A device for combining exhaust pipes of marine diesel engines

A technology for marine diesel engines and exhaust pipes, which is applied to exhaust devices, mufflers, mechanical equipment, etc., can solve problems such as high temperature flue gas intrusion, safety accidents, diesel engine failures, etc., to save energy, improve efficiency, and facilitate maintenance. and manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

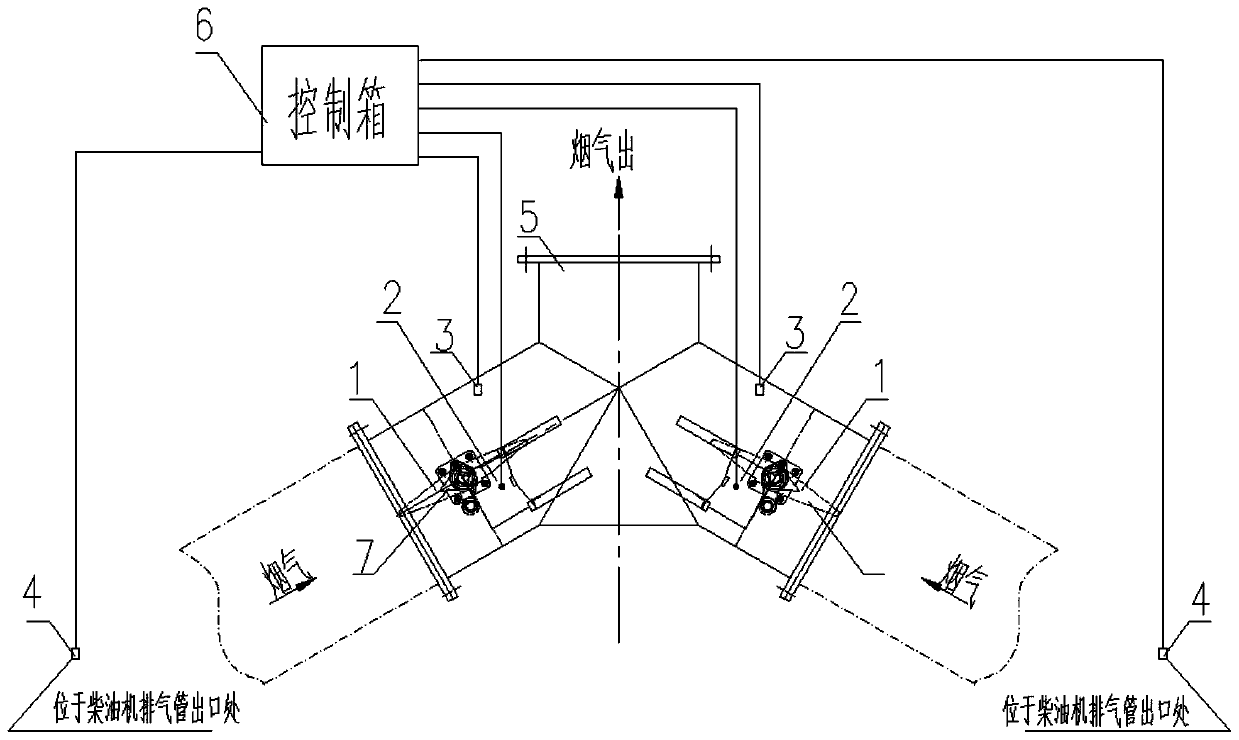

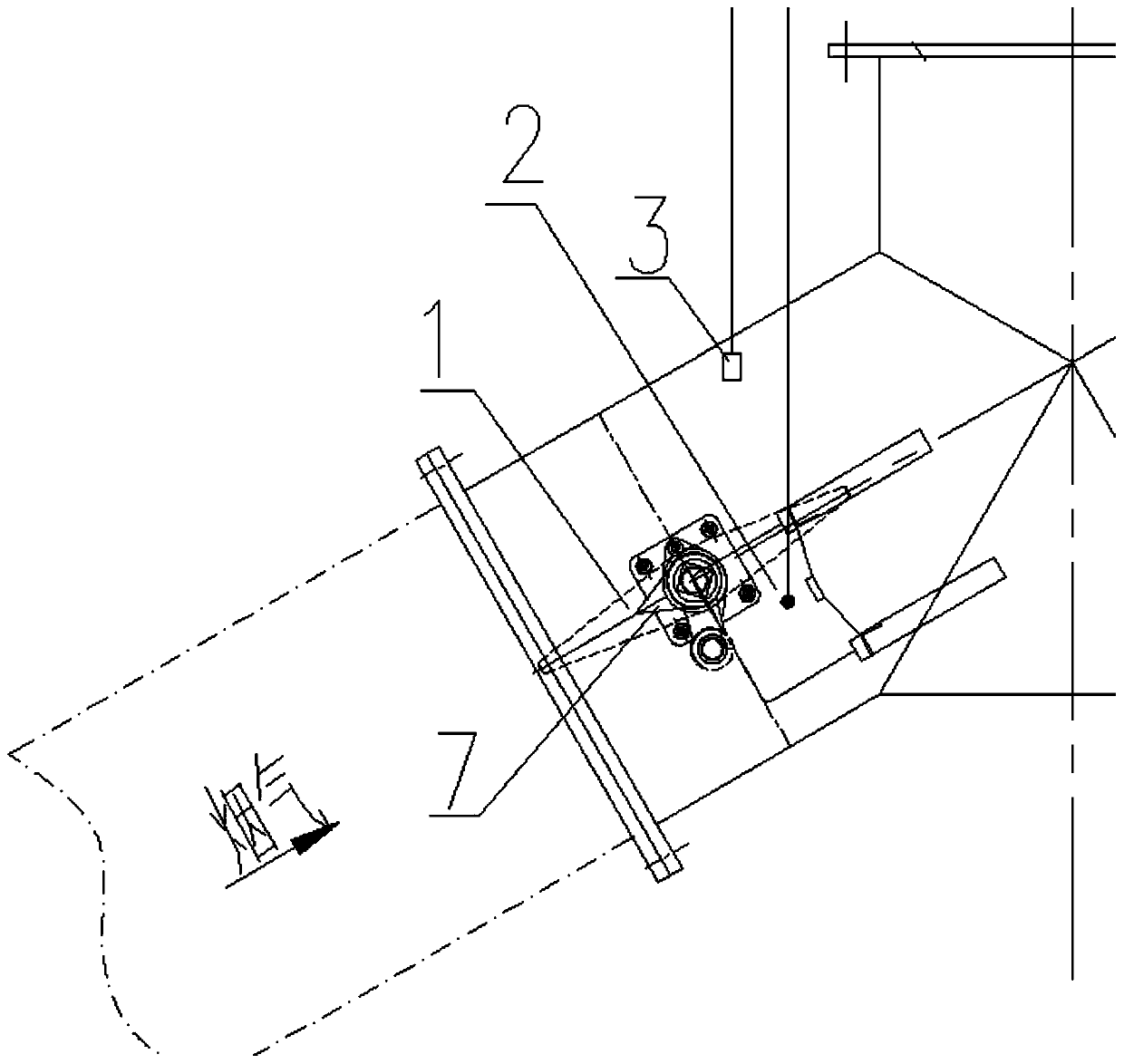

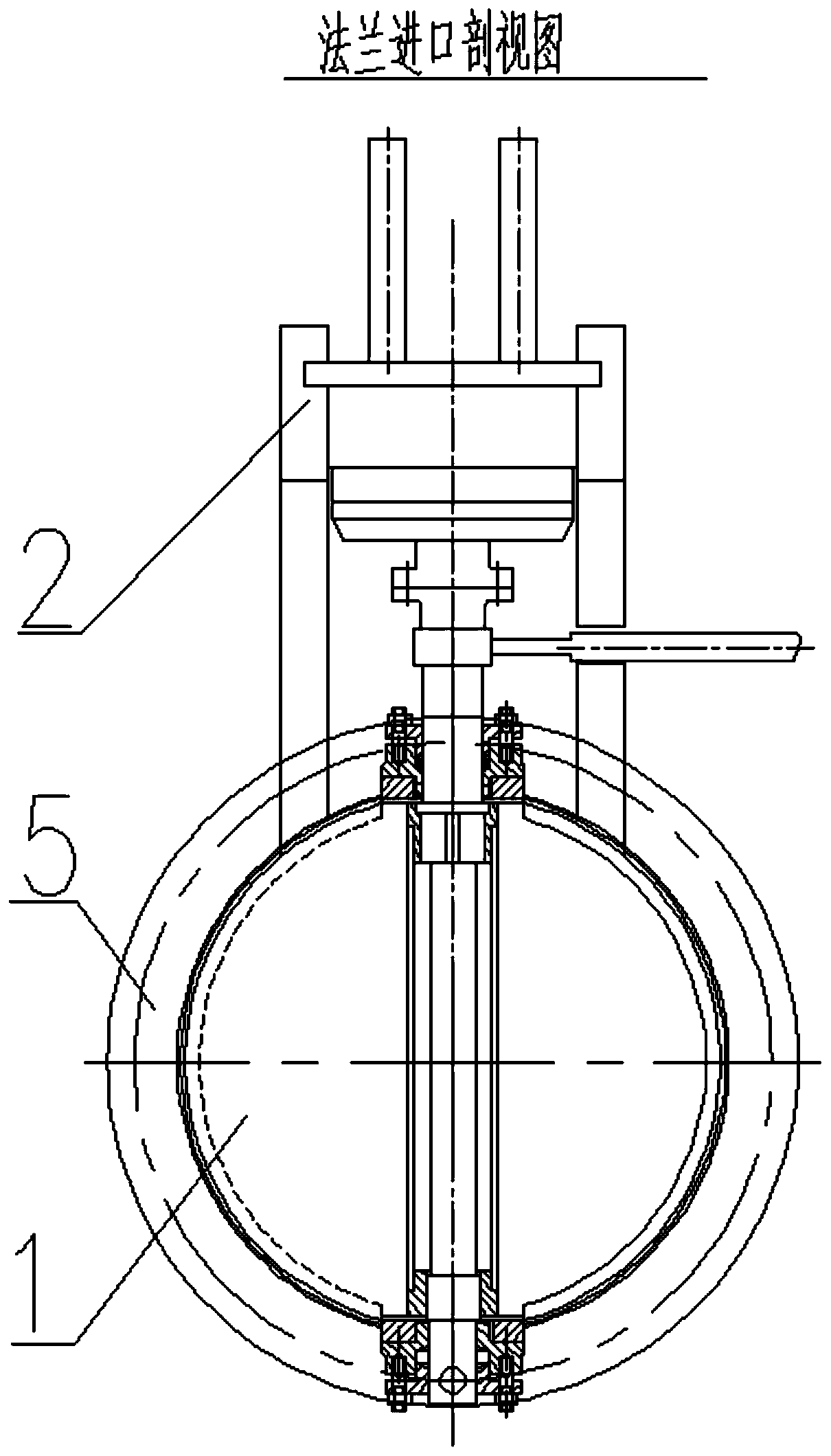

[0025] see Figure 1-Figure 3 , a device for combining exhaust pipes of marine diesel engines, including a valve body 5, a controller, a first temperature sensing element 3, and a second temperature sensing element 4; the valve body 5 has an exhaust port upward, There are at least two flue gas inlets downward, each flue gas inlet is provided with an adjustment plate 1, the central axis of the adjustment plate is connected with the electric actuator 2, and the electric actuator 2 can drive the adjustment plate 1 to rotate, so that the flue gas inlet On or off; the regulating plate is provided with a first temperature-sensing element 3 near the exhaust port, and a second temperature-sensing element 4 is provided near the exhaust pipe of the diesel engine; the controller is connected with the first and second temperature-sensing elements When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com