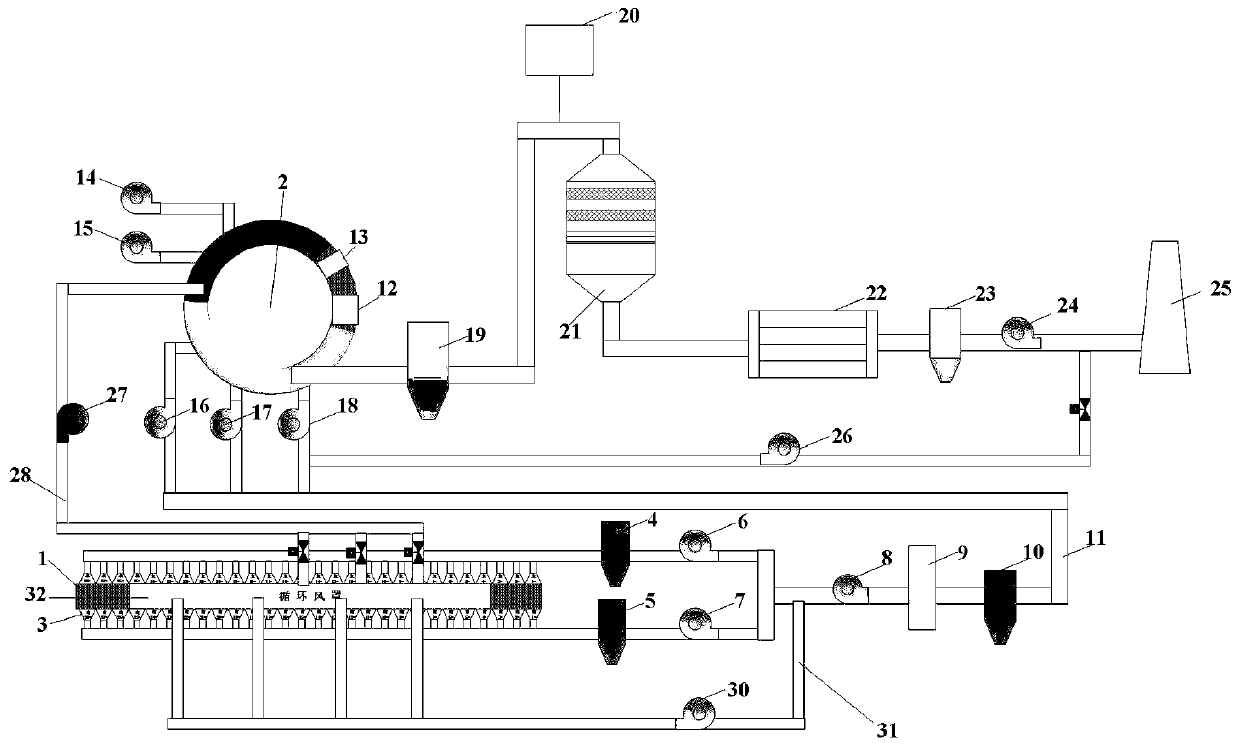

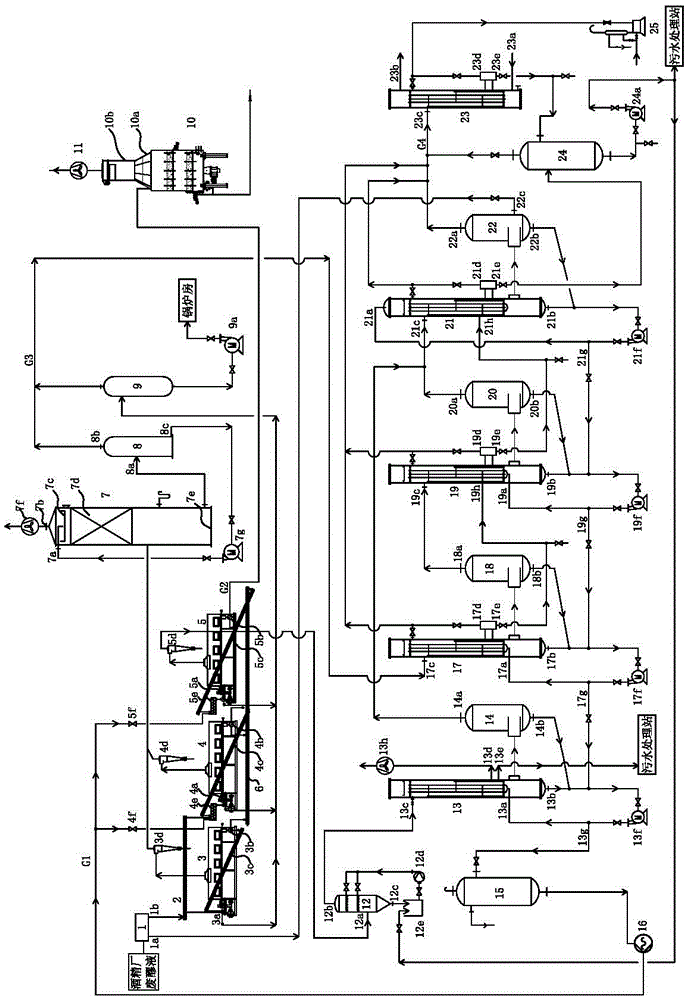

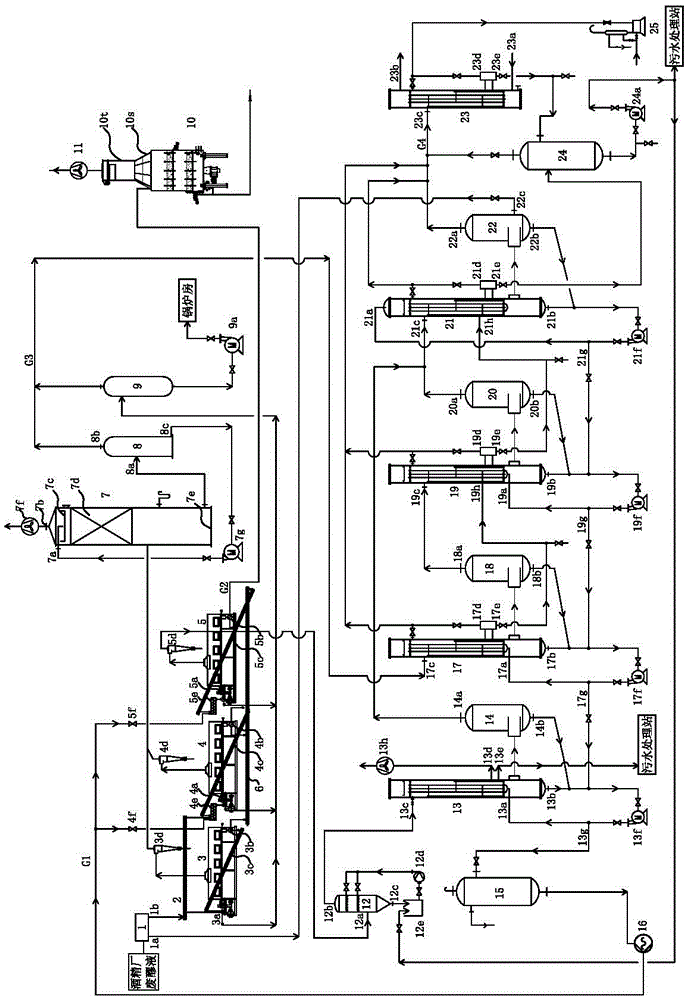

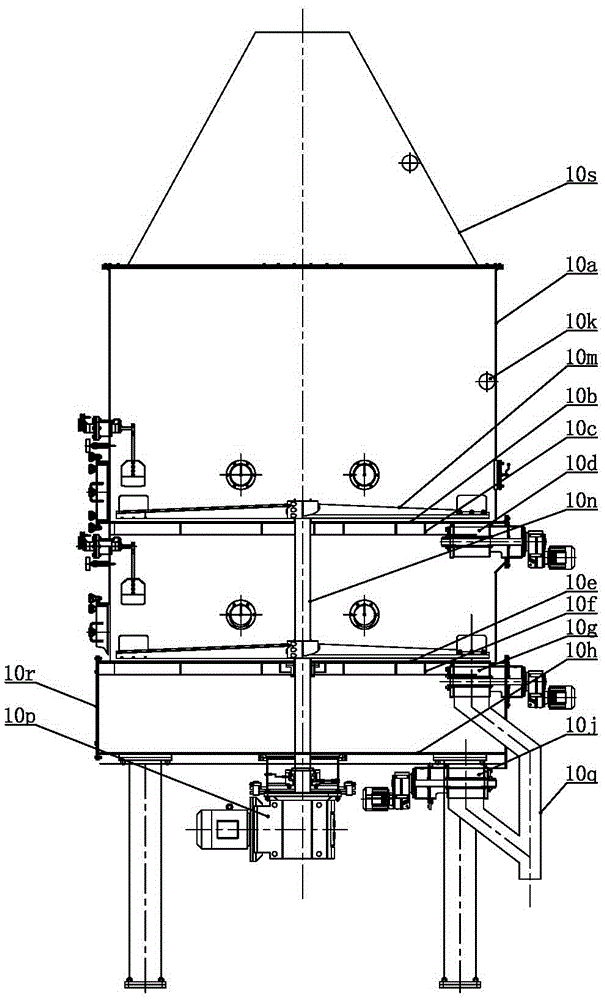

Production process of DDGS feed

ActiveCN106071109AImprove qualityConducive to waste heat recoveryFood processingAnimal feeding stuffExhaust gasChemistry

The invention relates to a production process of DDGS feed. The production process successively comprises the following steps: separating waste liquor of an alcohol plant into wet alcohol residues and clear liquid; concentrating the clear liquid into concentrated liquid; feeding the wet alcohol residues to a first tube bundle dryer, carrying out first-stage drying and controlling return ratio; after first-stage drying, carrying out first pulp adding by using the concentrated liquid; after mixing evenly, feeding into a second tube bundle dryer, carrying out second-stage drying and controlling return ratio; after second-stage drying, carrying out second pulp adding by using the concentrated liquid; after mixing evenly, feeding into a third tube bundle dryer, carrying out third-stage drying and controlling return ratio; defining alcohol residues discharged after third-stage drying as the DDGS feed; and cooling the DDGS feed in a multi-stage reverse flow cooling tower. High-quality tail gas of the first tube bundle dryer and the second tube bundle dryer and low-quality tail gas of the third tube bundle dryer are respectively subjected to dust removal and waste heat recycling, and the recycled heat is used for concentrating the clear liquid into the concentrated liquid step by step. The production process of the DDGS feed is low in steam and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

Multi-effect heater

PendingCN107816800AIncrease the heat exchange areaImprove thermal efficiencyWater heatersCombustorCombustion chamber

The invention discloses a multi-effect heater. The multi-effect heater is mainly composed of an outer shell, an inner shell, a water jacket, turbulent flow pieces and a combustion barrel which are combined in a sleeving mode from outside to inside; a fire outlet of a fire spraying combustor serving as a heat source is connected with the combustion barrel; an annular heat exchange cavity is formedbetween the outer shell and the inner shell; an annular tail gas cavity is formed between the inner shell and the outer wall of the water jacket, and the semicircular annular turbulent flow pieces which are staggered around the water jacket are arranged in the tail gas cavity; an annual gas cavity is formed between the inner wall of the water jacket and the combustion barrel; a liquid inlet, a liquid outlet and a vent hole are formed in the water jacket; a tail gas outlet is formed in the inner shell and penetrates out of the outer shell; and a heat exchange medium inlet and a heat exchange medium outlet are formed in the outer shell.

Owner:佛山市国能宏基投资有限公司

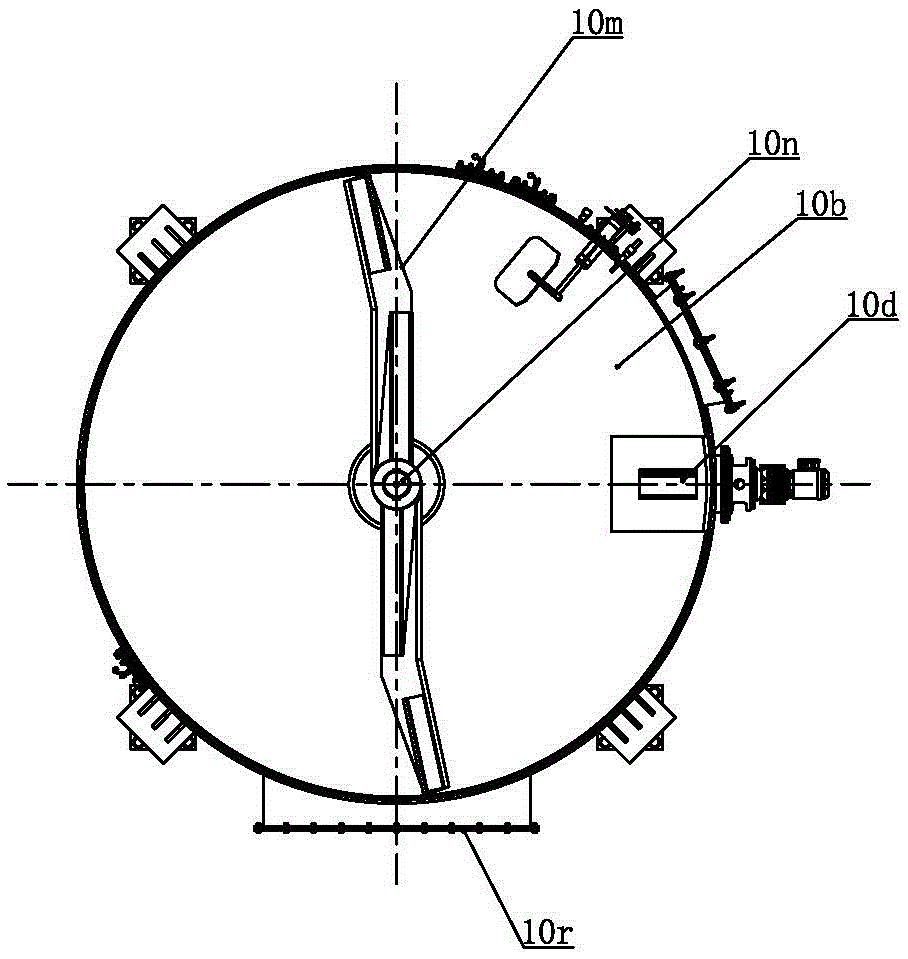

Process method and device for batch rectification of crude maleic anhydride

PendingCN110922370AHigh purityShort processOrganic chemistryDistillation regulation/controlThermodynamicsReboiler

The invention discloses a process method for batch rectification of crude maleic anhydride. The steam flow in the batch rectification process of crude maleic anhydride is stabilized. Crude anhydride is pumped into a standing tank through a pump, a reboiler is immersed in the standing tank, medium-pressure steam is used as a heat source, the gas phase of a refining tower enters a reflux tank afterbeing condensed by a tower top condenser, one part of the material in the reflux tank flows back, and the other part of the material in the reflux tank is collected out of a desorption tower or tank area. Heavy component residual anhydride in the standing tank is pumped out of the device, the overhead condenser uses hot water or other heat taking media to take heat. Except for entering the condenser, the other part of the heating medium passes through an auxiliary line and enters the heater after being converged, and the heater uses medium-pressure steam as a heat source. The flow of the heating medium is stabilized through the condenser auxiliary line regulating valve, the temperature is stabilized by heating the heated medium through steam of the heater, the effect of stabilizing the steam usage amount of the whole refining tower is achieved, the flow and the temperature of the heating medium are stable and waste heat recovery of the heating medium is facilitated.

Owner:HUIZHOU YUXIN NEW MATERIALS CO LTD

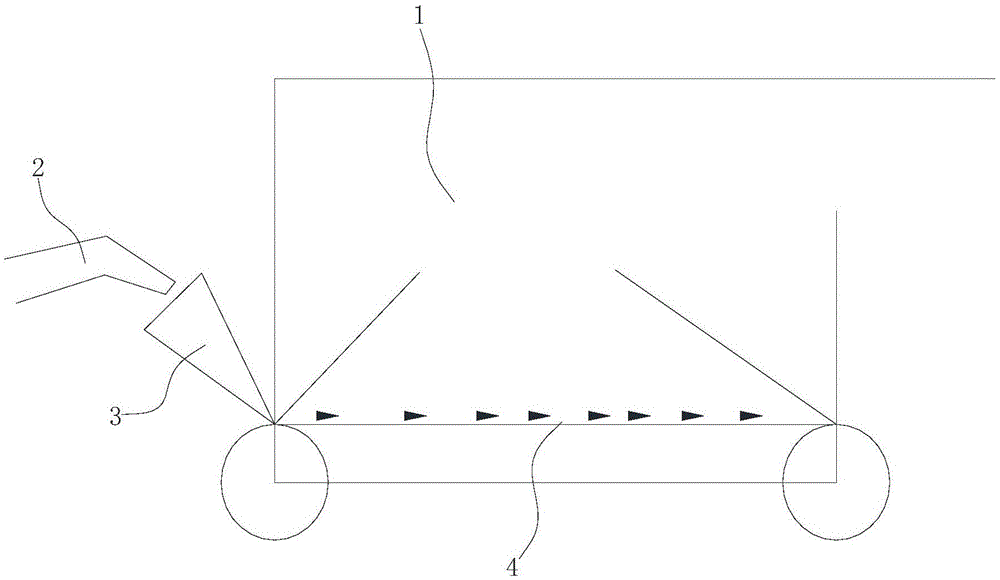

Low-oxygen low-nitrogen combustion system for coal-fired chain grate boiler

InactiveCN105546517AImprove combustion efficiencyConducive to waste heat recoverySolid fuel combustionLump/pulverulent fuel preparationProcess engineeringLow nitrogen

The invention discloses a low-oxygen low-nitrogen combustion system for a coal-fired chain grate boiler. The low-oxygen low-nitrogen combustion system comprises a hearth, combustion cylinders, a fan coal mill and a fuel conveying pipe. A partition plate is arranged in the hearth and partitions the hearth into a combustion region and a heat absorption region. The partition plate is provided with at least one heat conducting passageway so that the combustion region can communicate with the heat absorption region. The two opposite side walls of the hearth are each provided with one combustion cylinder. The combustion cylinders communicate with the hearth. The heat absorption region is provided with an opening connected with a first smoke lead-in pipe. The first smoke lead-in pipe is connected with the fan coal mill. The fan coal mill is connected with a raw coal input pipe. An output opening of the fan coal mill is connected with the combustion cylinders through the fuel conveying pipe. The low-oxygen low-nitrogen combustion system for the coal-fired chain grate boiler has the following beneficial effects that complete combustion can be achieved, and the highest calorific power can be released; raw coal combustion acceleration is facilitated, the burnout rate is increased, and waste heat recovery is facilitated; and complete combustion of raw coal can be guaranteed, and meanwhile emission of nitrogen oxide can be reduced by over 30%.

Owner:董龙标

Waste heat recovery furnace

ActiveCN104121786BEfficient recyclingReduce dosageEnergy industryWaste heat treatmentRecovery boilerWaste management

The invention provides a waste heat recycling furnace. According to the waste heat recycling furnace, waste heat of sintered ore can be sufficiently and efficiently recycled. The waste heat recycling furnace comprises a cooling cylinder. A feeding opening is formed in the upper surface of the cooling cylinder, a sealing cover for sealing the feeding opening is arranged on the feeding opening, an air outlet is formed in the upper end of the side wall of the cooling cylinder and connected with an induced draft fan, a conical cold feeder is connected to the lower end of the cooling cylinder, a discharging opening is formed in the lower end of the cold feeder, a vibration discharging machine is installed in the discharging opening, a center cooling air pipe extending to the center of the cooling cylinder is installed on the waste heat recycling furnace, a conical center air cap with the upward top end is connected to the upper end of the center cooling air pipe, a plurality of air holes are formed in the conical wall of the center air cap, one or more peripheral cooling air pipes are formed on the conical wall of the cold feeder in the mode of surrounding the conical wall, a discharging mechanism is arranged between the cooling cylinder and the cold feeder and comprises an upper discharging plate and a lower discharging plate, and the upper discharging plate and the lower discharging plate can be opened and closed and can achieve discharging through reciprocating movement.

Owner:TIANJIN ZHENGYUANHE TECH DEV CO LTD

Energy-saving and environment-friendly combustion system of layer-burning boiler

InactiveCN105546522AImprove combustion efficiencyConducive to waste heat recoveryCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelProcess engineeringCoal

The invention discloses an energy-saving and environment-friendly combustion system of a layer-burning boiler. The energy-saving and environment-friendly combustion system comprises a hearth, a combustion cylinder, a fan coal mill and a fuel conveying pipe, wherein at least one combustion cylinder is arranged on the side wall of the hearth, and the combustion cylinder connects and communicates with the hearth; an opening is formed in the upper part of the hearth and is connected with a first smoke inlet guide pipe; the first smoke inlet guide pipe is connected with the fan coal mill; the fan coal mill is connected with a raw coal input pipe; and the output opening of the fan coal mill is connected with the combustion cylinder through the fuel conveying pipe. The energy-saving and environment-friendly combustion system has the advantages that the low-oxygen combustion of coal powder can be facilitated, sufficient combustion can be ensured, and the highest heat value is released; the acceleration of coal powder combustion is facilitated, the burn-off rate is improved, and the recycling of residual heat is facilitated; and full coal powder combustion can be ensured, and at the same time, the emission of more than 40% of nitric oxide can be reduced.

Owner:GUANGDONG UNIV OF TECH

Production process for preparing calcium carbide from calcium coke pellets in graded oxygen heating mode

ActiveCN107089661AReduce difficulty of useReduce processing difficultyEnergy inputCalcium carbideThermal insulationUranium carbide

The invention discloses a production process for preparing calcium carbide from calcium coke pellets in a graded oxygen heating mode. The production process comprises the steps that the calcium coke pellets with the particle size being 5 to 30 mm are added into a moving bed preheater through a feeder, are subjected to counterflow heat exchange with air combustion flue gas rising from the bottom to reach 600 to 1300 DEG C in temperature, and then flow into a kiln tail of a rotary kiln reactor under control of a plug valve at the bottom of the preheater; the hot calcium coke pellets are heated to 1400 to 1900 DEG C by coke powder and oxygen high-temperature flames blown by a kiln head in a rotary kiln with the inclination being 1.5 to 10 degrees and the rotating speed being 2.0 to 5.0 rpm, reaction is conducted to generate the calcium carbide and exhaust CO, and high-temperature reaction gas containing CO and H2 reversely flows to the kiln tail to be combined with the added air and coke powder for combustion to generate air combustion flue gas used for preheating; after flowing into a thermal insulation moving bed from a kiln outlet to be subjected to reinforced reaction for 5 to 90 minutes, the generated calcium carbide flows into a fine-toothed cooler from the bottom of the thermal insulation moving bed to be cooled to 100 DEG C or below to serve as a product, and heated inert gas is subjected to heat recovery and then pressurized and circulated back into the fine-toothed cooler for adsorbing heat; and air combustion gas at the top of the moving bed after exchange is subjected to heat recovery through an afterburning waste boiler and then exhausted out by an induced draft fan.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

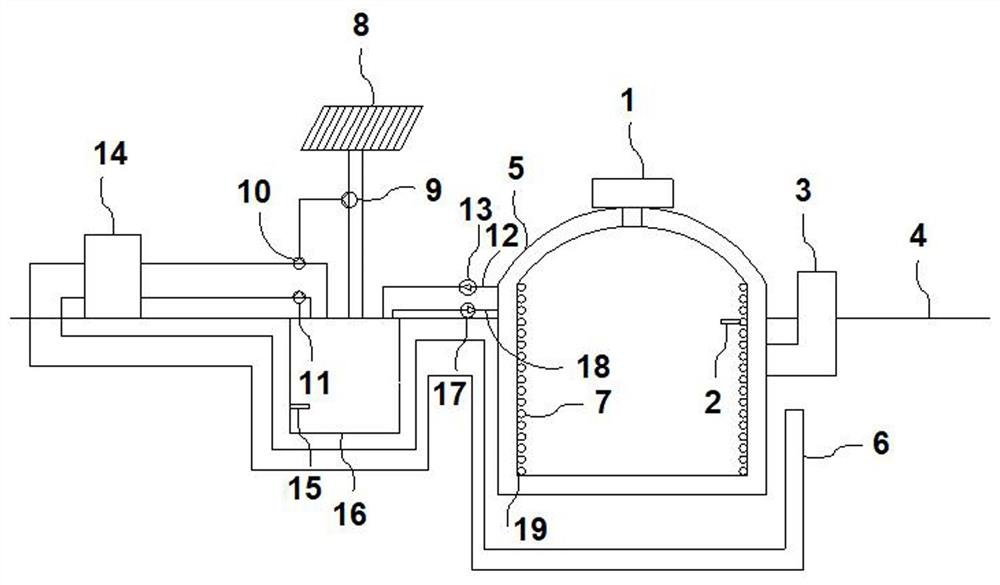

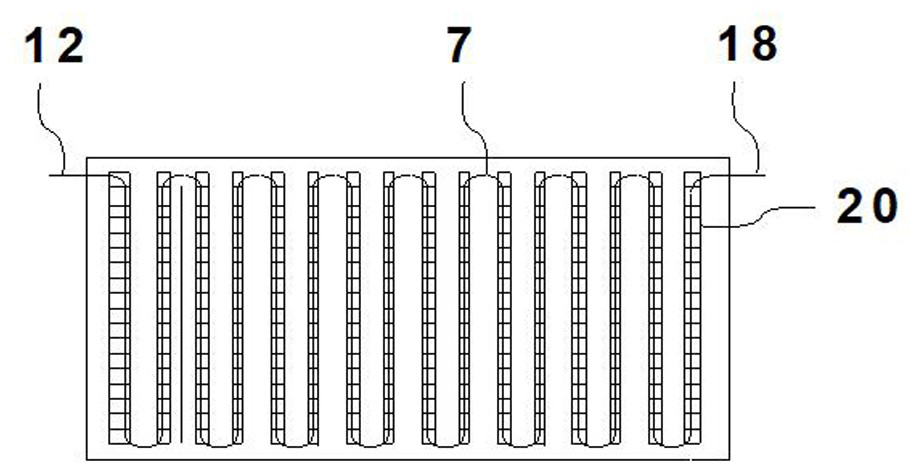

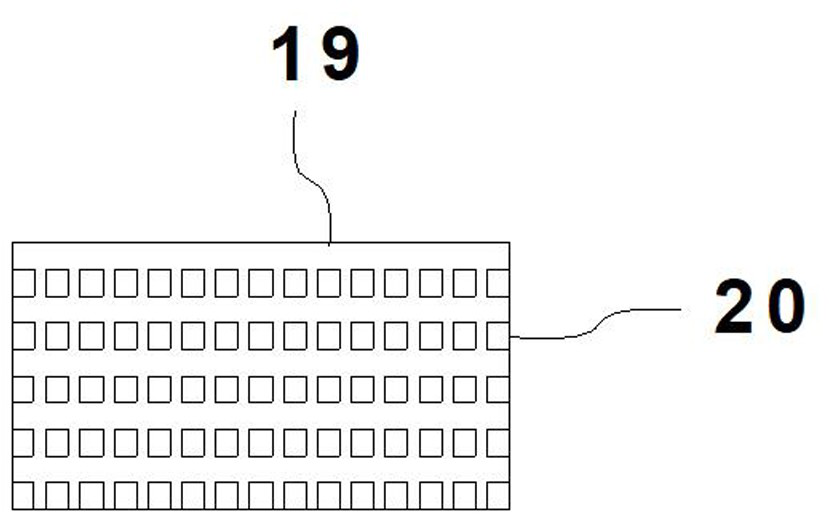

Energy-saving biogas fermentation tank heating constant-temperature equipment and using method thereof

PendingCN112662530AImprove transfer efficiencyGentle temperature fluctuationsBioreactor/fermenter combinationsBiological substance pretreatmentsCapillary networkCapillary Tubing

The invention relates to an energy-saving biogas fermentation tank heating thermostat and a using method thereof. The energy-saving biogas fermentation tank heating thermostat comprises a fermentation tank (5), a solar heat collector (8), a ground source heat pump (14), a heat preservation water tank (16) and a control module. A working medium outlet of the heat preservation water tank (16) is communicated with a working medium inlet of the capillary network heat exchanger (7); a working medium outlet of the capillary network heat exchanger (7) is communicated with a working medium inlet of the heat preservation water tank (16); a working medium outlet of the ground source heat pump (14) is communicated with a working medium inlet of the heat preservation water tank (16); a working medium outlet of the heat preservation water tank (16) is communicated with a working medium inlet of the ground source heat pump (14) through a ground source heat pump inlet numerical control valve (10); and a working medium outlet of the solar heat collector (8) is communicated with a working medium inlet of the heat preservation water tank (16) through a solar heat collector numerical control valve (9). The invention has the advantages of low energy consumption, low cost, high heat transfer efficiency, and uniform and stable temperature adjustment of each part in the tank.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A kind of calcium coke pellets graded oxygen thermal method to produce calcium carbide production process

ActiveCN107089661BReduce difficulty of useReduce processing difficultyEnergy inputCalcium carbideCombustionFlue gas

The invention discloses a production process for preparing calcium carbide from calcium coke pellets in a graded oxygen heating mode. The production process comprises the steps that the calcium coke pellets with the particle size being 5 to 30 mm are added into a moving bed preheater through a feeder, are subjected to counterflow heat exchange with air combustion flue gas rising from the bottom to reach 600 to 1300 DEG C in temperature, and then flow into a kiln tail of a rotary kiln reactor under control of a plug valve at the bottom of the preheater; the hot calcium coke pellets are heated to 1400 to 1900 DEG C by coke powder and oxygen high-temperature flames blown by a kiln head in a rotary kiln with the inclination being 1.5 to 10 degrees and the rotating speed being 2.0 to 5.0 rpm, reaction is conducted to generate the calcium carbide and exhaust CO, and high-temperature reaction gas containing CO and H2 reversely flows to the kiln tail to be combined with the added air and coke powder for combustion to generate air combustion flue gas used for preheating; after flowing into a thermal insulation moving bed from a kiln outlet to be subjected to reinforced reaction for 5 to 90 minutes, the generated calcium carbide flows into a fine-toothed cooler from the bottom of the thermal insulation moving bed to be cooled to 100 DEG C or below to serve as a product, and heated inert gas is subjected to heat recovery and then pressurized and circulated back into the fine-toothed cooler for adsorbing heat; and air combustion gas at the top of the moving bed after exchange is subjected to heat recovery through an afterburning waste boiler and then exhausted out by an induced draft fan.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

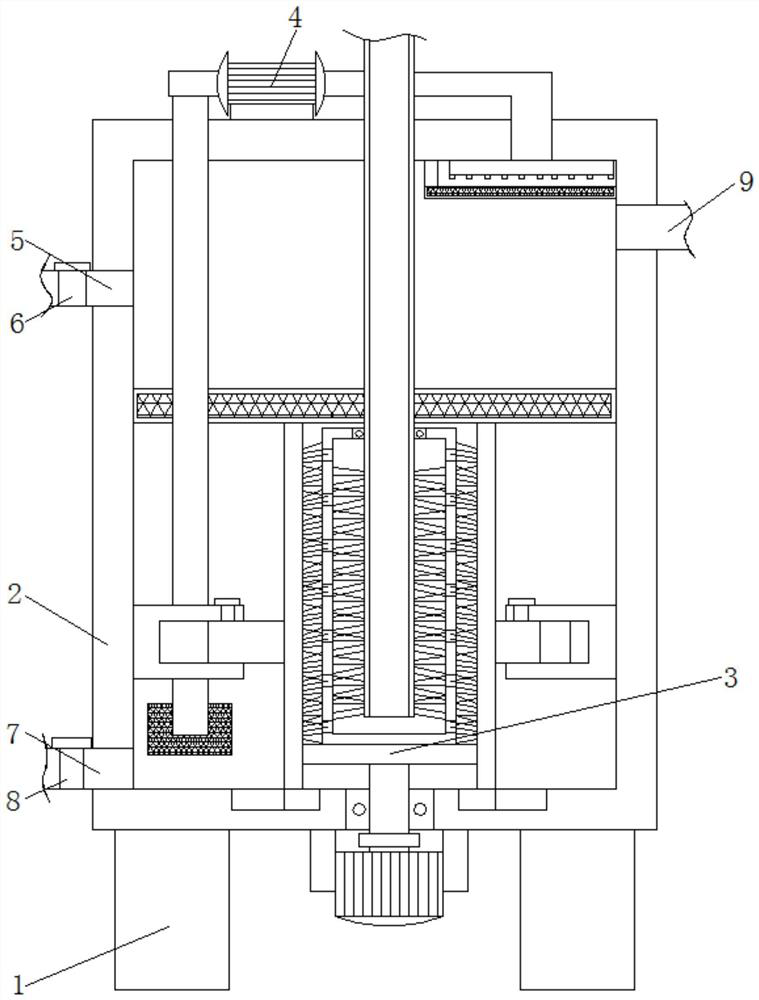

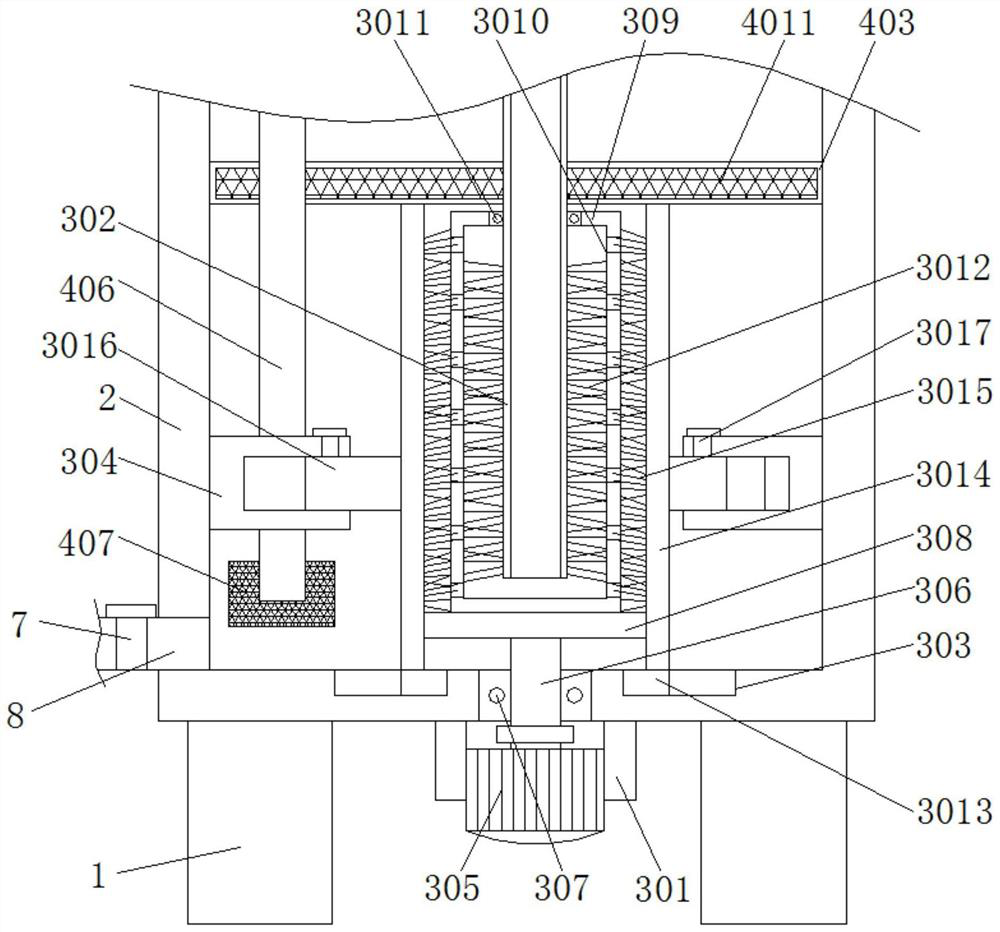

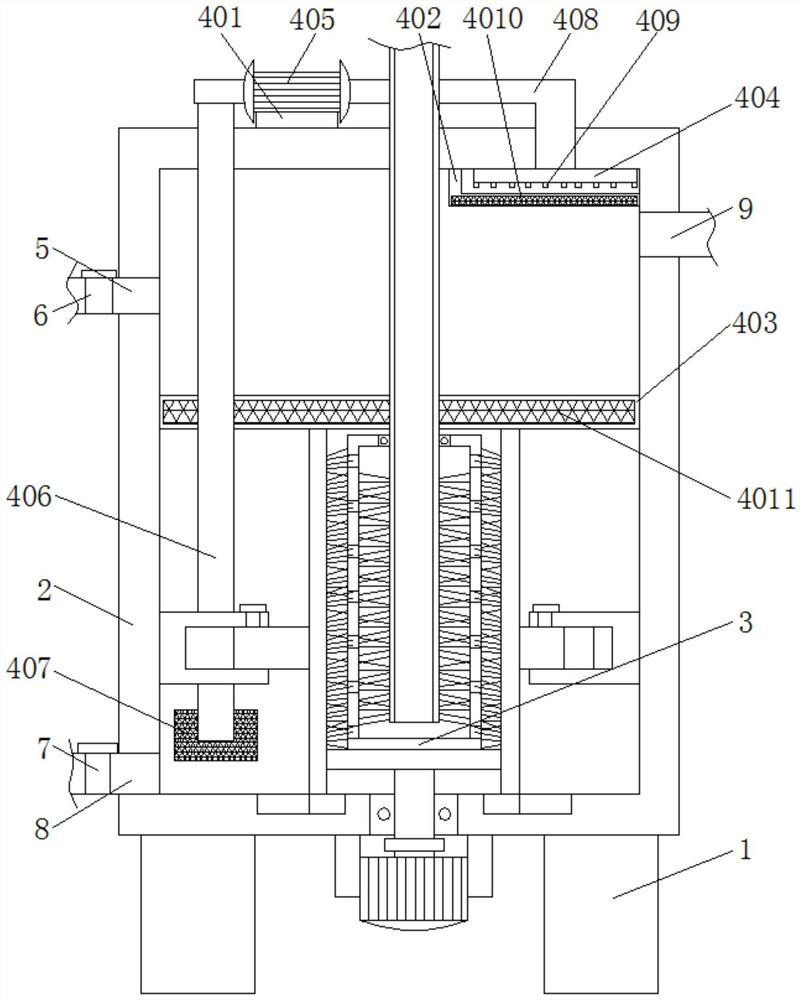

Metallurgy device facilitating residual heat recovery and metal powder recovery

InactiveCN109696058AConducive to waste heat recoverySolve wasteIncreasing energy efficiencyWaste heat treatmentFlueFlue gas

The invention discloses a metallurgy device facilitating residual heat recovery and metal powder recovery. The metallurgy device comprises a supporting plate, wherein supporting legs are fixedly connected to the surface of the supporting plate, the surfaces of the supporting legs are fixedly connected to a smelting furnace, a heating chamber is fixedly connected to the bottom of the smelting furnace, and a flue gas outlet is formed in the surface of the smelting furnace. According to the metallurgy device facilitating residual heat recovery and metal powder recovery, when the heat in flue gasneeds to be recycled, a first water pump is started, the first water pump pumps cold water into a heat exchange pipe from the interior of a first water tank through a first water inlet pipe and a first water outlet pipe, and the cold water is conveyed in the pipe from right to left to take away the heat in a flue gas outlet pipe; and the temperature of the water after heat exchange is increased, the water is delivered into a second water tank through a heat exchange water outlet pipe, the effect of recovering the residual heat of the high-temperature flue gas is achieved, so that the problem that energy waste is caused to a certain degree due to the fact that residual heat and the metal powder are not easily recycled by general metallurgical equipment is effectively solved.

Owner:扬州市品众体育用品有限公司

A kind of production system of corn pulping fiber

The invention relates to a production system of corn pulp addition fibers. The production system comprises a spiral dewaterer for dewatering corn fibers, wherein a fiber outlet of the spiral dewaterer is spirally connected with charging of a first pipe bundle drier through a feeding spiral conveyer, an outlet of the first pipe bundle drier returns materials through a first tee material distribution valve, a discharge opening of the first tee material distribution valve is connected with a second material returning spiral conveyer through a discharging spiral conveyer, and an outlet of the second material returning spiral conveyer, a second discharge opening of the feeding spiral conveyer and an outlet of a first pulp adding valve are connected with a first mixing machine; an outlet of the first mixing machine is spirally connected with the second charging of a second pipe bundle drier; and in like manner, materials after second-class drying are subjected to secondary pulp addition, then the materials after the secondary pulp addition enter a third pipe bundle drier for third-class drying, a material returning ratio is controlled through a third tee material distribution valve, and a discharge opening of the third tee material distribution valve is connected with a corn pulp addition fiber finished product pipe. The production system disclosed by the invention is low in steam consumption and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

Air dust separator for fine dust removal

ActiveCN108822899BImprove filtering effectIncrease contact timeUsing liquid separation agentEnergy inputEngineeringDust abatement

The invention provides an air-dust separator for fine dust removal, which includes a support leg, a fine dust treatment heat exchange chamber is fixedly connected to the surface of the support leg, and a fine dust treatment mechanism is arranged through the fine dust treatment heat exchange chamber , the fine dust treatment heat exchange chamber is provided with an outlet spray filter mechanism, the side of the fine dust treatment heat exchange chamber is sleeved with a cold water input pipe, and the surface of the cold water input pipe is threadedly connected with a water inlet bolt, Involved in the field of environmental protection. The gas-dust separator for removing dust from waste pot low-temperature semi-water gas gas can block the water containing dust in the arc-shaped surrounding block on the one hand by setting the third filter screen, and on the other hand, it does not affect the water between water Heat exchange is convenient for waste heat recovery, which effectively solves the problem that ordinary heat exchangers are not suitable for heat exchange and dust removal with semi-water gas from the newly combined waste pot, which is easy to waste heat energy and generate dust pollution.

Owner:浙江五梅开酒业有限公司

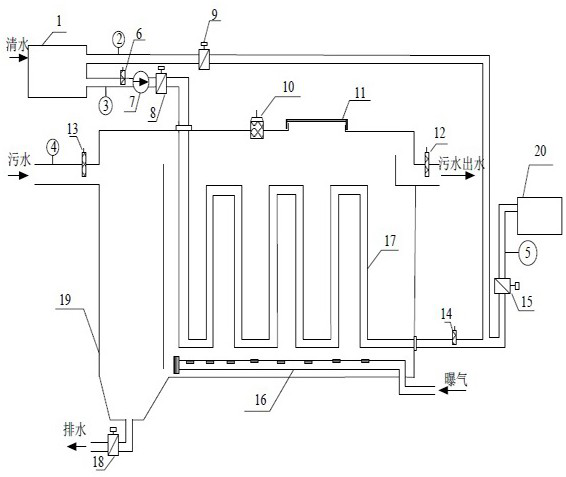

Sewage waste heat recovery device and working method thereof

PendingCN112665436AThe overall structure design is simple and reasonableEasy to operateWater aerationIndirect heat exchangersEnvironmental geologySewage treatment

The invention relates to a sewage waste heat recovery device and a working method thereof, and belongs to the field of sewage treatment and energy conservation. The sewage waste heat recovery device comprises a clear water buffer tank, a water supply pump, a first valve, a second valve, a third valve, an aeration device, a heat exchanger, a fourth valve, a heat exchange device and a clear water recycling tank, wherein the clear water buffer tank is connected with the water supply pump; an outlet of the water supply pump is connected with an inlet of the heat exchanger; the first valve is arranged between the outlet of the water supply pump and the inlet of the heat exchanger; the heat exchanger is installed in the heat exchange device, the outlet of the heat exchanger is connected with the clear water buffer tank and the clear water recycling tank; the second valve is installed on a branch pipe connected to the clear water buffer tank; the third valve is installed on another branch pipe connected to the clear water recycling tank; the aeration device is arranged at the bottom of the heat exchange device; and the fourth valve is arranged on a drain outlet pipeline at the bottom of the heat exchange device. The sewage waste heat recovery device is simple and reasonable in structural design, can effectively recover waste heat of sewage, prevents impurities from adhering to the interior of the heat exchange device and the surface of the heat exchanger, and meets usage requirements.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

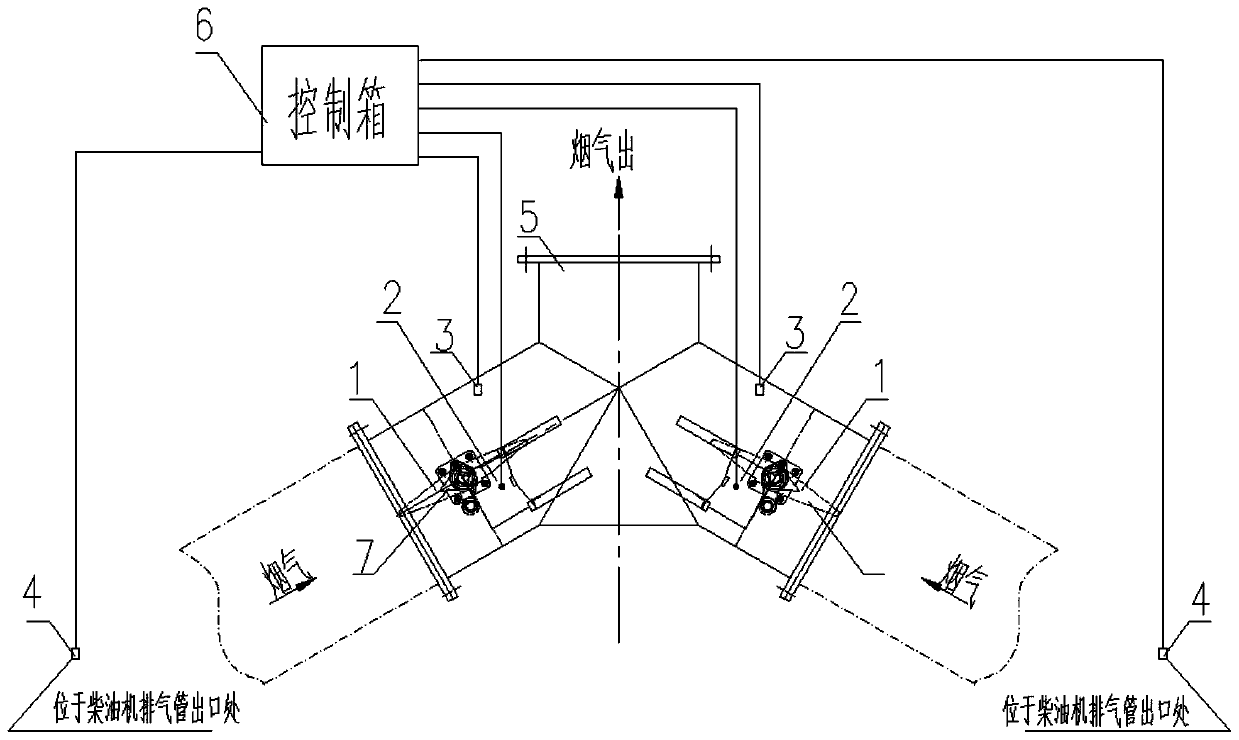

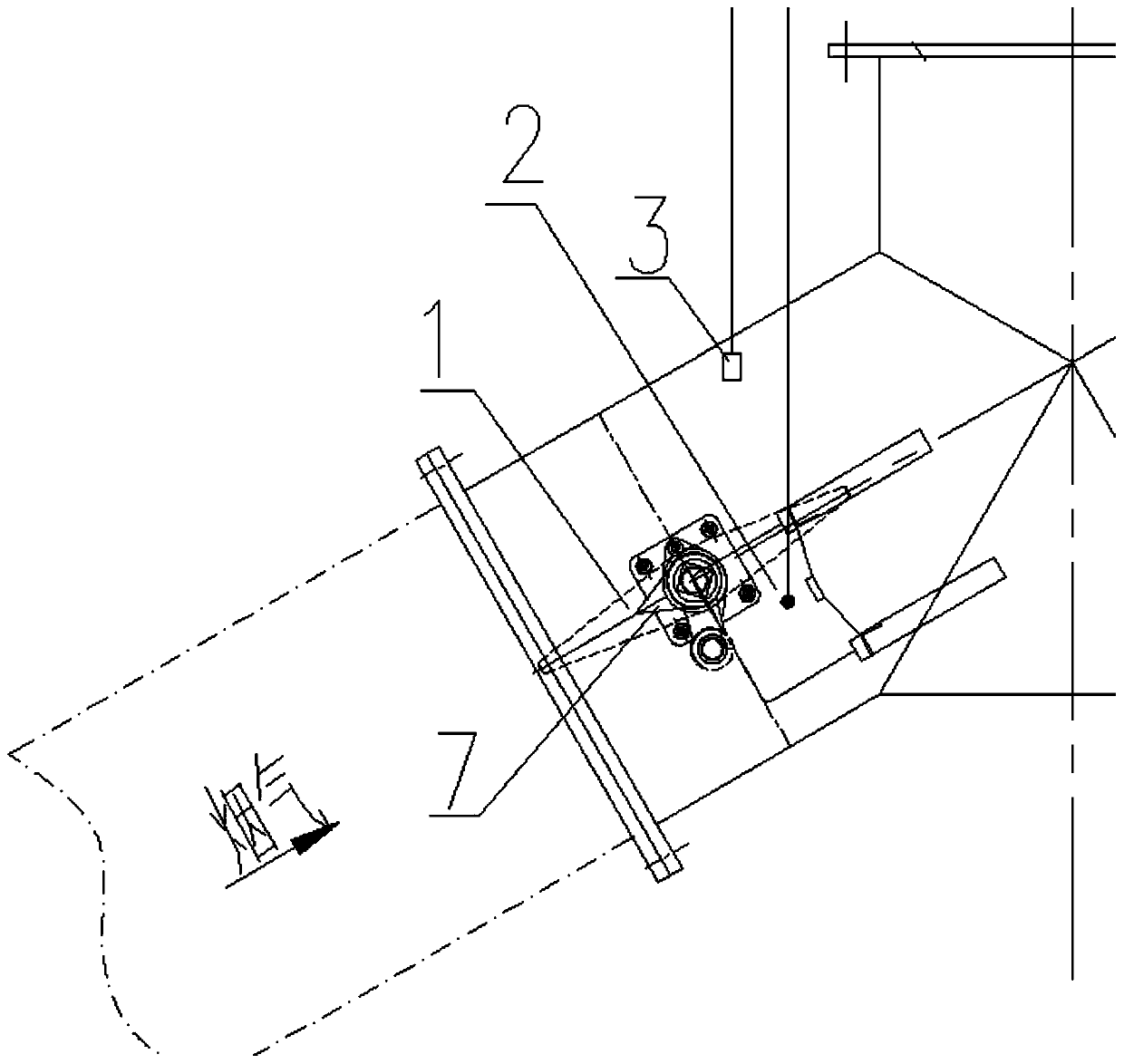

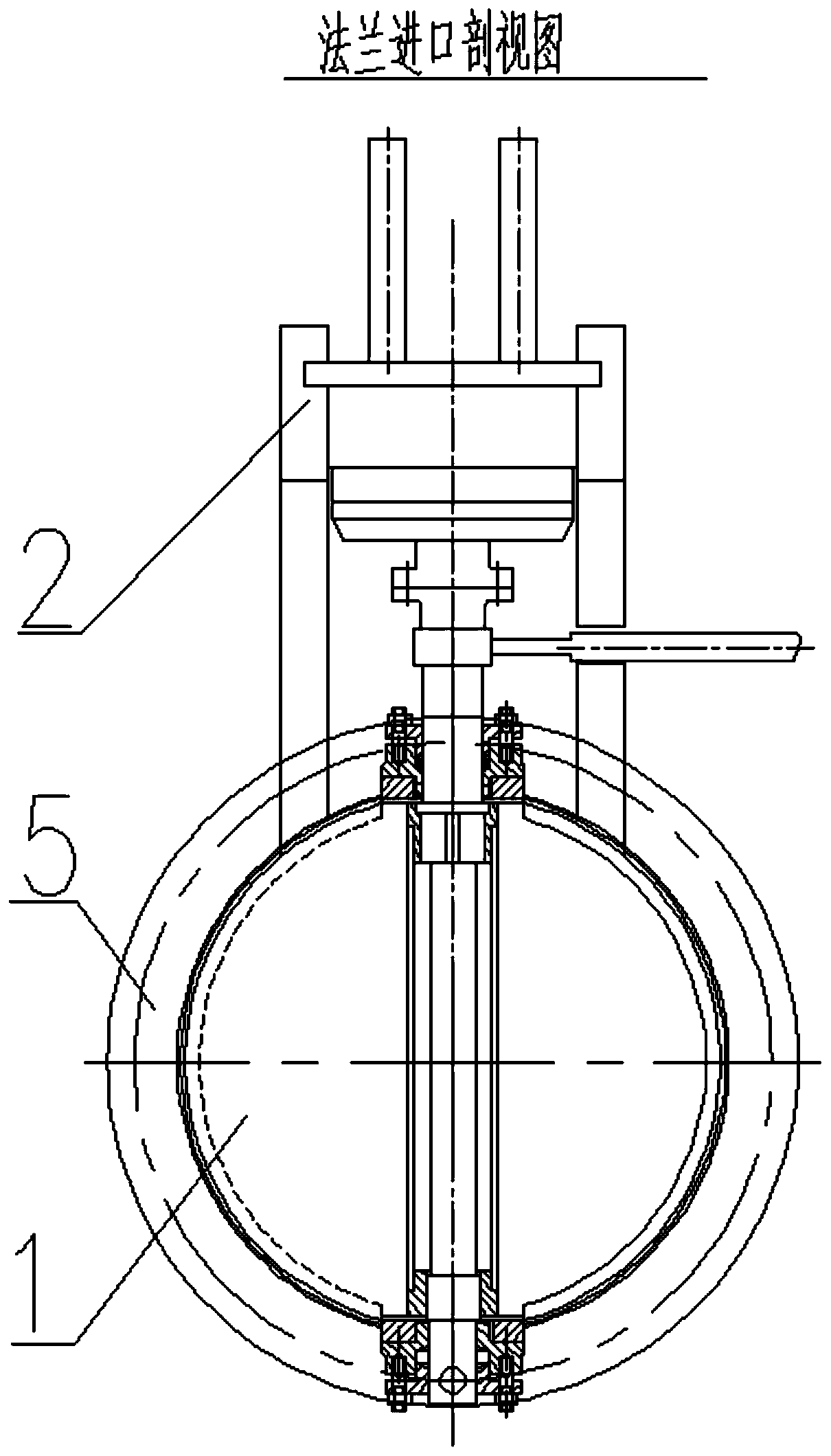

A device for combining exhaust pipes of marine diesel engines

InactiveCN108661769BEffective isolationSave layout spaceExhaust apparatusSilencing apparatusFlue gasEngineering

The invention relates to a device for merged exhaust by exhaust pipes of a marine diesel engine. A valve body is provided with an exhaust port upward and is provided with at least two flue gas inletsdownward, wherein an adjusting plate is arranged in each flue gas inlet, the axis part of each adjusting plate is connected to an electric executor, and the electric executor can drive the adjusting plate to rotate, so that the flue gas inlet is opened or closed; a first temperature sensing element is arranged on the side, close to the exhaust port, of the adjusting plate, and a second temperaturesensing element is arranged at the part, close to an exhaust pipe of the diesel engine, of the adjusting plate; a controller is connected to the first and second temperature sensing elements and is collected to the electric executor simultaneously, and when the temperature of the second temperature sensing element is higher than that of the first temperature sensing element, the electric executoropens the adjusting plate, and otherwise, closes the adjusting plate. According to the device provided by the invention, the merged exhaust pipes can be isolated effectively according to different conditions, so that the arrangement space of the exhaust pipes on a ship is saved; and all waste heat in exhaust gas of the diesel engine is recovered conveniently, so that the energy sources are savedand the efficiency is improved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

A gas-dust separator for removing fine dust from waste pot low-temperature semi-water gas

InactiveCN108865289BImprove filtering effectIncrease contact timeUsing liquid separation agentEnergy inputDust controlEnvironmental engineering

The invention provides a gas-dust separator for removing fine dust from waste pot low-temperature semi-water gas gas, which includes a support leg, the surface of the support leg is fixedly connected with a fine dust treatment heat exchange chamber, and the fine dust treatment heat exchange chamber is A micro-dust treatment mechanism is provided throughout, and an outlet spray filter mechanism is provided throughout the micro-dust treatment heat exchange chamber. A cold water input pipe is sleeved on the side of the micro-dust treatment heat exchange chamber, and the surface of the cold water input pipe The threaded connection has water inlet bolts and relates to the field of environmental protection. The gas-dust separator for removing dust from waste pot low-temperature semi-water gas gas can block the water containing dust in the arc-shaped surrounding block on the one hand by setting the third filter screen, and on the other hand, it does not affect the water between water Heat exchange is convenient for waste heat recovery, which effectively solves the problem that ordinary heat exchangers are not suitable for heat exchange and dust removal with semi-water gas from the newly combined waste pot, which is easy to waste heat energy and generate dust pollution.

Owner:山东润蒙应急救援装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com