Thermosetting resin composition, prepreg, laminated board and printed circuit board

A resin composition and thermosetting technology, used in the field of dielectric layers for laminates and laminates, can solve the problems of poor interfacial bonding, increased water absorption of composite materials, and few applications, and achieve excellent dielectric constant and improve interfacial bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] As a method for preparing the resin composition of the present disclosure, it can be prepared by known methods such as compounding, stirring, mixing fillers, thermosetting resins, curing agents and curing accelerators, and various additives.

[0062] The present disclosure may also provide a prepreg comprising a reinforcing material and the thermosetting resin composition as described in any one of the above adhering thereon after being impregnated and dried.

[0063] Examples of reinforcing materials may include fiberglass cloth. In the following description, glass fiber cloth reinforcing material and glass fiber cloth can be used interchangeably.

[0064] Specifically, the thermosetting resin composition is formulated into a glue solution by mechanical stirring, emulsification or ball mill dispersion, and then the glue solution is used to impregnate the glass fiber cloth and dried to obtain a prepreg. A laminate can be produced by hot pressing the prepreg and metal f...

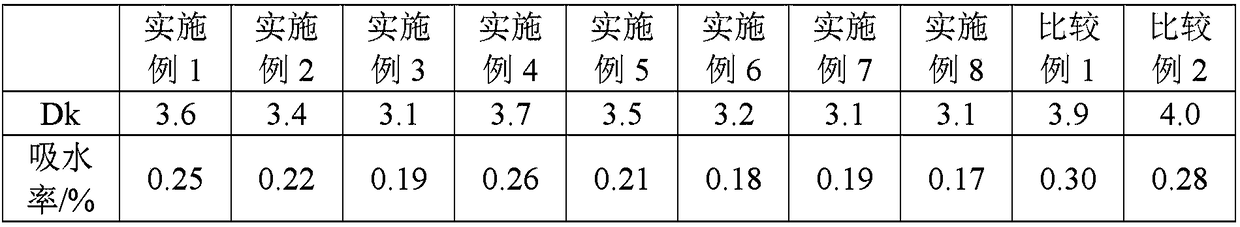

Embodiment

[0083] The technical solutions of the present disclosure will be further described below through specific embodiments. In the following examples and comparative examples, percentages, ratios and the like are by weight unless otherwise specified.

[0084] Each code used in embodiment and comparative example and composition thereof are as follows:

[0085] Thermosetting resin A (polyphenylene ether resin): SABIC (USA), product name MX9000.

[0086] Thermosetting resin B (brominated epoxy resin): Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530.

[0087] o-cresol novolak resin: Kolon (Korea), product name KPH-2004, hydroxyl equivalent 105

[0088] Hollow glass sphere powder: 3M (USA), product name S60 (30 microns), IM16K (20 microns), IM16K (10 microns)

[0089] Reinforcement material (glass fiber cloth): Japan Huber, 7628

[0090] Copper foil: Suzhou Futian, loz

[0091] Median particle size: When the cumulative degree distribution curve based on...

preparation Embodiment 1

[0093] Preparation of hollow glass spheres coated with silica (i.e. hollow glass spheres with a silica coating)

[0094]Add 100 g of hollow glass sphere powder into 400 ml of ethylene glycol, and ultrasonically disperse for 30 min to obtain a suspension. The suspension was added into a three-necked flask, heated to 80°C with a water bath and kept at 80°C. After that, slowly dropwise add 0.1mol / L of Na 2 SiO 3 aqueous solution, and with 1 wt% H 2 SO 4 The pH of the aqueous solution was adjusted to 10.5, and then kept at this temperature for 3 hours. Filter, wash, and dry to obtain hollow glass spheres coated with silica.

[0095] By adjusting 0.1mol / L Na 2 SiO 3 The dripping amount of the aqueous solution is used to control the coating amount.

[0096] Preparation of aluminum oxide-coated hollow glass spheres (i.e., hollow glass spheres with an aluminum oxide coating)

[0097] The method of coating the aluminum oxide of the hollow glass sphere:

[0098] Add 100 g of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com