Patents

Literature

649 results about "Changing equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

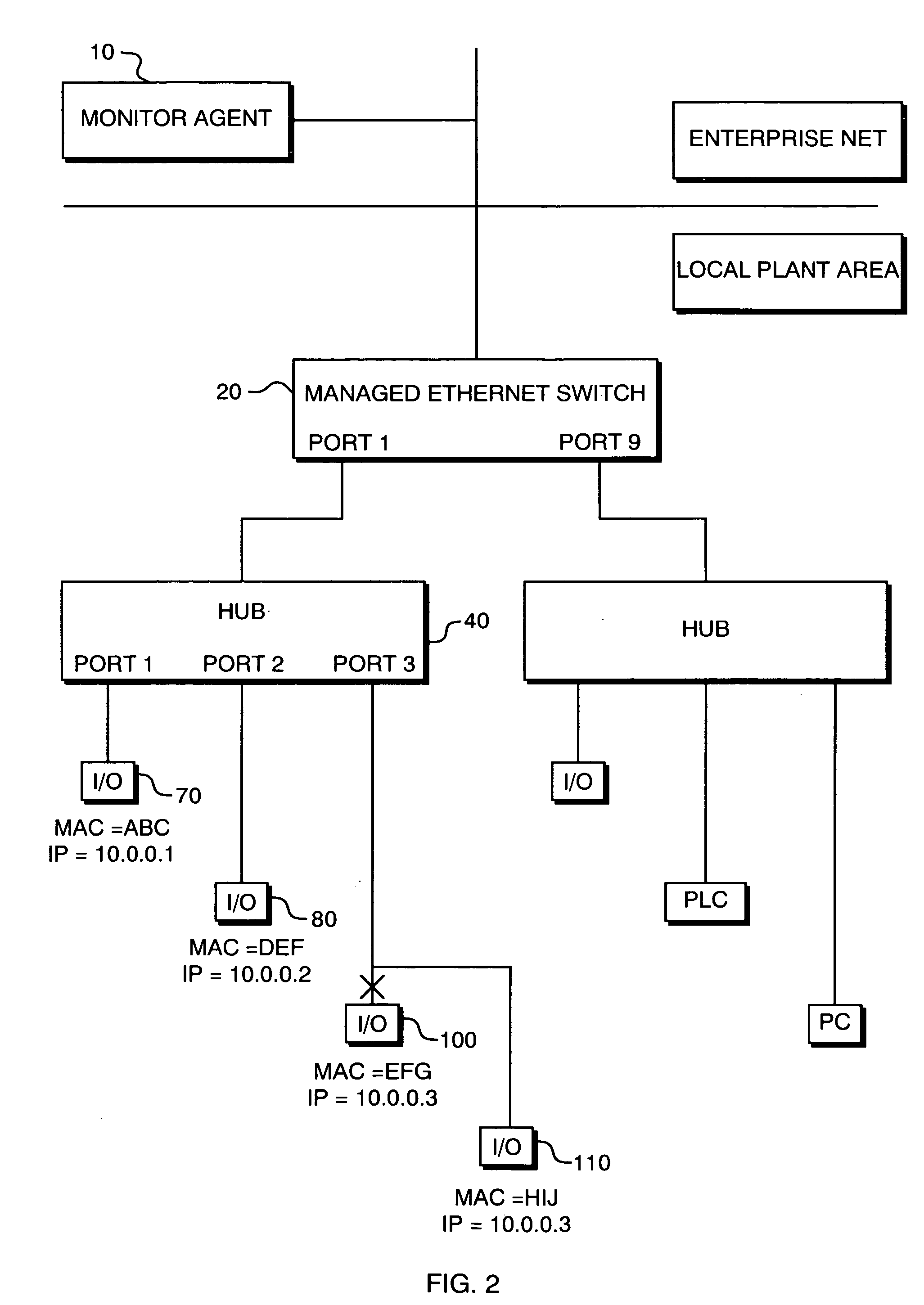

Automatic determination of correct IP address for network-connected devices

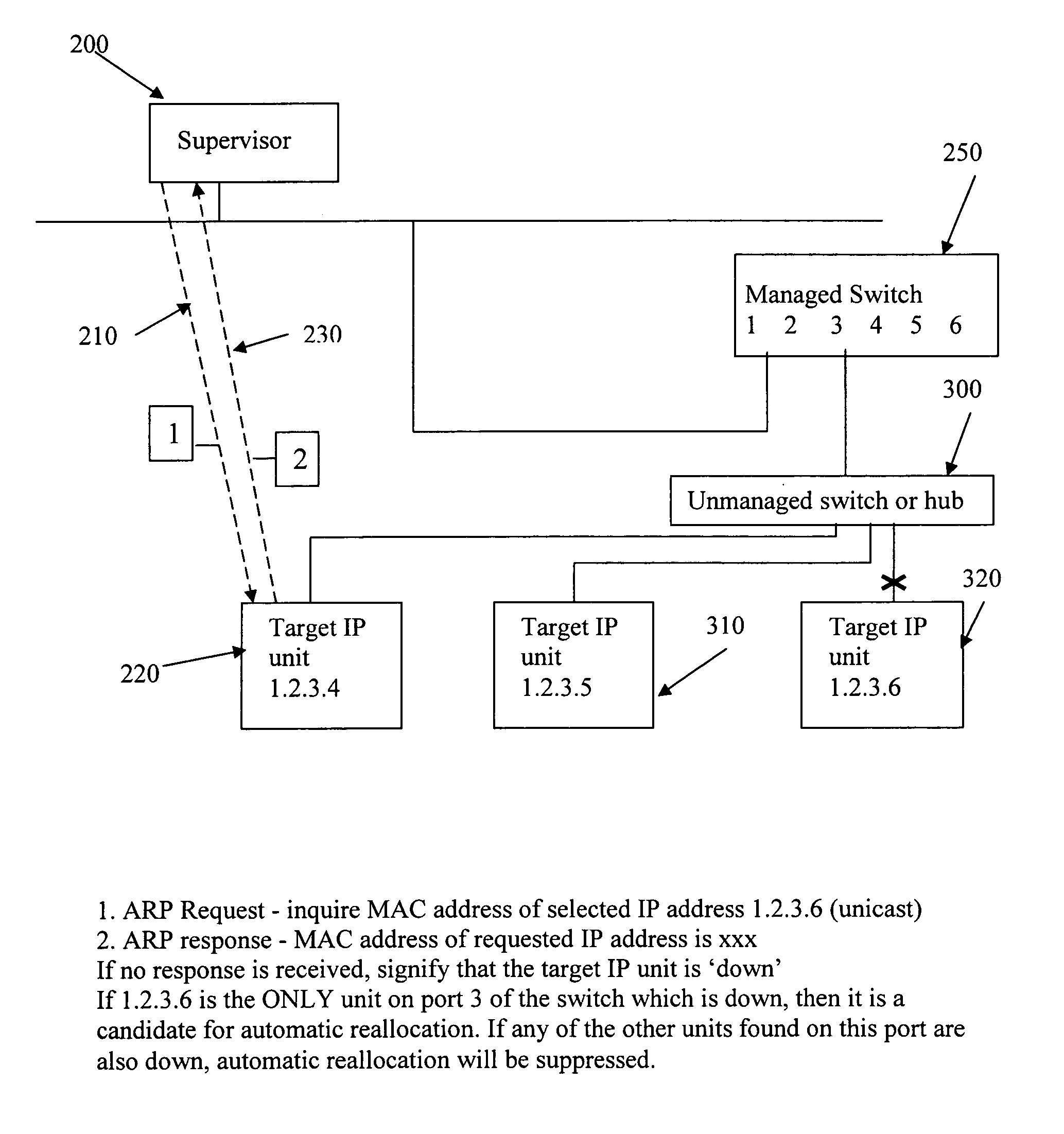

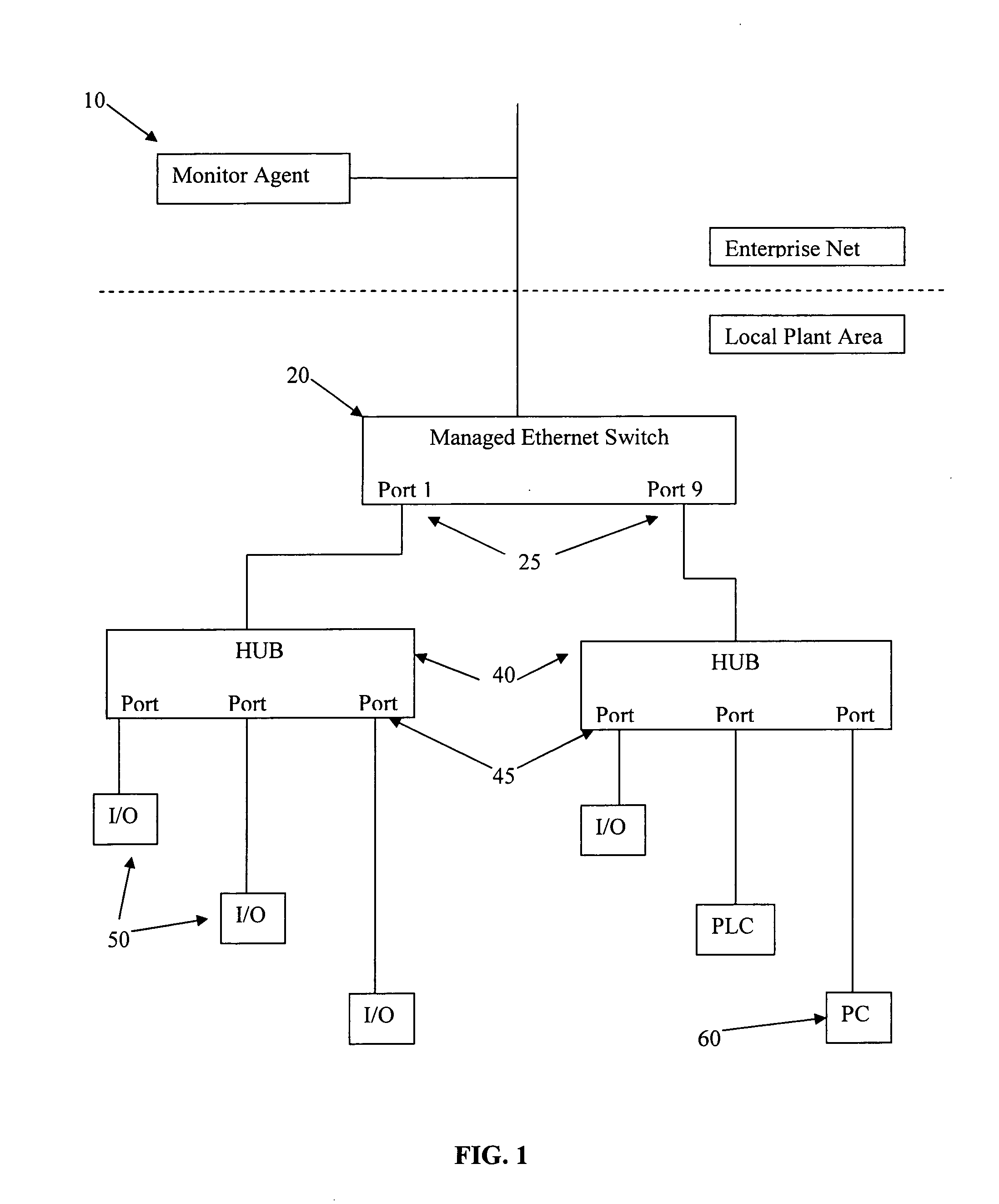

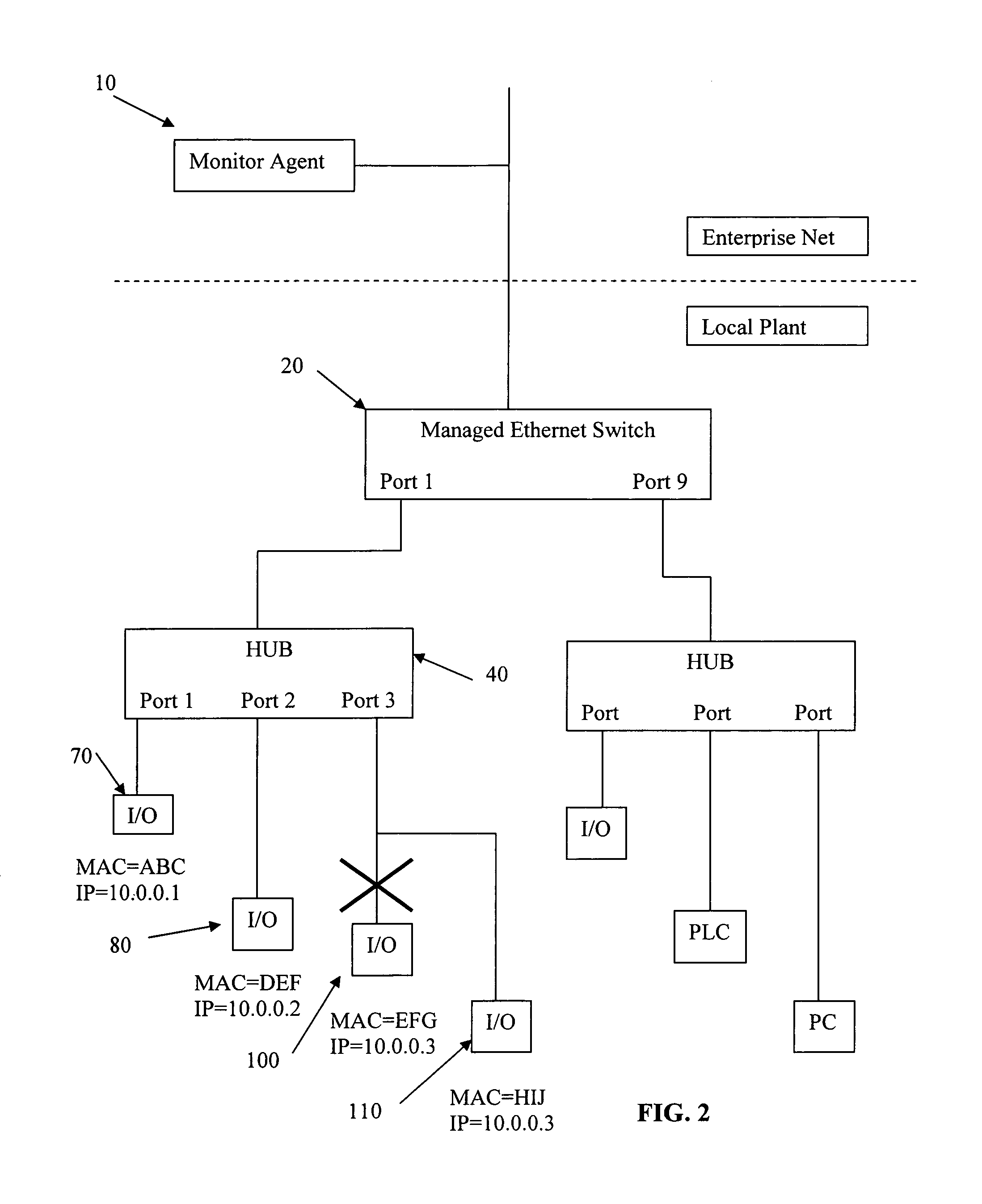

The present invention is for automatic reconfiguration of industrial networked devices. More particularly, the system described herein facilitates use of TCP / IP networks, such as Ethernet, as an alternative for industrial fieldbus or device buses by removing the need to perform significant reconfiguration of devices such as I / O modules, sensors, or transducers under field replacement situations. The present invention uses a monitor agent to track the IP and MAC addresses of networked devices as well as port information. If a device fails, maintenance personnel make an in-field replacement of the failed device and the monitor agent automatically reassigns the IP address to the replacement device.

Owner:SCORPION CONTROLS

System and method for automatically replacing nodes in a network

ActiveUS20060159007A1Error preventionFrequency-division multiplex detailsNetwork variableAutomatic control

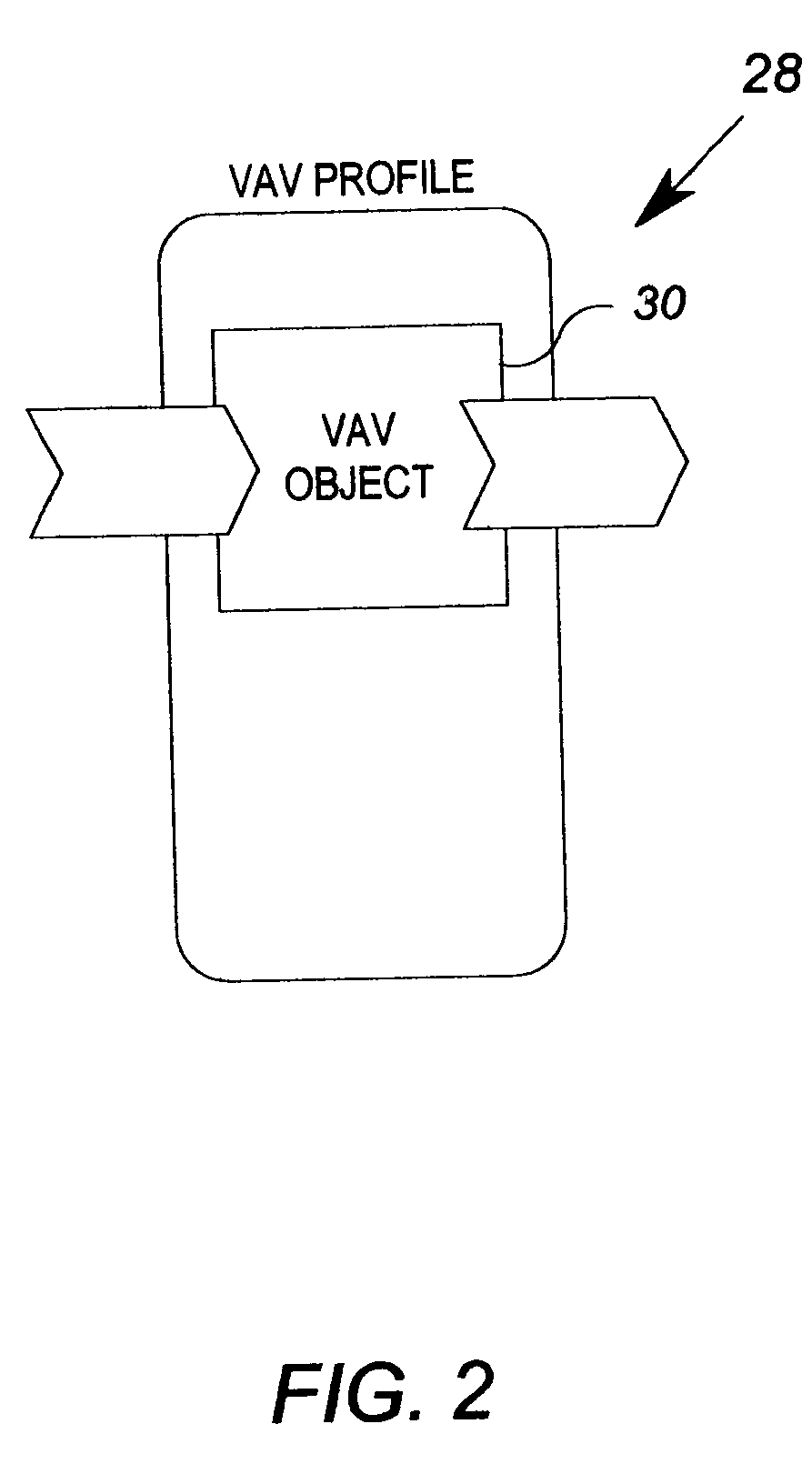

A tool is provided for use when replacing devices in an automatically controlled distributed processing system. In one embodiment a network management tool reestablishes all or a portion of the logical connections formerly provided to a bound node where a replacement device is or will be located. The network management tool compares data associated with the logical connections of the bound node and data associated with the logical connections for the replacement device to determine proper logical connection. The network management tool identifies network variables associated with the bound node that are not associated with the replacement device and deletes those network variables from other devices on the network if the network variable is not useful in the network after the replacement device is bound.

Owner:SIEMENS IND INC

Automatic determination of correct IP address for network-connected devices

InactiveUS20060031488A1Easy to useFast deliveryDigital computer detailsTransmissionIp addressTransducer

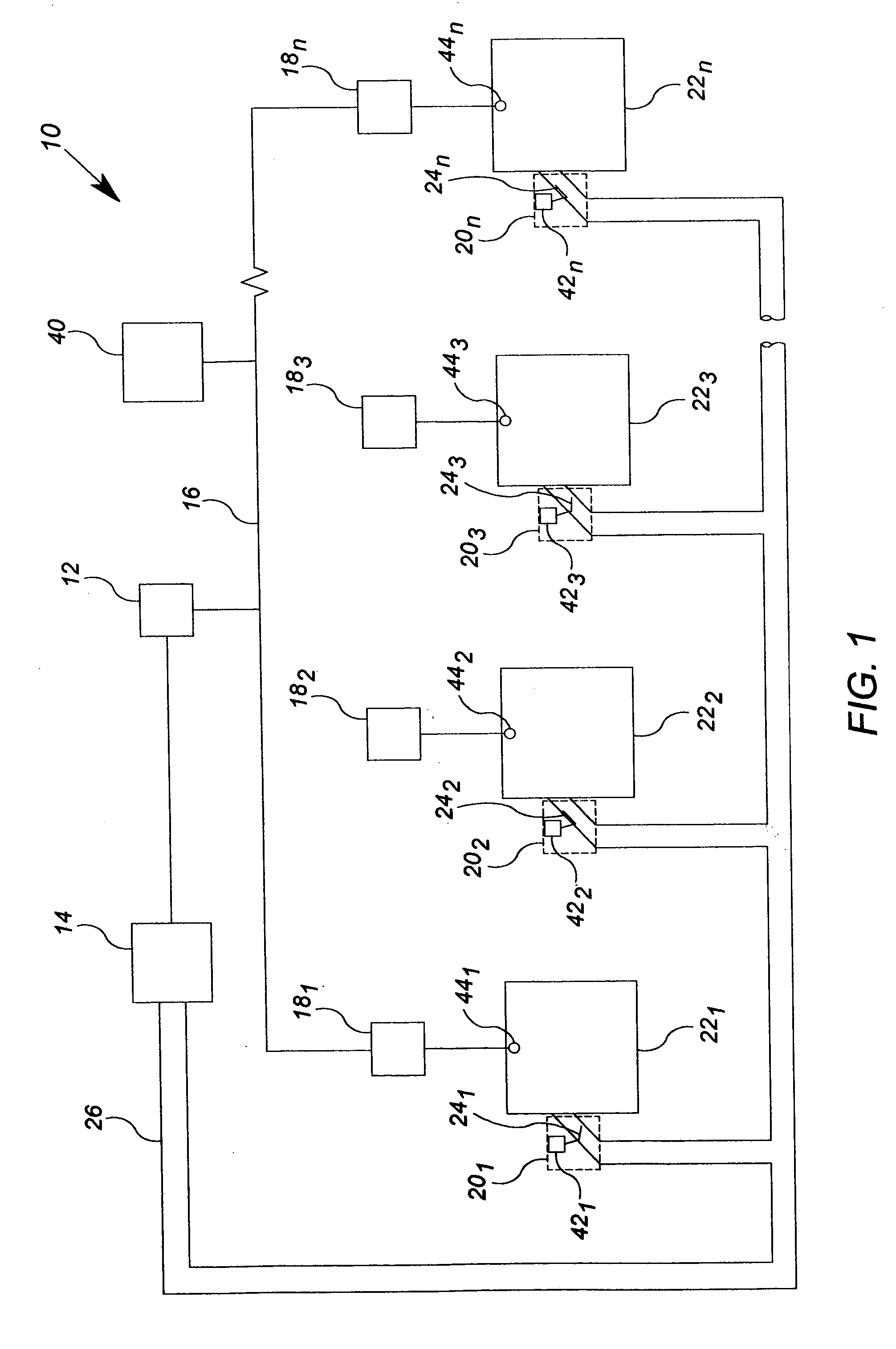

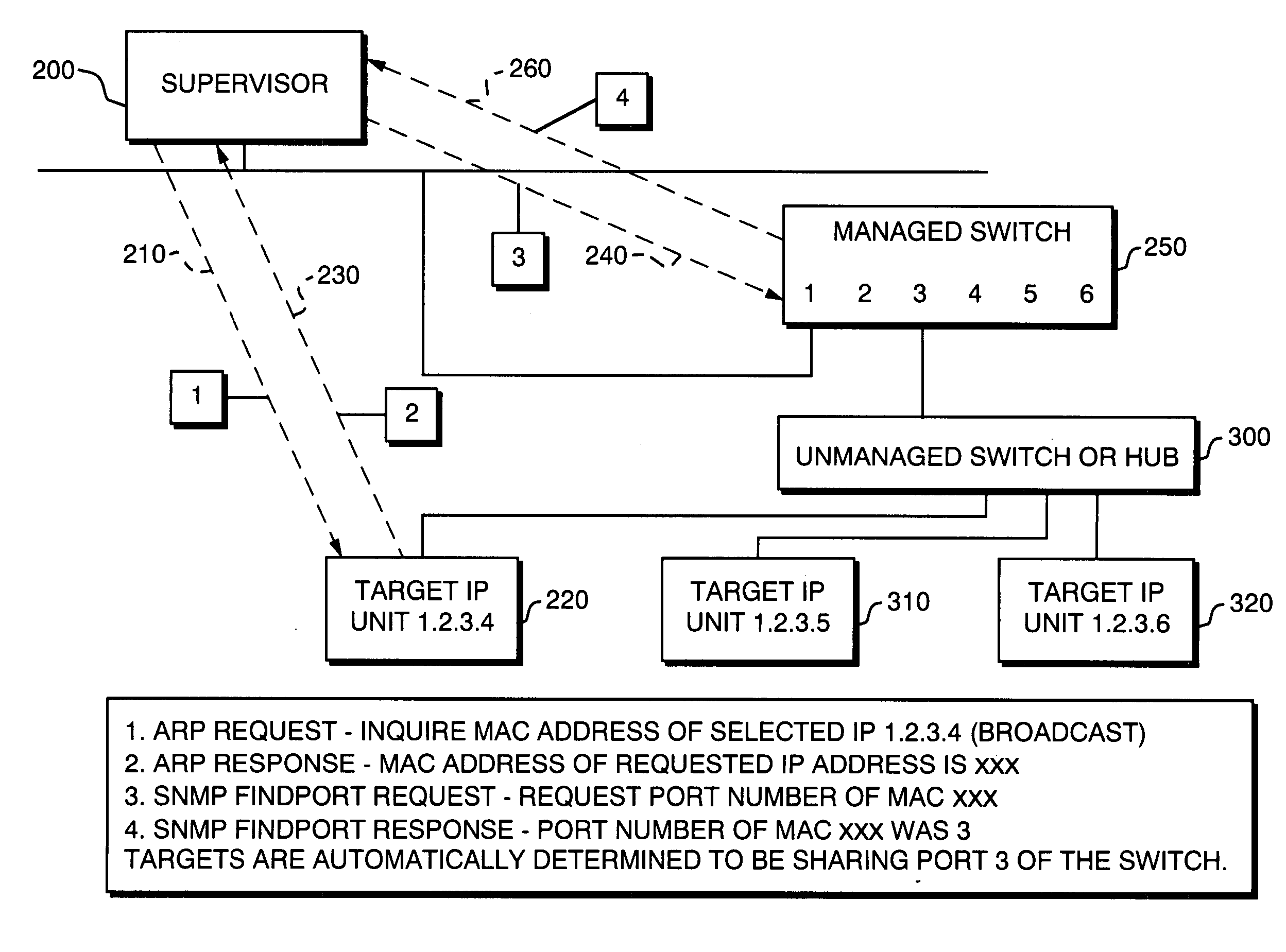

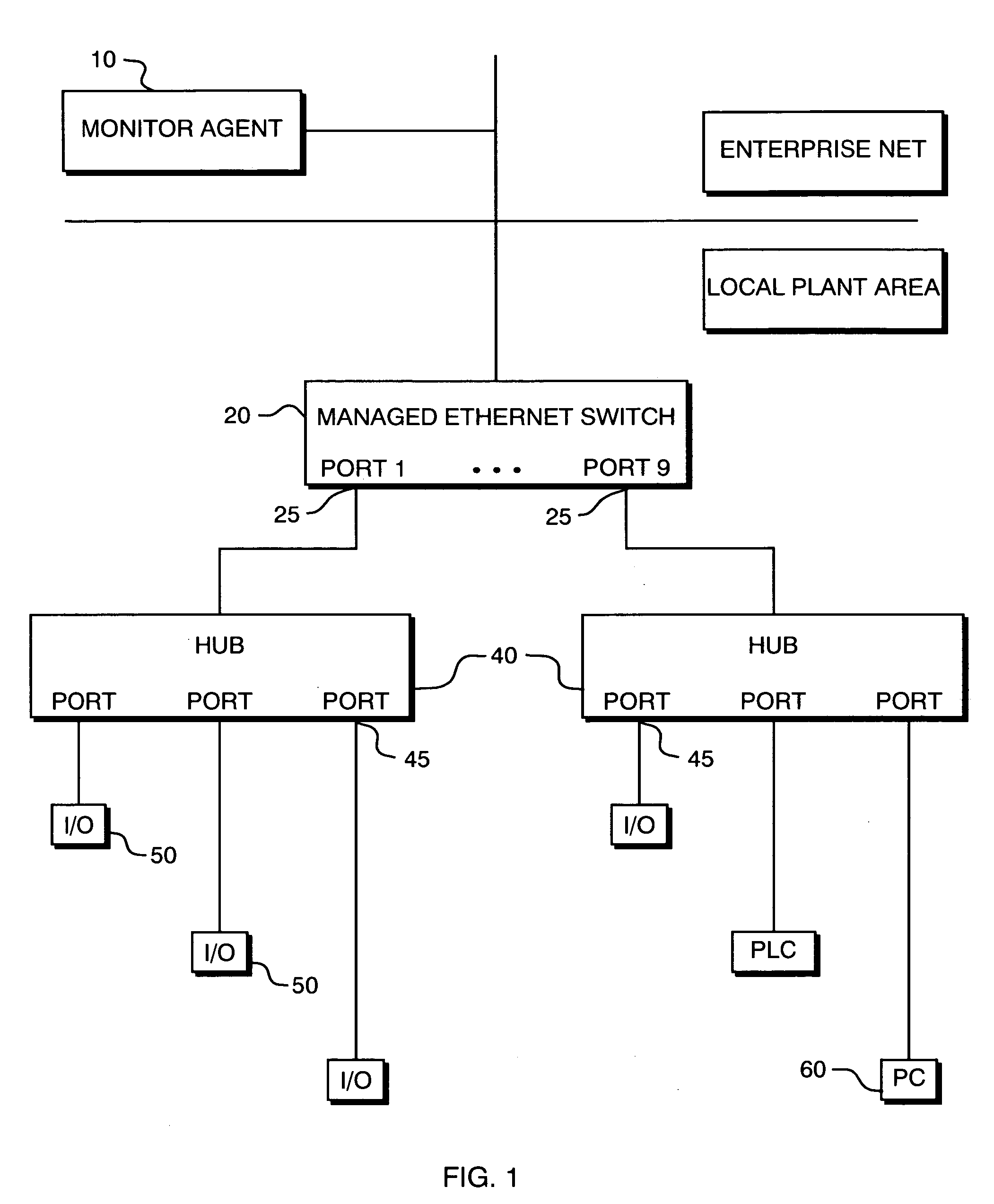

An automatic reconfiguration system for industrial networked devices. The system facilitates use of TCP / IP networks, such as Ethernet, as an alternative for industrial fieldbus or device buses by removing the need to perform significant reconfiguration of devices such as I / O modules, sensors, or transducers under field replacement situations. In one embodiment the invention uses a monitor agent to track the IP and MAC addresses of networked devices as well as port information. If a device fails, maintenance personnel make an in-field replacement of the failed device and the monitor agent automatically reassigns the correct IP address to the replacement device.

Owner:SCORPION CONTROLS

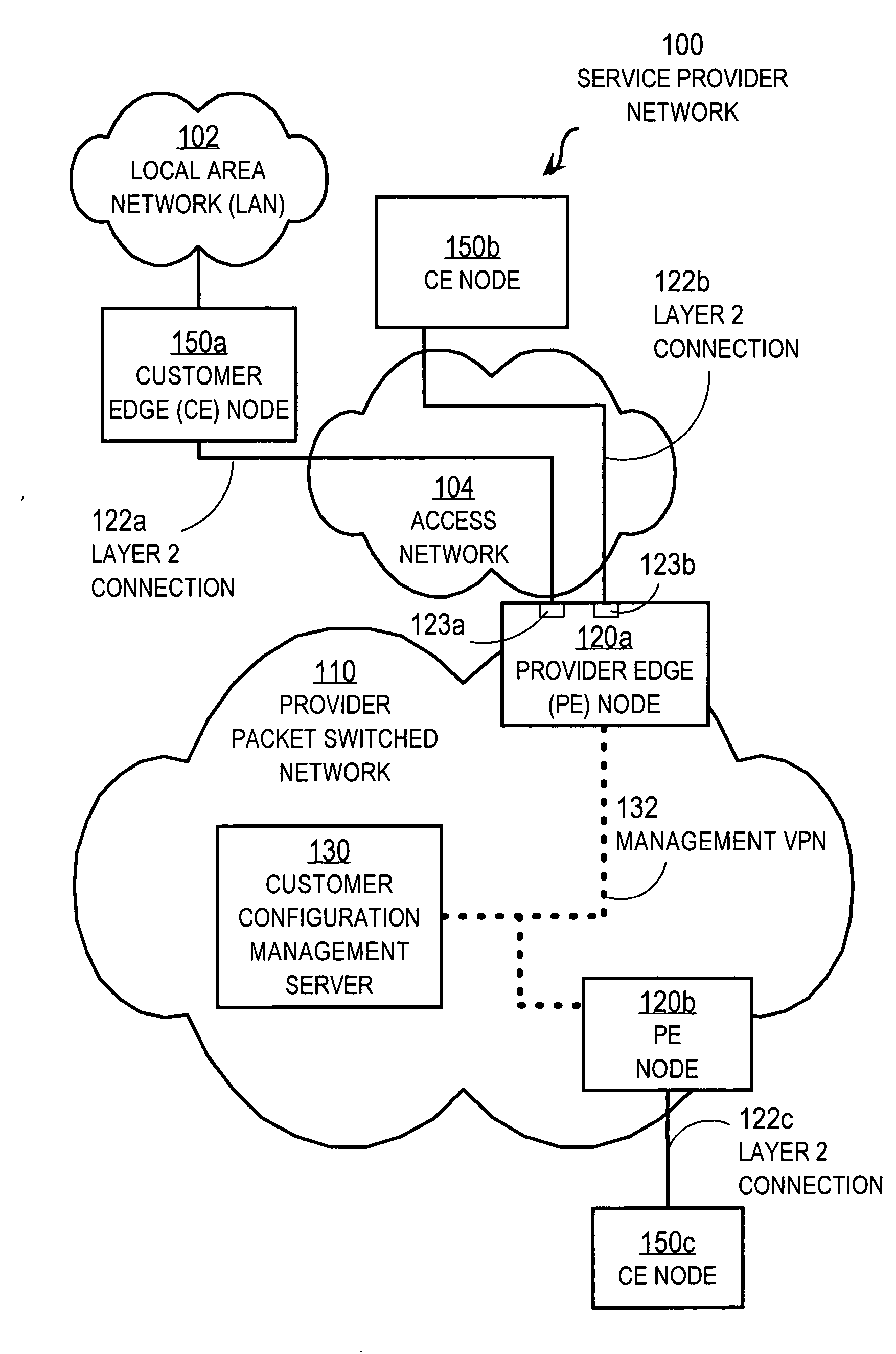

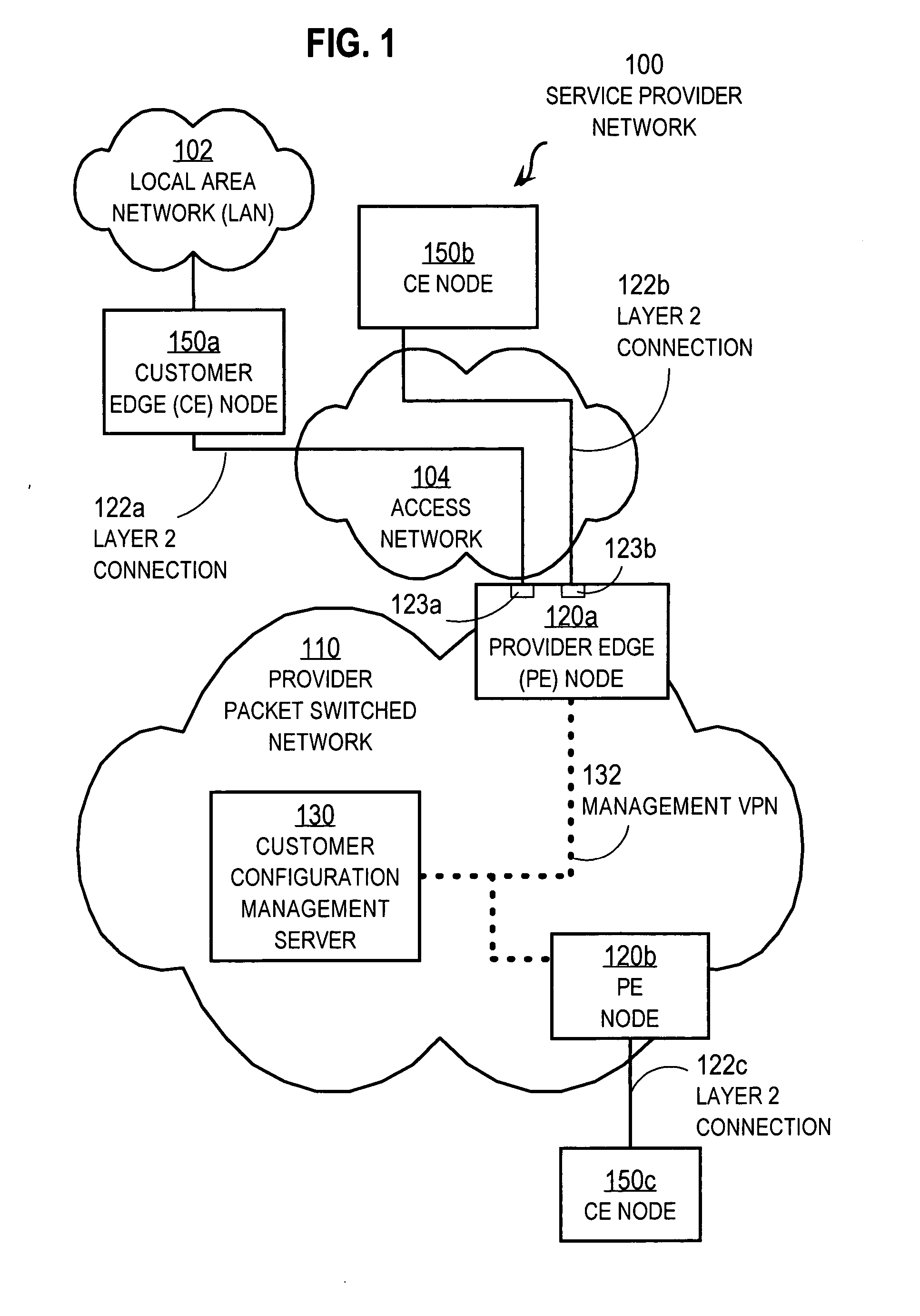

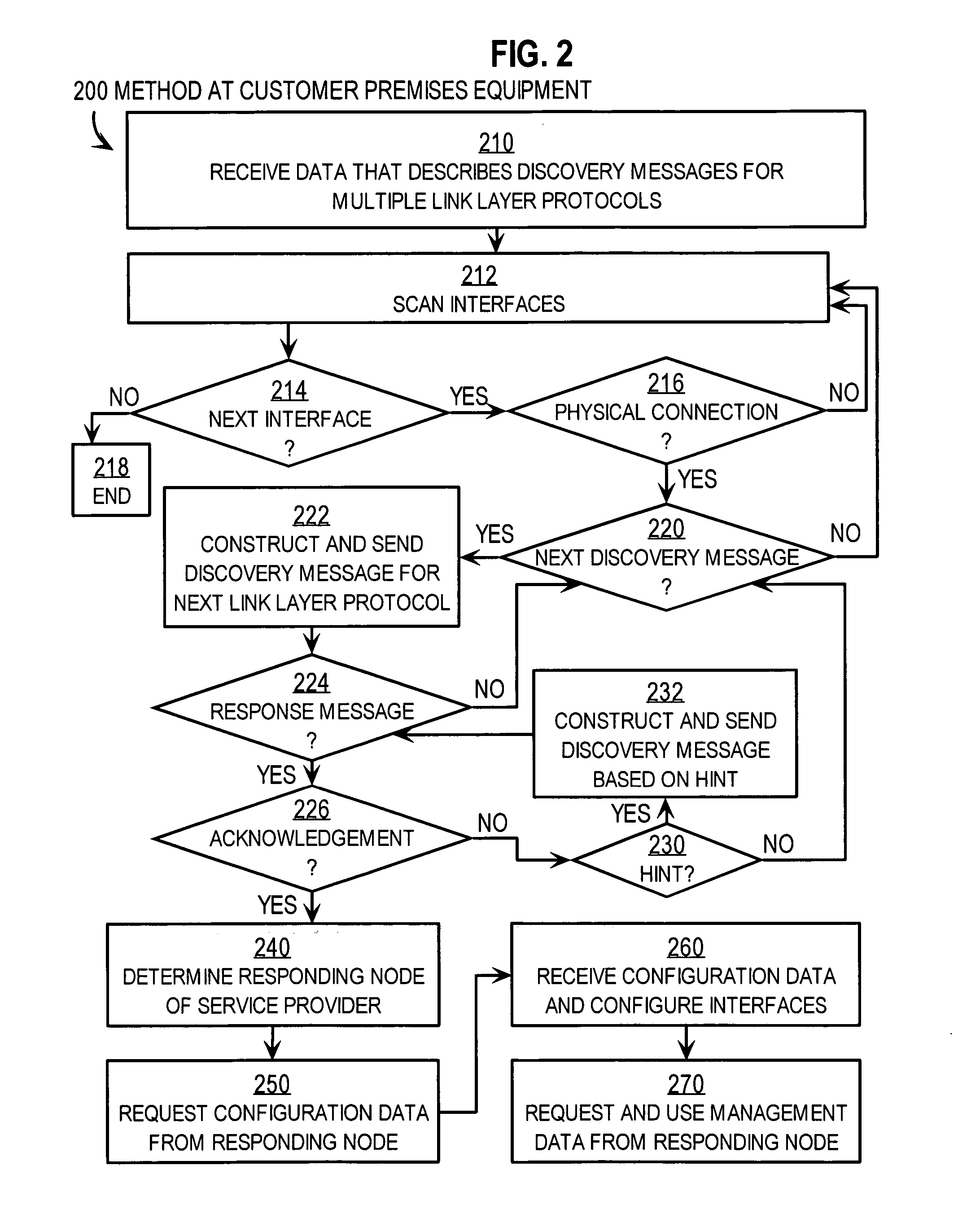

Techniques configuring customer equipment for network operations from provider edge

Techniques for configuring customer premises equipment for communication with a provider network include establishing a physical layer network connection between a particular customer node and a first provider node. The particular customer node is an intermediate network node on a customer premises. The first provider node is an intermediate network node on a first provider network of a first service provider different from the customer. Configuration data for one or more network interfaces on the particular customer node are automatically received through the physical layer network connection. The particular customer node is automatically configured based on that configuration data. The automatic provisioning of the customer node allows equipment to be more economically shipped and installed at customer premises and allows upgraded or replacement equipment to be more economically swapped in place of equipment previously installed. Traffic management data can also be automatically received and used at the particular customer node.

Owner:CISCO TECH INC

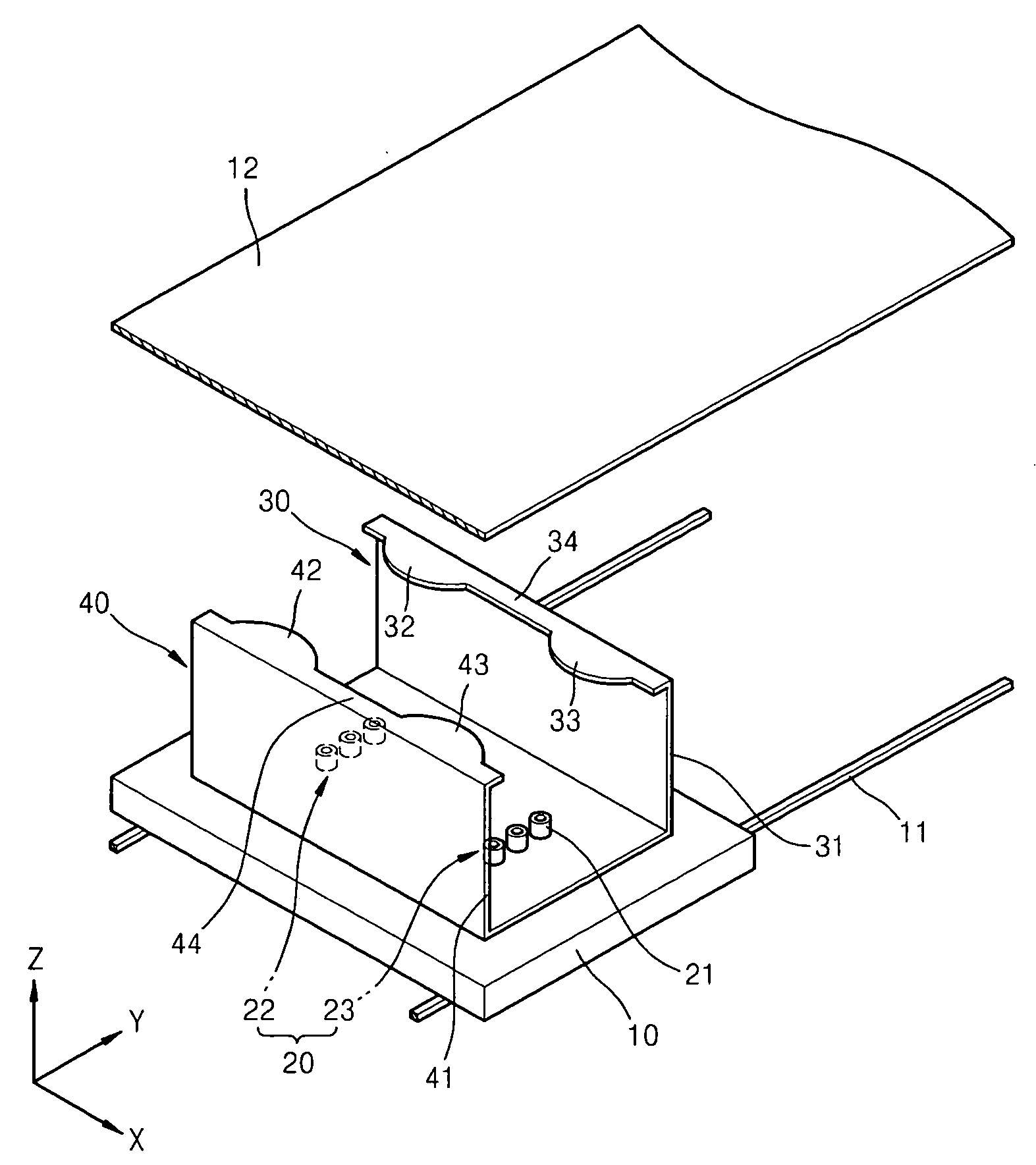

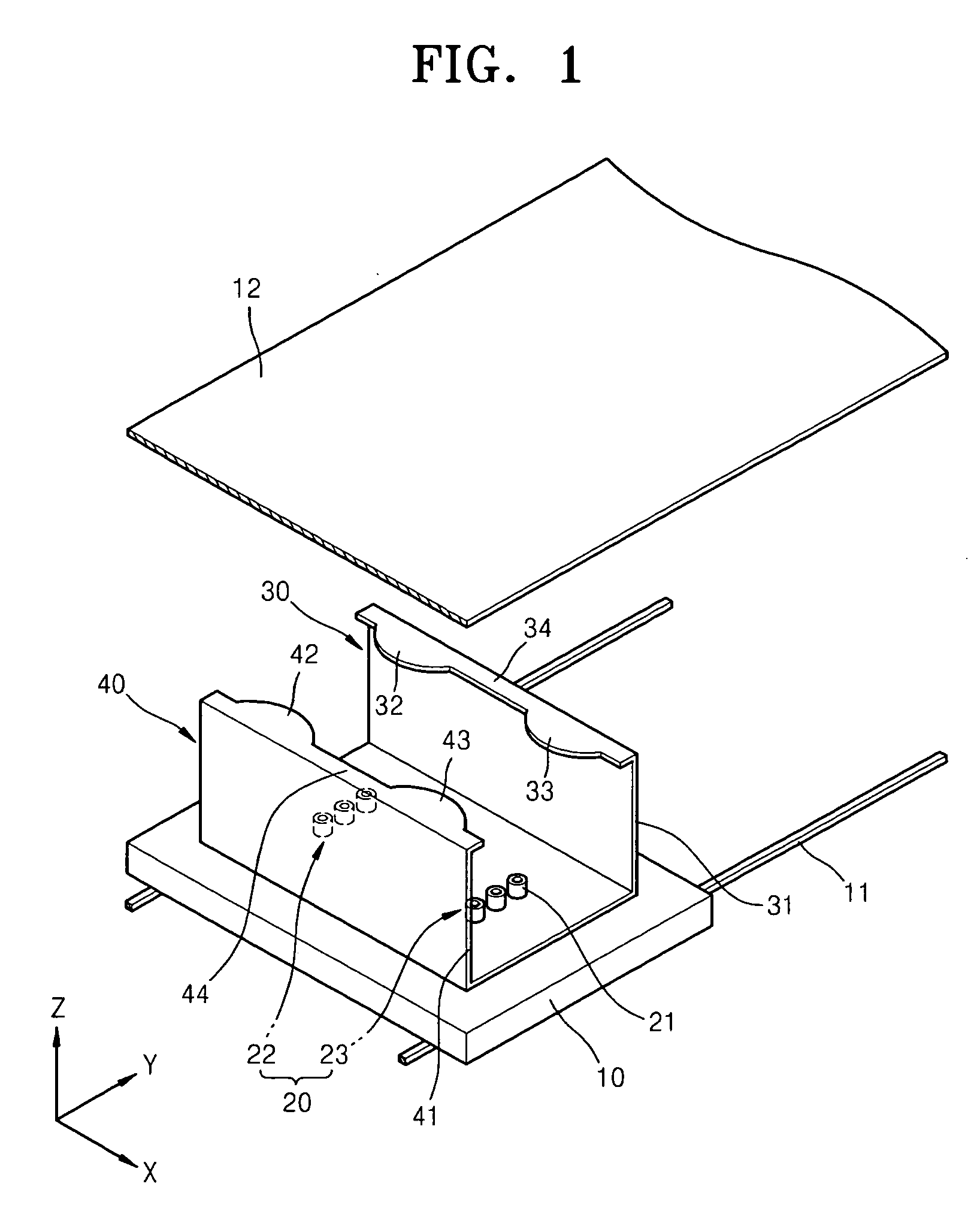

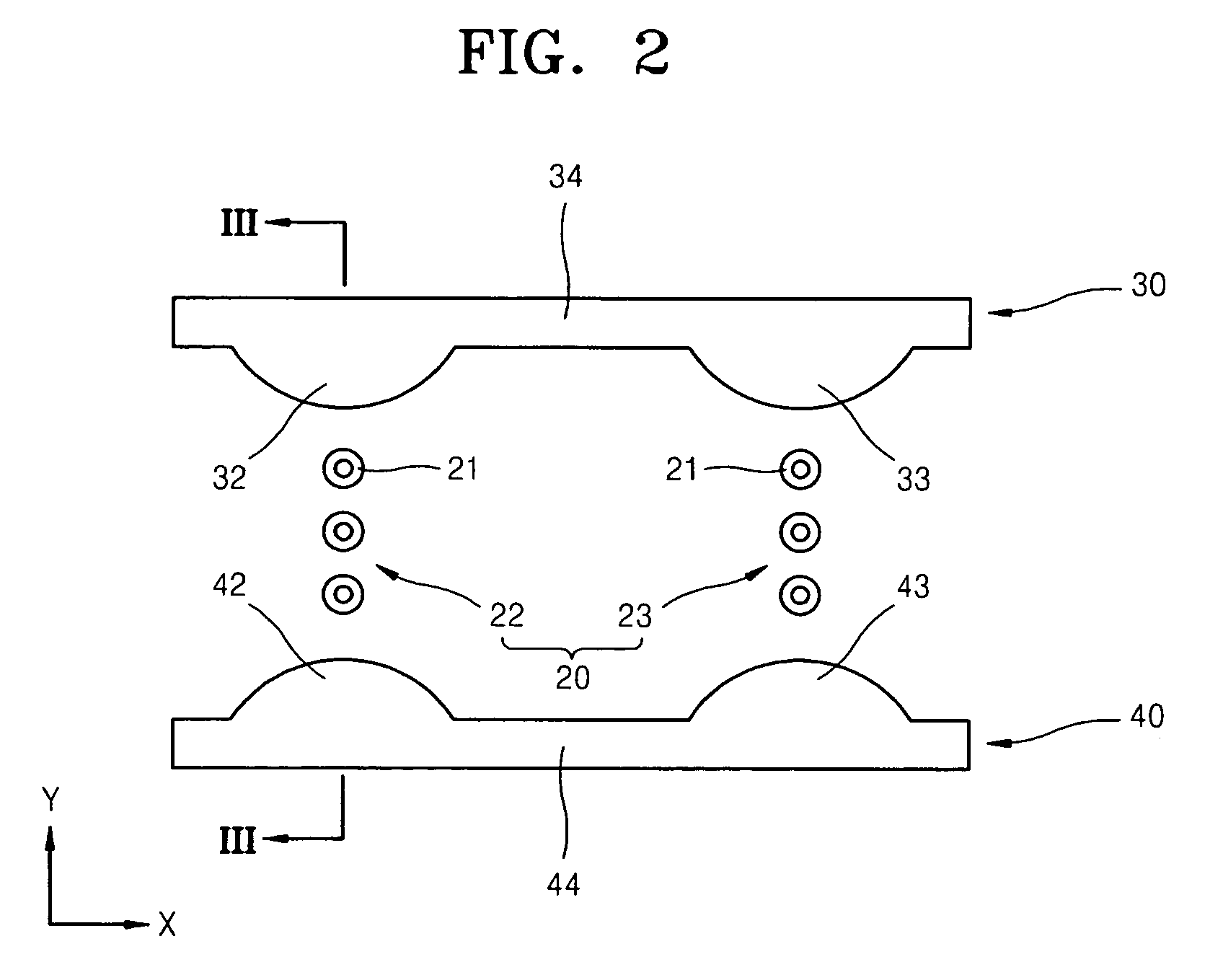

Evaporation apparatus and thin film forming method using the same

Provided are an evaporation apparatus and a thin film forming method using the same. The evaporation apparatus and the thin film forming method are used to form a uniform thin film, even for a large substrate, and can be easily employed without changing equipment even if a substrate size is changed. The evaporation apparatus includes a first evaporation source, a second evaporation source separated from the first evaporation source, and a compensation member disposed between a target object and the first and second evaporation sources. The compensation member performs a linear movement simultaneously with the first and second evaporation sources. The compensation member includes a first compensation plate disposed in a position corresponding to the first evaporation source, and a second compensation plate disposed in a position corresponding to the second evaporation source.

Owner:SAMSUNG DISPLAY CO LTD

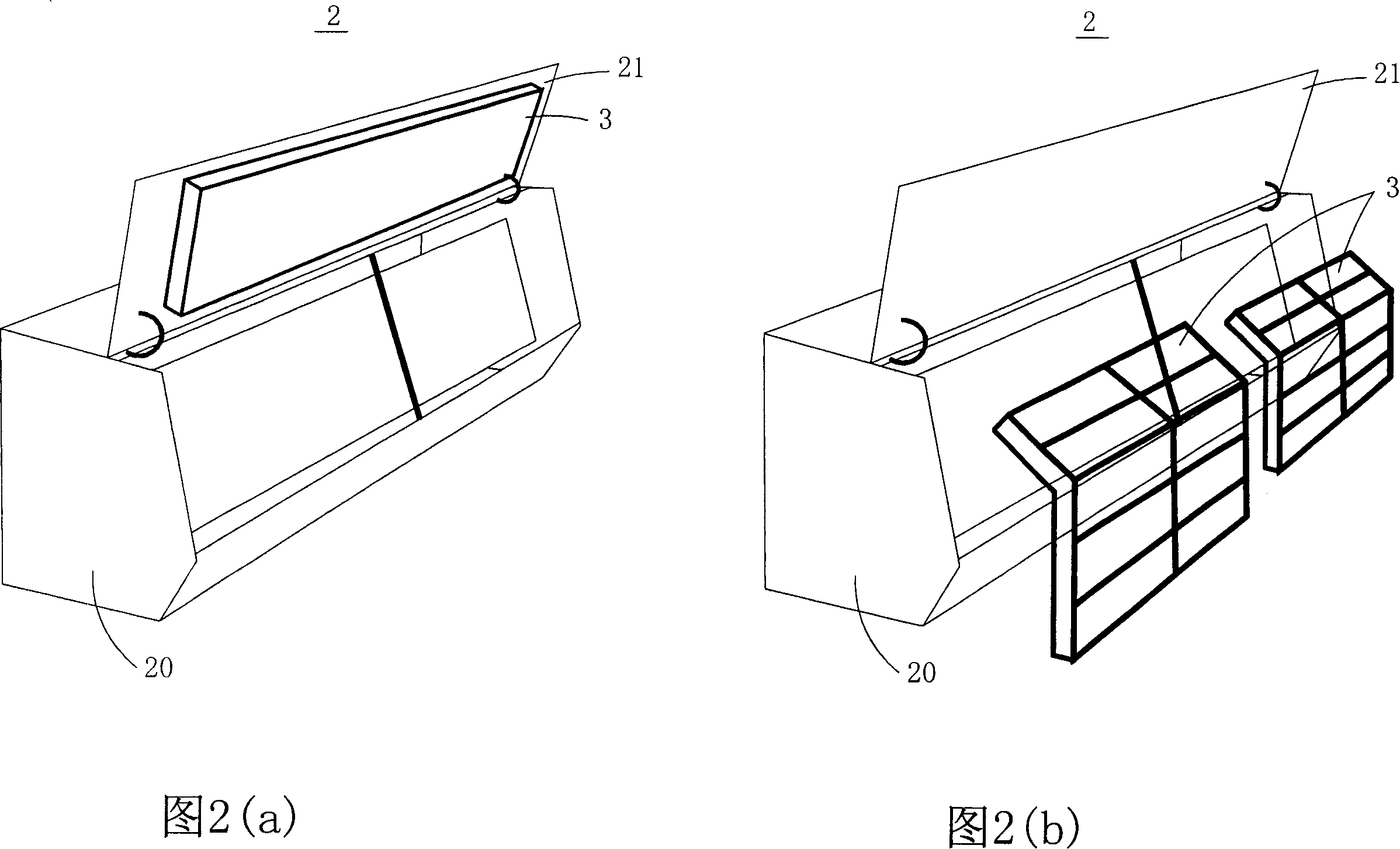

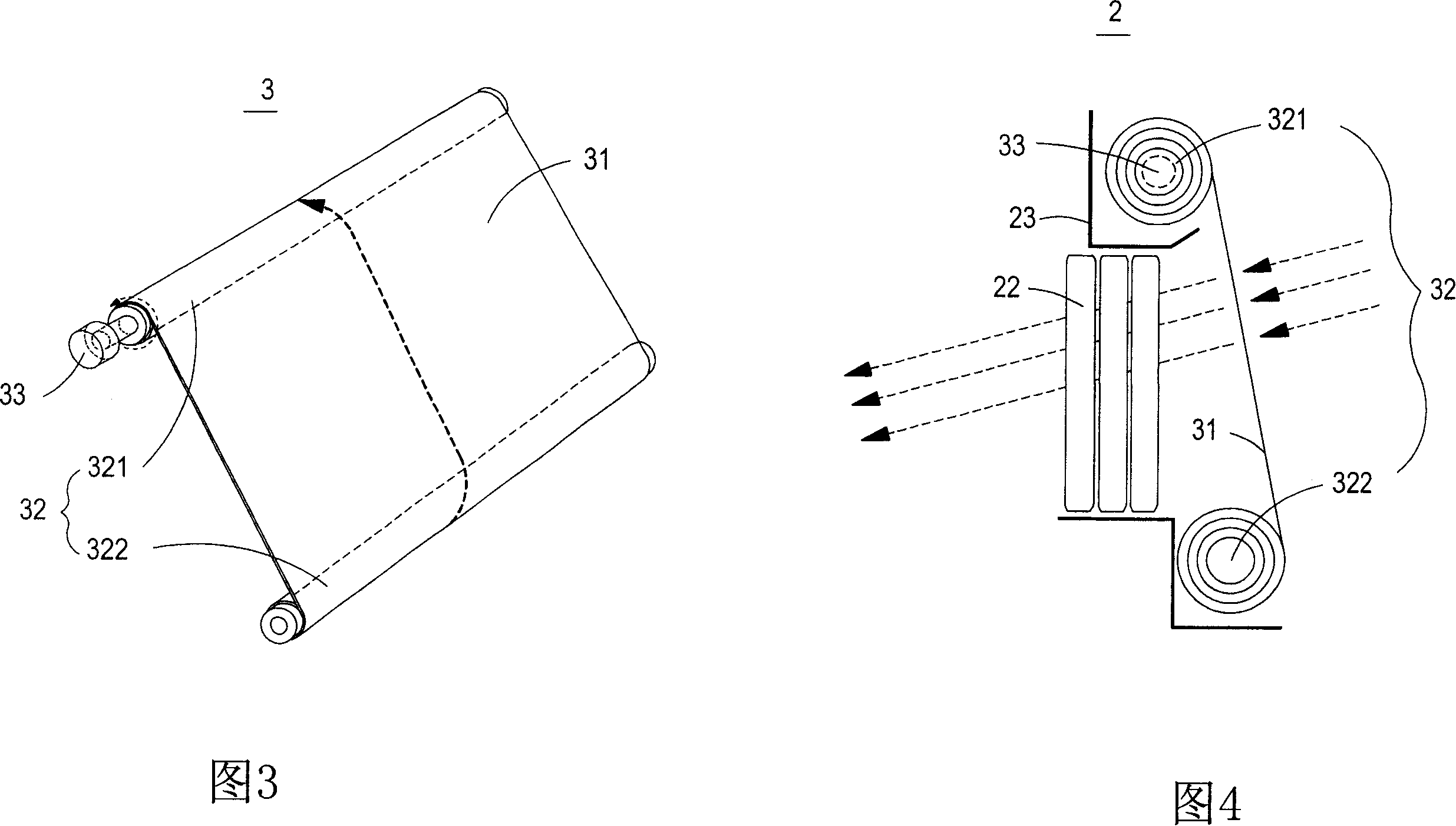

Automatic renewing device of filter screen

InactiveCN101152611APrevent inflowReduce riskDispersed particle filtrationStationary filtering element filtersAutomatic controlEngineering

The invention discloses a filter mesh automatic updating device, which is applied in a piece of equipment or a system. The filter mesh automatic updating device includes at least a filter mesh, a transmission device and a power device. The transmission device is used to drive the filter mesh to move; the power device is connected with the transmission device, so as to automatically drive the transmission device to drive the filter mesh to move according to the use state of the filter mesh, automatically update the filter mesh. The filter mesh automatic updating device of the invention can clean or replace the filter mesh in the equipments or the system by automatic control, so as to reduce potential risks and problems when the users remove the filter mesh. In addition, the filter mesh automatic updating device of the invention can also prevent the dust and particles collected by the filter mesh during updating of the filter mesh from flowing into the equipment or the system or back flowing to the environment from the equipment or the system.

Owner:TECO ELECTRIC AND MACHINERY

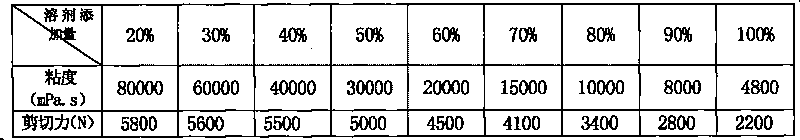

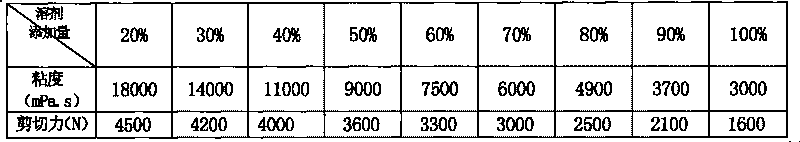

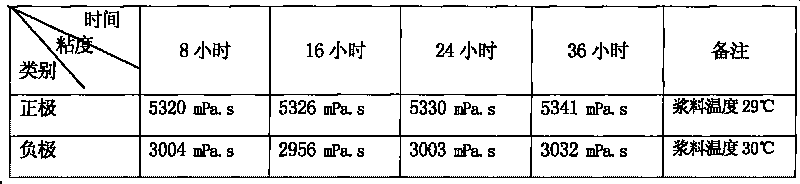

Mixing preparation method of pulp of lithium ion battery

InactiveCN101694872AImprove stabilityImprove consistencyElectrode manufacturing processesSolventLithium-ion battery

The invention discloses a mixing preparation method of pulp of a lithium ion battery, which is used for solving the problems of long time consumption of mixing and not easy uniform dispersion of the pulp. In the technical scheme, the method comprises the following steps: for anodal pulp, firstly stirring a conductive agent, active substances, part of binders and solvents, and then adding the balance of raw materials to stir; and for cathodal pulp, firstly stirring a conductive agent, active substances, part of thickening agents and solvents, and then adding the balance of thickness agents and solvents to stir, and finally adding binders to stir. The method is simple to operate without replacing equipment, improves the uniform coating in the next process, is beneficial to improving the stability and the consistence of the battery and ensures that the production efficiency is nearly two times and the pulp is uniformly dispersed and not easy to deposit.

Owner:BAODING FENGFAN NEW ENERGY

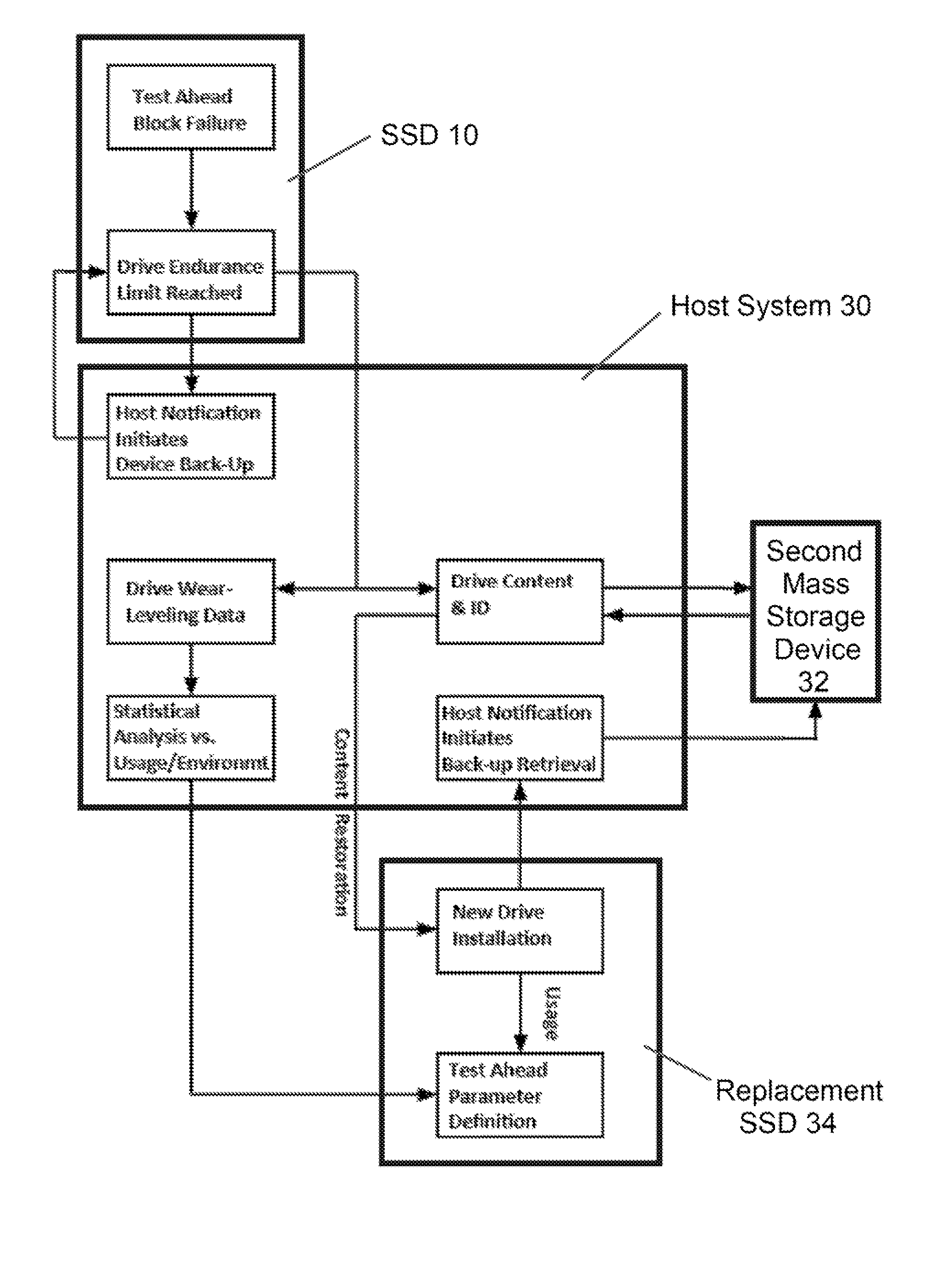

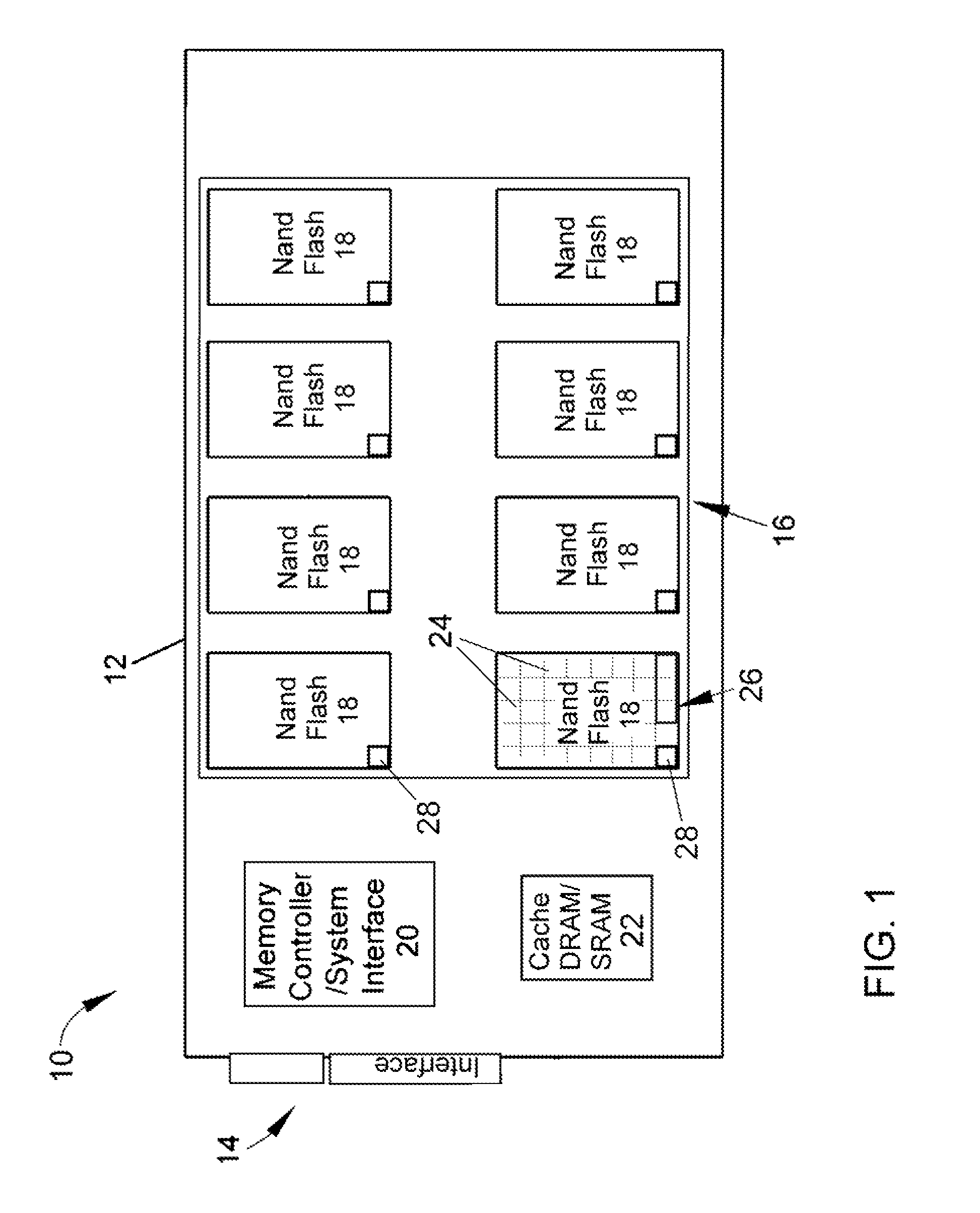

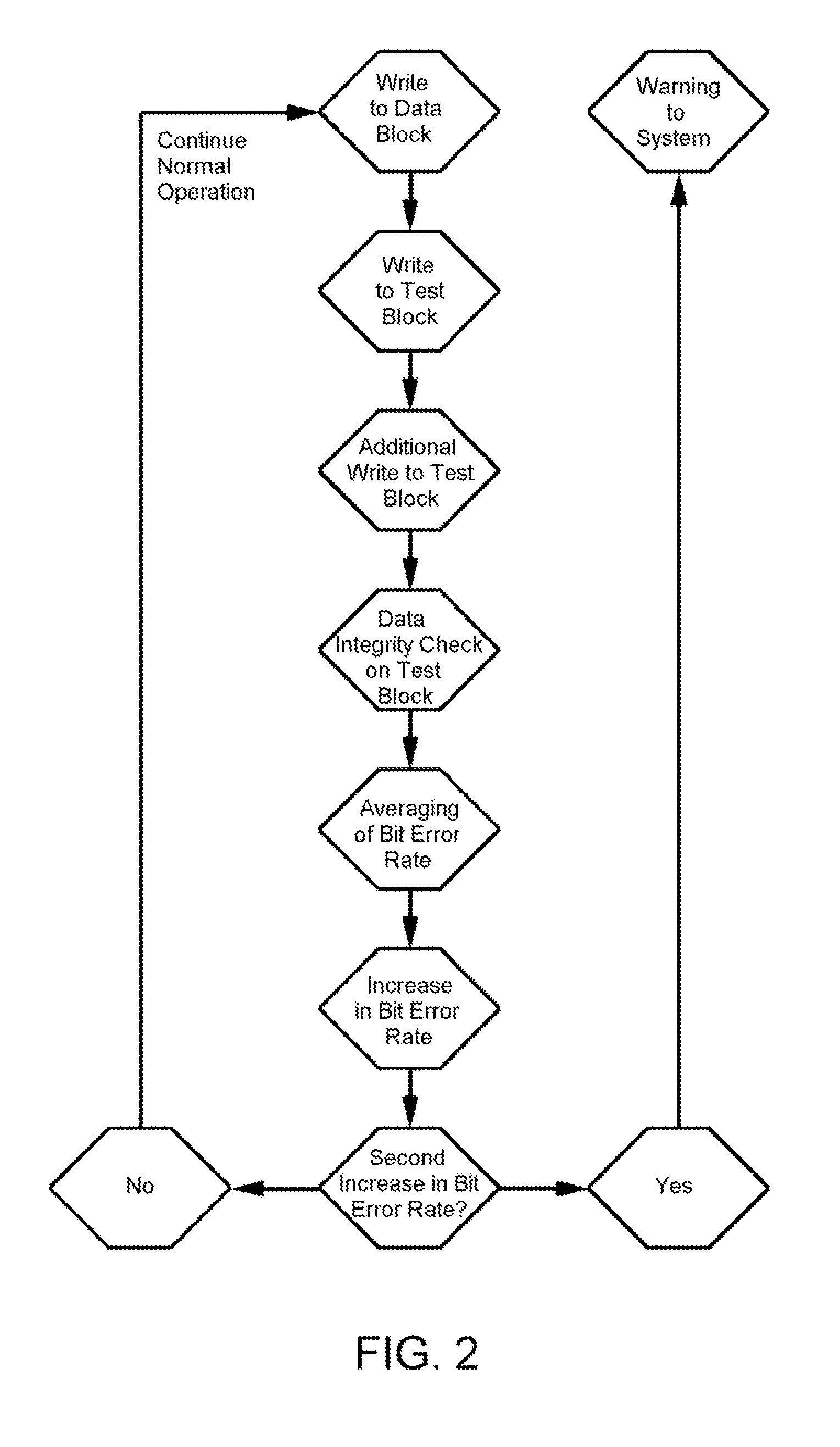

Computer system with backup function and method therefor

ActiveUS8464106B2Avoid lostPredict the fatigue threshold of a solid-state mass storage deviceRead-only memoriesError avoidanceMass storageComputerized system

A solid-state mass storage device and method of anticipating a failure of the mass storage device resulting from a memory device of the mass storage device reaching a write endurance limit. A procedure is then initiated to back up data to a second mass storage device prior to failure. The method includes assigning at least a first memory block of the memory device as a wear indicator, using other memory blocks of the memory device as data blocks for data storage, performing program / erase (P / E) cycles and wear leveling on the data blocks, subjecting the wear indicator to more P / E cycles than the data blocks, performing integrity checks and monitoring the bit error rate of the wear indicator, and taking corrective action if the bit error rate increases, including the initiation of the backup procedure and generating a request to replace the device.

Owner:KIOXIA CORP

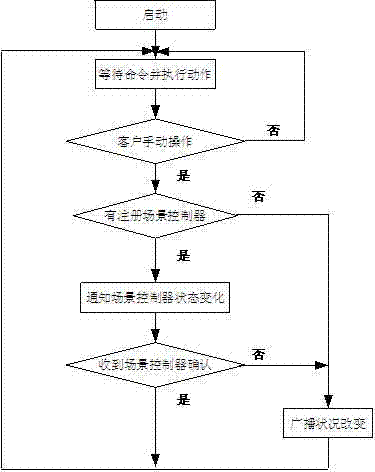

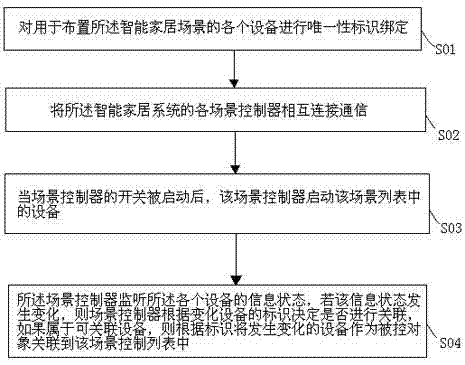

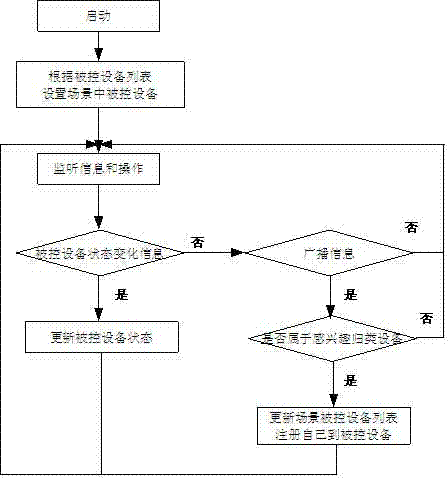

Automatically-correlated scene control networking method of intelligent home system

InactiveCN102891786ARemove complexityRealize associative designData switching by path configurationChanging equipmentEmbedded system

The invention relates to an automatically-correlated scene control networking method of an intelligent home system. Intelligent home equipment is subjected to characteristic information identification; all scene controllers of the intelligent home system are in connection communication; when a switch of each scene controller is turned on, each scene controller starts equipment in a scene list; each scene controller monitors the information state of the equipment; if the information state of the equipment is changed, each scene controller takes an identification behavior of the equipment as reference for correlation; and if the equipment is correlated equipment, the changed equipment serves as a controlled object and is correlated with the scene controllers. By adoption of the method provided by the invention, the complexity of correlation operation of customer intelligent home scene application can be eliminated. A customer needs to directly use the intelligent home system, the equipment in the scene automatically performs intelligent grouping judgment according to hobbies of the customer, humanized equipment correlation design is realized, and great significance is provided for promotion of intelligent home scene control.

Owner:兴泓昇(福州)智能科技有限公司

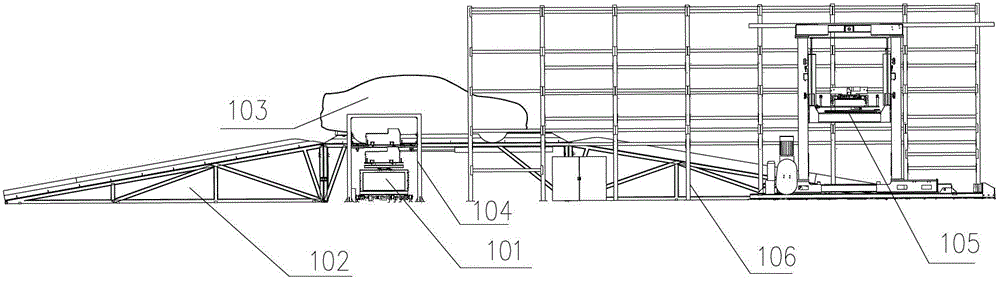

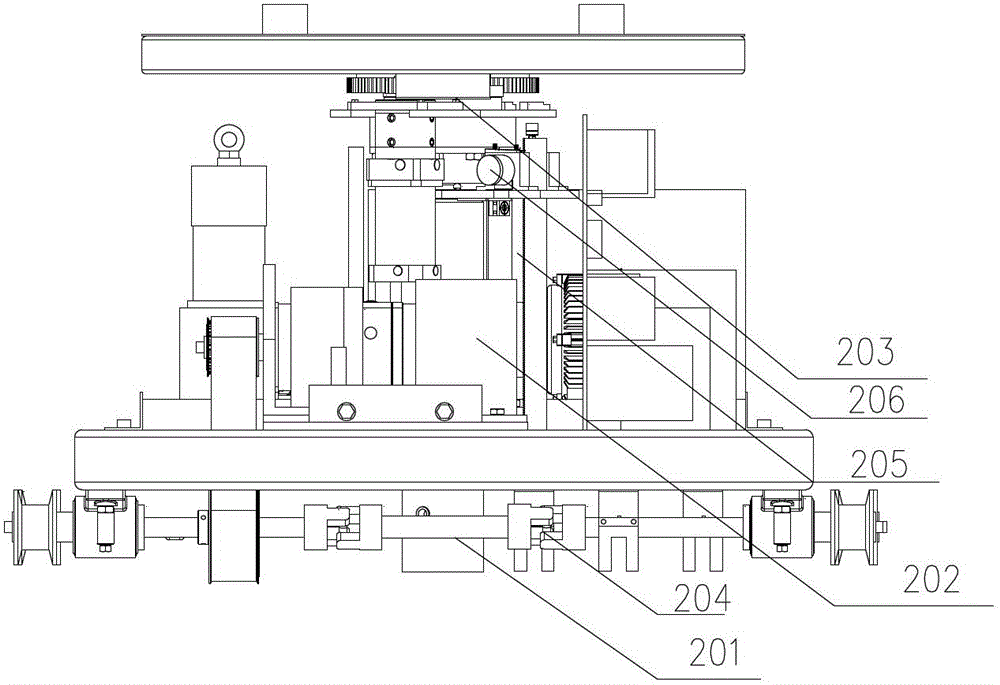

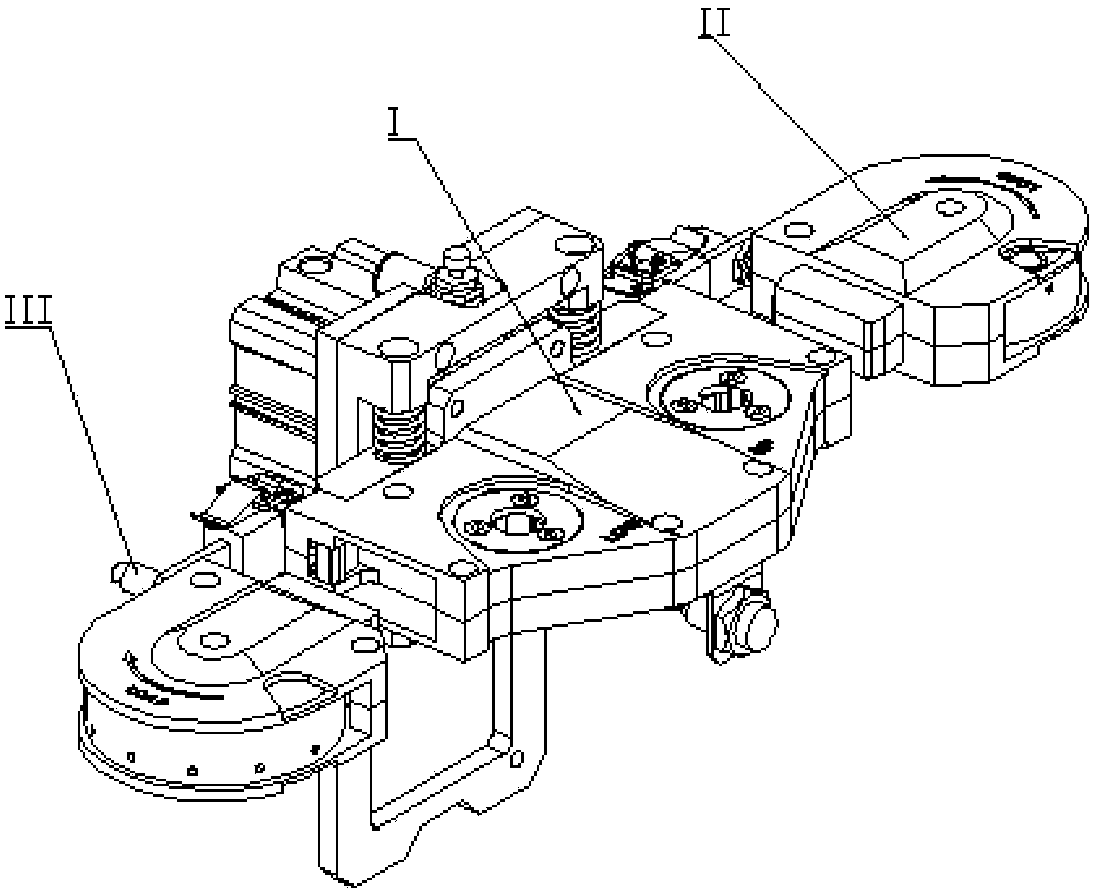

Chassis battery change system for electric passenger cars and method of the system

ActiveCN102717778APrecise positioningLow costProgramme-controlled manipulatorElectric propulsion mountingElectricityIndustrial Ethernet

The invention discloses a chassis battery change system for electric passenger cars. The chassis battery change system comprises a rapid change robot, a battery change platform, a transfer platform, a background monitoring system, a stacking machine and a charging frame, wherein the transfer platform, the stacking machine and the charging frame are arranged on one side of the battery change platform; the rapid change robot is arranged between the battery change platform and the transfer platform; an electric passenger car is capable of passing through the battery change platform; a locking mechanism which corresponds to a battery box supported by the rapid change robot is arranged on the electric passenger car; and the background monitoring system is connected with the rapid change robot and the stacking machine respectively through an industrial Ethernet. At the same time, the invention also discloses a using method of the system. A mechanical positioning mechanism of the battery change platform is simple, correct in positioning and low in manufacturing cost; a hydraulic lifting mechanism is used in the rapid change robot, so that the whole change process is reliable and stable, the size of the change equipment is decreased effectively and the actual occupied area of the change system is saved; and the transfer platform is used as a battery change interaction link between the rapid change robot and the stacking machine, so that the time spent by the battery change is further shortened.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

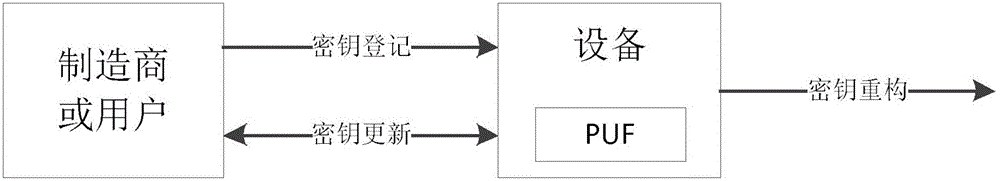

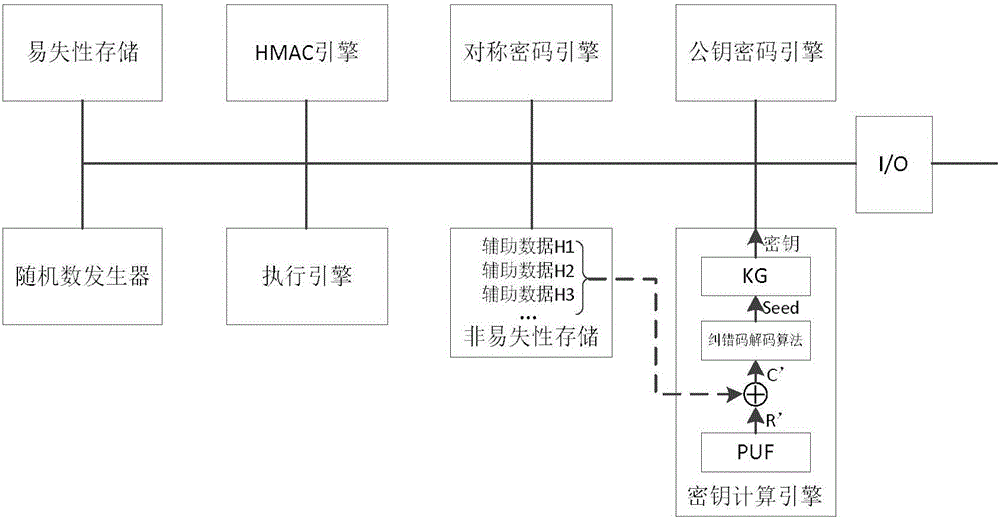

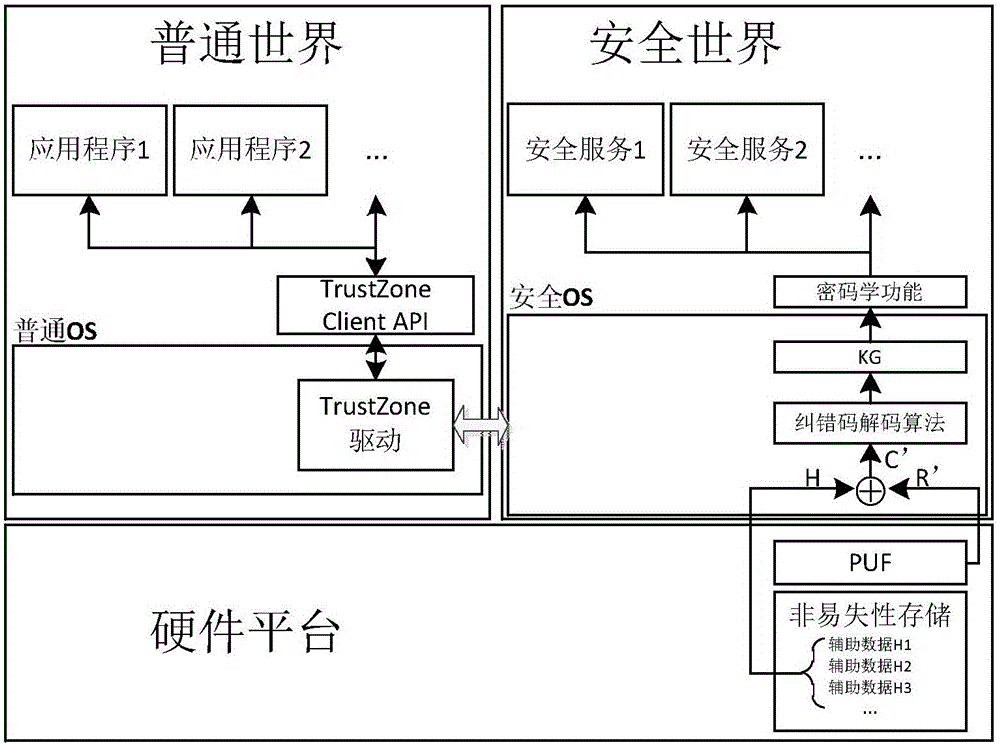

Key protection method and safety chip based on physical no-cloning function

ActiveCN105007285AImprove security strengthProtection securityKey distribution for secure communicationUser identity/authority verificationComputer hardwareChanging equipment

The present invention discloses a key protection method based on a physical no-cloning function. The method comprises a key registration phase and a key reconstruction phase. The key registration phase is generally in an equipment manufacturing stage and is used for using the physical no-cloning function on equipment and binding equipment key to the equipment. The key reconstruction phase is in an equipment using stage and is used for calculating the key bound on the equipment in the registration phase. The method also comprises a key updating phase for updating the equipment key. According to the method and the safety chip, a plurality of keys can be safely bound for the equipment, and the safety of other keys is not affected by the leakage of one key. In addition, the invention provides a key updating mechanism, and the equipment key is updated in the condition of not replacing equipment hardware.

Owner:NANJING WANDAO ELECTRONICS TECH CO LTD

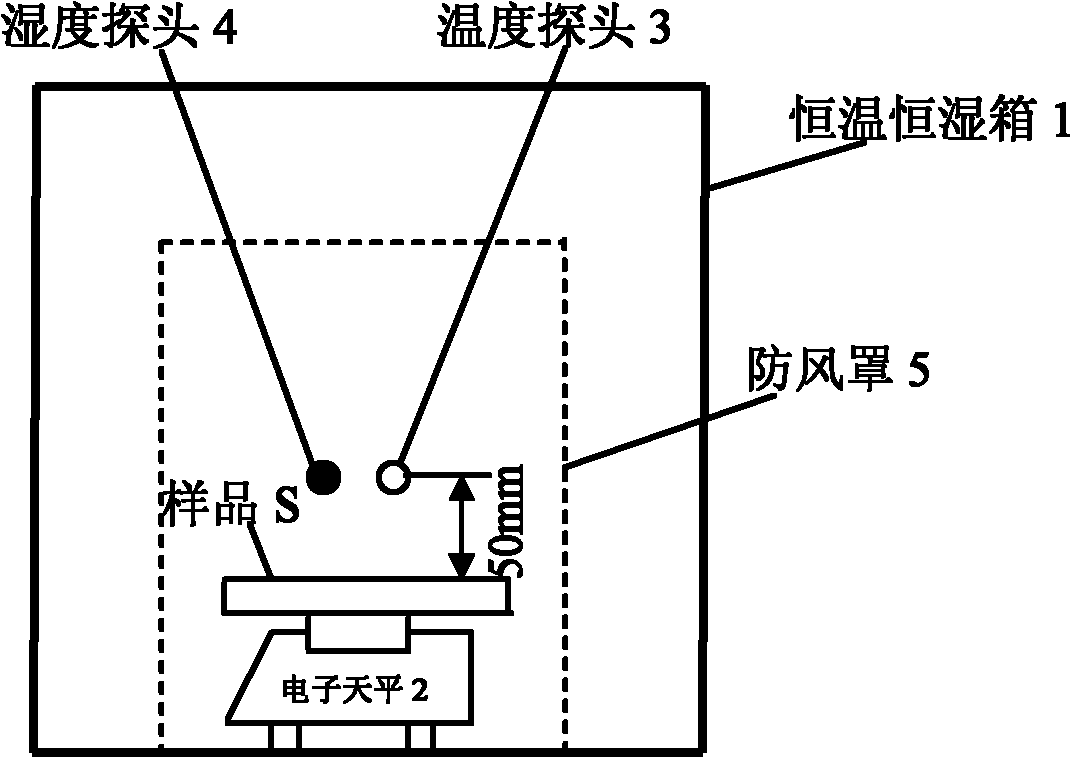

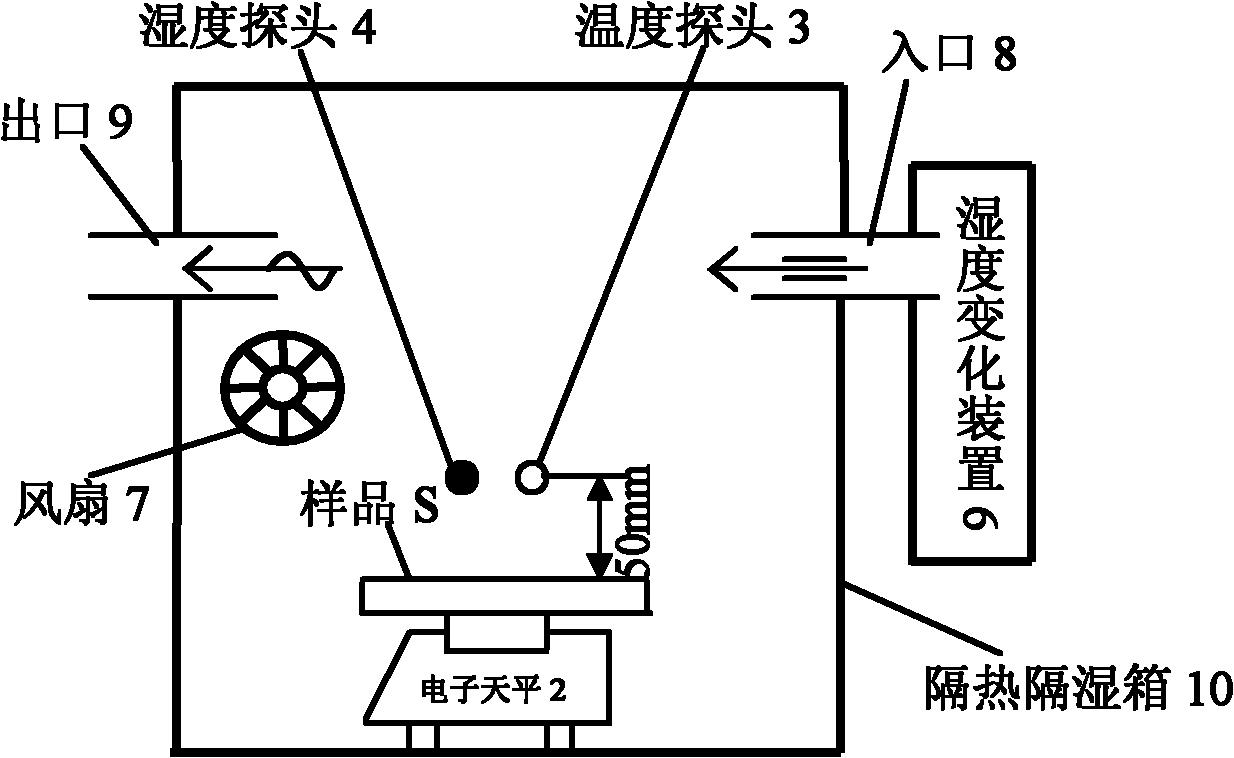

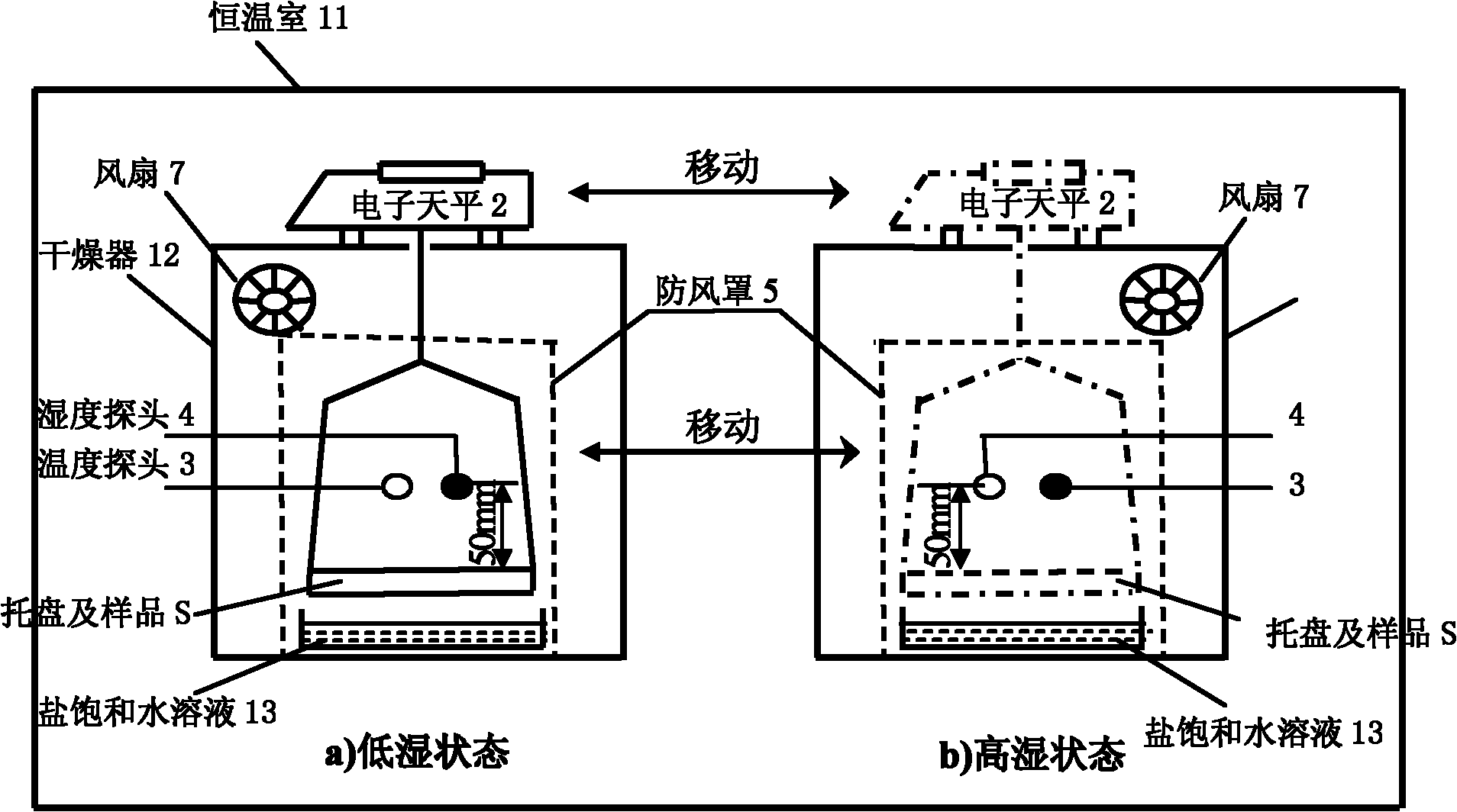

Performance testing equipment for humidifying function material and testing method

ActiveCN102252932AAccurate humidity controlImprove stabilityWeighing by removing componentWeighing by absorbing componentSaline waterEngineering

The invention discloses performance testing equipment for a humidifying function material and a testing method. The equipment disclosed by the invention comprises a relative humidity control part, a weighing part and a temperature and humidity monitoring part, wherein the relative humidity control part is a mechanical constant temperature cabinet system, a humidity change equipment system or a saturated saline water solution system and is provided with a closed space with adjustable temperature and humidity; a temperature probe and a humidity probe of the weighing part and the temperature andhumidity monitoring part are arranged in the closed space; the weighing part is an electronic balance; and the electronic balance, the temperature probe and the humidity probe are connected with a computer which is arranged outside the closed space. By means of different temperature and humidity control modes, the humidity absorption and release performances of the material are detected through ahumidity reaction method; the computer records the data of a detection sample which is weighed by the electronic balance in real time; and the humidity absorption and release capabilities of the sample are obtained by computing. The invention can accurately detect the humidifying performance of the material, and a testing result has good stability.

Owner:CHINA BUILDING MATERIALS ACAD

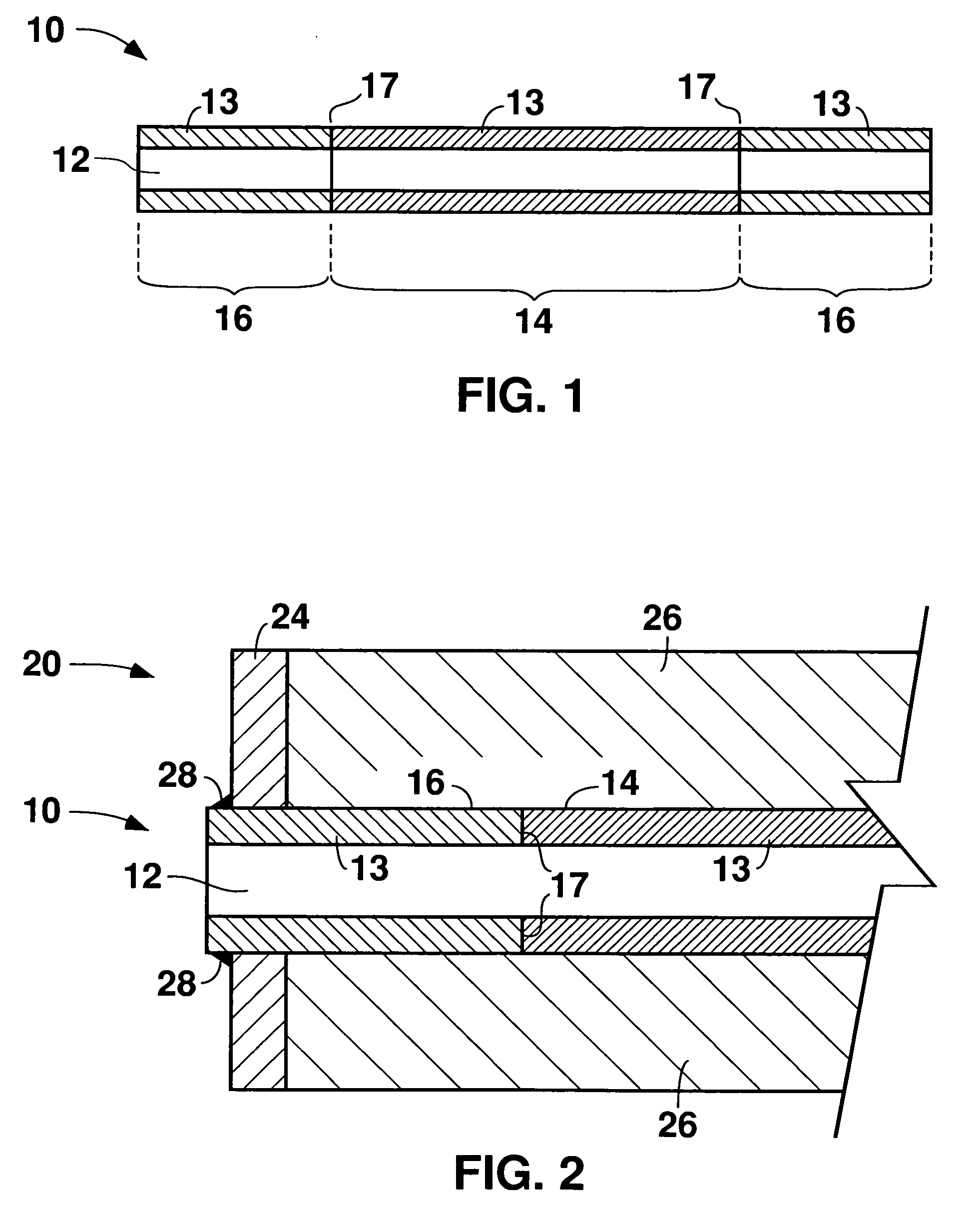

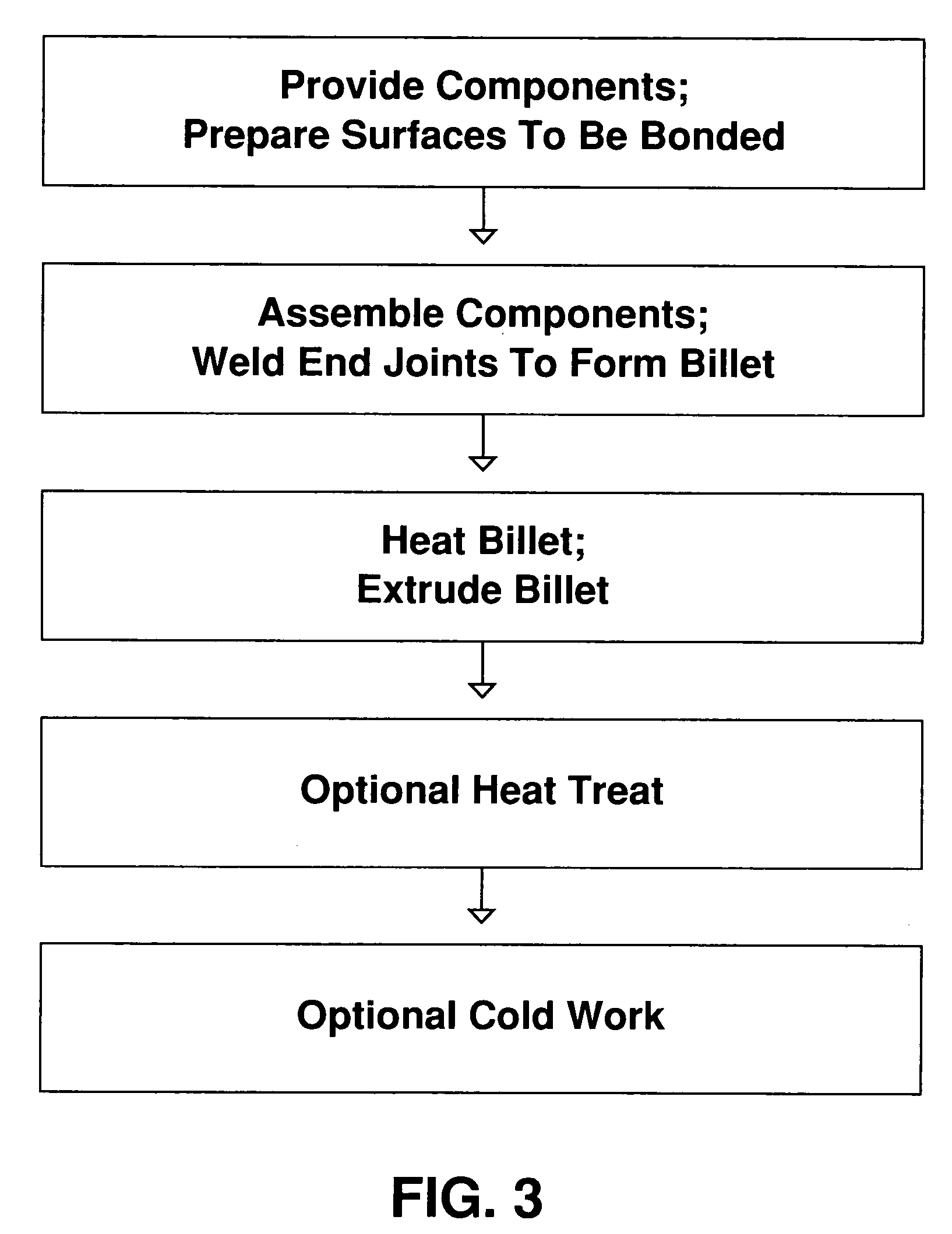

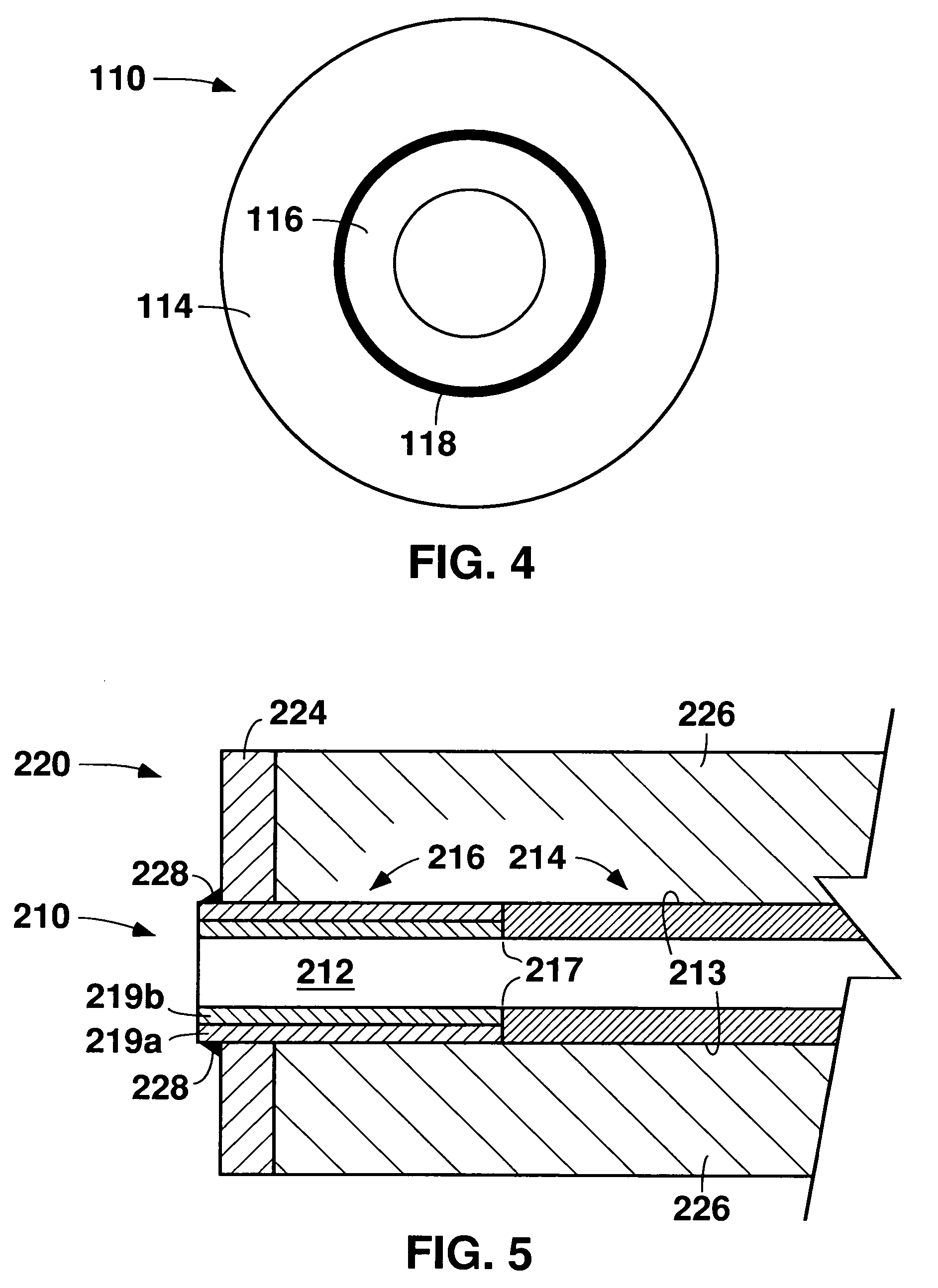

Corrosion resistant fluid conducting parts, methods of making corrosion resistant fluid conducting parts and equipment and parts replacement methods utilizing corrosion resistant fluid conducting parts

ActiveUS20060027628A1Readily cold workedReduced corrosion resistanceWelding/cutting auxillary devicesHeat exhanger sealing arrangementFusion weldingReplacement method

According to one aspect of the present disclosure, a part for an article of equipment includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The first region and the second region are either directly or indirectly joined by solid state welding to form a unitary fluid conducting part. According to another aspect of the present disclosure, a method for replacing at least one fluid conducting part of an article of equipment is disclosed wherein a replacement part is provided that includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The second material is substantially identical to the material of a region of the equipment on which the replacement part is mounted. The first and second regions are either directly or indirectly joined by solid state welding to form a unitary fluid conducting replacement part. The replacement part is secured to the article of equipment by a process comprising fusion welding the second material of the second region of the replacement part to the substantially identical material of the mounting region of the article of equipment.

Owner:ATI PROPERTIES LLC

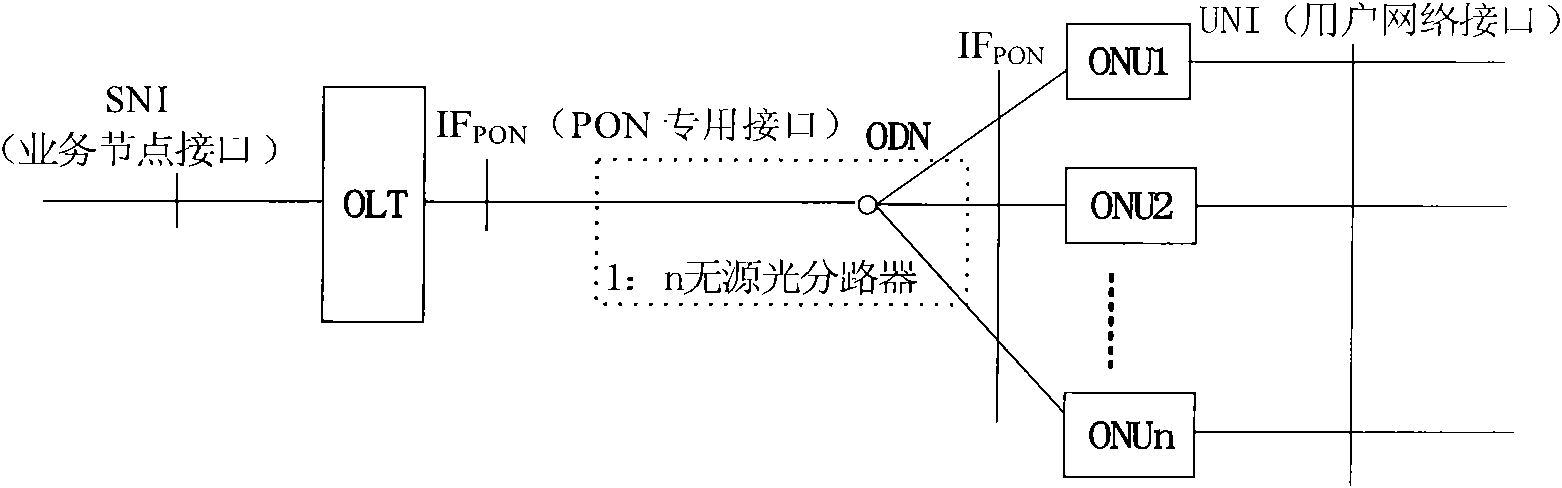

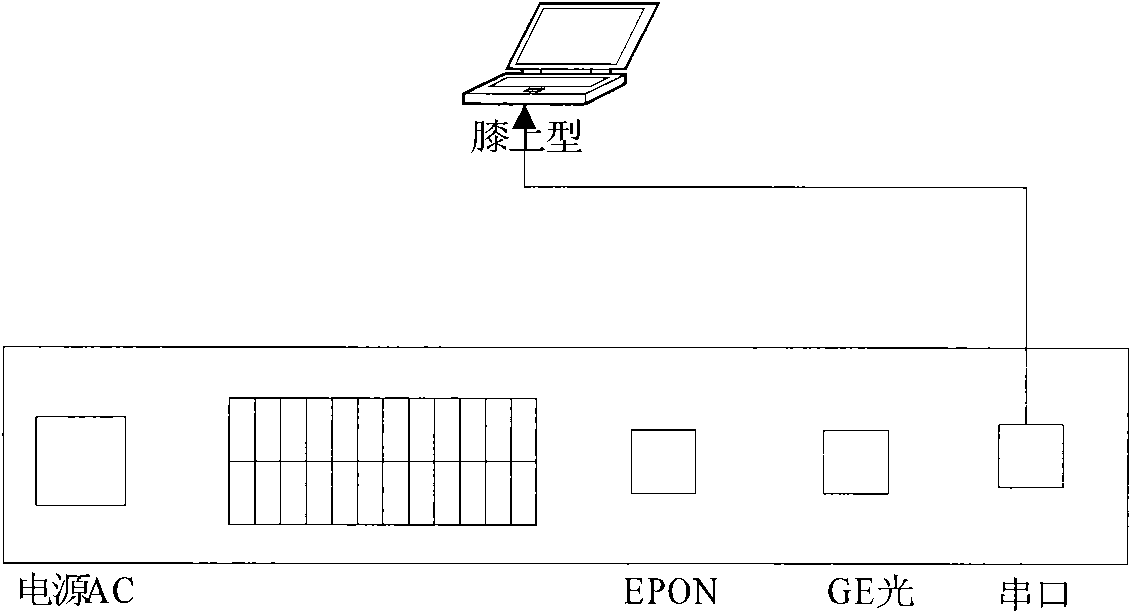

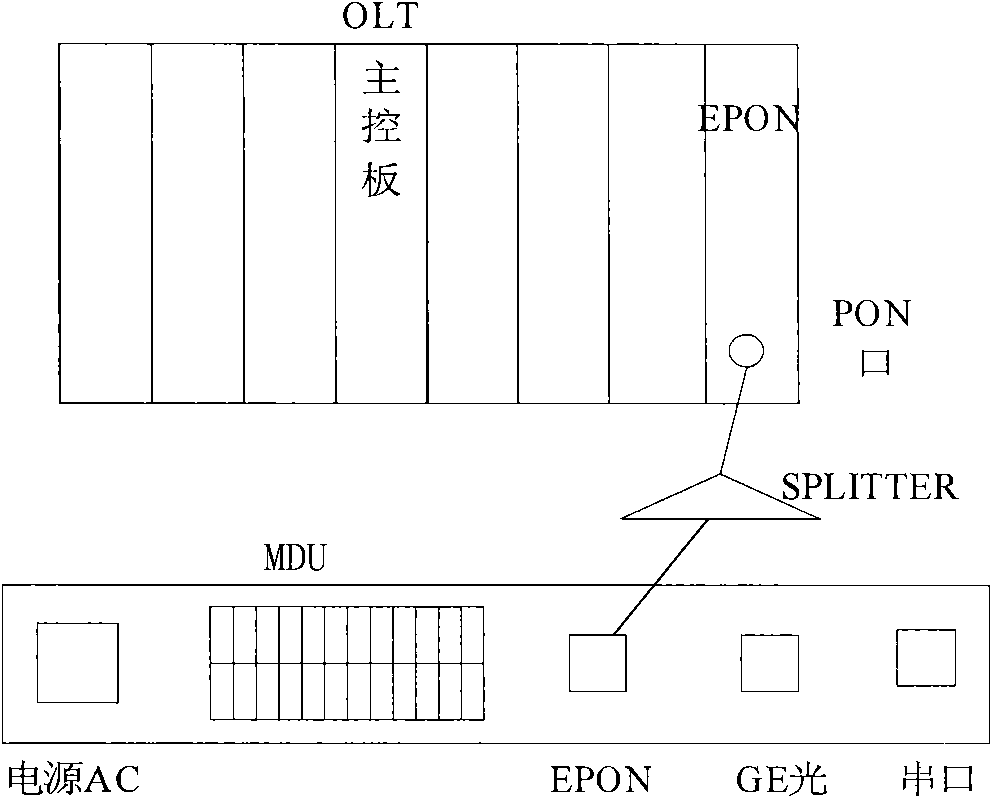

Method, device and system for building management and maintenance channel in passive optical network system

InactiveCN101594250ASolve the shortcomings of not being able to open the maintenance channelImprove satisfactionTime-division multiplexData switching by path configurationNetwork managementData error

The invention discloses a method, a device and a system for building a management and maintenance channel in a passive optical network system. The method of the invention comprises the following steps: configuration information transmitted by a network management equipment is received, and the configuration information comprises a first configuration information and a second configuration information; according to the first configuration information, a management and maintenance channel between an optical line terminal and the network management equipment is built; the second configuration information is transmitted to a customer premises equipment; and the second configuration information is used for building a management and maintenance channel between the optical line terminal and the customer premises equipment. The method lowers soft cost for installing equipment, lowers complexity of installing new equipment, improves customer satisfaction, needs no on-site data configuration, reduces the probability of configuration data errors and improves equipment installation speed; in addition, the method is simple to replace equipment, needs no on-site re-configuration of data, and reduces maintenance cost.

Owner:HUAWEI TECH CO LTD

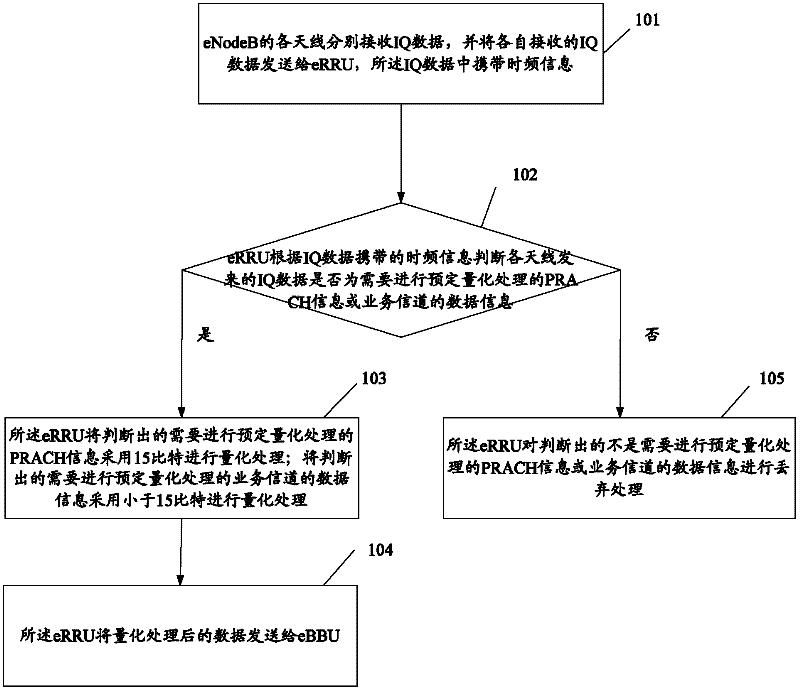

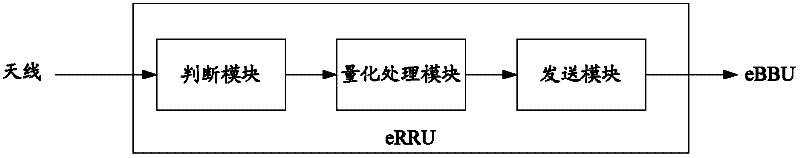

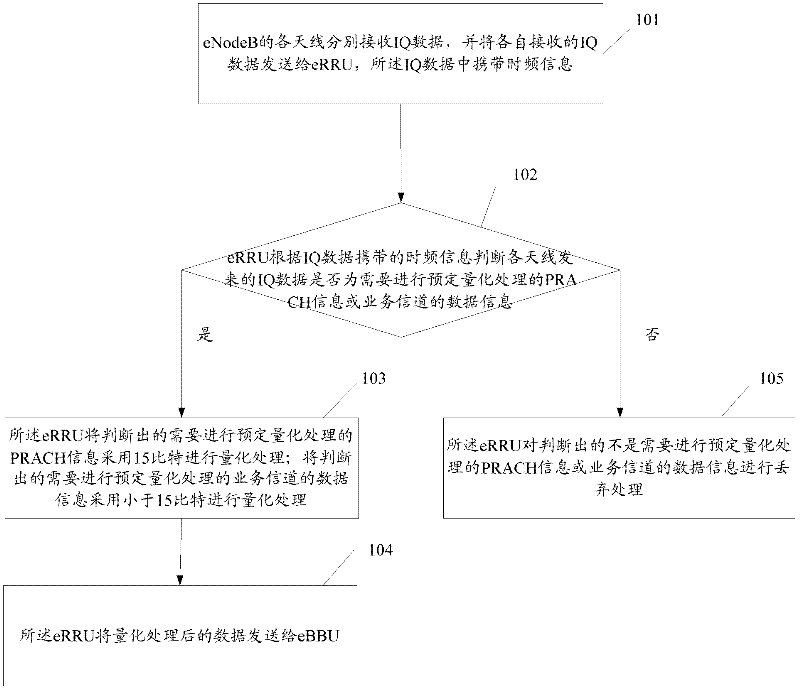

Same-phase IQ(In-phase Quadrate) data compression method and device

InactiveCN102340823AReduce bit widthReduce rateError preventionNetwork traffic/resource managementData compressionData information

The invention discloses a same-phase IQ (In-phase Quadrate) data compression method, which comprises the following steps: an eRRU(evolved Radio Remote Unit) judges whether the IQ data is PRACH (Physical Random Access Channel) information or data information of a service channel, which is needed to be subjected to quantitative preprocessing, according to time frequency information carried in the IQ data sent by each antenna; the PRACCH information which is judged to be subjected to quantitative preprocessing is subjected to quantitative processing by adopting 15 bits, and the data information of the service channel, which is judged to need to be subjected to quantitative processing is subjected to quantitative process by adopting 15 bits; and the data subjected to quantitative processing is transmitted to an eBBU(Evolved Building Baseband Unit). The invention simultaneously discloses an eRRU and an eNode B. According to the invention, the optical interface speed can be reduced, and frequent equipment replacement is avoided.

Owner:ZTE CORP

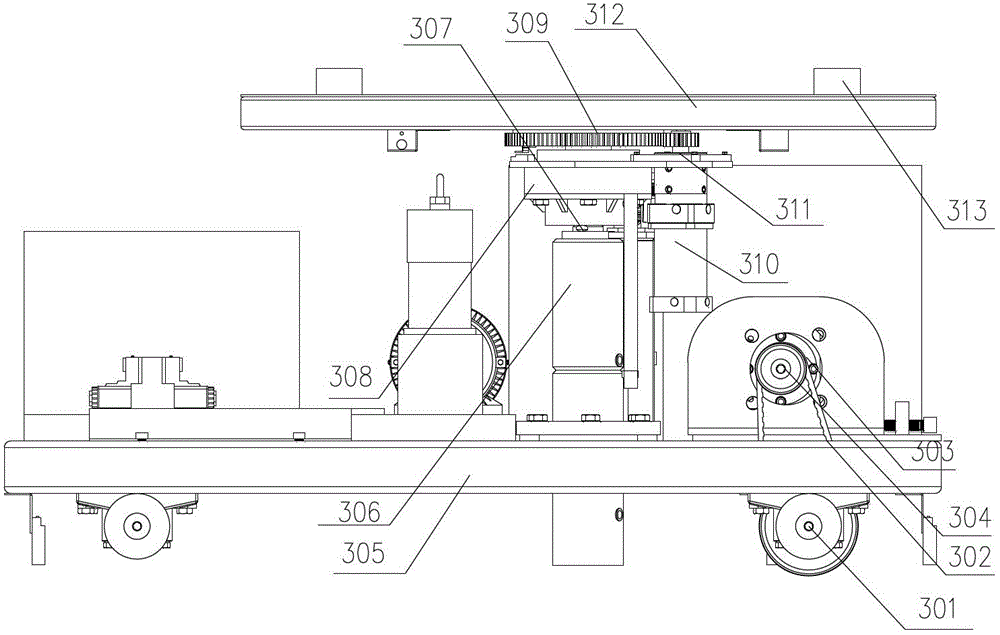

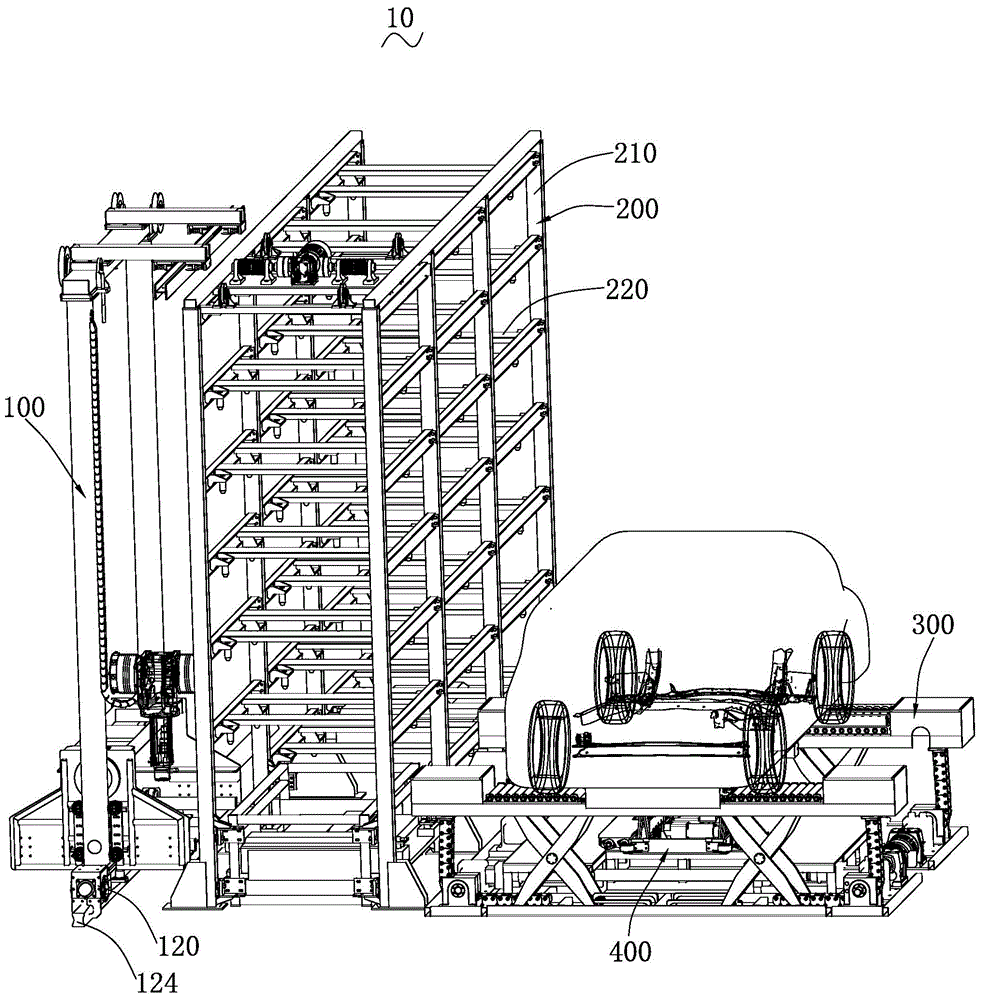

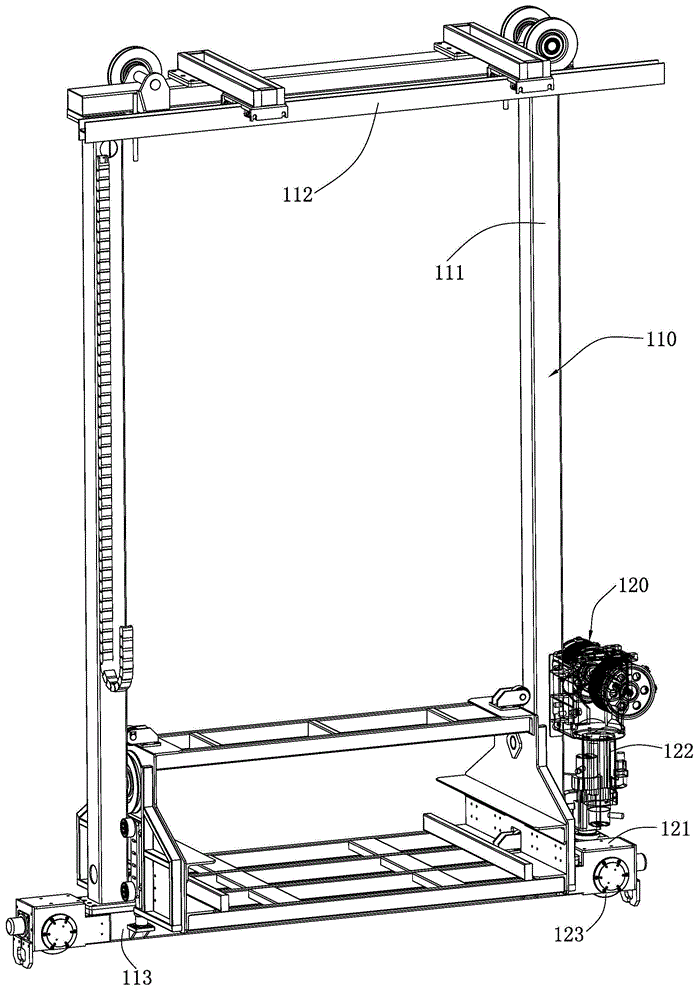

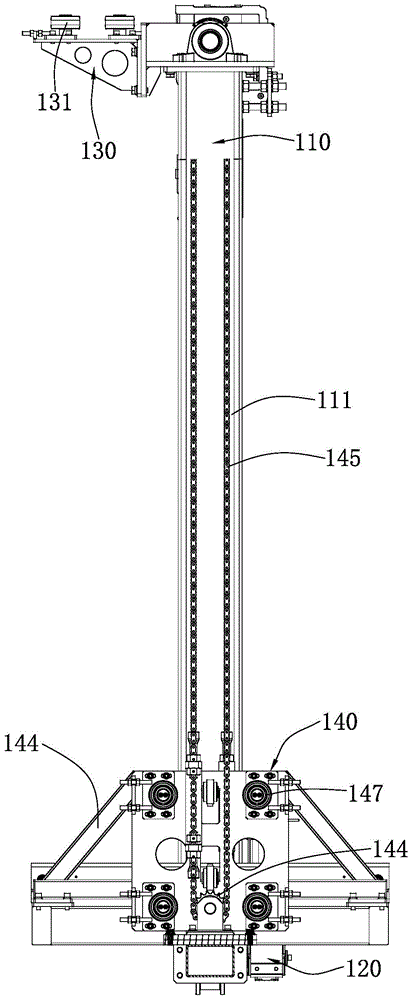

Lifting device and battery changing equipment

ActiveCN104787010ARealize matchingCompact structureElectric propulsion mountingLifting framesElectricityElectrical battery

The invention relates to a lifting device and battery changing equipment. The lifting device comprises a base, a crane platform, a battery conveying passage, a lifting mechanism and a lifting platform, wherein the crane platform is installed on the base; the battery conveying passage comprises a conveying platform and a guide rail, the guide rail is arranged on the outer side of the conveying platform, and part of the conveying platform extends into the crane platform; the lifting mechanism comprises a lifting motor, a lifting sprocket and a lifting rigid chain, the lifting motor is installed on the base, the lifting sprocket is connected with the lifting motor, the lifting rigid chain is meshed with the lifting sprocket, and the lifting platform and the lifting rigid chain are fixed. The lifting device is provided with the crane platform, the lifting mechanism and the lifting platform and can lift an electric car of which a battery needs changing, the structure is compact, and the occupied space is small. In addition, compared with a traditional lifting device, the lifting device does not need matching of a foundation pit.

Owner:SHENZHEN JINGZHI MACHINE

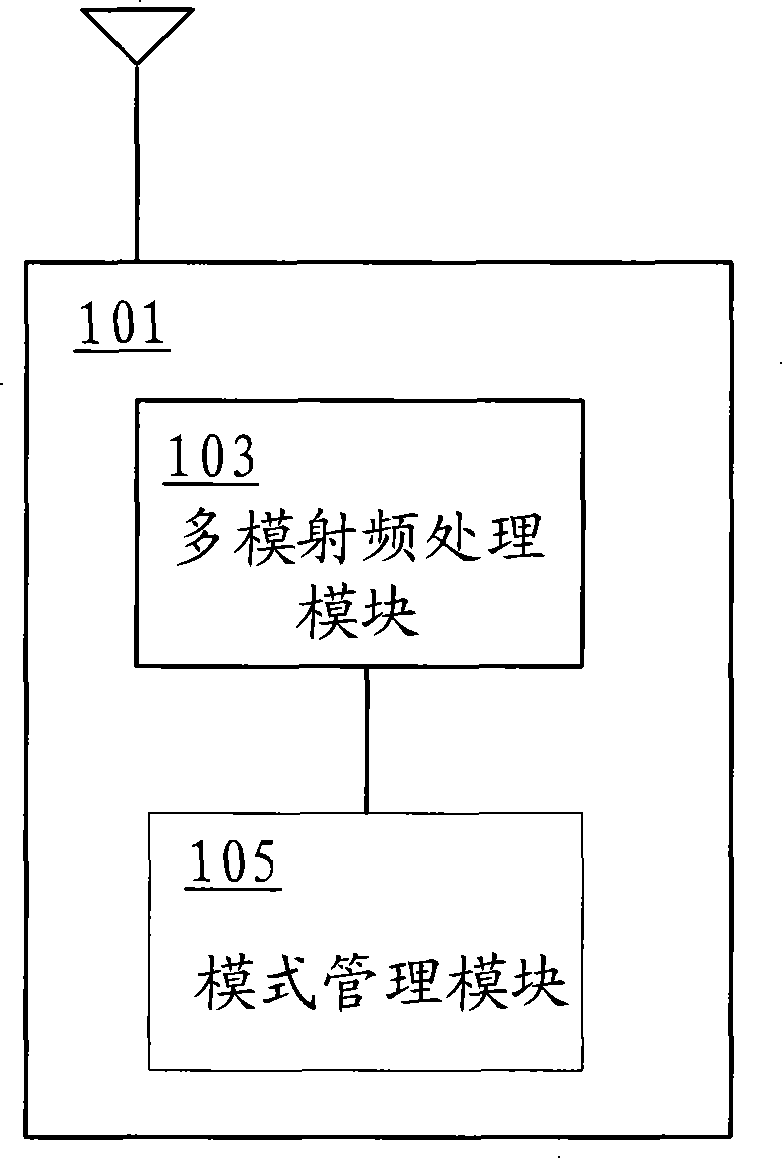

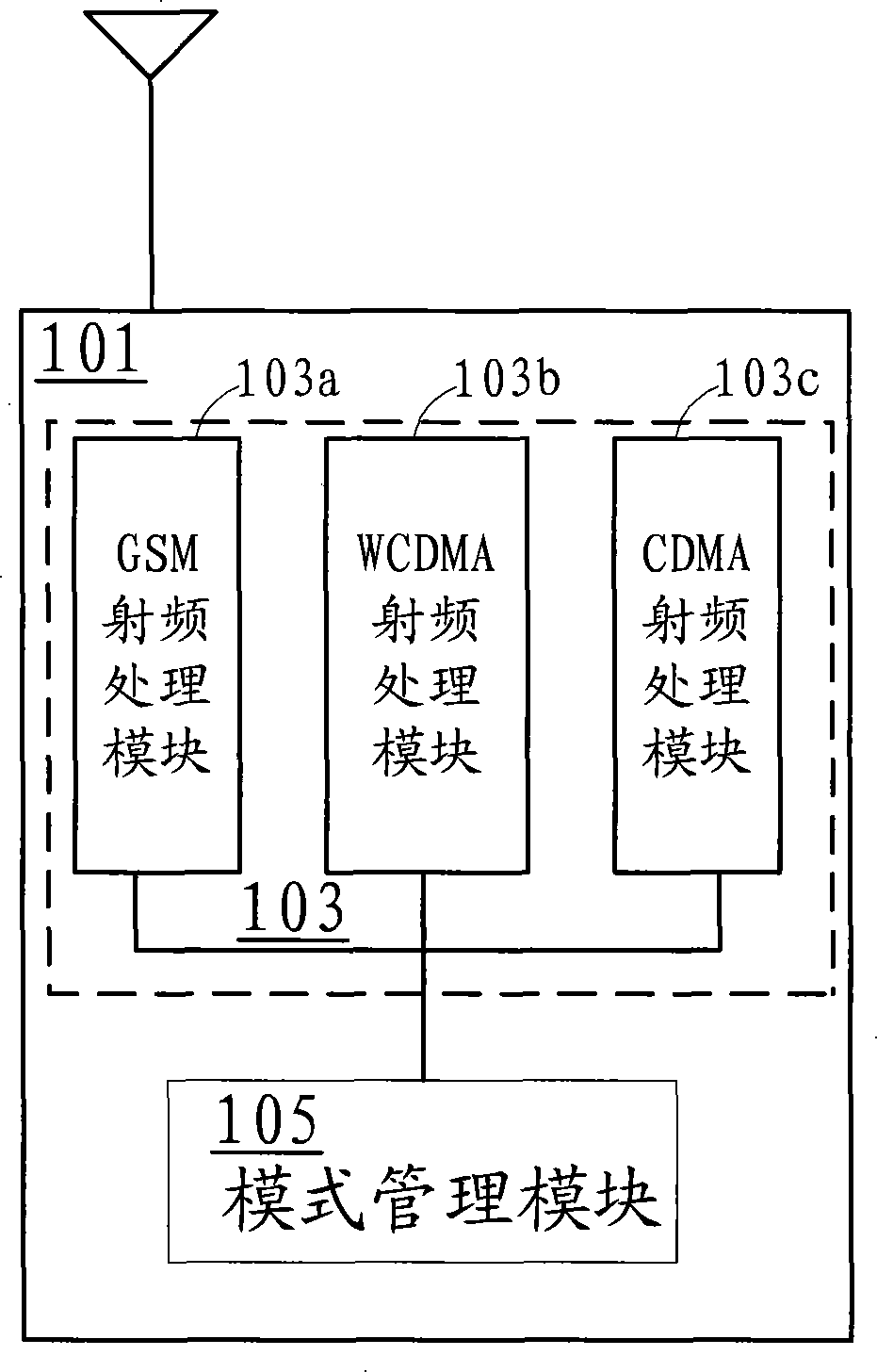

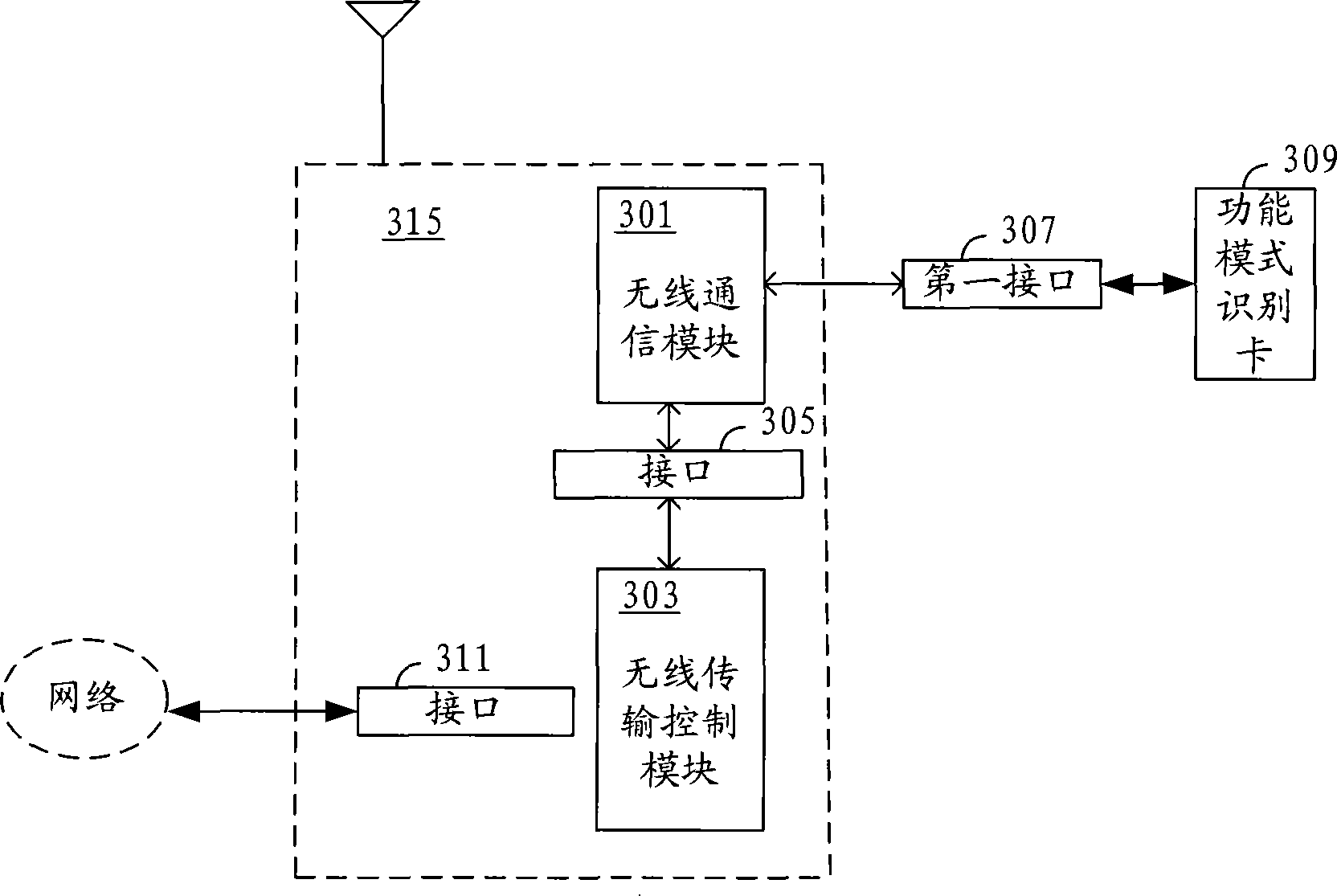

Wireless communication system, wireless communication module and wireless communication device

ActiveCN101252757AMeet different needsFlexible useData switching by path configurationRadio/inductive link selection arrangementsThe InternetOperation mode

The embodiment of the invention discloses a wireless communication system, which comprises a wireless communication module which can support radio frequency processing in two or more kinds of communication patterns and is used for working under one or two or more communication patterns according to the configuration of the wireless communication module by the user; a wireless transmitting control module coupled with the wireless communication module and used for processing the baseband, the transmission, and the operation maintenance of the wireless communication; the wireless communication system is connected with the Internet. The wireless communication system can support terminals in a plurality of patterns, such as GSM, UMTS, WIFI, WIMAX, etc. A variety of different working modes, such as the single mode or the multi-mode, etc. can be achieved through the setting of a mode management module, in order to meet deferent requirements of users to the largest extent. Operations such as setting and replacing the operation mode of equipment, etc. can be controlled by the users, the operation for the users is flexible enough, and the maintenance cost required to be invested by the service provider is also reduced greatly.

Owner:HUAWEI TECH CO LTD

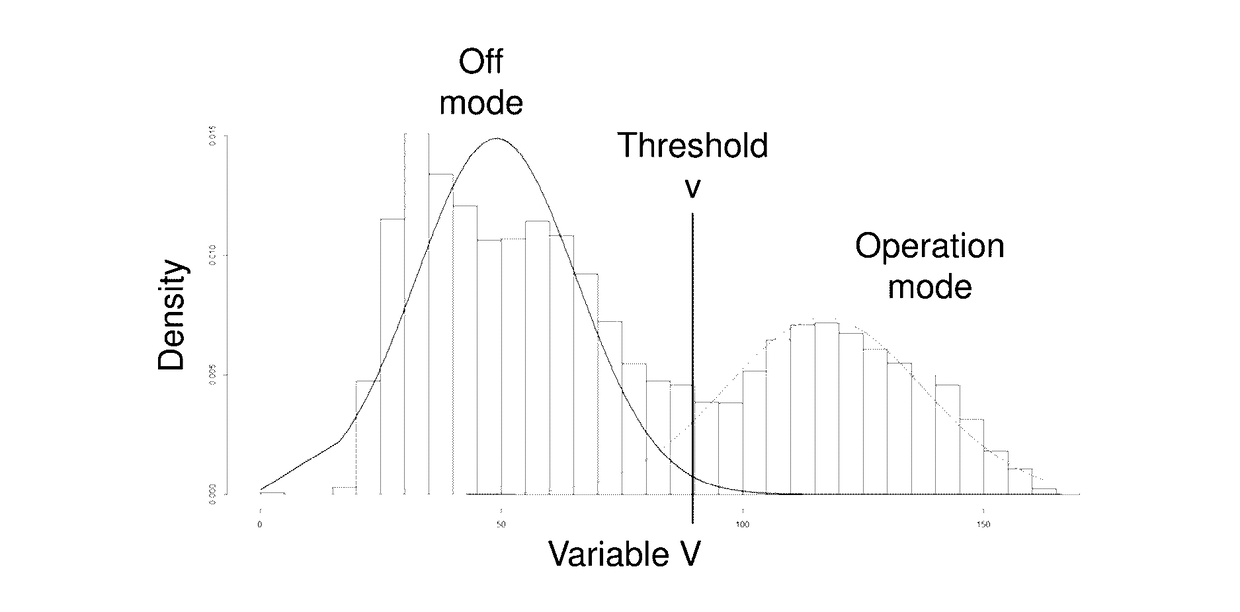

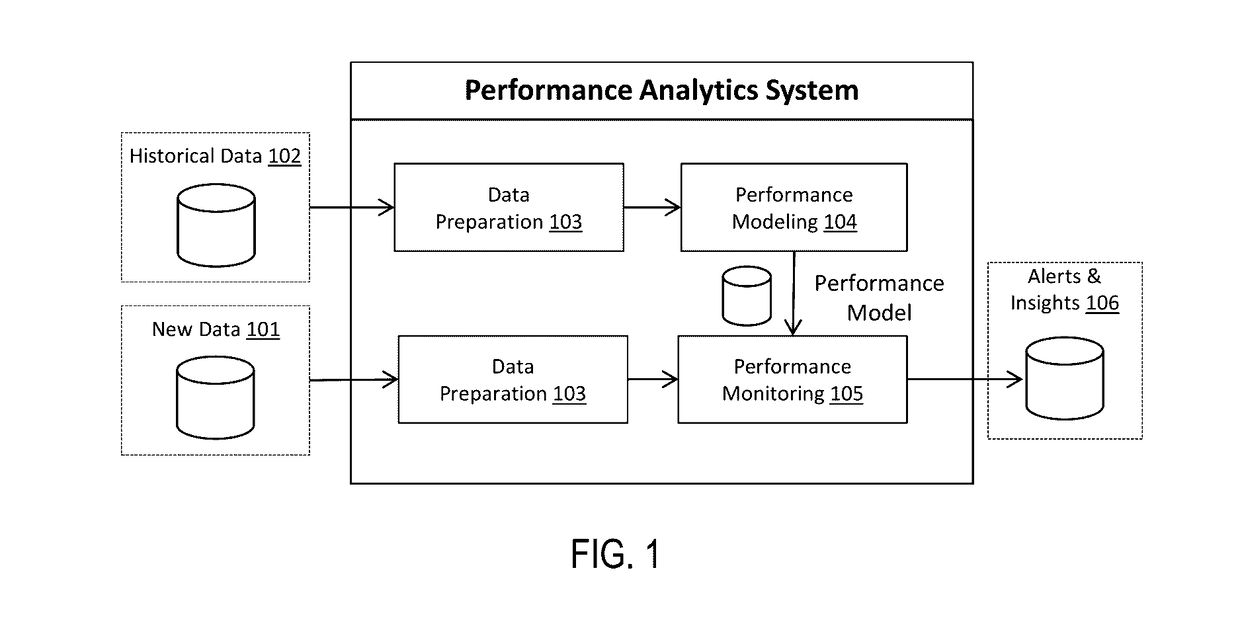

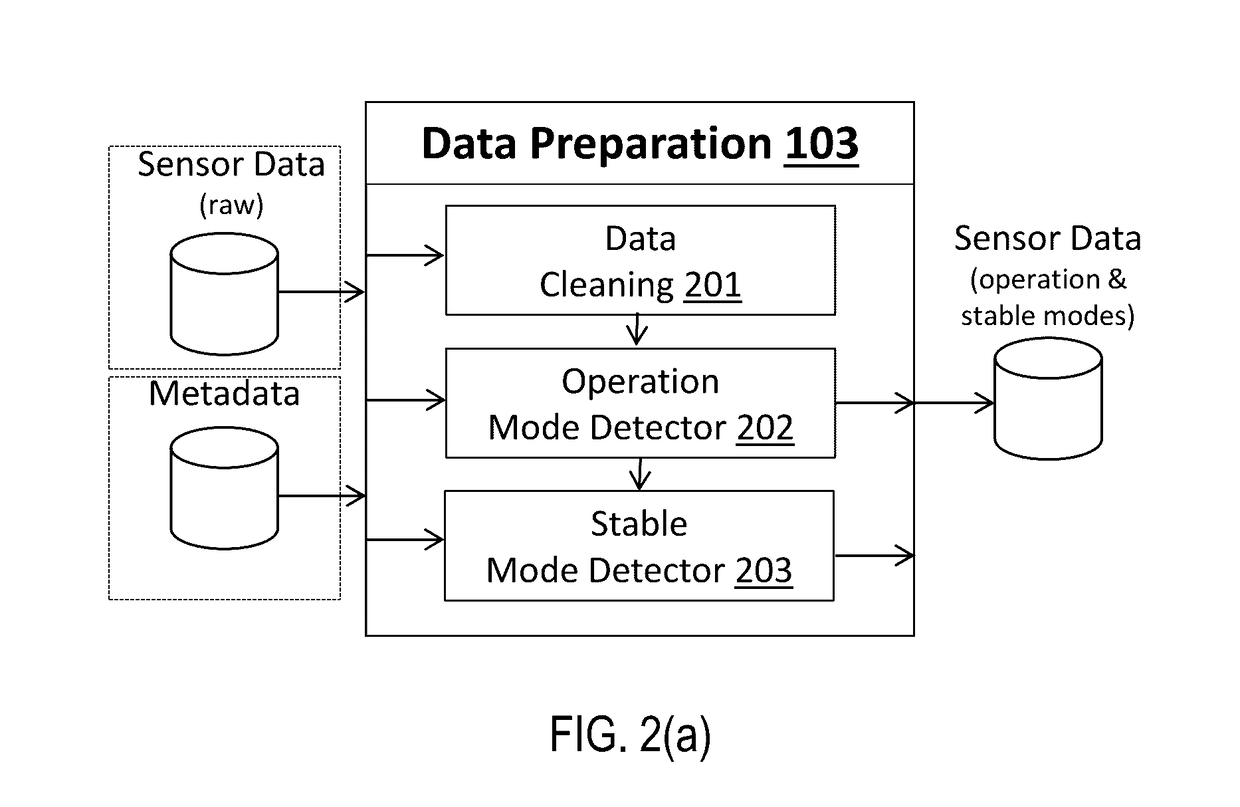

System for maintenance recommendation based on performance degradation modeling and monitoring

ActiveUS20170169143A1Labor savingImprove usabilityDesign optimisation/simulationComplex mathematical operationsPredictive maintenanceData-driven

Example implementations described herein are directed to predictive maintenance of equipment using data-driven performance degradation modelling and monitoring. Example implementations described herein detect degradation in performance over a period of time, and alert the user when degradation occurs. Through the example implementations, the operator of equipment undergoing predictive maintenance modeling can determine a more optimized time in repairing or replacing the equipment or its components.

Owner:HITACHI LTD

Automatic battery pack changing system for electric automobile and battery conveying method thereof

ActiveCN101890942AIncreased interest in purchasing electric vehiclesEnhance interestElectric propulsion mountingElectric/fluid circuitElectricityAutomotive battery

The invention provides an automatic battery pack changing system for an electric automobile and a battery conveying method thereof. The system comprises two conveying lines, a shifting device, battery changing equipment and a vehicle positioning platform, wherein the battery changing equipment comprises a coupled twin positioning conveying vehicle and a lifting device; two conveying lines respectively used for conveying a full battery and a feed battery are arranged in parallel; the coupled twin positioning conveying vehicle provided with two battery storing seats fixed together move between the two conveying lines in three station areas vertical to a conveying direction of the conveying lines; the lifting device is arranged on a battery changing station; the coupled twin positioning conveying vehicle loads the full battery conveyed by the conveying line and the feed battery unloaded by the lifting device and moves one station to one side of the feed battery seat; the full battery is arranged on the battery changing station; the lifting device loads the full battery; and at the same time, the feed battery is unloaded from the feed battery seat of the coupled twin positioning conveying vehicle, so that the changing of the batteries is finished.

Owner:BEIJING KEY POWER TECH

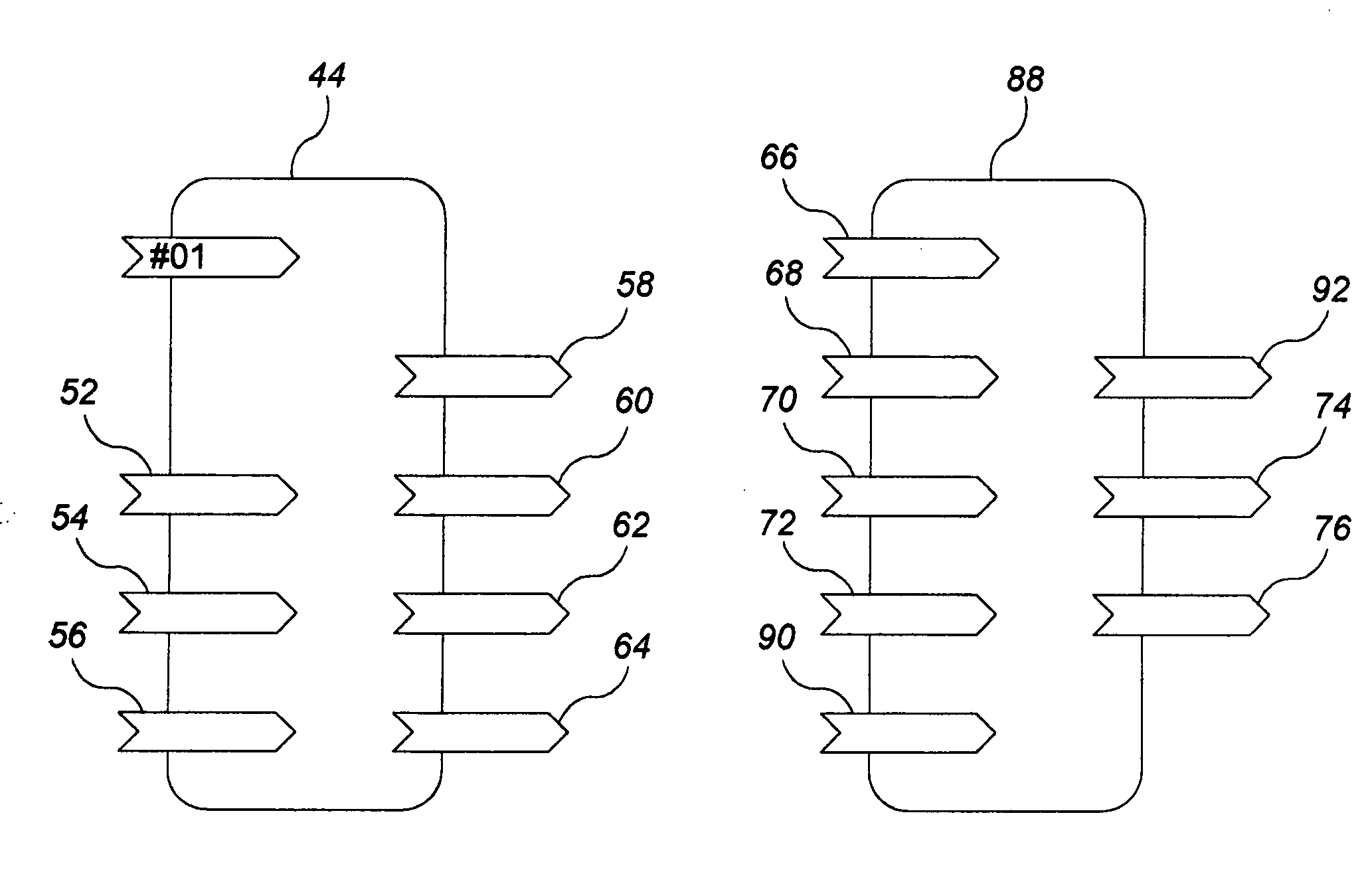

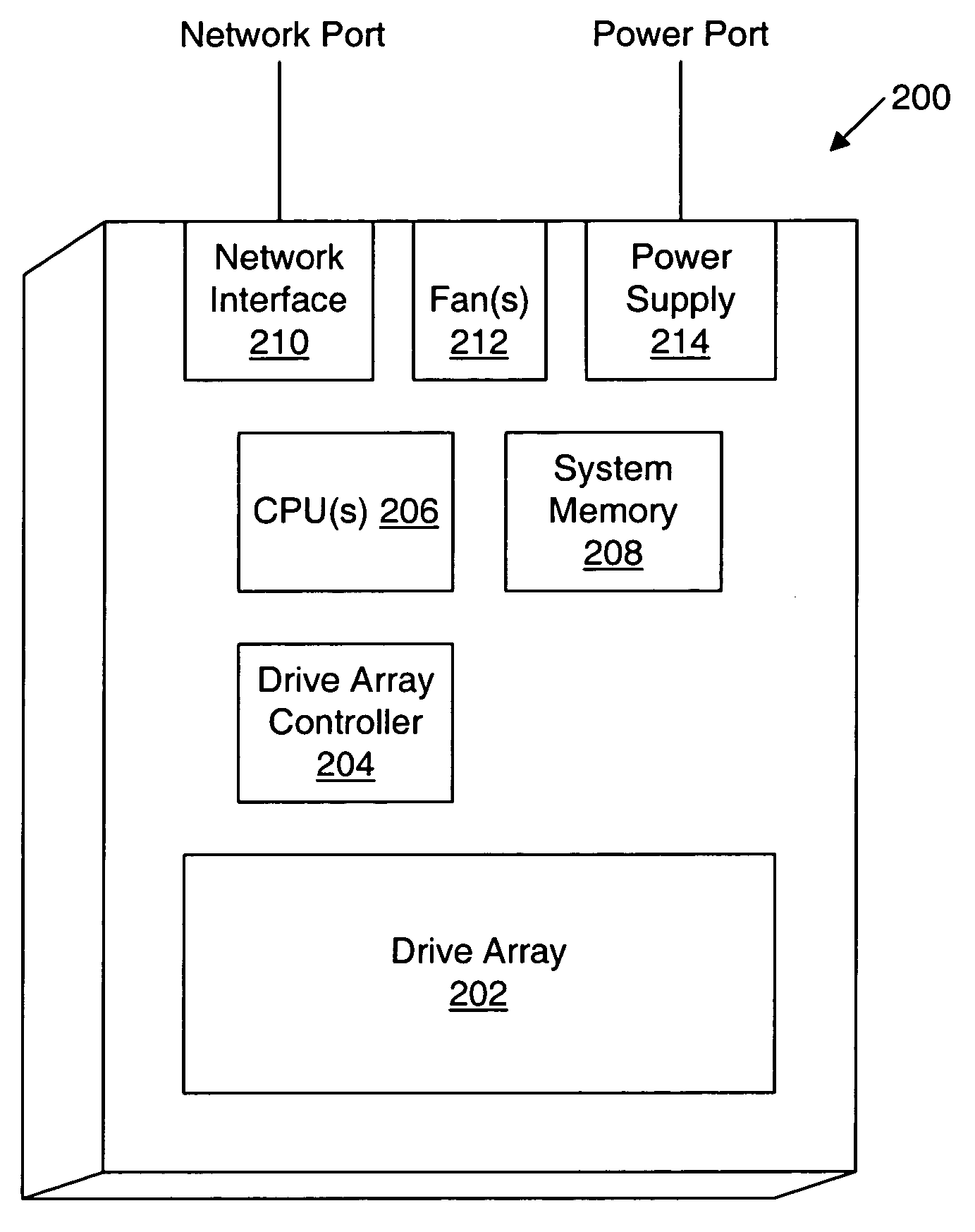

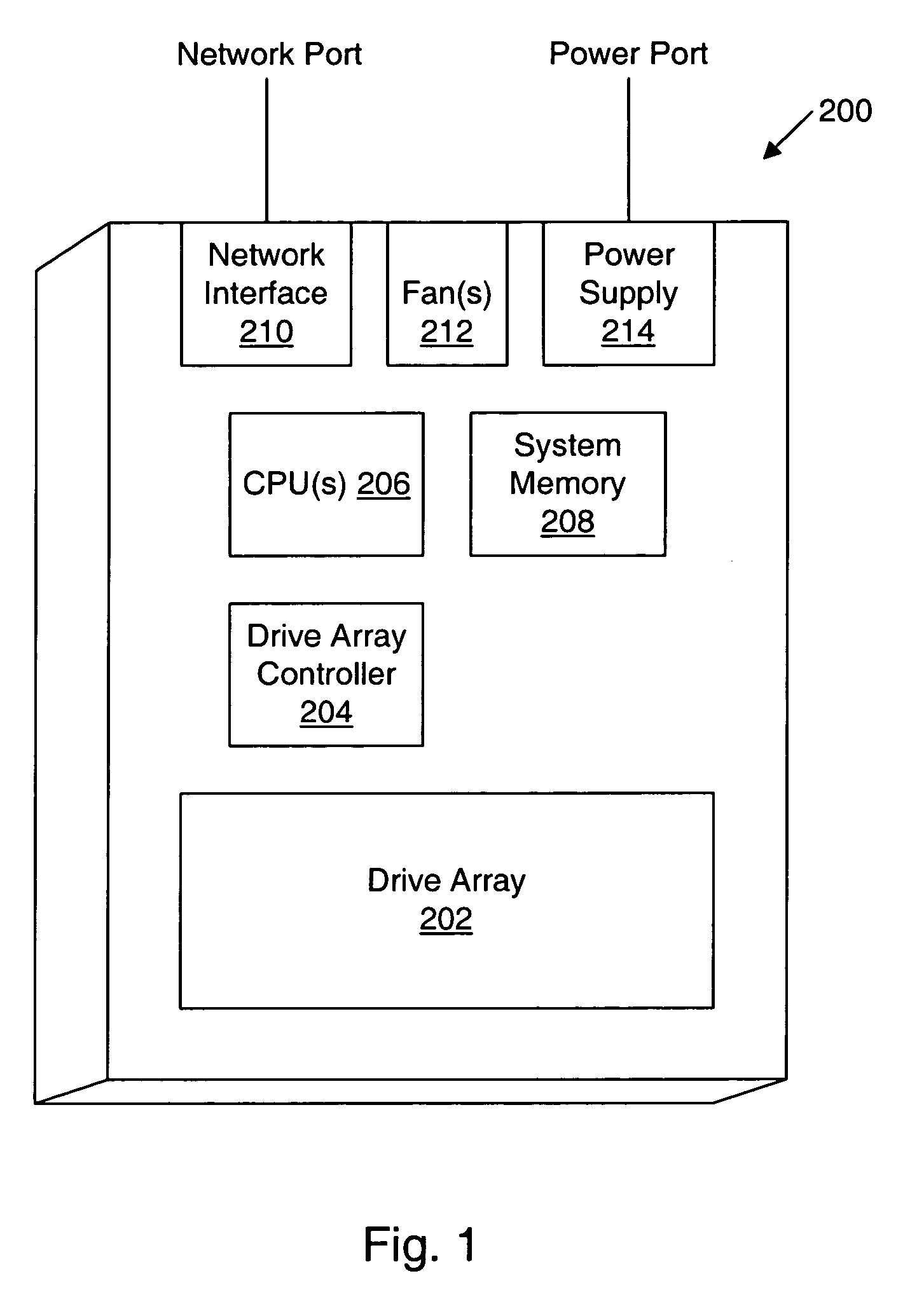

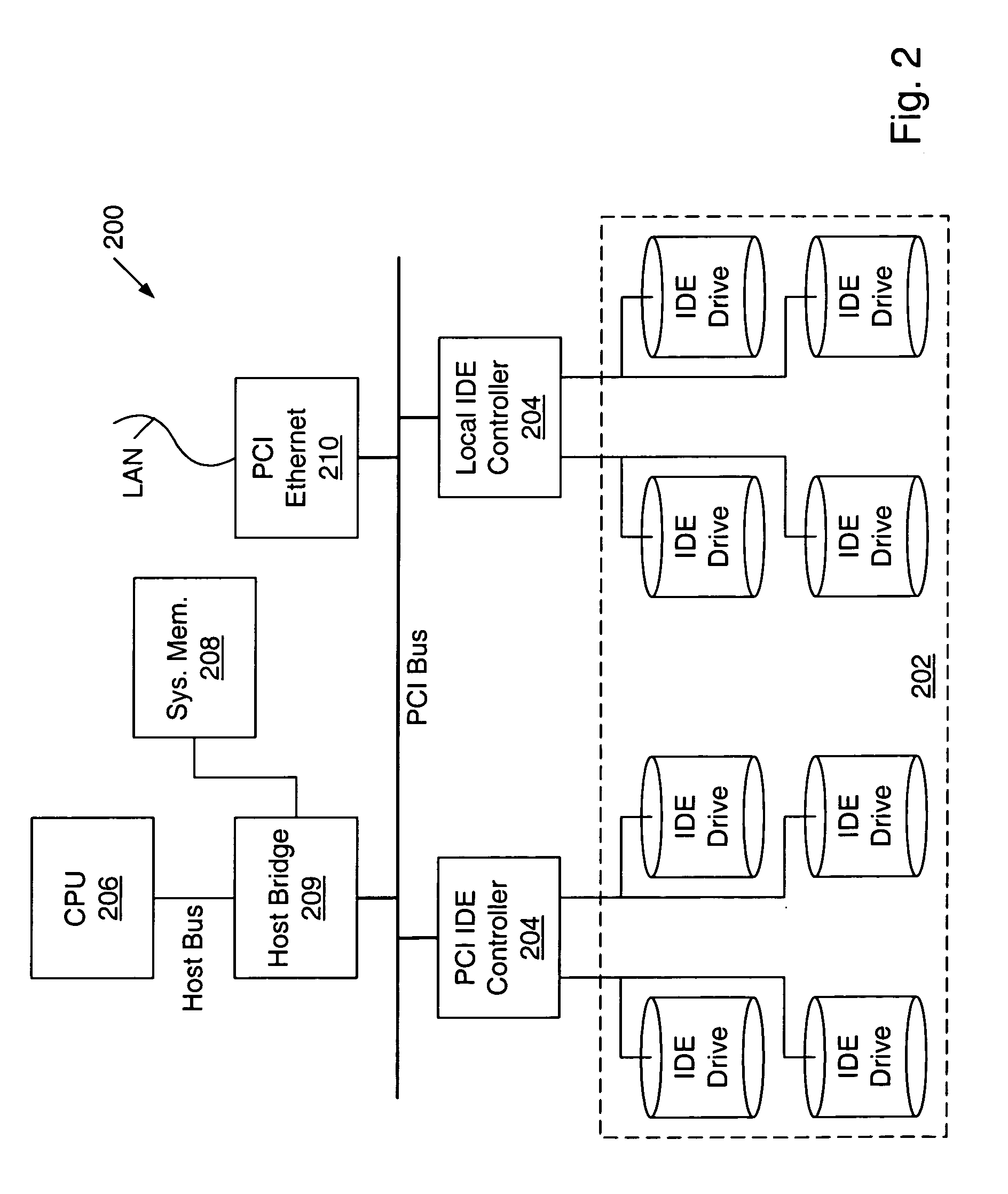

Field replaceable storage array

A single field replaceable storage or computer system may include a processor coupled to a peripheral bus by a bridge device. The field replaceable unit (FRU) may also include system memory coupled to the processor and a network interface coupled to the peripheral bus. One or more drive controllers may also be included coupled to the peripheral bus. Additionally, the single field replaceable unit includes an array of disk drives coupled to the one or more drive controllers. The array of disk drives may be configured as one or more RAID logical volumes and exported or presented to client machines as one or more file systems through the network interface. The processor, system memory, network interface, drive controllers, and array of disk drives are all packaged together as a single field replaceable unit. The processor, system memory, network interface, drive controllers, and array of disk drives may be configured not to be individually field serviceable or replaceable. If the unit fails and needs servicing or replacement, the unit may be replaced as a whole.

Owner:ORACLE INT CORP

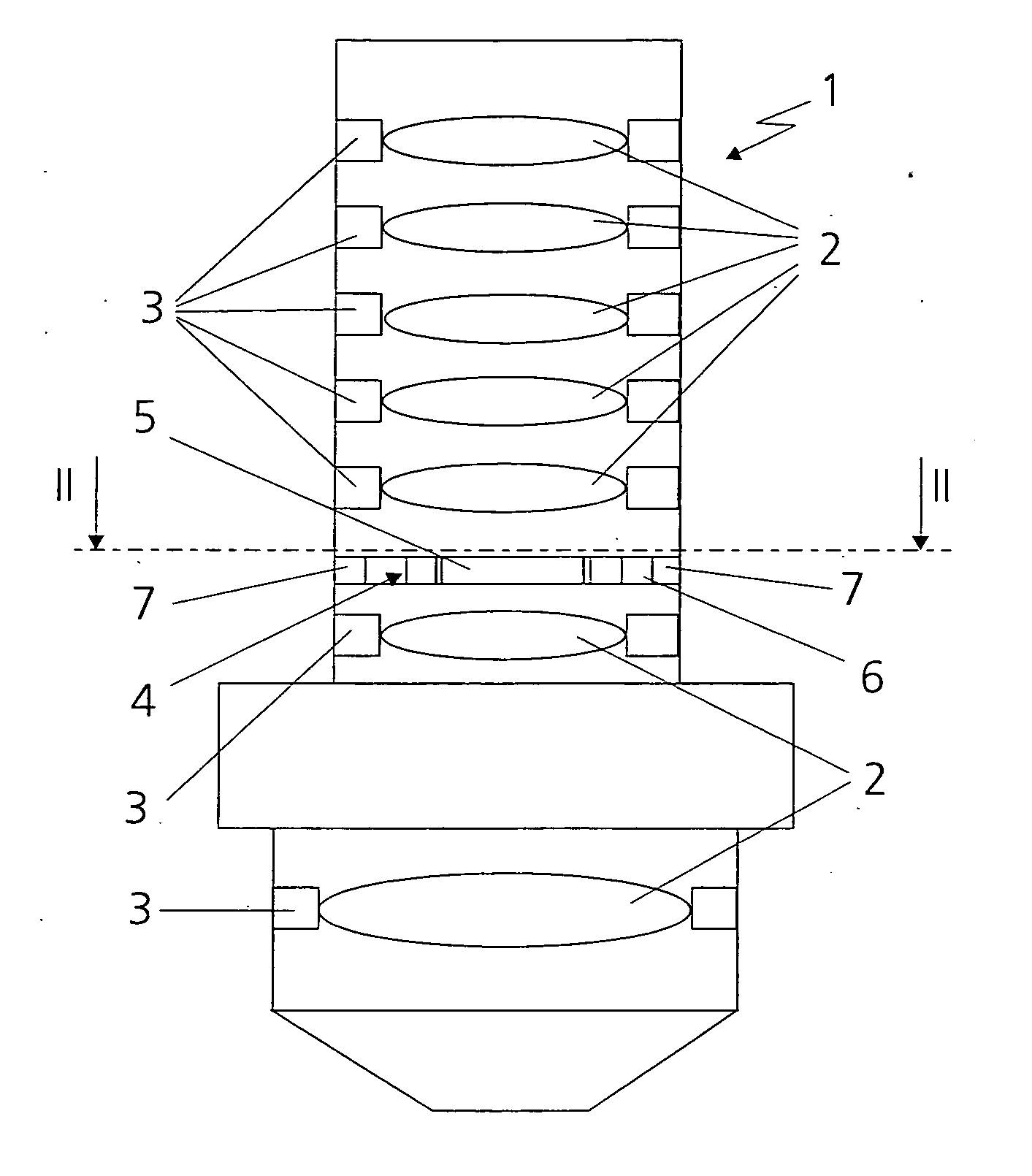

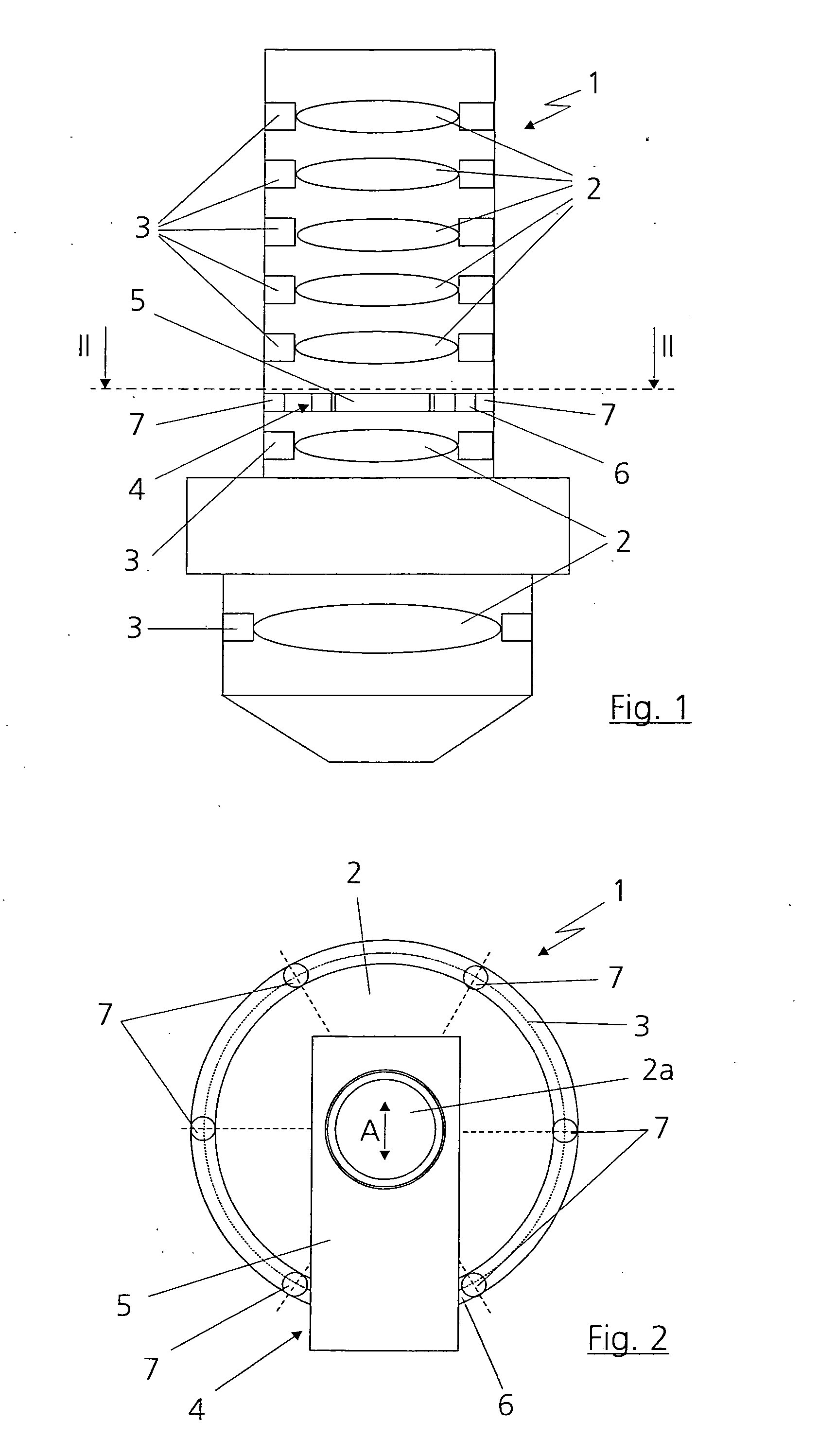

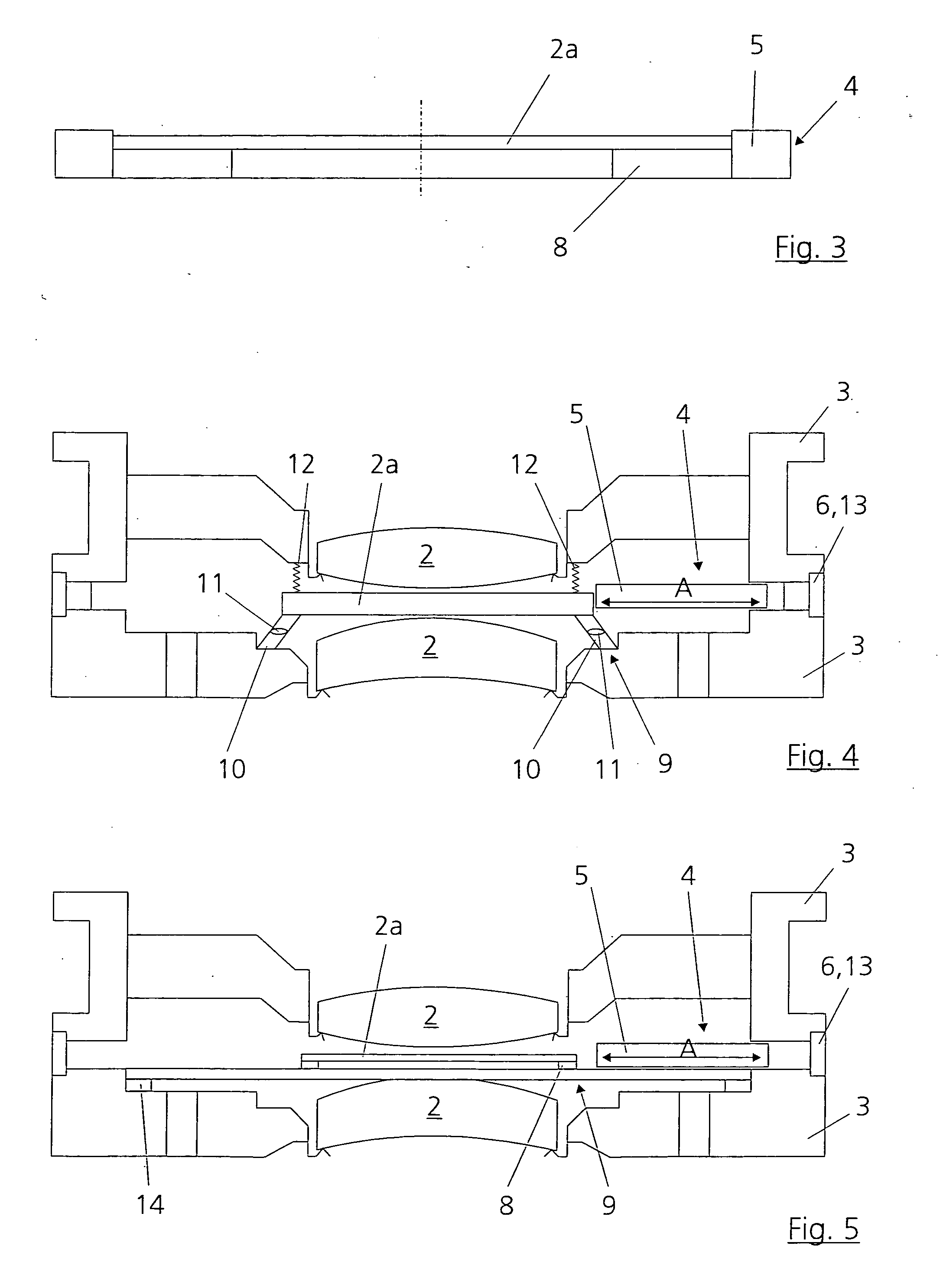

Replacement apparatus for an optical element

ActiveUS20050134972A1Precise positioningImprove performanceMaterial analysis using wave/particle radiationMicroscopesLithographic artistEngineering

Owner:CARL ZEISS SMT GMBH

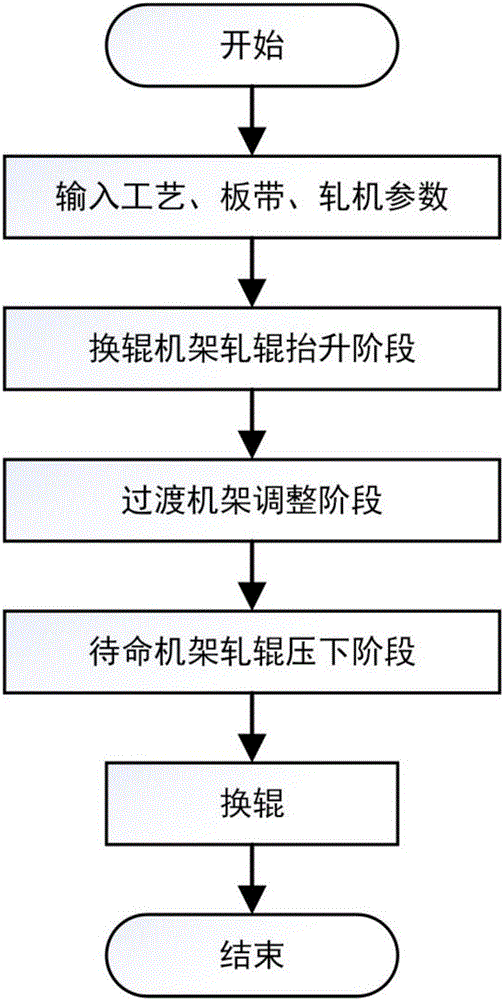

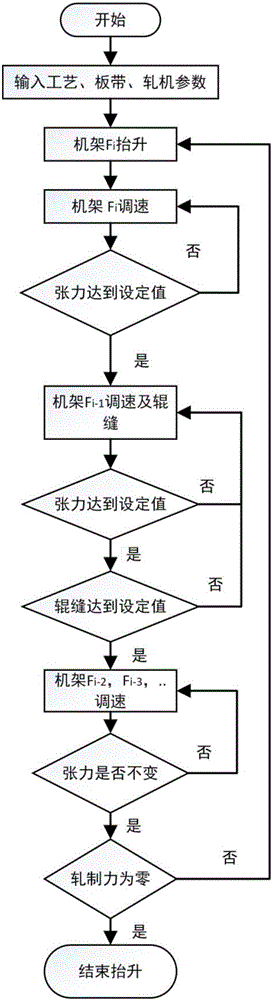

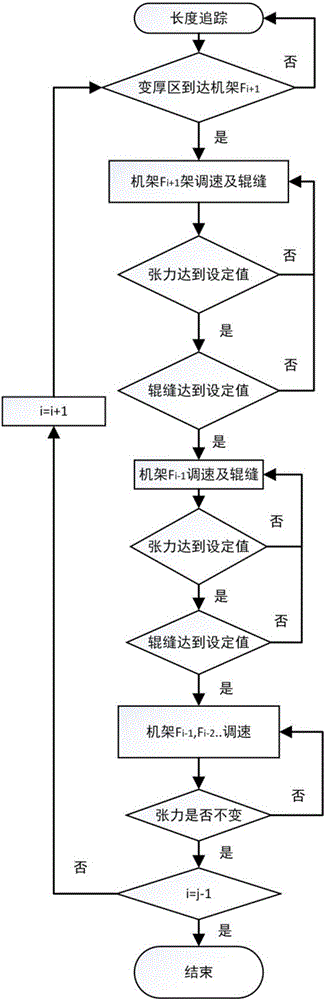

Counterflow roller changing method for realizing online roller changing of ESP (endless strip production) finishing mill unit

ActiveCN106269888AImprove roll changing efficiencyImprove stabilityRoll force/gap control deviceMetal rolling stand detailsPulp and paper industryChanging equipment

The invention provides a counterflow roller changing method for realizing online roller changing of ESP (endless strip production) finishing mill unit. The method is used for ESP finishing mill unit online roller changing equipment equipped with six racks. During normal rolling production, any five racks are put into operation, and one rack is used as a standby rack. The method adopts a counterflow roller changing strategy and comprises the following steps: (1) collecting and inputting of collecting technology, strip and mill parameters; (2) roller lifting and speed regulation of the roller changing rack Fi; (3) roller speed regulation and roller gap adjustment of the transition rack F (i+1); (4) roller speed regulation and roller gap adjustment of the transition rack F (i+2); (5) adjustment of the transition racks in the upstream of the standby rack Fj; (6) pressing down and roller speed regulation of the standby rack Fj. By control of the roller changing process according to the mathematic model provided by the method, the roller changing efficiency and the roller changing process stability can be improved, the control precision of the product thickness is improved, and the industrial application accuracy requirement can be met.

Owner:YANSHAN UNIV

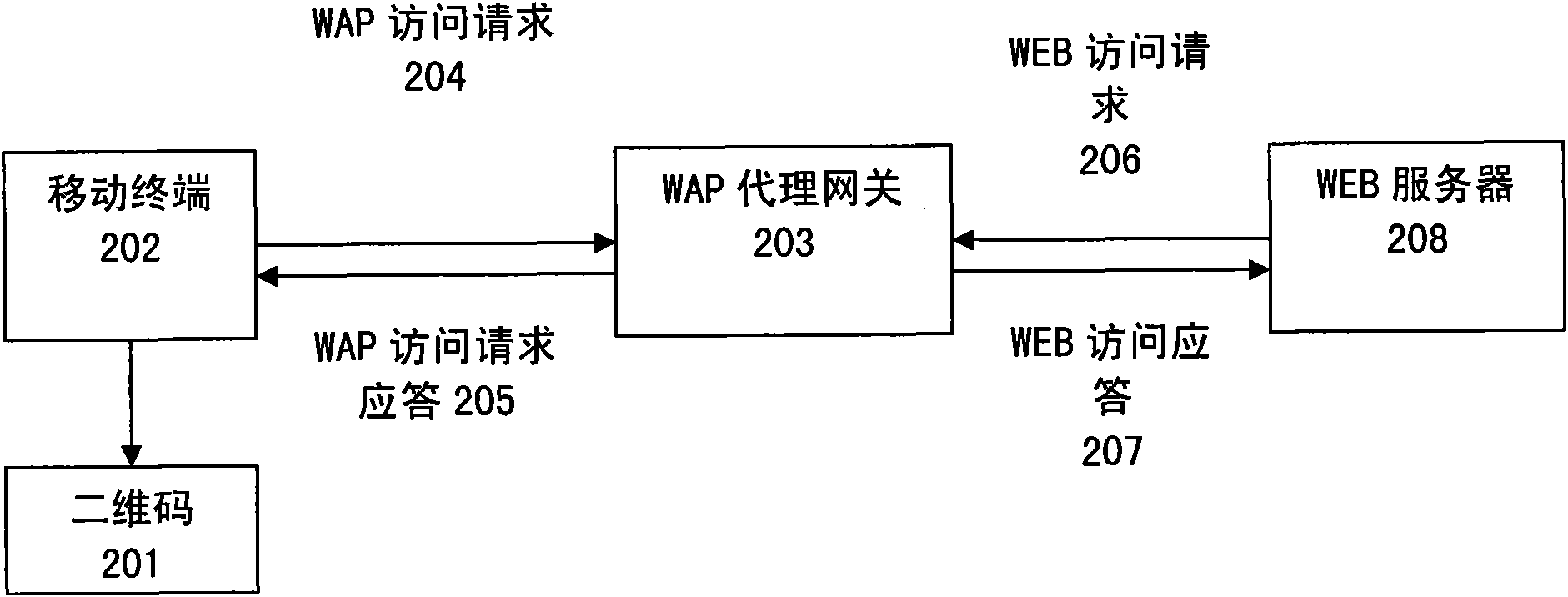

Method and system for guiding mobile terminal to access world wide web by two-dimensional code

InactiveCN101626395ALow costNetwork connectionsSensing by electromagnetic radiationWireless Application ProtocolComputer terminal

The invention relates to a method and a system for guiding a mobile terminal to access a world wide web by a two-dimensional code. Specifically, the method for guiding the mobile terminal to access the world wide web by the two-dimensional code comprises the following steps: using the mobile terminal to scan the two-dimensional code which comprises world wide web access guide information; sending WAP access request to a wireless application protocol agent gateway by the mobile terminal according to the world wide web access guide information; and responding to the WAP access request, wherein the wireless application protocol agent gateway requests a world wide web page to be accessed and converts the world wide web page into a format adaptive to the access of the mobile terminal to be accessed by the mobile terminal. By using the method and the system, the mobile terminal which only supports WAP access can conveniently realize transparent access to the world wide web, and does not need to update or change equipment or software of the mobile terminal, the wireless application protocol gateway or a world wide web server.

Owner:GMEDIA TECH BEIJING +1

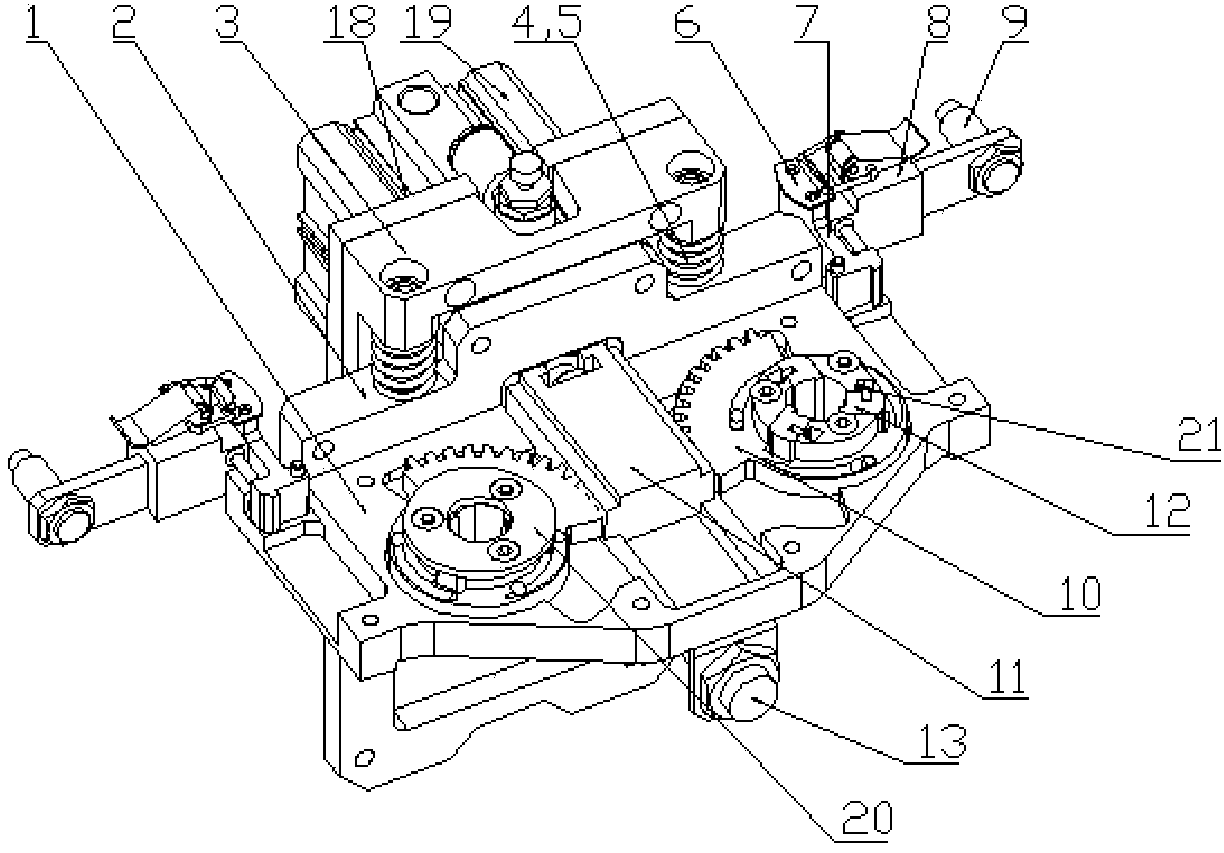

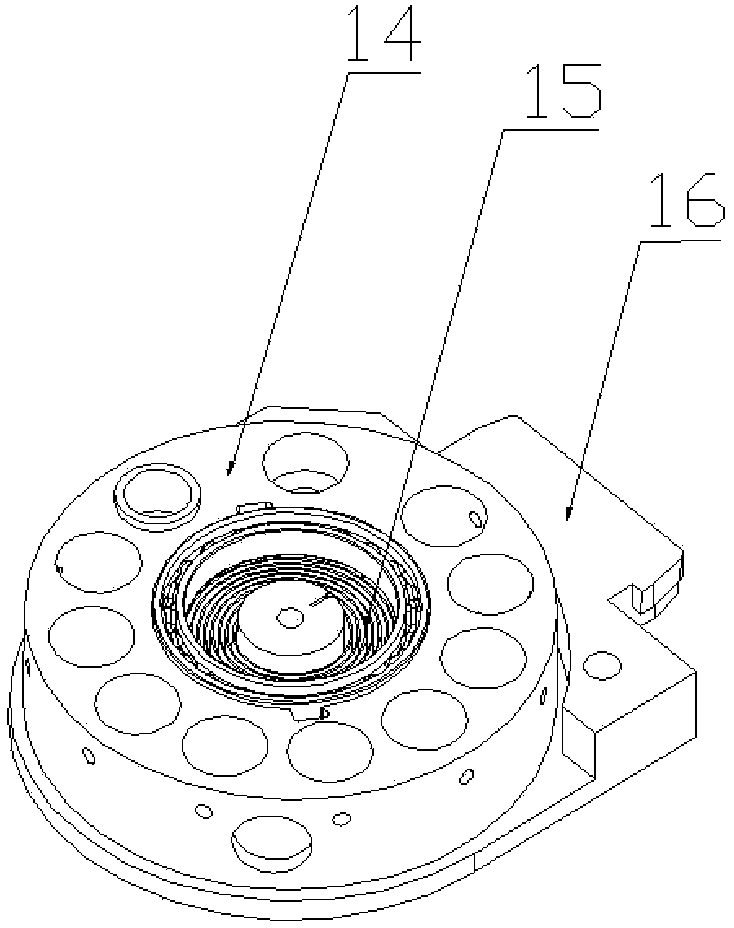

Independent automatic electrode cap replacement unit

ActiveCN103465006AEasy upgrade functionImprove efficiencyMetal working apparatusResistance welding apparatusElectricityChanging equipment

The invention relates to the field of automatic production of automobiles, in particular to an independent automatic electrode cap replacement unit comprising an electrode cap removal unit, an electrode cap storage unit and a sensing detection unit. The electrode cap storage unit and the sensing detection unit are disposed on two sides of the electrode cap removal unit and are connected in a quick plugging manner. The sensing detection unit comprises an electrode cap removal detection sensor, two electrode cap amount detection sensors and two travel detection sensors. The independent automatic electrode cap replacement unit has the advantages that the unit which is highly modular can be combined with any automatic grinder to allow for automatic die repair and cap replacement, and the function can be updated for customers still replacing caps with hands; the twist and pull cap removal technology is utilized innovatively, efficiency and reliability are improved greatly, upper and lower electrode caps are removed respectively with the cap replacement unit in different rotation directions, the risk of electrode bar looseness due to cap removal torque can be reduced, the electrode cap storage unit can be removed freely, and the size of the whole cap replacement unit is reduced.

Owner:上海卡格机电设备有限公司

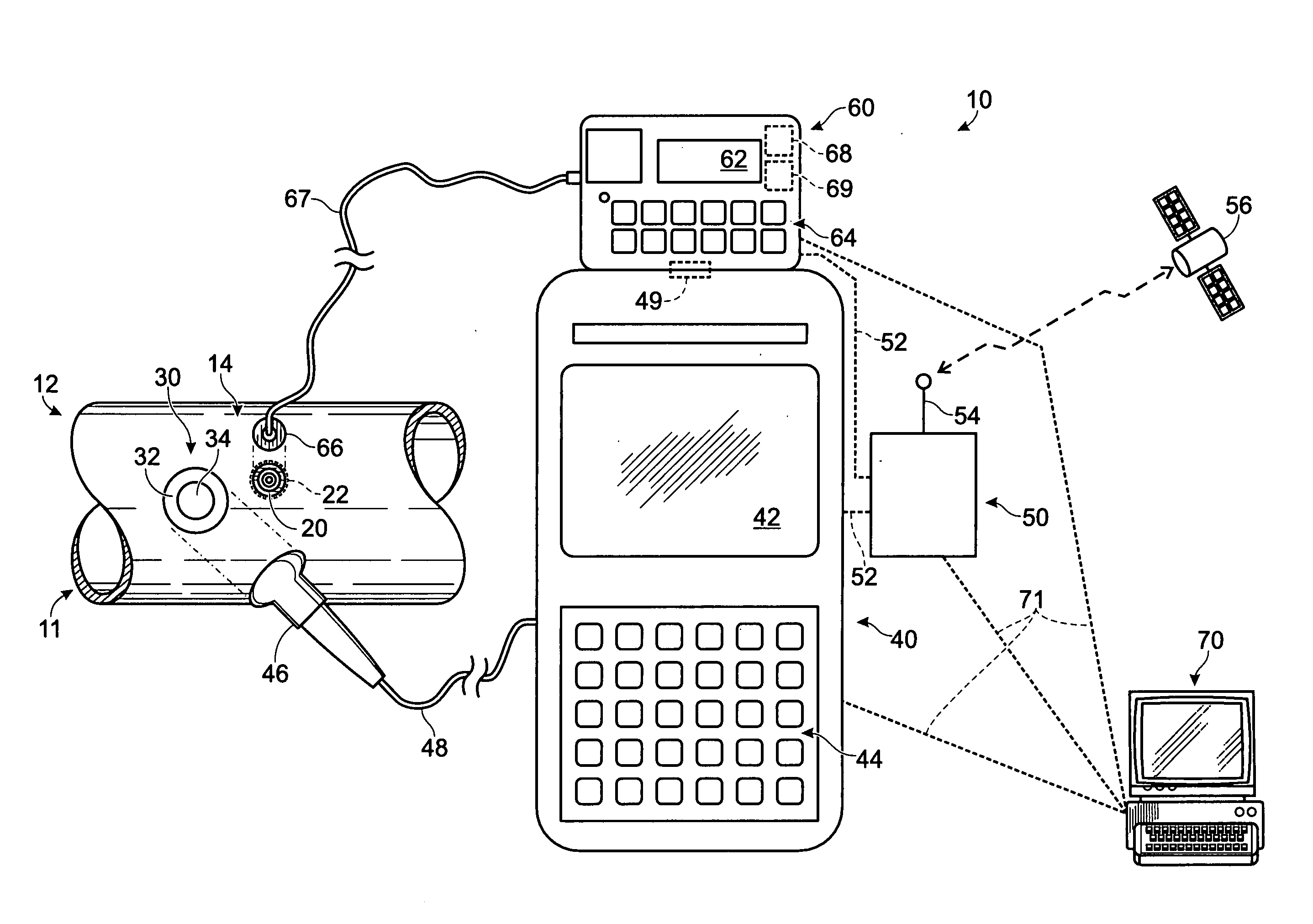

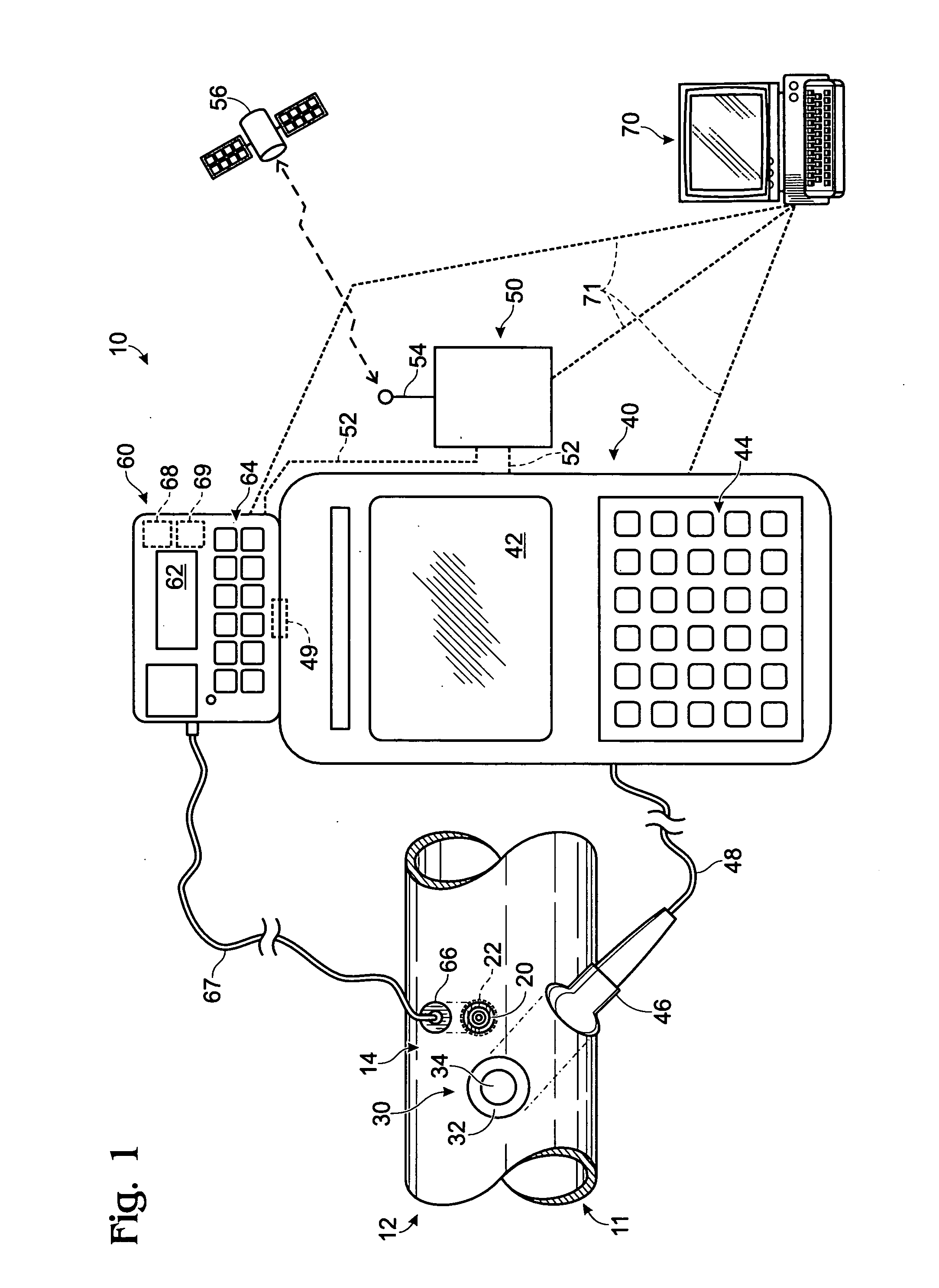

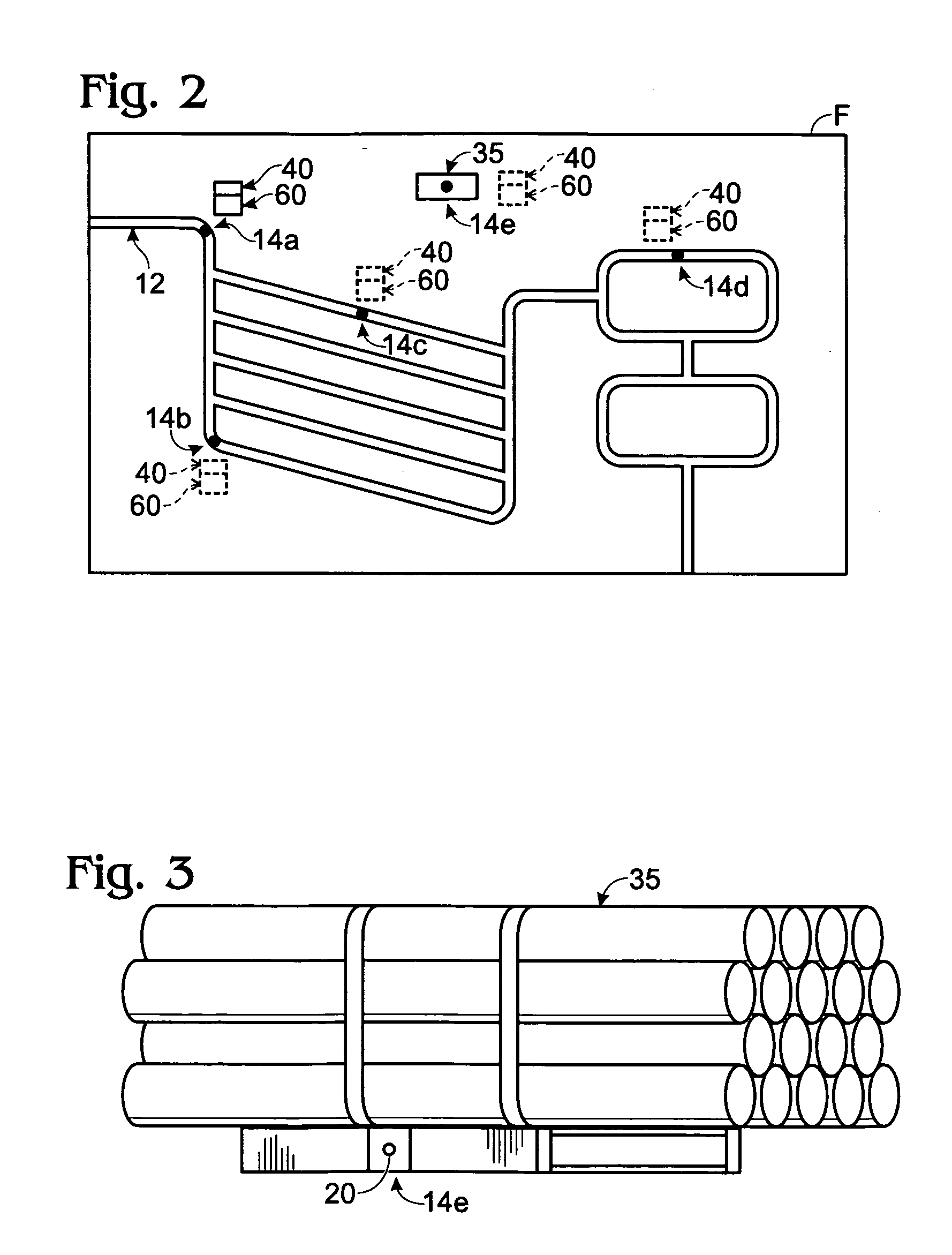

System and methods for testing, monitoring, and replacing equipment

InactiveUS20090037146A1Vehicle testingVibration measurement in fluidMeasurement deviceComputer module

A system and method for testing and replacing equipment are disclosed. The system may include a first memory module configured to store first characteristics of the first equipment; a second memory module configured to store second characteristics of the second equipment; and a portable reader configured to read the first and second memory modules and to compare the second characteristics with the first characteristics to determine if the second equipment is a suitable replacement for the first equipment. The method may include storing first characteristics of a first equipment on a first memory module; transmitting the first characteristics to a portable reader; measuring second characteristics of a second equipment using a measuring device associated with the portable reader; and comparing, with the portable reader, the second characteristics with the first characteristics to determine if one of the first and second equipment is a suitable replacement for the other equipment.

Owner:E P I EURO DE PARTICIPATIONS IND +1

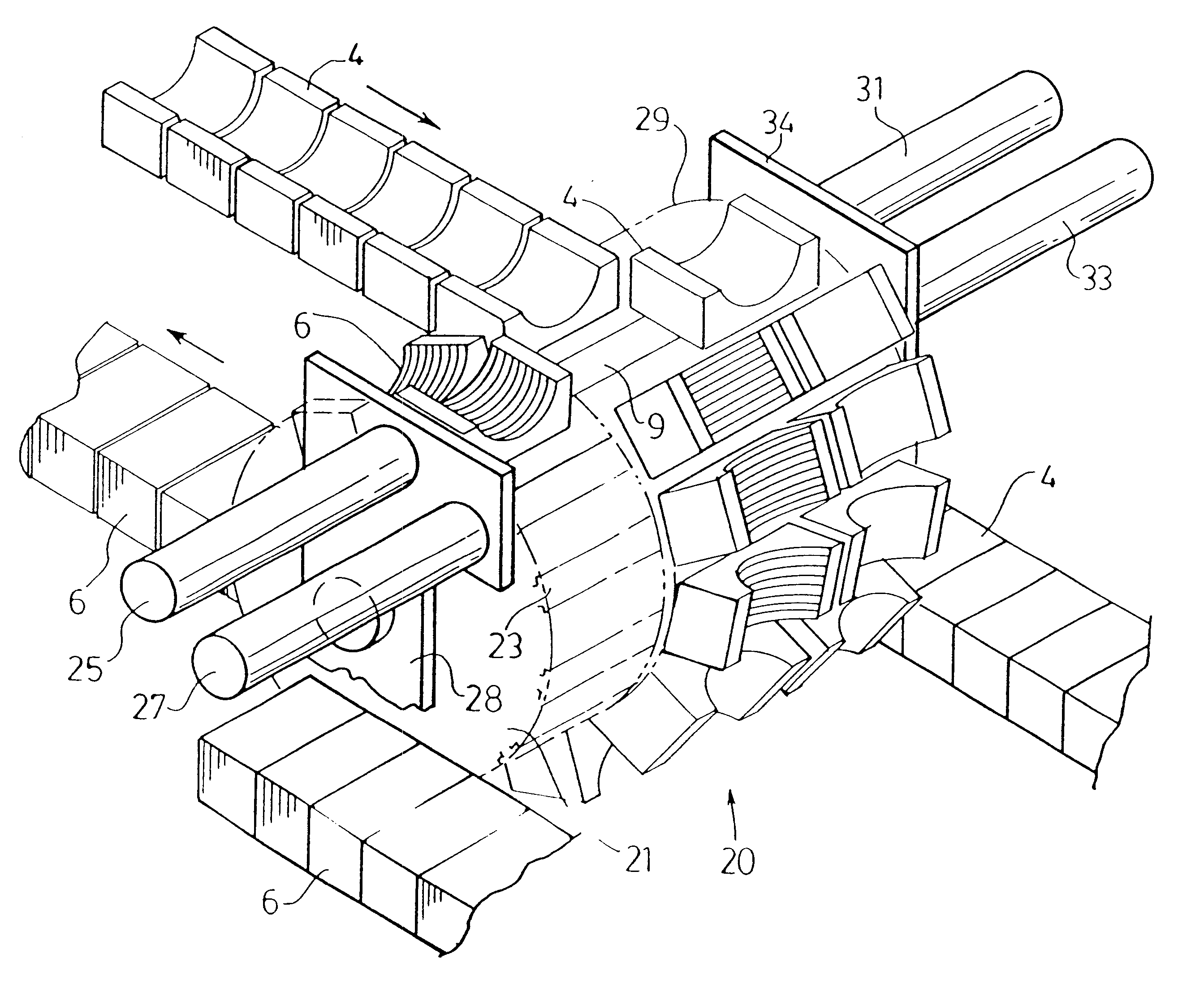

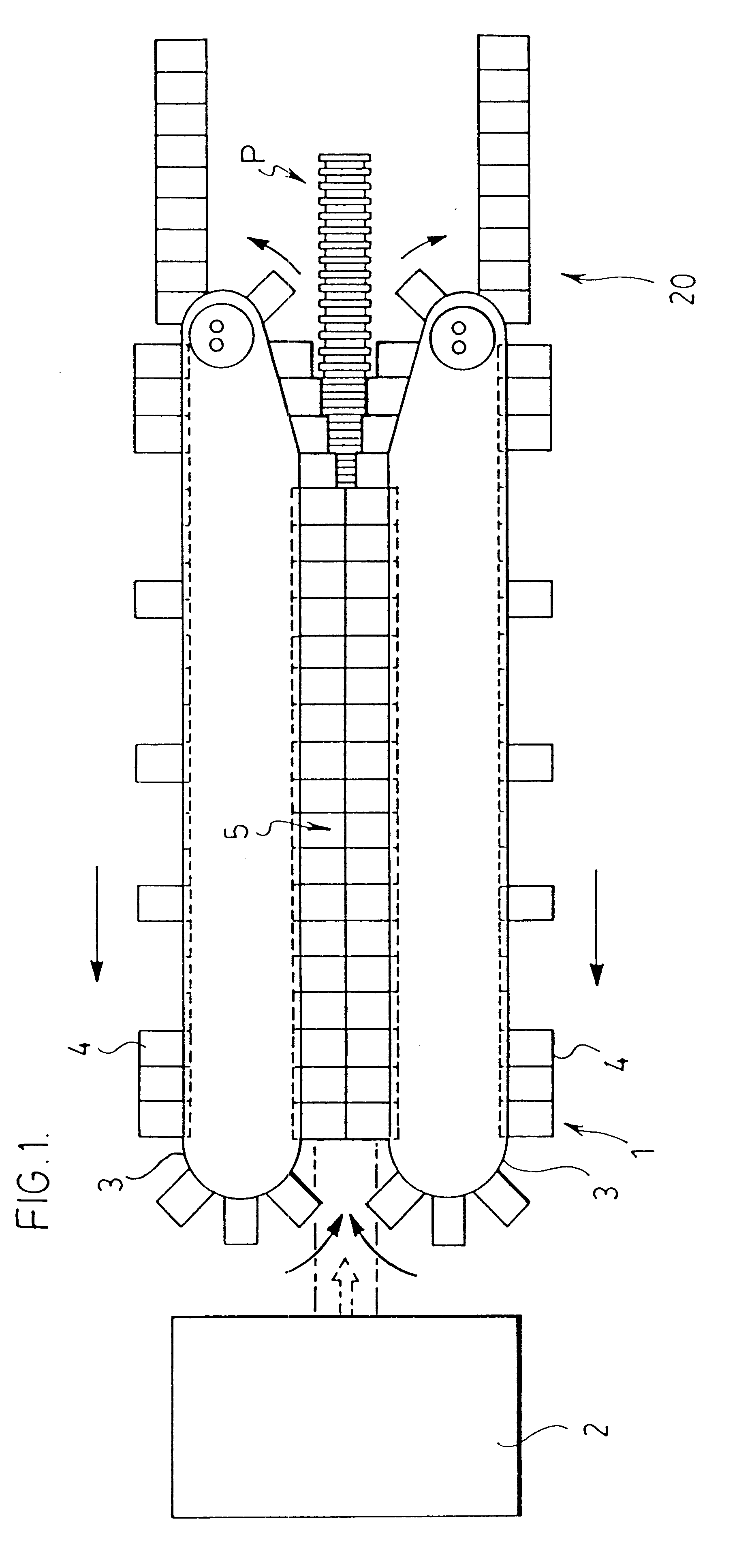

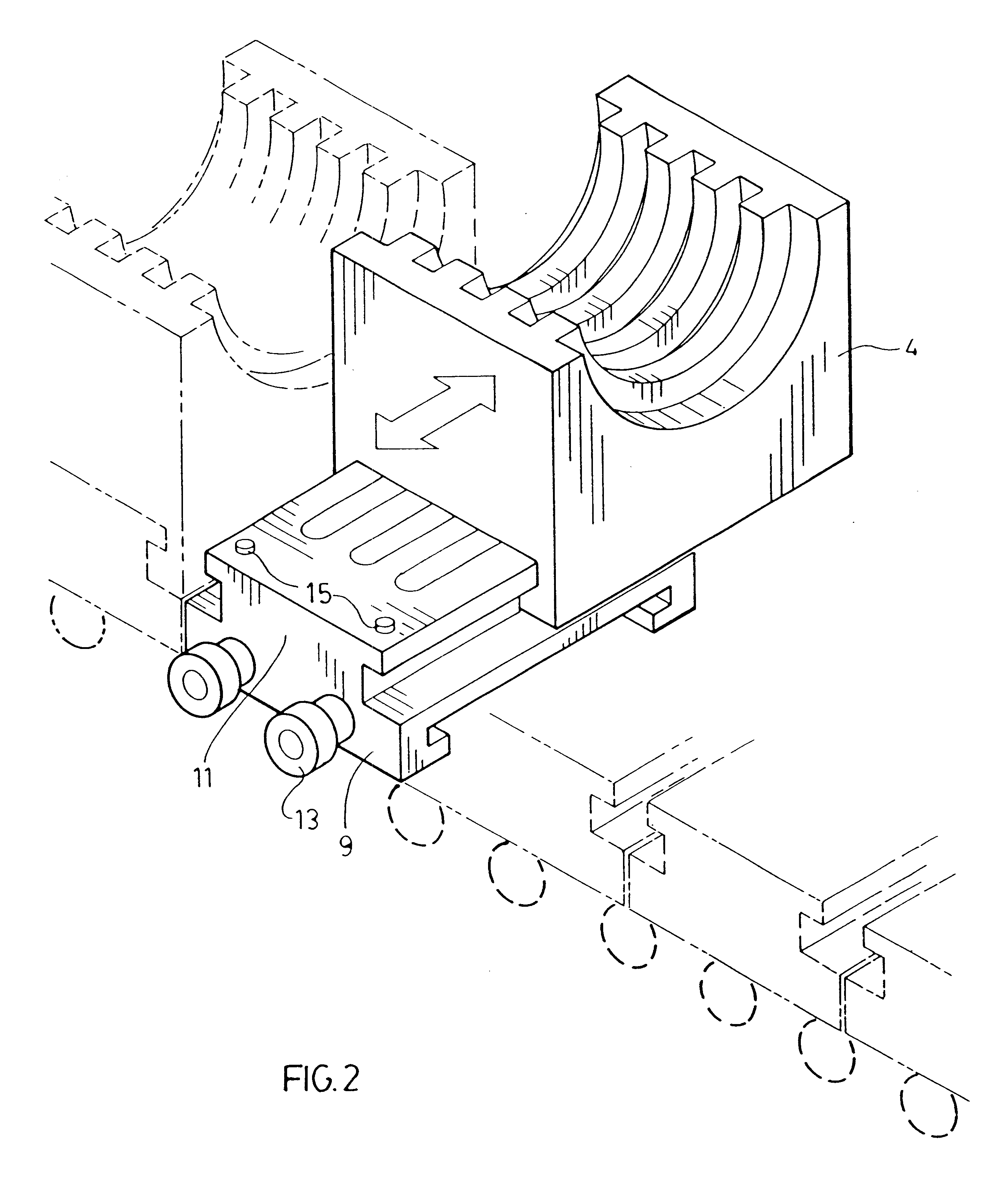

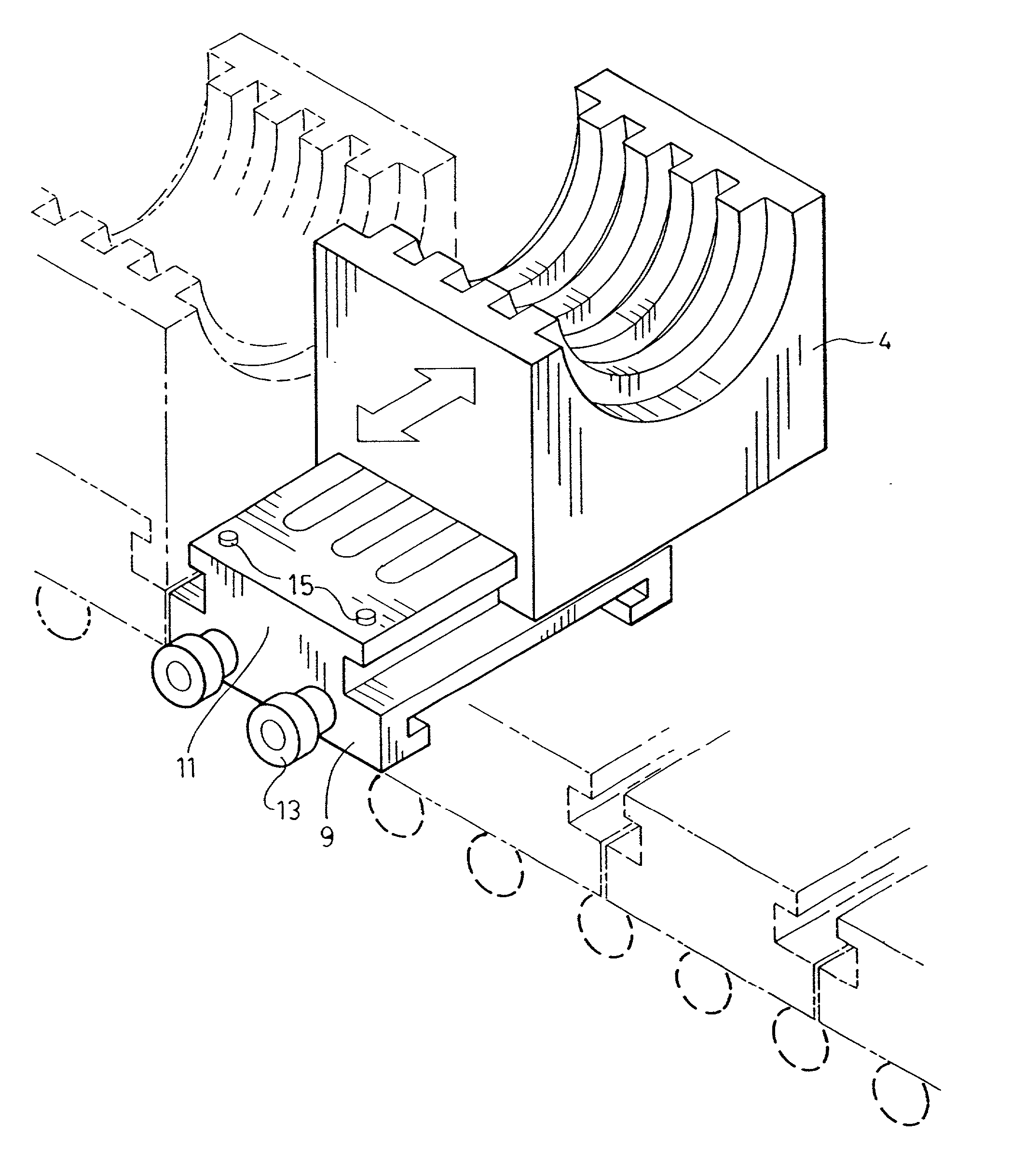

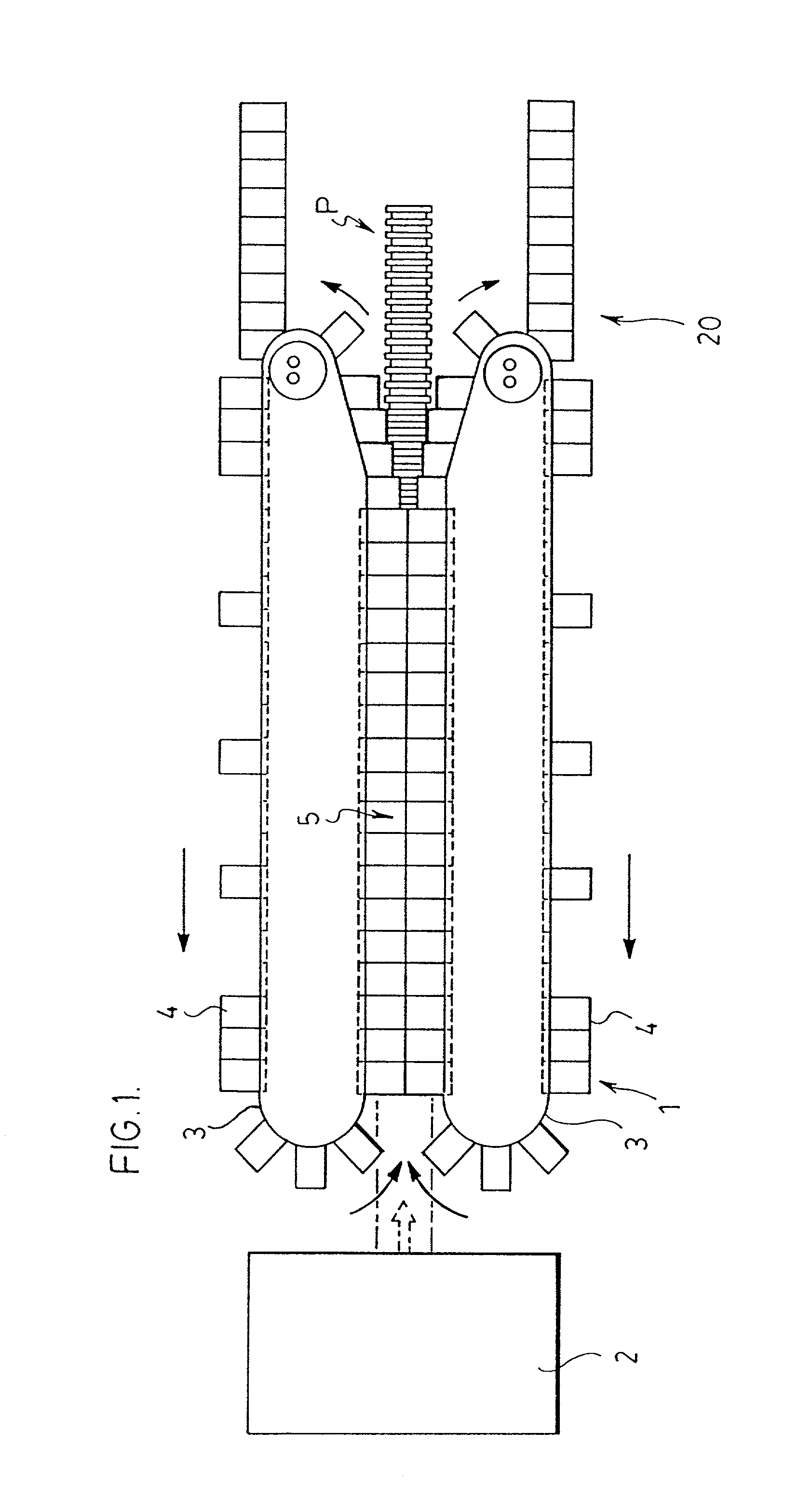

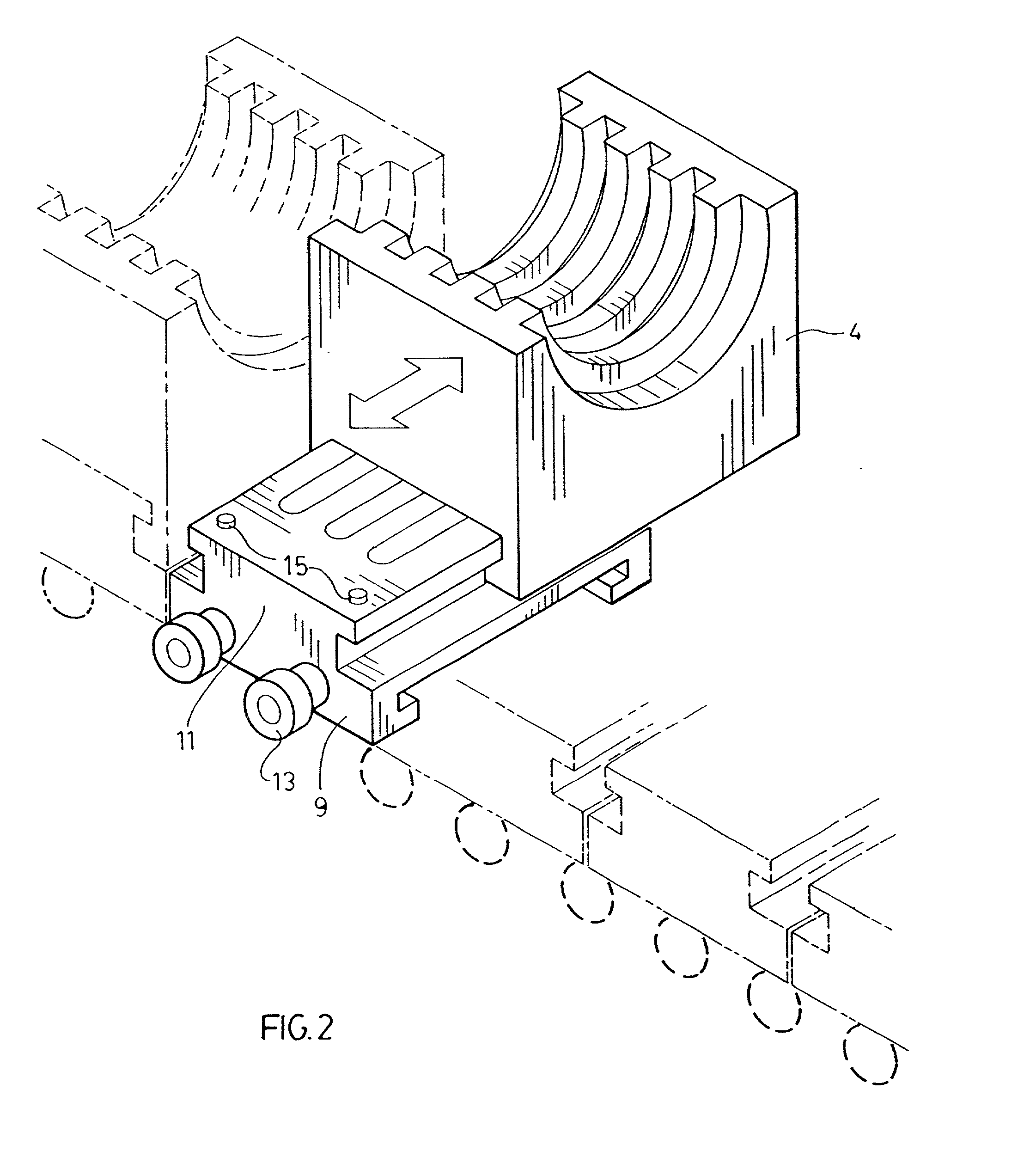

Molding apparatus with mold block section transfer system

InactiveUS6644951B2Mechanical working/deformationDough-sheeters/rolling-machines/rolling-pinsShell moldingTransfer system

A molding apparatus which is used in a continuous molding operation includes an endless looped track, track carriers which are moved around the track to and from a product shaping mold region and a transfer system for replacement of mold block members used in the apparatus. The transfer system, which operates without interrupting the molding operation includes transfer carriers controlled to move synchronized with the track carriers at a transfer location remote from the mold region and actuators which slide the mold block members between the track carriers and the transfer carriers at the transfer location when the transfer carriers are synchronized with the track carriers.

Owner:LUPKE MANFRED A A +1

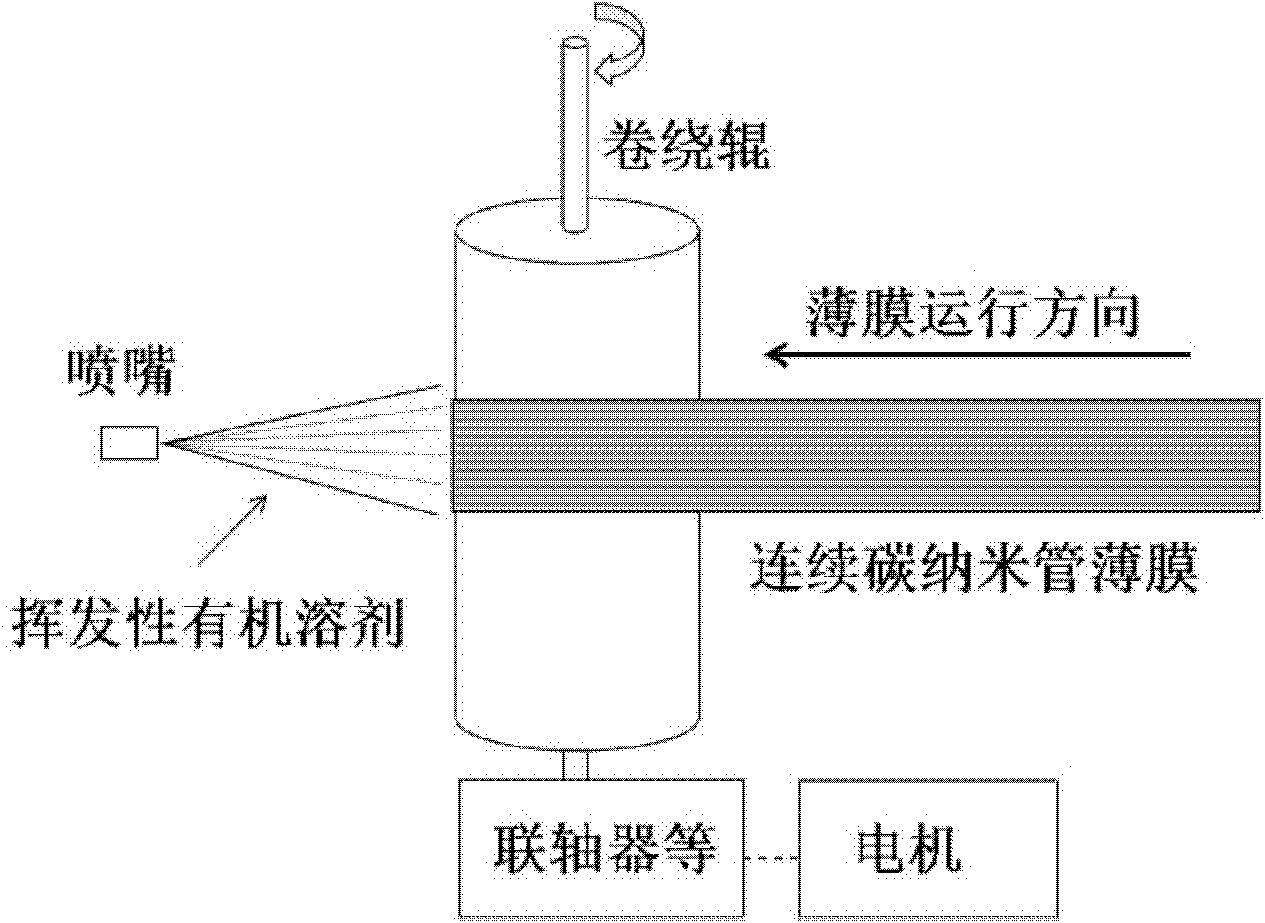

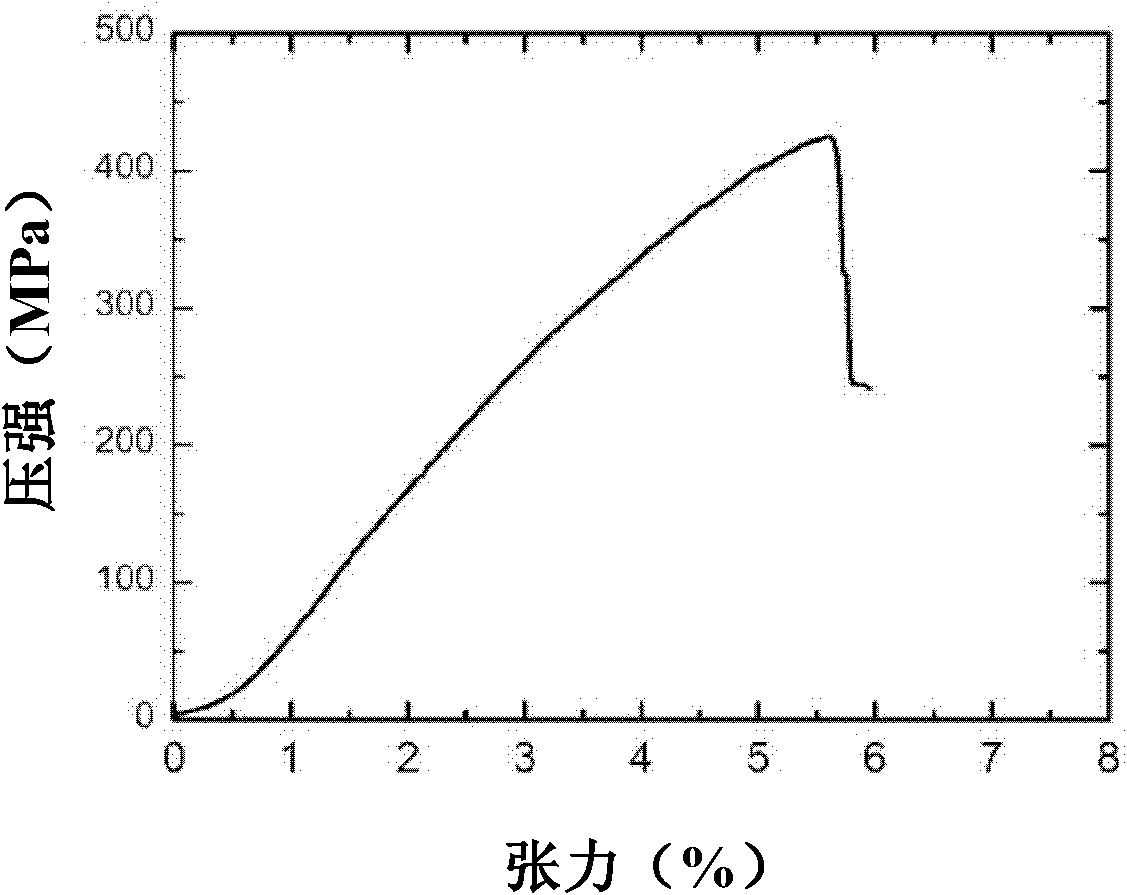

Preparation method of highly-oriented carbon nanotube paper

The invention relates to a preparation method of a piece of highly-oriented carbon nanotube paper. The preparation method comprises the following steps: sticking and wrapping a carbon nanotube film onto a winding roller, then winding the carbon nanotube film, simultaneously, spraying a volatile solvent onto the winding roller, and then preparing the carbon nanotube paper with controllable orientation after the volatile solvent is fully volatilized. The preparation method is simple and efficient in process, avoids the damage of the structure and the morphology of a carbon nanotube and can achieve the carbon nanotube paper with controllable thickness, size and internal structure by changing equipment parameters; and the prepared carbon nanotube paper can be widely applied to batteries and filtering materials and further has a good application prospect.

Owner:DONGHUA UNIV

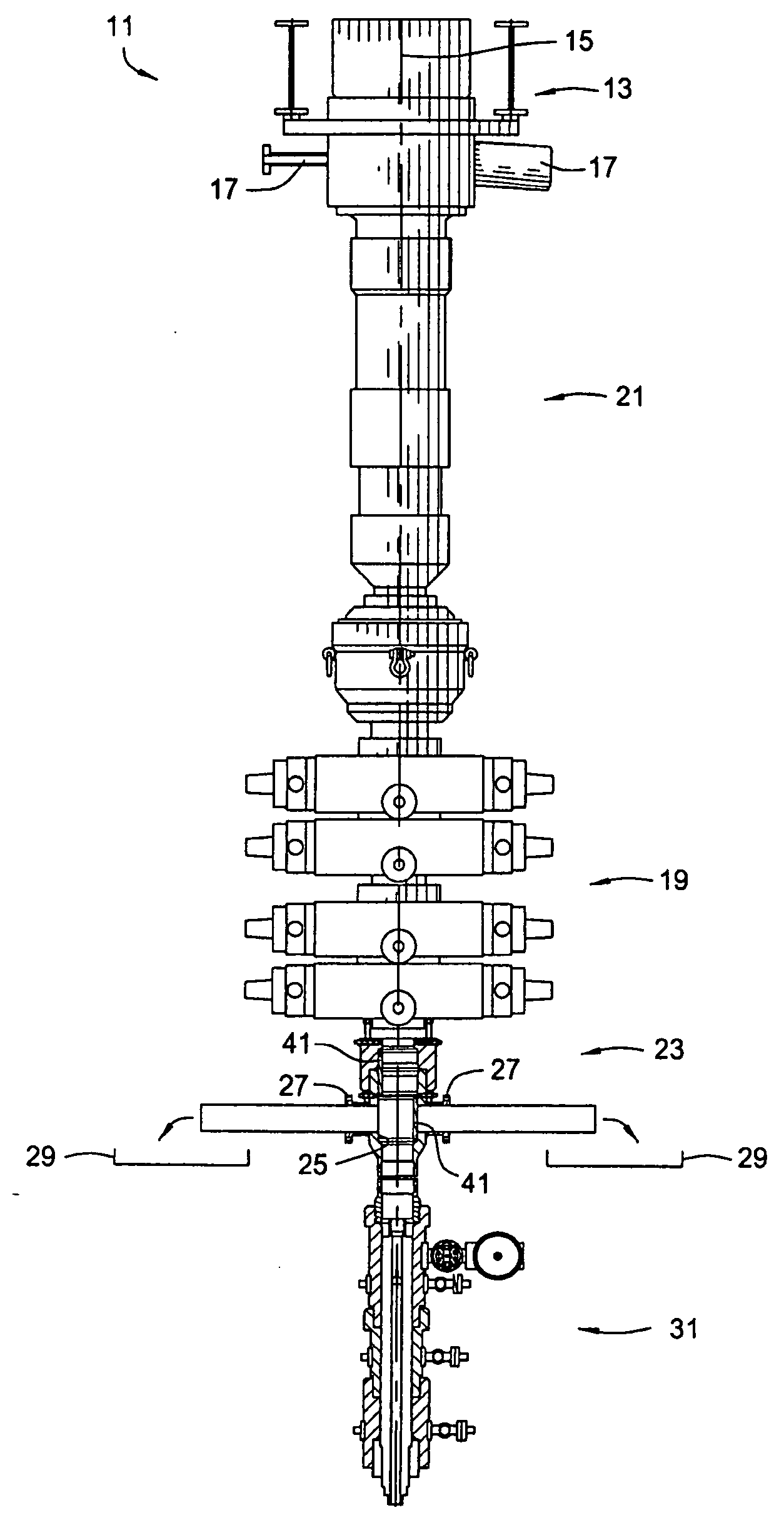

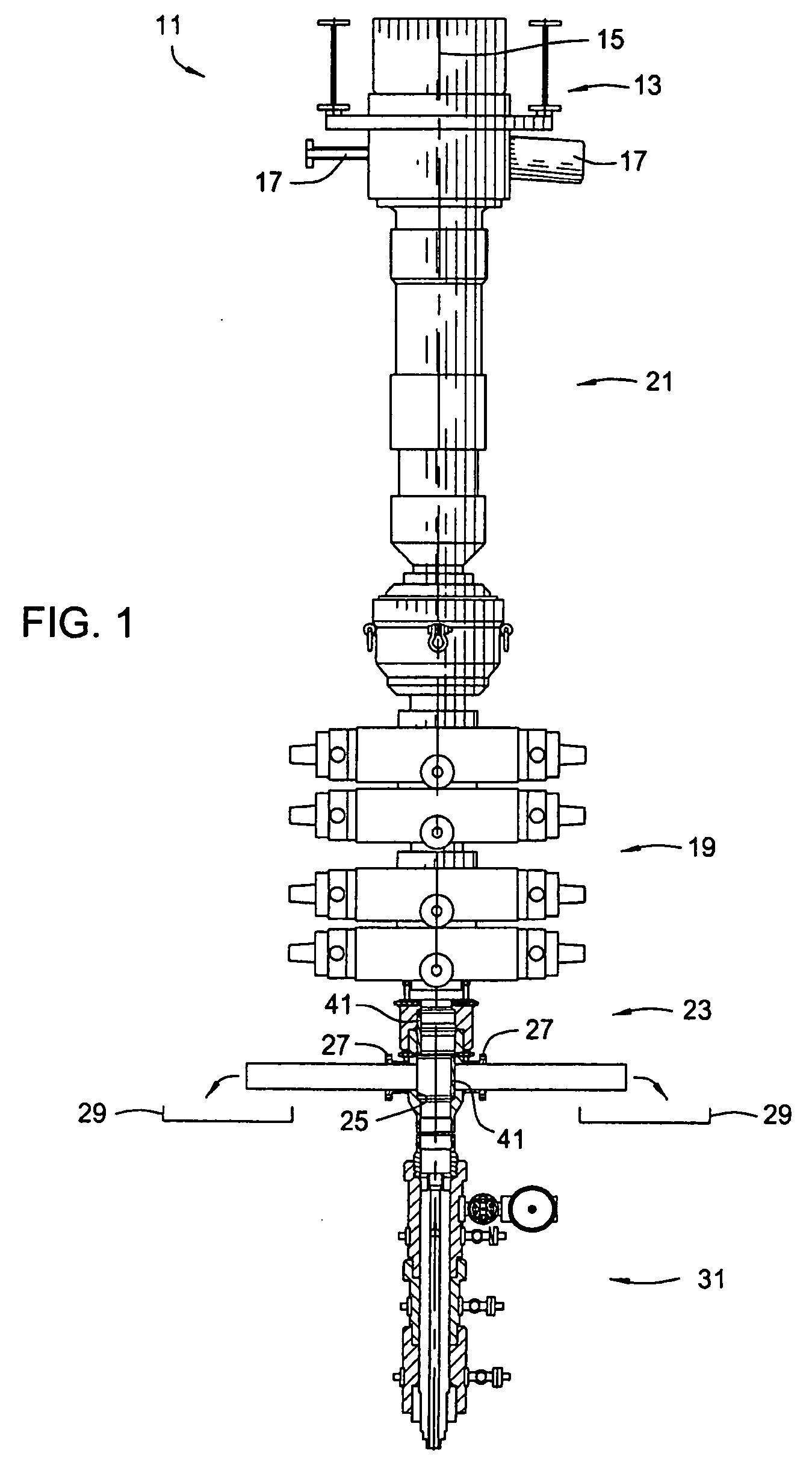

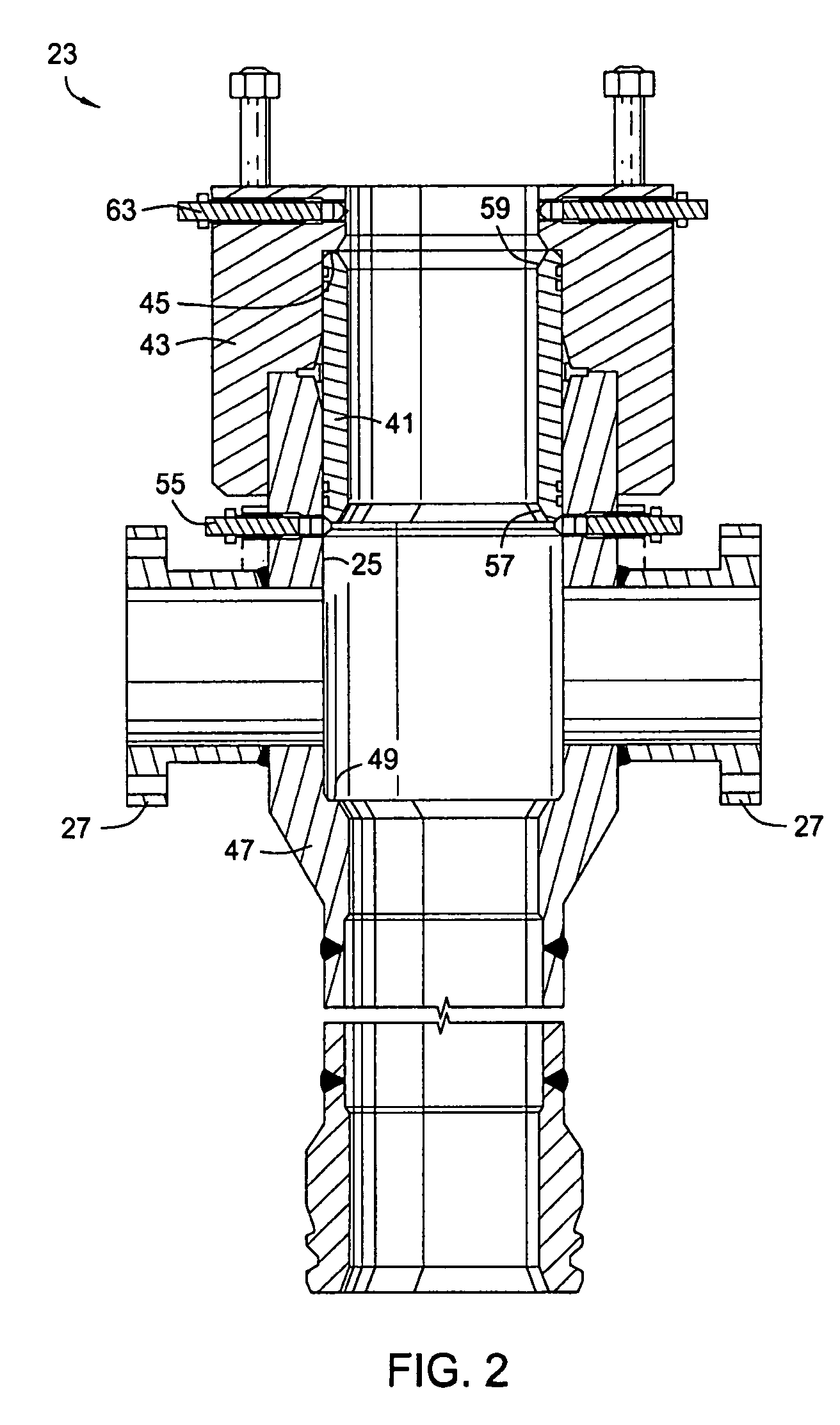

System, method, and apparatus for accessing outlets in a two-stage diverter spool assembly

ActiveUS20070079990A1Save rig time operationOperational savingDrilling rodsFluid removalLine tubingFlow diverter

A wellhead system diverter spool contains an internal sleeve that can be axially shifted internal to the spool with a handling tool. The sleeve permits access to outlets in the spool when required. When higher pressures are required, the internal sleeve is shifted downward to close off access to the outlets without change out of equipment or changing the BOP stack riser system. The low pressure lines connected to the outlets can remain installed but are isolated from the higher pressure BOP stack pressures.

Owner:VETCO GRAY LLC

Molding apparatus with mold block section transfer system

InactiveUS20020025355A1Mechanical working/deformationDough-sheeters/rolling-machines/rolling-pinsTransfer systemShell molding

A molding apparatus which is used in a continuous molding operation includes an endless looped track, track carriers which are moved around the track to and from a product shaping mold region and a transfer system for replacement of mold block members used in the apparatus. The transfer system, which operates without interrupting the molding operation includes transfer carriers controlled to move synchronized with the track carriers at a transfer location remote from the mold region and actuators which slide the mold block members between the track carriers and the transfer carriers at the transfer location when the transfer carriers are synchronized with the track carriers.

Owner:LUPKE MANFRED A A +1

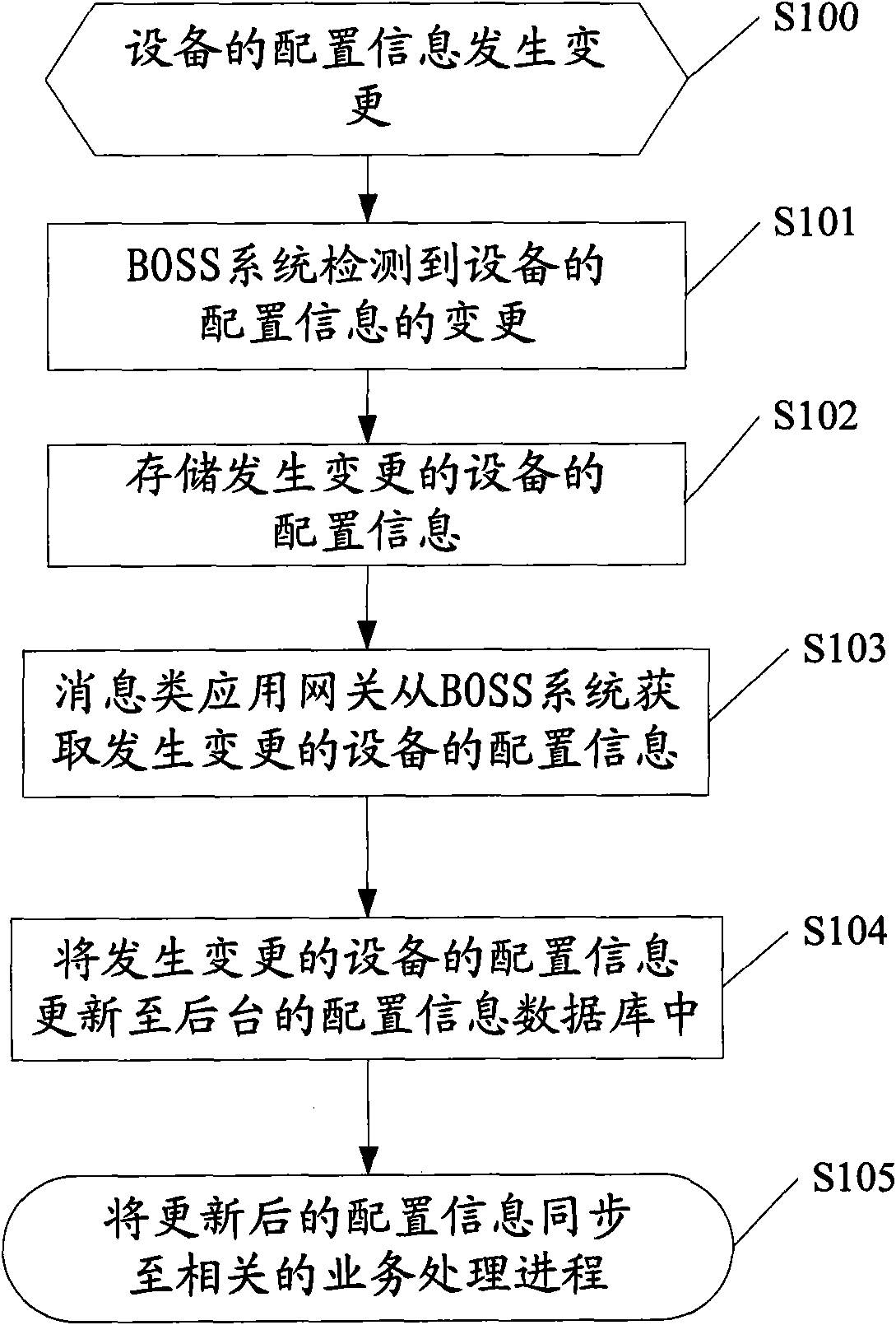

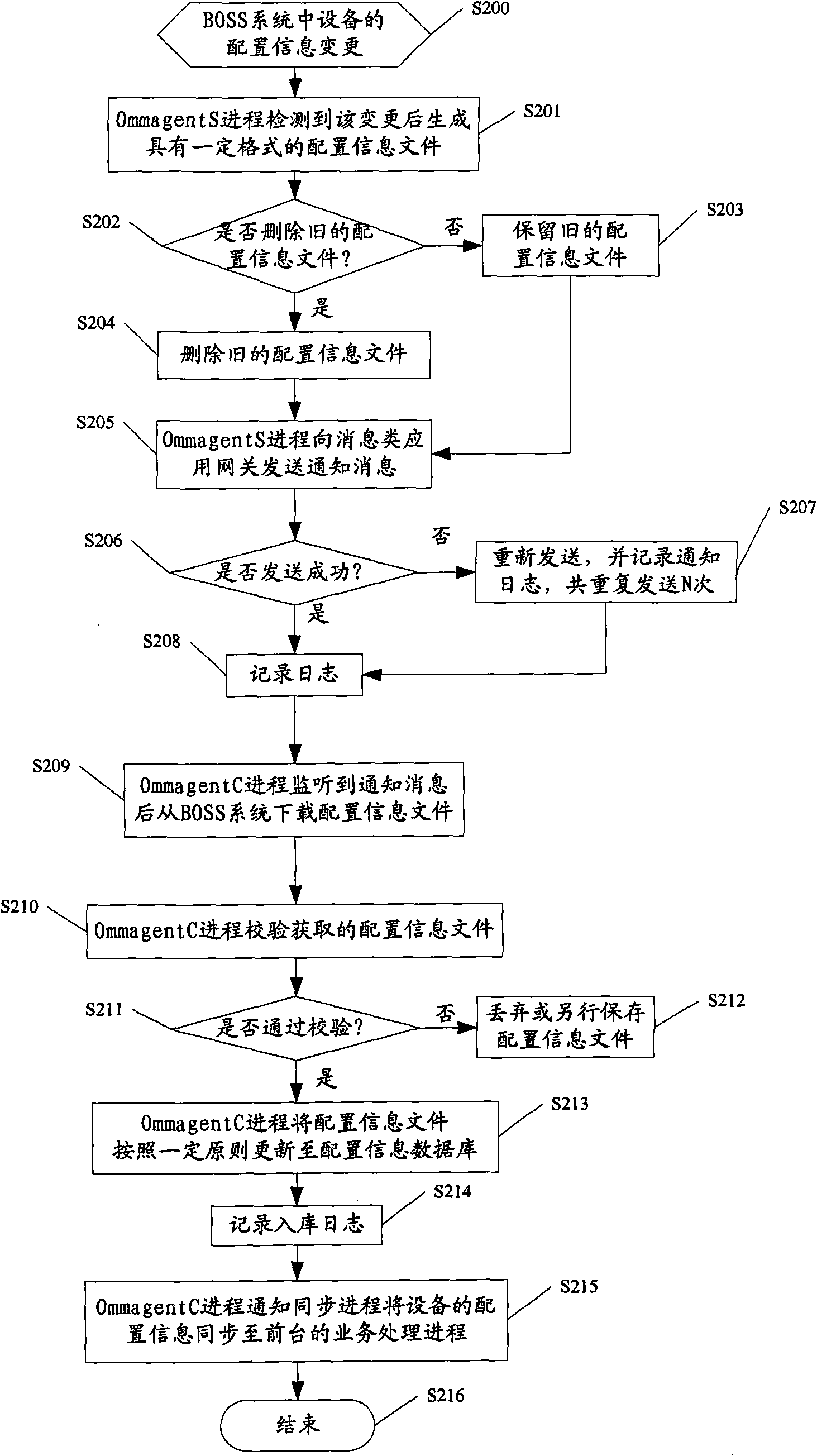

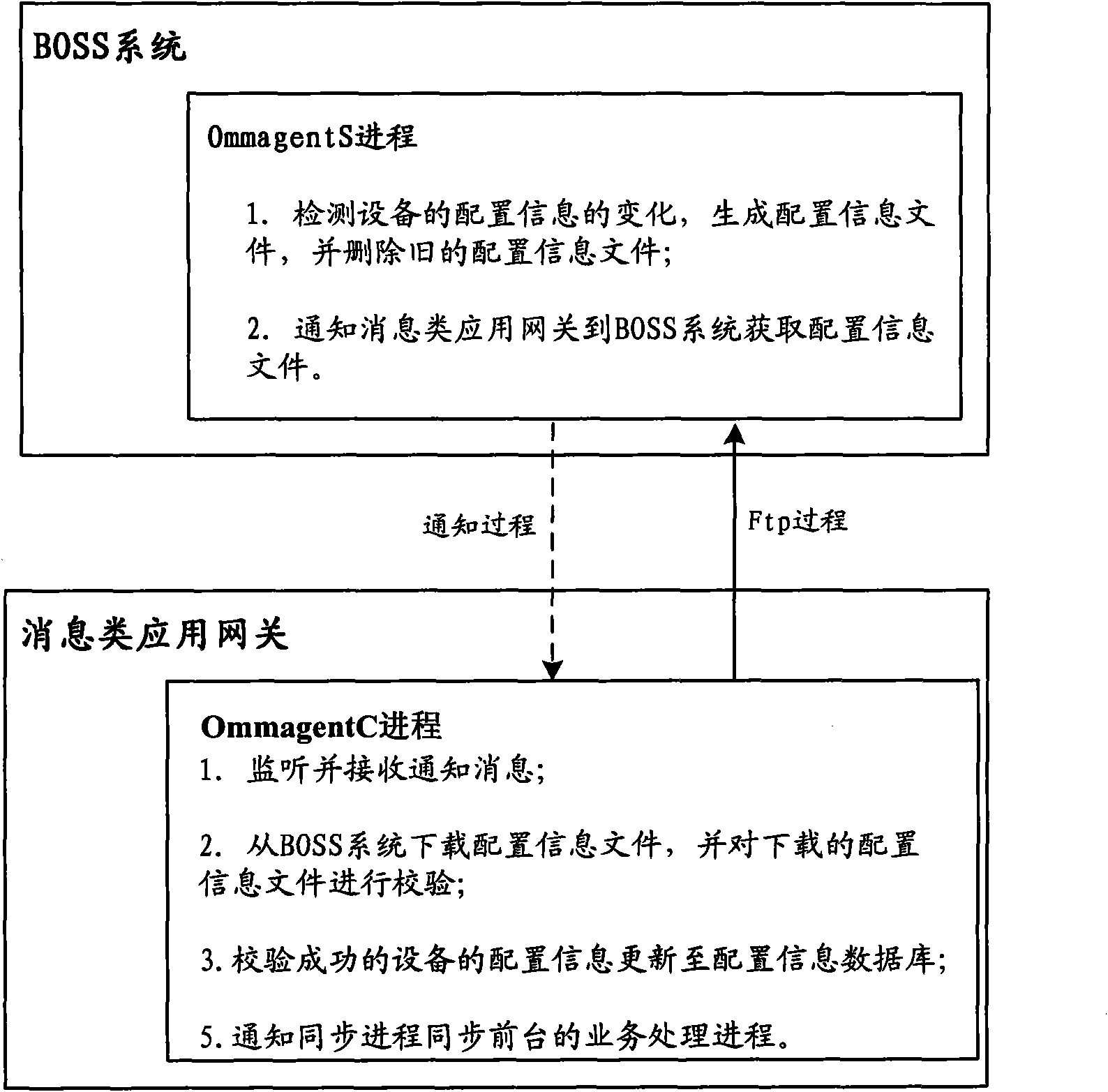

Method and system for updating equipment configuration information of message-type application gateway

ActiveCN101640867ARealize automatic maintenanceImprove accuracyCommmunication supplementary servicesSupporting systemMessage type

The invention discloses a method and a system for updating equipment configuration information of a message-type application gateway. The method comprises the following steps: a service operation supporting system stores changed equipment configuration information when the equipment configuration information changes; the message-type application gateway obtains the changed configuration information from the service operation supporting system and updates a background configuration information database with the changed configuration information; and the message-type application gateway synchronizes a foreground service-processing process with the updated equipment configuration information in the background configuration information database. The method and the system for updating the equipment configuration information of the message-type application gateway automatically maintain the configuration information of various kinds of equipment, remarkably improve the configuration efficiency and enhance the accuracy and the reliability of data processing.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com