Photocatalytic degradation treatment device of wastewater with organic pollutants

A technology for organic pollutants and wastewater treatment, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of great disparity in water quality, complex intermediate products, unfavorable system full reaction, etc., to achieve activity and benefit improvement, The effect of uniform and stable reaction and prolonging compounding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

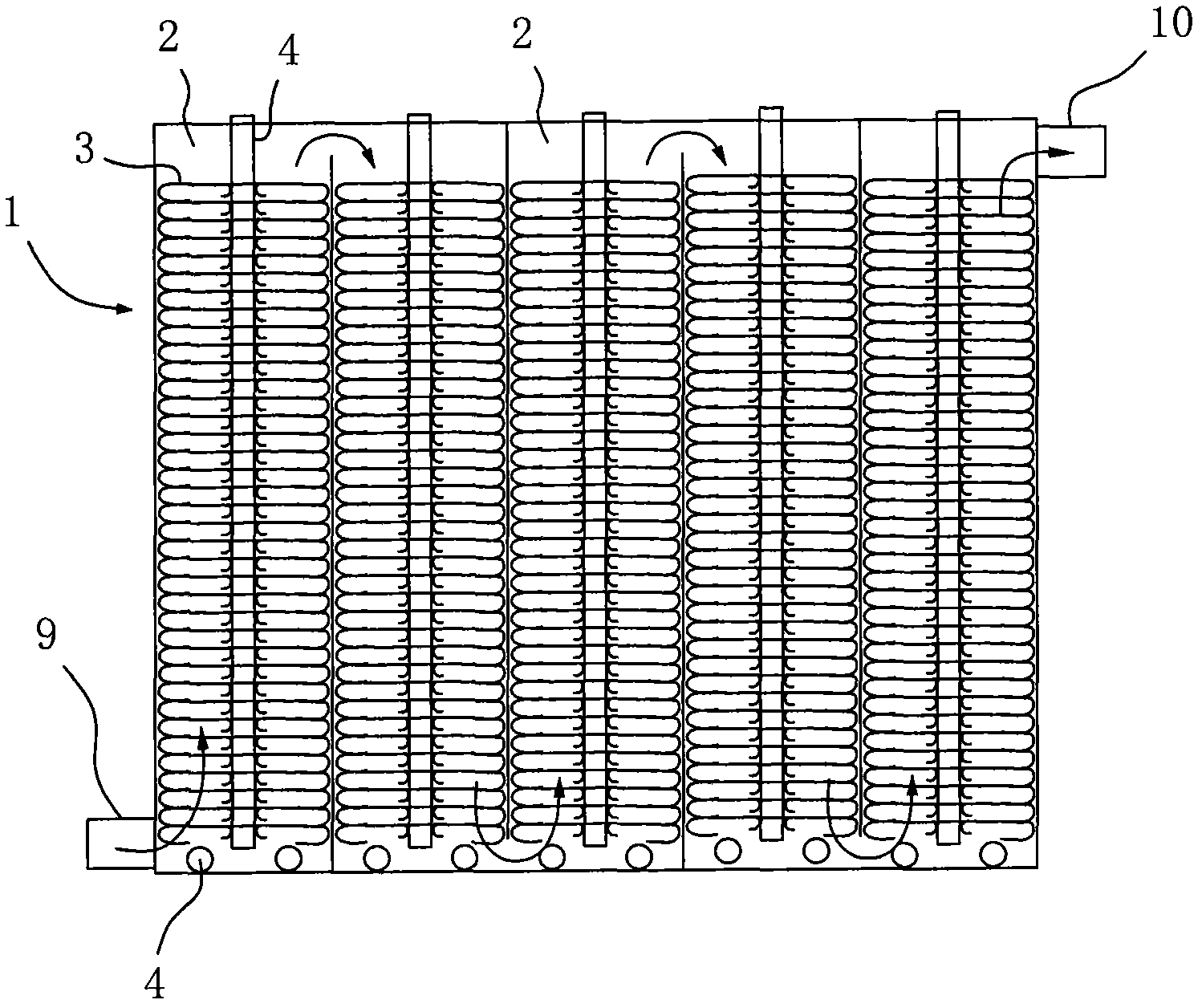

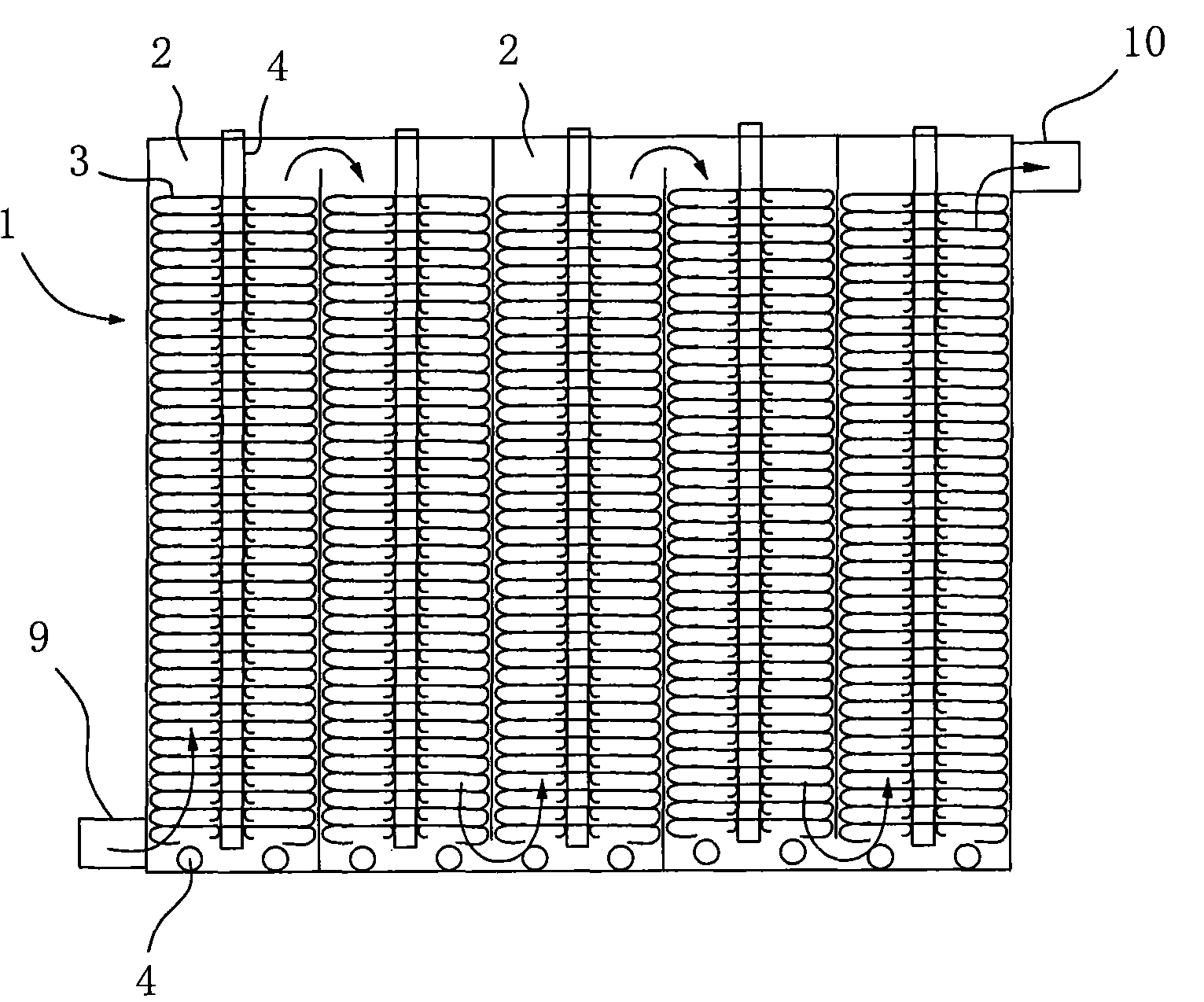

Method used

Image

Examples

Embodiment 1

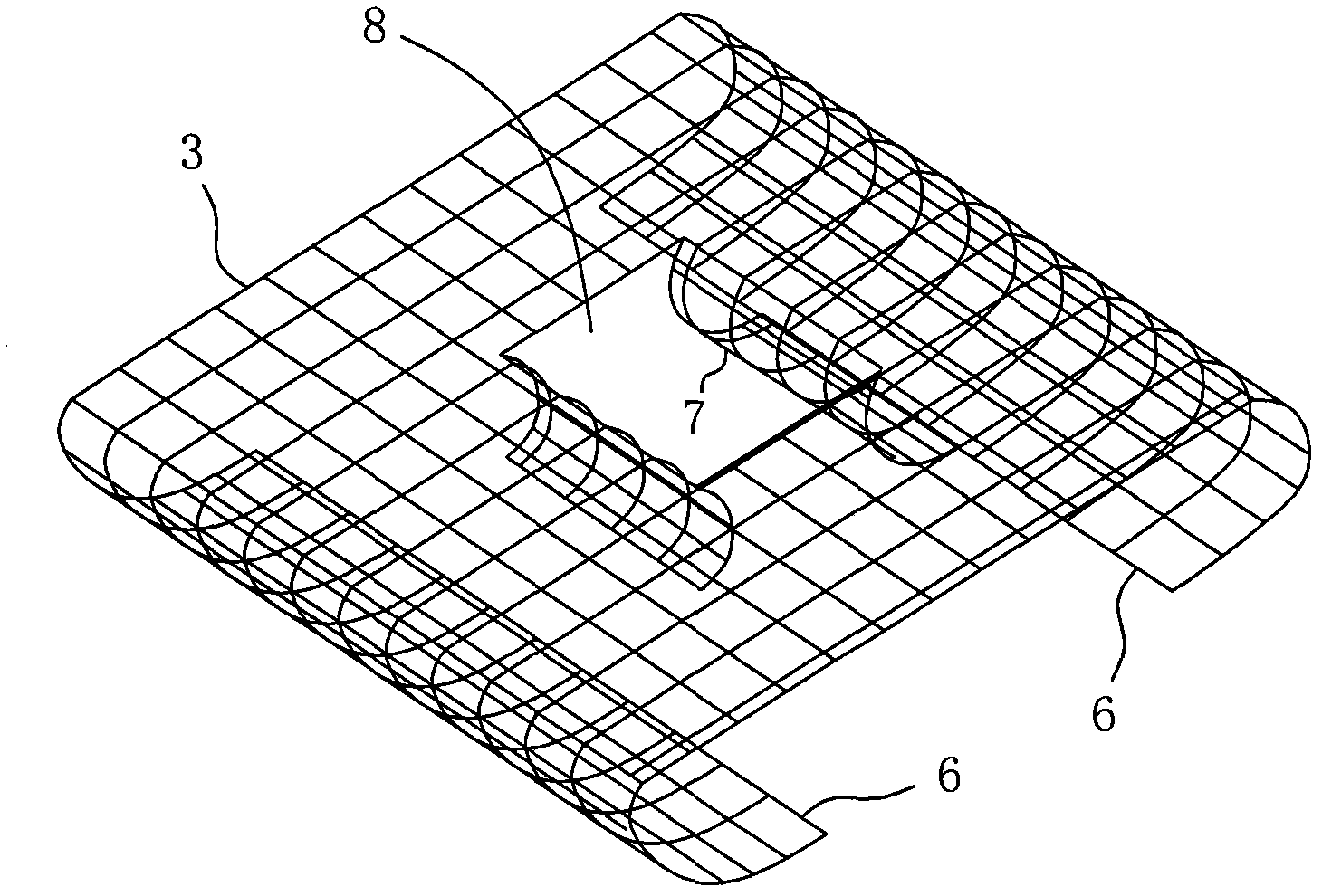

[0028] The production method of the net catalyst for the photocatalytic degradation of organic pollutants in wastewater, the steps are as follows:

[0029] (1) Choose 8-mesh stainless steel mesh and cut it into small squares, soak it with dilute acid, here use more commonly used dilute hydrochloric acid, wait for it to corrode, take it out and rinse it with clean water until there is no residual acid, dry it at room temperature, and keep the rust spots (rust spots) on the net It is a compound of various transition metals such as Cr, Ni, Fe and other elements in the stainless steel composition).

[0030] (2), take 1 part of nano TiO by weight 2 Stir and disperse with 4 parts of acetone, then take 2 parts of epoxy resin, 2 parts of curing agent and a little plasticizer, add acetone and TiO 2 In the dispersion system, fully mix and grind evenly.

[0031] (3) Coating the evenly ground catalyst jelly on a stainless steel mesh. During the coating process, the rust spots (compound...

Embodiment 2

[0036] The present embodiment photocatalytically degrades the reticular catalyst production method of organic pollutants in wastewater, which is different from Embodiment 1 in that:

[0037] (1) Choose 1 / 4 purpose ordinary barbed wire, nickel-plated by electroplating method, the amount of nickel plating is less than 5% of the surface area of the mesh substrate, then cut into a certain specification for later use, soak in dilute hydrochloric acid, wait for it to corrode, and take it out Rinse with clean water until there is no residual acid, dry at room temperature, and keep the rust spots on the net (rust spots are compounds of transition metal Ni, Fe and other elements).

[0038] (2), take 1 part of nano TiO by weight 2 Stir and disperse with 4 parts of acetone, then take 6 parts of epoxy resin, 6 parts of curing agent and a little plasticizer, add acetone and TiO 2 In the dispersion system, fully mix and grind evenly.

[0039] (3) Place the coated net-shaped supported ca...

Embodiment 3

[0043] The present embodiment photocatalytically degrades the reticular catalyst production method of organic pollutants in wastewater, which is different from Embodiment 1 in that:

[0044] (1) Select 4-mesh stainless steel mesh.

[0045] (2), take 1 part of nano-TiO 2 Add 3 parts of acetone to stir and disperse, then add 1 part of epoxy resin, 1 part of curing agent and a little plasticizer to fully mix and grind evenly.

[0046] (3) Take it out after immersing in acetone for 15 minutes to destroy the dense surface film layer to increase the specific surface area of the catalyst.

[0047] Others are the same as in Example 1.

[0048] After testing the wastewater discharged after the above three treatments, the removal rate of LAS, the main substance in organic compounds, is above 90%, and the effluent fully meets the design requirements, which is much higher than the existing removal rate of less than 50%. % standard. Moreover, the smaller the grid width of the mesh ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com