Patents

Literature

196results about "Nitrous acid preparation ester preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

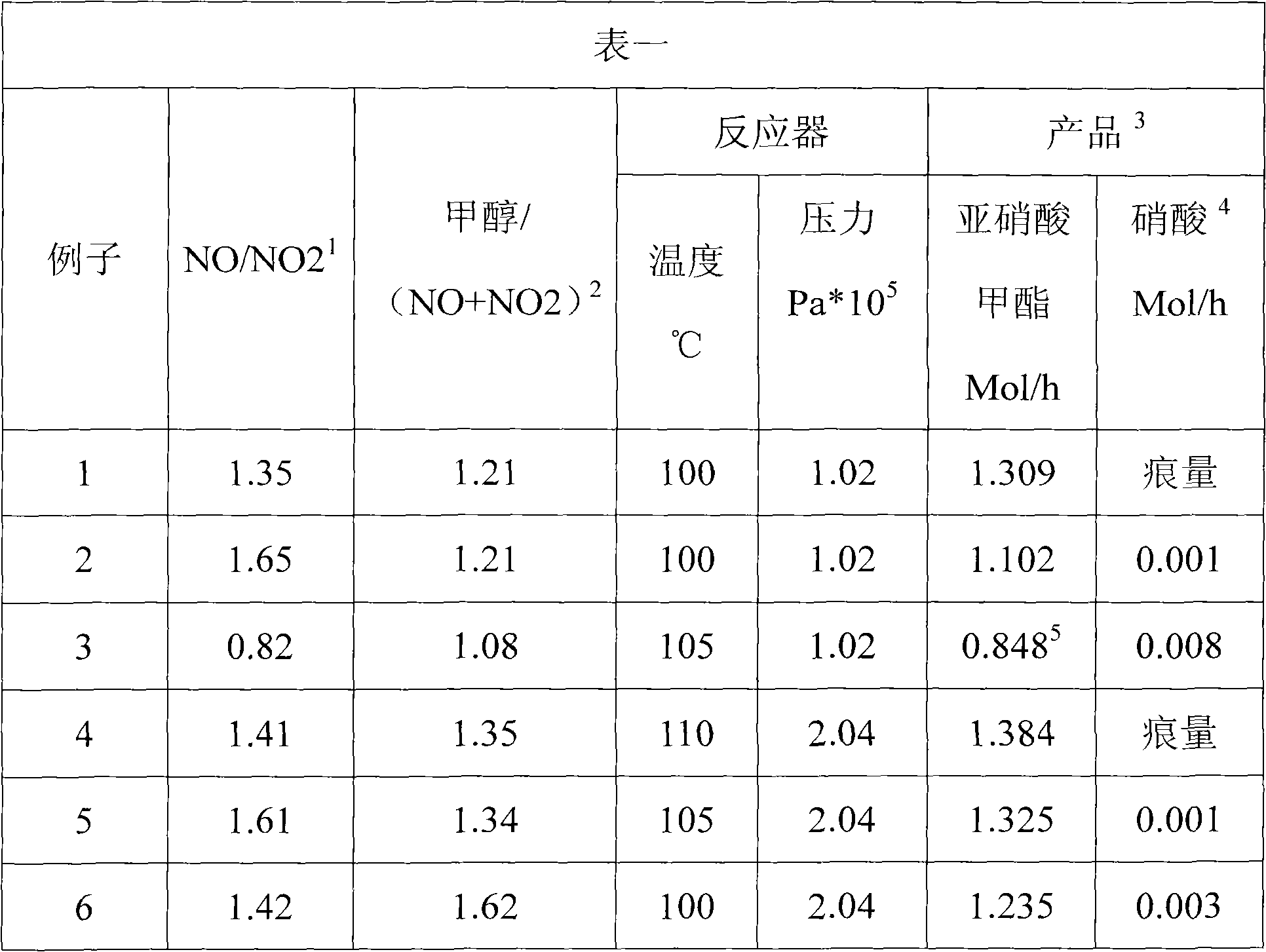

Process for the preparation of C1-C4-alkyl nitrites

ActiveCN101096340AAvoid it happening againReasonable useNitrous acid preparation ester preparationNitrogen oxidesPhysical chemistry

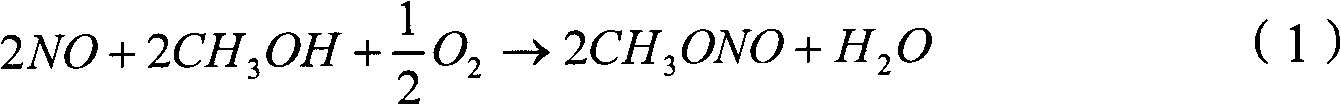

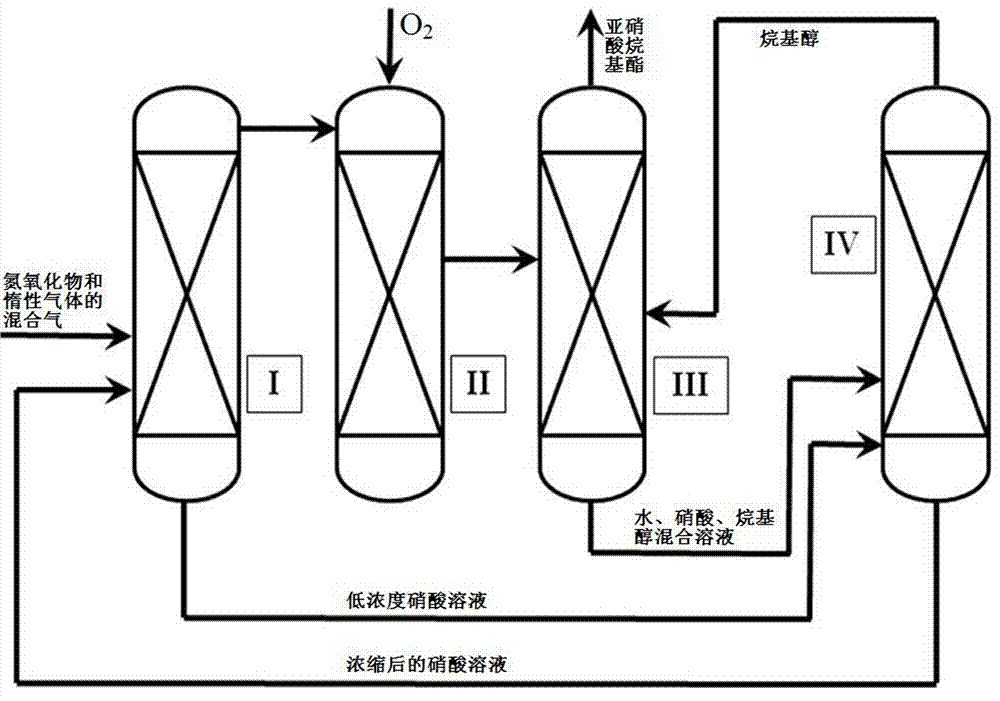

The invention discloses a making method of C1-C4 alkyl ester of nitrous acid, which comprises the following steps: doing the oxidizing reaction and esterifying reaction in two reactors separately; doing the oxidizing reaction in the oxidizing reactor; doing the esterifying reaction in the esterifying tower reactor; inputting nitrogen oxide, oxygen and one or more of inert gas into oxidizing reactor; selecting the nitrogen oxide from one or more composite gas of NO, N2O3, NO2 and N2O4 with NO constantly; making the mole of NO more than the mole of NO2; using 0.15-0.3 m oxygen for each NO m; making the bulk of inert gas at 0-90% corresponding to total gas; inputting the oxidizing reacting product into the esterifying tower reactor to react with C1-C4 alkanol; using 0.8-3.0 m alkanol for each gram atom nitrogen. The invention can transfer heat effectively to reduce by-product, which is smaller than traditional equipment.

Owner:SHANGHAI HUAYI ENERGY CHEM

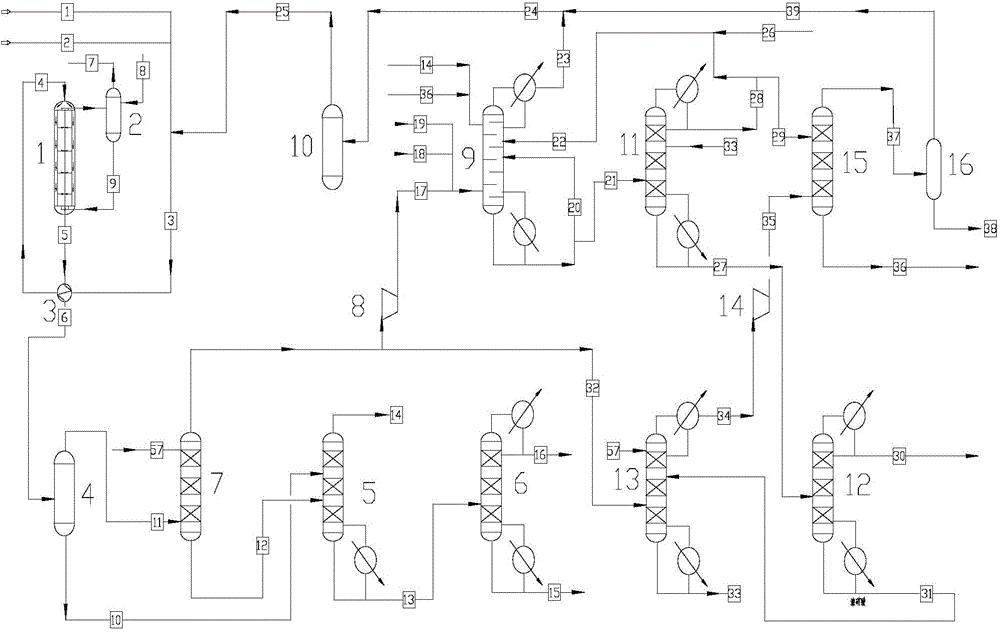

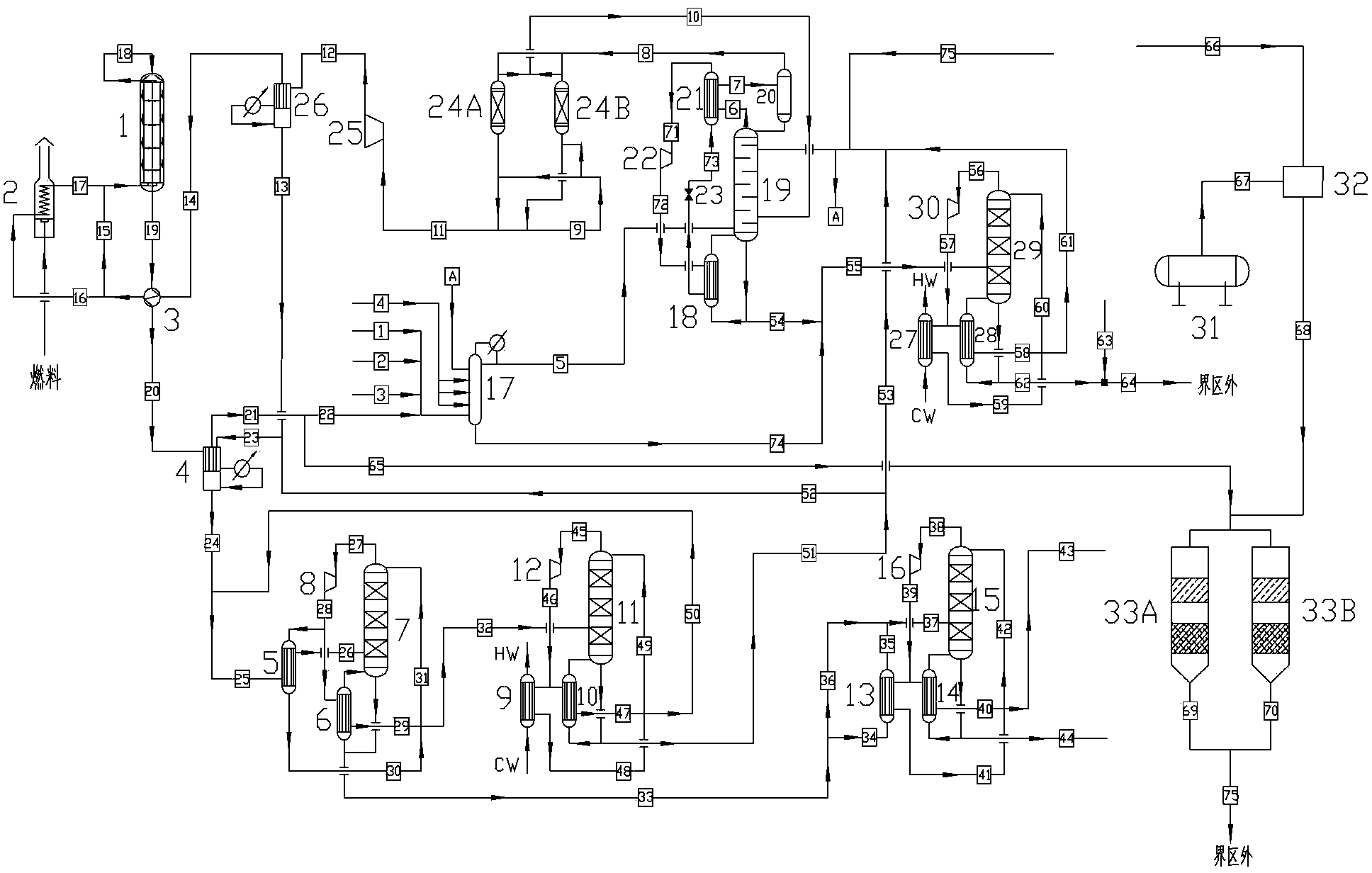

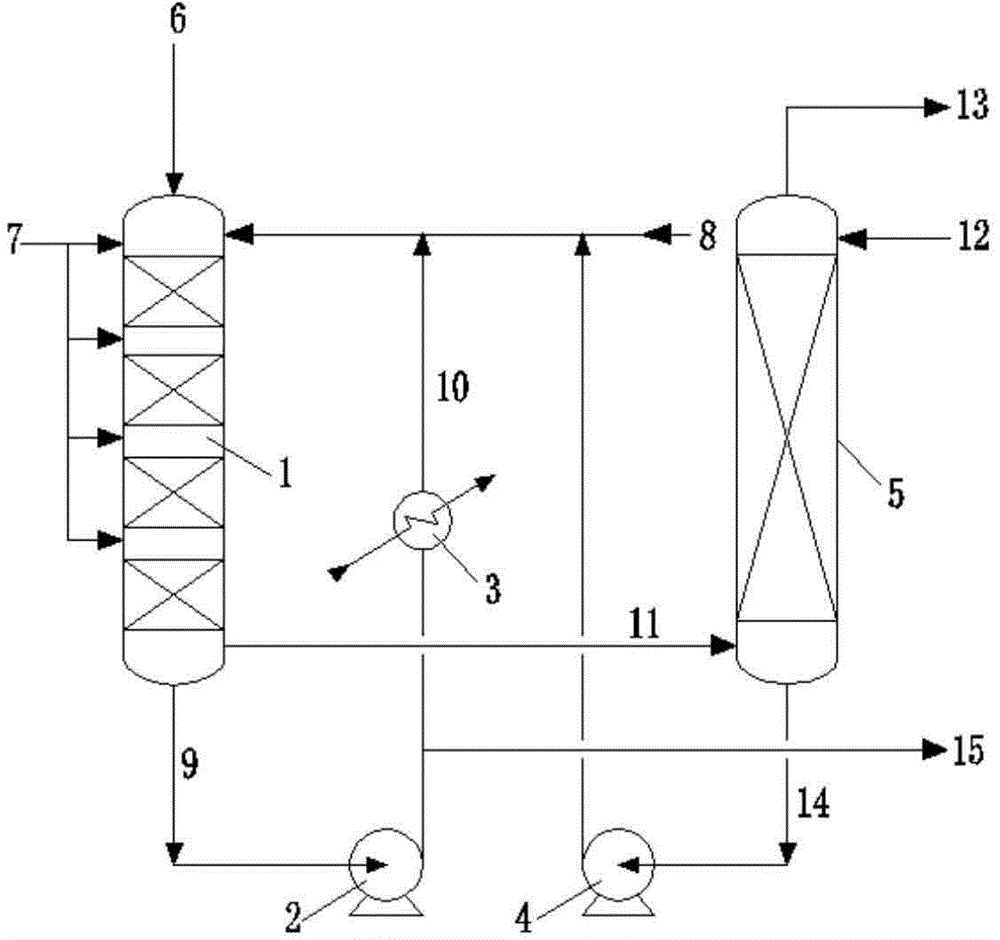

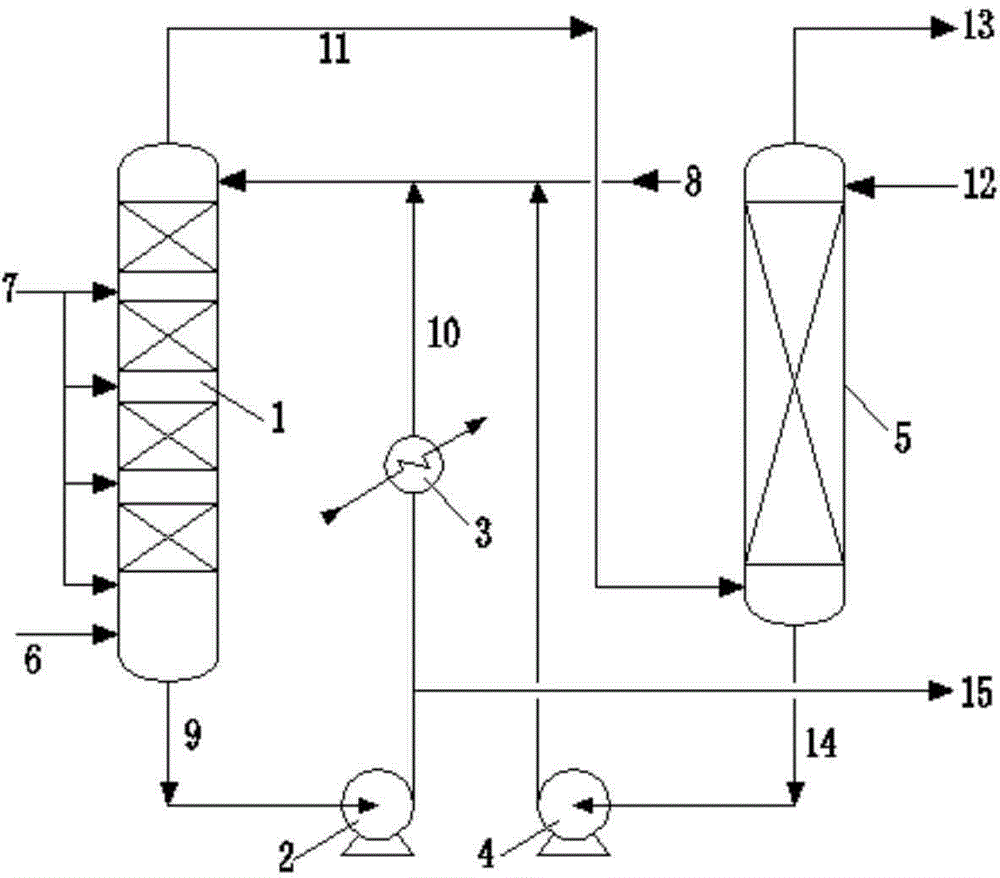

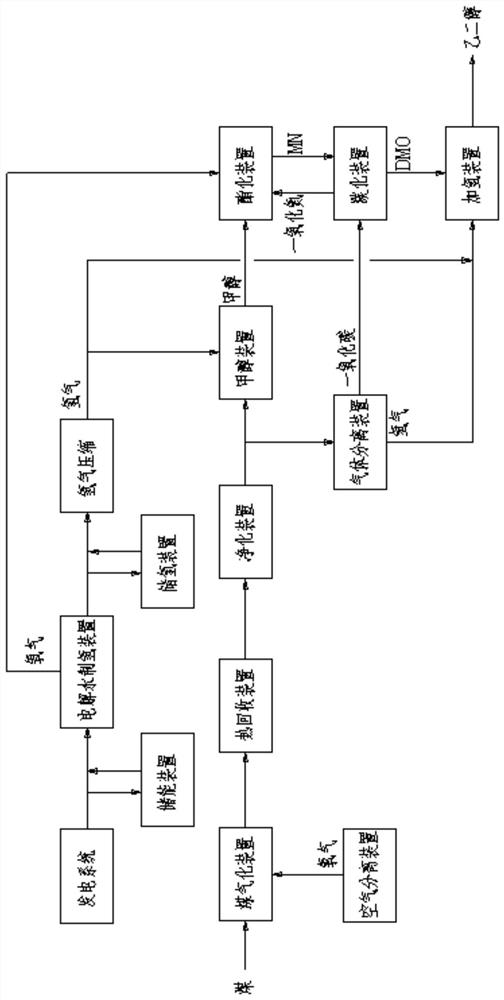

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

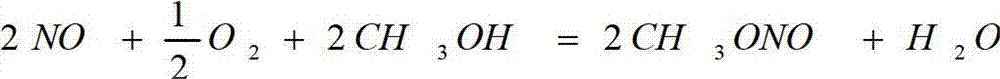

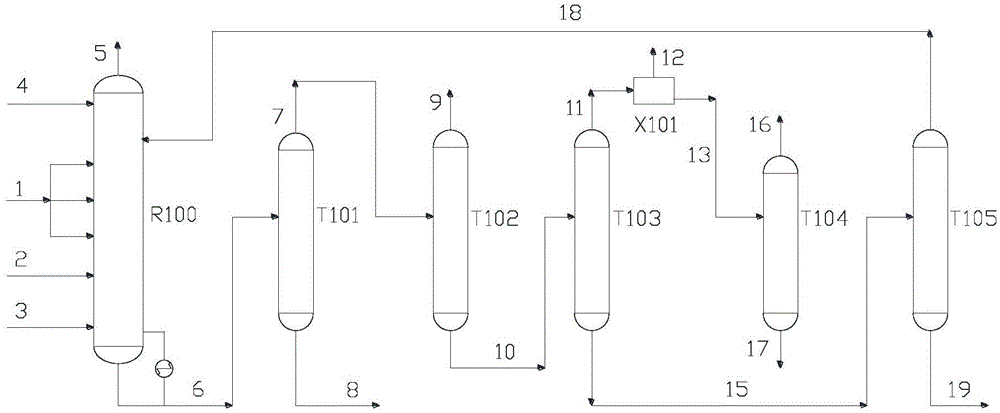

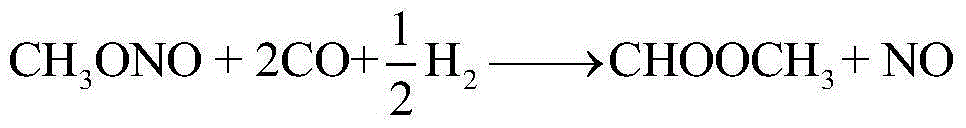

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

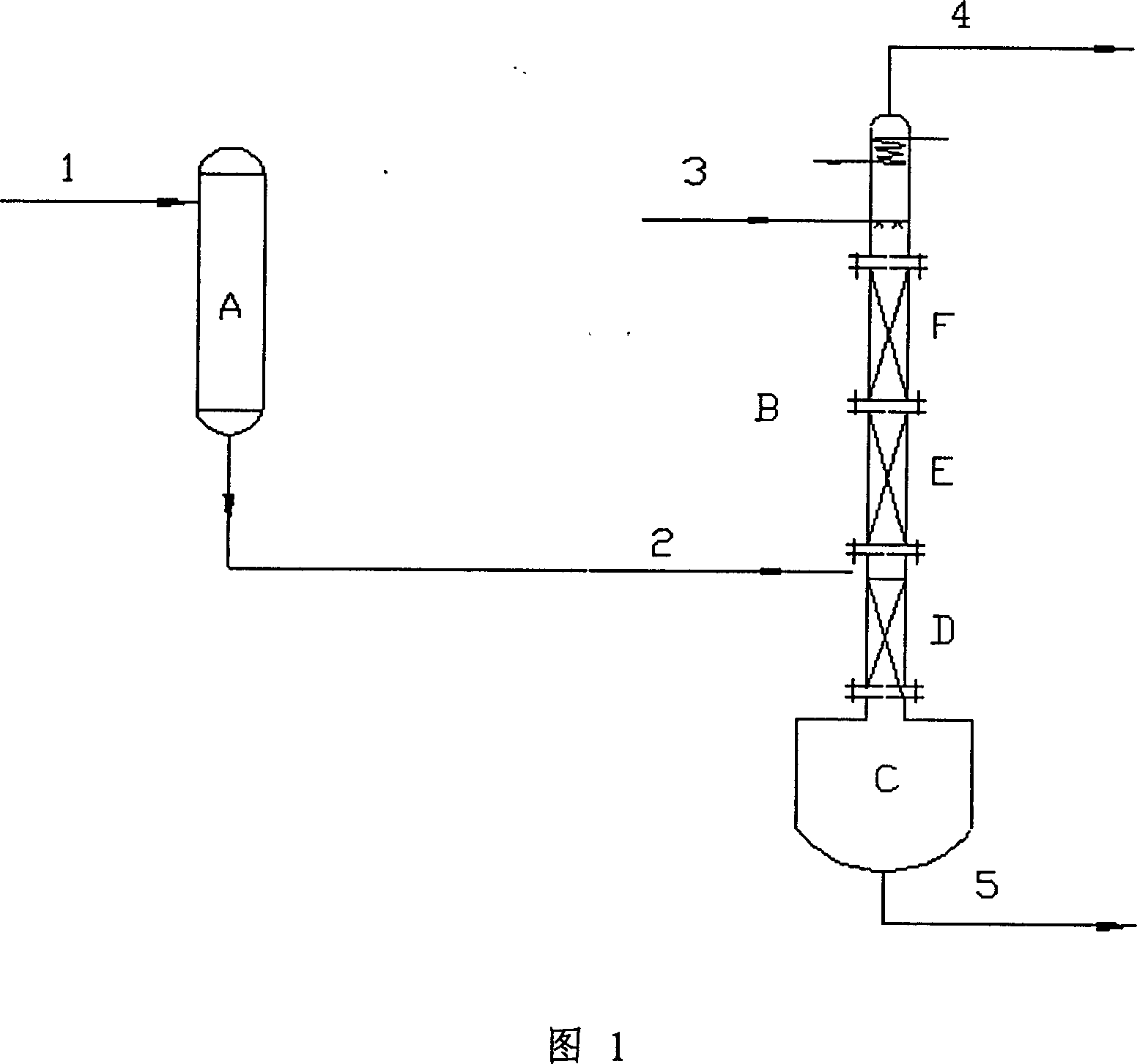

Reaction system and preparation method for nitrous alkyl ester

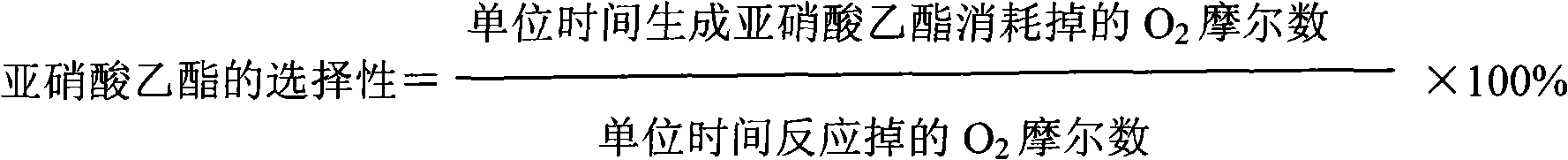

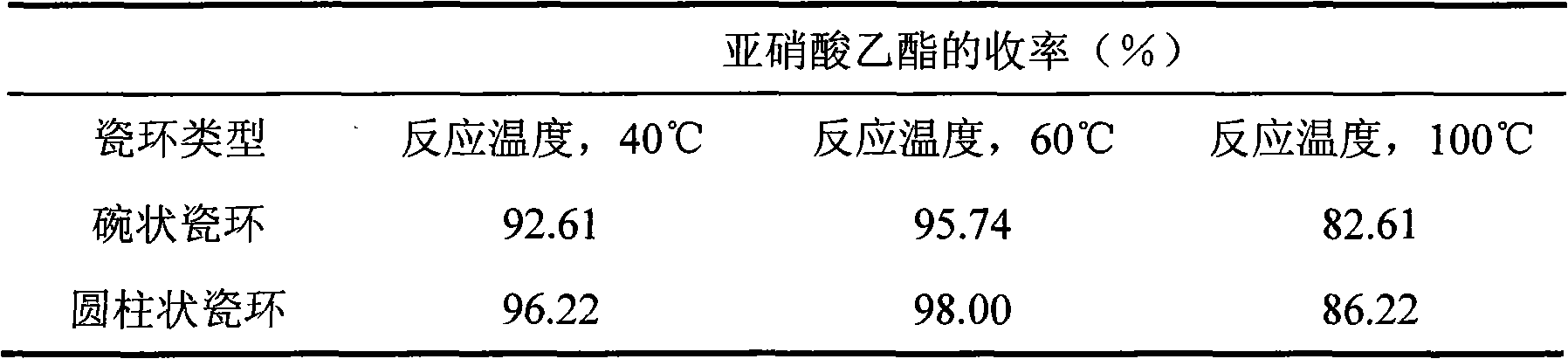

InactiveCN101314569AHigh yieldImprove efficiencyLiquid-gas reaction processesNitrous acid preparation ester preparationRetention timeGas phase

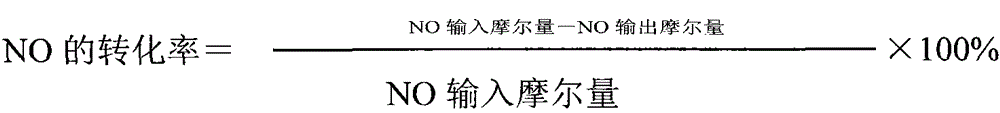

The invention relates to a reaction system for alkyl nitrite and a preparation method for the alkyl nitrite. The preparation method comprises the following steps that: a trickle-bed reactor is adopted and porcelain ring filler is filled into the trickle-bed reactor; liquid added into the reactor forms liquid membranes on the filler; alkyl alcohol is taken as a liquid-phase raw material and nitric monoxide, oxygen and nitrogen are taken as gas-phase raw materials; and gas and liquid phases are reacted in the trickle-bed reactor by means of co-current flow or countercurrent flow under the condition of nitrogen protection so as to generate the alkyl nitrite. The mol ratio of the alkyl alcohol to NO is between 2 to 1 and 7 to 1, and the mol ratio of the NO to O2 is between 4 to 1 and 8 to 1; the reaction temperature is between 40 and 100 DEG C, and the reaction pressure is between 0.1 and 1.0 MPa; and the retention time of continuous feeding of liquid-phase alkyl alcohol in the trickle-bed reactor is between 10 and 500 minutes, and the retention time of continuous feeding of gas phase in the trickle-bed reactor is between 0.02 and 1 minute. The reaction system and the preparation method have the advantages that: the operating condition is mild; the reaction time is short; the conversion rate of the raw materials, and the selectivity and the yield of products are high; and the whole reaction system is convenient for realizing continuous production, etc.

Owner:TIANJIN UNIV

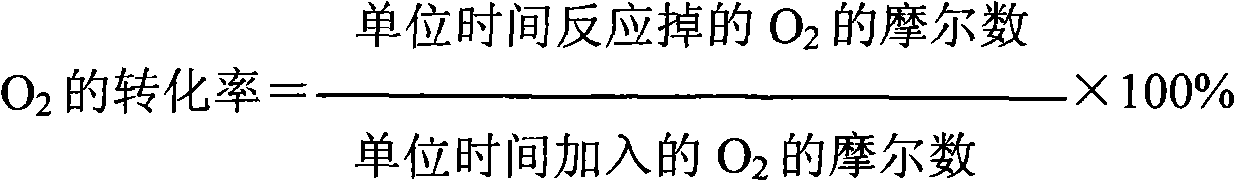

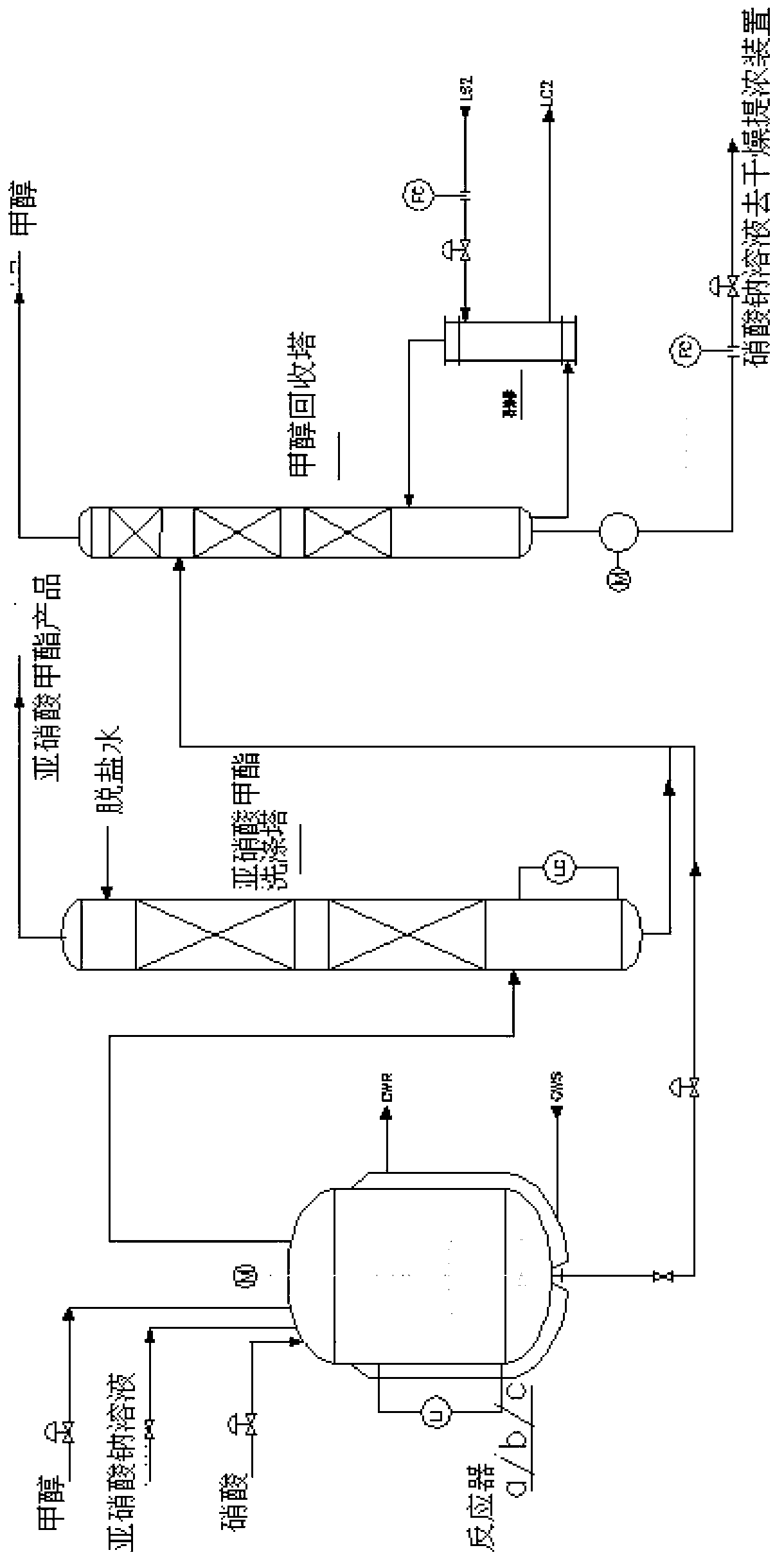

Preparation method for methyl nitrite

ActiveCN103373925AReduce heat supplyHigh yieldNitrous acid preparation ester preparationWastewaterNo conversion

The invention relates to a preparation method for methyl nitrite. The preparation method is characterized by comprising the following steps of: taking NO-containing gas, O2 and methanol as raw materials, inputting the NO-containing gas, the O2 and the methanol into at least one esterification column, reacting to obtain methyl nitrite, and recycling nitric acid and the residual methanol, wherein the residual methanol is recycled in at least one methanol recycling column, and the nitric acid is recycled in at least one nitric acid recycling column. Compared with the prior art, the preparation method for the methyl nitrite has the advantages that MN can be effectively generated, the NO conversion rate can be improved, the yield of the MN can be increased, the heating capacity of the bottom of the esterification column can be reduced, and the wastewater discharged from a system does not contain the nitric acid; the problem of the nitric acid wastewater generated in a process for generating methyl nitrite from NO is thoroughly solved, and the preparation method is beneficial to environmental protection and has a good practical application value and production significance.

Owner:PUJING CHEM IND SHA +1

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Process device for producing methyl nitrite

ActiveCN102807492ATake advantage ofSave Process Soft WaterChemical industryNitrous acid preparation ester preparationReboilerGlycol synthesis

The invention provides a process device for producing methyl nitrite. The process device comprises a reactive distillation tower, a pre-reactor, a pre-heater, a reboiler, a methanol recovering and buffering groove and an acid water groove, wherein a condenser is arranged in reactive distillation tower; the pre-reactor, the pre-heater, the reactive distillation tower, the reboiler and the methanol recovering and buffering groove are connected in sequence; the input end of the pre-reactor is connected with an NO recycle gas pipeline and an oxygen pipeline in a carbonylation reaction process respectively; the oxygen pipeline is provided with an air separating device; the two ends of a subcooler are communicated with the condenser and the reactive distillation tower respectively; one end of the subcooler is connected with a carbonylation reaction system; the input port of the acid water groove is connected with an acid water pipe and a process soft water pipe respectively; and a first circulation pump and a second circulation pump are arranged among the methanol recovering and buffering groove, the acid water groove and the reactive distillation tower respectively. The process device is simplified, production equipment is saved, the production cost is lowered, and the process device can be better applied to an ethylene glycol process.

Owner:PUJING CHEM IND SHA

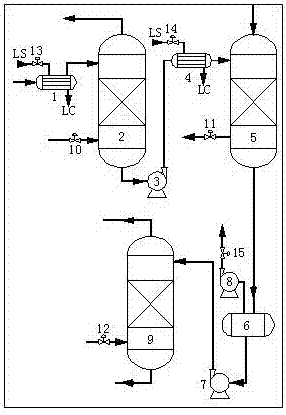

Method and equipment for continuously producing methyl nitrite

InactiveCN102898311AReduce generationInvestment minimizationNitrous acid preparation ester preparationMethyl nitrateOxygen

The invention relates to a method and equipment for continuously producing methyl nitrite in large scale. The method for producing methyl nitrite comprises the following steps of: carrying out the esterification of methanol, oxygen and a nitrogen oxide in an esterification reaction tower to obtain methyl nitrite; circulating and returning the liquid flow from the outlet at the bottom of the esterification reaction tower to the top of the tower, leading the gas flow from the outlet at the bottom of the esterification reaction tower to a purification tower and washing the gas from the bottom of the esterification tower by countercurrent contact with an organic purifier; drying the gas from the top of the purification tower in a dryer to obtain methyl-nitrite-containing dry gas; and leading liquid at the bottom of the purification tower to a recovery tower, and separating a recovery purifier. The methyl nitrite produced by the method can be directly used to prepare dimethyl oxalate through oxidization, carbonylation and coupling reaction with CO. Compared with the conventional production process, the method for producing methyl nitrite has the characteristics of economy, environment friendliness, less waste water and the like.

Owner:SHANGHAI HUAYI ENERGY CHEM

Process method and method for regenerating methyl nitrite in production of dimethyl oxalate

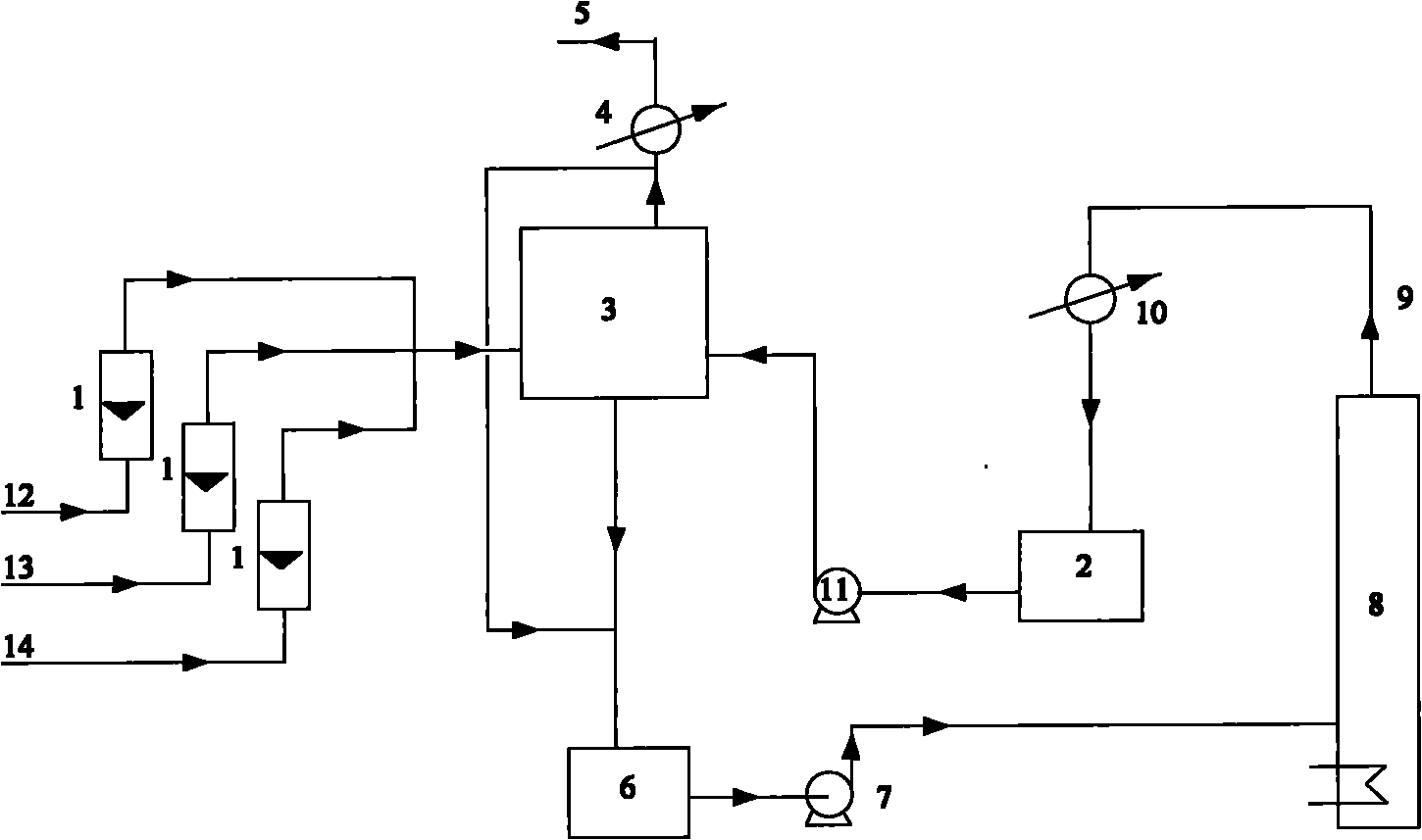

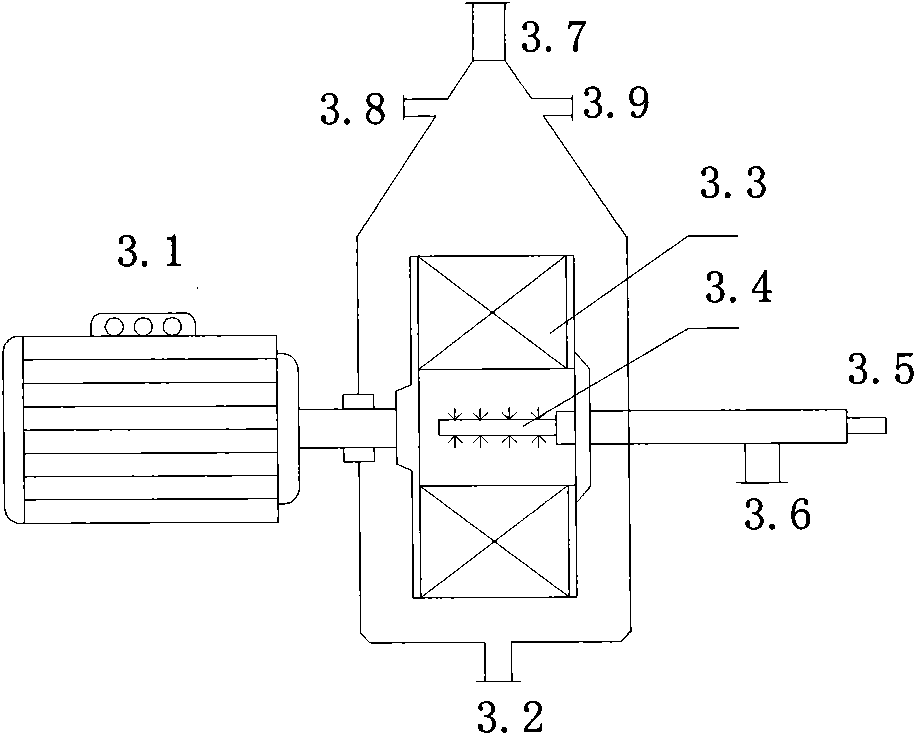

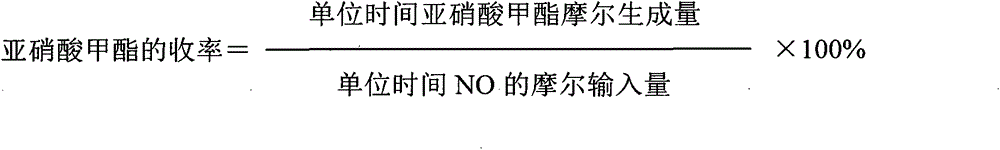

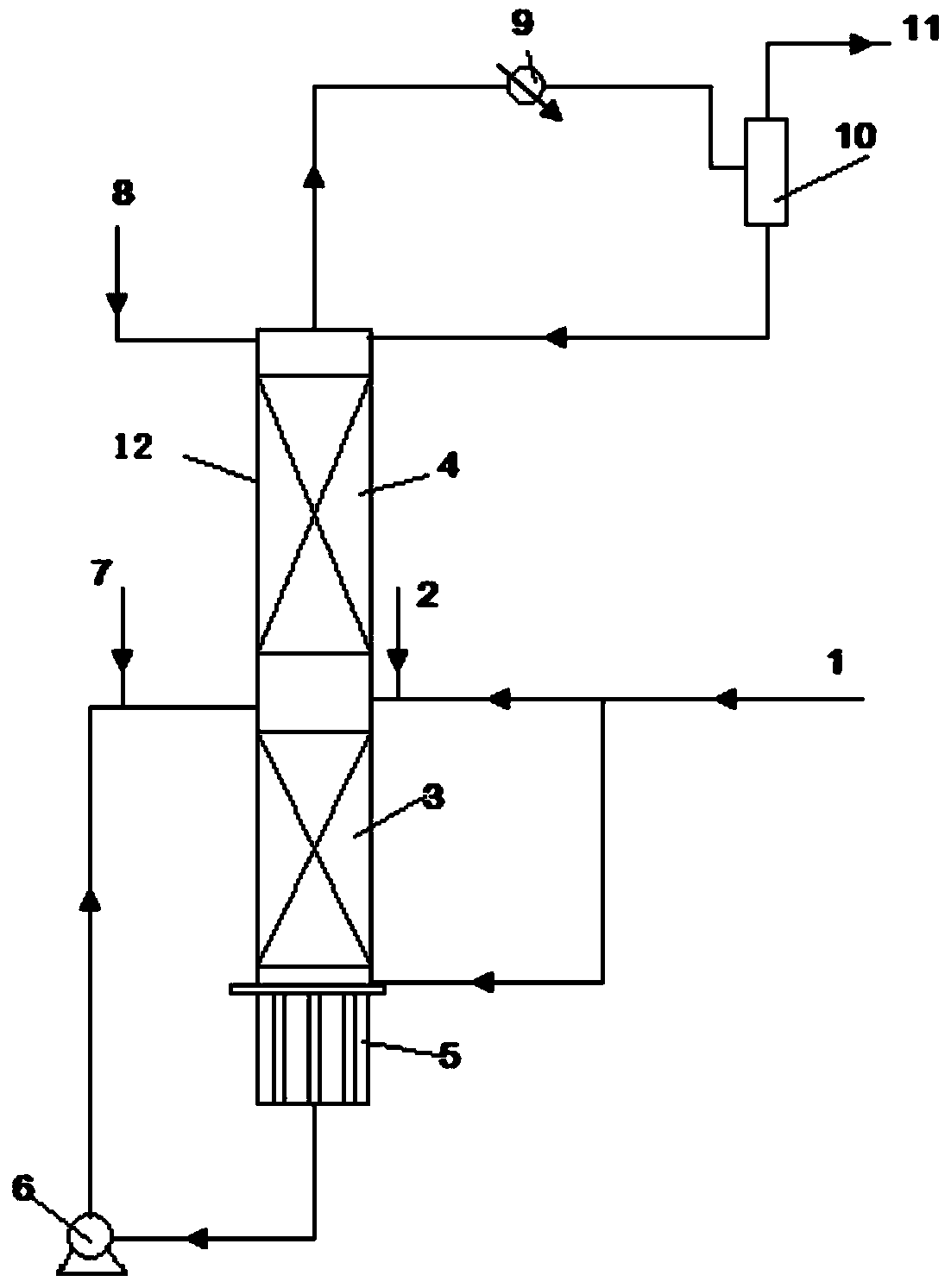

InactiveCN102008922AEfficient use ofEfficient recyclingNitrous acid preparation ester preparationChemical/physical processesGas phaseNitric oxide

The invention belongs to the technical field of the production of dimethyl oxalate, and particularly relates to a process method and a device for regenerating methyl nitrite in the production of the dimethyl oxalate. In the method, the utilization rate of nitric oxide in the regenerative process is improved, and the using amount of methanol is reduced. The device comprises a rotary filler bed, wherein a gas inlet of the rotary filler bed is connected with sources of nitrogen, oxygen and nitric oxide respectively, a liquid inlet is connected with a methanol storage tank, a liquid outlet is connected with an inlet of a methanol-water mixture storage tank, and a gas outlet is connected with a condenser I. The process method comprises the following steps of: opening the rotary filler bed, so that the nitric oxide, the nitrogen and the oxygen are contacted and reacted with absolute methanol in the rotary filler bed to form a gas phase and a liquid phase; and discharging the gas phase, condensing, and allowing the liquid phase to flow into the methanol-water mixture storage tank. The process method has the advantages that: the process reaction efficiency is high; all NO is used efficiently; and the equipment has a compact structure and small volume and requires a small investment. The equipment has the advantages of making operation easy, along with simple structure, small energy consumption, simple flow, convenience for starting and stopping and the like.

Owner:ZHONGBEI UNIV

Preparation method of catalyst used in dilute nitric acid treating and alkyl nitrite generating

ActiveCN104338550ASimple methodEasy to operateMolecular sieve catalystsNitrous acid preparation ester preparationForming gasReaction temperature

The invention relates to a preparation method of a catalyst used in dilute nitric acid treating and alkyl nitrite generating and mainly aims at solving the disadvantages of introducing O2 in the nitrate regeneration process and a series of problems of easy generation of nitric acid, failure in dilute nitric acid treatment, low reaction efficiency, and low nitrite selectivity, and the like in the regeneration process in the prior art. The following technical scheme is adopted: in the presence of an activated carbon coated molecular sieve membrane catalyst, NO reacts with an aqueous solution of alkyl alcohol and nitric acid in a manner of being contacted with the catalyst under the re-circulating conditions in which the reaction temperature is within the range of 60-100 DEG C, a reaction pressure is within the range of 0.28-0.35Mpa, the synthetic gas flow is within the range of 800-1000L / h, the mass fraction of the NO is 8-20%, the mass fraction of the alkyl alcohol is 30-60% in the liquid phase solution and the content of the dilute nitric acid is 1%-10%, due to the reaction, the dilute nitric acid can be completely decomposed into nitrous acid, and the nitrous acid is capable of further reacting with the alkyl alcohol to generate the alkyl nitrite. The catalyst is capable of well being used for catalyzing in the reaction of the dilute nitric acid decomposing and the alkyl nitrite generating with high efficiency, and therefore, the series of problems can be solved. The catalyst can be applied to the regeneration production of the alkyl nitrite in the industry of producing ethylene glycol from coal.

Owner:TONGLIAO GOLD COAL CHEM

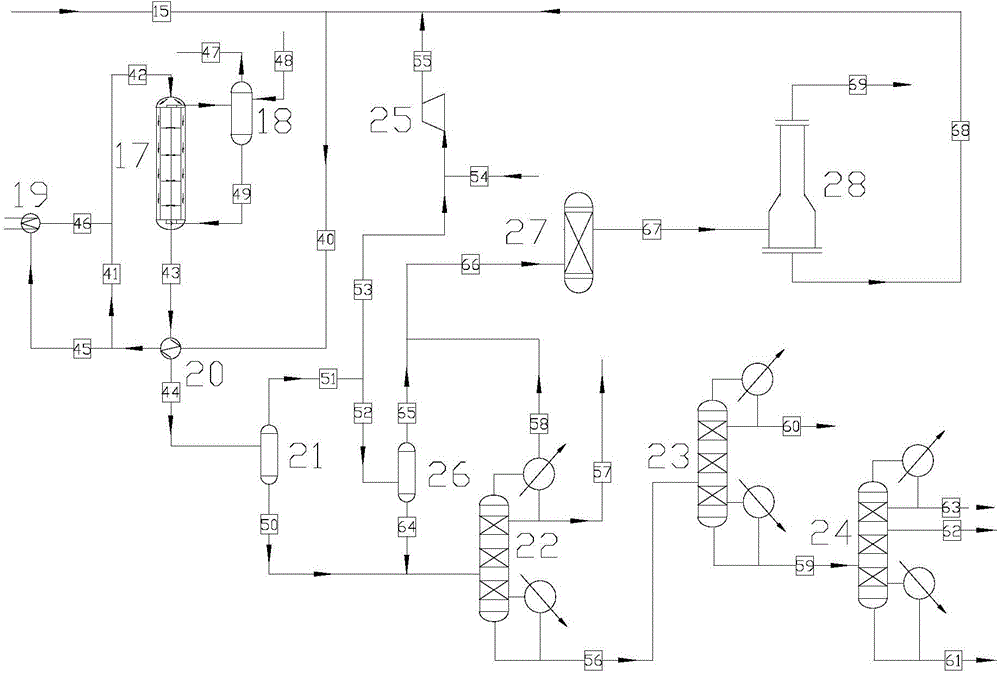

Regeneration process and regeneration device system of methyl nitrite in process for preparation of ethylene glycol from synthesis gas

PendingCN106588667ASolve the problem of dissolving methyl nitriteReduce consumptionNitrous acid preparation ester preparationNitrogen oxideMethyl nitrate

The invention relates to a regeneration process and a regeneration device system of methyl nitrite in a process for preparation of ethylene glycol from a synthesis gas, the regeneration process comprises the following steps: (1) methyl nitrite regeneration, to be more specific, a liquid containing methanol and nitric acid and a gas containing nitrogen oxides from a methyl nitrite synthesis reactor are introduced into a methyl nitrite regeneration tower for reaction to obtain methyl nitrite; and (2) methyl nitrite stripping recovery, to be more specific, a methyl nitrite regeneration tower kettle components and a gas or gases selected from one or more of N2, CO2, CH4, CO and the nitrogen oxides are introduced into a methyl nitrite regeneration stripping tower for stripping for recovery of the methyl nitrite dissolved in the methanol. The regeneration process reduces the consumption of the nitric acid in the process for preparation of the ethylene glycol from the synthesis gas, the nitric acid produced by side reaction is economically and efficiently recovered, and the problem that a methanol solution dissolves the methyl nitrite can be solved.

Owner:SHANGHAI HUAYI ENERGY CHEM

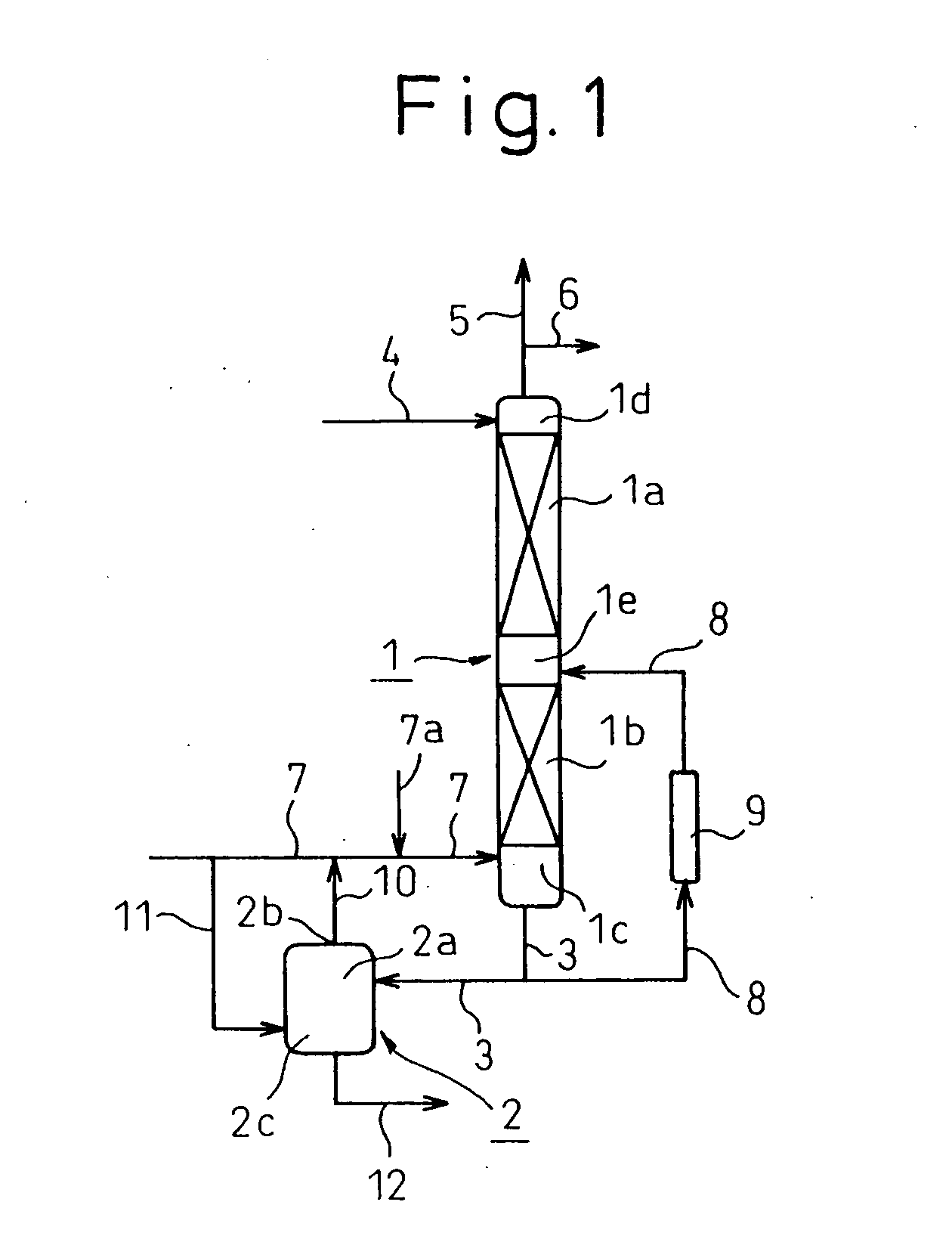

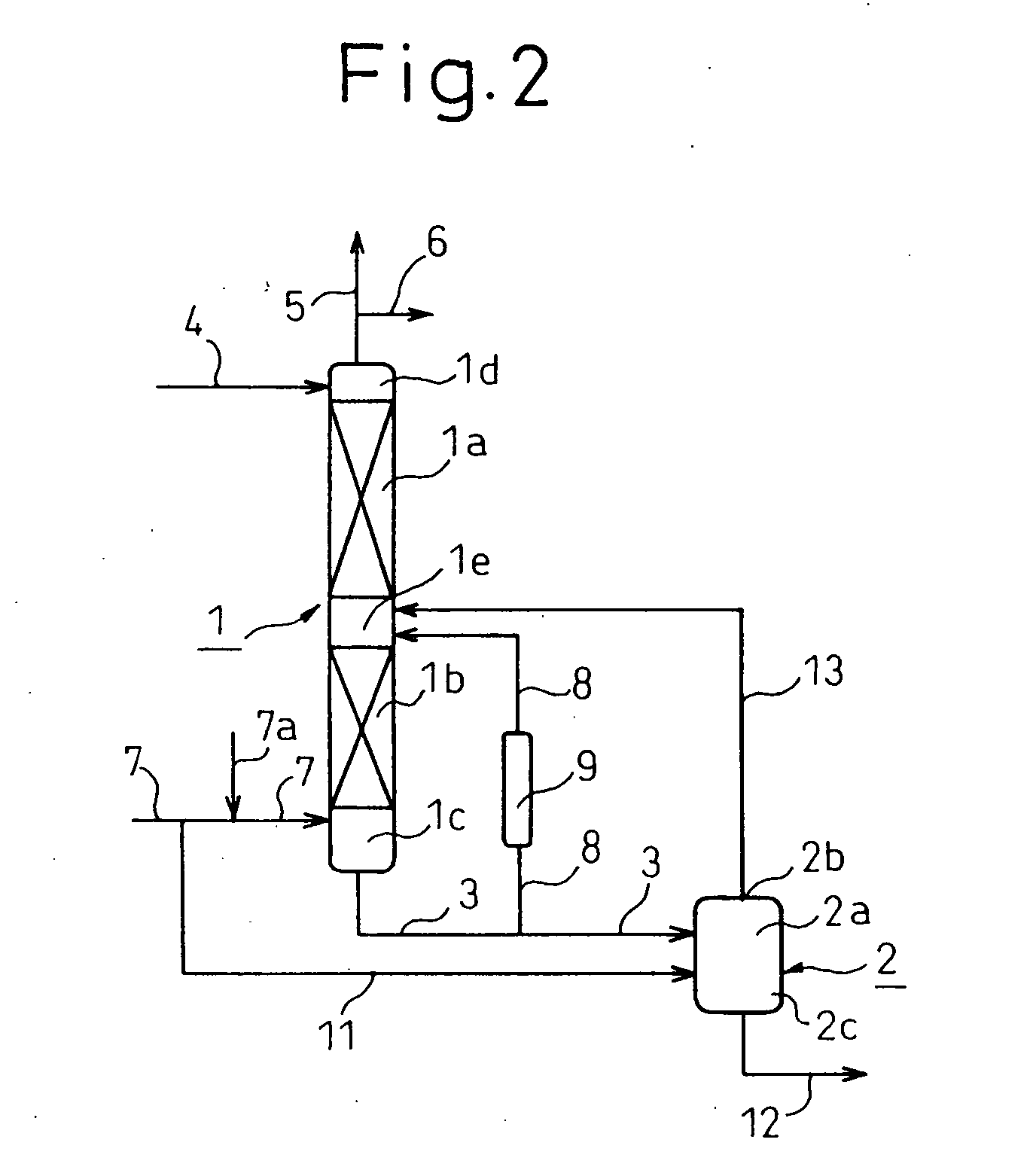

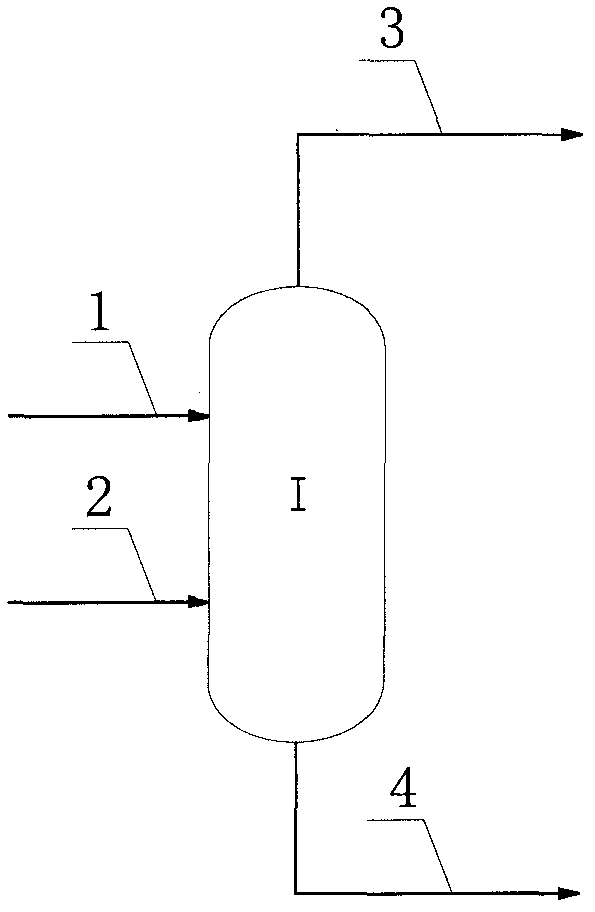

Process for producing alkyl nitrite

ActiveUS20050038282A1Improve efficiencyIncrease profitNitrous acid preparation ester preparationNitrogen monooxideNitrite

An alkyl nitrite is produced with high efficiency by bringing a nitrogen monoxide gas into contact with an aqueous solution of an alkyl alcohol and nitric acid in a reactor 2, which aqueous solution may be a liquid fraction generated in an alkyl nitrite-production process in which an alkyl alcohol is reacted with nitrogen monoxide and oxygen in a reaction column 1.

Owner:UBE CORP

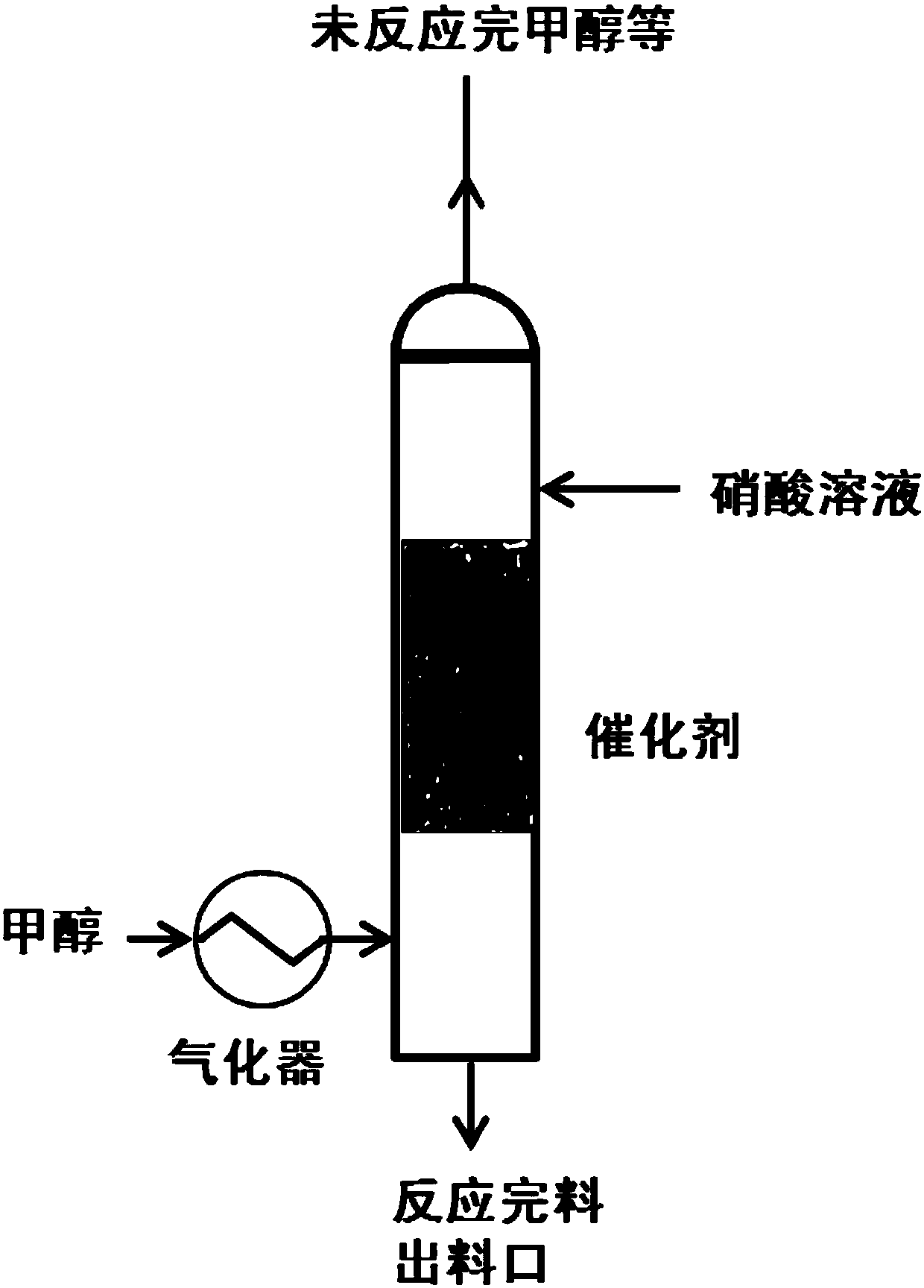

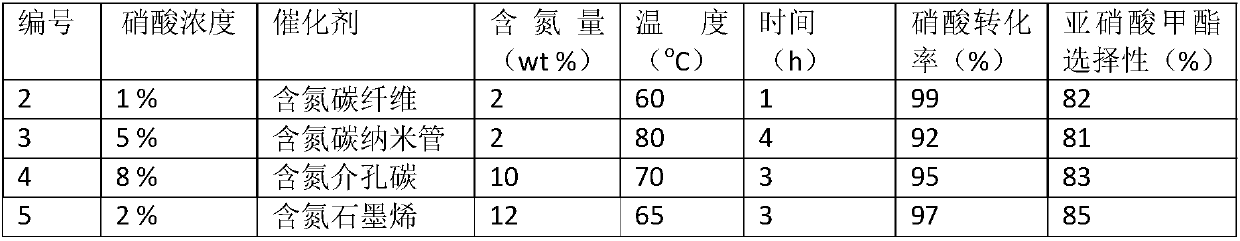

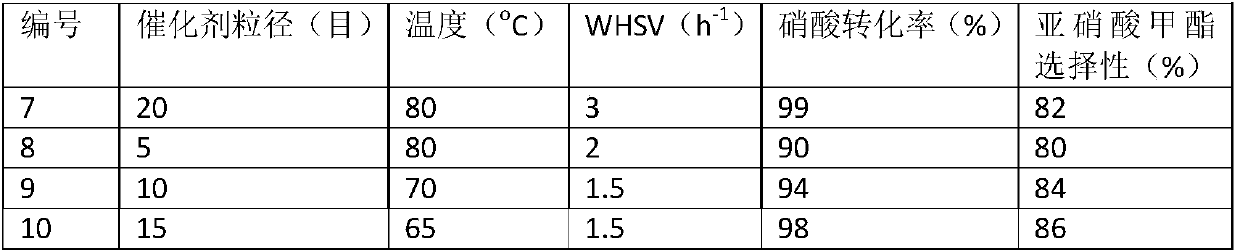

Method for preparing methyl nitrite through catalyzing dilute nitric acid

InactiveCN107663152AReduce dosageHigh selectivityNitrous acid preparation ester preparationNitrogenFixed bed

The invention discloses a method for preparing methyl nitrite through catalyzing dilute nitric acid. The method comprises the following steps of using dilute nitric acid and methanol as substrates; under the effect of a nitrogen-containing carbon-based catalyst, one-step reaction and high-selectivity conversion are performed to obtain the methyl nitrite. A continuous fixed bed reactor is used; under the effect of the nitrogen-containing carbon-based catalyst, the nitric acid is promoted to be reduced into methyl nitrite for reaction; the nitrogen ingredients in the catalyst are favorable for the proceeding of the esterification process. The catalyst has high dilute nitric acid conversion efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

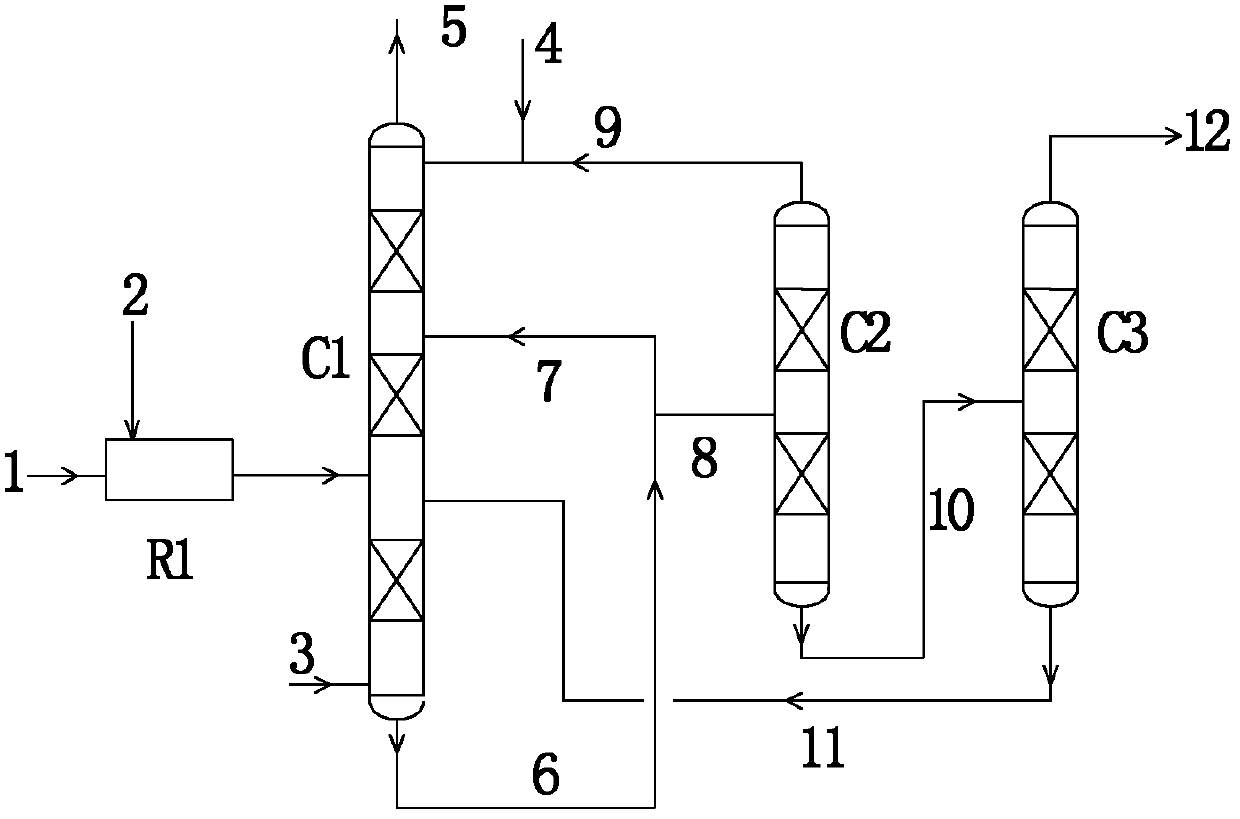

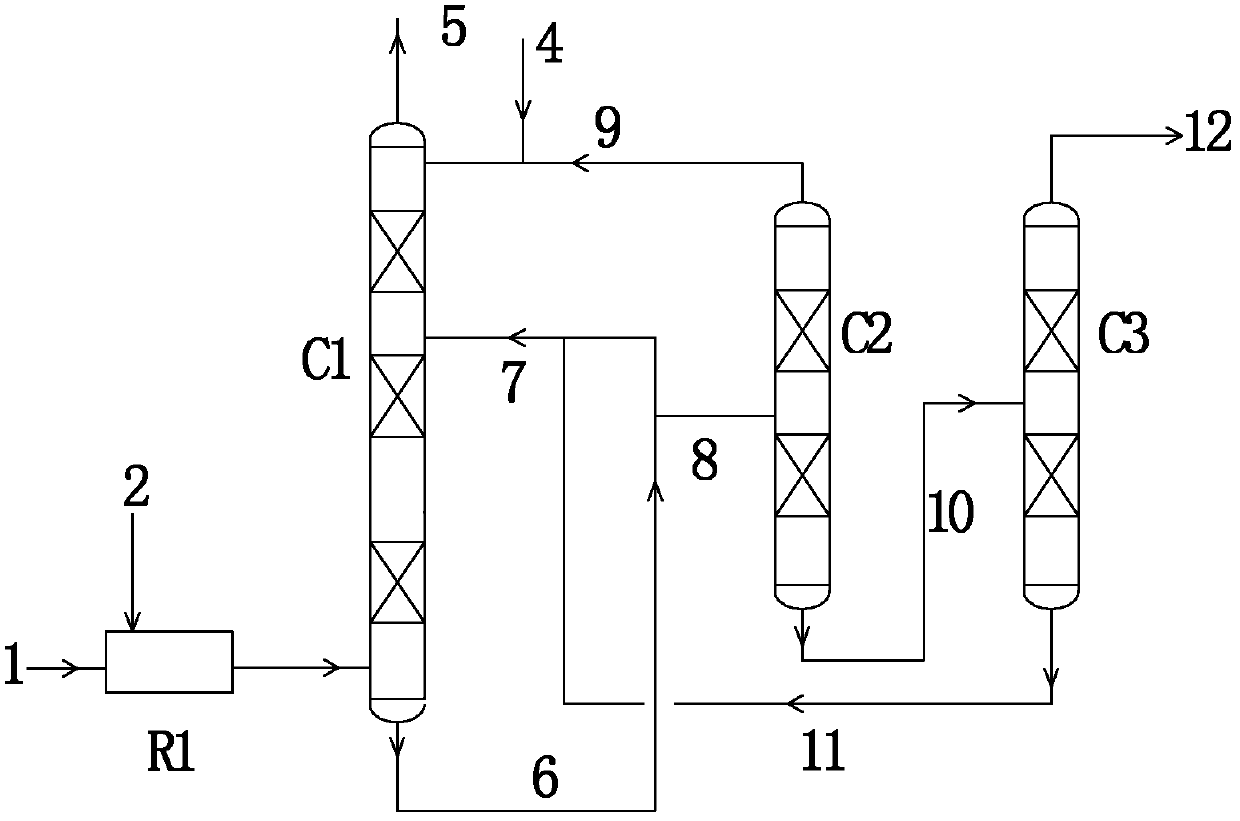

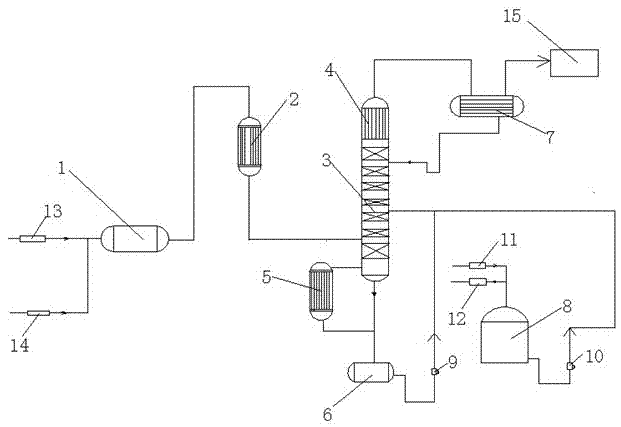

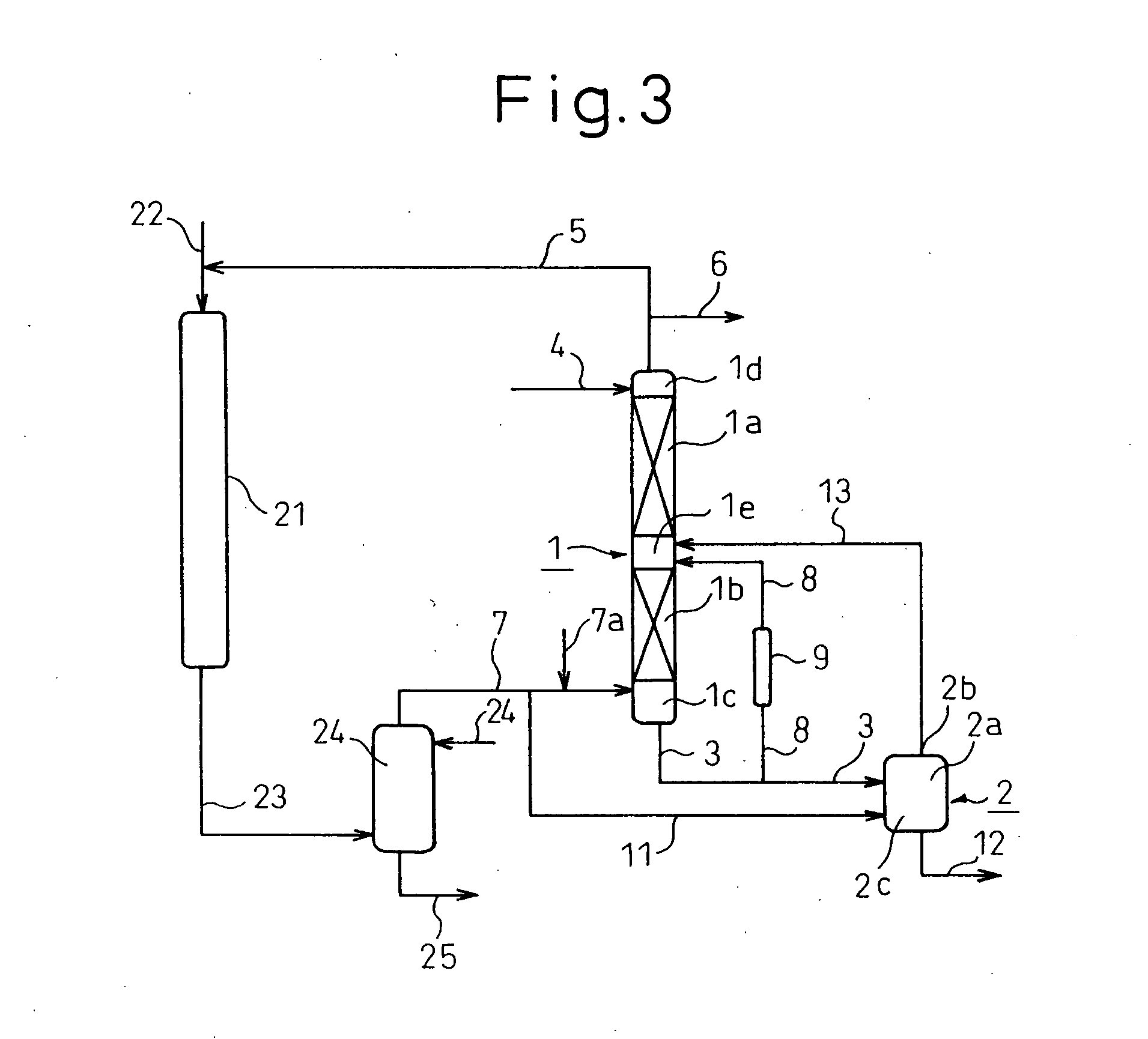

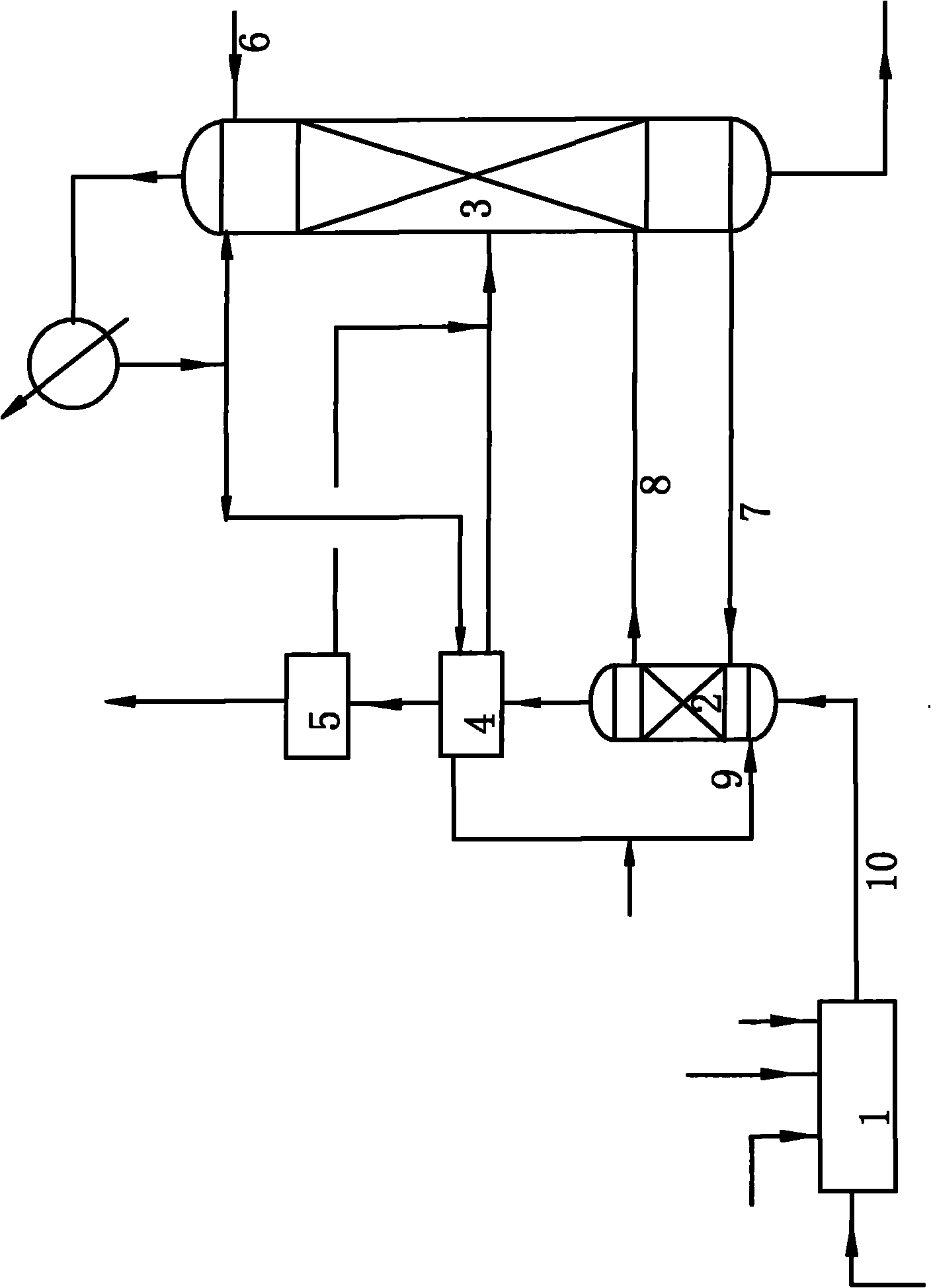

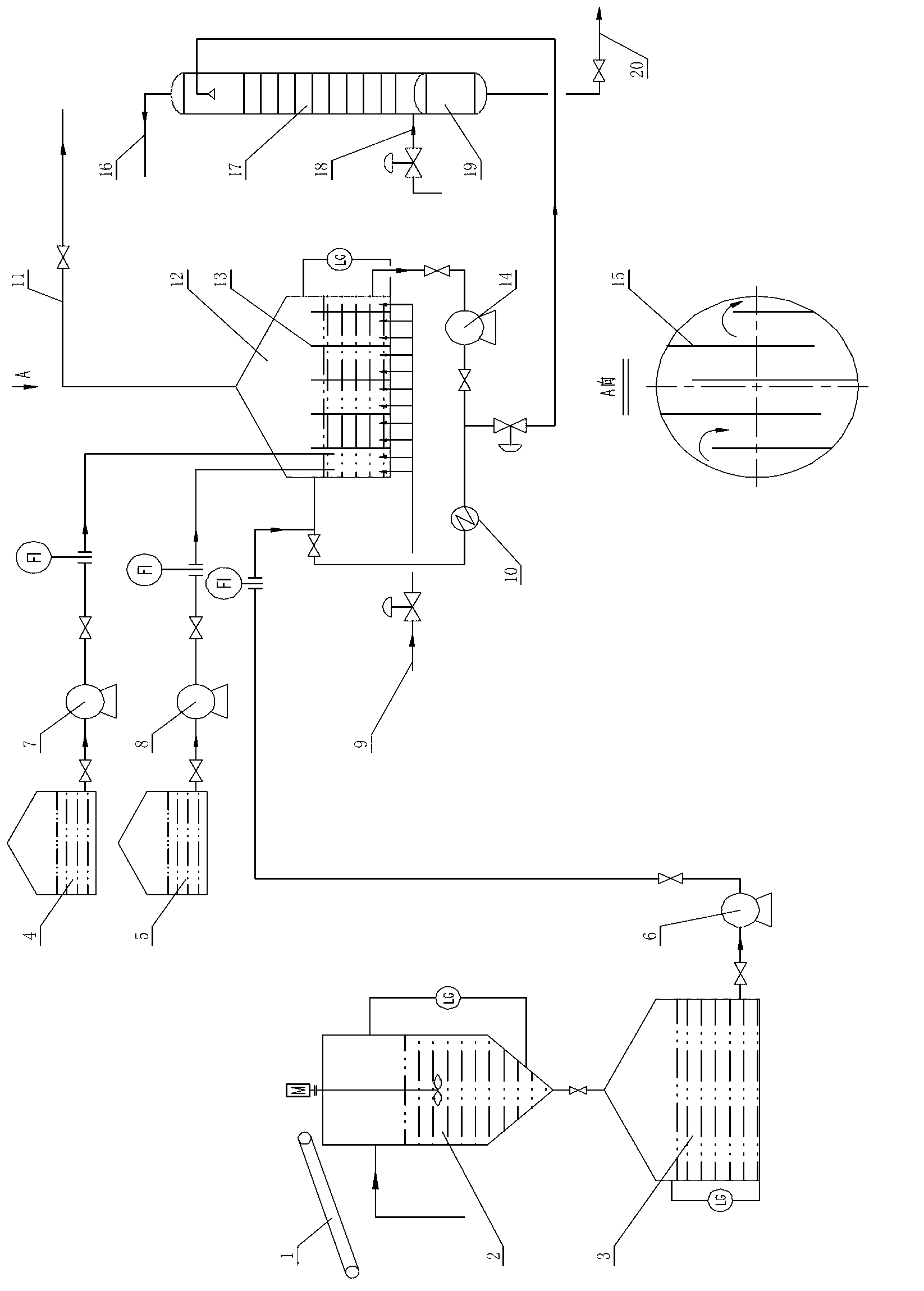

Synthesizing device and process for alkyl nitrite

ActiveCN101830807ARemove in timeEasy to operateNitrous acid preparation ester preparationEngineeringHigh selectivity

The invention discloses a synthesizing device and a synthesizing process for alkyl nitrite, and belongs to the technical field of chemistry. An oxidizer is provided with a plurality of inlets for changing a connection mode with other components; and a reactor, a rectifying tower, a cooling device vaporizer and a heat exchanger are arranged to be respectively independent operation units, the independent operation units are connected with the vaporizer through a reactor tube stroke, and connected with the rectifying tower through the cooling device vaporizer and a heat exchanger liquid phase pipeline, so that the procedures of reacting, rectifying, separating and cooling the product can be carried out independently. The process comprises the steps of: (1), gasification of alkanol; (2), oxidation; (3), generation of the alkyl nitrite; and (4), separation of a by-product. The synthesizing device and the synthesizing process realize the removal and utilization of the reaction heat and gasification of the alkanol by using the heat of the reaction product. The synthesizing device and the synthesizing process for the alkyl nitrite have the advantages of high operation stability, mild reaction condition, high raw material conversion ratio, high selectivity of the product, high yield, suitability for large-scale continuous production of the alkyl nitrite and the like.

Owner:WUXI HUACHENG PETROCHEM EQUIP

Methyl nitrite recovery method during CO coupling dimethyl oxalate synthesis process

InactiveCN102911059AReduce lossIncrease profitNitrous acid preparation ester preparationRefluxRecovery method

The invention provides a methyl nitrite recovery method during a CO coupling dimethyl oxalate synthesis process. A gas-phase material containing methyl nitrite is delivered into an upper-middle part of a rectification tower; a liquid-phase material and a gas-phase material containing methyl nitrite are delivered into the rectification tower; a tower-top material contains methyl nitrite, and a tower-kettle material contains methanol and water; a tower plate number of the rectification tower is 10-50, the tower kettle temperature is 50 DEG C to 200 DEG C, a tower top temperature is -10 DEG C to 100 DEG C, a reflux ratio is 0.2-3.0, and an operation pressure is 50-400kPa. With the methyl nitrite recovery method provided by the invention, methyl nitrite loss can be reduced, methyl nitrite utilization rate can be improved, and cost can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method and equipment of alkyl nitrite

InactiveCN104945263AAdd processing stepsReduce generationNitrous acid preparation ester preparationPartial oxidationDecomposition

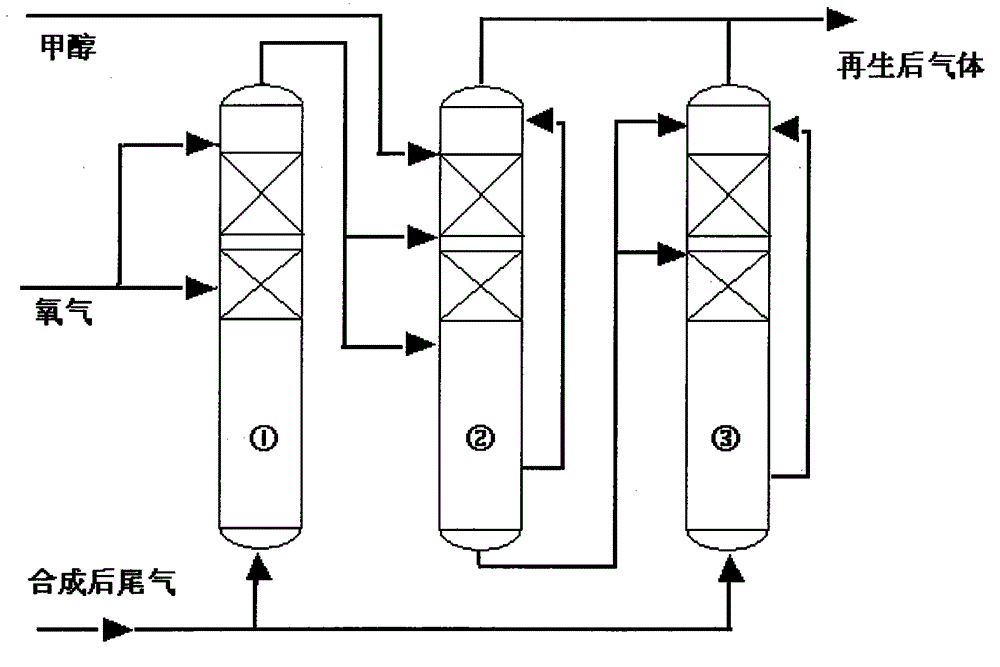

The invention discloses a synthesis method and equipment of alkyl nitrite. The method mainly includes the following points that: a) the alkyl nitrite regeneration raw materials are the NO in the tail gas generated in production of oxalic acid alkyl ester by coupling reaction of CO and alkyl nitrite, and O2, alkyl alcohol and other raw materials supplemented from the outside; b) the tail gas of the coupling reaction in step a) mainly are unreacted CO, alkyl nitrite, and the NO gas generated by alkyl nitrite decomposition in reaction, O2 is introduced to oxidize most of NO into N2O3; c) the gas mixture in step b) and alkyl alcohol are subjected to esterification regeneration reaction to obtain alkyl nitrite; and d) the by-product nitric acid is inevitably produced in step c), and is also applied to the regeneration process of alkyl nitrite to re-react with the synthesis tail gas so as to generate alkyl nitrite, thus realizing atom economy. The invention also provides equipment for carrying out the reaction. The equipment is composed of three sets of small towers in series connection, i.e. (1) a full mixing tower; (2) an esterification tower; and (3) a nitric acid treatment tower. The method and the equipment provided by the invention have the advantages of mild operation conditions, high regeneration efficiency, good adaptability, strong economical efficiency and the like.

Owner:JIANGSU JINJU ALLOY MATERIAL

System and method for recovering methyl nitrite through coal ethylene glycol carbonyl synthesis system

InactiveCN107056582AReduce shortingReduce pollutionOrganic compound preparationHydroxy compound separation/purificationChemical reactionFluid phase

The invention relates to the field of coal ethylene glycol chemical engineering and particularly relates to a system and method for recovering methyl nitrite through a coal ethylene glycol carbonyl synthesis system. According to the method, the main target of effectively recovering a methyl nitrite gas is achieved in the coal ethylene glycol carbonyl synthesis system through the methods of combining air stripping, flash evaporation and nitric acid reduction. The recovery system mainly comprises a front air stripping system for methyl nitrite, a nitric acid reduction system and a rear air stripping system, wherein the front air stripping system is provided with a liquid-phase preheater, a front air stripping tower and a liquid-phase discharge centrifugal pump; the nitric acid reduction system is provided with a liquid-phase feeding preheater and a nitric acid reduction tower; and the rear air stripping system is provided with the flash evaporation tank, the liquid-phase feeding centrifugal pump and the rear air stripping tower. Stable content of nitric oxide and the methyl nitrite in a gas-phase component of the synthesis system is ensured through the method of combining a physical process and chemical reaction, the losses of the nitric oxide and the methyl nitrite are avoided to a great extent, the waste is changed into treasure, and resource waste and water source pollution are reduced.

Owner:安阳永金化工有限公司

Methyl nitrite regeneration method

ActiveCN103936591AHigh regeneration rateFull recoveryChemical recyclingNitrous acid preparation ester preparationAlcoholReboiler

The invention discloses a methyl nitrite regeneration method, and is used for solving the problems of low regeneration rate of methyl nitrite, poor operational stability of a system caused by improper side reaction control, increase of operating cost and the like. The methyl nitrite regeneration method comprises the following steps: forming recycled gas containing 5-20% of nitric oxide after synthesis of methyl nitrite and carbon monoxide carbonyl, and entering the recycled gas to a methyl nitrite regeneration reactor in two parts, wherein a small part of recycled gas enters the lower section of the regeneration reactor from the bottom, the rest part of recycled gas and supplementing oxygen gas enter the upper section of the regeneration reactor from the middle part together; spraying fresh methyl alcohol into the tower top of the regeneration reactor, discharging methyl nitrite-containing gas from the tower top, pressurizing tower bottoms led out from the tower by using a pump and entering the tower bottoms to the lower section of the regeneration reactor from the middle part of the regeneration reactor; arranging a reboiler on the tower of the regeneration reactor, filling the lower section of the regeneration reactor with a catalyst, and arranging stuffing and / or a tower plate on the upper section of the regeneration reactor. The methyl nitrite regeneration method is simple in process, low in equipment investment and operating cost and high in regeneration rate of methyl nitrite and can be used for effectively solving the side reaction problem.

Owner:WUHUAN ENG +2

Production apparatus and production method for methyl nitrite

ActiveCN102936201AGuaranteed continuous supplyContinuous supply can be achieved by ensuring the continuous supply of raw materialsNitrous acid preparation ester preparationSocial benefitsEconomic benefits

The present invention provides a production apparatus and a production method for methyl nitrite. The apparatus comprises: a belt conveying device, a dissolving stirring tank, a first storage tank for storing sodium nitrite, a reactor, a second storage tank for storing methanol, a third storage tank for storing nitric acid, and a rectification tower. The production method comprises that: three solutions of sodium nitrite, methanol and nitric acid are added to the reactor; complete and uniform mixing is performed under stirring to carry out a reaction; the material outflowing from the reactor enters the rectification tower through adjustment valve control, and is subjected to gas-liquid two phase separation through the rectification tower; and the gas and the liquid are respectively discharged from a gas outlet and a sodium nitrate solution outlet, and the sodium nitrate solution discharged from the bottom of the rectification tower is conveyed to a sodium nitrate drying crystallization device to be adopted as a byproduct. According to the present invention, the conventional concept of multi-reaction kettle intermittent switching operation is broken through, continuous and uninterrupted production is achieved, characteristics of simple and short process route, safe operation and reasonable design are provided, and good economic benefits, social benefits and environmental protection benefits are provided.

Owner:SINOPEC HUBEI CHEM FERTILIZER

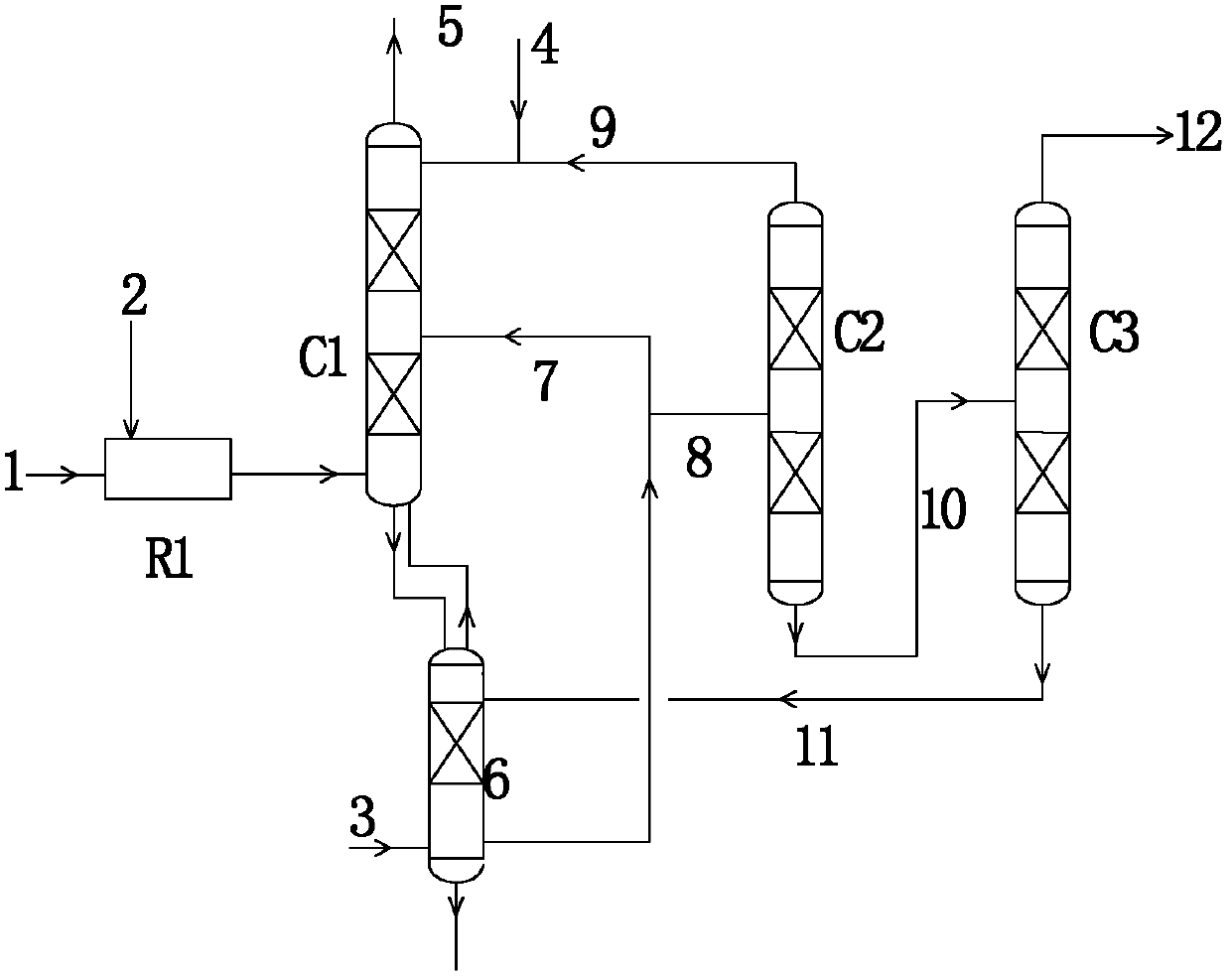

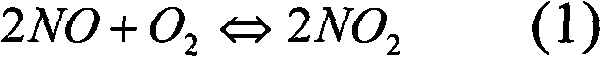

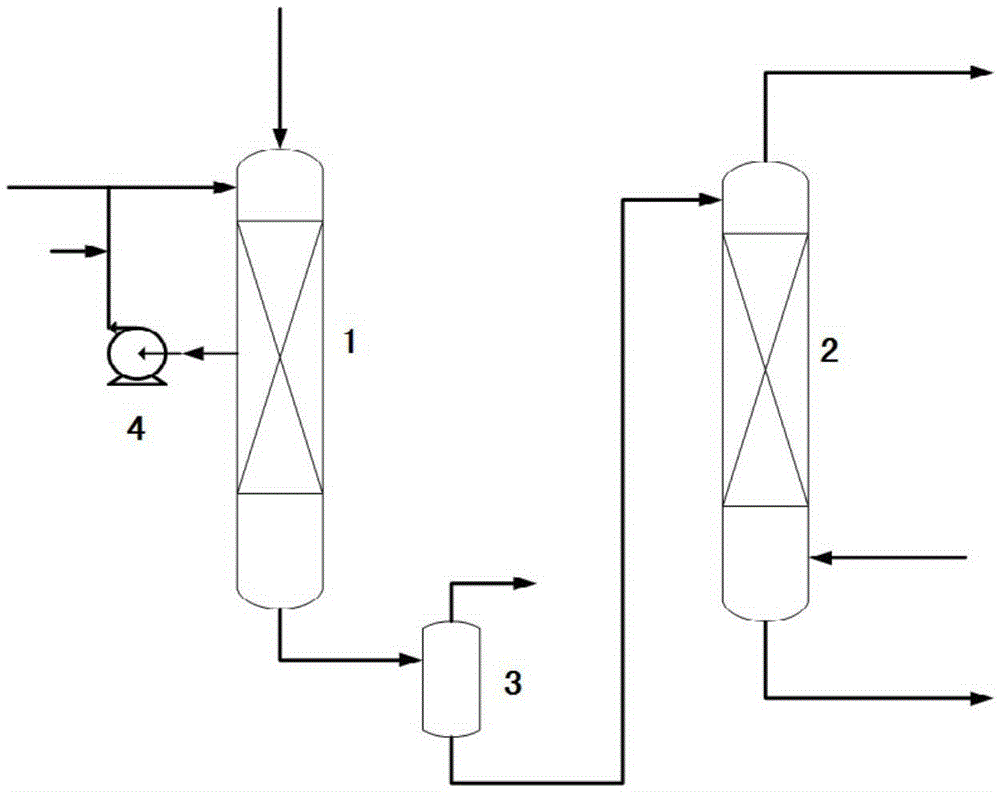

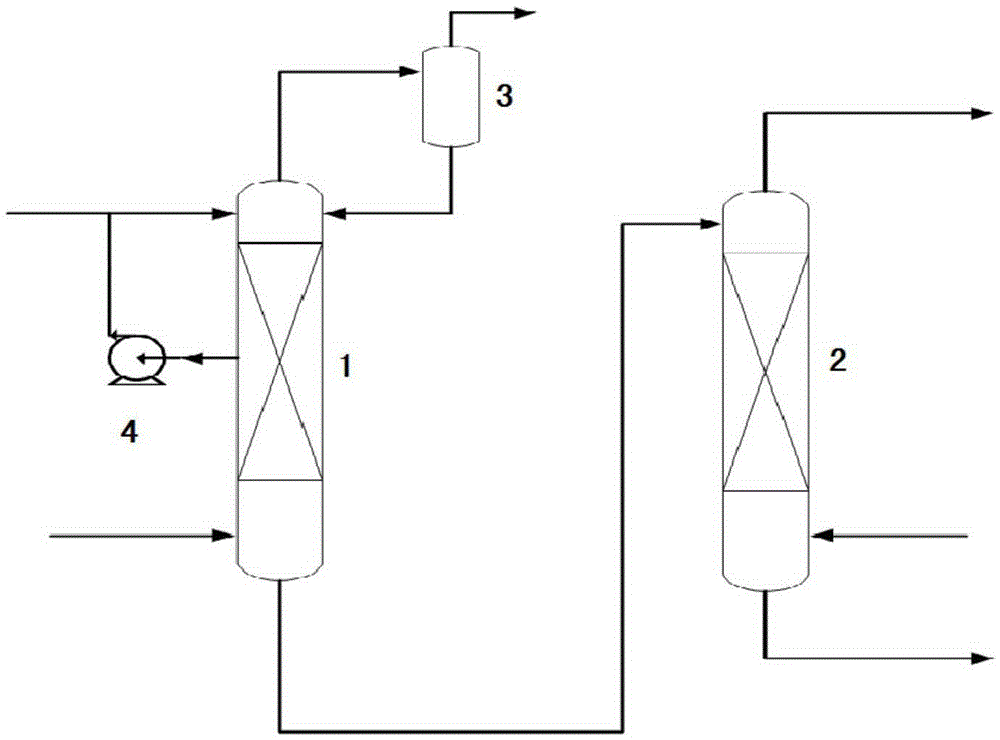

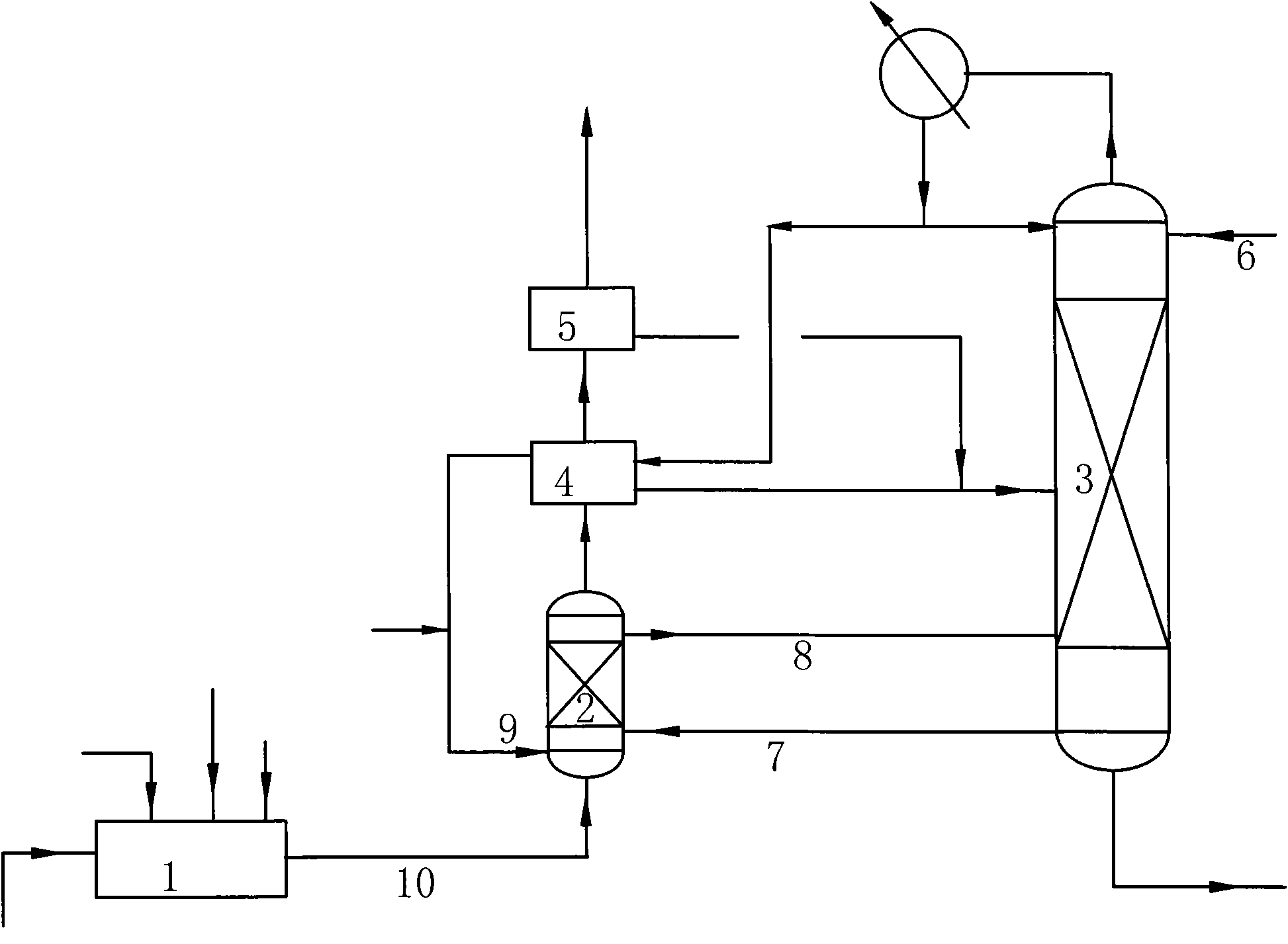

Method for preparing C1-C4 alkyl nitrites

InactiveCN101993374AMolecular sieve catalystsNitrous acid preparation ester preparationNitric oxideAlkyl nitrites

The invention relates to a method for preparing C1-C4 alkyl nitrites, which mainly solves the technical problems of low target product selectivity and high content of nitric acid as side products in the prior art. The method comprises the following steps of: a, enabling nitric oxide and oxygen to firstly enter a reactor I, reacting to generate an effluent I containing NO2 and unreacted NO; b, enabling the effluent I and C1-C4 alkanols to enter a reactor II, reacting to generate an effluent II containing the nitrites; and c, obtaining the nitrites after separating the effluent II containing the nitrites, enabling the nitrites subjected to the dryness to enter a subsequent reaction unit for use, wherein the nitric oxide contains the NO, and the mol number of the NO is more than that of the NO2, the mol ratio of the NO to the oxygen in the nitric oxide is 4-25:1. The invention better solves the problems, and can be used in the industrialized production for increasing the yield of C1-C4 alkyl nitrites.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

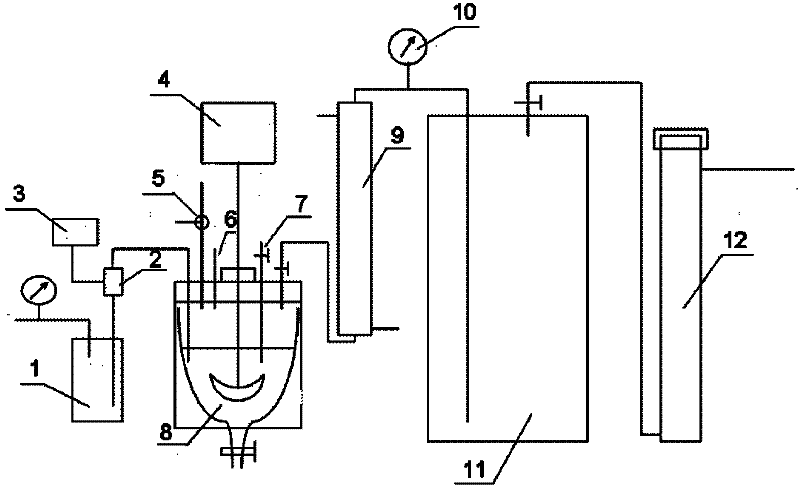

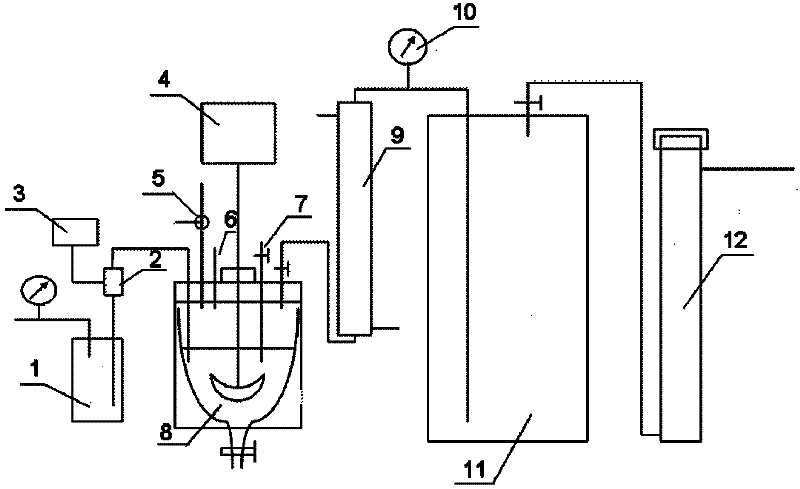

Continuous feeding device of nitrite gas

ActiveCN102372637AAchieve continuous supplySuccessful life testNitrous acid preparation ester preparationOxalateProcess engineering

The invention discloses a continuous feeding device of nitrite gas. The device comprises a nitrite gas preparing system, a purifying system and a storage and feeding system. The gas generated after charging raw material to the nitrite gas preparing system once is stored in a storage tank to be used by a micro catalytic evaluation device after being purified by the purifying system. After the raw material is used up, a pipeline between the preparing system and the storage tank is closed. At the moment, the gas in the storage tank can be continuously used by the micro catalytic evaluation device. The nitrite gas can be prepared again by using the preparing system; and the pipeline between the preparing system and the storage tank is opened to continuously feed the nitrite gas while the pressure of the generated gas rises to a certain value. By using the continuous feeding device of nitrite gas, disclosed by the invention, the problem that the service life of the catalyst for the reaction of preparing oxalate through CO (Carbon Monoxide) gaseous phase carbonylation is unable to test due to incapability of continuously feeding the nitrite gas in the lab is solved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

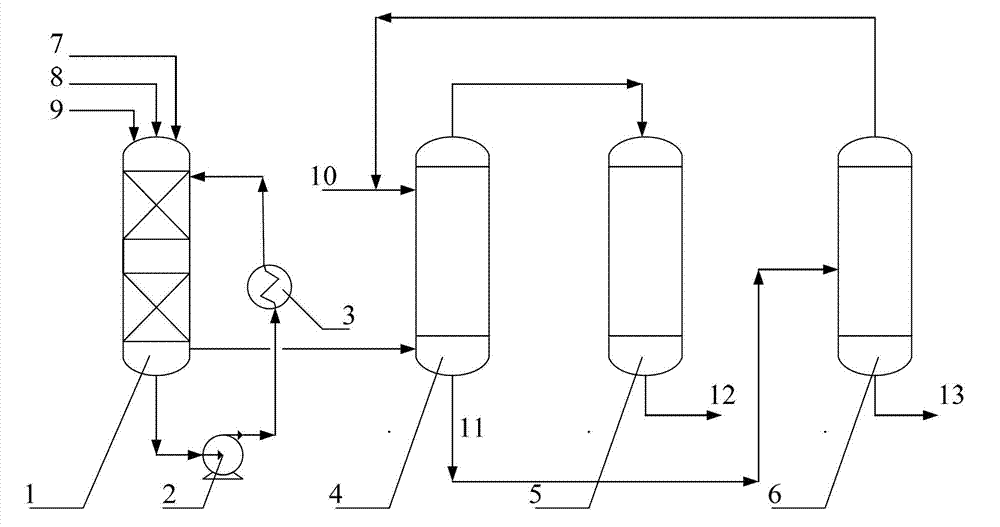

Method for synthesizing alkyl nitrite

InactiveCN105218374ASmall sizeLow investment costNitrous acid preparation ester preparationNitriteAlcohol

The invention relates to a method for synthesizing alkyl nitrite to mainly solve the problems of large reactor diameter, high investment cost and high operation cost existing in the prior art. The method comprises the following steps: an oxynitride-containing gas, oxygen and a first flow of alkyl alcohol enter an esterification reactor, and flow through the reactor from top to bottom, gases and liquid flow in parallel, and contact and react with each other to obtain an alkyl alcohol-containing top kettle liquid phase material flow and an alkyl nitrite-containing tower bottom gas phase material flow; the alkyl nitrite-containing tower bottom gas phase material flow is cycled through a cycle approach; and the alkyl nitrite-containing tower bottom gas phase material flow enters the bottom of a washing tower, and is in countercurrent contact with a second flow of alkyl alcohol entering from the top of the washing tower, a washing solution obtained from the bottom of the washing tower enters the top of an esterification reactor, and an alkyl nitrite product flow can be obtained from the top of the washing tower. The method adopting the above technical scheme well solves the problems, and can be used in industrial production of the alkyl nitrite.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing alkyl nitrite

ActiveCN102924282AHigh yieldAchieve recyclingNitrous acid preparation ester preparationIndustrial effluentNitrite

The invention discloses a process for producing alkyl nitrite. The process comprises the following step of: based on a nitric oxide and alkyl alcohol as raw materials, preparing alkyl nitrite by recycling by-products formed in the reaction process of the nitric oxide (NOx) and alcoholic solution. The process is applicable under the condition that O2 is involved or not involved, and before the nitric oxide and O2 are in contact reaction, a molar ratio of O2 to NO in the nitric oxide is not more than 0.5 under the condition that O2 is involved. According to the process, nitrogen is basically not consumed, the yield of alkyl nitrite is improved, and the reaction rate is improved; generated nitric acid is concentrated and can be recycled, the solvent is not consumed, wastewater is not generated, and the effects of recycling industrial effluent gas, saving energy, reducing emission and changing wastes into valuable materials are achieved; and meanwhile, the process is applicable under the condition that O2 is involved or not involved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for separating dimethyl carbonate

ActiveCN106278897AEfficient separationDMC content decreasedOrganic compound preparationHydroxy compound preparationAlcoholDimethyl oxalate

The invention relates to a method for separating dimethyl carbonate. The method adopts an oxidative esterification reactor, ahigh low boiling fraction removaltower, a linaethol recovery tower, a low boiling fraction removaltower, an alkaline bath, a methyl alcohol recovery tower and a dimethyl carbonate separating tower to separate methanol and dimethyl carbonate. By adopting the method, the process energy consumption is reduced while the quality of products is ensured, and the method can be used for industrial production of dimethyl carbonate separation in the dimethyl oxalate synthesis process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing alkyl nitrite by reaction between nitric oxide and nitric acid and alkyl alcohol

The invention relates to a method for preparing alkyl nitrite by a reaction between nitric oxide and nitric acid and alkyl alcohol. The method comprises the step as follows: a gas-phase raw material containing nitric oxide and a liquid-phase raw material containing nitric acid and alkyl alcohol react in a trickle bed reactor so as to obtain alkyl nitrite. The method can be used for industrial production of synthesis gas preparation of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

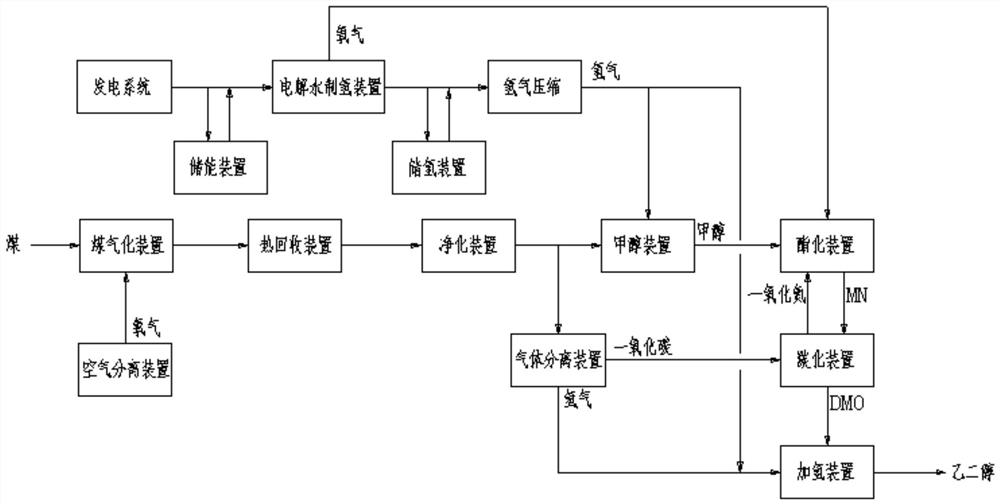

Method for realizing methanol/ethylene glycol co-production through coal chemical industry and green hydrogen coupling

PendingCN113956131AReduce coal consumptionEmission reductionElectrolysis componentsHydrogen separationGlycol synthesisHydrogen production

The invention relates to the field of carbon neutralization energy conservation and emission reduction, and particularly discloses a method for realizing methanol / ethylene glycol co-production through coal chemical industry and green hydrogen coupling. A device comprises a power generation system, an energy storage device, a water electrolysis hydrogen production device, a hydrogen storage device, a hydrogen compression device, a coal gasification device, an air separation device, a heat recovery device, a purification device, a gas separation device, a methanol device, an esterification device, a carbonylation device and a hydrogenation device. Through comprehensive utilization of a power generation system, the energy storage device, the water electrolysis hydrogen production device and the hydrogen storage device, green production and reliable supply of hydrogen are achieved, hydrogen generated by coal gasification is replaced, the carbon emission of coal-to-methanol and ethylene glycol is reduced, and the effective utilization rate of carbon elements in coal is increased.

Owner:HUALU ENG & TECH

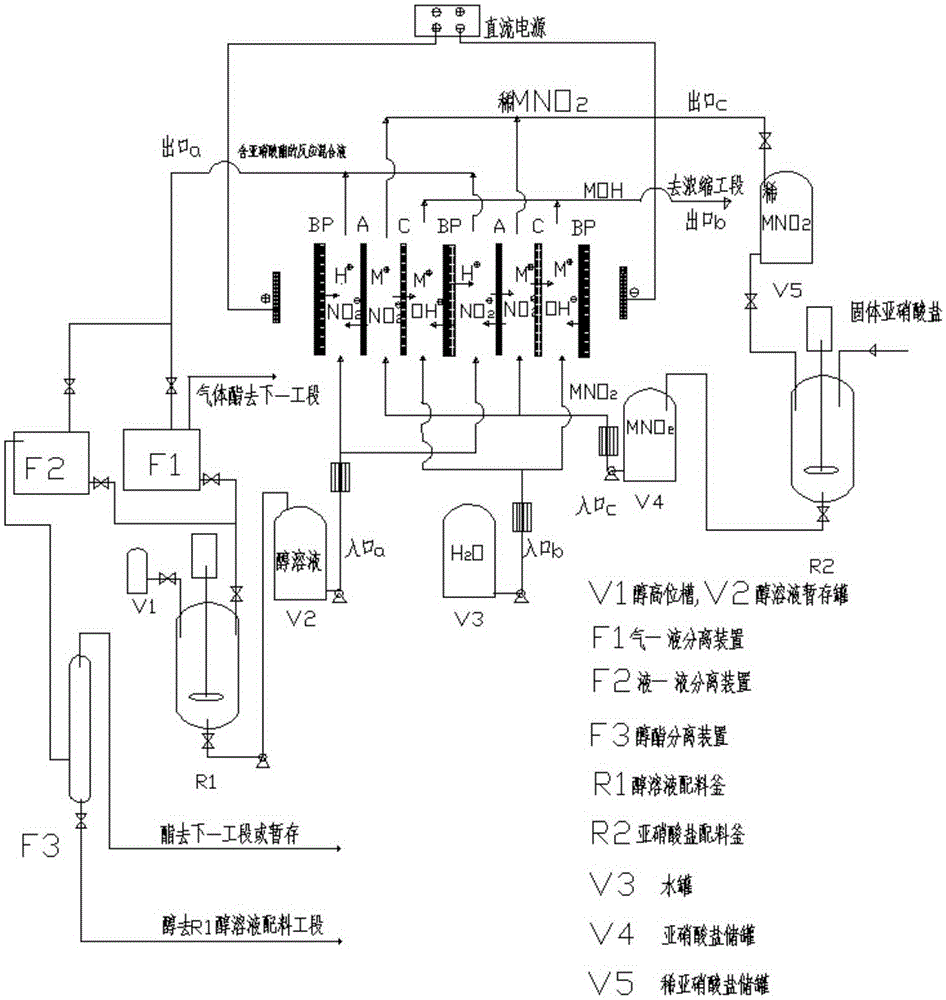

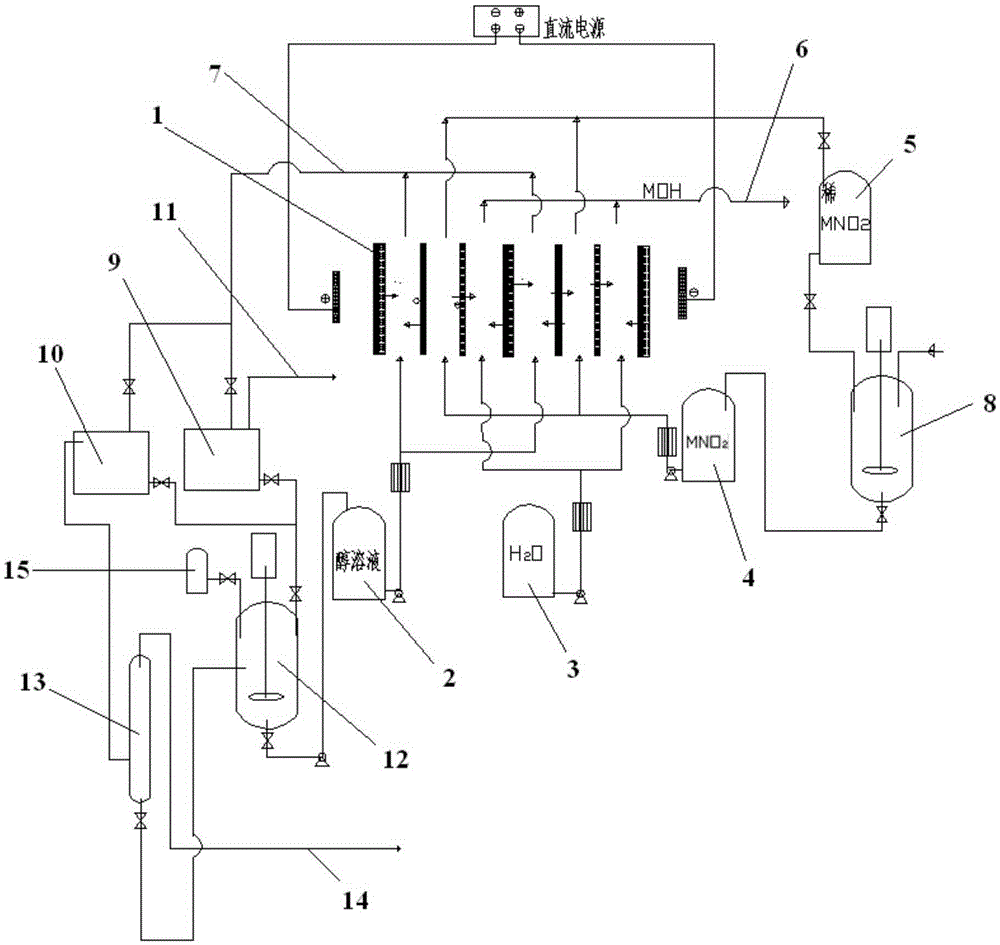

Method and device capable of continuously preparing nitrous acid ester

ActiveCN105237402AWon't happenProduction process is environmentally friendlyNitrous acid preparation ester preparationNitriteAlcohol

The invention provides a method and device capable of continuously preparing nitrous acid ester. The method comprises the following steps: taking a nitrite solution and an alcohol solution as the raw materials, individually introducing the nitrite solution and alcohol solution into a bipolar membrane electrodialysis device to carry out reactions to obtain three products: reaction mixed liquid containing nitrous acid ester, a residual nitrite solution, and an alkali solution; recovering the residual nitrite as raw materials for cycle use; recovering the alkali solution; making the reaction mixed liquid containing nitrous acid ester go through a gas-liquid separator or a liquid-liquid separator to obtain nitrous acid ester and an alcohol solution, collecting the target product namely nitrous acid ester, and recovering the alcohol solution as raw materials for cycle use. The provided method does not generate waste gas and waste liquid, the produced alkali liquid can be recovered for industrial production, the generated mother liquor can be completely recovered and reutilized in the reaction system, the production technology is environment-friendly, the reaction temperature is low, the reaction process is safe, and no safety hazard exists.

Owner:SHANDONG LANGHENG CHEM CO LTD +1

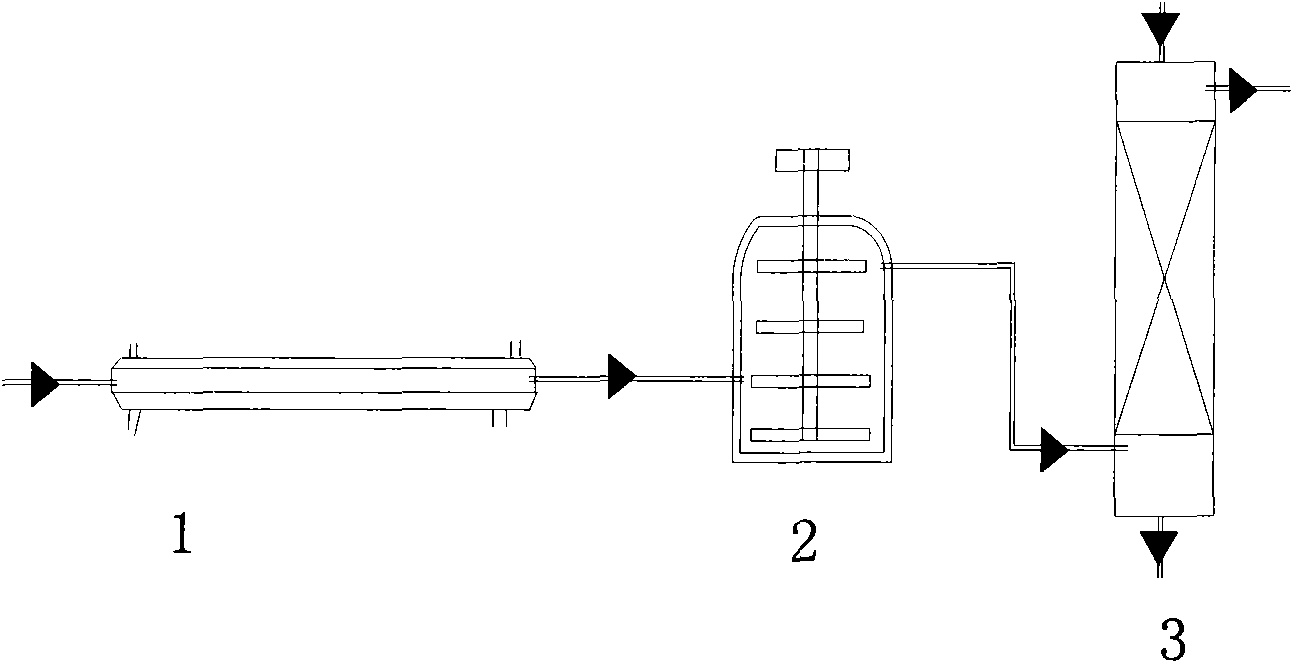

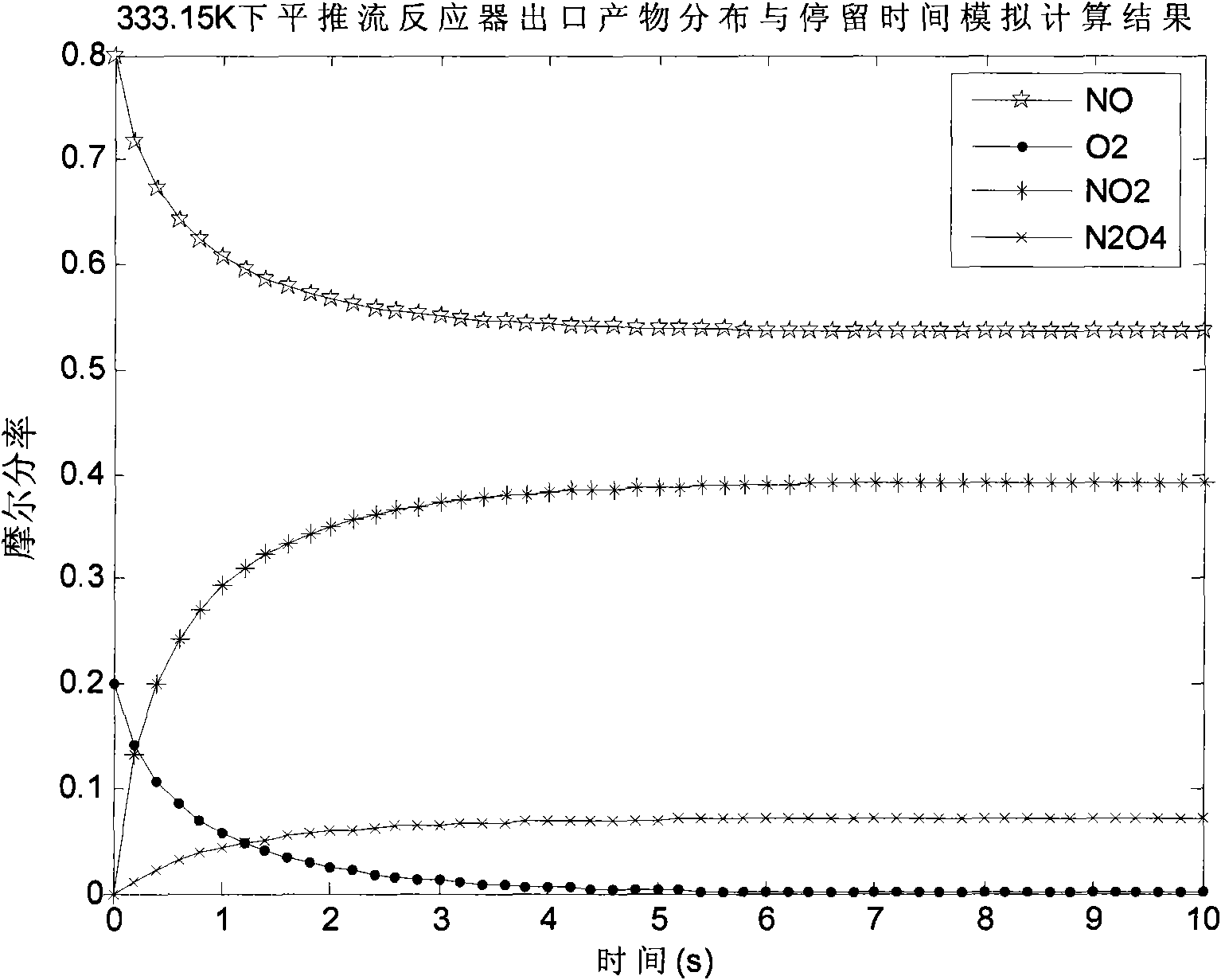

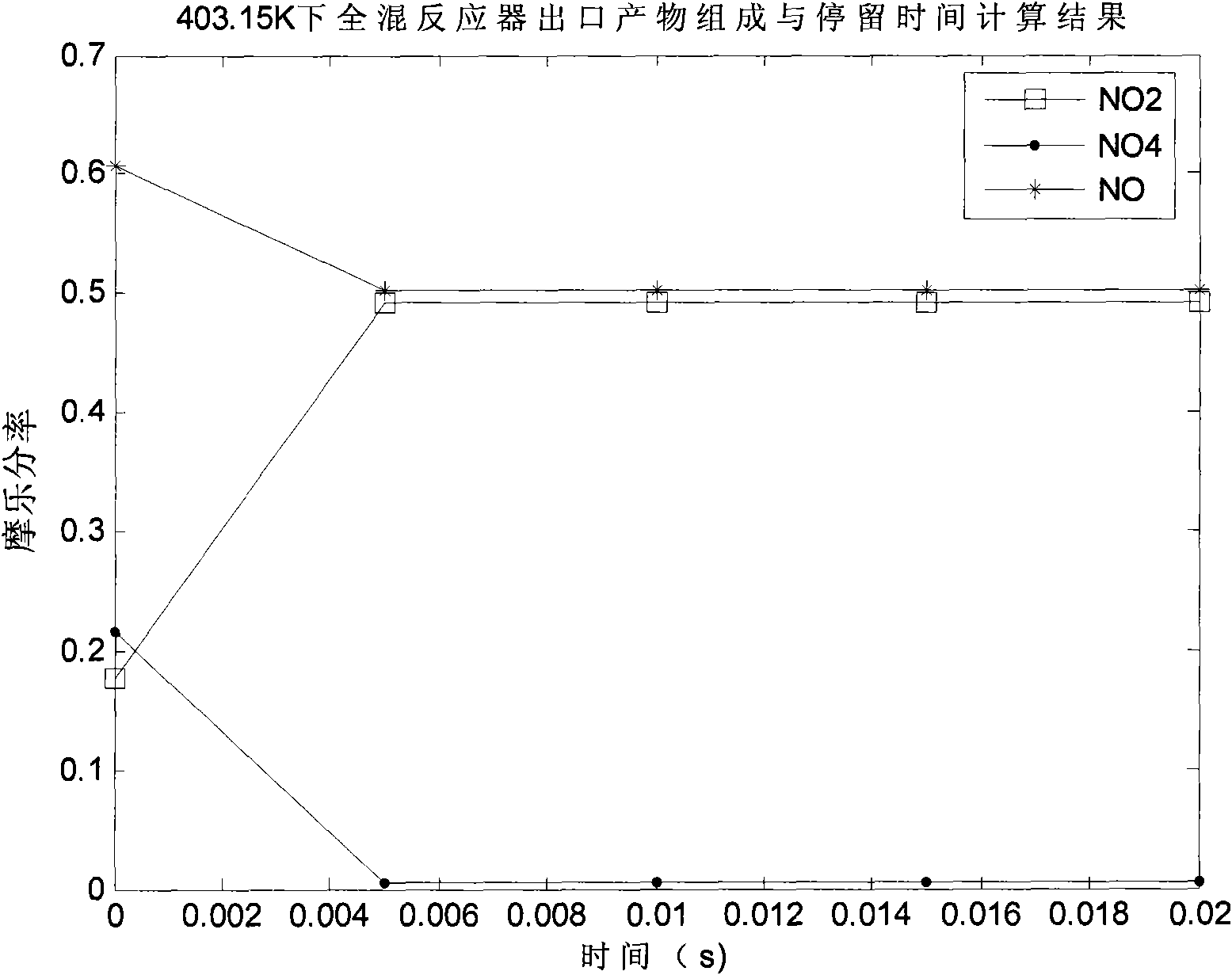

Preparation method of C1-C4 alkyl nitrite and reaction equipment implementing same

ActiveCN101885683AImprove conversion rateThe reaction equipment is simpleLiquid-gas reaction processesNitrous acid preparation ester preparationNitriteProduct gas

The invention discloses a preparation method of C1-C4 alkyl nitrite, comprising the following steps: a) oxidizing the gases containing NO to generate a gas mixture basically formed by N2O4, NO2 and NO; b) carrying out chemical balance adjustment on the gas mixture generated in the step a) to obtain a gas mixture basically formed by NO and NO2 with molar ratio of 1:1; and c) reacting the gas mixture generated in the step b) with C1-C4 alkanol to obtain the C1-C4 alkyl nitrite. The invention also provides a reaction device implementing the method, comprising i) a plug flow isothermal reactor, ii) a perfectly mixed isothermal reactor and iii) an esterification packed tower. The invention has the advantages of moderate operation conditions, short reaction time, high product purity, strong suitability to the raw materials, etc.

Owner:PUJING CHEM IND SHA +1

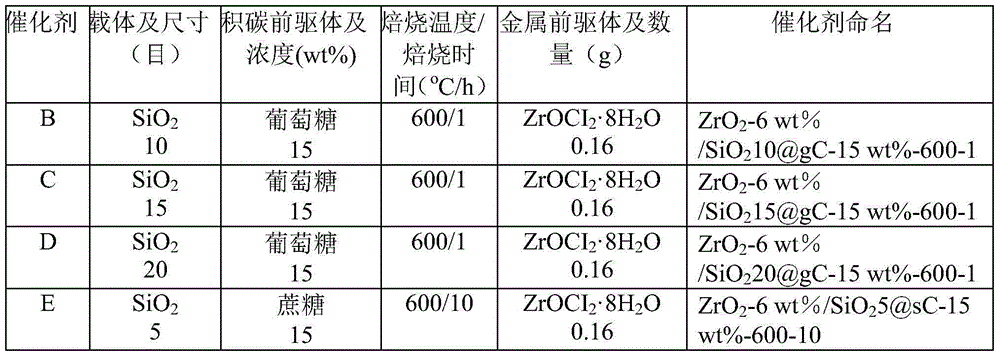

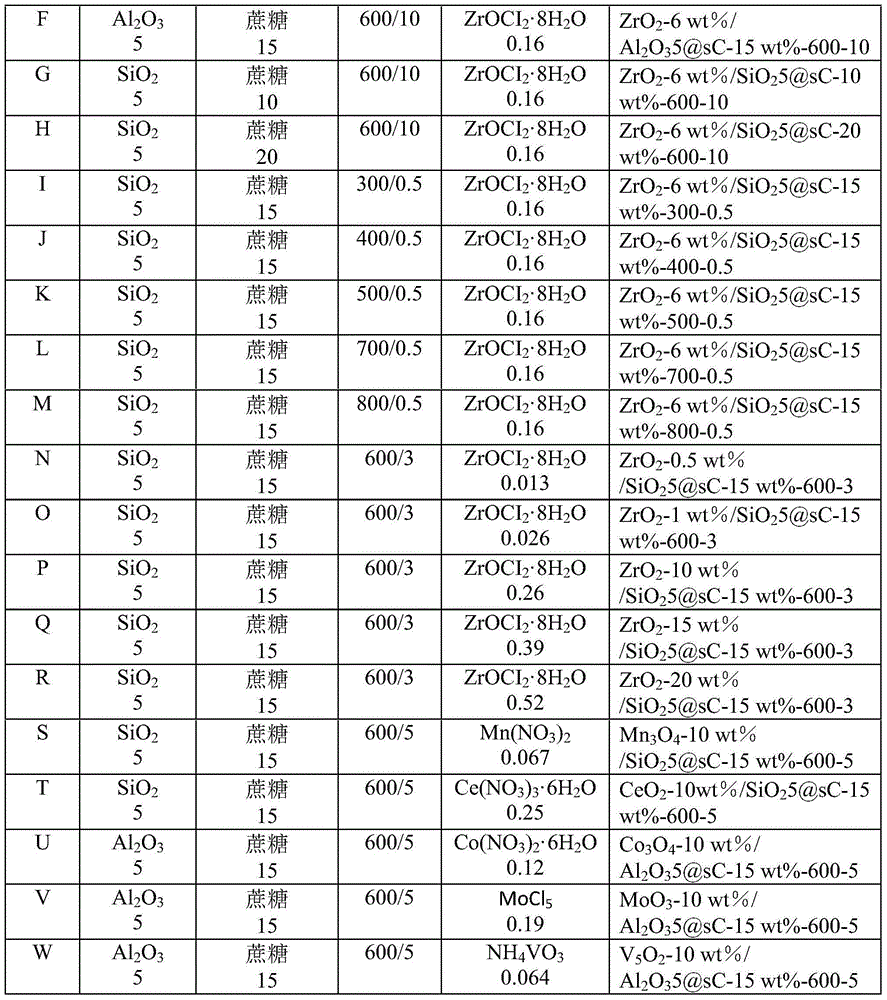

Catalyst for preparing methyl nitrite by reducing dilute nitric acid through methanol and preparation thereof

ActiveCN104941619AHigh surface areaGood dispersionMetal/metal-oxides/metal-hydroxide catalystsNitrous acid preparation ester preparationCarbon depositHigh activity

The invention discloses a catalyst for preparing methyl nitrite by reducing dilute nitric acid through methanol and preparation thereof. The catalyst is characterized in that SiO2 and Al2O3 pellets with the particle sizes being 5-20 meshes are adopted as carriers, transition metal oxides with oxidation reduction are taken as active components, carbon deposits are taken as auxiliary active components, the active components are highly dispersed on the carriers, the content range is 0.5-5wt%, and the carriers are wrapped by the auxiliary active components. The transition metal oxides with oxidation reduction are one or two of Mn3O4, CeO2, ZrO2, Co3O4, MoO3 and V2O5. The precursors of the carbon deposits are one of glucose and saccharose. According to the catalyst, the carriers have the advantages of high strength and wear resistance; an auxiliary catalyst has the advantage of high specific surface, the active components can be highly dispersed on the carriers due to the assistance of the auxiliary catalyst, so that the high activity is shown in the process of preparing methyl nitrite by reducing dilute nitric acid through methanol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing C1-C4 alkyl nitrites

ActiveCN101993375AMolecular sieve catalystsNitrous acid preparation ester preparationAlkyl nitritesNitrogen oxide

The invention relates to a method for producing C1-C4 alkyl nitrites, which mainly solves the technical problems of low objective product selectivity and high side reaction product nitric acid content in the prior art. The method comprises the following steps of: a) delivering a nitrogen oxide raw material generated by oxidation of ammonia and air and a first stream of C1-C4 alkanol into a reactor I to generate an effluent I containing C1-C4 alkyl nitrites, and separating the effluent to obtain a gas effluent II and a liquid effluent III; b) delivering the gas effluent II and a first stream of oxygen into a reactor II to contact with an aluminosilicate catalyst to generate an effluent IV; c) delivering a second stream of C1-C4 alkanol and the effluent IV into a reactor III to generate an effluent V by reaction, and separating the effluent to obtain a non-condensed gas effluent VI and an effluent VII containing C1-C4 alkyl nitrites; and d) drying the effluent VII, and then delivering the dried effluent VII to a subsequent reaction unit for use. According to the technical scheme, the method well solves the problems, and can be used for industrial production of the increased C1-C4 alkyl nitrites.

Owner:CHINA PETROLEUM & CHEM CORP +1

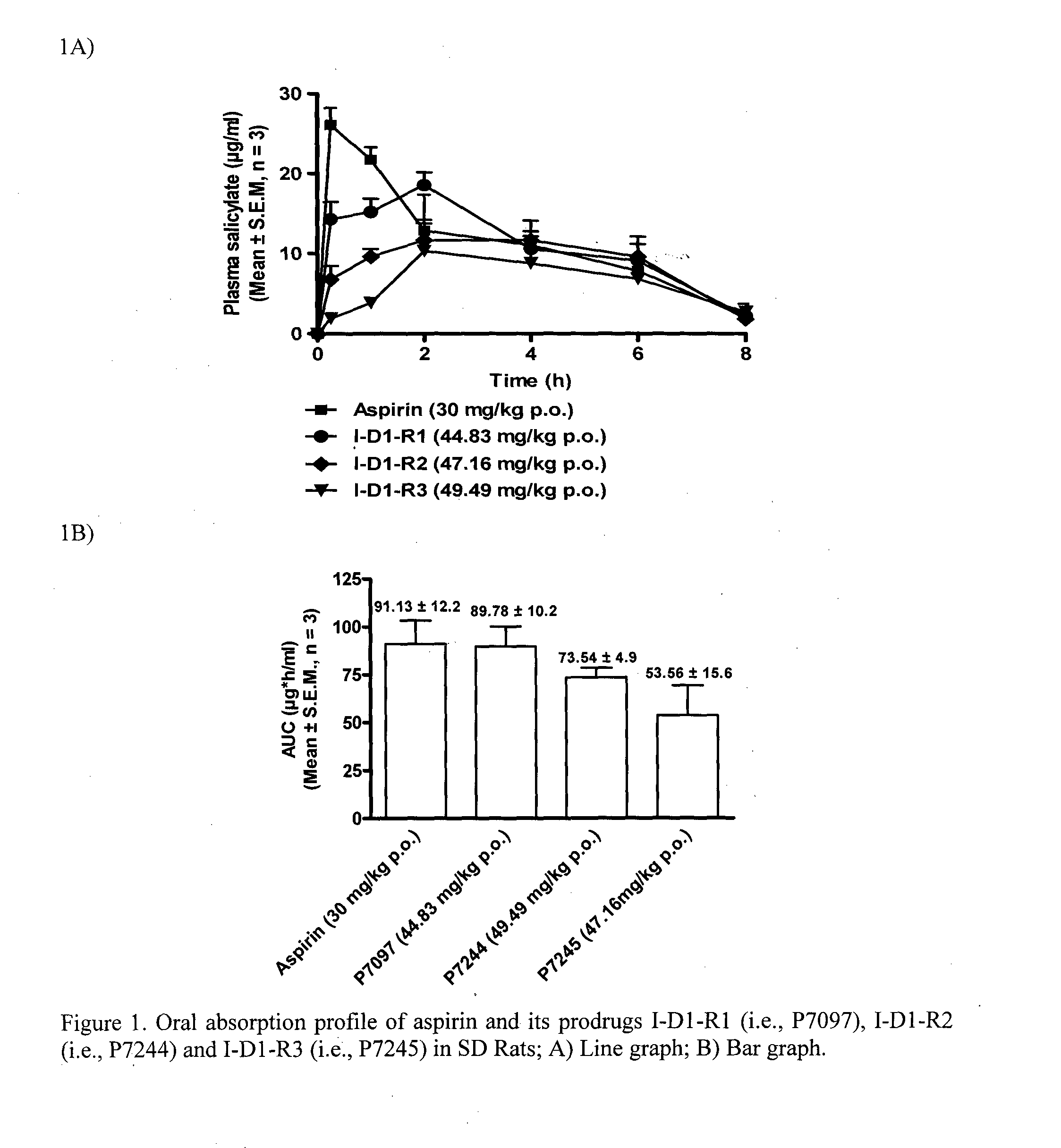

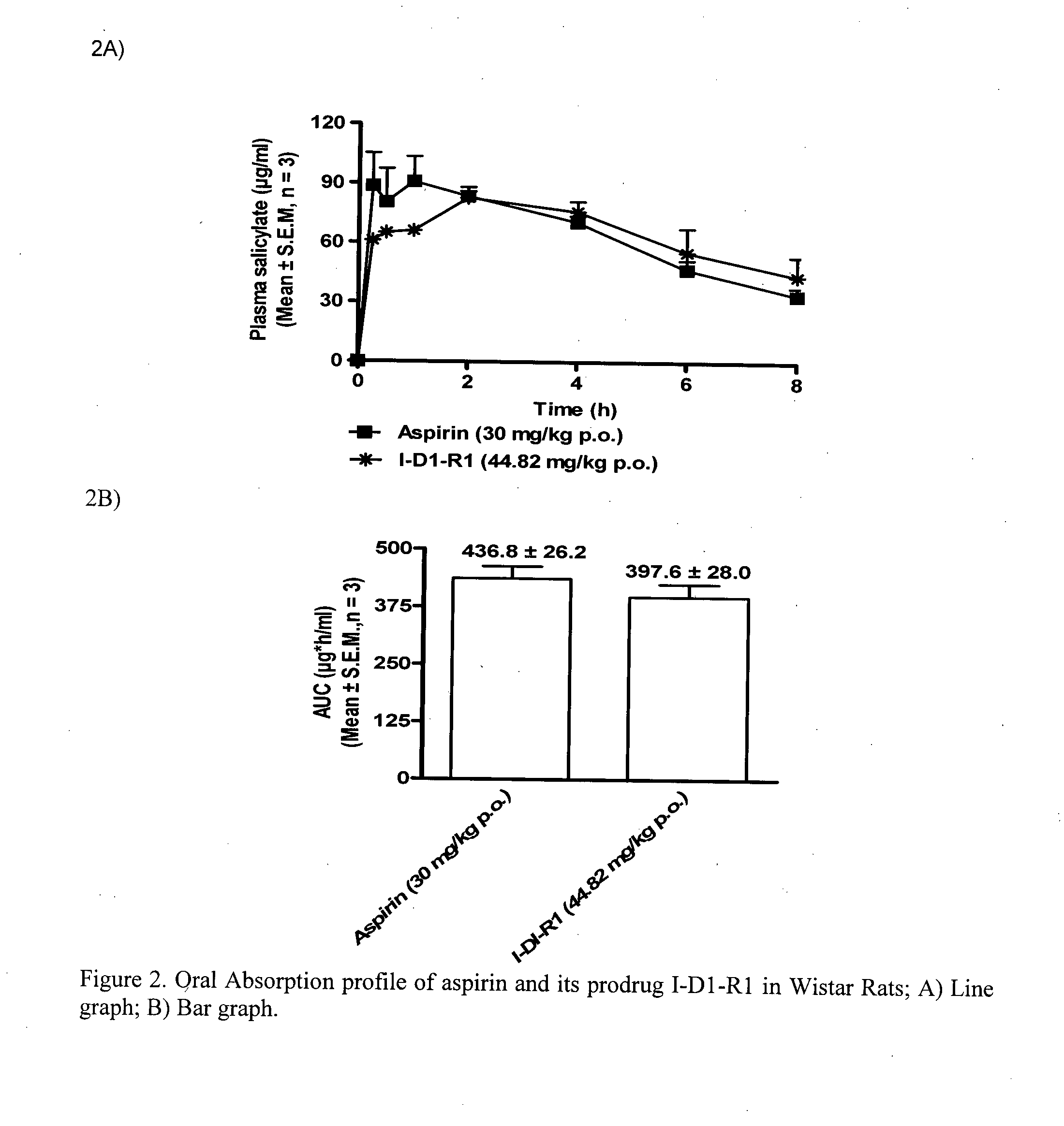

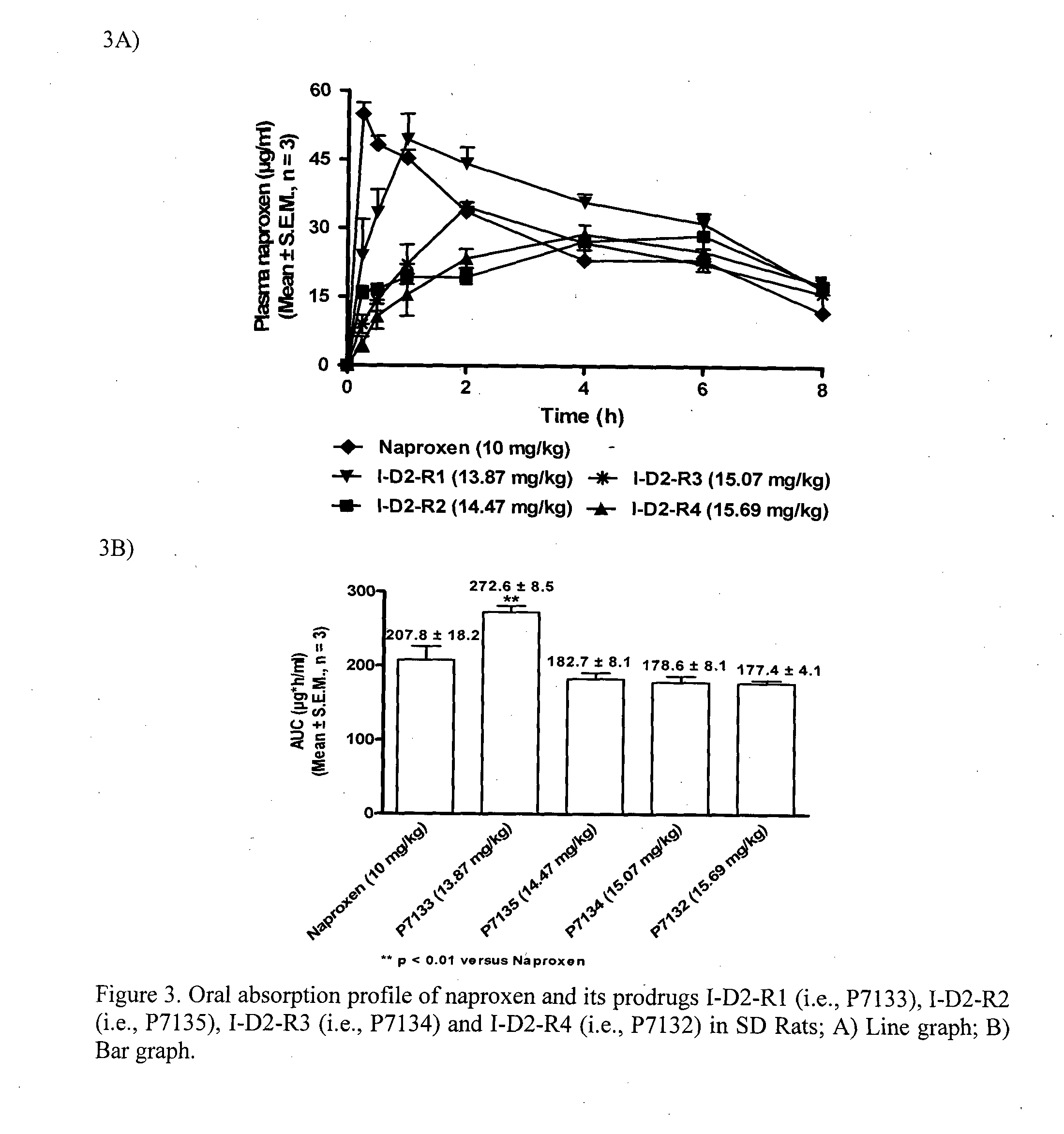

Nitric Oxide Releasing Produgs of Therapeutic Agents

The present invention relates to nitric oxide releasing prodrugs of known drugs or therapeutic agents wherein the drug or therapeutic agents contain at least one carboxylic acid group. The invention also relates to processes for the preparation of these nitric oxide releasing prodrugs, to pharmaceutical compositions containing them and to methods of using these produgs.

Owner:SATYAM APPARAO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com