Counterflow roller changing method for realizing online roller changing of ESP (endless strip production) finishing mill unit

A finishing rolling mill and countercurrent technology, applied in rolling mill control devices, metal rolling stands, metal rolling mill stands, etc., can solve the problems affecting the production efficiency of continuous casting and rolling of thin slabs, frequent roll changes, and roll wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

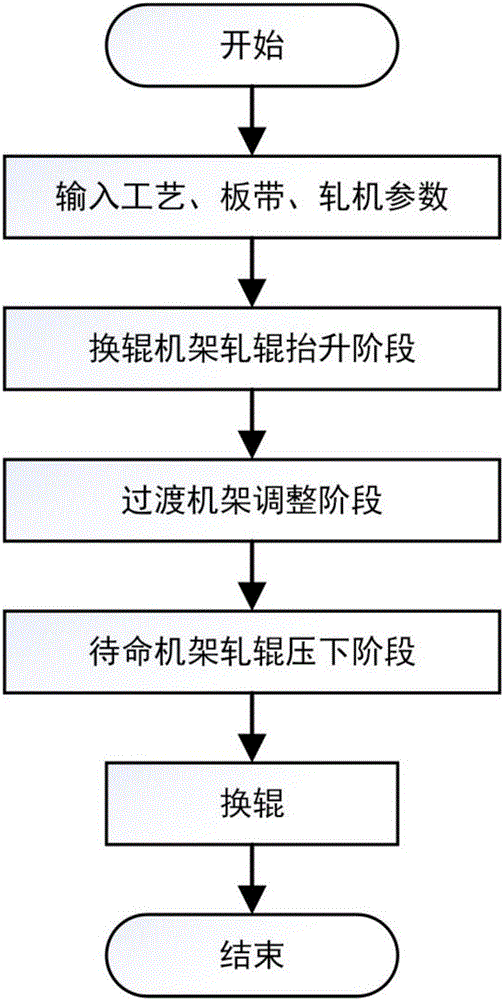

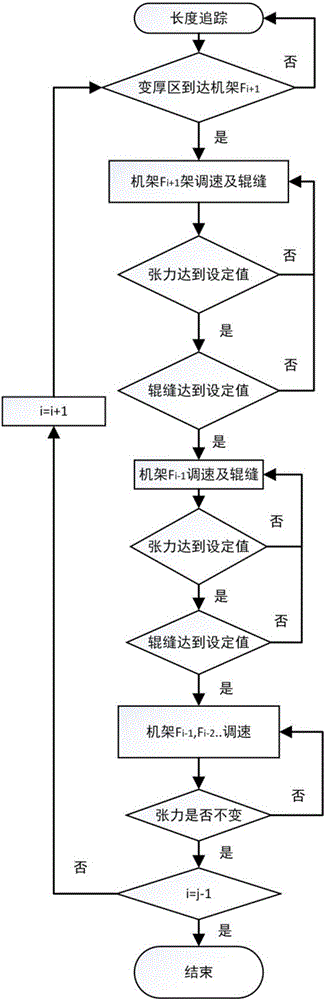

[0082] refer to Figure 1~4 , a kind of counter-current roll changing method that realizes ESP finishing mill line changing roll in the embodiment of the present invention comprises the following steps:

[0083] Step 1: Collect and input process, strip and mill parameters:

[0084] Described process, strip, rolling mill parameters include working roll diameter D, rolling mill stiffness K m , distance L between racks, rack F 1 ~F 6 Entrance thickness H 1 ~H 6 , outlet thickness h 1 ~ h 6 , unit front tension σ f,1 ~σ f,6 , unit back tension σ b,1 ~σ b,6 , the steel plate width b, the exit speed V of the final frame;

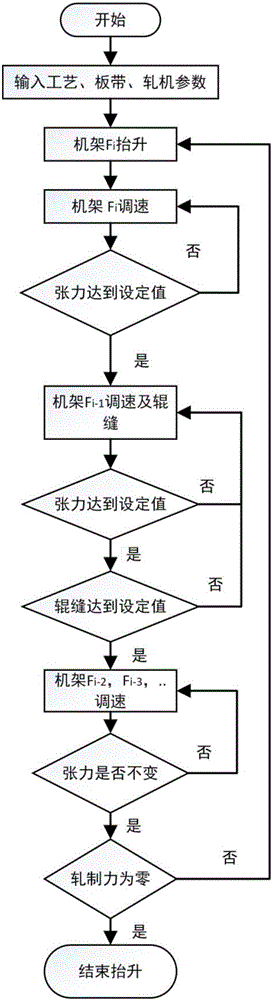

[0085] Step 2: Roll Change Rack F i Roll lifting and speed regulation stage:

[0086] 2.1) Roll changing stand F i Roll lift and speed regulation:

[0087] 2.1a) From the roll changing stand F i From the moment the roll is lifted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com