Mixing preparation method of pulp of lithium ion battery

A lithium-ion battery and slurry technology, applied in electrode manufacturing and other directions, can solve the problems of large gap between the front and back of the coating, poor battery consistency, and difficulty in stirring evenly, and achieve the improvement of consistency, production efficiency, and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

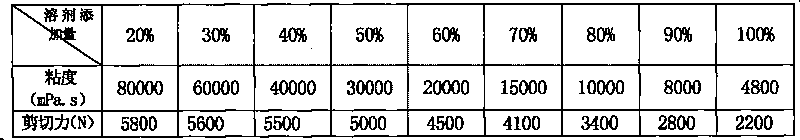

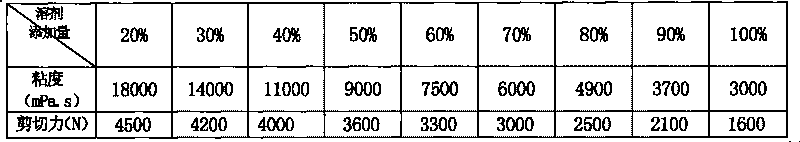

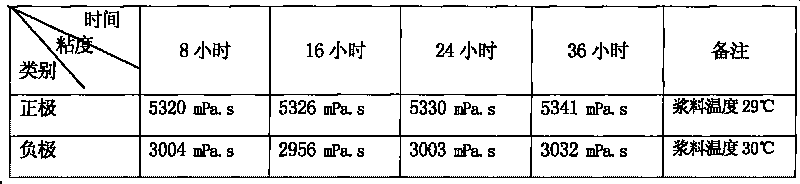

[0034] Embodiment 1: a. Weigh the raw materials according to the positive electrode battery slurry proportioning, and its mass ratio is positive electrode active material: binder: KS6: Carbon ECP=96: 2: 1: 1, wherein the solvent is N-methylpyrrolidone , NMP accounts for 40% of the mass percentage of the positive electrode active material, the binding agent is polyvinylidene fluoride PVDF, the conductive agent is KS6 type conductive graphite and Carbon ECP conductive carbon black, and the active material is lithium cobaltate; b. take the raw material Mix the solvent and binder in the raw material, stir fully, take the conductive agent in the raw material, active material mix and fully stir; c. take the mixture of 50% binder and solvent in step b and all the conductive agent, active material The mixture is mixed and fully stirred evenly; d. The remaining amount of binder and solvent mixture is added to the mixture in step c and stirred evenly. At this time, the viscosity of the o...

Embodiment 2

[0035] Embodiment 2: a. Weigh the raw materials according to the positive electrode battery slurry ratio, and its mass ratio is positive electrode active material: binder: KS6: Carbon ECP=85: 6: 4: 5, wherein the solvent is N-methylpyrrolidone , NMP accounts for 50% by mass of the positive electrode active material, the binder is polyvinylidene fluoride PVDF, the conductive agent is KS6 type conductive graphite and Carbon ECP conductive carbon black, and the active material is the ternary material nickel cobalt lithium manganese oxide; b. get the solvent in the raw material and the binder to mix, fully stir evenly, get the conductive agent in the raw material, the active material mix and fully stir; c. get the mixture of 60% of the binder and the solvent in step b and all Mix the conductive agent and the active material mixture, and stir well; d. Add the remaining binder and solvent mixture to the mixture in step c and stir evenly. At this time, the viscosity of the slurry obta...

Embodiment 3

[0036] Embodiment 3: a. Weigh the raw materials according to the positive electrode battery slurry ratio, and its mass ratio is positive electrode active material: binder: KS6: Carbon ECP=92: 5.5: 1.25: 1.25, wherein the solvent is N-methylpyrrolidone , NMP accounts for 48% of the mass percentage of the positive electrode active material, the binding agent is polyvinylidene fluoride PVDF, the conductive agent is KS6 type conductive graphite and Carbon ECP conductive carbon black, and the active material is lithium iron phosphate; Mix the solvent and binder in the raw material, stir well, take the conductive agent in the raw material, active material mix and fully stir; c. take the mixture of 40% binder and solvent in step b and all the conductive agent, active material The mixture is mixed and fully stirred evenly; d. The remaining amount of binder and solvent mixture is added to the mixture in step c and stirred evenly. At this time, the viscosity of the obtained slurry is 520...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com