Multi-element alloy foam material and preparation method thereof

A foam material and multi-component alloy technology are applied in the field of multi-component alloy foam materials and their preparation to achieve the effects of improving catalytic activity, simple process and improving overall toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

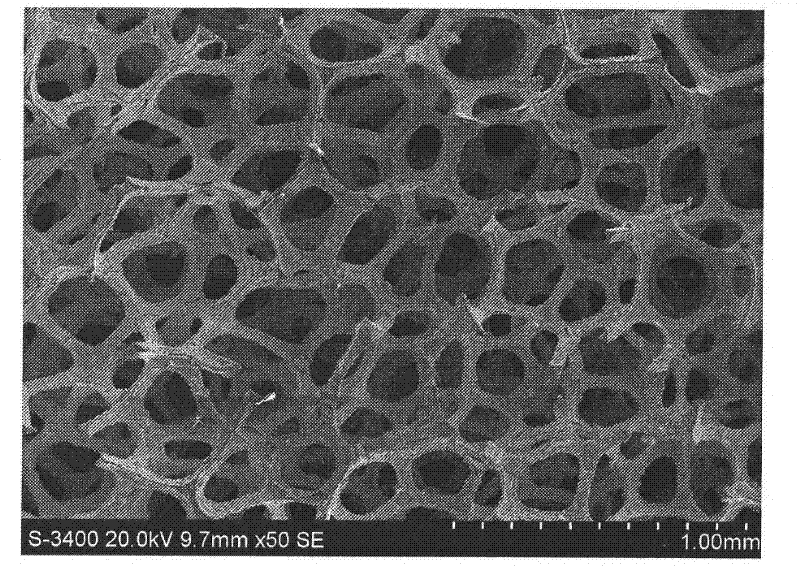

[0033]The preparation method of the multi-component alloy foam material developed by the present invention is mainly an electrodeposition method. As the basic framework for preparing foamed alloy electrodes, foamed plastics are the basis for ensuring the performance of electrodes. The foamed plastics with thickness (0.1-10mm), porosity (85%-99%) and pore diameter (0.1-22mm) were selected, and various roughening processes were studied on this basis. As the precursor foam material, one or a combination of open-cell organic materials such as polyurethane, plastic, polyether, and polystyrene can be selected as the precursor material of the multi-component alloy foam material.

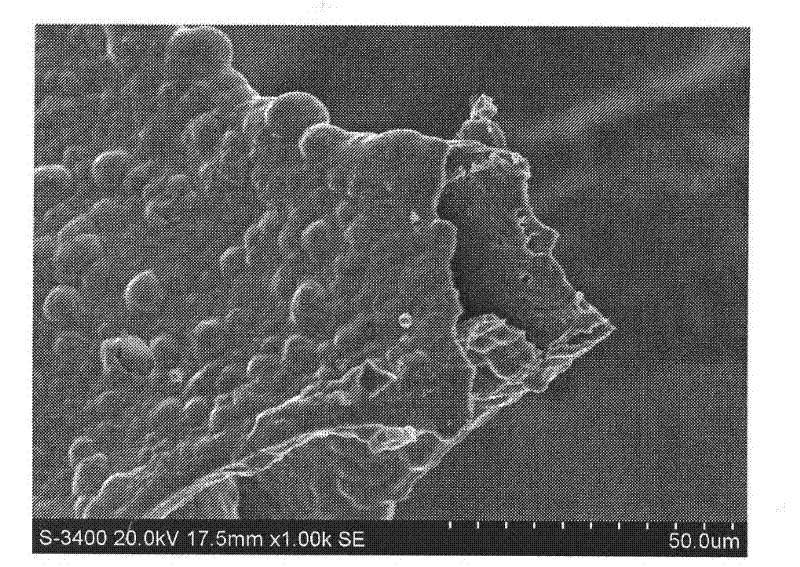

[0034] The organic precursor material itself is not conductive, so a conductive layer needs to be applied. Before preparing the conductive layer, the organic solvent degreasing, chemical degreasing, hot water washing, strong etching, weak etching, ion washing and other processes are carried out. The way o...

Embodiment 1

[0041] (1), precursor selection and processing: select an organic foam material from open-cell organic materials such as polyurethane, plastic, polyether, polystyrene, etc., this embodiment selects a polyurethane foam material, and is cut into 20mm × 20mm × 2mm samples are subjected to pre-treatment processes such as alkali washing and degreasing, acetone degreasing, hot water washing, strong etching and weak etching, and finally washed with deionized water for use;

[0042] (2), surface conductive treatment: the method of conductive treatment can be electroless nickel, chromium, cobalt and other metals, or coating graphite and other conductive particles and vapor deposition, etc., this embodiment selects electroless nickel plating as conductive layer preparation;

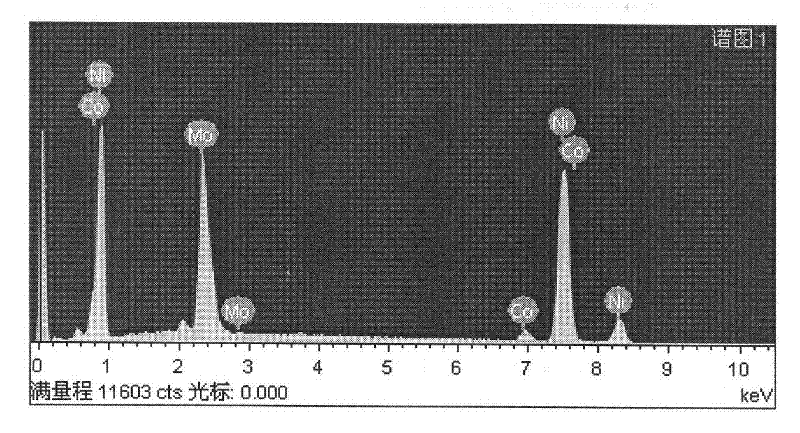

[0043] (3), configure the ternary alloy plating solution: the composition of the plating solution is NiSO 4 ·6H 2 O 40g / L, CoSO 4 ·7H 2 O 2g / L, Na 2 MoO 4 ·2H 2 O 10g / L, Na 3 C 6 H 5 O 7 ·2H 2 O 10g / L, ...

Embodiment 2

[0050] (1), precursor selection and processing: select an organic foam material from open-cell organic materials such as polyurethane, plastic, polyether, polystyrene, etc., this embodiment selects a polyurethane foam material, and is cut into 20mm × 20mm × 2mm samples are subjected to pre-treatment processes such as alkali washing and degreasing, acetone degreasing, hot water washing, strong etching and weak etching, and finally washed with deionized water for use;

[0051] (2), surface conductive treatment: the method of conductive treatment can be electroless nickel, chromium, cobalt and other metals, or coating graphite and other conductive particles and vapor deposition, etc., this embodiment selects electroless nickel plating as conductive layer preparation;

[0052] (3), configure the ternary alloy plating solution: the composition of the plating solution is NiSO 4 ·6H 2 O 40g / L, CoSO 4 ·7H 2 O 2g / L, Na 2 WO 4 ·2H 2 O 8g / L, Na 3 C 6 H 5 O 7 ·2H 2 O 10g / L, Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com