Patents

Literature

42results about How to "Add processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Harmless and resource utilization method of steel industry chromium-containing wastewater

InactiveCN109052711ALess investmentGuaranteed uptimeSludge treatment by de-watering/drying/thickeningWater contaminantsSteelmakingResource utilization

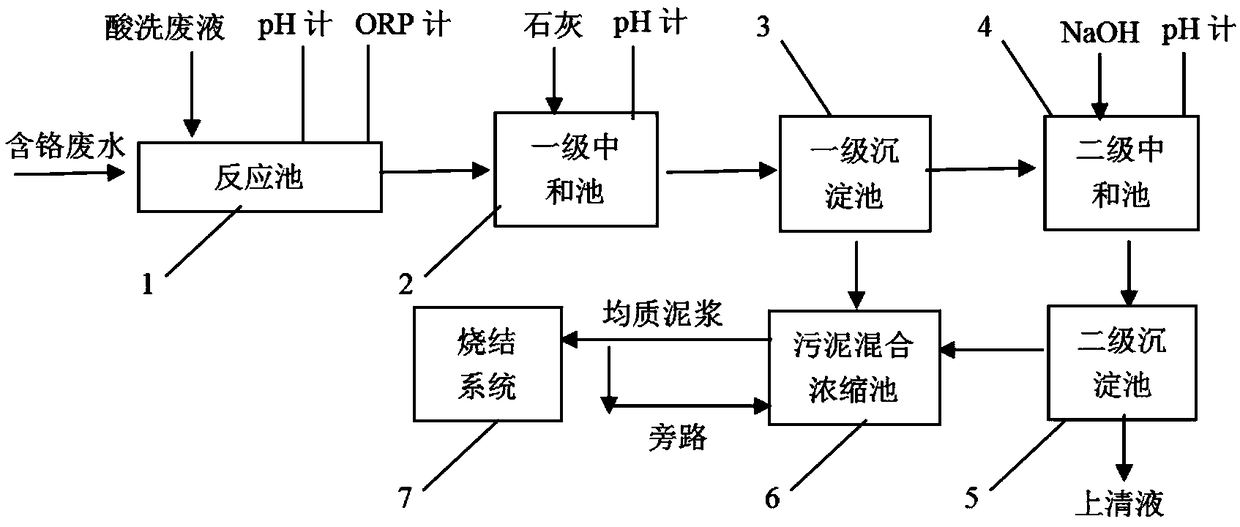

The invention discloses a harmless and resource utilization method of steel industry chromium-containing wastewater. The harmless and resource utilization method of the steel industry chromium-containing wastewater comprises the following steps: 1) adding steel rolling system acid-washing waste liquid into the chromium-containing wastewater, reducing Cr<6+> in the chromium-containing wastewater into Cr<3+> by utilizing the acidic environment provided by the acid-washing waste liquid and the Fe<2+> therein, and oxidizing the Fe<2+> into Fe<3+>; 2) adding alkali into the reduced wastewater, neutralizing, enabling the Cr<3+> to generate Cr(OH)3 precipitate and the Fe<3+> to generate Fe(OH)3 precipitate, and performing mud and water separation to obtain sludge containing chromium and iron; 3)performing concentration treatment on the sludge containing chromium and iron to obtain homogenous slurry; and 4) feeding the homogenous slurry into a sintering system, mixing the homogenous slurry and the sintering raw materials according to a certain proportion and sintering to obtain a sintered ore finished product for ironmaking and steelmaking. By the method, up-to-standard discharge of the chromium-containing wastewater is realized and resource utilization of the chromium element in the wastewater is realized.

Owner:武汉钢铁有限公司

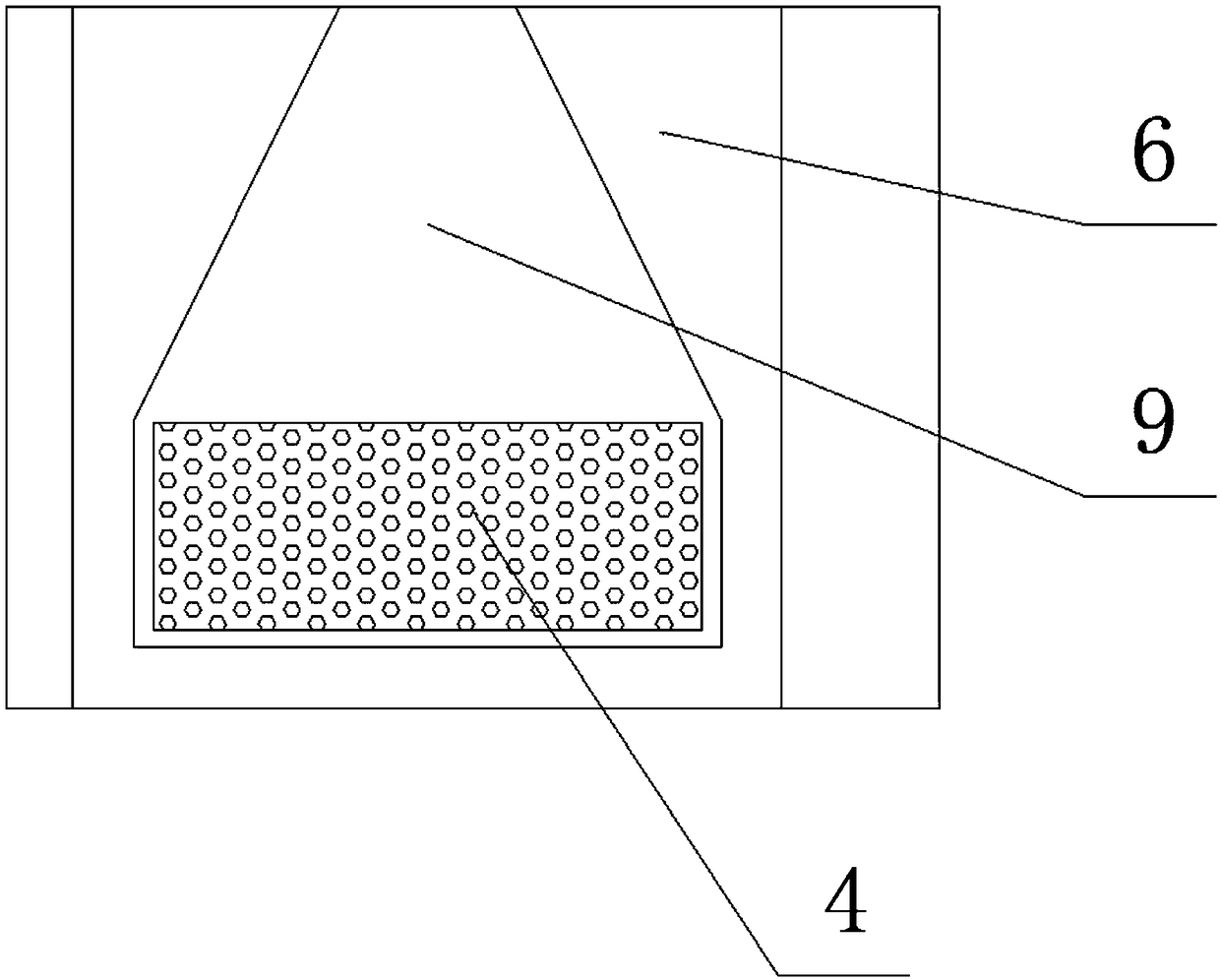

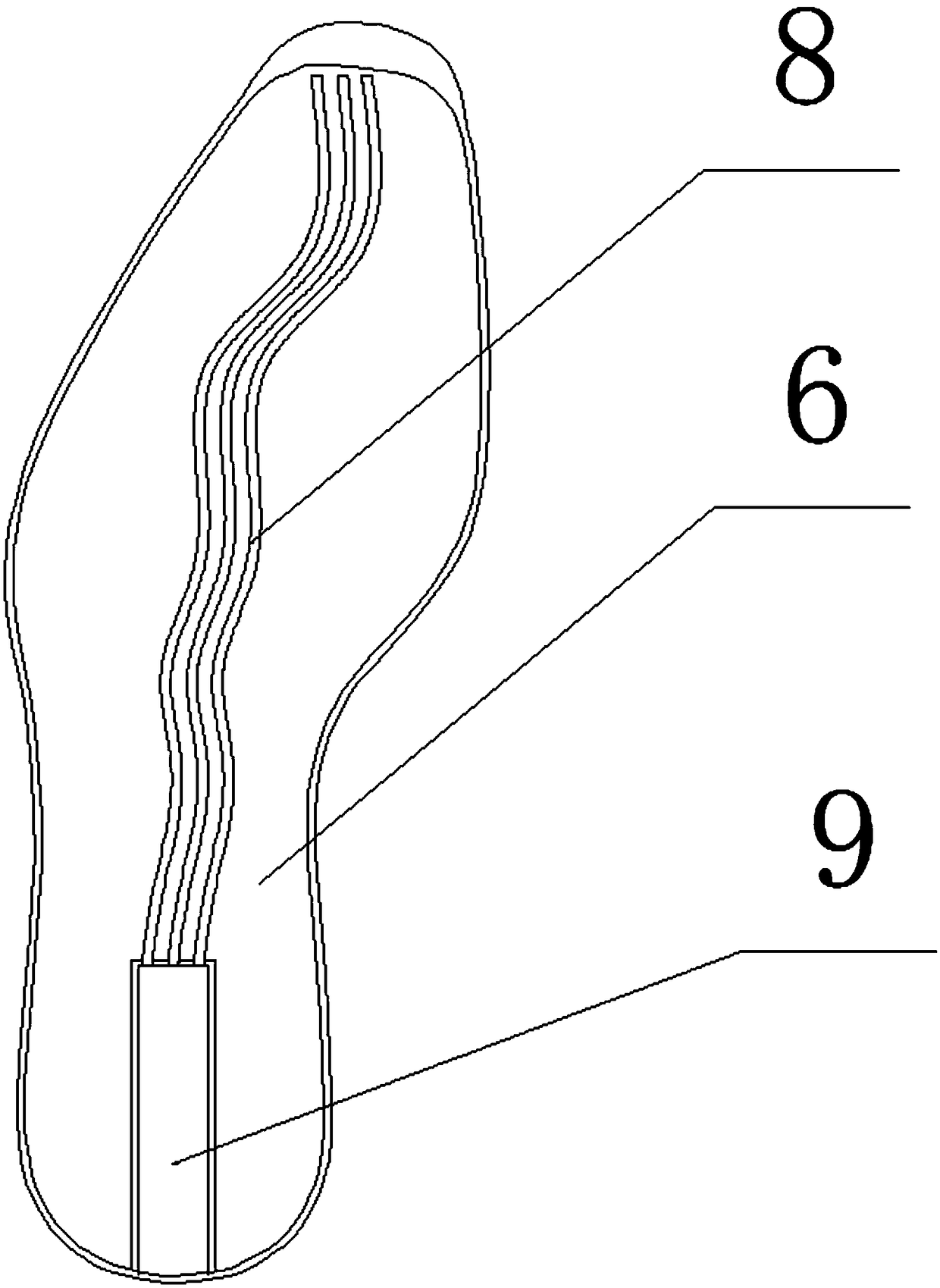

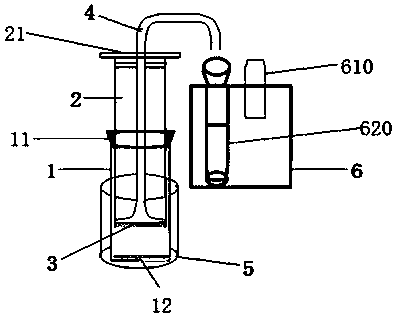

Soft-shelled turtle hatching method and special incubator

InactiveCN102919193APrecise temperature controlAccurately Control HumidityAnimal husbandryEconomic benefitsObserved Survival

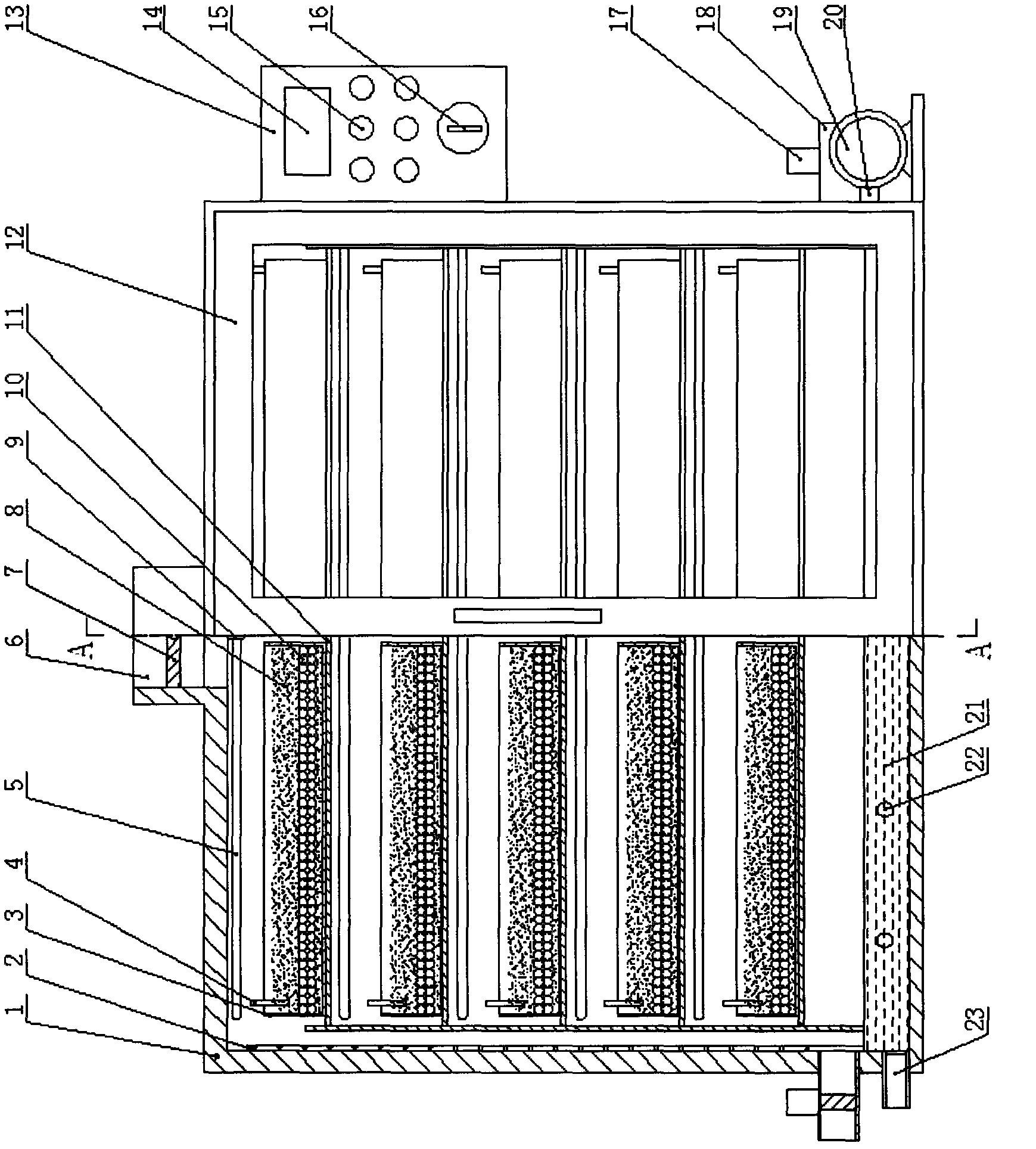

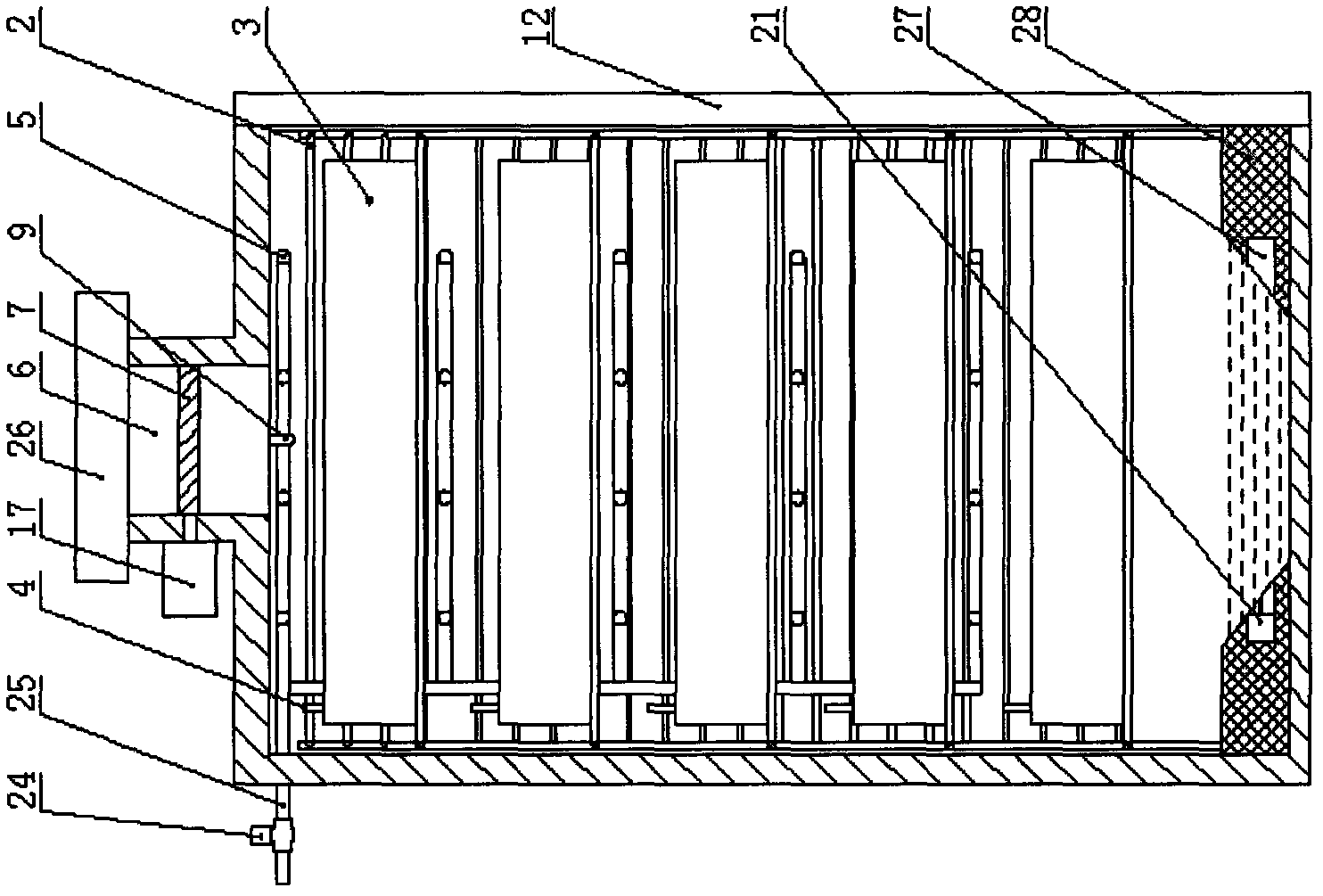

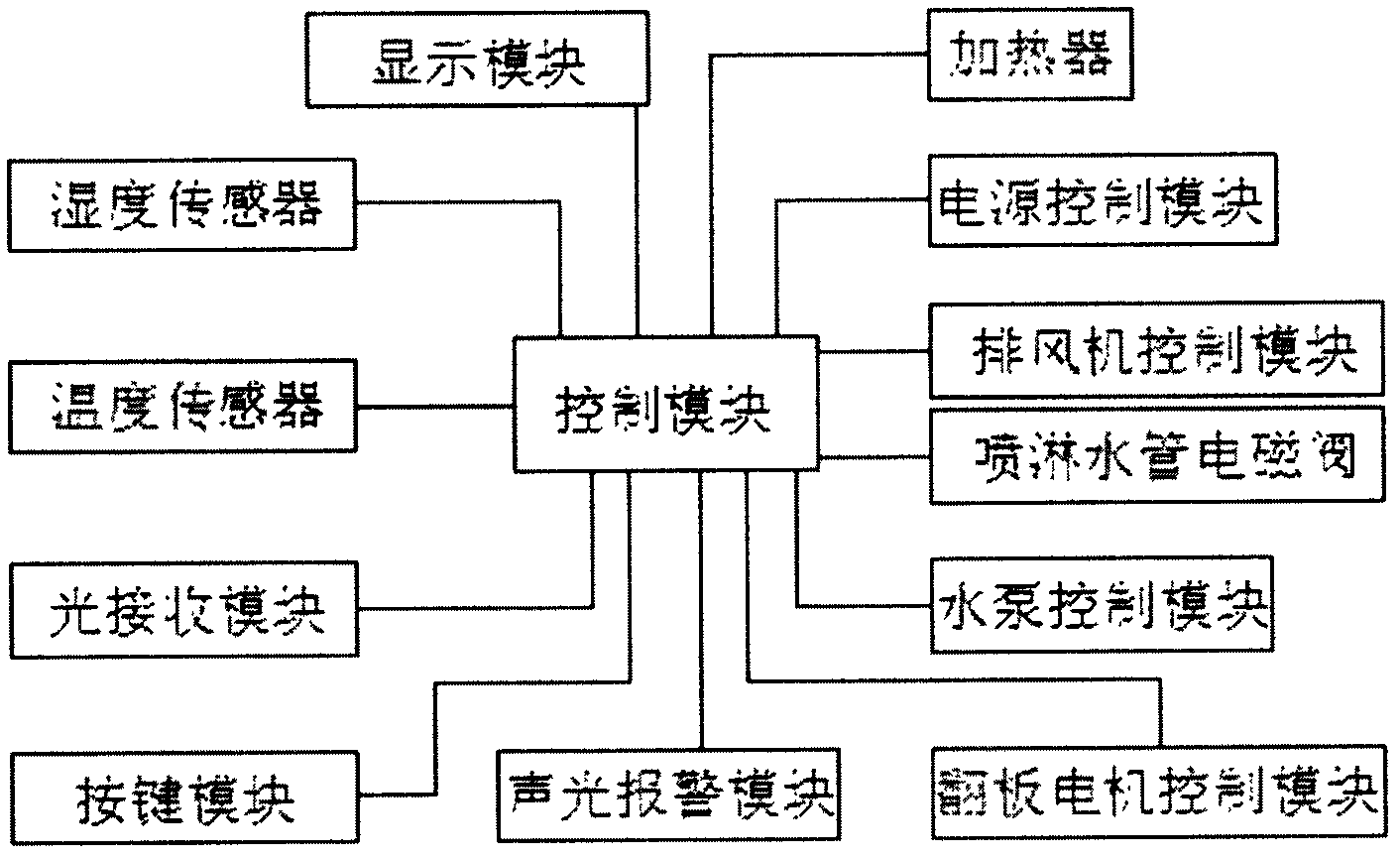

The invention relates to a soft-shelled turtle hatching method, which comprises the following steps of: (1) stacking fertilized soft-shelled turtle eggs layer by layer on the surface of a sand layer of a hatching tray in an incubator, wherein the thickness of the sand layer is 2 to 3 centimeters, and the water content of the sand layer is 7 to 8 percent; (2) covering a sand layer with the thickness of 2 to 3 centimeters and the water content of 7 to 8 percent on the soft-shelled turtle eggs; and (3) after the steps (1) and (2) are finished, regulating the temperature in the incubator to be 33 to 34 DEG C, keeping the relative humidity of air at 85 to 88 percent, ventilating for 1 to 2 hours at noon of every day in the hatching process, and finishing hatching of the soft-shelled turtle eggs after 43 to 45 days. The hatching method is simple and feasible; the special incubator is scientific and reasonable in design and convenient to operate; and manpower is greatly saved, the hatching cost is reduced, the survival rate of soft-shelled turtle fries is improved, and economic benefits of an enterprise are increased.

Owner:天津漫河甲鱼养殖专业合作社

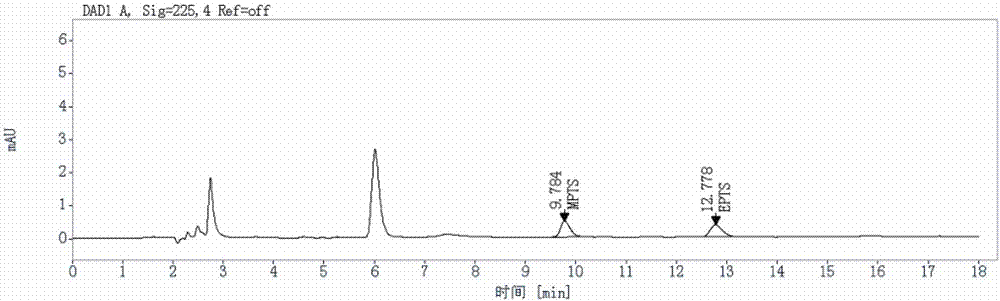

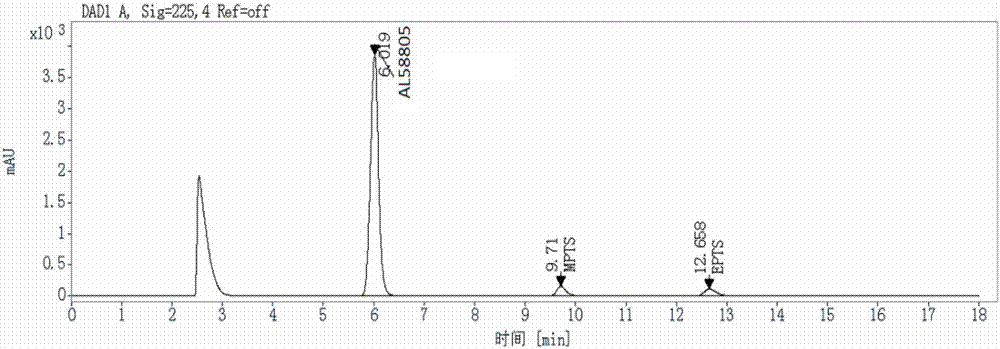

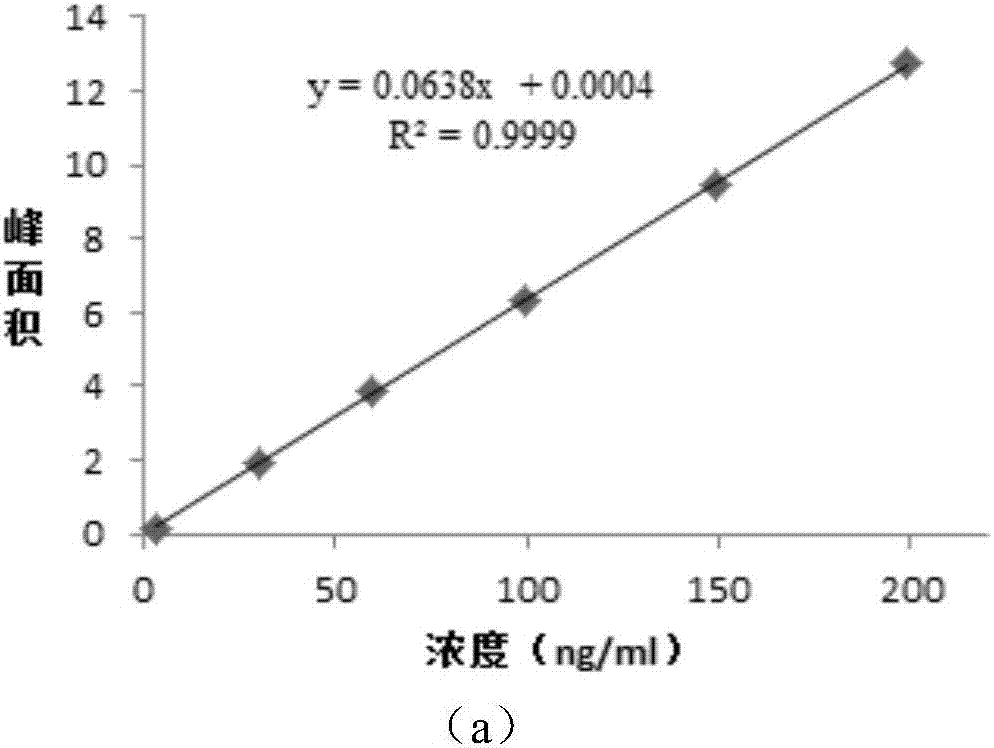

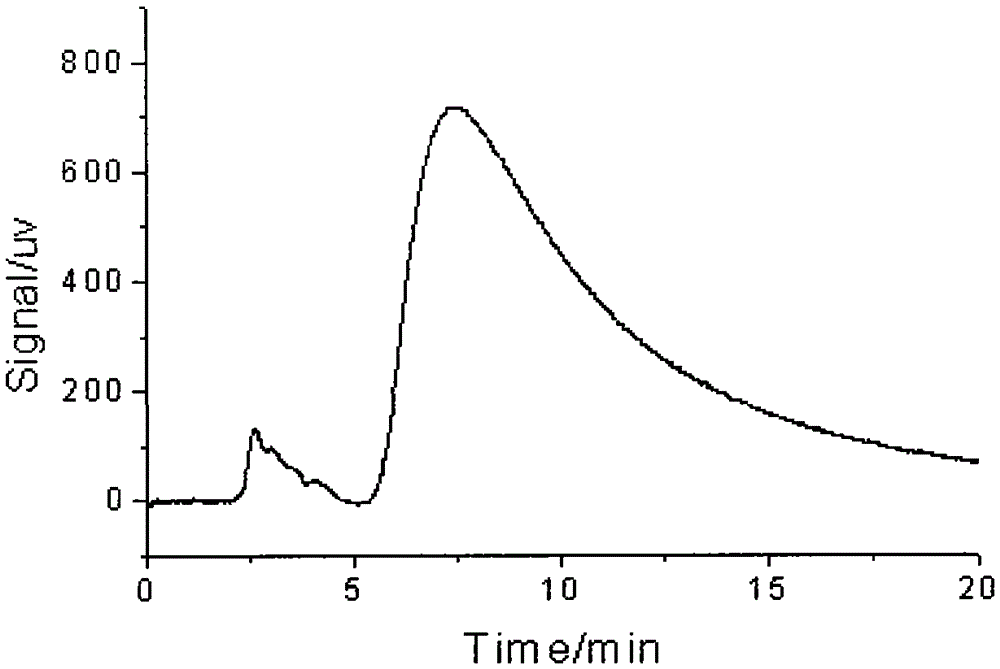

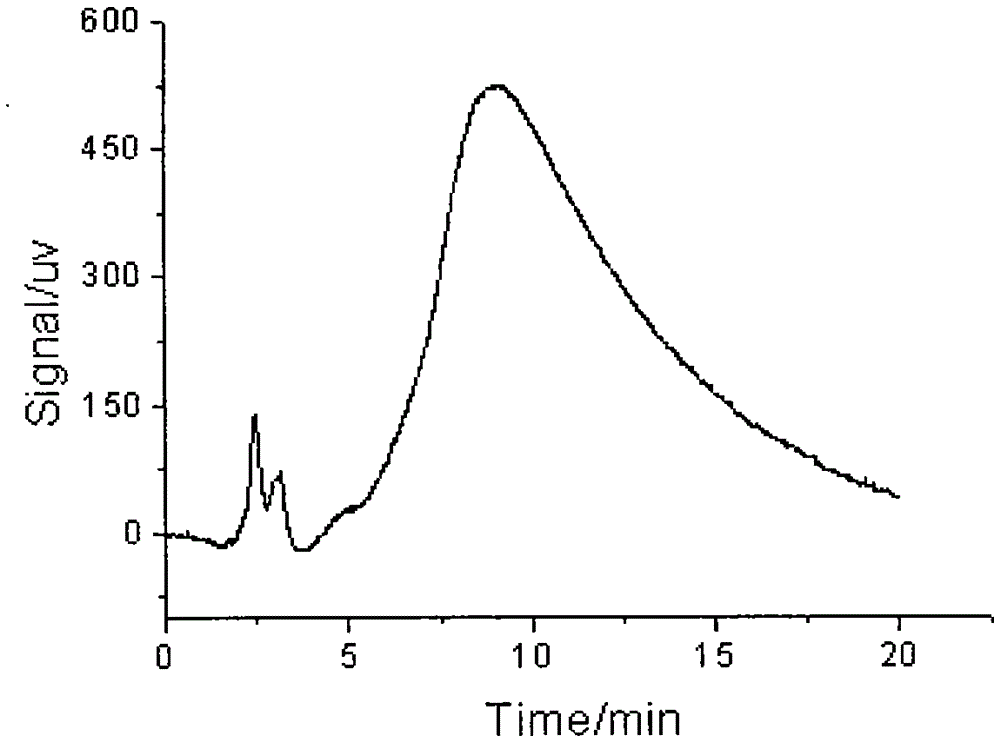

Method for detecting genotoxic impurities in AL58805 bulk drug or medicinal preparation by using high-performance liquid chromatography

ActiveCN107037153AEfficient separationDo not interfere with detectionComponent separationPhosphoric acidColumn temperature

The invention relates to a method for detecting genotoxic impurities in an AL58805 bulk drug or medicinal preparation by using high-performance liquid chromatography. The method is directed at methyl p-toluenesulfonate (MPTS) and ethyl p-toluenesulfonate (EPTS); a sample undergoes pre-treatment at first; and then high-performance liquid chromatography is employed for determination, wherein a C18 chromatographic column is employed; detection wavelength is 225 nm; an aqueous acetonitrile-phosphoric acid solution is used as a mobile phase; flow velocity is 0.8 to 1.2 mL / min; column temperature is 30 to 40 DEG C; a sample size is 20 [mu]L; and elution time is 18 min. Results show that the detection limit of MPTS is 0.3 ppm and the limit of quantitation of MPTS is 1 ppm; and the detection limit of EPTS is 0.5 ppm and the limit of quantitation of EPTS is 1.4 ppm. The method has the advantages of good specificity, simple operation, high sensitivity and accurate results and is applicable to determination of MPTS and EPTS in AL58805.

Owner:常州佳德医药科技有限公司

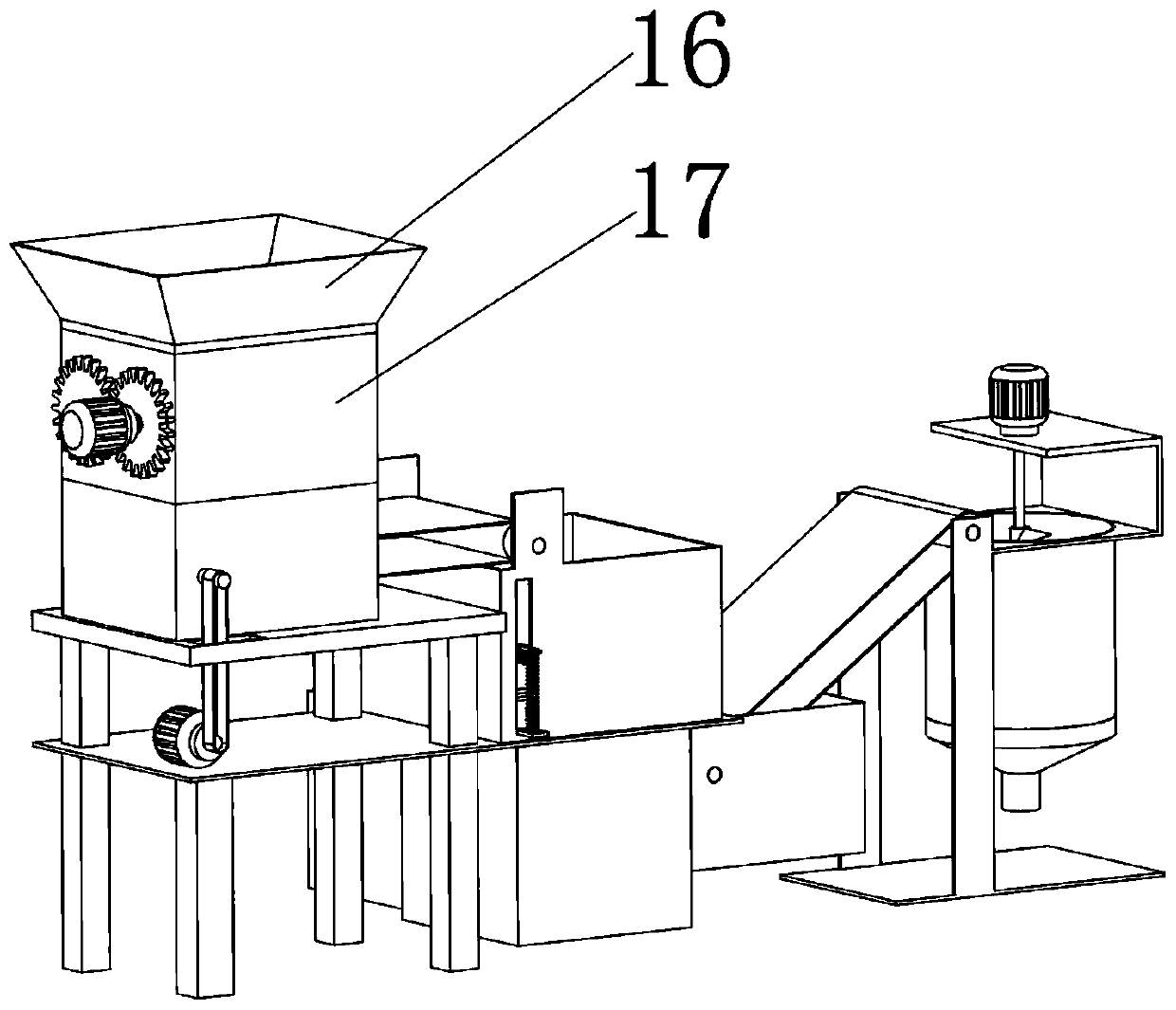

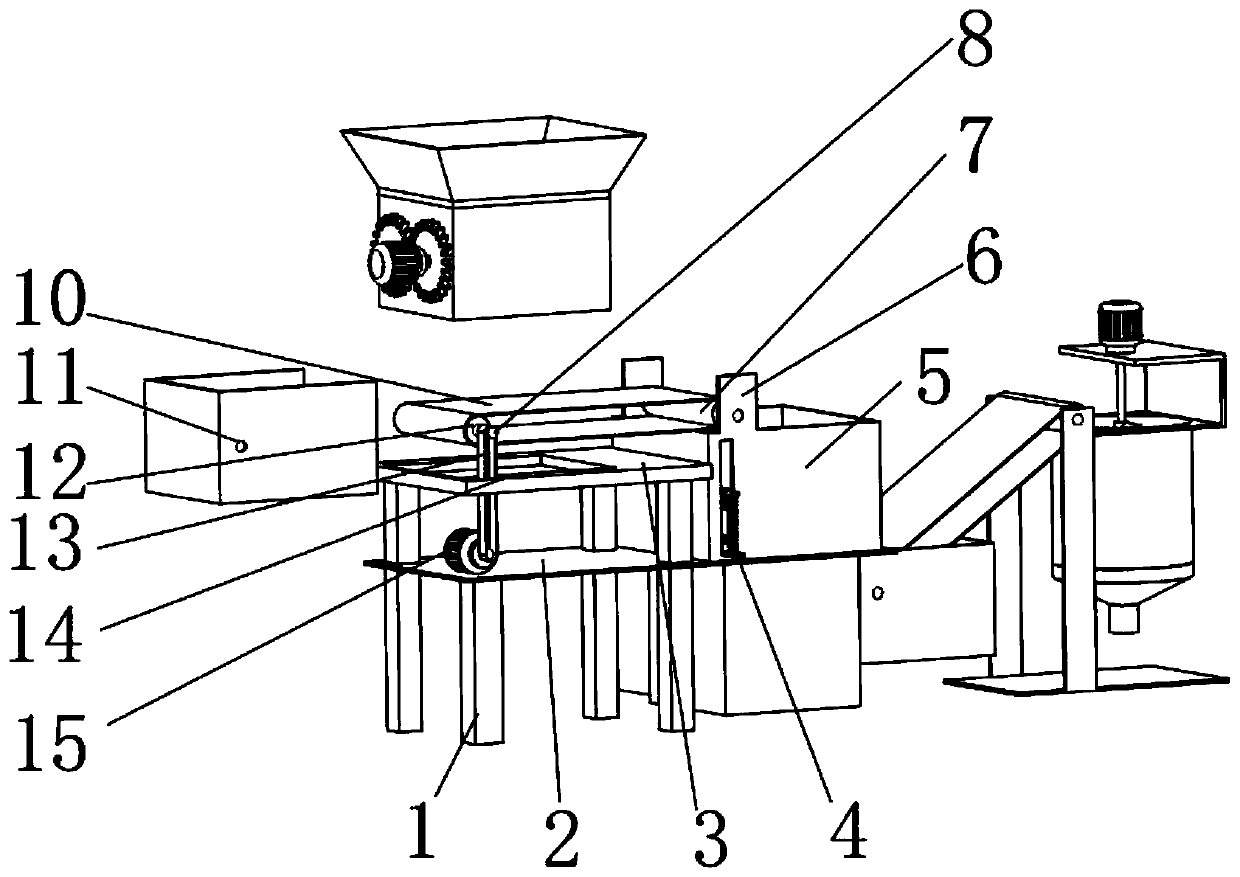

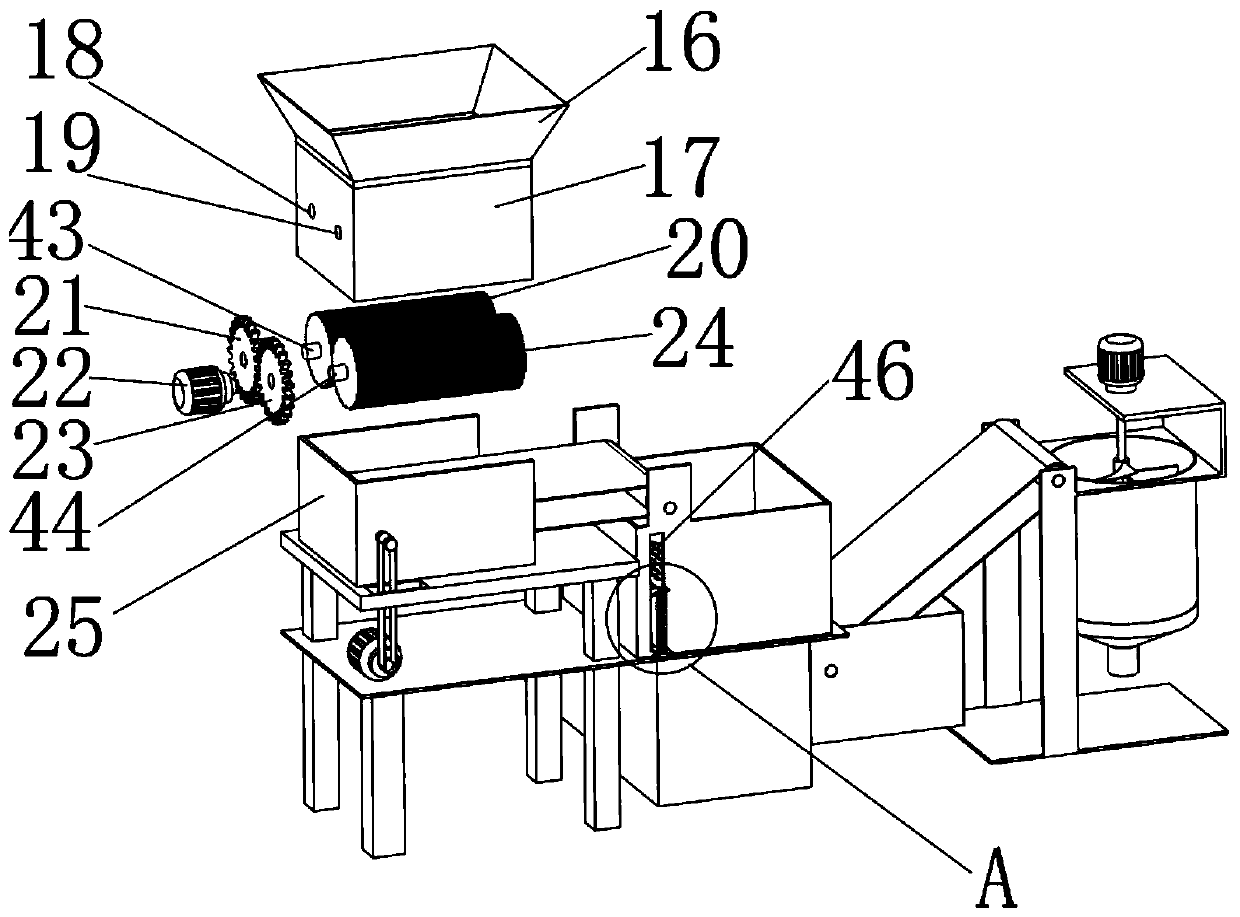

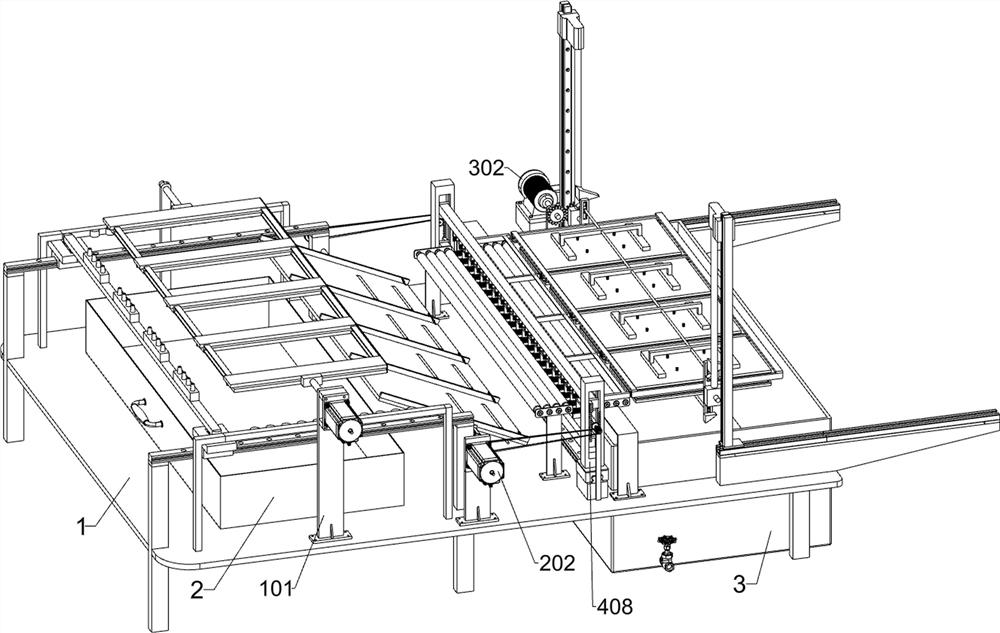

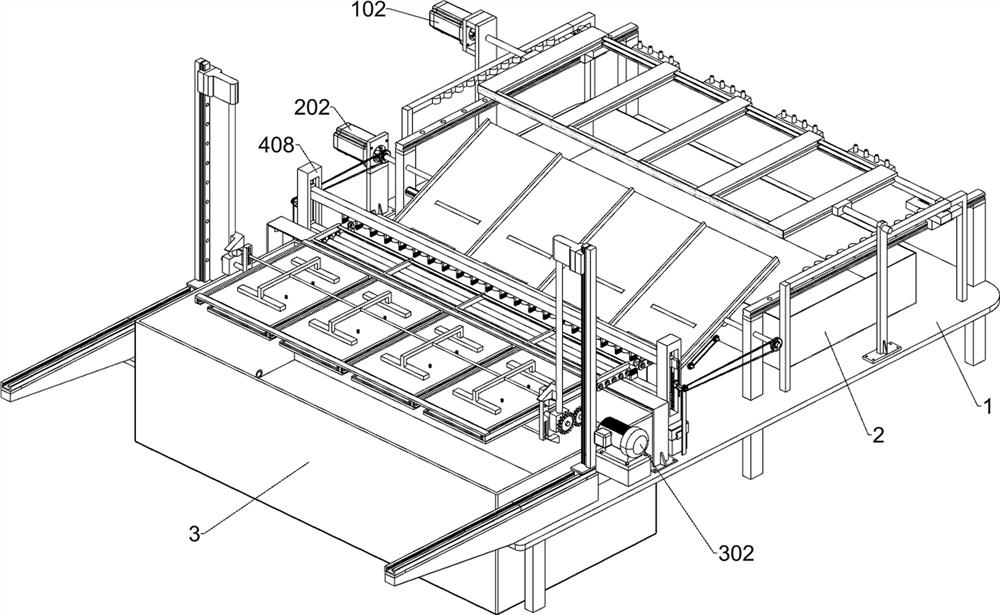

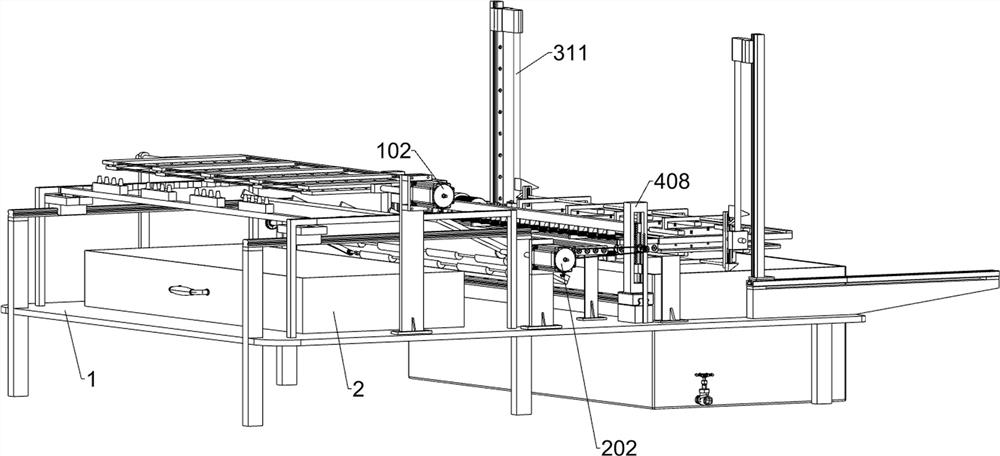

Concrete crushing regeneration equipment

PendingCN111113679AAdd processing stepsEliminate manual crushingMixing operation control apparatusPretreatment controlConstruction engineeringMechanical engineering

The invention discloses concrete crushing regeneration equipment, and relates to the technical field of building equipment. The concrete crushing regeneration equipment comprises a supporting frame, asupporting plate is arranged in the middle of the supporting frame, a supporting table is arranged at the top end of the supporting frame, a roller box is arranged at the top end of the supporting table, a crushing box is arranged at the top end of the roller box, a first extruding roller is arranged in the crushing box, a second extruding roller matched with the first extruding roller is arranged on the side face of the first extruding roller, and a feeding hopper is arranged at the top end of the crushing box. The concrete crushing regeneration equipment has the beneficial effects that thefirst extruding roller and the second extruding roller are utilized to crush mass concrete firstly, then a screening device is utilized to screen the crushed concrete, aggregates conforming to the specified particle size are screened out, manual crushing is omitted, using of labor is reduced, the crushing efficiency is improved, the crushed coarse aggregates are conveyed into a stirring barrel, the stirring barrel is utilized to stir and mix concrete blocks, the treatment steps of the concrete are increased, and thus the concrete treatment equipment is more perfect.

Owner:HEFEI DONGKAI NEW BUILDING MATERIALS

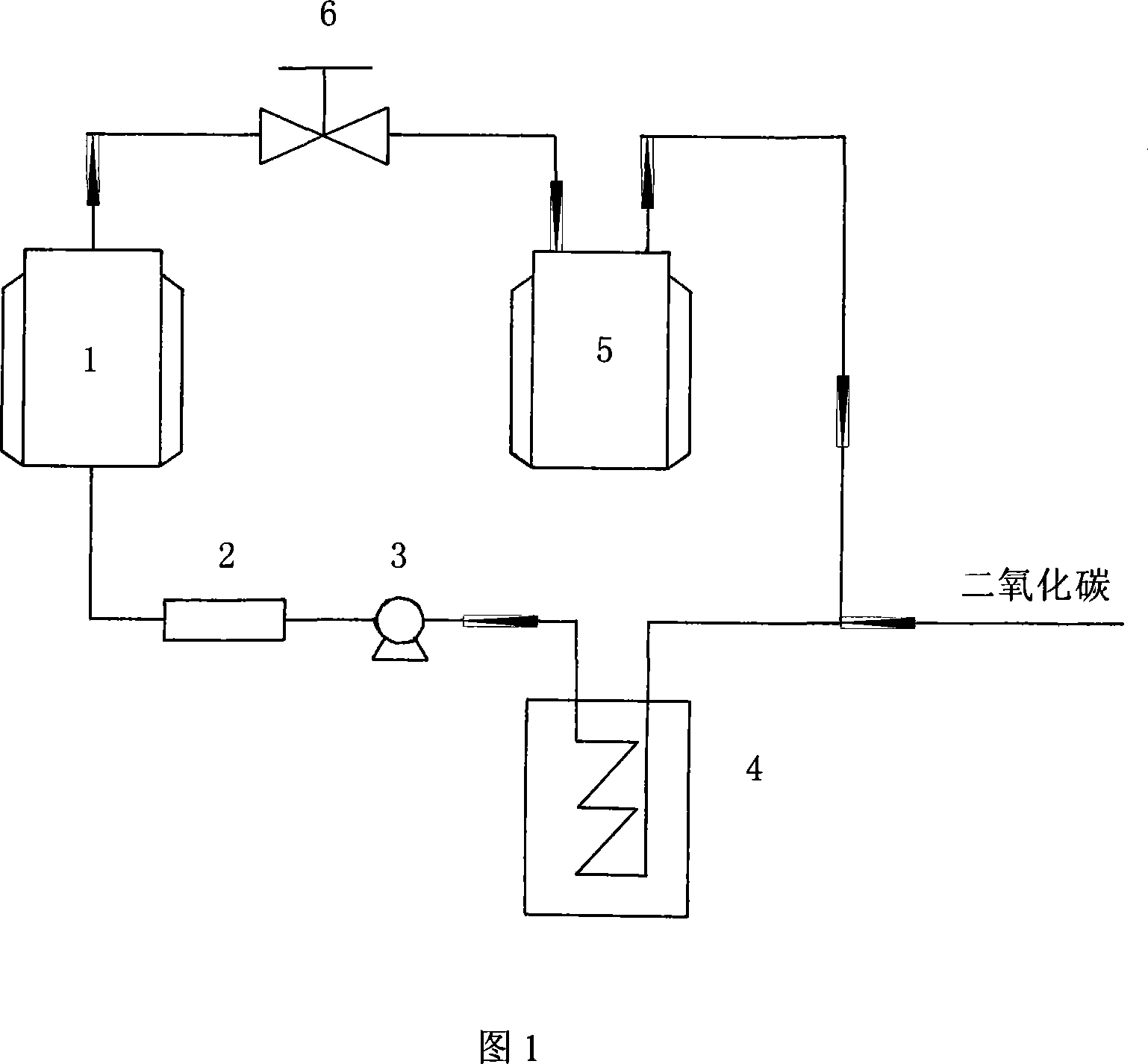

Method for extracting cholesterine in lanosterol by supercritical CO2

InactiveCN101074257APurity effectIncrease contentSteroids preparationBulk chemical productionLanosterolCholesterol

A method for extracting cholesterol from lanosterol by supercritical CO2 is carried out by putting lanosterol and laminating agent into extractor, delivering CO2 into extractor by compressing pump, adjusting CO2 extractor pressure and temperature, controlling CO2 flow speed, extracting to obtain CO2 with solute, decompressing CO2 with solute, separating to obtain cholesterol and lanosterol, dissolving for cholesterol by solvent, lowering temperature and crystallizing to obtain high-content final product. It's simple and inodorous, has better purity and light color.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

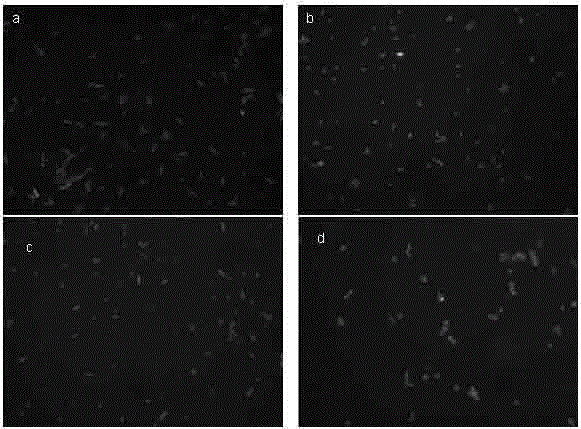

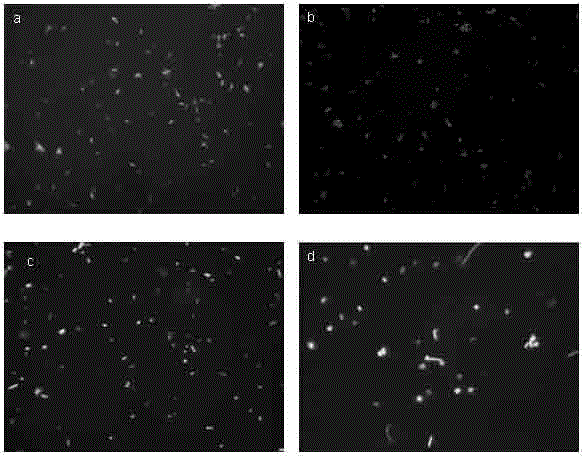

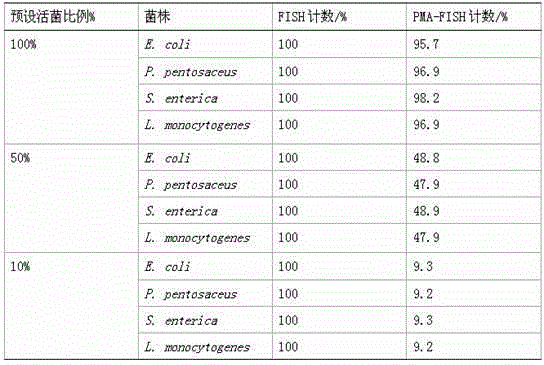

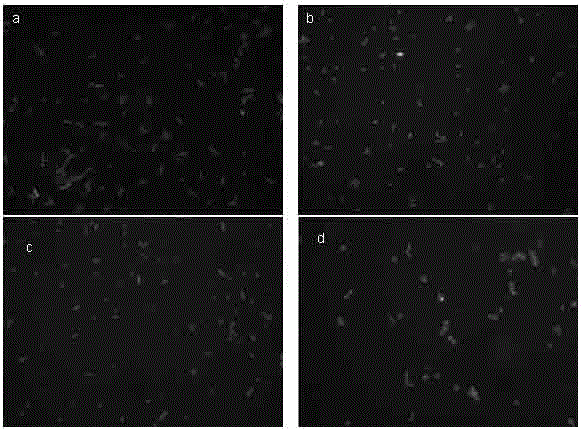

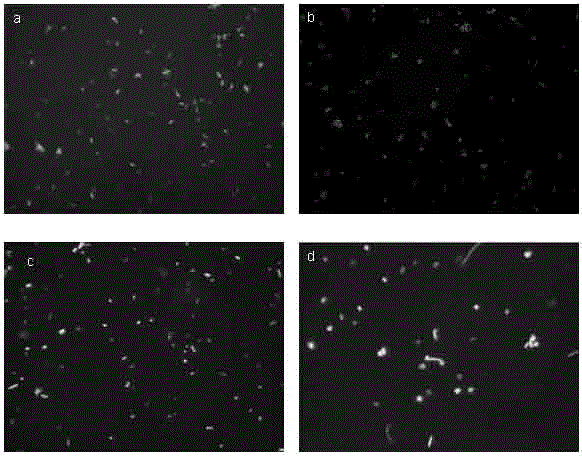

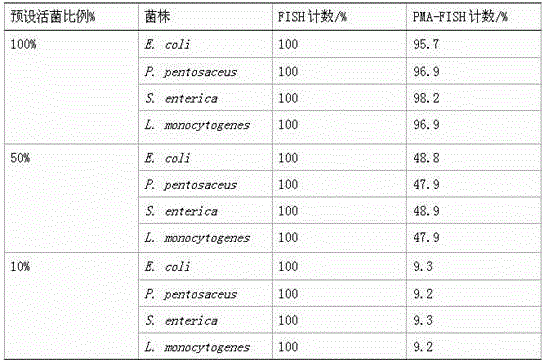

Quantitative detection method of live bacteria based on FISH technique

ActiveCN104561354AAdd processing stepsAchieve effective distinctionMicrobiological testing/measurementCovalent bindingBiophysics

The invention belongs to the field of microbiological detection, and relates to a quantitative detection method of live bacteria based on an FISH technique. The method comprises the following steps: adding a PMA nucleic acid dye for pre-treating before an implementation process of a conventional fluorescence in-situ hybridization method; carrying out covalent binding of nucleic acid in dead bacterium cells and PMA in the PMA treatment process, and sending out orange fluorescence under blue light excitation of a fluorescence microscope, so as to know that the bacteria in the orange fluorescence are dead bacteria in an original system; combining rRNA in live bacterium cells with a fluorescence probe in a hybridization step, and sending out green fluorescence under blue light excitation of the fluorescence microscope by the fluorescence probe, so as to know that the bacteria in the green fluorescence are the live bacteria in the original system. Through improvement of a fluorescent in-situ hybridization technique, the step of adding PMA dye for treating is increased, and effective distinguishing of the dead bacteria and the live bacteria in a sample system is achieved; and a set of method capable of rapidly and quantitatively detecting the live bacteria in the sample is built. The method has relatively high universality in bacterial quantization.

Owner:FUZHOU UNIV

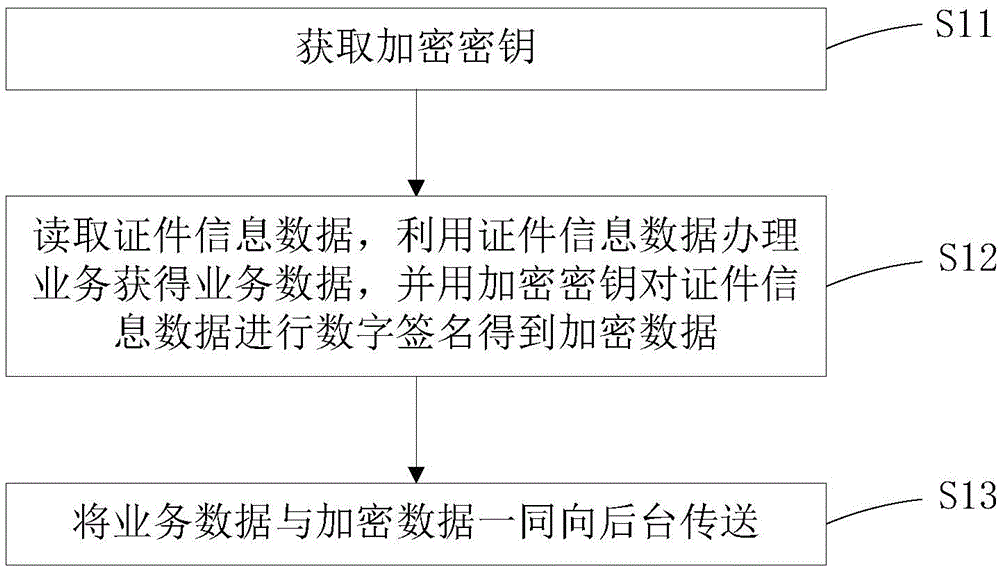

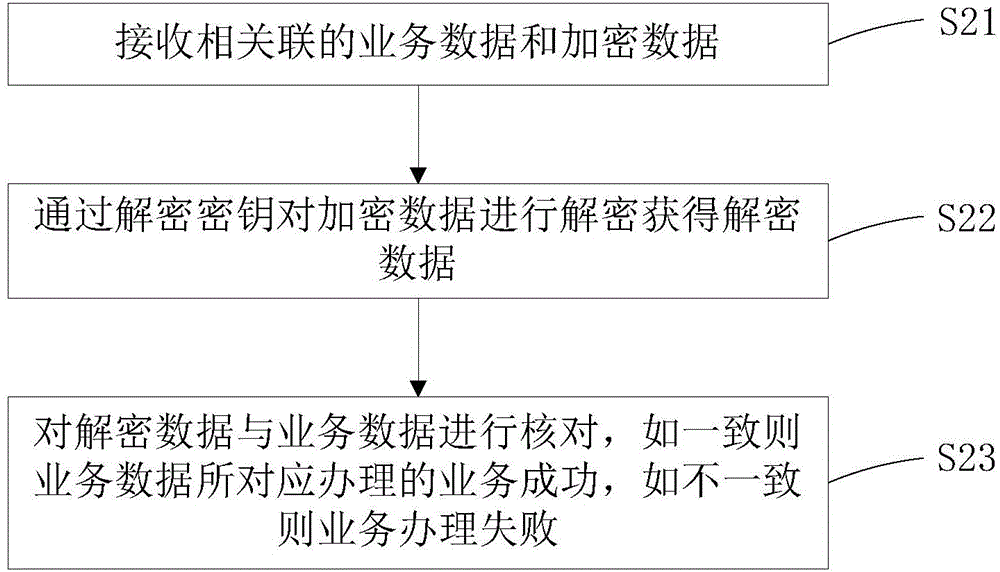

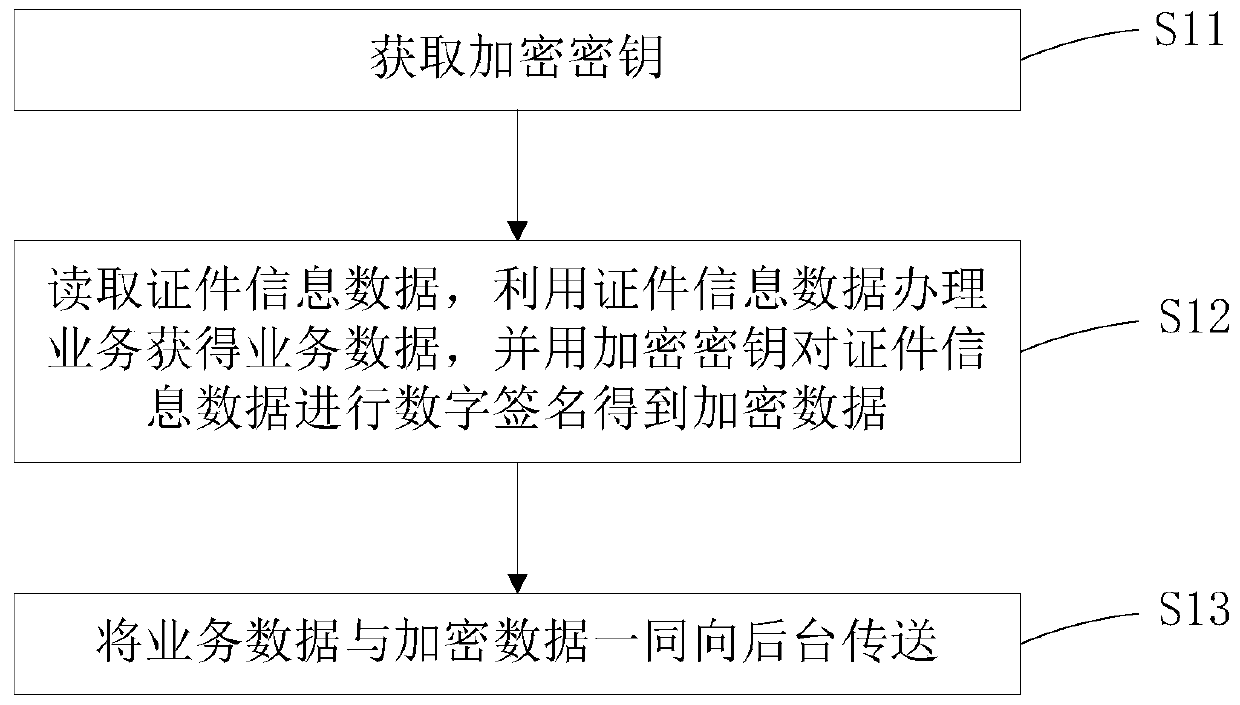

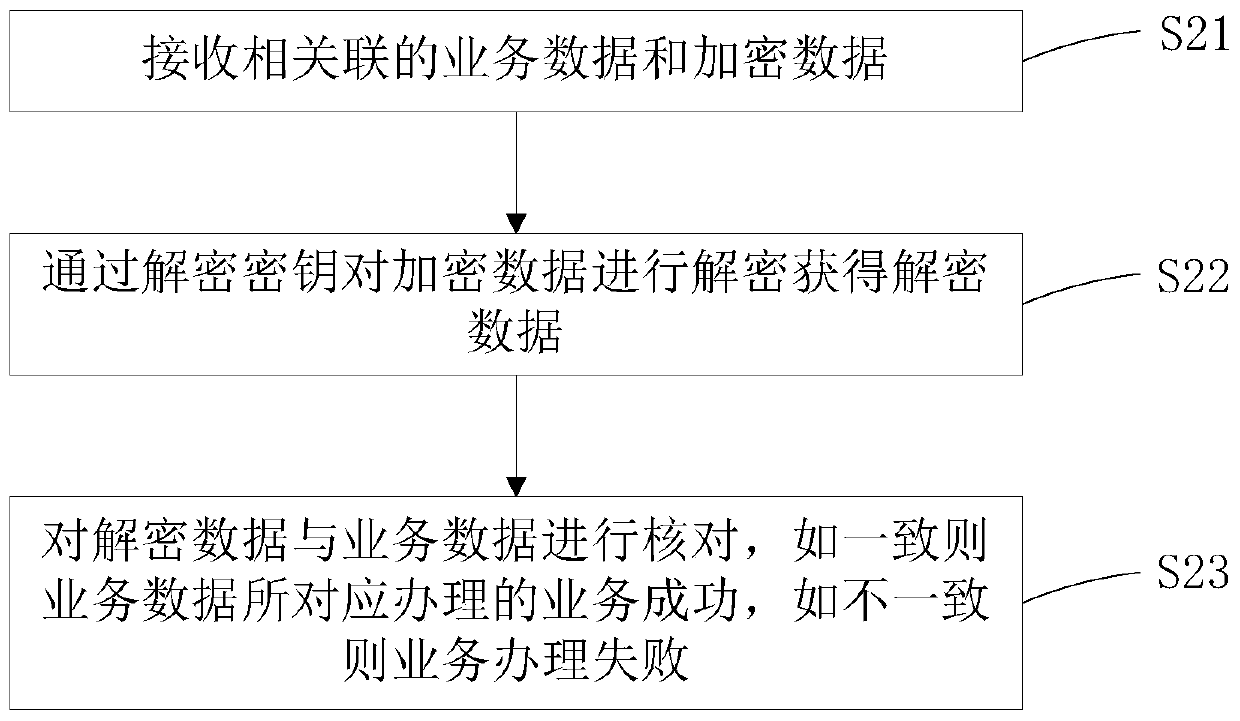

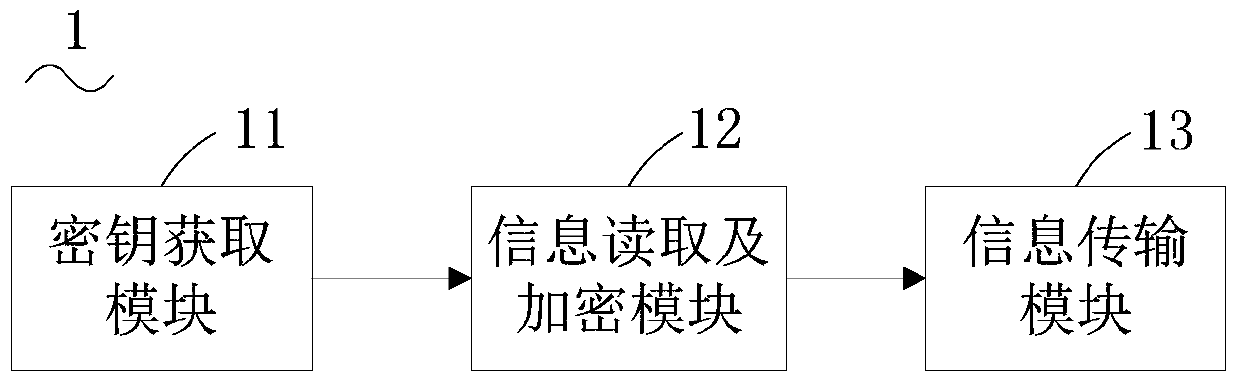

Certificate information processing and verification methods, processing terminal, and verification server

ActiveCN104883260AGuarantee authenticityPrevent software from simulating card reading operationsUser identity/authority verificationBusiness dataBusiness transactions

The invention provides certificate information processing and verification methods, a processing terminal, and a verification server. The certificate information processing method includes the steps of acquiring an encryption key; reading certificate information data, performing the business transaction to obtain business data by means of the certificate information data, and performing digital signature on the certificate information data with the encryption key to obtain encryption data; and transmitting the business data and the encryption data together to the back end. The certificate information verification method includes the steps of receiving relevant business data and encryption data; decrypting the encryption data with a decryption key to obtain decryption data; and checking the encryption data with the business data, if the data is consistent, the business transaction corresponding to the business data is successful, if not, the business transaction is failed. The certificate information processing and verification methods can guarantee the authenticity and the integrity of certificate information when the business transaction is carried out based on the certificate information, prevent software stimulation operation, and perfect the information management function.

Owner:SHENZHEN EPS TECH CO LTD

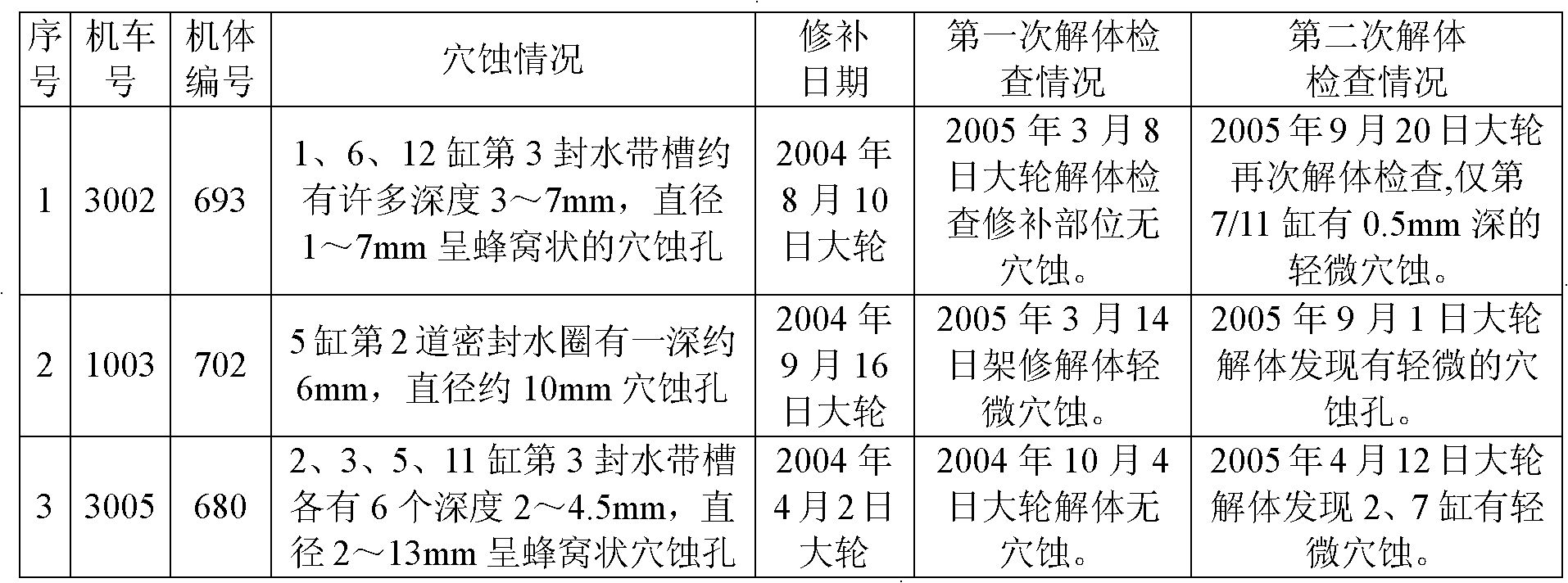

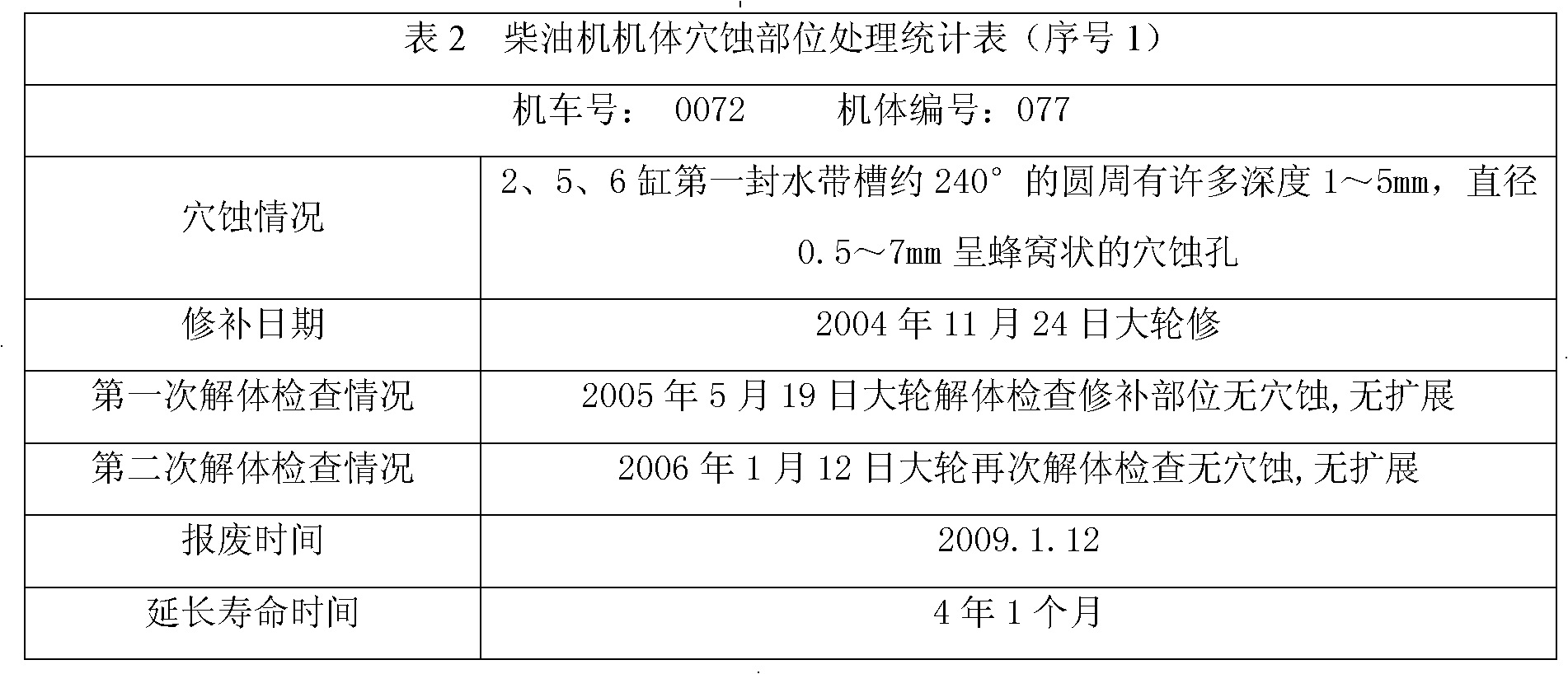

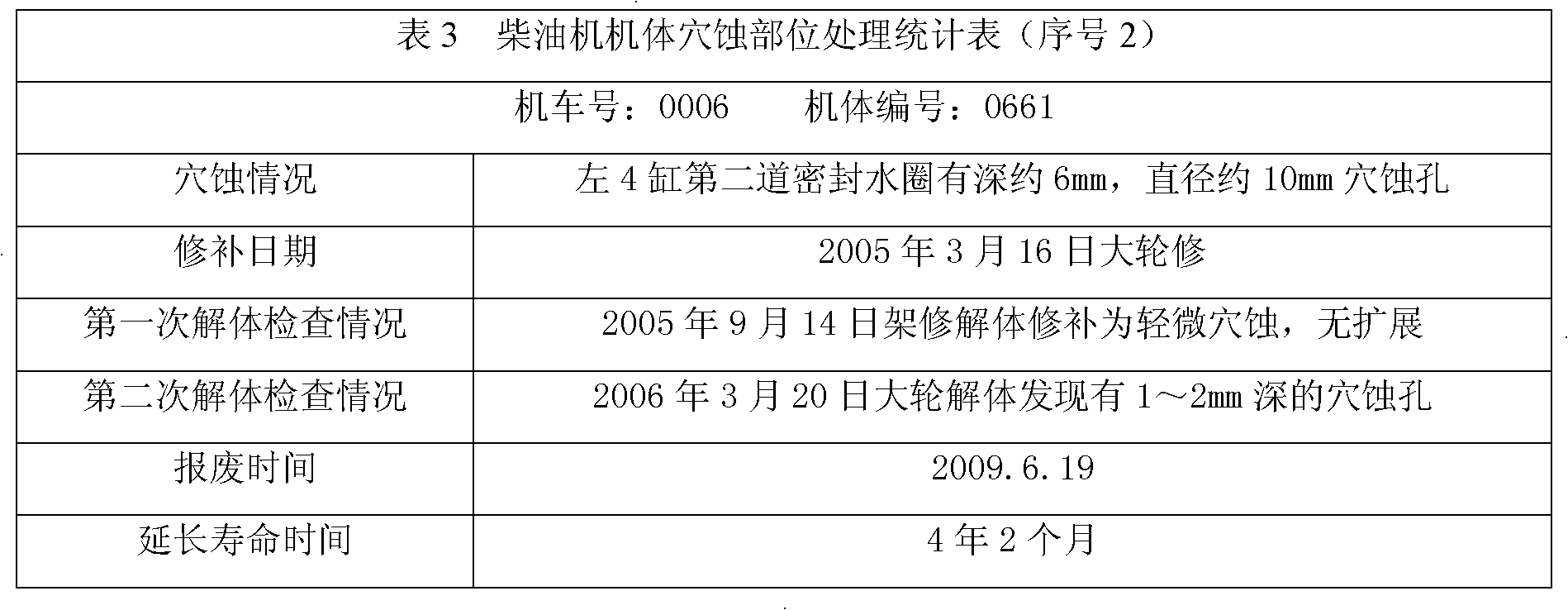

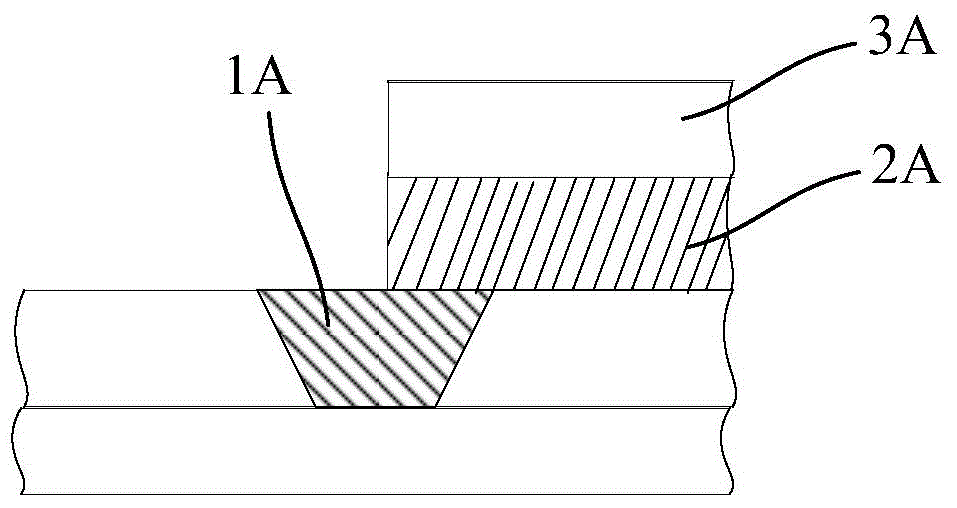

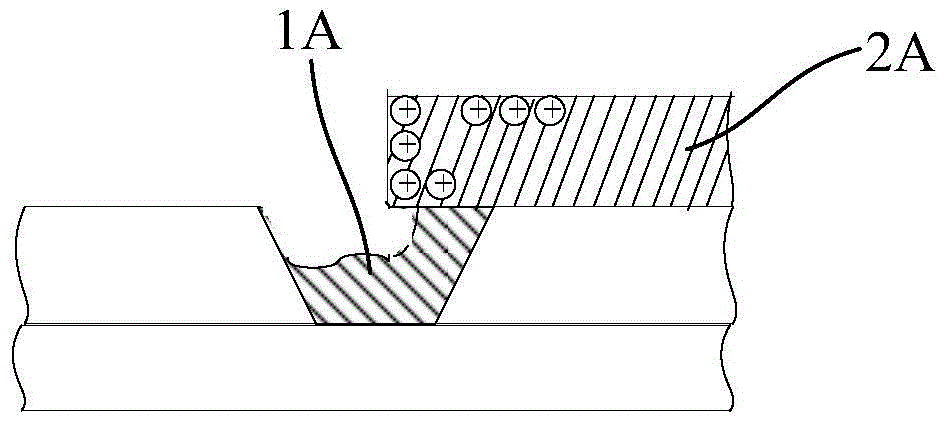

Repairing method of body cave

InactiveCN101974742AFully combinedImprove mechanical propertiesMachines/enginesMetallic material coating processesEngineeringLife time

The invention belongs to the field of body repairing, in particular relates to a repairing method of a body cave, in particular to the devices of a diesel engine, an engine, and the like which work under a high-temperature condition. The invention solves the technical problem of providing a novel method for repairing the body cave to increase the service life of the device. The repairing method comprises the following steps of: A, cleaning the surface of a body cave part; B, coating an industrial repairing agent on the body cave part; C, initially solidifying: maintaining 2-3 hours at the temperature condition of 25-30 DEG C; D, finally solidifying: heating the repaired part of the body to the temperature of 70-100 DEG C and maintaining at least 24 hours at the temperature of 70-100 DEG C; and E, processing: mechanically processing the completely-solidified surface to be repaired according to the use requirement of the body. The repairing method can ensure the body of the diesel engine not to be repaired again in an un-wheeling repair period, and the service life of the diesel engine body is prolonged to 8-10 years from 5-6 years.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

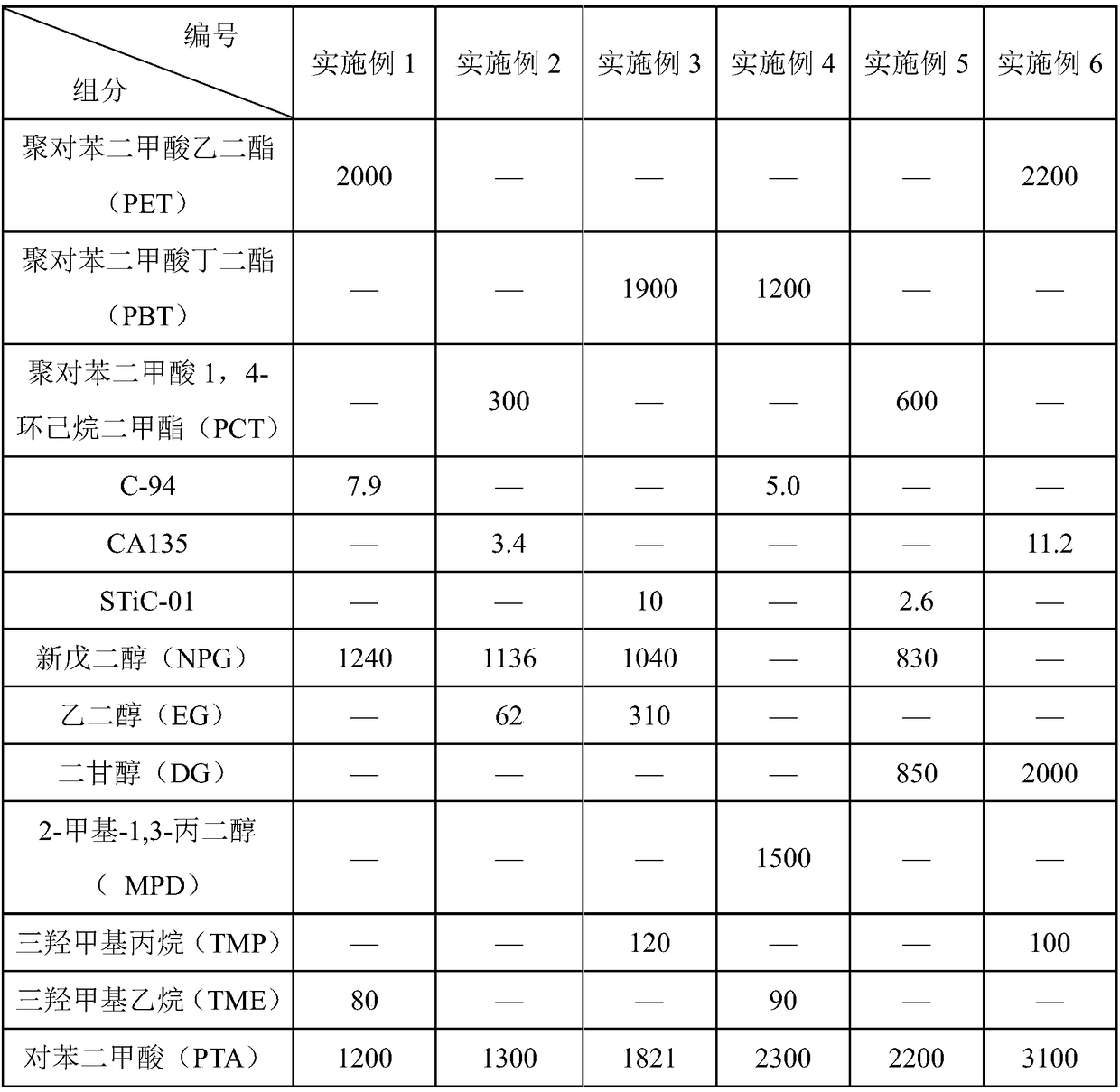

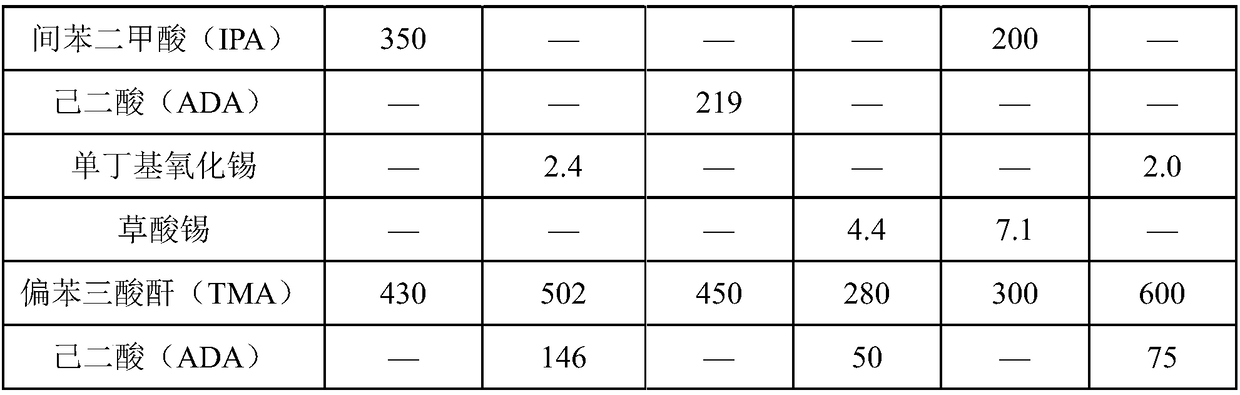

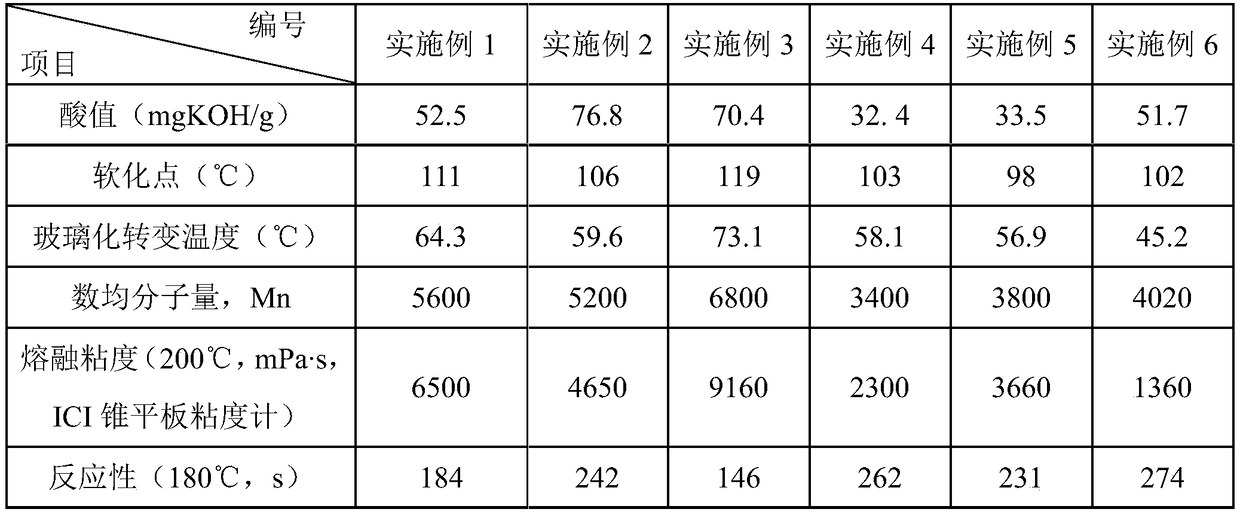

Polyester resin and preparation method and application thereof

InactiveCN109232866ANo generationGood surface appearancePlastic recyclingPowdery paintsSalt resistancePolyol

The invention discloses a polyester resin and a preparation method and application thereof. The polyester resin has an acid value of 30 to 80 mgKOH / g, a glass transition temperature of 40 to 80 DEG C,a melt viscosity of 1000 to 10000 mPa.s at 200 DEG C, a softening point of 80 to 123 DEG C, a reactivity of 100 -300 s at 180 DEG C and a number average molecular weight of 3000-7000; and the polyester resin is prepared from polyester waste, polyol, polybasic acid, and a blocking agent. The above-mentioned properties of the polyester resin have a wide range of variations, and thus have higher applicability; at the same time, the polyester resin is prepared from the polyester waste, so that the preparation conditions are mild, no by-products are formed during the preparation, and the pure polyester resin is completely prepared through one-step reaction; and powder coating prepared from the polyester resin has better surface appearance, excellent mechanical properties and adhesion, chemicalresistance, salt resistance and high boiling performance, and is suitable for various indoor coating fields.

Owner:GUANGZHOU KINTE IND

Process for refining meloxicam

A process for refining meloxicam, a new non-steroids antipyretic analgesics, includes such steps as adding the crude meloxicam to dimethyl formamide (DMF), thermal dissolving, decolouring, filtering, cooling the filtrate to educe out crystal; dissolving in alkaline alcohol solution, stirring while dripping the diluted hydrochloric acid to regulate pH value to 2-3, filtering, and washing the collected solid until it become neutral to obtain the product. Its advantages are simple process, no poison, and low DMF content.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

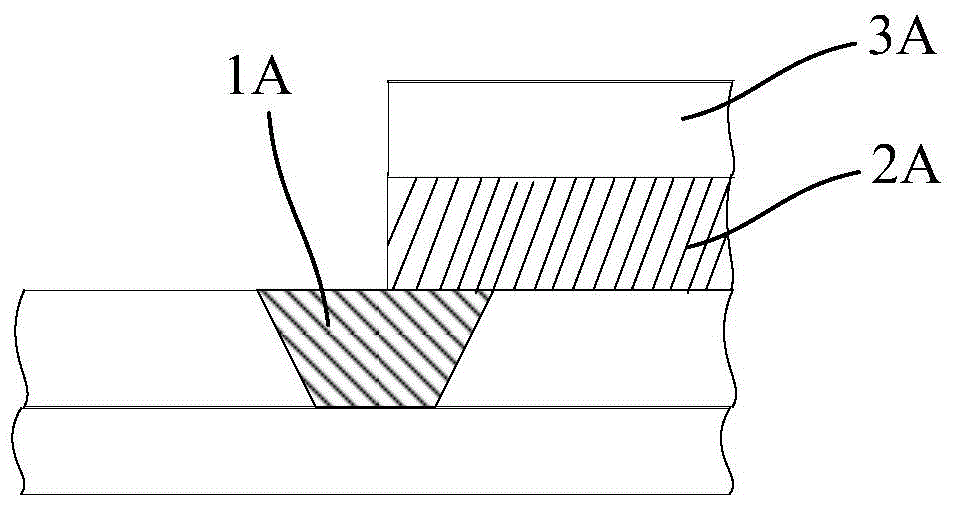

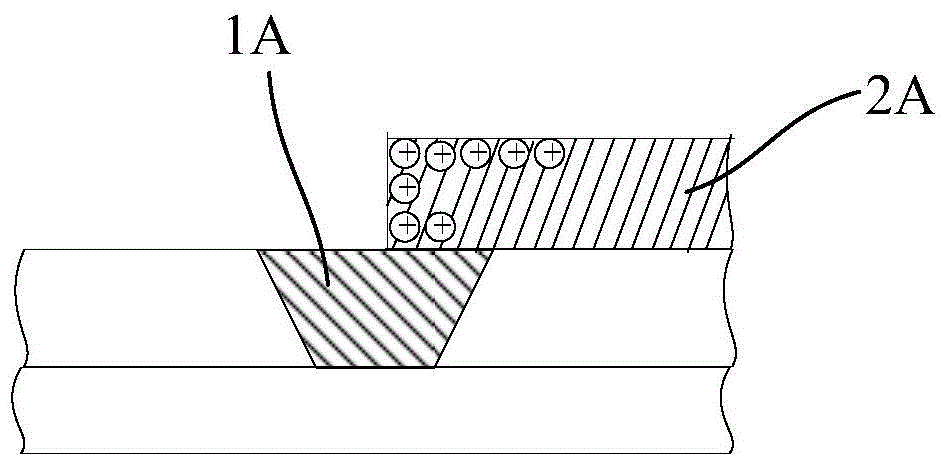

Method for determining inorganic negative ions in tobacco gene editing material

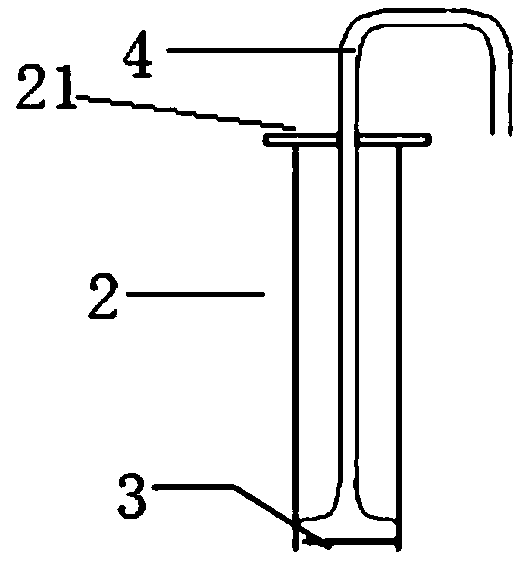

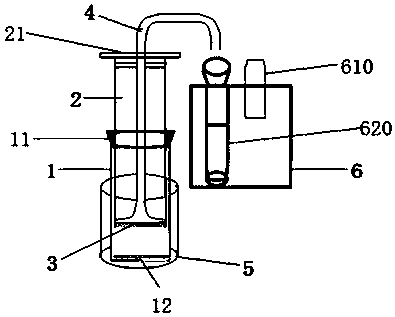

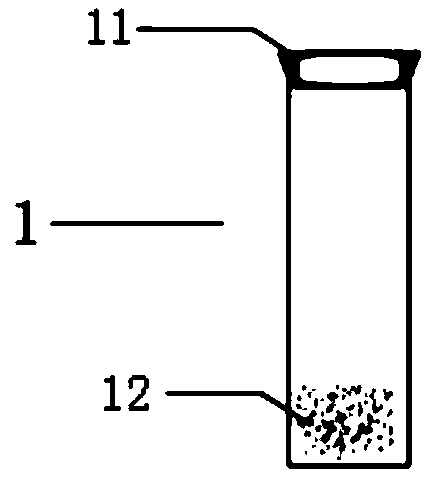

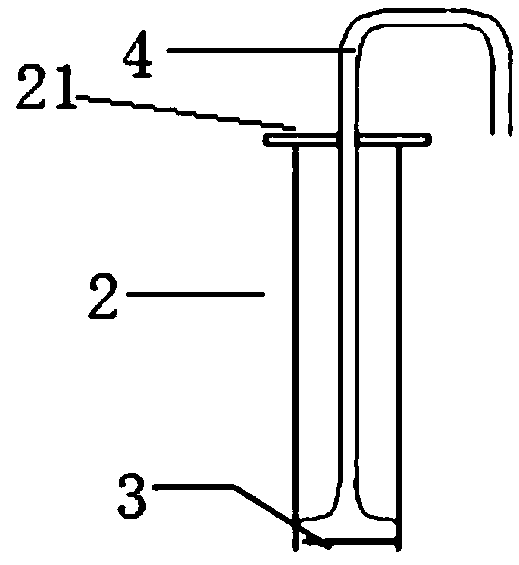

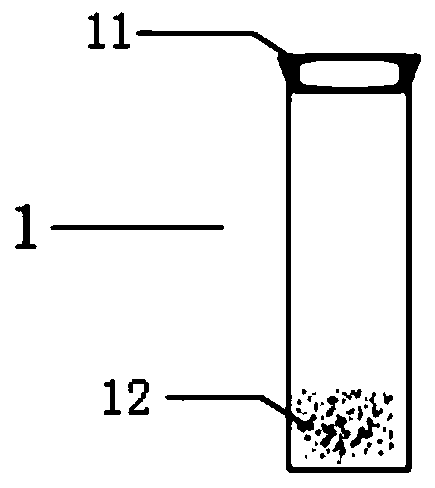

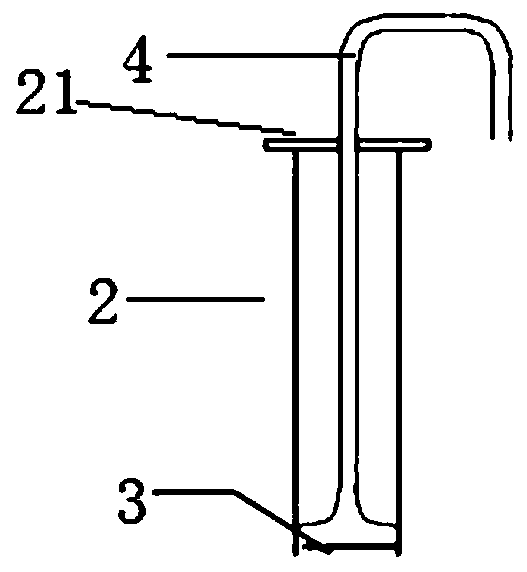

ActiveCN108828078AEnables high-throughput analytical assaysEasy to useComponent separationOuter CannulaBottle

The invention discloses a method for determining six inorganic negative ions in a tobacco gene editing material. An apparatus is used, which comprises a sample extraction bottle, an outer cannula (1),an inner cannula (2), a liquid-guiding pipe (4), and a sieve plate (3) which can be one or more and positioned in a lower opening of the inner cannula (2); The method comprises the following steps: 1) tobacco leaf extraction; 2) filtering and transferring; 3) analysis for making a chromatogram; 4) acquisition of a peak area of the standard chromatogram to obtain the inorganic negative ions of thetobacco gene editing material. The determination method of the present invention is characterized in that an on-line solid phase extraction purifying column is added before first usage of an ion chromatographic column, the processing is simple and convenient, the effect is good, the determination method has the advantages of accurate quantification, good repeatability, and low detecting limit, and can effectively realize the high flux analysis determination of the inorganic negative ions in tobacco gene editing material.

Owner:CHINA TOBACCO YUNNAN IND

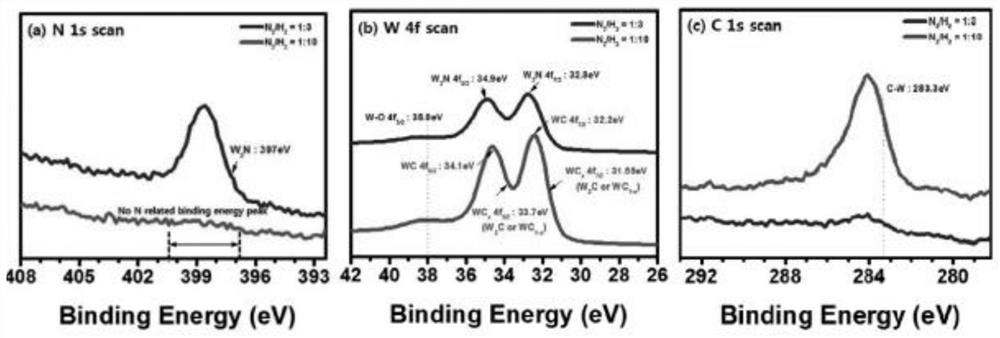

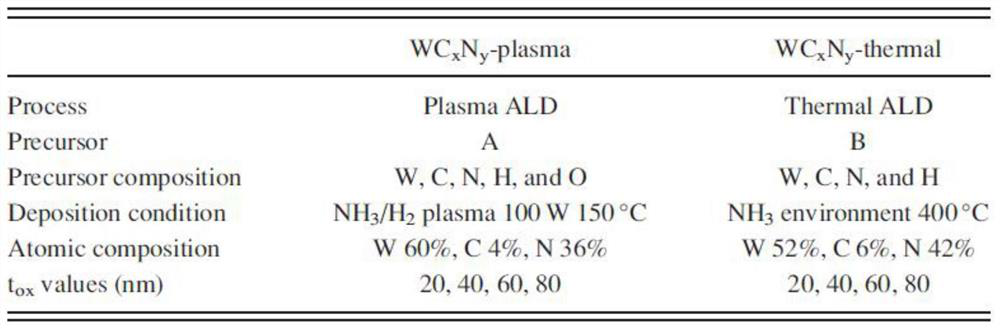

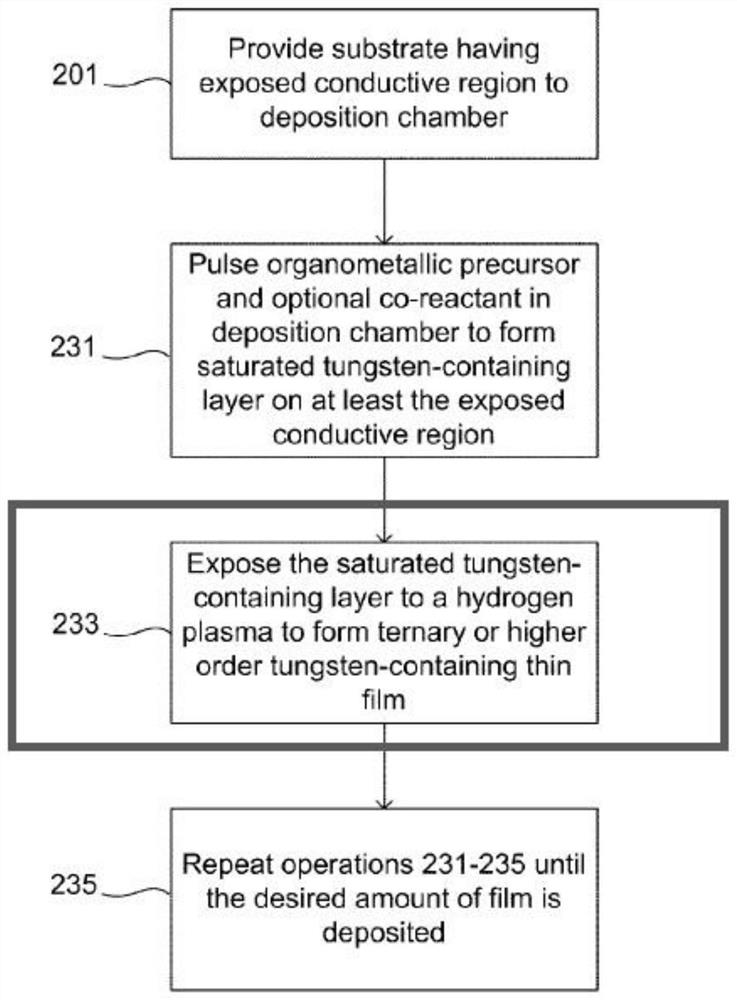

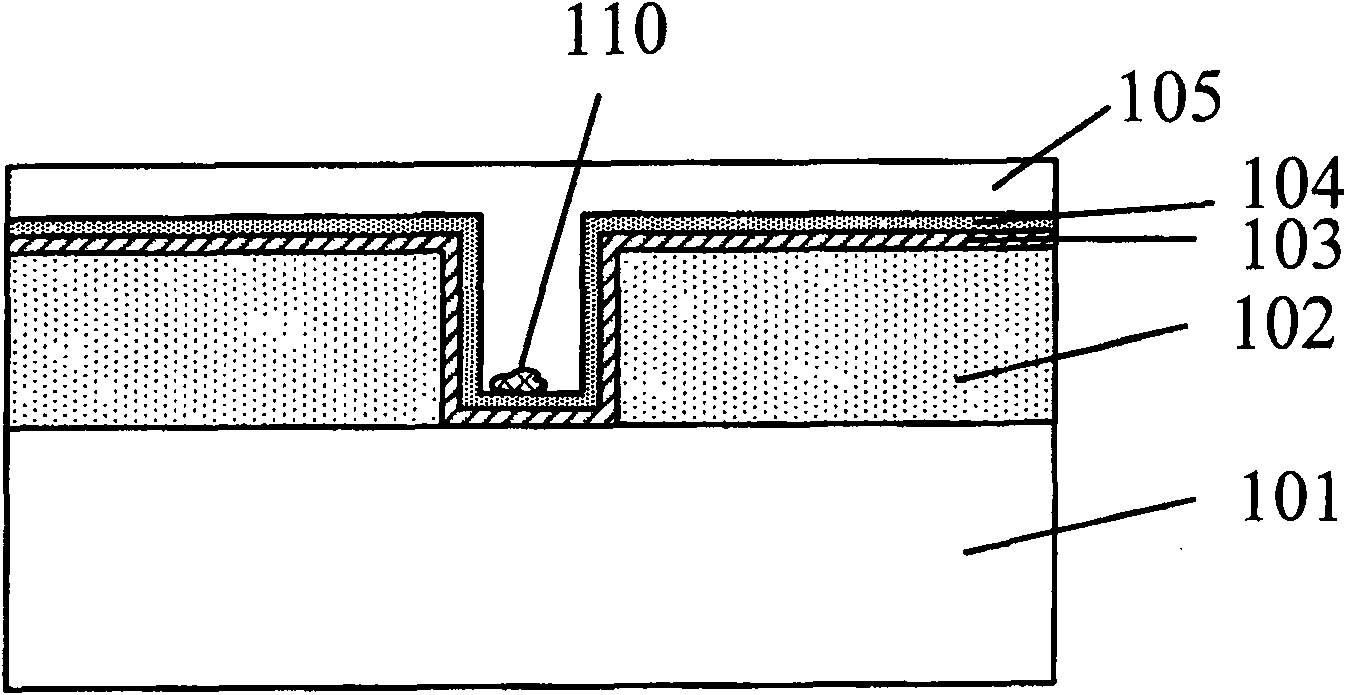

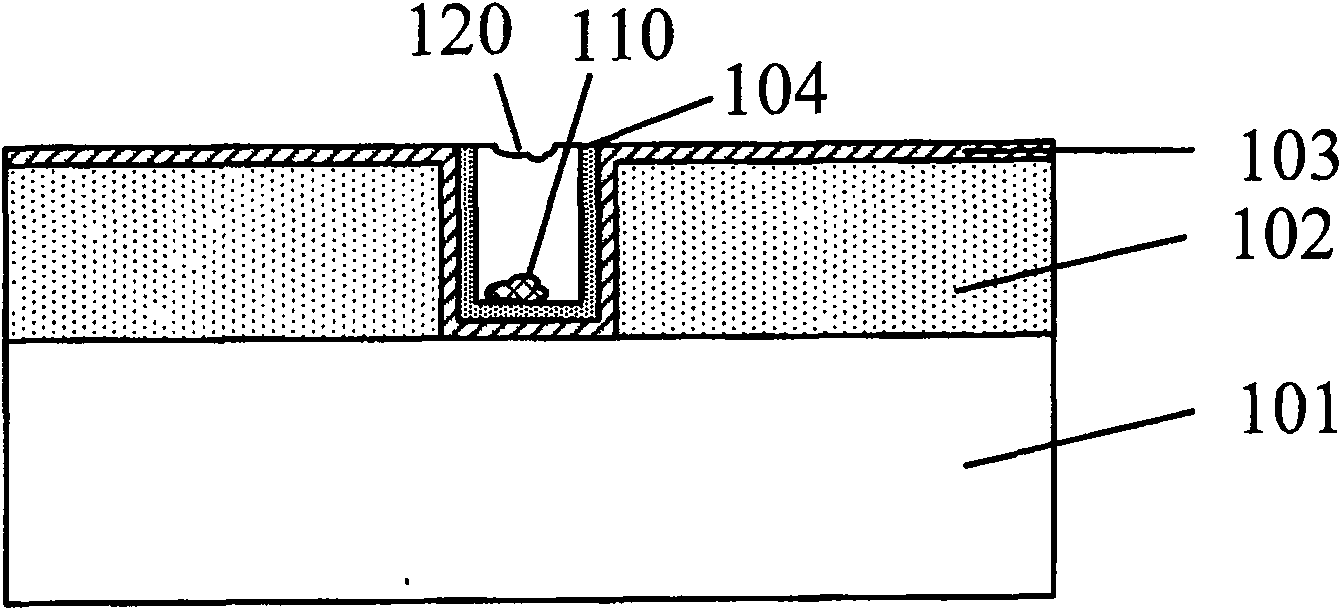

WCN thin film deposition method with adjustable work function

PendingCN114836729AGuaranteed stabilityAdd processing stepsChemical vapor deposition coatingThin membraneReactive deposition

The invention discloses a work function adjustable WCN thin film deposition method which comprises the following steps: firstly, heating a tungsten precursor to 80-150 DEG C, and preheating a precursor conveying pipeline and an ALD cavity; forming a monatomic layer WN thin film through NH3 plasma and tungsten precursor reaction deposition, and repeating X times to form X layers of WN thin films; forming a monatomic layer WC thin film through reaction deposition of H2 plasma and a tungsten precursor, and repeating the step Y times to form a Y-layer WC thin film; and repeating the steps for Z times until the WCN thin film with the expected thickness is obtained. According to the WCN thin film prepared through the method of alternately depositing the WC thin film and the WN thin film, atom combination between WCN can be achieved, the existing mode that the proportion of C to N in the WCN is adjusted by adjusting the deposition technological parameters of the single WCN thin film is replaced, the content of C and N can be accurately adjusted, and therefore the work function can be adjusted.

Owner:合肥安德科铭半导体科技有限公司

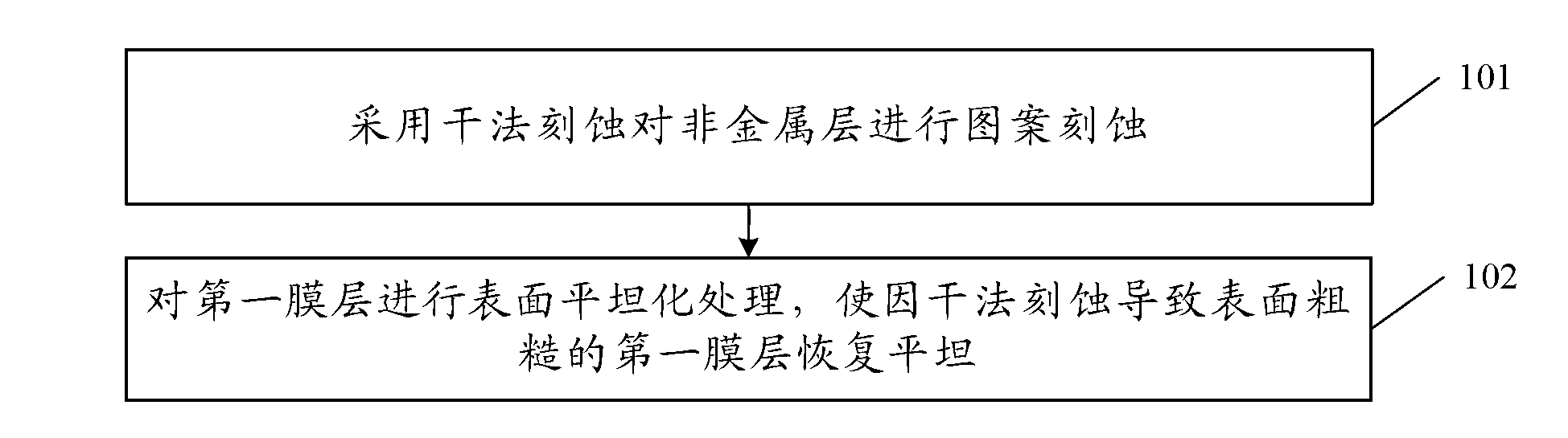

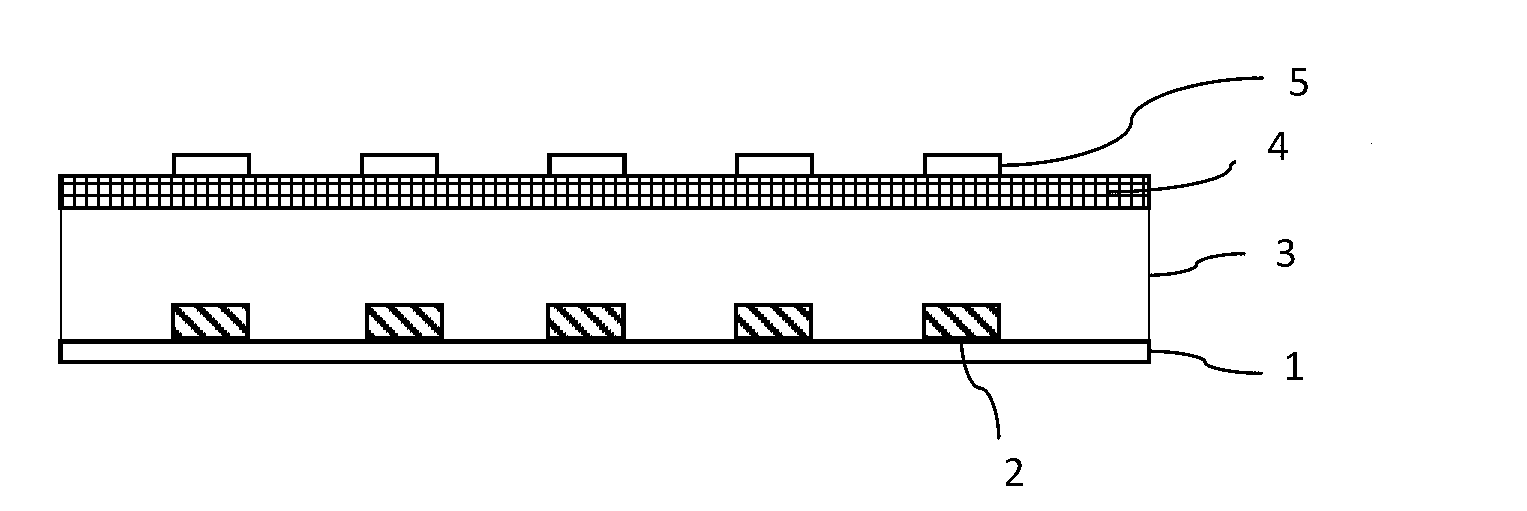

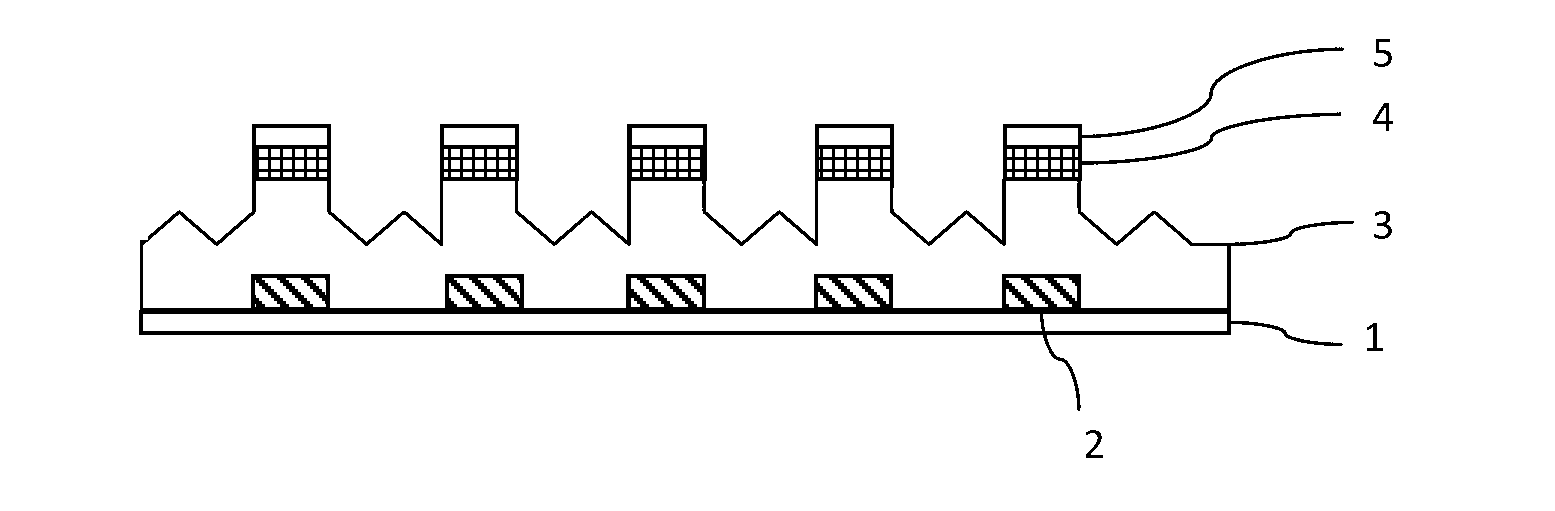

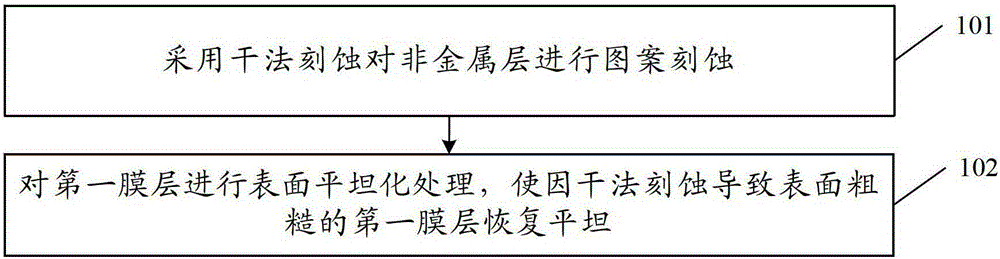

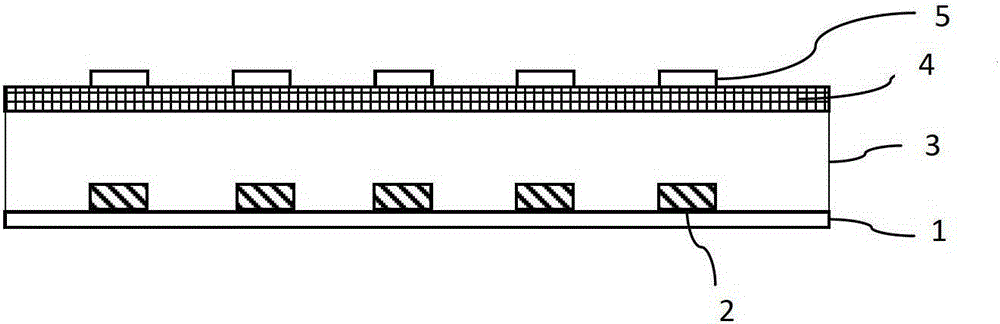

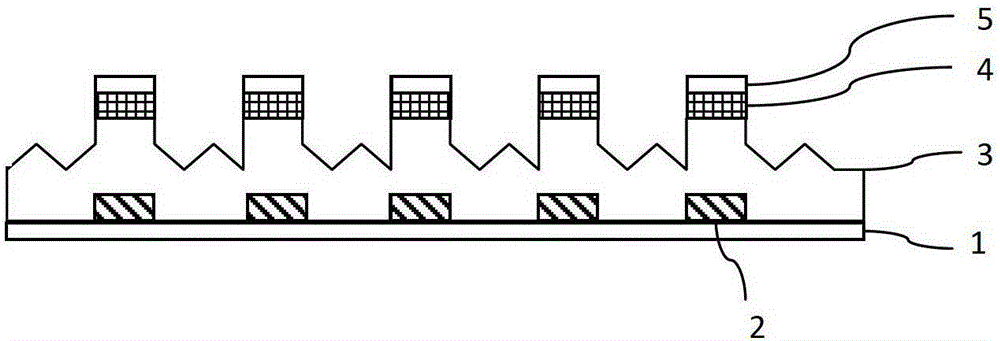

Thin film surface planarization method, array substrate, manufacturing method of array substrate and display device

InactiveCN103258726AImprove transmittanceIncrease contrastSemiconductor/solid-state device manufacturingNon-linear opticsRough surfaceLiquid-crystal display

The invention discloses a thin film planarization method, an array substrate, a manufacturing method of the array substrate and a display device, and relates to the field of display. The technical problem that in existing dry etching, damage to the planeness of the surfaces of other film layers below a film layer which is etched is large can be solved, and accordingly the displaying performance of a liquid crystal displayer is improved. The manufacturing method of the array substrate comprises the steps of conducting pattern etching on a non-metal layer by the adoption of the dry etching, and after conducting pattern etching on the non-metal layer by the adoption of the dry etching, conducting surface planarization processing on a first film layer to enable the first film layer with a rough surface caused by the dry etching to recover to planeness. The first film layer is located below the non-metal layer.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Copper foil removing equipment for UWB positioning base station substrate production

PendingCN114423162AAvoid damageReduce adverse effectsPrinted circuit liquid treatmentInsulating layers/substrates workingMetallurgyEngineering

The invention relates to the technical field of electronics, in particular to copper foil removing equipment for UWB positioning base station substrate production. The technical problem is that a copper foil on a substrate has impurity particles during pressing, after the copper foil is etched and removed, the impurity particles fall into blind holes of the substrate, and additional processing steps need to be added for processing, so that the production cost is increased. According to the technical scheme, the copper foil removing equipment for UWB positioning base station substrate production comprises a bottom frame, a collecting box and the like; a collecting box is connected to the left portion of the bottom frame. When the device is used, residual glue residues in the blind holes of the substrate are cleaned through the air jet, the damage to the substrate is avoided, meanwhile, the adverse effect of the glue residues on etching is avoided, only the lower surface of the substrate is etched through overturning each time, the upper surface is sealed and protected, and the production efficiency is improved. Impurity particles are prevented from falling into the blind holes of the substrate after the copper foil is etched and removed when the copper foil is pressed, and additional processing steps are avoided.

Owner:HANGZHOU CCRFID MICROELECTRONICS

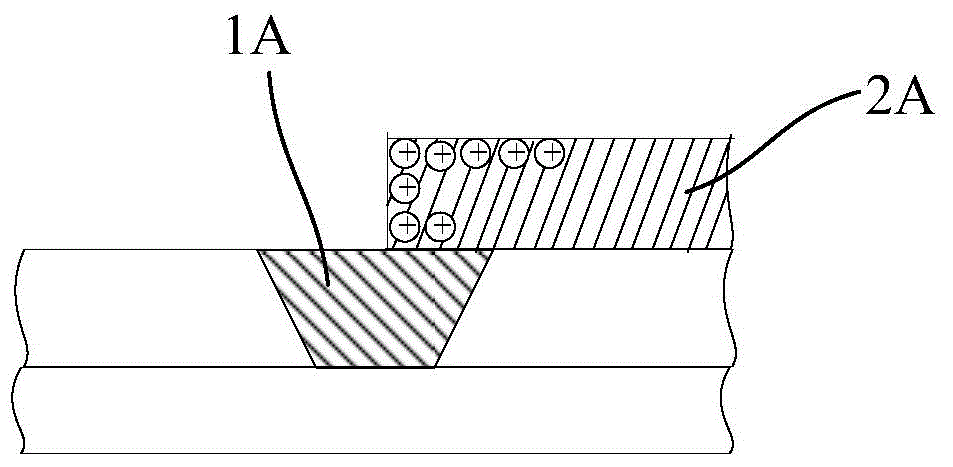

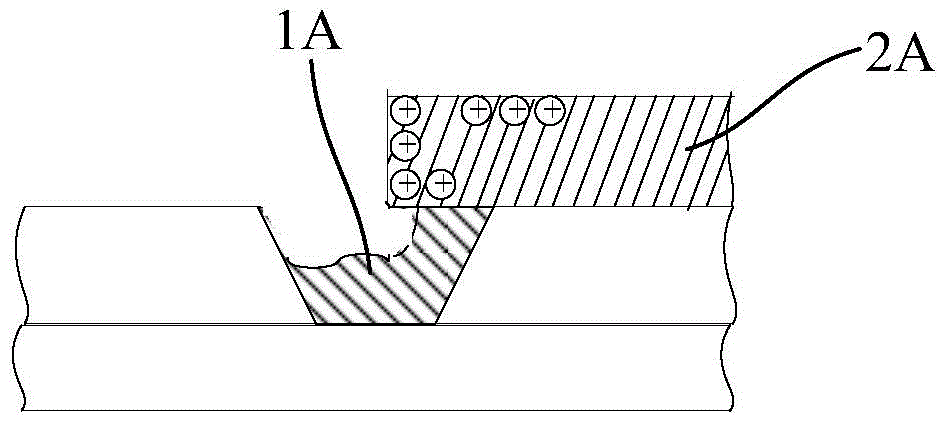

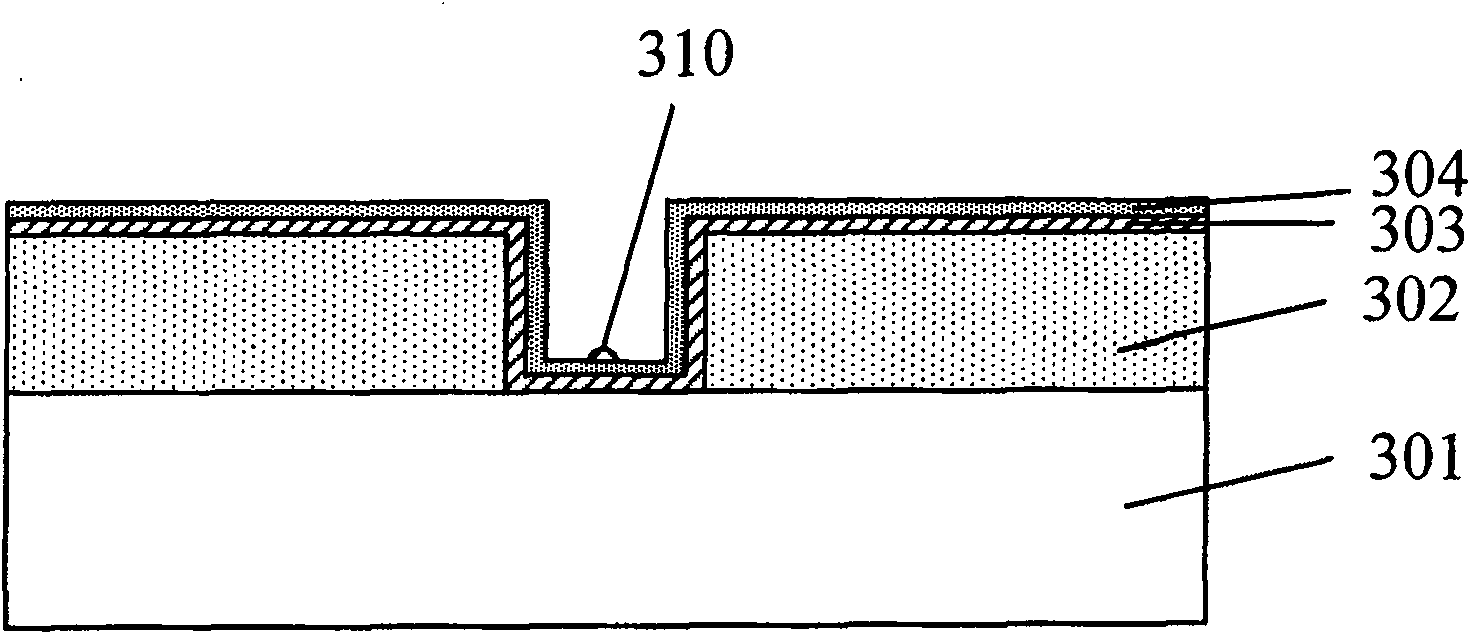

Processing method capable of preventing electrochemical corrosion of through-hole metals

ActiveCN104576512AAvoid Galvanic CorrosionAdd processing stepsSemiconductor/solid-state device manufacturingIonizationElectrochemical response

The invention provides a processing method capable of preventing electrochemical corrosion of through-hole metals. The processing method at least comprises the following steps: firstly, providing a metal interconnection structure including a first metal layer, an insulating layer which is positioned on the first metal layer and is provided with a through hole and a second metal layer which is positioned on the insulating layer; filling the through hole with a third metal layer communicated with the first metal layer and the second metal layer; then, putting the metal interconnection structure into a reaction cavity, introducing mixed gas of N2 and H2O and performing ionization on the mixed gas of N2 and H2O to dissociate H2O to form hydrogen atoms, wherein the hydrogen atoms capture positive charge in the second metal layer to prevent the third metal layer in the through hole from being corroded by performing electrochemical reaction on the positive charge; the second metal layer is made of aluminum-copper alloy; the third metal layer is made of tungsten.

Owner:SEMICON MFG INT (SHANGHAI) CORP

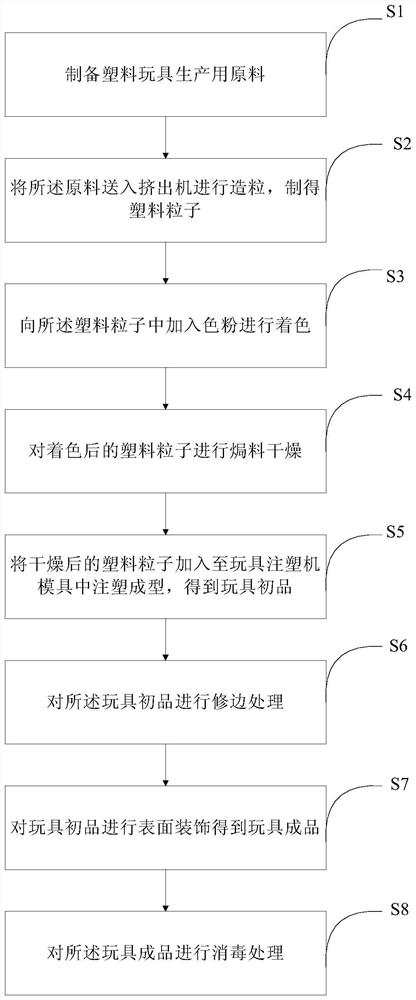

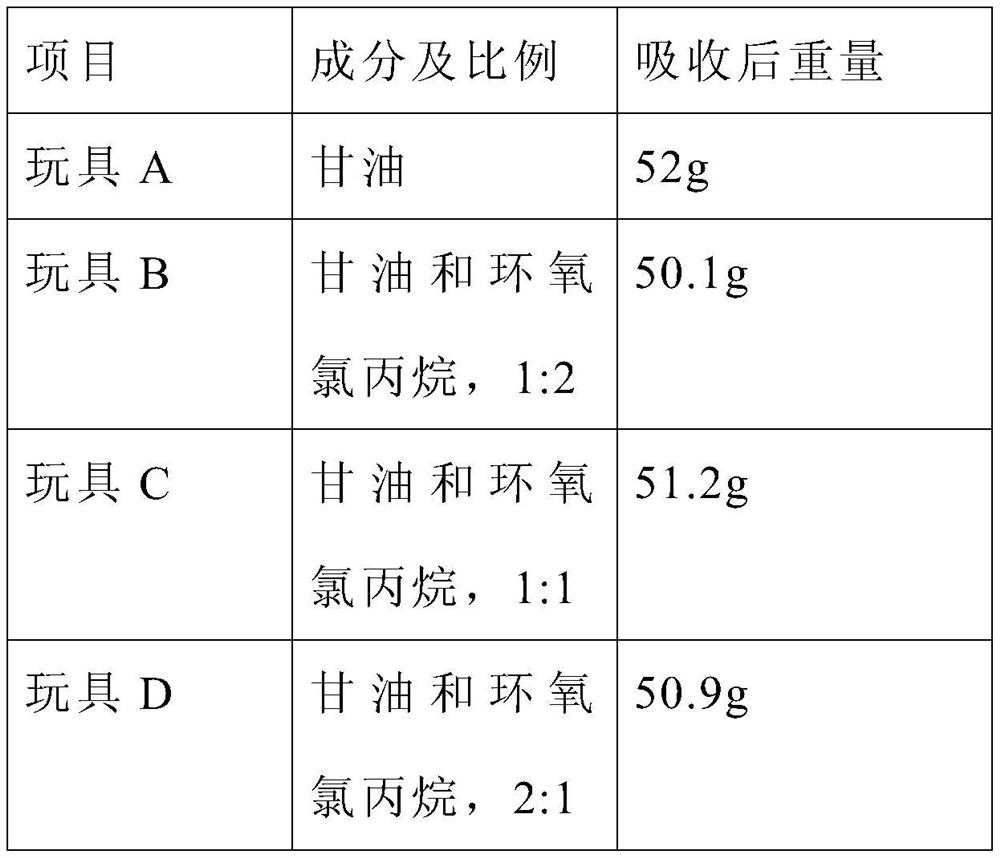

Preparation method of water-resistant easily-degradable plastic toy

PendingCN114163770AImprove water resistanceIncreased strength and antimicrobial propertiesPelletizingPlasticizer

The invention discloses a preparation method of a water-resistant easily-degradable plastic toy. The preparation method comprises the following steps: S1, preparing raw materials for producing the plastic toy; s2, the raw materials are fed into an extruder to be granulated, and plastic particles are prepared; s3, adding toner into the plastic particles for coloring; s4, baking and drying the colored plastic particles; s5, the dried plastic particles are added into a toy injection molding machine mold for injection molding, and a toy primary product is obtained; s6, the primary toy product is subjected to trimming treatment; s7, performing surface decoration on the toy primary product to obtain a toy finished product; and step S8, performing disinfection treatment on the toy finished product. Compared with the prior art, the full-biodegradation agent is adopted, degradation is thorough, the plasticizer is composed of glycerin and epoxy chloropropane, water resistance is higher, the inorganic filler improves the strength and antibacterial property of toys, the trimming and sterilizing lamp treatment steps are added, and the safety coefficient and sanitary coefficient of the toys are increased.

Owner:河源新昊塑胶制品有限公司

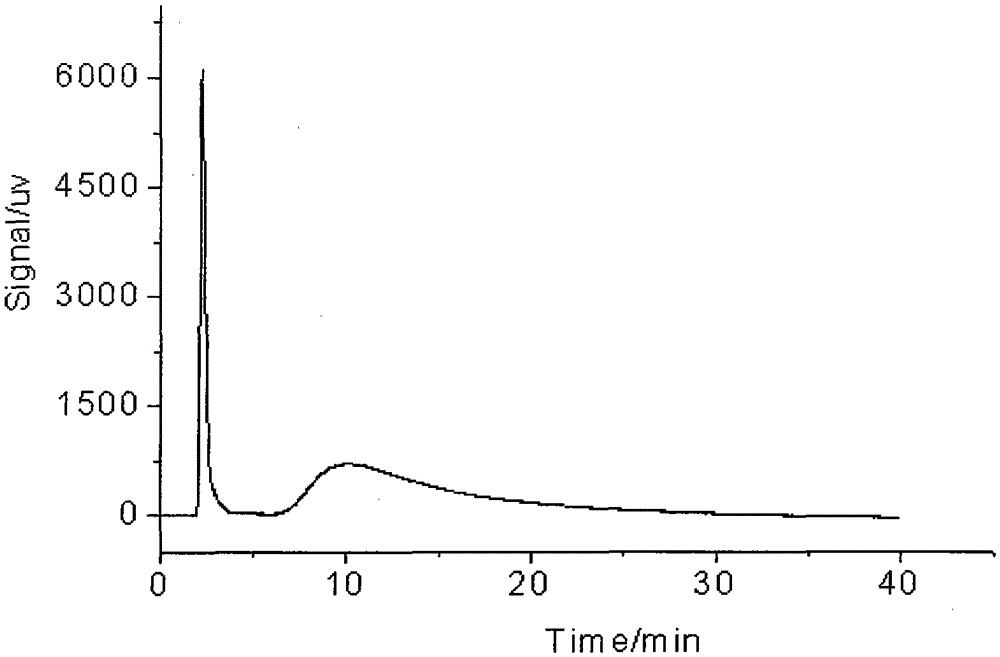

Method for determining inorganic positive ions in tobacco gene editing material

ActiveCN108828079AAdd processing stepsEasy to operateComponent separationOuter CannulaSolid phase extraction

The invention discloses a method for determining five inorganic positive ions in a tobacco gene editing material. An apparatus is used, which comprises a sample extraction bottle, an outer cannula (1), an inner cannula (2), a liquid-guiding pipe (4), and a sieve plate (3) which can be one or more and positioned in a lower opening of the inner cannula (2). The method comprises the following steps:1) tobacco leaf extraction; 2) filtering and transferring; 3) analysis for making a chromatogram; 4) acquisition of a peak area of the standard chromatogram to obtain the inorganic positive ions of the tobacco gene editing material. The determination method of the present invention is characterized in that an on-line solid phase extraction purifying column is added before first usage of an ion chromatographic column, the processing is simple and convenient, the effect is good, the determination method has the advantages of accurate quantification, good repeatability, and low detecting limit, and can effectively realize the high flux analysis determination of the inorganic positive ions in tobacco gene editing material.

Owner:CHINA TOBACCO YUNNAN IND

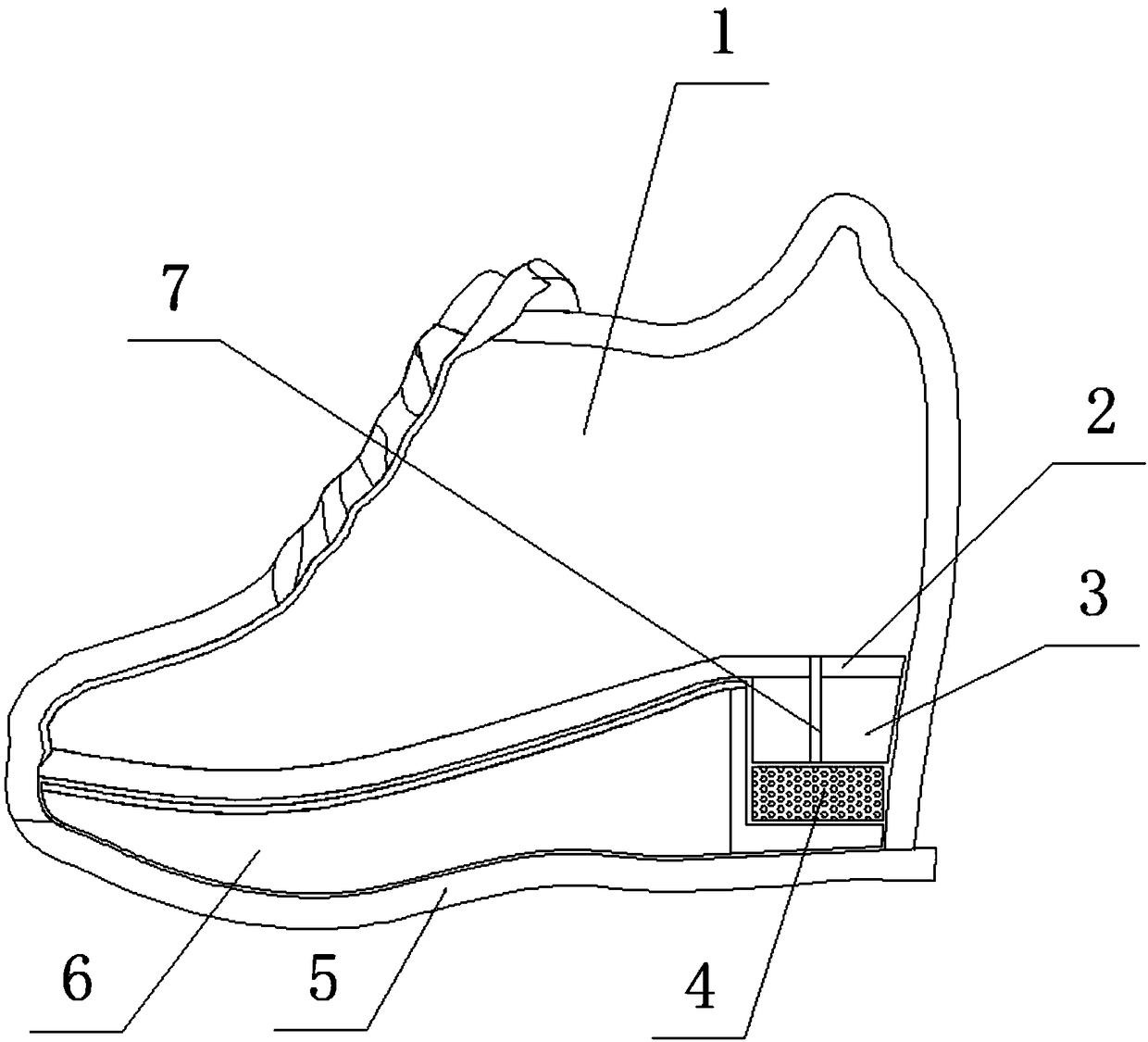

Manufacturing method of shoes with internal height increase

InactiveCN108634477AImprove antibacterial propertiesLong duration of antibacterialBiocideNon-macromolecular adhesive additivesHeight increasedControllability

The invention provides a manufacturing method for shoes with internal height increase, relating to a manufacturing method of shoes. The method comprises the following steps: designing shoe trees of the shoes and the style of the shoes, manufacturing a paper sample, and manufacturing shoe vamps, shoe soles and pads for internal height increase according to the paper sample; fixing the pads for internal height increase to the shoe trees, sleeving the shoe trees with the shoe vamps, carrying out shoe forming and sizing, adhering the shoe soles to the bottoms of the sized shoes, and carrying out packaging after glue is dry. According to the manufacturing method, when the shoes are made, the pads for internal height increase and the shoe trees for making shoes are directly fixed, after the shoes are made, the pads for internal height increase form a whole with the shoes, thus the secondary processing difficulty is reduced, the controllability for the appearance construction of shoe patternsis strong, the deformation of the pads for internal height increase can be controlled, and thus the foot shapes of shoe wearers are well adapted; in addition, the material for manufacturing the shoesin the method is the material capable of realizing sterilizing and drying or automatic cleaning, thus the wearing comfort of the shoes is improved, and the generation of moisture and bacteria insidethe shoes is avoided.

Owner:广州市鸿峥实业有限公司

A quantitative detection method for living bacteria based on fish technology

ActiveCN104561354BAdd processing stepsAchieve effective distinctionMicrobiological testing/measurementFluoProbesFluorescence microscope

Owner:FUZHOU UNIV

Certificate information processing and verification method, processing terminal and verification server

ActiveCN104883260BAdd processing stepsGuarantee authenticityUser identity/authority verificationInformation processingDigital signature

The invention provides certificate information processing and verification methods, a processing terminal, and a verification server. The certificate information processing method includes the steps of acquiring an encryption key; reading certificate information data, performing the business transaction to obtain business data by means of the certificate information data, and performing digital signature on the certificate information data with the encryption key to obtain encryption data; and transmitting the business data and the encryption data together to the back end. The certificate information verification method includes the steps of receiving relevant business data and encryption data; decrypting the encryption data with a decryption key to obtain decryption data; and checking the encryption data with the business data, if the data is consistent, the business transaction corresponding to the business data is successful, if not, the business transaction is failed. The certificate information processing and verification methods can guarantee the authenticity and the integrity of certificate information when the business transaction is carried out based on the certificate information, prevent software stimulation operation, and perfect the information management function.

Owner:SHENZHEN EPS TECH CO LTD

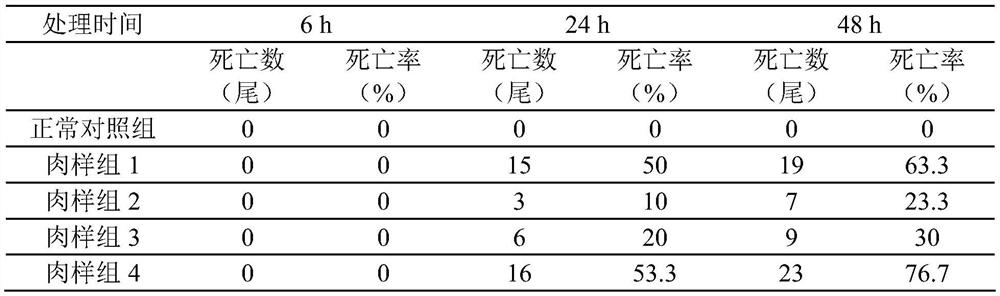

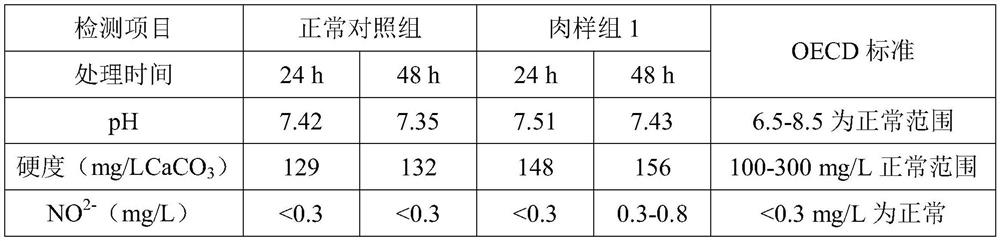

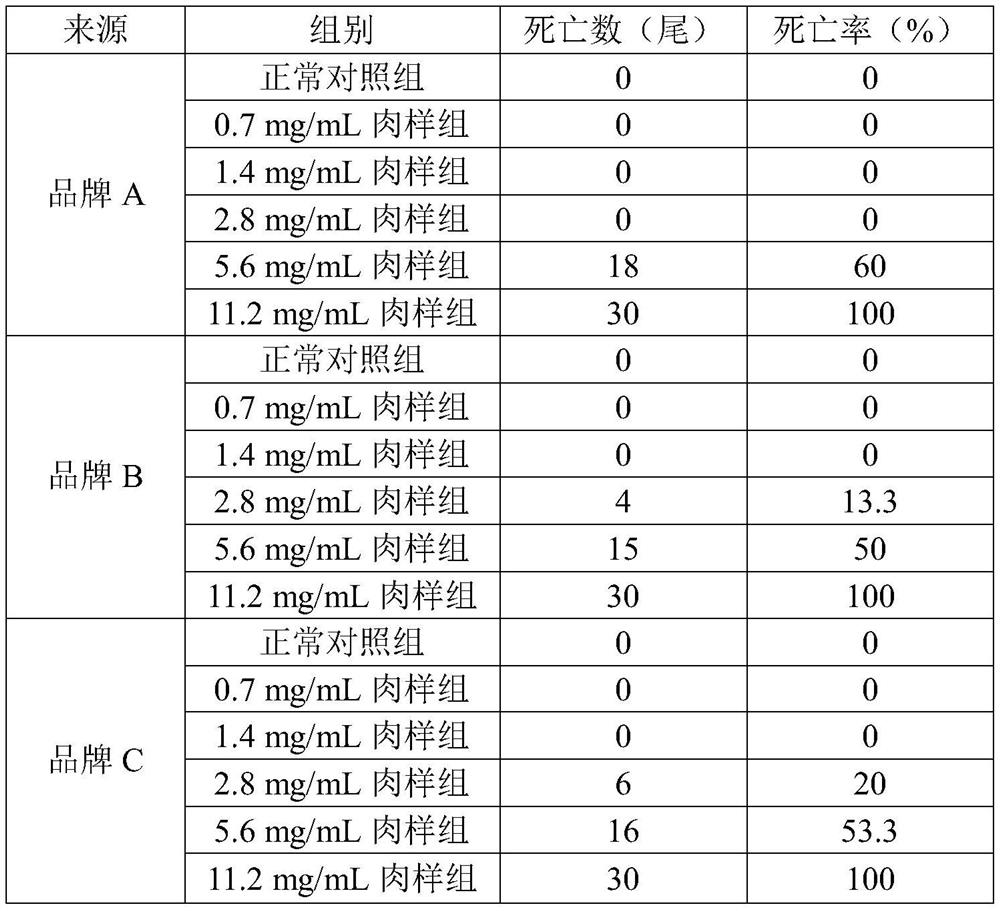

A method for evaluating the safety of meat products using zebrafish

ActiveCN111766354BAdd processing stepsThe real environment of the evaluation resultsPreparing sample for investigationTesting foodBiotechnologyAnimal science

The invention provides a method for evaluating the safety of meat products by using zebrafish. Firstly, the meat product is treated with bionic digestion and extraction to obtain the meat sample extract, and then the processing time of the meat sample extract is determined to be 24 hours. The treatment concentration was 1.4-5.6 mg / mL to construct a zebrafish model and evaluate the safety of meat products. The zebrafish model constructed by the present invention and the method for evaluating the safety of meat products have high detection accuracy, the detection method is scientific and reasonable, and the short modeling cycle greatly reduces the detection cost, which provides a basis for popularizing and popularizing the detection method to the general public, enterprises and governments. Realistic feasibility.

Owner:HANGZHOU HUANTE BIOLOGICAL TECH CO LTD +1

Preparation method and application of a camphor molecularly imprinted polymer and its monolithic column and packed chromatographic column

InactiveCN103265665BAdd processing stepsEasy to manufactureOther chemical processesComponent separationFunctional monomerNitrogen gas

Owner:XINJIANG UYGUR AUTONOMOUS REGION PROD QUALITY SUPERVISION & INSPECTION RES INST +1

A treatment method for avoiding electrochemical corrosion of through-hole metal

ActiveCN104576512BAvoid Galvanic CorrosionAdd processing stepsSemiconductor/solid-state device manufacturingElectrochemical responseHydrogen atom

The invention provides a processing method capable of preventing electrochemical corrosion of through-hole metals. The processing method at least comprises the following steps: firstly, providing a metal interconnection structure including a first metal layer, an insulating layer which is positioned on the first metal layer and is provided with a through hole and a second metal layer which is positioned on the insulating layer; filling the through hole with a third metal layer communicated with the first metal layer and the second metal layer; then, putting the metal interconnection structure into a reaction cavity, introducing mixed gas of N2 and H2O and performing ionization on the mixed gas of N2 and H2O to dissociate H2O to form hydrogen atoms, wherein the hydrogen atoms capture positive charge in the second metal layer to prevent the third metal layer in the through hole from being corroded by performing electrochemical reaction on the positive charge; the second metal layer is made of aluminum-copper alloy; the third metal layer is made of tungsten.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for flattening thin film surface, array substrate and its preparation method, and display device

InactiveCN103258726BImprove transmittanceIncrease contrastSemiconductor/solid-state device manufacturingNon-linear opticsRough surfaceLiquid-crystal display

The invention discloses a thin film surface planarization method, an array substrate and a preparation method thereof, and a display device, which relate to the display field and can solve the damage to the surface flatness of other film layers below the etched film layer by existing dry etching Large technical problems, thereby improving the display performance of liquid crystal displays. The method for preparing the array substrate of the present invention includes performing pattern etching on the non-metal layer by dry etching, and after performing pattern etching on the non-metal layer by dry etching, further includes: The layer is subjected to surface planarization treatment, so that the rough surface of the first film layer due to dry etching is restored to a flat surface, and the first film layer is located under the non-metallic layer.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Method for forming copper layer and copper mosaic structure

InactiveCN100590812CImprove formation qualityAdd processing stepsSemiconductor/solid-state device manufacturingShielding gasCopper

The invention discloses a copper layer formation method, including the following steps: providing a substrate which is provided with a copper inoculating crystal layer on the surface; transferring thesubstrate into copper electroplating equipment; introducing protecting gas into the annealing device of the copper electroplating equipment and processing a first annealing treatment to the substrate; electroplating copper on the substrate through the electroplating device of the electroplating equipment; processing fringe washing treatment to the substrate through the fringe washing device of the electroplating equipment; and processing a second annealing treatment to the substrate through the annealing device of the copper electroplating equipment. In this way, the process of electroplatingthe copper can be finished. The invention further discloses a corresponding copper mosaic structure formation method. The copper mosaic structure formation method can effectively reduce the number ofthe pores in the copper layer, thus improving the quality of the copper layer or the copper mosaic structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of Ganoderma lucidum spore oil and its soft capsule preparation method

The invention provides a preparation method of Mythic Fungus spore oil. The preparation method comprises the following steps: carrying out wall breaking on Mythic Fungus spores and sporophores as a raw material, screening, granulating, carrying out supercritical extraction, and collecting to obtain the Mythic Fungus spore oil; and mixing the Mythic Fungus spore oil with ingredients, and carrying out a series of technologies to prepare a Mythic Fungus spore oil softgel. The Mythic Fungus spore oil extraction method provided by the invention has the advantages of wide range of suitable raw materials, simple technology, convenient operation and easy implementation; and the Mythic Fungus spore oil softgel prepared by using the Mythic Fungus spore oil extracted through the method is convenient to carry and administrate, and can promote absorption.

Owner:广东润源中天生物科技有限公司

A method for the determination of inorganic cations in tobacco gene editing materials

ActiveCN108828079BAdd processing stepsEasy to operateComponent separationBiotechnologyNicotiana tabacum

The invention discloses a method for determining five inorganic positive ions in a tobacco gene editing material. An apparatus is used, which comprises a sample extraction bottle, an outer cannula (1), an inner cannula (2), a liquid-guiding pipe (4), and a sieve plate (3) which can be one or more and positioned in a lower opening of the inner cannula (2). The method comprises the following steps:1) tobacco leaf extraction; 2) filtering and transferring; 3) analysis for making a chromatogram; 4) acquisition of a peak area of the standard chromatogram to obtain the inorganic positive ions of the tobacco gene editing material. The determination method of the present invention is characterized in that an on-line solid phase extraction purifying column is added before first usage of an ion chromatographic column, the processing is simple and convenient, the effect is good, the determination method has the advantages of accurate quantification, good repeatability, and low detecting limit, and can effectively realize the high flux analysis determination of the inorganic positive ions in tobacco gene editing material.

Owner:CHINA TOBACCO YUNNAN IND

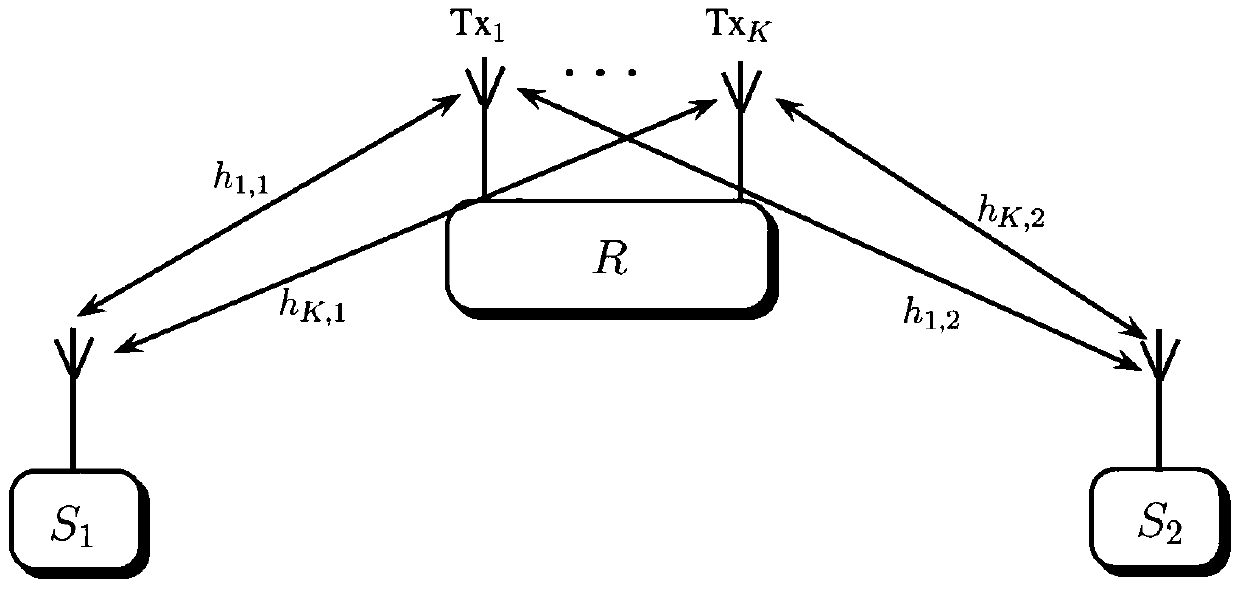

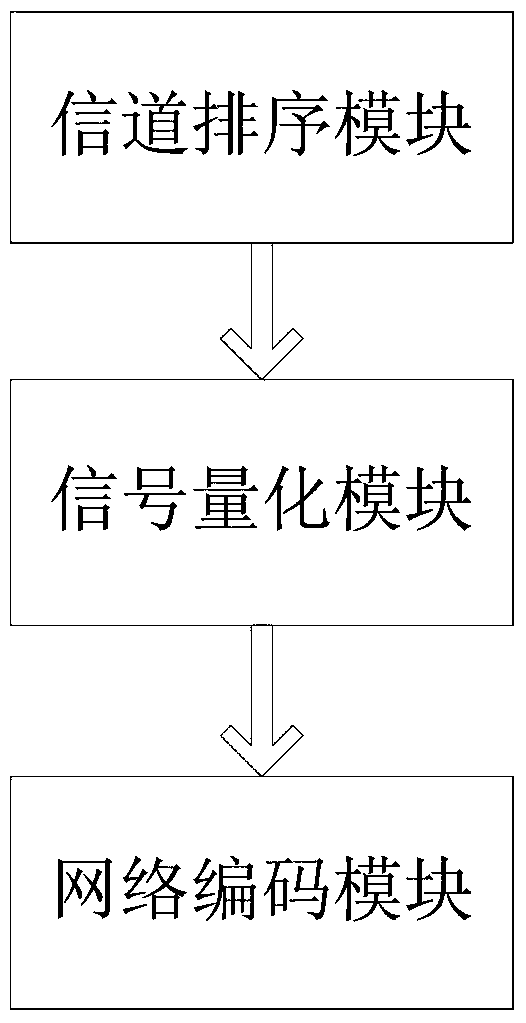

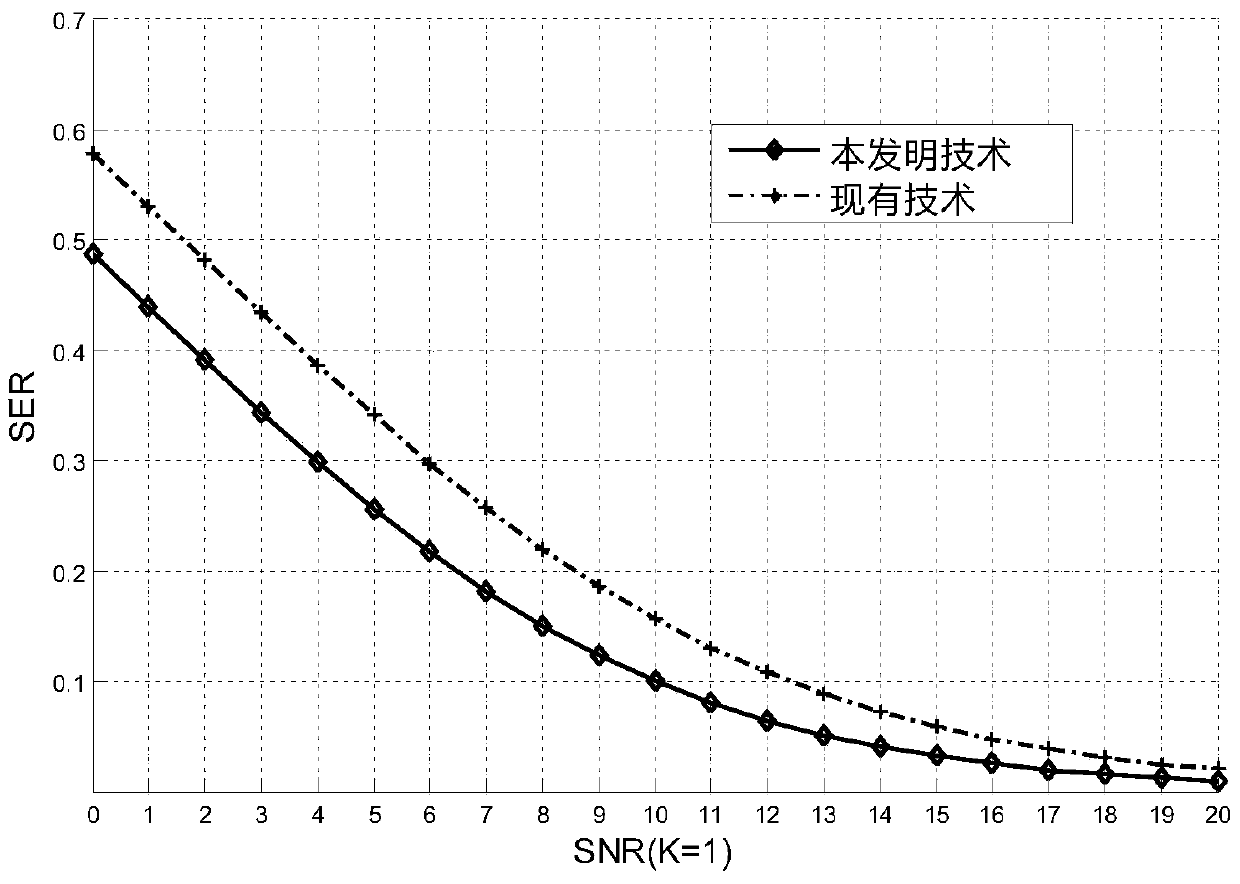

Relay Communication System and Channel Sorting Method Based on Channel Sorting and Network Coding

ActiveCN104811277BReduce symbol error rateAdd processing stepsError preventionActive radio relay systemsSystem capacityRadio channel

Owner:合肥庐阳科技创新集团有限公司

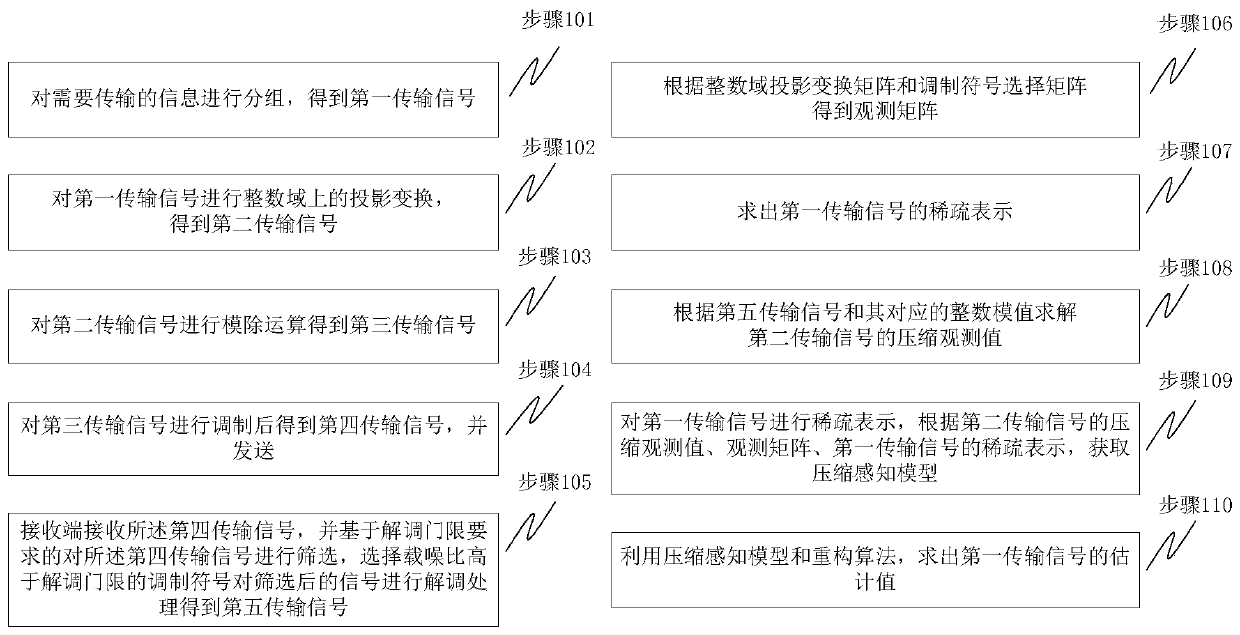

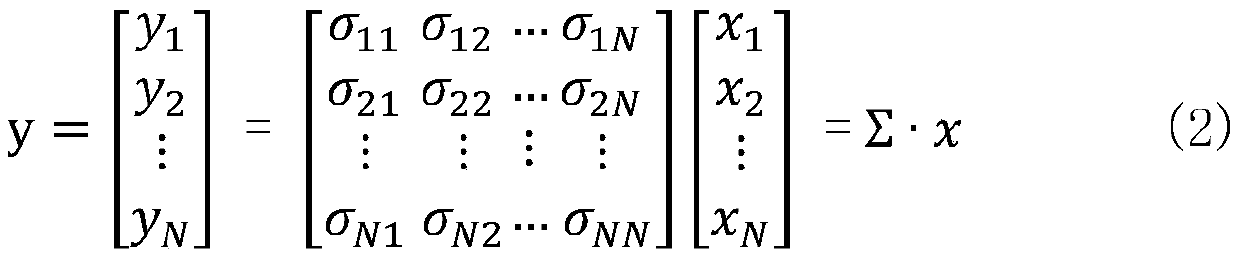

A Method for Integer Finite Field Compressive Sensing

The invention discloses an integer finite field compressed sensing method, which comprises the following steps: carrying out fixed-length grouping, projection transformation on an integer field, modular division operation and modulation on information needing to be transmitted to obtain a transmission signal, and sending the transmission signal; The receiving end receives the transmission signal and screens and demodulates the transmission signal; Obtaining a compressed sensing model based on the compressed observation value according to the demodulated signal and the corresponding integer modulus compressed observation value; And solving an original signal by using the compressed sensing model and a reconstruction algorithm. According to the invention, the compressed sensing processing isdirectly performed on the signal of the digital domain, and the digitized signal source symbol is directly processed at the signal source end, so that the process of compressing the information redundancy in the signal source coding is omitted, and the complexity of the signal source equipment end is reduced. Due to the fact that processing is directly carried out in a digital domain, the algorithm is achieved through a digital circuit, meanwhile, the function similar to channel error correction coding is achieved, and the anti-jamming capability of a communication system can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

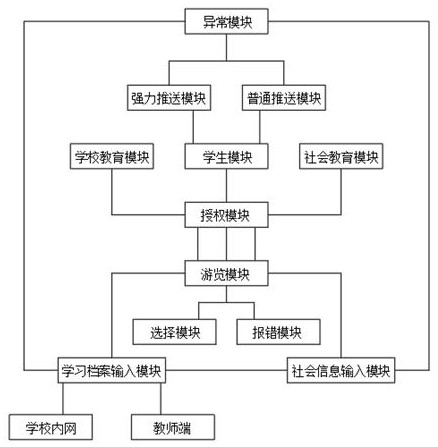

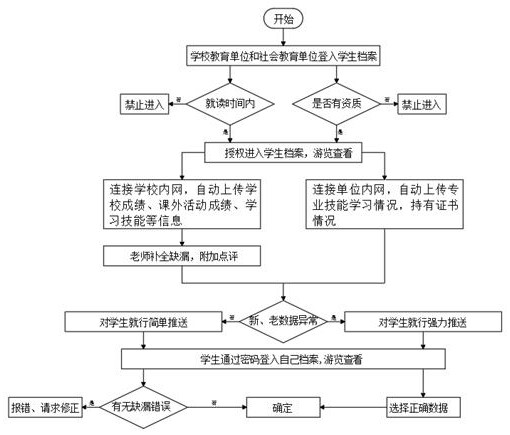

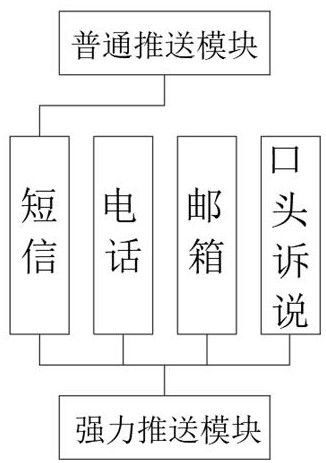

Update and management system based on learning archives

InactiveCN113590631AAvoid forgettingImprove accuracyDatabase updatingSpecial data processing applicationsKnowledge managementManagement system

The invention discloses an updating and management system based on learning archives, which comprises a school education module, a student module, a social education module, an authorization module, a touring module, a learning archive input module, a social information input module, a school intranet, a teacher end, a common push module, an abnormal module and a reinforced push module. The school education module is used for summarizing, sorting, deploying, adjusting and planning all education information and education activities of a school; the student module is used for the students to inquire own learning archives; and the social education module is used for summarizing, sorting, deploying, adjusting and planning all education information and education activities of the unit. According to the updating and management system based on the learning archives, the input module is connected with the intranet, so that the archive and the school network can be updated synchronously, the management personnel or teachers are prevented from forgetting, the workload is reduced, and the information accuracy is improved.

Owner:东莞市亚太未来软件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com