A kind of green preparation method of sodium chabazite with through stepped pores

A technology of gmelinite and stepped pores, which is applied in the field of green preparation of gmelinite, can solve the problems of template agent structure damage, inability to recycle, cumbersome template removal methods, etc., and achieve the goal of avoiding emissions and realizing recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 0.363g NaAlO 2 Add 0.67g of CK-2 to 0.374g of 50% NaOH aqueous solution, add 2.42g of water and stir until clear, add 2.5g of Ludox-AS 40, and the molar ratio of the feed meets: 10SiO 2 / Al 2 o 3 / 2Na 2 O / 140H 2 O / 0.01CK-2, aged at 25°C for 48h, transferred the gel to a stainless steel reactor with a polytetrafluoroethylene liner and placed it in a homogeneous reactor at 110°C for crystallization for 15d, after the product was centrifuged and washed, Dry at 100°C to obtain a solid sample. Weigh 0.2 g of the above sample and add it to 10 mL of chloroform, stir at 60°C for 4 hours, extract and remove CK-2, centrifuge the obtained product, wash thoroughly with deionized water, and dry in an oven at 110°C.

[0025] The preparation process of CK-2 used in this example is as follows: 1,4-cyclohexanedimethanol (69.4mmol) and ethylene glycol (17.34mmol) were dissolved in 60mL freshly distilled cyclohexane, and added to 100mL strip distilled In the first three-necked flask...

Embodiment 2

[0028] The order of adding raw materials is the same as in Example 1, using sodium metaaluminate and aluminum sulfate as the aluminum source, and tetraethyl orthosilicate as the silicon source, and adjusting the addition amount so that the molar ratio of the feeding material satisfies: 15SiO 2 / Al 2 o 3 / 2Na 2 O / 140H 2 O / 0.01CK-2, aged at 25°C for 96h, transferred the gel to a stainless steel reactor with a polytetrafluoroethylene liner and placed it in a homogeneous reactor at 100°C for crystallization for 20d, after the product was centrifuged and washed, Dry at 100°C to obtain a solid sample. Weigh 0.2 g of the above sample and add it to 10 mL of n-hexane, stir at 50°C for 12 hours, extract and remove CK-2, centrifuge the obtained product, wash thoroughly with deionized water, and dry in an oven at 110°C.

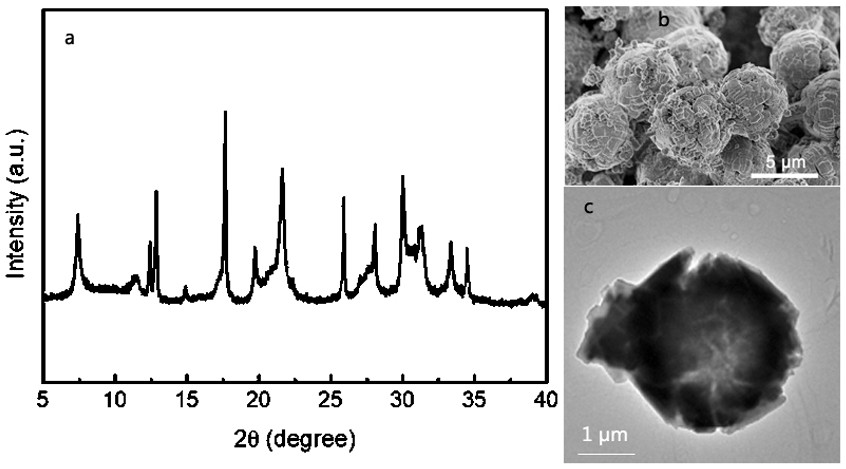

[0029] The phase of the obtained product as determined by XRD belongs to gmelinite, and the specific surface area is 380m 2 / g, the pore volume is 0.22cm 3 / g, the...

Embodiment 3

[0031]The order of adding raw materials is the same as in Example 1, using aluminum sulfate as the aluminum source, silica sol and white carbon black as the silicon source, and adjusting the addition amount so that the molar ratio of the feed is satisfied: 6SiO 2 / Al 2 o 3 / 2Na 2 O / 140H 2 O / 0.01CK-2, aged at 25°C for 60h, transferred the gel to a stainless steel reactor with a polytetrafluoroethylene liner and placed it in a homogeneous reactor at 120°C for crystallization for 10d, after the product was centrifuged and washed, Dry at 100°C to obtain a solid sample. Weigh 0.2 g of the above sample and add it to 10 mL of n-hexane, stir at 80°C for 4 hours, extract and remove CK-2, centrifuge the obtained product, wash thoroughly with deionized water, and dry in an oven at 110°C.

[0032] The phase of the obtained product as determined by XRD belongs to gmelinite, and the specific surface area is 400m 2 / g, the pore volume is 0.18cm 3 / g, the pore size distribution is aroun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com