Patents

Literature

114results about How to "Small liquid holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

ActiveCN104355973AHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveTower

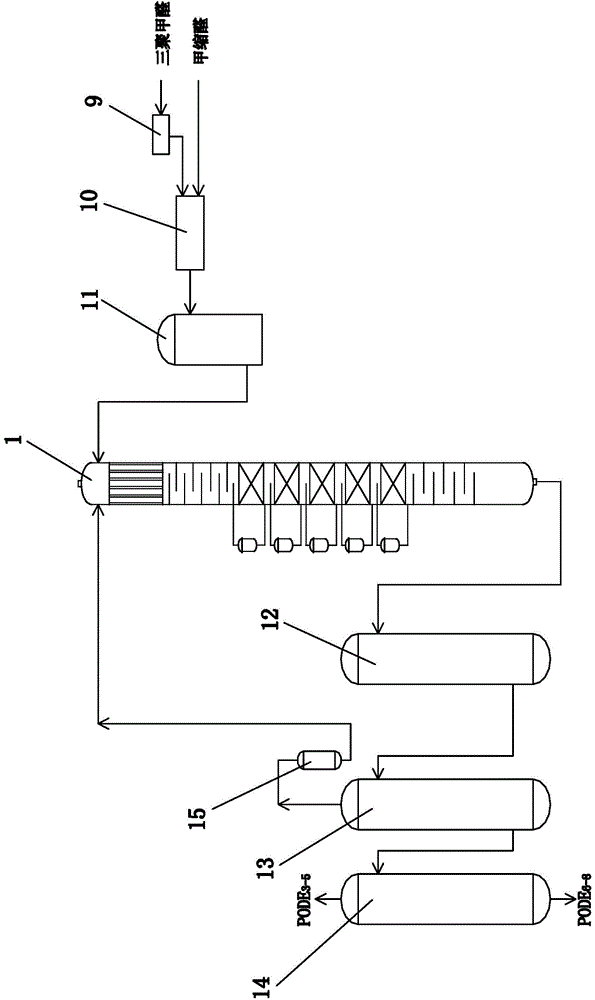

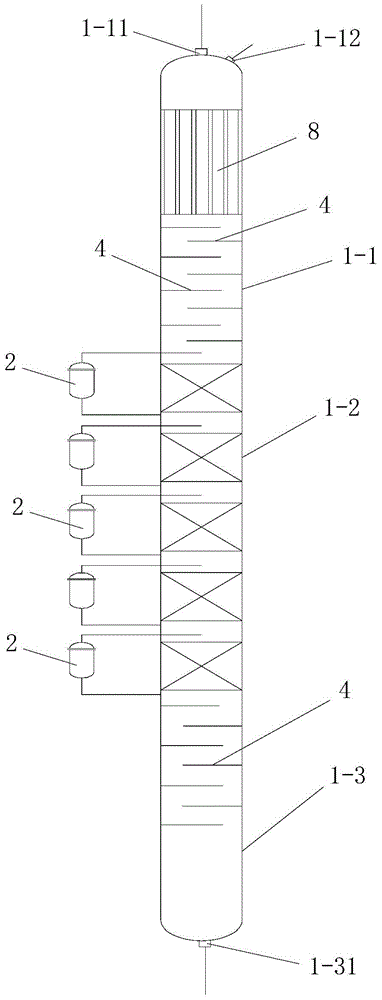

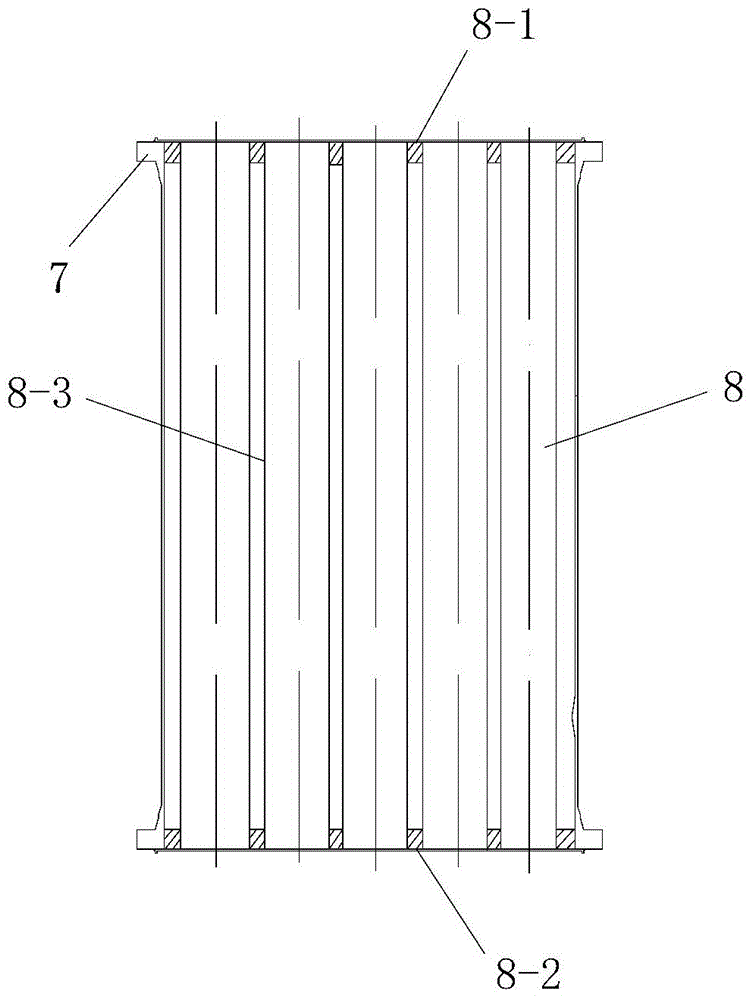

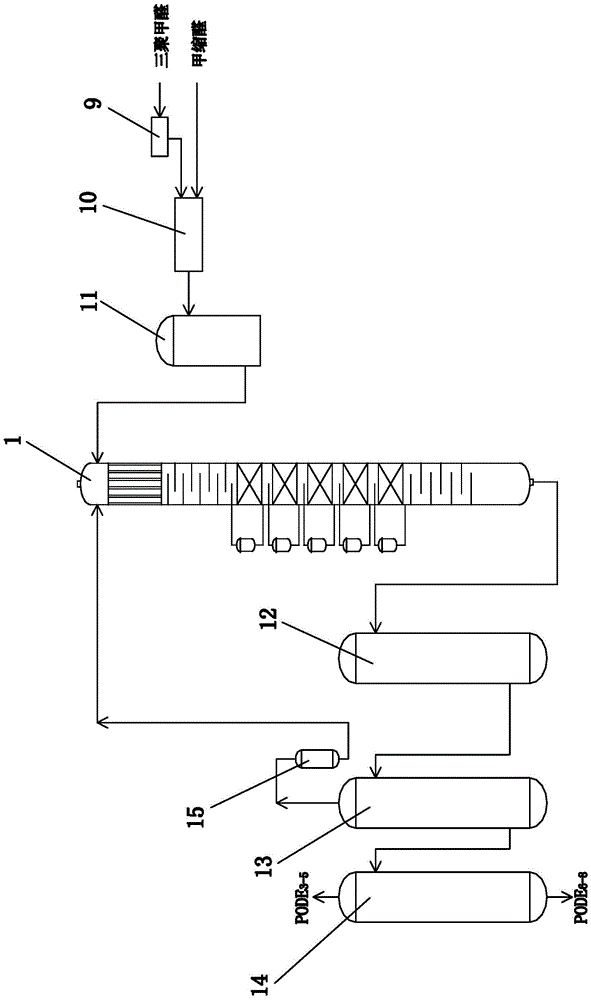

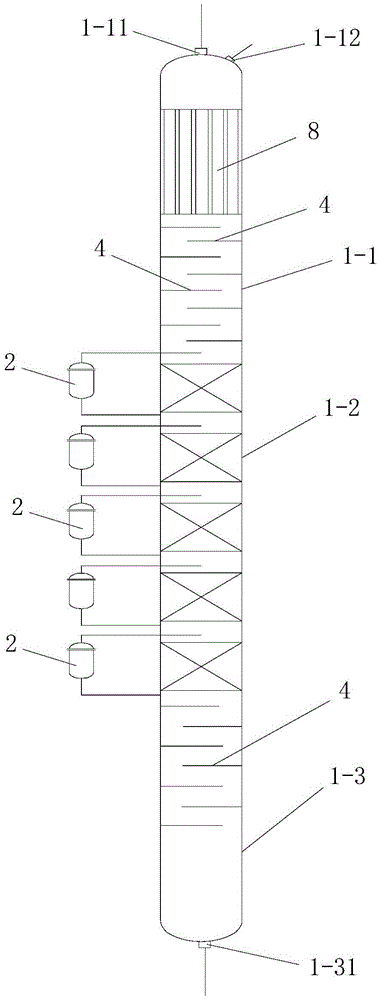

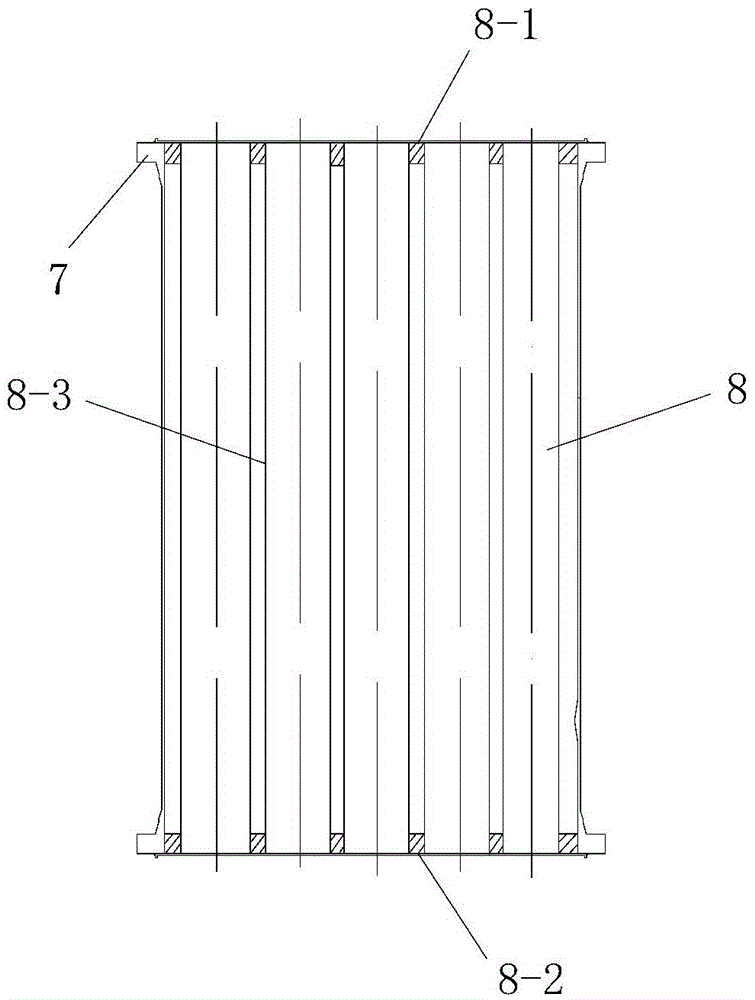

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

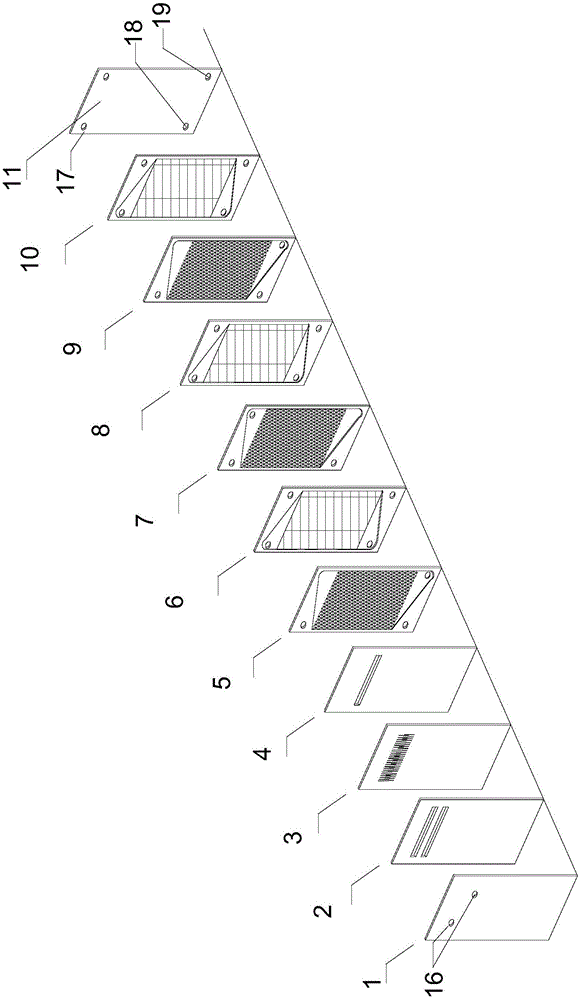

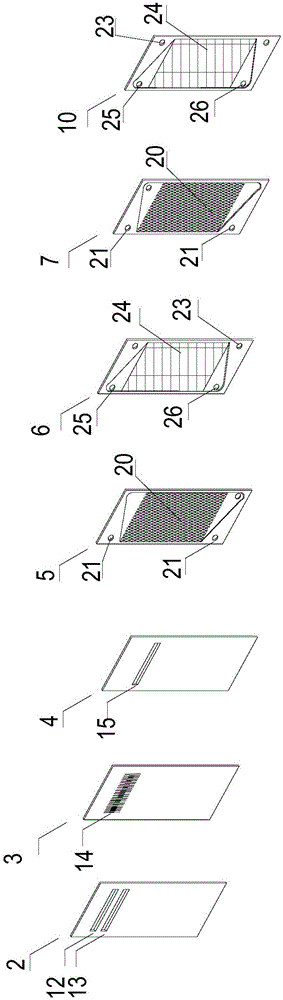

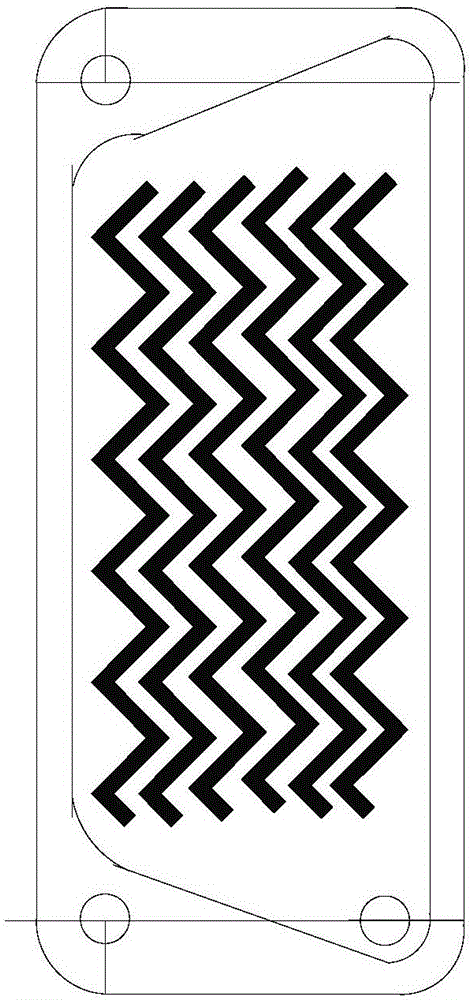

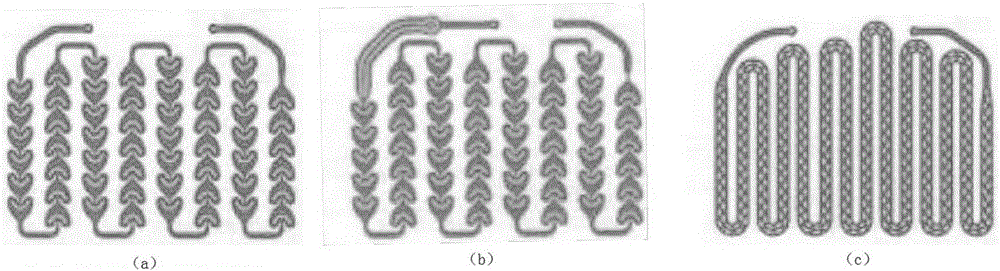

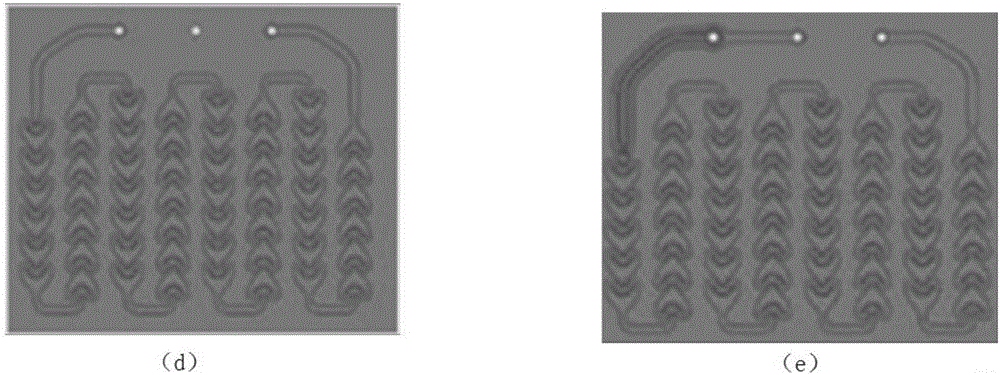

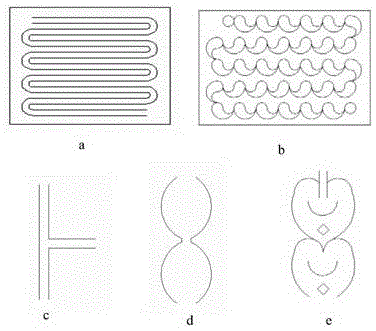

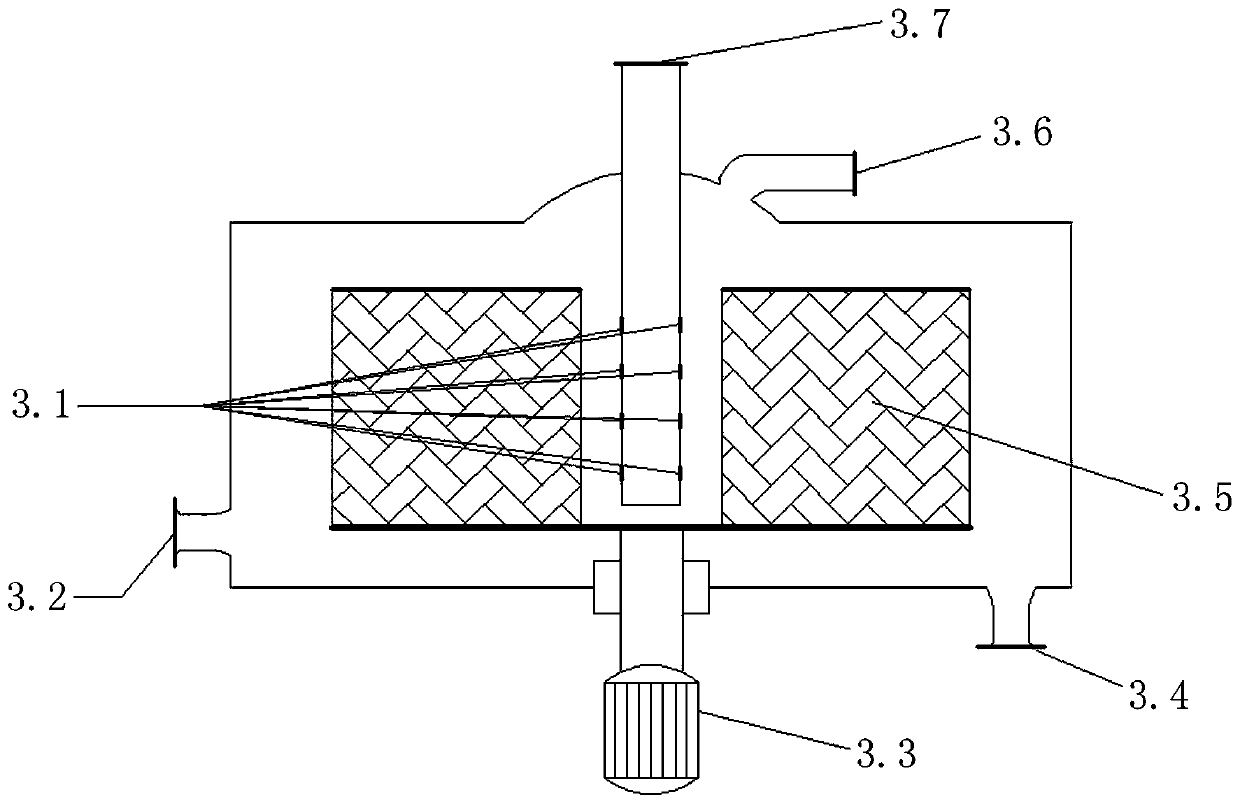

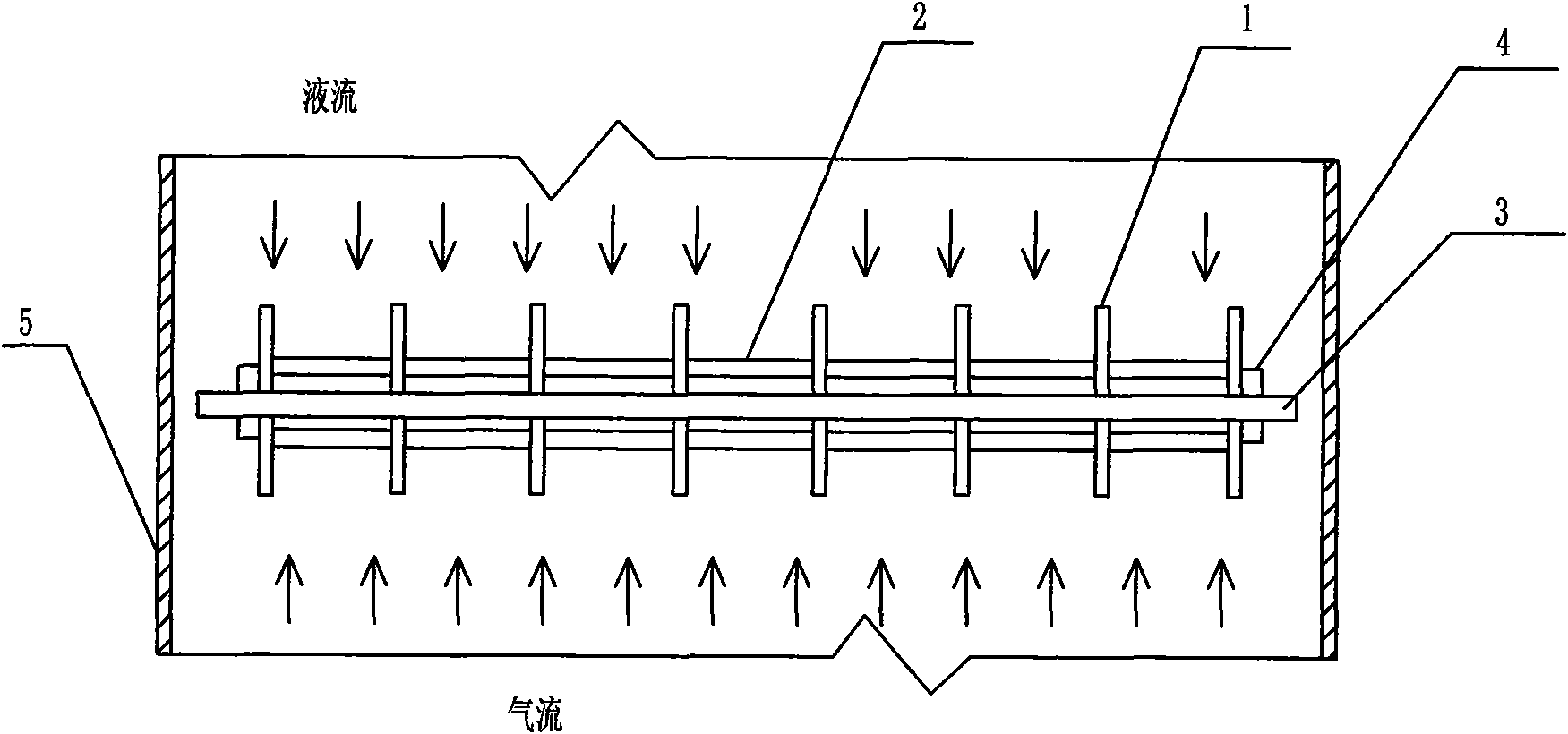

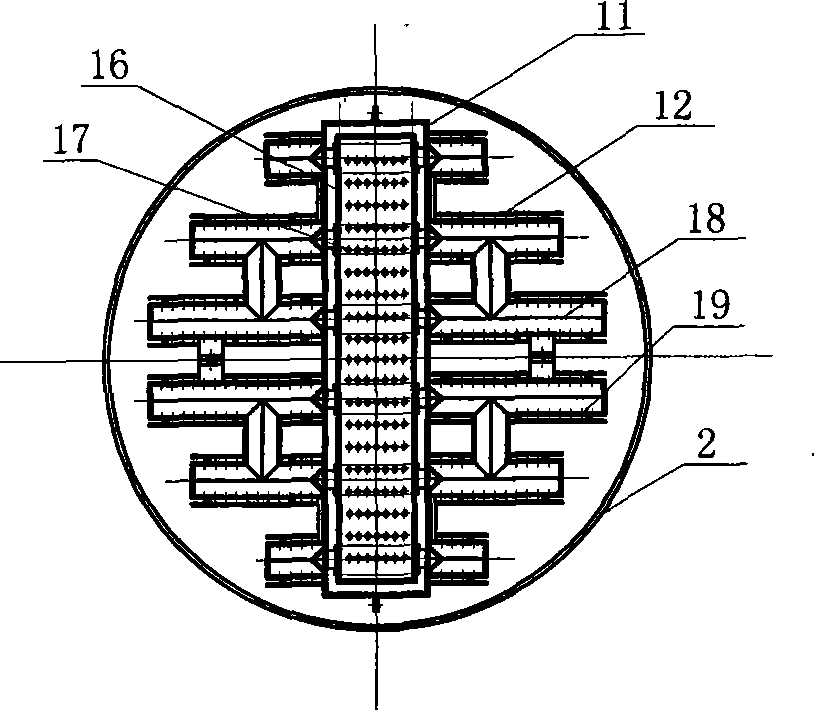

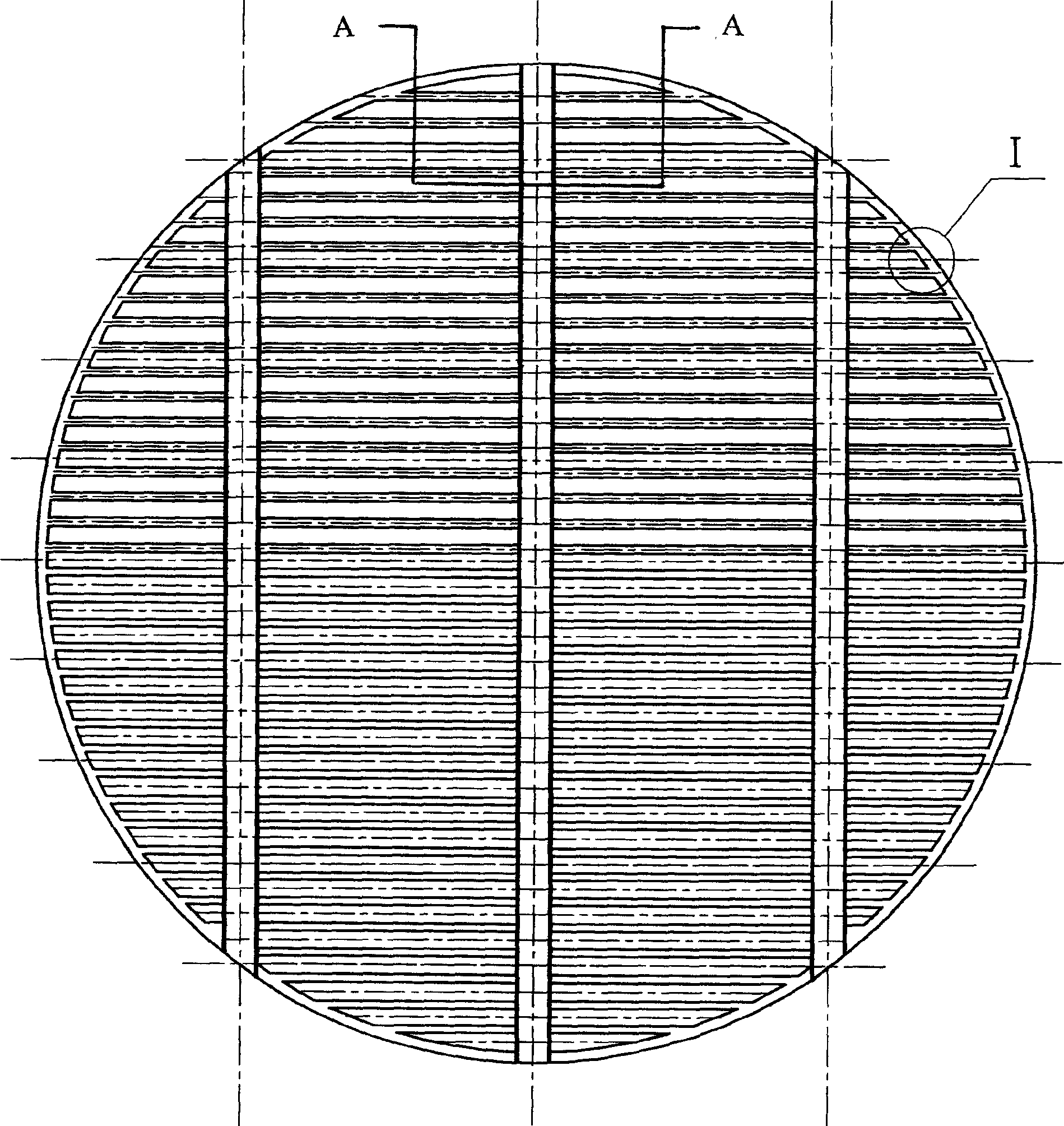

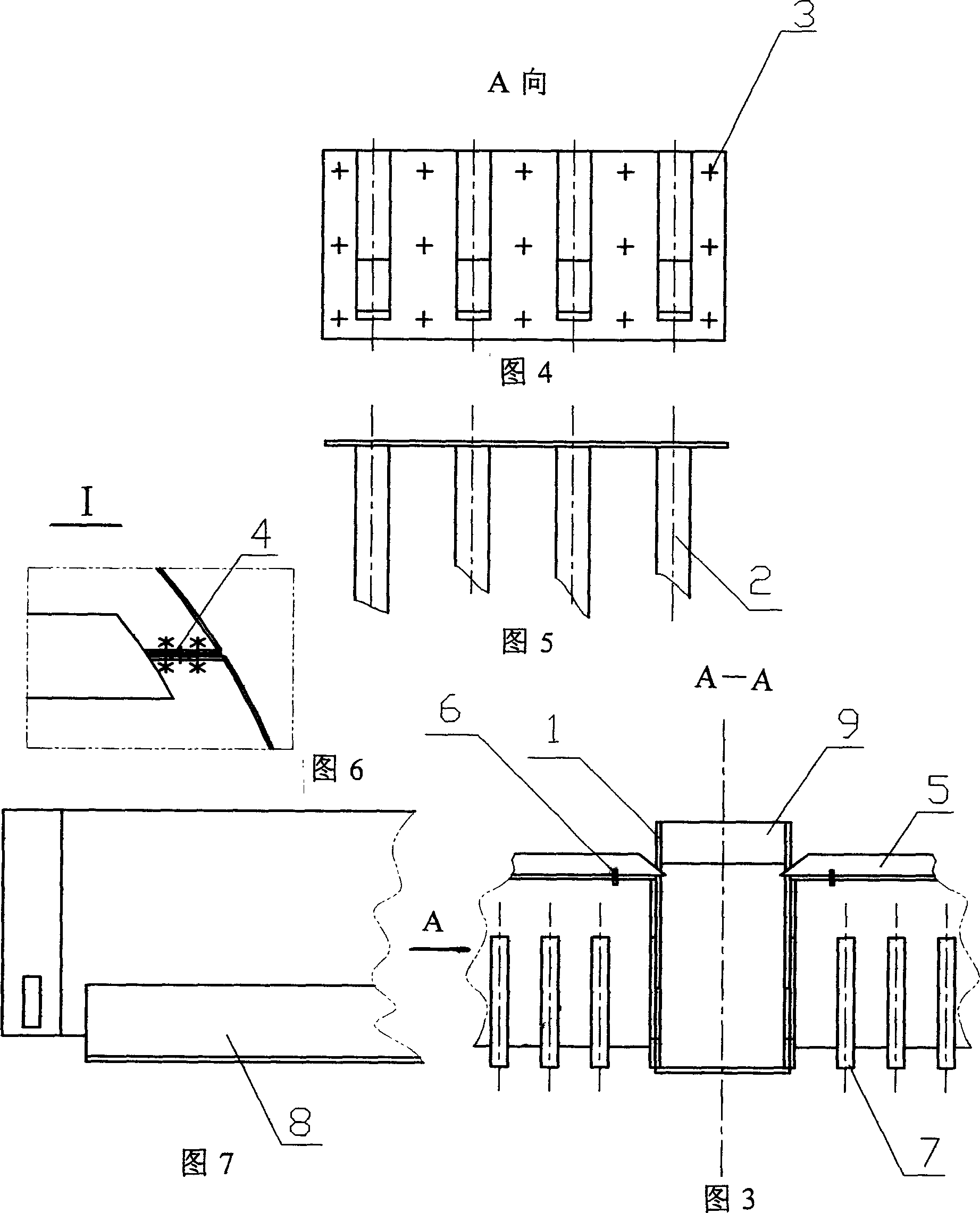

Efficient mixing heat exchange micro-channel reactor

InactiveCN105107443AReduce inputReduce usageChemical/physical/physico-chemical processesSolventEnvironmentally friendly

The invention discloses an efficient mixing heat exchange micro-channel reactor. The efficient mixing heat exchange micro-channel reactor comprises a dispersive mixing component, multiple reaction liquid passageway matrixes and heat exchange medium passageway matrixes. The reaction liquid passageway matrixes and the heat exchange medium passageway matrixes are arranged alternately. The dispersive mixing component is provided with dispersive mixing channels allowing two or more kinds of reaction liquid to dispersively flow in and be mixed to form mixed reaction liquid. The reaction liquid passageway matrixes are provided with reaction liquid passageways and heat exchange medium via holes. The heat exchange medium passageway matrixes are provided with reaction liquid via holes, heat exchange medium passageways, inflow holes and outflow holes, wherein the inflow holes and the outflow holes are communicated with the heat exchange medium passageways. The reaction liquid passageways of every two adjacent reaction liquid passageway matrixes are of a cascaded structure. The heat exchange medium passageways of every two adjacent heat exchange medium passageway matrixes are of a parallel structure. According to the efficient mixing heat exchange micro-channel reactor, the heat transfer problem is completely solved; mass transfer and heat transfer are enhanced, input of heat and cold is reduced, use of a solvent is reduced, the reaction yield is increased, energy is saved, consumption is reduced, and the efficient mixing heat exchange micro-channel reactor is environmentally friendly.

Owner:NANJING NEWWEEL ELECTRIC CO LTD

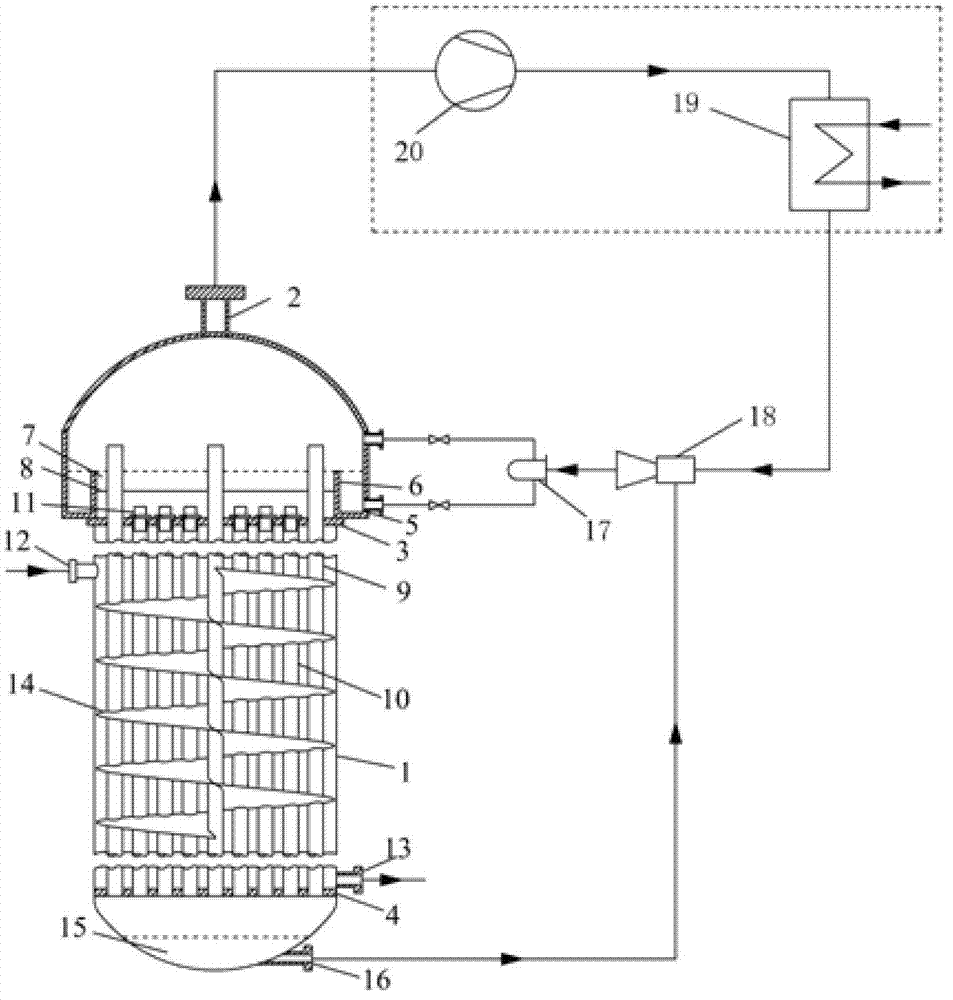

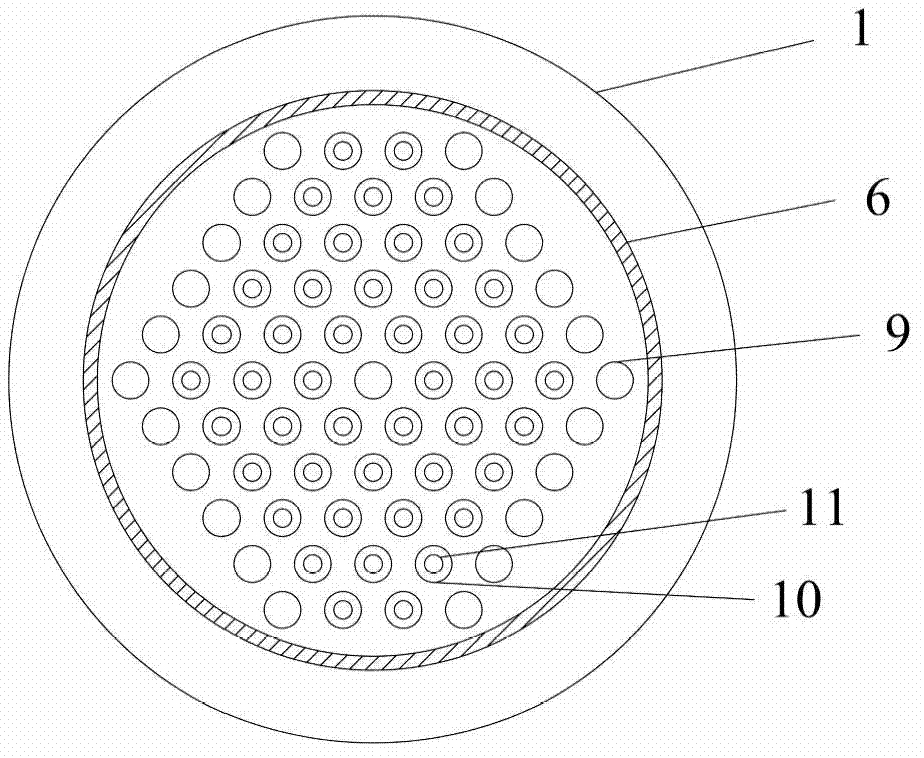

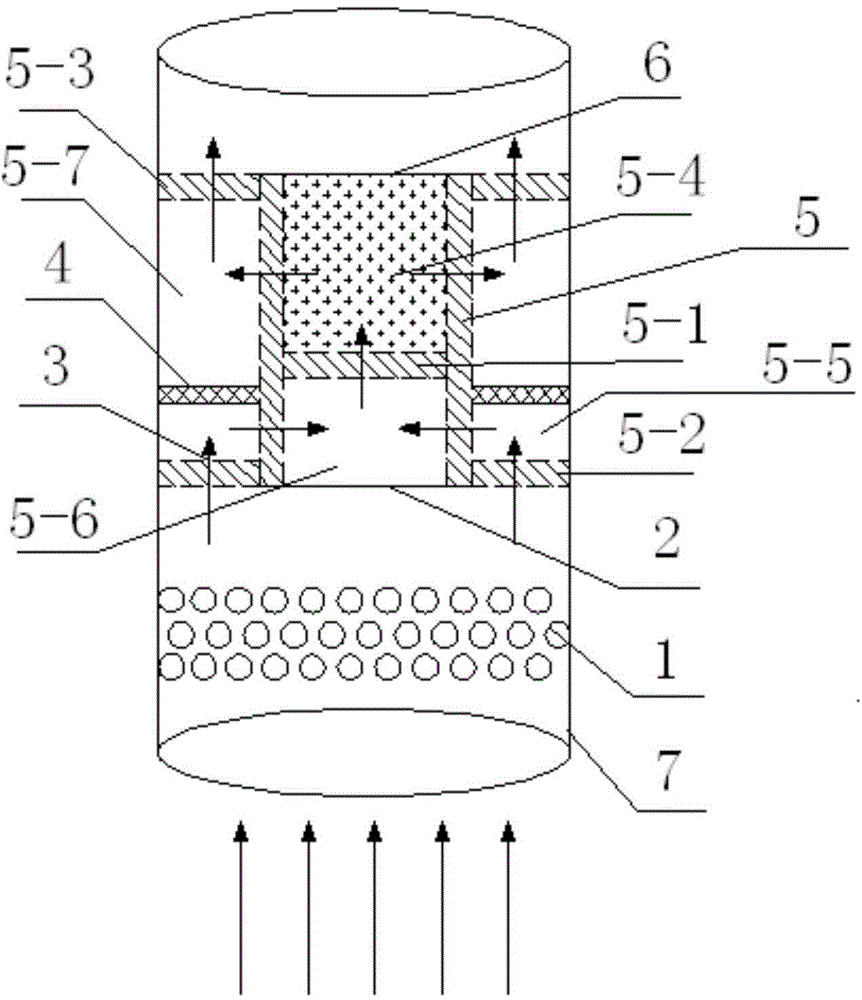

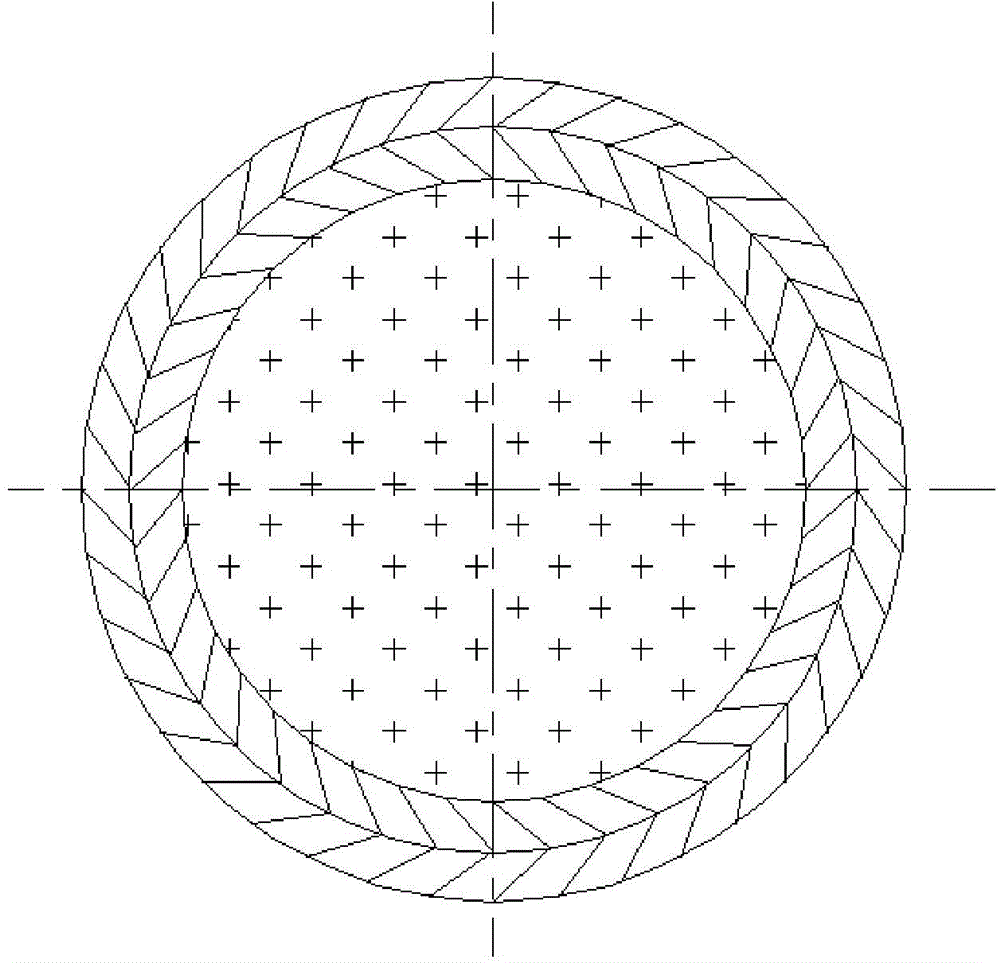

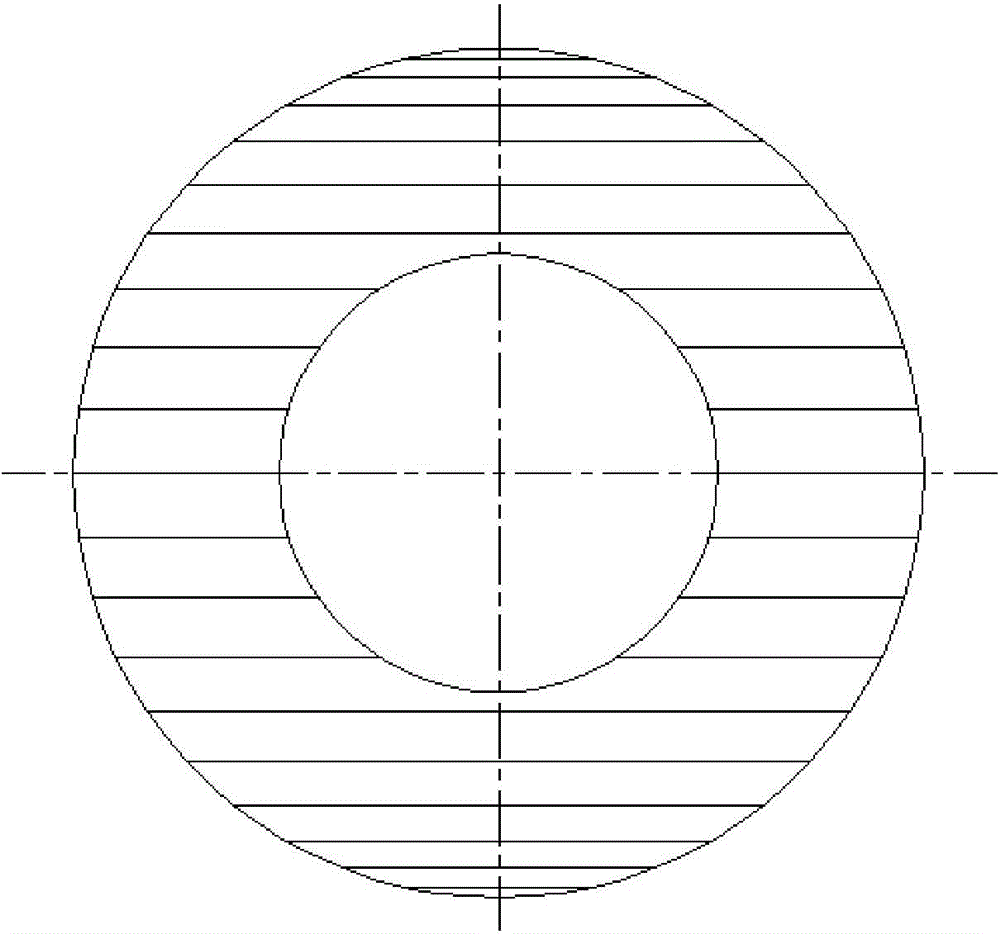

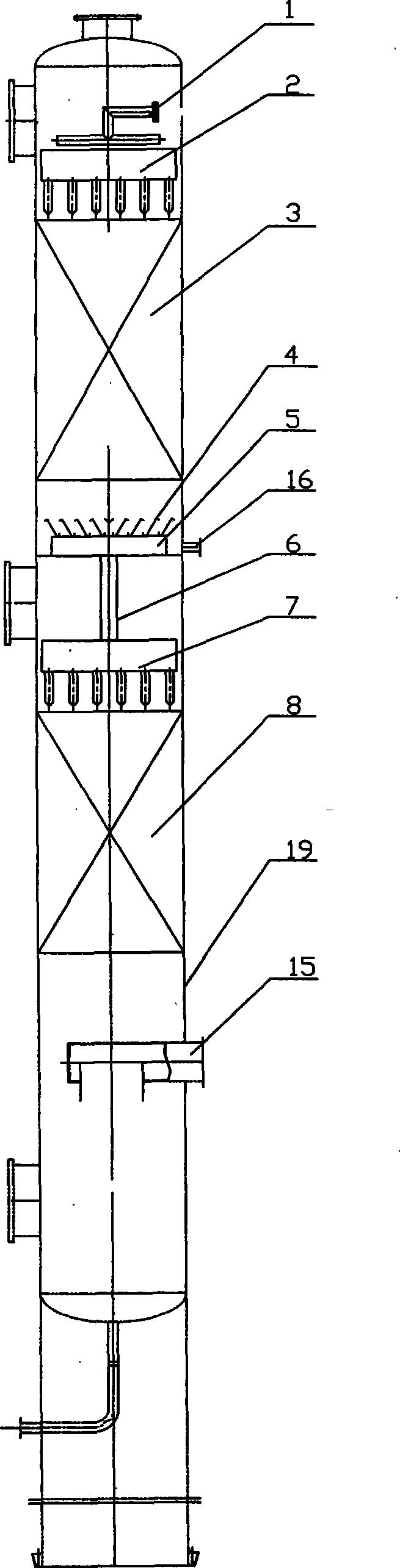

Riser spiral-flow type falling-film evaporator for refrigerating air conditioner

InactiveCN102759225AImprove heat transfer performanceSmall liquid holding capacityEvaporators/condensersHeat exchanger casingsRefrigerantFalling film evaporator

The invention discloses a riser spiral-flow type falling-film evaporator for a refrigerating air conditioner. The riser spiral-flow type falling-film evaporator comprises a shell, a refrigerant steam conveying pipe bundle, a falling-film evaporation pipe bundle, a damping hole plate and a spiral baffle plate, wherein the refrigerant steam conveying pipe bundle is arranged in the center in the shell and along the circumferential direction of the inner all of the shell, the falling-film evaporation pipe bundle is surrounded by the refrigerant steam conveying pipe bundle, the refrigerant steam conveying pipe bundle and the falling-film evaporation pipe bundle are both vertically arranged inside the shell, the upper part of an inlet of the falling-film evaporation pipe bundle is horizontally provided with the damping hole plate, the spiral baffle plate is fixed inside the shell and spirally arranged along a vertical direction, and is provided with through holes allowing the refrigerant steam conveying pipe bundle and the falling-film evaporation pipe bundle to pass through, an ejector is arranged between a refrigerant outlet pipe and a refrigerant inlet pipe, the inlet of the falling-film evaporation pipe bundle is provided with a flow guiding nozzle which has an outer diameter smaller than the inner diameter of the falling-film evaporation pipe bundle and is sealed at two ends, and the flow guiding nozzle is provided with a circular ring with three chutes formed along a circumferential direction uniformly. The riser spiral-flow type falling-film evaporator has the characteristics of small heat transfer temperature difference, high heat transfer coefficient, large evaporative power of unit area capable of preventing dry evaporation, low manufacture cost, less liquid holdup, small floor area and high safety.

Owner:XI AN JIAOTONG UNIV

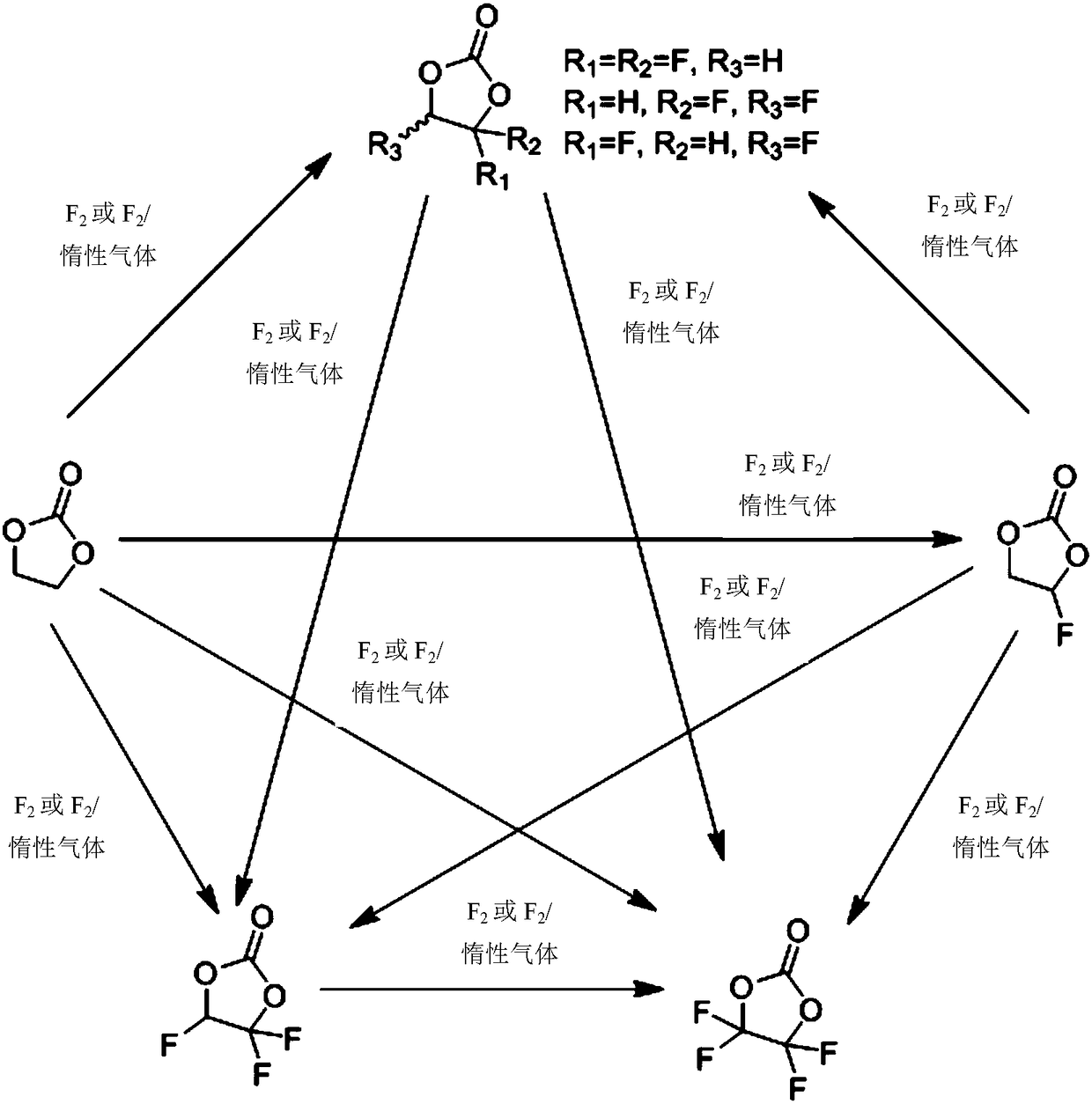

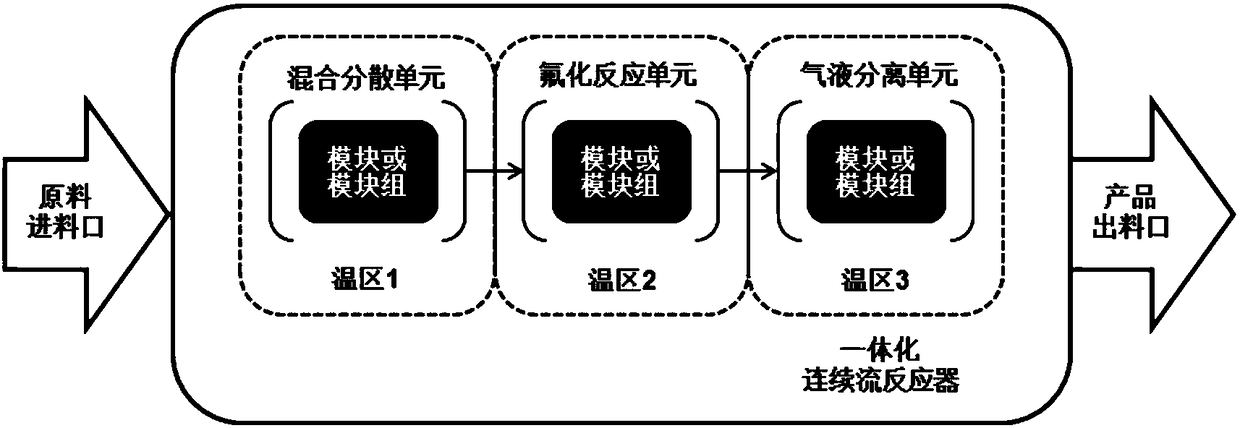

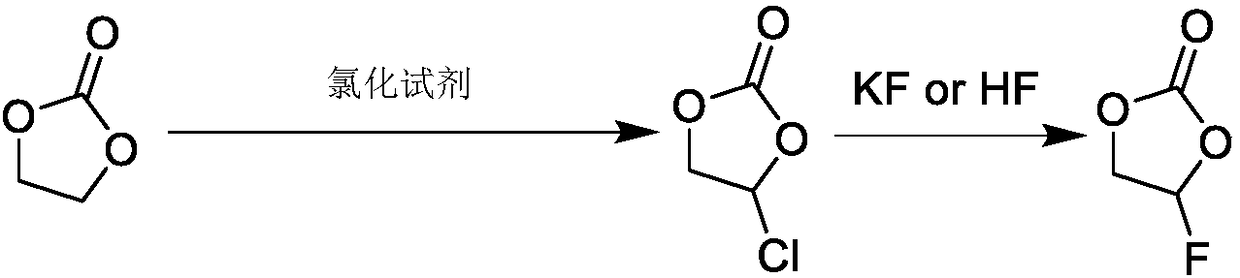

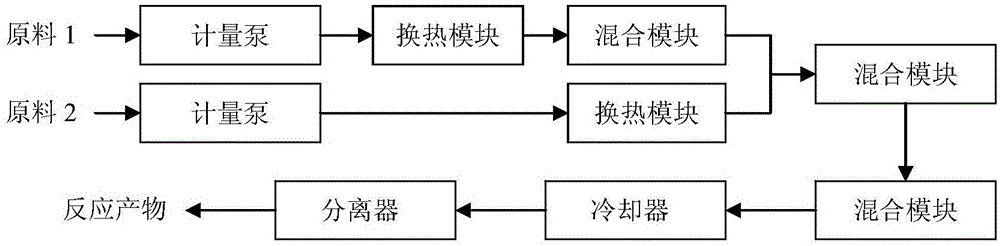

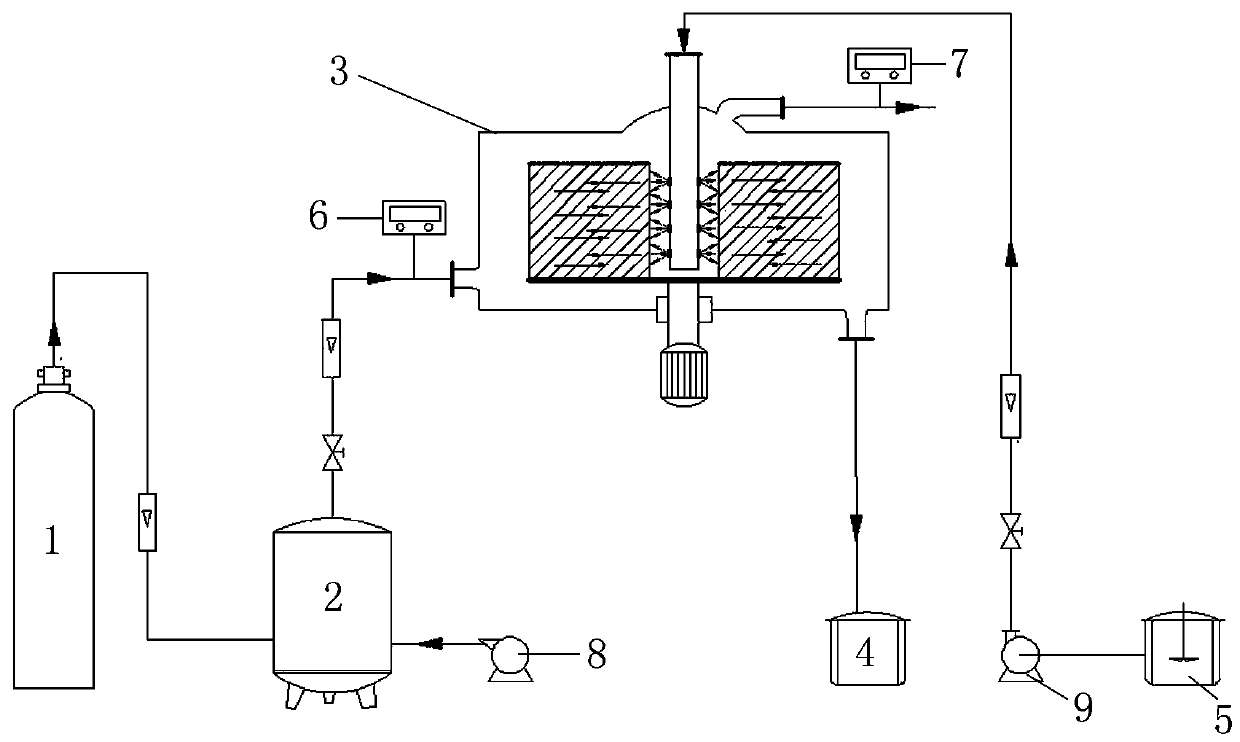

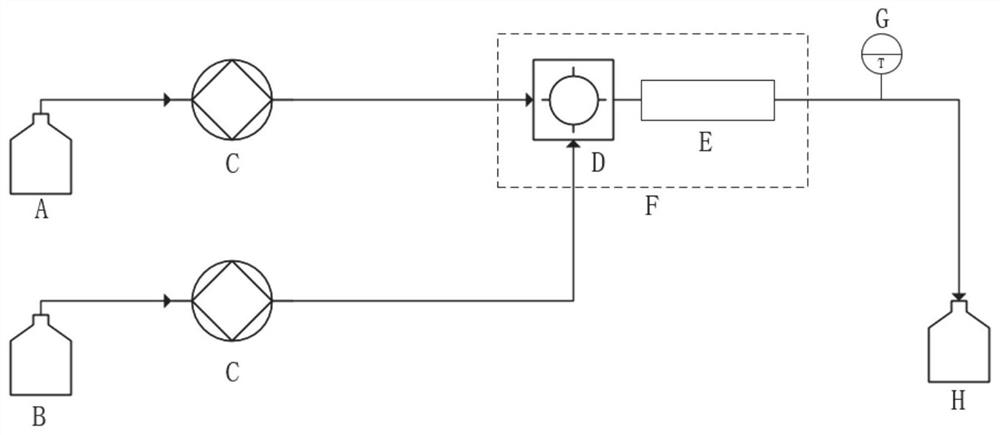

Rapid continuous flow synthesis process of fluoroethylene carbonate

InactiveCN108250176AOvercoming the defect of amplification effectNo effect on yieldOrganic chemistryContinuous flowCarbonate

The invention relates to a rapid continuous flow synthesis process of fluoroethylene carbonate and an integrated continuous flow reactor for realizing the process. The continuous flow synthesis process is characterized in that a raw material to be fluorinated and fluorine gas are used as reactants, and are continuously and successively subjected to steps of mixed dispersion, fluorination reaction,gas-liquid separation, so as to obtain the fluoroethylene carbonate; and the synthesis process is carried out in the integrated continuous flow reactor, the raw material to be fluorinated and the fluorine gas are continuously added to a feed inlet of the integrated continuous flow reactor, and the fluoroethylene carbonate is continuously obtained from a discharge port of the integrated continuousflow reactor with the reaction time equal to or less than 600 s. The process is a rapid, safe, efficient, highly versatile and easy for mass production continuous synthesis process of the fluoroethylene carbonate.

Owner:SHANGHAI HYBRID CHEM TECH

A kind of method for preparing polyoxymethylene dimethyl ether by fixed-bed reactive distillation

ActiveCN104355973BHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

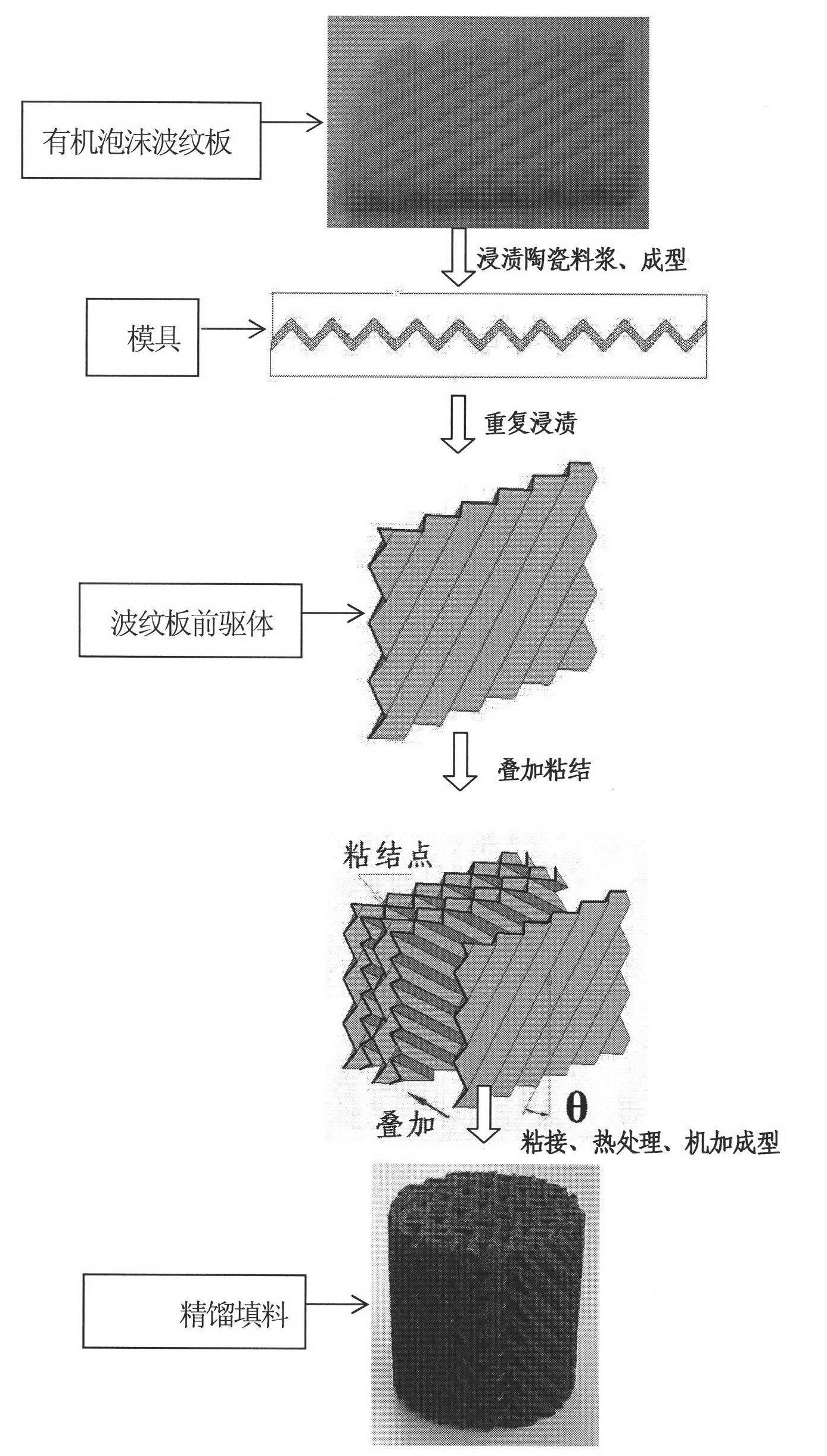

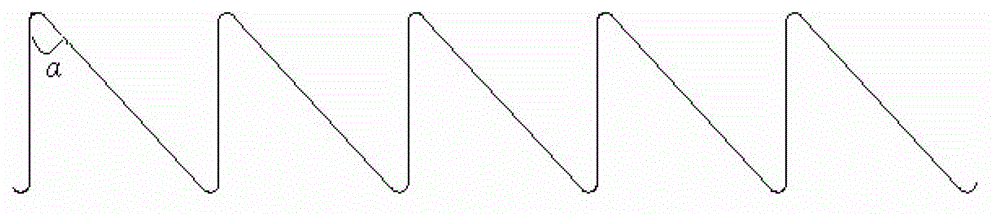

Cheap and high efficiency rectification filler and preparation method thereof

ActiveCN102247795ALarge specific surface areaFully contactedChemical/physical/physico-chemical processesNetwork structureEngineering

The invention which relates to the field of structured fillers concretely relates to a cheap and high efficiency rectification filler and a preparation method thereof. The filler which is suitable for a rectification operation under a temperature of less than 300 DEG C is formed by stacking filler unit plates with corrugated shapes, the filler unit plates are foamed resin-based filler unit plateswith three-dimensional connected network structures, the foam pore sizes are between 10PPi and 80PPi, and the volume fraction is controlled between 10% and 80%. A plurality of the filler unit plates are stacked, the filler unit plates of the odd-numbered layers have a consistent channel direction, and the filler unit plates of the even-numbered layers have a consistent channel direction, and an angle between the channel direction of the filler unit plates of the odd-numbered layers and the channel direction of the filler unit plates of the even-numbered layers is 30-170 DEG; a corrugation angle between a corrugation parallel direction and a vertical direction of a filler disc is 15-85 DEG, corrugations of adjacent filler unit plates have a same angle and opposite directions; and the filler unit plates are bonded after being stacked, and are subjected to a heat treatment to obtain the filler. The foamed resin-based structured filler unit plates of the invention allows the three-dimensional network connectivity characteristic of a polyurethane foamed plastic template to be kept, and has the characteristics of large specific surface area, thin wall, cheapness, high chemical stabilityand the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Continuous synthesis method for 2-methyl-5-nitroimidazole

InactiveCN111362876ASmall liquid holding capacityImprove securityOrganic chemistryNitroimidazoleCombinatorial chemistry

The invention provides a continuous synthesis method for 2-methyl-5-nitroimidazole. The 2-methyl-5-nitroimidazole is synthesized in a micro-channel reactor. The synthesis method provided by the invention can realize continuous synthesis, is safe and stable in production process, extremely short in reaction time and high in yield, and can reduce the usage amount of concentrated sulfuric acid and lower cost.

Owner:SHANDONG HIMILE CHEM TECH

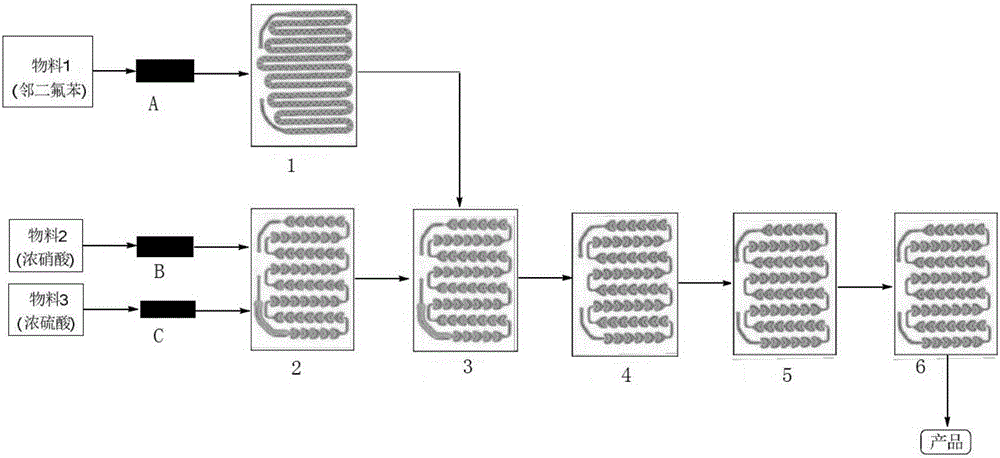

Method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using micro-channel reactor

ActiveCN106397358AReduce energy consumptionEfficient mass and heat transferOrganic chemistryAcetic acidHydrogen

The invention provides a method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using a micro-channel reactor. The micro-channel reactor comprises a preheating module group composed of one or more parallely-connected preheating modules and a reaction module group composed of one or more tandemly-connected reaction modules, wherein the preheating module group is series connection with the reaction module group. The method comprises the following steps: separately preheating difluorobenzene, concentrated nitric acid and concentrated sulfuric acid, then subjecting the preheated difluorobenzene, concentrated nitric acid and concentrated sulfuric acid to a reaction in the reaction module group and carrying out treatment so as to obtain 3,4-difluoronitrobenzene; dissolving 3,4-difluoronitrobenzene in an organic solvent, adding organic base, dissolving morpholine in the organic solvent, carrying out preheating, allowing the obtained solution to enter the reaction module group for a reaction and carrying out treatment so as to obtain 4-(2-fluoro-4-nitrophenyl)morpholine; and dissolving 4-(2-fluoro-4-nitrophenyl)morpholine in ethyl acetate, adding a catalyst, carrying out preheating, allowing the obtained solution and hydrogen to enter the reaction module group for a reaction and carrying out treatment so as to obtain 3-fluoro-4-(4-morpholinyl)aniline. The method has the advantages of low energy consumption, high yield, high product purity, safety, flexibility, etc.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

Multichannel-type composite demister and demisting method

ActiveCN104815501ADisadvantages of changing single-stage defoggingInsufficient changeCombination devicesFilling materialsMechanical engineering

The invention discloses a multichannel-type composite demister and a demisting method. The multichannel-type composite demister comprises a demister case and a cylindrical structure enclosed by a baffle plate and arranged in the demister case with axial direction, the inner part of the cylindrical structure is divided into a filling material chamber and an intermediate rectification chamber; a second baffle plate and a third baffle plate are arranged between an upper end of the cylindrical structure and the demister case as well as a lower end of the cylindrical structure demister case; a support plate is arranged between central section of the outer wall of the cylindrical structure and the demister case, a bottom circulation chamber is formed by a cavity defined by the second baffle plate and the support plate, a top circulation chamber is formed by a cavity defined by the support plate and the third baffle plate; air flow is introduced into the bottom circulation chamber, an intermediate rectification chamber, a filling material chamber and the top circulation chamber from the bottom of the demister case in order, and is discharged from the top of the demister case. By employing a composite demisting effect with combination of multichannel separating, baffle plate inertia separating and filling material separating, little liquid drop can be removed, so that the demister can better solve the raining or gypsum rain phenomenon of a chimney.

Owner:SOUTH CHINA UNIV OF TECH

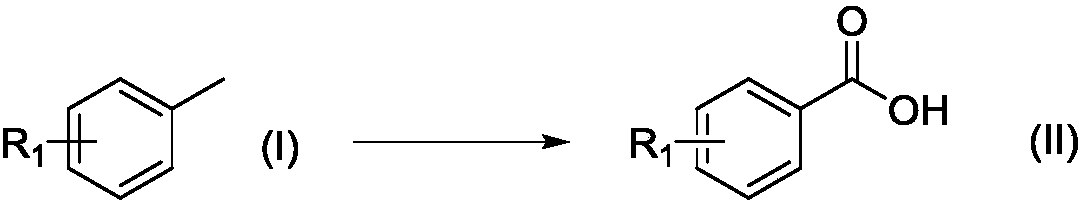

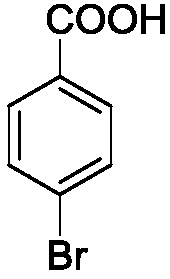

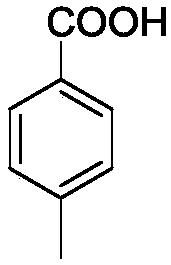

Method for preparing aryl formic acid compound with microchannel continuous flow reactor

InactiveCN108623453AReduce generationSystem greenOrganic compound preparationCarboxylic compound preparationIron saltsContinuous flow

The invention discloses a method for preparing an aryl formic acid compound with a microchannel continuous flow reactor. The method comprises the following steps: with methyl aromatics represented bythe formula (I) as a raw material, a mixture of cobalt salt, manganese salt and iron salt as a ternary complex catalyst, hydrogen peroxide with mass concentration of 30% as a cocatalyst, and acetonitrile or acetic acid as an organic solvent, uniformly mixing to form a homogeneous solution, pumping the homogeneous solution into the microchannel continuous flow reactor through a metering pump, reacting at 25 to 150 DEG C in an oxygen atmosphere of 0.5 to 10 MPa for 4 to 100 seconds to obtain a reaction mixture, and carrying out post-treatment to obtain the aryl formic acid compound represented by the formula (II). According to the invention, with cleaning agents such as oxygen and hydrogen peroxide as oxidants and cocatalysts, by-products toxic and harmful to the environment are reduced, thesystem is greener and cleaner, the reaction can be continuously carried out, the production efficiency is high, and industrialized amplified production is facilitated.

Owner:杭州陶瑞生物科技有限公司

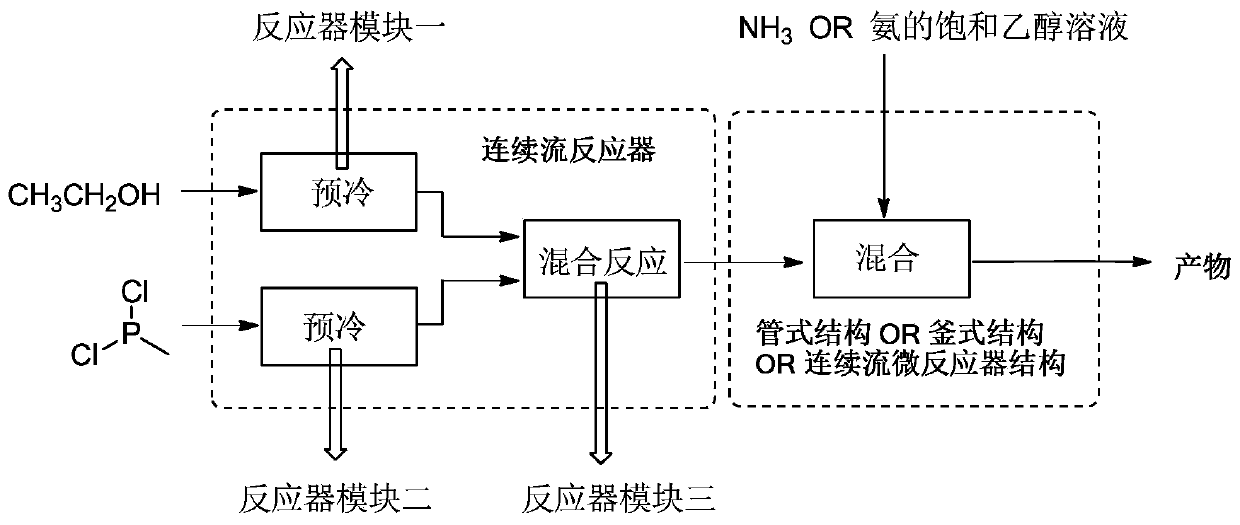

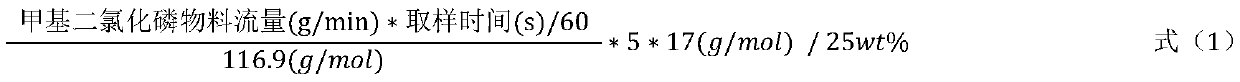

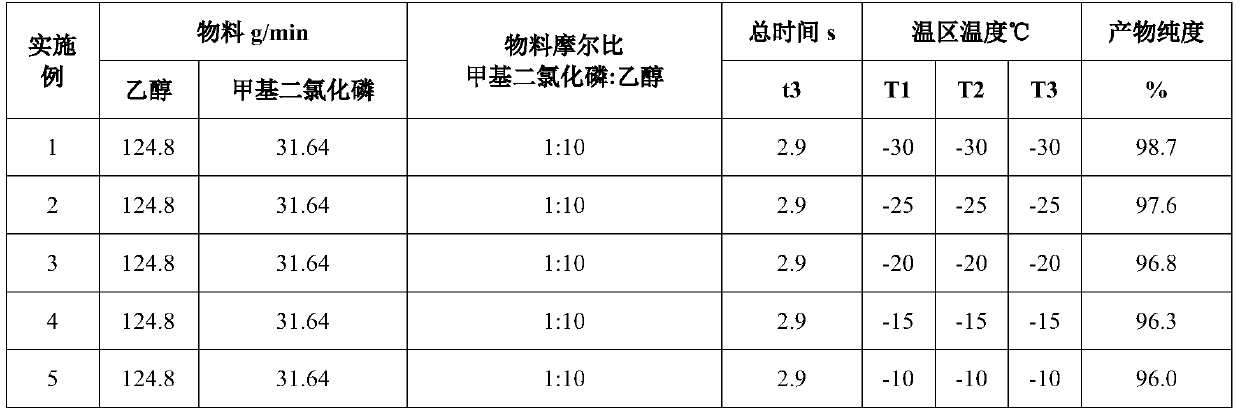

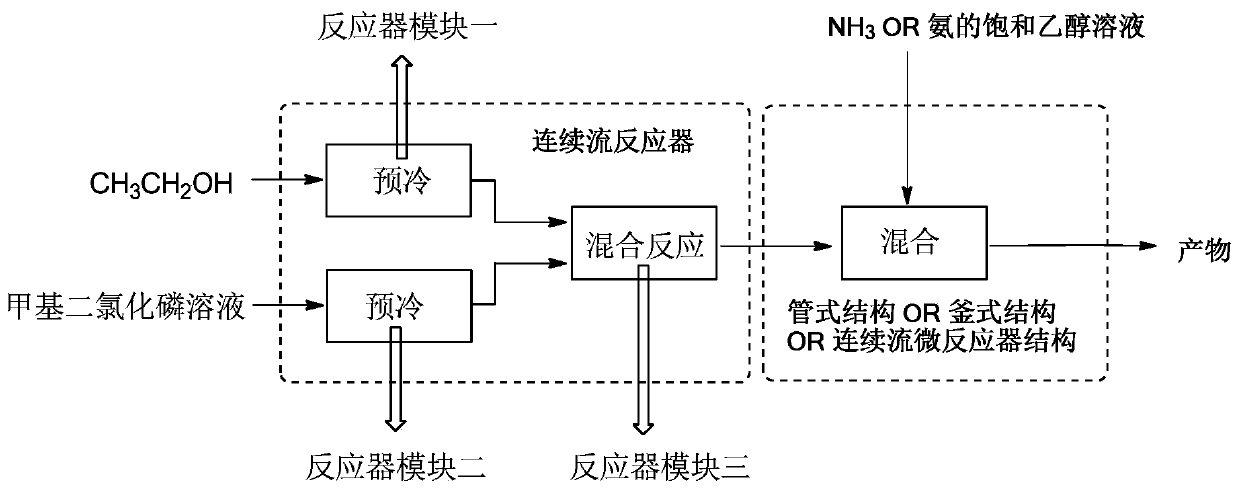

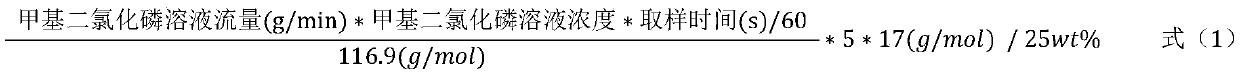

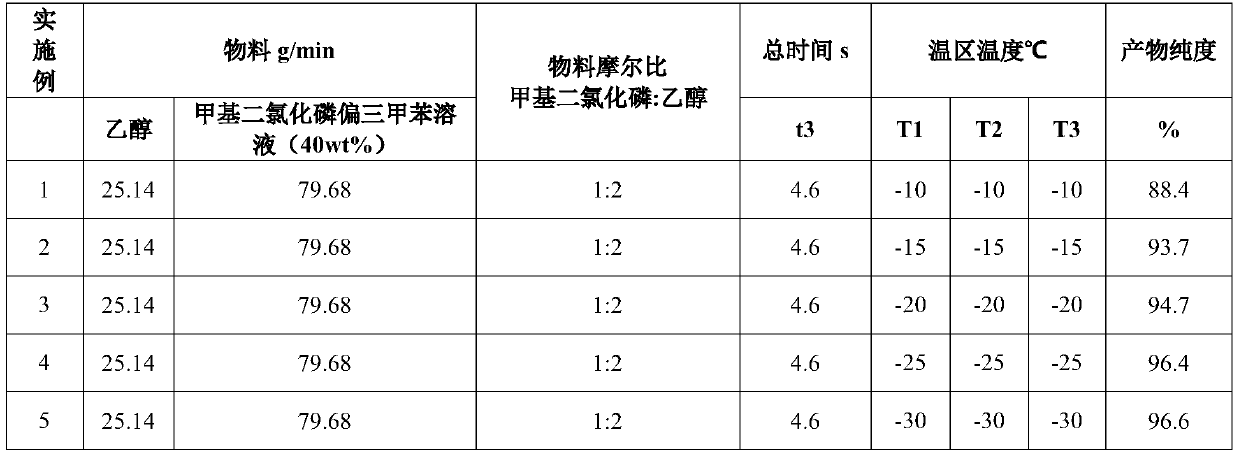

Continuous flow preparation method of diethyl methyl phosphite

PendingCN111004280ASmall liquid holding capacitySafe and efficient productionGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateCombinatorial chemistry

The invention discloses a continuous flow preparation method of diethyl methyl phosphite, which comprises the following steps: continuously adding ethanol and methyl phosphorus dichloride into a feedport of a continuous flow reactor, and continuously obtaining diethyl methyl phosphite at a discharge port of the continuous flow reactor. The method has the advantages of small liquid holdup, safe and efficient production process, solving of the problems of long reaction time and low efficiency in kettle type reaction, high product yield and purity, and simple and efficient process operation.

Owner:LIER CHEM CO LTD +1

Method for synthesizing lenalidomide

InactiveCN107033126AImprove recycling ratesQuick responseOrganic chemistryChemical recyclingNitro compoundActivated carbon

The invention provides a method for synthesizing lenalidomide, belongs to the field of anti-tumor and anti-leukemia medicines in organic synthesis, and particularly relates to the method for synthesizing lenalidomide. To solve the problems of low yield, low purity, environmental pollution caused by massive harmful waste, excessive cost for environment-friendly treatment, easily occurred risk of violent explosive, degradation caused by long reacting time at high temperature and low catalyst recycling frequency in a traditional lenalidomide synthesis reaction, the method comprises the following steps: 1, adding a lenalidomide precursor nitro compound into an organic solvent, adding an activated carbon catalyst having a Pd loading capacity of 10 percent, then leading the mixture serving as a material I into a pre-heating module of a microchannel reactor; and 2, respectively pumping preheated material I and a material II hydrogen into a reaction module of the microchannel reactor into a reactor, collecting outflowing reaction liquid, and treating to obtain the lenalidomide. The method is environment-friendly, and has the advantages of high reaction yield, high purity and good economical efficiency.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

Method for preparing nitrourea by utilizing microchannel reactor

ActiveCN105111109ASmall liquid holding capacityReduce security risksUrea derivatives preparationOrganic compound preparationNitroureaOrganic synthesis

The invention discloses a method for preparing nitrourea by utilizing a microchannel reactor and belongs to the technical field of organic synthesis application. In the microchannel reactor with a special internal structure, urea, concentrated sulphuric acid and concentrated nitric acid serve as raw materials, and nitrourea is synthesized in reaction time of tens of seconds to several minutes through the novel method. The materials enter the microchannel reactor through a metering pump and then undergo preheating, mixing, reaction and aftertreatment to obtain the nitrourea product. The method has the advantages that the microchannel reactor has excellent heat and mass transport effects and is simple and safe to operate, the product yield is high, and the emission of waste acid is greatly reduced.

Owner:HANGZHOU HI TECH FINE CHEM

Method for enhanced capture of acid gas by cooperation of supergravity and nanofluid technology

ActiveCN109999648AImprove mass transfer efficiencyHigh strengthGas treatmentDispersed particle separationSolventCentrifugal pump

The invention belongs to the technical field of environmental protection, and provides a method for enhanced capture of acid gas by cooperation of supergravity and nanofluid technology in order to overcome defects of low gas-liquid mass transfer efficiency and low absorption efficiency of a traditional gas absorption technology. The method comprises steps as follows: nanofluid is prepared from nano amine functionalized mesoporous-structure particles, a surfactant and an absorbent solution, an acid-containing gas mixture enters from a gas inlet, the nanofluid enters from a liquid inlet througha centrifugal pump, the acid-containing gas mixture and the nanofluid are in countercurrent contact in a supergravity rotating packed bed to remove acid gas, and purified gas and the nanofluid are discharged from a gas phase outlet and a liquid phase outlet respectively; the absorptive amount of the acid gas by an absorbent is increased, the use quantity of a solvent is reduced, and the removing time is shortened; a high viscosity liquid and a solid particle contained system can be treated. The device is simple and efficient, occupies a small area, meets the environmental requirement, and canbe applied to the fields of acid gas capture of a thermal power plant, acid gas removal of the chemical industry, acid gas separation from natural gas and the like.

Owner:ZHONGBEI UNIV

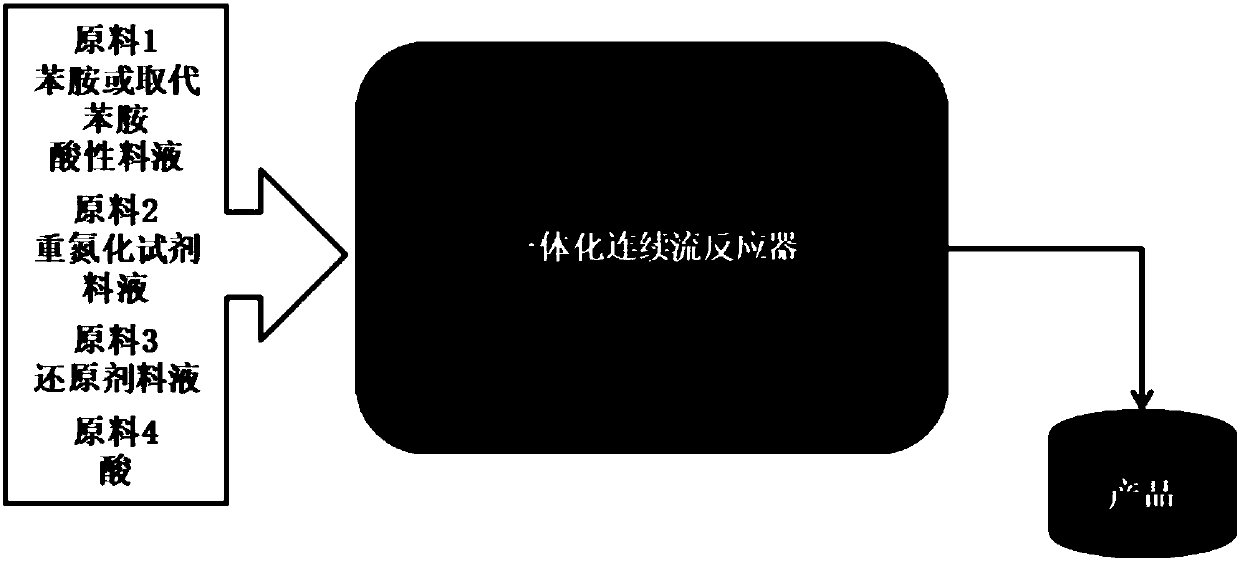

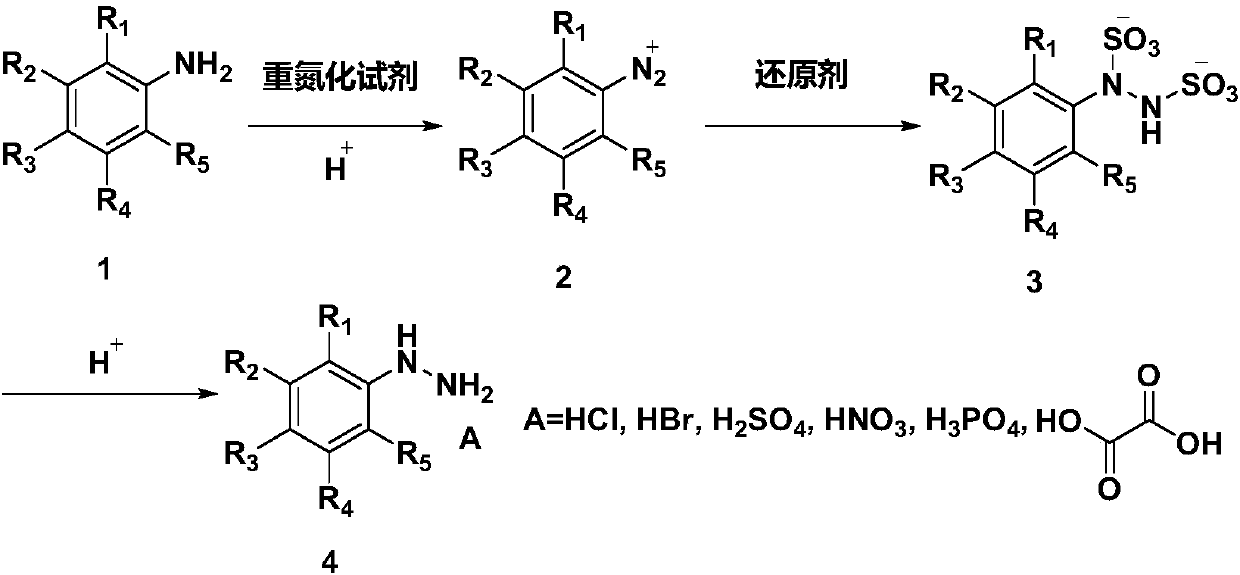

Phenyl hydrazine and substituted phenyl hydrazine continuous flow synthesis process

ActiveCN107663161ARealize the whole process of continuous flow synthesisSolve the technical problems of continuous production in the whole processHydrazine preparationSequential/parallel process reactionsReaction intermediateDiazoamino Compounds

The invention provides a phenyl hydrazine and substituted phenyl hydrazine continuous flow synthesis process. Three-step reactions of diazotization, reduction and acidolysis salt formation are creatively and organically integrated; phenylamine or substituted phenylamine acid material liquid, diazotization reagents, reducing agents and acid are used as raw materials to be subjected to three-step reaction of diazotization, reduction and acidolysis salt formation to obtain phenyl hydrazine derivative salts. The synthesis process is performed in an integral reactor, and belongs to an integrated solution. The reaction raw materials are continuously added through a feeding opening of the integral reactor; the reactions of diazotization, reduction and acidolysis salt formation are continuously performed in the integral reactor; the phenyl hydrazine derivative salts are continuously obtained in the integral reactor; the total reaction time is less than or equal to 20min. Compared with a conventional production process, the continuous flow synthesis process has the advantages that the total reaction time is greatly shortened; the safety is greatly improved; no reaction byproducts (such as diazoamino compounds and reduction reaction midbodies) are included in the reaction process and the reaction products; the continuous flow process can prepare the high-purity products with the purity as high as 99 percent or higher without the additional purification steps.

Owner:SHANGHAI HYBRID CHEM TECH

Grid packing and packing structure

InactiveCN101623617AReduce resistanceHigh porosityChemical/physical/physico-chemical processesTwo gridTower

The invention relates to grid packing and a packing structure. The grid packing comprises a plurality of grid plates which are arranged in parallel; each grid plate is provided with more than two through holes; a pipe spacer is arranged between every two grid plates; pull rods in a number corresponding to the number of the through holes alternately penetrate through the grid plates and the pipe spacers; both ends of each pull rod are provided with fastening pieces so that the grid plates and the pipe spacers are connected into a whole; each pull rod is a screw with threads at both ends; and each fastening piece is a nut which is in threaded connection with the screw. The packing structure applied to a packing tower comprises a plurality of layers of grid packing which is arranged vertically; the grid plates of the grid packing are perpendicular to the cross section of the packing tower, and two vertical adjacent layers of the grid packing are staggered and arranged at 45 degrees. The grid plates of the grid packing have small thickness, smooth surfaces, stable integrity, large specific surface area in use, strong anti-clogging capability, little resistance and long service life, thereby being practical, high-efficiency and energy-saving packing.

Owner:HANGZHOU HUANA TOWER TECH

Method for hydro-upgrading coal tar containing heavy distillate

The invention relates to a method for hydro-upgrading coal tar containing heavy distillate. The method comprises the following steps: adding visbreaking hydrocarbon which mainly comprises hydrocarbons with a boiling range of between 250 and 550 DEG C into a preposed catalyst bed which is filled with hydrogenation demetallization agent, wherein the visbreaking hydrocarbon can be hydrocarbons obtained through separating effluent of a coal tar hydrogenation upgrading reaction. The coal tar raw material and other hot feeds of the preposed catalyst bed are directly mixed and enter the preposed catalyst bed so as to reduce high temperature section time before contacting the catalyst. The method can reduce pressure drop of the preposed catalyst bed, slow down coking, prolong operation period, and is particularly applicable to hydro-upgrading of coal tar containing high-viscosity heavy distillate.

Owner:何巨堂

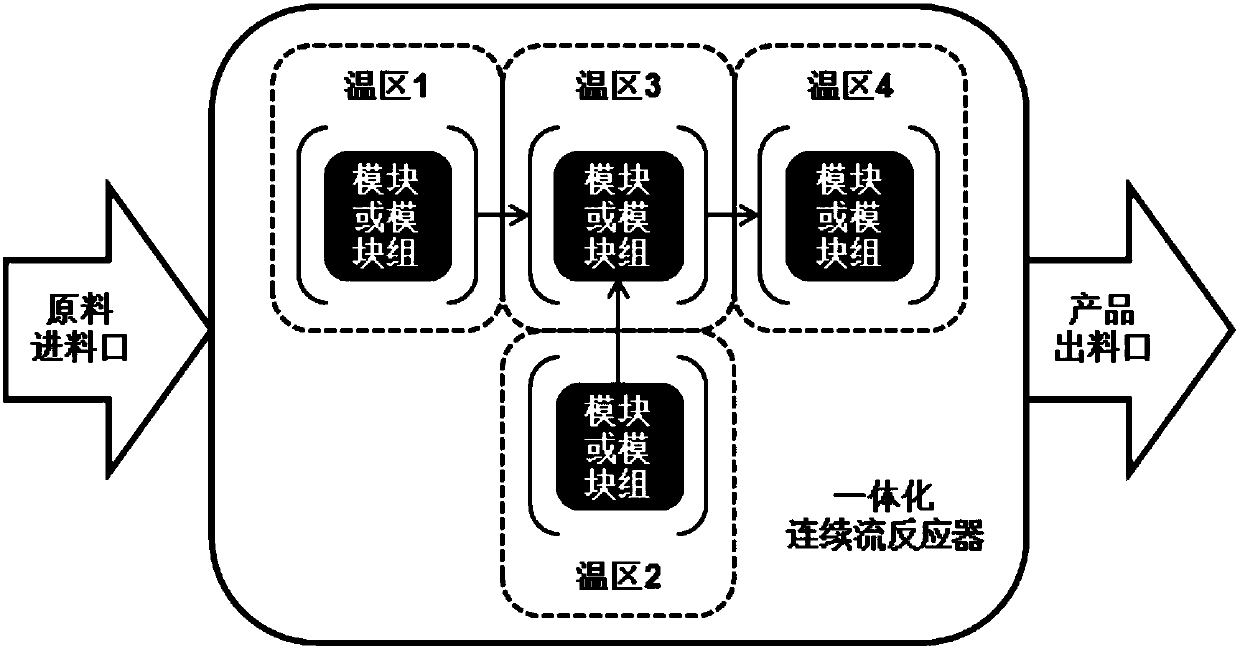

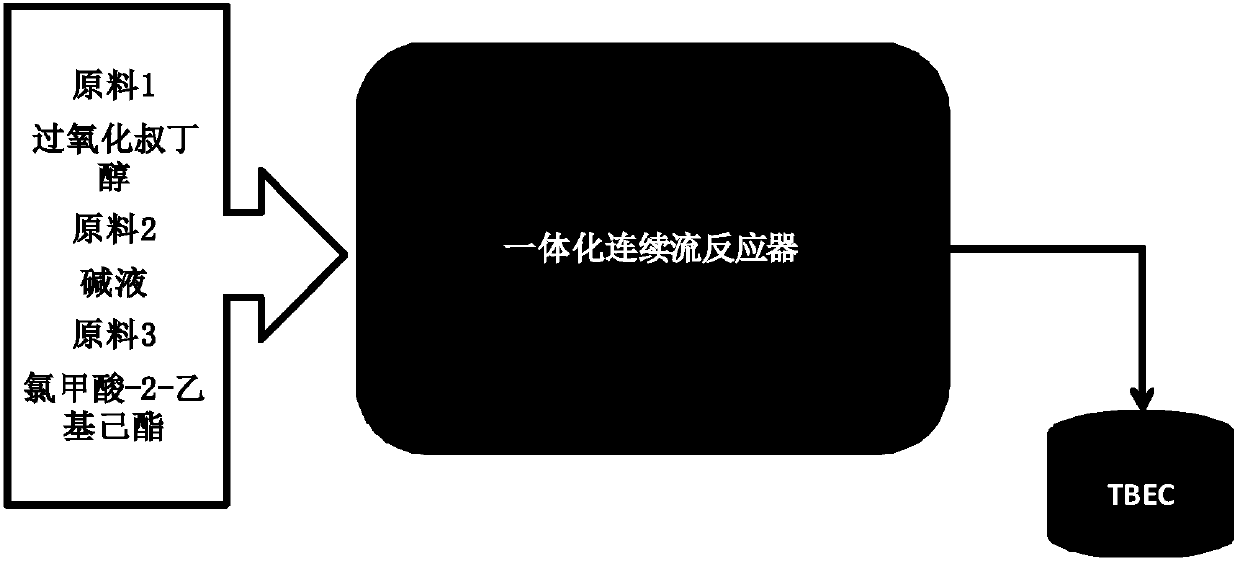

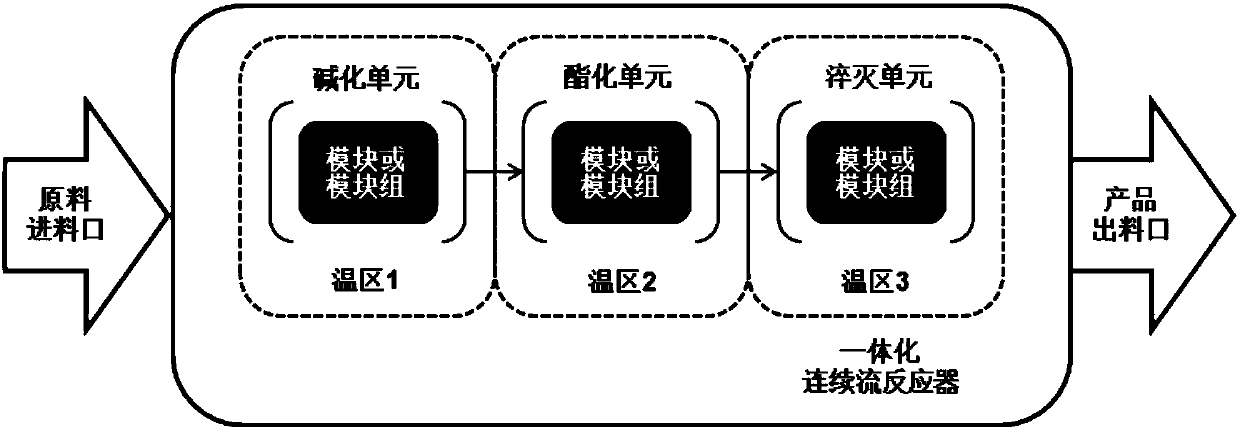

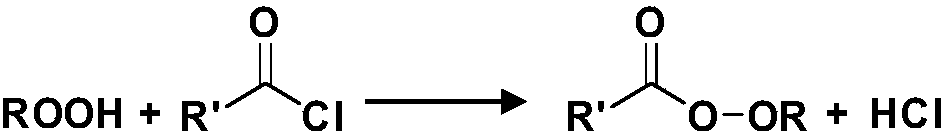

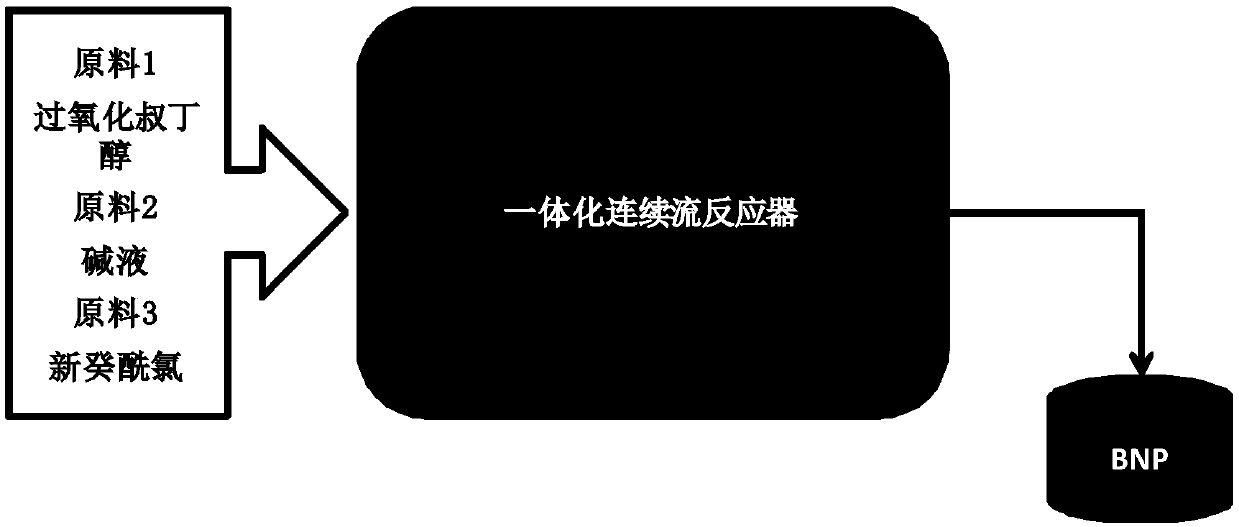

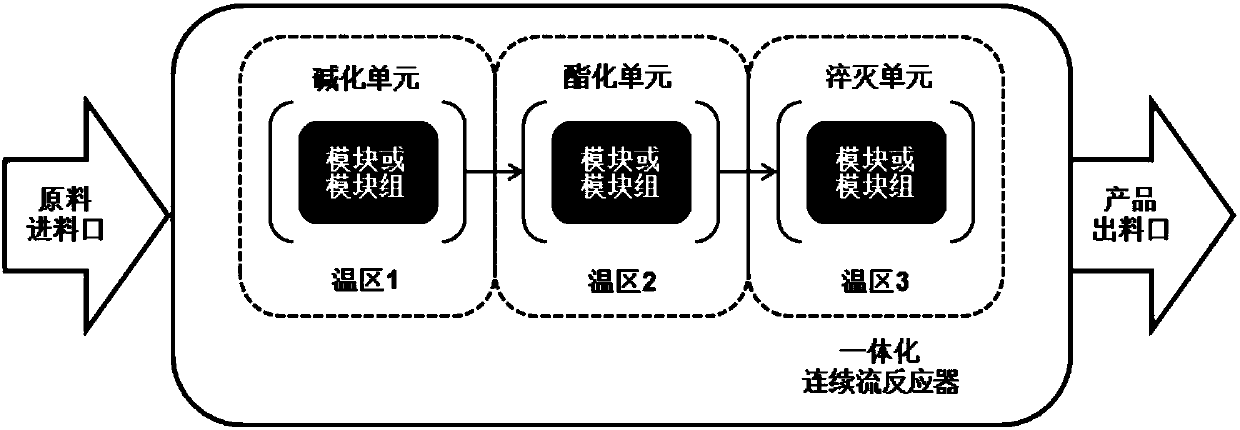

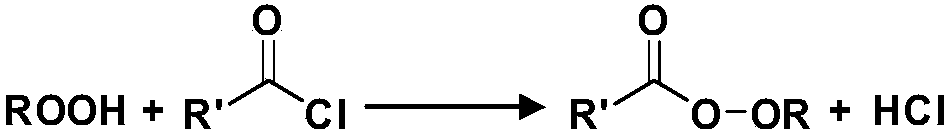

Amplification-effect-free continuous flow synthesis process of tert-butyl peroxy-2-ethylhexyl carbonate

InactiveCN107698479AIncrease productivityAvoid magnificationOrganic compound preparationChemical/physical/physico-chemical processesContinuous flowChloroformate

The present invention provides an amplification-effect-free continuous flow synthesis process of tert-butyl peroxy-2-ethylhexyl carbonate. According to the synthesis process, tert-butyl hydroperoxide,an alkali liquid and 2-ethylhexyl chloroformate are used as raw materials and are continuously and sequentially subjected to an alkalization reaction, an esterification reaction and a quenching stepto obtain the tert-butyl peroxy-2-ethylhexyl carbonate; and the synthesis process is performed in an integrated continuous flow reactor, the reaction raw materials such as the tert-butyl hydroperoxide, the alkali liquid and the 2-ethylhexyl chloroformate are continuously added into the material inlet of the integrated continuous flow reactor, and the tert-butyl peroxy-2-ethylhexyl carbonate is continuously obtained from the material outlet of the integrated continuous flow reactor, wherein the amplification effect does not exist, and the total reaction time is less than or equal to 180 s. Compared with the traditional production process, the synthesis process of the present invention has advantages of substantially improved temperature, substantially shortened total reaction time, no amplification effect, stable product index and good reproducibility.

Owner:SHANGHAI HYBRID CHEM TECH

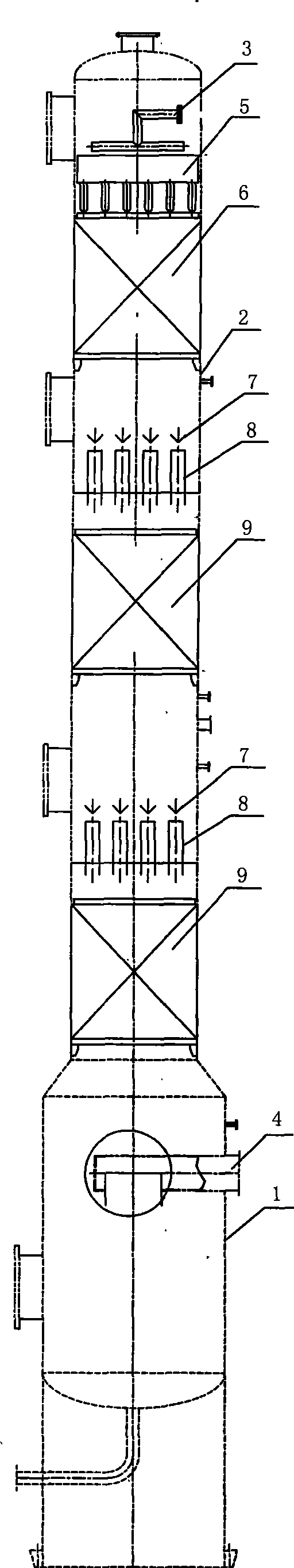

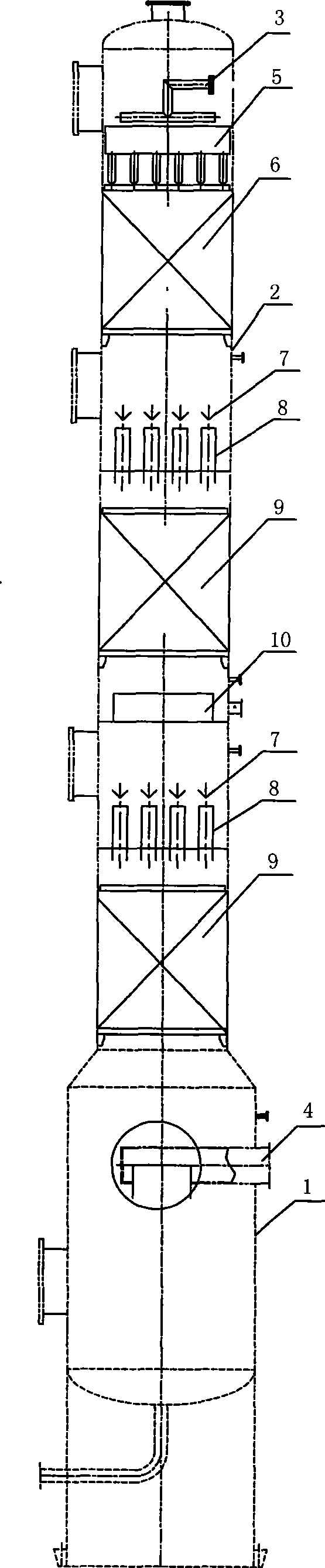

Phosgene absorbing tower

InactiveCN101480558ATake advantage ofEvenly distributedDispersed particle separationGas phaseDistillation

The invention discloses a phosgene adsorbing tower which consists of a tower foundation, a tower body, a feeding hole and a gas phase inlet. The top inside the tower body is provided with an adsorbent distributing groove communicated with the feeding hole, an upper filling layer is arranged above the adsorbent distributing groove, liquid collectors, liquid distributors and filling layers are arranged at intervals below the upper filling layer, and the numbers of the liquid collectors, the liquid distributors and the filling layers are same. The invention has the characteristics of simple structure, easy disassembly and assembly, low cost, small pressure reduction inside the tower, adaptability to high gas phase load, high mass transfer efficiency, higher absorbing efficiency than a floating distillation tower, remarkably-improved phosgene treating ability, good phosgene absorbing effect and stable working.

Owner:YANTAI JULI ISOCYANIC ESTER

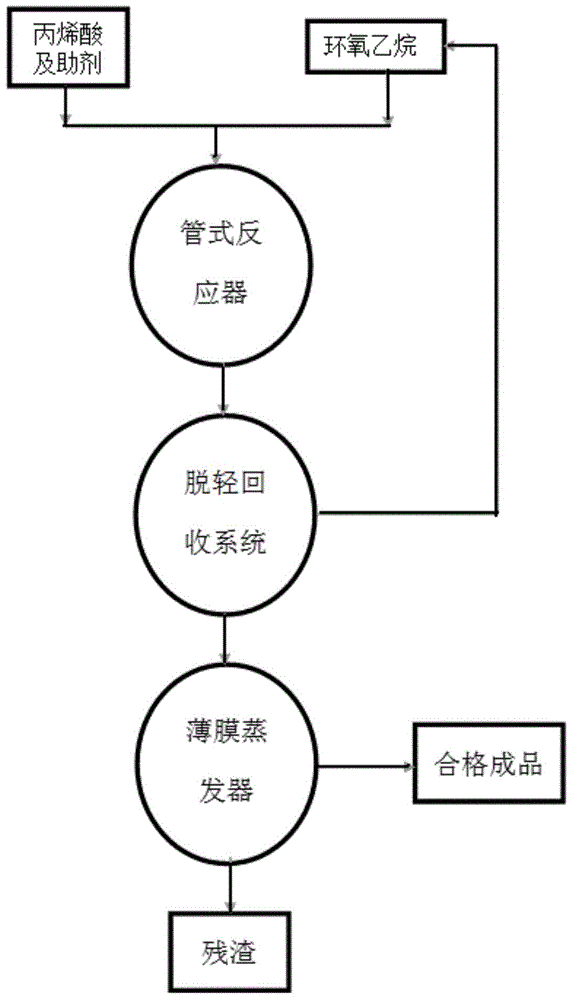

Clean technique for producing acrylate-hydroxy ester by adopting continuous process

InactiveCN104557540ASmall liquid holding capacityImprove controlOrganic compound preparationCarboxylic acid esters preparationNitrogen gasControllability

The invention discloses a clean technique for producing acrylate-hydroxy ester by adopting a continuous process. The clean technique for producing acrylate-hydroxy ester by adopting the continuous process comprises the following steps: 1) dissolving a catalyst and a polymerization inhibitor in acrylic acid, mixing and measuring, and then continuously pumping the obtained mixture into a tubular reactor with ethylene oxide at a certain ratio, wherein the mole ratio of acrylic acid to ethylene oxide is 1:(1.1-1.5); and 2) after reaction is finished, recycling ethylene oxide through low boiling fraction removal, and causing the rest reaction product to continuously enter an evaporator, so that the finished product is obtained. The clean technique for producing the acrylate-hydroxy ester by adopting the continuous process has the beneficial effects that ethylene oxide is excessive, so that the reaction time is short, and less byproducts are produced; reaction polymerization and reaction exotherm controllability is improved, and the production safety is greatly improved; the reaction time is short, the usage amount of the polymerization inhibitor is reduced, colour number can be effectively reduced, and the production cost is reduced; no steam is consumed in a continuous reaction process, and the production energy consumption is reduced; no replacement is required to be carried out after reaction is normally carried out, basically no nitrogen is consumed during production, and the amount of waste gas discharged out is reduced; and ethylene oxide in a degassing process during normal production can be recycled and is not discharged out, so that no pollution is produced to the air and water.

Owner:山东兴鲁生物科技有限公司

Continuous flow preparation method of diethyl methyl phosphite

PendingCN111004281ASmall liquid holding capacitySafe and efficient productionGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateCombinatorial chemistry

The invention discloses a continuous flow preparation method of diethyl methyl phosphite, which comprises the following steps: continuously adding ethanol and methyl phosphorus dichloride solution into a feed port of a continuous flow reactor, and continuously obtaining diethyl methyl phosphite at a discharge port of the continuous flow reactor. The method has the advantages of small liquid holdup, safe and efficient production process, solving of the problems of long reaction time and low efficiency in a kettle type reaction, high product yield and purity, and simple and efficient process operation.

Owner:LIER CHEM CO LTD +1

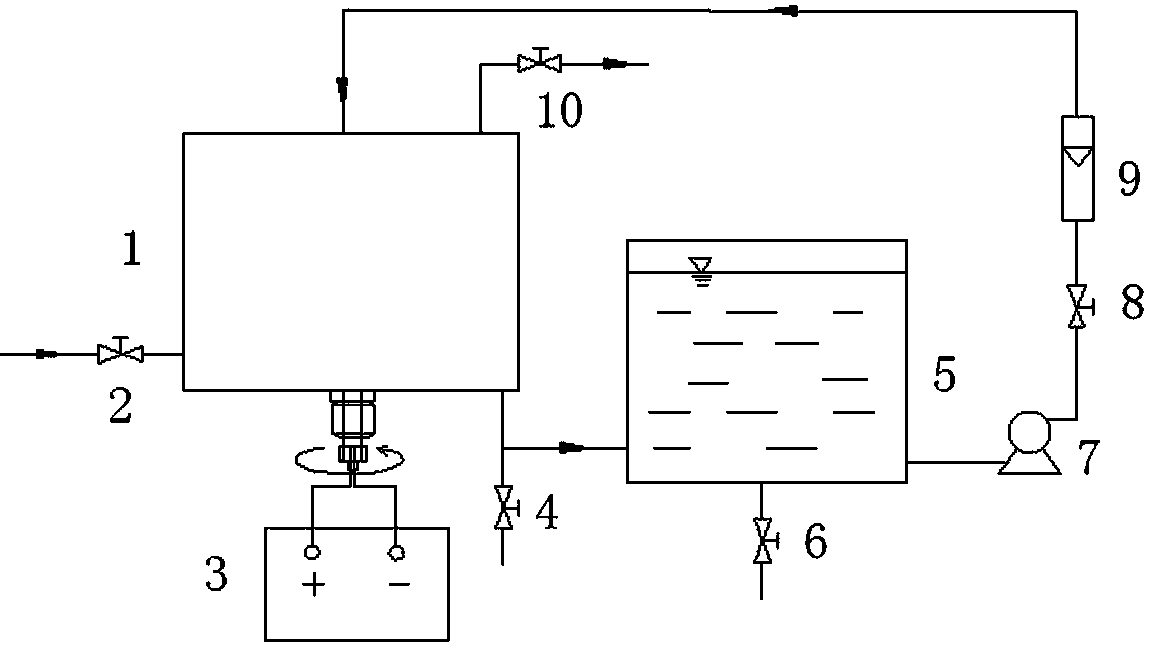

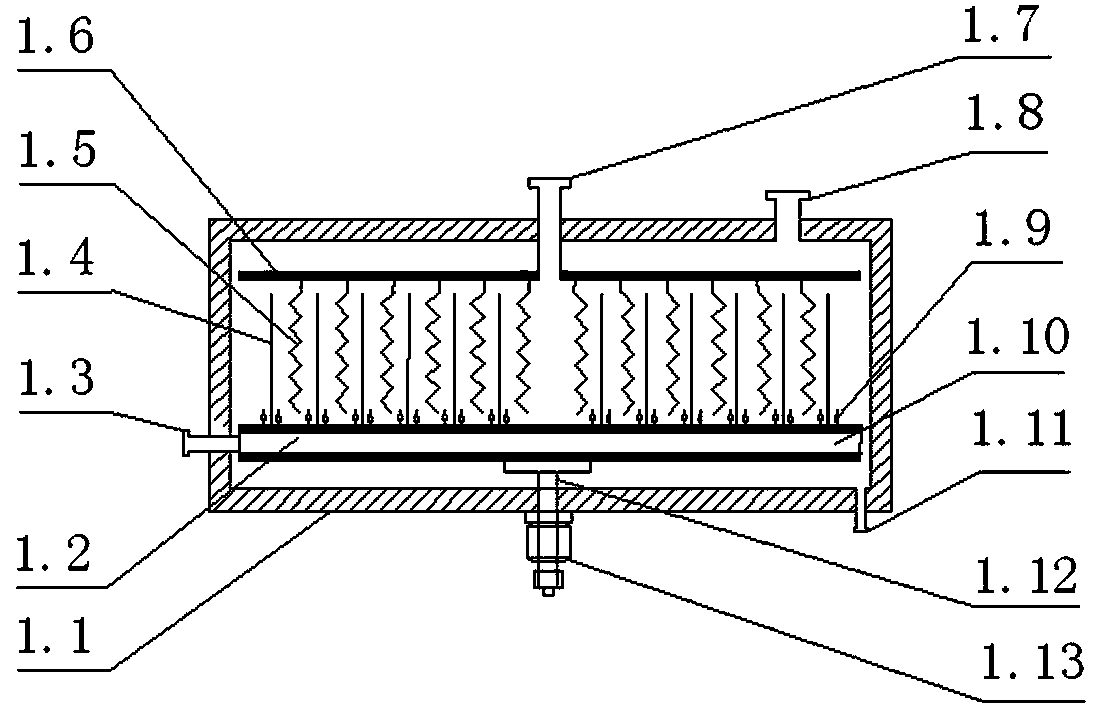

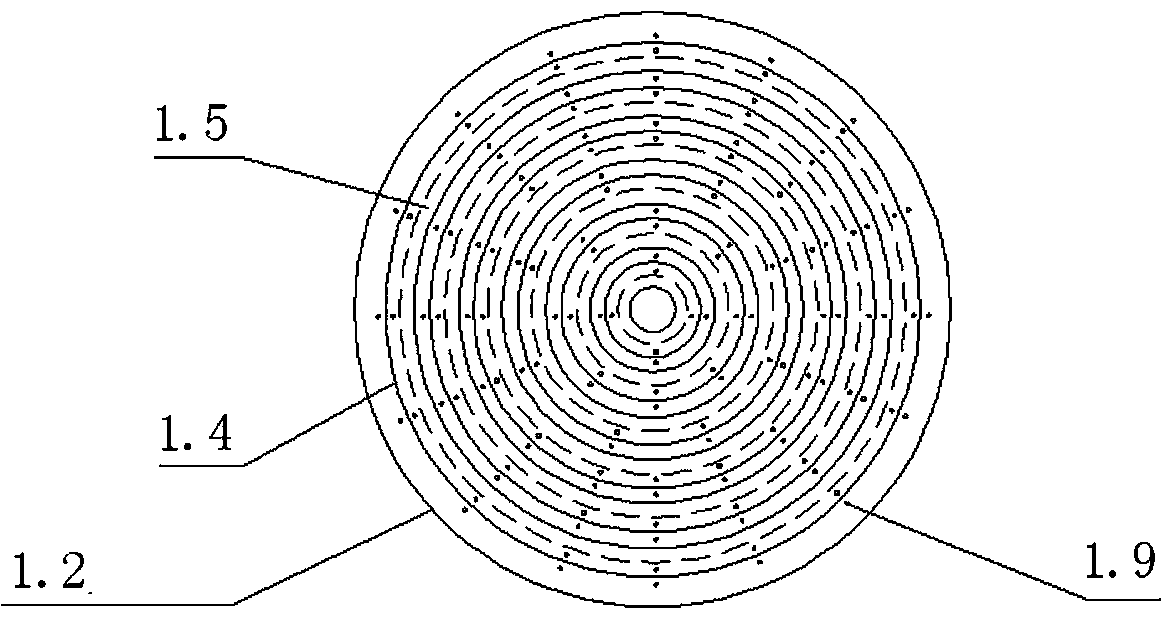

Device and process for mass transfer process for treating wastewater through supergravity enhanced electric Fenton method

ActiveCN103145277BImprove processing efficiencyReduce mass transfer resistanceMultistage water/sewage treatmentWastewaterEngineering

The invention belongs to the technical field of water treatment, and in particular relates to a device and a process for a mass transfer process for treating wastewater through a supergravity enhanced electric Fenton method, aiming at solving the problem of limited mass transfer while treating wastewater through the conventional electric Fenton method. The device comprises a plurality of cylinder cathodes and cathode connecting discs as well as a plurality of corrugated cylinder anodes and anode connecting discs, wherein the corrugated cylinder anodes and the anode connecting discs are static relatively to a shell; the centers of the cathode connecting discs are connected with rotating shafts; intake holes are distributed on the cathode connecting discs; and gas circulating chambers are arranged at the bottoms of the cathode connecting discs. According to the process, a supergravity electric Fenton reaction system is formed through the rotating cathode connecting discs and cylinder cathodes as well as the static anode connecting discs and cylinder anodes, and inflated oxygen. The device and the process disclosed by the invention not only solve the problem of limited mass transfer in the conventional sacrificial anode electric Fenton technology application process, so as to improve treatment efficiency, but also the device is low in liquid holdup, low in load, small in equipment and low in energy consumption.

Owner:ZHONGBEI UNIV

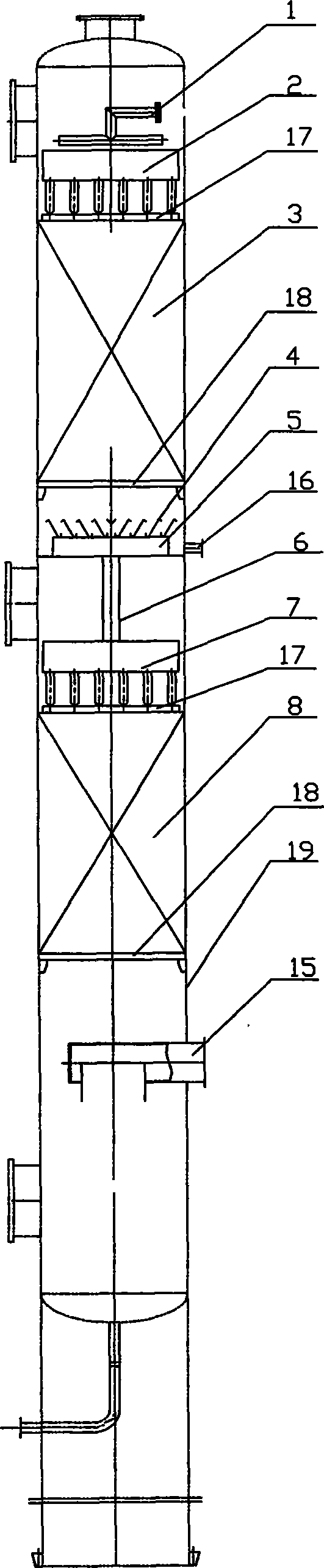

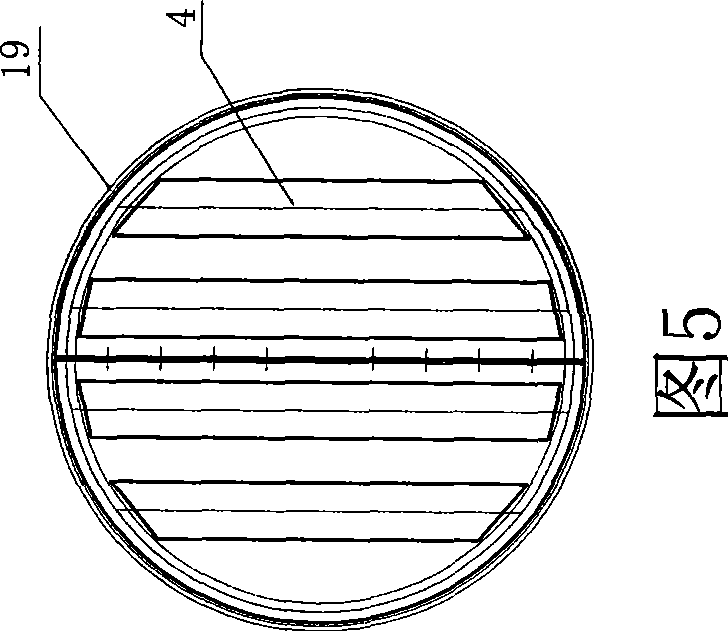

TDA dehydrating tower

InactiveCN101444677AEvenly dispersedImprove throughputAmino compound purification/separationFractional distillationEngineeringTower

The invention disclose a TDA dehydrating tower, which comprises a tower body, a circumfluence supply pipe, a recycle gas phase inlet and a TDA feeding hole. An upper distributing groove communicated with the circumfluence supply pipe is formed at the top in the tower body, an upper packing layer is arranged below the upper distributing groove, a liquid catch plate is arranged at the lower part of the upper packing layer, a liquid receiving tank is fixed at the lower part of the liquid catch plate, a liquid downtake communicated thereof is arranged at the bottom of the liquid receiving tank, the liquid downtake is communicated with a lower distributing groove formed at the lower part of the liquid downtake, and a lower packing layer is arranged at the lower part of the lower distributing groove. The TDA dehydrating tower has the advantages of simple structure, easy disassembly and assembly, low cost, high degree of the heat change and quality change of two phases of gas and liquid, good separating effect and high efficiency.

Owner:YANTAI JULI ISOCYANIC ESTER

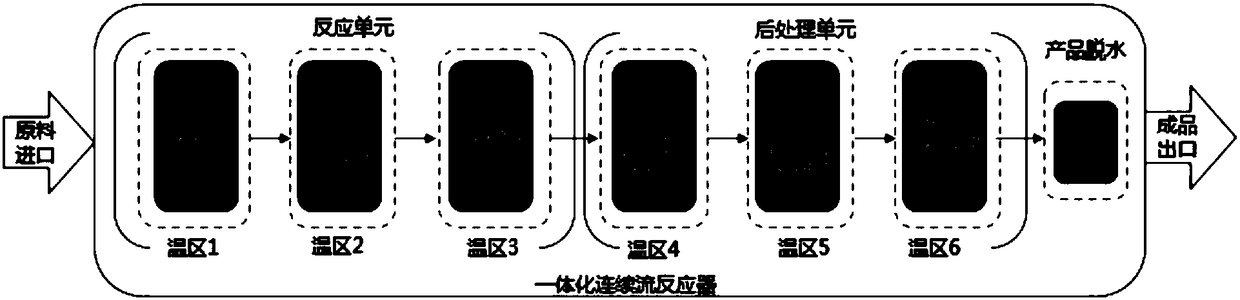

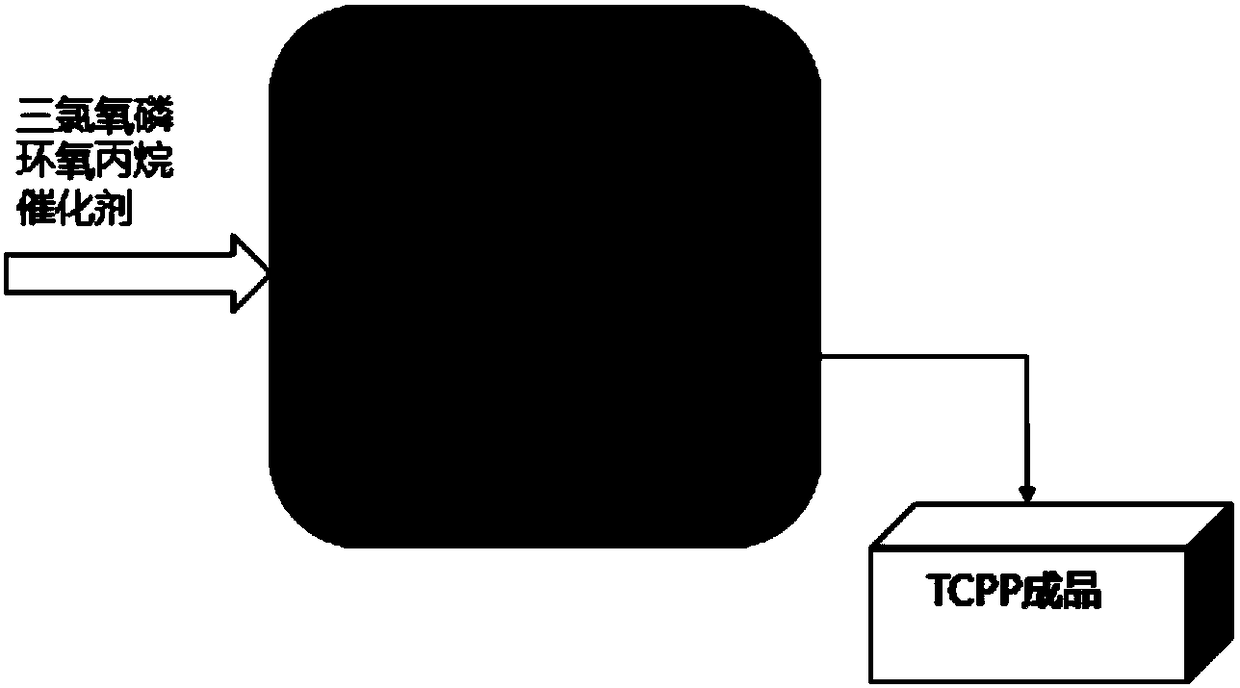

Full-continuous flow production process of phosphoric acid tri(1-chlorine-2-propyl) ester

ActiveCN108794522AQuality improvementAcid value stablePhosphorus organic compoundsPhosphoric acidWastewater

The invention relates to a full-continuous flow production process of a phosphoric acid tri(1-chlorine-2-propyl) ester. According to the process, a reaction period and an aftertreatment period are adopted as a whole process which is continuously carried out without interruption, raw materials, namely phosphorus oxychloride, epoxypropane and a catalyst are continuously fed into the feeding hole ofa reactor, a finished product of the phosphoric acid tri(1-chlorine-2-propyl) ester which meets marketing standards is continuously prepared at the outlet of the reactor, and the purpose that a high-quality finished product of the phosphoric acid tri(1-chlorine-2-propyl) ester (TCPP) is rapidly prepared is achieved. By adopting the full-continuous flow production process provided by the invention,efficient production, high-quality finished products and stable storage are achieved, the TCPP finished product is free of aldehyde impurity, free of acid regurgitation and free of metallic cation corresponding to the catalyst, and in addition, the process is small in wastewater amount, low in phosphorus containing, beneficial to environment protection and applicable to security industrial production.

Owner:ZHEJIANG WANSHENG

Large-scale detachable tray liquid distributor

InactiveCN1843548AAvoid magnificationSimple structureDistillation separationEngineeringMagnification

The invention relates to a large detachable table liquid separator, which is used to distribute the in-tower liquid, belonging to the liquid-liquid separation and liquid-gas separation device. Wherein, it arranges beam inside the tower wall as the liquid collection groove on which the liquid distribution groove is arranged; the liquid distribution groove is connected to the block connecting plate as a monomer to connect the beam liquid collecting groove, while another opposite edges are connected via the connecting plate; the beam liquid collecting groove, liquid distributing groove, block connecting plate and connecting plate are connected as a whole. The invention has simple structure, enlarged application range, high rigidity, uniform liquid distribution, lower height, lower weight and balanced gas channels. And it can cover magnification effect.

Owner:朱夏霖

Amplification-effect-free continuous flow synthesis process of tert-butyl peroxyneodecanoate

ActiveCN107698480AAdequate responseImprove processing efficiencyOrganic compound preparationChemical/physical/physico-chemical processesChlorideContinuous flow

The present invention provides an amplification-effect-free continuous flow synthesis process of tert-butyl peroxyneodecanoate. According to the synthesis process, tert-butyl hydroperoxide, an alkaliliquid and neodecanoyl chloride are used as raw materials and are continuously and sequentially subjected to an alkalization reaction, an esterification reaction and a quenching step to obtain the tert-butyl peroxyneodecanoate; and the synthesis process is performed in an integrated continuous flow reactor, the reaction raw materials such as the tert-butyl hydroperoxide, the alkali liquid and theneodecanoyl chloride are continuously added into the material inlet of the integrated continuous flow reactor, and the tert-butyl peroxyneodecanoate is continuously obtained from the material outlet of the integrated continuous flow reactor, wherein the amplification effect does not exist, and the total reaction time is less than or equal to 180 s. Compared with the traditional production process,the synthesis process of the present invention has advantages of substantially improved temperature, substantially shortened total reaction time, no amplification effect, stable product index and good reproducibility.

Owner:SHANGHAI HYBRID CHEM TECH

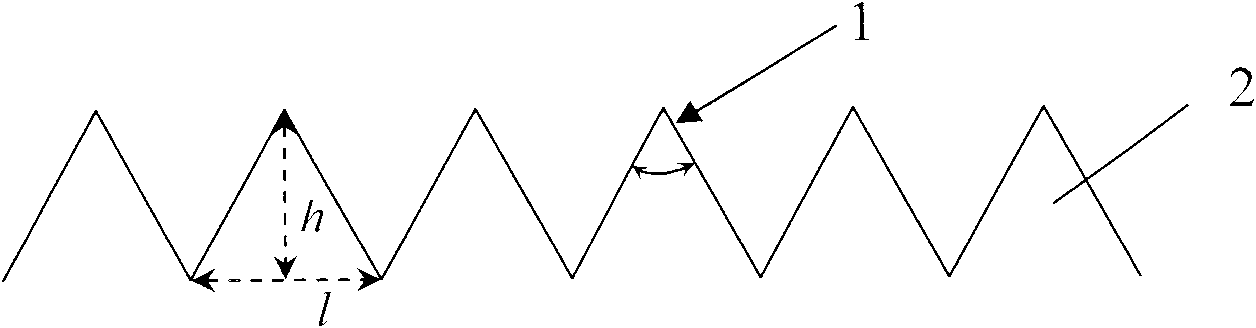

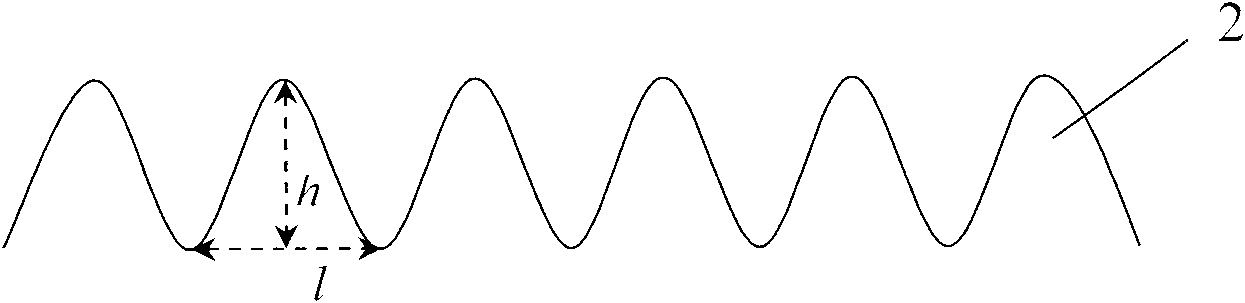

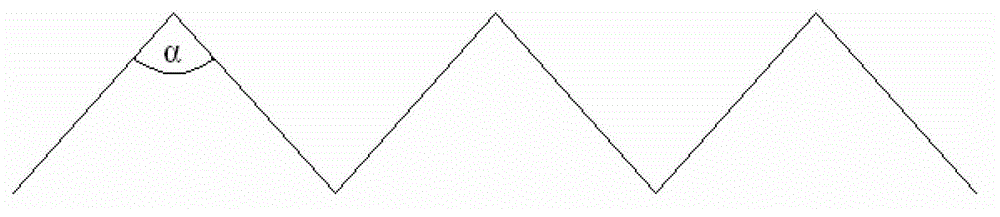

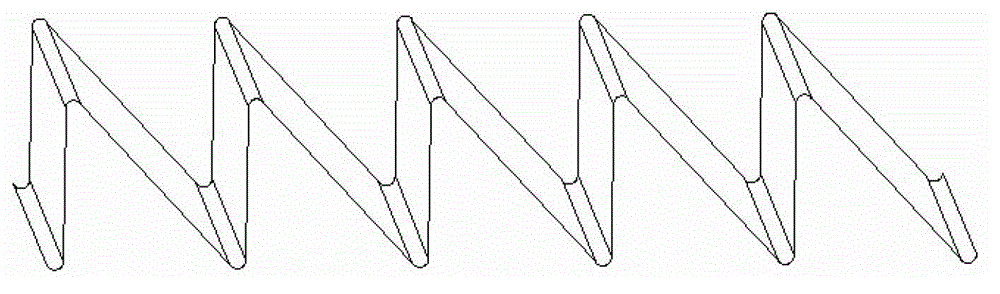

Serrate double-layer wire mesh corrugated packing

ActiveCN102908976AIncreased lateral mixing performanceAchieve a breakthroughChemical/physical/physico-chemical processesEngineeringIsotope

The invention relates to a serrate double-layer wire mesh corrugated packing which forms a serrate corrugated packing sheet structure by mechanically rolling double-layer wire mesh materials, wherein the top end of the wave crest and the top end of the wave trough of a corrugated packing sheet are respectively formed by connecting smooth arc surfaces, and an arc serrate corrugated structure with a smooth tooth top is formed, and a formed corrugated ridge and the axial direction of the packing form an included angle. Compared with the prior art, the serrate double-layer wire mesh corrugated packing is easy to manufacture, excellent in fluid mechanics and mass transfer performance, especially applicable to separating of small-coefficient mixtures which are difficult to separate, such as separation preparing of isotopes, and capable of being popularized and used in the precise separation field of traditional purification of flavors, fragrances and medical intermediates.

Owner:SHANGHAI RES INST OF CHEM IND

Continuous production method for vulcanization accelerator DPG

ActiveCN108586295ARealize continuous productionSmall liquid holding capacityOrganic chemistryOrganic compound preparationVulcanizationOrganic solvent

The invention provides a continuous production method for a vulcanization accelerator DPG. The method comprises the following steps that (1) diphenylthiourea, a catalyst, ammonium hydroxide and an organic solvent are mixed to obtain a reaction raw material mixture; (2) the reaction raw material mixture and an oxidizing agent are subjected to an oxidation reaction in a continuous flow reactor to obtain a reaction product; (3) the reaction product is post-treated to obtain the vulcanization accelerator DPG, wherein the organic solvent in step (1) can dissolve the diphenylthiourea and the vulcanization accelerator DPG. The method reduces the pressure in the reaction process, improves the utilization rate of the raw materials, stabilizes the product quality, greatly shortens the reaction timecompared with a conventional technology, improves the reaction yield, and effectively overcomes the disadvantage of traditional kettle type batch production.

Owner:KEMAI CHEM

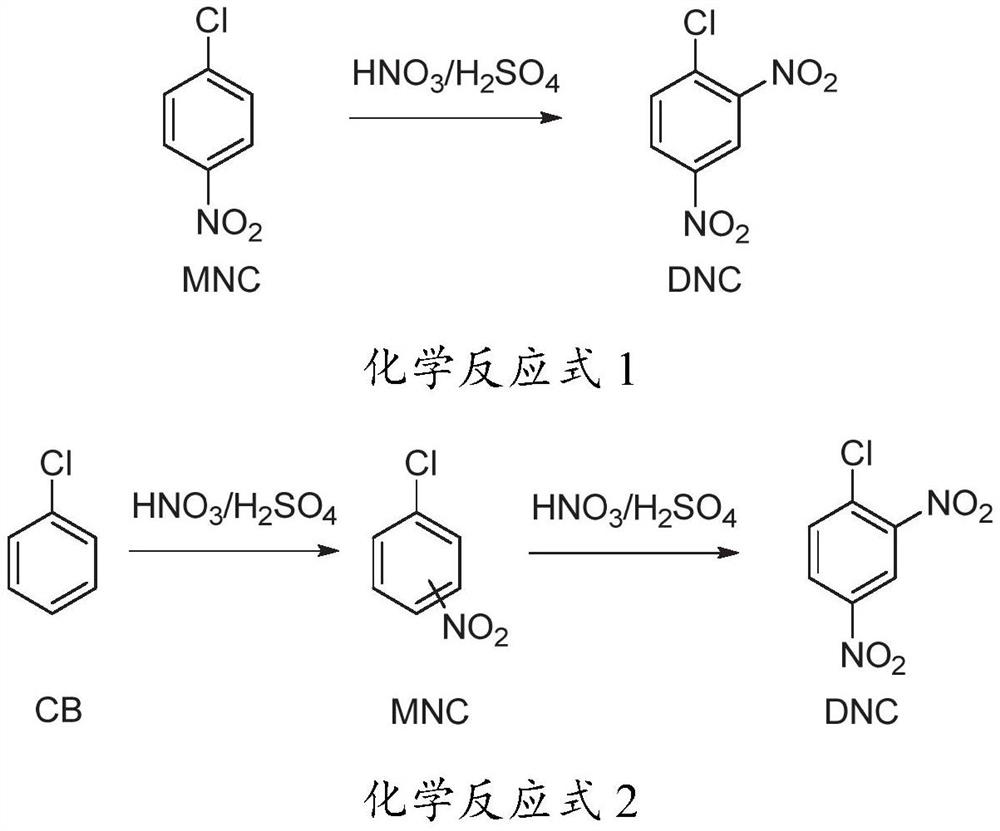

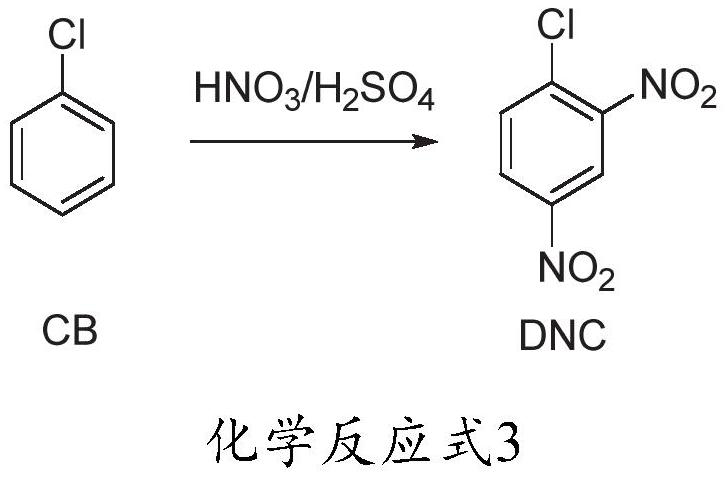

Method for preparing 2, 4-dinitrochlorobenzene by one-step adiabatic continuous nitration of chlorobenzene

ActiveCN112707822ASmall liquid holding capacityHarm reductionChemical/physical/physico-chemical microreactorsNitro compound preparationMicroreactorChlorobenzene

The invention discloses a method for preparing 2, 4-dinitrochlorobenzene by one-step adiabatic continuous nitration of chlorobenzene, which comprises the following steps: adding a mixed acid solution and an organic phase solution into a microreactor for adiabatic nitration reaction to obtain 2, 4-dinitrochlorobenzene, wherein the mixed acid solution is a mixture of concentrated sulfuric acid and concentrated nitric acid. The organic phase solution is a mixture of chlorobenzene and a heat carrier, and the heat carrier is 2, 4-dinitrochlorobenzene; and a micro-sieve pore structure is arranged in the micro-reactor. The method provided by the invention has the advantages of greenness, energy conservation and high efficiency.

Owner:DONGYING ANNUOQI TEXTILE MATERIALS +1

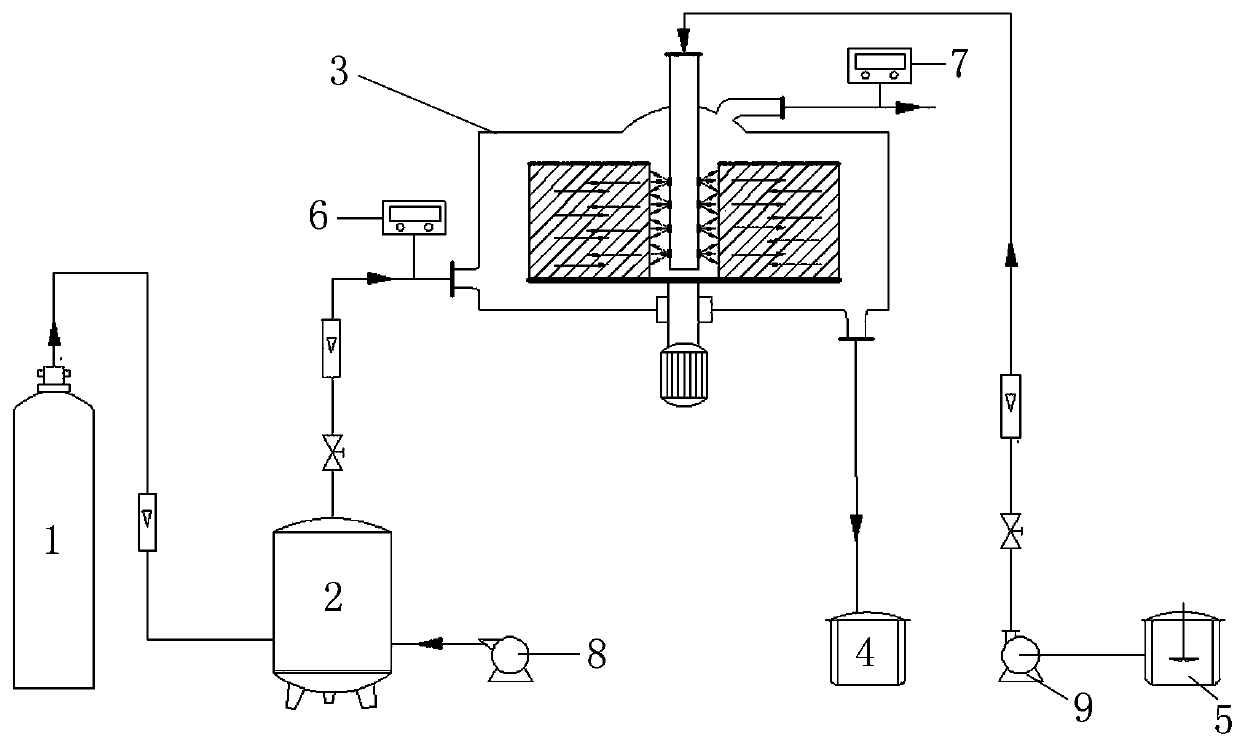

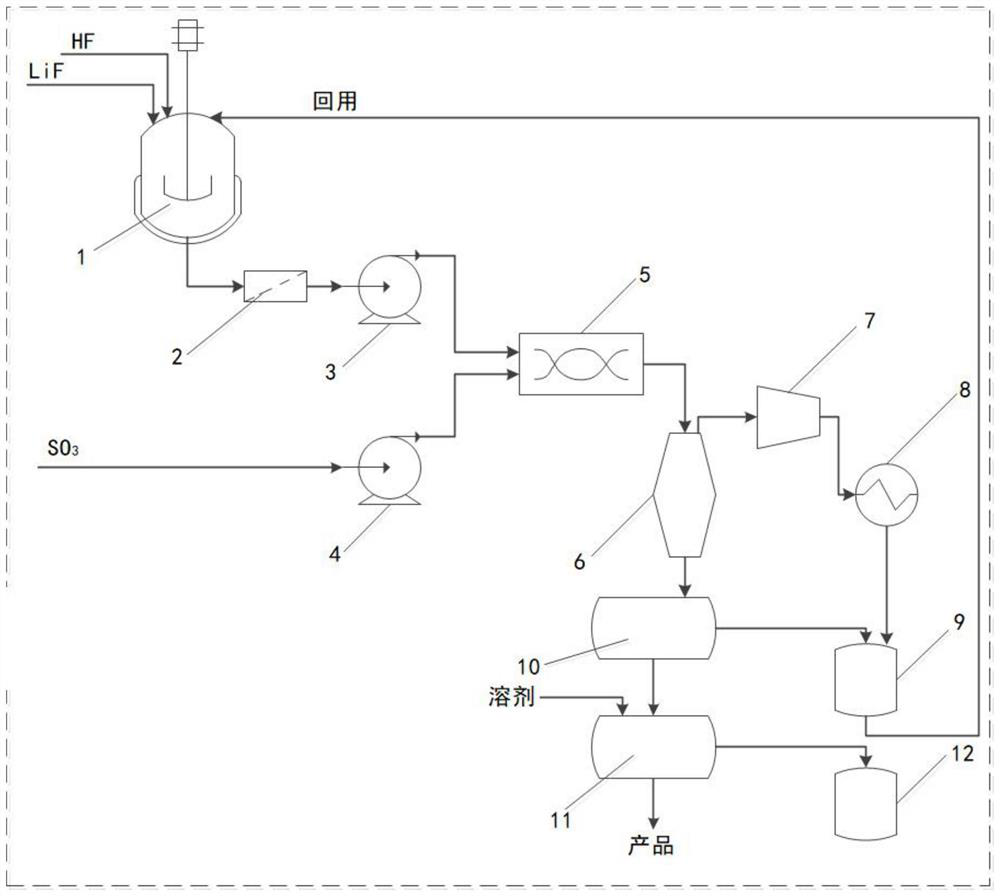

Device and method for continuously preparing lithium fluorosulfonate

The invention discloses a method for continuously preparing lithium fluorosulfonate, which synthesizes the lithium fluorosulfonate in one step by using anhydrous hydrogen fluoride, lithium fluoride and sulfur trioxide or fuming sulphuric acid as raw materials. The invention further discloses a device for continuously preparing the lithium fluorosulfonate, which comprises a anti-pressure dissolution tank, a filter, a first metering pump, a second metering pump, a micro-reactor, an evaporator, a compressor, a condenser, a recovery acid tank, a crystallizer, a recrystallization device and a solvent recovery tank. The anti-pressure dissolution tank is provided with two charging openings which are respectively used for charging the anhydrous hydrogen fluoride and the lithium fluoride; a feed inlet on the second metering pump is used for charging the sulfur trioxide; a stirring device is arranged on the anti-pressure dissolution tank; a discharge port at the bottom of the anti-pressure dissolution tank is connected to the inlet end of the filter by a pipeline; the outlet end of the filter is connected to the first metering pump by a pipeline; and discharge ports of both the first metering pump and the second metering pump are connected to the micro-reactor. According to the invention, in the machining process, the lithium fluorosulfonate is synthesized by adopting a one-step method;product quality is stable; and yield is high.

Owner:湖北迈可凯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com