Patents

Literature

43 results about "Chemical reaction engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical reaction engineering (reaction engineering or reactor engineering) is a specialty in chemical engineering or industrial chemistry dealing with chemical reactors. Frequently the term relates specifically to catalytic reaction systems where either a homogeneous or heterogeneous catalyst is present in the reactor. Sometimes a reactor per se is not present by itself, but rather is integrated into a process, for example in reactive separations vessels, retorts, certain fuel cells, and photocatalytic surfaces. The issue of solvent effects on reaction kinetics is also considered as an integral part.

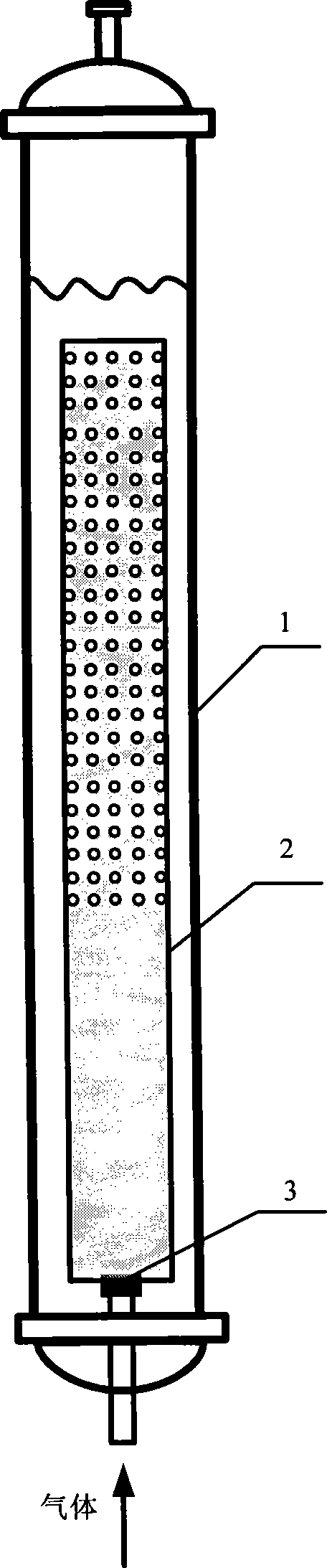

Air-lift type circular current reactor

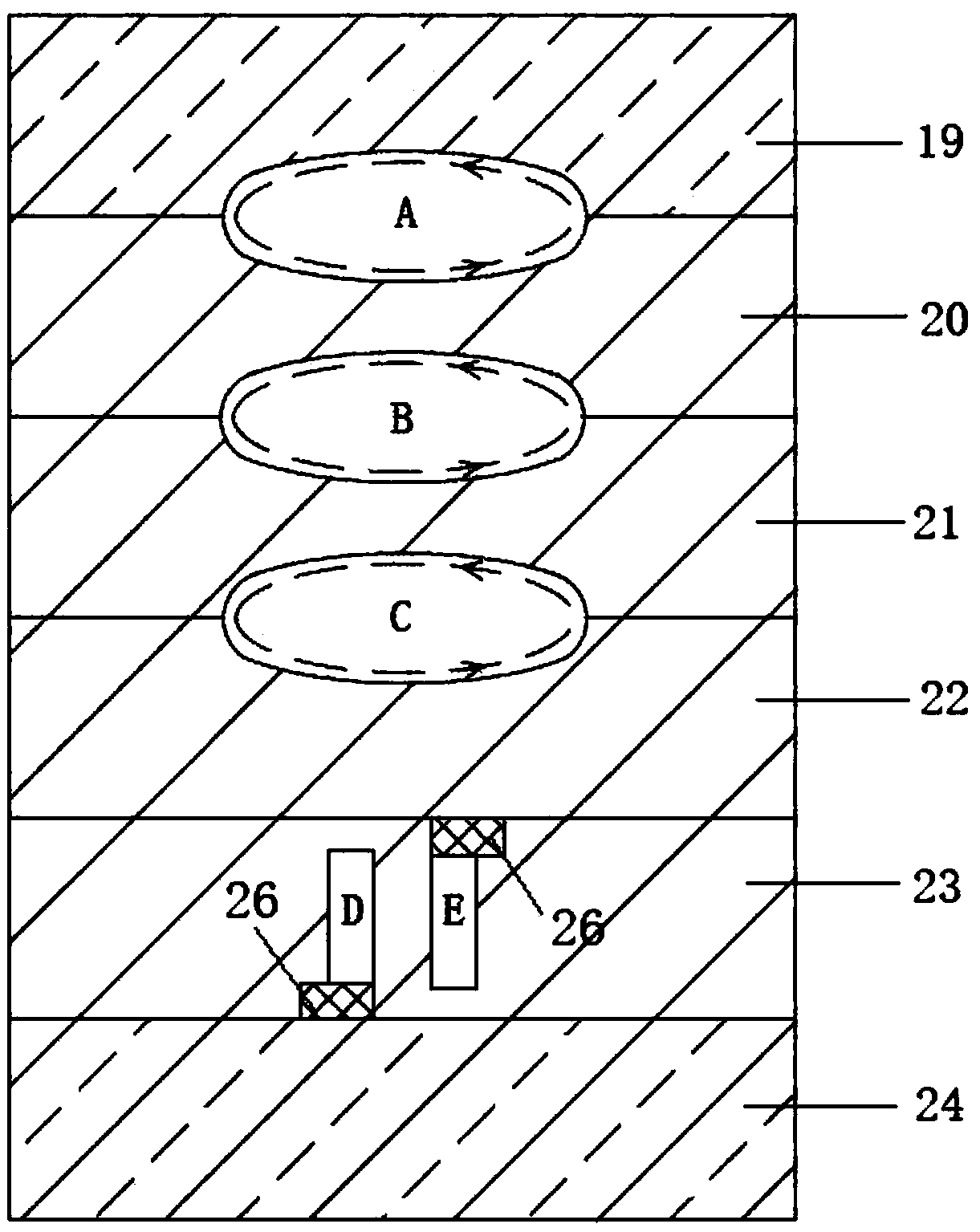

InactiveCN101249405AIncrease gas holdupImprove efficiencyLiquid-gas reaction processesDiameter ratioEngineering

A loop reactor with a porous guide flow cylinder is applied in gas-liquid two-phase reaction or gas-liquid-solid three-phase reaction and belongs to chemical reaction engineering field. The guide flow cylinder is characterized in including an upper sealing section and a lower hole opened section. Distribution holes are opened on the hole opened section at a certain ratio, and both gas and liquid can flow out of the holes. After gas enters the guide flow cylinder through a gas distributor, gas and liquid flow out of the gas distribution holes of the hole opened section and the top of the guide flow cylinder and downwards into the guide flow cylinder from the bottom of the guide flow cylinder to form a circulation flow. Gas flowing out of the hole opened section is carried by fluid and descends to the reactor bottom. Even when the height / diameter ratio of the reactor is larger, the reactor bottom can have a high gas content. Therefore, the multi-hole guide flow cylinder breaks through a limit of a conventional circulation flow reactor on height / diameter ratio, and satisfies requirement of height / diameter ratio of a circulation flow reactor in industrial application.

Owner:SINOPEC YANGZI PETROCHEM

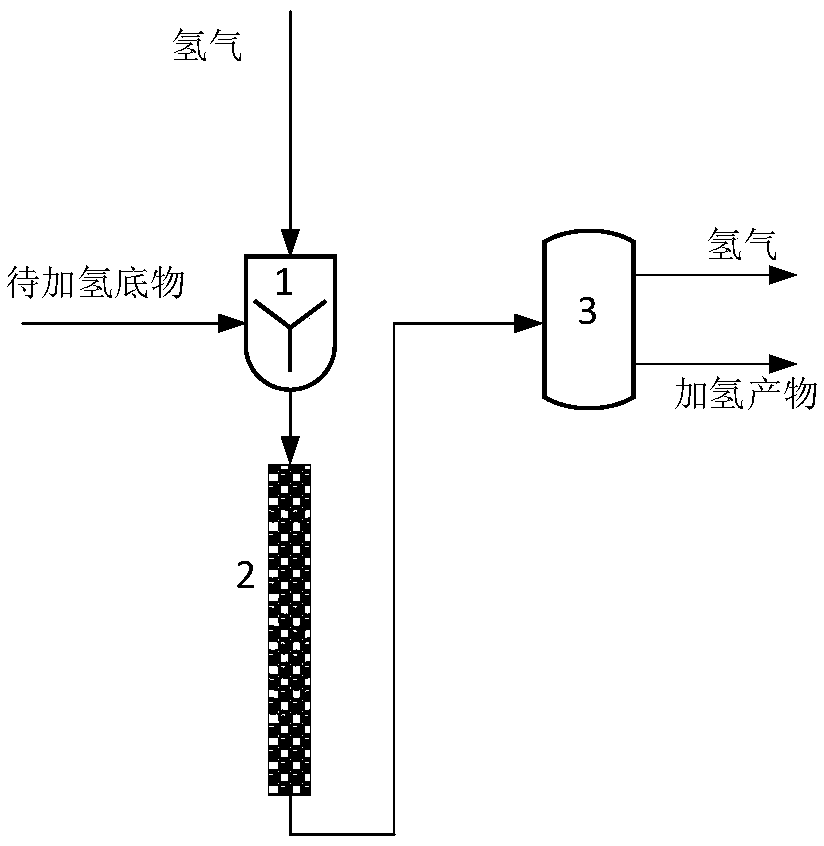

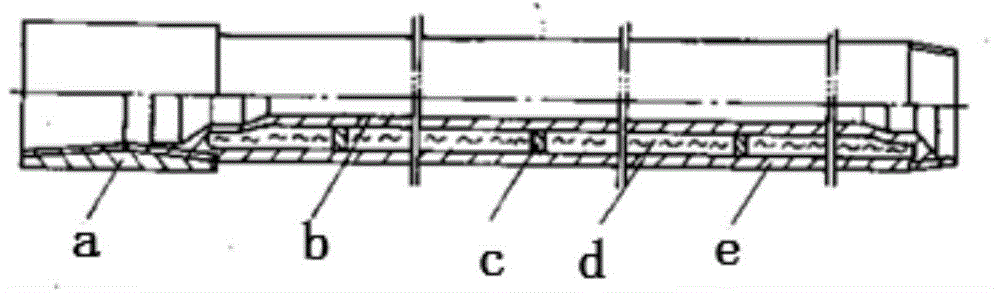

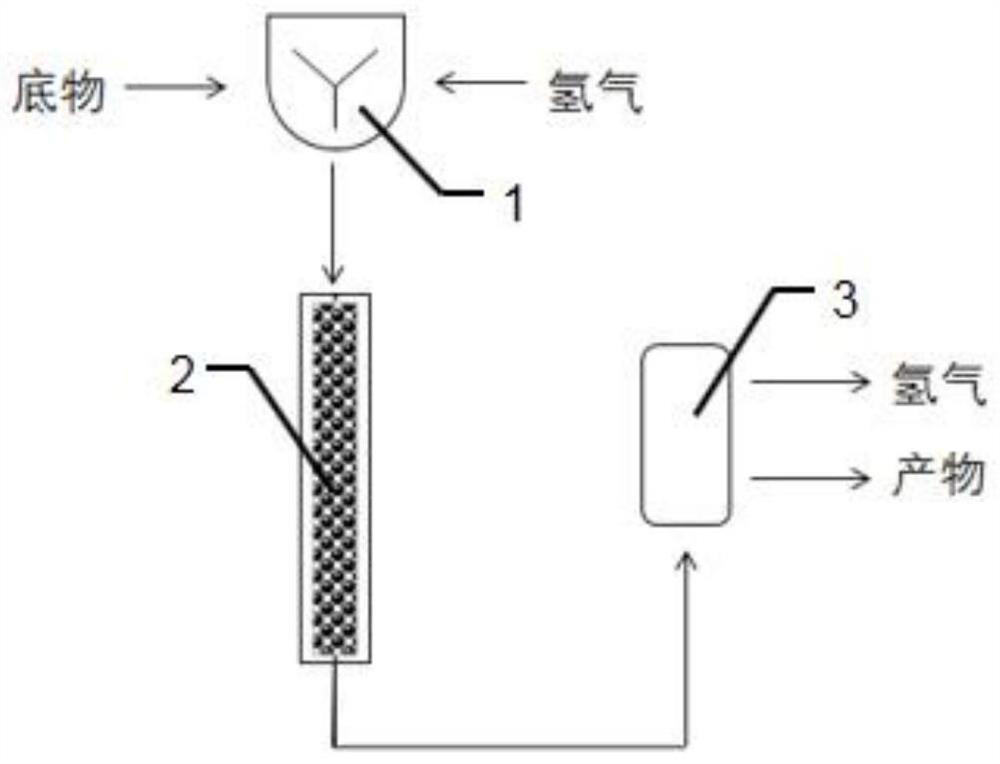

Hydrogenation reaction device in micropacked bed and method for hydrogenation reaction by using same

ActiveCN109225073AIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPetrochemicalChemical reaction engineering

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

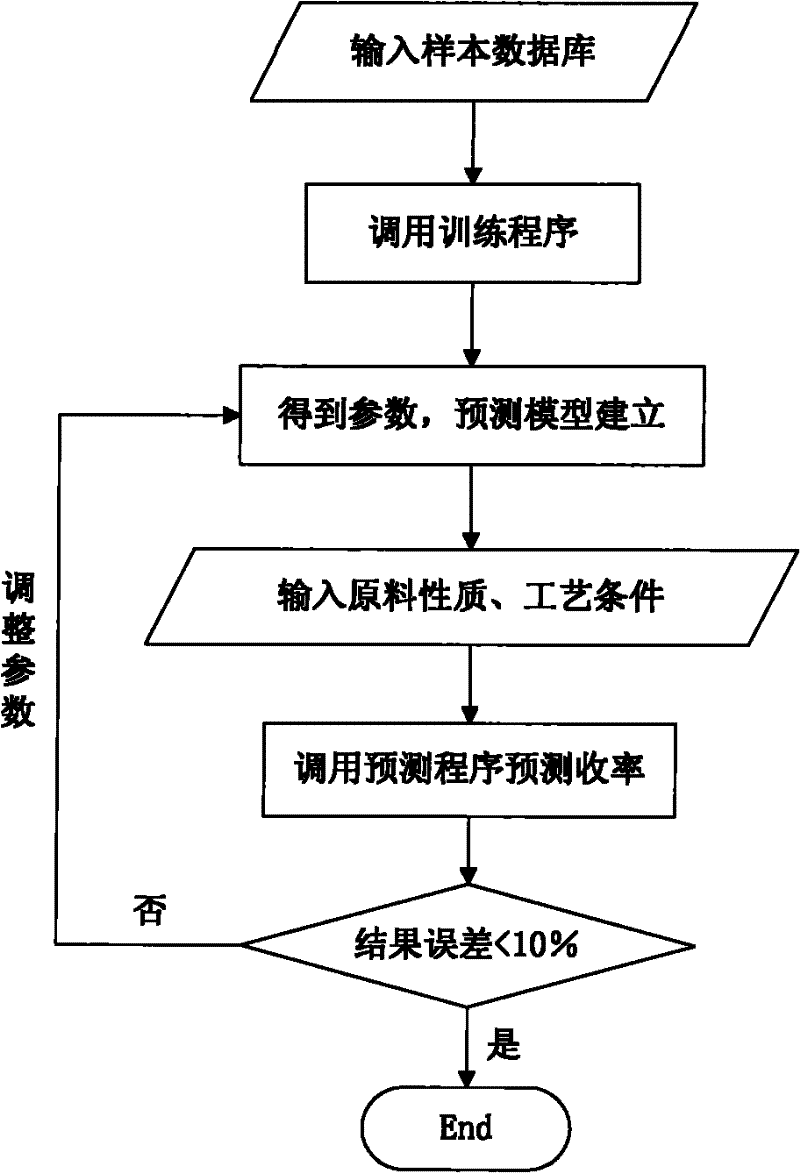

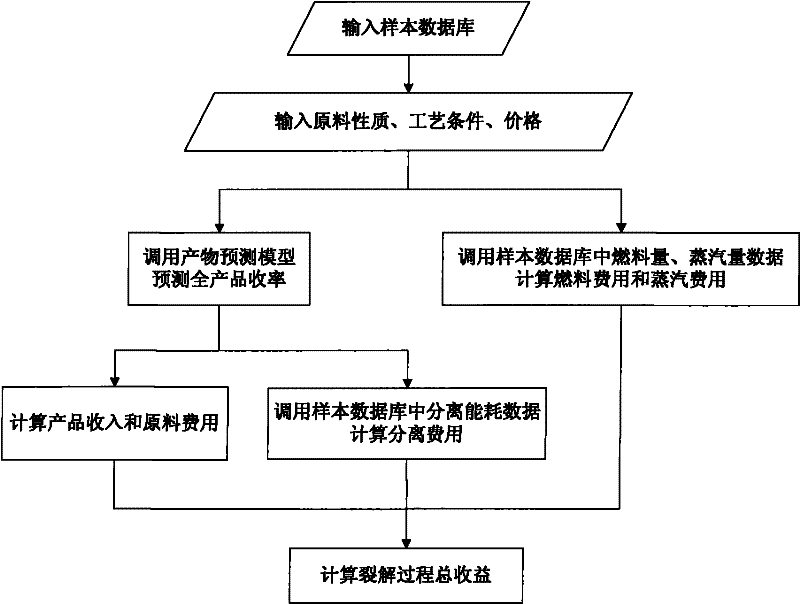

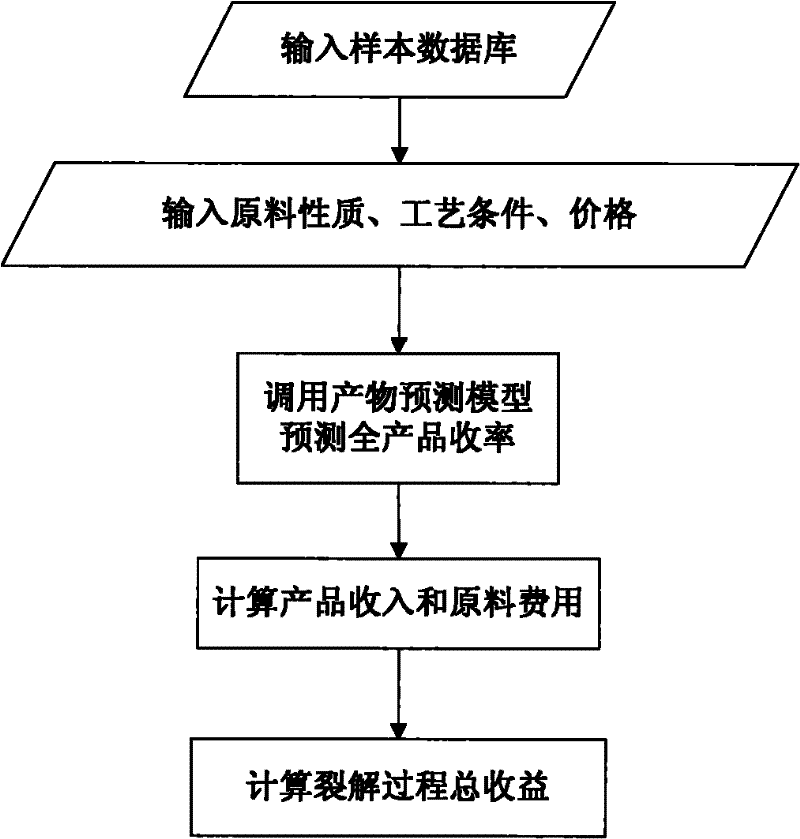

Method for optimizing value of ethylene device

ActiveCN102213949AExtended operating cycleSmall cleaning costThermal non-catalytic crackingAdaptive controlEconomic benefitsProcess engineering

The invention belongs to the field of chemical reaction engineering and particularly relates to a method for optimizing the operation of an ethylene cracking device. In the method provided by the invention, value maximization is utilized as a scale and the operation optimization scheme of a cracking furnace is formulated aiming at the constitution and market price of different raw materials and the process characteristics of the device by virtue of establishing a yield prediction model, a value prediction model and a value optimization model. After the optimization scheme provided by the invention is adopted, the optimal cracking temperature is lower than the cracking temperature obtained by the optimization scheme which is formulated by the maximum yield of principal products such as ethylene and the like; the operating period of the device is effectively prolonged; the decoking cost is lower; the separation energy consumption is reduced; the potential of the processing capability of the device is further enhanced; and the highest economic benefits are simultaneously obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

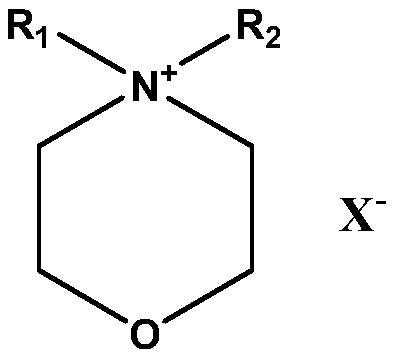

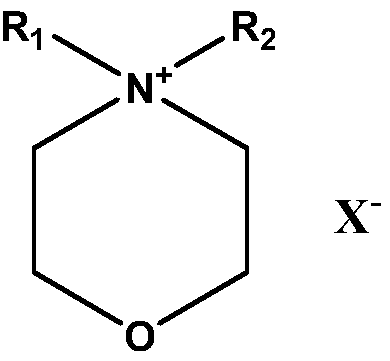

Application method of catalysts capable of synthesizing cyclic carbonate under normal temperature and atmosphere

ActiveCN108707131AHigh activityLow priceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyMorpholine

The invention discloses an application method of catalysts capable of synthesizing cyclic carbonate under normal temperature and atmosphere and relates to the field of chemical reaction engineering. The application method of the catalysts capable of synthesizing cyclic carbonate under the normal temperature and atmosphere includes the steps that an epoxy compound and carbon dioxide are adopted asreactants, a morpholine ionic liquid or ionic liquid crystal is adopted as the main catalyst, and a metal inorganic salt the chemical formula of which is MY is adopted as the auxiliary catalyst, wherein without presence of organic solvents, the reaction temperature is 25-40 DEG C, the reaction time is 1-24 hours, the reaction pressure is 0.1 Mpa, and the molar proportion of the reactants to the catalysts is (100:1)-(10:1); the epoxy compound and carbon dioxide are subjected to a cycloaddition reaction to obtain cyclic carbonate. The reaction conditions are mild and friendly, the reaction can be carried out under the normal temperature and pressure, the technological process is simple, and meanwhile, the morpholine ionic liquid or ionic liquid crystal is adopted as the main catalyst. Prepared cyclic carbonate is adjustable in structure, high in the stability and easy to separate and can be used repeatedly several times without changing the catalytic activity, and the auxiliary catalystand the main catalyst are low in price and high in activity.

Owner:WUHAN IL CHEM TECH

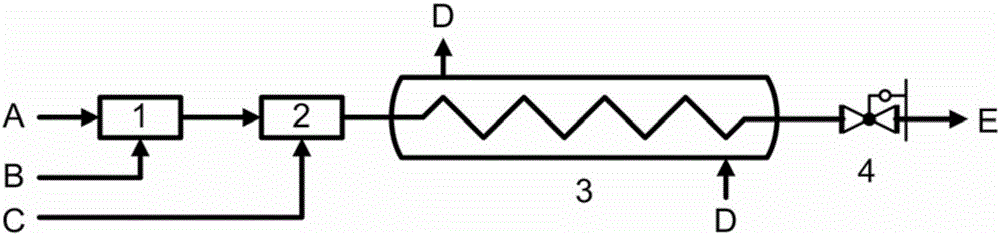

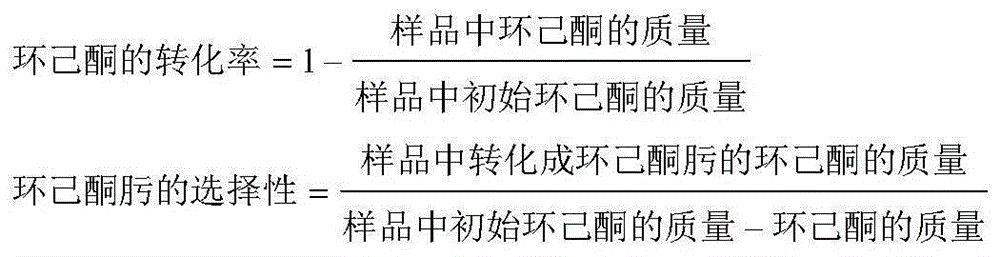

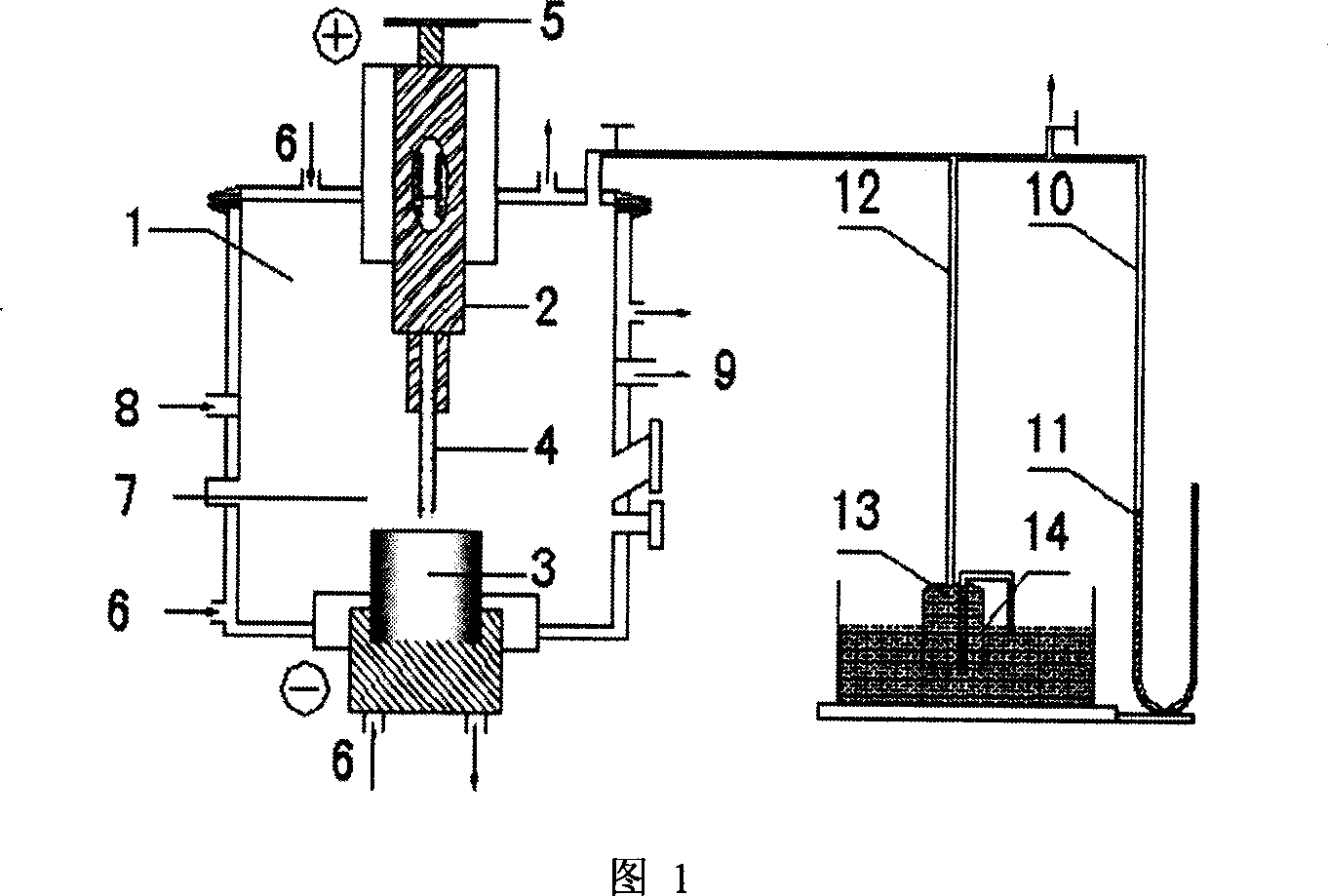

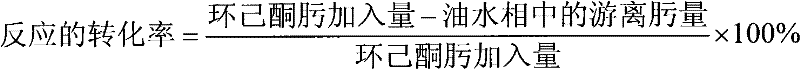

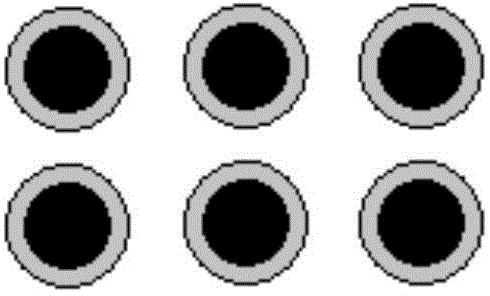

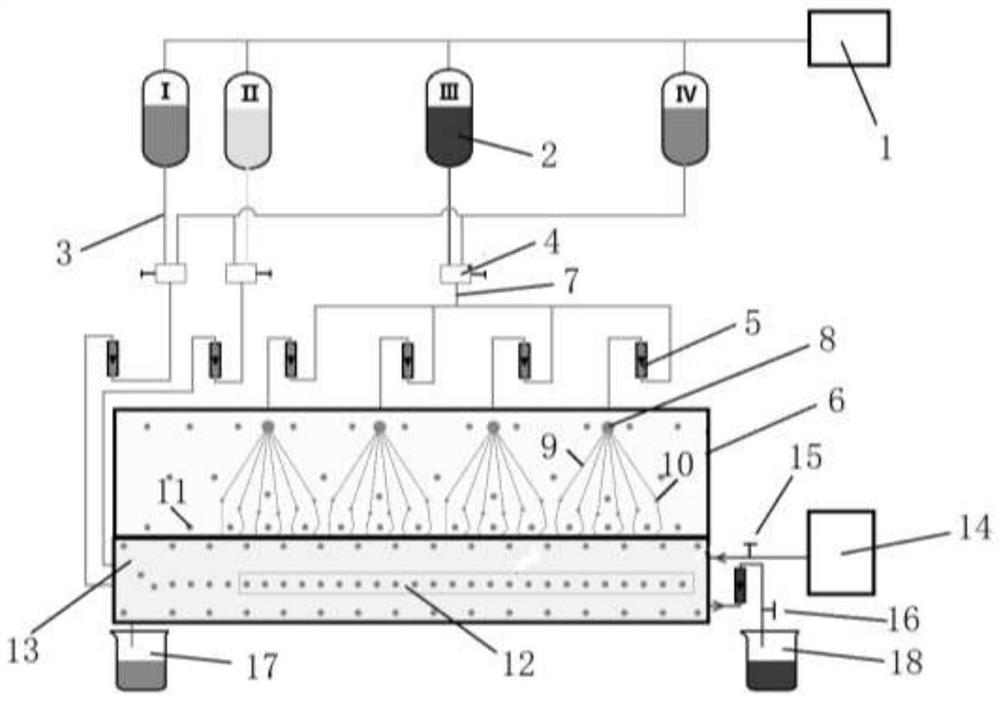

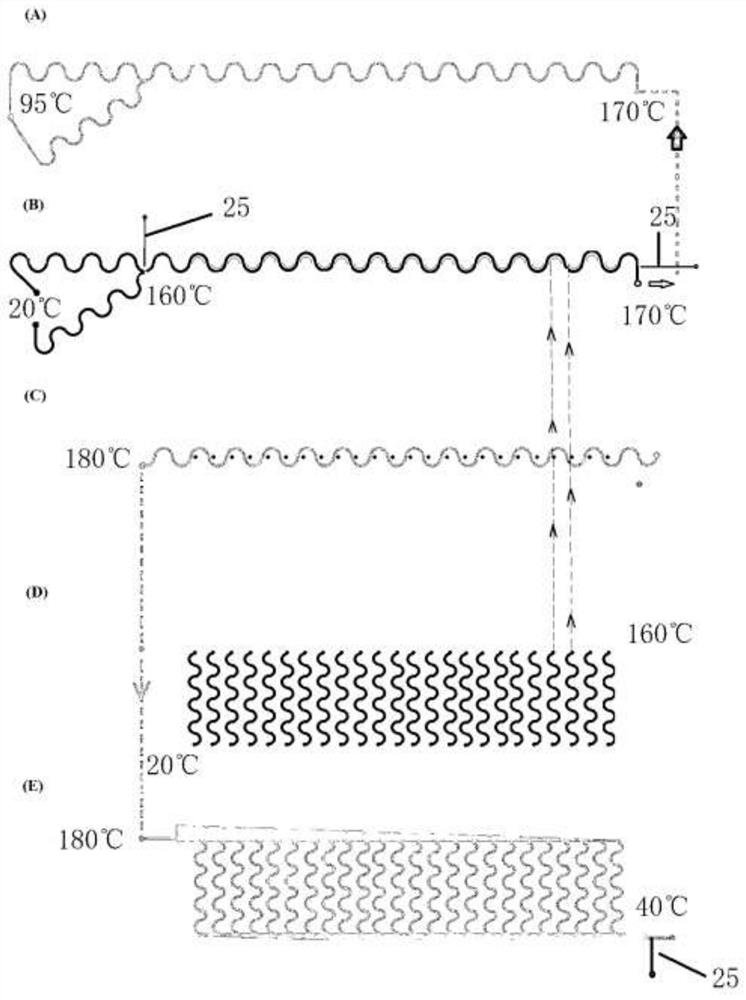

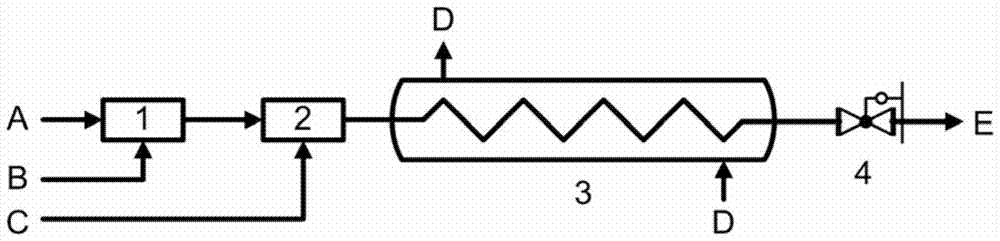

System and method for synthesizing cyclohexanone-oxime by micro-reactor

ActiveCN105017068ASmall stagnationImprove controllabilityOximes preparationSlurryChemical reaction engineering

The invention discloses a system and a method for synthesizing cyclohexanone-oxime by a micro-reactor and belongs to the field of chemical reaction engineering. The system is composed of a first micro-mixer, a second micro-mixer, a reaction pipeline provided with a heat exchange jacket and a counterbalance valve which are connected in series. The method comprises: firstly mixing slurry containing a titanium silicon molecular sieve and ammonia with a hydrogen peroxide solution by using the first micro-mixer; then dispersing cyclohexanone into the mixed slurry by using the second micro-mixer to initiate ammoximation reaction; and finally accomplishing the reaction process in the reaction pipeline. The system can achieve a high conversion rate (greater than 99%) and high selectivity (greater than 99%) within a reaction time of 0.5-20 minutes. The material stagnation amount of materials in the micro-reaction system is small, so that the controllability and the safety of ammoximation reaction are improved.

Owner:TSINGHUA UNIV

Self-supportable fuel cell catalyst layer with gradient distribution structure

InactiveCN107665997AIncrease profitIncreased durabilityCell electrodesElectrochemical responseOrganic synthesis

The invention relates to a self-supportable fuel cell catalyst layer with a gradient distribution structure. The catalyst layer can realize the gradient distribution of a catalyst active center, a proton channel and a mass transfer channel. Compared with the prior art, the self-supportable fuel cell catalyst layer not only can provide more active centers and a bigger gas-liquid-solid three-phase reaction interface and has the characteristics of smooth proton channel and product / reactant mass transfer channel at the same time. By adopting the self-supportable fuel cell catalyst layer, the utilization rate and electrochemical cyclic stability of the catalyst active center can be improved, and the diffusion of a reaction raw material and a product can be promoted; moreover, the self-supportable fuel cell catalyst layer has the advantages of simple production process and easiness in mass preparation. The performance of the catalyst layer can be improved, and the production cost can be decreased. The catalyst layer obtained by the invention not only can be applied to the field of energy storage and conversion, such as proton exchange membrane fuel cells (PEMFC) and other power supply systems, but also can be applied to the fields such as electrochemical organic synthesis, electrochemical reaction engineering and chemical reaction engineering.

Owner:TONGJI UNIV

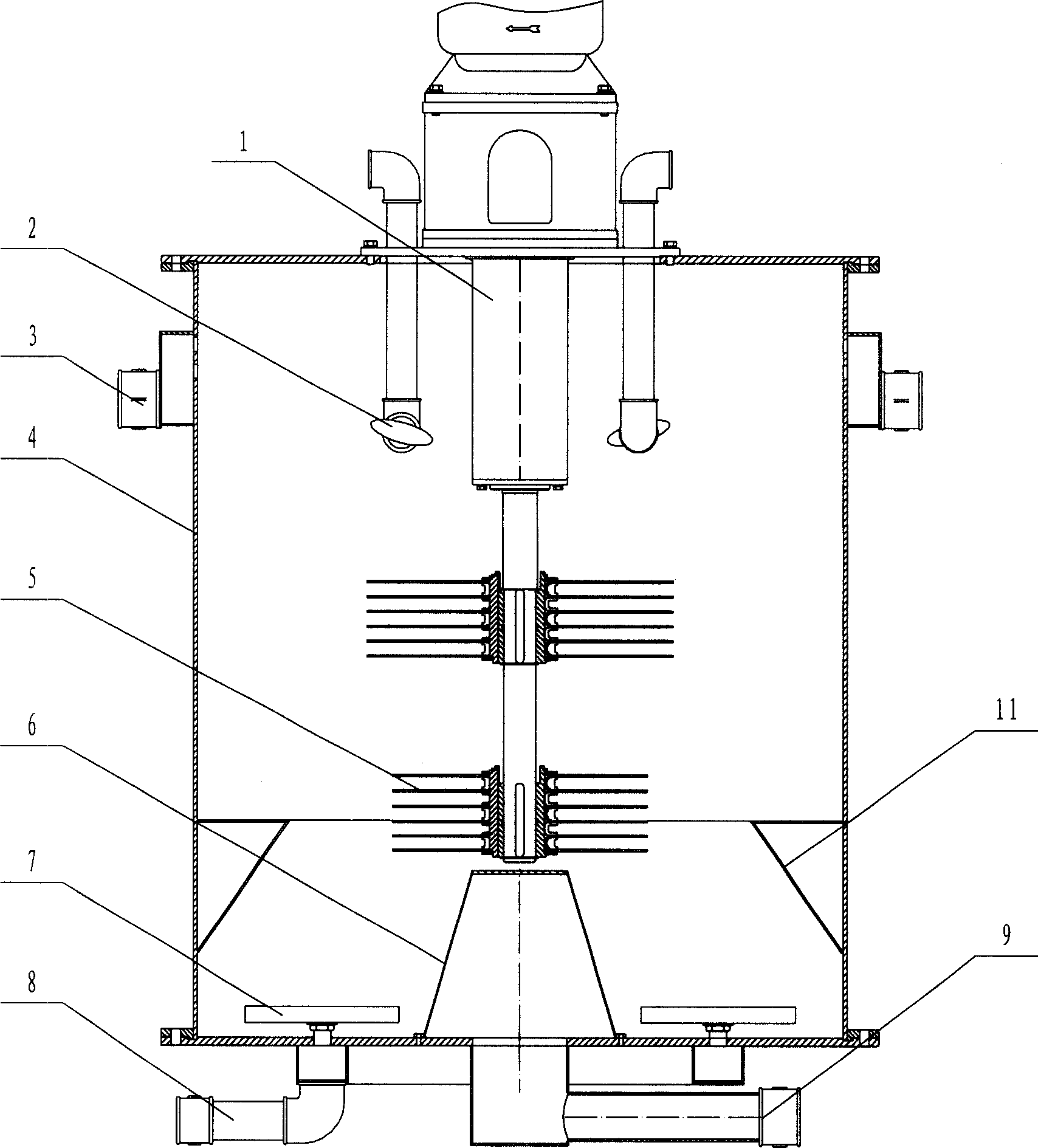

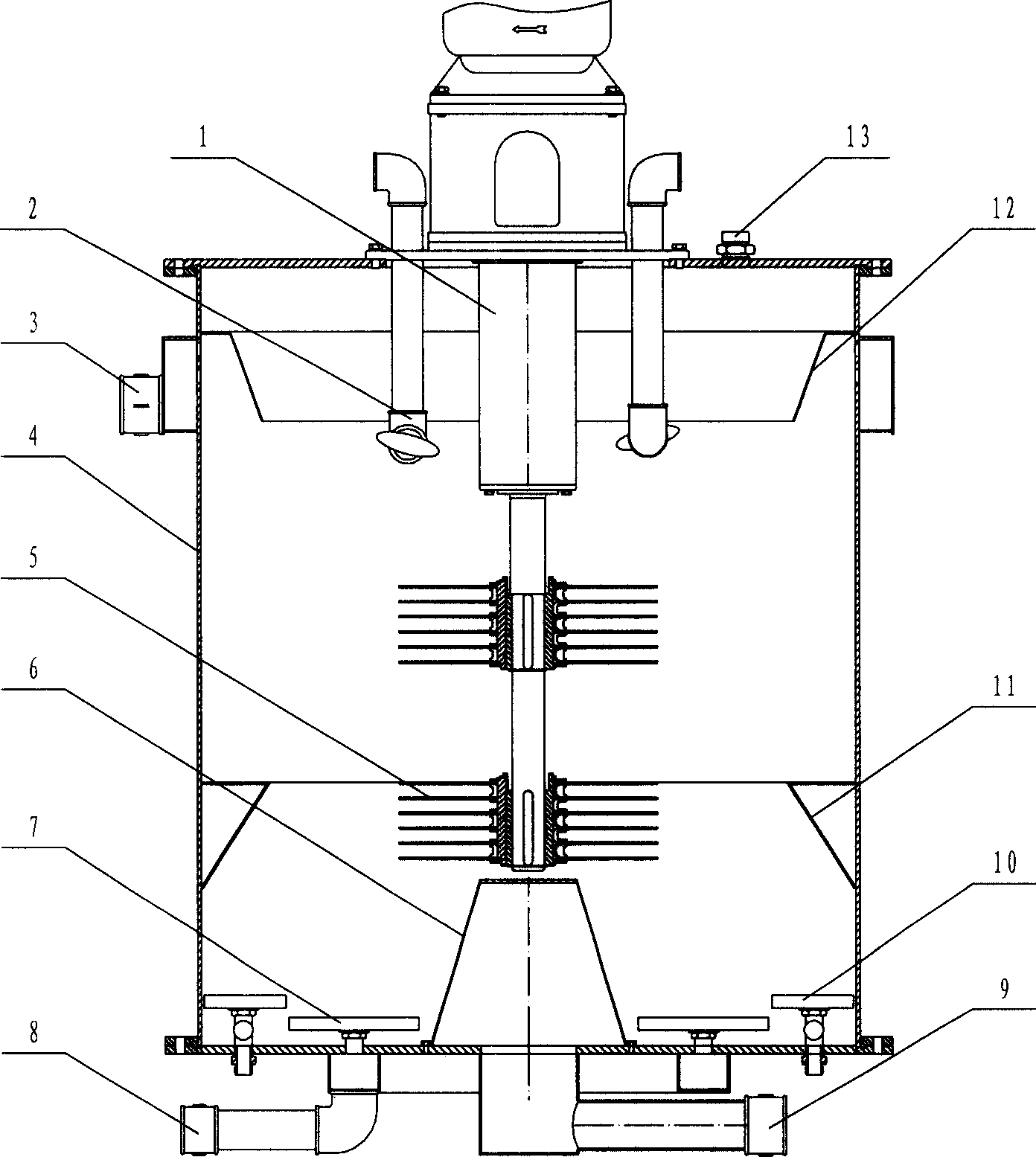

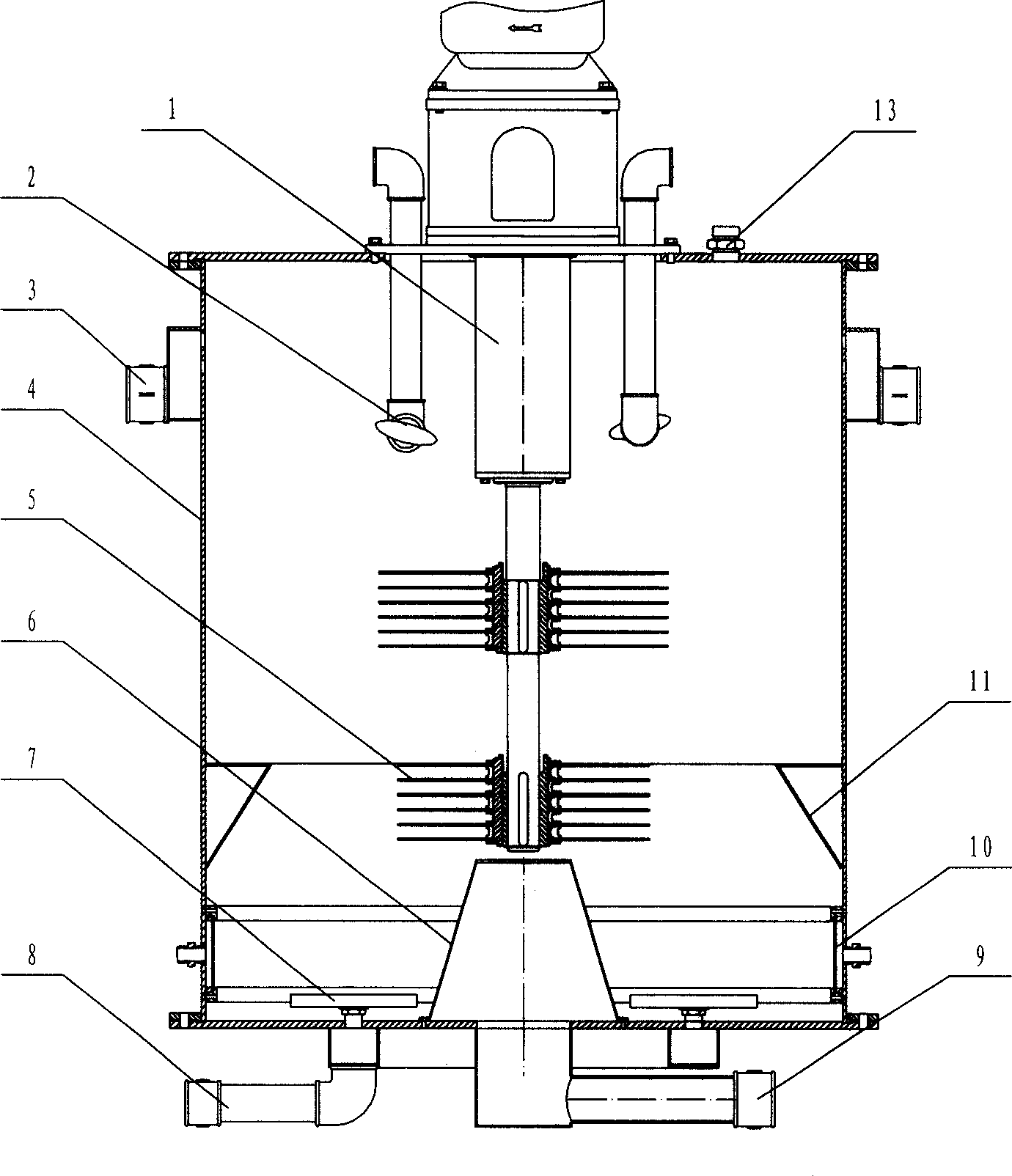

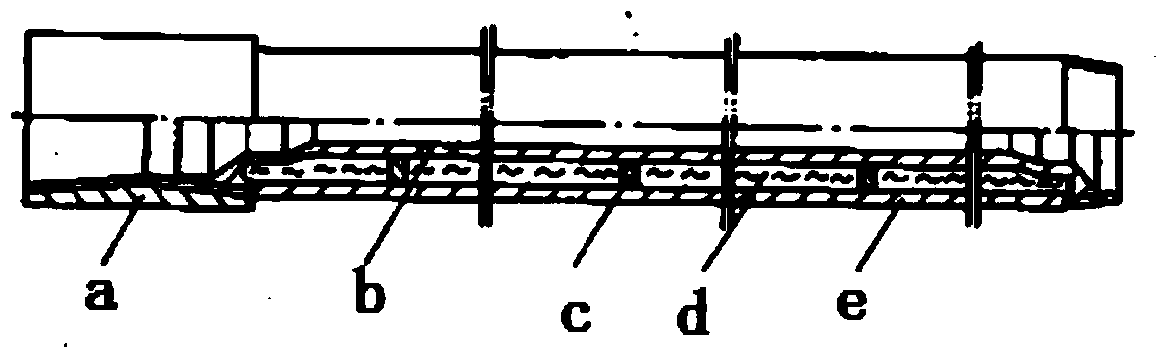

Extracting device

InactiveCN1631482AHigh extraction rateImprove extraction efficiencyLiquid solutions solvent extractionChemical industryChemical reaction

The invention of extract equip belongs to the chemical and separating technique field. The current extract equip has the flows of low rate of extracting, big tower. The invention of extract equip include: house4, moving equip1, two rounds5, liquid equip6 fixed below. Round5 is made of stings of U shape. The invention of extract equip strengthen the effect of separating, dissolve the returning, strengthen the process of mixing and separating, increase the rate of extract by times and the equip is lighter. The invention can be used in chemical industry, medical, metallurgy, and the chemical action engineering.

Owner:高根树

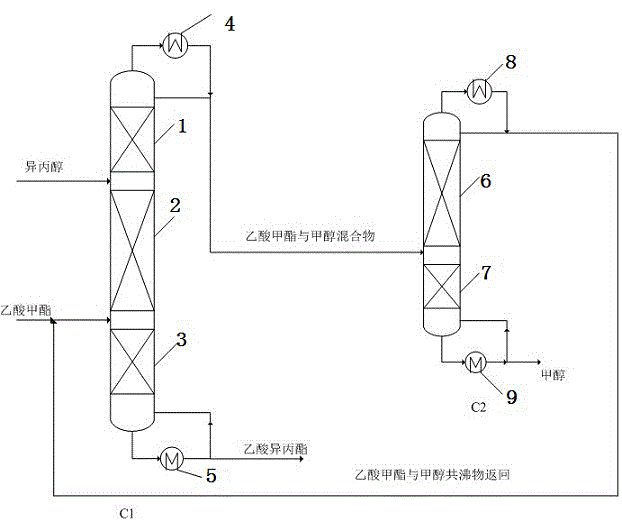

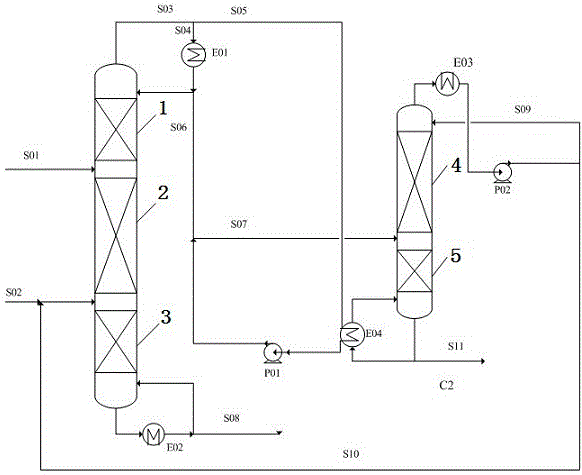

Method for preparing isopropyl acetate through rectification

InactiveCN104945251ANo pollution in the processSimple processOrganic compound preparationPreparation by ester-hydroxy reactionChemical reactionChemical reaction engineering

The invention belongs to the field of chemical reaction engineering and relates to a method for producing isopropyl acetate, in particular to a method for preparing isopropyl acetate through rectification and reaction between methyl acetate and isopropyl alcohol. By utilizing a reactive distillation column and a methyl acetate recovery tower, the isopropyl acetate is prepared and the raw material methyl acetate is recycled under normal pressure, the reactant isopropyl alcohol of high boiling point is fed into the upper portion of a reaction zone located in the middle portion of the reactive distillation column, the mixture of methyl acetate and methyl alcohol which are low in boiling point are fed into the lower portion of the reaction zone located in the middle portion of the reactive distillation column, it is guaranteed that the concentration of the methyl acetate in the liquid phase in the lower portion of the reaction zone is kept high, the concentration of the isopropyl alcohol in the liquid phase in the upper portion of the reaction zone is high, so that the concentration of the two reactants on a column plate in the whole reaction zone is kept high comparatively, meanwhile, products, namely the methyl alcohol and the methyl acetate, form the minimum azeotrope and are removed from the column top, the product, namely the isopropyl acetate, of higher boiling point is removed from the column bottom through a stripping section, and therefore the reaction equilibria can move rightward faster.

Owner:CHANGZHOU UNIV

Energy-saving method for preparing isopropyl acetate

InactiveCN105017019AReduce contentLess investmentPreparation by ester-hydroxy reactionOrganic compound preparationReboilerTransesterification

The invention belongs to the field of chemical reaction engineering and relates to a production method for isopropyl acetate, particularly an energy-saving process for preparing isopropyl acetate by reacting-distillation of methyl acetate and isopropanol. By taking methyl acetate and isopropanol as raw materials, the raw materials are prepared and recovered by reaction of a pressurized reaction rectifying tower and a normal pressure methyl acetate recovery tower, and the reaction of synthesizing isopropyl acetate in the pressurized reaction rectifying tower by virtue of a transesterification method is a pressurized reaction, so that the composition of a binary azeotrope formed by a reaction product methanol and the raw material methyl acetate is changed, the content of methyl acetate in the azeotrope is reduced, and the produced quantity at the tower top is reduced, and therefore, the equipment investment on the normal pressure methyl acetate recovery tower is reduced. The steam temperature of the binary azeotrope of methanol and methyl acetate in a rectifying section at the tower top of the pressurized reaction rectifying tower is enhanced, heat of a kettle reboiler is provided for the normal pressure methyl acetate recovery tower, and the pressurized reaction rectifying tower and the normal pressure methyl acetate recovery tower realize the purpose of saving energy and reducing consumption through heat integration.

Owner:CHANGZHOU UNIV

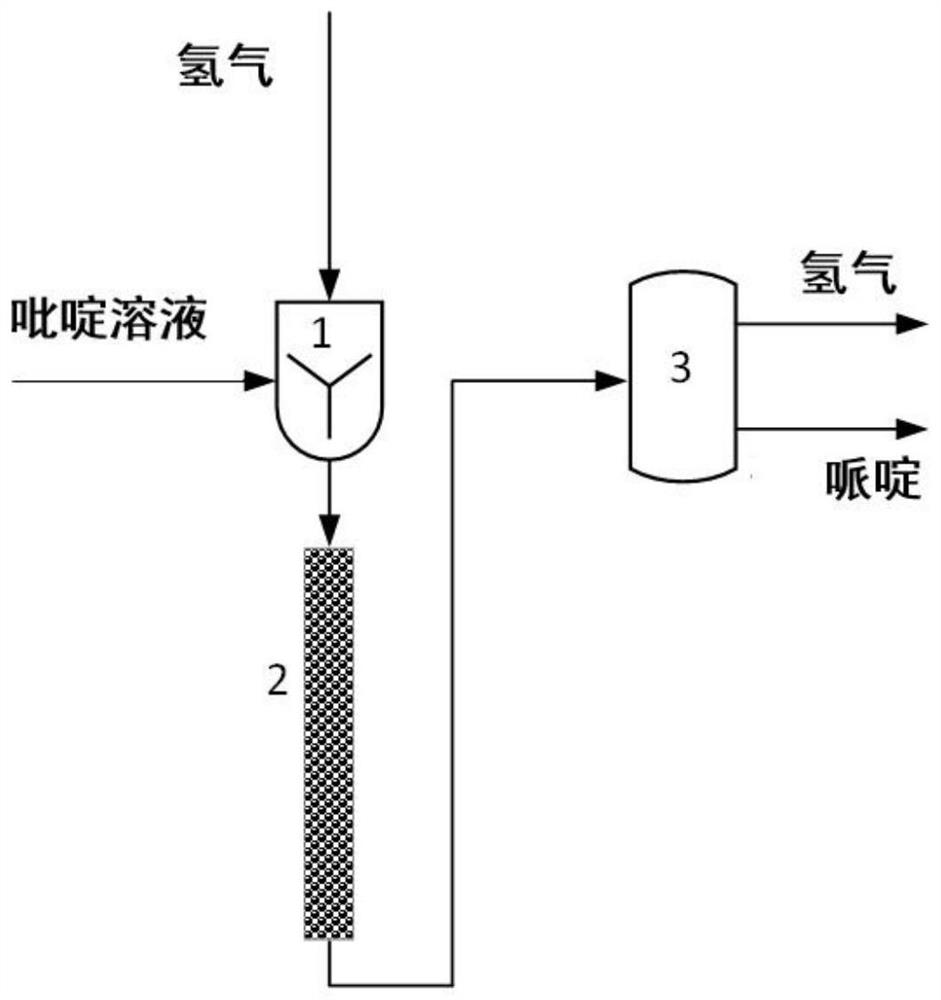

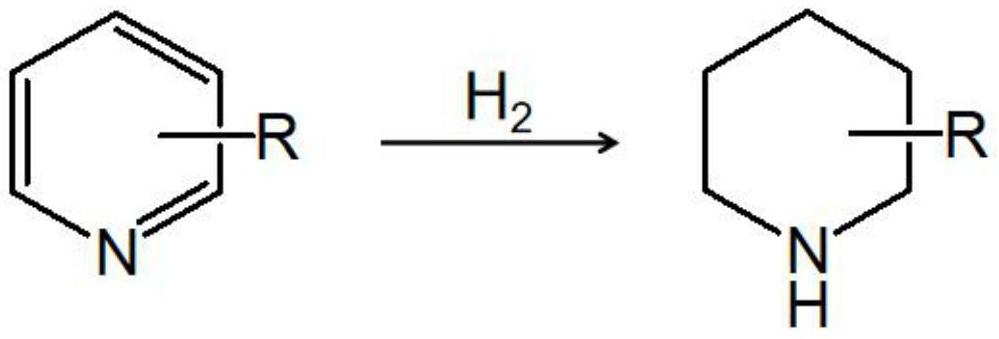

Method for synthesizing piperidine through continuous liquid-phase hydrogenation of pyridine in microreactor

ActiveCN112979583AEnhanced gas-liquid-solid three-phase mass transferMild reaction conditionsOrganic chemistryChemical/physical/physico-chemical microreactorsMicroreactorChemical reaction

The invention discloses a method for synthesizing piperidine through continuous liquid-phase hydrogenation of pyridine in a microreactor, and belongs to the technical field of chemical reaction engineering. According to the method, pyridine is used as a raw material, and catalytic hydrogenation is carried out under 1-5 MPa and 50-150 DEG C to obtain piperidine. According to the method, a micro-reactor hydrogenation technology is utilized, gas-liquid-solid three-phase mass transfer is enhanced, the reaction temperature and pressure conditions are milder, the reaction time is greatly shortened, and the use amount of hydrogen is lower; meanwhile, continuity and automation of the process can be realized, the energy consumption of the process is lower, the safety is higher, and the product selectivity and the conversion rate of pyridine both reach 99.5% or above.

Owner:鹤壁中昊新材料科技有限公司 +1

Method for preparing epoxy chloropropane by cyclizing dichloropropanol in microreactor

ActiveCN102603680AShort stayImprove conversion rateOrganic chemistryChemical industryEpoxyRetention time

The invention discloses a method for preparing epoxy chloropropane by cyclizing dichloropropanol in a microreactor, belonging to the technical field of chemical reaction engineering. The method comprises the following steps: quickly mixing a dichloropropanol water solution with a sodium hydroxide water solution in the microreactor; controlling the temperature of the cyclization reaction to be 40-100 DEG C; finishing reaction in a delay tube; and finally separating in a rectifying tower to obtain epoxy chloropropane. According to the method, the reaction material solutions are quickly mixed in the microreactor, so that the cyclization reaction is fully finished while side reactions caused by non-uniformly mixing are prevented and the usage amount of alkali liquor is guaranteed to be closer to the theoretical value. Compared with the traditional cyclization tower and the reactive distillation coupling technology, the method for preparing epoxy chloropropane by cyclizing dichloropropanol in the microreactor has the advantages of short material retention time, high conversion rate, high selectivity and the like, so that the production cost can be saved, the material consumption can be reduced and the byproduct amount can be decreased.

Owner:JIANGSU ANPON ELECTROCHEM +1

Method for preparing benzil by oxidation of benzoin in microreactor

ActiveCN109232218AIncrease productivityReduce volumeCarbonyl compound preparation by oxidationMicroreactorSolvent

The invention belongs to the technical field of chemical reaction engineering, and discloses a method for preparing benzil by oxidation of benzoin in a microreactor. The method utilizes efficient mixing and excellent mass transfer and heat transfer performance of the microreactor, nitric acid is used as a dispersion phase in the microreactor, benzoin is dissolved into an inert solvent as a continuous phase, the dispersion phase and the continuous phase are mixed to initiate reaction, the reaction is completed in a retardation tube behind the microreactor, and the separation of a product from unreacted nitric acid is achieved in a phase separation tank. In the method, a conversion rate of 99.8+% and high selectivity of 99.5+% can be achieved in 5 minutes, so that a reactor volume can be significantly reduced, and the safety of a reaction process can be improved.

Owner:TSINGHUA UNIV +1

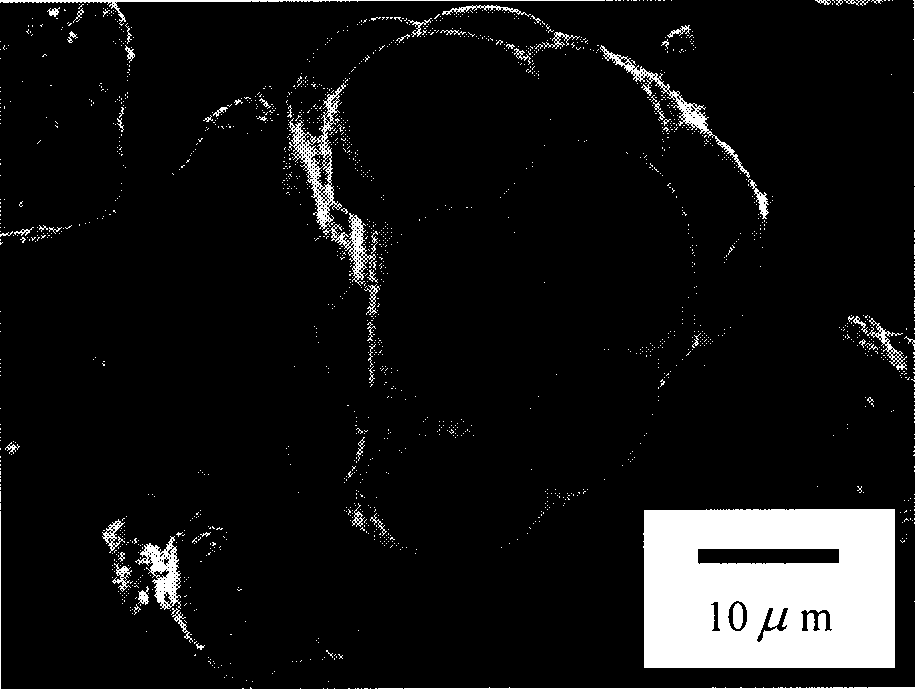

Preparation method and apparatus for amorphous nano carbon tube

InactiveCN1923680AIncrease productionLow costNanostructure manufactureNitrogen gasChemical reaction engineering

The invention discloses a preparing method and device of amorphous nanometer carbon pipe in the mutual crossing domain of coal chemical, chemical reacting engineering and charcoal material, which is characterized by the following: blending pulverized coke, coal oil and nickel powder; moulding and charring to prepare anodic coke bar of arc discharge in the buffer gas (helium or nitrogen) and other gas (acetylene or acetylene and carbon dioxide).

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for inhibiting chloroform acidifying during separation of N-methylpyrolidone and chloroform by adding stabilizing agent

ActiveCN105367471APrevent acidificationImprove recycling efficiencyHalogenated hydrocarbon separation/purificationAlcoholBoiling point

The invention discloses a method for inhibiting chloroform acidifying during separation of N-methylpyrolidone (NMP) and chloroform by adding a stabilizing agent, and belongs to the technical field of chemical reaction engineering. According to the method, a high-boiling-point alcohols and phenols stabilizing agent is added into the NMP / chloroform system, and gives play to effect of inhibiting acidifying during separation of NMP / chloroform. The method is capable of effectively inhibiting acidifying phenomenon during separation of NMP / chloroform and improving NMP recovery utilization efficiency, and possesses the advantages of simple operation, low cost, high safety and the like.

Owner:AFCHINA CORP CO LTD +1

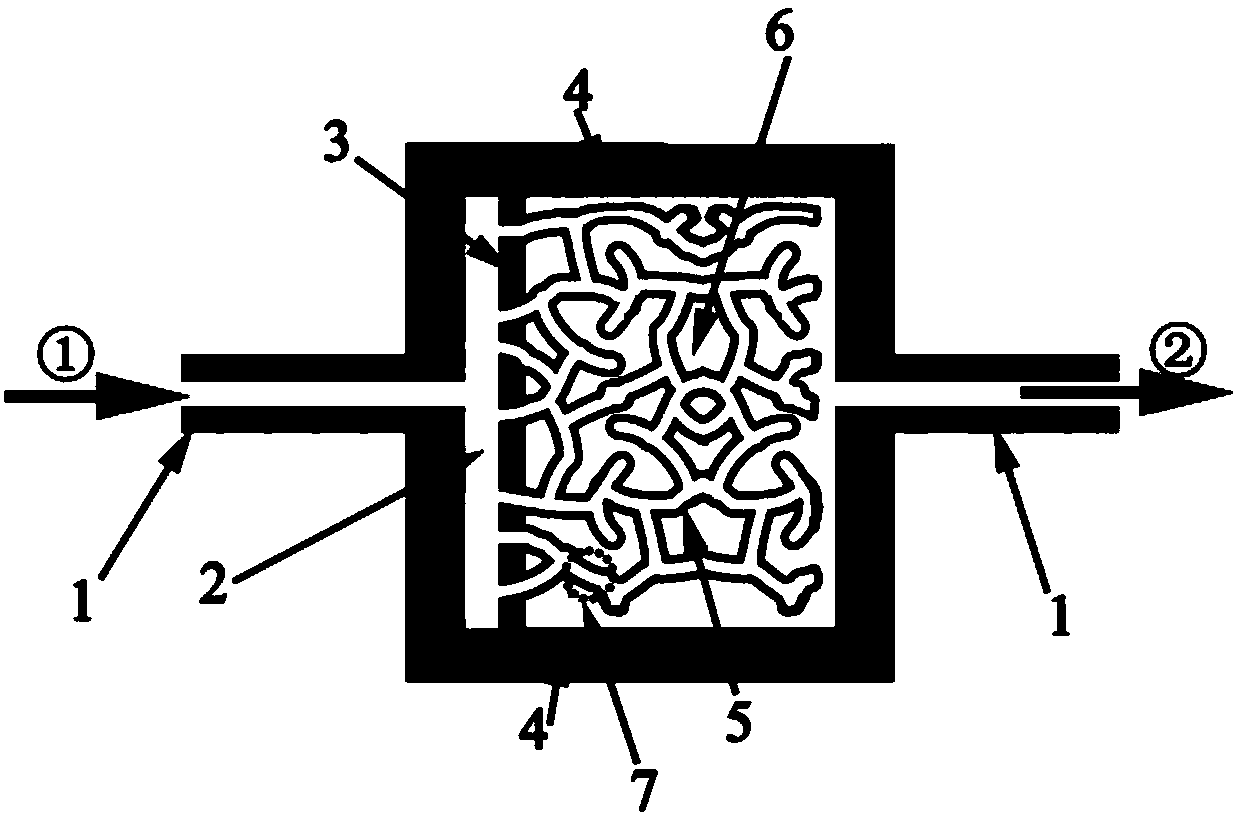

Miniature reaction device based on hollow foam material and application thereof

ActiveCN109745931AFacilitate the control of the flow stateImprove reaction efficiencyChemical/physical/physico-chemical processesEngineeringChemical reaction engineering

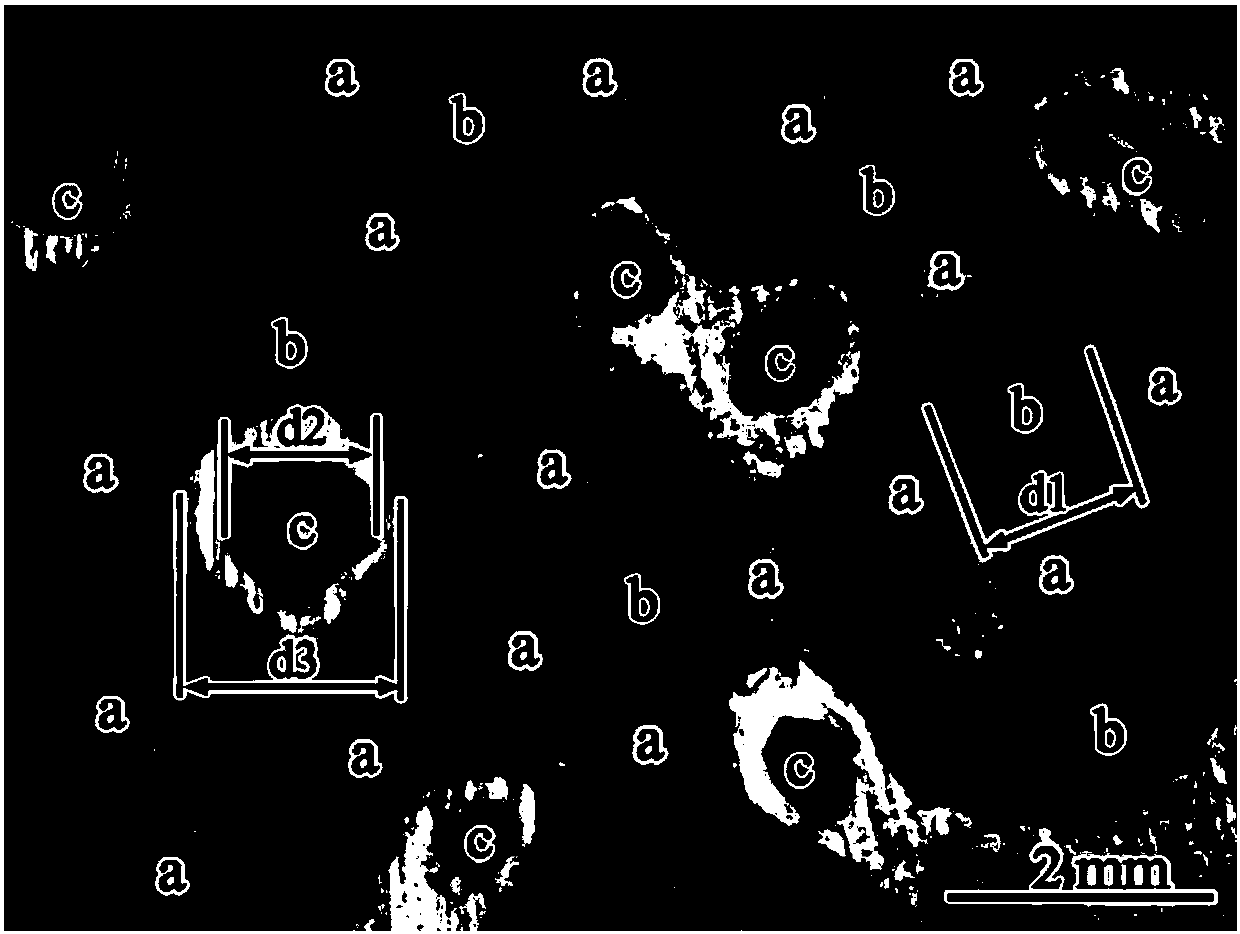

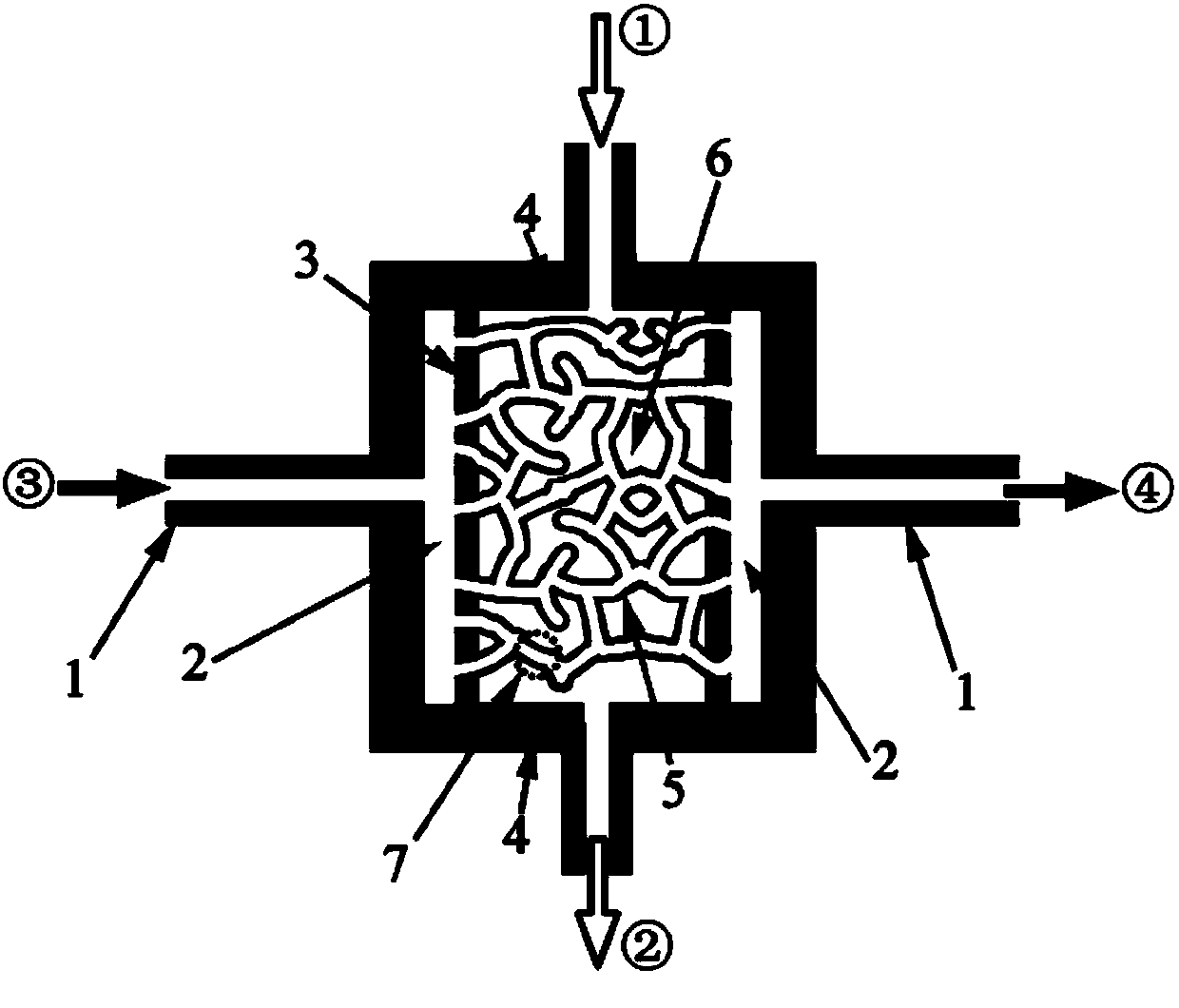

The invention relates to the field of chemical reaction engineering, in particular to a miniature reaction device based on a hollow foam material and application thereof. A main function area of the miniature reaction device contains the hollow foam material which is formed by macroscopically networking three-dimensionally communicated support frames; the support frames are three-dimensionally communicated hollow microchannels. All the size of the macroscopic three-dimensionally communicated pores, inner chamber size of the three-dimensionally communicated hollow microchannels and the wall thickness of the hollow microchannels in the main function area of the miniature reaction device herein are adjustable. The miniature reaction device has the advantages that efficient mass transfer and heat transfer occur in the macroscopic three-dimensionally communicated porous network, wall bodies of the hollow microchannels can effectively isolate the reaction material enriched phase and the product enriched phase during reaction, and heat generated by the reaction or required by the reaction is transferred or exchanged across the wall bodies of the hollow microchannels.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

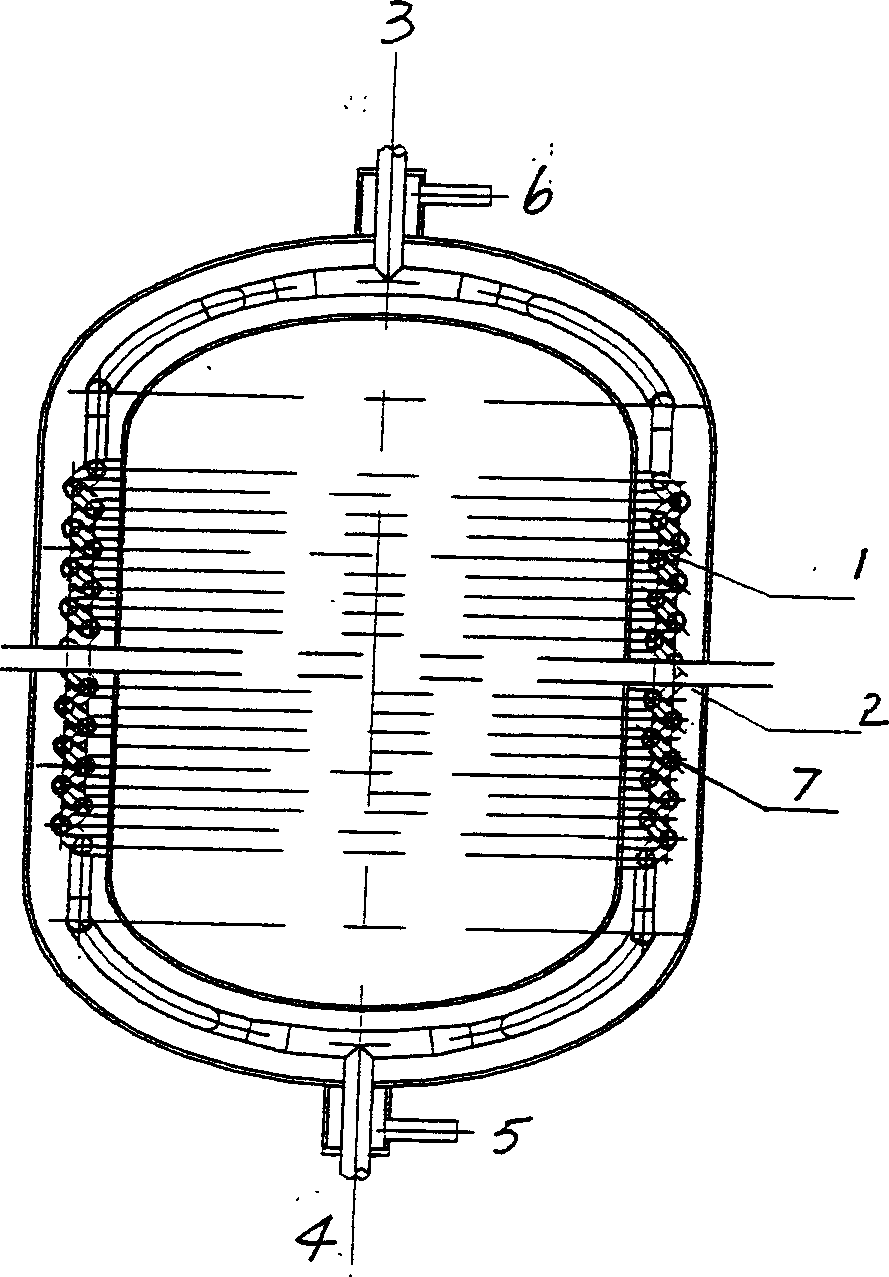

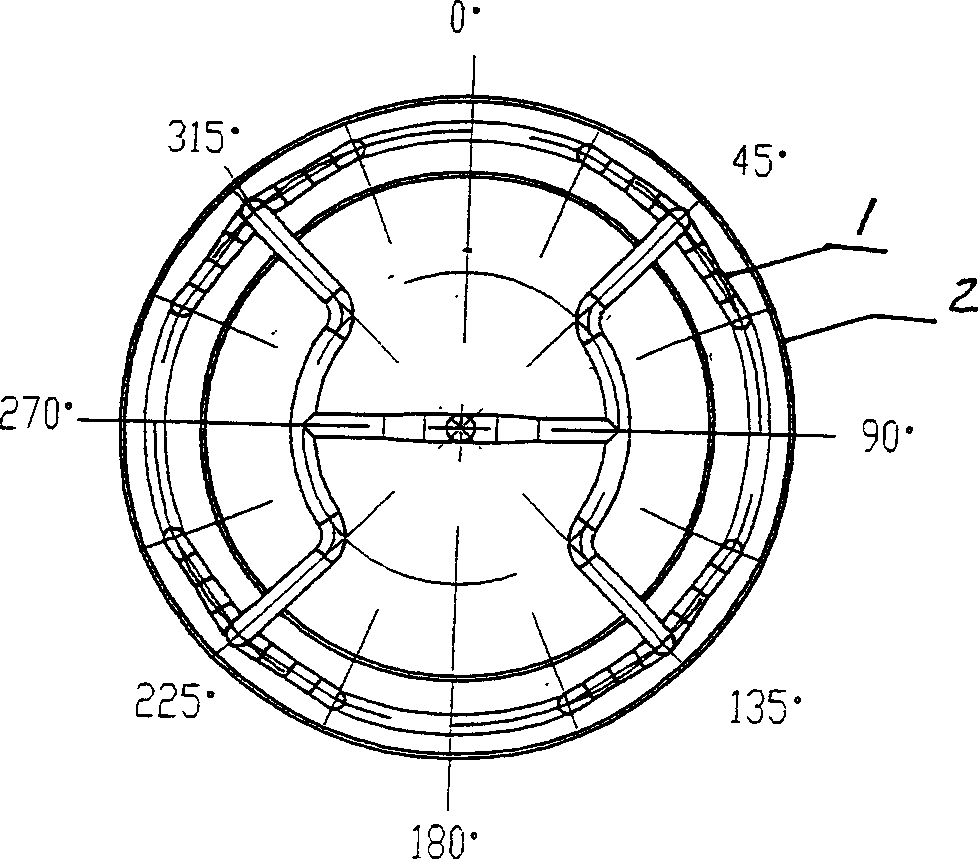

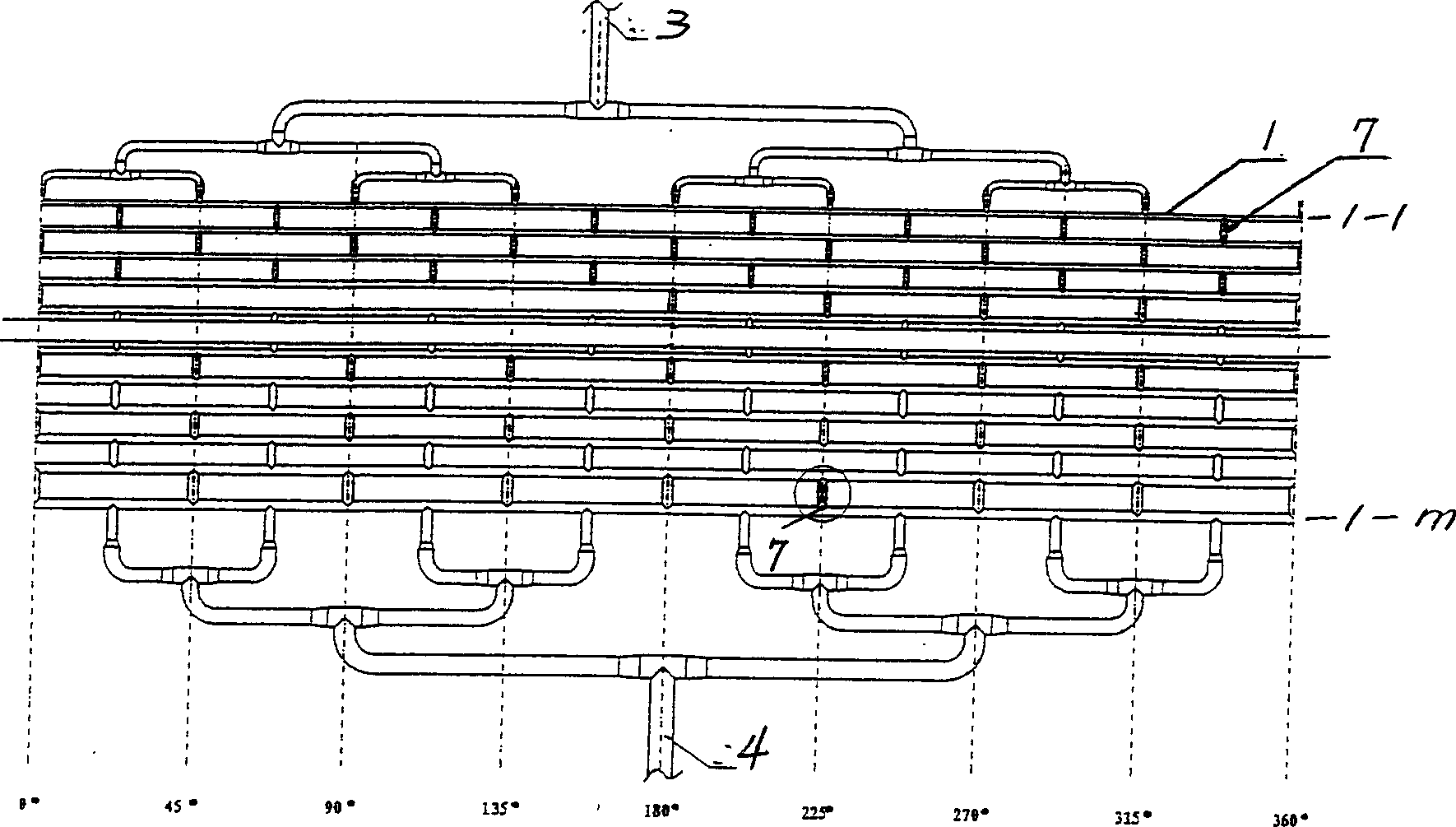

Reactor with multiple ring canal

InactiveCN1445018ADestroy in timeImprove heat transfer coefficientChemical/physical/physico-chemical stationary reactorsEngineeringChemical reaction engineering

A multi-layer ring tube reactor is composed of m-layers of ring tubes, where m=2-hundreds, and heat exchanging chamber which has cylinder or dual-cylinder structure for containing said ring tubes, upper and lower sealing covers, and inlet and outlet of heat or cold medium. Said ring tube has top and bottom holes. The relative top holes of lower ring tube are communicated to the bottom holes of upper ring tube. Its advantages are simple structure, low cost, and high heat exchange efficiency.

Owner:刘兆彦

Novel Beckmann rearrangement method for preparing caprolactam from cyclohexanone oxime

ActiveCN101891681BSmall stagnationImprove controllabilityLactams preparationChemical/physical/physico-chemical processesBeckmann rearrangementSolvent

Owner:TSINGHUA UNIV

Method for preparing epoxy chloropropane by cyclizing dichloropropanol in microreactor

ActiveCN102603680BShort stayImprove conversion rateOrganic chemistryChemical industryEpoxyRetention time

The invention discloses a method for preparing epoxy chloropropane by cyclizing dichloropropanol in a microreactor, belonging to the technical field of chemical reaction engineering. The method comprises the following steps: quickly mixing a dichloropropanol water solution with a sodium hydroxide water solution in the microreactor; controlling the temperature of the cyclization reaction to be 40-100 DEG C; finishing reaction in a delay tube; and finally separating in a rectifying tower to obtain epoxy chloropropane. According to the method, the reaction material solutions are quickly mixed in the microreactor, so that the cyclization reaction is fully finished while side reactions caused by non-uniformly mixing are prevented and the usage amount of alkali liquor is guaranteed to be closer to the theoretical value. Compared with the traditional cyclization tower and the reactive distillation coupling technology, the method for preparing epoxy chloropropane by cyclizing dichloropropanol in the microreactor has the advantages of short material retention time, high conversion rate, high selectivity and the like, so that the production cost can be saved, the material consumption can be reduced and the byproduct amount can be decreased.

Owner:JIANGSU ANPON ELECTROCHEM +1

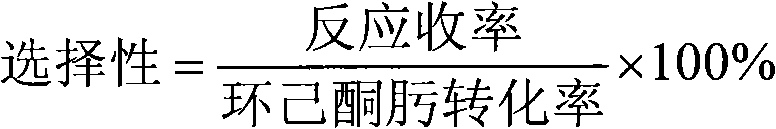

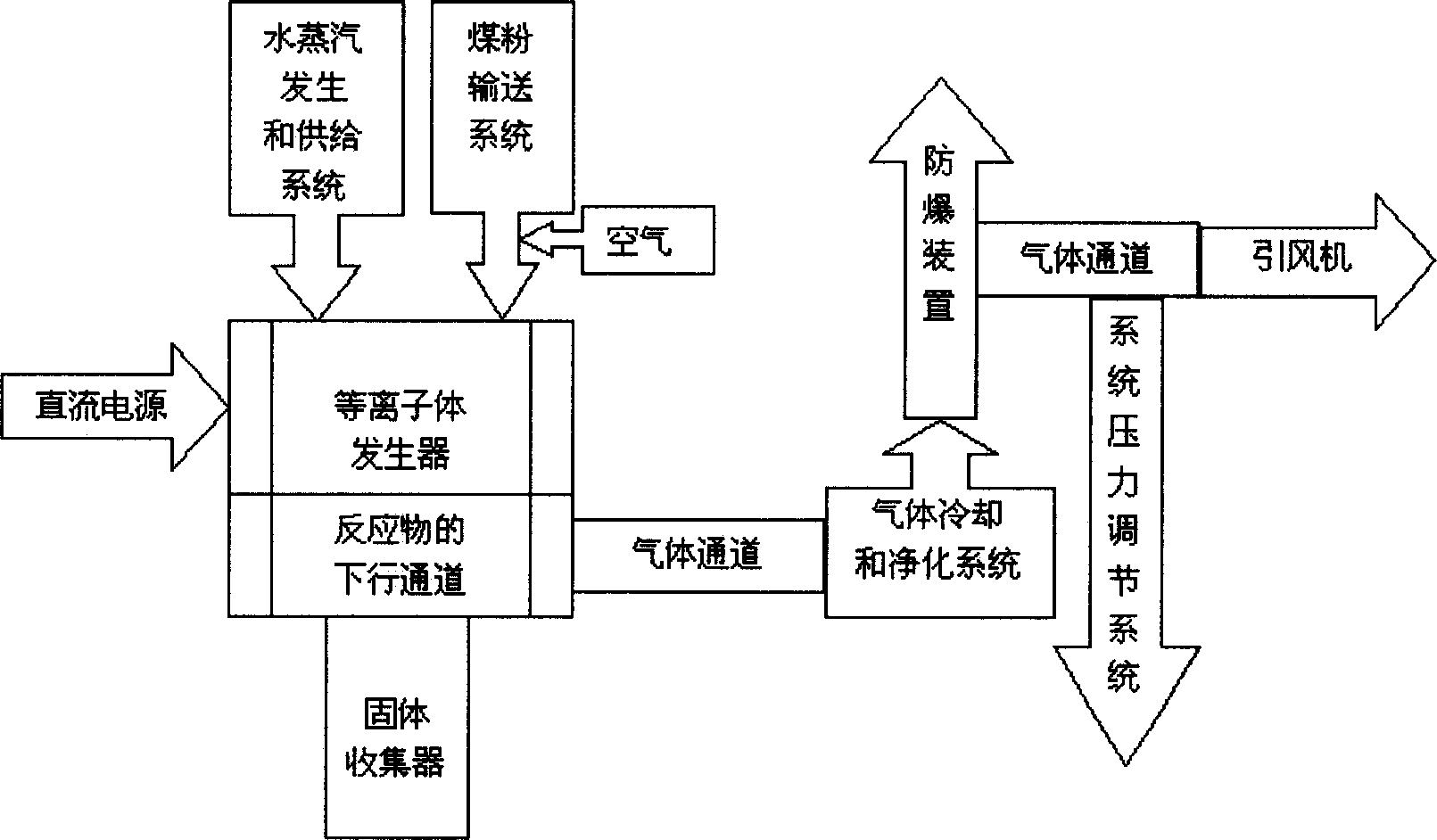

Method and apparatus for continuously preparing foam carbon material from coal

InactiveCN1528861AHigh degree of graphitizationIncrease profitIndirect heating destructive distillationChemical reactionExplosion protection

The invention belongs to a cross technology field of coal chemistry, chemical reaction project, plasma science and charcoal material science. It refers to a method and device for using coal and water steam as materials to produce foam charcoal material continuously. The method sprays powder coal and high temperature steam into direct current arc plasma and produce foam charcoal material continuously, the mixing, foaming, synthesizing charring and graphitizing are all completed in one step. The device is made up of steam generating and supplying system, coal powder transmitting system, plasma generator, solid collector, gas cooling and purifying system, explosion protection device, system pressure adjusting system and draught fan. The invention can be operated conveniently; it can be controlled, and can be operated continuously with low cost.

Owner:DALIAN UNIV OF TECH

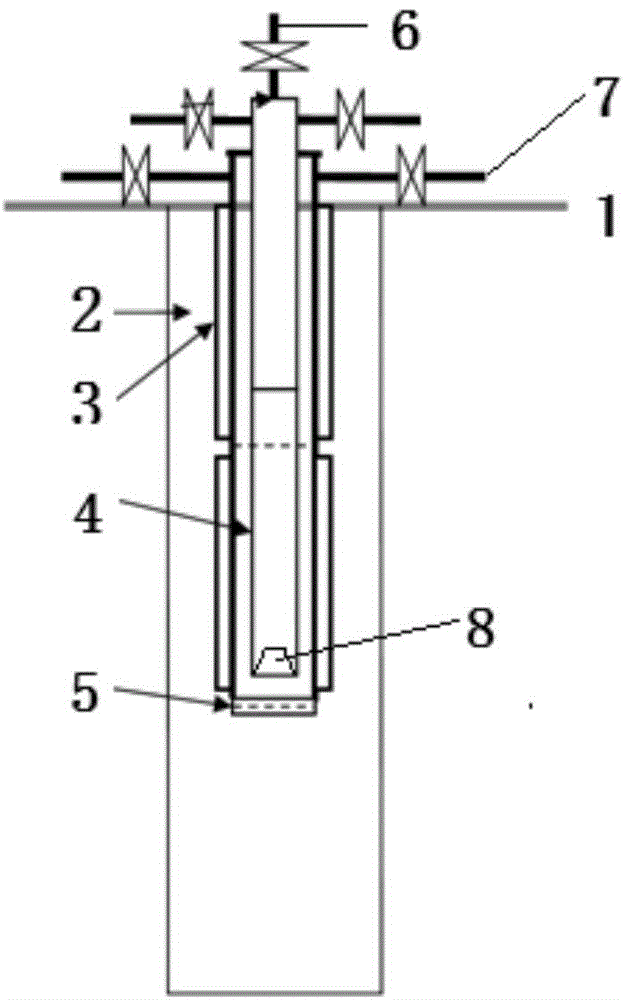

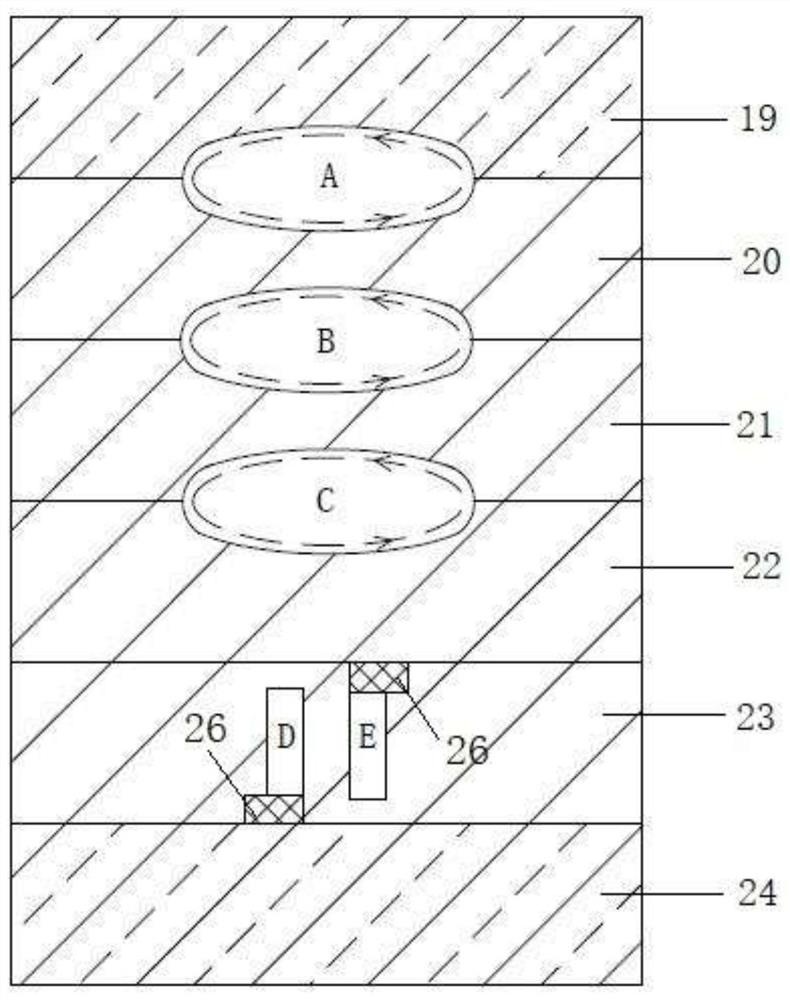

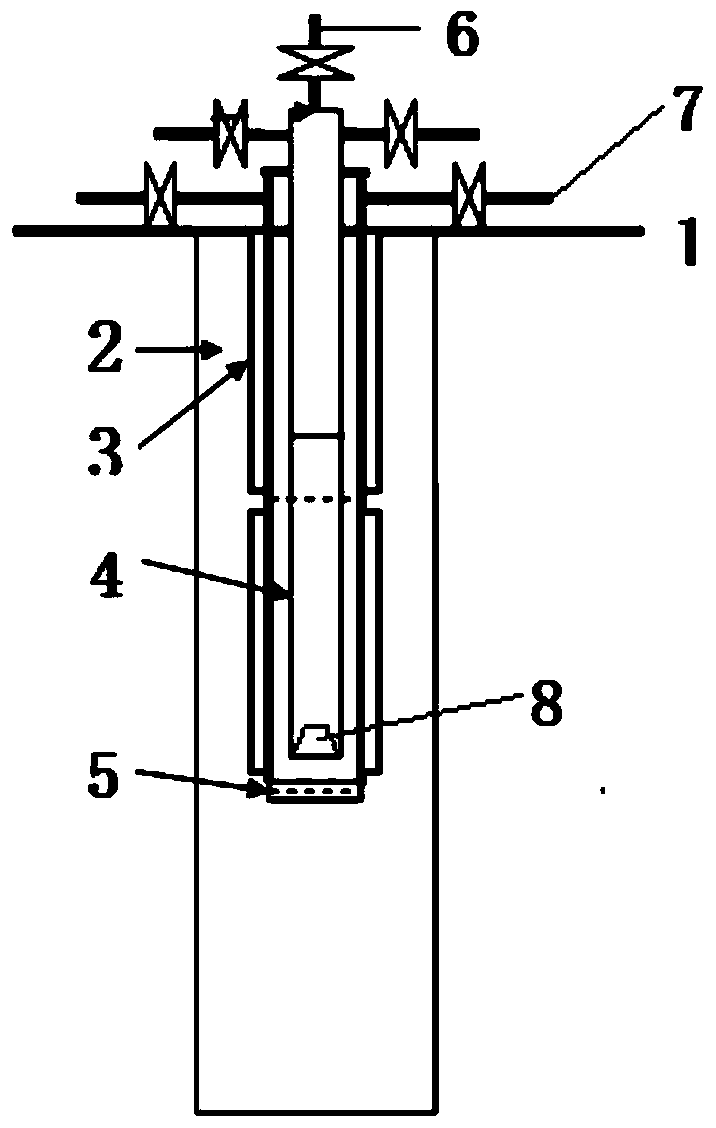

Underground heat insulation air-suspended bed reactor

ActiveCN105013411AProtect the environmentImprove securityChemical/physical processesChemical reactionProcess engineering

The invention provides an underground heat insulation air-suspended bed reactor which is suitable for a heavy oil hydrogenation lightweighting technology, a hydrogenation direct liquidation technology for coal and biomass and a mixing coprocessing lightweighting machining technology for coal, biomass and heavy oil in a petroleum refining process and a high-temperature and high-pressure chemical reaction process of other fluid materials.

Owner:仲兴行(上海)商务服务有限公司

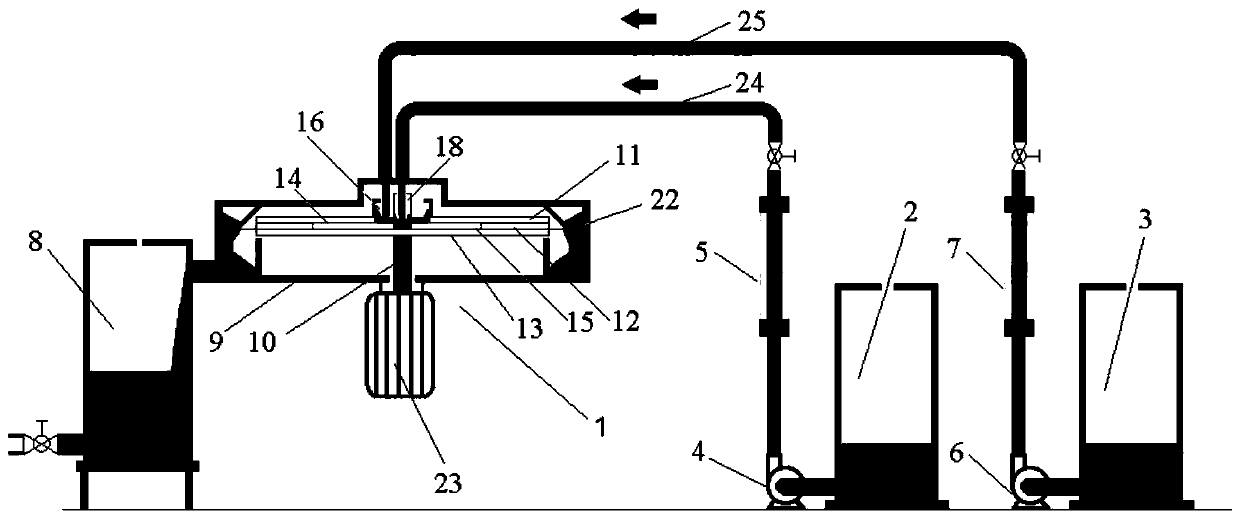

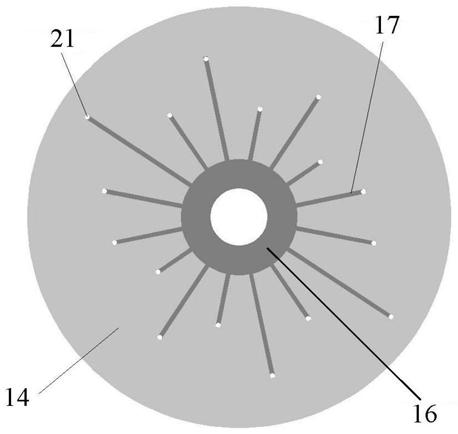

High-efficiency enhanced multi-scale mixed mass transfer device and method

InactiveCN111185132AEfficient productionFit closelyTransportation and packagingChemical/physical/physico-chemical microreactorsChemical reactionLiquid storage tank

The invention relates to the field of chemical reaction engineering and technologies, particularly to an efficient reinforced multi-scale mixed mass transfer device and method. The efficient reinforced multi-scale mixed mass transfer device comprises a supergravity rapid reactor, a first feed liquid storage tank and a second feed liquid storage tank, wherein the first feed liquid storage tank is communicated with the inlet I of the supergravity rapid reactor through a first centrifugal pump and a first flow meter, the second feed liquid storage tank is communicated with the inlet II of the supergravity rapid reactor through a second centrifugal pump and a second flow meter, a metering tank is arranged at the outlet of the supergravity rapid reactor, and the supergravity rapid reactor comprises a stator and a rotor. The device disclosed by the invention has the effects of efficiently strengthening the mass transfer and multi-scale mixing process, so that a rapid reaction is carried outaccording to the direction of intrinsic dynamics; and the device is compact in matching, simple and convenient to regulate and control, efficient in production, convenient to disassemble and assemble,easy to clean, easy to simulate and easy to amplify, and can easily realize large-scale, low-cost and efficient production of materials with various microstructures.

Owner:ZHEJIANG OCEAN UNIV

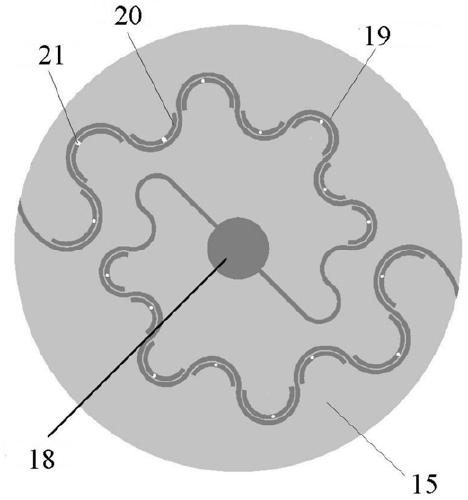

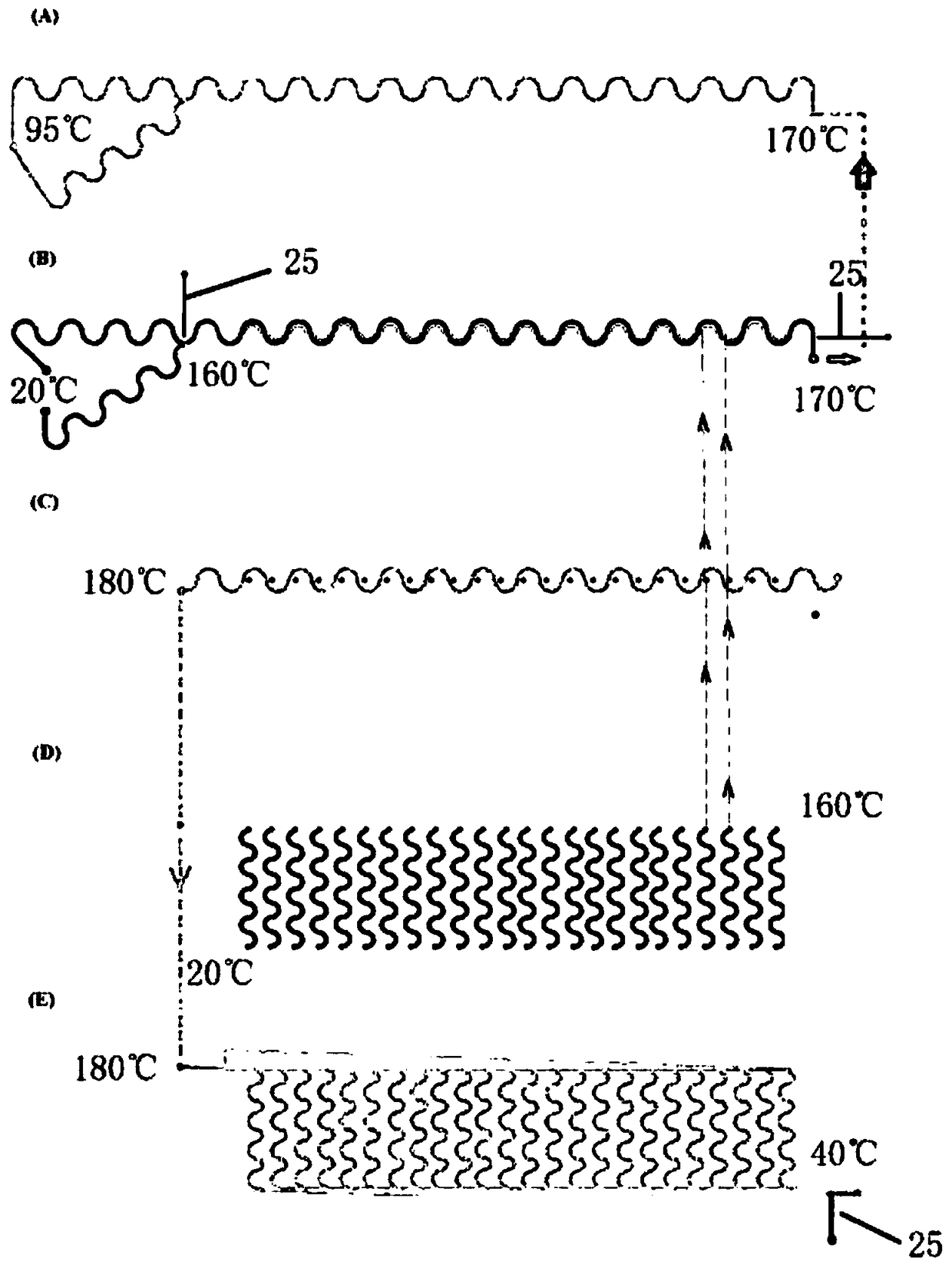

Apparatus and method for rapid hydrothermal synthesis

ActiveCN108905895AQuality improvementImprove performanceChemical/physical/physico-chemical processesPressure vessels for chemical processSynthesis methodsEngineering

The invention relates to the technical field of chemical reaction engineering, and especially relates to a method and an apparatus for rapid hydrothermal synthesis. The apparatus comprises a power mechanism, a plurality of liquid storage devices and a reactor, the liquid storage devices are connected with the reactor through a channel transition mechanism, and the channel transition mechanism is provided with a flow rate control device; and the reactor includes a channel distribution structure and a multiple heat exchange assembly, the multiple heat exchange component uses a high temperature and high pressure hot liquid as a heat source, the multiple heat exchange assembly is composed of a plurality of pinch plates which can be vertically buckled up and down, grooves are arranged at two sides of the middle pinch plate, the grooves of the adjacent pinch plate are buckled to form a plurality of closed channels, and the channel distribution structure is communicated with the closed channels of the multiple heat exchange assembly. The apparatus has a strong heat exchange function, and can prepare nano-composite particles with various crystal phases and a complicated structure under hydrothermal conditions, and the obtained nano-composite particles can be directly used without hydrothermal aging treatment, so the process flow is obviously shortened, and the process cost of the product is reduced.

Owner:ZHEJIANG OCEAN UNIV

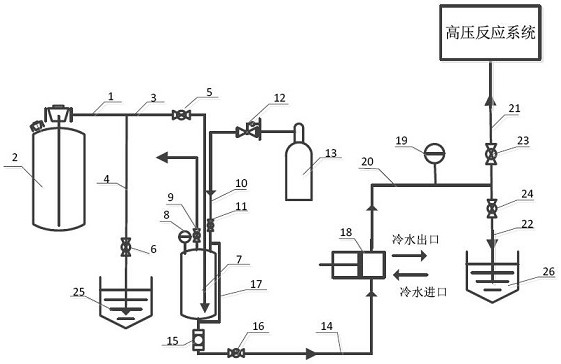

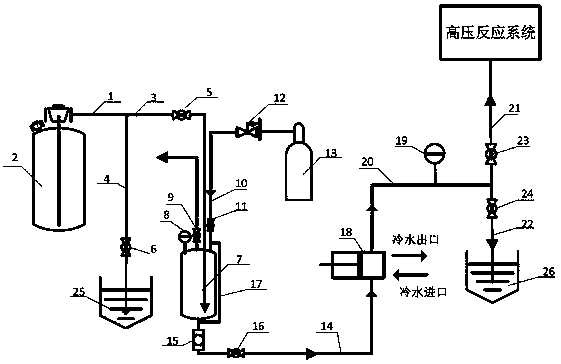

Method and device for continuously feeding low-boiling point materials to high-pressure devices

ActiveCN109529722BGuaranteed continuityGuaranteed stabilityPressure vessels for chemical processThermodynamicsChemical reaction

The invention belongs to the technical field of chemical reaction engineering, and relates to a method and a device for continuously feeding low-boiling point materials to high-pressure devices. The specific steps are: transport the low-boiling point material to the pressure-resistant buffer tank through the material storage tank; add a certain pressure of protective gas to the pressure-resistant buffer tank; the low-boiling point material enters the high-pressure reaction system from the pressure-resistant buffer tank through the metering pump ; When the material reserve in the pressure-resistant buffer tank decreases, repeat the steps to achieve continuous, stable and uniform feeding. The invention realizes the liquid feeding of low-boiling materials, and ensures the continuity, stability and uniformity of the feeding, effectively reduces the problem of stopping the pump caused by the bubbles caused by the vaporization of the materials, and ensures the stability of the reaction in the reactor .

Owner:SHANDONG YUHUANG CHEM CO LTD

A kind of rapid hydrothermal synthesis device and method

ActiveCN108905895BWith strong heat exchange functionShort processChemical/physical/physico-chemical processesPressure vessels for chemical processChemical physicsChemical reaction

The invention relates to the technical field of chemical reaction engineering, and especially relates to a method and an apparatus for rapid hydrothermal synthesis. The apparatus comprises a power mechanism, a plurality of liquid storage devices and a reactor, the liquid storage devices are connected with the reactor through a channel transition mechanism, and the channel transition mechanism is provided with a flow rate control device; and the reactor includes a channel distribution structure and a multiple heat exchange assembly, the multiple heat exchange component uses a high temperature and high pressure hot liquid as a heat source, the multiple heat exchange assembly is composed of a plurality of pinch plates which can be vertically buckled up and down, grooves are arranged at two sides of the middle pinch plate, the grooves of the adjacent pinch plate are buckled to form a plurality of closed channels, and the channel distribution structure is communicated with the closed channels of the multiple heat exchange assembly. The apparatus has a strong heat exchange function, and can prepare nano-composite particles with various crystal phases and a complicated structure under hydrothermal conditions, and the obtained nano-composite particles can be directly used without hydrothermal aging treatment, so the process flow is obviously shortened, and the process cost of the product is reduced.

Owner:ZHEJIANG OCEAN UNIV

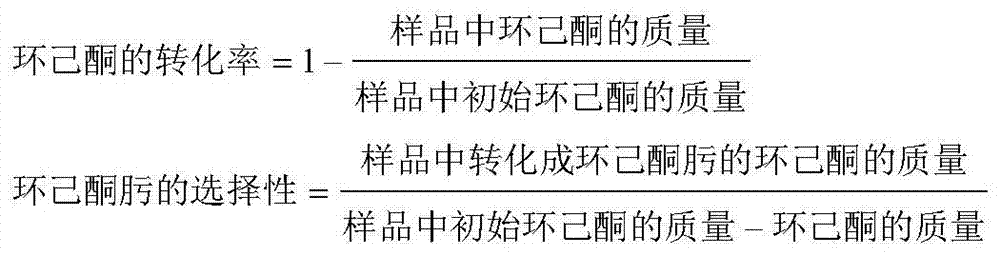

A system and method for synthesizing cyclohexanone oxime in a microreactor

The invention discloses a system and a method for synthesizing cyclohexanone oxime with a microreactor, belonging to the field of chemical reaction engineering. The system is composed of a first micro-mixer, a second micro-mixer, a reaction pipeline with a heat exchange jacket and a back pressure valve connected in series. First, use the first micro-mixer to mix the slurry containing titanium-silicon molecular sieve and ammonia with hydrogen peroxide solution, and then use the second micro-mixer to disperse cyclohexanone into the mixed slurry to initiate the ammoximation reaction, and finally in the reaction The reaction process is completed in the pipeline. The system can achieve high conversion rate (>99%) and high selectivity (>99%) within a reaction time of 0.5min to 20min. The amount of stagnation of materials in the micro-reaction system is small, which improves the controllability and safety of the ammoximation reaction.

Owner:TSINGHUA UNIV

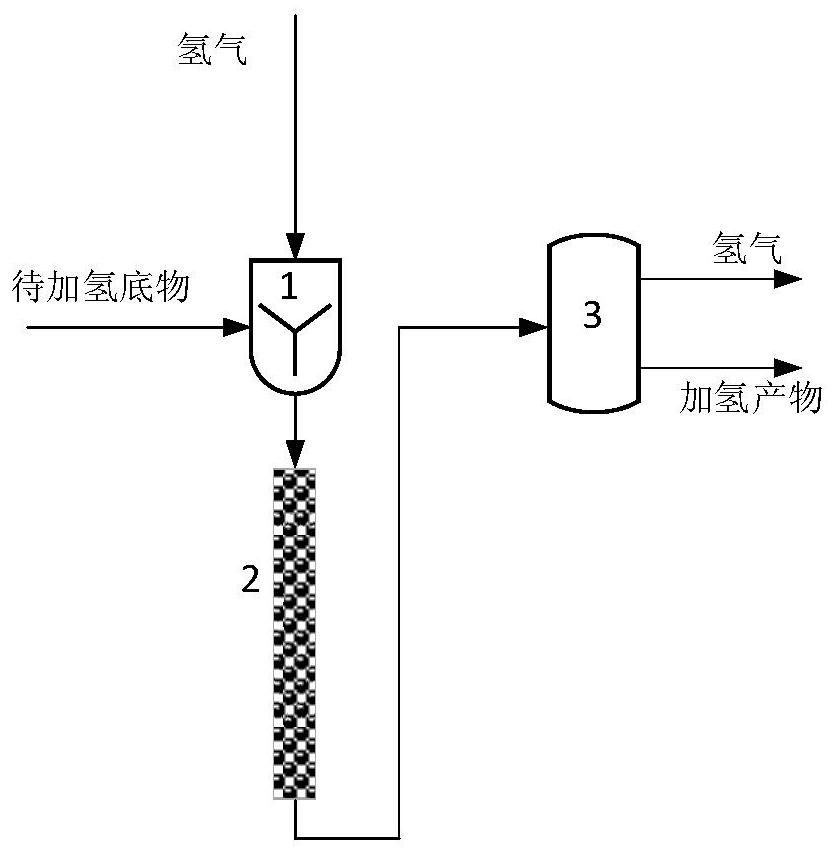

Method for one-step continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazolinone based on fixed bed microreactor

PendingCN114394937AImprove securityIncrease contact areaOrganic chemistryChemical/physical/physico-chemical microreactorsPtru catalystChemical reaction

The invention provides a method for one-step continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazolinone based on a fixed bed microreactor, and belongs to the technical field of chemical reaction engineering. The method comprises the following steps: firstly, mixing a substrate solution to be hydrogenated with formaldehyde to obtain a mixed solution, or adding homogeneous acid into the mixed solution, mixing with hydrogen in an inlet micromixer to obtain a gas-liquid mixed fluid, and then enabling the gas-liquid mixed fluid to pass through a micropacked bed filled with a catalyst to continuously finish a heterogeneous hydrogenation process by a one-step method. According to the method, efficient mixing and excellent mass and heat transfer performance of the microreactor are utilized, gas-liquid and liquid-solid mass transfer in the heterogeneous hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is improved, the volume of the reactor can be reduced, and the reaction yield is increased. The method can solve the problems of low production efficiency, poor product purity and high device risk in a hydrogenation kettle process, realizes continuous automatic operation of the process, and has the advantages of high yield, good safety and the like.

Owner:河北康壮环保科技股份有限公司 +1

A hydrogenation reaction device in a micro-packed bed and a method for hydrogenation reaction thereof

ActiveCN109225073BIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPtru catalystChemical reaction

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

A kind of method that adds stabilizing agent to suppress the chloroform acidification of n-methylpyrrolidone/chloroform separation process

ActiveCN105367471BPrevent acidificationImprove recycling efficiencyHalogenated hydrocarbon separation/purificationAlcoholBoiling point

The invention discloses a method for inhibiting chloroform acidifying during separation of N-methylpyrolidone (NMP) and chloroform by adding a stabilizing agent, and belongs to the technical field of chemical reaction engineering. According to the method, a high-boiling-point alcohols and phenols stabilizing agent is added into the NMP / chloroform system, and gives play to effect of inhibiting acidifying during separation of NMP / chloroform. The method is capable of effectively inhibiting acidifying phenomenon during separation of NMP / chloroform and improving NMP recovery utilization efficiency, and possesses the advantages of simple operation, low cost, high safety and the like.

Owner:AFCHINA CORP CO LTD +1

Method and device for continuously feeding low-boiling material to high-pressure device

ActiveCN109529722ASmooth feedingUniform and stable feedingPressure vessels for chemical processBuffer tankBoiling point

The invention belongs to the technical field of chemical reaction engineering, and relates to a method and a device for continuously feeding a low-boiling material to a high-pressure device. The method comprises the following concrete steps: conveying the low-boiling material into a pressure-resistant buffer tank by means of a material storage tank; supplementing shielding gas with a certain pressure to the pressure-resistant buffer tank; enabling the low-boiling material to enter a high-pressure reaction system from the pressure-resistant buffer tank through a metering pump; when the materialstorage amount in the pressure-resistant buffer tank is reduced, repeating the previous steps to realize continuous, stable and uniform feeding. After the method and the device are adopted, the liquid feeding of the low-boiling material is realized, and continuity, stability and uniformity of feeding are guaranteed, so that the problem of pump stopping caused by bubbles generated by material vaporization is effectively reduced, and the stability of a reaction in the reactor is guaranteed.

Owner:SHANDONG YUHUANG CHEM CO LTD

A Downhole Insulated and Empty Suspension Bed Reactor

ActiveCN105013411BProtect the environmentImprove securityChemical/physical processesOil processingChemical reaction

The invention provides a downhole heat-insulated and empty suspended bed reactor. The reactor is suitable for the heavy oil hydrogenation and lightening process in the petroleum processing process, the hydrogenation direct liquefaction process of coal and biomass, the mixed co-refining hydrogenation and lightening process of coal, biomass and heavy oil, and High temperature and high pressure chemical reaction engineering of other fluid materials.

Owner:仲兴行(上海)商务服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com