Phosgene absorbing tower

An absorption tower and phosgene technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of difficulty in operation and maintenance, stuck float valve, and large pressure drop on the tray. Small liquid holdup, reduced channel wall flow, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

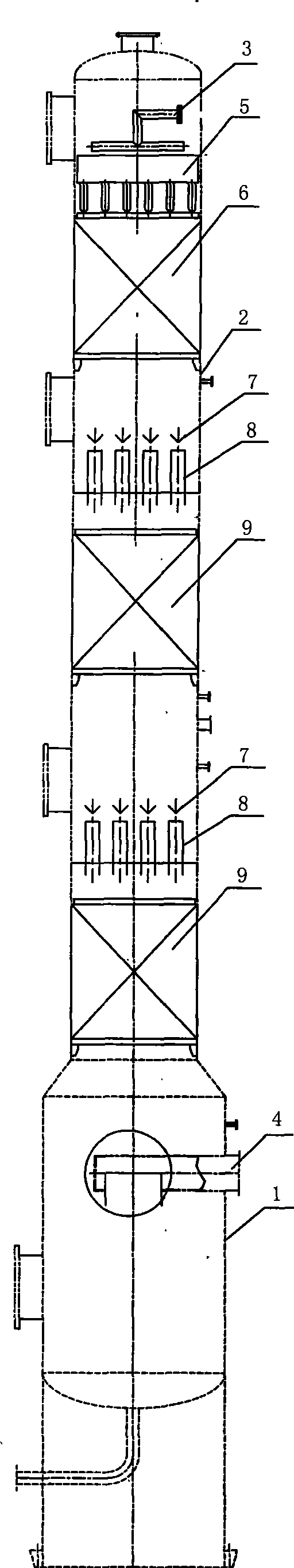

[0023] Embodiment 1, a kind of phosgene absorption tower, with reference to figure 1 , the tower body 2 is fixed on the tower base 1, the upper part of the tower body 2 is provided with a feed port 3, the tower base 1 is provided with a gas phase inlet 4, and the top of the tower body 2 is provided with an adsorption An agent distribution groove 5, an upper packing layer 6 is arranged below the adsorbent distribution groove 5, and the adsorbent distribution groove 5 can evenly distribute the adsorbent to the filler of the upper packing layer 6 below it, and a liquid is arranged at intervals below the upper packing layer 6. Collector 7, liquid distributor 8 and packing layer 9, the number of liquid collector 7, liquid distributor 8 and packing layer 9 is the same, liquid collector 7, liquid distributor 8 and packing layer 9 are 1-5 layers, this The embodiment adopts two layers, that is, the liquid collector 7, the liquid distributor 8, the packing layer 9, the liquid collector ...

Embodiment 2

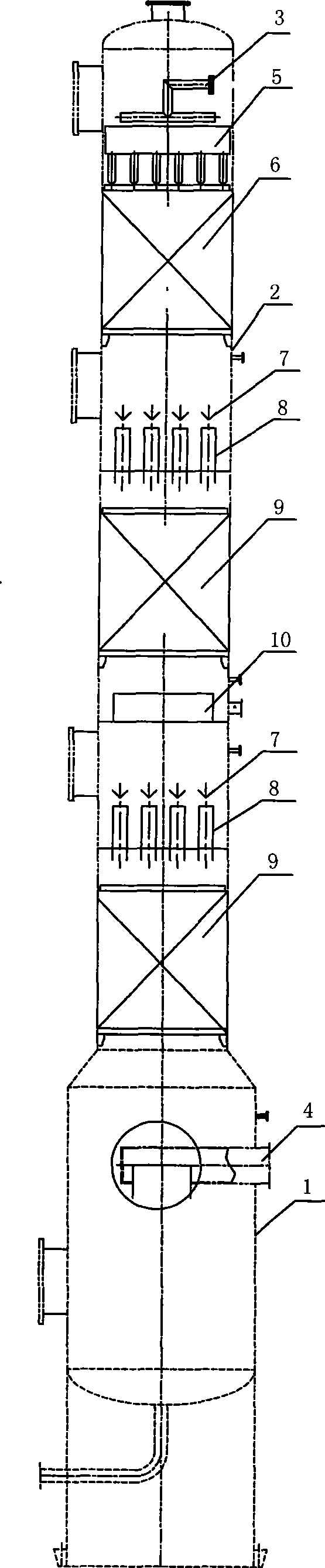

[0024] Embodiment 2, a kind of phosgene absorption tower, with reference to figure 2 , on the basis of Example 1, a liquid pre-distributor 10 is provided above the lowermost liquid collector 7, and the adsorbent flowing to the bottom of the tower body 2 is sent to the liquid pre-distributor 10 by a circulation pump, Then it is distributed to the liquid collector 7 below it for reuse, and the others are identical to Embodiment 1.

Embodiment 3

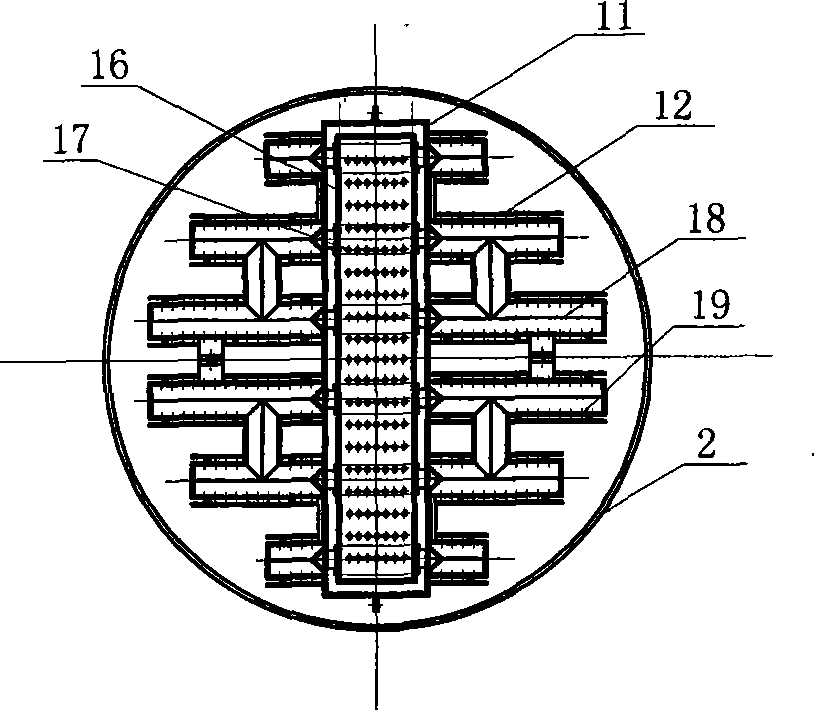

[0025] Embodiment 3, a kind of phosgene absorption tower, with reference to figure 2 , on the basis of Example 2, the adsorbent distribution tank 5 is composed of a first-level tank 11 and a second-level tank 12, the first-level tank is a rectangular tank body, and a shallow groove 16 with serrated edges is fixed in the middle of the tank body , the bottom of the primary tank 11 is separated by a primary distribution port 17, the secondary tank 12 is composed of interconnected tank bodies 18, the tank body 18 is directly opposite the primary distribution port 17 above, and a secondary distribution port is distributed below the tank body 18. The hole 19, the upper packing layer 6 and the packing layer 9 are fixed with stainless steel corrugated plate structured packing 15 between the upper packing pressure ring 13 and the lower packing support ring 14, and the stainless steel corrugated plate structured packing 15 is corrugated with grooves and small holes on the surface. Shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com