Sintering flue gas desulfurization and denitrification process

A technology for sintering flue gas, desulfurization and denitrification, applied in the field of metallurgical industry, can solve the problems of high denitration cost, high operation cost, secondary pollution, etc., and achieve the effect of ensuring denitration effect, realizing rational utilization, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

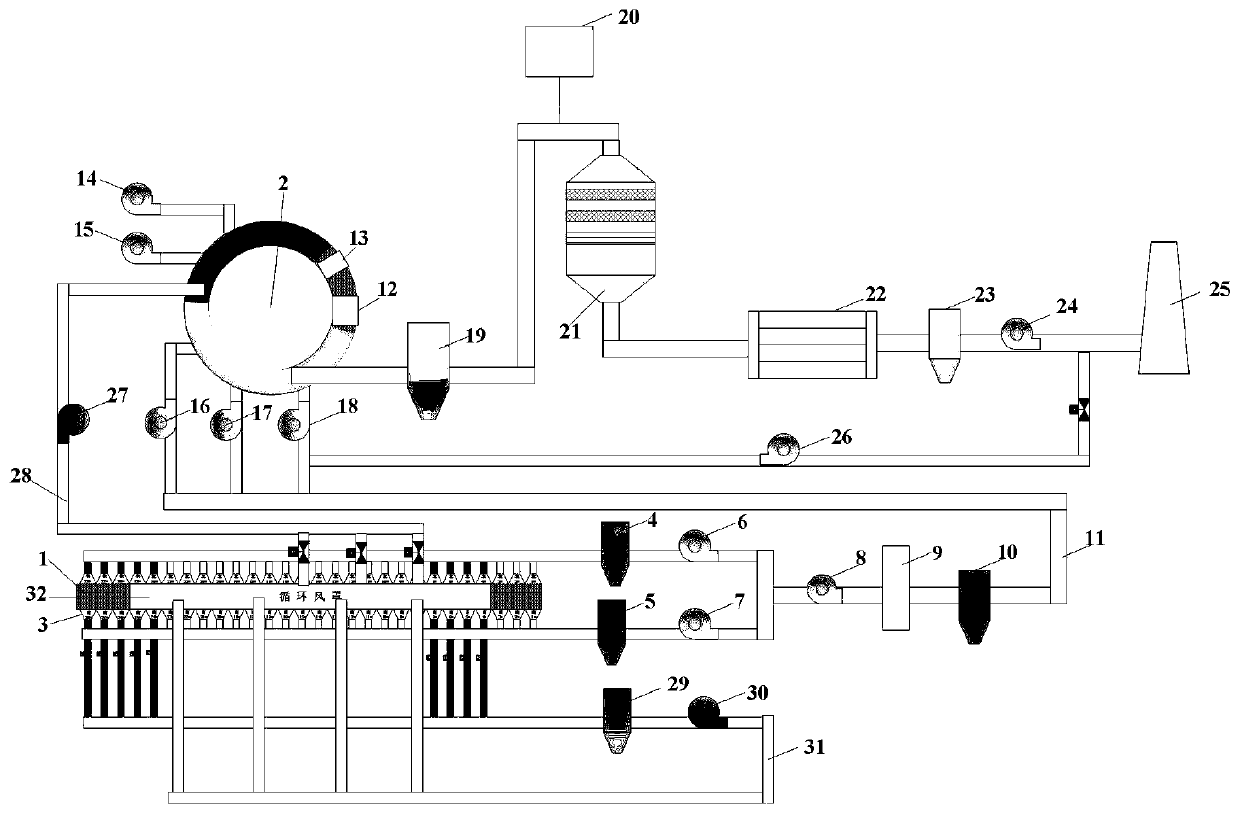

[0084] Such as figure 1 As shown, the sintering flue gas desulfurization and denitrification device used in the sintering flue gas desulfurization and denitration process provided in this embodiment includes a 400m 2 Sintering machine 1, 28 bellows 3 on each side of the upper and lower sides of sintering machine 1, of which the upper bellows are compiled from right to left as A1-A28, and the lower bellows are compiled from right to left as B1-B28, and A4- The A7, B4-B7, A24-A28, B24-B28 wind boxes are directly connected to the circulating flue 31. This configuration can achieve a flue gas circulation volume of 31%, and the oxygen content in the circulating flue gas> 18%, temperature> 180℃, so by using this part of the flue gas sensible heat can reduce the energy consumption of the sintering machine, saving energy> 1%, the quality of sintered ore can be ensured by controlling the proper oxygen concentration of the circulating flue gas as the gas source. This arrangement enables pa...

Embodiment 2

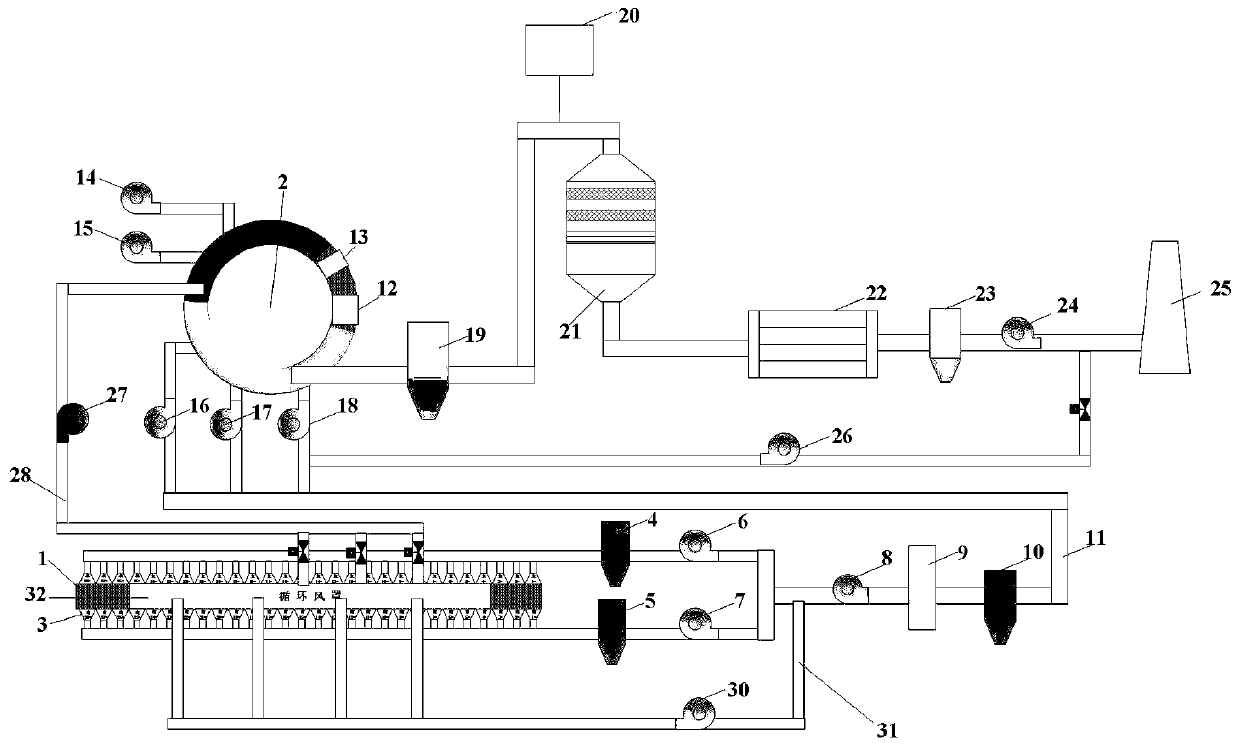

[0091] Such as figure 2 As shown, the sintering flue gas desulfurization and denitration device used in the sintering flue gas desulfurization and denitration process provided in this embodiment includes a 360m 2 Sintering machine 1, 28 wind boxes 3 on each side of the upper and lower sides of the sintering machine 1. The upper wind boxes are connected to flue A. The first dust collector 4 and the first main exhaust fan 6 are arranged in the flue A. The lower wind boxes are all Connected to flue B, flue B is provided with a second dust collector 5 and a second main exhaust fan 7 in sequence, flue A and flue B are combined and connected to circulating flue 31 and main flue gas pipe 11 through a three-way unit ; The arrangement on the main flue gas pipe 11 is the same as that of the first embodiment, and will not be repeated here.

[0092] Specifically, a circulating fan 30 is provided on the circulating flue 31, and the flue gas passes through the circulating fan 30 and reaches th...

Embodiment 3

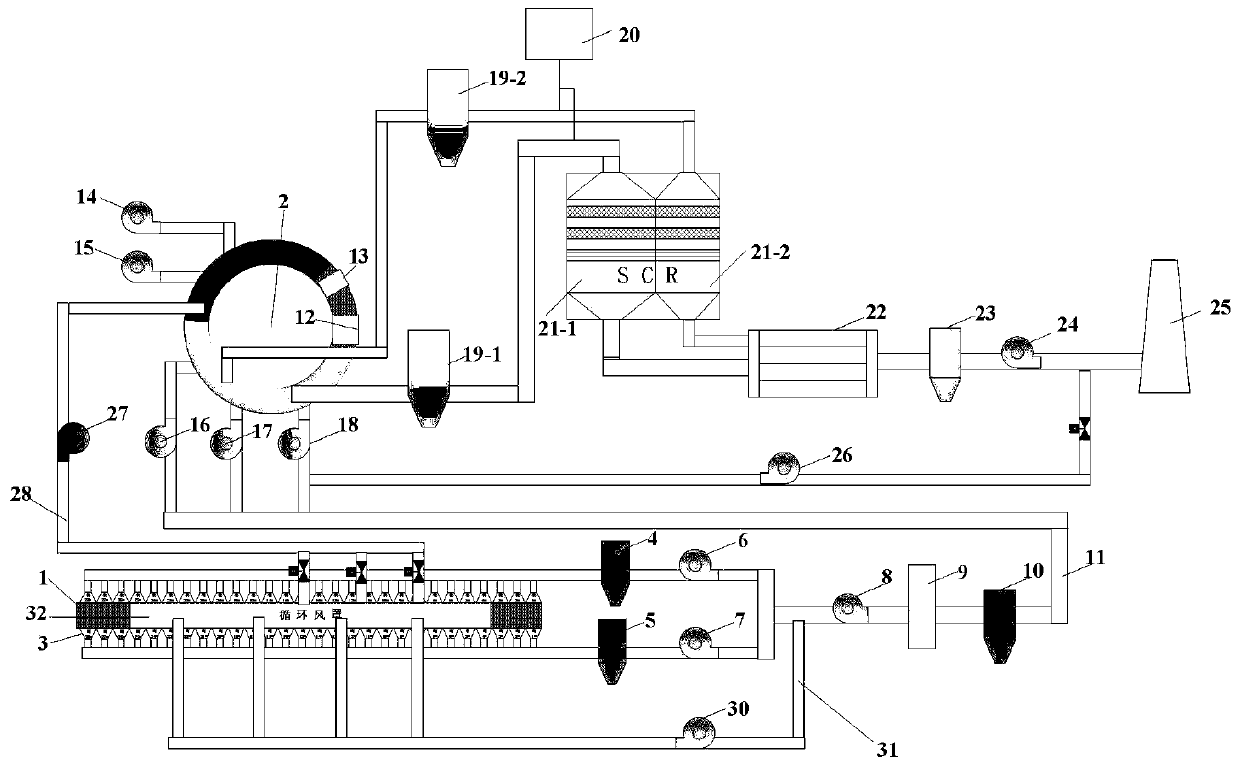

[0097] Such as image 3 As shown, the difference between the sintering flue gas desulfurization and denitrification device provided in this embodiment and the second embodiment is that the boiler in the waste heat recovery unit 22 is a dual-pressure boiler, so there are two flue gases with different temperatures when entering the waste heat recovery unit 22 The high-temperature section of the annular cooler has two flue gas outlets; the flue gas leads out two flue gases from the hood of the high-temperature section of the annular cooler 2. The flue gas temperature of one way is higher, and the flue gas temperature is 400℃. The gas passes through the first high-temperature dust collector 19-1 for coarse dust removal, and then enters the first denitration reactor 21-1 for denitration, and then enters the first heat exchange tube in the boiler in the waste heat recovery unit 22 after denitration; The flue gas temperature is 270°C. The flue gas firstly passes through the second high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com