Efficient mixing heat exchange micro-channel reactor

A micro-channel reactor, mixed heat transfer technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of ineffective mass transfer and heat transfer, etc. To improve product quality, solve mass transfer problems, and achieve good mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

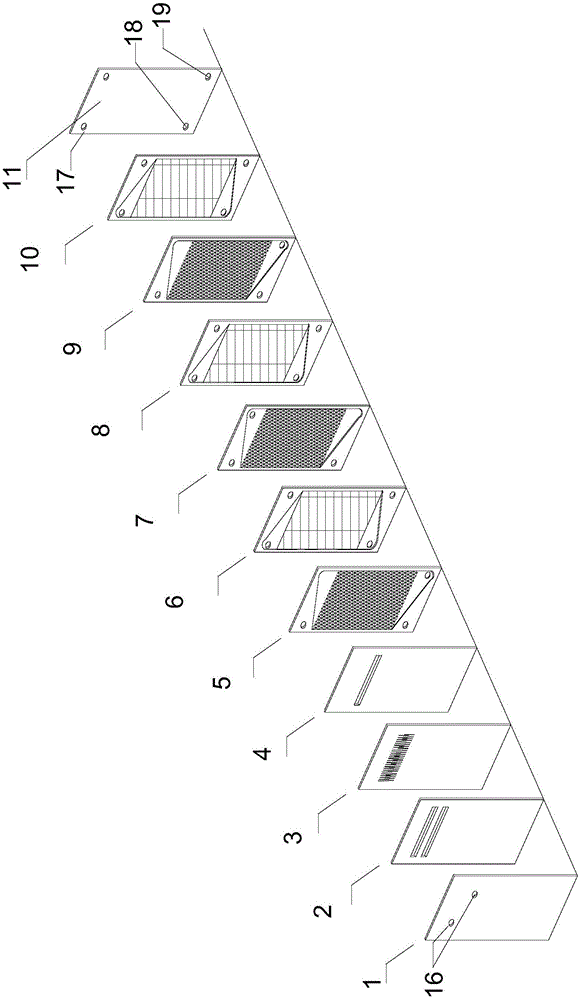

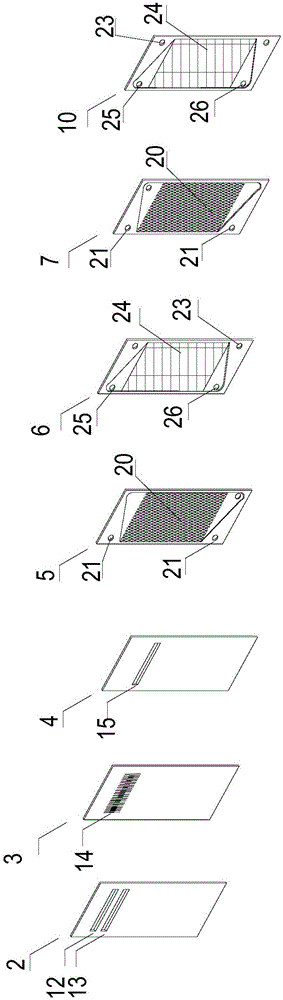

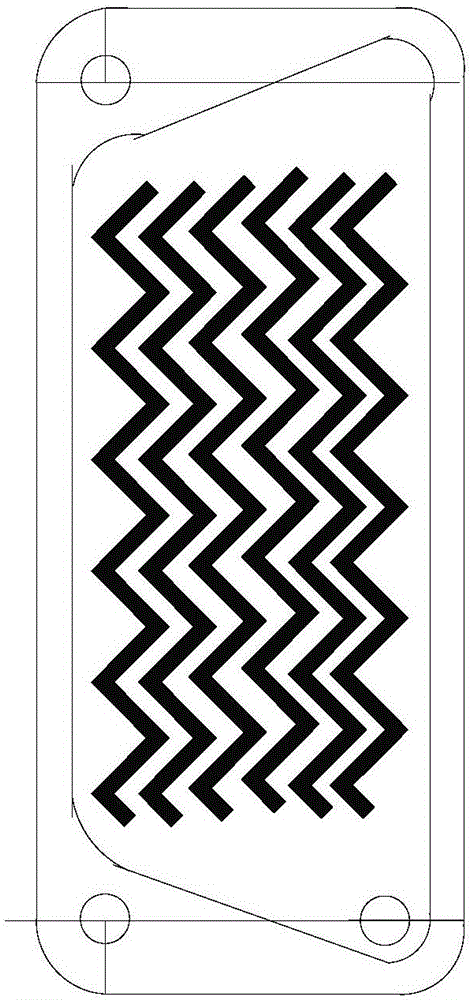

[0030] Such as figure 1 , 2 , 3, and 4, the high-efficiency mixing heat-exchanging microchannel reactor of the present invention includes a dispersion mixing member, several reaction liquid flow channel dies 5, 7, 9 and heat exchange medium flow channels arranged at the rear end of the dispersion mixing member Molds 6, 8, 10, the reaction liquid flow channel dies 5, 7, 9 and heat exchange medium flow channel dies 6, 8, 10 are arranged at intervals; the dispersion mixing member is provided with two or two The above reaction liquid disperses and flows into and mixes to form a dispersed mixing channel for the mixed reaction liquid. The reaction liquid flow channel die is provided with a reaction liquid flow channel 20 and a heat exchange medium conduction hole 21. The heat exchange medium flow channel die 6 , 8, 10 are provided with reaction liquid conduction hole 23, heat exchange medium flow channel 24 and inflow hole 25, outflow hole 26 that conduct with heat exchange medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com