A method for synthesizing dodecylbenzenesulfonic acid in a circulating microreactor

A technology of dodecylbenzenesulfonic acid and dodecylbenzenesulfonate, which is applied in the field of fine chemical raw material synthesis, can solve the problems of incomplete mixing of dodecylbenzene and sulfonating agent, long aging time of waste acid, and hot spots and other problems, to avoid excessive local concentration, increase the ratio, and prevent by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

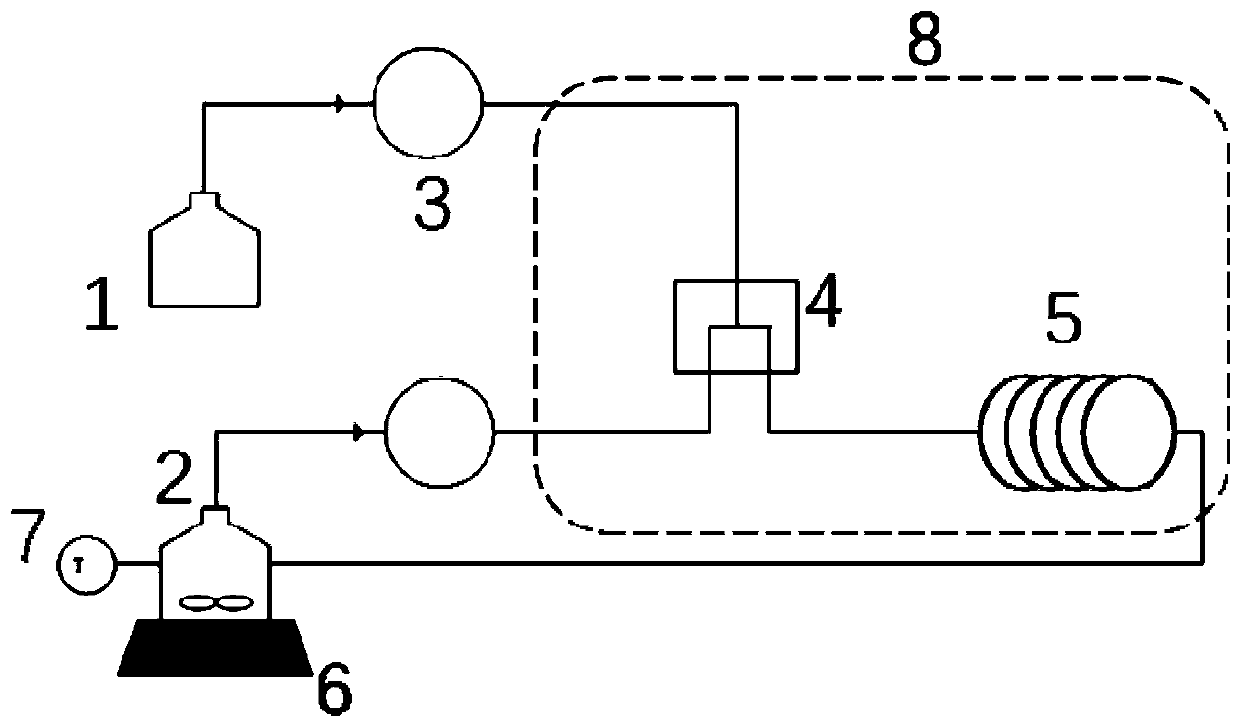

[0035] (1) Evaporate sulfur trioxide from 20% oleum, prepare the material liquid A that mass fraction is about 5wt%, use the acid-base titration method to determine the concentration of the substance of sulfur trioxide to be 1.01mol / L, configure the mole For dodecylbenzene feed solution B with a concentration of 1.0mol / L, the concentration ratio of sulfur trioxide to dodecylbenzene is 1.01:1.

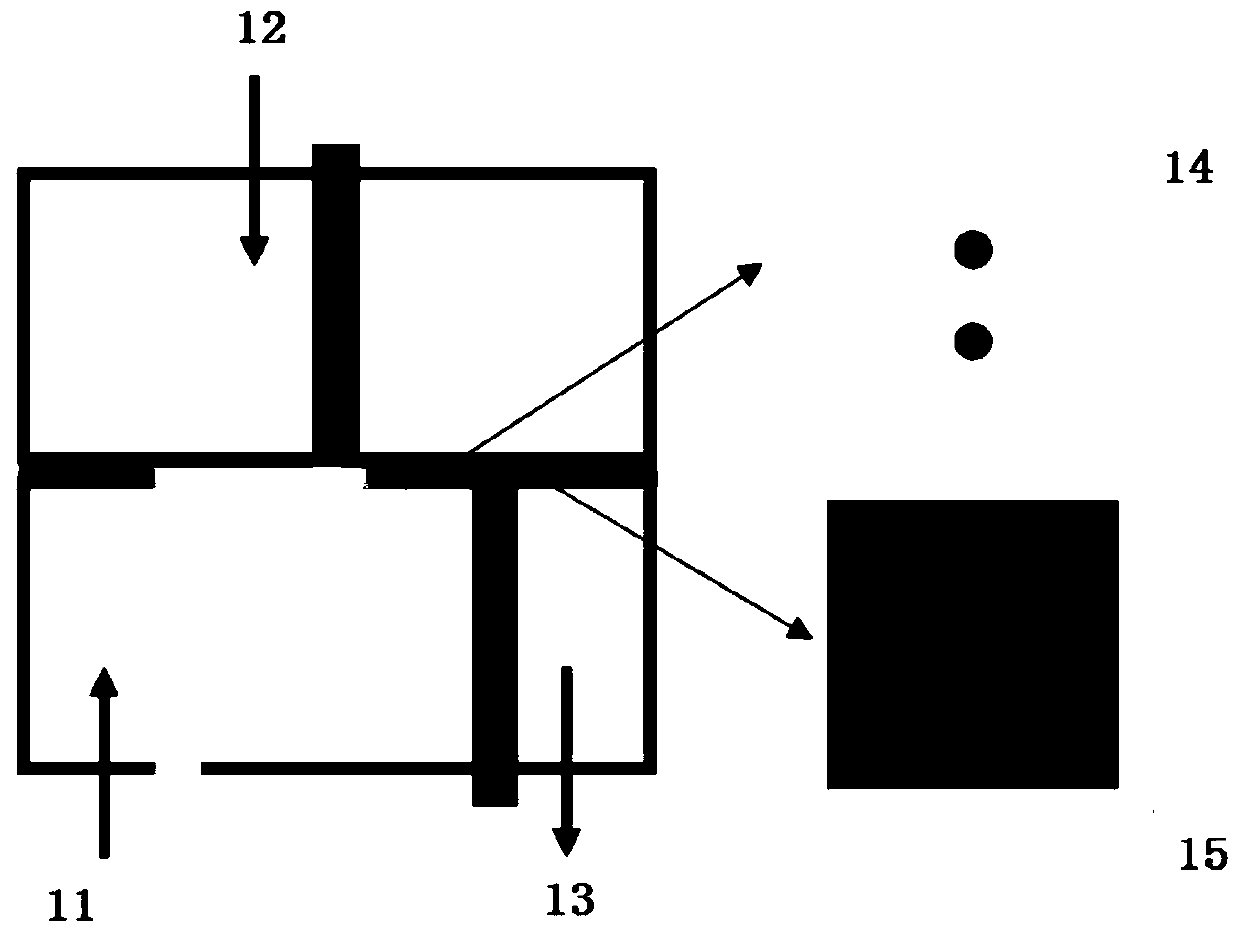

[0036] (2) Maintain the temperature of the water bath and the temperature of the storage tank 2 at a constant temperature of 30°C. Feed liquid A and feed liquid B are passed into the microporous disperser at a feed flow rate of 1ml / min and 10ml / min respectively, wherein A is the dispersed phase and B is the continuous phase. The structure of the microporous dispersing reactor is as follows: figure 2 shown. The reaction coil is a stainless steel tube with a length of 0.1 m and an inner diameter of 2 mm, and the feeding time of the liquid A is 20 min. The yield of dodecylbenzenesulfoni...

Embodiment 2

[0039] (1) evaporate sulfur trioxide from 20% oleum, be mixed with the feed liquid A that mass fraction is about 7.5wt%, use the acid-base titration method to determine the concentration of the substance of sulfur trioxide to be 1.2261mol / L, configure For dodecylbenzene feed solution B with a molar concentration of 1.2140mol / L, the concentration ratio of sulfur trioxide to dodecylbenzene is 1.01:1.

[0040] (2) Maintain the temperature of the water bath at a constant temperature of 50° C., and the storage tank 2 is not heated. Feed liquid A and feed liquid B are passed into the microporous disperser at a feed flow rate of 10ml / min and 50ml / min respectively, wherein A is the dispersed phase and B is the continuous phase. The structure of the microporous disperser is as follows: figure 2 shown. The reaction coil is a polytetrafluoroethylene tube with a length of 1 m and an inner diameter of 2 mm, and the residence time of the mixed solution in the microreactor is 3.14 s. Feed...

Embodiment 3

[0043] 1) Evaporate sulfur trioxide from 20% oleum, prepare feed liquid A with a mass fraction of about 7.5wt%, use acid-base titration to determine the concentration of sulfur trioxide as 1.2261mol / L, configure the molar For dodecylbenzene feed solution B with a concentration of 1.1681mol / L, the concentration ratio of sulfur trioxide to dodecylbenzene is 1.05:1.

[0044] 2) The temperature of the water bath is maintained at a constant temperature of 50°C, and the storage tank 2 is not heated. Feed liquid A and feed liquid B are passed into the microporous disperser at a feed flow rate of 10ml / min and 50ml / min respectively, wherein A is the dispersed phase and B is the continuous phase. The structure of the microporous disperser is as follows: figure 2 shown. The microreactor uses a polytetrafluoroethylene tube with a length of 5 m and an inner diameter of 1 mm, and the feeding time of the liquid A is 10 min. The yield of dodecylbenzenesulfonic acid was determined to be 79....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com