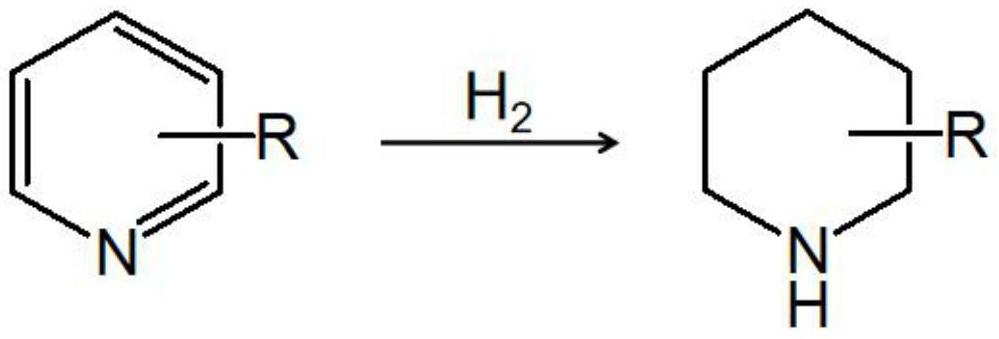

Method for synthesizing piperidine through continuous liquid-phase hydrogenation of pyridine in microreactor

A pyridine continuous liquid and micro-reactor technology, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the problems of excess hydrogen, high reaction temperature and pressure, transmission Low mass efficiency and other problems, to achieve the effect of high efficiency reaction, small liquid holding capacity and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

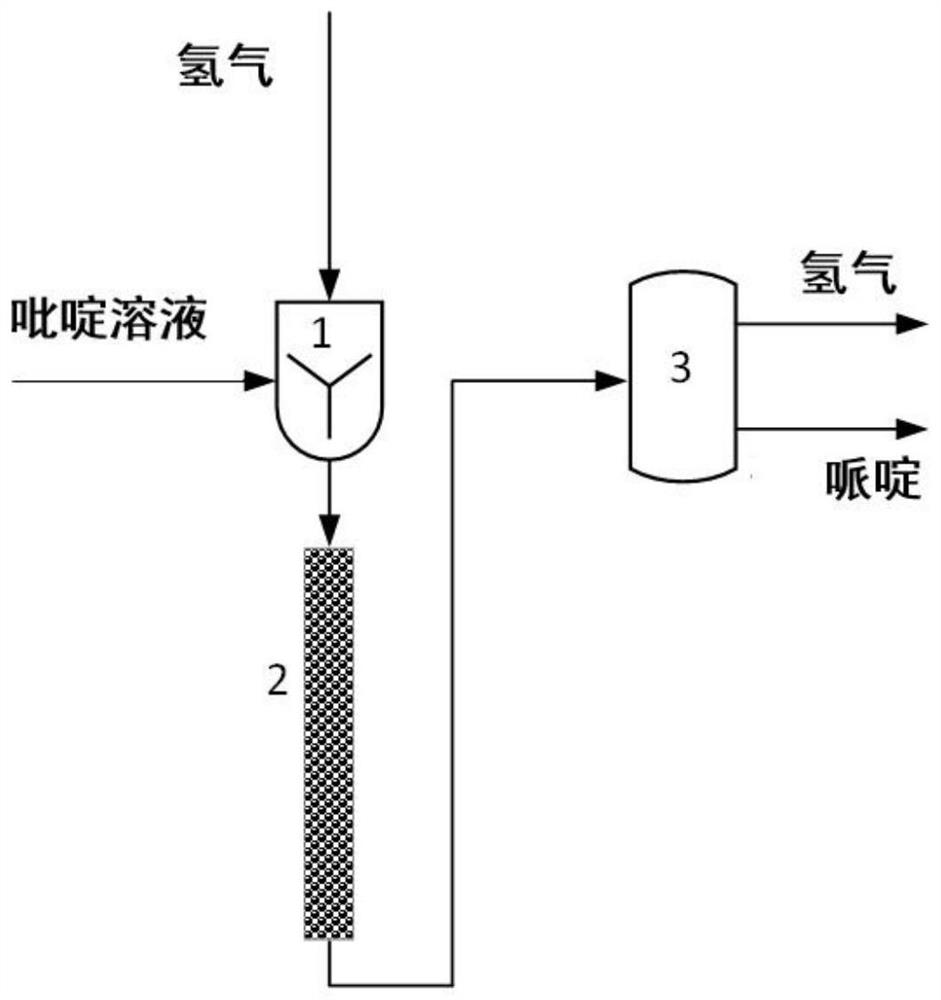

Embodiment 1

[0039] Carry out experiments according to this method, prepare the methanol solution of pyridine, the mass concentration is 10%, the molar ratio of pyridine and hydrogen is 1: 6; The solution and hydrogen are mixed in the inlet T-shaped micro-mixer, forming a well-dispersed gas-liquid state; Flow through a micro-packed bed equipped with ruthenium / carbon catalyst; control the reaction temperature to 60°C, the reaction pressure to 2.0Mpa, and the residence time to 100s; after being separated by a gas-liquid separator, the product at the lower end is collected and analyzed, and the conversion rate of pyridine About 100%, the selectivity of piperidine is close to 100%.

Embodiment 2

[0041] Carry out experiment according to this method, prepare the ethanol solution of pyridine, mass concentration is 40%, the mol ratio of pyridine and hydrogen is 1: 10; Solution and hydrogen are mixed in the inlet micro-mesh mixer, form the well-dispersed gas-liquid state; Flow through a micro-packed bed equipped with a ruthenium / alumina catalyst; control the reaction temperature to 80°C, the reaction pressure to 5.0Mpa, and the residence time to 150s; after separation by a gas-liquid separator, the product at the lower end is collected and analyzed, and the conversion of pyridine The yield was 99.9%, and the selectivity to piperidine was 99.8%.

Embodiment 3

[0043]Carry out experiment according to this method, prepare the aqueous solution of pyridine, mass concentration is 2%, the mol ratio of pyridine and hydrogen is 1: 3.5; Solution and hydrogen are mixed in inlet membrane dispersion mixer, form the well-dispersed gas-liquid state; Flow through A micro-packed bed equipped with platinum / alumina catalyst; the reaction temperature is controlled at 50°C, the reaction pressure is 1.0Mpa, and the residence time is 10s; after separation by a gas-liquid separator, the product at the lower end is collected and analyzed, and the conversion of pyridine is 99.8%, the selectivity of piperidine is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com