Patents

Literature

264results about How to "Small device size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

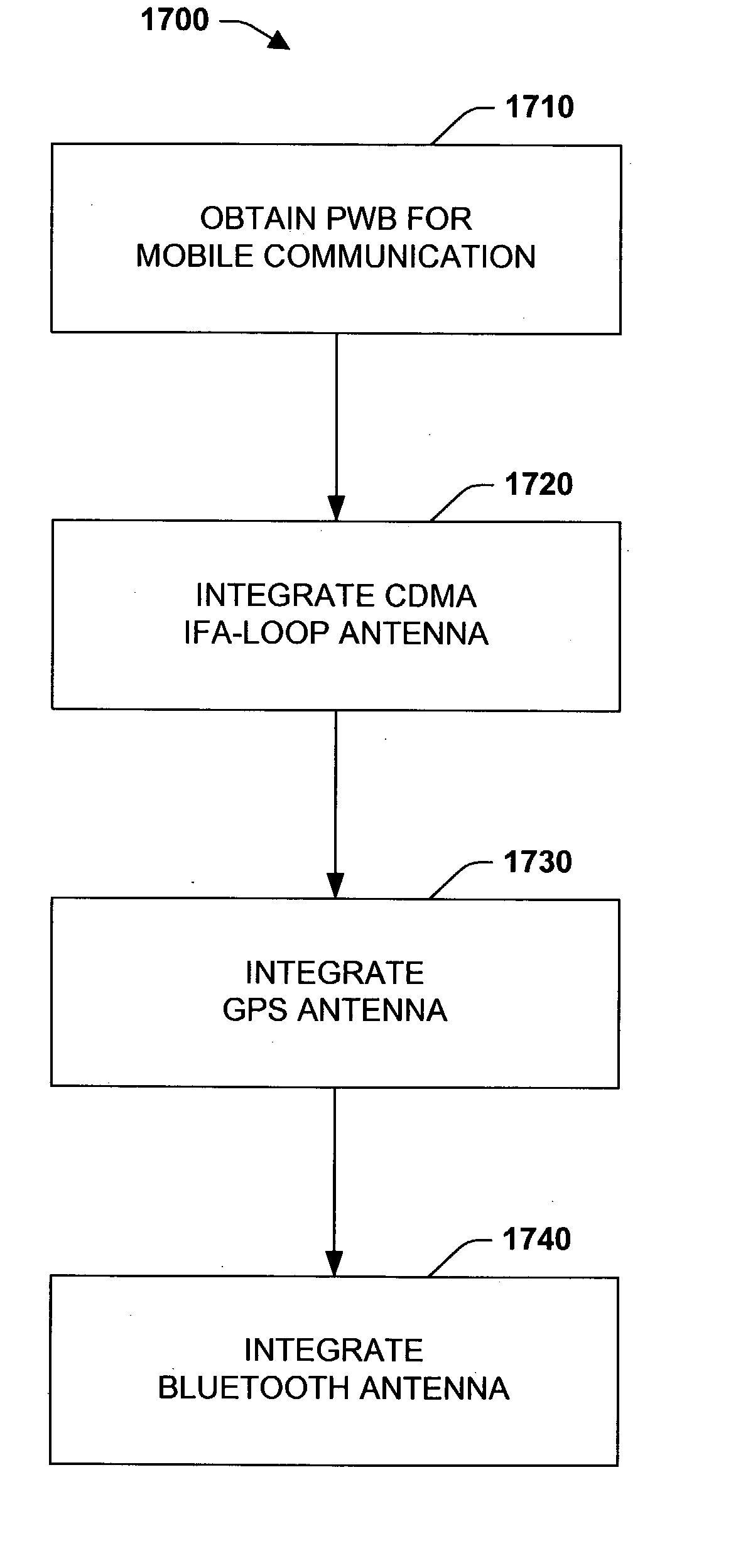

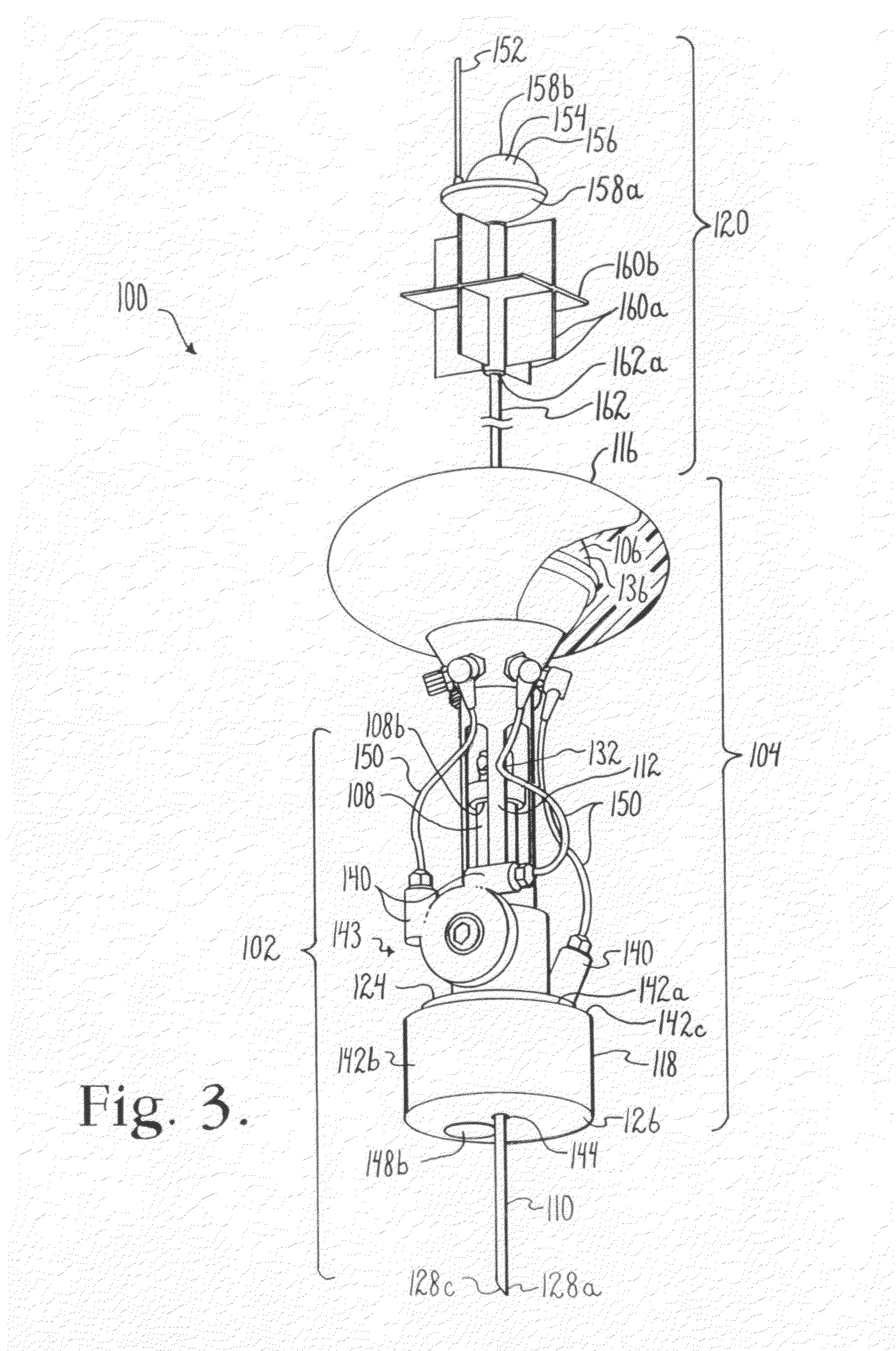

Systems and methods that employ a dualband IFA-loop CDMA antenna and a GPS antenna with a device for mobile communication

InactiveUS20050041624A1Reduce antenna sizeReduce componentsAntenna supports/mountingsBeacon systemsCapacitanceAntenna gain

The present invention comprises systems and methods for cellular, PCS, GPS and / or Bluetooth mobile communication (e.g., a mobile telephone). The systems and methods employ a fully integrated dual band IFA / loop CDMA antenna for cellular and PCS communication. Fully integrating the CDMA antenna within a PWB provides for mitigation of lumped elements to establish dual banding, and can provide for reduced antenna size, device size, cost and interference form a user's hand. The IFA antenna is configured to transmit and receive within the cellular frequency band via a capacitive tap, and the loop antenna is configured to transmit and receive within the PCS frequency band via an impedance matching stub and ground location. The system and methods further employ a firewall to mitigate antenna coupling, and a metal reflector to reduce the electromagnetic reflection, and improve antenna gain and efficiency.

Owner:NOKIA CORP

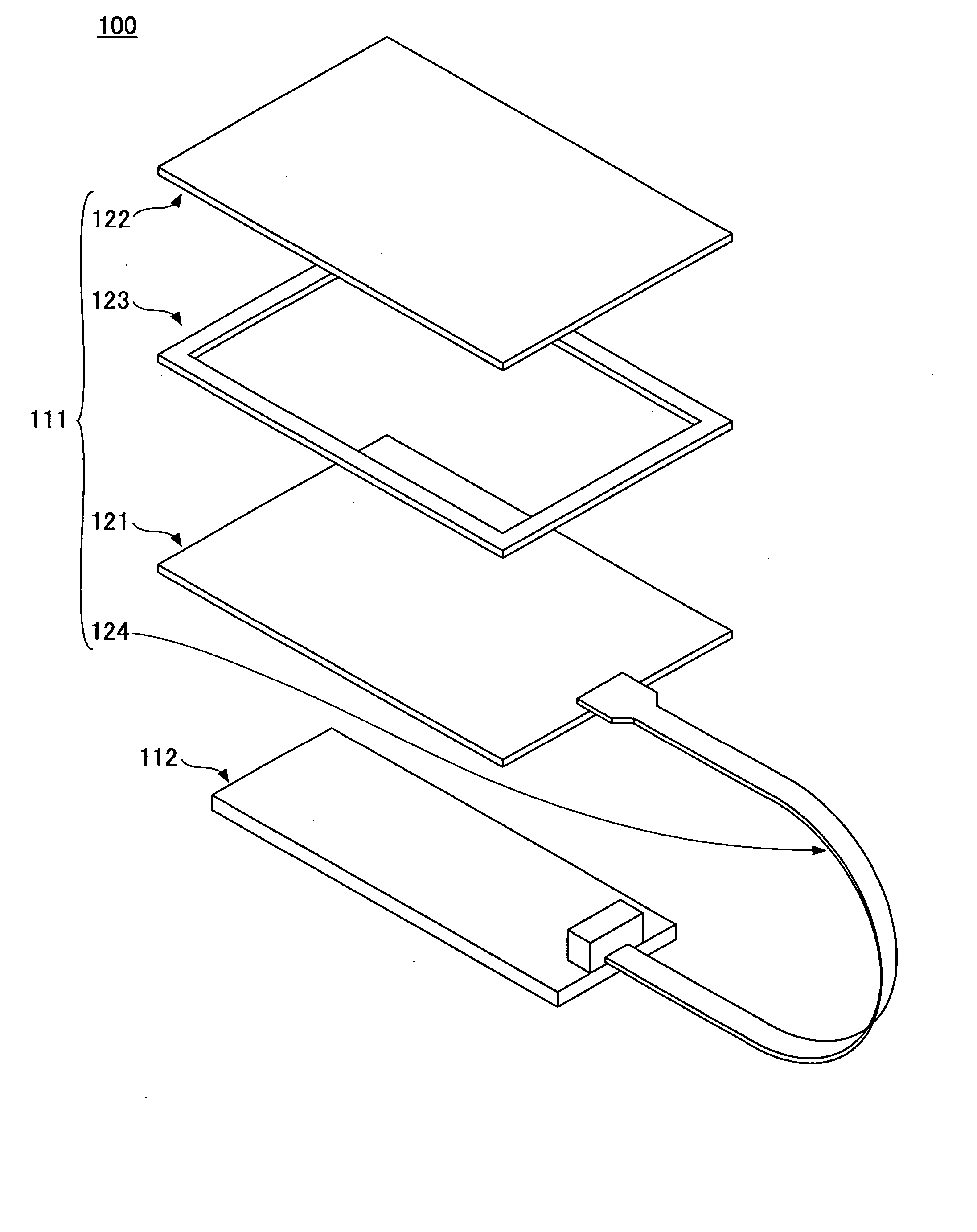

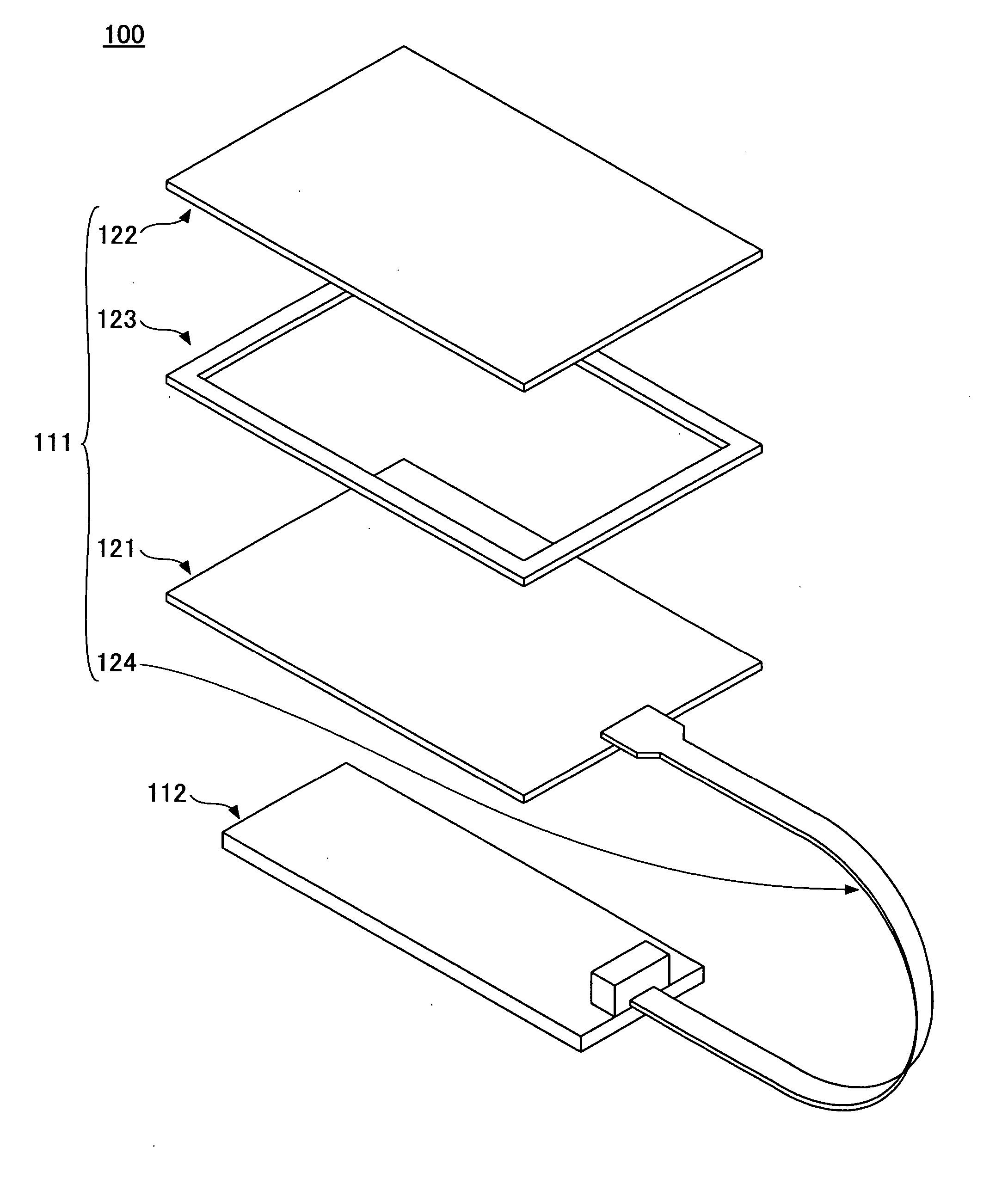

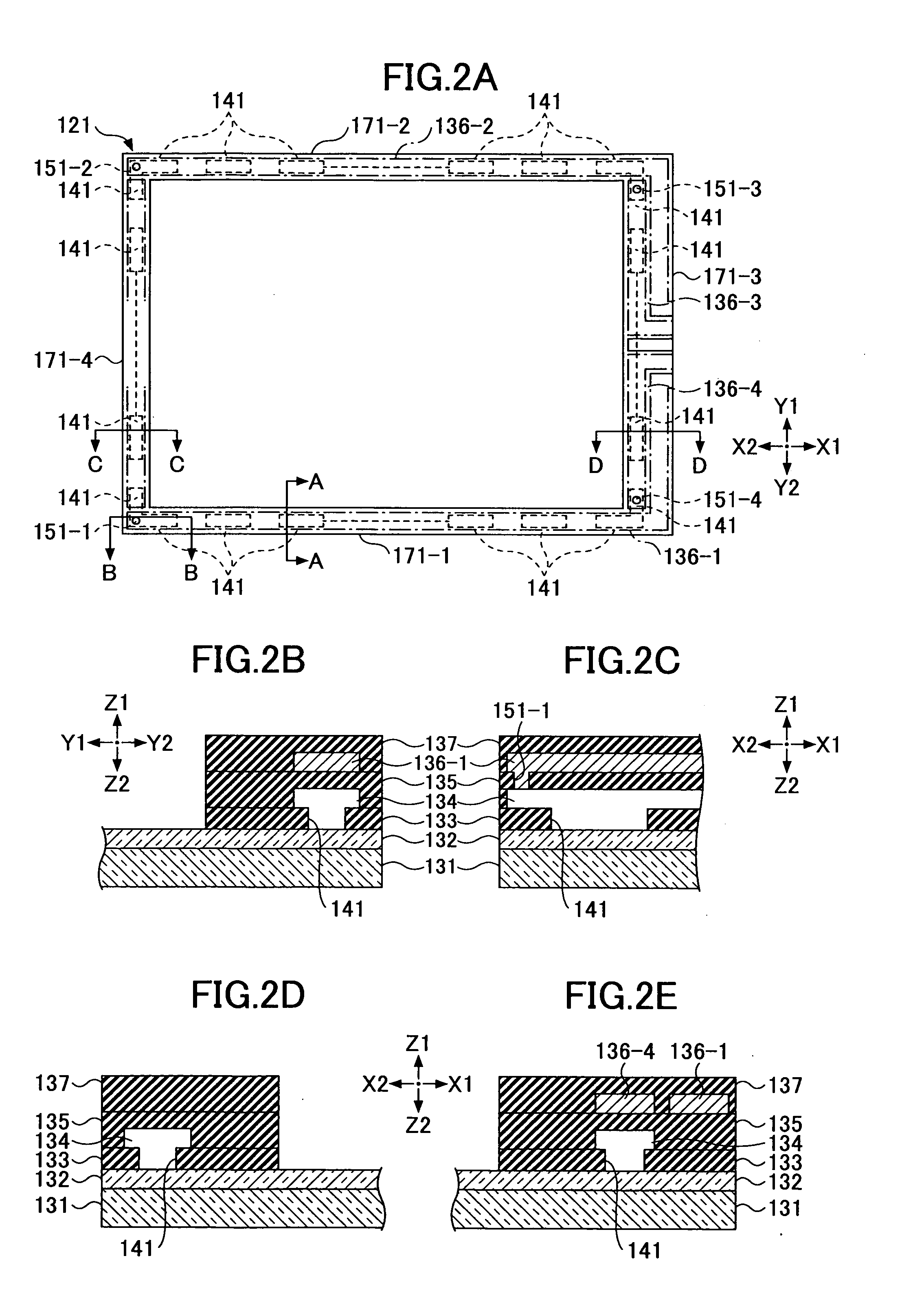

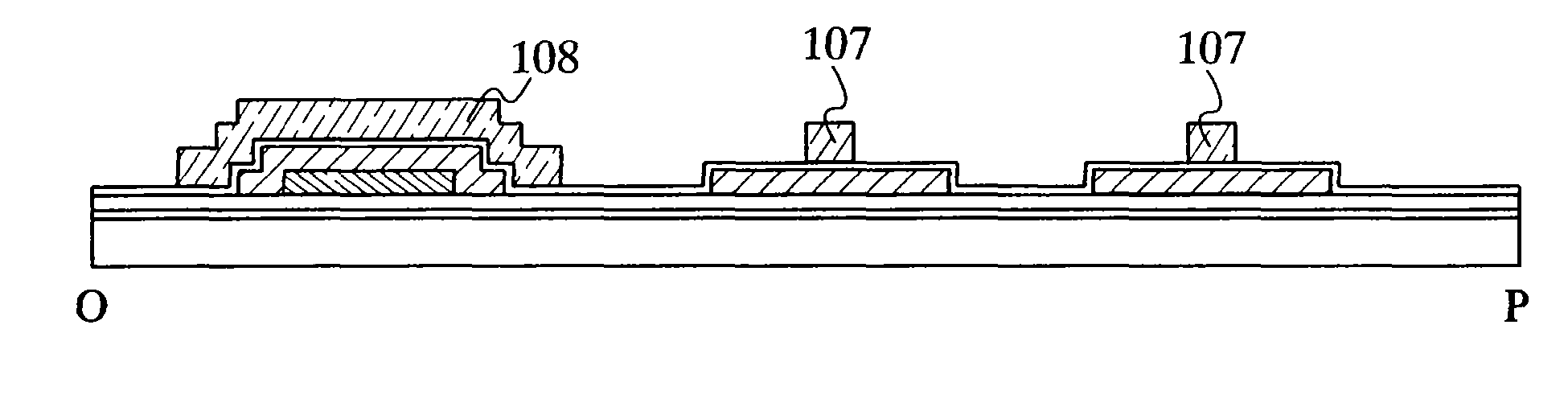

Coordinate detecting device

InactiveUS20070013678A1High matching precisionSmall device sizeCathode-ray tube indicatorsInput/output processes for data processingElectric potentialVoltage

A coordinate detecting device is disclosed. The coordinate detecting device includes a resistance film, a common electrode which applies electric potential to the resistance film, a voltage supplying section which supplies a voltage to the common electrode, wiring which supplies the voltage to the voltage supplying section, an insulation film disposed between the common electrode and the resistance film, and an electric potential supplying section formed in the insulation film for supplying the electric potential from the common electrode to the resistance film. The coordinate detecting device detects a coordinate of a position on a panel when a user touches the position while an electric potential distribution is generated in the resistance film by being applied electric potential from the common electrode.

Owner:FUJITSU COMPONENENT LTD

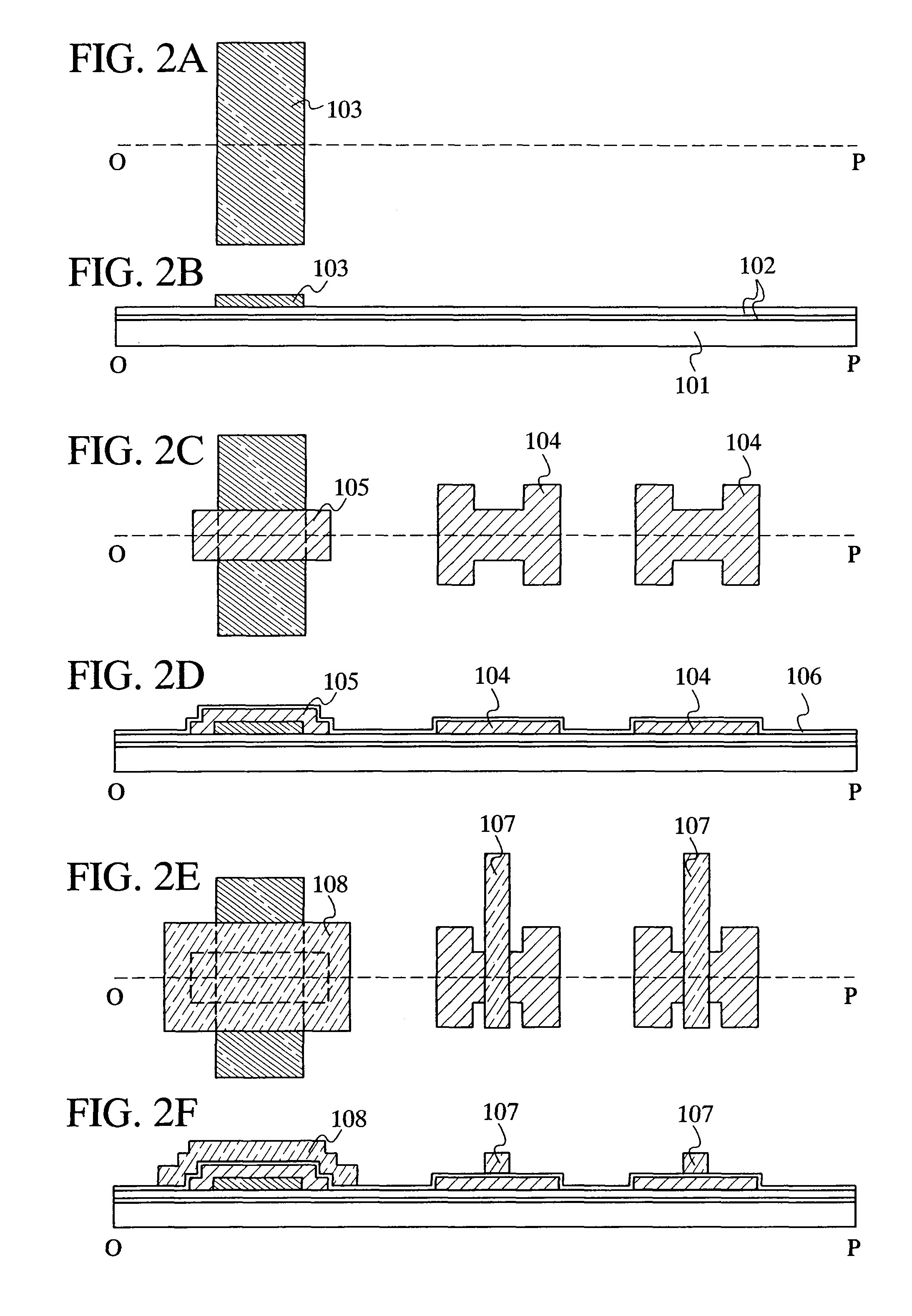

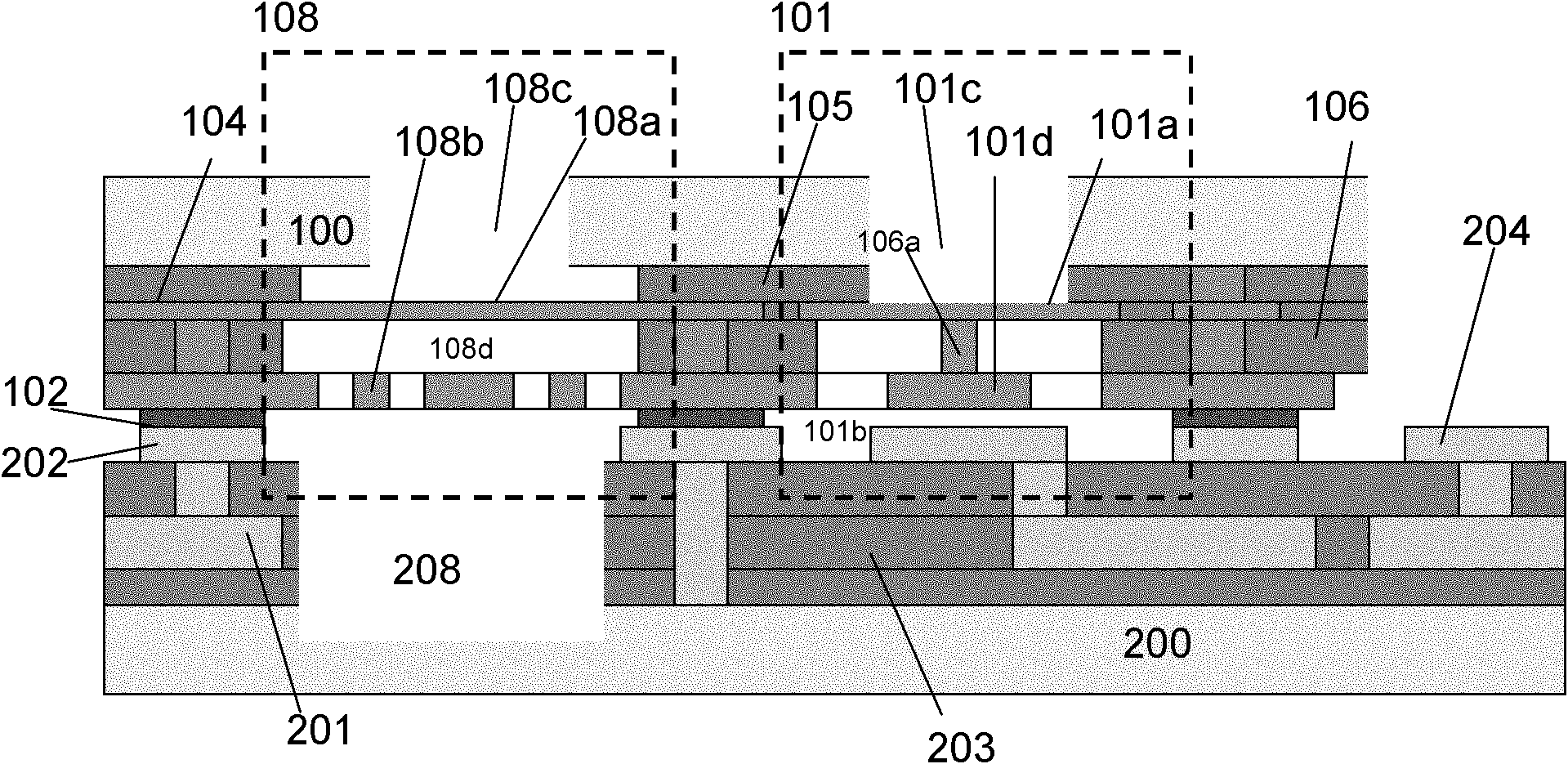

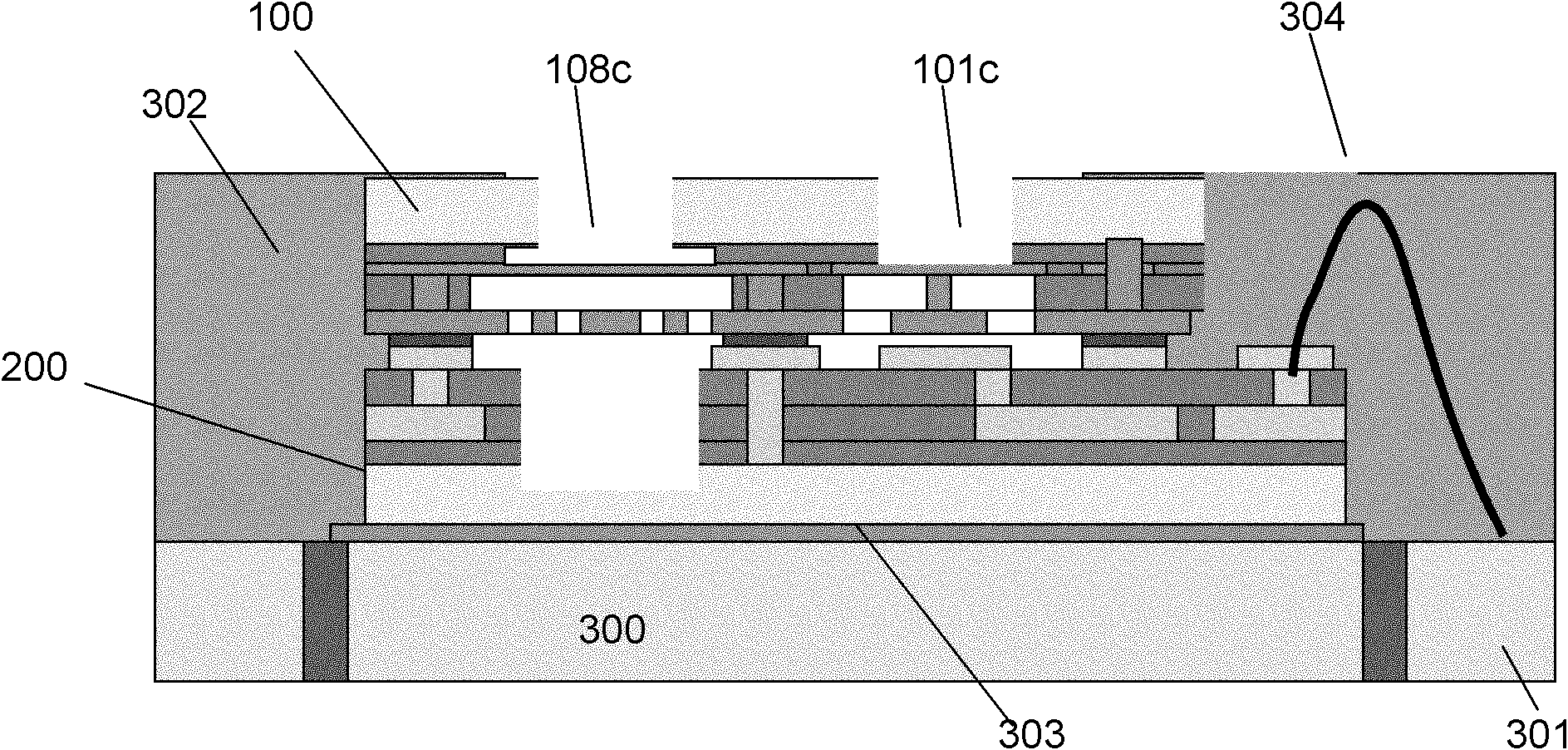

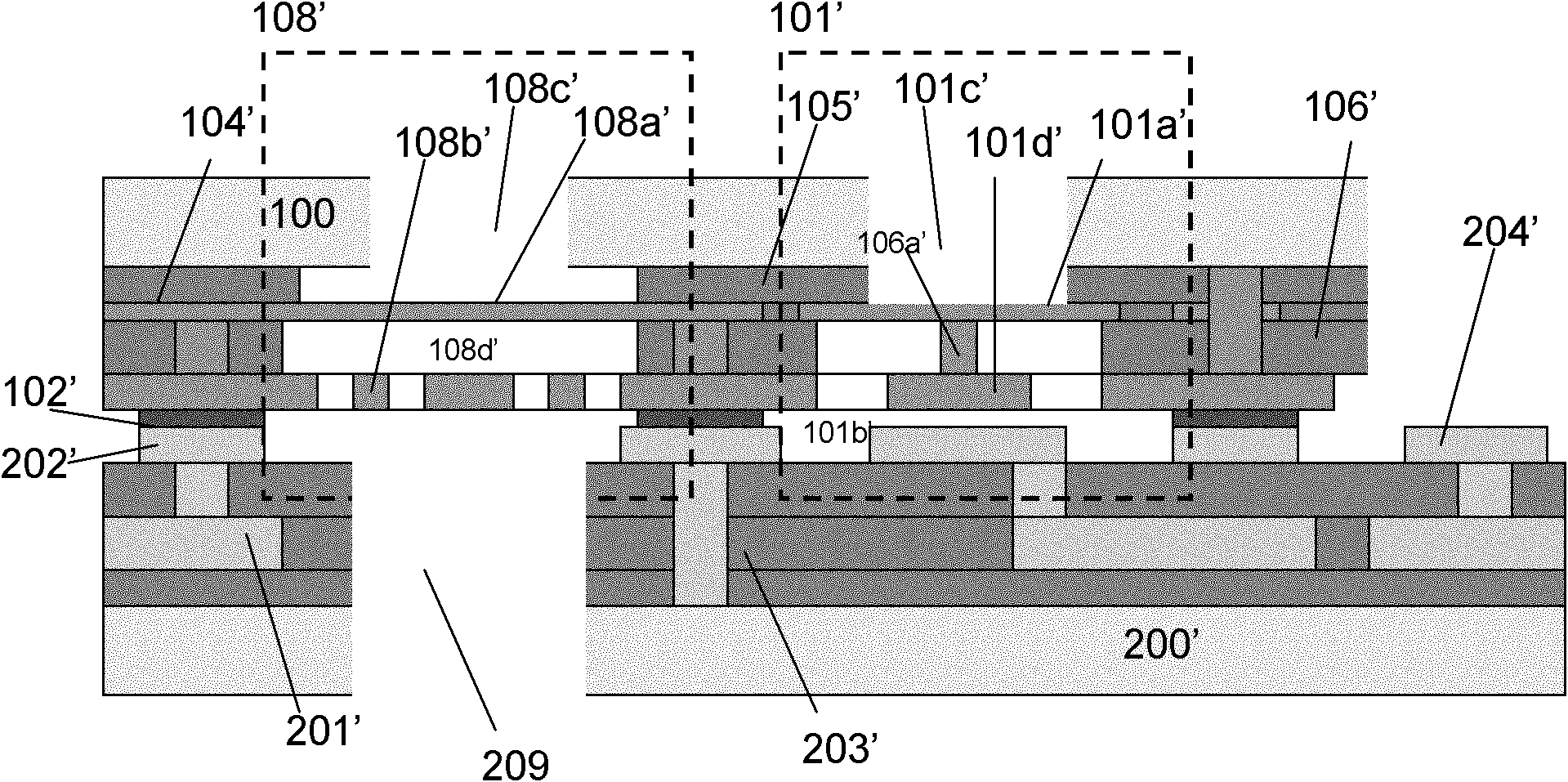

Semiconductor device and method for manufacturing the same

InactiveUS20060270238A1Improve device characteristicsLow costFluid pressure measurement by electric/magnetic elementsSolid-state devicesHigh intensityMetal

A microstructure and a semiconductor element which are included in a micromachine have been generally formed in different steps. It is an object to provide a method for manufacturing a micromachine in which a microstructure and a semiconductor element are formed over one insulating substrate. A feature of the invention is a micromachine including a movable layer containing polycrystalline silicon which is thermally crystallized or crystallized by a laser using metal and a space below or above the layer. Such polycrystalline silicon has high strength and is formed on an insulating surface, so that it is used as a microstructure and used for forming a semiconductor element. Accordingly, a semiconductor device in which a microstructure and a semiconductor element are formed over one insulating substrate can be formed.

Owner:SEMICON ENERGY LAB CO LTD

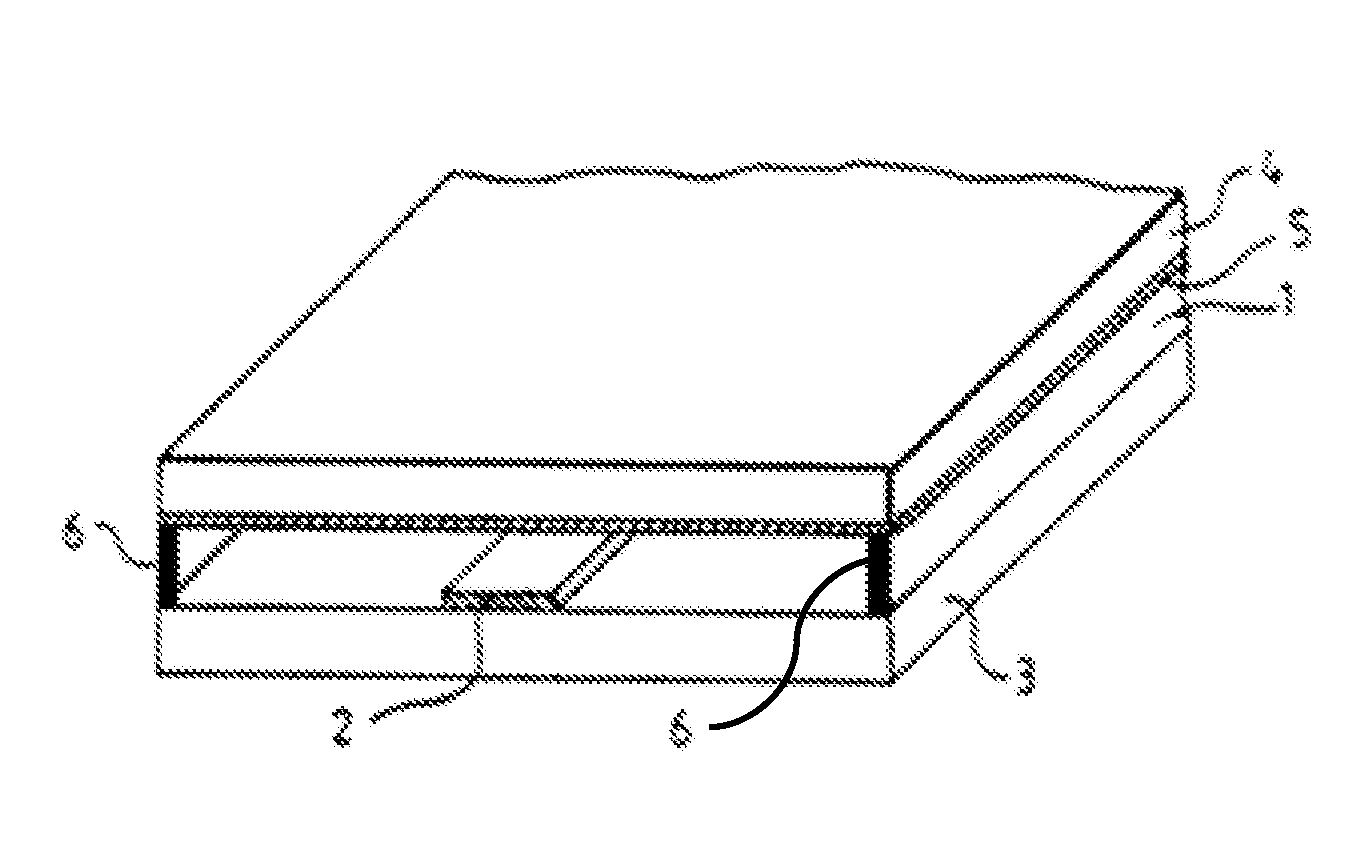

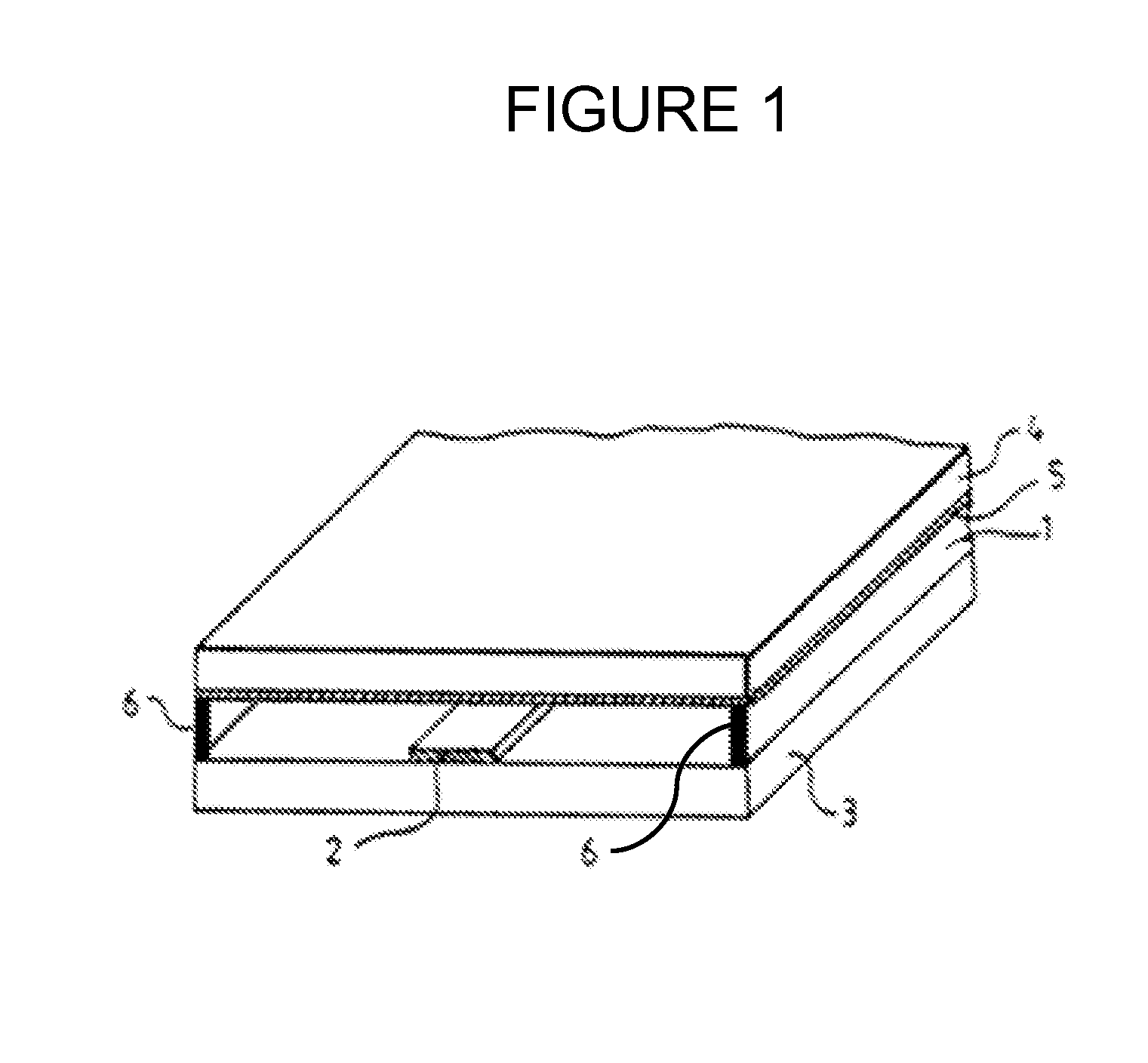

Nanoparticle-enhanced liquid crystal radio frequency phase shifter

InactiveUS20140022029A1Improve circuit performanceMinimal insertion lossNanoopticsDelay linesNanoparticleGround plane

A nanoparticle-enhanced liquid crystal phase shifter is provided including a first substrate layer, a plurality of electrodes attached to the substrate layer, a ground plane layer attached to a second substrate layer, and a liquid crystal layer between the ground plane layer and the first substrate layer, including a suspension of a liquid crystal material and highly polarizable nanoparticles having specific shape and size characteristics.

Owner:UNIV OF COLORADO THE REGENTS OF

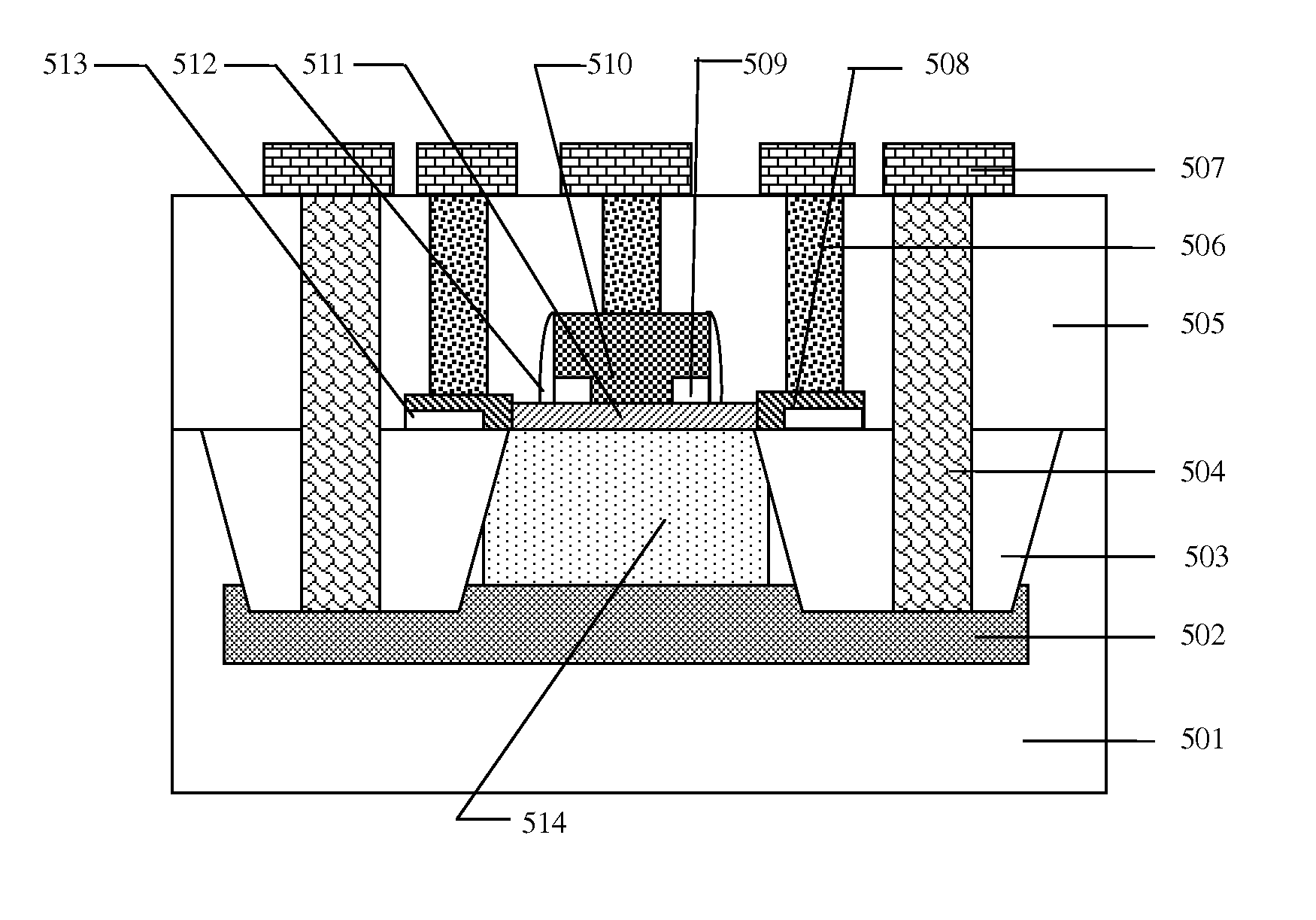

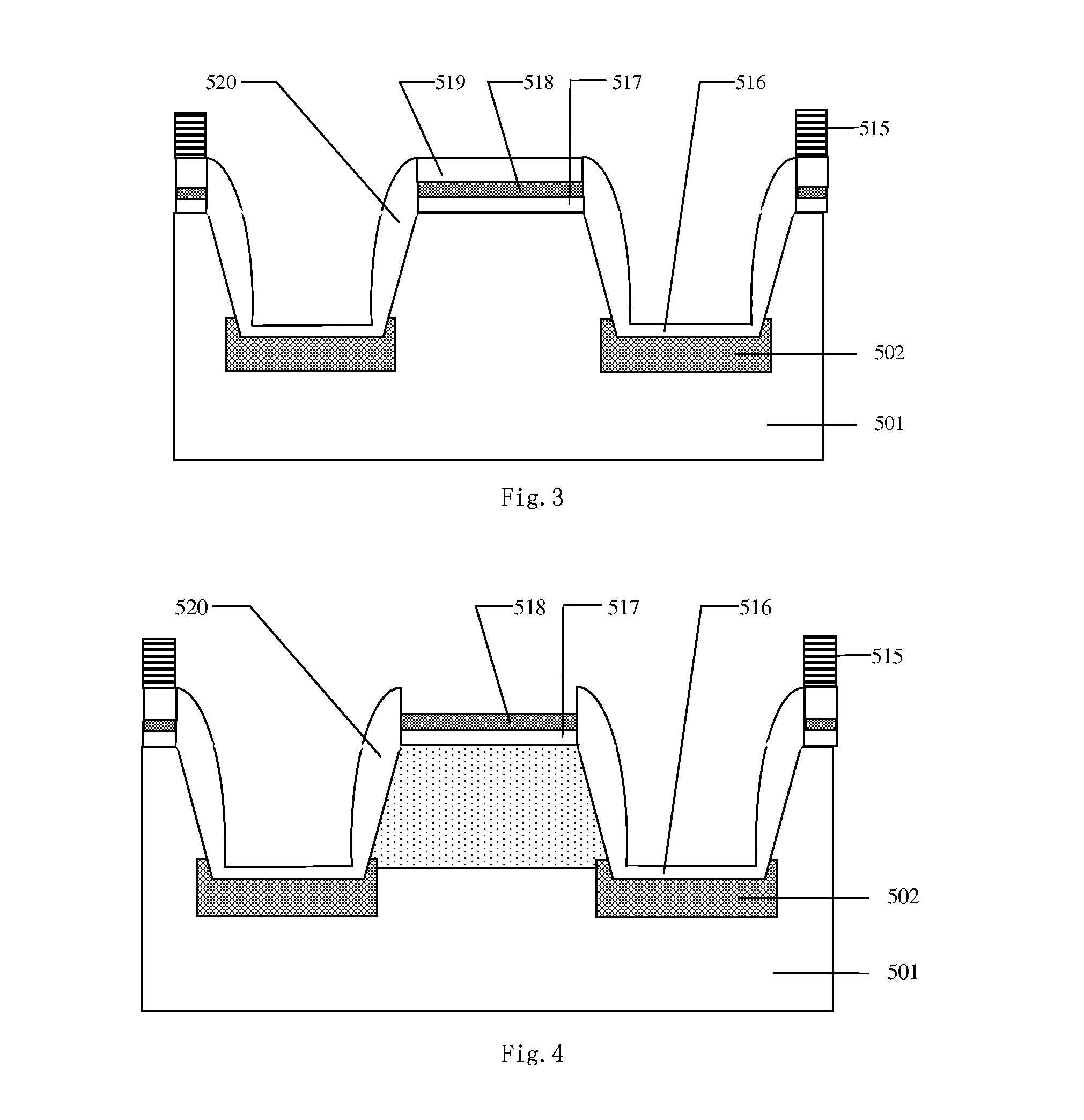

MEMS (Micro Electro Mechanical System) microphone and pressure integration sensor, and manufacturing method thereof

ActiveCN102158787AImprove standardization and unificationSmall device sizeSemiconductor electrostatic transducersElectrostatic transducer microphonesSignal-to-noise ratio (imaging)Mems microphone

The invention relates to an MEMS (Micro Electro Mechanical System) microphone and pressure integration sensor and a manufacturing method thereof. The sensor provided by the invention comprises a first substrate and a second substrate, wherein the first substrate is provided with an induction film of a capacitance pressure sensing unit, a sensitive film of a microphone unit and a first bonding layer on the surface of the first substrate; the second substrate is provided with a dielectric layer between conductors, a conductor wiring layer positioned in the dielectric layer between the conductors and / or a second bonding layer on the surface of the second substrate; the second substrate and the first substrate are oppositely arranged and fixedly connected through the first bonding layer and the second bonding layer; and the patterns of the first bonding layer and the second bonding layer correspond to each other and are conductive materials. In the MEMS microphone and pressure sensor and the manufacturing method thereof provided by the invention, the capacitance pressure sensing unit and the microphone unit through the two substrates, thus the sensor and method provided by the invention are suitable for chip structures produced in a large scale and integrated with various MEMS sensors, are beneficial to the compatibility with an integrated circuit process, have the advantages that the standardization of a manufacturing process and a packaging process is enhanced, the volumes of devices are small, the signal-to-noise ratio performance is excellent, and the interference resistance is high.

Owner:MEMSEN ELECTRONICS

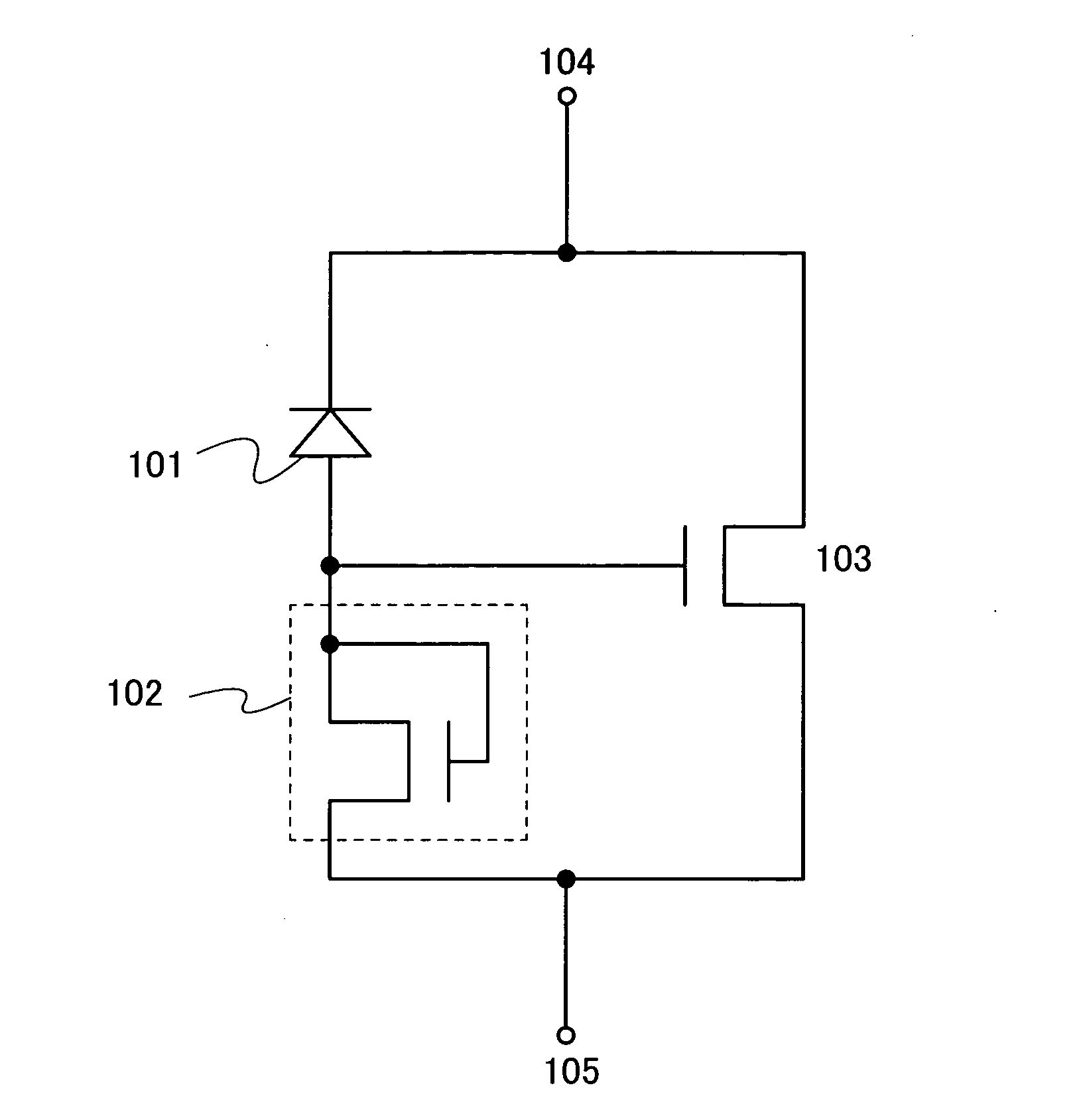

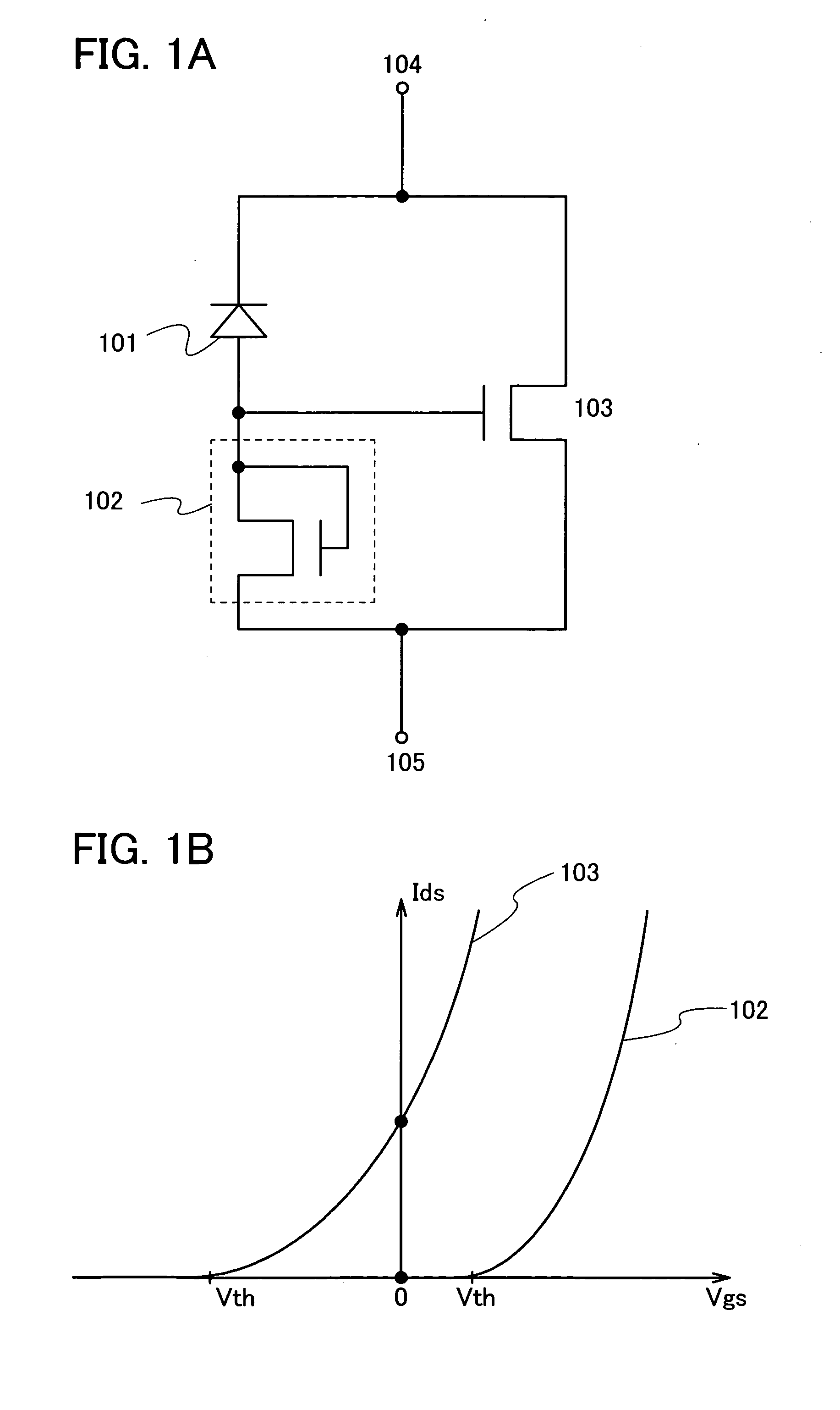

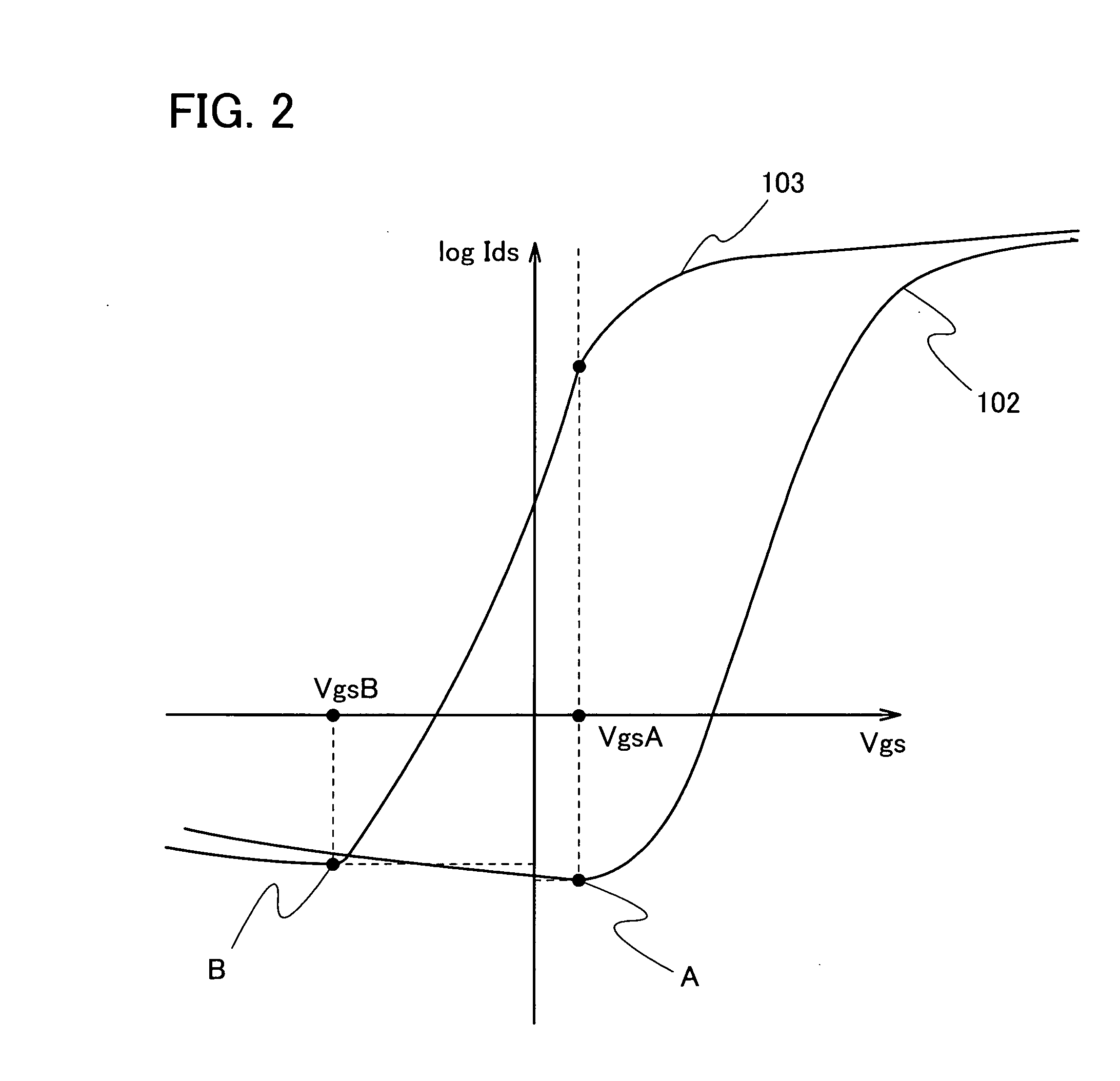

Semiconductor device and electronic device using the same

ActiveUS20080246064A1Low lightFirmly connectedTelevision system detailsTelevision system scanning detailsEngineeringElectrical and Electronics engineering

To provide a semiconductor device which can detect low illuminance. A photoelectric conversion element, a diode-connected first transistor, and a second transistor are included. A gate of the first transistor is electrically connected to a gate of the second transistor. One of a source and a drain of the first transistor is electrically connected to one of a source and a drain of the second transistor through the photoelectric conversion element. The other of the source and the drain of the first transistor is electrically connected to the other of the source and the drain of the second transistor. By using transistors which have different threshold voltages for the first transistor and the second transistor, a semiconductor device which can perform detecting of low illuminance can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

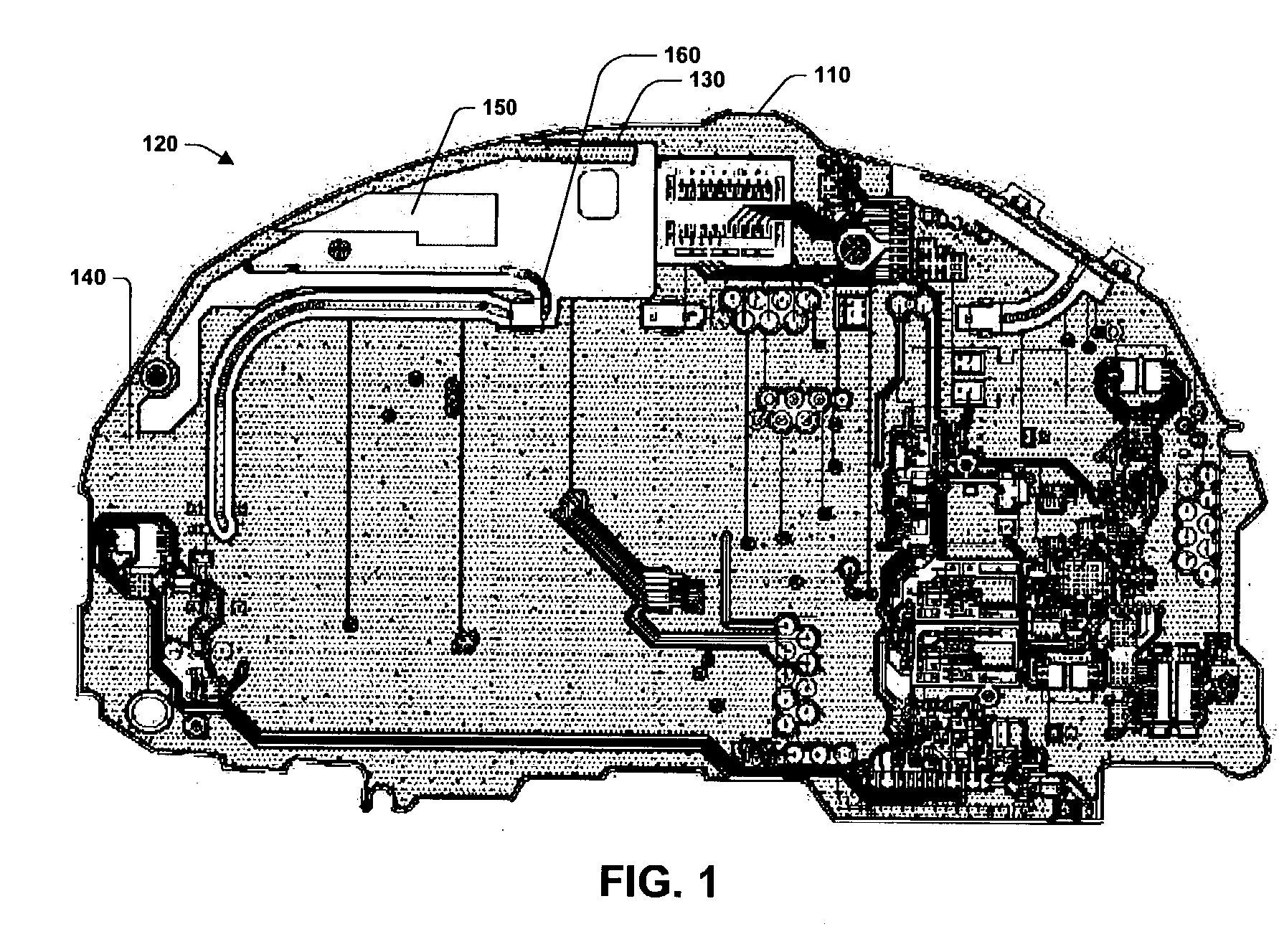

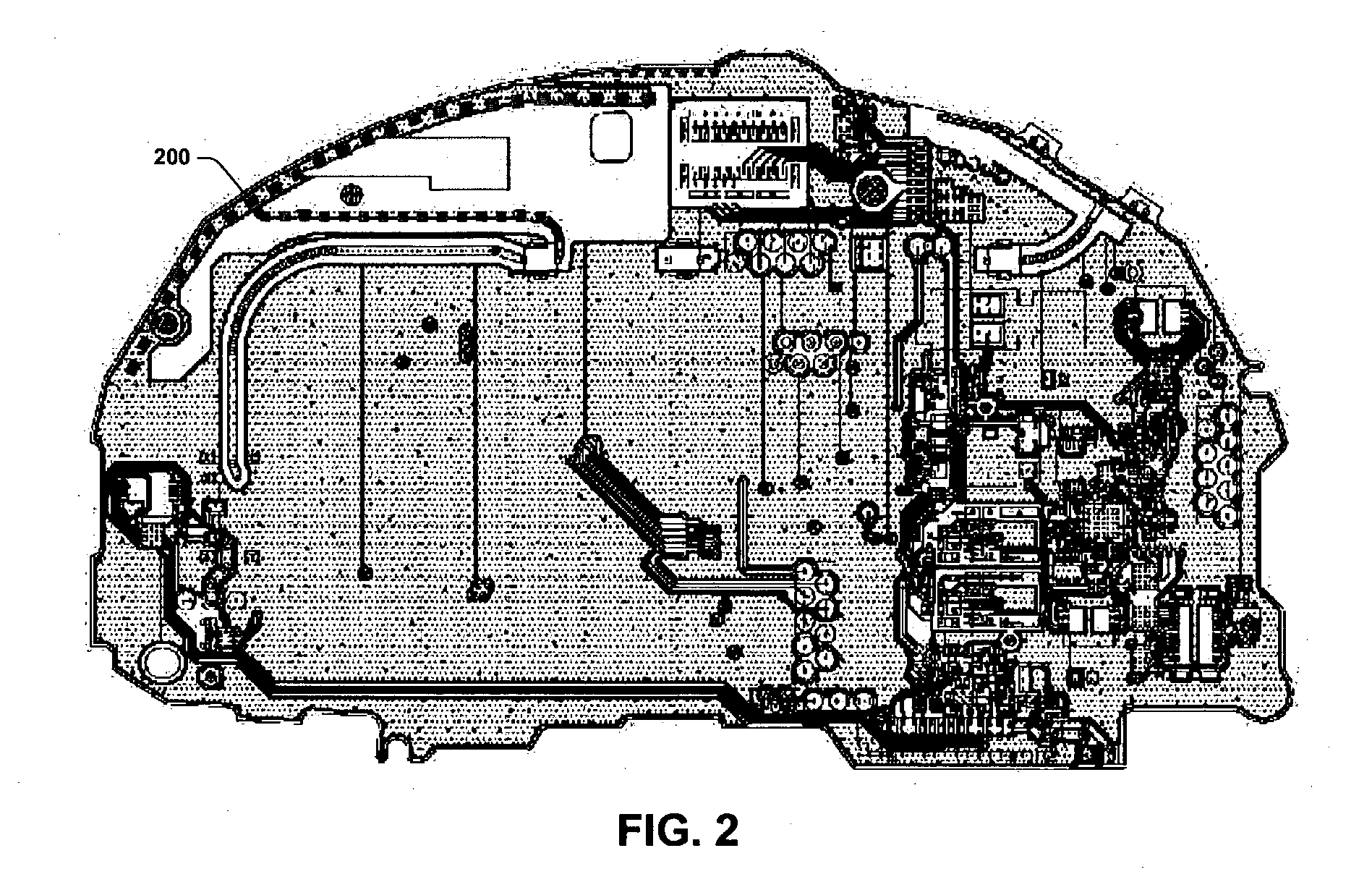

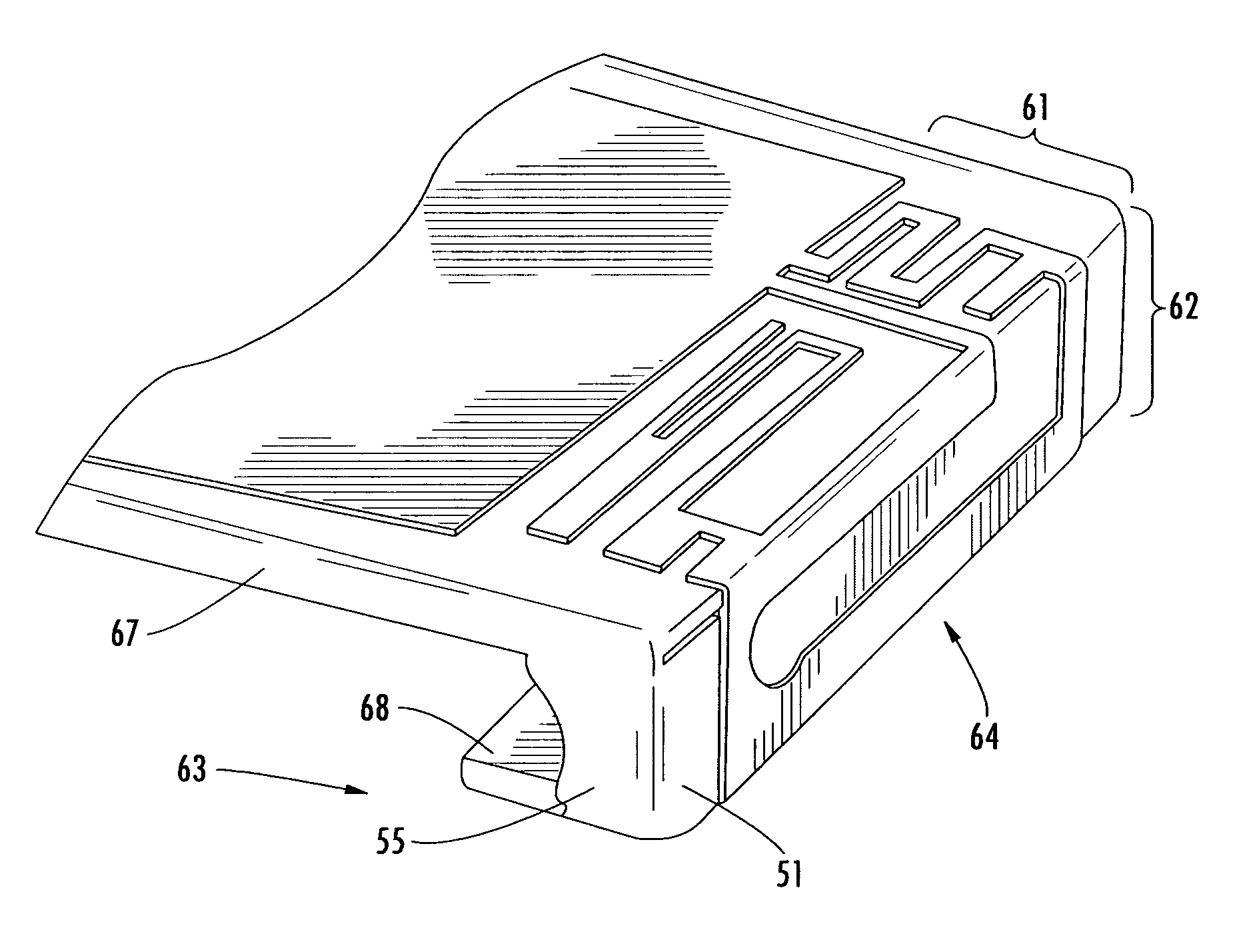

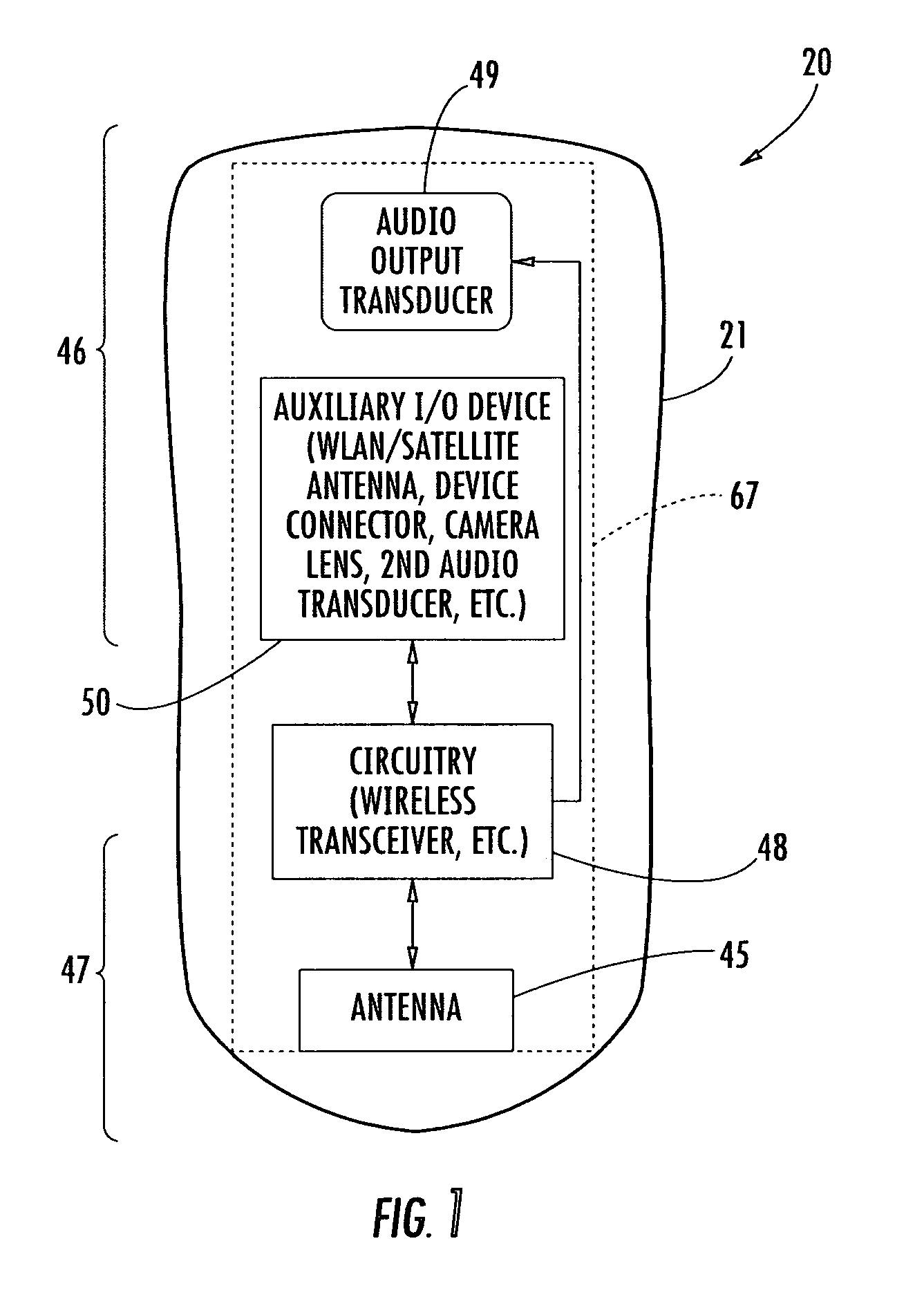

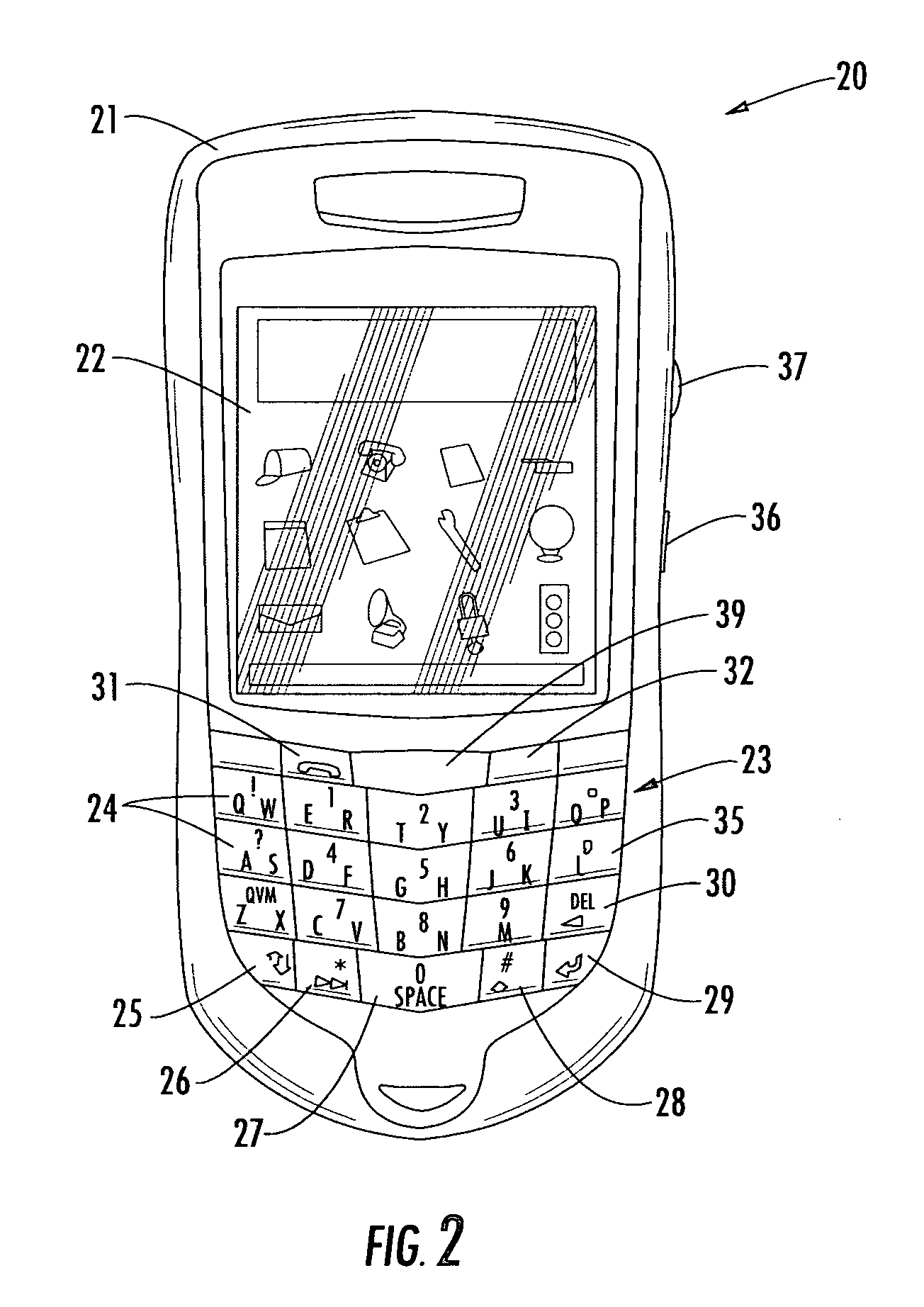

Mobile wireless communications device comprising multi-frequency band antenna and related methods

ActiveUS7068230B2Small device sizeDesired performanceSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorEngineering

A mobile wireless communications device may include a housing and a multi-frequency band antenna carried within the housing. The multi-frequency band antenna may include a main loop conductor having a gap therein defining first and second ends of the main loop conductor, a first branch conductor having a first end connected adjacent the first end of the main loop conductor and having a second end defining a first feed point, and a second branch conductor having a first end connected adjacent the second end of the main loop conductor and a second end defining a second feed point. The antenna may further include a tuning branch conductor having a first end connected to the main loop conductor between the respective first ends of the first and second branches.

Owner:GOOGLE TECH HLDG LLC

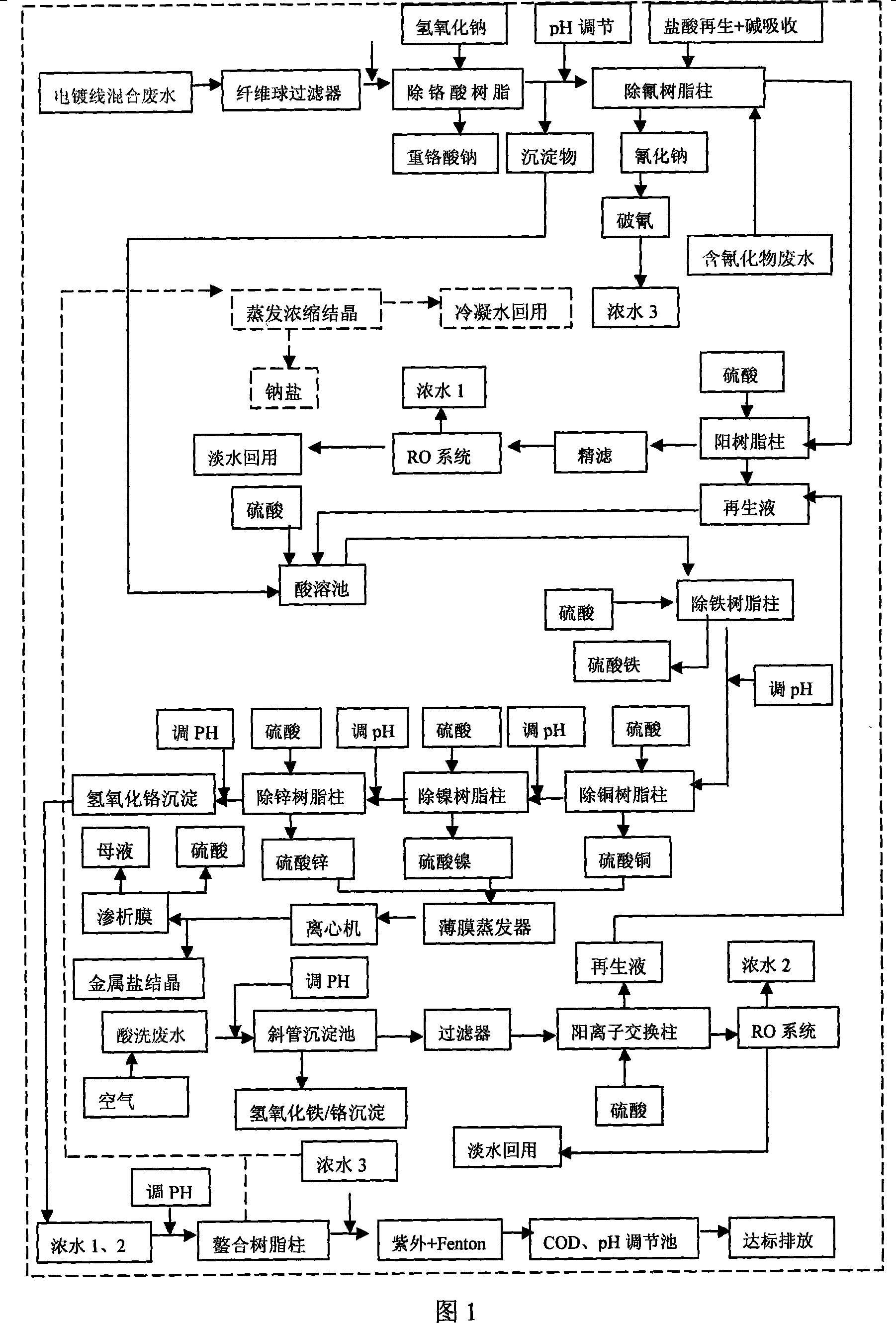

Electroplating wastewater zero-discharge or low-discharge handling method

InactiveCN101157509ASolve pollutionReduce processing costsFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationIonAutomatic control

The invention provides a processing method for zero draining or low draining of electroplating wastewater. The method adopts an integrative technique, such as barrier concentration, barrier separation, ion exchange, and ultraviolet light catalytic oxidation, etc. The following steps are adopted: the pretreatment of the electroplating wastewater; the treatment for the three types of wastewater including pickling wastewater, wastewater containing cyanide and passivating and electroplating rinsing composite wastewater; and the treatment for the wastewater in an acid-soluble pool. Compared with the wastewater in an integrative electroplating plant with universal generic multi-plating species, only the prior water separation method with no need to control the troubled water strictly can realize : first, zero draining of the electroplating wastewater is performed; second, when operating in the low energy consumption way, 65 to 85 percent of water recovery is realized, the left wastewater which can not be recovered is discharged when reaching the primary discharge standard of National Standard; third, the processing cost is reduced; fourth, the metallic ion in the wastewater can be effectively recovered and utilized, at the same time, the benefit disinvestment cost is produced; fifth, the amount for causing solid waste is reduced; sixth, the invention is advantageous to realize the automatic control and the operation.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV +1

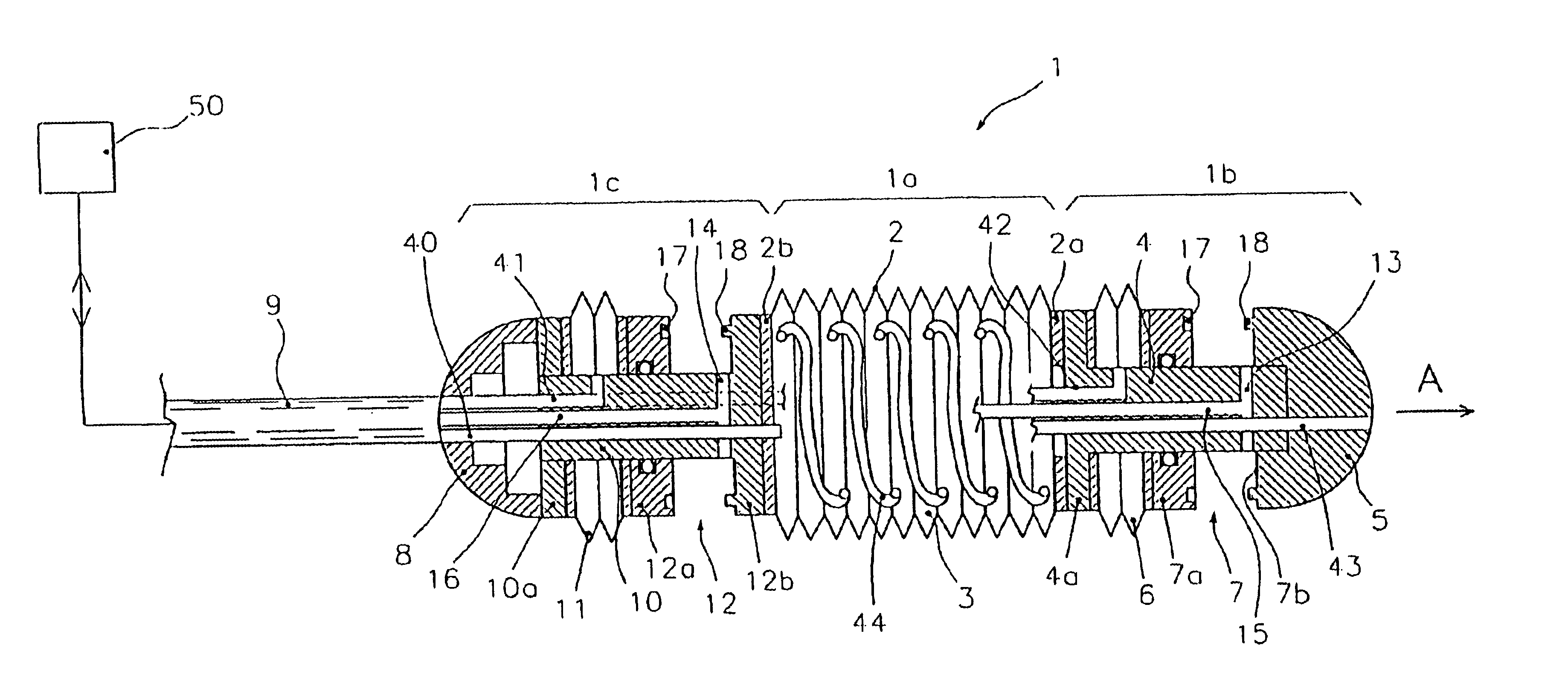

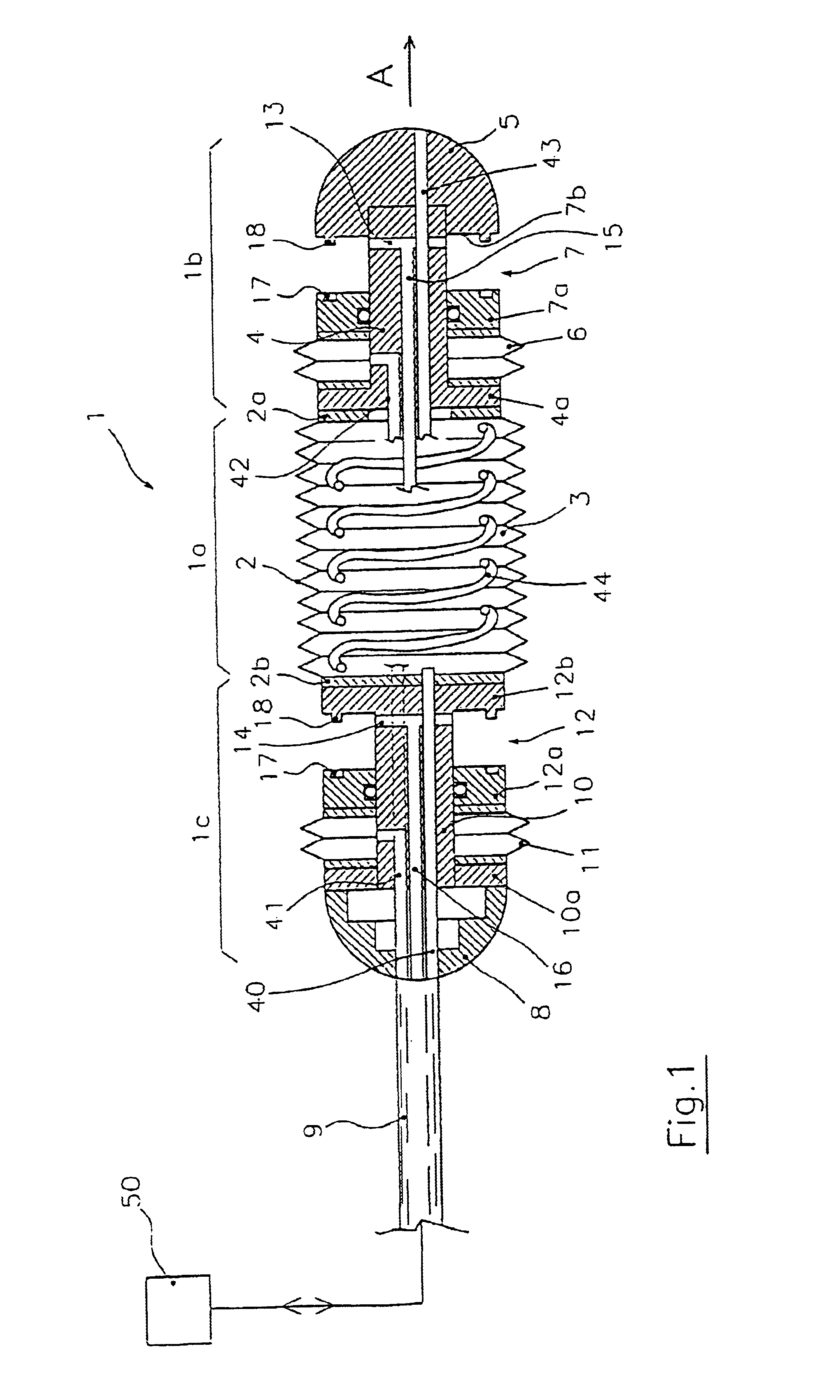

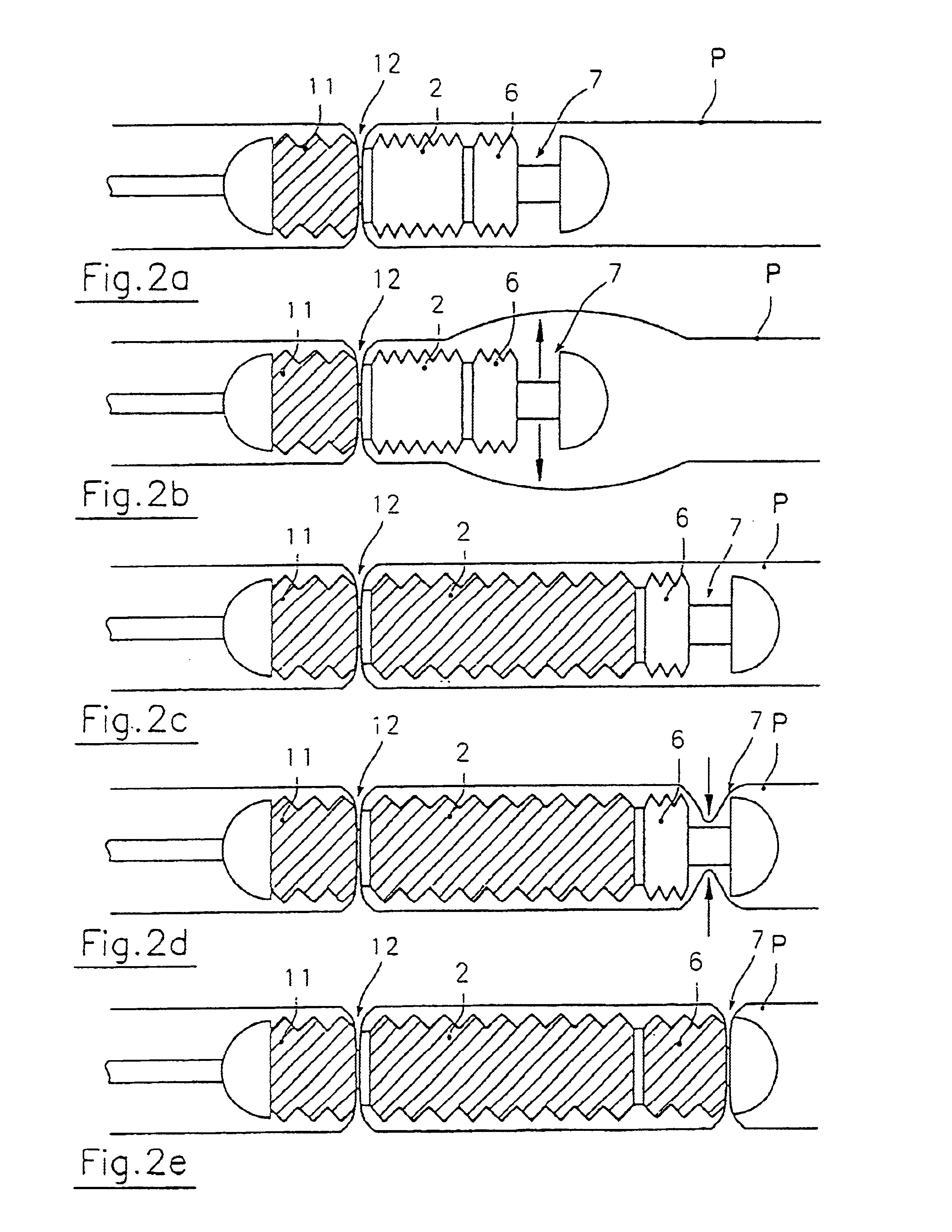

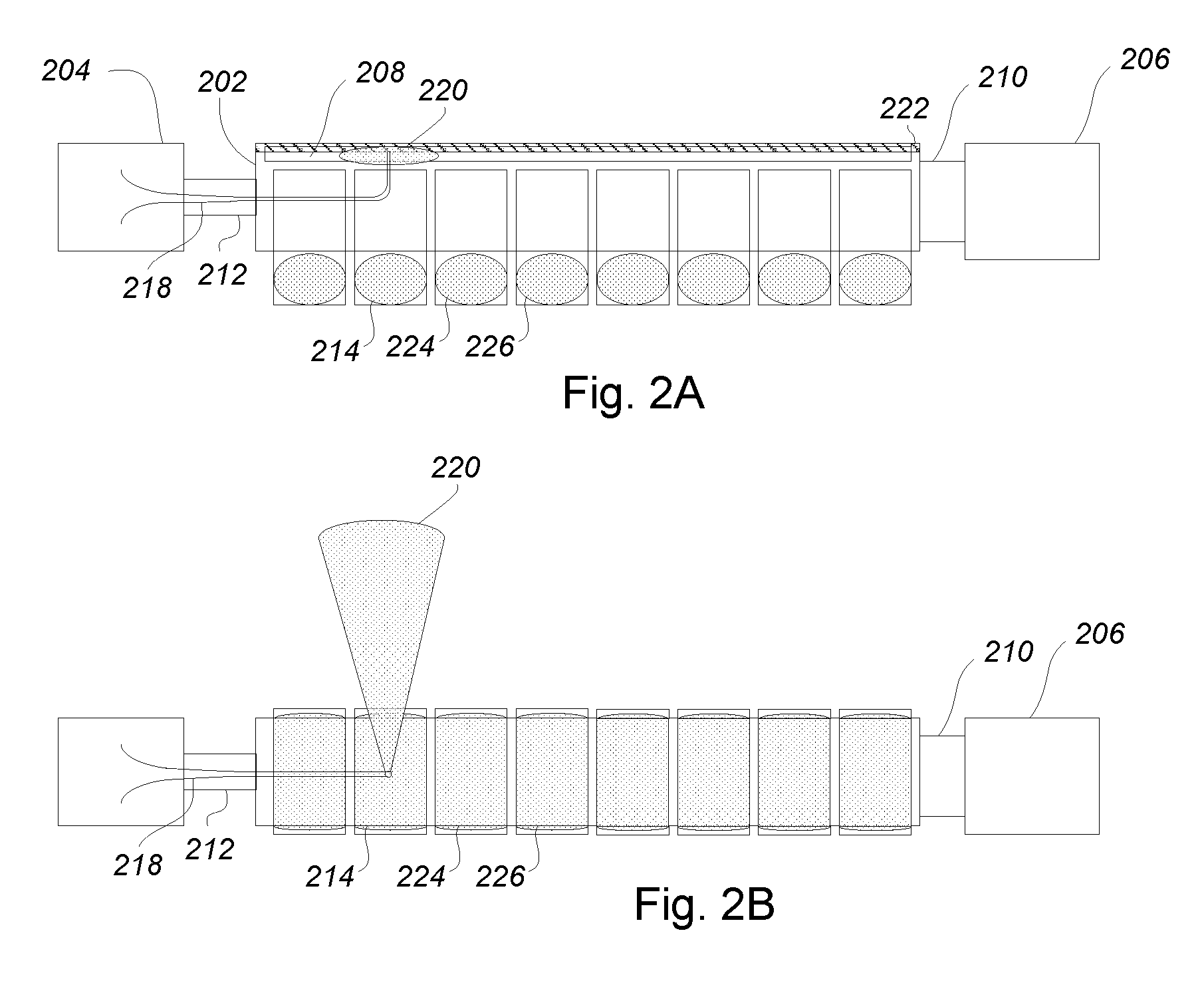

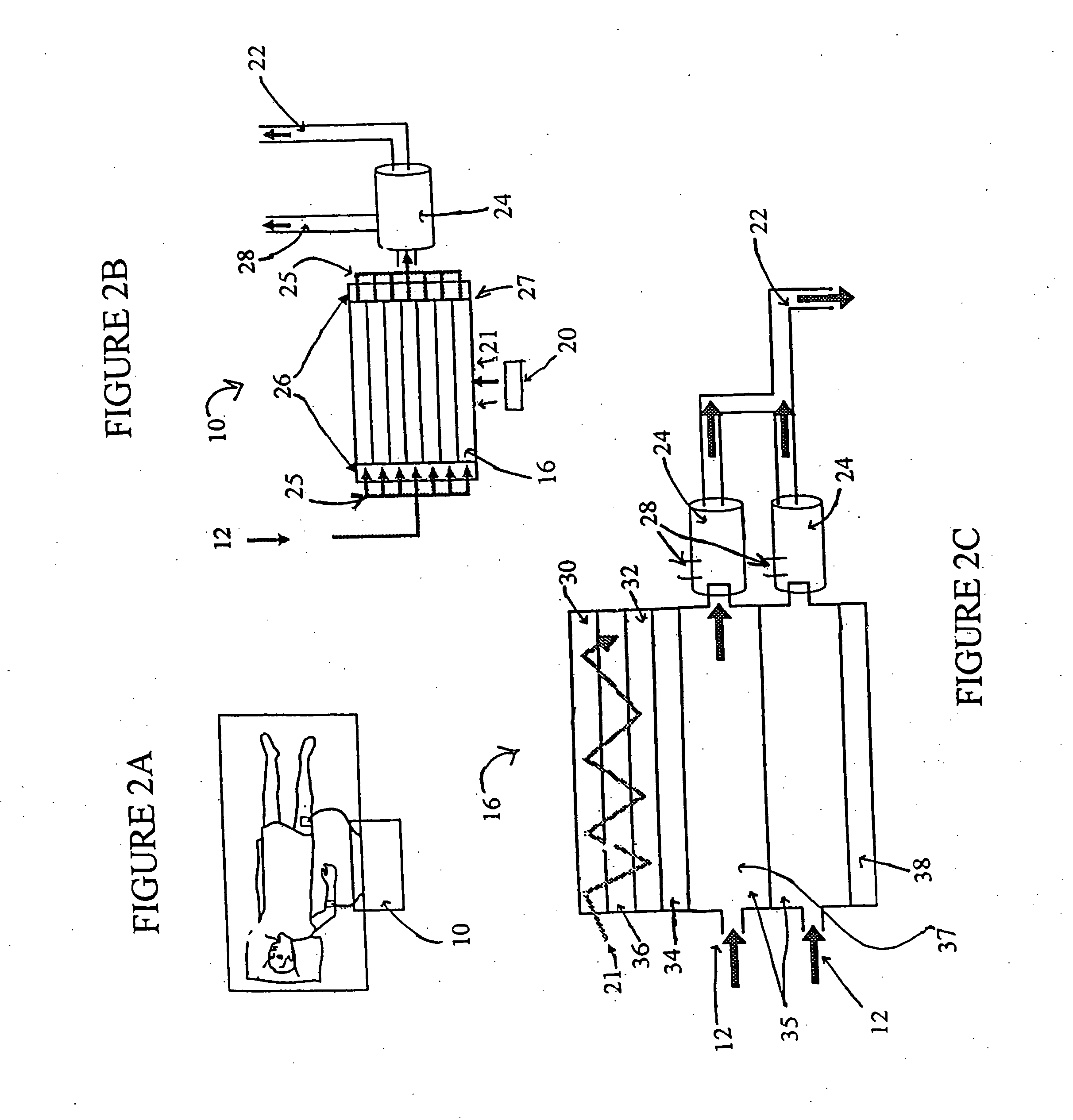

Endoscopic device for locomotion through the gastro-intestinal tract

An endoscopic device for locomotion in a body cavity according to a prefixed advancing direction (A) comprising at least a variable length intermediate section (1a, 21a) extending between a front end section (1b, 21b) and a rear end section (1c, 21c). First and second clamping means (7, 12, 27, 32) are integral to the front and rear section, for alternately grasping respective surrounding portions of wall (P) of the body cavity. Sucking means (13, 14, 37, 38) are associated to the first and second clamping means for creating a depression sufficient to cause the body cavity wall portions to collapse within the first and second clamping means while they are in an open condition. Means for actuating alternate extensions and retractions of the intermediate section and actuating means (6, 11, 26, 31) of the first and second clamping means are further provides for synchronous operation to generate a forward motion of the rear end section due to a retraction of the intermediate section, the wall portion (P) surrounding the first clamping means being firmly held therebetween, and to generate a forward motion of the front end section due to an extension of the intermediate section, the wall portion (P) surrounding the second clamping means being firmly held therebetween.

Owner:ERA ENDOSCOPY

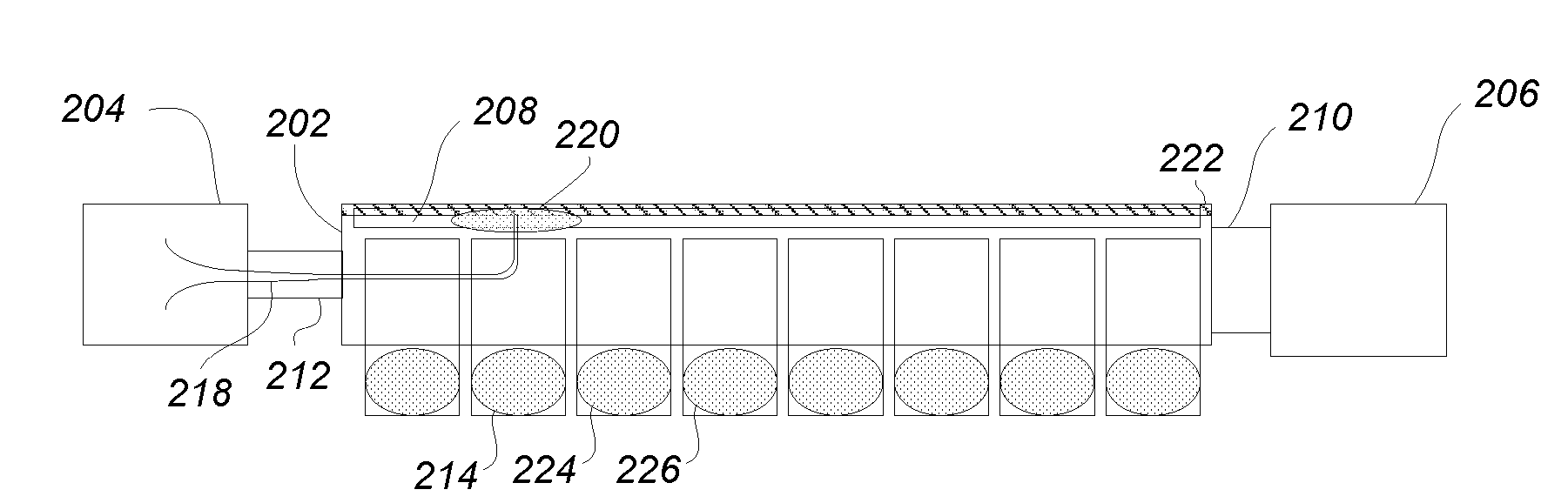

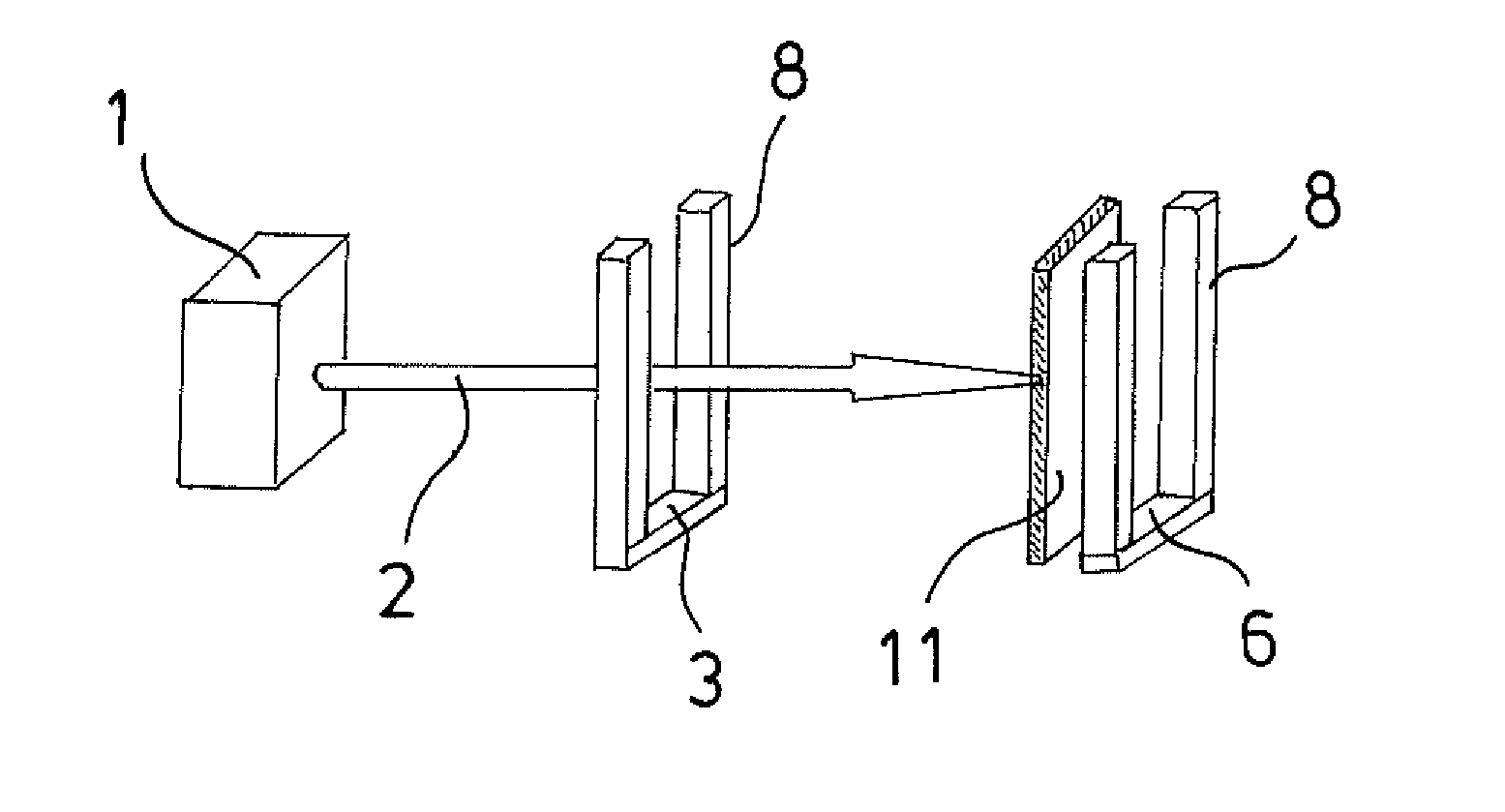

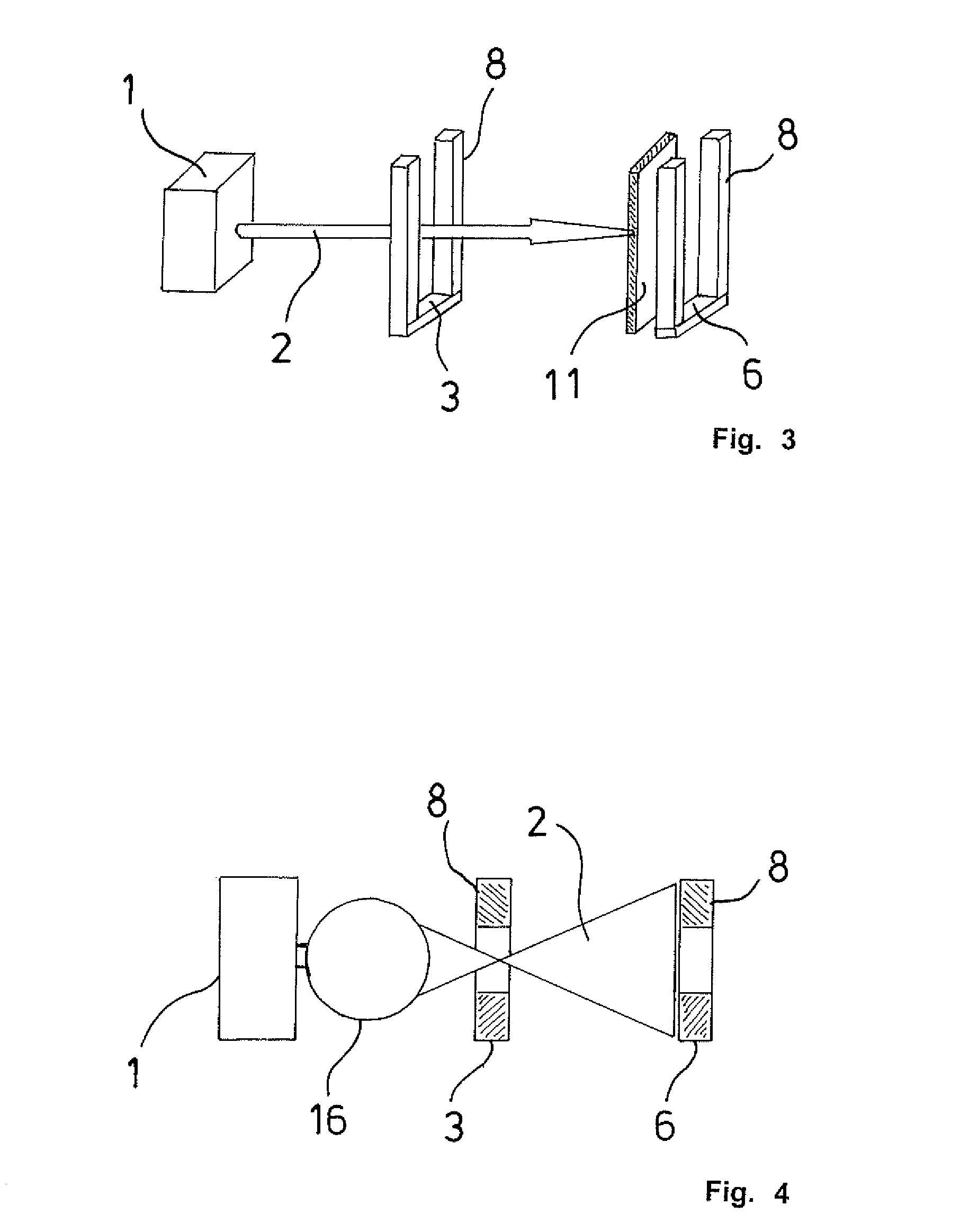

Compact scanned electron-beam x-ray source

ActiveUS20080198970A1Small device sizeAvoid dwell timeRadiation/particle handlingX-ray tube gas controlX-rayLight beam

A compact, reliable scanning electron-beam x-ray source achieves reduced complexity and cost. In particular, the x-ray source includes an electron beam that is propagated parallel to an x-ray target and is swept across the target in response to a moving magnetic cross field. Rather than scanning the beam by deflecting it about a single point, the point of deflection is translated along the target length, dramatically reducing the volume of the device. The magnetic cross field is translated along the target length using either mechanical systems to move permanent magnets, or electrical systems to energize an array of electromagnets.

Owner:L3 TECH INC

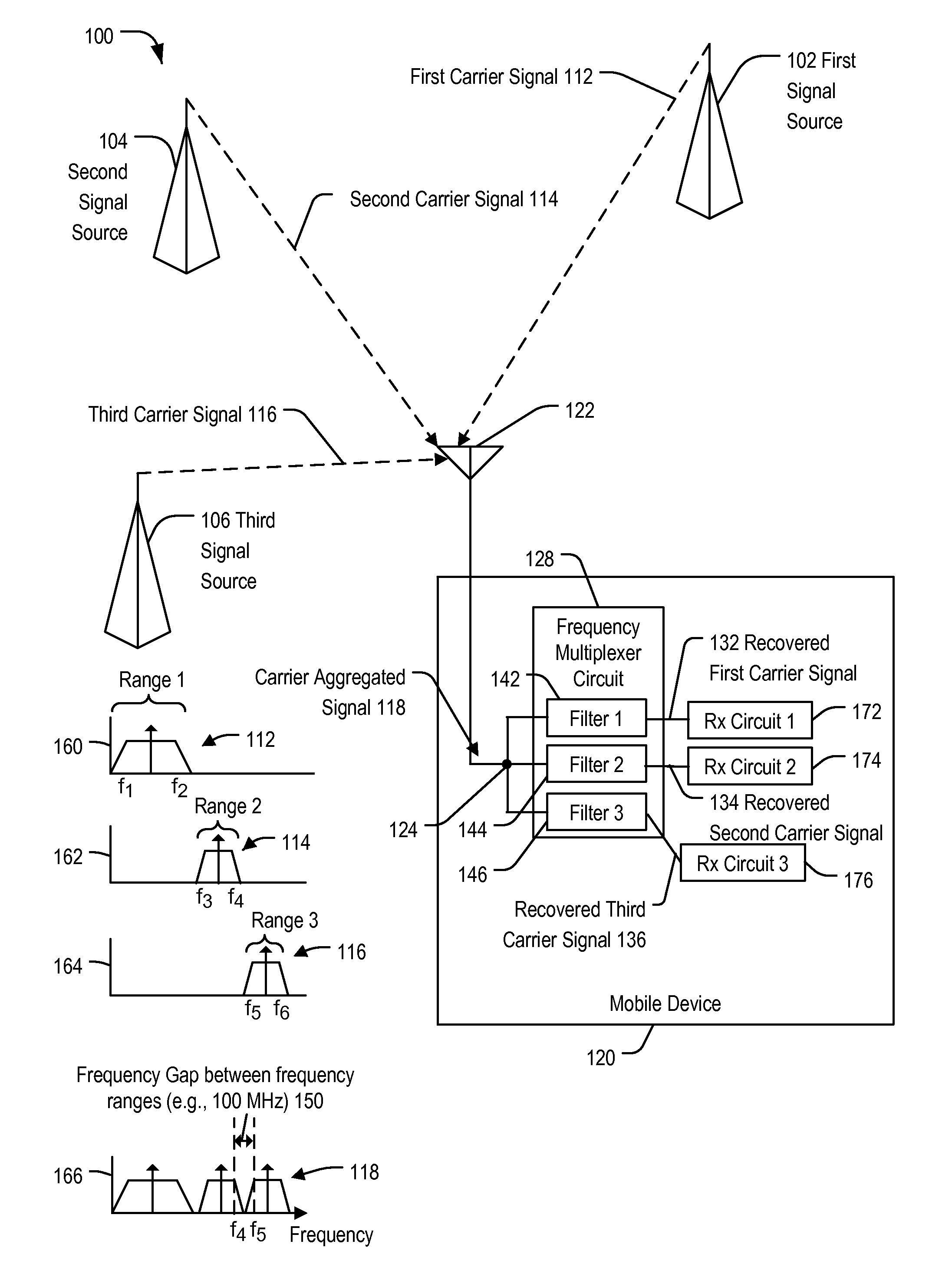

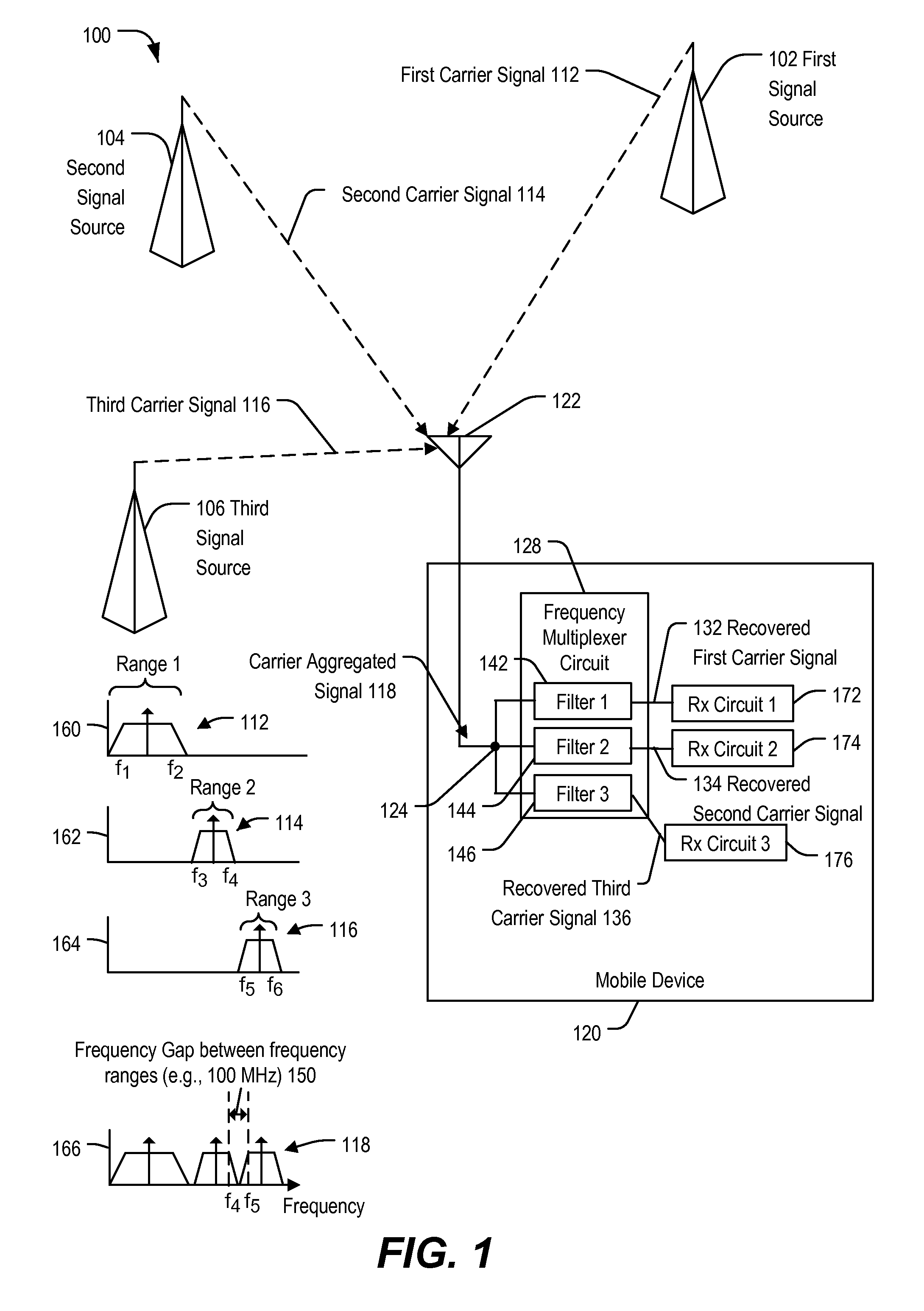

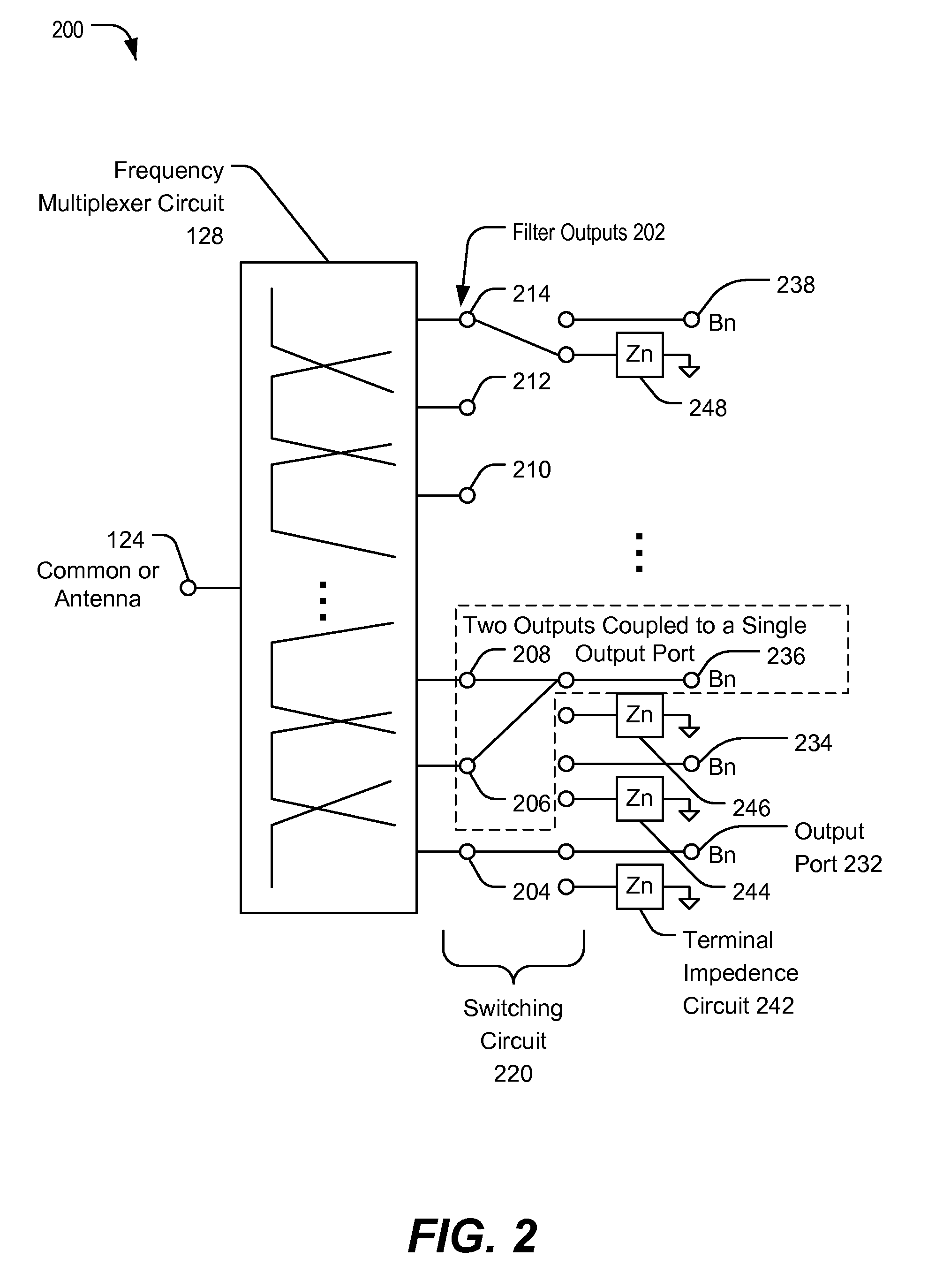

Frequency multiplexer

ActiveUS20150304059A1High resolutionSmall device sizeMultiple-port networksFrequency-division multiplex detailsMultiplexer

An apparatus is disclosed that includes a frequency multiplexer circuit coupled to an input node and configured to receive an input signal via the input node. The frequency multiplexer circuit comprises a first filter circuit, a second filter circuit, and a third filter circuit. The apparatus also includes a switching circuit that is configurable to couple at least two of a first output of the first filter circuit, a second output of the second filter circuit, or a third output of the third filter circuit to a single output port.

Owner:QUALCOMM INC

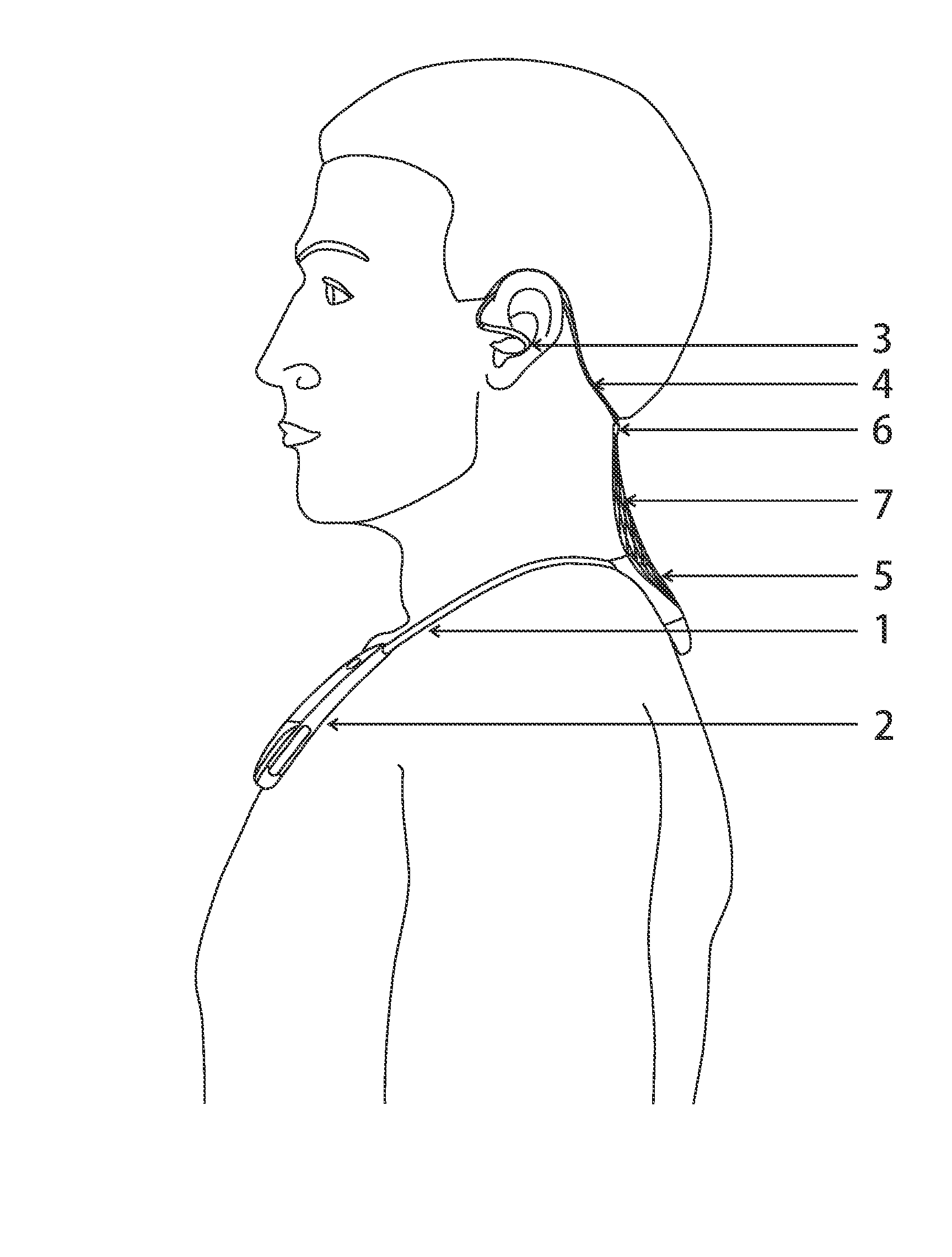

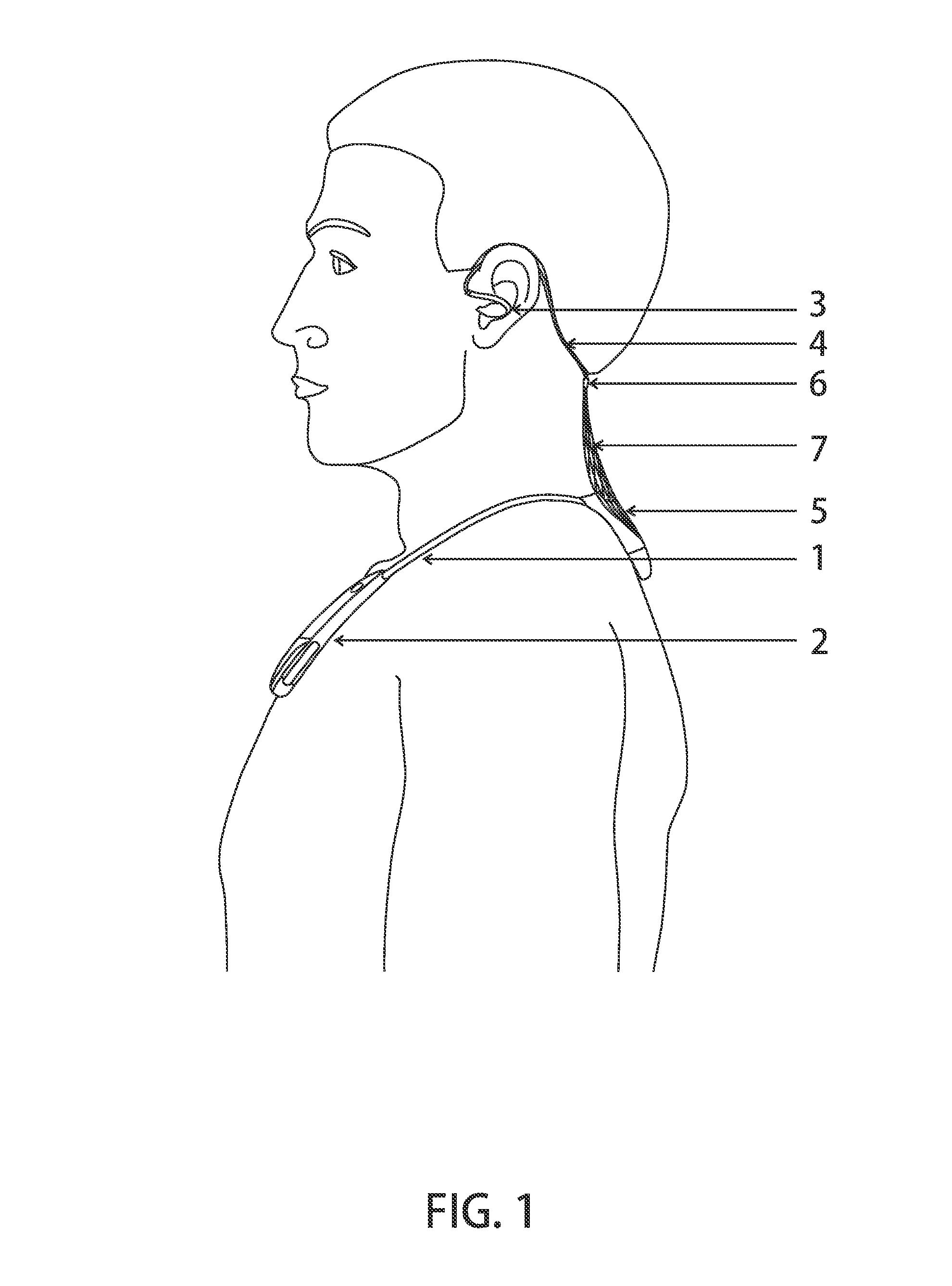

Neck-wearable communication device with microphone array

ActiveUS20160381453A1Optimize locationGood effectEar treatmentNoise generationTarget signalEngineering

A wearable electronic device includes a neck-wearable housing, generally U-shaped, with an electrical connector; two in-ear earphones; two cords, with one end connected to one of the earphones and the other end connected to the connector. The two cords are mechanically connected to the housing. Points of connection of the cords to the housing are close to each other and form a dorsal node, and the two cords are mechanically connected to each other in their portions between the in-ear earphones and the dorsal node to form a suboccipital node. A microphone is placed in the housing on a front (chest) side of the user. A microphone is placed in the dorsal and / or in the suboccipital node. The microphones are used for determination of correlated and non-correlated components of audio signals. The correlated components are treated as a noise signal and the non-correlated components are a target signal.

Owner:USHAKOV ALEXEY LEONIDOVICH

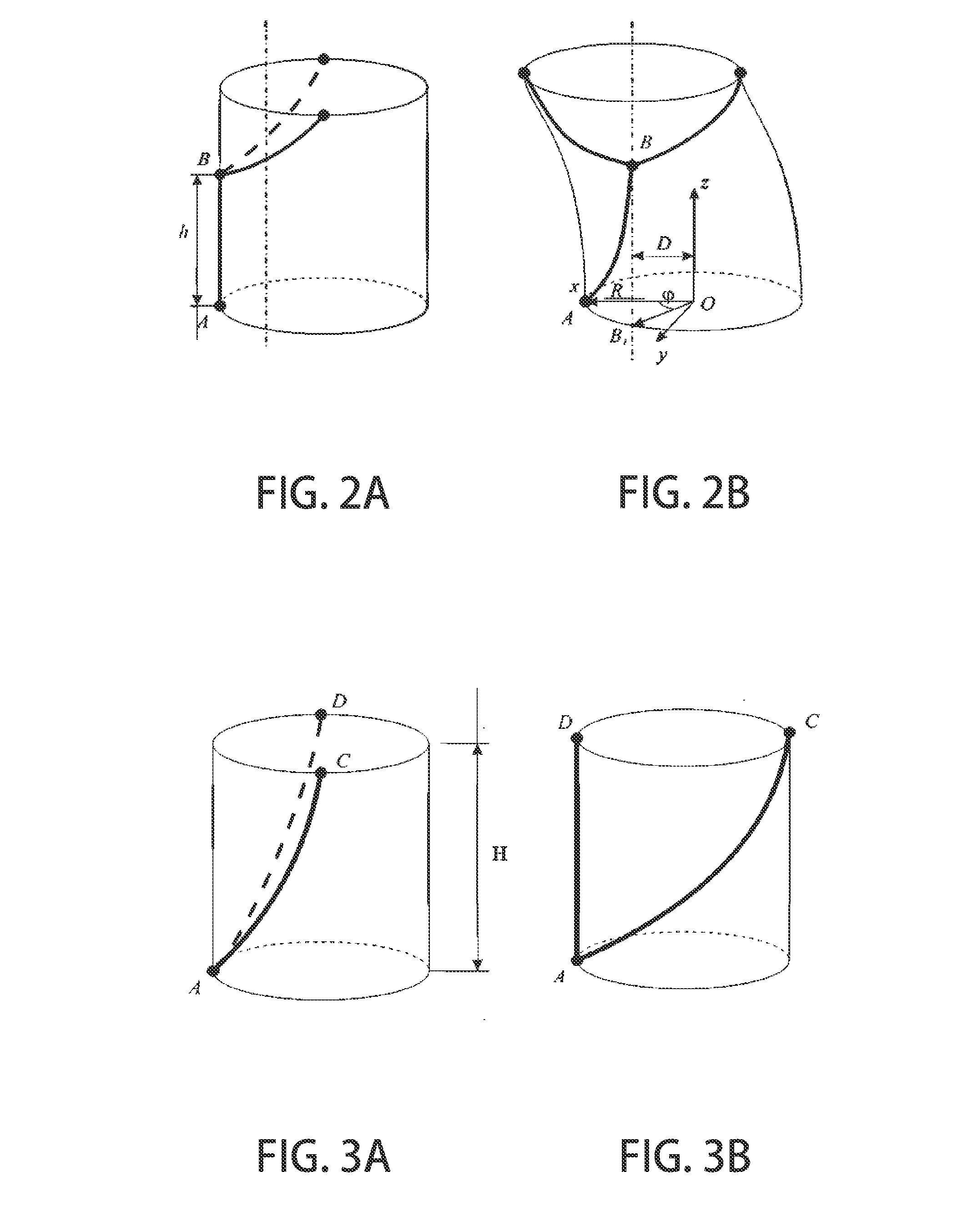

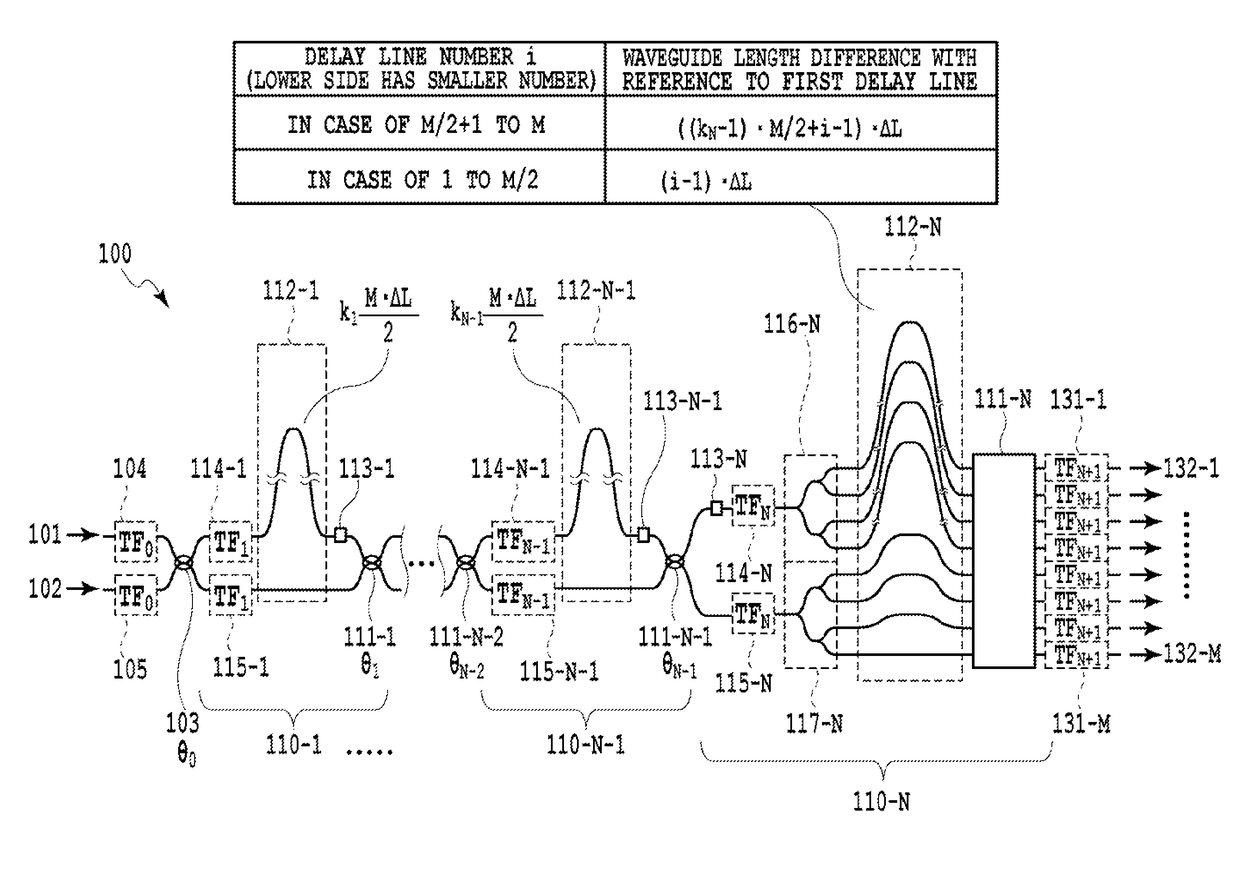

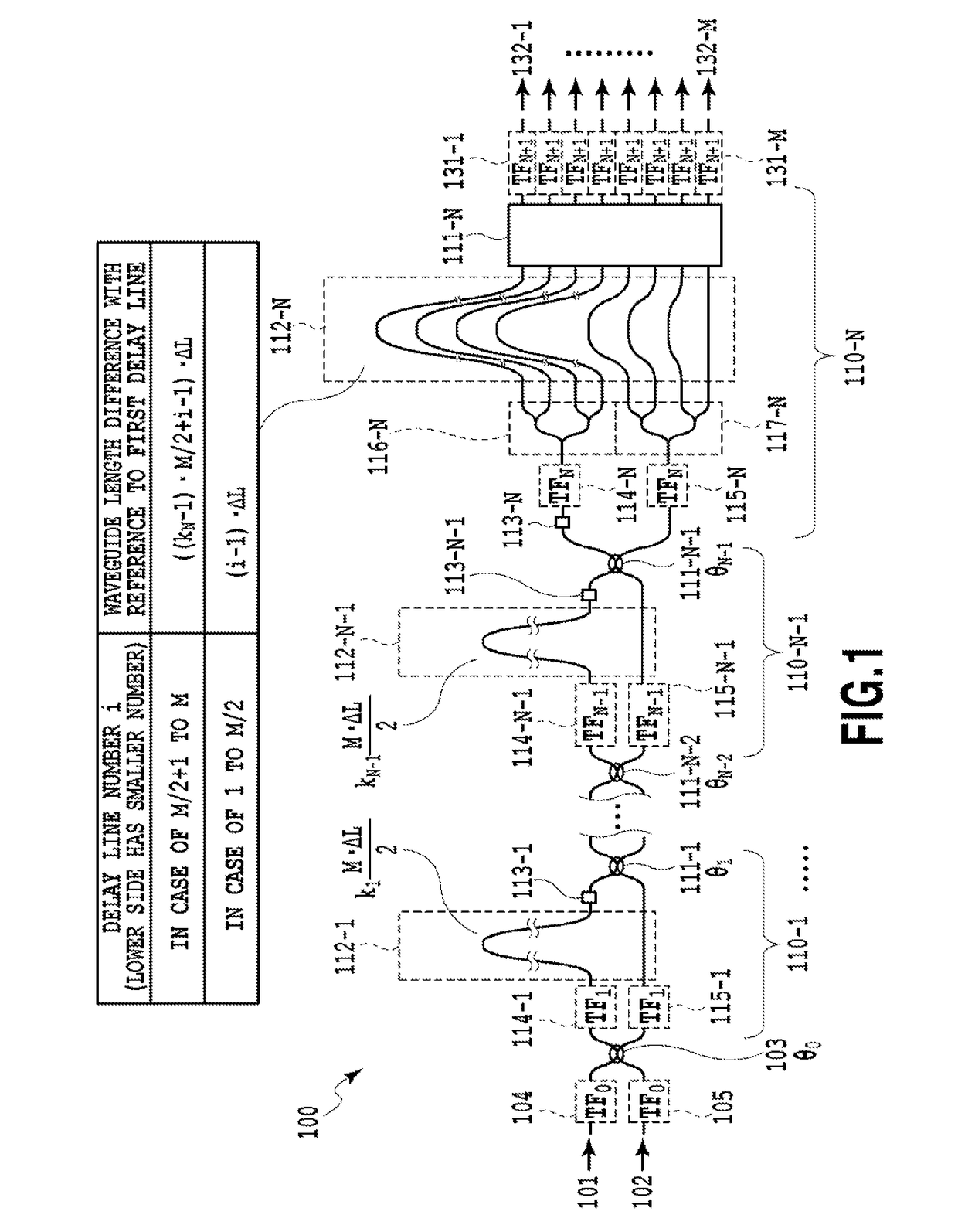

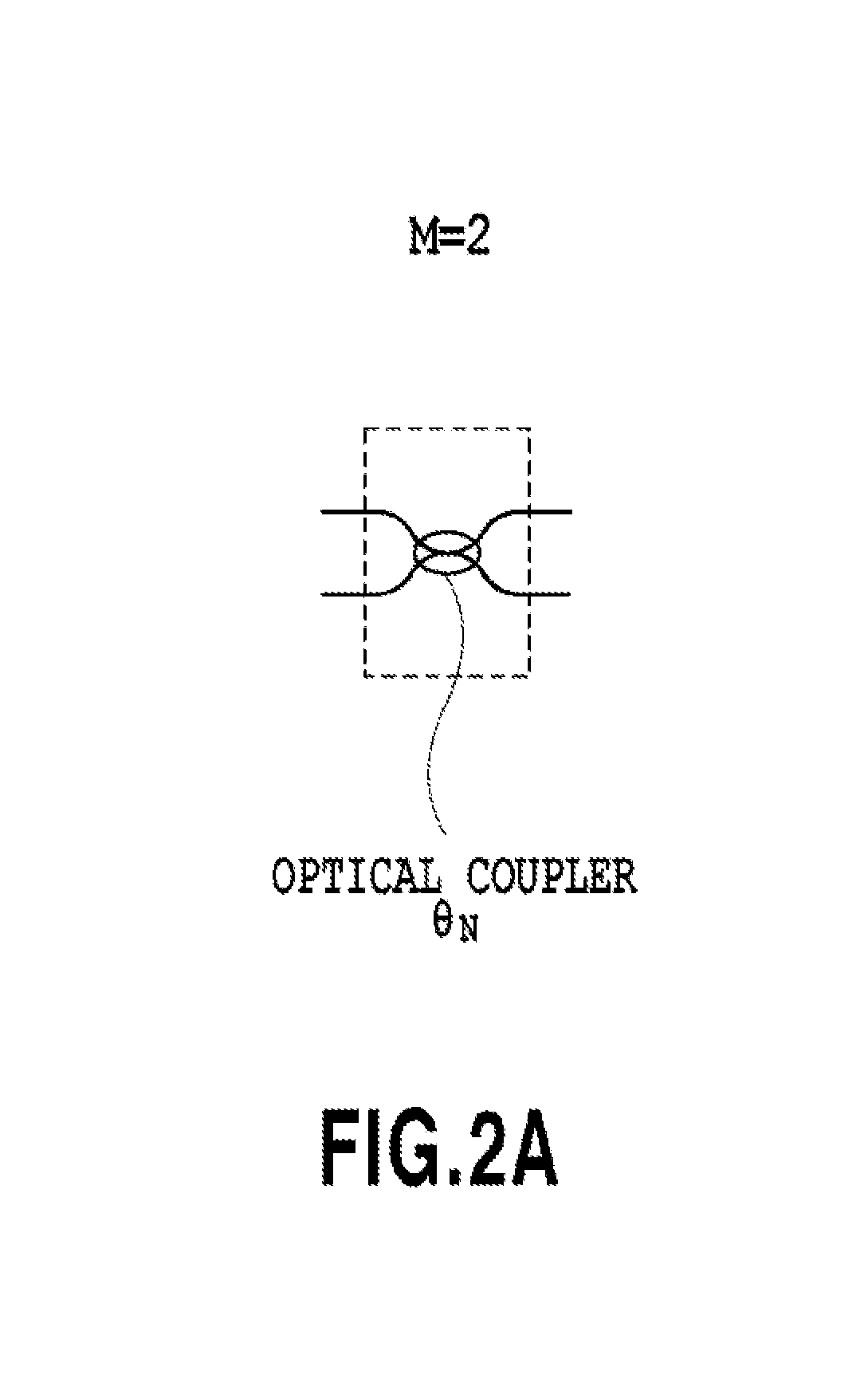

Multi-stage interferometer circuit with waveform shaping function

ActiveUS20180034555A1Device sizeSmall device sizeOptical multiplexElectromagnetic receiversOptical couplerPhysics

A multi-stage interferometer circuit of the present invention includes: a multiplexing port; (N-1) stages of lattice type two-beam interferometers, wherein each stage includes a two-beam delay circuit having a path length difference of an integral multiple of M·Δ L / 2, and wherein the two-beam delay circuit of the lattice type two-beam interferometer of the first stage is connected to the multiplexing port; an M-beam interferometer including: two sets of 1×(M / 2) optical couplers connected to the first optical coupler of the lattice type two-beam interferometer at the final stage; an M-array delay circuit, each delay circuit of which has a delay length different from each other by ΔL; and M×M optical couplers; and M demultiplexing ports, wherein one or more transversal filters are arranged inside the multi-stage interferometer circuit so that the light guided between the demultiplexing port and the multiplexing ports passes therethrough at least once.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

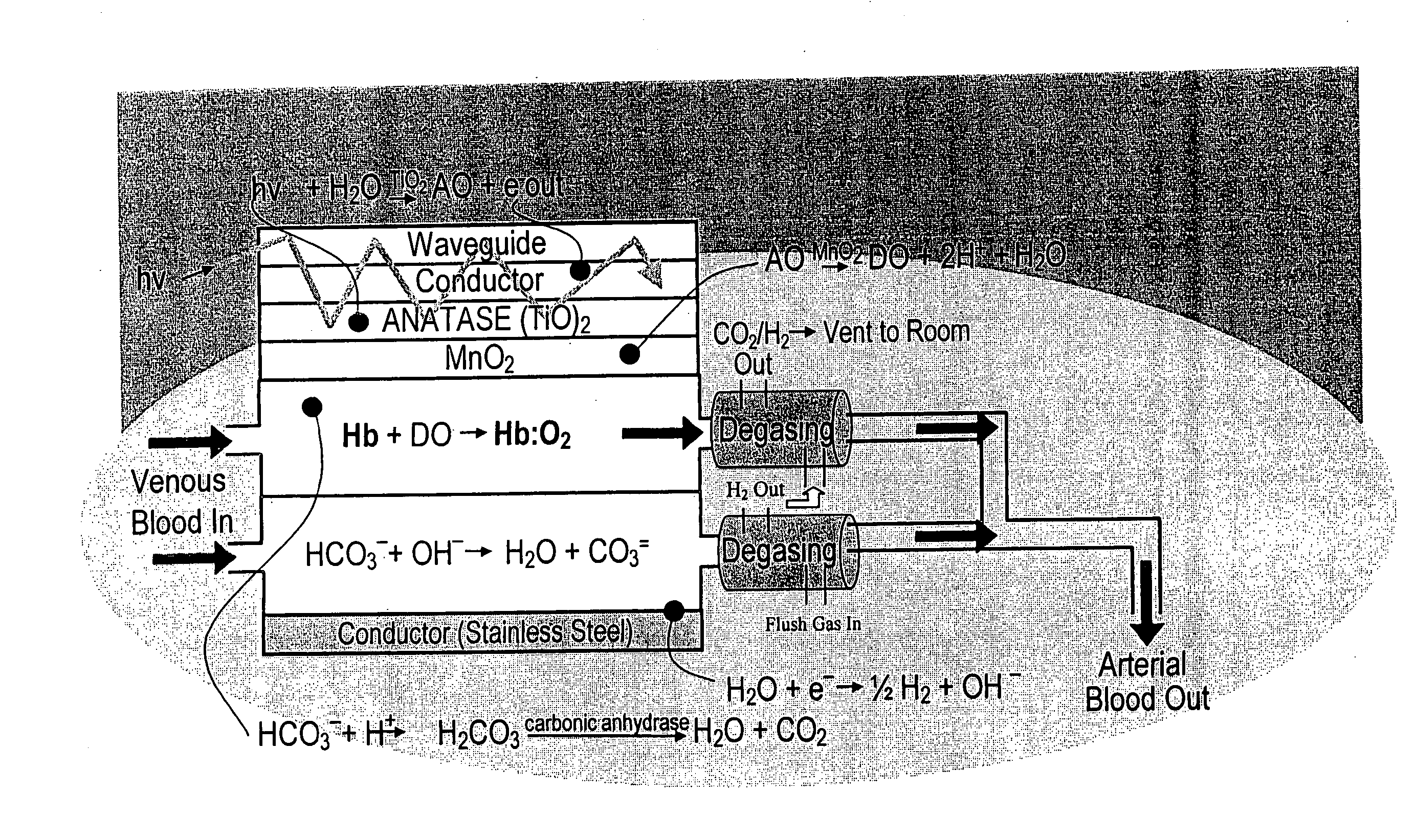

Photolytic cell for providing physiological gas exchange

InactiveUS20050025680A1Low costLimited commercial valueOther blood circulation devicesMedical devicesChemical reactionCompound (substance)

The present invention is directed to a photolytic cell, and to a photolytic artificial lung incorporating such a cell. The photolytic artificial lung converts water to oxygen for blood absorption, regulates pH, the removes carbon dioxide, and co-produces electrical power. The photolytic artificial lung includes a photolytic cell where all of the chemical reactions occur. Additionally, the present invention relates to photolytically sensitive materials for oxygen generation. These materials are useful for gas-free artificial lung fabrication. The photolytic cell disclosed herein can also be used to direct chemical reactions in organs other than the lung. It can also be used to maintain breathing air in confined systems.

Owner:THORATEC CORPORTION +1

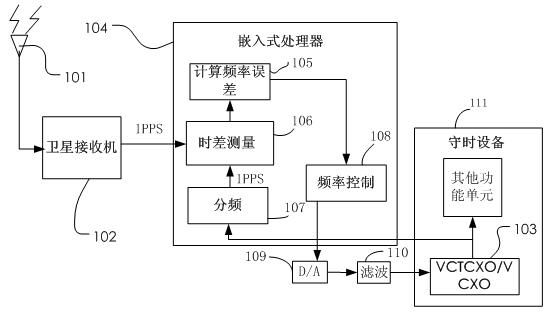

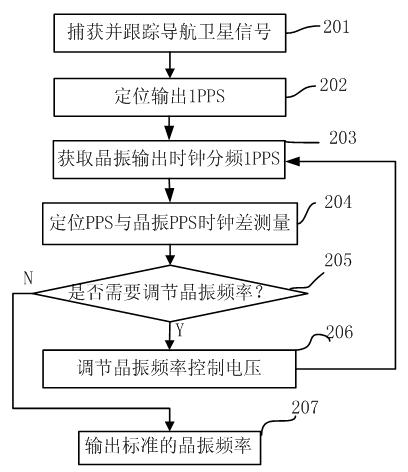

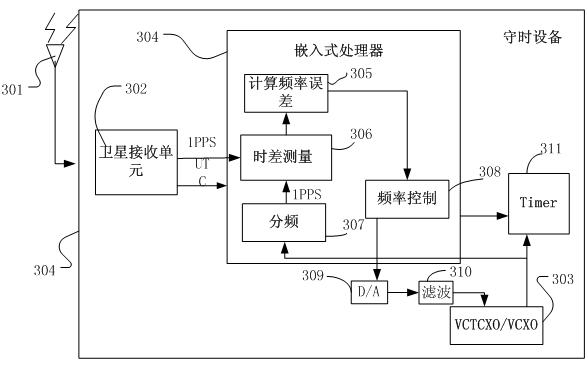

Method and corresponding device for taming crystal oscillation frequency of time-keeping device

InactiveCN102436174AReduce manufacturing costSmall device sizeSynchronous motors for clocksRadio-controlled time-piecesNavigation systemFirst generation

The invention discloses a method and corresponding device for taming crystal oscillation frequency of a time-keeping device, which comprises the following steps of: step 1, acquiring the standard time pulse A that is located and output by a navigation satellite; step 2, acquiring the standard time pulse B output by device crystal oscillation fractional frequency; step 3, measuring the clock difference between the standard time pulse A and the standard time pulse B; and step 4, if clock difference exists between A and B, adjusting the crystal oscillation frequency of the device to make the clock difference be in the allowed scope. For the time-keeping equipment with pressure control and temperature compensating crystal oscillation or pressure control crystal oscillation, the frequency deviation of the corrected crystal oscillation can be detected in real time by the method provided by the invention to eliminate the time-keeping error caused by crystal oscillation frequency deviation and avoid accumulation of error. Therefore, the invention is suitable for various satellite navigation systems, such as GPS, Beidou first generation navigation satellite, Beidou second generation navigation satellite, GLONASS, GALILEO and other satellite navigation systems.

Owner:TECHTOTOP MICROELECTRONICS

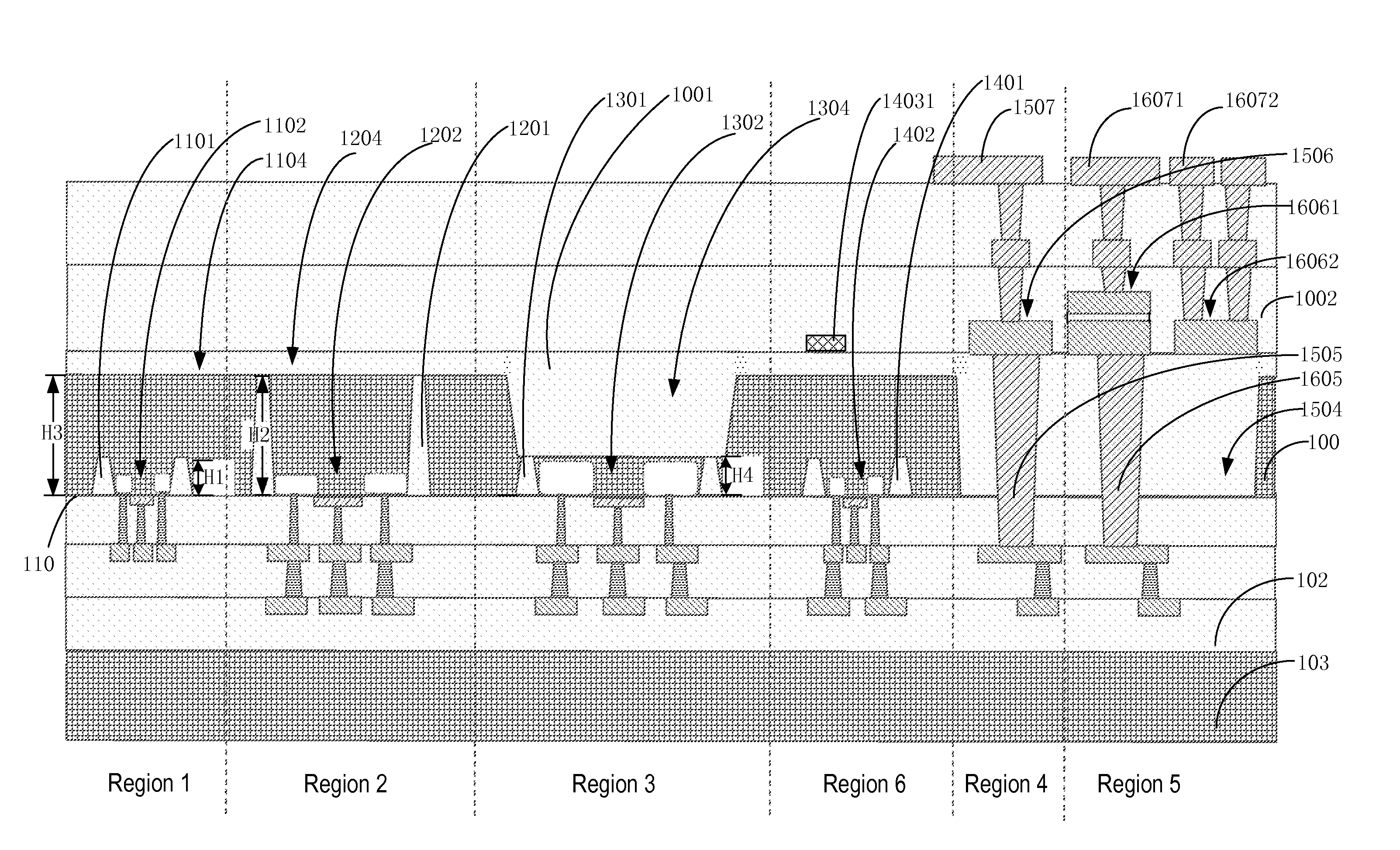

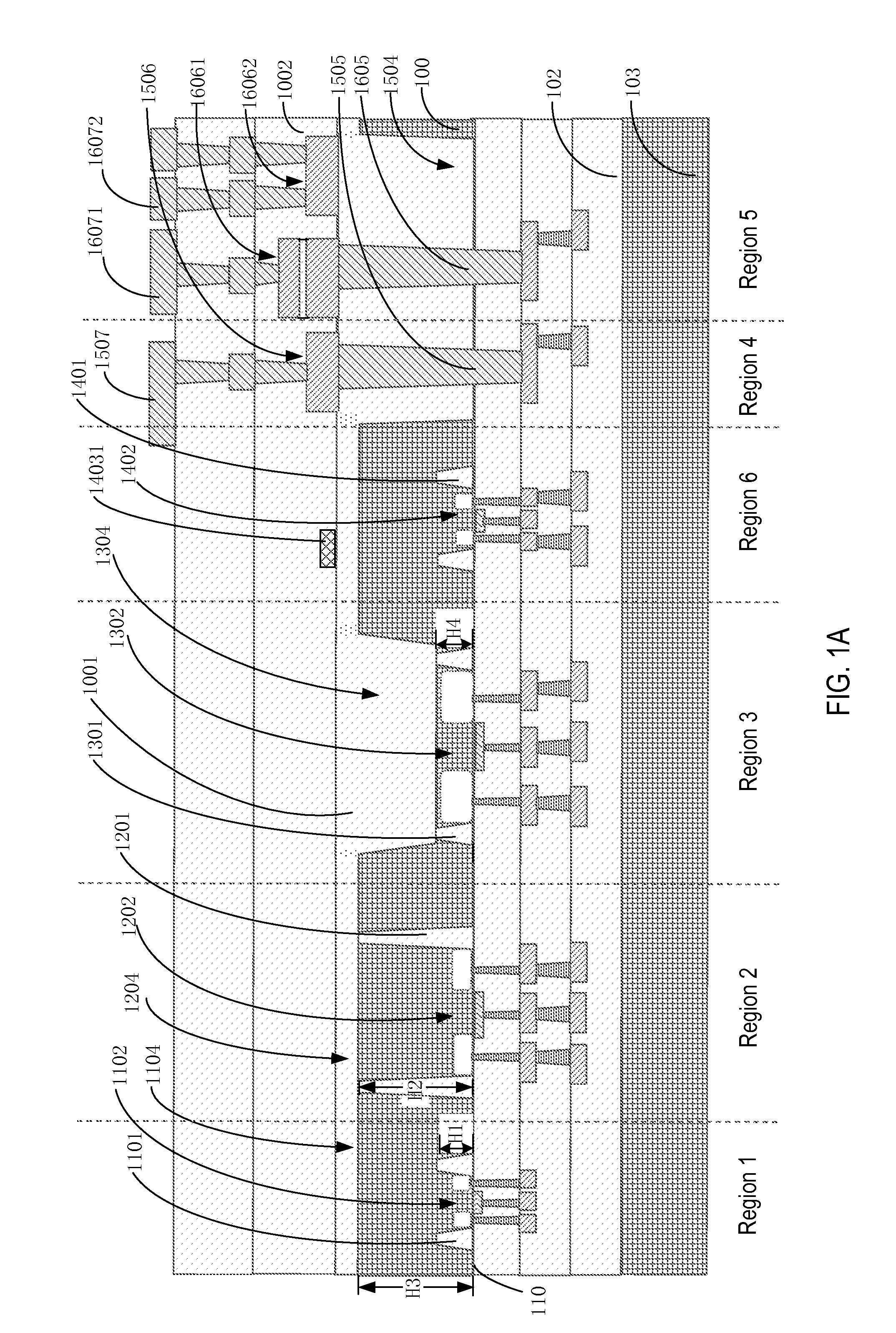

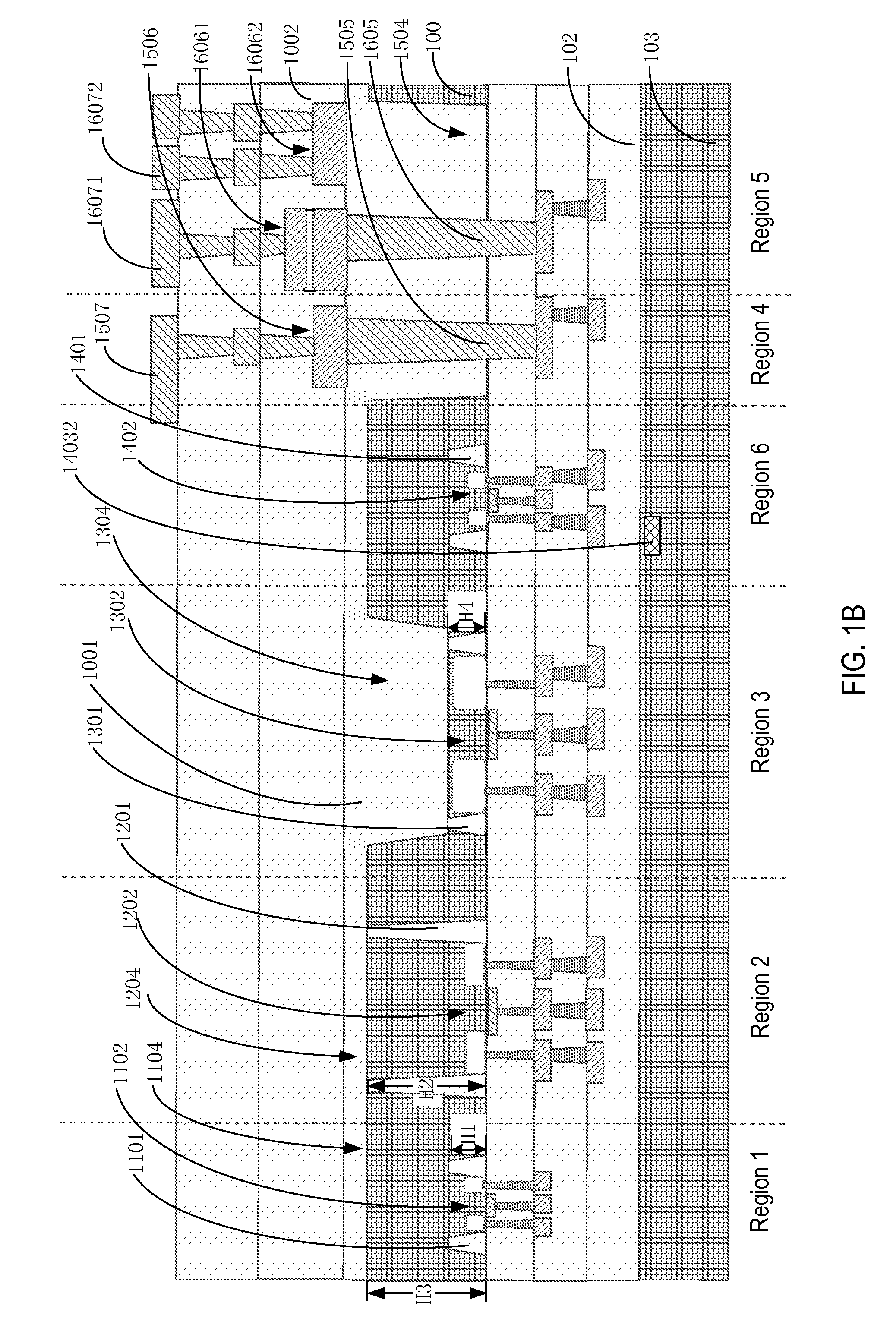

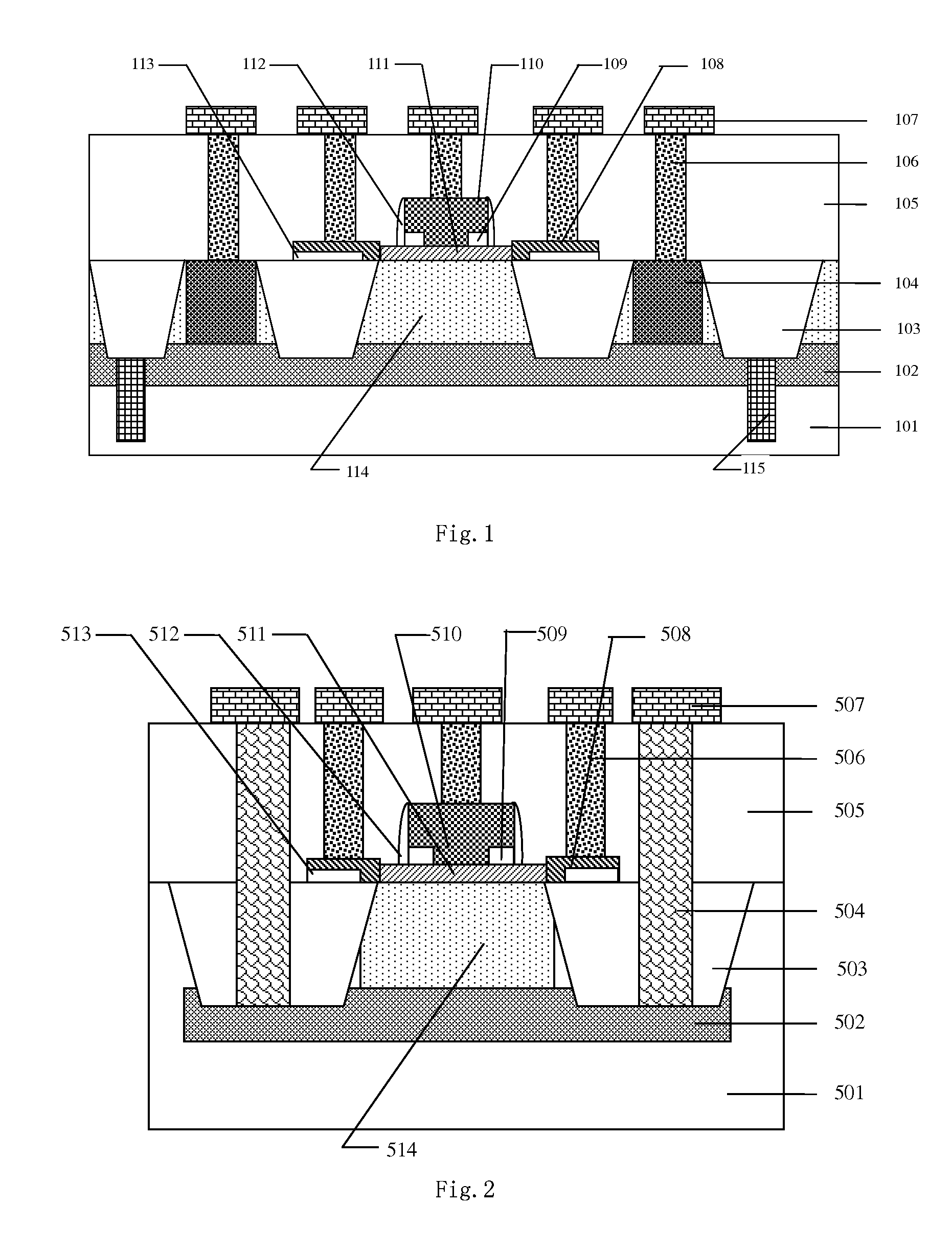

Double-side process silicon mos and passive devices for RF front-end modules

ActiveUS20140367777A1Small sizeLow signal noiseTransistorSolid-state devicesRF front endIsolation layer

A method for forming integrated circuit includes providing a first semiconductor substrate having a front surface and a back surface that is opposite to the front surface. One or more first trenches are in the first semiconductor substrate from the front surface side, the first trenches being characterized by a first depth. One or more second trenches are formed in the first semiconductor substrate from the front surface side, the second trenches being characterized by a second depth which greater than the first depth. A horizontal isolation layer is formed parallel to the front surface and at a third depth from the front surface. The method also includes forming a first recessed region extending in the first semiconductor substrate from the back surface side to the horizontal isolation layer that results in a thinned semiconductor region having a thickness substantially equal to the third depth. The method further includes forming a bulk dielectric layer covering the back surface side of the first semiconductor substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

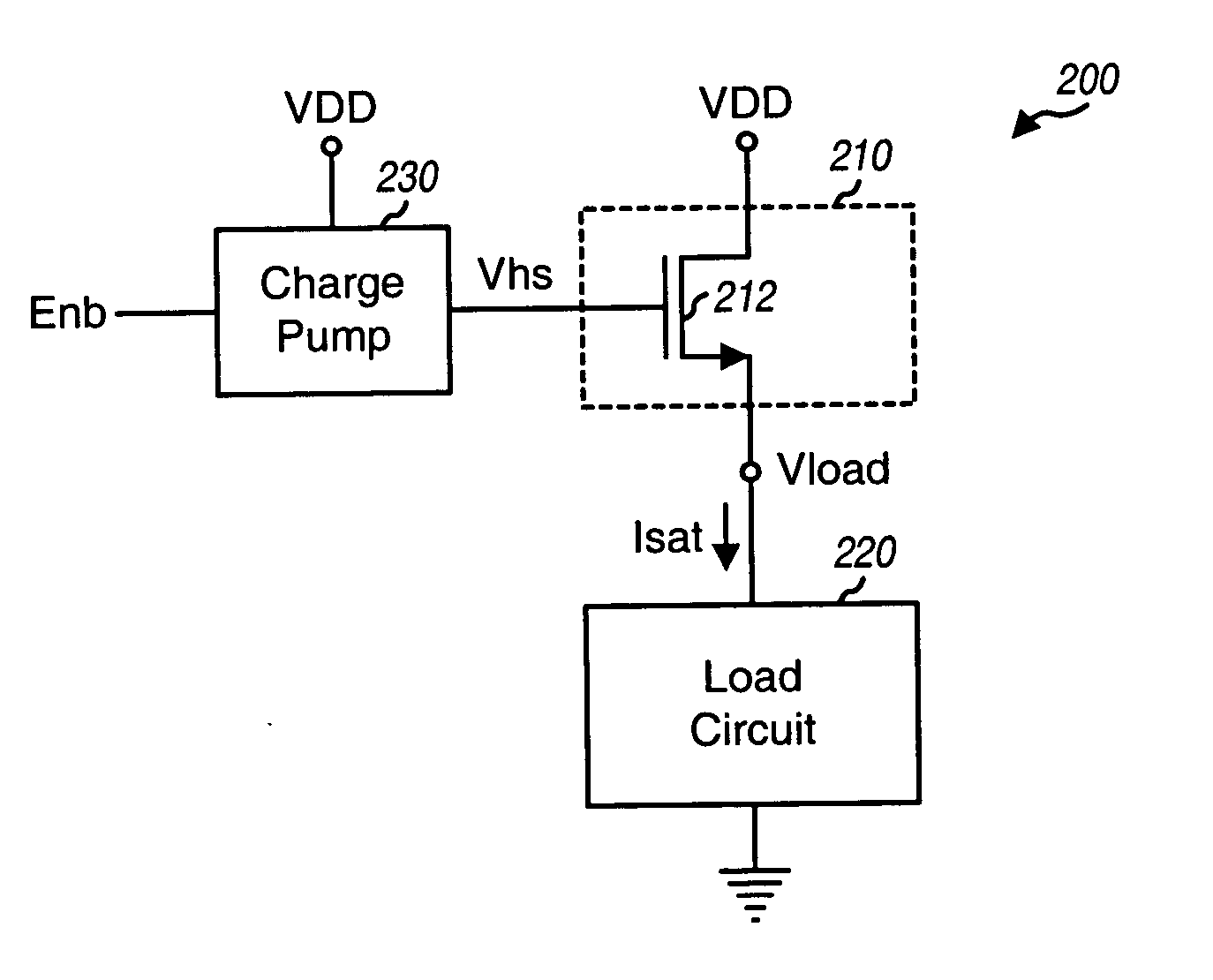

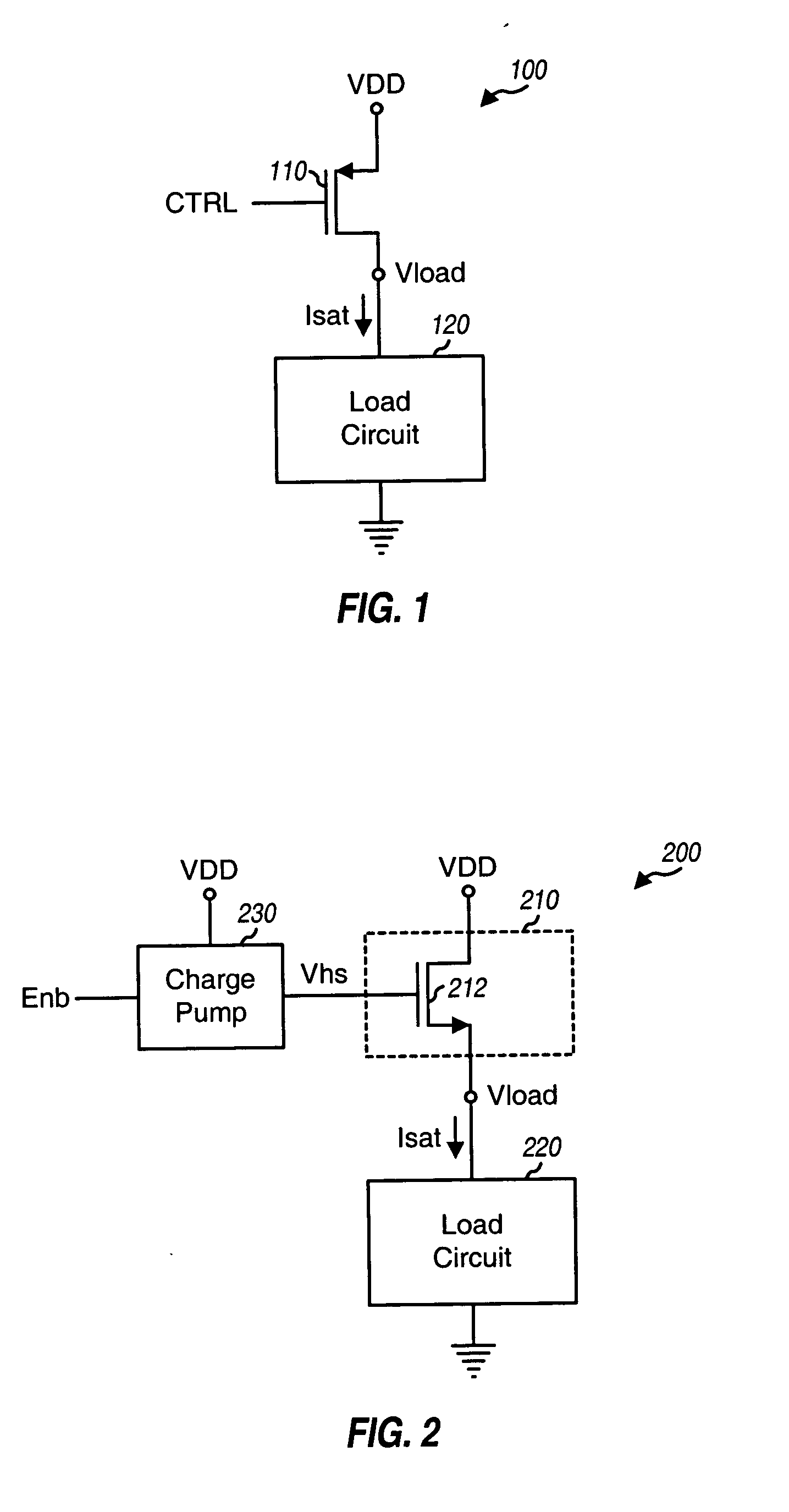

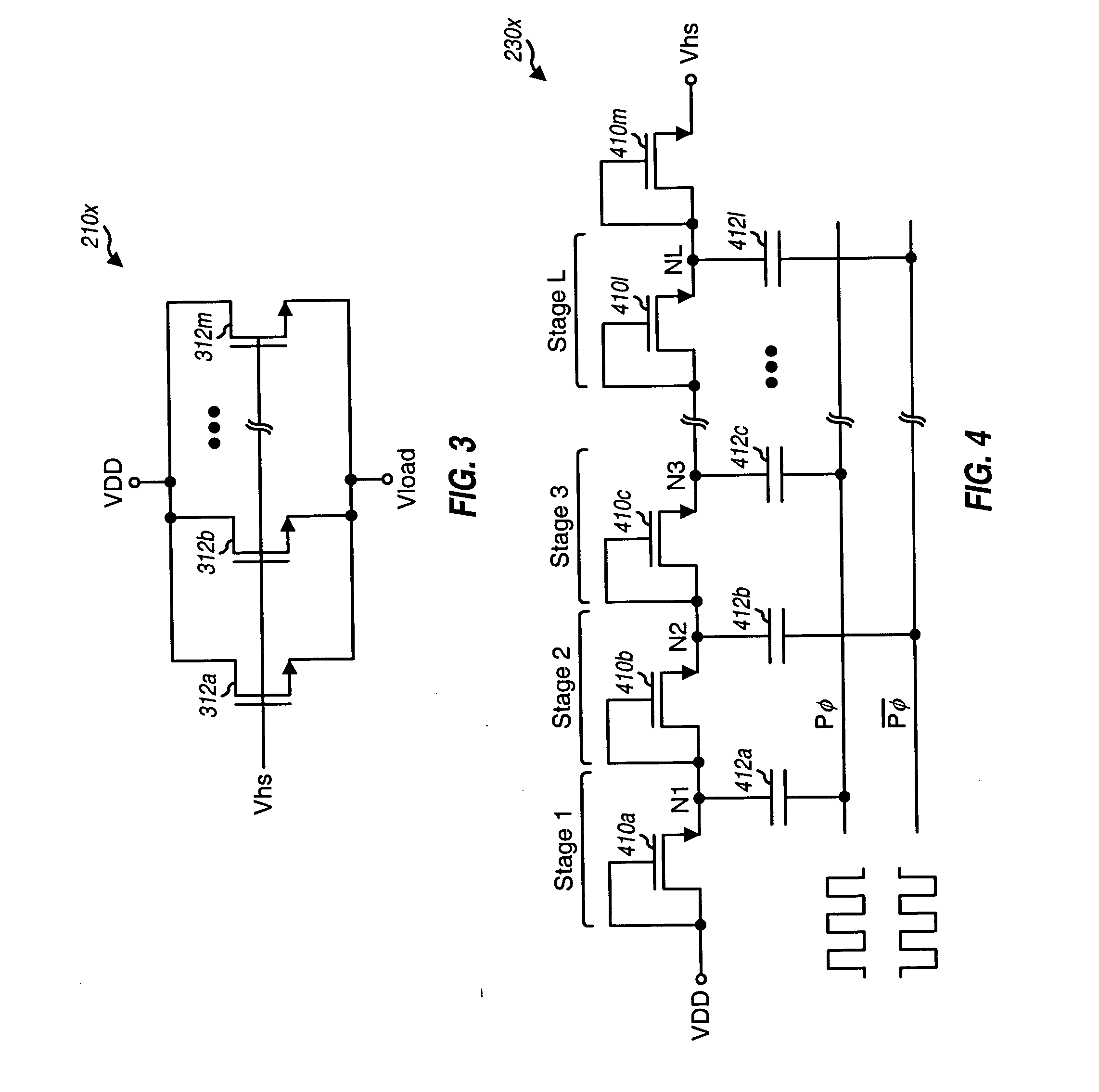

Low-power, low-area power headswitch

ActiveUS20050007178A1Improve performanceAvoid excessive currentTransistorElectronic switchingLoad circuitControl signal

An N-FET headswitch has improved performance (e.g., less leakage current, lower ON resistance, and smaller area) over a conventional P-FET headswitch. The N-FET headswitch includes at least one N-FET device and couples between a power supply and a load circuit, which may be, e.g., a microprocessor, a digital signal processor, or a memory unit. The headswitch couples the power supply to the load circuit when the headswitch is enabled and cuts off the power supply from the load circuit when disabled. A charge pump couples to the headswitch and provides a control signal. This control signal is sufficiently high when the headswitch is enabled to ensure that the N-FET device operates in a linear region and has a small drain to source voltage drop. The headswitch may be operated as a power switch or in a feedback configuration to implement a linear or a digital voltage regulator.

Owner:QUALCOMM INC

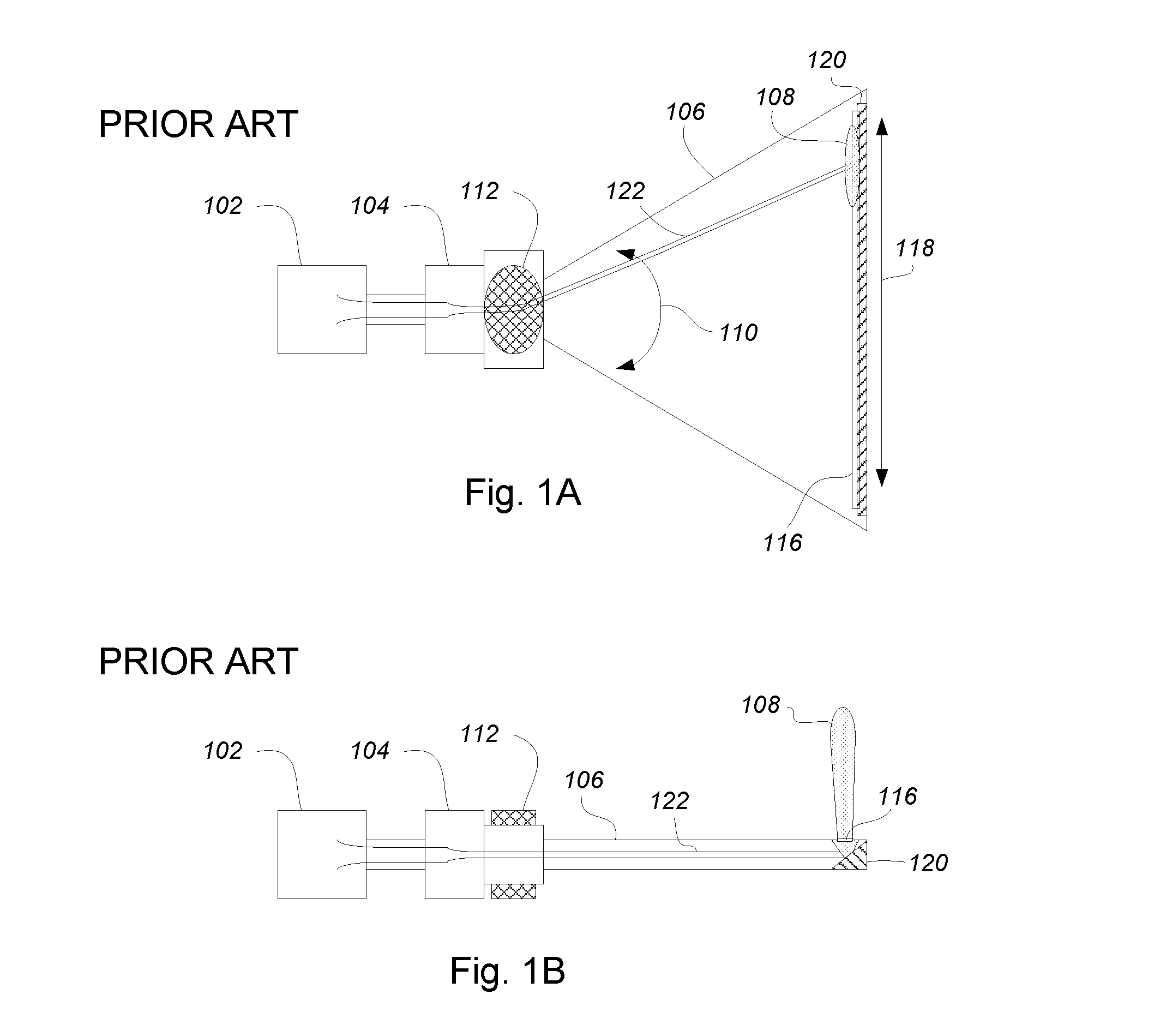

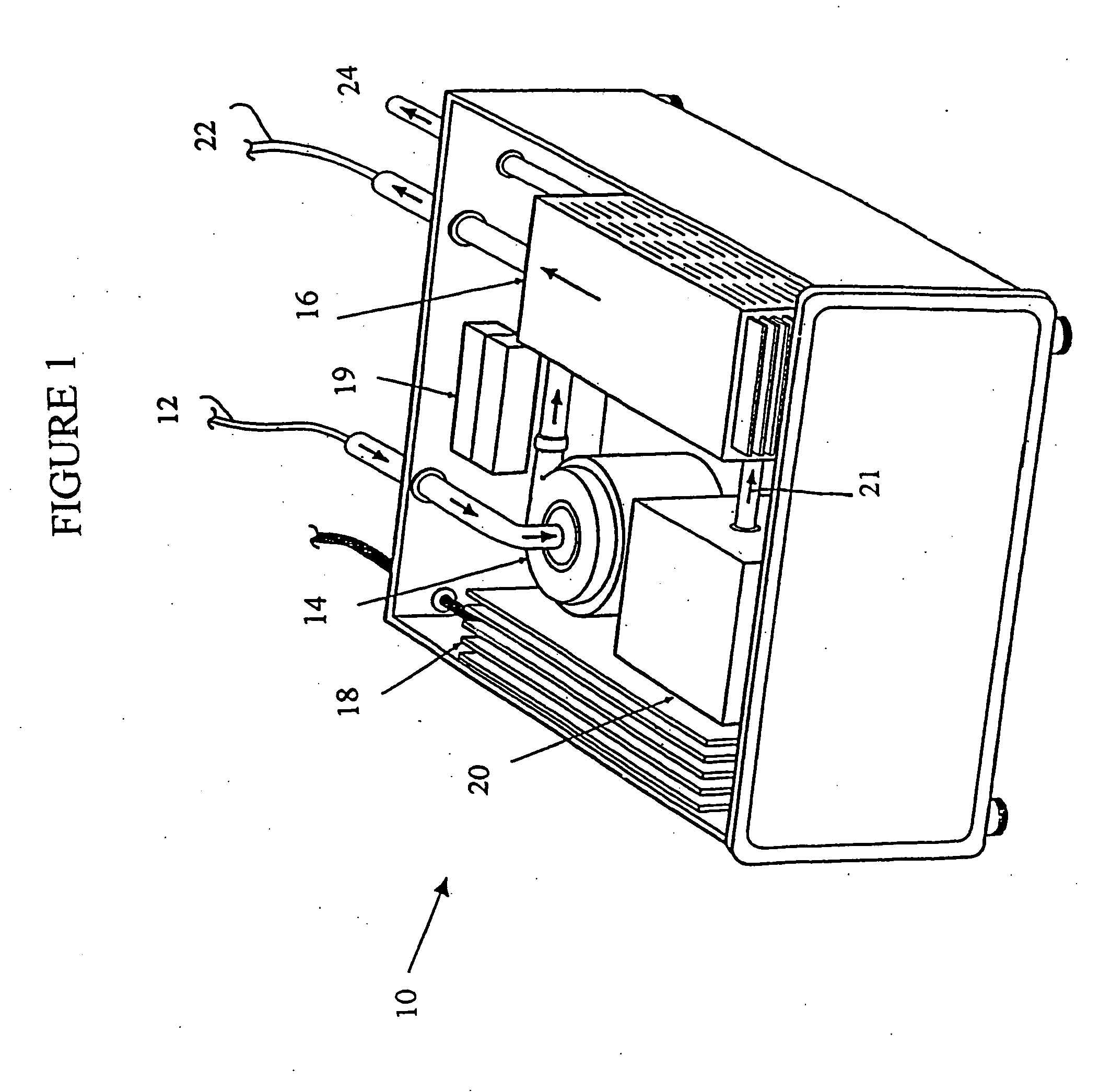

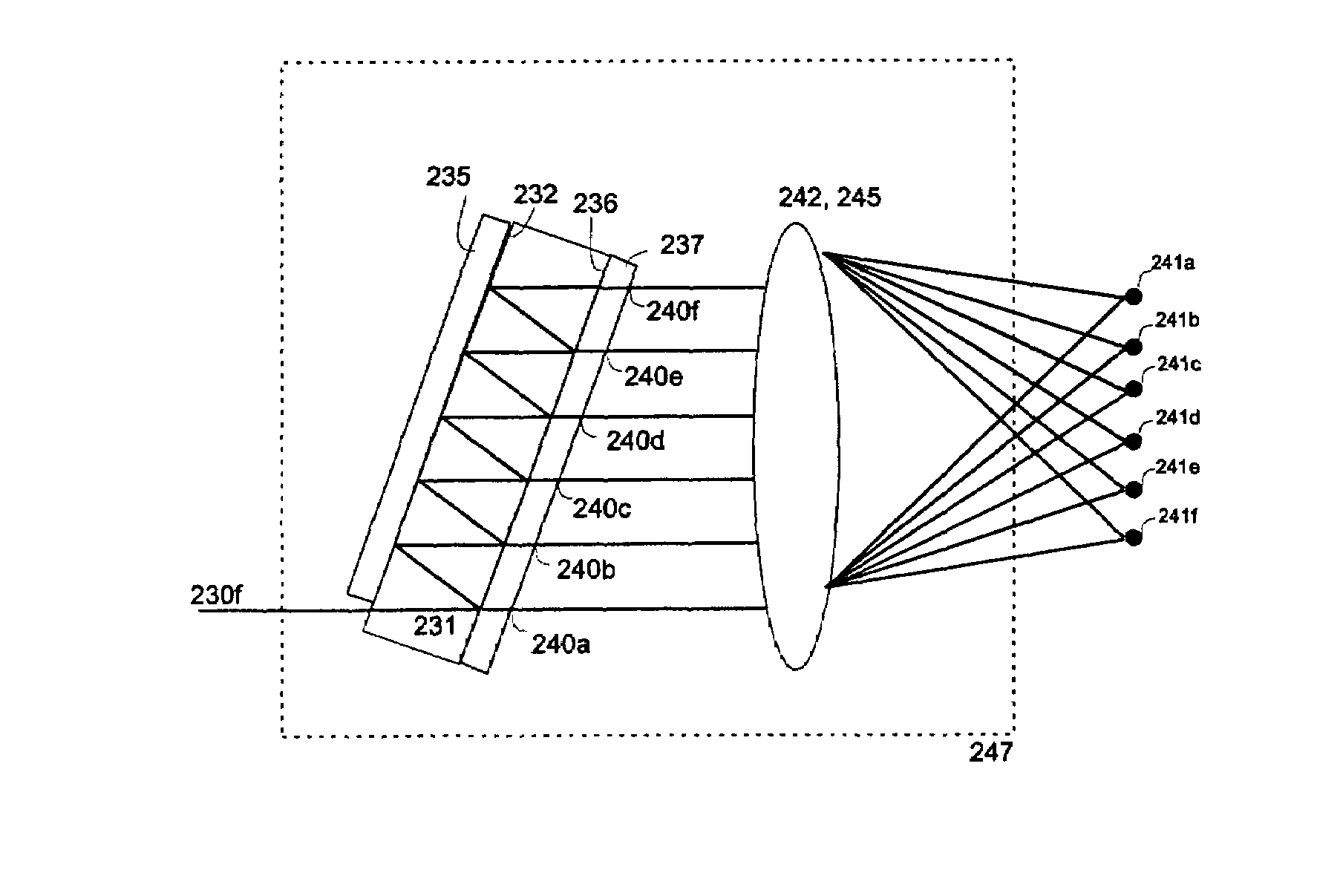

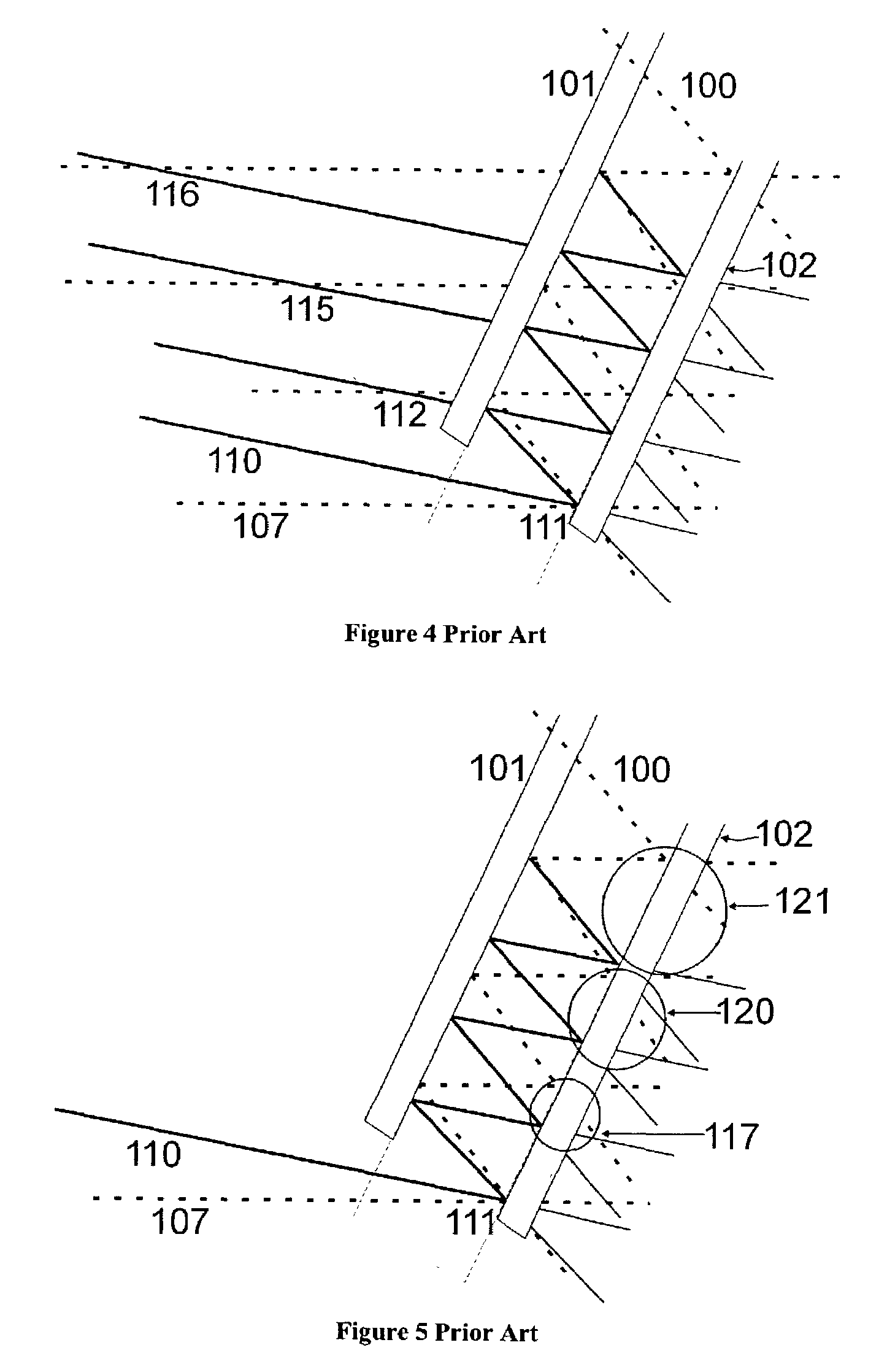

Method and apparatus for optical signal processing using an optical tapped delay line

ActiveUS7509048B2Small component sizeSmall device sizeWavelength-division multiplex systemsCoupling light guidesMultiplexingFrequency spectrum

An Optical Tapped Delay Line (OTDL), which resolves multiple wavelength signals having extremely narrow wavelength spacing, is combined with other known optical devices to provide a wide variety of optical signal processing applications, including: multiplexing and de-multiplexing a multi-channel signal; adding a signal to, or dropping a signal from, a multi-channel optical signal; specialized coding processing such as generating code division multiple access signals; wavelength locking (stabilizing) a signal; filtering a signal; and analyzing and monitoring a signal spectrum. The OTDL spatially separates individual channels to allow separate processing on each channel. Fixed and tunable embodiments are identified in appropriate cases. Bulk, hybrid, and integrated optical embodiment and methods of fabrication are described, as are curved self-focusing and evanescent embodiments of OTDL devices. The devices and processes disclosed have particular application to dense wavelength division multiplexing (DWDM) and permit a significant improvement in the quantity of information that can be carried on DWDM signals while enhancing signal quality.

Owner:NORTHROP GRUMMAN SYST CORP

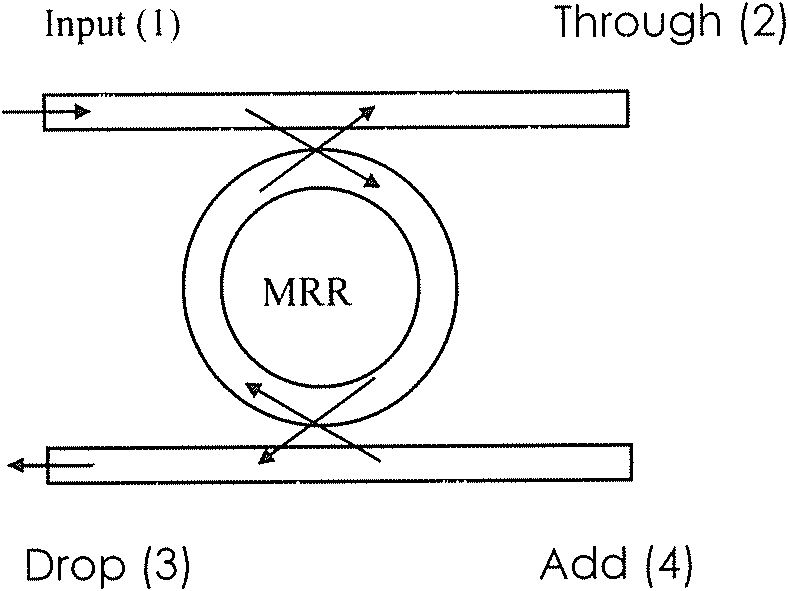

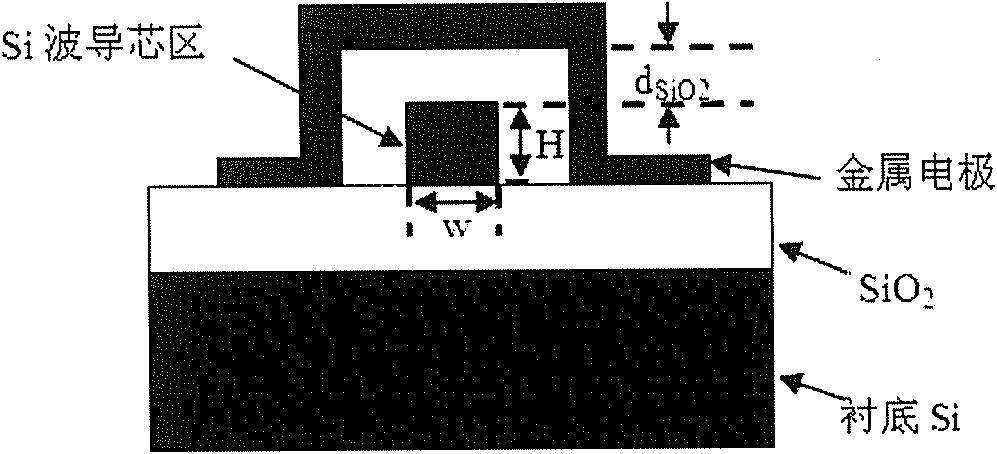

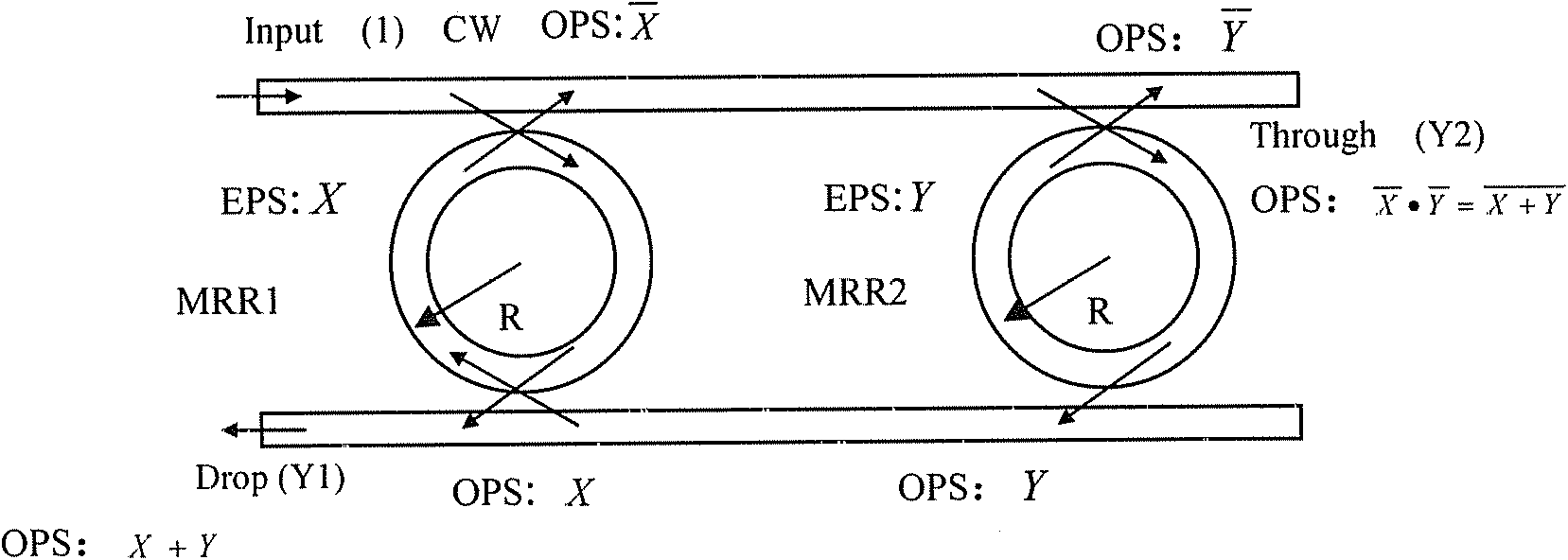

Optical logic gate based on double parallel microring resonators

InactiveCN102062988ASmall device sizeReduce power consumptionLogic circuits using opto-electronic devicesInstrumentsPhysicsOptical logic gates

The invention discloses an optical logic gate based on double parallel microring resonators. The optical logic gate is realized by two parallel microring resonators (MRR) and waveguides of two parallel namometer wires, two inputs are electric pulse sequences to be calculated, and calculated results to be output are optical pulse sequences. By the optical logic gate, the problems of speed bottleneck, power consumption and gate delay and competition and risks brought by the gate delay in a traditional electric logic gate are solved, the optical information processing and the speed of information processing in optical calculation are improved, and the small volume, low power consumption and low cost of devices can be guaranteed.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Exhaust gas recirculation device of engine

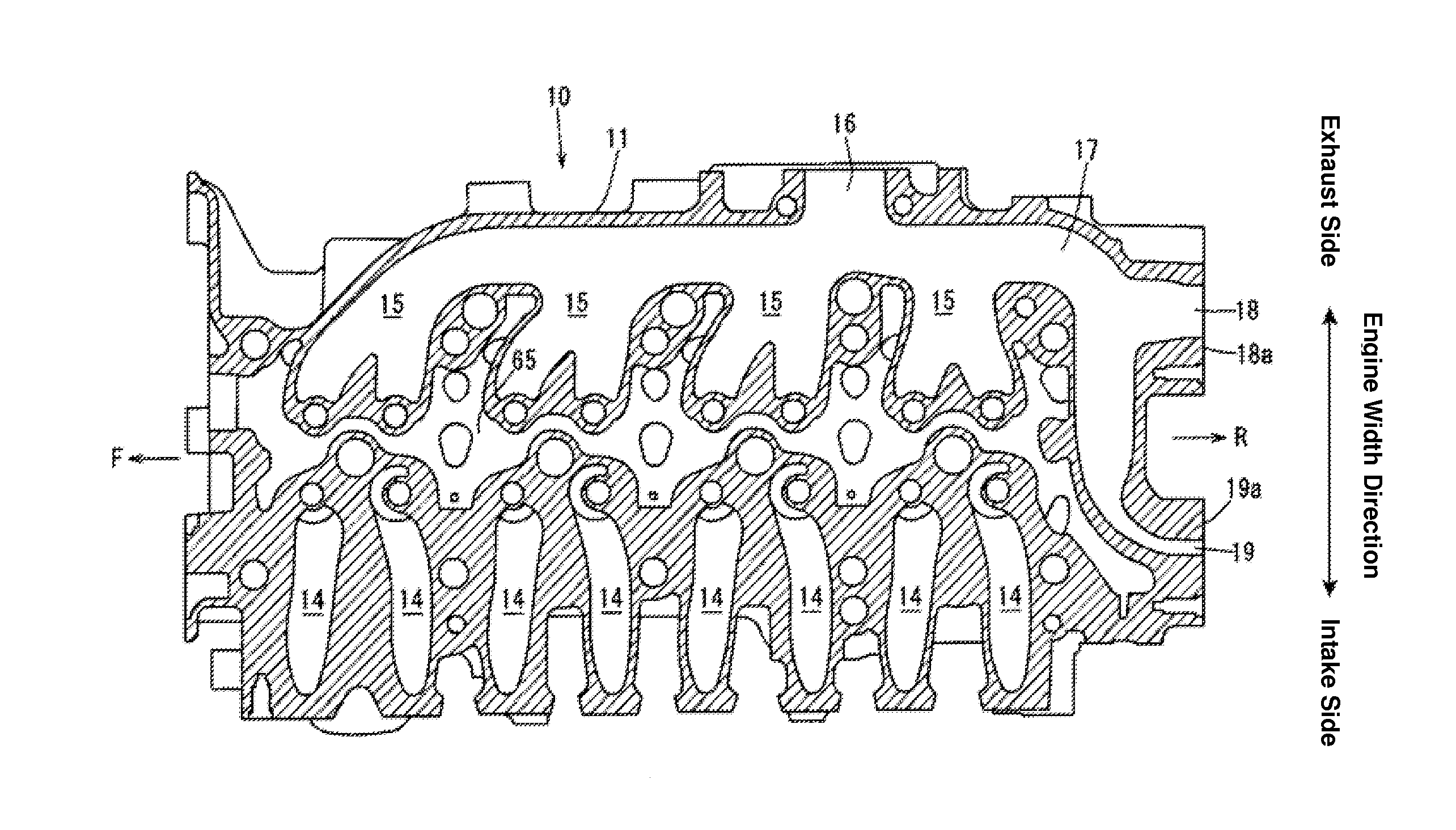

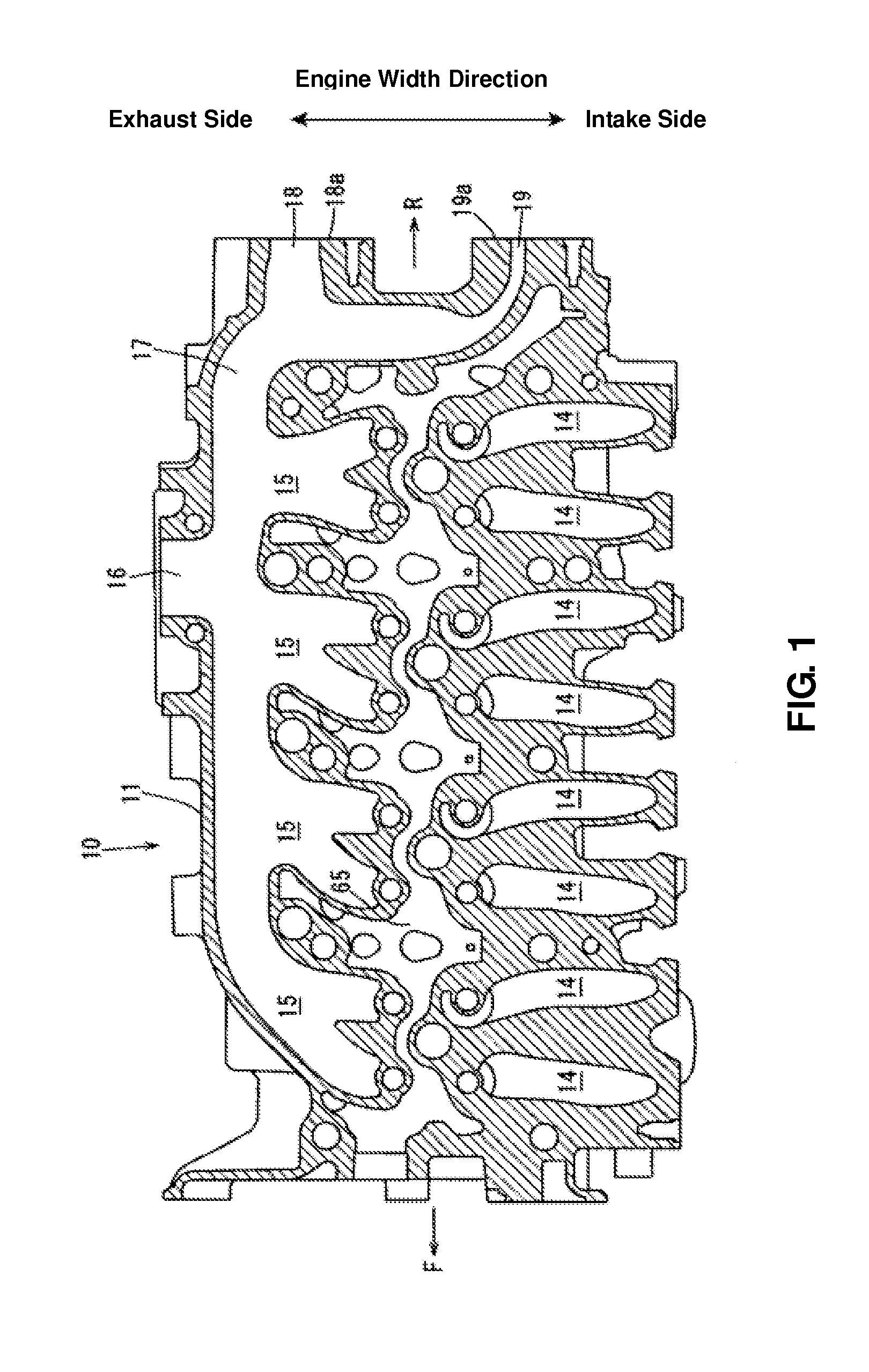

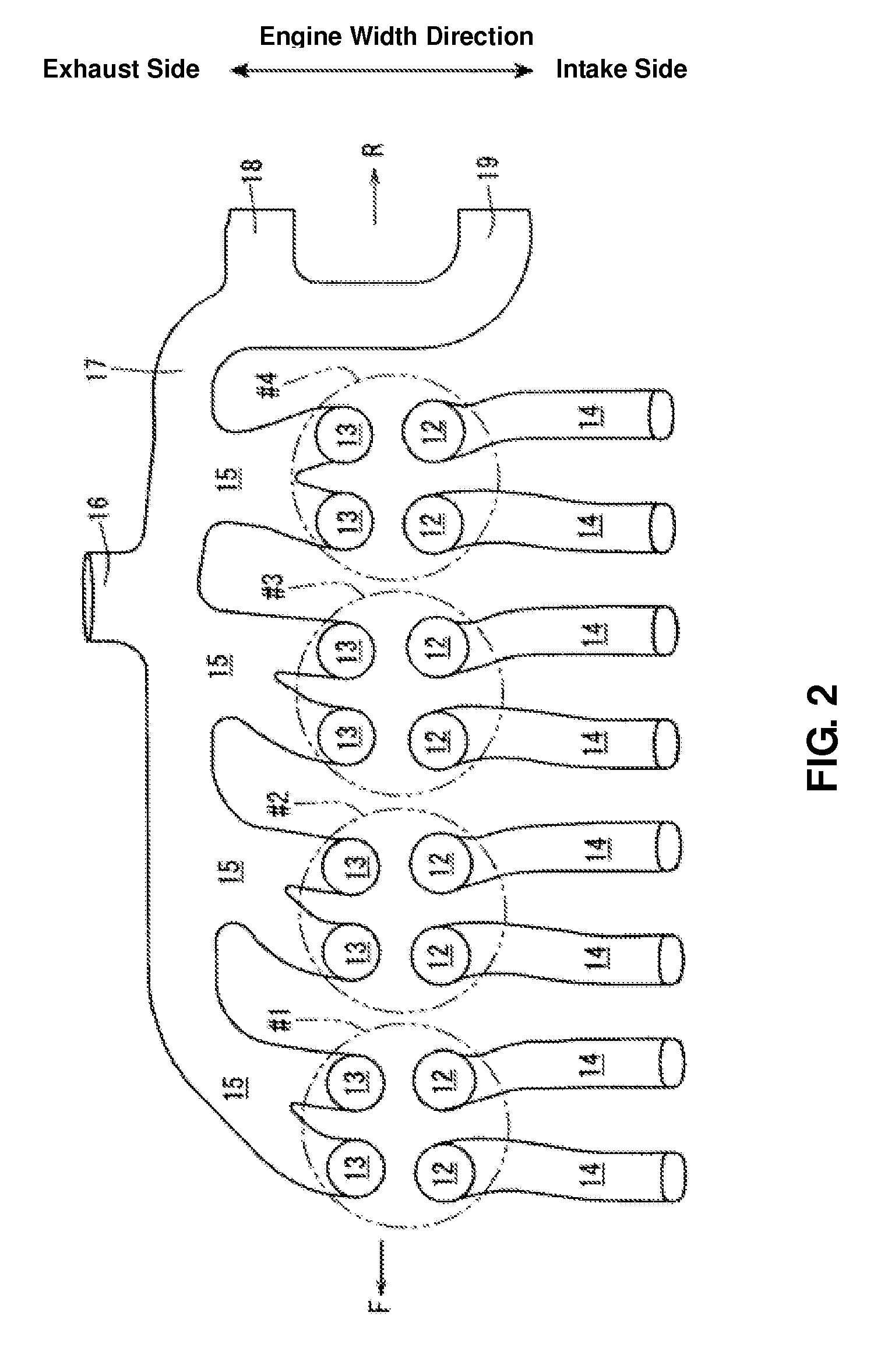

InactiveUS20110315129A1Small device sizeBypass pipe can be easierNon-fuel substance addition to fuelInternal combustion piston enginesCylinder headEngineering

A connecting passage is formed inside a cylinder head, which extends rearward from an exhaust passage and connects to the exhaust passage. The connecting passage branches inside the cylinder head into two branch passages, which open at a rear end face of the cylinder head, respectively. An opening portion, one of opening portions of the branch passages, connects to an EGR cooler, and another opening portion, the other of opening portions of the branch passages, connects to a bypass pipe. Accordingly, the exhaust gas recirculation device of an engine which can restrain the device from being improperly large sized, providing the EGR cooler and the bypass pipe, can be provided.

Owner:MAZDA MOTOR CORP

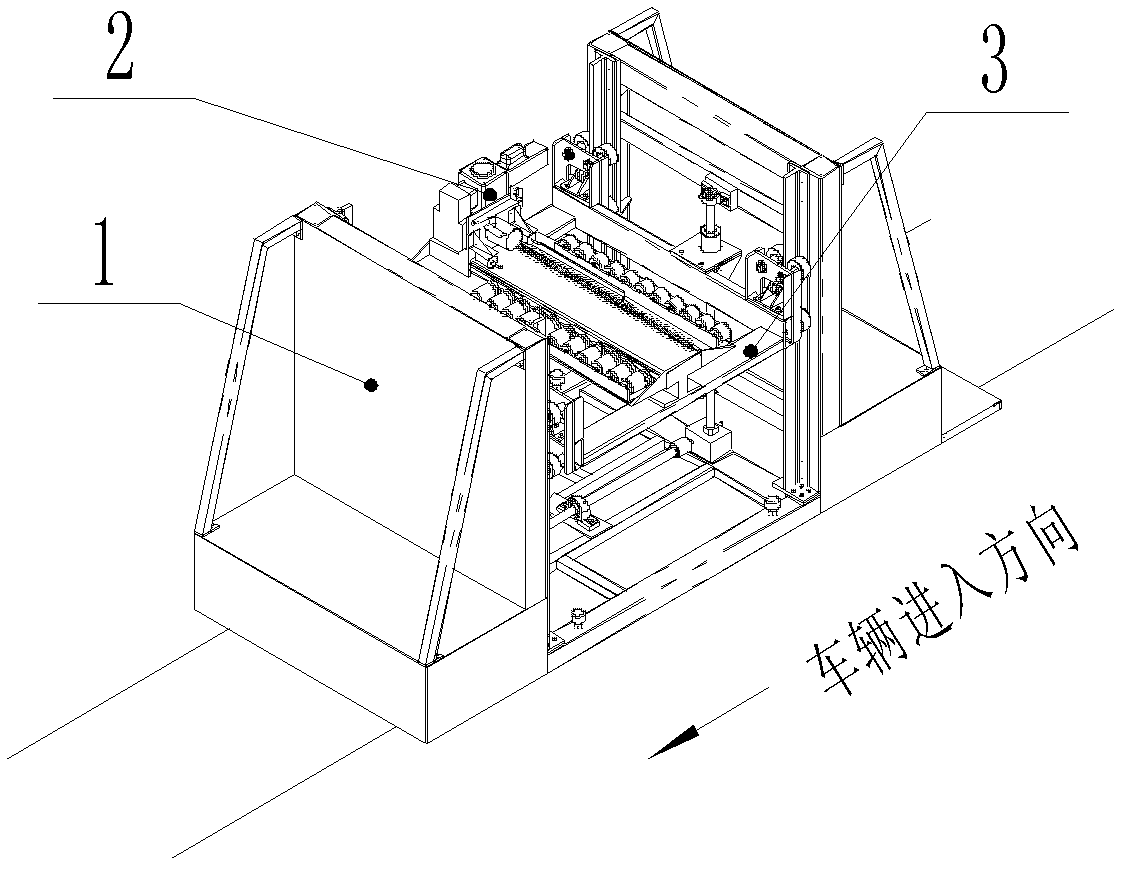

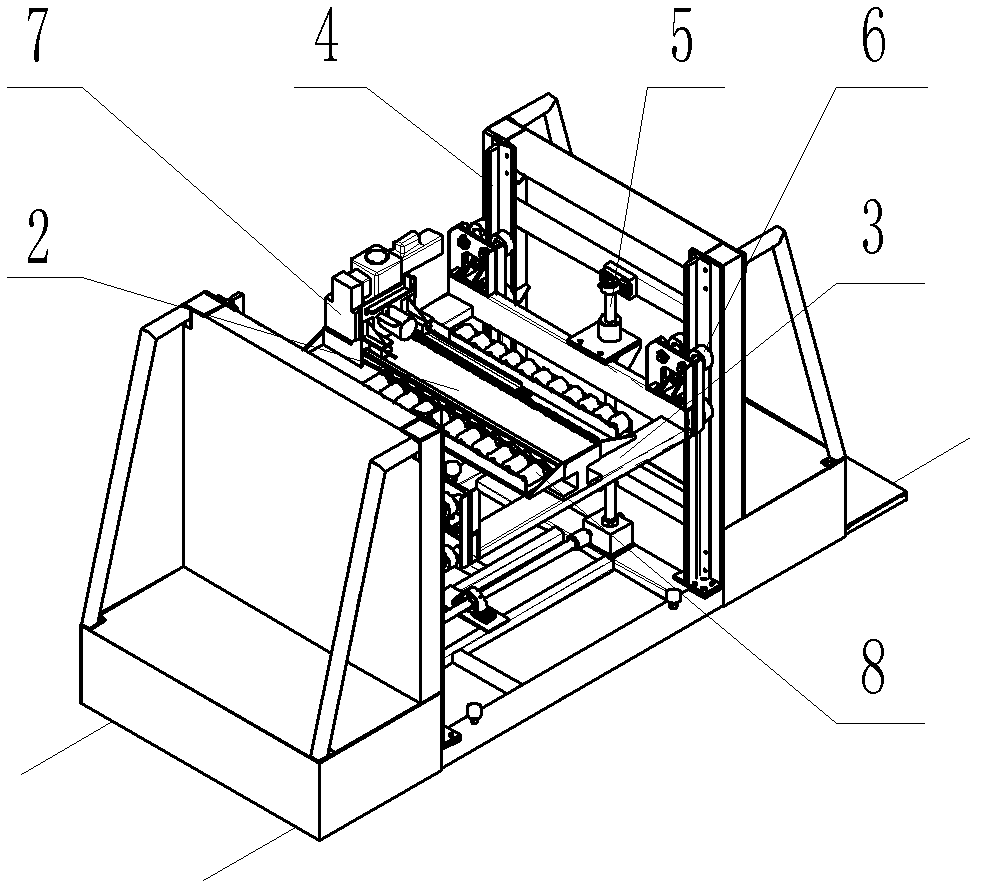

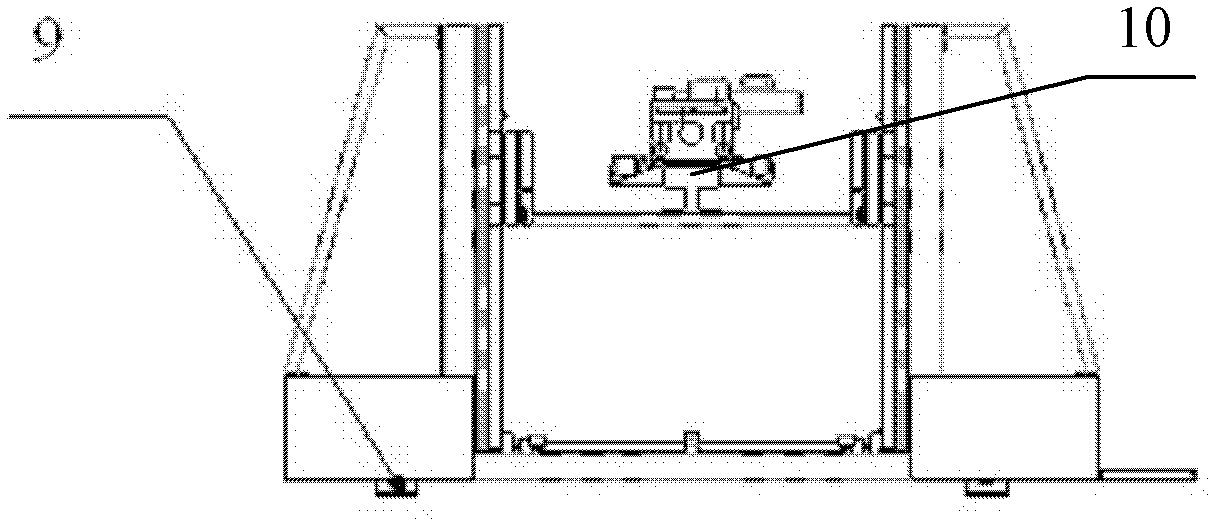

Replacing device for battery boxes of electric vehicle

ActiveCN102556009ALow manufacturing costSmall device sizeElectric propulsion mountingElectric/fluid circuitChanging equipmentElectric vehicle

The invention provides a replacing device for battery boxes of an electric vehicle, which is used for taking down one undercharged battery box from the vehicle, conveying the undercharged battery box to a battery transfer rack or conveying one fully-charged battery box on the battery transfer rack, and mounting the fully-charged battery box on the vehicle. The battery boxes don't need to rotate when being replaced by the device, so that replacing time is saved, and the problem that a large rotating space is needed for replacing the battery boxes is solved. The device comprises a translational device, a mechanical arm and a lifting device, the mechanical arm has a bidirectional moving function, namely, the mechanical arm is capable of extending along the vehicle direction and extending along a battery rack, and two rows of rollers are arranged on the mechanical arm so as to be convenient for drawing off the battery boxes. The device has the advantages that the device consisting of various conventional products is lower in manufacture cost, small in size, flexible in action and fine in universality, the required moving passage width is obviously decreased, and occupied area for replacing is saved.

Owner:BEIJING STATE GRID PURUI EXTRA HIGH VOLTAGE POWER TRANSMISSION TECH CO LTD +1

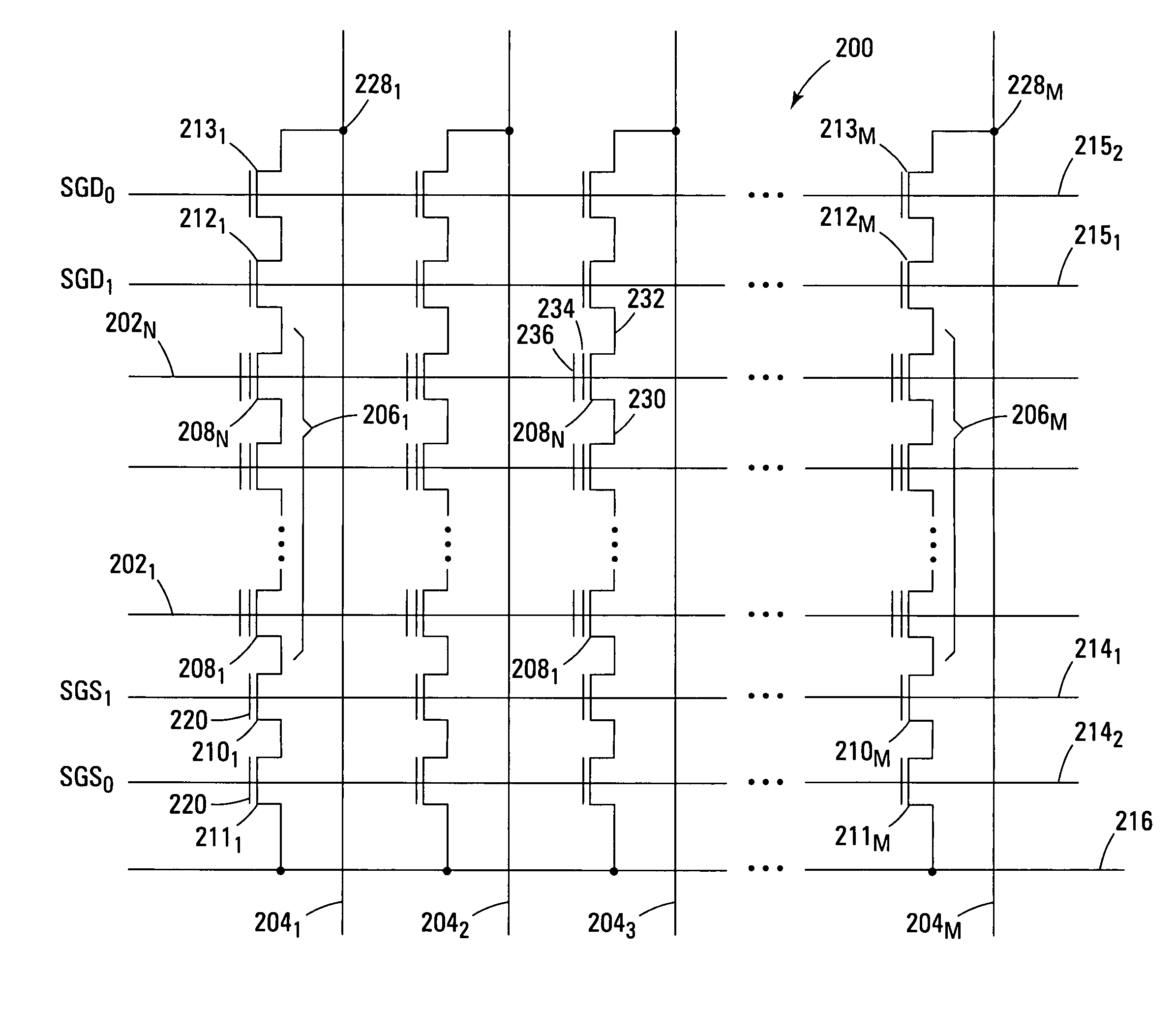

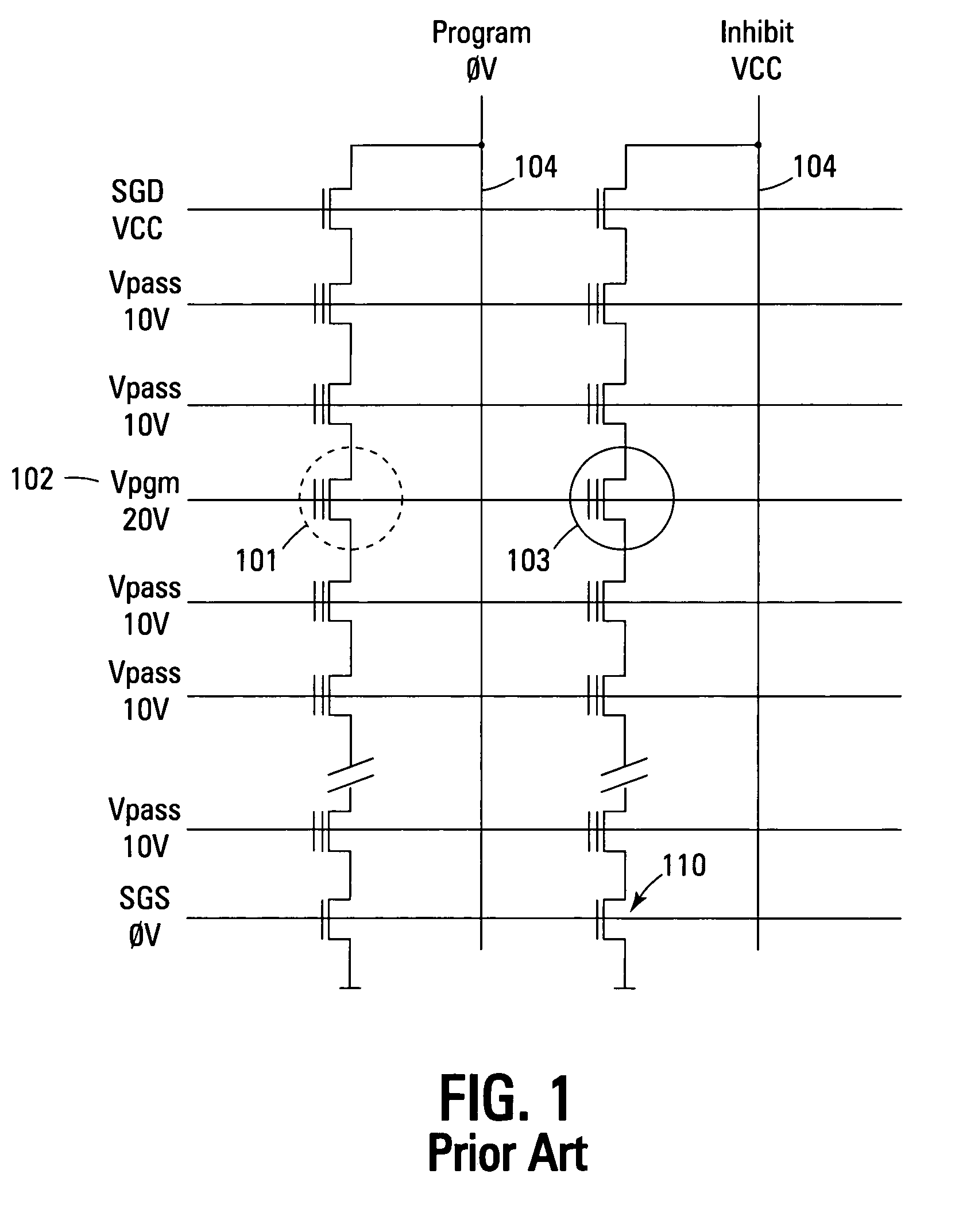

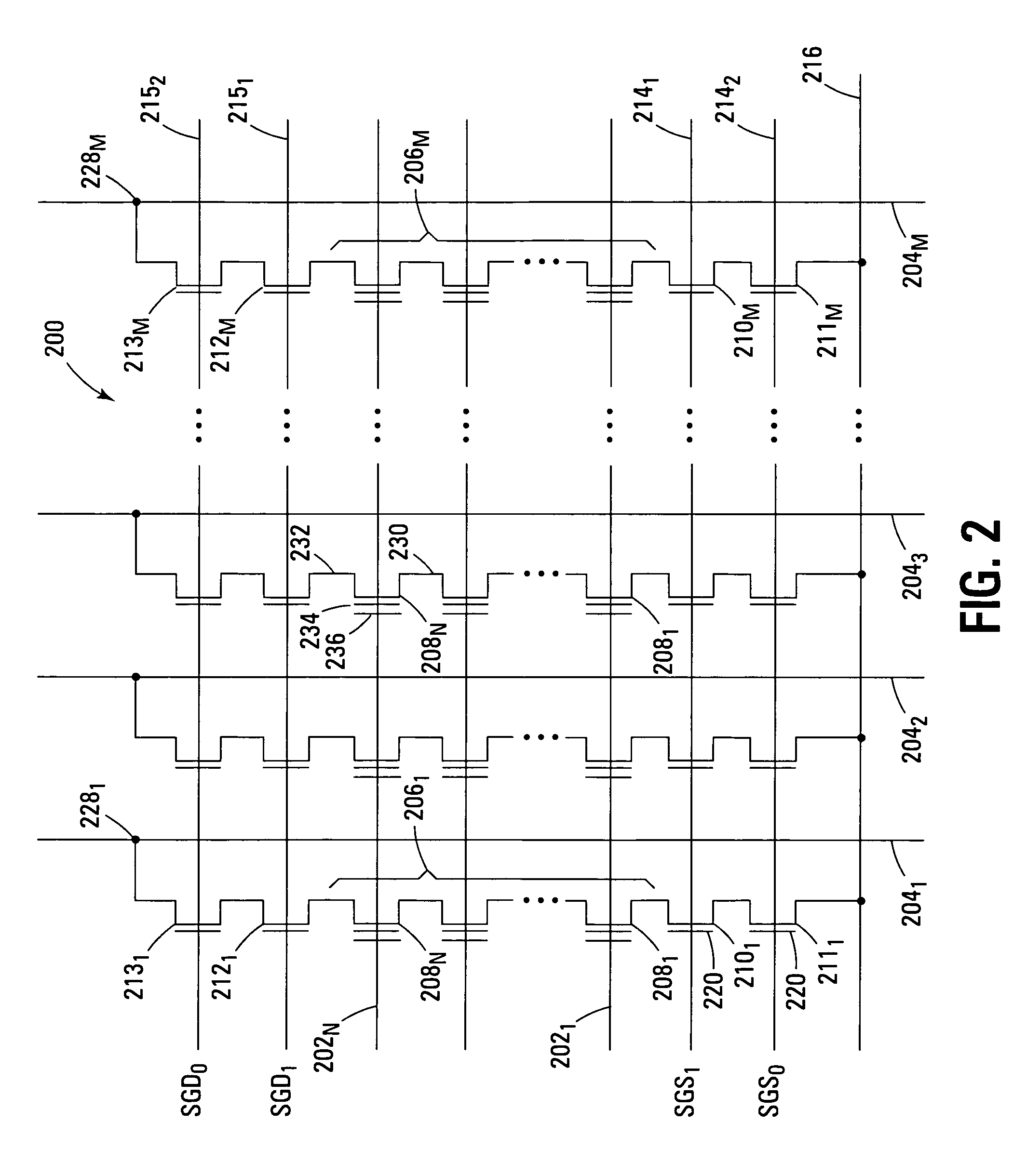

Operation of multiple select gate architecture

ActiveUS7259991B2Same level of protectionReduced footprintSolid-state devicesRead-only memoriesEngineeringNon-volatile memory

Methods of operating non-volatile memory devices including multiple series-coupled select gates on the drain and / or source ends of strings of non-volatile memory cells facilitate mitigation of gate-induced drain leakage and program disturb.

Owner:MICRON TECH INC

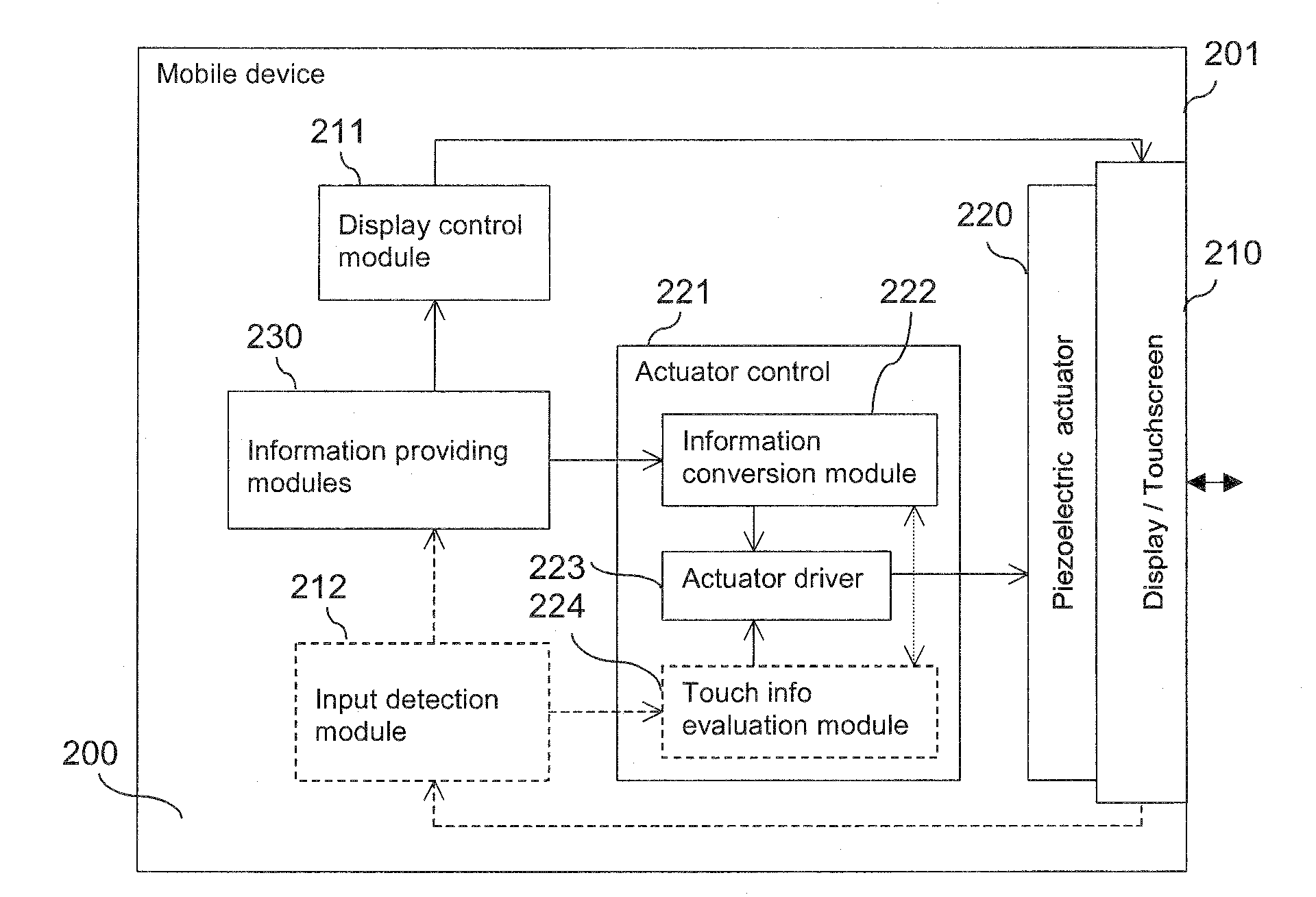

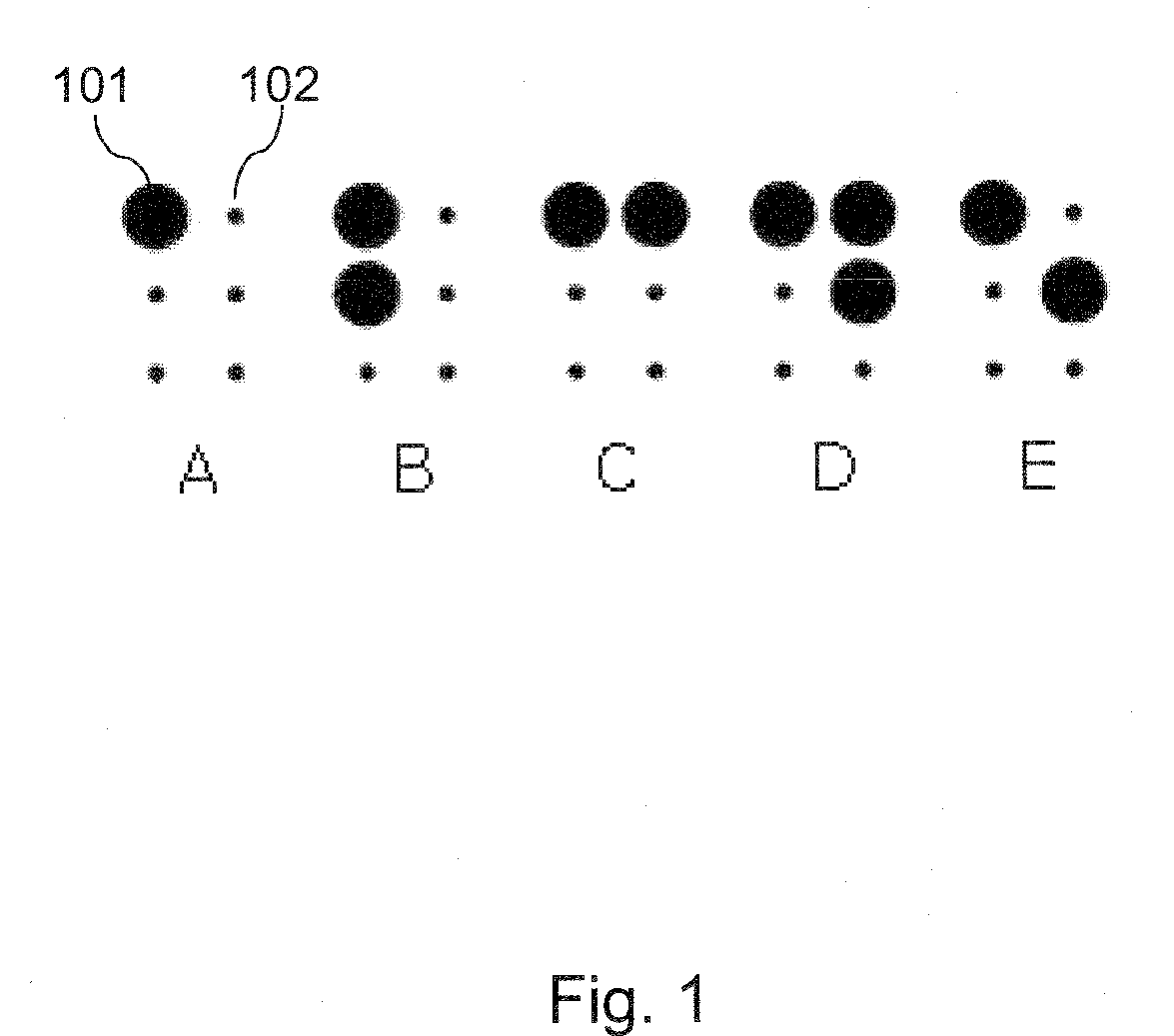

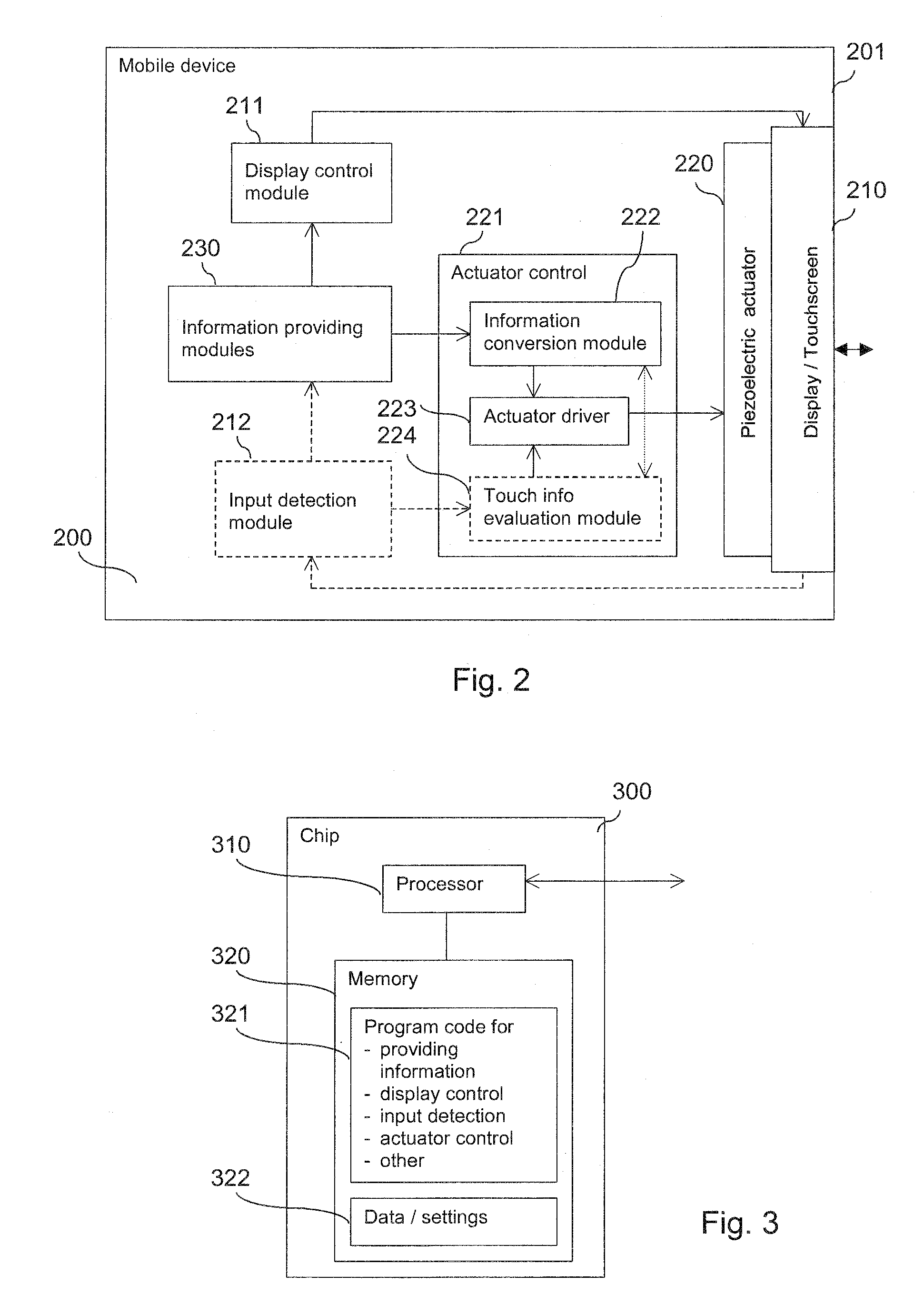

Tactile feedback

ActiveUS20100055651A1Small device sizeSize of display limitedTeaching apparatusGraphicsTouch Perception

For providing a tactile feedback to a user of a device, textual or graphical information is converted into instructions for a sequence of pulses representing the information. An actuator is then caused to move at least a part of a display according to the obtained instructions.

Owner:NOKIA CORP +1

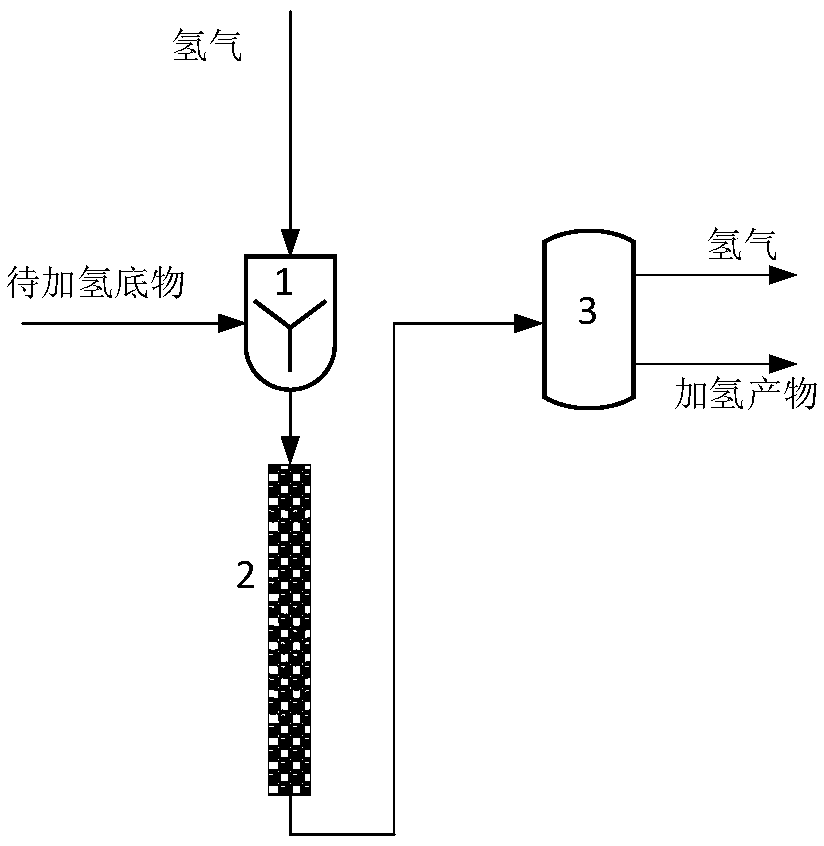

Hydrogenation reaction device in micropacked bed and method for hydrogenation reaction by using same

ActiveCN109225073AIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPetrochemicalChemical reaction engineering

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

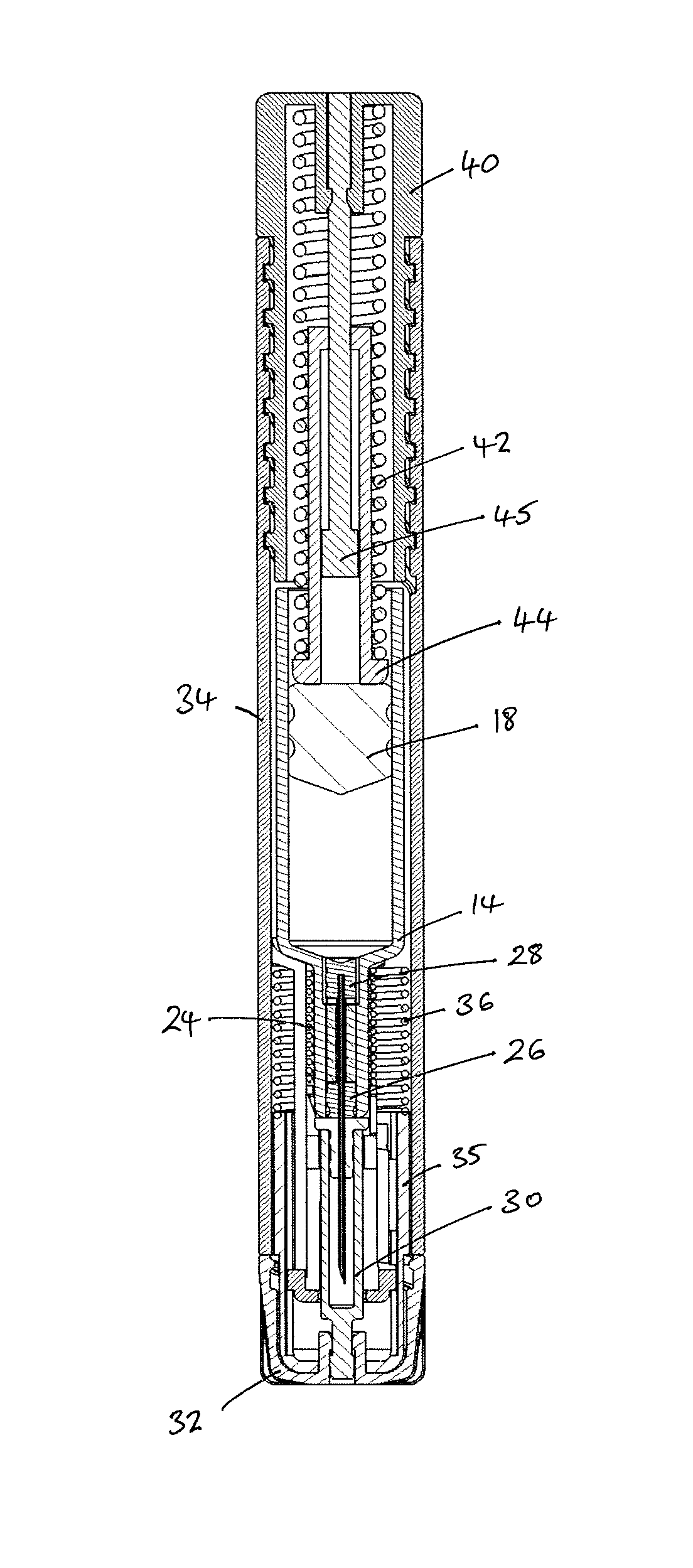

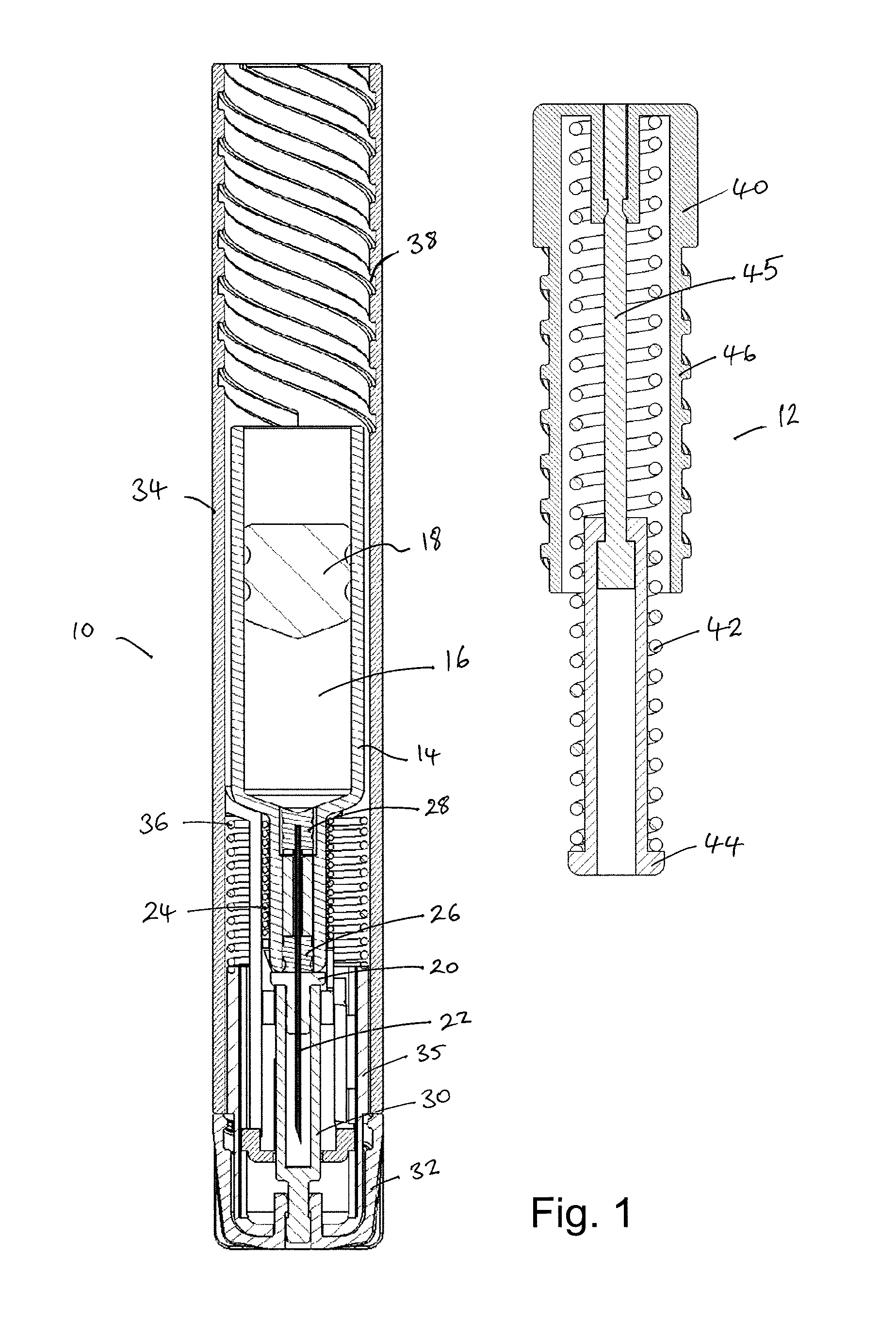

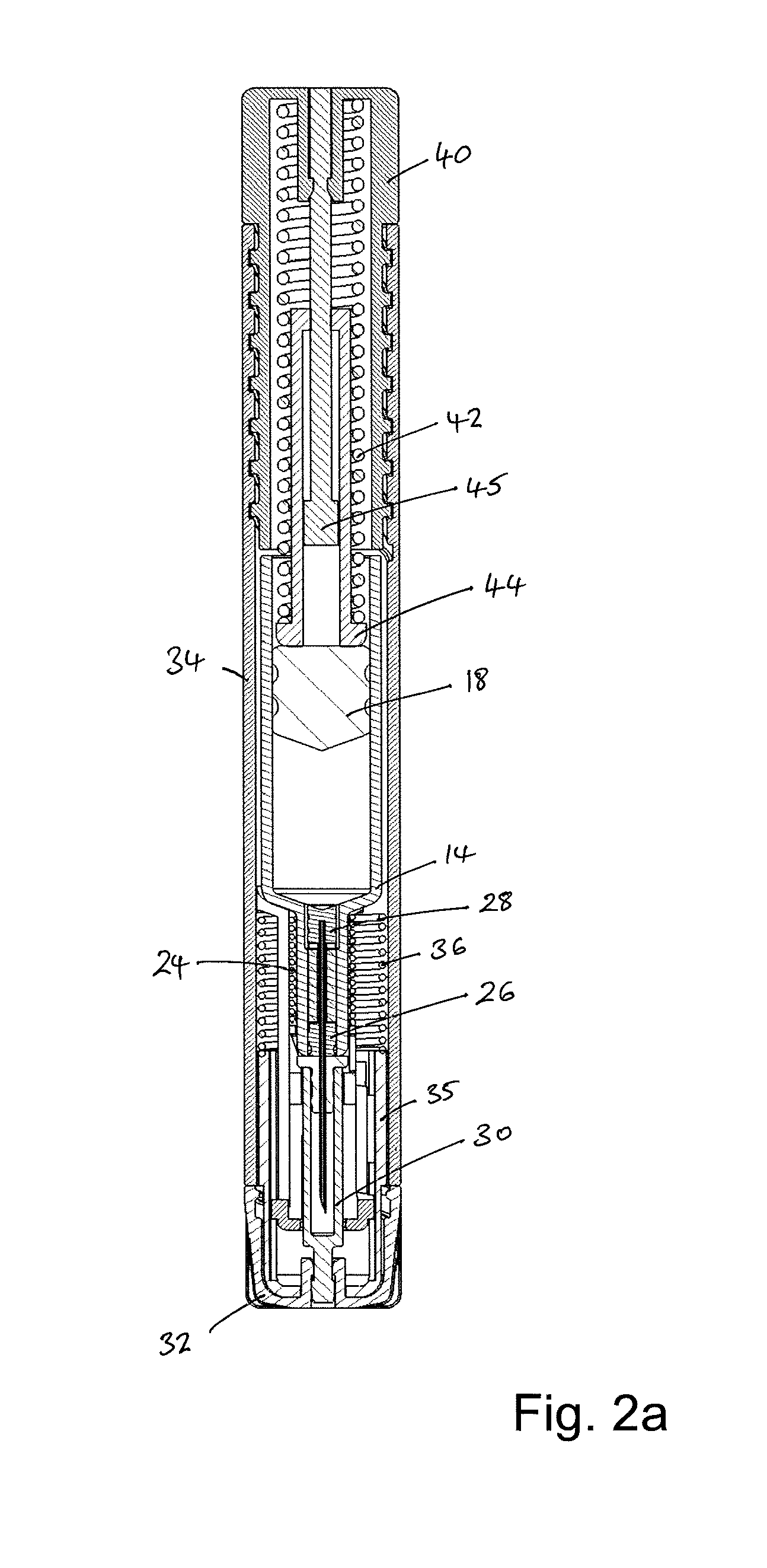

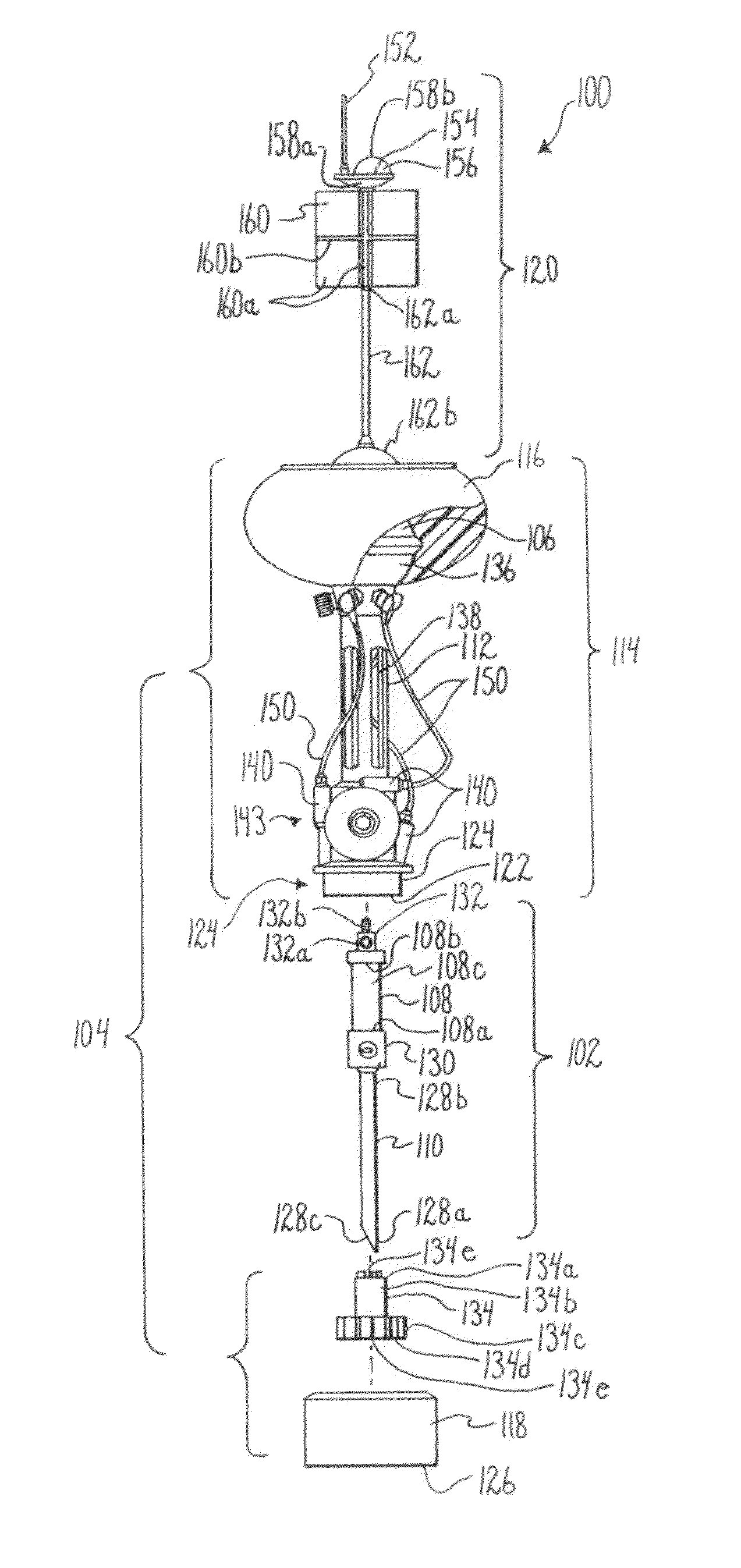

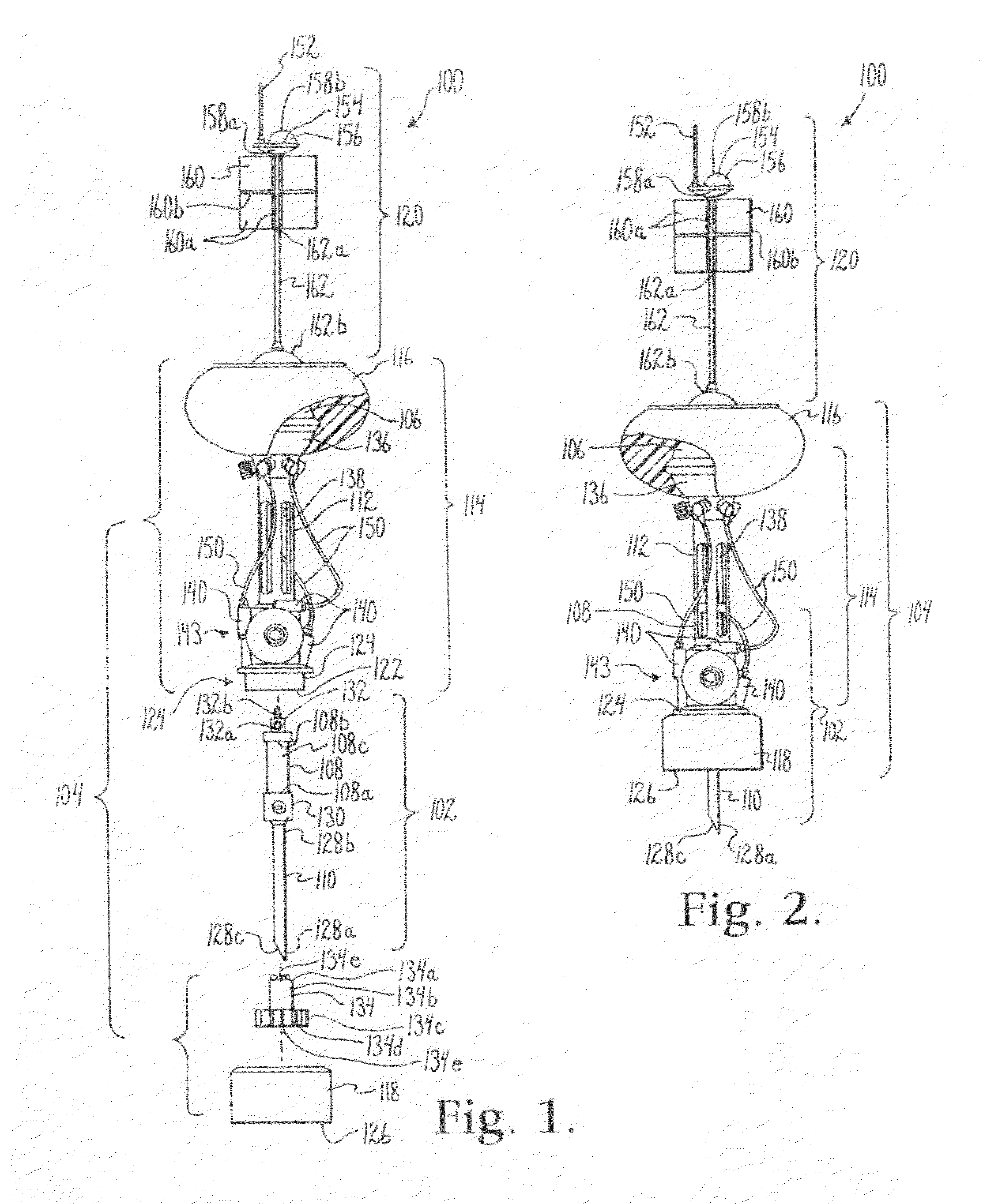

Automatic drug delivery devices

ActiveUS20150283323A1Reduces of device operationSmall device sizeAmpoule syringesAutomatic syringesStored energySyringe needle

The invention provides in one aspect a drug delivery device comprising a drug container (16), and a plunger (18) positioned within the container assembly, the drug container assembly having an outlet for dispensing the drug, wherein, in an initial position, the outlet is sealed; a drive mechanism comprising a first stored energy source (42) operable to apply pressure on the plunger or the drug container to pressurise the drug, and a first release mechanism operable to unseal the outlet after the drug has been pressurised. In another aspect, there is provided a drug delivery device comprising a housing, including an external housing portion configured to be held in use and a drug containing portion containing a drug, a needle assembly comprising a needle fixed to a needle hub, the needle hub configured to move relative to the drug containing portion from an initial position within the housing to an insertion position in which the needle extends beyond the housing, a first stored energy source configured to move the needle hub from the initial position to the insertion position, and a plunger within the housing and configured to move relative to the drug containing portion to eject the drug through the needle when the needle is in the insertion position.

Owner:OVAL MEDICAL TECH

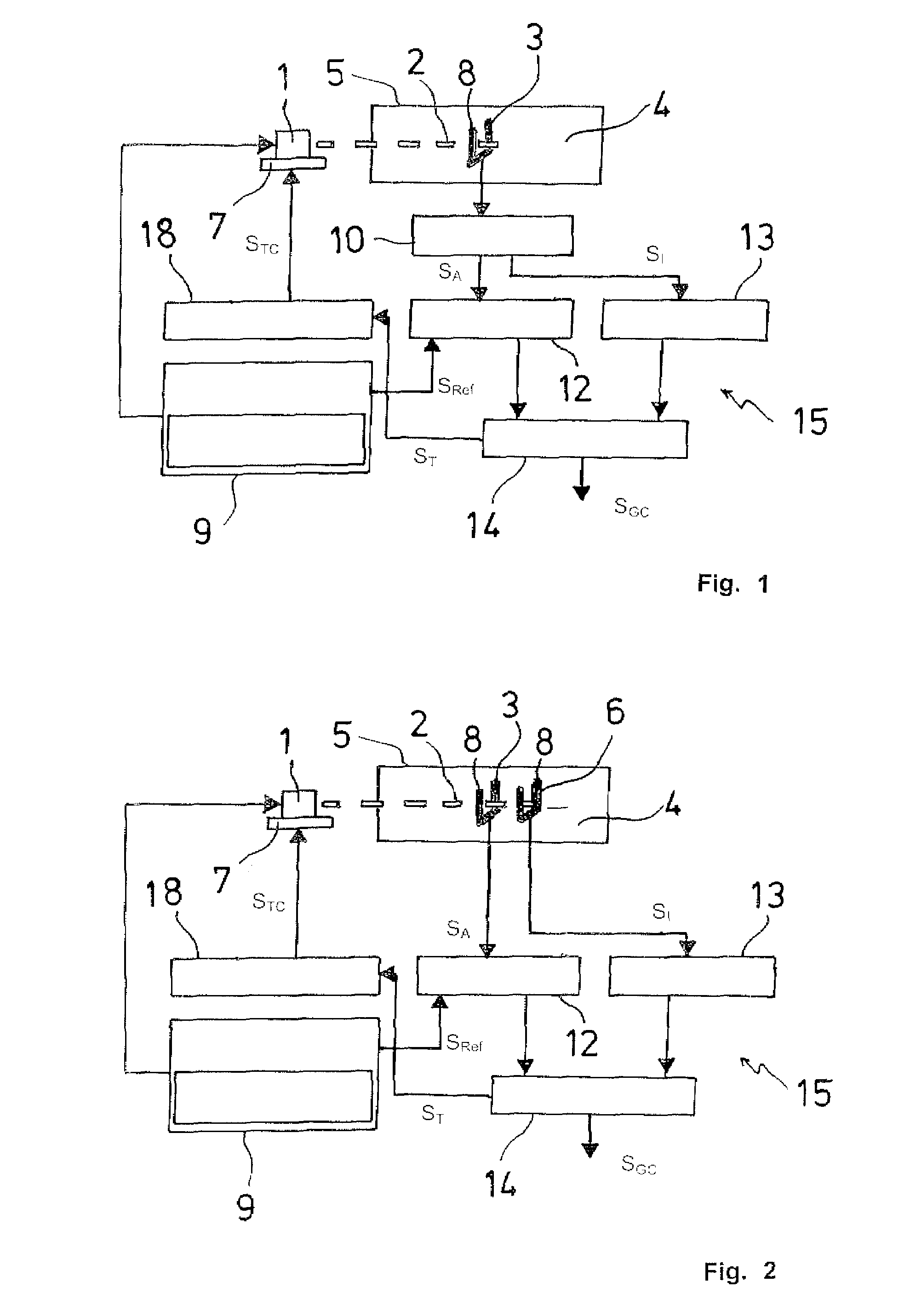

Method and gas sensor for performing quartz-enhanced photoacoustic spectroscopy

ActiveUS7605922B2Reduce contributionLow costRadiation pyrometryMaterial analysis using sonic/ultrasonic/infrasonic wavesPhotoacoustic microscopyLaser intensity

A method for performing quartz-enhanced photoacoustic spectroscopy of a gas, includes providing a light source configured to introduce a laser beam having at least one wavelength into the gas such said at least one molecule within in the gas is stimulated generating an acoustic signal, accumulating the acoustic signal in a resonant acoustic detector, generating a resonant absorption signal (SA) relative to the gas concentration by at least one tuning fork serving as resonant acoustic detector, generating additionally a resonant intensity signal (SI) proportional to the intensity of the laser beam travelling through the gas, and providing an output signal (SGC) from said absorption signal (SA) and said intensity signal (SI) being independent of the intensity of the light relative to the presence or concentration of the gas.

Owner:AXETRIS AG

Bipolar Transistor with Pseudo Buried Layers

InactiveUS20110147892A1Small device sizeLess parasitic effectSemiconductor/solid-state device manufacturingSemiconductor devicesImpurityPolycrystalline silicon

A structure and fabrication method for a bipolar transistor with shallow trench isolation (STI) comprises a collector formed by implanting first electric type impurity in active area; pseudo buried layers at the bottom of STI at both sides of active area by implanting heavy dose of first electric type impurity; deep contacts through field oxide to connect to pseudo buried layers and to pick up the collector; a base, a thin film deposited on the collector and doped with second electric type impurity; an emitter, a polysilicon film doped by heavy dose implant of first electric type impurity. This transistor has smaller device area, less parasitic effect, less photo layers and lower process cost.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Sea floor sampling device and method

InactiveUS20100238025A1Rapid and low cost collectionEasy data collectionWithdrawing sample devicesElectric signalling detailsOcean bottomMarine engineering

Owner:VERHULST GALEN G

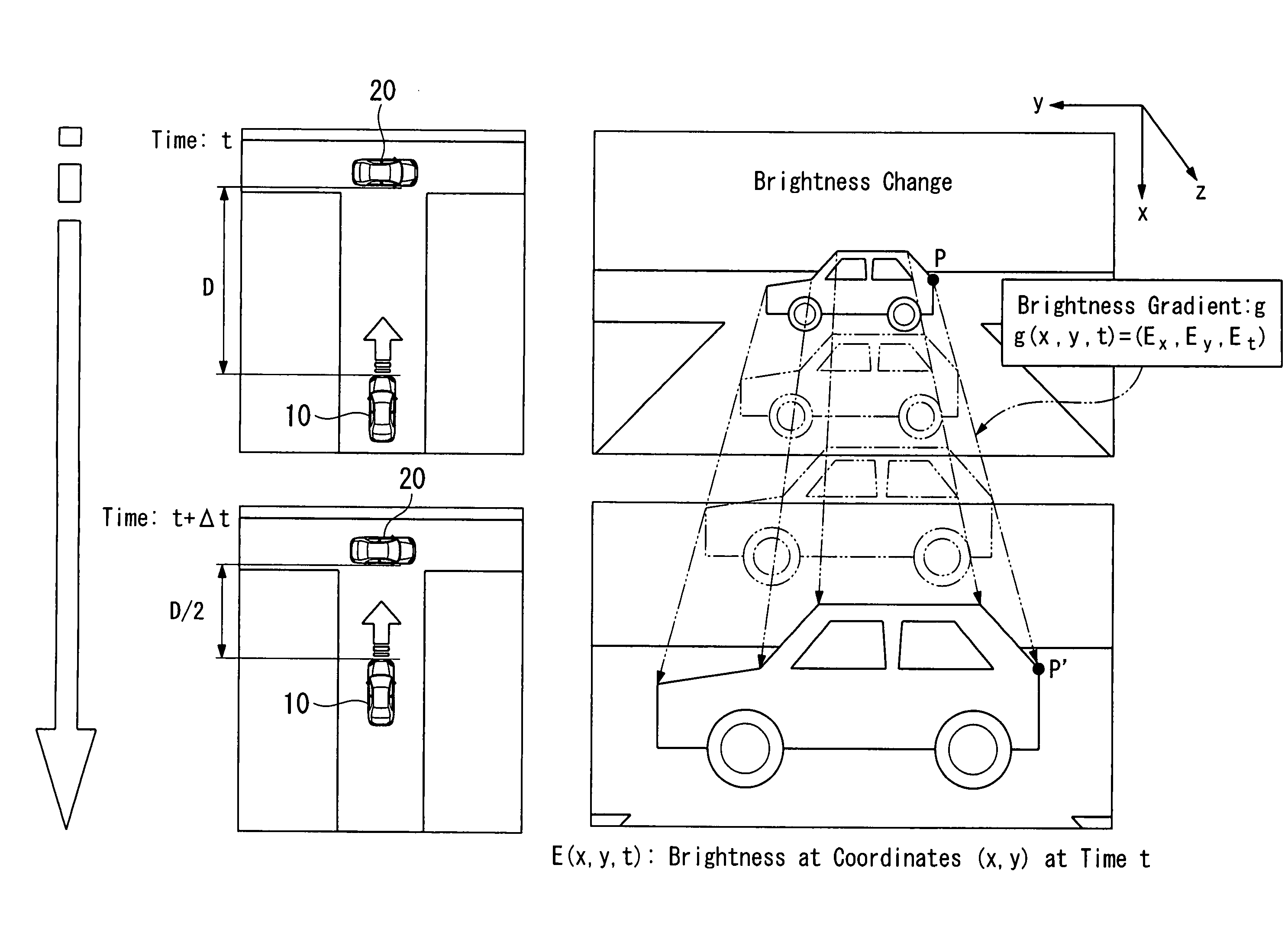

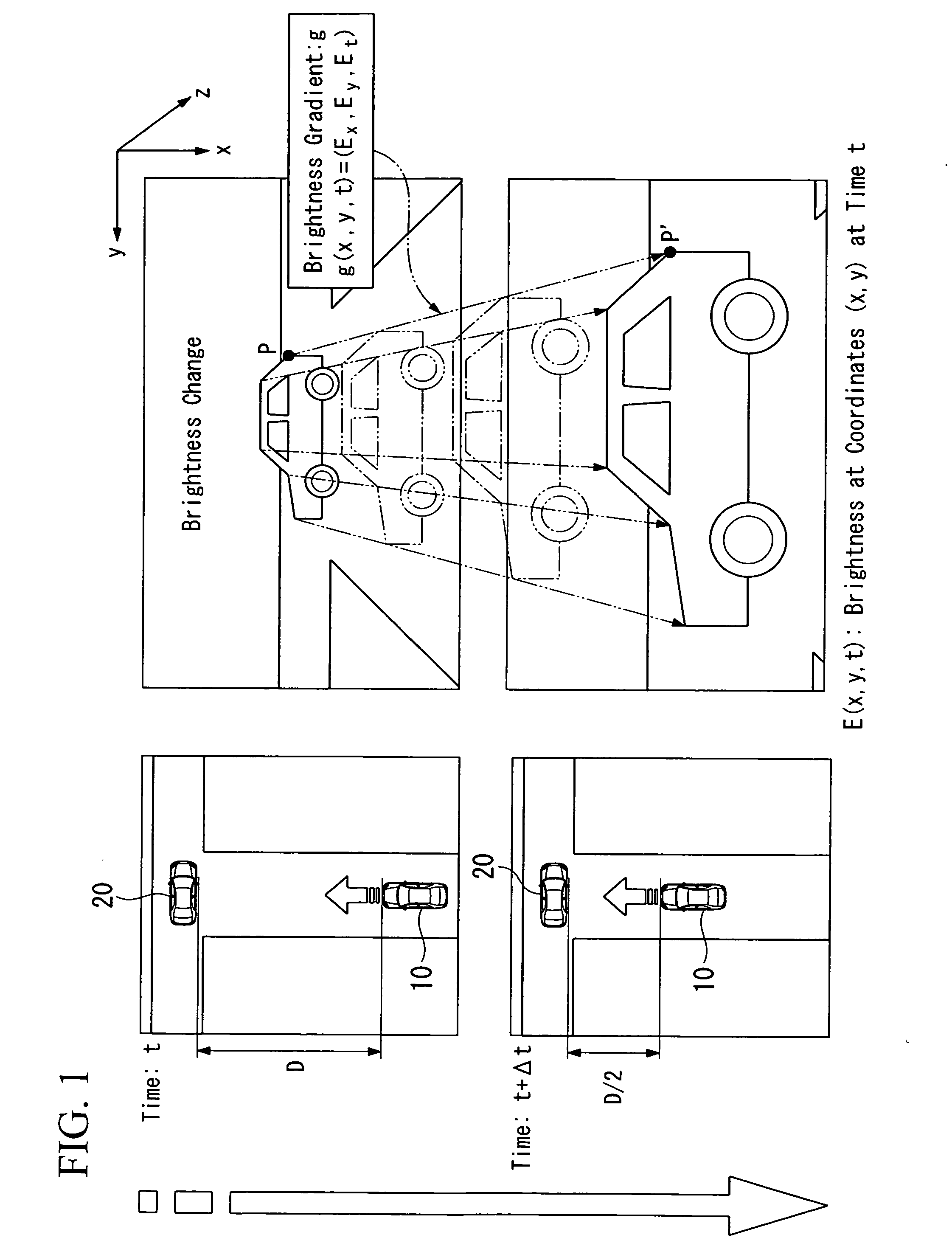

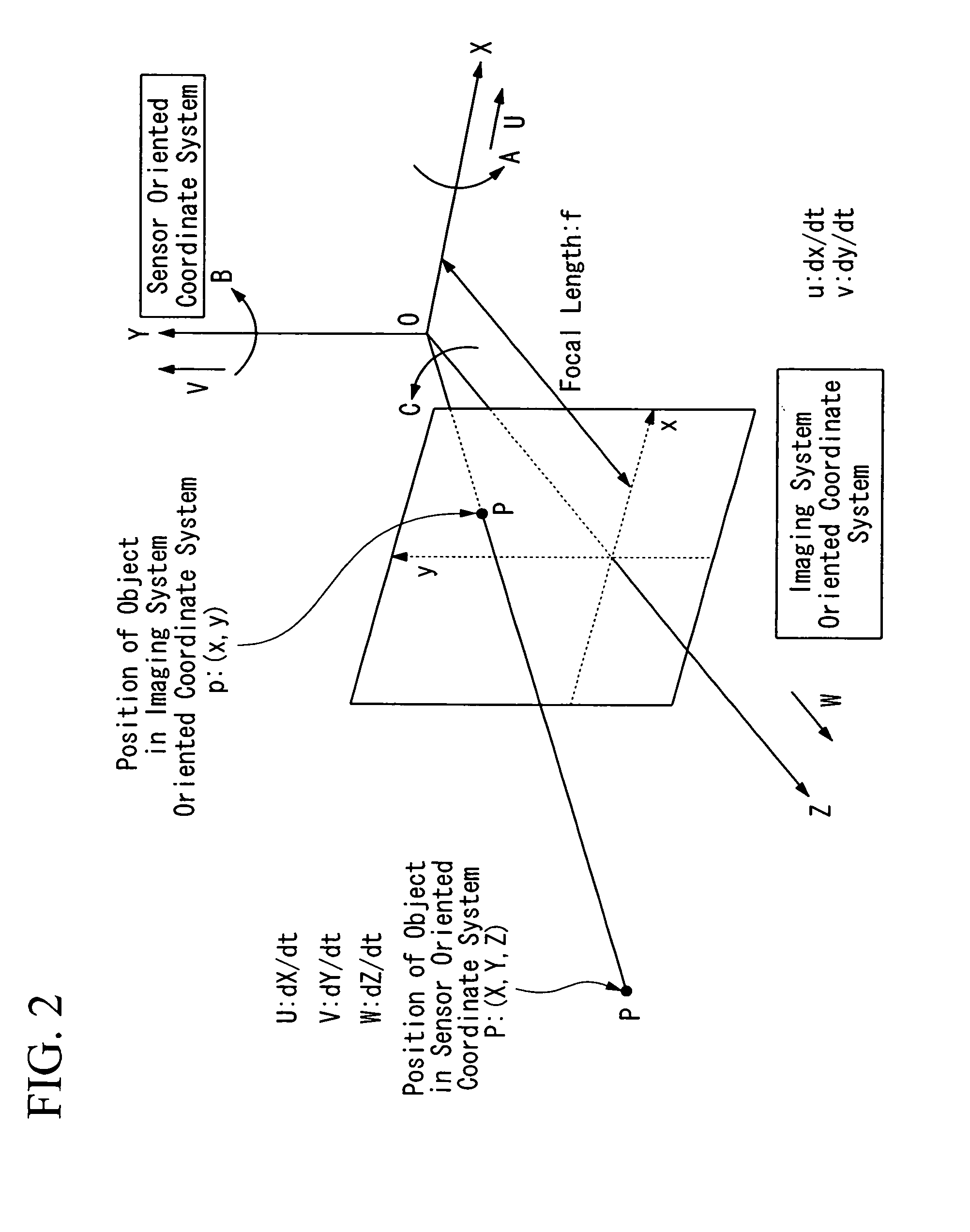

Time-to-contact estimation device and method for estimating time to contact

ActiveUS20080046181A1Lower latencyComputationally efficientImage enhancementImage analysisObject basedBrightness gradient

A time-to-contact estimation device for estimating a time to contact of a moving body to an object in surroundings of the moving body, includes: an image sensor provided on the moving body, and continuously capturing time-varying images of the surroundings of the moving body; a brightness change calculation unit calculating brightness changes in pixels between the time-varying images captured one after another; and a time-to-contact calculation unit calculating optimized brightness gradients based on the brightness changes calculated by the brightness change calculation unit, and calculating the time to contact of the moving body to the object based on the optimized brightness gradients.

Owner:VEONEER SWEDEN AB +1

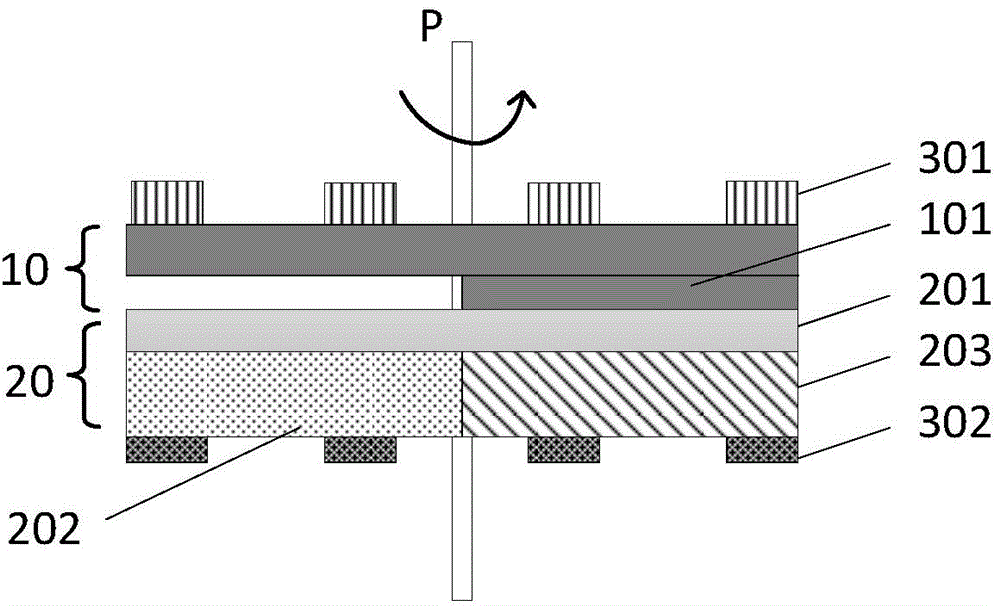

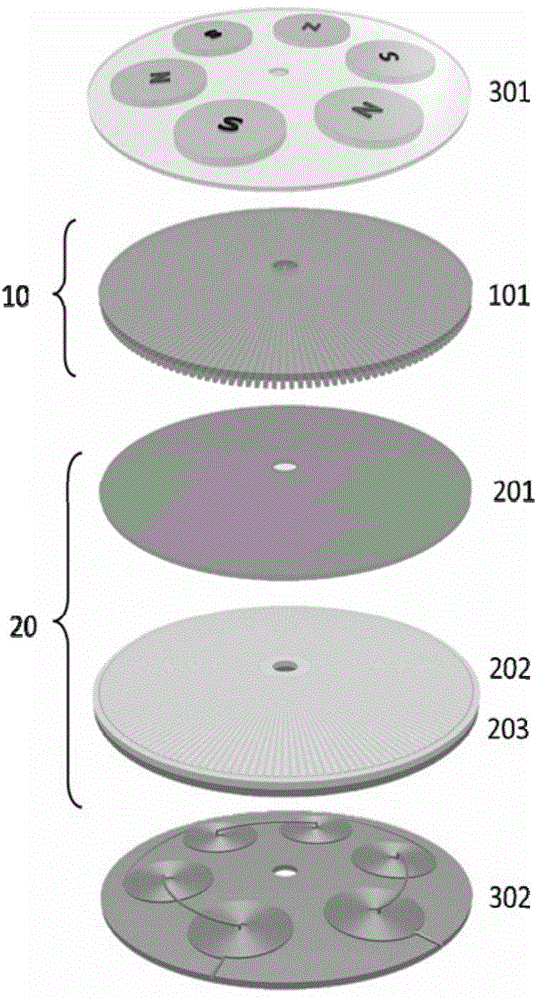

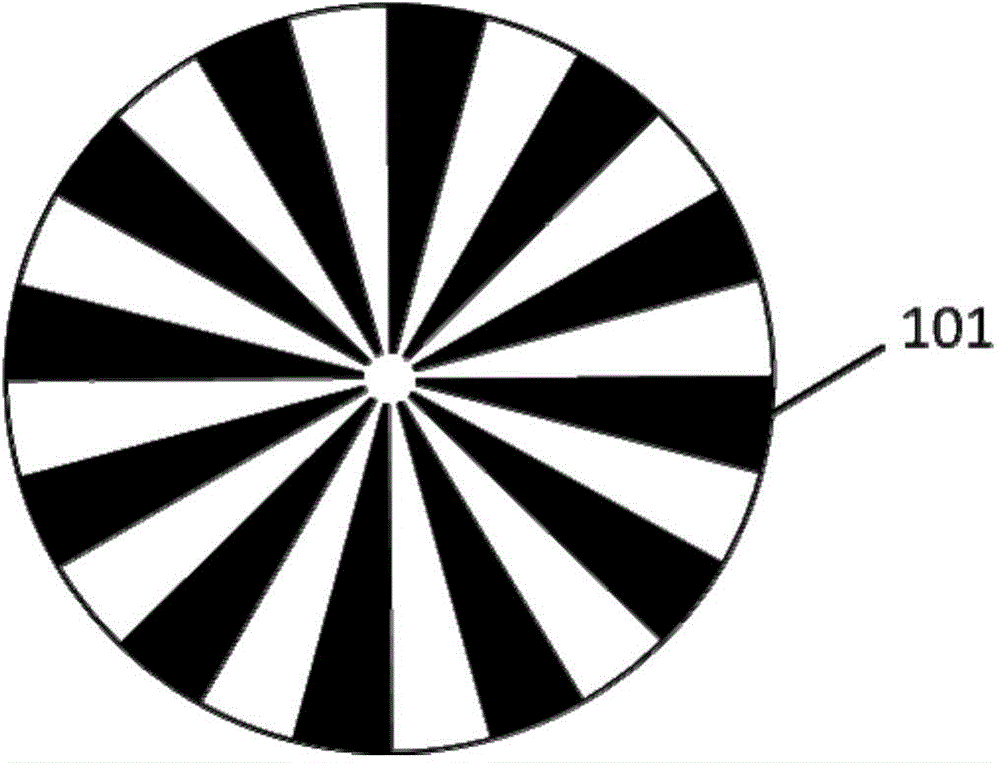

Rotary-type compound nanometer power generator

InactiveCN105680716AImprove energy conversion efficiency and output currentSmall device sizeFriction generatorsSynchronous machines with stationary armatures and rotating magnetsStatorMagnet

The invention provides a rotary-type compound nanometer power generator. The rotary-type compound nanometer power generator comprises a friction nanometer power generation assembly and a magnetic-electric sensing power generation assembly, wherein the friction nanometer power generation assembly comprises a rotor and a stator which are provided with a command rotation shaft, a friction layer is arranged on the lower surface of the rotor and is formed by outwards and radially arranging a plurality of friction units taking the rotation shaft as a circle center, an electrode layer of the stator comprises a first electrode and a second electrode which are formed by outwards and radially arranging a plurality of first electrode units and a plurality of second electrode units at intervals in the same plane from the rotation shaft, electron gain-loss capability difference exists between the friction units and the upper surface material of the stator, a magnet part and a coil part of the magnetic-electric sensing power generation assembly are separately arranged on the rotor and the stator, and under the effect of an external force, induction potential difference is generated between the two electrodes, and meanwhile, induction current is generated in the coil part. The power generator provided by the invention can acquire current output with milliamperes and can be used for directly supplying power to a small-sized power utilization device.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com