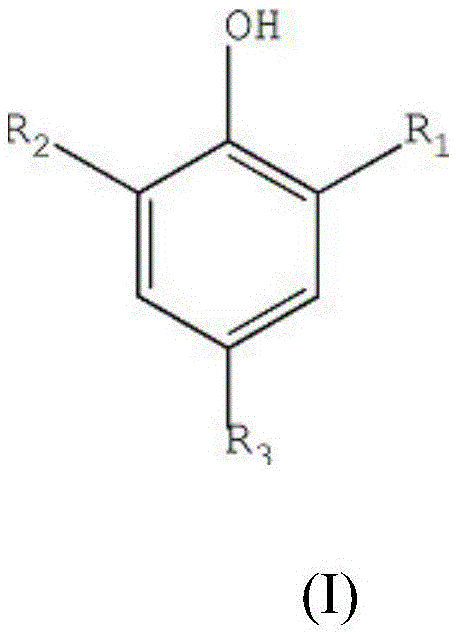

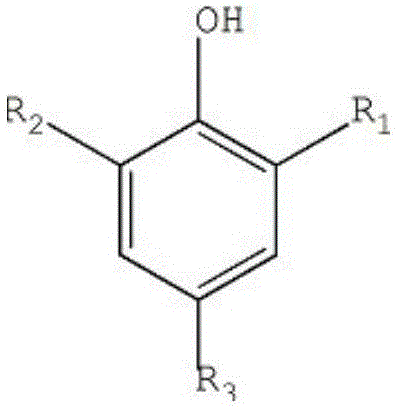

A kind of synthetic method of phenolic resin

A synthesis method, phenolic resin technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of low resin yield, increased production cost, environmental pollution, etc., and achieve saving The effect of processing cost and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiment 1: the synthesis of phenolic resin

[0114] The implementation steps of this embodiment are as follows:

[0115] A. Raw material mixing

[0116] Under a nitrogen atmosphere and a temperature of 10°C, let o-cresol and formaldehyde be mixed uniformly at a molar ratio of 1.0:1.2 to obtain a mixed solution:

[0117] B. Preparation of catalyst

[0118] A phosphoric acid catalyst aqueous solution with a concentration of 4% by weight was prepared under the condition of a temperature of 50°C.

[0119] C. Synthesis

[0120] The mixed solution obtained in step A is pumped into the preheater preheated by Bayer-Ehrfeld Microtechnology Company under the trade name Miprowa to reach 80 °C; the catalyst solution obtained in step B is pumped into the Bayer-Ehrfeld Preheating to 30°C in a modular preheater by Feld Microtechnologies under the trade name Miprowa;

[0121] Then, according to the mass ratio of the solute in the catalyst solution to the phenol compound of gene...

Embodiment 2

[0125] Embodiment 2: the synthesis of phenolic resin

[0126] The implementation steps of this embodiment are as follows:

[0127] A. Raw material mixing

[0128] Under the condition of nitrogen atmosphere and temperature 100°C, m-cresol and paraformaldehyde were mixed uniformly according to the molar ratio of 1.0:4.0 to obtain a mixed solution:

[0129] B. Preparation of catalyst

[0130] An aqueous oxalic acid catalyst solution with a concentration of 15% by weight was prepared under the condition of a temperature of 90°C.

[0131] C. Synthesis

[0132] The mixed solution obtained in step A is pumped into the modular preheater under the trade name Miprowa by Bayer-Ehrfeld Microtechnology Company to preheat to 150°C; the catalyst solution obtained in step B is pumped into the Preheating to 90°C in a modular preheater by Feld Microtechnologies under the trade name Miprowa;

[0133]Then, according to the mass ratio of the solute in the catalyst solution to the phenolic com...

Embodiment 3

[0137] Embodiment 3: the synthesis of phenolic resin

[0138] The implementation steps of this embodiment are as follows:

[0139] A. Raw material mixing

[0140] Under the conditions of nitrogen atmosphere and temperature 15°C, let p-ethylphenol and trioxane be mixed uniformly according to the molar ratio of 1.0:0.5 to obtain a mixed solution:

[0141] B. Preparation of catalyst

[0142] An aqueous acetic acid catalyst solution with a concentration of 1% by weight was prepared under the condition of a temperature of 10°C.

[0143] C. Synthesis

[0144] The mixed solution obtained in step A is pumped into the preheater of the Miprowa modular preheater produced by Bayer-Ehrfeld Microtechnology Company to preheat to 30°C; the catalyst solution obtained in step B is pumped into the Preheating to 50°C in a modular preheater by Feld Microtechnologies under the trade name Miprowa;

[0145] Then, according to the mass ratio of the solute in the catalyst solution and the phenol c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com