Energy-saving biogas fermentation tank heating constant-temperature equipment and using method thereof

A technology of biogas fermentation and constant temperature device, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., which can solve the problem of affecting the efficient and stable operation of biogas projects and increasing the cost of biogas projects , Susceptible to weather and other issues, to achieve high heat transfer efficiency, reduced damage, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] The purpose of the present invention is to use low-grade energy to solve the problem that the low temperature of biogas fermentation feed liquid in winter and spring leads to a large drop in gas production and gas production rate of biogas projects, additional power supply is required for heating, low environmental protection and economic efficiency, and the heating end is too high during the heating process. The high thermal load leads to the problem of excessive local temperature and large temperature fluctuation range, and uneven temperature in the tank.

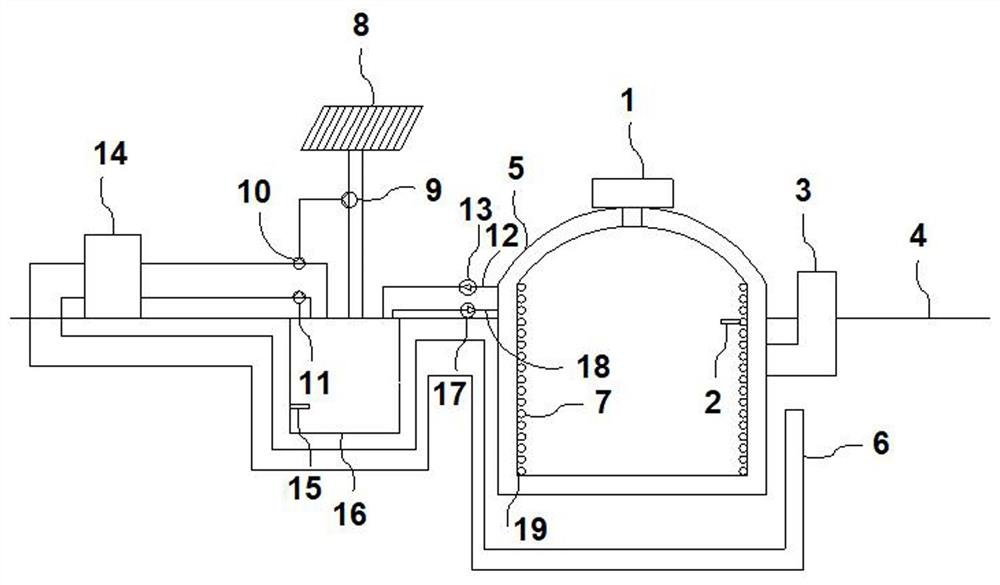

[0071] The energy-saving biogas fermentation tank temperature increasing and constant temperature device is mainly composed of a fermentation tank 5, a capillary network heat exchanger 7, an insulated water tank 16, a solar heat collector 8, a ground source heat pump 14 and various auxiliary components.

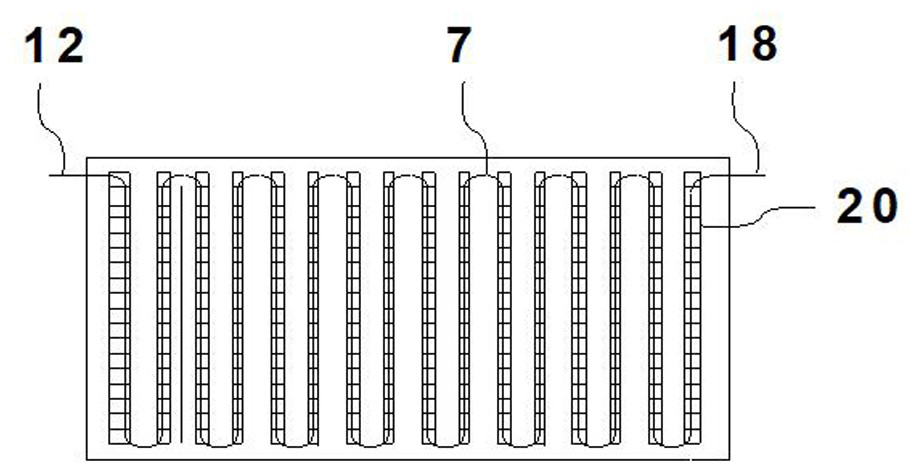

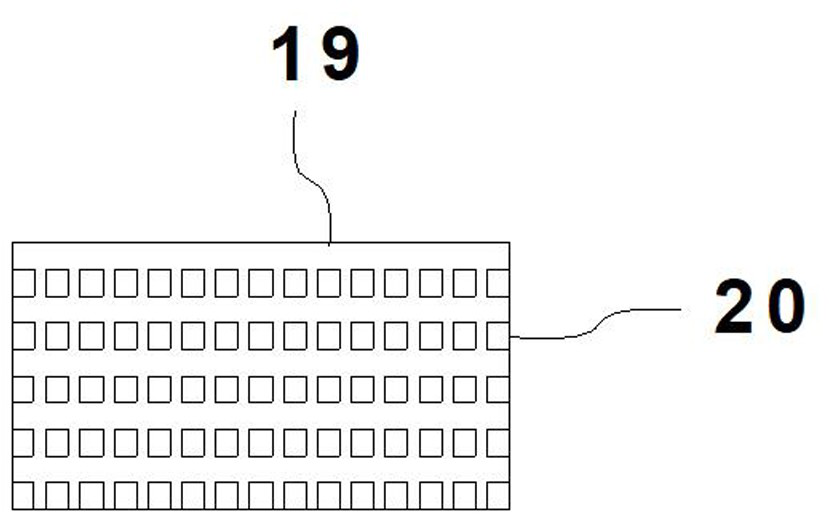

[0072] Principle of the present invention: the capillary network heat exchanger 7 is made of PPR material with g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com