Patents

Literature

45results about How to "Solving Mass Transfer Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

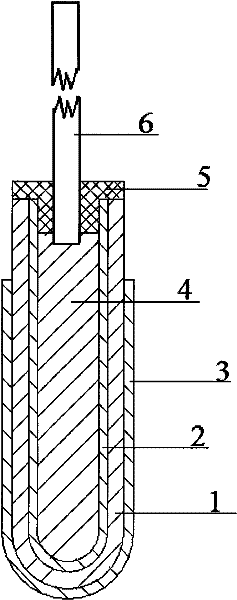

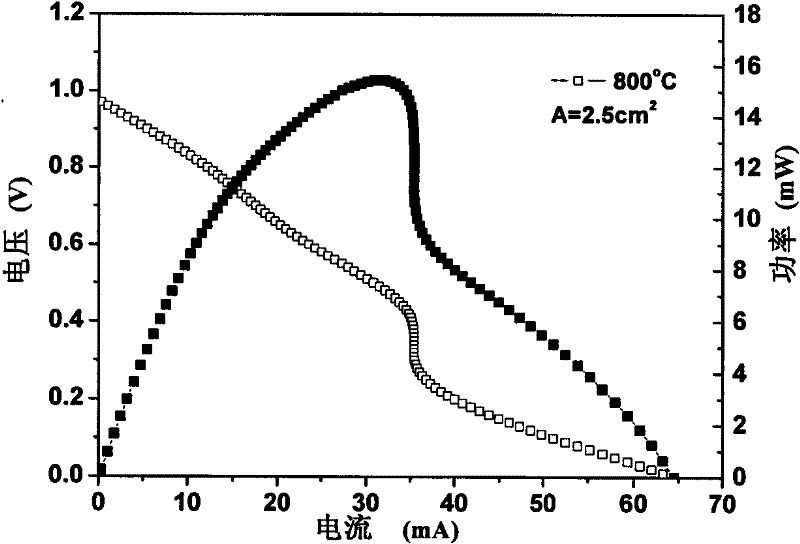

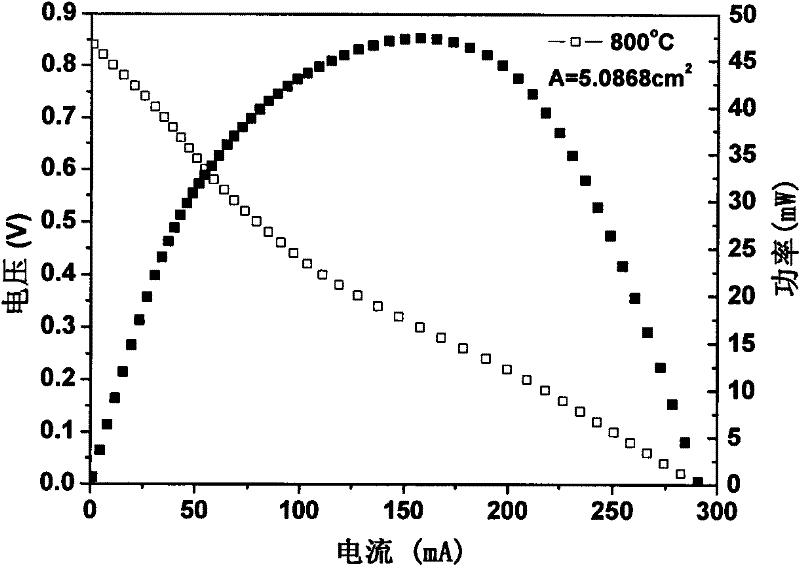

Direct carbon solid oxide fuel cell

ActiveCN101694883AImprove efficiencyReduce pollutionElectrolyte holding meansCell electrodesFuel cellsSolid structure

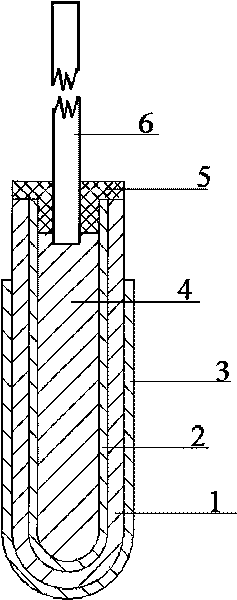

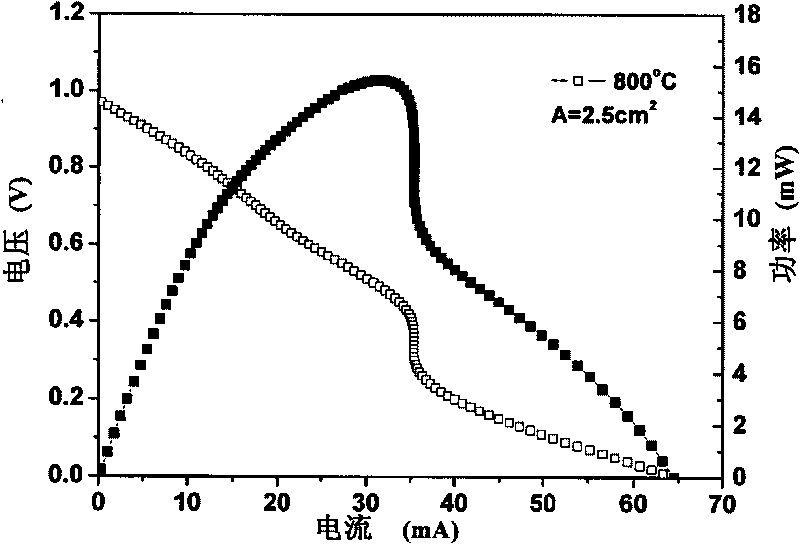

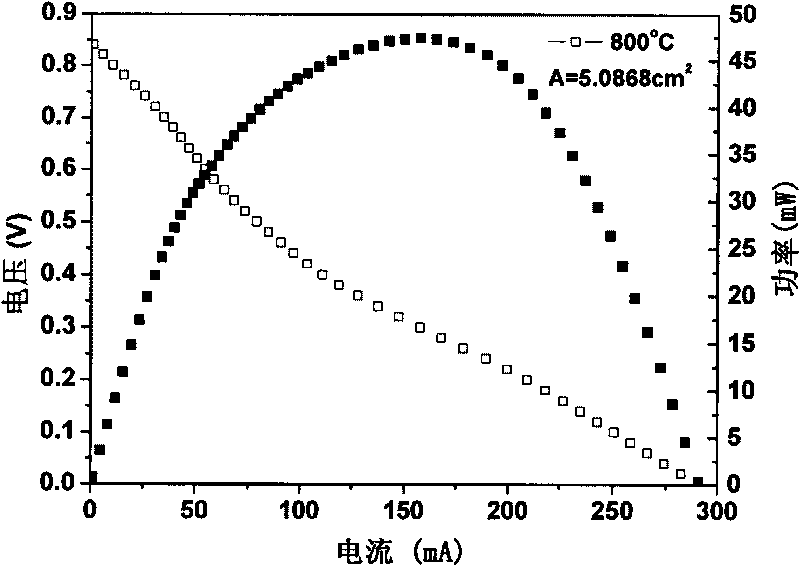

The invention discloses a direct carbon solid oxide fuel cell, wherein an electrolyte tube support body is a tubular structure with one closed end, the tubular inner wall of the electrolyte tube support body is provided with a porous anode film and the outer wall thereof is provided with a porous cathode film; powder carbon is in the porous anode film of the electrolyte tube support body, and a gas-guide tube is sealed at an opening end of the electrolyte tube support body; the opening end of the electrolyte tube support body and the gas-guide tube are sealed through a heat-resistant sealing-in material; the material of the electrolyte tube support body is yttrium-stabilized zirconia; and a slip casting forming method or dipping method is adopted for preparation and the fuel cell is formed by sintering for 3-4h in the air at the temperature of 1, 400-1, 600 DEG C. The cell is a solid oxide fuel cell directly using carbon fuel and is of a full solid structure. Electric energy output can be obtained by heating the cell with gas discharged simultaneously. The cell has the advantages of simple structure, easy operation, high conversion efficiency and the like and has great significance to the high efficient and clean use of coal-based fuel.

Owner:SOUTH CHINA UNIV OF TECH

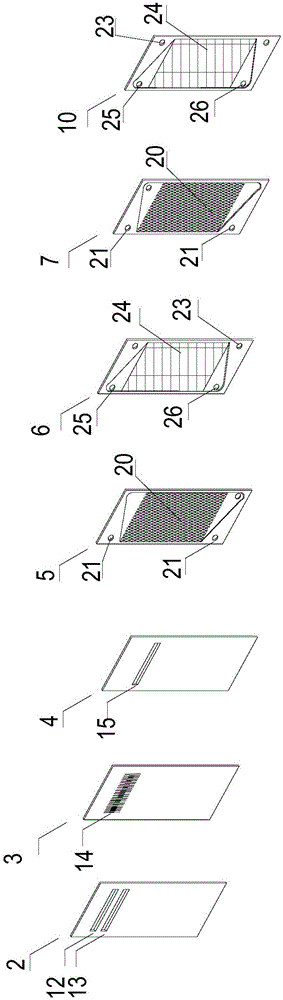

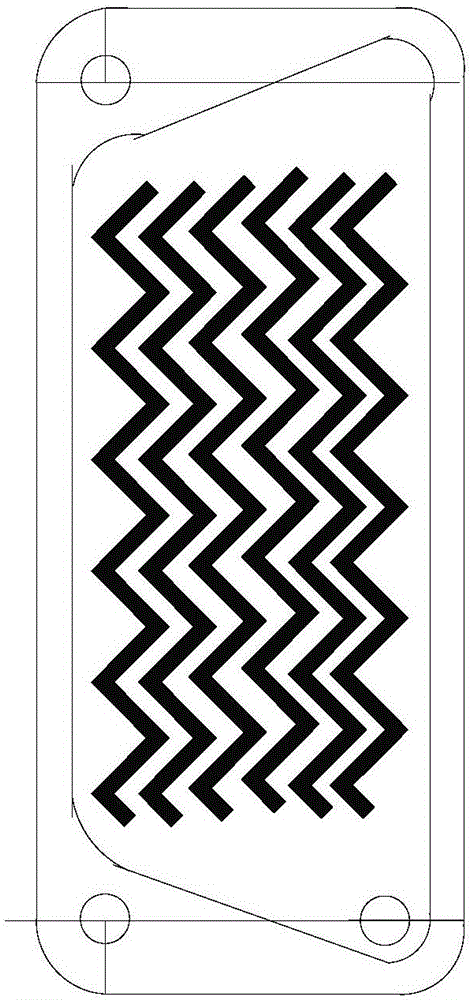

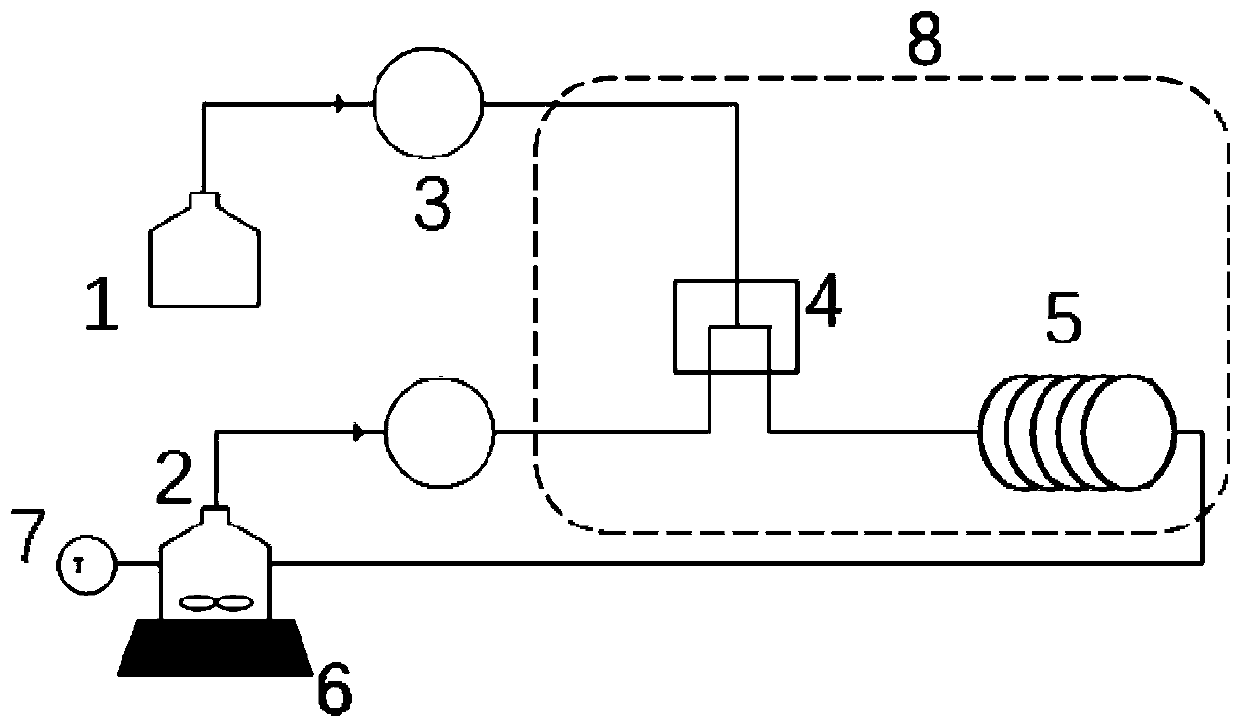

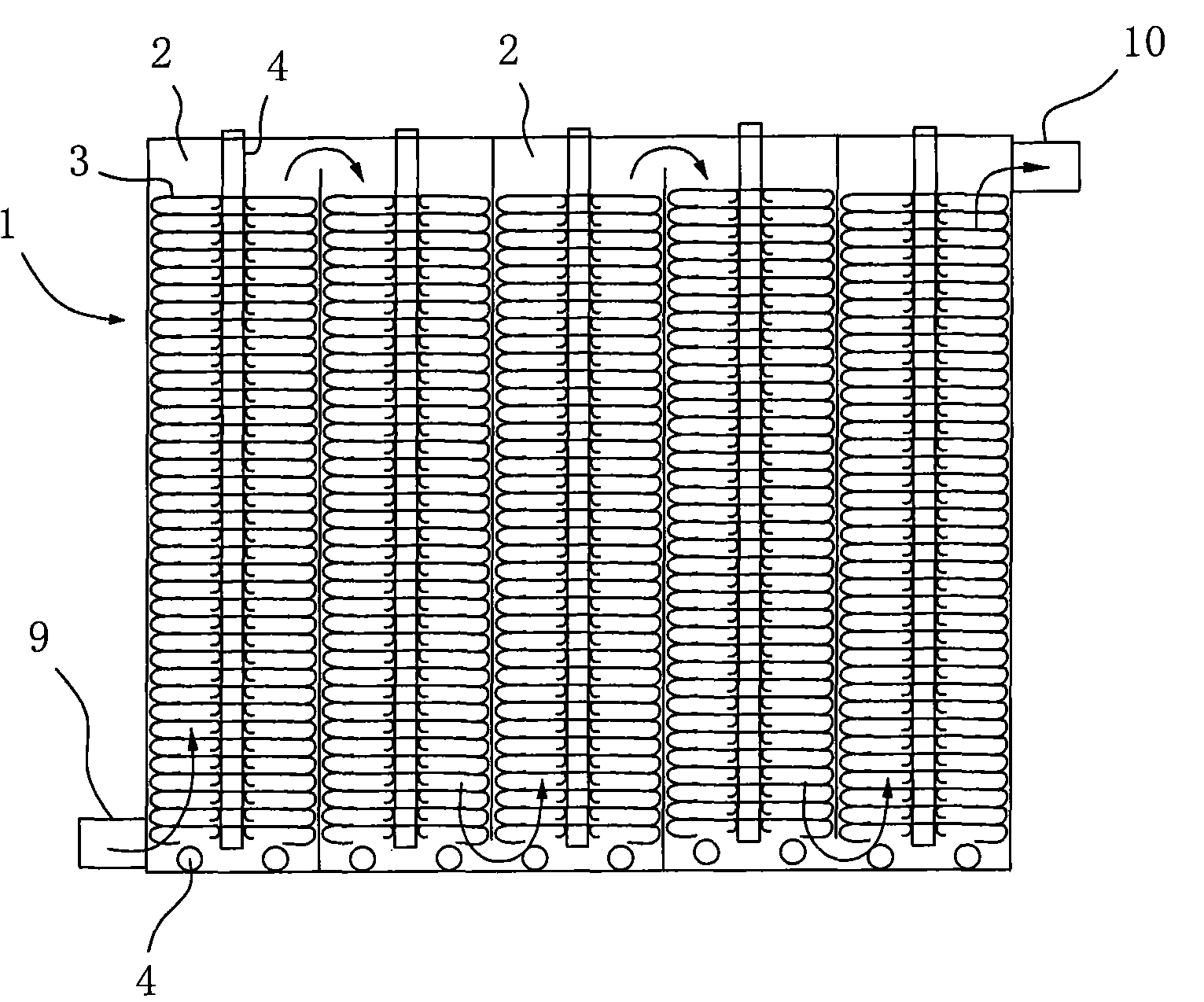

Efficient mixing heat exchange micro-channel reactor

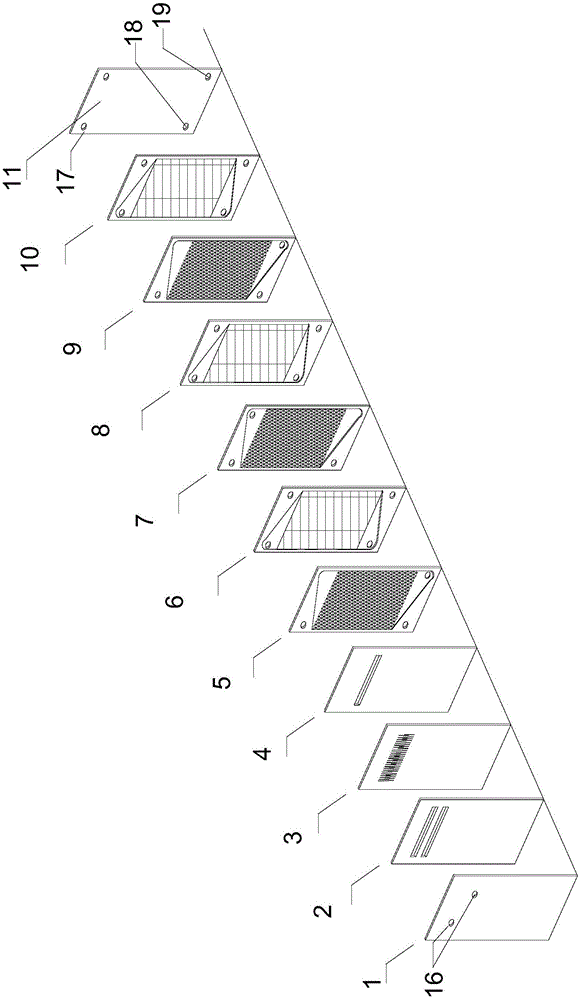

InactiveCN105107443AReduce inputReduce usageChemical/physical/physico-chemical processesSolventEnvironmentally friendly

The invention discloses an efficient mixing heat exchange micro-channel reactor. The efficient mixing heat exchange micro-channel reactor comprises a dispersive mixing component, multiple reaction liquid passageway matrixes and heat exchange medium passageway matrixes. The reaction liquid passageway matrixes and the heat exchange medium passageway matrixes are arranged alternately. The dispersive mixing component is provided with dispersive mixing channels allowing two or more kinds of reaction liquid to dispersively flow in and be mixed to form mixed reaction liquid. The reaction liquid passageway matrixes are provided with reaction liquid passageways and heat exchange medium via holes. The heat exchange medium passageway matrixes are provided with reaction liquid via holes, heat exchange medium passageways, inflow holes and outflow holes, wherein the inflow holes and the outflow holes are communicated with the heat exchange medium passageways. The reaction liquid passageways of every two adjacent reaction liquid passageway matrixes are of a cascaded structure. The heat exchange medium passageways of every two adjacent heat exchange medium passageway matrixes are of a parallel structure. According to the efficient mixing heat exchange micro-channel reactor, the heat transfer problem is completely solved; mass transfer and heat transfer are enhanced, input of heat and cold is reduced, use of a solvent is reduced, the reaction yield is increased, energy is saved, consumption is reduced, and the efficient mixing heat exchange micro-channel reactor is environmentally friendly.

Owner:NANJING NEWWEEL ELECTRIC CO LTD

Method for synthesizing phenolic resin

ActiveCN104327227ASynthetic Method AdvantagesReduce volumeChemical/physical/physico-chemical processesCompound (substance)Treatment costs

The invention relates to a method for synthesizing phenolic resin. The method comprises the following steps: mixing raw materials, preparing a catalyst, synthesizing, extracting and distilling. By using a micro-channel reactor, the heat conduction process is intensified, the mass transfer problem is well solved, the material waste is greatly reduced, and the later treatment cost is also reduced. As a parallel 'quantity enlargement' mode is adopted during the industrial enlargement of the micro-channel reactor, direct enlargement from a laboratory to the industrial production process is achieved, and the practical production is relatively flexible. Modern high-efficiency chemical development and production windows are opened, and the modern chemical engineering develops towards environment protection, safety and high efficiency.

Owner:XIAN ORIGIN CHEM TECH

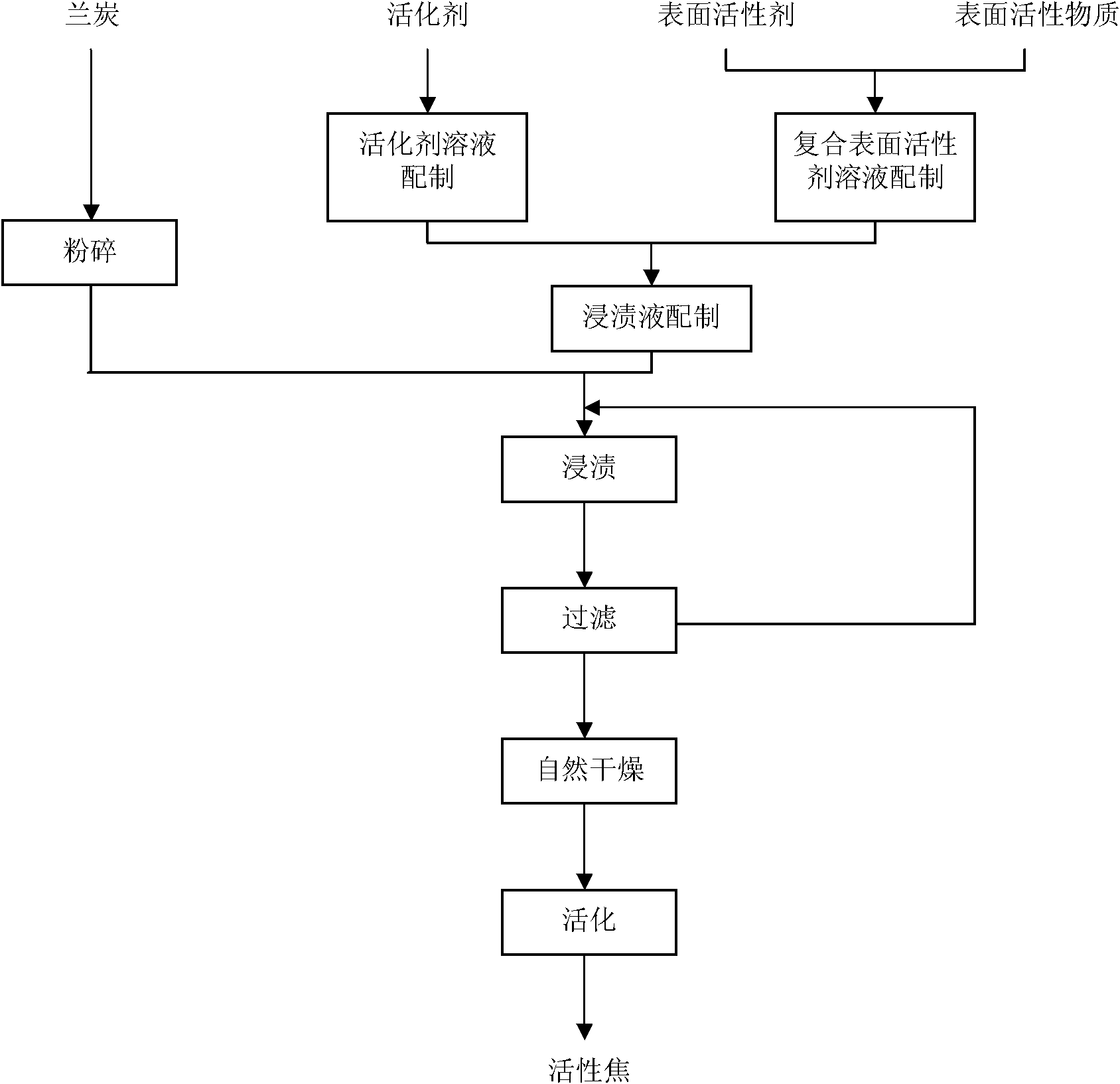

Activated coke for absorbing dioxin in flue gas and preparation method thereof

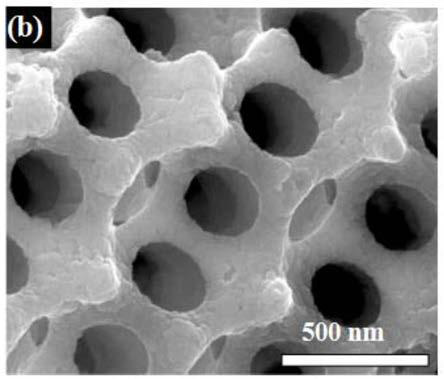

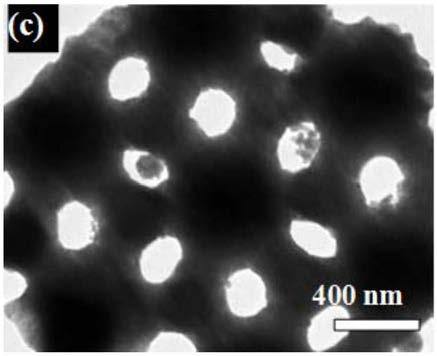

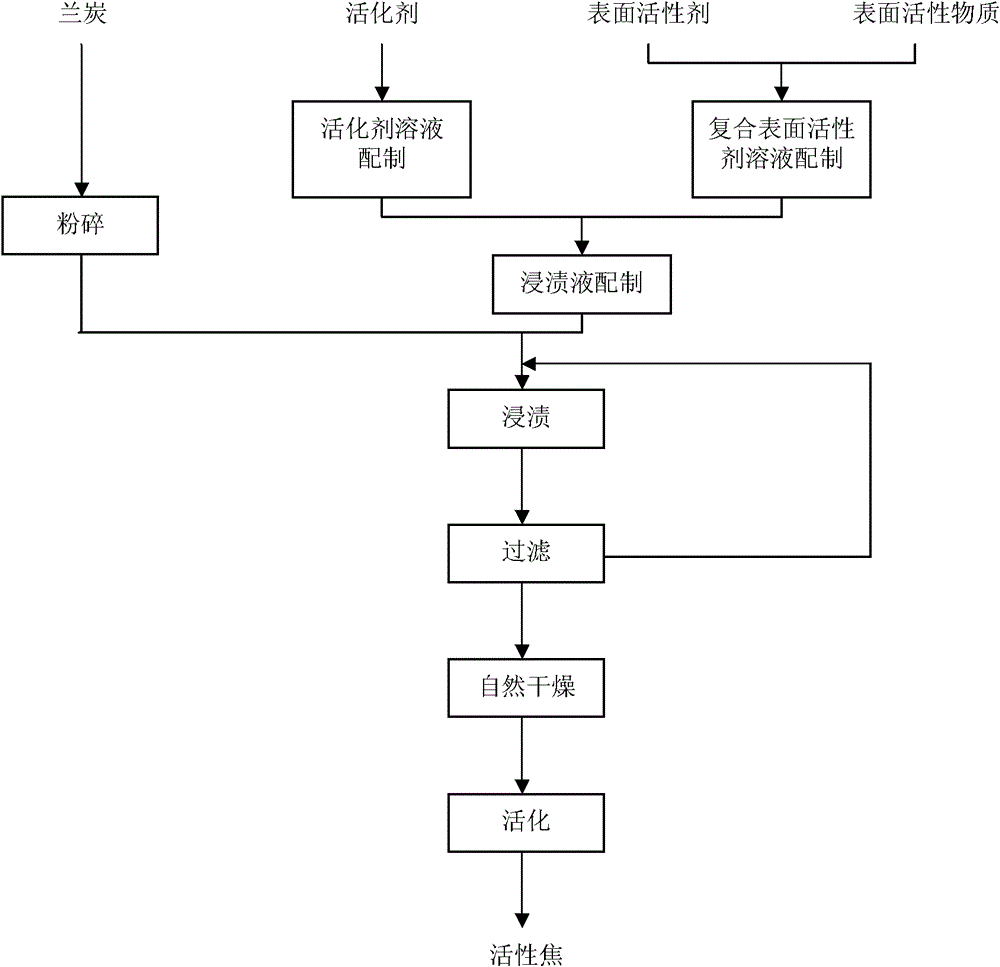

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

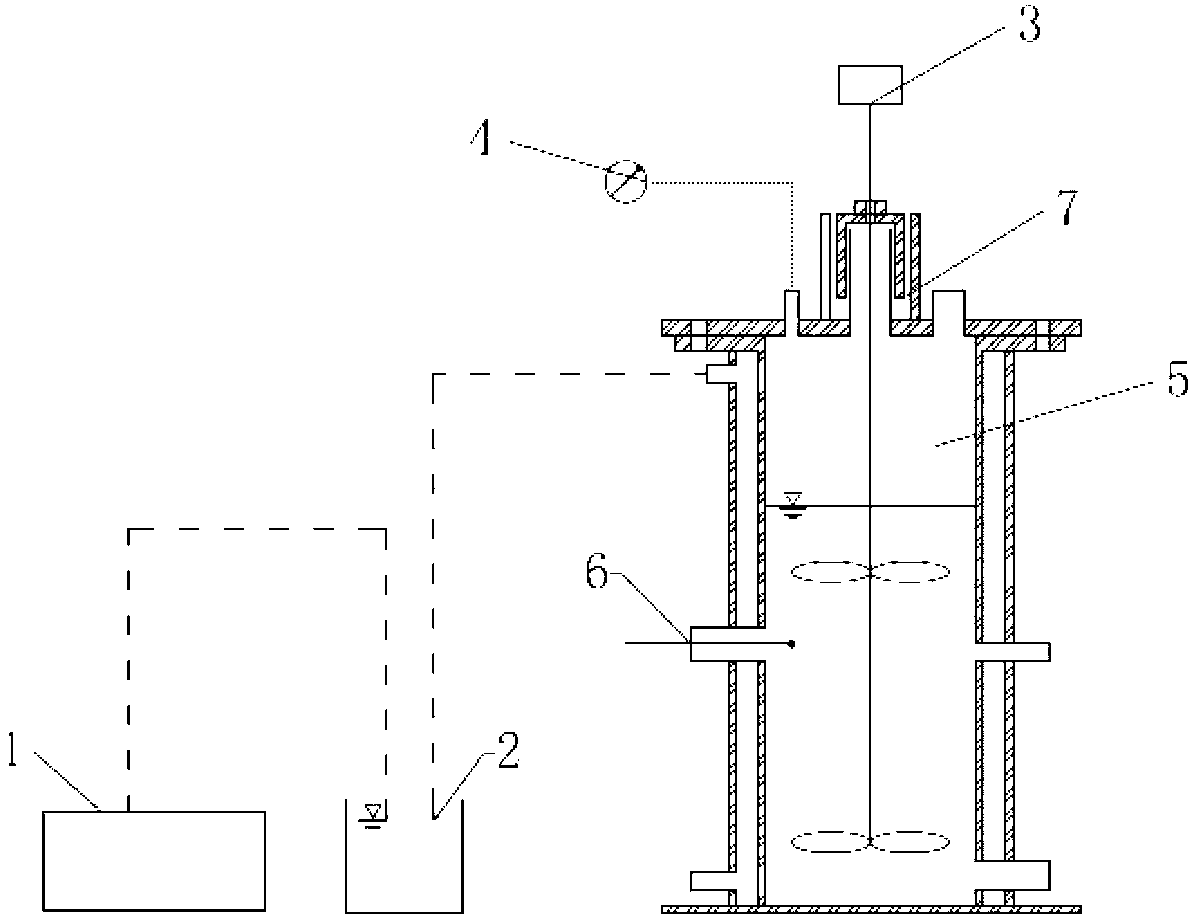

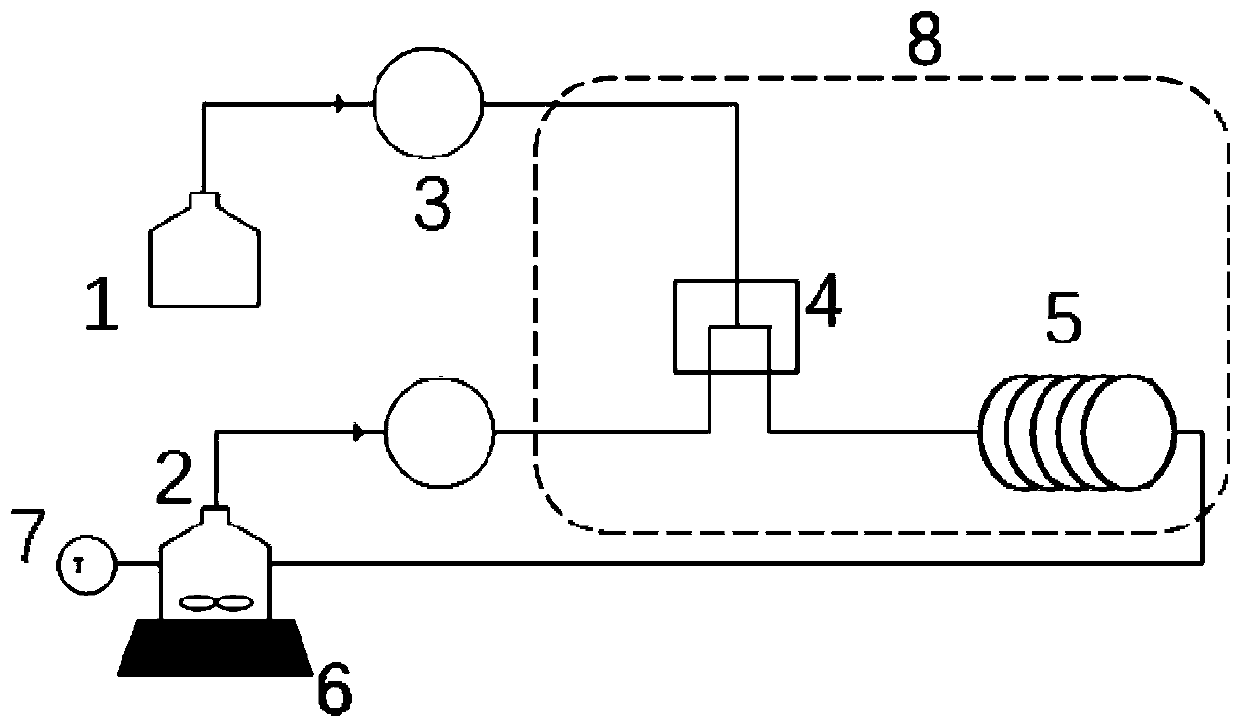

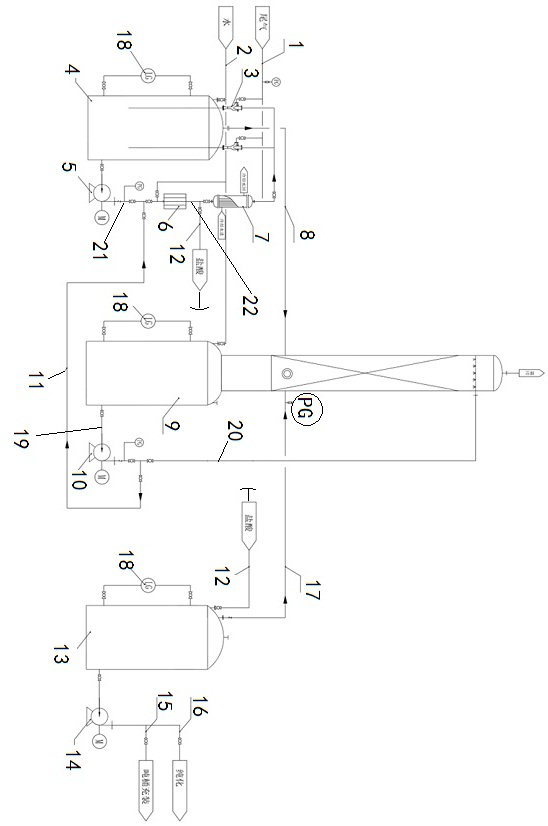

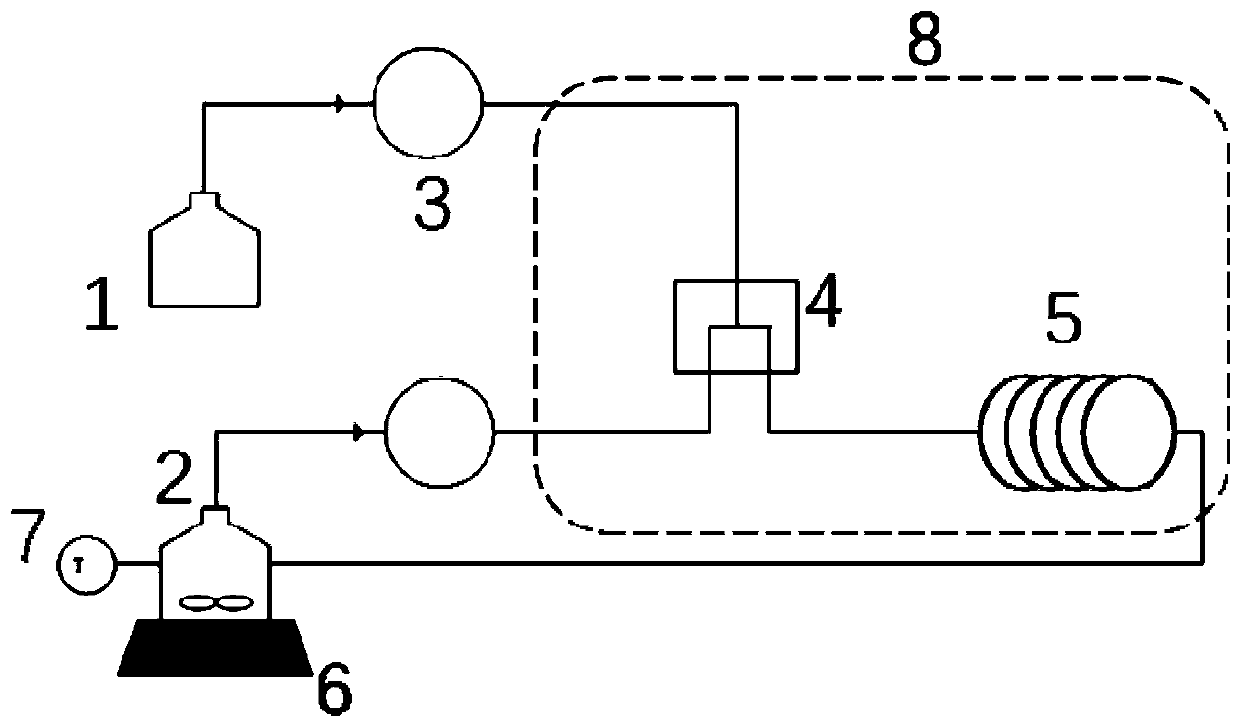

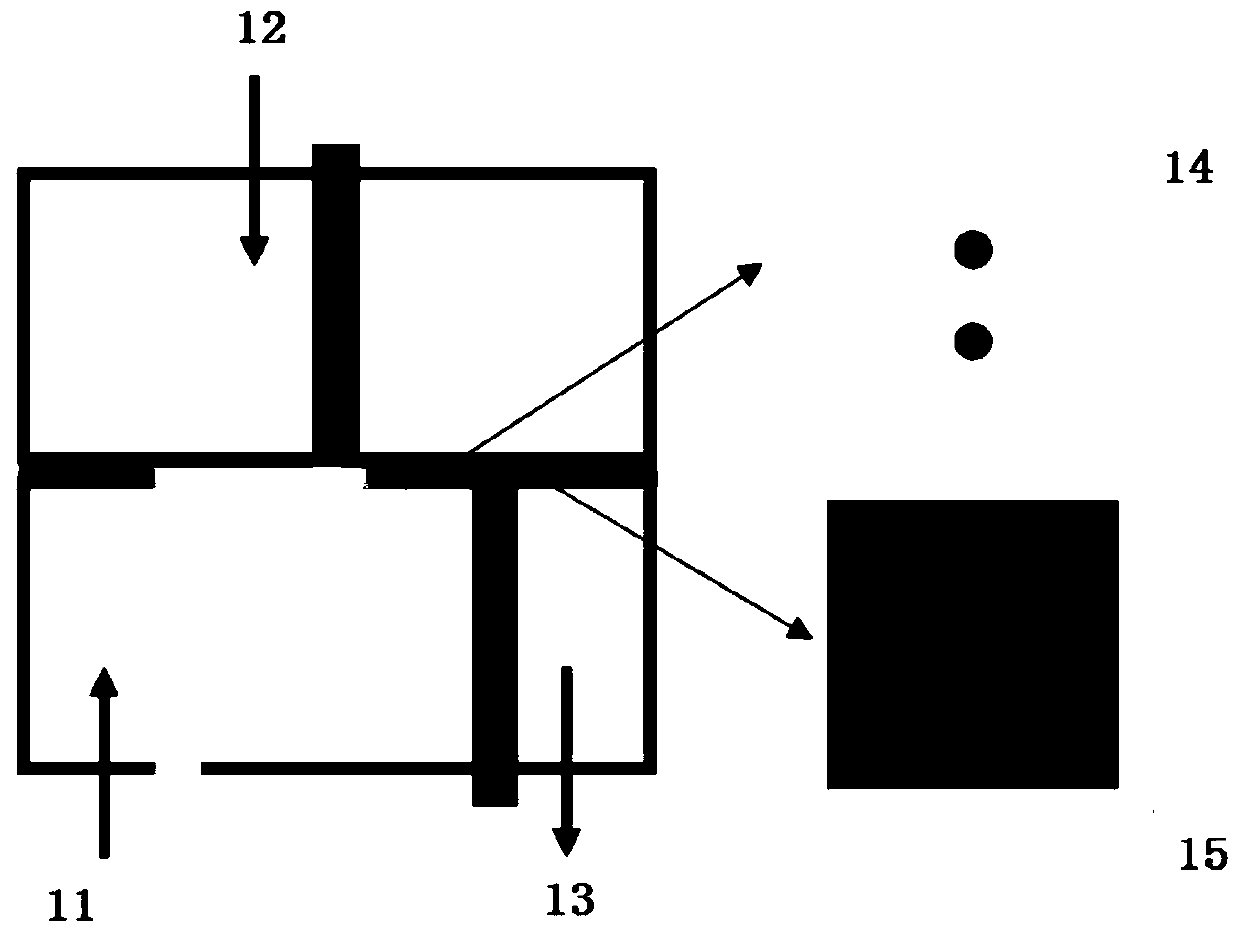

Anaerobic digestion device and process for pre-treating sludge with high solid content by heating method

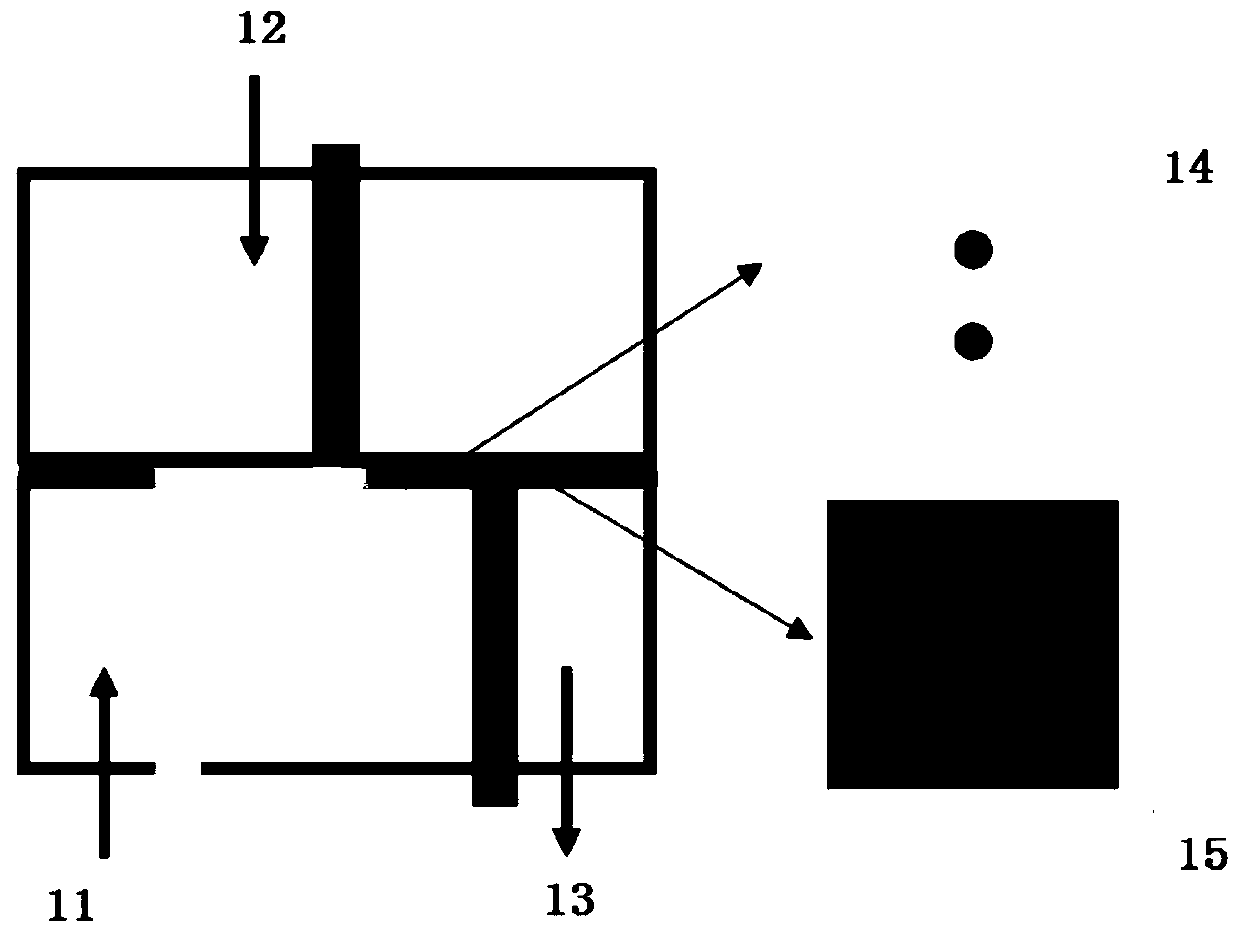

InactiveCN103011542AIncreased rate of hydrolytic acidificationSolving Mass Transfer ProblemsSludge treatment by thermal conditioningBiological sludge treatmentPeristaltic pumpPhysical chemistry

The invention discloses an anaerobic digestion device and process for pre-treating sludge with high solid content by a heating method. The anaerobic digestion process comprises the following steps of: forming sludge with solid content of 10% in a sludge mixing unit; pumping the sludge to a heating tube of a heating tank by a peristaltic pump; heating and pre-heating the sludge for 30-60 minutes at the temperature of 70 DEG C; and adding the pre-treated sludge to an anaerobic digestion tank for carrying out stirring anaerobic digestion. According to the anaerobic digestion device and process provided by the invention, the problems that the sludge anaerobic digestion has larger traffic volume, the cost is high, and the sludge is difficult to hydrolyze and acidize are solved; and the reduction, reclamation and innoxious disposal of the sludge are realized.

Owner:TSINGHUA UNIV

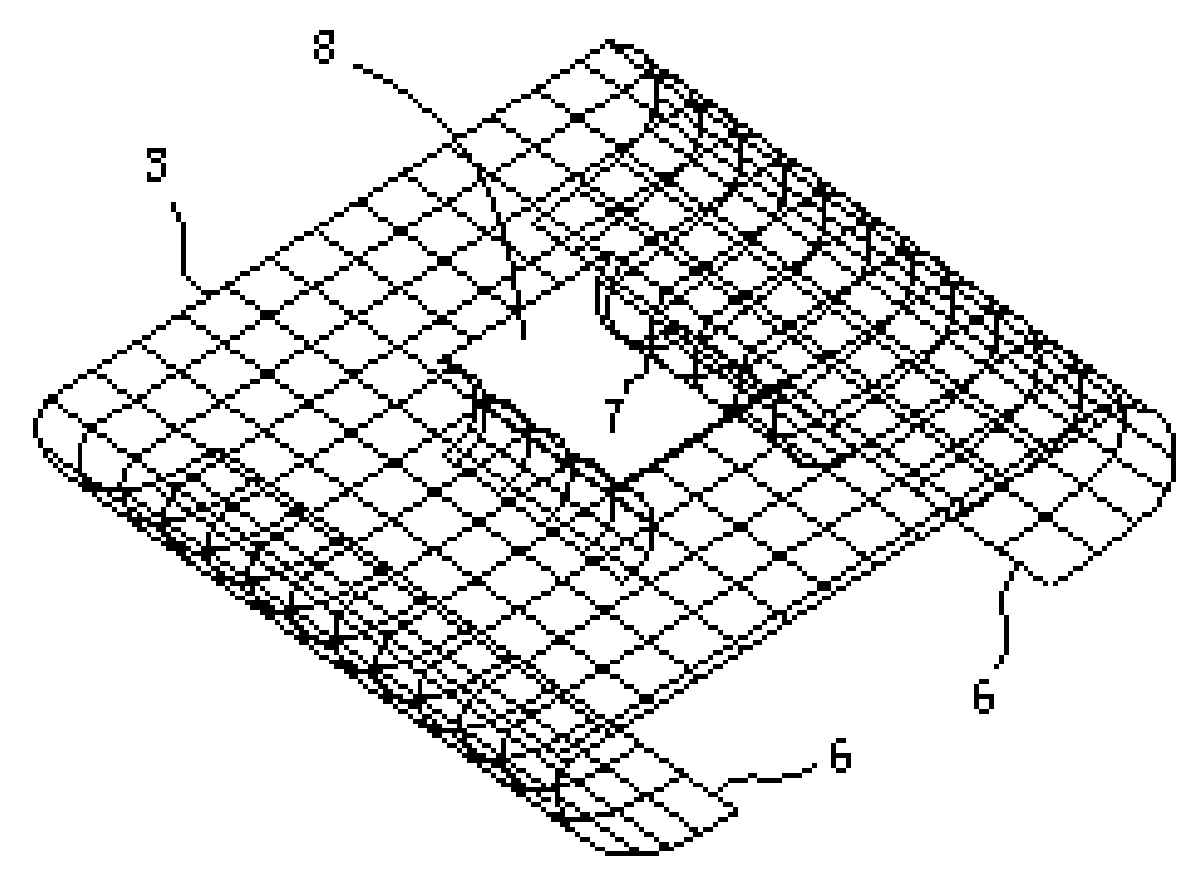

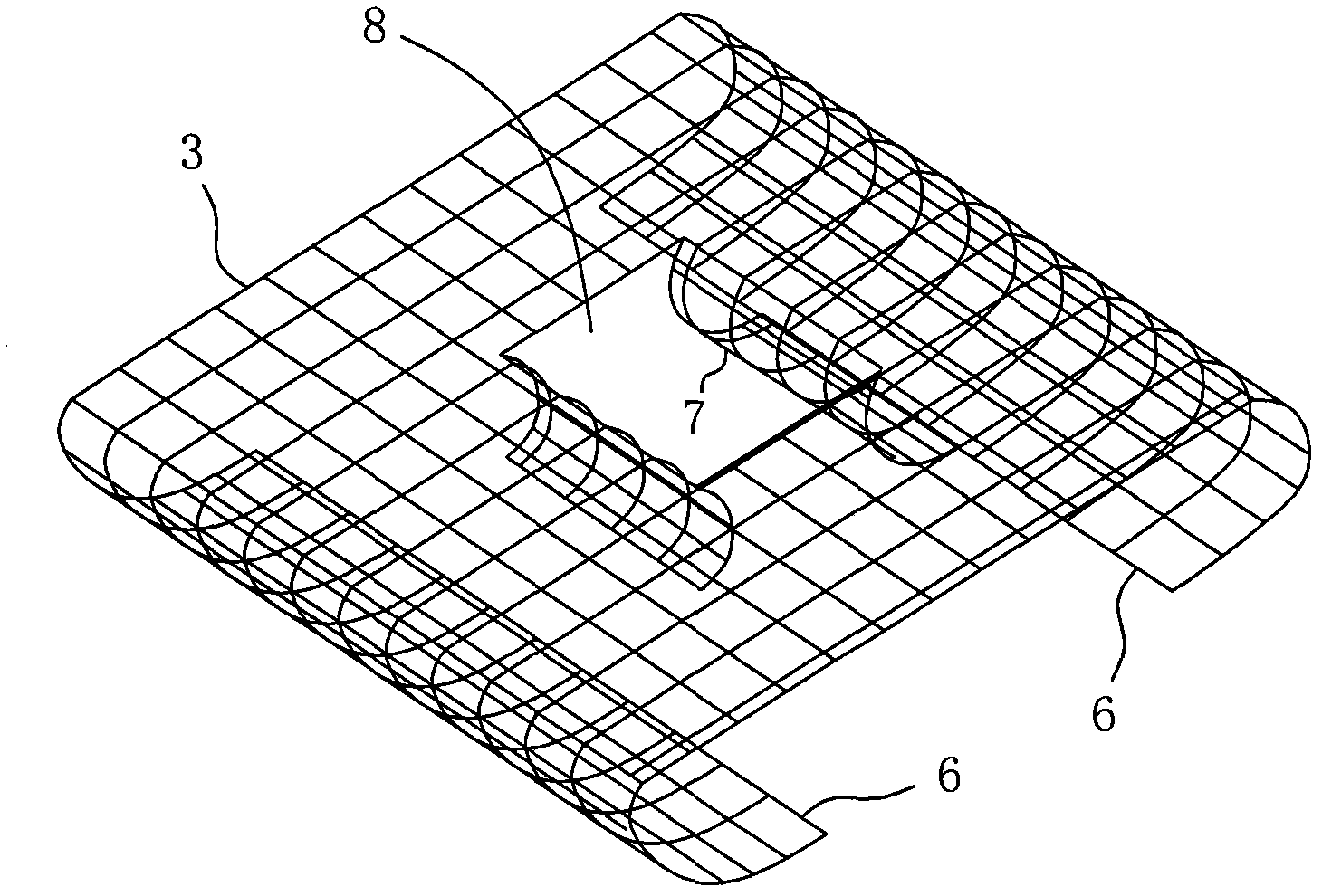

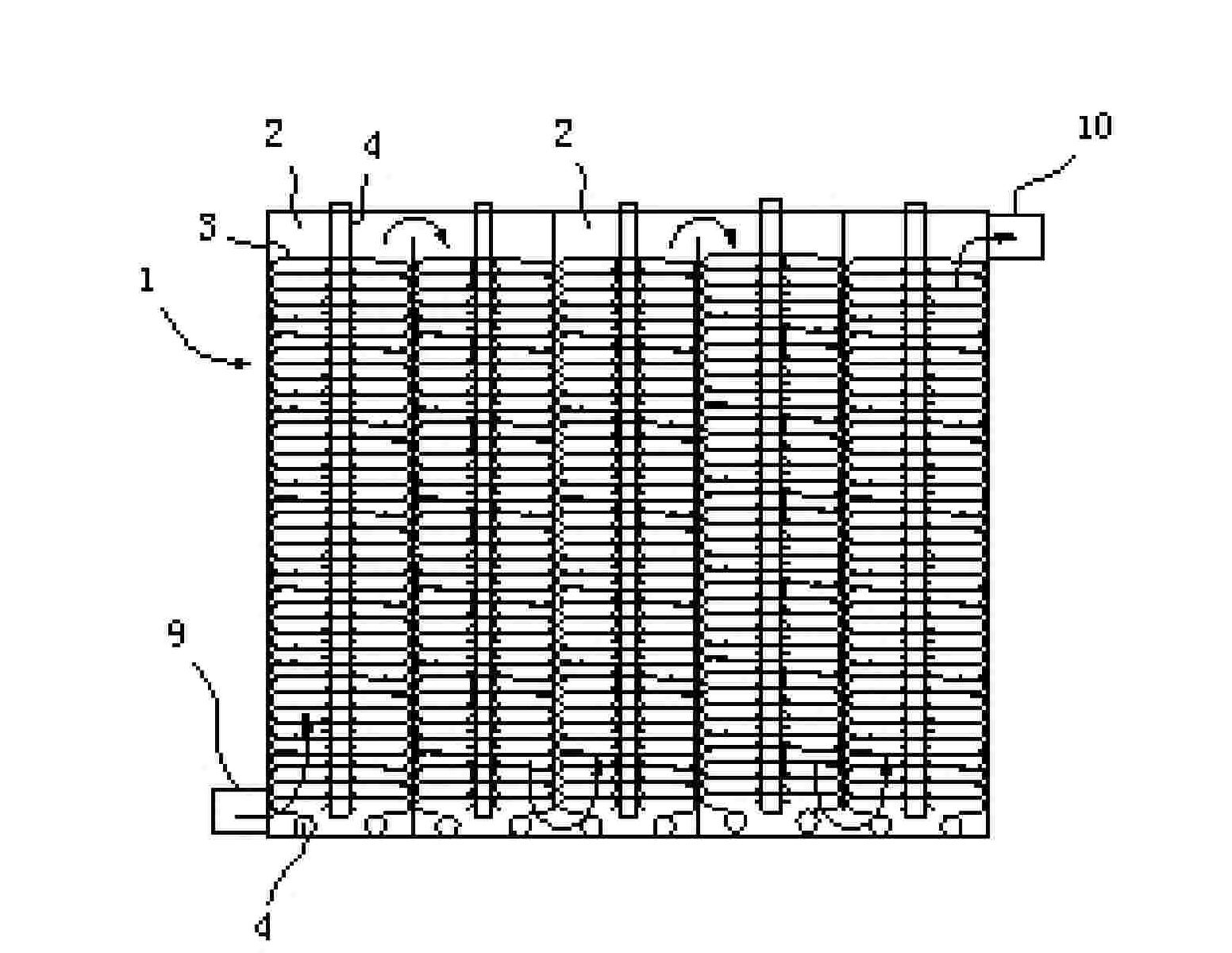

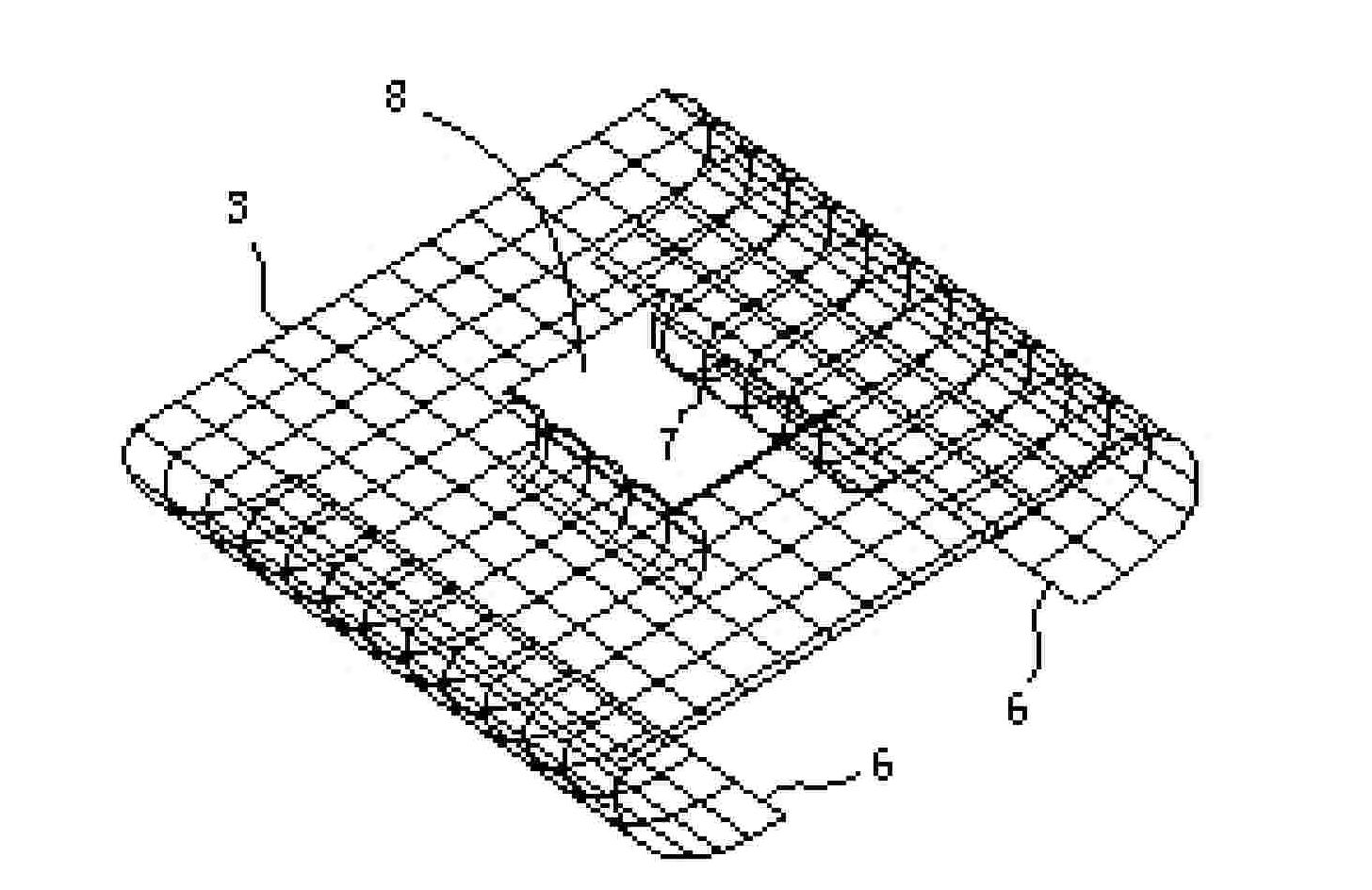

Manufacturing method of netted catalyst for degrading organic pollutant in wastewater by photocatalysis and organic pollutant wastewater treating device

ActiveCN101584996ATroubleshoot enhancementsExtend compound timeWater/sewage treatment by irradiationWater contaminantsEpoxyUltraviolet lights

The invention relates to a manufacturing method of a netted catalyst for degrading the organic pollutant in wastewater by photocatalysis and a wastewater treating device. The manufacturing method comprises: using the wire net plated with nickel as a carrier, coating a catalyst for solidification, wherein the catalyst mixed liquid includes nano TiO2, acetone, epoxy resin, solidifying agent and appropriate plasticizer, soaking in the acetone solution. A case of the treatment device is provided with a plurality of independent deflecting chambers connected end-to-end in turn, two ends of which are provided with a water inlet and a water outlet. A plurality of solid netted bodies solidified with the catalyst are overlapped at intervals in the deflecting chamber. A through hole is opened in the middle of the solid netted body. An ultraviolet light source is inserted in the through hole. An aeration pipe is arranged on the bottom of the deflecting chamber. The device can deeply degrade the organic matter in wastewater.

Owner:深圳市世纪清源环保技术有限公司

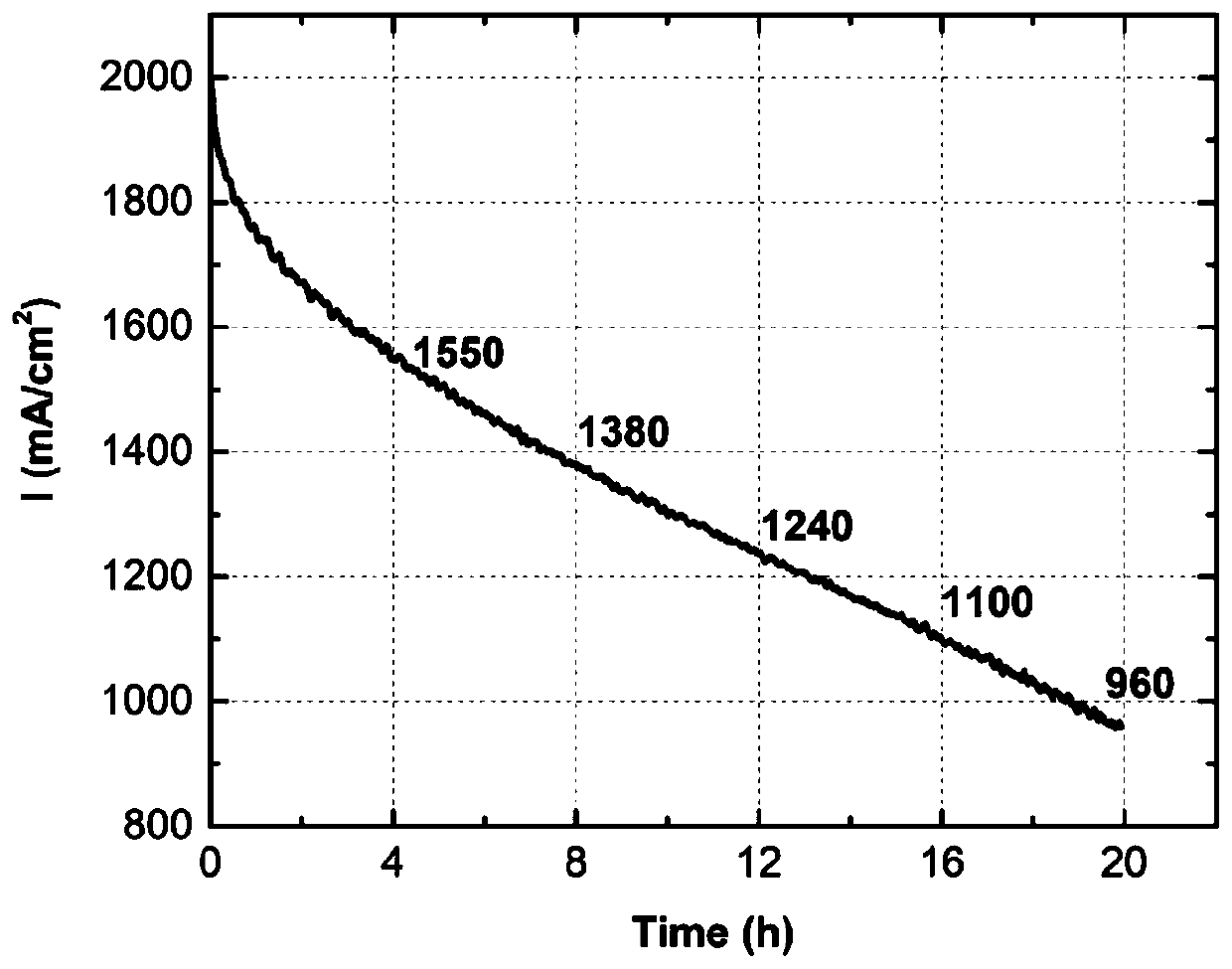

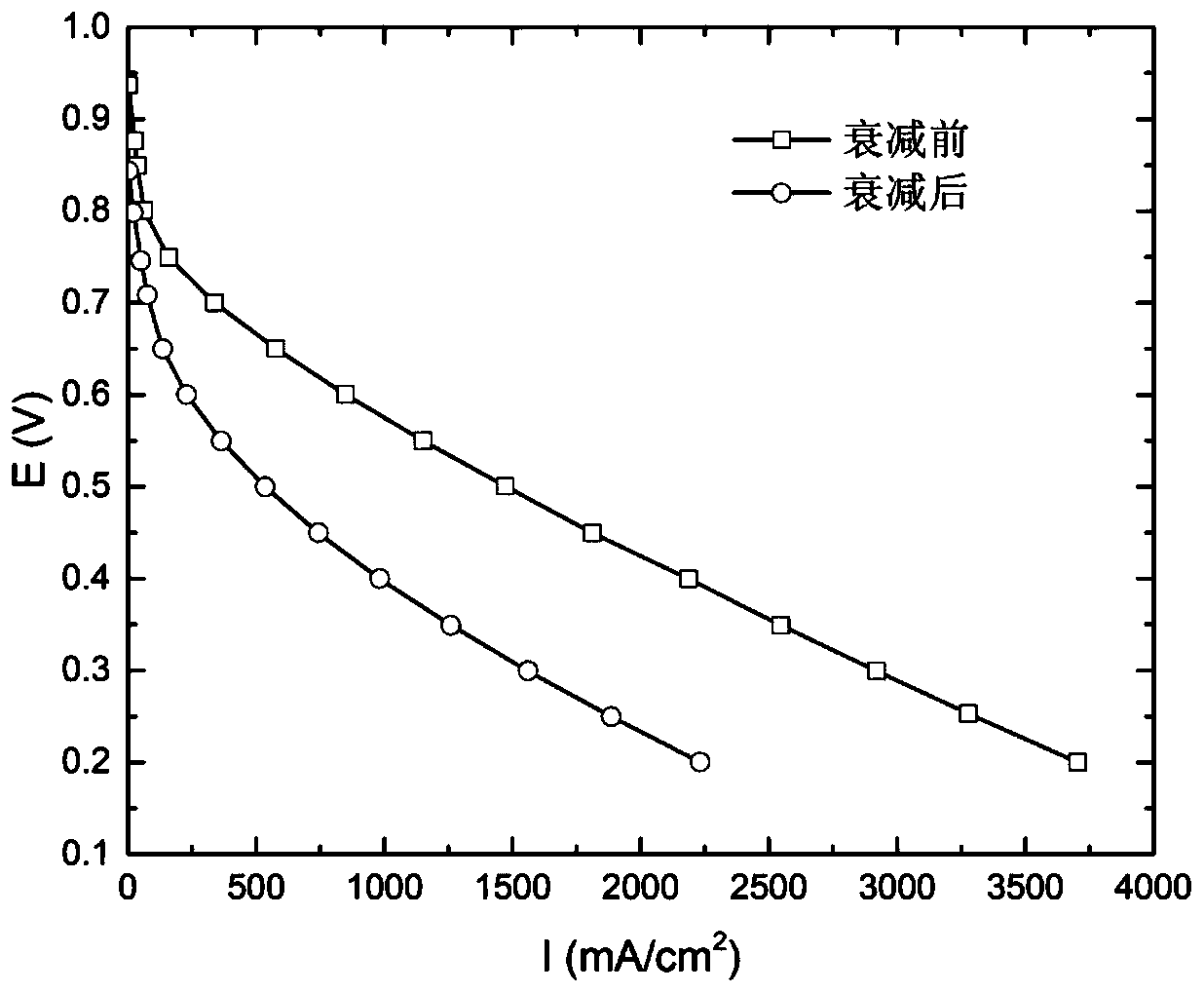

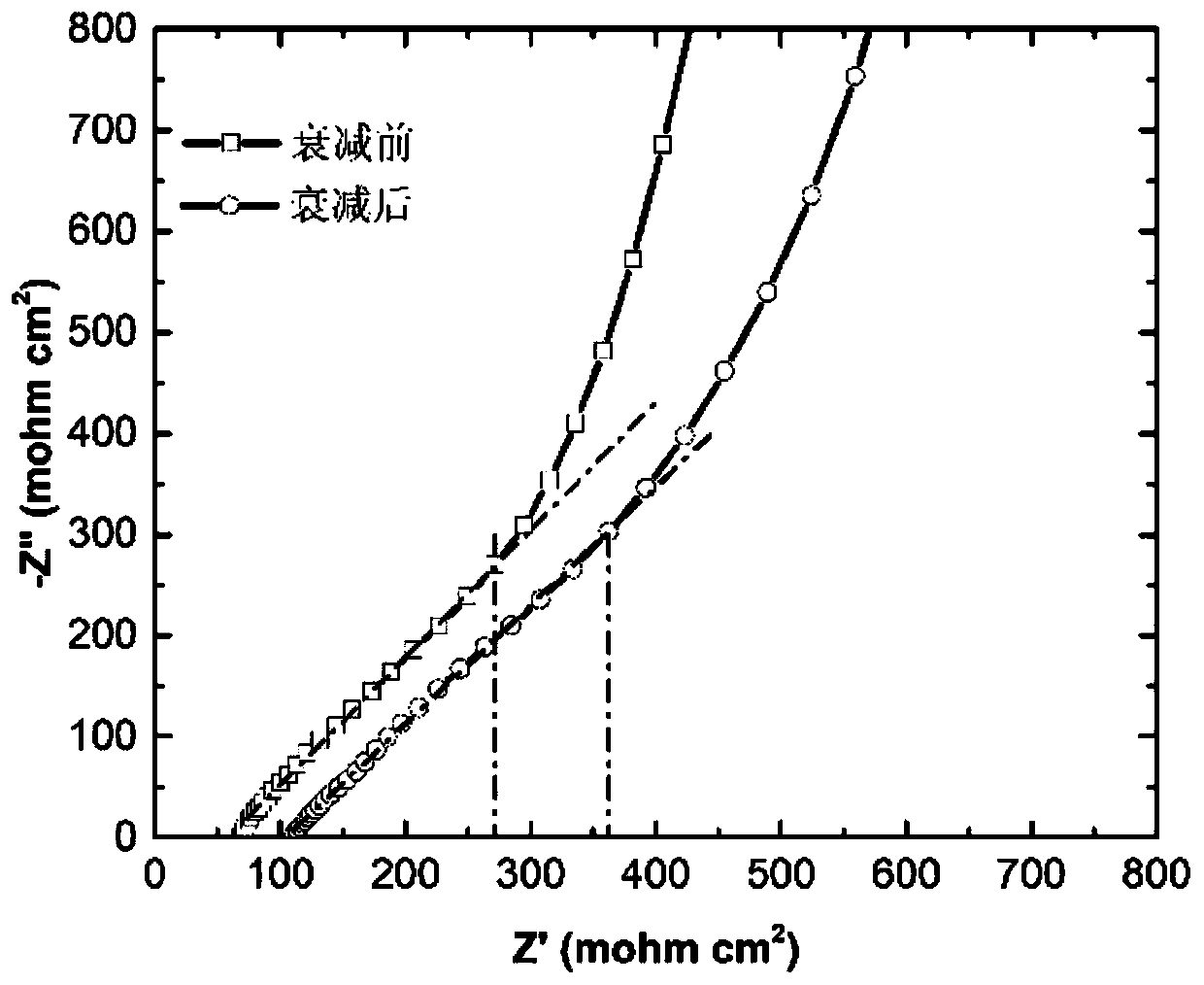

Non-noble metal catalyst film electrode endurance test method

ActiveCN110530954APrevent floodingSolving Mass Transfer ProblemsMaterial analysis by electric/magnetic meansFuel cellsUltrasound attenuationNitrogen

The invention discloses a non-noble metal catalyst film electrode endurance test method. The method comprises the steps of respectively testing a polarization curve, ohmic resistance and cathode catalyst layer proton conduction impedance of a film electrode at the beginning; then performing constant-voltage discharge attenuation test on the film electrode; further testing the polarization curve, ohmic resistance and cathode catalyst layer proton conduction impedance of the film electrode after attenuation; then inputting dry nitrogen into the film electrode for purging; and at last testing thepolarization curve of the film electrode after nitrogen purging by using an electrochemical workstation. According to the method, as for the non-noble metal catalyst film electrode, the polarizationcurves, ohmic resistance and cathode catalyst layer proton conduction impedance of the film electrode before and after constant-voltage discharge attenuation, and the polarization curves of the film electrode before and after nitrogen purging are tested, the test condition is the same as the film electrode test condition, and test data is true and reliable. The film electrode endurance test can beperformed from three aspects: activation polarization, ohmic polarization and mass transfer polarization, and the method is of great significance to development of the non-noble metal catalyst film electrode.

Owner:SHANGHAI JIAO TONG UNIV

Method for synthesizing dodecylbenzene sulfonic acid in circulating microreactor

ActiveCN109912462AInhibit side effectsAchieve uniform mixed reactionChemical/physical/physico-chemical processesSulfonic acid preparationReaction temperatureAlkylbenzenes

The invention discloses a technology for synthesizing dodecylbenzene sulfonic acid in a circulating microreactor. The technology is characterized in that a dodecylbenzene solution and a sulfonating agent which is a sulfur trioxide solution are rapidly mixed in a microporous dispersion reactor so as to realize sulfonation process; the obtained product flows back and is mixed with dodecylbenzene, and the mixture circularly enters a microreactor for further reacting; after sulfur trioxide is fed, the mixture is aged for 30-50min, and then the solvent which is 1, 2-dichloroethane is recovered by rotary evaporating so as to obtain the dodecylbenzene sulfonic acid product. According to the technology, the microporous dispersion technology is carried out to fully mix dodecylbenzene and the sulfonating agent, so that byproducts produced due to high local concentration of sulfur trioxide can be effectively avoided; moreover, the reaction temperature can be accurately controlled, so that local overheat due to heat produced in the reaction can be avoided; the reaction process and the ageing process are combined, so that the conversion rate of dodecylbenzene is increased; the dodecylbenzene sulfonic acid in the main product is up to 98% by mass; and the product is basically free from waste acid; and the product is easily separated.

Owner:TSINGHUA UNIV

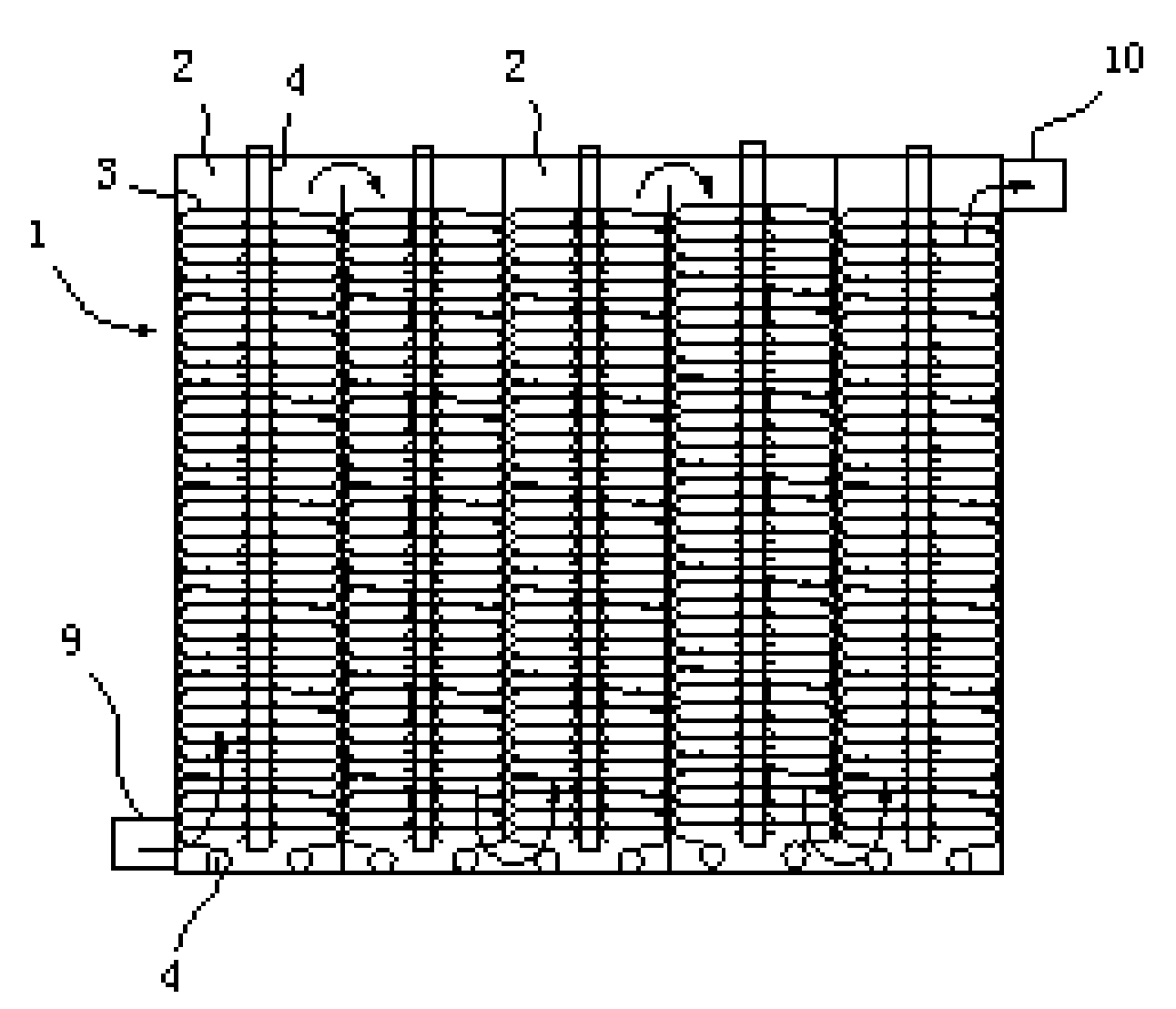

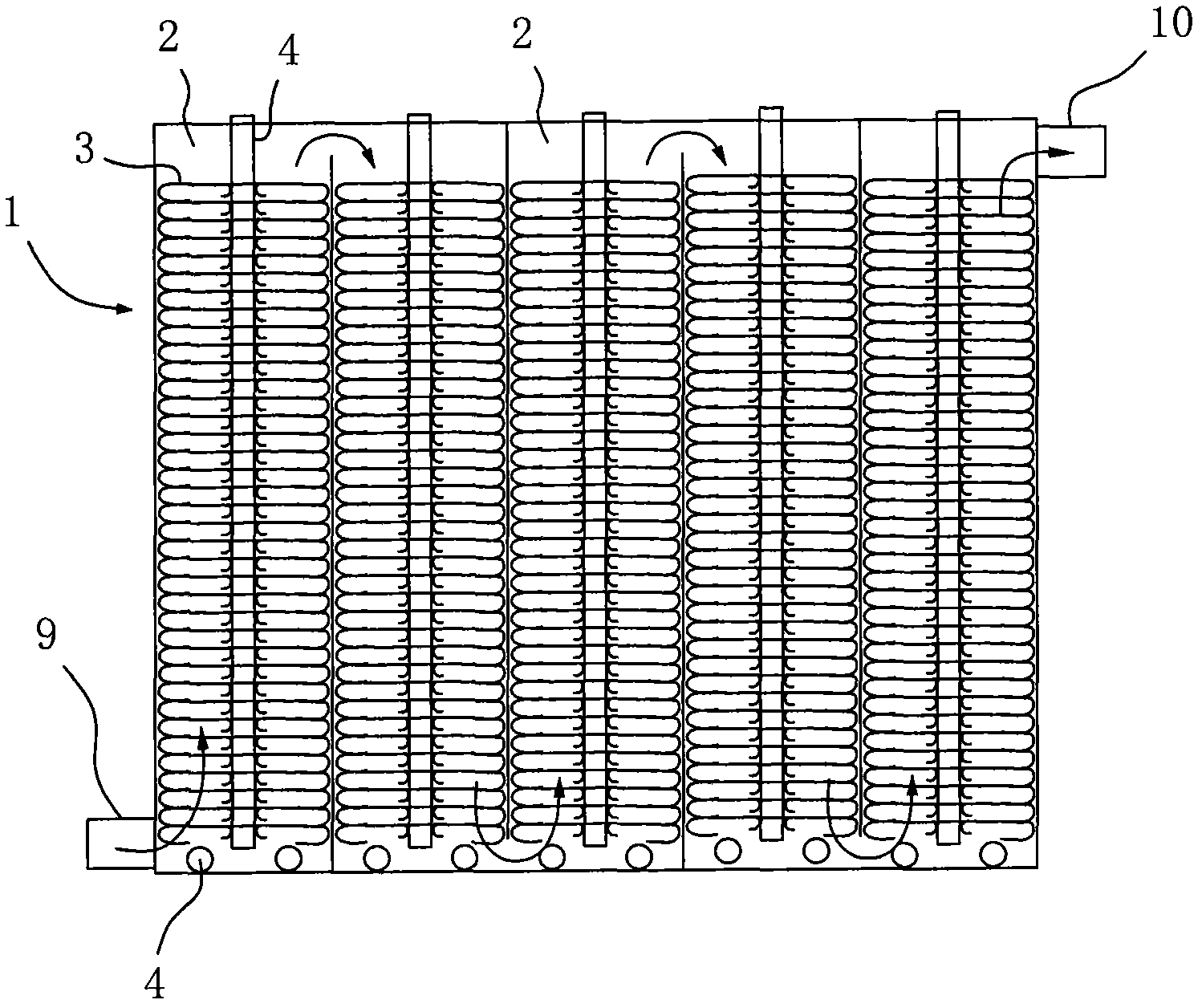

Photocatalytic degradation treatment device of wastewater with organic pollutants

ActiveCN102107927ATroubleshoot enhancementsExtend compound timeWater/sewage treatment by irradiationWater/sewage treatment by oxidationUltraviolet lightsWastewater

The invention relates to a photocatalytic degradation treatment device of the wastewater with organic pollutants. The treatment device contains a box. The treatment device is characterized in that the inside of the box is provided with a plurality of relatively independent baffled chambers which are connnected end to end; the both ends of the box are separately provided with a water inlet and a water outlet; in each baffled chamber, a plurality of three-dimensional reticular bodies with immobilized catalyst are stacked at intervals, the center of each three-dimensional reticular body is provided with a through hole, a ultraviolet light source is inserted in the through hole, and an aeration pipe is arranged at the bottom of the baffled chambers; and each three-dimensional reticular body is formed by stacking several layers of reticular carrier, the space between the layers of reticular carrier is 1-3 times of the reticular width, the periphery of the reticular carrier is bent to the bottom surface relatively, the center of the reticular carrier is provided with an I-shaped notch, and the notch is bent to the bottom surface. An illumination device is inserted in the notch. By adopting the device of the invention, the organic matter in wastewater can be decomposed to a large extent.

Owner:深圳市世纪清源环保技术有限公司

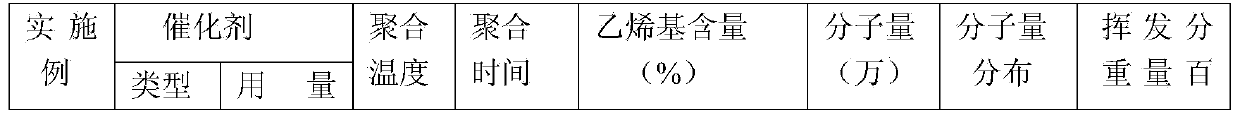

Preparation method of heat curing fluorosilicone raw rubber

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

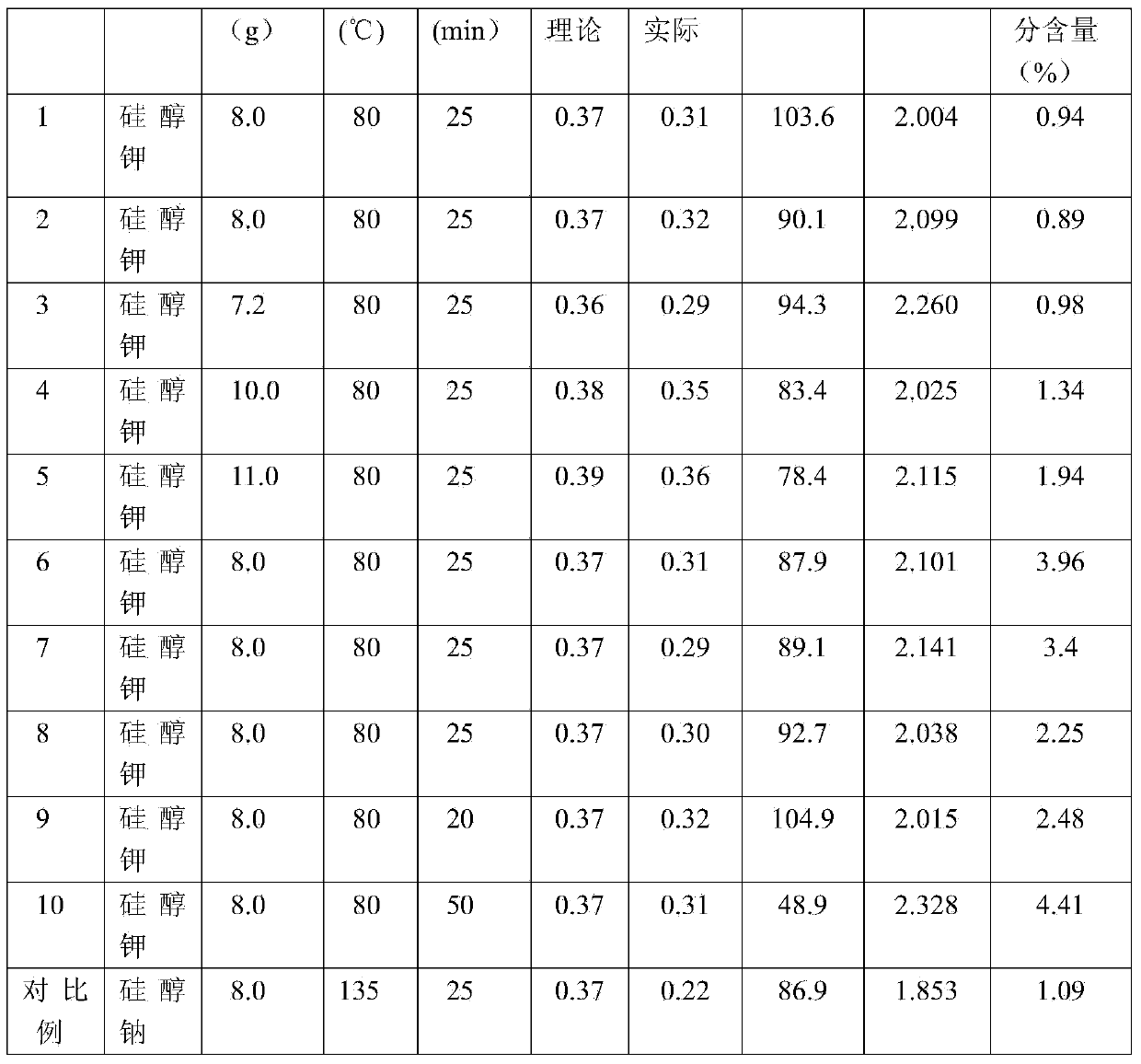

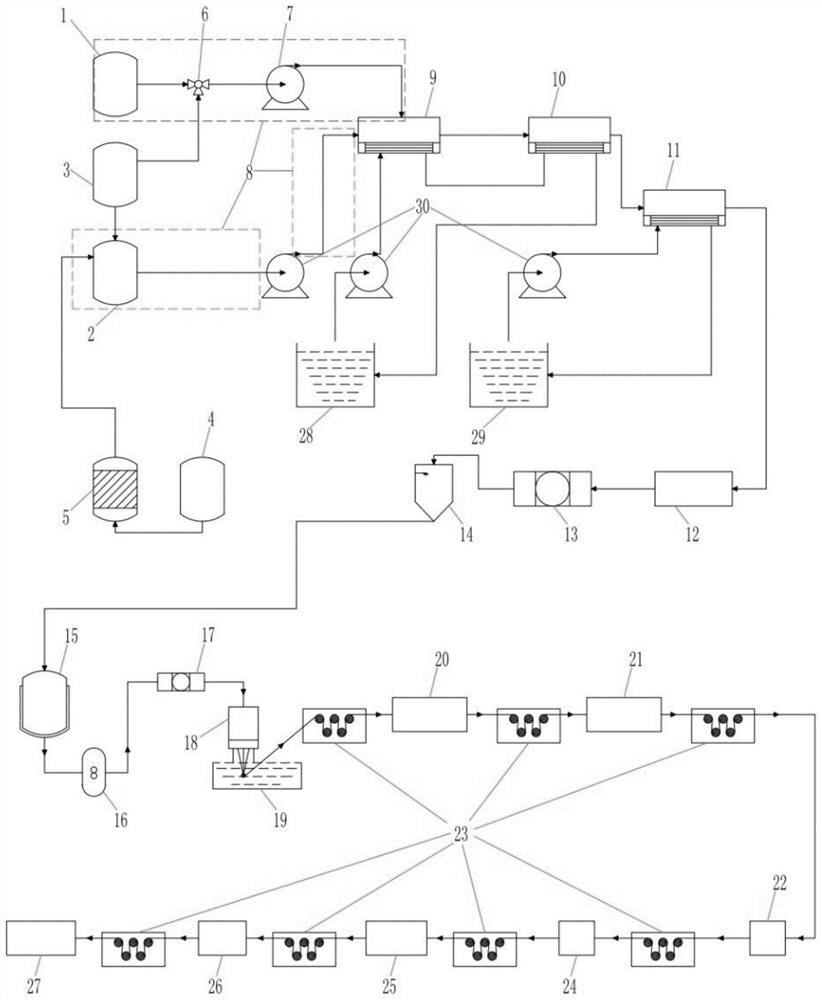

Preparation method of all-solid-state Z-shaped heterojunction photocatalyst

ActiveCN109225265AEfficient photohydrolysis hydrogen production activitySolve the problem of easy recombination of photogenerated carriersCatalyst activation/preparationHydrogen productionHeterojunctionCysteine thiolate

The invention discloses a preparation method of an all-solid-state Z-shaped heterojunction photocatalyst. The preparation method comprises the following steps: 1) adding tungstic acid and ammonia water into deionized water A, after uniformly stirring, adding oxalic acid and anhydrous ethanol, then adding a PS template, then carrying out vacuum impregnation, drying and calcination to obtain a 3DOM-WO3 catalyst, then adding deionized water B, then adding a chloroplatinic acid solution, stirring under irradiation of an xenon lamp by a photo-reduction method to obtain a 3DOM-WO3 / Pt catalyst, finally carrying out heat treatment to obtain 3DOM-HxWO3 / Pt; 2) adding L-cysteine, Cd(NO3)2 and 3DOM-HxWO3 / Pt into water, then uniformly stirring to obtain a mixed solution; and 3) adding a Na2S solution into the mixed solution, then carrying out hydrothermal reaction, after reaction is ended, cooling to room temperature, then carrying out washing, centrifugal separation, freezing and drying to obtainthe Z-shaped heterojunction photocatalyst. The all-solid-state Z-shaped heterojunction photocatalyst prepared by the invention has the characteristics of high quantum efficiency and difficult composition of photon-generated carriers, and the photocatalytic activity is higher.

Owner:XI AN JIAOTONG UNIV

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322BReduce dosageUniform adsorptionOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

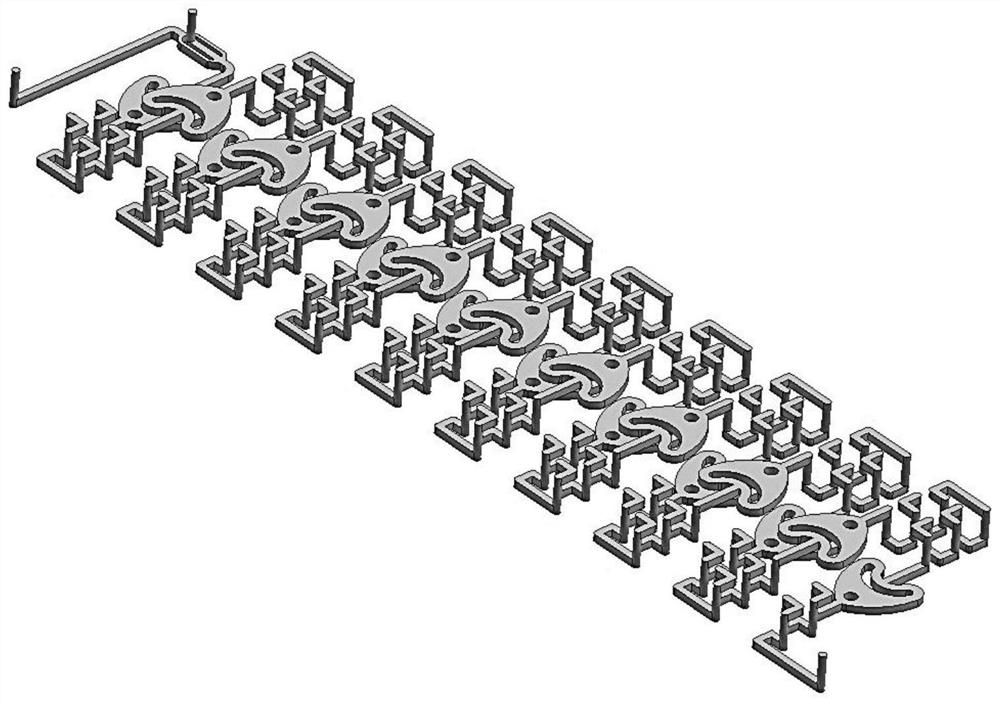

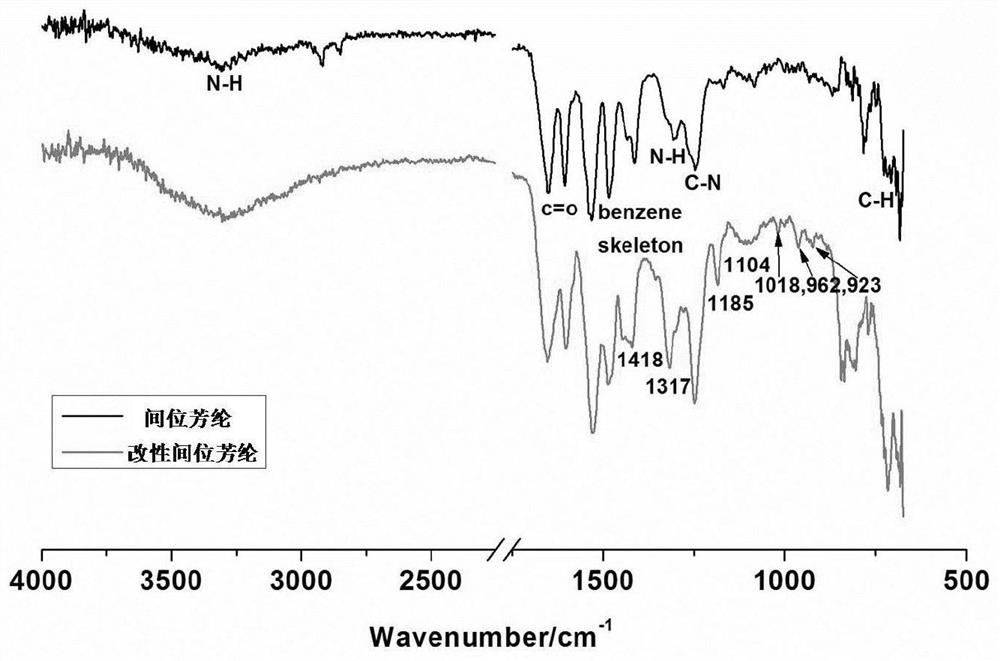

Method and device for preparing modified meta-aramid fiber through continuous polymerization-dry-wet spinning

ActiveCN113774509AImprove spinnabilityHigh molecular weightFlow mixersTransportation and packagingMicroreactorPolymer science

The invention discloses a method and a device for preparing modified meta-aramid fiber through continuous polymerization-dry-wet spinning. The method comprises the following steps that (1), a DMAc mixed solution of m-phenylenediamine and a copolymerized diamine monomer is prepared by using a cosolvent; (2), the isophthaloyl dichloride melt is mixed with a DMAc mixed solution of m-phenylenediamine and a copolymerized diamine monomer, and pre-polycondensation and polycondensation are carried out to obtain a modified meta-aramid resin solution; and (3), auxiliaries are added into the modified meta-aramid resin solution, filtering, defoaming, and spinning are carried out by a dry-wet method to obtain modified meta-aramid fibers. A pre-polymerization system of the continuous polymerization-dry-wet spinning device comprises a micro-mixer and a micro-reactor which are connected in sequence, and a micro-channel of the micro-reactor is designed to be heart-shaped; and the polycondensation system is a multi-stage microscrew combination. The problems in the preparation process of the meta-position aramid fiber are comprehensively solved, the obtained product is complete in structure, excellent in performance, stable and controllable, and continuous and efficient production can be achieved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

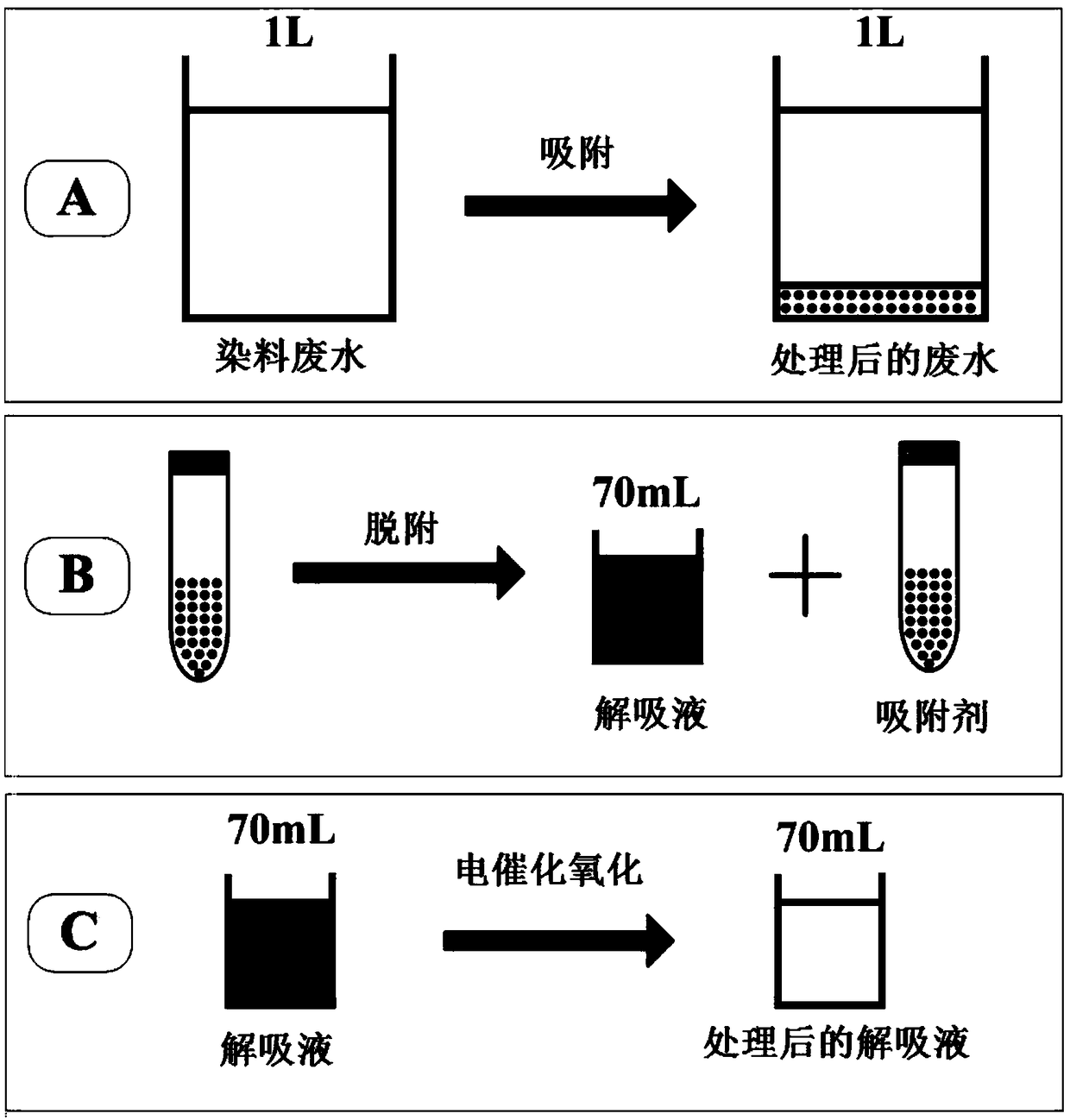

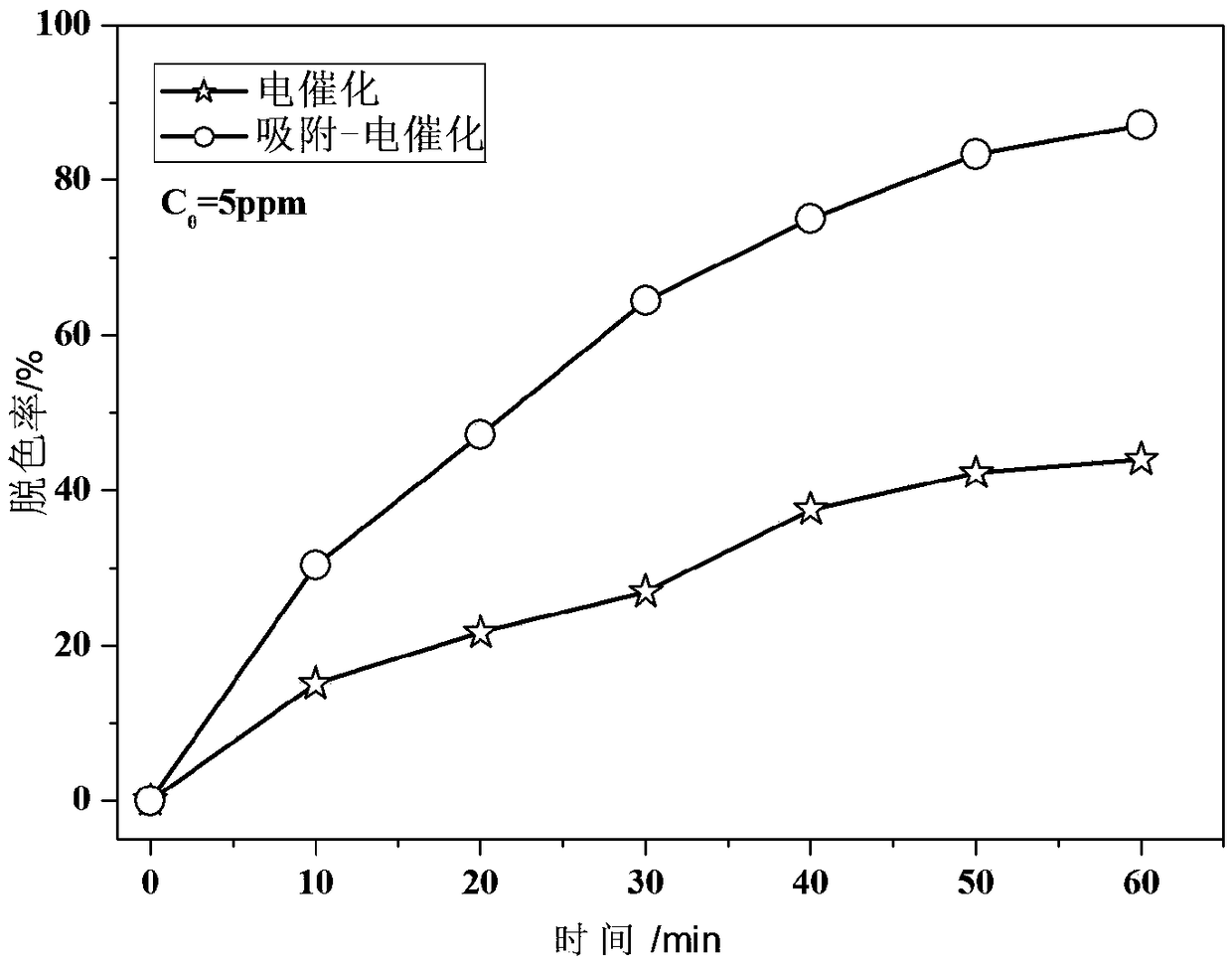

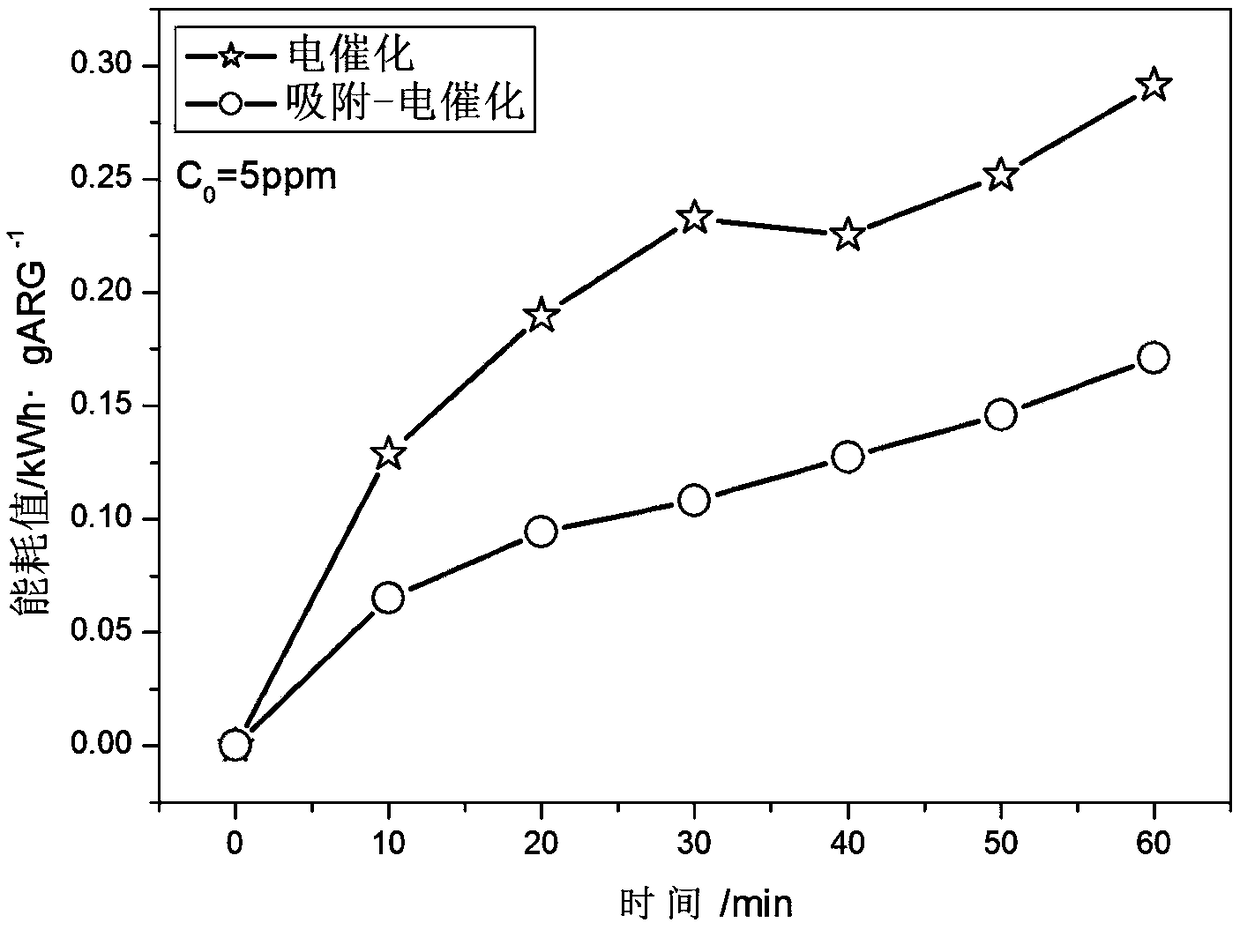

Method for treating low-concentration difficult-to-degrade organic wastewater through adsorption-electrocatalysis combination

InactiveCN108773944AIncrease concentrationSolving Mass Transfer ProblemsWater contaminantsMultistage water/sewage treatmentChemistrySorbent

The invention relates to a wastewater treatment process, in particular to a method for treating low-concentration difficult-to-degrade organic wastewater through adsorption-electrocatalysis combination. The method comprises the steps of adding an adsorbent into the low-concentration non-biodegradable organic wastewater, after the adsorption time T, carrying out solid-liquid separation, feeding thewastewater reaching to the follow-up treatment standard or the emission standard into a follow-up treatment process, and feeding an adsorbent obtained through separation into a follow-up desorption process; adding the separated adsorbent into a desorption solution, after desorbing for a certain time, carrying out solid-liquid separation, feeding an adsorbent obtained through separation into a next adsorption process or aftertreatment process, and carrying out electrocatalytic oxidation treatment on the rest desorption solution; adding the desorption solution into an electrocatalysis reactor,powering up, and carrying out electrocatalysis treatment on organic matters in the desorption solution; feeding liquid reaching to the follow-up treatment standard or the emission standard into a follow-up process.

Owner:山东深信节能环保科技有限公司

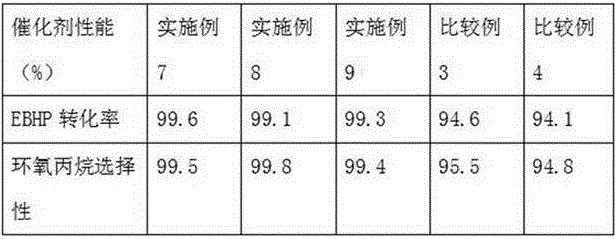

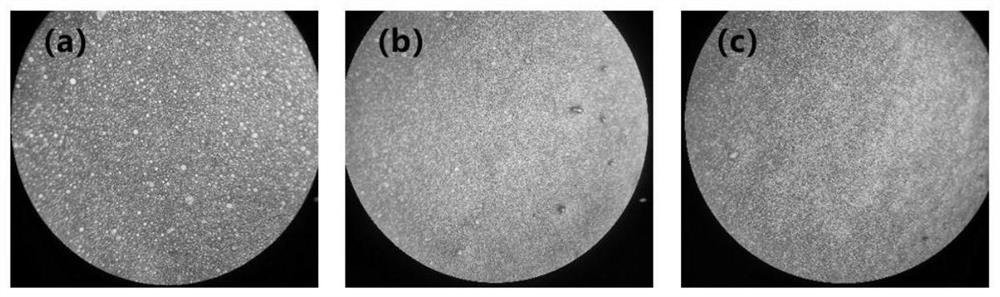

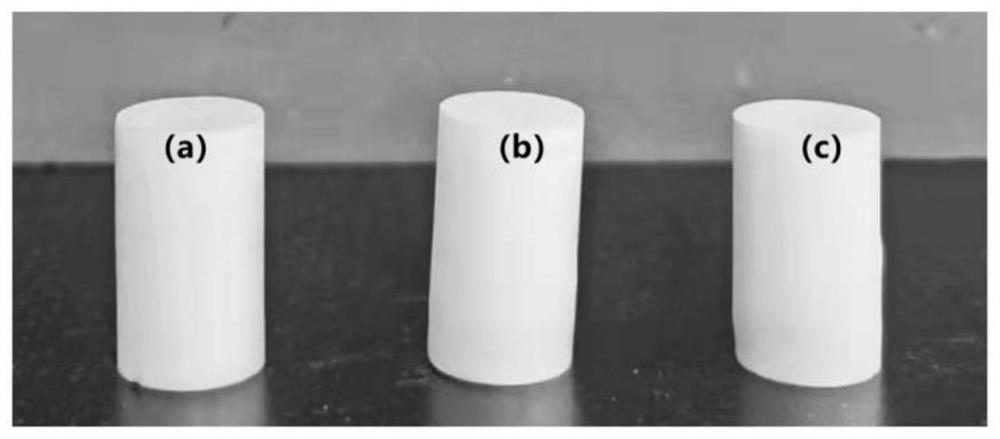

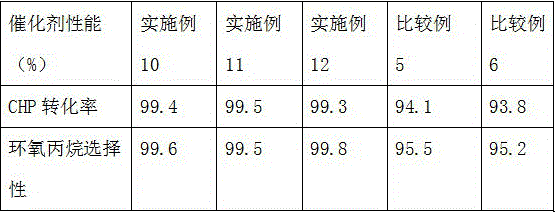

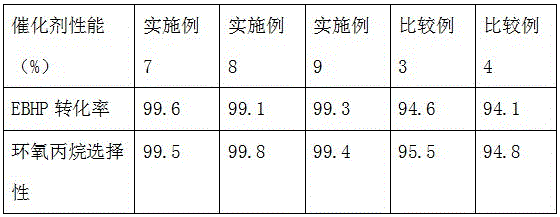

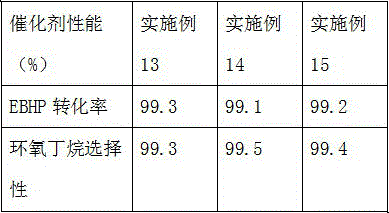

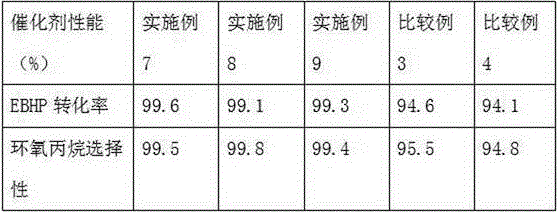

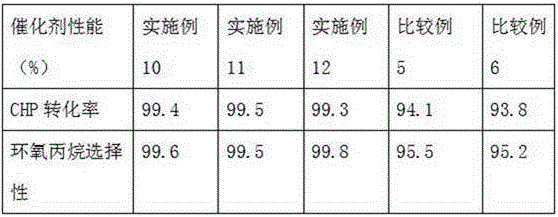

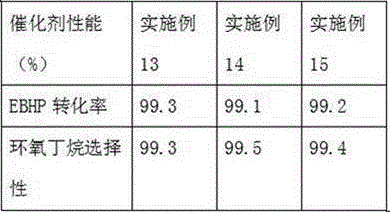

Titanium silicate molecular sieve catalyst comprising organic functional group

InactiveCN106315607ASolving Mass Transfer ProblemsGood selectivity and stabilityMolecular sieve catalystsMolecular-sieve silicatesSolventEpoxide

The invention relates to a titanium silicate molecular sieve catalyst comprising an organic functional group. The titanium silicate molecular sieve catalyst comprises a silicon source, a titanium source, a template, a mineralizer and a solvent, wherein the silicon source is Si(OR1)4, (R2O)3Si-(CH2)n1-Si(OR3)3 and (R4)n2Si(OR5)4-n2, the titanium source is Ti(OR6)4, the template is [(CH3)3CH3(CH2)n3N<+>]X<->, the mineralizer is [(CH3Cn4H2n4)4NH4]<+>OH<->, and the solvent is a mixture of water and alcohol. As the structure of a molecular sieve comprises the hydrophobic anti-carbon organic functional group and a composite hole, the hydrophobicity and the mass transfer performance of the catalyst are excellent, the activity and the selectivity are high, the stability is good, and the catalyst is applied to production of a corresponding epoxide through alkene epoxidation, wherein H2O2, hydrogen peroxide, cumyl hydroperoxide and tert-butyl hydroperoxide are taken as oxidizing agents in the alkene epoxidation.

Owner:QINGDAO WINCHANCE TECH

Hierarchical pore structure high polymer material and preparation method thereof

The invention discloses a hierarchical pore structure high polymer material and a preparation method thereof, and belongs to the field of porous polymer materials. The preparation method comprises the following steps: (1) mixing hydrophobic silicon dioxide particles with an initiator, then adding a polymerizable monomer, a cross-linking agent, an assistant cross-linking agent and a pore-foaming agent, and uniformly stirring to obtain a reaction mixed solution; (2) adding water into the reaction mixed solution, and stirring until a gel emulsion is formed; and (3) performing staged thermal polymerization on the gel emulsion to obtain the hierarchical pore structure high polymer material. According to the invention, the content and size of pores and pore throats in the material can be effectively regulated and controlled, and the high polymer material with the multistage micron pore structure is obtained. The material is good in heat transfer in the polymerization process, free of implosion phenomenon and high in product percent of pass; a wet material obtained by polymerization is rich in pores, small in resistance in a mass transfer process and relatively high in drying rate; meanwhile, the hierarchical pore structure high polymer material disclosed by the invention has excellent machining performance and static load resistance.

Owner:SHAANXI NORMAL UNIV

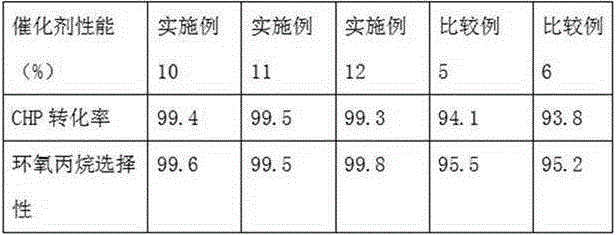

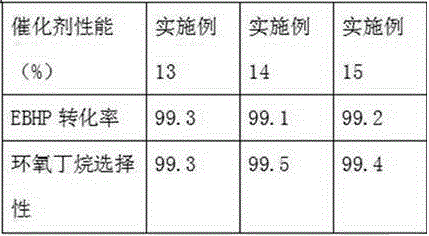

Titanium-silicon molecular sieve catalyst as well as preparation method and application thereof

InactiveCN106111185ASolving Mass Transfer ProblemsGood selectivity and stabilityOrganic chemistryMolecular sieve catalystsSolventEpoxide

The invention relates to a titanium-silicon molecular sieve catalyst. The titanium-silicon molecular sieve catalyst is prepared from a silicon resource, a titanium source, a template agent, a mineralizer and a solvent, wherein the silicon resource is Si(OR1)4, (R2O)3Si-(CH2)n1-Si(OR3)3 and (R4)n2Si(OR5)4-n2; the titanium source is Ti(OR6)4; the template agent is [(CH3)3CH3(CH2)n3N<+>]X<->; the mineralizer is [(CH3Cn4H2n4)4NH4]<+>OH<->; the solvent is water; and hydrothermal crystallization is performed, so that the titanium-silicon molecular sieve catalyst with a composite hole structure and high hydrophobic characters is prepared. The titanium-silicon molecular sieve catalyst disclosed by the invention has the following advantages that the catalyst is simple in preparation process, and high in production efficiency; besides, a molecular sieve structure contains organic functional groups of Si-(CH2)n1-Si, Si-O-Si(R4)n2 and Ti-O-Si(R4)n2 and composite holes having hydrophobic characters and anti-carbon-deposition functions, so that the catalyst has excellent hydrophobic character and mass transfer performance, is high in activity and selectivity and good in stability, can be used in the process of producing corresponding epoxides from alkenes through epoxidation by using H2O2, ethylbenzene hydroperoxide, cumene hydroperoxide, tert-butyl hydroperoxide and the like as oxidizers.

Owner:JIANGSU RUICHEN CHEM +1

An efficient titanium silicalite molecular sieve catalyst

InactiveCN106378182AGood choiceImprove stabilityOrganic chemistryMolecular sieve catalystsSolventHigh activity

The invention relates to an efficient titanium silicalite molecular sieve catalyst. The catalyst comprises a silicon source, a titanium source, a template, a mineralizer and a solvent, wherein the silicon source is Si(OR1)4, (R2O)<3>Si-(CH2)<n1>-Si(OR3)<3> and (R4)<n2>Si(OR5)<4-n2>, the titanium source is Ti(OR6)4, the template is [(CH3)<3>CH<3>(CH2)<n3>N<+>]X<->, the mineralizer is [(CH3C<n4>H<2n4>)<4>NH<4>]<+>OH<->, and the solvent is a mixture of water and ethanol. The molecular sieve structure comprises hydrophobic and carbon-deposition-preventing organic functional groups and composite pores, and therefore the catalyst has excellent hydrophobicity and mass transfer performance, high activity, high selectivity and high stability, and the catalyst can be used for alkene epoxidation processes adopting H2O2, 1-hydroperoxyethylbenzene, cumene hydroperoxide, tert-butyl hydroperoxide, and the like as oxidants to produce corresponding epoxides.

Owner:QINGDAO WINCHANCE TECH

Green preparation method of sodium chabazite with through stepped holes

ActiveCN112591761ASolving Mass Transfer ProblemsAchieve recyclingCrystalline aluminosilicate zeolitesPhysical chemistryCopolymer

The invention relates to a green preparation method of sodium chabazite with through stepped holes, and the method comprises the following steps: uniformly mixing a neutral copolymer, deionized water,an aluminum source, an alkali source and a silicon source according to a certain proportion, carrying out hydrothermal crystallization, centrifuging the obtained product, performing drying, performing extracting to remove a template agent, and obtaining the sodium chabazite with through stepped holes. According to the method, the structural characteristics of the sodium chabazite are completely reserved, and the template agent can be recycled, so the method is a green preparation method. The sodium chabazite prepared by the method has the advantages of penetrating through the stepped hole zeolite, being high in specific surface area and pore volume and the like, and is beneficial to selective adsorption and mass transfer application of macromolecules.

Owner:FUZHOU UNIV

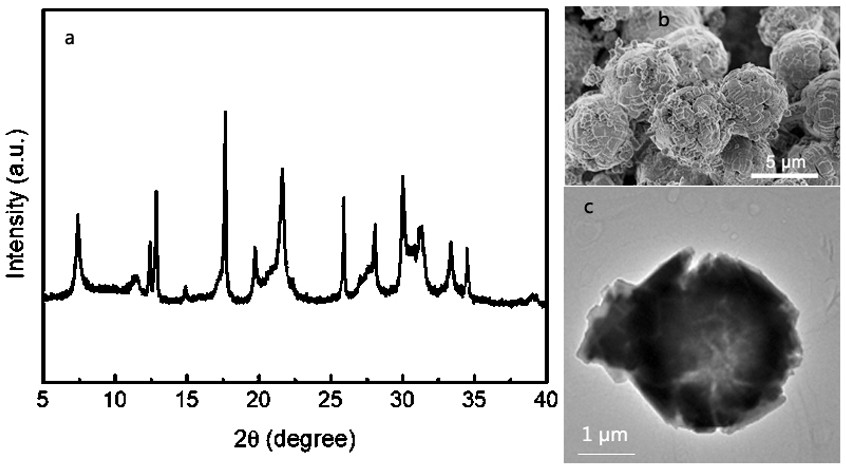

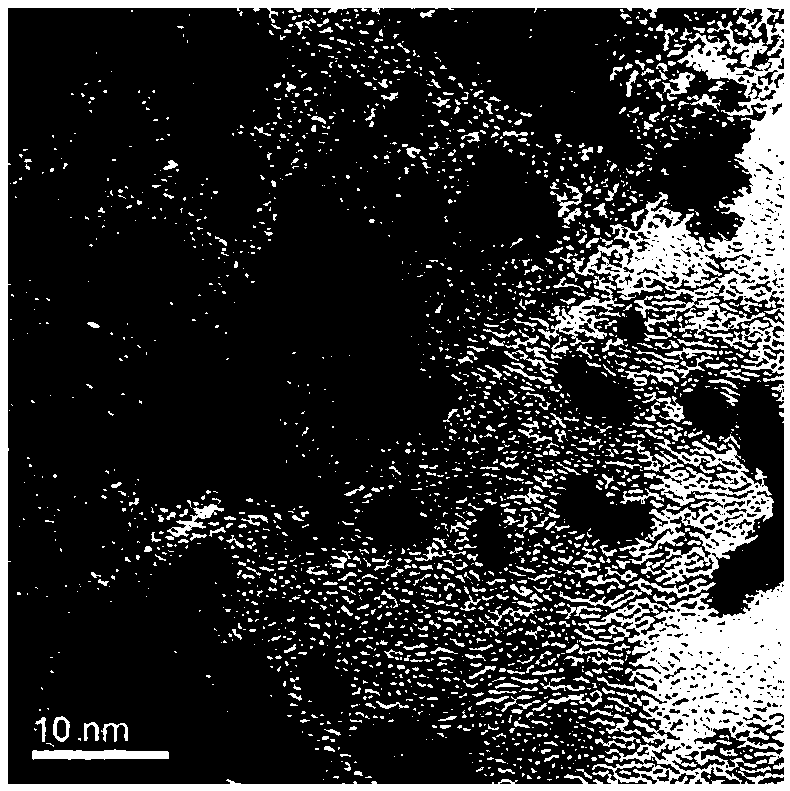

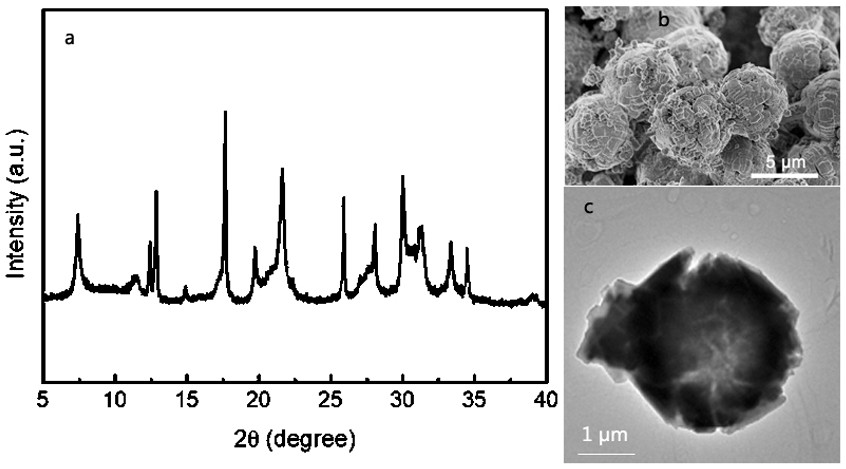

Method for compounding multistage hole mesh molecular sieves

ActiveCN104944438APore Structure RegulationSolving Mass Transfer ProblemsCrystalline aluminosilicate zeolitesMolecular-sieve compoundsMolecular sieveWater baths

The invention provides a method for compounding multistage hole mesh molecular sieves, which comprises the steps: P123 is dissolved into diluted hydrochloric acids, OP-10 is dissolved into water, the P123 and the OP-10 are magnetically stirred in 36.5 DEG C-37.5 DEG C water bath after being mixed, then tetraethylortho silicate and potassium fluoride are added, are put into a stainless steel cauldron after going on to stir 5.8-6.2 hours, are crystallized for 23.5-24.5 hours in 95 DEG C-105 DEG C, are cooled in room temperature, are pumped, filtered and dried, thereby obtaining white powder-shaped multistage hole mesh molecular sieves by being roasted in the air for 5.8-6.2 hours in 540 DEG C-560 DEG C. The multistage hole mesh molecular sieves which are compounded through the method for compounding multistage hole mesh molecular sieves are not single in structure, novel in shape and high in hydrothermal stability.

Owner:QIQIHAR UNIVERSITY

A kind of synthetic method of phenolic resin

ActiveCN104327227BSynthetic Method AdvantagesReduce volumeChemical/physical/physico-chemical processesLaboratory facilityTreatment costs

Owner:XIAN ORIGIN CHEM TECH

Novel method for preparing core-shell structure catalyst

InactiveCN108878908AEase of industrial productionQuality improvementCell electrodesMicroreactorPolyol

The invention belongs to the technical field of core-shell structure catalysts, and particularly relates to a novel method for preparing a core-shell structure catalyst. The novel method for preparingthe core-shell structure catalyst is different from the prior art. A microreactor is adopted in the novel method for preparing the core-shell structure catalyst, and a carbon-supported metal core isprepared in the microreactor, a shell metal is reduced by using polyol, and the shell metal is reacted with the carbon-supported metal core to prepare the core-shell catalyst. The method for preparingthe core-shell structure catalyst has higher preparation efficiency, less required raw materials and simple operation.

Owner:南京东焱氢能源科技有限公司

Method for preparing biological diesel oil by esterifying, ester interchanging greases in high acid number

InactiveCN100439474CFew reaction stepsSolving Mass Transfer ProblemsBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

A process for preparing biologic diesel oil from the fat with high acid number by esterifying and ester exchange includes such steps as proportionally loading said fat and methanol into high-pressure reactor, proportionally adding Lewis acid as catalyst, reation, distilling the resultant to separate methanol, centrifugal separation or filter to remove part of catalyst, water washing to remove residual glycerin and catalyst, and refining.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

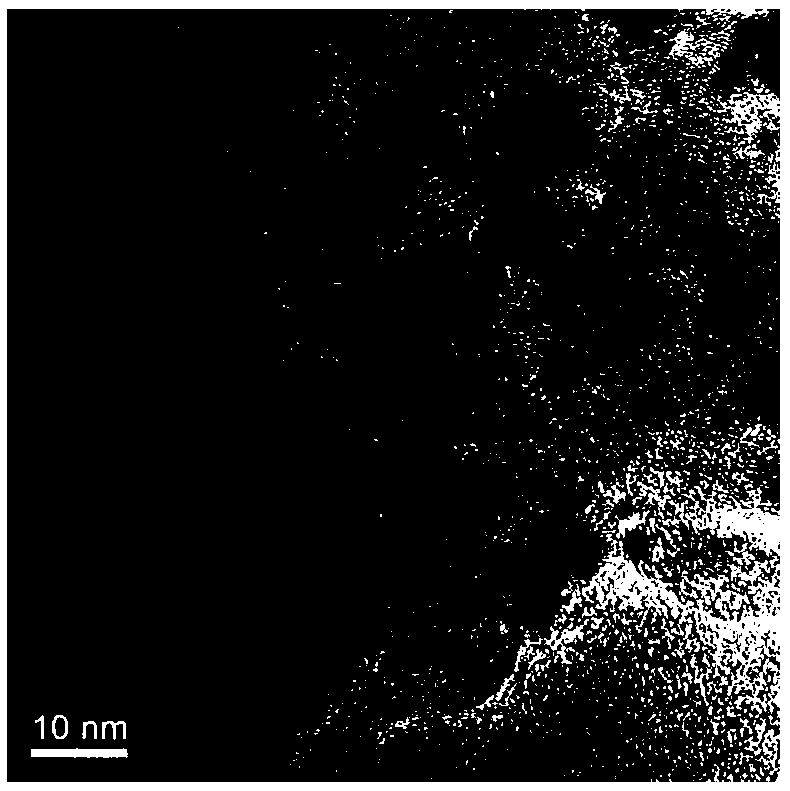

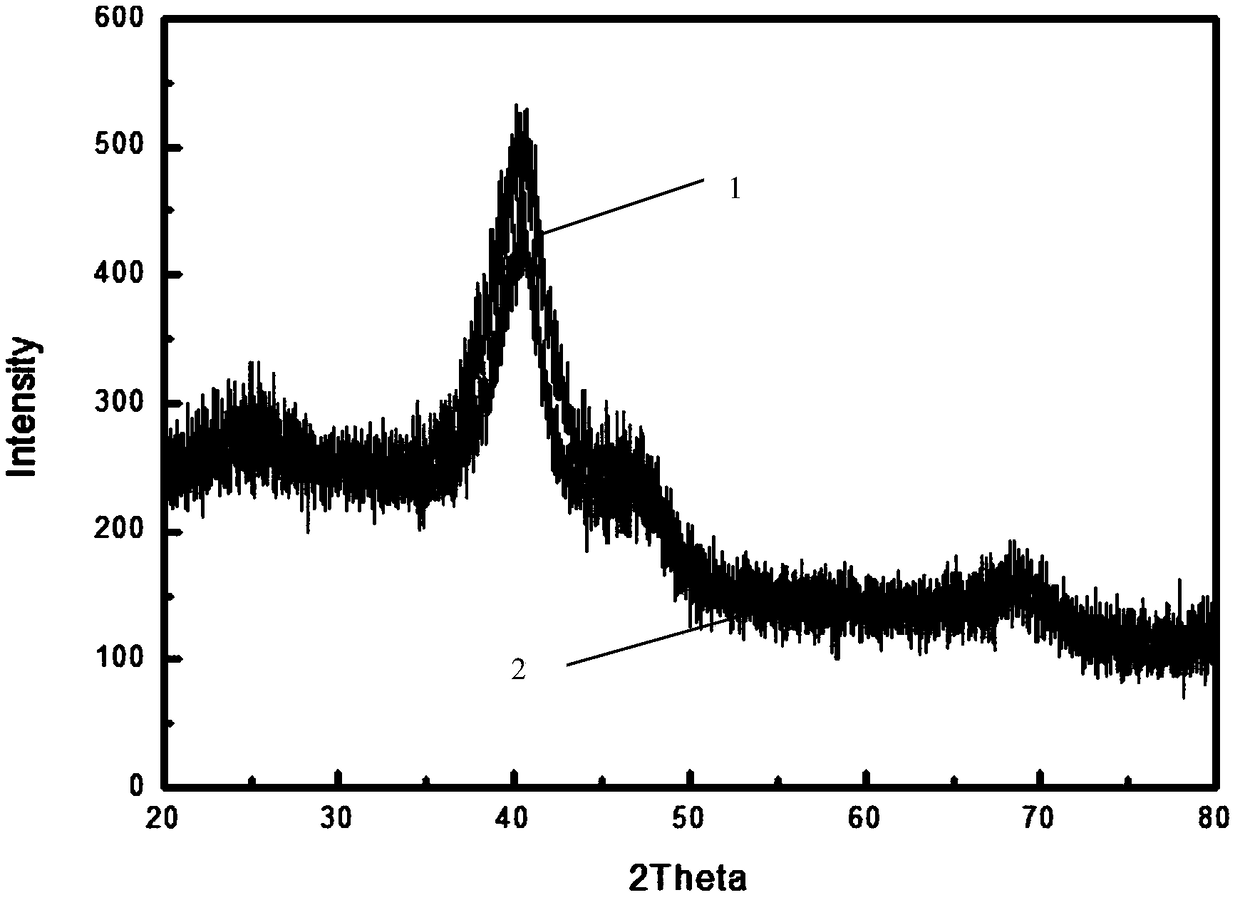

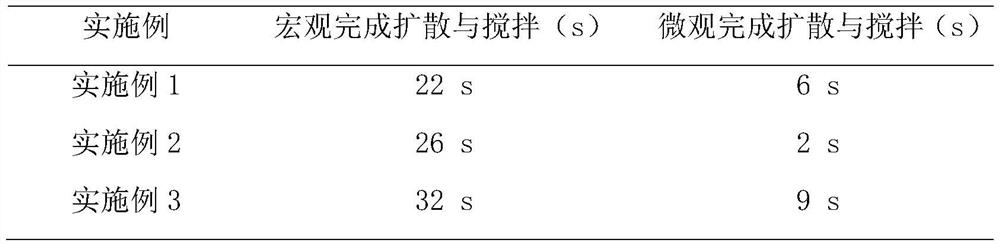

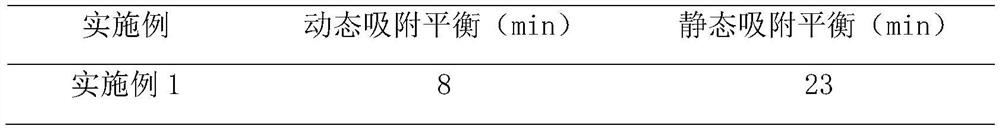

Magnetic response nanorod-shaped desulfurization adsorbent as well as preparation method and application thereof

PendingCN114713200AEnhanced Quick TouchThe adsorption process is fastOther chemical processesAluminium silicatesPhysicsLiquid system

The invention discloses a magnetic response nanorod-shaped desulfurization adsorbent which has a stirring function under the action of a magnetic field and can improve mass transfer rates in macroscopic and microscopic solid-liquid / liquid-liquid / gas-liquid systems. The magnetic response nanorod-like desulfurization adsorbent is composed of a magnetic nanorod and a coated porous shell layer, the length range of the magnetic nanorod is 1-30 [mu] m, the magnetic saturation susceptibility is 1000-15000 Oe, and the thickness range of the coated porous shell layer is 50-300 nm.

Owner:NANJING UNIV OF TECH

Chloride-carbonaceous skeleton composite adsorbent and preparation method thereof

ActiveCN101961644BIncrease load strengthReduce consumptionOther chemical processesAdsorption refrigerationAdhesive

The invention belongs to the fields of adsorptive refrigeration / heat pumps, adsorptive separation purification and hydrogen storage, and particularly relates to a chloride-carbonaceous skeleton composite adsorbent and a preparation method thereof. The adsorbent is characterized by comprising the following raw materials: based on a carbonaceous precursor, 0.5 to 2 percent of chloride, 0 to 25 percent of adhesive and 0 to 50 percent of heat conducting material. The preparation method for the chloride-carbonaceous skeleton composite adsorbent is characterized by comprising the steps of crushing of the carbonaceous precursor, preparation of impregnation liquid, impregnation of the carbonaceous precursor, forming, air-blasting drying, carbonization and activation and the like. The adsorbent prepared by the method fully solves the problem of mass transfer coefficient decline caused by filling the chloride and pressing a plugging micropore at the same time of ensuring efficient heat transfer, and obviously improves the loading strength and the utilization rate of the chloride.

Owner:SHANDONG UNIV

Manufacturing method of netted catalyst for degrading organic pollutant in wastewater by photocatalysis

ActiveCN101584996BSolve the problem of enhanced catalytic activityTroubleshoot enhancementsWater/sewage treatment by irradiationWater contaminantsEpoxyUltraviolet lights

The invention relates to a manufacturing method of a netted catalyst for degrading the organic pollutant in wastewater by photocatalysis and a wastewater treating device. The manufacturing method comprises: using the wire net plated with nickel as a carrier, coating a catalyst for solidification, wherein the catalyst mixed liquid includes nano TiO2, acetone, epoxy resin, solidifying agent and appropriate plasticizer, soaking in the acetone solution. A case of the treatment device is provided with a plurality of independent deflecting chambers connected end-to-end in turn, two ends of which areprovided with a water inlet and a water outlet. A plurality of solid netted bodies solidified with the catalyst are overlapped at intervals in the deflecting chamber. A through hole is opened in themiddle of the solid netted body. An ultraviolet light source is inserted in the through hole. An aeration pipe is arranged on the bottom of the deflecting chamber. The device can deeply degrade the organic matter in wastewater.

Owner:深圳市世纪清源环保技术有限公司

Device for recovering high-concentration hydrochloric acid from chlorine-containing tail gas and working method

PendingCN114572937AImprove absorption efficiencyImprove solubilityGas treatmentChlorine/hydrogen-chloride purificationBoron trichlorideHydrogen chloride

Owner:FUJIAN JIUCE GAS GRP CO LTD

A direct carbon solid oxide fuel cell

ActiveCN101694883BImprove efficiencyReduce pollutionElectrolyte holding meansCell electrodesFuel cellsSolid structure

The invention discloses a direct carbon solid oxide fuel cell, wherein an electrolyte tube support body is a tubular structure with one closed end, the tubular inner wall of the electrolyte tube support body is provided with a porous anode film and the outer wall thereof is provided with a porous cathode film; powder carbon is in the porous anode film of the electrolyte tube support body, and a gas-guide tube is sealed at an opening end of the electrolyte tube support body; the opening end of the electrolyte tube support body and the gas-guide tube are sealed through a heat-resistant sealing-in material; the material of the electrolyte tube support body is yttrium-stabilized zirconia; and a slip casting forming method or dipping method is adopted for preparation and the fuel cell is formed by sintering for 3-4h in the air at the temperature of 1, 400-1, 600 DEG C. The cell is a solid oxide fuel cell directly using carbon fuel and is of a full solid structure. Electric energy output can be obtained by heating the cell with gas discharged simultaneously. The cell has the advantages of simple structure, easy operation, high conversion efficiency and the like and has great significance to the high efficient and clean use of coal-based fuel.

Owner:SOUTH CHINA UNIV OF TECH

A kind of green preparation method of sodium chabazite with through stepped pores

ActiveCN112591761BSolving Mass Transfer ProblemsAchieve recyclingCrystalline aluminosilicate zeolitesPhysical chemistryGmelinite

A green preparation method of gmelinite with through-step pores, in which neutral copolymer, deionized water, aluminum source, alkali source, and silicon source are mixed uniformly in a certain proportion, and the obtained product is centrifuged through hydrothermal crystallization , drying, extracting and removing the template agent to obtain gmelinite with through-step pores. This method completely retains the structural characteristics of gmelinite and the template agent can be recycled. It is a green preparation method. The gmelinite prepared by the method has the advantages of penetrating step-pore zeolite, high specific surface area and pore volume, and is beneficial to the application of selective adsorption and mass transfer of macromolecules.

Owner:FUZHOU UNIV

A method for synthesizing dodecylbenzenesulfonic acid in a circulating microreactor

ActiveCN109912462BInhibit side effectsAchieve uniform mixed reactionChemical/physical/physico-chemical processesSulfonic acid preparationMicroreactorReaction temperature

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com