Patents

Literature

260 results about "Glass spheres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

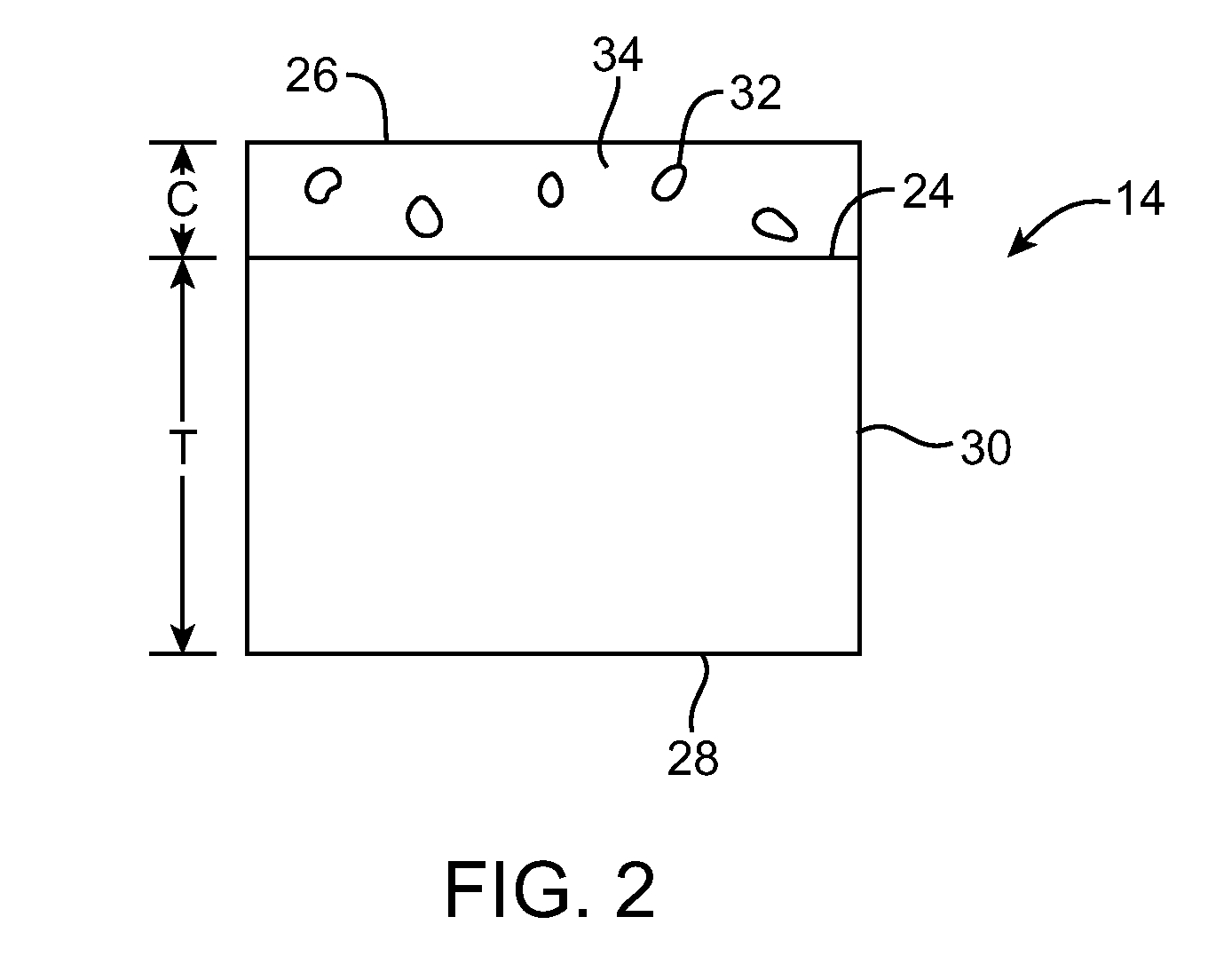

Cementing compositions and methods of cementing in a subterranean formation using an additive for preventing the segregation of lightweight beads.

Cementing compositions and methods of cementing in a subterranean formation are provided. The cement composition includes a hydraulic cement, lightweight beads, and a desegregating agent for inhibiting segregation of the beads. The lightweight beads may be, for example, cenospheres, glass spheres, and ceramic spheres. The desegregating agent comprises a particulate substrate such as precipitated silica. It also comprises a polar molecule producing chemical disposed on the particulate substrate. Preferably, the polar molecule producing chemical is absorbed on the particulate substrate. The polar molecule producing chemical comprises at least one of a polar molecule producing acid such as glacial acetic acid, a salt of such an acid, and an acid anhydride. The method of cementing includes forming a pumpable slurry using the cement composition, pumping the slurry into a subterranean formation, and allowing the slurry to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Dentifrices incorporating spherical particles for enhanced cleaning of teeth

InactiveUS6083489AGreat tendencyTrend downCosmetic preparationsToilet preparationsToothpasteVolumetric Mass Density

Toothpaste and other dentifrices formulated to include substantially spherical cleaning particles for enhanced plaque-removal capability. The cleaning particles are relatively large, having a diameter in a range from about 10 microns to about 200 microns, and are substantially round-edge and nonjagged so as to be far less abrasive compared to conventional abrasive particles, which tend to have a more jagged profile. Preferred cleaning particles include hollow glass spheres, which not only provide enhanced plaque-removal properties but which yield dental compositions having greatly reduced density. Air and other gases may optionally be entrained into the inventive dental compositions, either during manufacture or upon dispensing the dental compositions onto a toothbrush.

Owner:ULTRADENT PROD INC

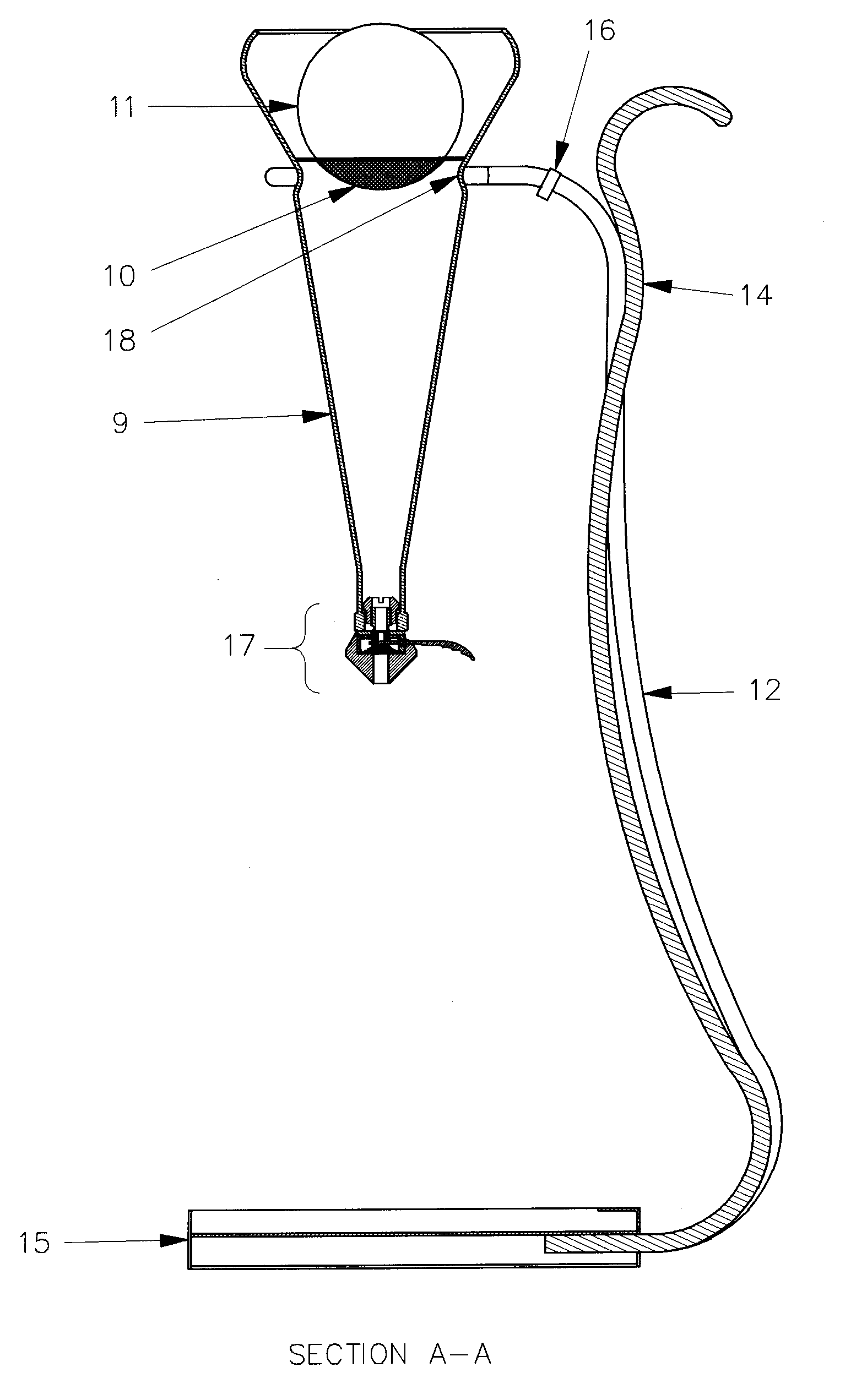

Aerating decanter with dispensing valve

This invention combines several processes into on easy to use product. The glass sphere dramatically enhances the aeration procedure by gently exposing air to thin waves of wine as wine passes over the surface of the sphere. The integrated filter provides a larger surface than normally found in wine filtration devices. The supporting structure secures the decanter in such a way that consumers can easily dispense wine without handling a wine bottle or conventional decanter.

Owner:COOPERS HAWK INTERMEDIATE HLDG LLC

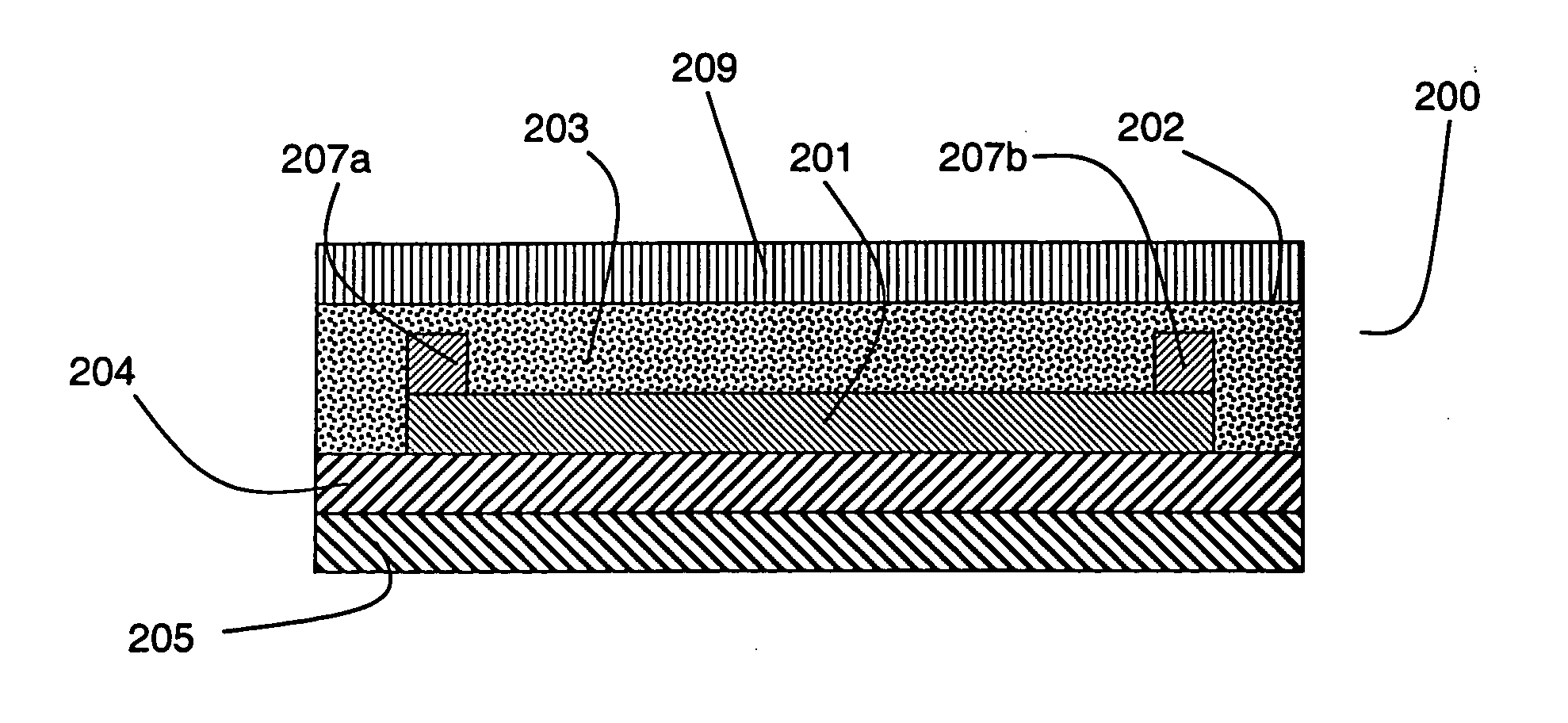

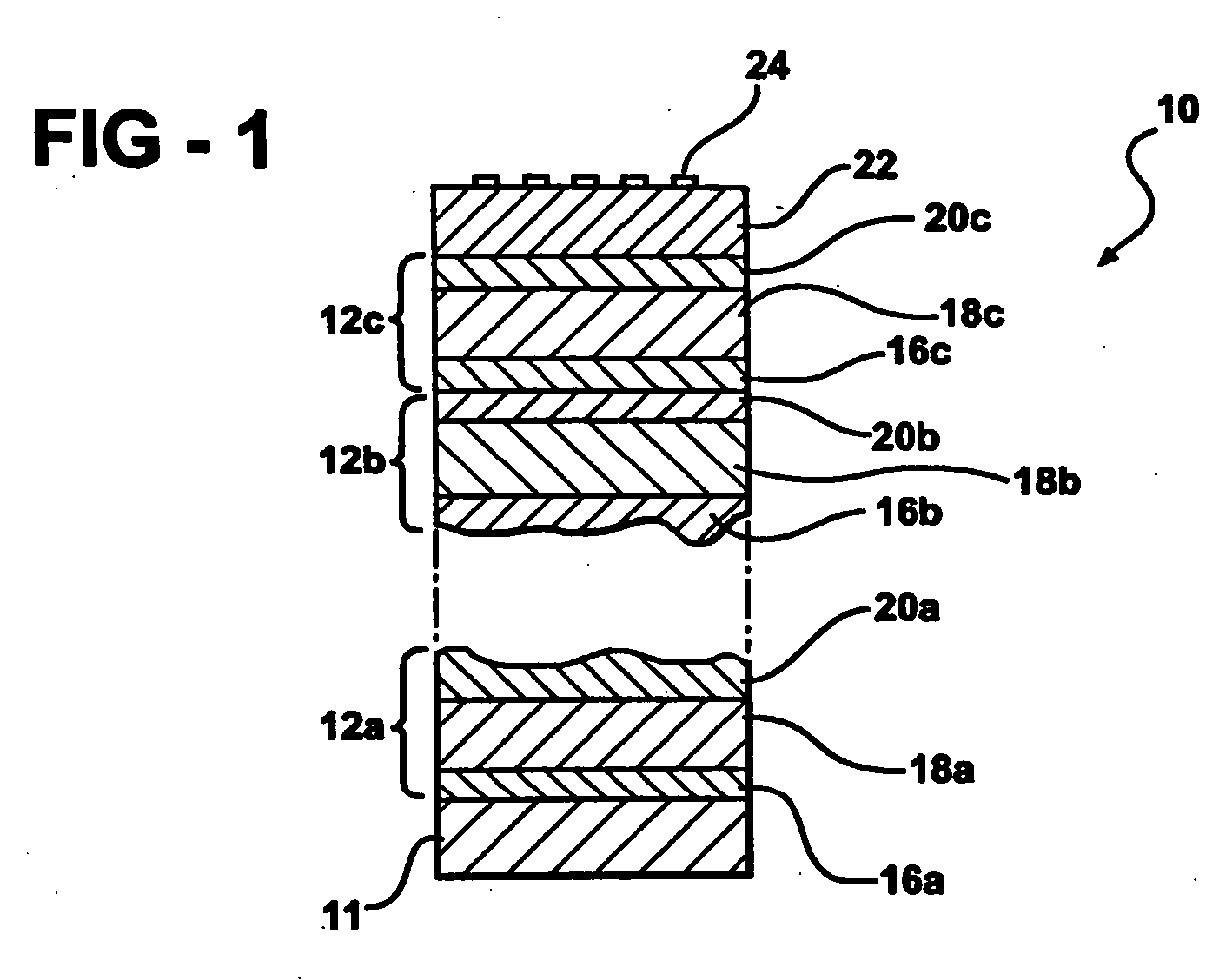

Fire resistant laminate and photovoltaic module incorporating the fire resistant laminate

InactiveUS20060201545A1Reduce manufacturing costSufficient transparencyPhotovoltaic supportsPV power plantsAmorphous siliconEngineering

The present invention discloses a fire resistant laminate and incorporating the laminate into an encapsulant for a photovoltaic module that may be used in a photovoltaic building material. More particularly, the present invention relates to fire resistant encapsulant that may be used in a triple junction amorphous silicon photovoltaic module that is fire resistant on a wide variety of buildings roofs, including residential housing, and that is flexible and lightweight. A fire resistant additive, such as solid glass spheres, may be added to encapsulant material to produce a fire resistant, cut resistant, lightweight photovoltaic device.

Owner:ENERGY CONVERSION DEVICES INC

Aerating Decanter with Dispensing Valve.

This invention combines several processes into on easy to use product. The glass sphere dramatically enhances the aeration procedure by gently exposing air to thin waves of wine as wine passes over the surface of the sphere. The integrated filter provides a larger surface than normally found in wine filtration devices. The supporting structure secures the decanter in such a way that consumers can easily dispense wine without handling a wine bottle or conventional decanter.

Owner:COOPERS HAWK INTERMEDIATE HLDG LLC

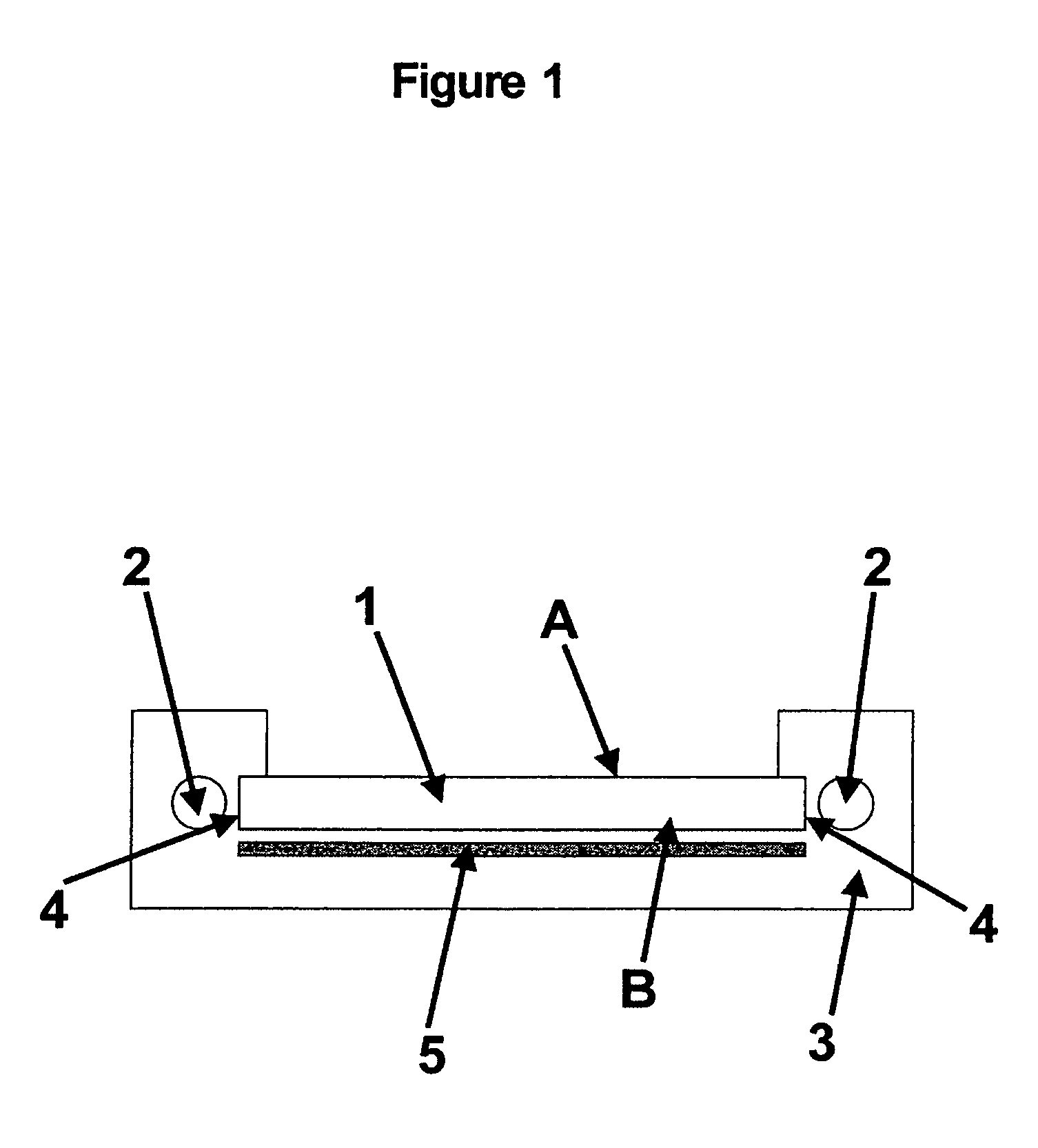

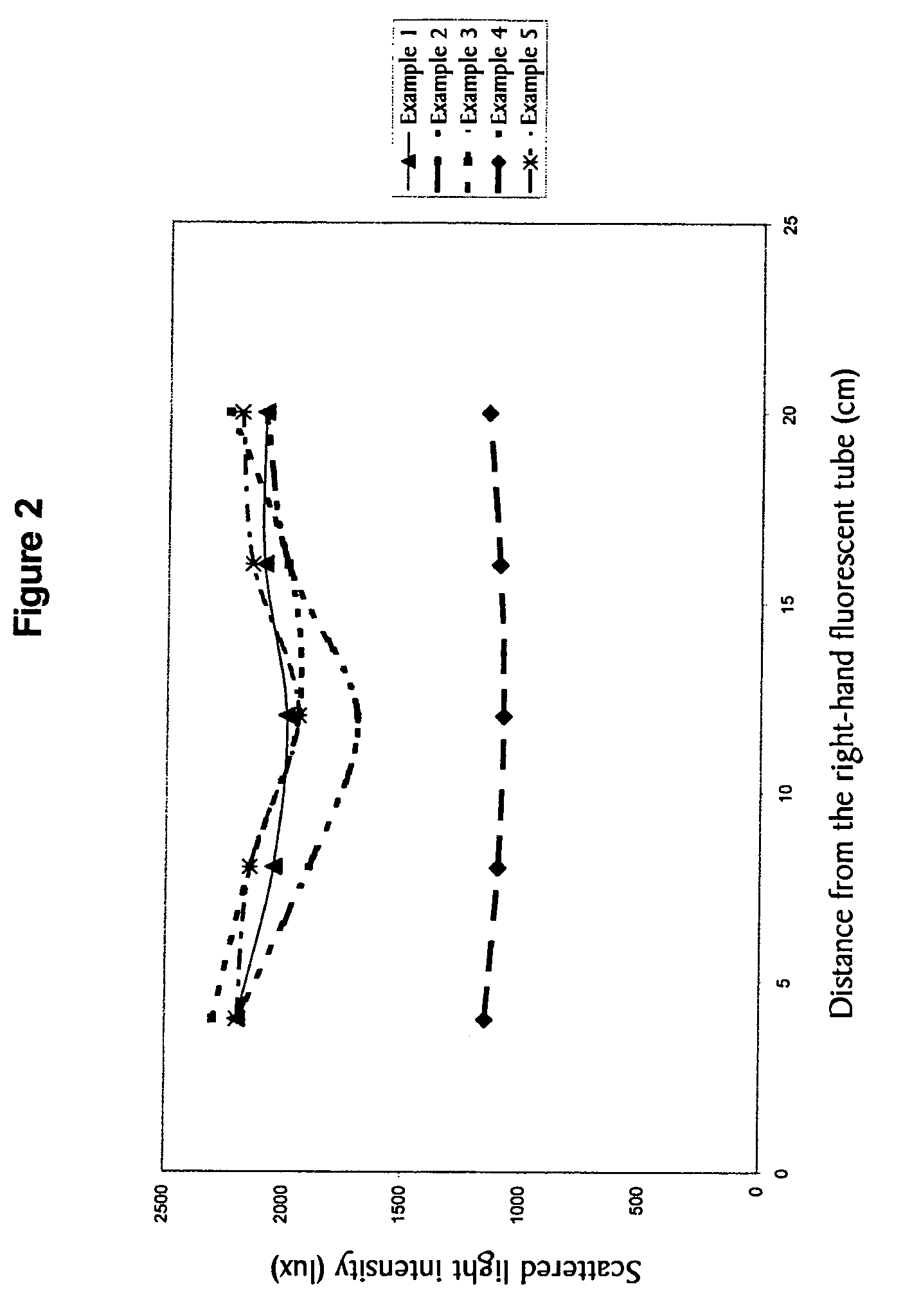

Transparent thermoplastic composition comprising hollow glass beads

InactiveUS7183001B1Good optical performanceHigh scattered light intensityMechanical apparatusElongate light sourcesThermoplasticMeth-

Thermoplastic composition comprising a (meth)acrylic (co)polymer and particles of hollow glass spheres—or a mixture of particles of hollow glass spheres and particles of a mineral and / or organic compound—the said particles scattering light:having a mean size of 0.5 μm to 200 μm;possessing a refractive index different from that of the transparent thermoplastic by at least ±0.05; andbeing used in an amount of 5 ppm to 1000 ppm by weight with respect to the total composition.Corresponding fashioned articles, especially sheets for backlight units.

Owner:ARKEMA FRANCE SA +1

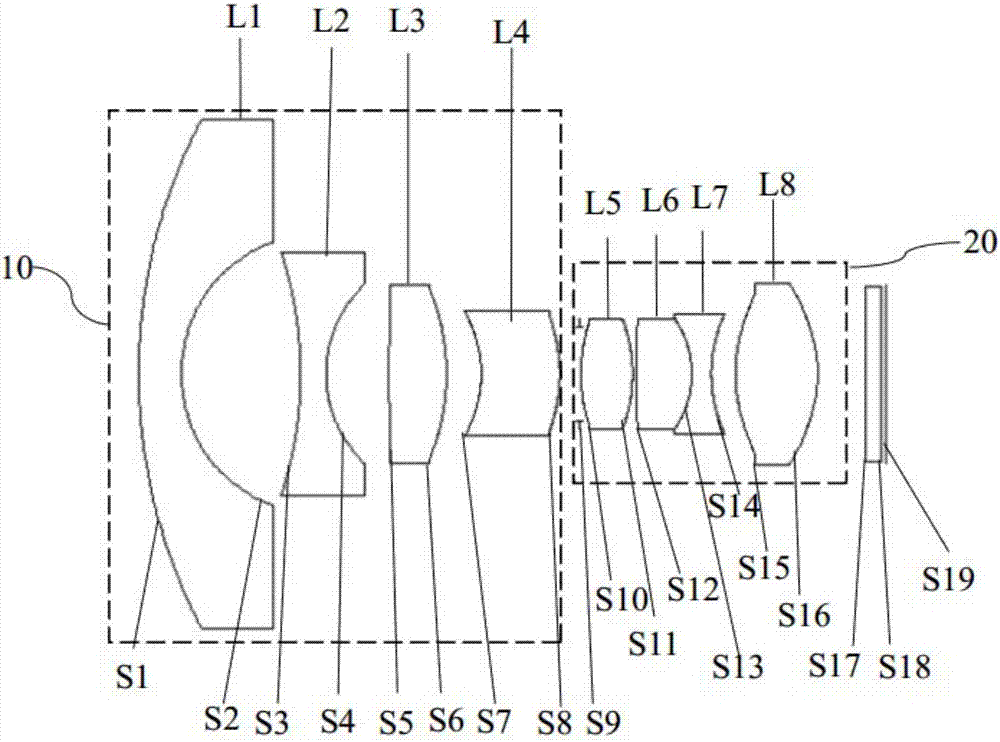

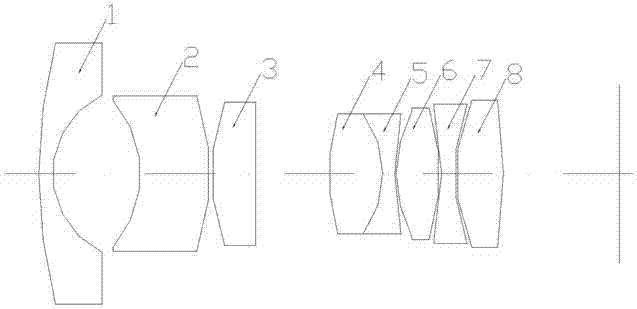

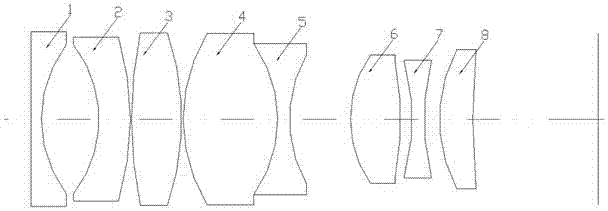

Fisheye lens

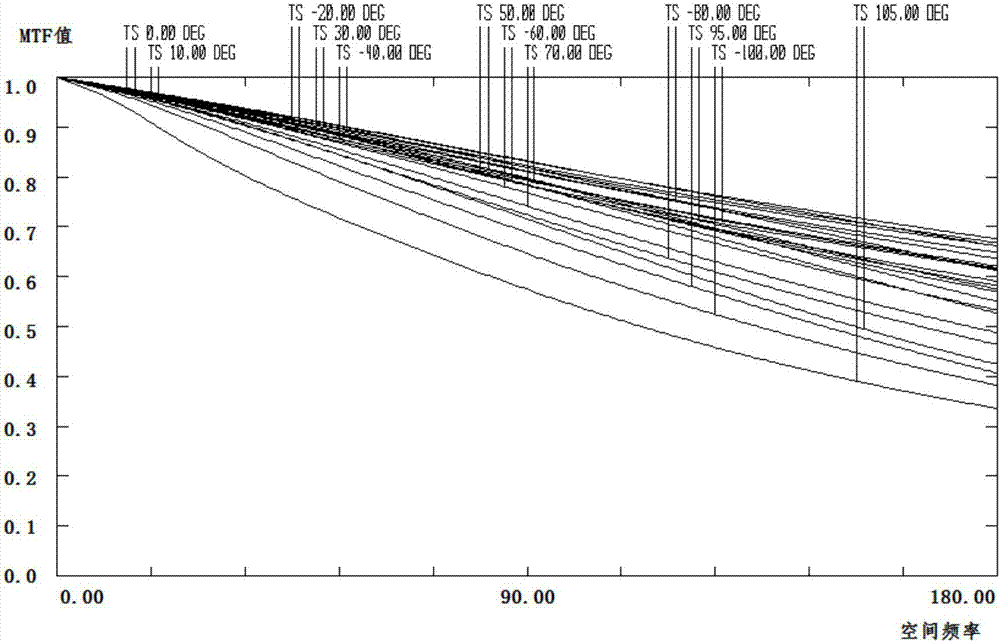

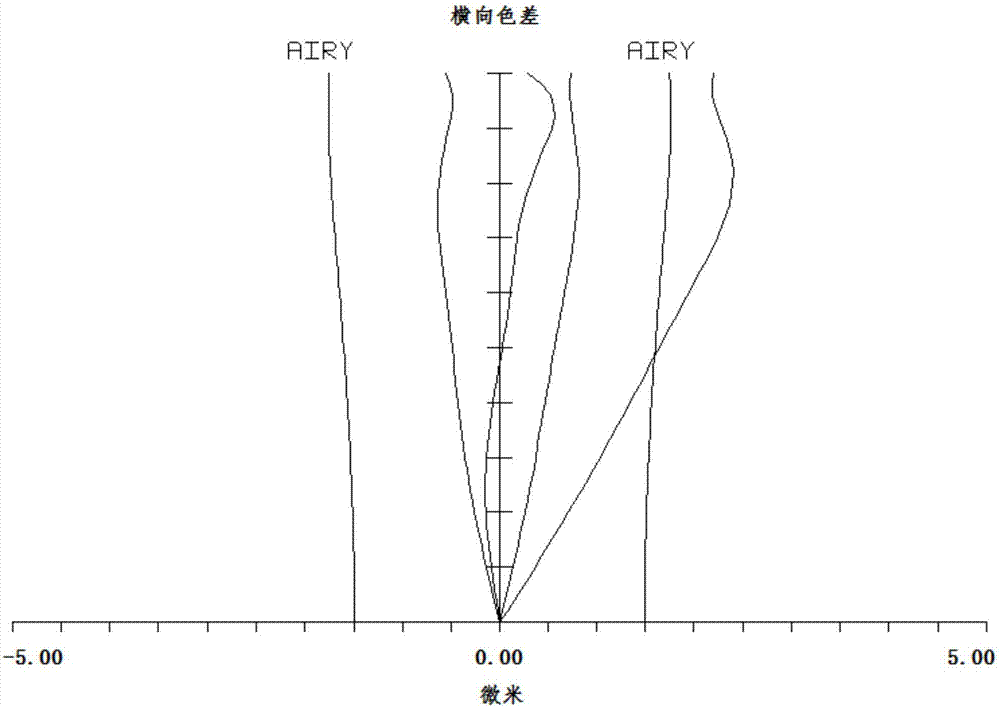

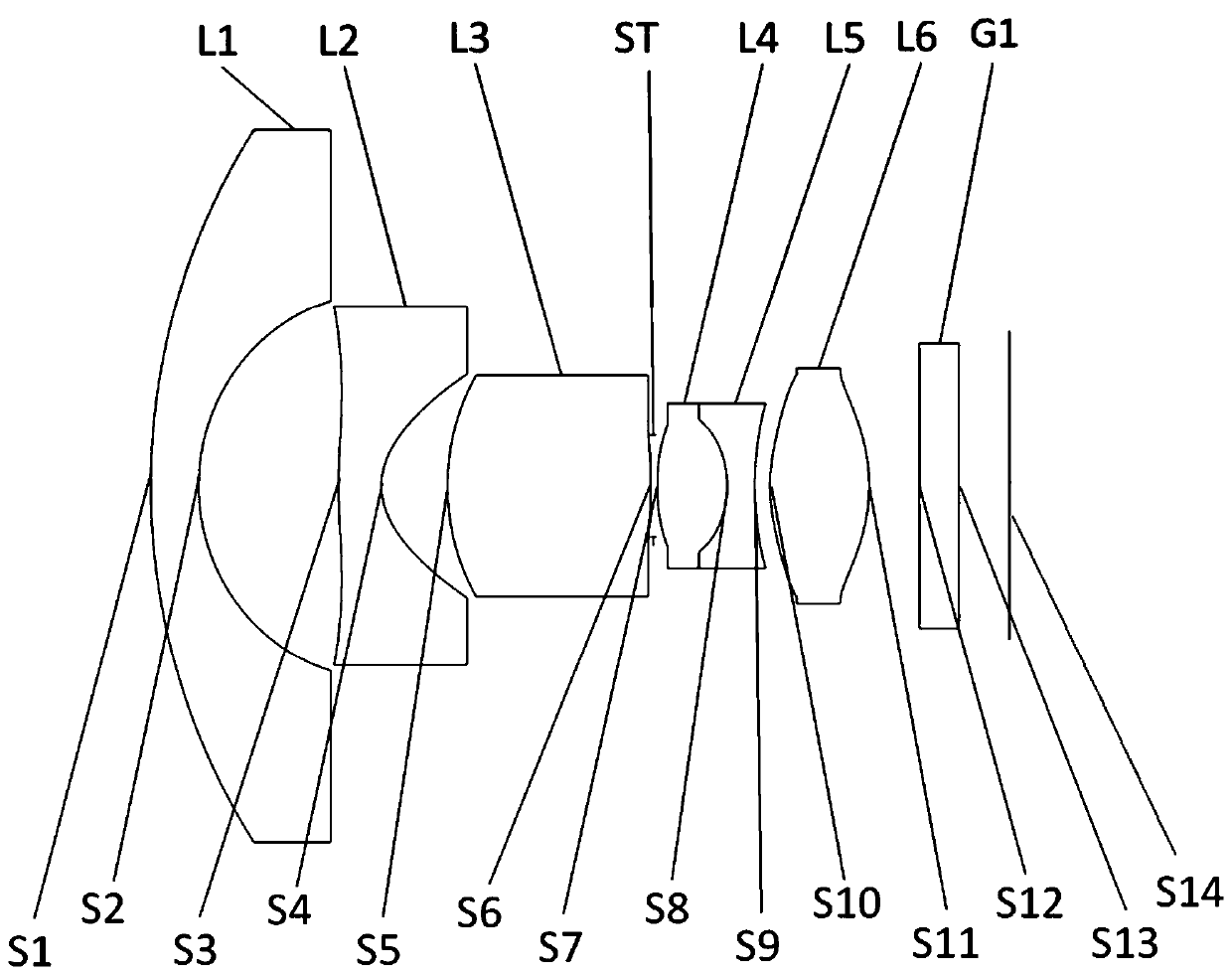

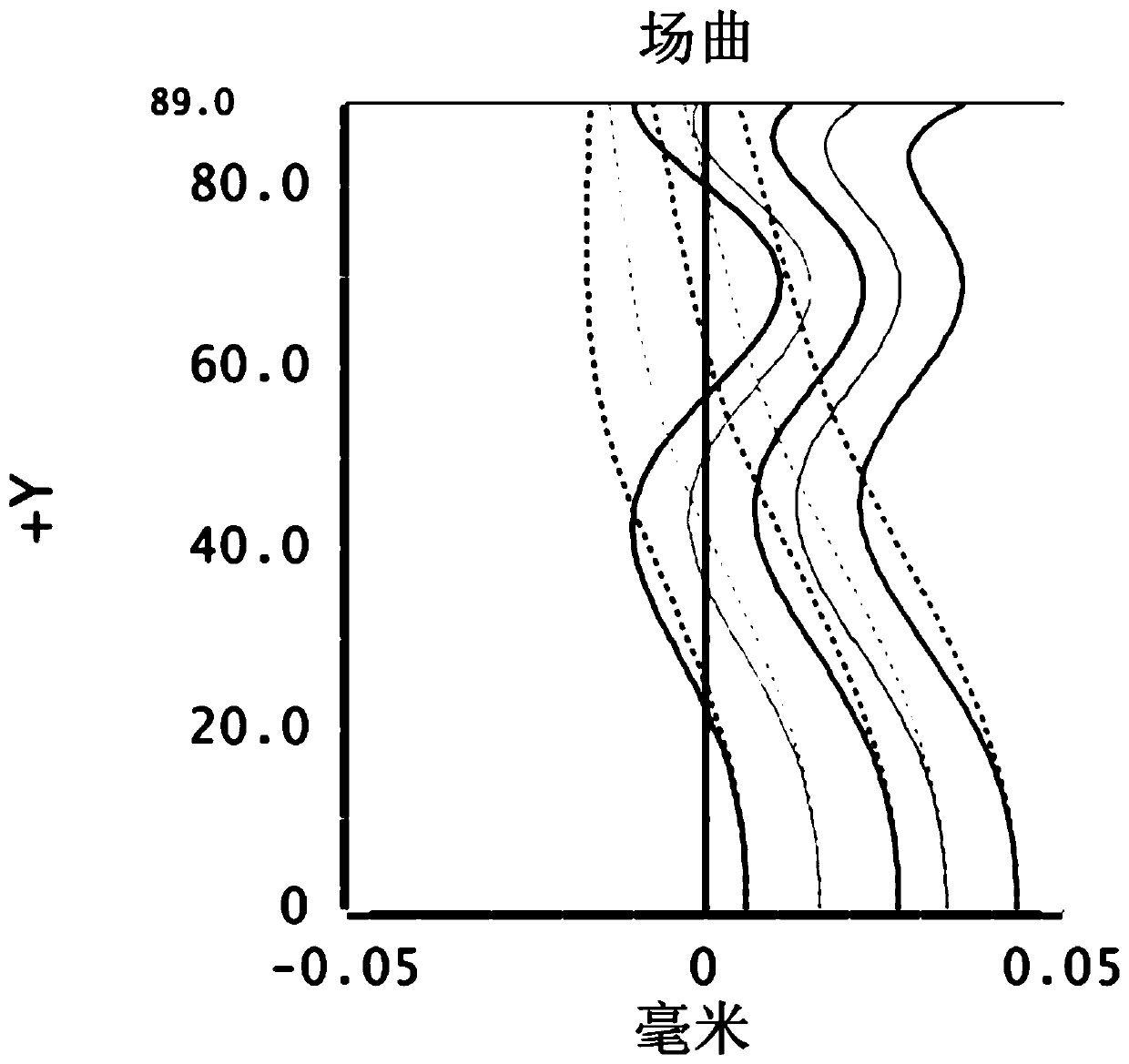

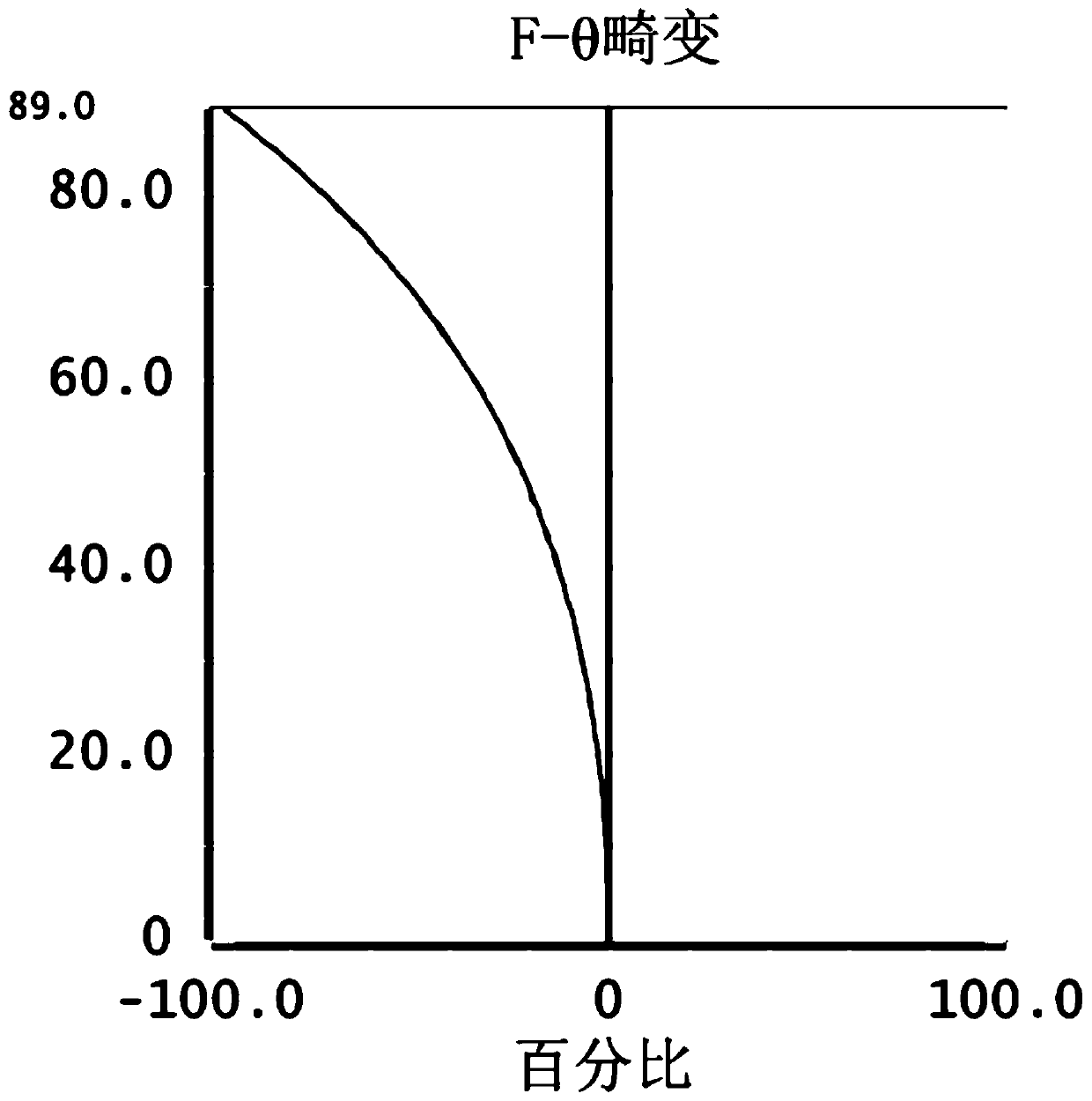

ActiveCN107167898AEasy to achieve magnification chromatic aberration correctionMeet practical application needsMountingsFisheye lensOphthalmology

The invention relates to a fisheye lens comprising a first lens group, a second lens group, and a diaphragm. The first lens group comprises a crescent first lens which has negative refractive power and of which the concave surface faces the imaging plane, a second lens which has negative refractive power and of which the image-side surface is concave, a third lens which has positive refractive power and of which the image-side surface is convex, and a fourth lens which has positive refractive power. The second lens group comprises a fifth lens which has positive refractive power and of which both surfaces are convex, a sixth lens which has positive refractive power and of which both surfaces are convex, a seventh lens which has negative refractive power and of which both surfaces are concave, and an eighth lens which has positive refractive power and of which both surfaces are convex. The first lens, the fifth lens, the sixth lens and the seventh lens are glass spherical lenses. The eighth lens is a glass aspheric lens. The fisheye lens provided by the invention has the characteristics of miniaturization and easy realization of magnification chromatic aberration correction. The fisheye lens can match an imaging chip of more than 16 million pixels, and meets the requirement of practical application.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

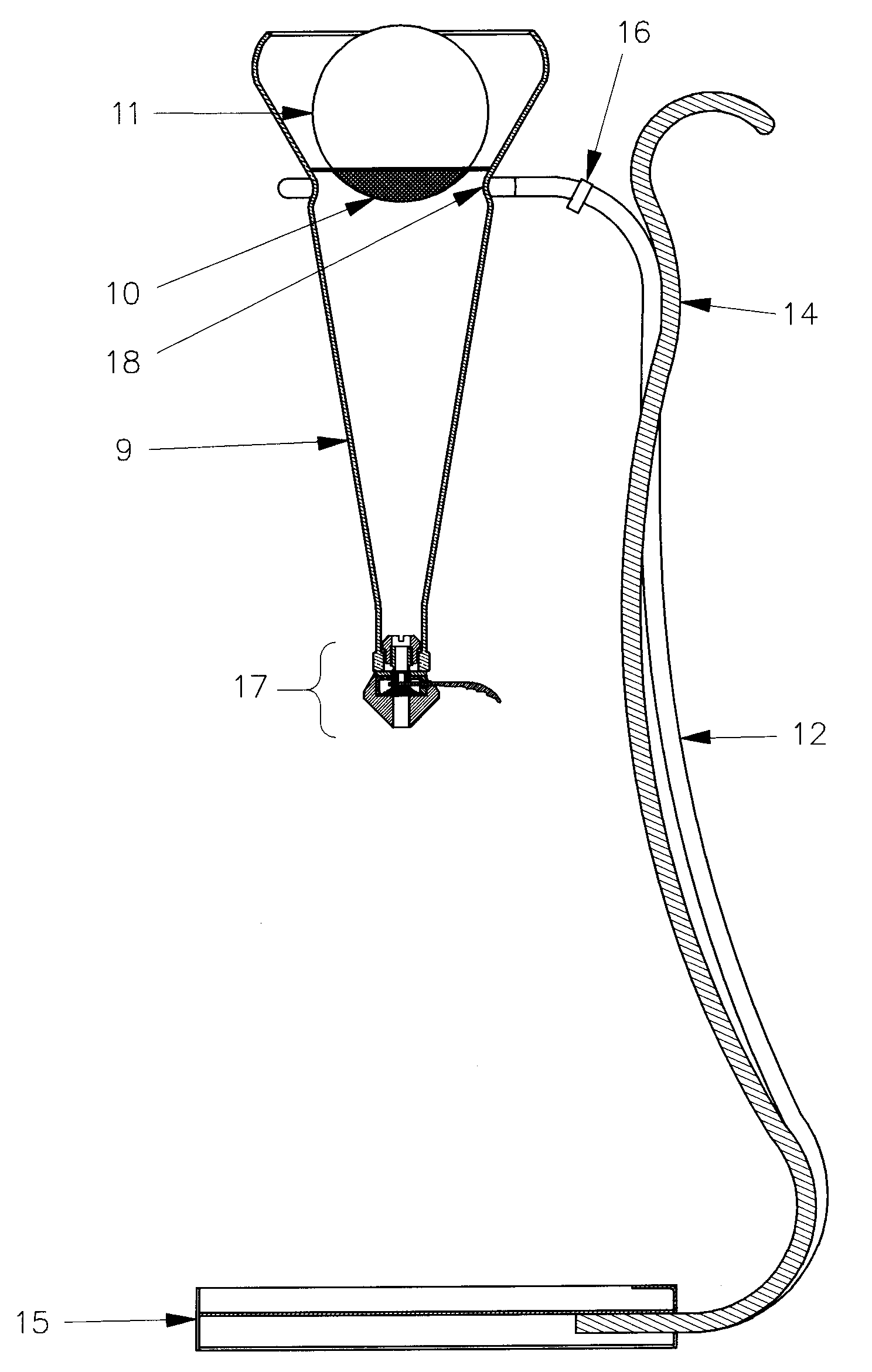

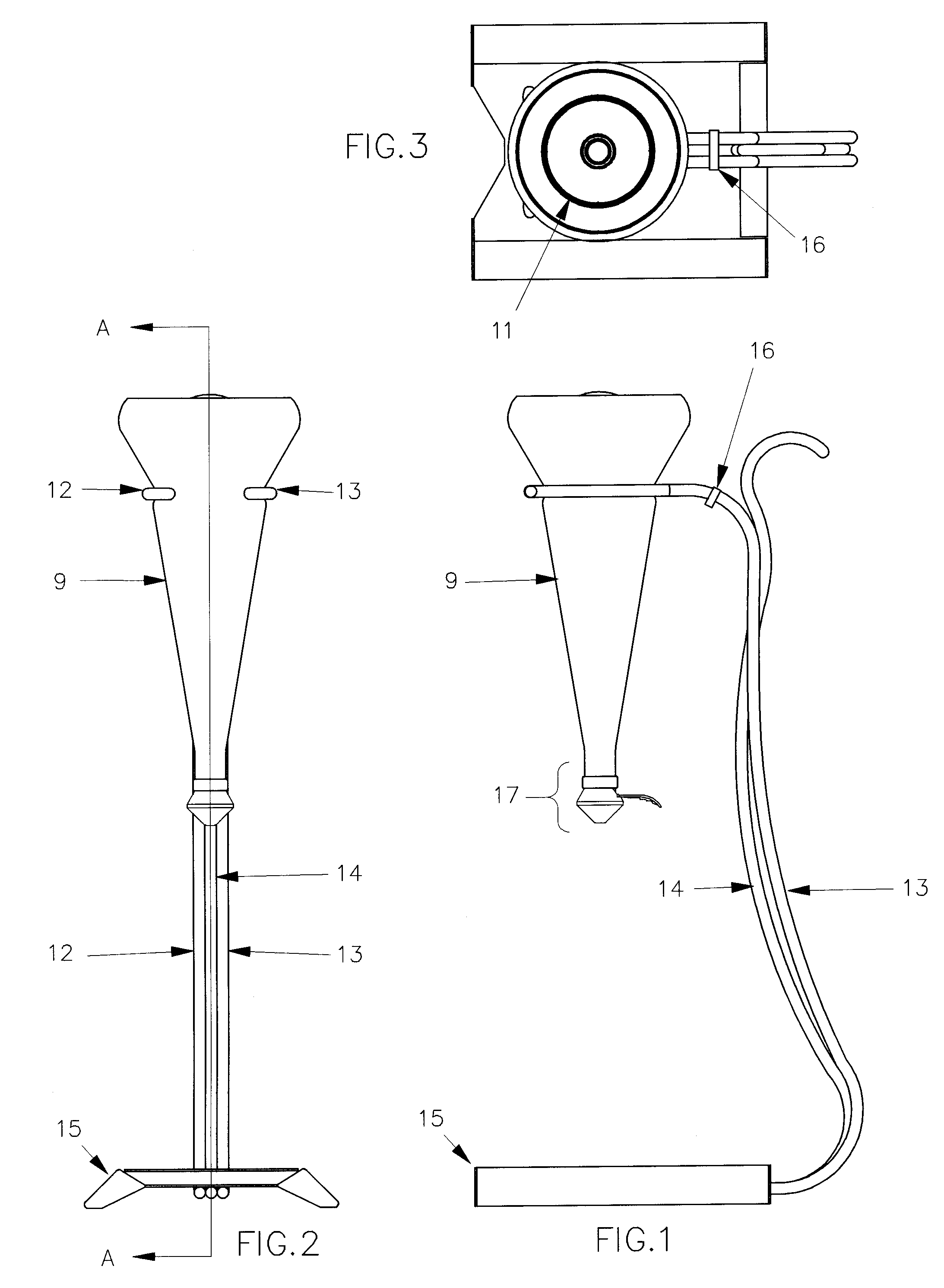

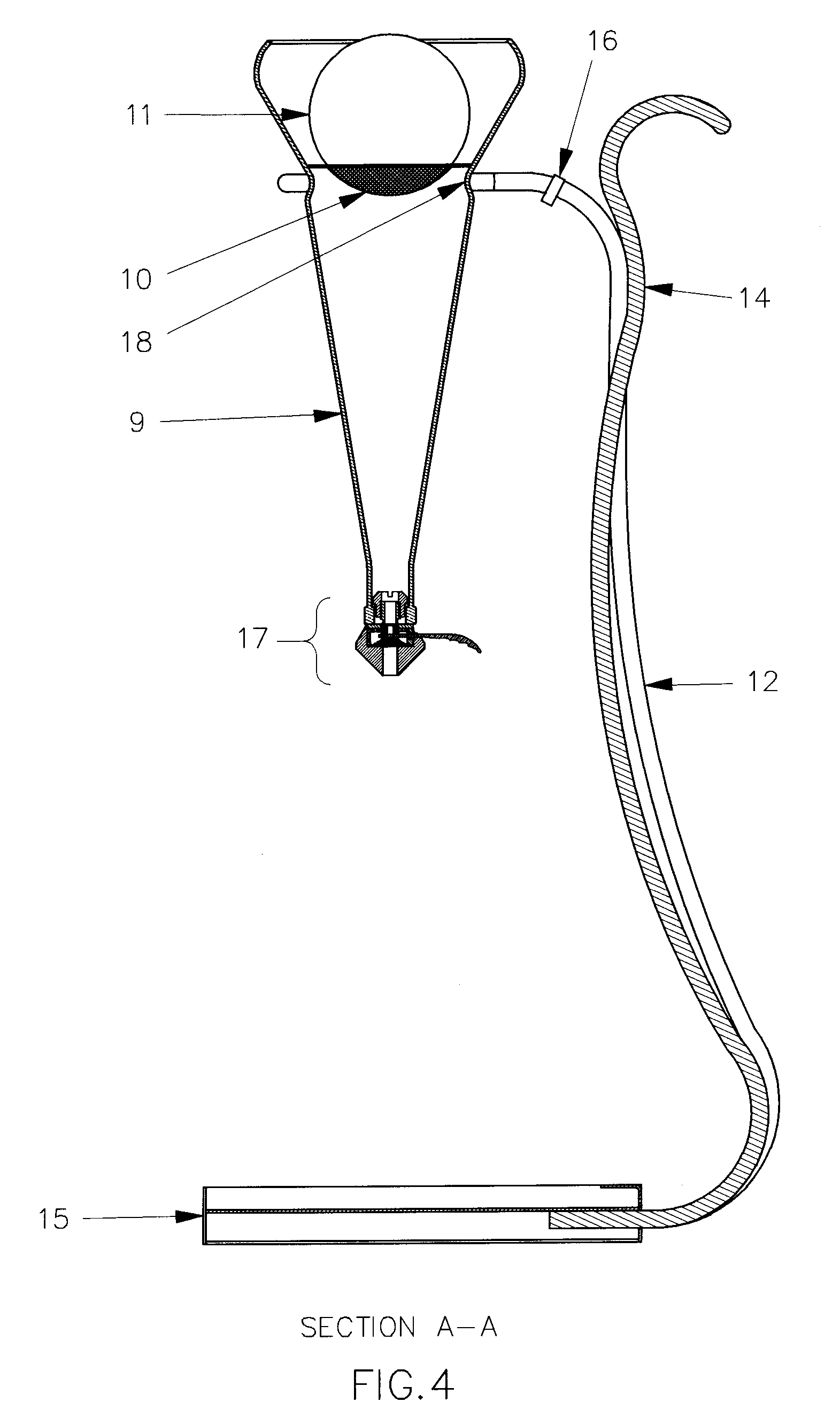

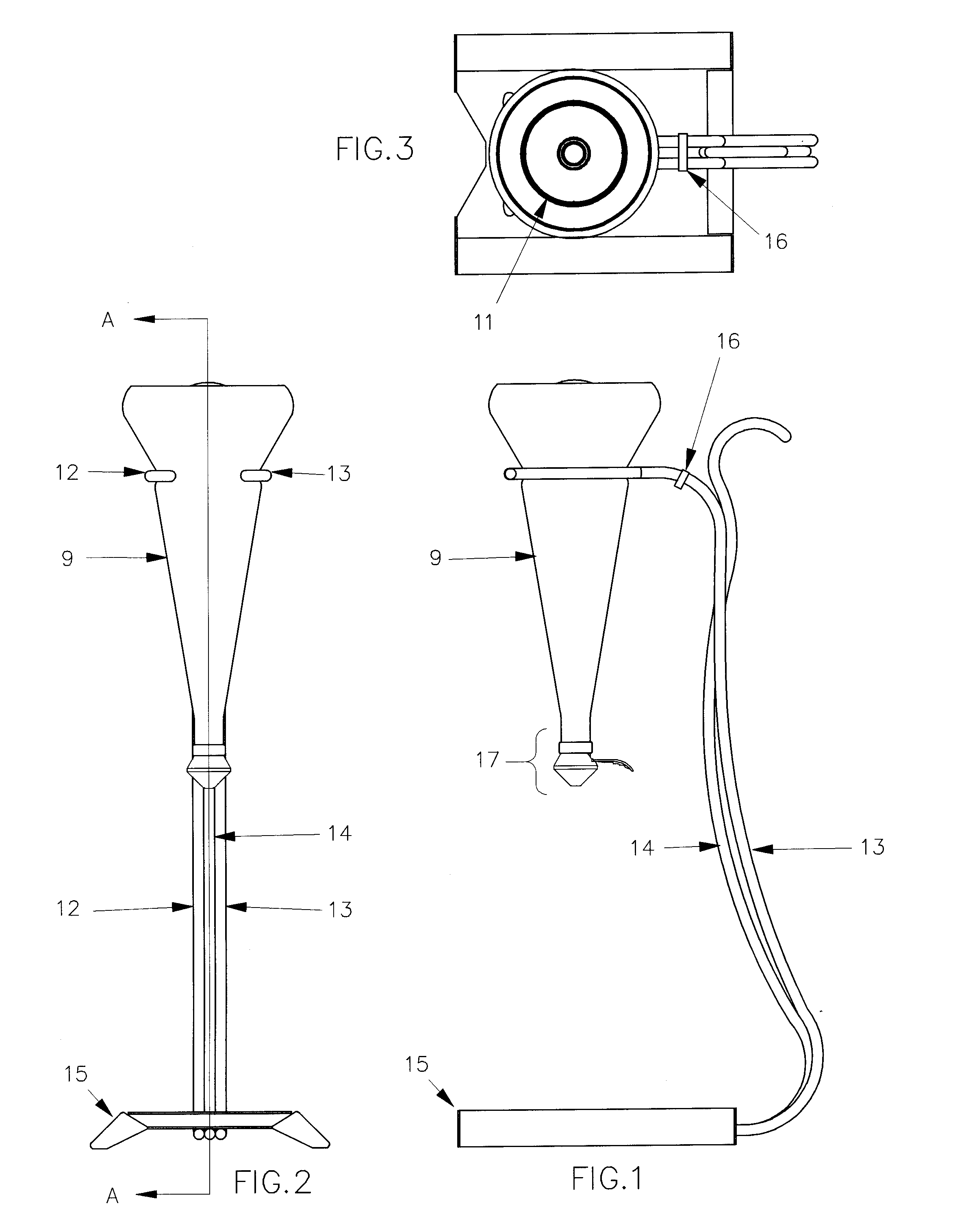

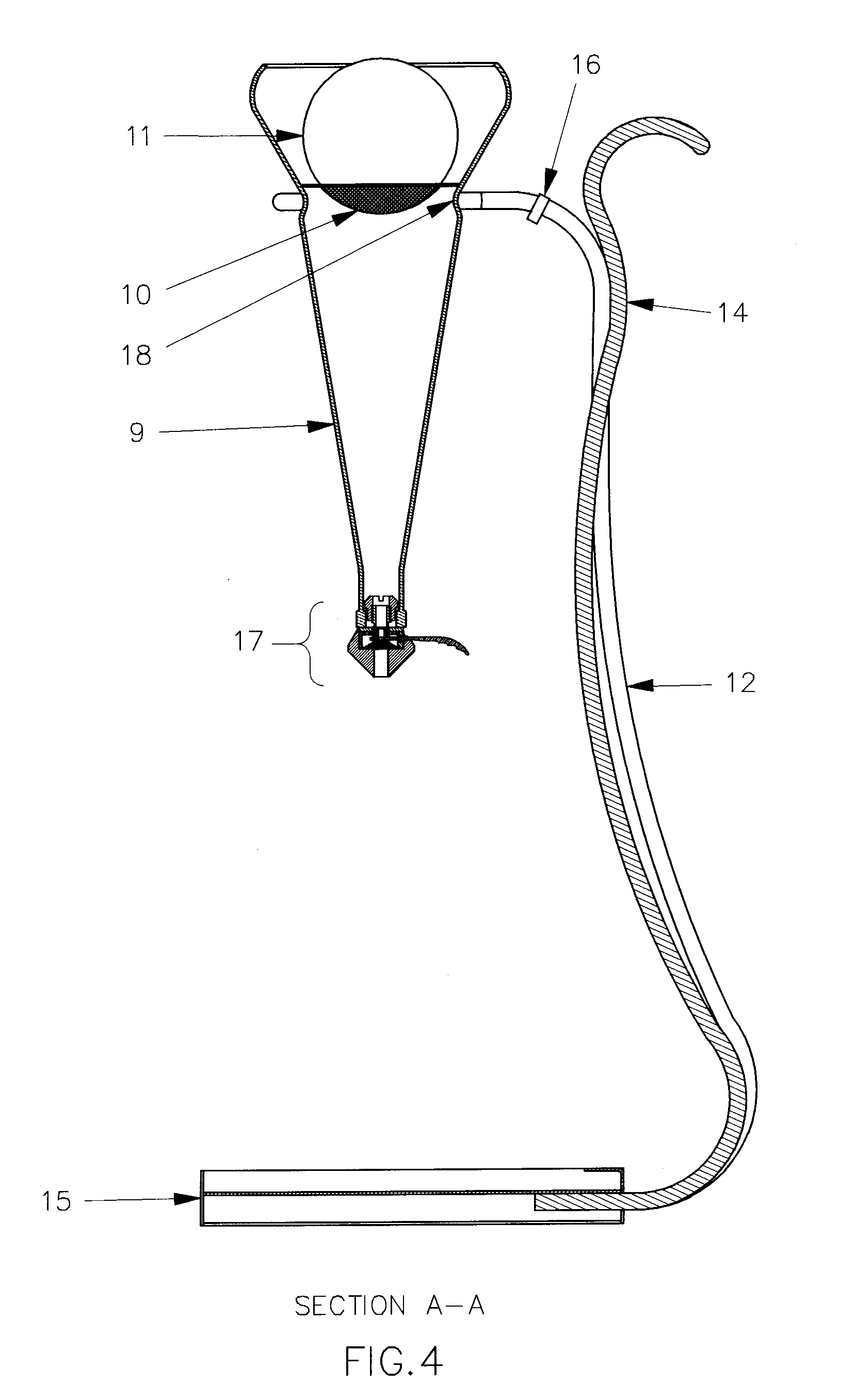

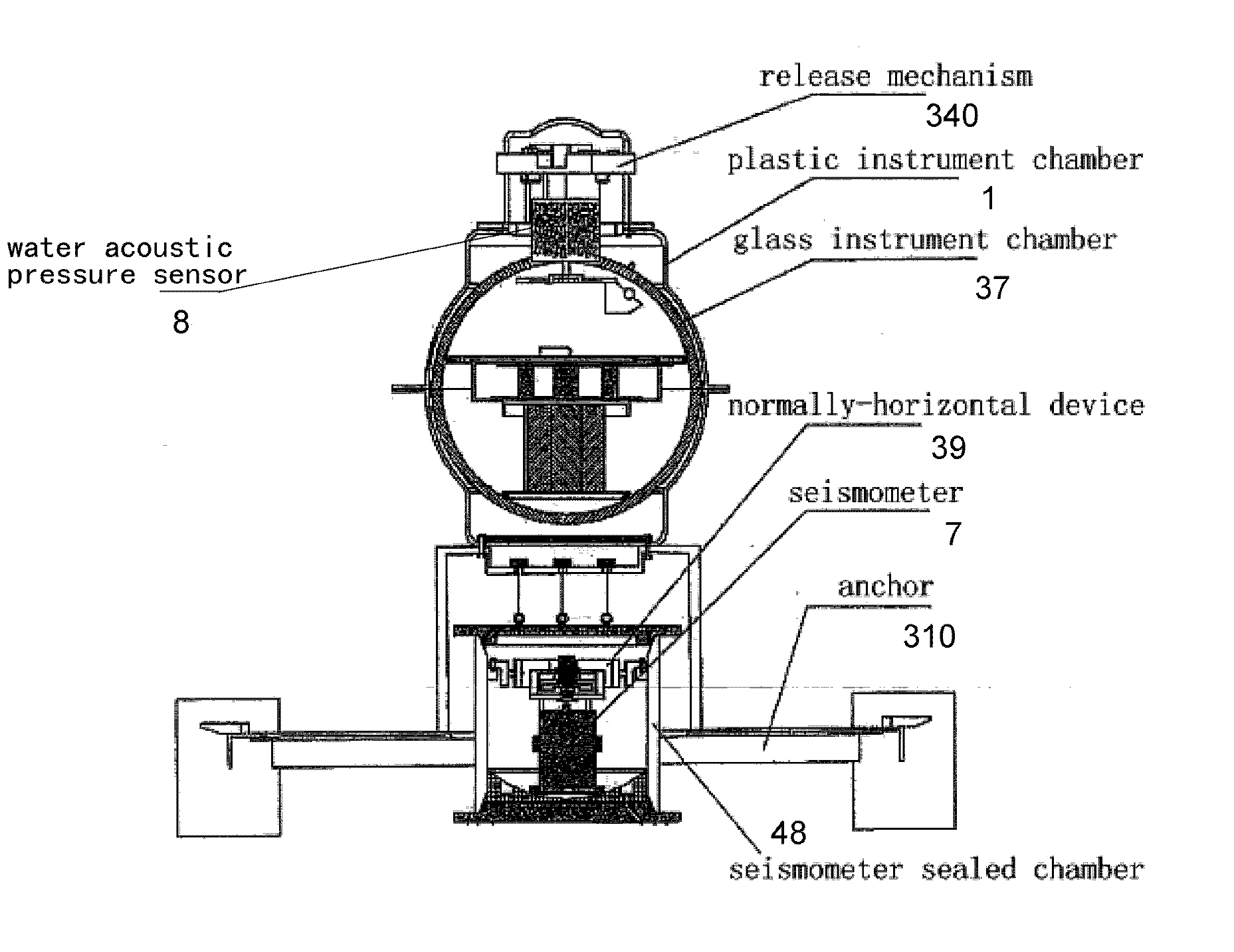

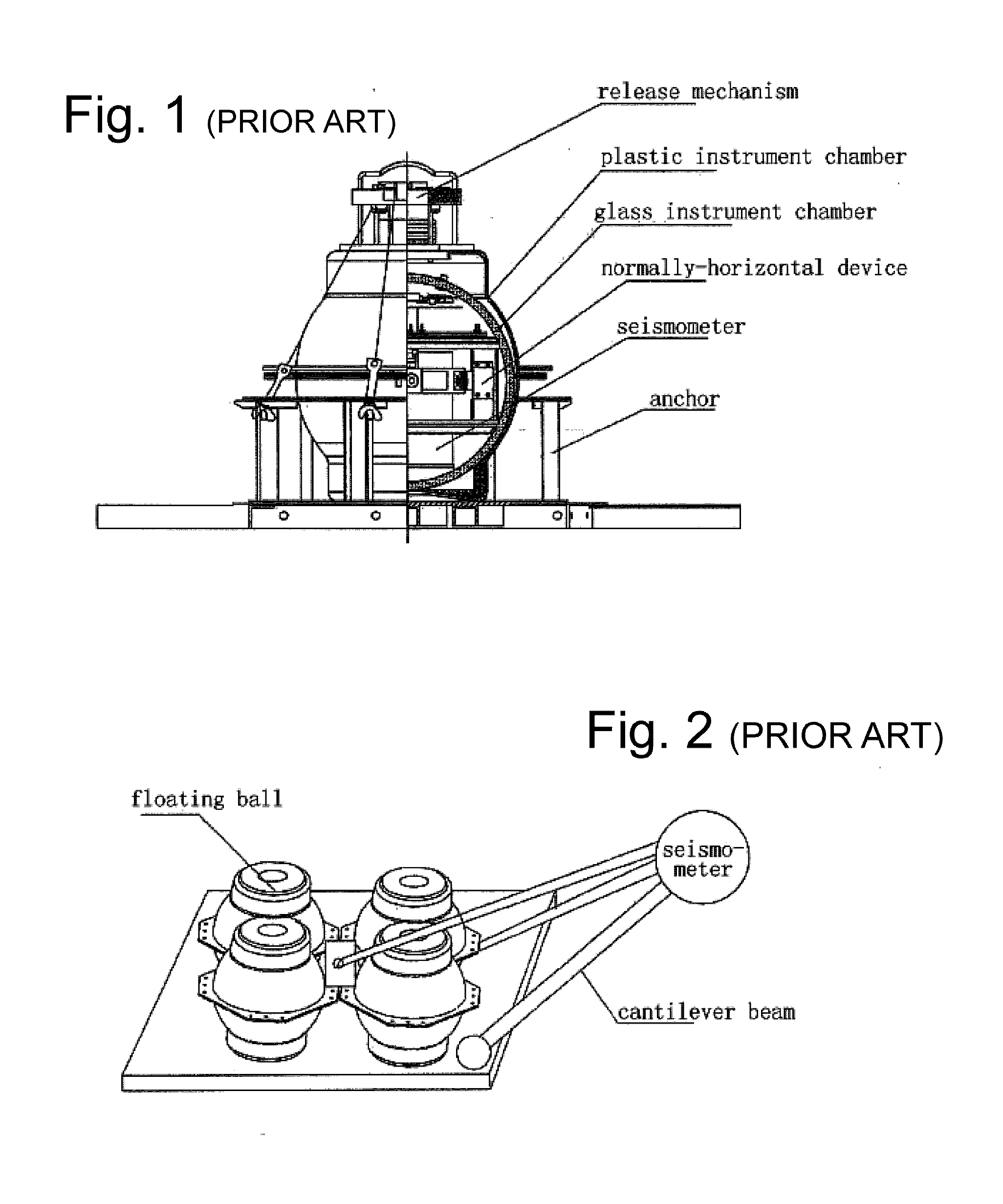

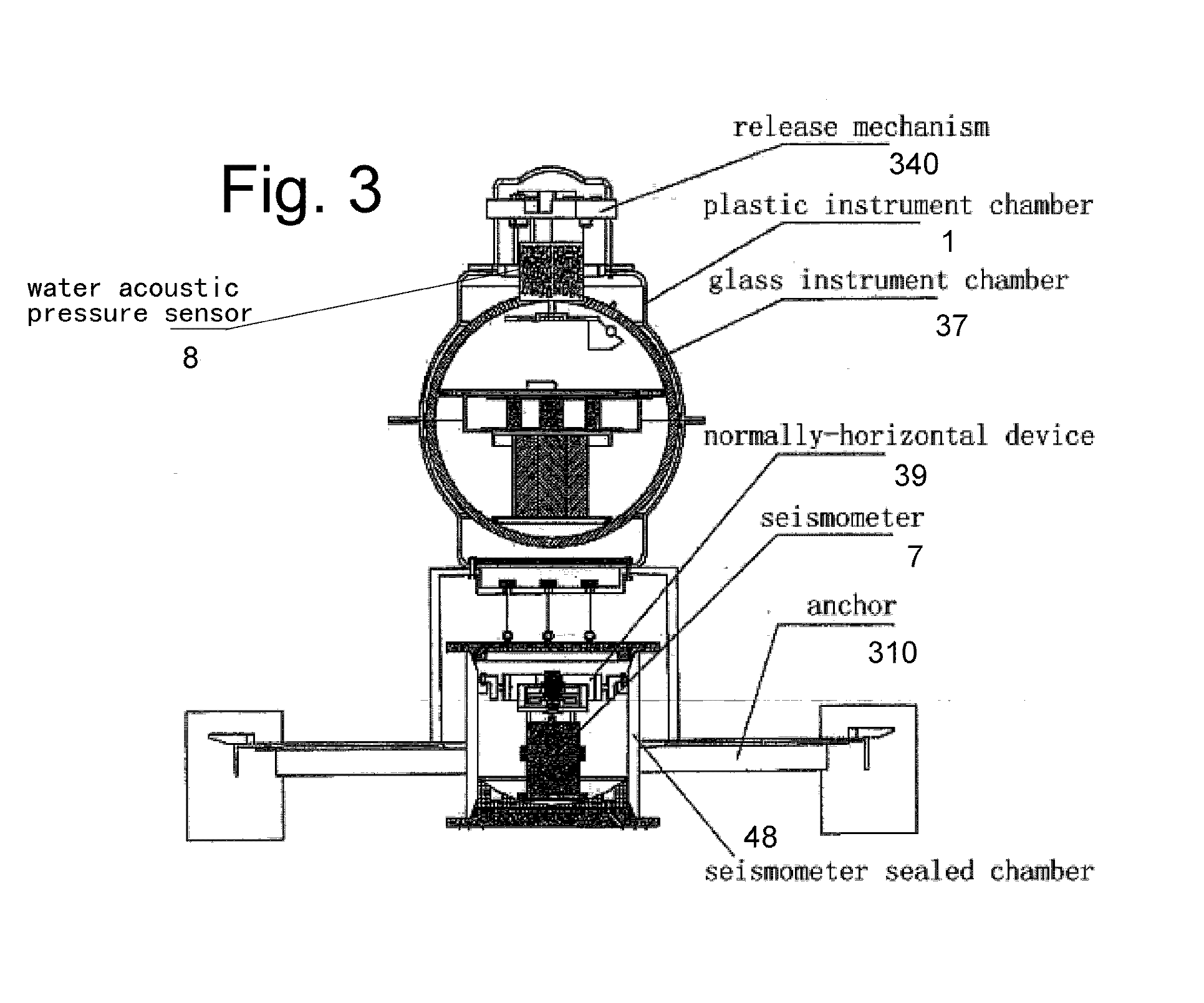

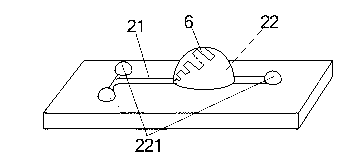

Combined broadband ocean bottom seismograph with single glass sphere

InactiveUS20120294123A1Coupling structureEliminate the effects ofSeismic signal receiversEngineeringBroadband

The invention provides a broadband ocean bottom seismograph with a single glass sphere. The seismograph comprises an anchor at its bottom having a frame structure with a rigid ring for accommodating a seismometer chamber. The seismometer chamber comprises a bell-shaped protective hood opening downward where a seismometer sealed chamber is suspended to the inner surface of the protective hood by cables. The bottom of the seismometer sealed chamber protrudes through the opening of the protective hood to be seated in direct contact with the seabed. A functional chamber comprises a plastic instrument chamber and a glass global instrument chamber secured in the plastic chamber. The plastic instrument chamber is fixedly mounted on top of the protective hood. A release mechanism is mounted on the top of the functional chamber, and connected to frame of the anchor via fusible tensioning steel wires.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Lightweight hollow particles for use in cementing

ActiveUS20130153222A1Retain its shapeEasy to handleGlass blowing apparatusDrilling compositionGlass fiberSodium Bentonite

A lightweight composite having an activated surface contains a lightweight hollow core particle having cement grains which may be adhered to the hollow core or embedded in the surface of the hollow core. The hollow core particle may be prepared from calcium carbonate and a mixture of clay, such as bentonite, and a glassy inorganic material, such as glass spheres, glass beads, glass bubbles, borosilicate glass and fiberglass.

Owner:BAKER HUGHES INC

Anti-corrosive zinc primer coating compositions comprising hollow glass spheres and a conductive pigment

ActiveUS20150232998A1Improve corrosion resistanceAlkali metal silicate coatingsLayered productsParticulatesEpoxy

The present invention concerns anti-corrosive coating compositions, in particular coating compositions for protecting iron and steel structures. In particular, the present invention relates to coating compositions comprising particulate zinc, conductive pigments, and hollow glass microspheres, e.g. epoxy based coatings. The invention furthermore concerns a kit of parts containing the composition, a method for its application, as well as metal structures coated with the composition.

Owner:HEMPEL AS

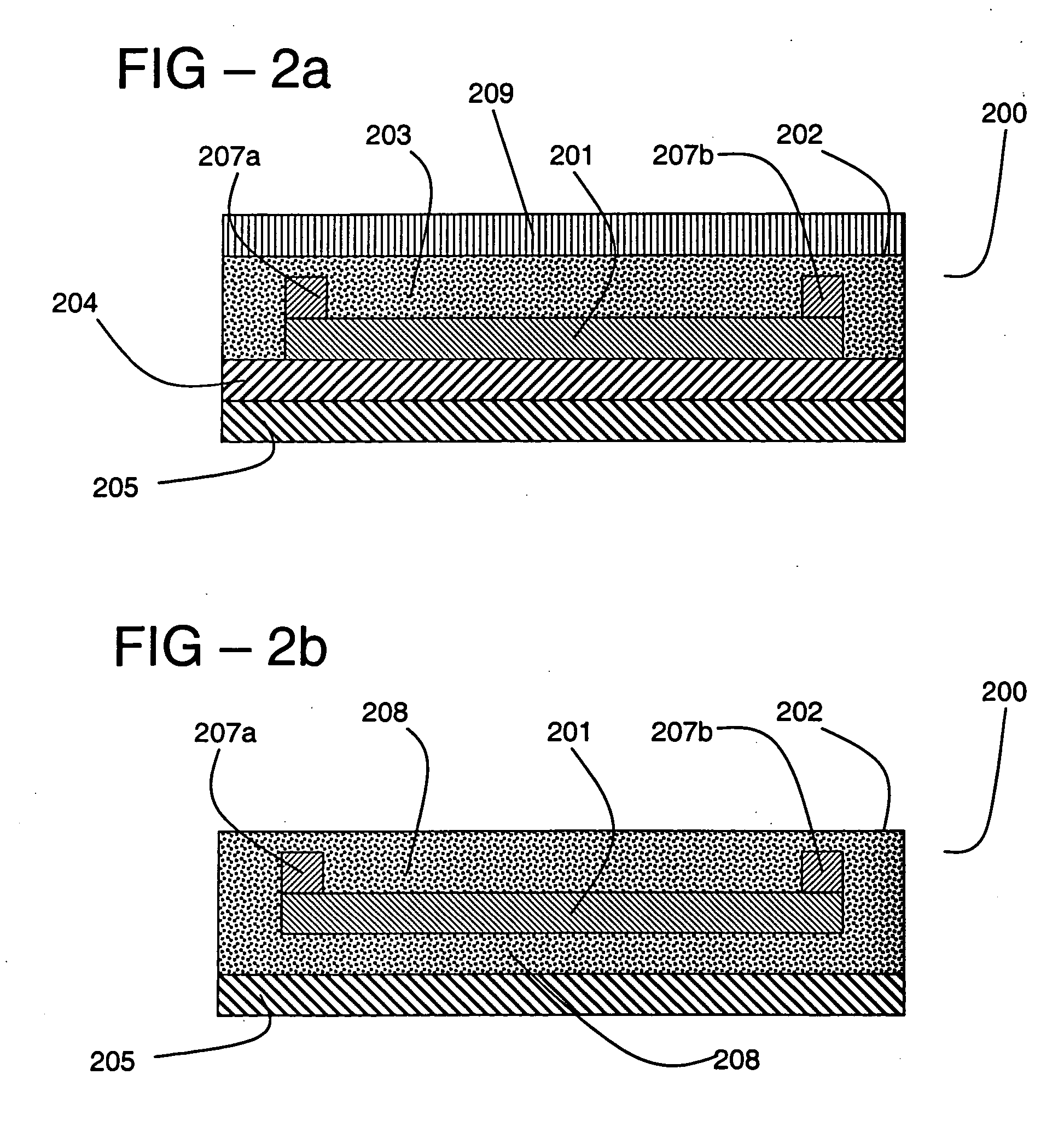

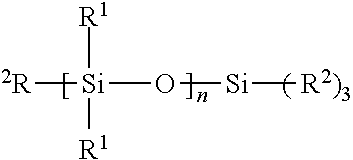

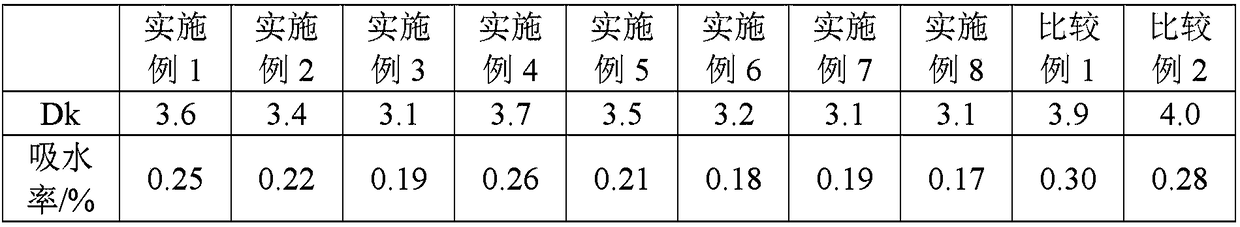

Thermosetting resin composition, prepreg, laminated board and printed circuit board

ActiveCN109233244AHigh dielectric constantEnhanced interface bindingSynthetic resin layered productsElectrical equipmentGlass spheresInterface bond

The disclosure provides a thermosetting resin composition, a prepreg, a laminated board and a printed circuit board. The thermosetting resin composition comprises thermosetting resin, a curing agent and a hollow glass sphere with an inorganic coating layer, wherein the inorganic coating layer is selected from at least one type of silicon dioxide coating layer and aluminium oxide coating layer; andthe weight of the inorganic coating layer occupies for 0.1 to 20% of the total weight of the hollow glass sphere with the inorganic coating layer. According to the disclosure, the thermosetting resincomposition and a dielectric layer for the laminated board, which is prepared from the thermosetting resin composition, can be provided, wherein interface bonding between the hollow glass sphere andthe resin can be improved, and the entire laminated board has an excellent dielectric constant.

Owner:GUANGDONG SHENGYI SCI TECH

Media with germicidal properties

InactiveUS6994794B2Strengthen associationSpecific water treatment objectivesTreatment involving filtrationEscherichia coliMicroorganism

Filtration media having germicidal for use in filtering particles and deactivating, removing and / or destroying microorganisms from a feed liquid passing through the media. The filtration media includes an effective amount of at least one germicidal agent associated to monomers polmerized and chemically grafted and covalently bonded to the surface of the media. The germicidal filter media is prepared by contacting the media with a grafting solution comprising one or more monomers, a catalyst, a surface agent, a curign agent, at least one graft initiator, and at least on germicide and subsequently curing the media at an elevated temperature to chemically graft the polmerizable monomers onto a surface of the media and associate at least one germicide thereto. Filter media suitable for use in the present invention include ceramic spheroids, hollow glass spheres, polmeric type meida, thermoset coated glass spheres, and crystalline microporous materials, such as zeolites. The germicidal filter media is effective for deactivating, destroying and / or removing from a feed liquid, such as water, escherichia coli, salmonella choleraesuis, staphylococcus, aspergsillus, klebisiella, listeria, clostridium, rotavirus, cysts and other microorganisms. Moreover, the filter media can be used repeatedly without a significant decrease in its germicidal effectiveness.

Owner:KINETICO

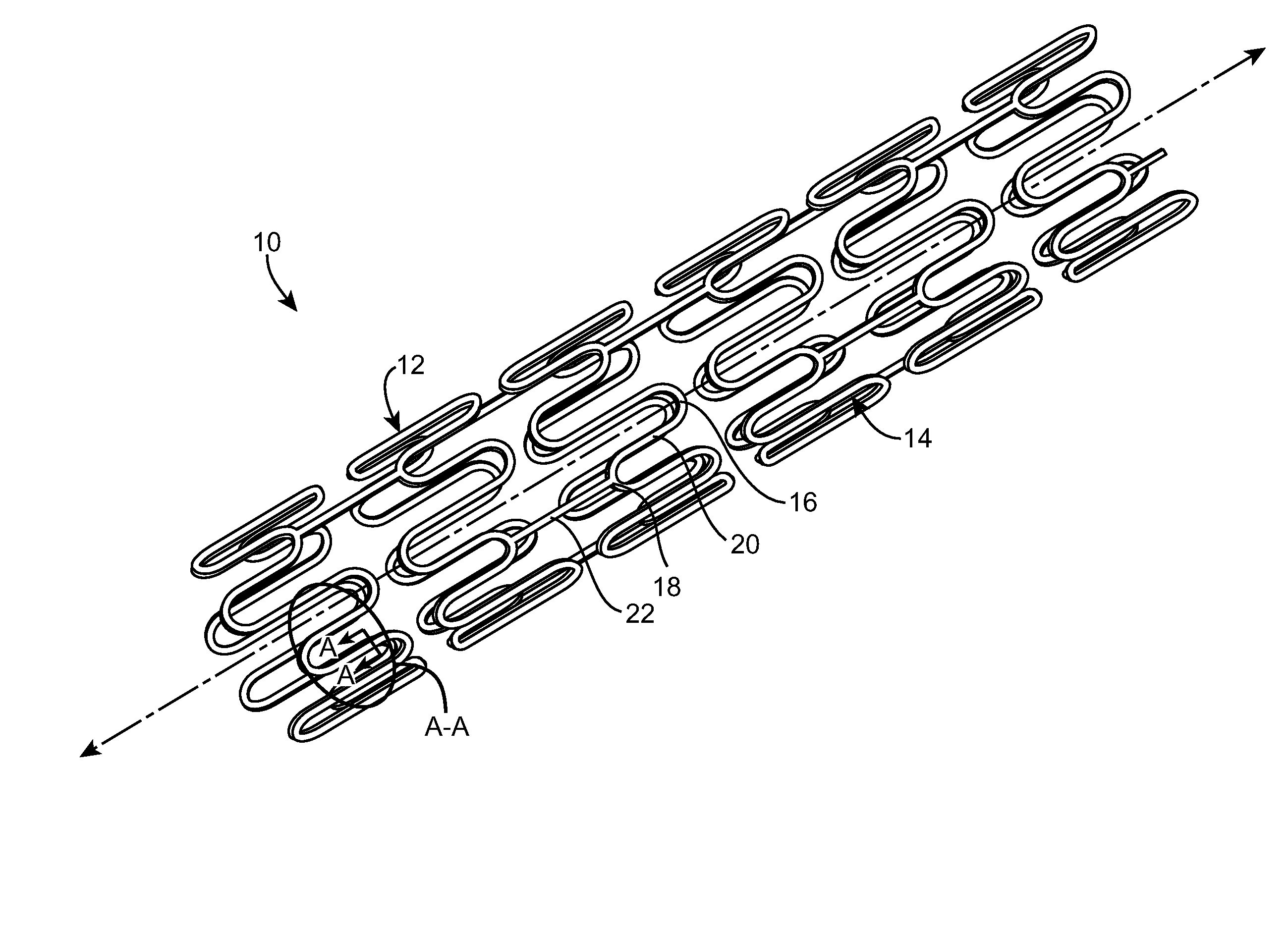

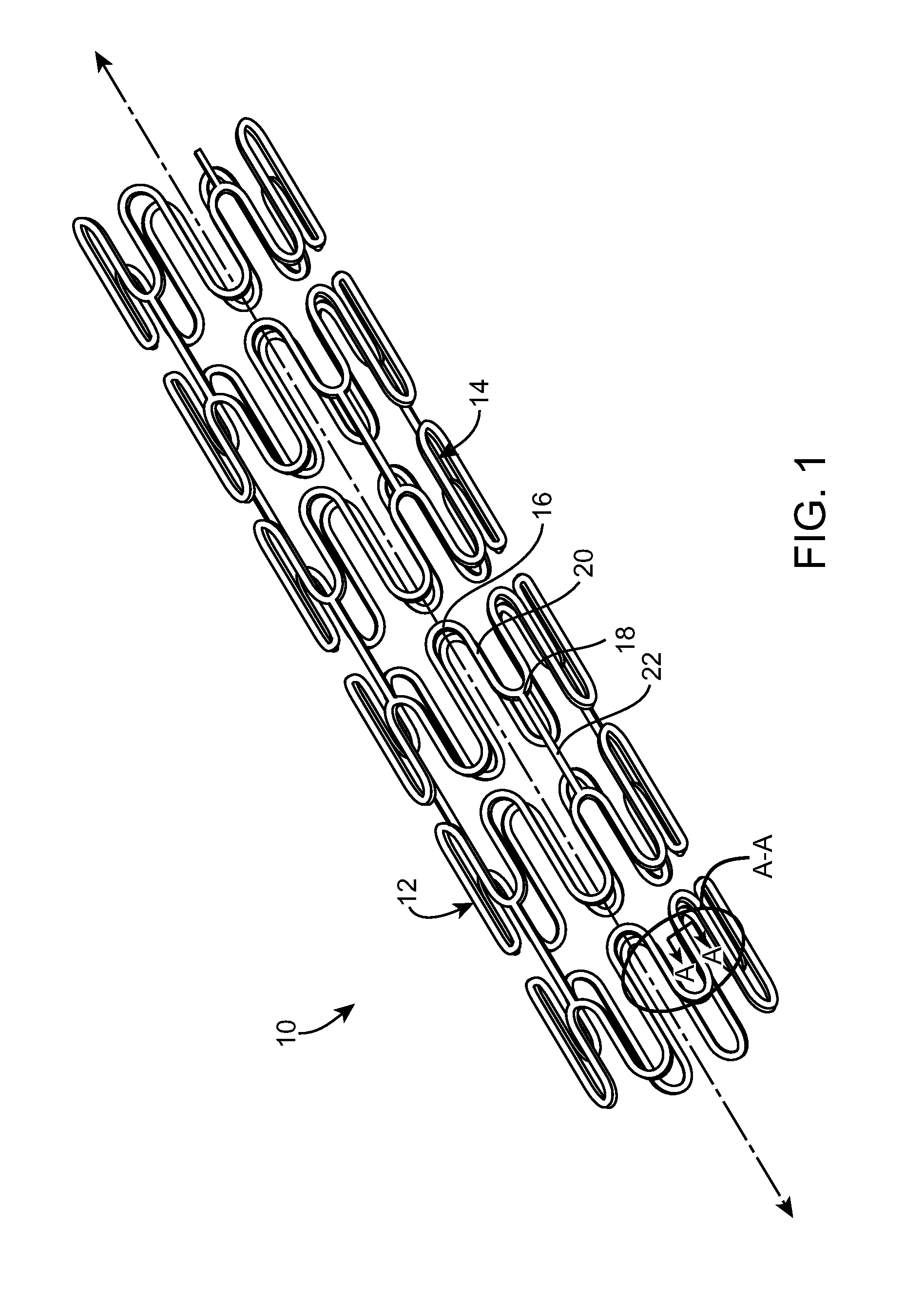

Stent Coating Including Therapeutic Biodegradable Glass, and Method of Making

A biocompatible polymeric coating composition for a stent having biodegradable glass spheres housing a therapeutic agent. The biodegradable glass spheres provide controlled, sustained release of the therapeutic agent in vivo. The biocompatible polymeric coating may be prepared without the use of a co-solvent.

Owner:MEDTRONIC VASCULAR INC

Glass spherical surface ultrasound focused cavitation reinforcement microreactor and preparation method thereof

InactiveCN103007859AControl the amount of liquidHigh densityEnergy based chemical/physical/physico-chemical processesMicroreactorCalcium bicarbonate

The invention discloses a glass spherical surface ultrasound focused cavitation reinforcement microreactor which comprises a substrate with a micro flow channel groove, a shallow groove and micro concave points and a system formed by the combination of glass wafers forming structures of glass micro flow channel cavities and spherical glass micro cavities corresponding to the micro flow channel groove and the shallow groove, wherein the system comprises a micro reaction cavity, a micro air chamber, a micro flow channel, an ultrasound excitation source, a fluid inlet and a fluid outlet; and in the structure, ultrasonic wave is utilized to be focused on the micro air chamber, and the cavitation reinforcement effect is realized. The invention also discloses a preparation method of the glass spherical surface ultrasound focused cavitation reinforcement microreactor. The preparation method of the glass spherical surface ultrasound focused cavitation reinforcement microreactor comprises the following steps of: firstly etching the micro flow channel groove and the micro concave points on a silicon substrate; adding a calcium bicarbonate solution in the grooves, then evaporating and heating, thereby obtaining a calcium carbonate high-temperature out-gassing agent finally; then carrying out anodic bonding on the silicon substrate with etched grooves and micro concave points and borosilicate glass wafers so as to form a sealed cavity body; and heating, releasing positive pressure generated by gases released by the high-temperature out-gassing agent so as to form small micro cavities. The glass spherical surface ultrasound focused cavitation reinforcement microreactor and the preparation method of the glass spherical surface ultrasound focused cavitation reinforcement microreactor provided by the invention have the advantages of good controllability and good cavitation effect.

Owner:SOUTHEAST UNIV

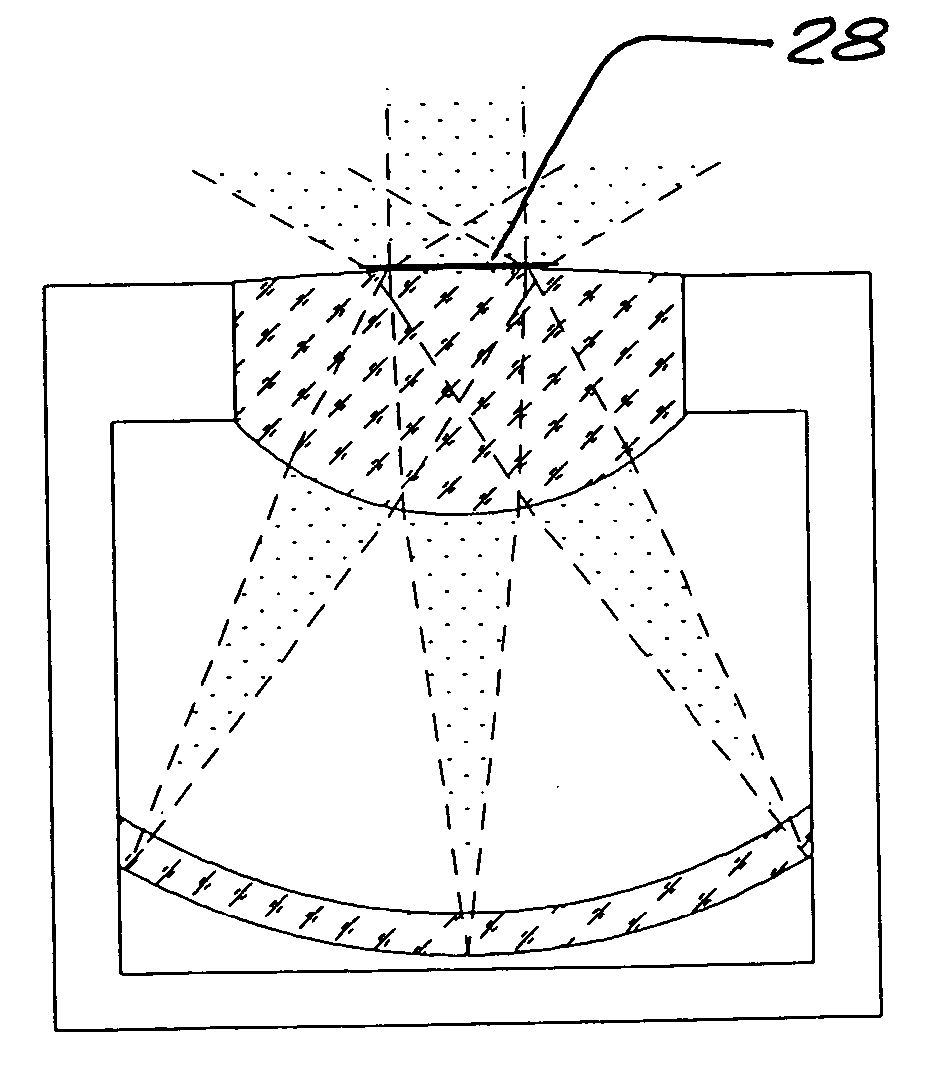

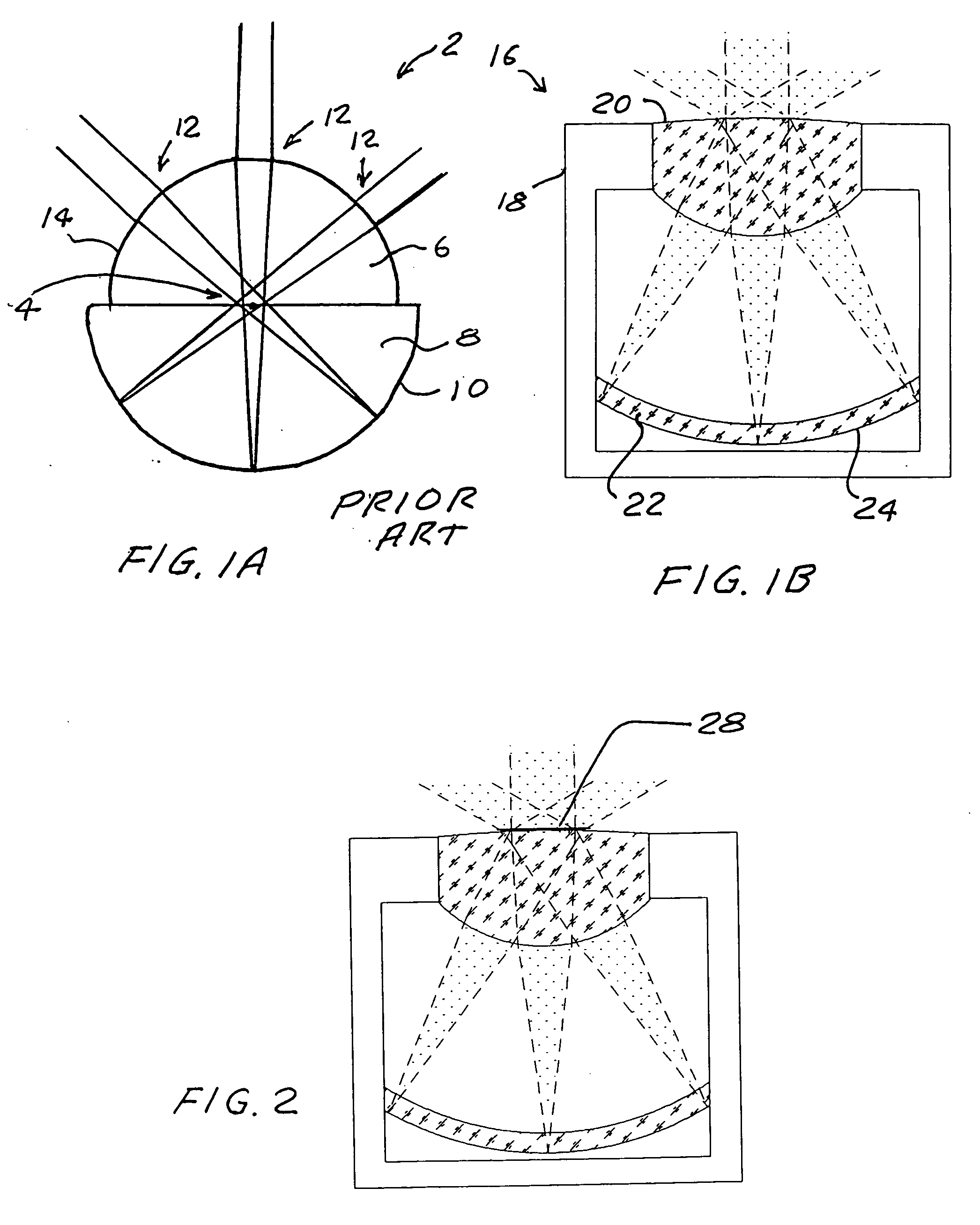

Large aperture retro-reflector

InactiveUS20050185283A1Improve optical efficiencyIncrease the apertureUsing optical meansOptical elementsGlass spheresRetroreflector

A large clear aperture cat's eye retro-reflector system that improves the optical efficiency by two orders of magnitude over conventional cat's eye retro-reflectors. It achieves this increase by using a wide-angle lens design with a curved focal plane, so the entrance aperture is not limited by the design constraints of a solid glass sphere. Since light reflected from a retro-reflector increases as the fourth power of the reflector aperture, light reflected from the retro-reflector of the present invention is increased by two orders of magnitude as compared to the prior art cat's eye retro-reflector of conventional size. When used as a communication device, the retro-reflector is preferably modulated by a quantum well modulator providing very high speed communication. In preferred embodiments a moving quantum well modulator is placed near the focal plane, where the beam footprint is much smaller than the entrance aperture, effectively allowing a small modulator to modulate a large diameter beam. A tracking system tracks the source of interrogating beams and positions the small modulator to intersect the incoming beam near the focal plane where the beam footprint is very small.

Owner:TREX ENTERPRISES CORP

Water containing powder composition

A powdery composition, comprising: a) core-shell particles having a shell of hydrophobic or hydrophobized particles; and b) a carrier powder comprising a carrier and at least one of an at least partially water soluble liquid and a water reactive substrate reversibly bound to the carrier by at least one of the capillary action, absorption and adsorption is provided. The core-shell particles have a core, comprising: water; and 0 to 10 wt. % of a total core weight of a dissolved or emulsified material. The carrier comprises at least one material selected from the group consisting of silica, a silica-metal mixed oxide, phyllosilicate, starch, hollow glass spheres, nylon, sugar, cyclodextrines and polysaccharides, and a weight ratio of the carrier powder to the core-shell particles is from 1 / 1 to 1 / 9. A creamy composition is manufactured from the powdery composition-by an energy input in form of pressure, shear, temperature, vibration and / or solvent addition, the energy input being sufficient to release the liquid water or the liquid aqueous phase from the core-shell material and subsequently dissolving or flushing the produce or products from the carrier.

Owner:EVONIK OPERATIONS GMBH

Cementing compositions and methods of cementing in a subterranean formation using an additive for preventing the segregation of lightweight beads

InactiveUS20050076812A1Avoid separationUniform density distributionSolid waste managementDrilling compositionParticulatesAcetic acid

Cementing compositions and methods of cementing in a subterranean formation are provided. The cement composition includes a hydraulic cement, lightweight beads, and a desegregating agent for inhibiting segregation of the beads. The lightweight beads may be, for example, cenospheres, glass spheres, and ceramic spheres. The desegregating agent comprises a particulate substrate such as precipitated silica. It also comprises a polar molecule producing chemical disposed on the particulate substrate. Preferably, the polar molecule producing chemical is absorbed on the particulate substrate. The polar molecule producing chemical comprises at least one of a polar molecule producing acid such as glacial acetic acid, a salt of such an acid, and an acid anhydride. The method of cementing includes forming a pumpable slurry using the cement composition, pumping the slurry into a subterranean formation, and allowing the slurry to set.

Owner:HALLIBURTON ENERGY SERVICES INC

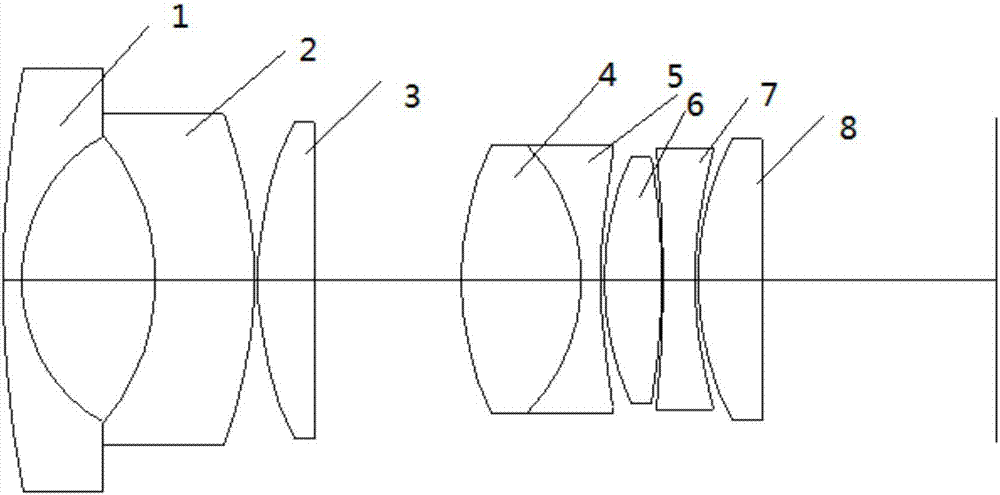

Large-aperture 4K prime lens

PendingCN107367828AHigh ability to correct aberrationsReduce in quantityOptical elementsPrime lensOphthalmology

The invention provides a large-aperture 4K prime lens which comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens which are sequentially arranged along an optical axis from an object space to an image space, wherein the first lens, the third lens, the fourth lens, the fifth lens and the eighth lens are glass lenses, and the second lens, the sixth lens and the seventh lens are plastic aspherical lenses. By the aid of an 8-piece optical structure with the five glass spherical lenses and the three plastic aspherical lenses, visible light and infrared light can simultaneously reach indexes such as 4K resolution ratio, F1.4 maximum aperture, 1 / 1.8' image surface maximum 160-degree field angles and optical overall length smaller than 30mm.

Owner:DONGGUAN YUTONG OPTICAL TECH

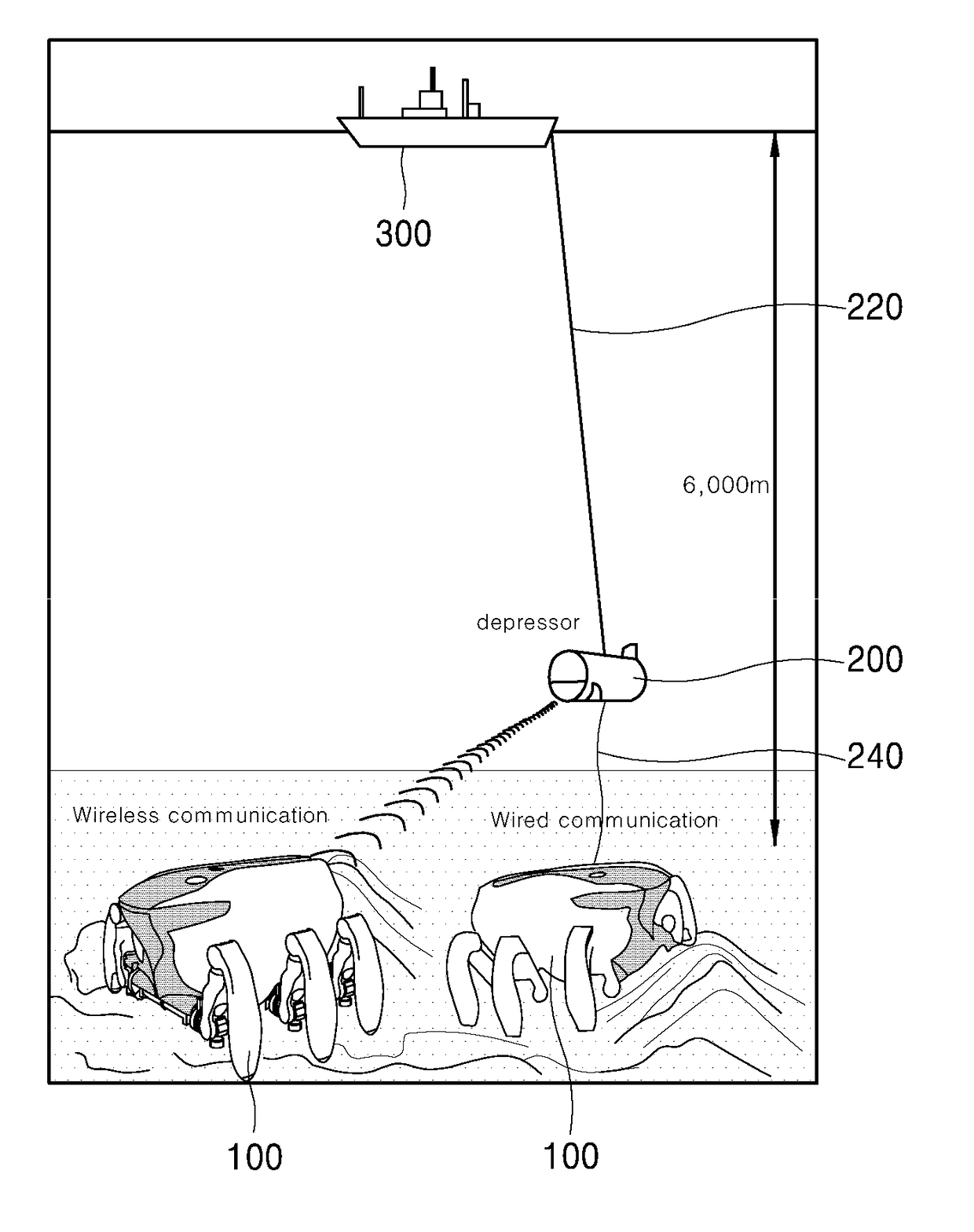

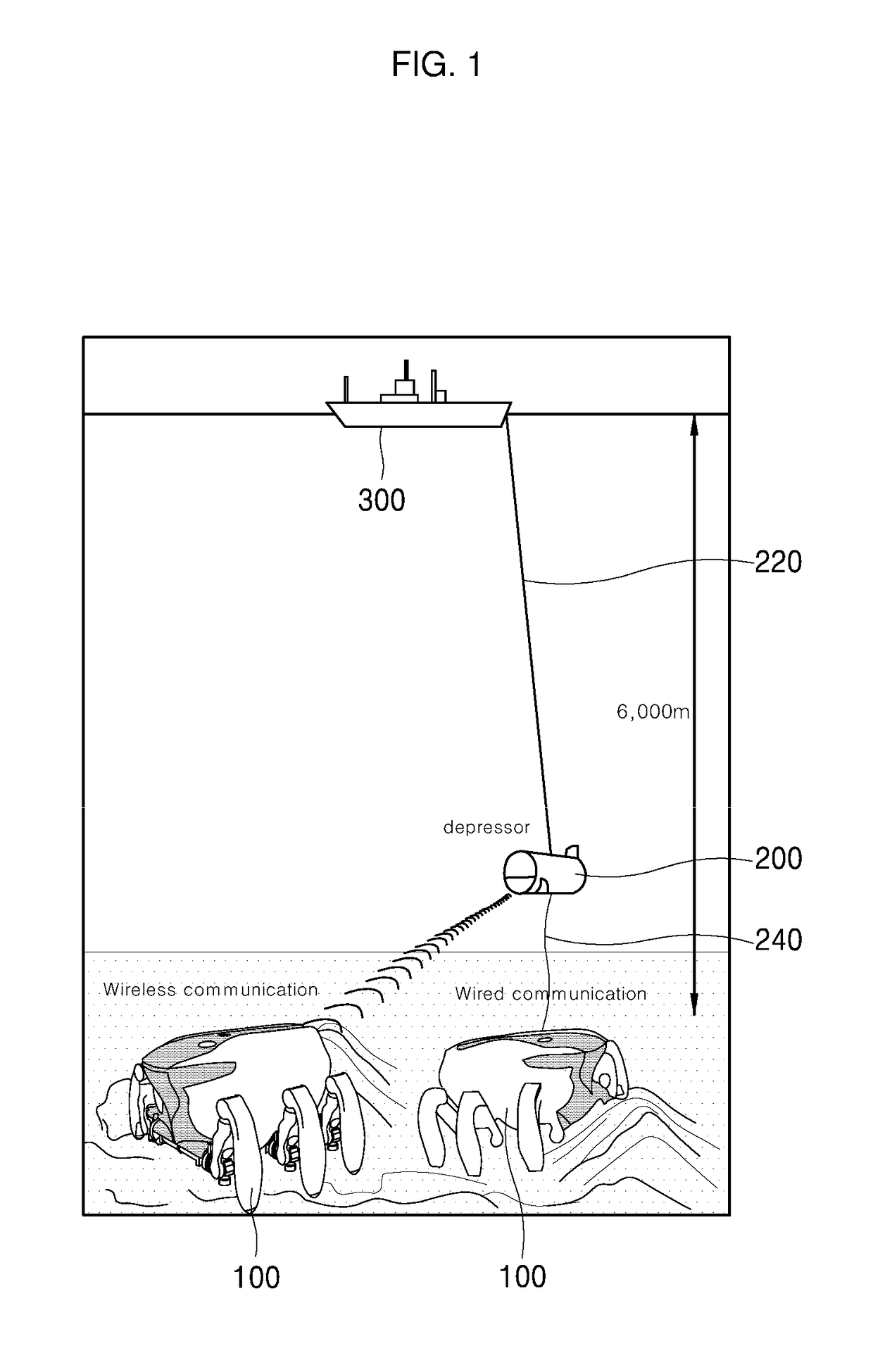

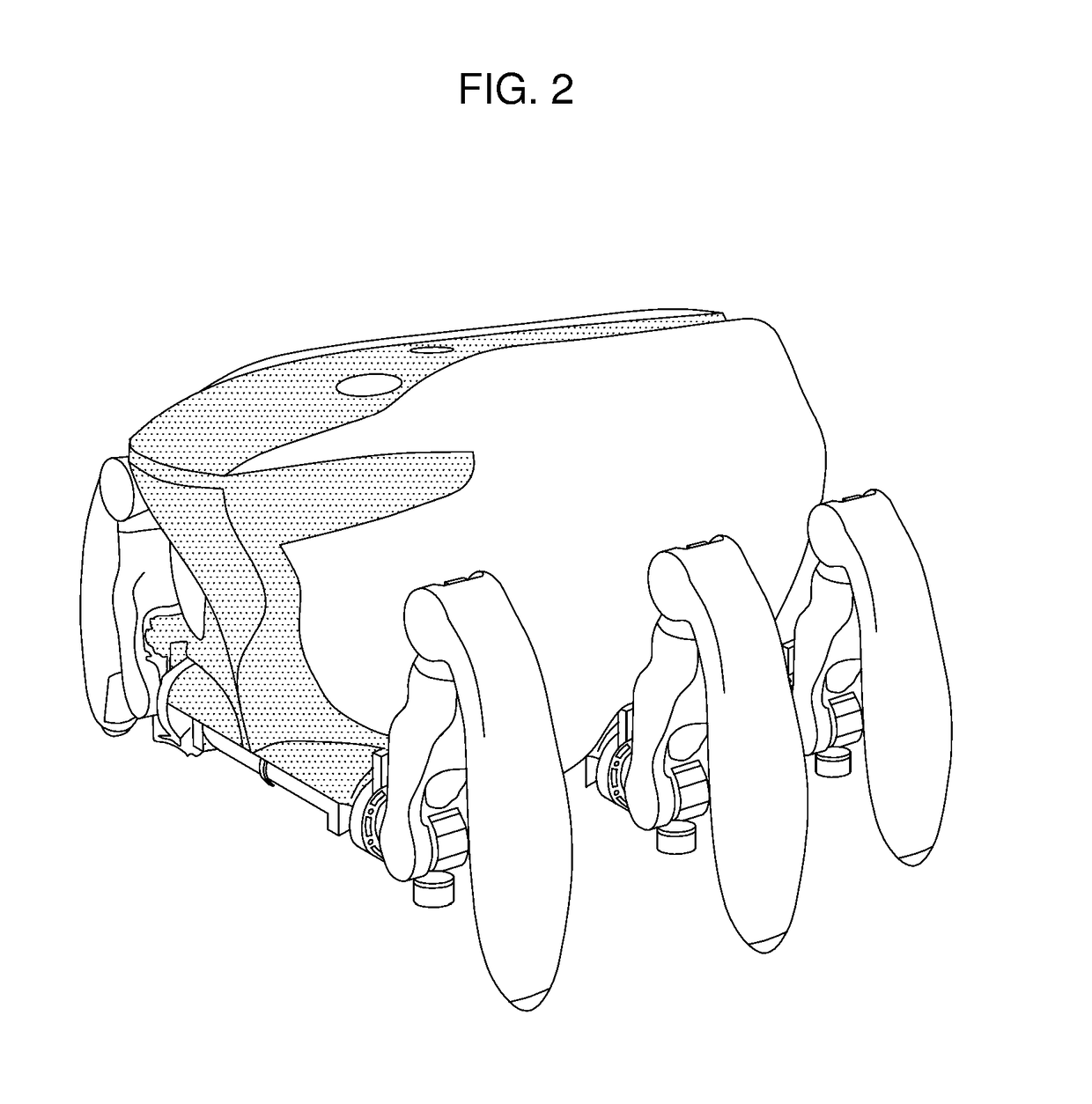

Glass sphere type pressure housing including titanium band and a multi-joint underwater robot system for deep sea exploration using the same

ActiveUS20170355431A1Stable and high-precision underwater operationGuaranteed uptimePropulsive elementsRobotOcean bottomBall type

A deep-sea exploration multi-joint underwater robot system and a spherical glass pressure housing including a titanium band are provided. The system includes a multi-joint underwater robot having a multiple of first and second pressure housings withstanding deep-sea pressure and shielding built-in equipment from seawater and performing close precision seabed exploration obtaining marine research data to transmit underwater status data, a mothership receiving and storing marine research and underwater status data and monitoring and controlling moving directions of multi-joint underwater robot, and a depressor having third pressure housing, linked with mothership by primary cable and multi-joint underwater robot by secondary cable, and preventing transmission of primary cable water resistance to multi-joint underwater robot, wherein first spherical pressure housings are mounted on robot body frame, second cylindrical pressure housings are mounted between left and right legs, and the third cylindrical pressure housing is mounted inside the depressor platform.

Owner:KOREA INST OF OCEAN SCI & TECH

Resin material, composite well repair material and well repair process

The invention discloses a resin material, a composite well repair material and a well repair process. The resin material comprises 20-33 parts by weight of waterborne epoxy resins, 32-53 parts by weight of polyamide and 17-86 parts by weight of water. The composite well repair material comprises 10 parts by weight of hollow glass spheres and 87-89 parts by weight of resin material. The well repair process adopting the composite well repair material has the following beneficial effects: the resisting temperature is 150 DEG C; the resisting pressure is 30MPa; and the modulus of elasticity is lower than 5GPa.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

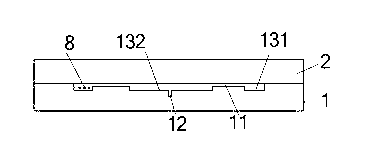

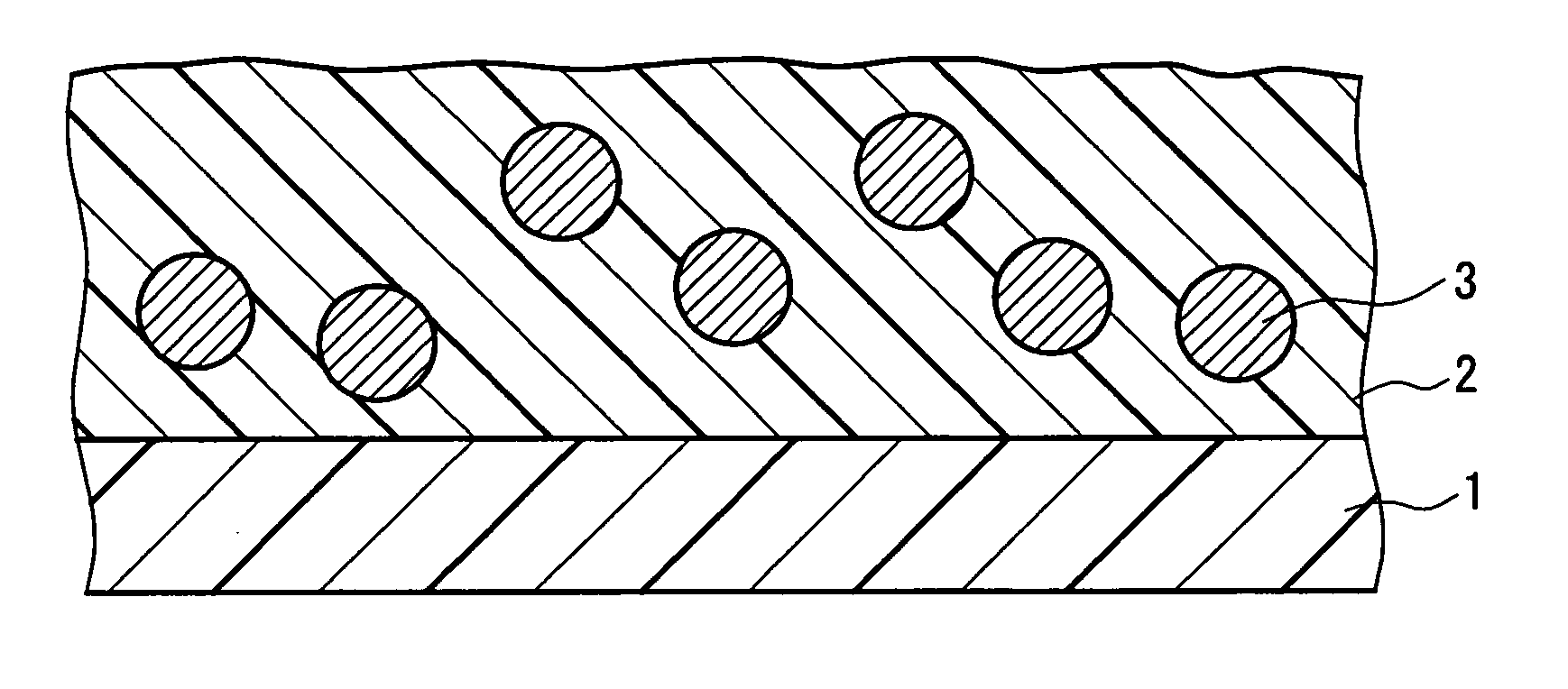

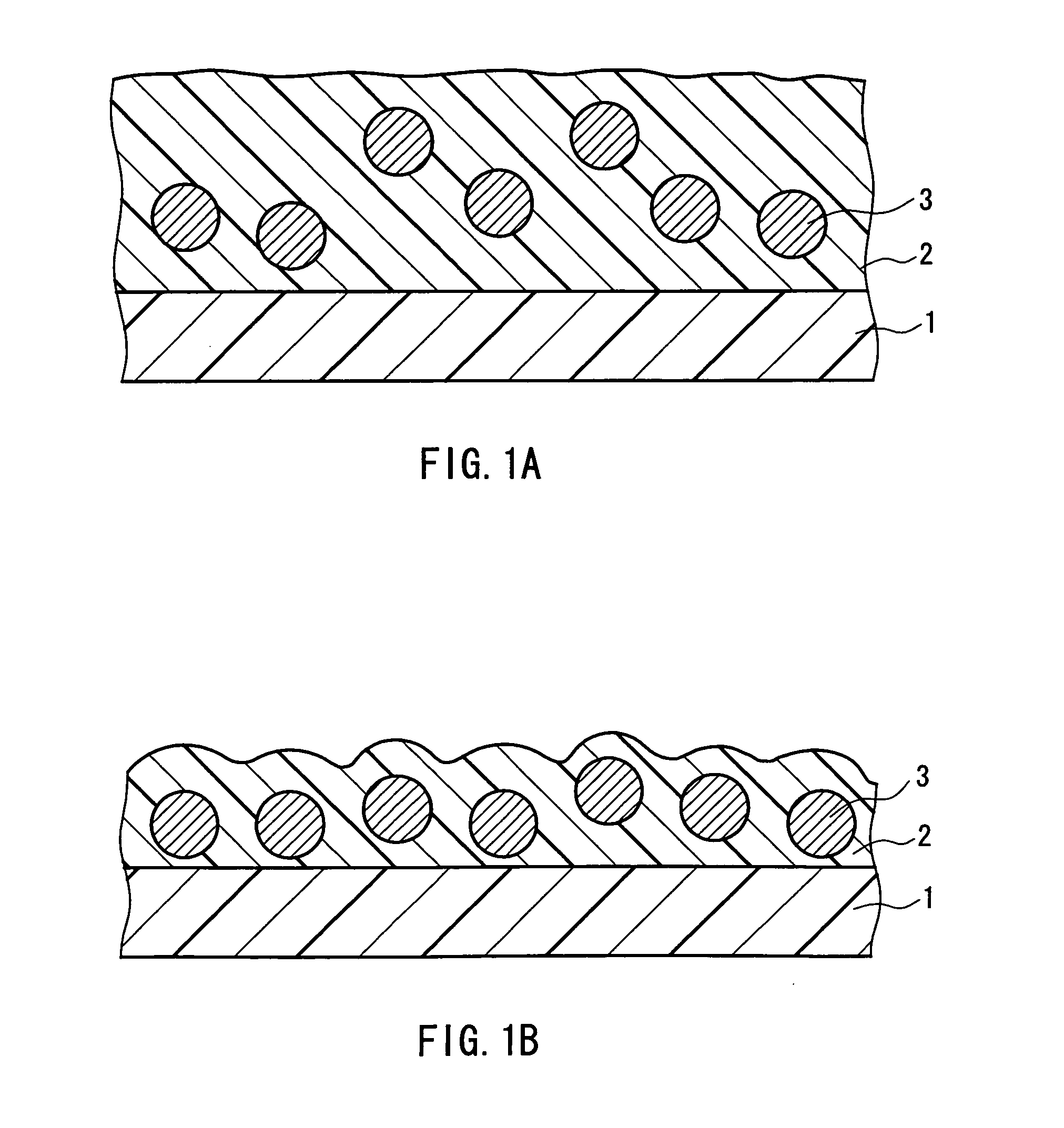

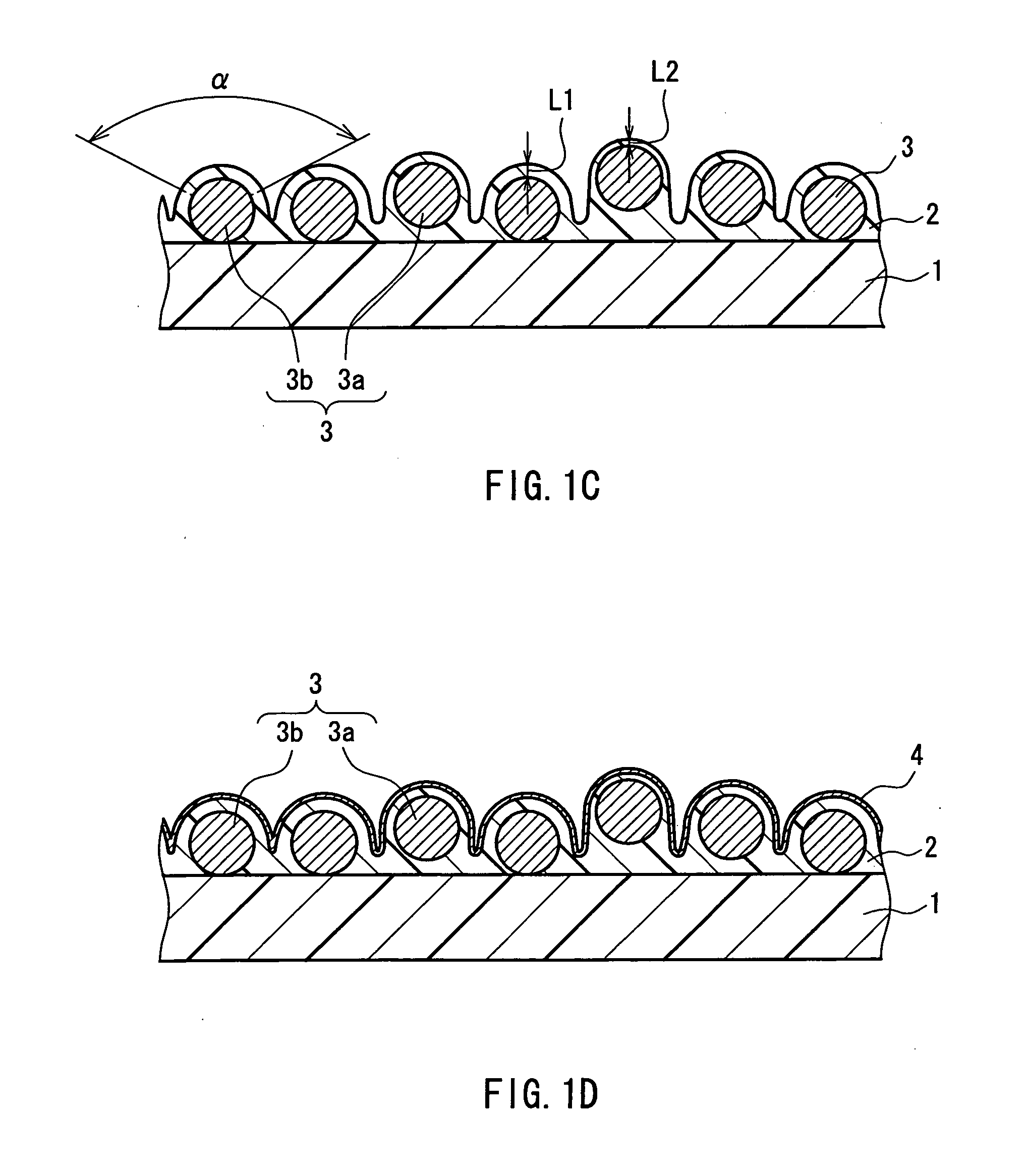

Retroreflection sheet and outer type illumination system

ActiveUS20060256439A1Improve reflective performanceIncrease the angle of incidenceSynthetic resin layered productsReflex reflectorsSurface layerEngineering

The retroreflective sheet of the present invention comprises a surface layer (1) including at least one layer, a focusing layer (2) containing glass spheres (3), and a metal reflective layer (4) on the back side of the focusing layer (2), wherein the glass spheres (3) are disposed at random locations in the thickness direction of the focusing layer (2). The external illumination system of the present invention comprises a sign having a sign face including the above-mentioned retroreflective sheet, and an external illumination source, and the distance from the illumination source to the sign face is within a range of at least 1 m and no more than 100 m. The present invention thereby provides a retroreflective sheet and an external illumination system with which wide-angle reflective performance with a wider incidence angle and observation angle can be ensured.

Owner:KIWA CHEM IND CO LTD

External wall insulation waterproof putty powder and production process thereof

The invention relates to the technical field of putty powder and discloses external wall insulation waterproof putty powder and a production process thereof. The external wall insulation waterproof putty powder is mainly prepared from the following raw materials in parts by weight: 300 to 500kg of white cement, 70 to 90kg of quartz sand, 40 to 60kg of talcum powder, 130 to 145kg of heavy calcium powder stone, 200 to 400kg of hollow glass spheres, 3 to 8kg of early strength agent, 3 to 5kg of hydroxypropyl methyl cellulose, 14 to 18kg of latex powder, 3 to 7kg of wood fiber, 3 to 5kg of polypropylene and 6 to 10kg of water repellent. The external wall insulation putty powder has a function of assisting a heat-insulated coating in insulating heat, has higher whiteness, texture and anti-cracking and anti-osmosis capabilities.

Owner:杭州正博新型建筑材料有限公司

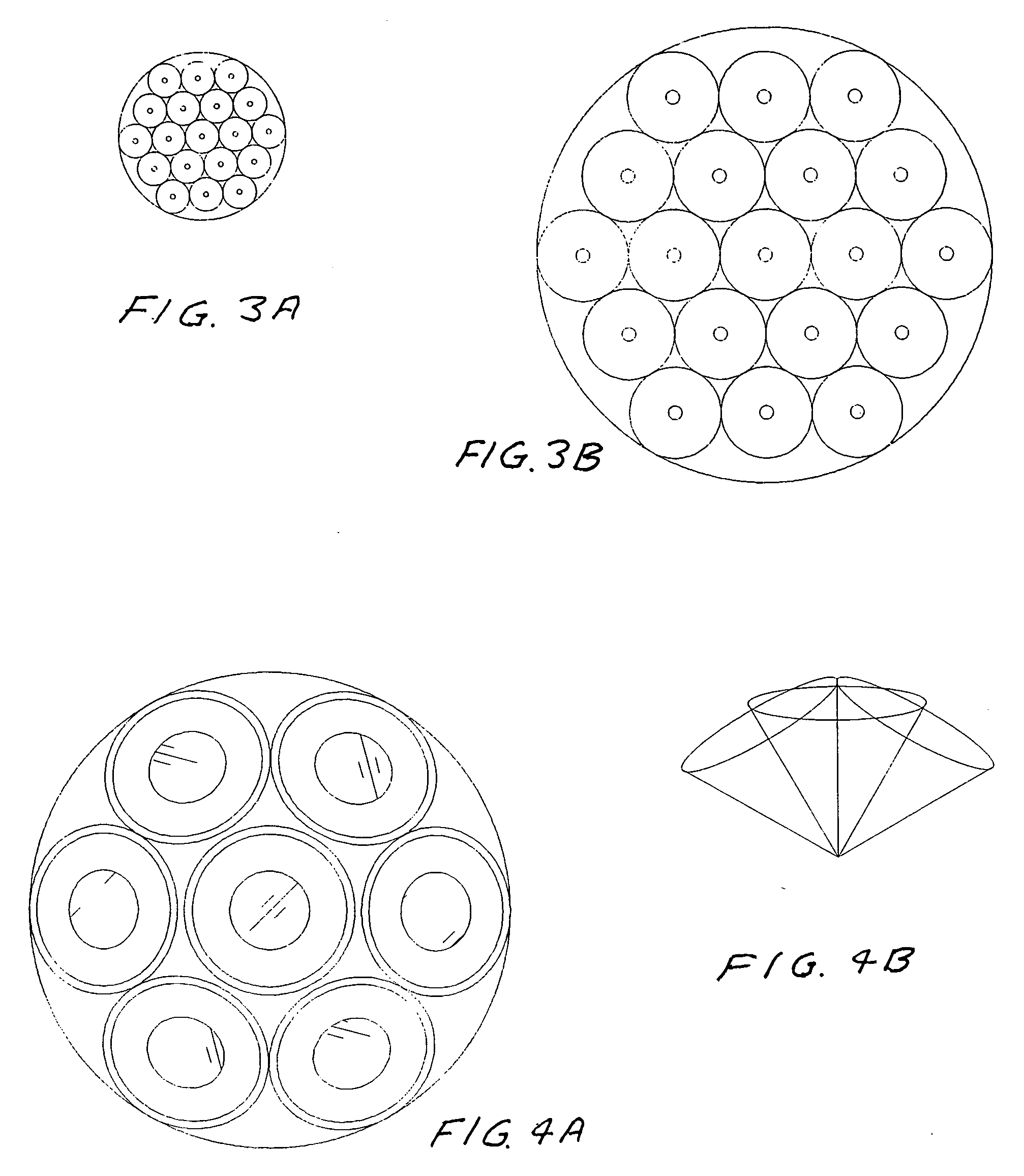

Lens of gradient dielectric constant and methods of production

Disclosed is a lens of gradient dielectric constant and methods for the production of same. The lens includes an inner core comprising a cured or fused substantially homogenous blend of glass spheres, curable or fusible binder and, as needed to increase dielectric constant, a low-loss dielectric material. The inner core preferably has a dielectric constant of about 2.0, and an interstitial void volume (representing trapped air space between elements of the cured or fused material) of from about 30 % to about 50 %. The lens also includes an outer shell layer comprising a cured or fused substantially homogenous blend of hollow glass spheres and curable or fusible resin. The outer shell layer preferably has a dielectric constant of about 1.0, and an interstitial void volume of from about 30 % to about 50 %. In addition, the lens includes a minimum of one, and preferably two or more intermediate layers, the intermediate layers having a dielectric constant falling between 1 and 2. The intermediate layers are comprised of a cured substantially homogenous blend of glass spheres, resin and, as needed to increase dielectric constant, a low-loss dielectric material. As is the case with the inner core and outer shell layers, the intermediate layer(s) have an interstitial void volume of from about 30 % to about 50 %. Also disclosed are methods of production for lenses of the type described above.

Owner:EMERSON & CUMING MICROWAVE PRODS

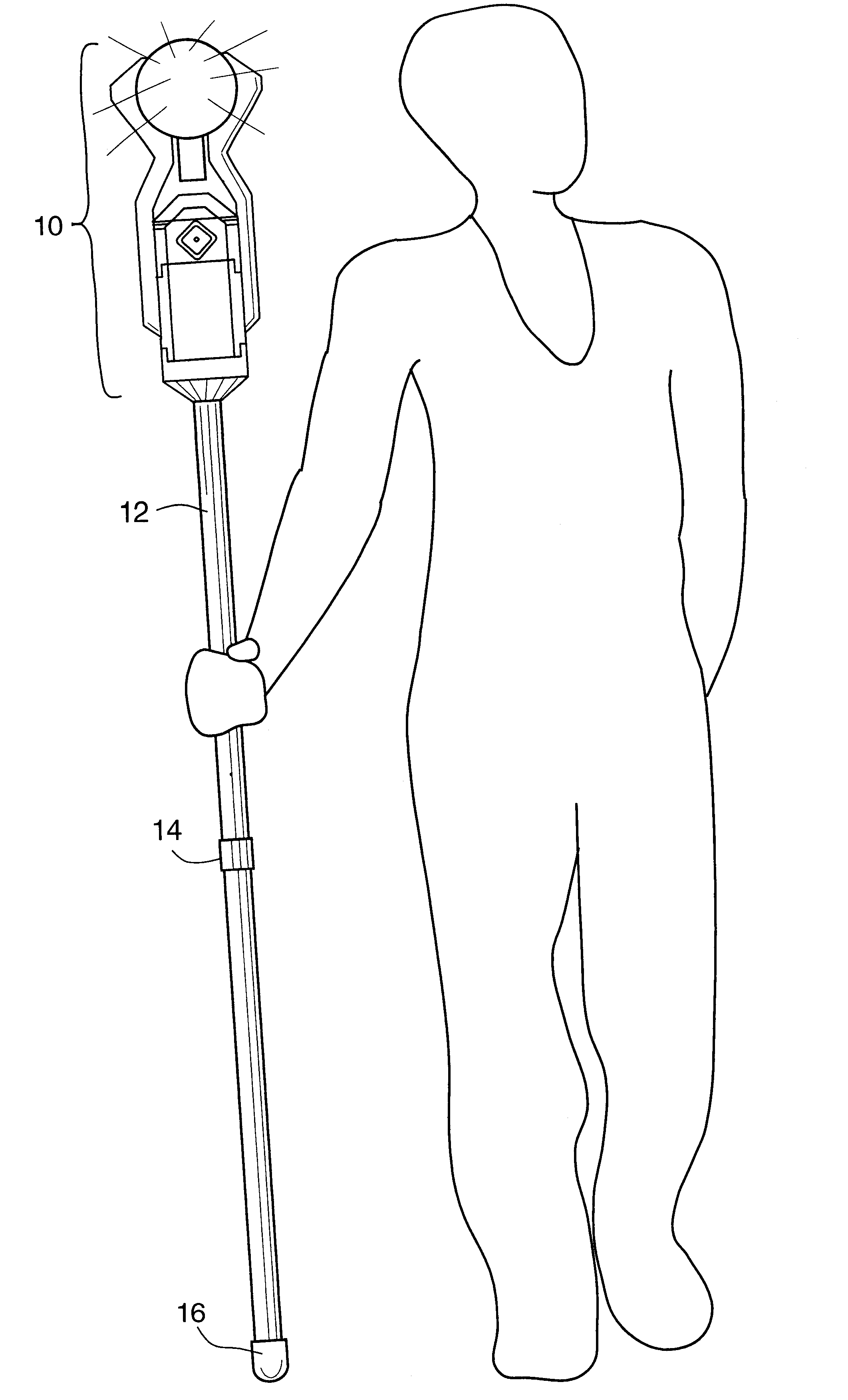

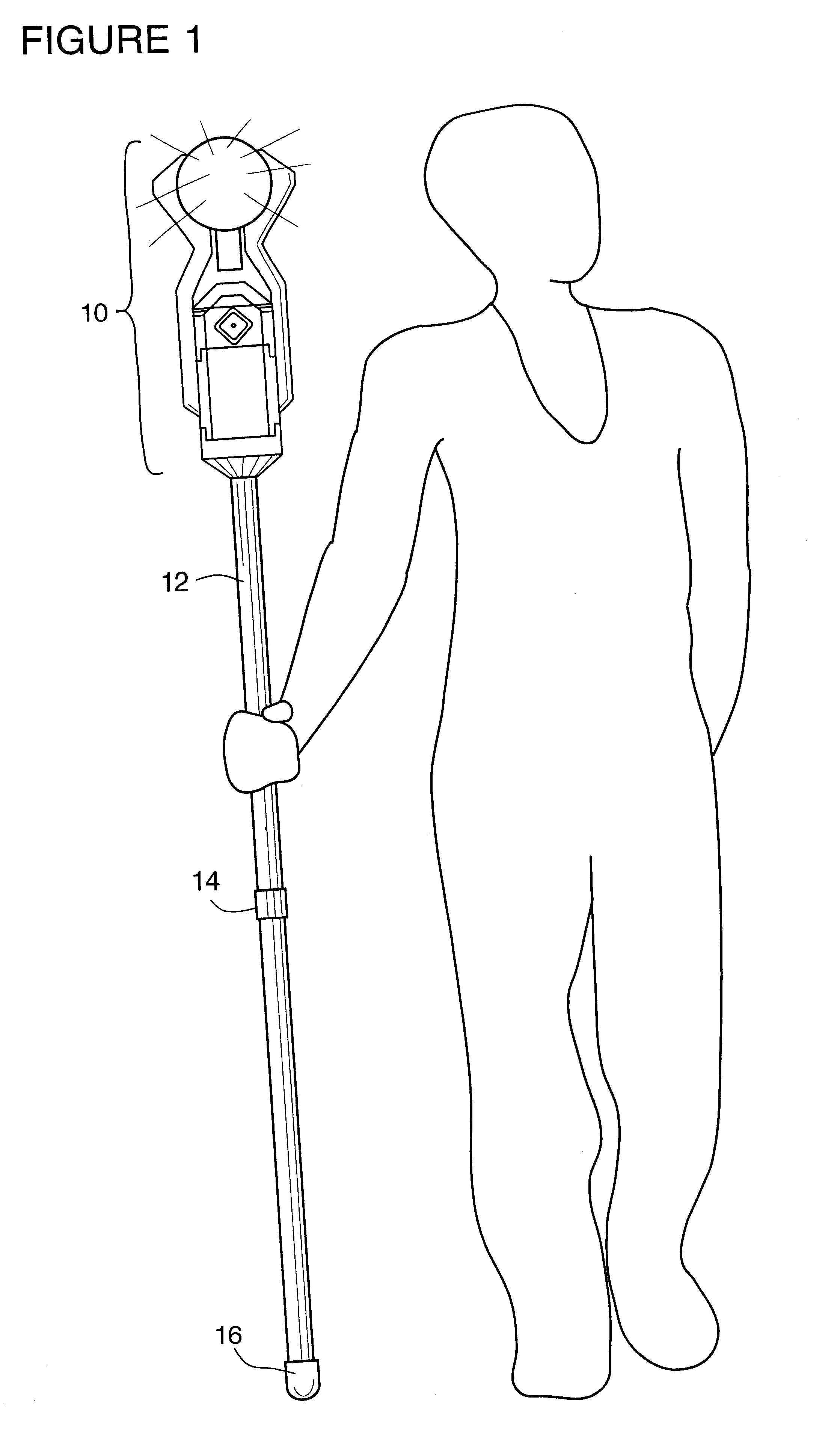

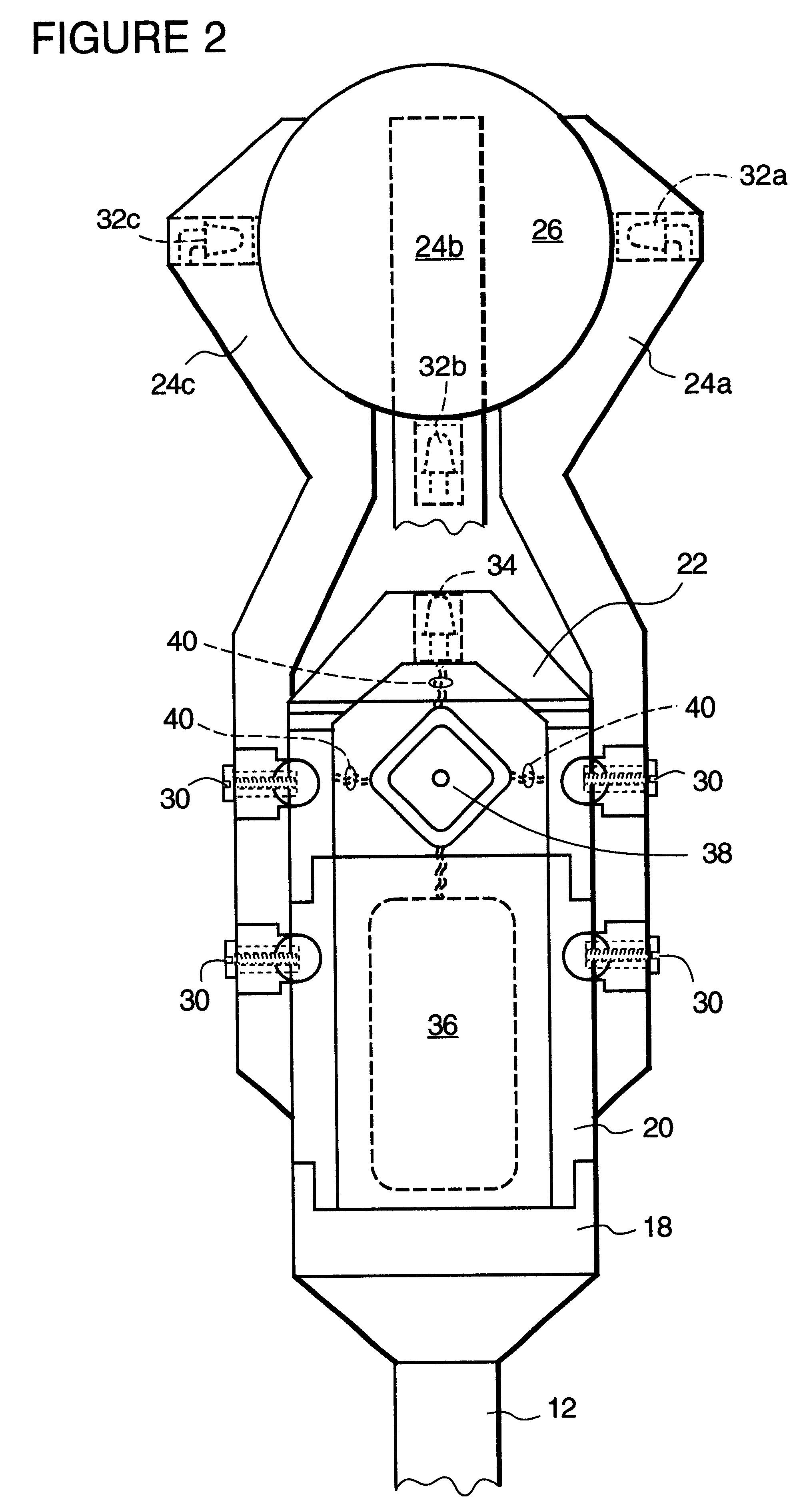

Illuminated walking staff

Owner:CRUZ ALBERT

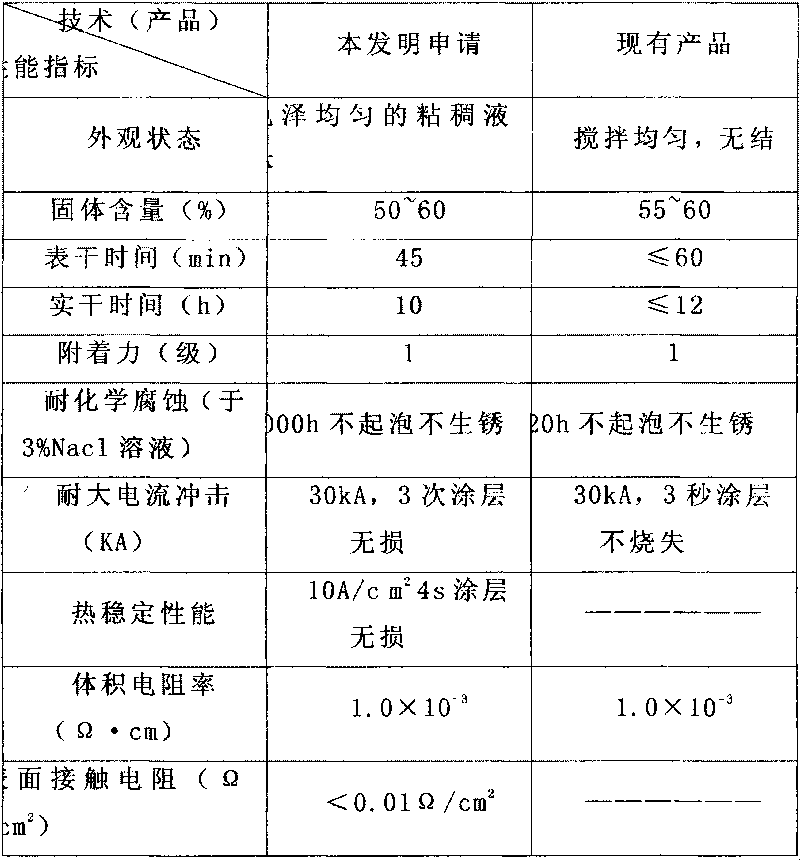

Conductive anti-corrosion coating of electric power grounding grid and preparation method thereof

ActiveCN101717608AExcellent power grounding anti-corrosion performanceGood groundingAnti-corrosive paintsElectrically-conductive paintsCross-linkMicrosphere

The invention provides a conductive anti-corrosion coating of an electric power grounding grid and a preparation method thereof. The raw materials in the preparation method comprise the following components: indoor vulcanized silicone rubber, at least one of dimethylbenzene or petroleum ether used as a thinner, nanometer conductive carbon black, a carbon black dispersant, silver-coated glass spheres, a titanate-based chelate used as a catalyst and methyl trialkoxysilane used as a cross-linking agent. The preparation method comprises the following steps of dispersedly mixing the indoor vulcanized silicone rubber, the thinner and the carbon black dispersant by metering; adding the nanometer conductive carbon black until homogeneous dispersion is achieved; adding the silver-coated glass microspheres until homogeneous dispersion is achieved; and conveying the mixture into a reactor for reaction and naturally cooling in a vacuum state to obtain the conductive anti-corrosion coating. The comprehensive technical performance indexes of the technical scheme are superior to those of the prior art, and the invention has the advantages of short tack-free time, favorable anti-corrosion performance, high thermal stability and low surface contact resistance.

Owner:LIAONING HUALONG ELECTRIC POWER TECH

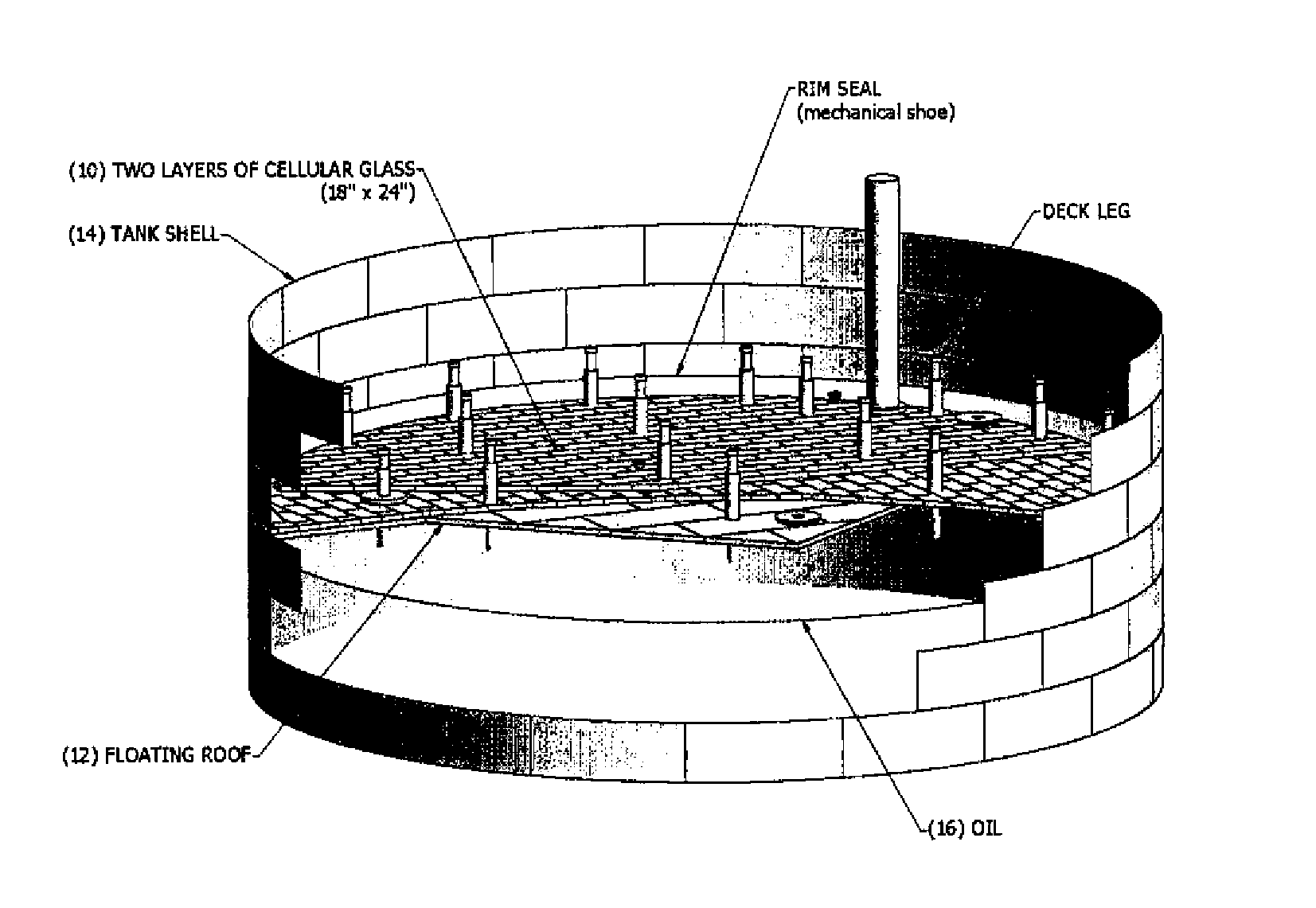

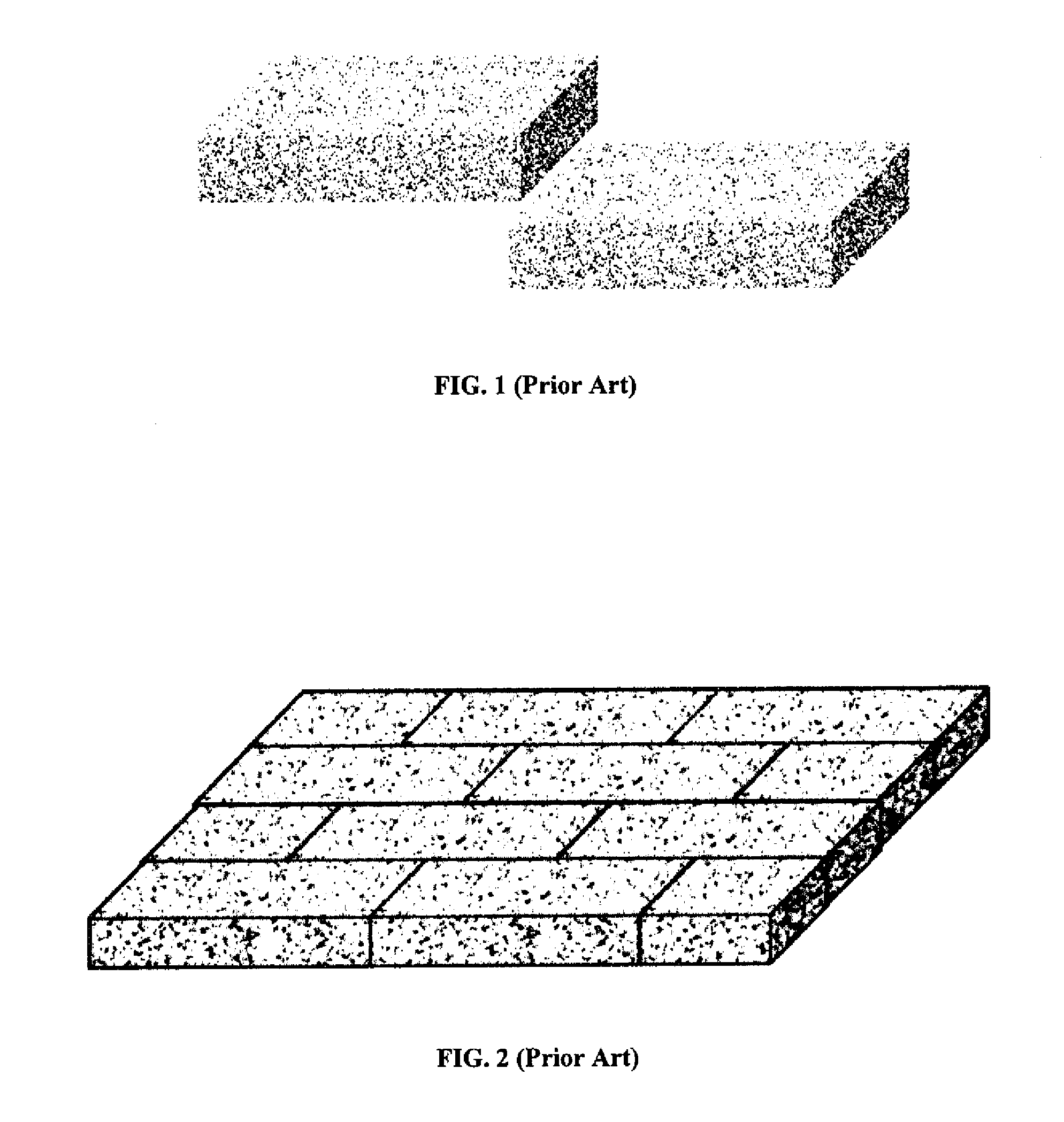

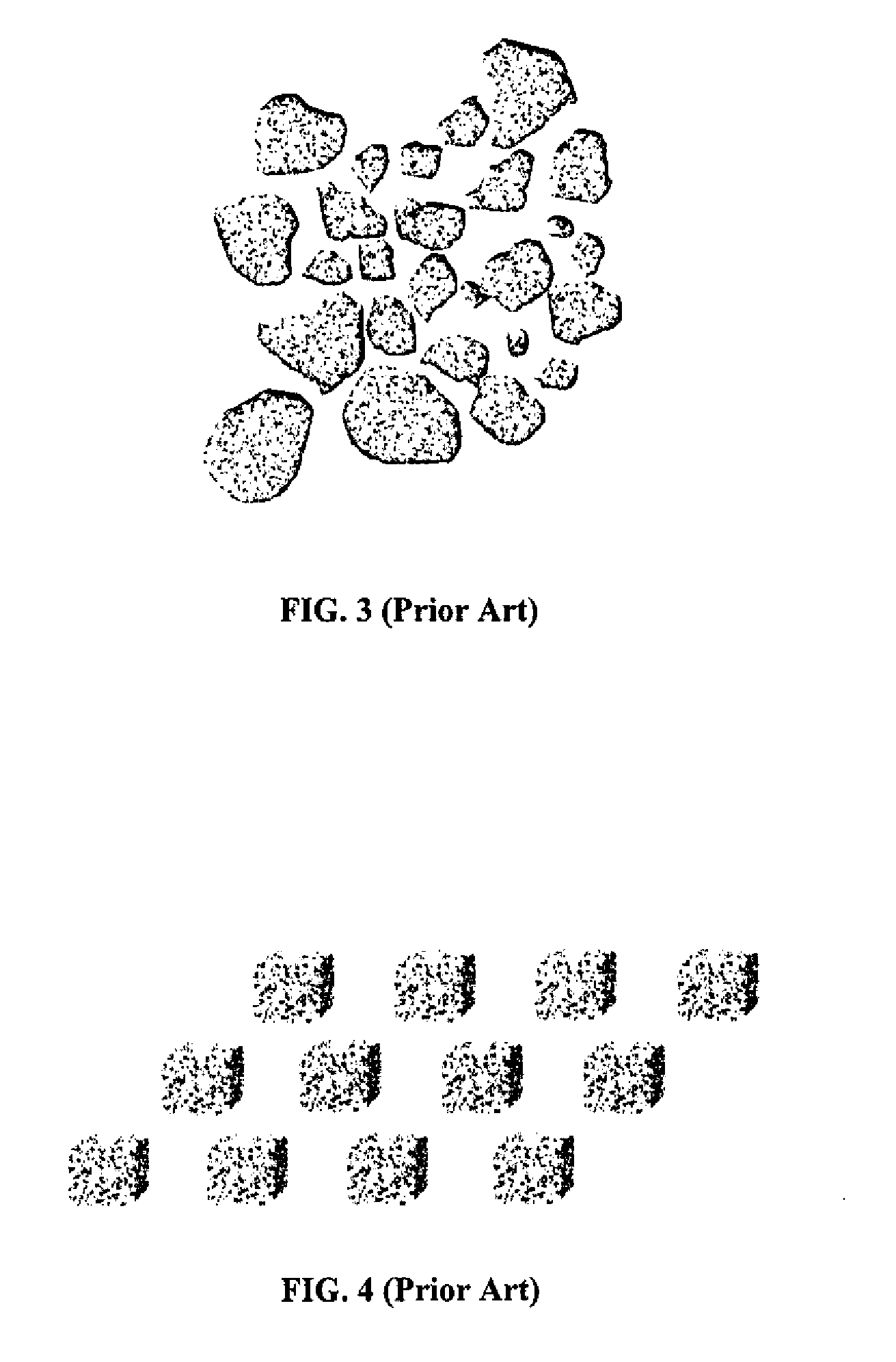

Oil Fire and Boil Over Attenuation Using Buoyant Glass Materials

ActiveUS20120018178A1Limiting thermal radiationReduce boilingFire rescueBoring toolsUltrasound attenuationMarine engineering

A method is described for using cellular glass blocks, cellular glass nodules, hollow glass spheres, or other buoyant glass materials to attenuate oil fire, limit thermal radiation from an oil fire, and reduce the risk of boil-over phenomenon. Cellular glass blocks, cellular glass nodules, hollow glass spheres, or other buoyant glass products may be deployed passively, prior to an ignition event, or actively, as a response to an ignition event to provide control. Cellular glass or other buoyant glass materials may be in any physical shape such as block, sheet, aggregate, or nodule.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Lightweight hollow particles for use in cementing

ActiveUS20160137902A1Retain its shapeEasy to handleDrilling compositionSealing/packingGlass spheresMechanical engineering

A lightweight composite having an activated surface contains a lightweight hollow core particle having cement grains which may be adhered to the hollow core or embedded in the surface of the hollow core. The hollow core particle may be prepared from calcium carbonate and a mixture of clay, such as bentonite, and a glassy inorganic material, such as glass spheres, glass beads, glass bubbles, borosilicate glass and fiberglass.

Owner:BAKER HUGHES HLDG LLC

Wide-angle lens

The invention discloses a wide-angle lens. The wide-angle lens sequentially comprises a first lens, a second lens, a third lens, a diaphragm, a fourth lens, a fifth lens and a sixth lens along an optical axis from an object side to an image surface, wherein the first lens has a negative focal power, the second lens has a negative focal power, the third lens has a positive focal power, the fourth lens has a positive focal power, the fifth lens has a negative focal power, the fourth lens and the fifth lens are combined to form a lens group, the sixth lens has a positive focal power, the first lens and the third lens both are glass spherical lenses, the second lens, the fourth lens, the fifth lens and the sixth lens are all plastic non-spherical lenses, the wide-angle lens conforms to a condition formula of 1.5<TTL / R3<3, TTL expresses optical overall length of the wide-angle lens, and R3 expresses curvature radius of an object side surface of the second lens. The wide-angle lens has the advantages of miniaturization, low cost, large wide angle and the like and can have favorable resolution in an outer extremely-severe environment.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

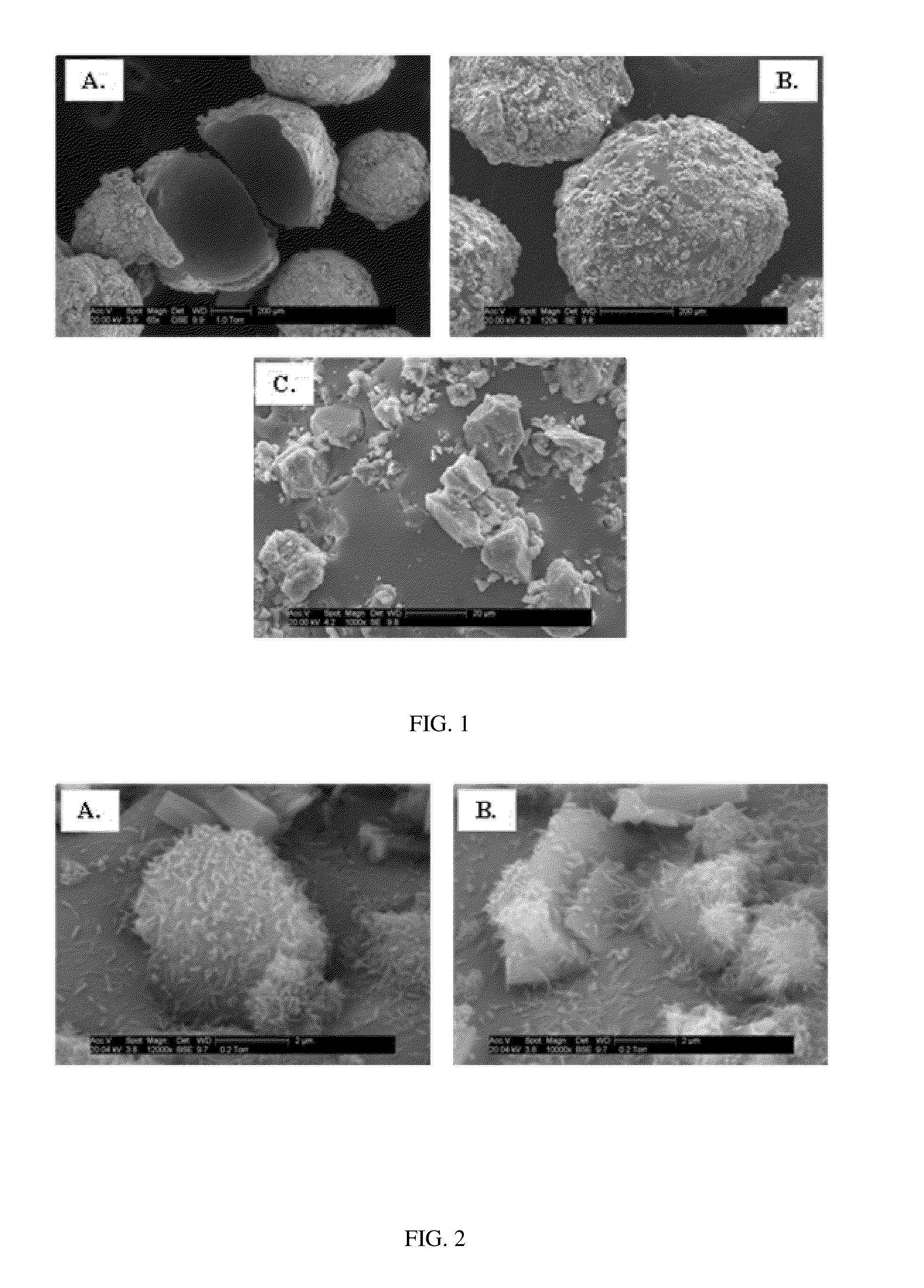

Method for producing hollow glass spheres by using waste glass

InactiveCN104891813AIncrease productivityIncrease temperatureGlass shaping apparatusGlass productionCelluloseSoluble glass

The invention provides a method for producing hollow glass spheres by using waste glass, which comprises the following step: washing waste glass and crushing, adding 3-10% of feldspar, 0-6% of talcum, 1-3% of soda ash, 1-5% of limestone, 1-3% of soluble glass, 1-2% of white copperas zinc sulfate and 1-3% of calcium sulfate according to waste glass weight, performing ball milling on mixed material, adding paste containing starch and cellulose, performing spray drying at 1100-1200 DEG C, heating and spheroidizing to obtain the hollow glass spheres. By using the method of the invention, waste can be changed into valuables, production efficiency of the hollow glass spheres can be increased, and cost is reduced.

Owner:周佐石

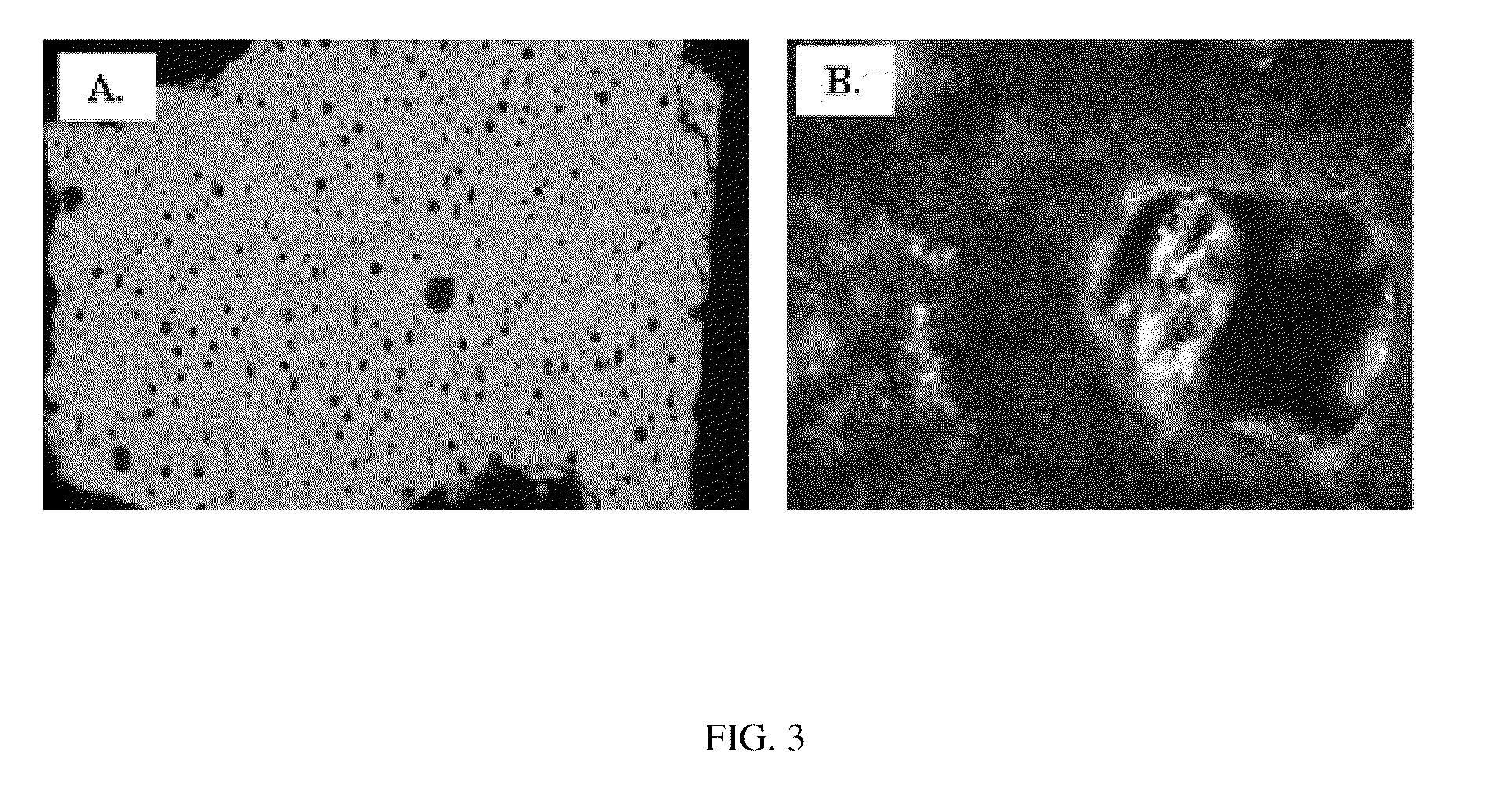

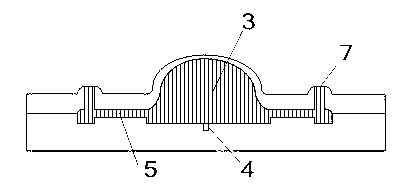

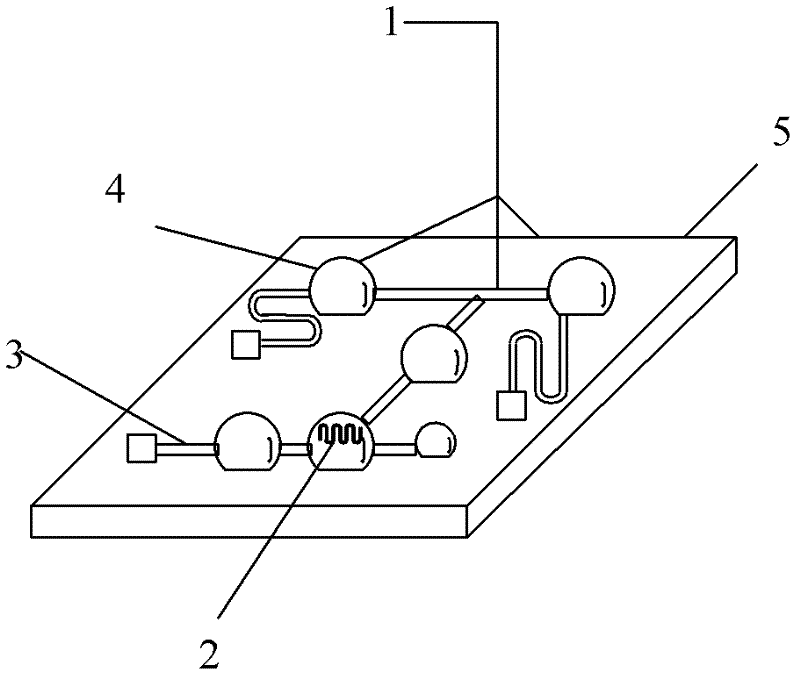

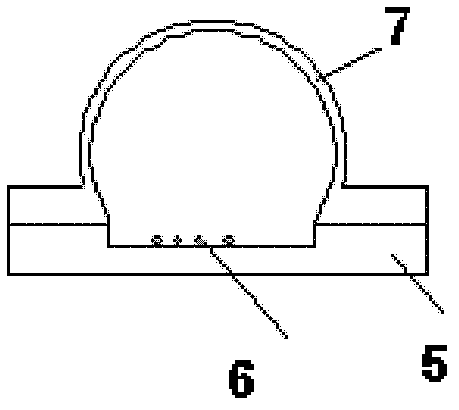

Integrated system on ultrasonic transducer sheet with MEMS (Micro-Electromechanical Systems) glass sphere and preparation method thereof

ActiveCN102430512AHigh forming heightIncrease processing costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringGlass spheres

The invention discloses a preparation method of an experimental system on a micro-runner grid sheet of a focusing ultrasonic transmitter integrated with spherical glass cavity, comprising the steps of: 1, preparing a spherical glass micro-cavity or a cylindrical micro-runner by a thermal forming method; 2, integrating vibration and excitation sources such as a metal strip on the prepared spherical glass micro-cavity or cylindrical micro-runner; 3, placing biological cells or molecules in the experimental system on the glass micro-runner grid integrated sheet with the excitation sources; and 4, treating the biological cells or molecules by the experimental system on the integrated sheet. The invention generates resonance with frequency which is 20kHz-1MHz based on the glass sphere cavity under external electric excitation or electromagnetic excitation. The frequency range of the resonance frequency is ultrasonic range. Cavitation effect generated by ultrasonic wave can be applied to micro-treatment in the field of biology or chemistry, such as cell disruption and DNA interruption and the like.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com