Device for inhibiting frost formation of evaporimeter by supersonic vibration

A technology of ultrasonic vibration and evaporator, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of commercialization and ambiguity, and achieve the effects of inhibiting and frosting, reducing frosting, and high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

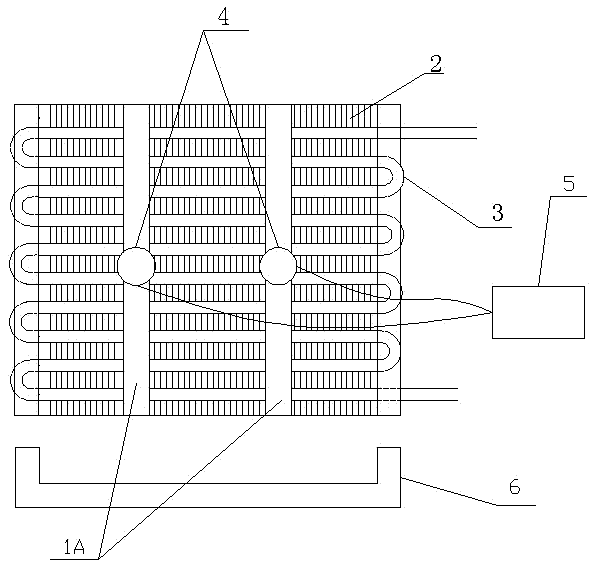

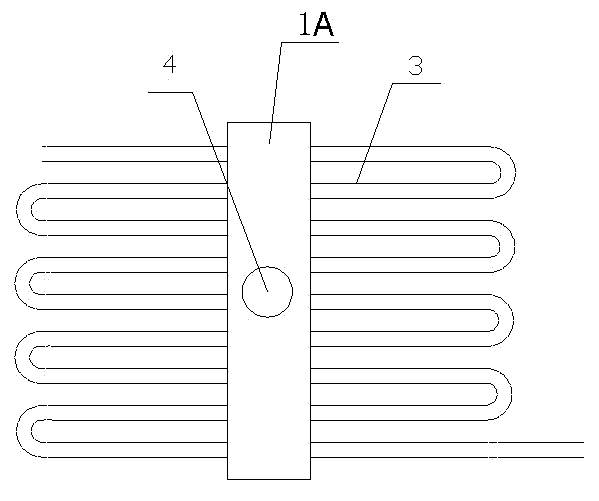

[0040] like figure 1 , figure 2 , Figure 5 to Figure 8As shown, the device of the present invention that uses ultrasonic vibration to suppress frosting on the evaporator includes an evaporator, and the evaporator includes a liquid pipe 3 (the liquid pipe 3 is a copper pipe or an aluminum pipe), and the liquid pipe 3 is connected with a finned tube in the form of an expansion tube. Sheet 2 (the connection method of the expansion tube can ensure that the perforation is an interference fit), the liquid tube 3 is connected with a vibration transmission plate, and the vibration transmission plate is preferably made of copper, aluminum or other metal alloys, mainly used for transmitting ultrasonic waves and High-frequency mechanical vibrations caused by ultrasonic mechanical effects. The vibration transmission plate includes a vibration receiving surface 1A, which is welded or glued on the liquid pipe 3, and a power ultrasonic transducer 4 is vertically and fixedly connected to ...

Embodiment 2

[0056] like image 3 and Figure 4 As shown, the differences between this embodiment and Embodiment 1 are:

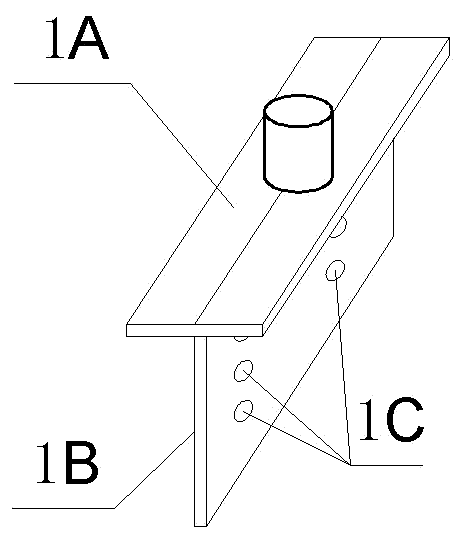

[0057] The vibration-receiving surface 1A is not welded or glued together with the liquid pipe 3, and the vibration-transmitting plate also includes a vibration-transmitting surface 1B integrally arranged or connected with the vibration-receiving surface 1A. 1B is perpendicular to the vibration-receiving surface 1A and inserted between the fins 2; the vibration-transmitting surface 1B is provided with a mounting hole 1C for insertion on the liquid pipe 3, and the liquid pipe 3 passes through the The mounting hole is fixedly connected to the vibration transmitting surface 1B in the form of an expansion tube.

[0058] Among them, such as image 3 and Figure 4 As shown, the vibration-receiving surface 1A and the vibration-transmitting surface 1B of the vibration-transmitting plate form a T-shape or an inverted L-shape, and the thicknesses of the vibration-receiving su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com