Preparation method of highly-oriented carbon nanotube paper

A carbon nanotube paper and carbon nanotube technology, applied in nanotechnology and other directions, can solve the problems of complex preparation process, limited application of carbon nanotube paper, and high equipment requirements, and achieve the effect of simple and efficient process and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

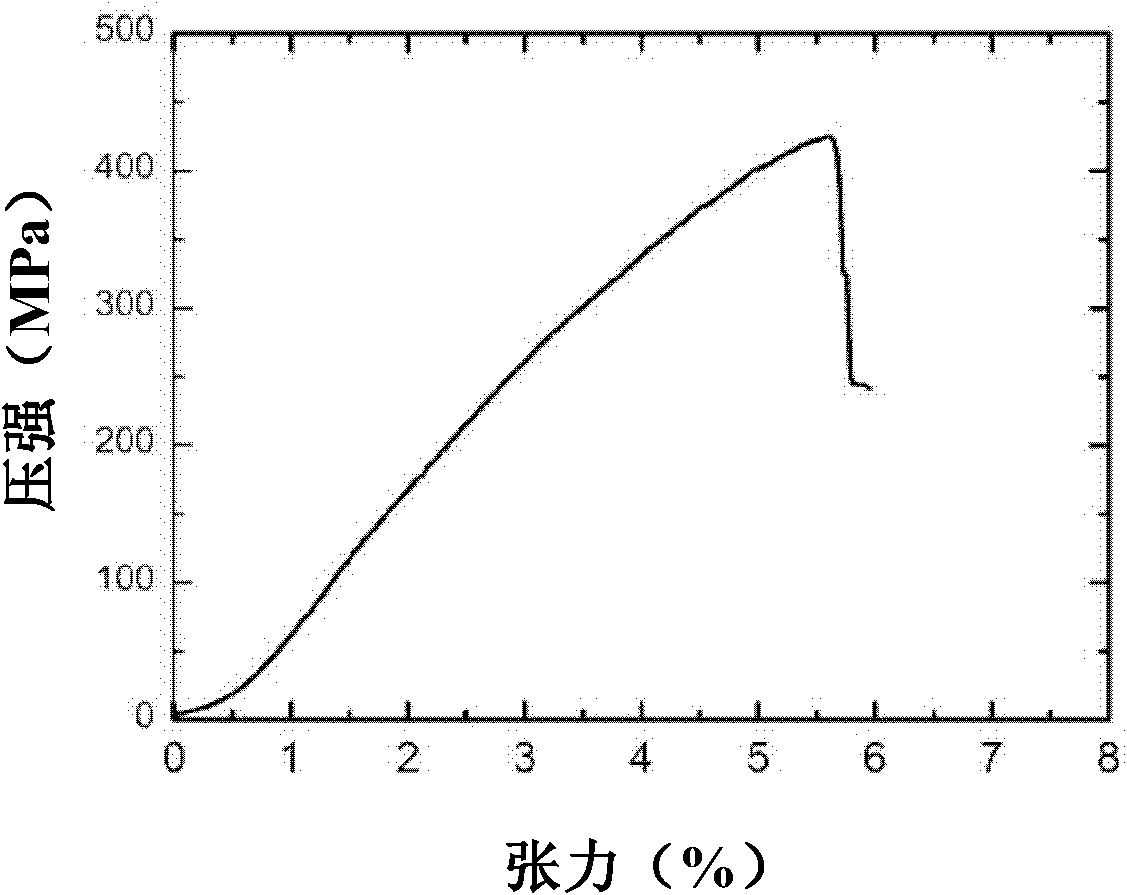

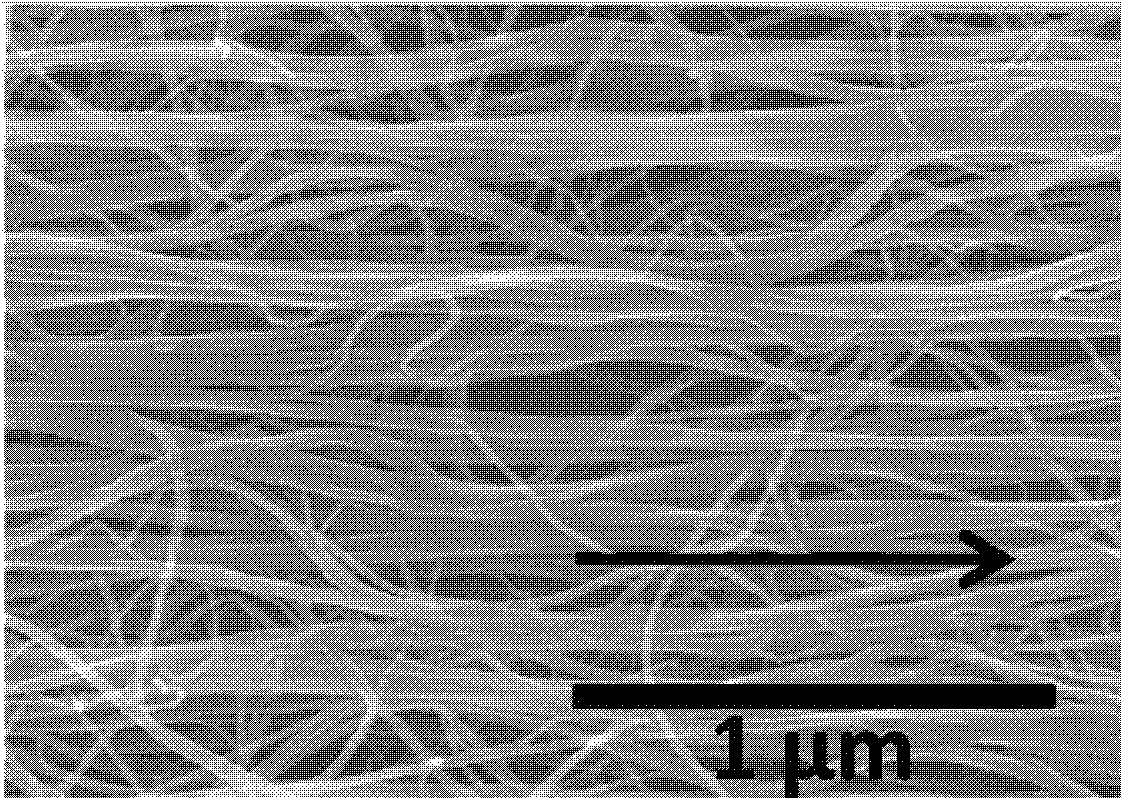

[0026] Preparation of High Strength and High Orientation Carbon Nanotube Paper

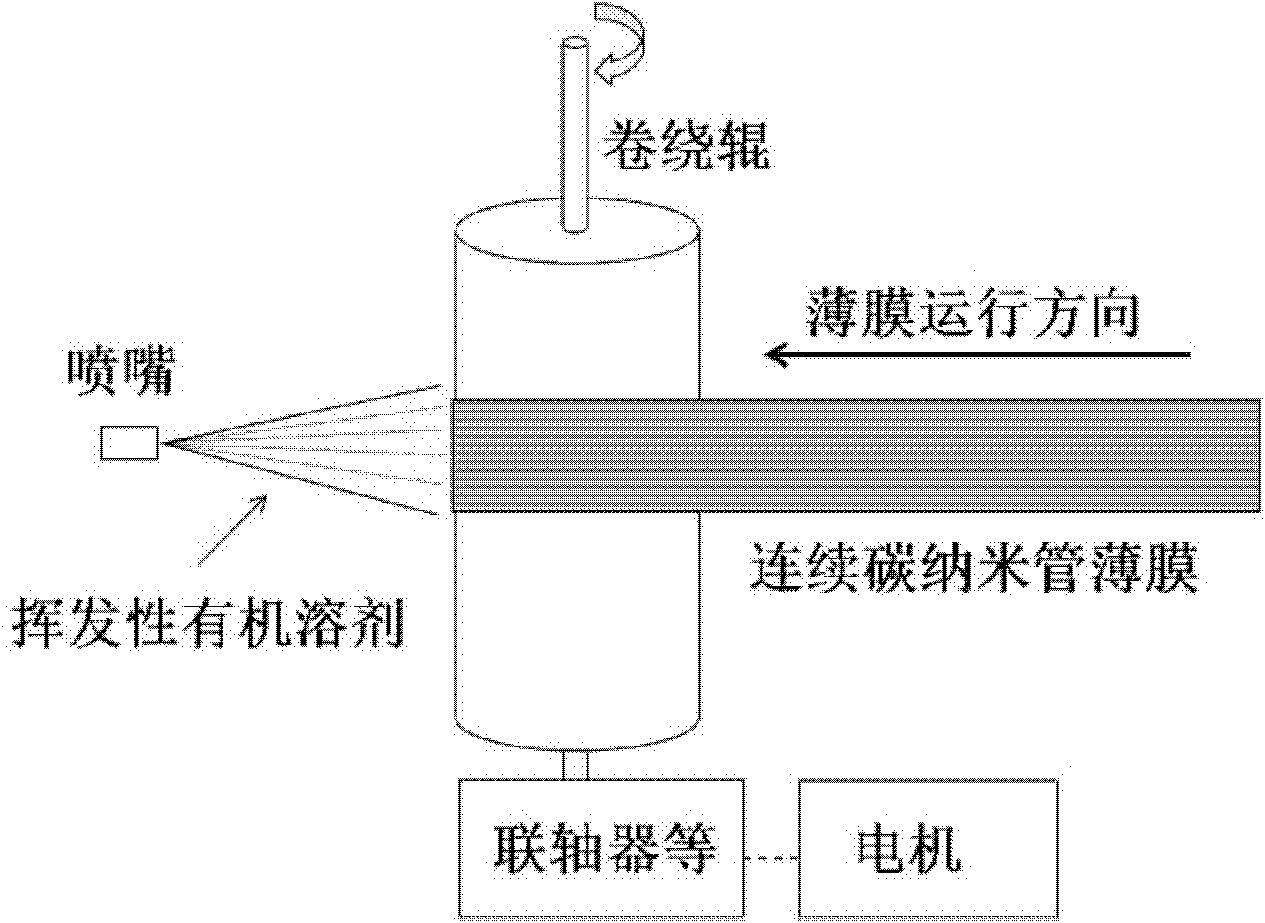

[0027] (1) Production of the winding device: the main component of the winding device is a winding roller made of stainless steel, and a glass tube with an outer diameter of 3 cm is set on the winding roller. The winding roll is connected with a small motor through a coupling and a belt. The motor is controlled by an adjustable power supply to control the speed of the winding roller; (the outer diameter of the winding roller in this step can be adjusted according to actual requirements)

[0028] (2) After spraying the release agent on the outer glass tube of the winding roller, the carbon nanotube film is pulled out from the spinnable carbon nanotube array and glued to the glass tube, and the motor is driven by the rotation of the winding roller The operation of carbon nanotubes, the direction of operation is perpendicular to the winding axis; (the experimental parameters in this step are aimed a...

Embodiment 2

[0034] Preparation of ultrathin highly oriented carbon nanotube paper.

[0035] (1) Manufacturing of the winding device: the main component of the winding device is a winding roller made of glass, and a glass tube with an outer diameter of 3 cm is set on the winding roller. The winding roll is connected with a small motor through a coupling and a belt. The motor is controlled by an adjustable power supply to control the speed of the winding roller; (the outer diameter of the winding roller in this step can be adjusted according to actual requirements)

[0036] (2) Coating a layer of polymer film on the winding roller, winding the solid-phase stretched film carbon nanotube film with a width of more than 1 cm on the winding roller;

[0037] (3) while carrying out step (2), volatile solvent is sprayed on the winding roller surface that is wound with carbon nanotube film, and solvent is made up of ethanol, and film running speed is set to 5 millimeters per second;

[0038](4) Af...

Embodiment 3

[0040] Preparation of carbon nanotube paper with different internal orientations.

[0041] (1) Manufacturing of the winding device: the main component of the winding device is a winding roller made of stainless steel, and a glass tube with an outer diameter of 3 cm is set on the winding roller. The winding roll is connected with a small motor through a coupling and a belt. The motor is controlled by an adjustable power supply to control the speed of the winding roller; (the outer diameter of the winding roller in this step can be adjusted according to actual requirements)

[0042] (2) if Figure 4 As shown in (a), during the winding process, the carbon nanotube film is wound on the winding roller at a winding angle of 90°, and the film covers the entire surface of the winding roller by moving the winding roller horizontally.

[0043] (3) while carrying out step (2), volatile solvent is sprayed on the winding roller surface that is wound with carbon nanotube film, and solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com