Electroplating wastewater zero-discharge or low-discharge handling method

A technology of electroplating wastewater and treatment methods, which is applied in the directions of heating water/sewage treatment, adsorption water/sewage treatment, light water/sewage treatment, etc., and can solve the problem that most or all of the water cannot be reused, and effective separation and recovery cannot be performed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A large-scale electroplating enterprise produces about 700 cubic meters of wastewater every day. The wastewater is classified into three routes. The first wastewater is pickling wastewater. The total amount is 200 cubic meters per day. The main components are: iron 362mg / l, pH value 2.9, Total dissolved solids 2200mg / L, grease 332mg / L, calcium and magnesium 446mg / L, total chlorine 917mg / L. The second waste water is cyanide-containing waste water, with a total amount of 200 cubic meters per day. The composition is: CN - 60mg / L, copper 6.1mg / L, zinc 117mg / L, iron 0.1mg / L, pH8.6. The third waste water is electroplating mixed waste water and passivation waste water, the total amount is 300 cubic meters per day, and the composition is: total chromium 73.6mg / L, hexavalent chromium 59.8mg / L, copper 11.34mg / L, nickel 34.5mg / L , Zinc 64.6mg / L, Iron 6.1mg / L, CN - 10mg / L, pH1.8.

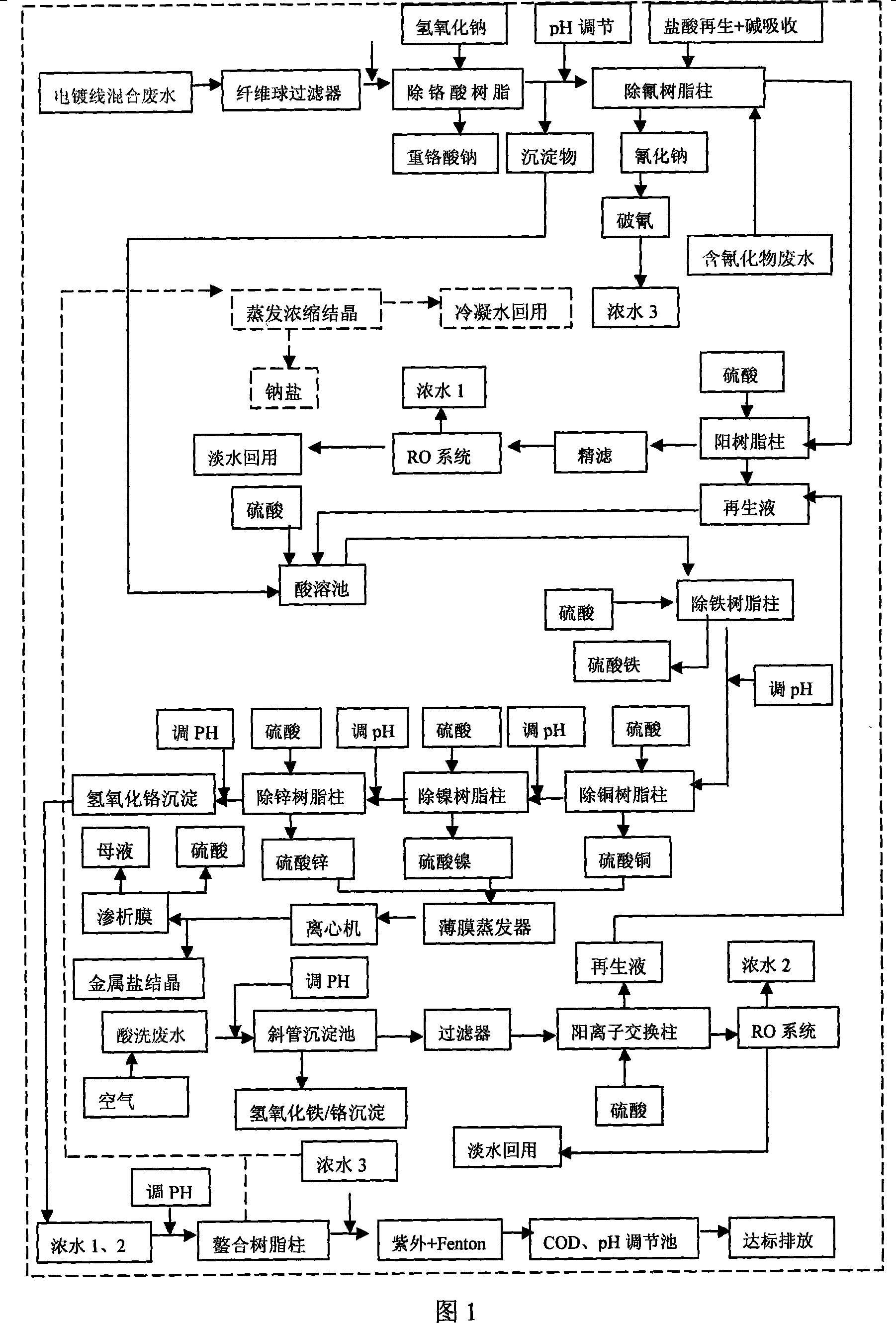

[0074] Fig. 1 is the technical process of the present embodiment, and its processing steps are:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com