Patents

Literature

76results about How to "Purity effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

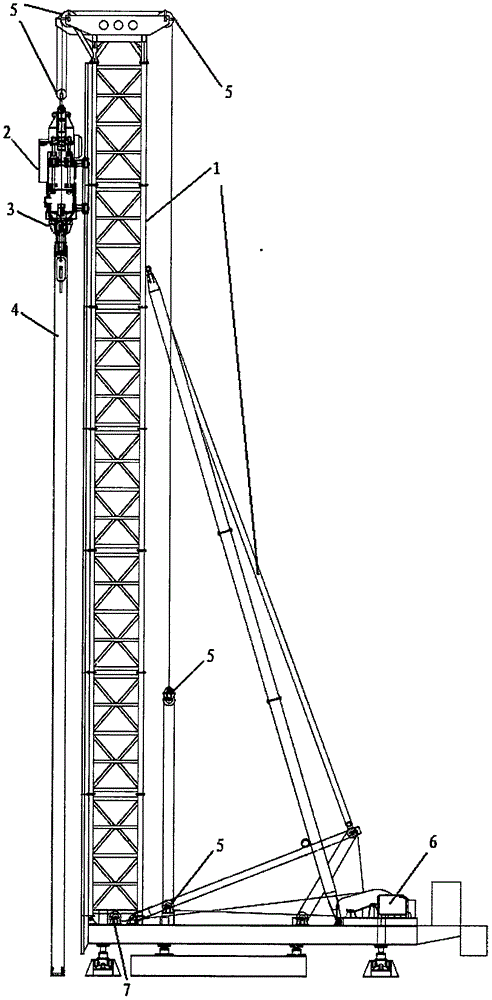

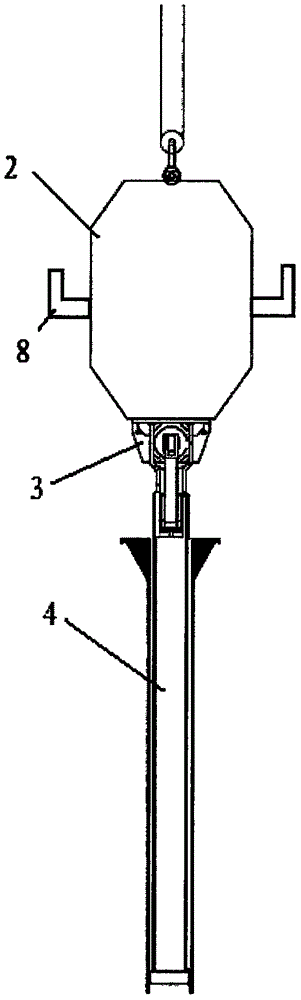

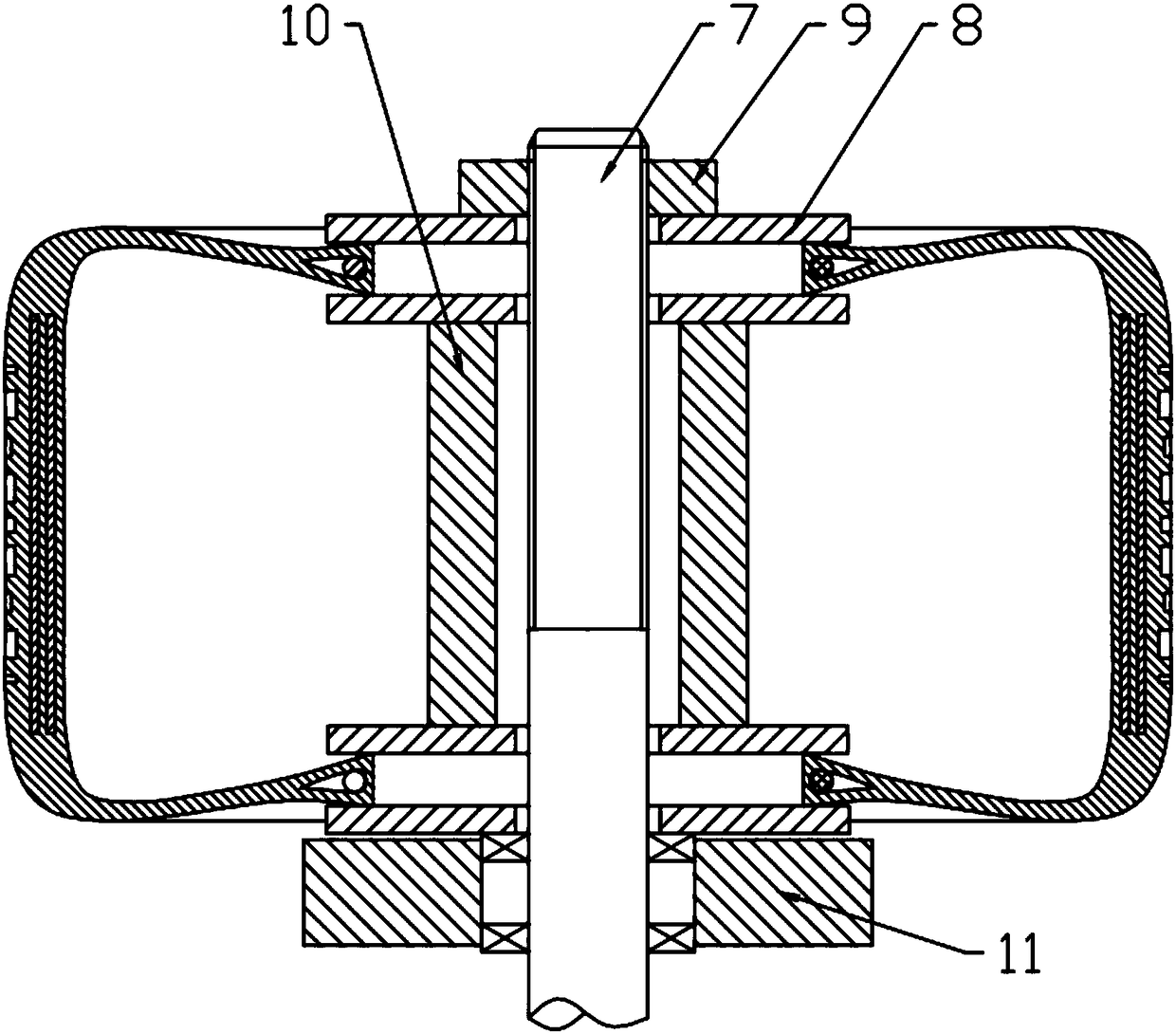

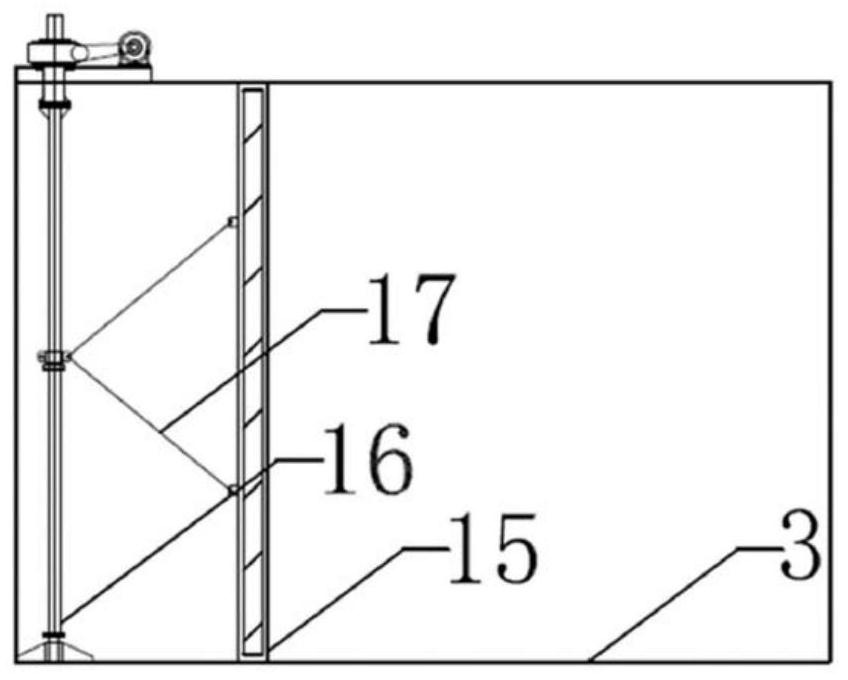

Vibratory hammer device and shaking press type pile body construction method adopting same

InactiveCN106168027AVibration pressure increasedFlexible adjustment of self-weightBulkheads/pilesArchitectural engineeringPulley

The invention discloses a vibratory hammer device. The device comprises a support, a vibratory hammer, a second pulley component, a winding plant and a balancing weight, wherein a first pulley component is installed on the support, the first end of the vibratory hammer is connected with the first pulley component, and the second end of the vibratory hammer is provided with a fixing structure used for fixing an inner pipe and an outer pipe; the second pulley component is installed on the support, the winding plant is installed on the support and connected with the vibratory hammer through the second pulley component and can apply a vertically downward force to the vibratory hammer, and the balancing weight is detachably connected to the vibratory hammer. In this way, construction noise is low, construction efficiency is high, and the dead weight of a hammer body can be adjusted flexibly to meet the requirement for pile forming. The invention further discloses a shaking press type pile body construction method adopting the vibratory hammer device.

Owner:刘献刚

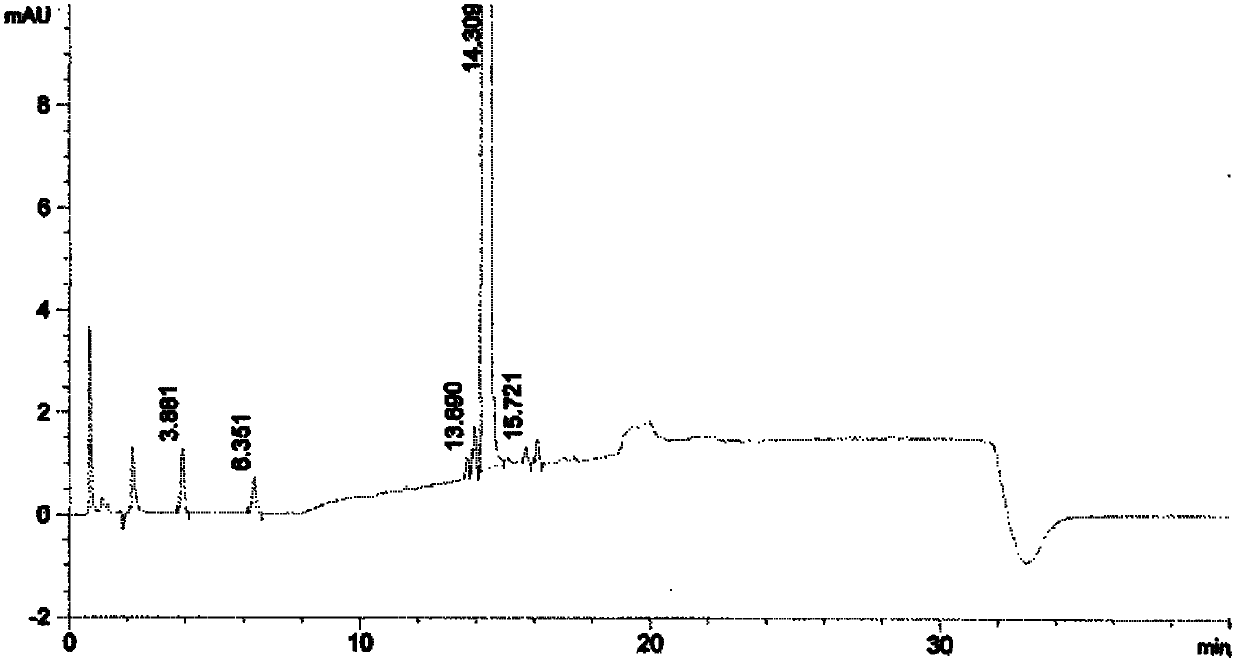

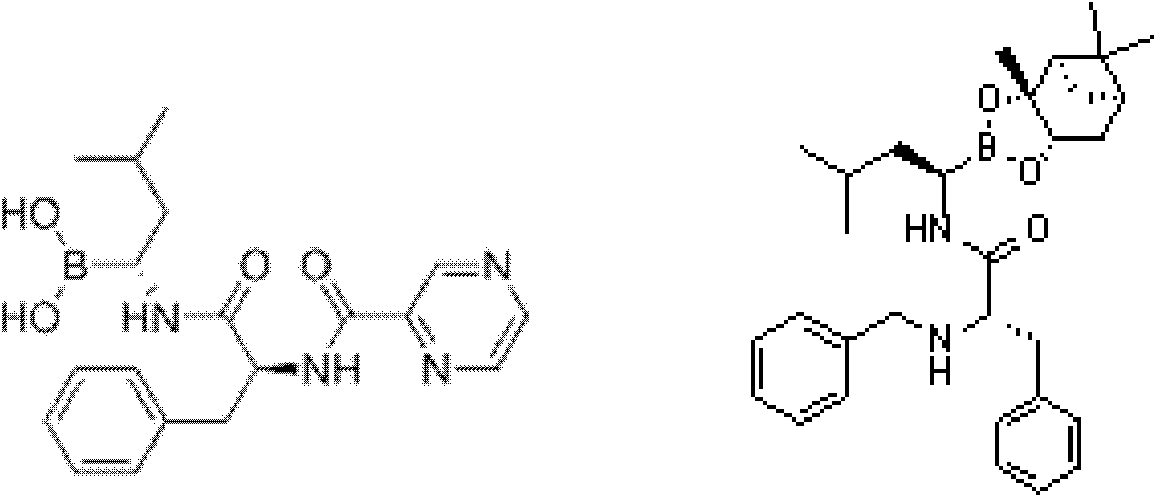

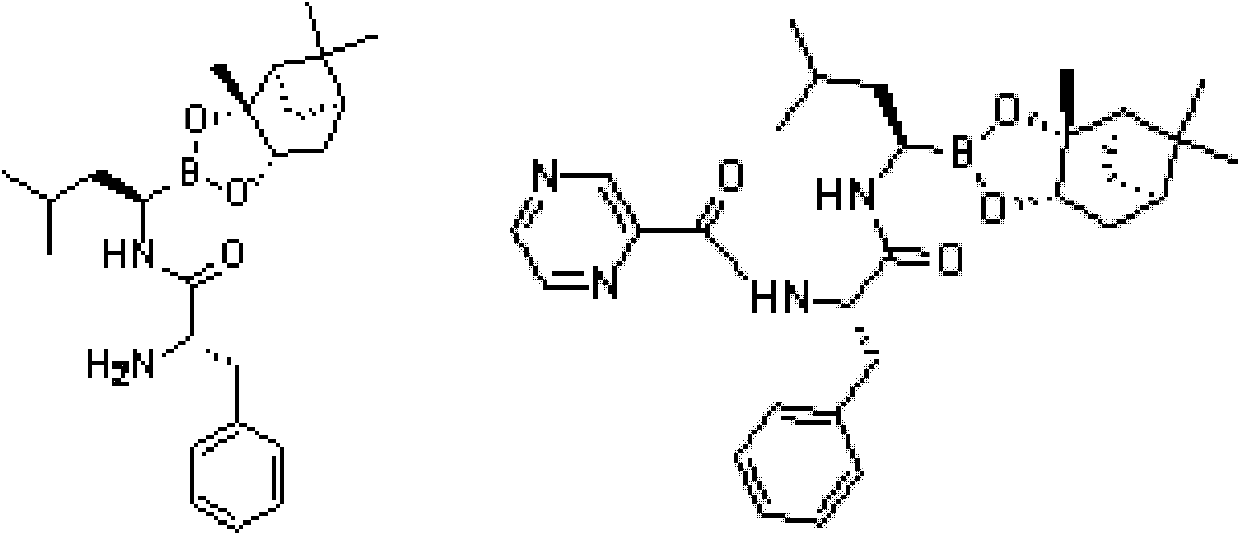

Method for synthesizing bortezomib

ActiveCN102351890APurity effectHigh purityGroup 3/13 element organic compoundsChemical synthesisToluene

The invention relates to the field of chemical synthesis, in particular to a method for synthesizing bortezomib shown as a structural formula I. The method comprises the followings steps of: performing condensation, debenzylation, condensation and oxidation deprotection on raw materials; and purifying with acetone, toluene and methyl tert-butyl ether to obtain bortezomib. The method for synthesizing the bortezomib provided by the invention has the advantages of low reagent price, a small number of reaction steps, mild reaction condition, increase in the purity of bortezomib tablets and contribution to industrial production. The formula I is shown in the specifications.

Owner:CHONGQING SINTAHO PHARM CO LTD

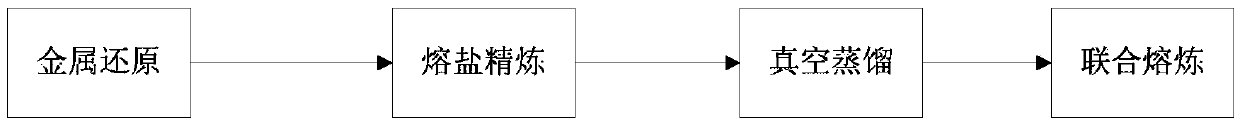

Zirconium and method for preparing zirconium

ActiveCN104195355APurity effectReduce oxygen contentProcess efficiency improvementAlkaline earth metalZone melting

The invention provides zirconium and a method for preparing the zirconium. The method comprises the following steps: metallothermic reduction, namely promoting zirconium oxide and alkaline-earth metal or alkaline-earth metal hydride to perform a metallothermic reduction reaction, and removing impurities to obtain primary zirconium; molten salt refining, namely promoting the primary zirconium and mixed molten salt to perform a molten salt refining reaction so as to obtain secondary zirconium; vacuum distillation, namely performing vacuum distillation on the secondary zirconium so as to obtain tertiary zirconium; and combined melting, namely sequentially performing smelting in suspension and electron beam zone melting on the tertiary zirconium so as to obtain the product zirconium, wherein the mixed molten salt consists of CaCl2 and Ca. According to the method, the zirconium oxide is used as a raw material, metallothermic reduction, molten salt refining, vacuum distillation and combined melting methods are sequentially adopted, the primary zirconium obtained after the metallothermic reduction is subjected to molten salt refining, the oxygen content of the intermediate product zirconium can be effectively reduced, and the mixed molten salt used in the method can be easily removed by means of water washing, and the purity of zirconium cannot be influenced.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Extraction separation method for rare earth and zinc in reverse extraction raffinate obtained in reduction extraction separation of europium

ActiveCN103922383AHigh extraction rateImprove the extraction and separation effectLiquid solutions solvent extractionRare earth metal compoundsChlorideSamarium

The invention relates to an extraction separation method for rare earth and zinc in reverse extraction raffinate obtained in reduction extraction separation of europium, belonging to the field of hydro-metallurgy of rare earth. According to the invention, the reverse extraction raffinate obtained in reduction extraction separation of europium is mixed solution of rare earth chloride and zinc chloride; ammonia water is added into the reverse extraction raffinate to neutralize spent acid, then NH4Cl is added, and then the reverse extraction raffinate with NH4Cl is used as a feed liquid, wherein the concentration of NH4Cl in the feed liquid is 3 mol / L; an organic phase is composed of P507-kerosene with a concentration of 1.5 mol / L; a GdCl3 solution with NH4Cl is used as a washing liquid, and the concentration of NH4Cl in the washing liquid is 3 mol / L; after multistage extraction separation, raffinate containing zinc and an organic phase with loaded rare earth are obtained, wherein the raffinate containing zinc is used as a raw material for preparation of zinc carbonate, and the organic phase with loaded rare earth is directly used as a feed liquid for extraction separation of samarium, europium and gadolinium. NH4Cl is added into the extraction separation feed liquid for rare earth and zinc and into the washing liquid, so a separating factor for rare earth and zinc is improved, the stages of extraction separation in industrial production and the volume of a mixing chamber can be reduced, and consumption of acid and alkali is decreased at the same time.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Production method of tetraamminepalladium sulfate

PendingCN107176625AHigh purityPurity effectRuthenium/rhodium/palladium/osmium/iridium/platinum compounds preparationSynthesis methodsSulfate

The invention discloses a production method of tetraammonia palladium sulfate, which comprises the steps of ammonia water complexation, ion exchange, sulfuric acid neutralization, recrystallization and purification. The synthesis method of the invention has simple process, few by-products, The product has high purity and high conversion rate, and the present invention adds a drying step in the complexation of ammonia water, so that the residual ammonia water on the solid surface is avoided from participating in the next reaction step, which affects the purity of tetraammonia palladium sulfate, so that tetraammine palladium sulfate The purity has been further improved.

Owner:LESHAN DONGCHEN ADVANCED MATERIAL

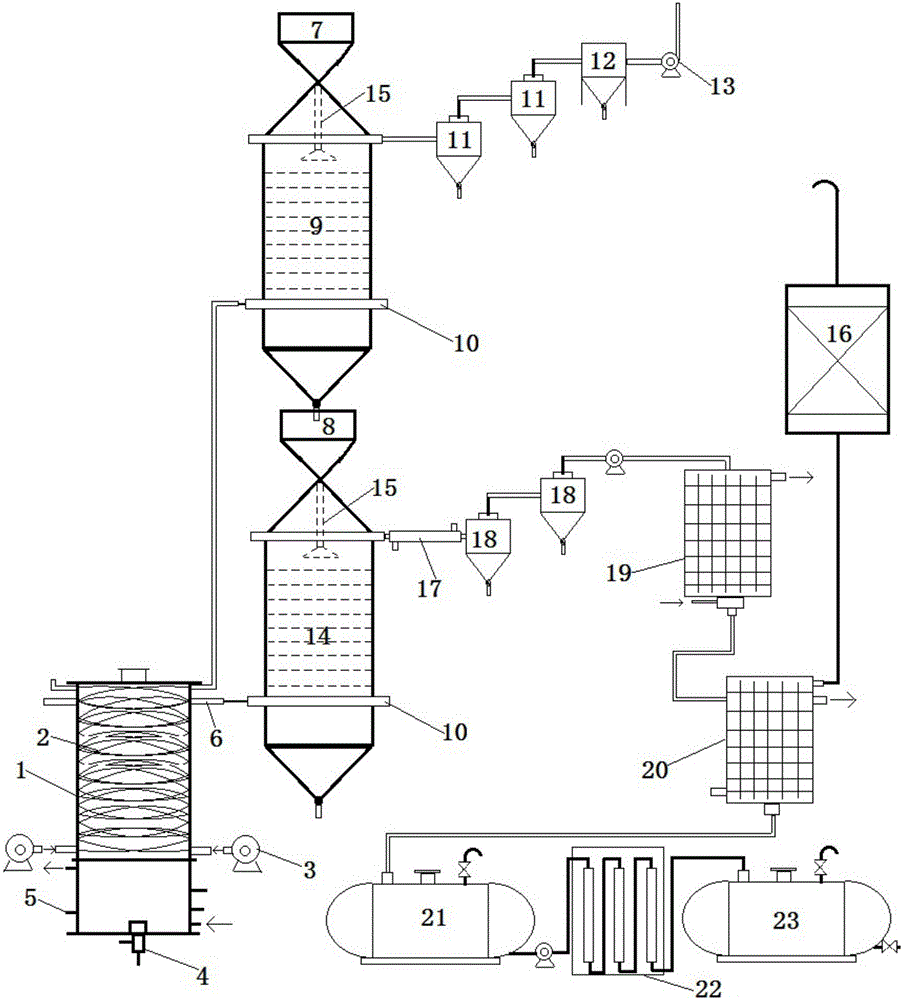

Method and device for preparing hydrochloric acid and purifying quartz sand

ActiveCN106219488AQuality assuranceHigh purityChlorine/hydrogen-chloride purificationSilicaMetal chlorideHydrogen

The invention provides a method and a device for preparing hydrochloric acid and purifying quartz sand. The method comprises the following steps: igniting hydrogen and chlorine in a synthetic furnace, carrying out a reaction to produce hydrogen chloride gas, releasing heat, and controlling the temperature of hydrogen chloride gas at the outlet of the synthetic furnace to be 500-1300 DEG C; heating cooling air in a gas cooling device, introducing the air into the bottom of a drying device filled with semi-finished quartz sand, allowing hot air to flow from the bottom upwards, drying the semi-finished quartz sand, and taking the moisture therein; allowing the dried semi-finished quartz sand into a chlorination impurity removal device by the drying device, and completing purification of the quartz sand; allowing the hydrogen chloride gas and metal chloride gas in the chlorination impurity removal device to flow out of the top, and allowing the gas to enter the gas cooling device. According to the method disclosed by the invention, the whole quartz sand purification process can be energy-saving and low in cost on the premise of guaranteeing the quality of synthetic hydrochloric acid, and the purified quartz sand is high in purity.

Owner:田晋丞

Method for selectively leaching vanadium from vanadium-contained stone coals

ActiveCN105624435AEfficient separationPurity effectProcess efficiency improvementOXALIC ACID DIHYDRATEPotassium fluoride

The invention relates to a method for selectively leaching vanadium from vanadium-contained stone coals. The method comprises the following steps: firstly, a crude ore of the vanadium-contained stone coals is crushed, and is ground to obtain vanadium-contained stone coal mineral powder with particle sizes lower than 0.074 mm of 65-80 wt%; the vanadium-contained stone coal mineral powder is added in water; 0.5-1.25 kg vanadium-contained stone coal mineral powder is added in each liter of water; then, a leaching agent is added; 0.3-1 kg leaching agent is added in each liter of water; the stirring is performed by 3-7 h under the condition of 80-100 DEG C; and the solid-liquid separation is performed to obtain vanadium-contained leaching liquid and leaching slag. The leaching agent is a mixture consisting of fluorides and oxalic acid; the mass ratio of the fluorides to the oxalic acid in the leaching agent is 1: (8-15); and the fluorides are more than one of calcium fluoride, sodium fluoride, potassium fluoride, ammonia fluoride and ammonium bifluoride. The method can selectively leach vanadium from the vanadium-contained stone coals, realizes effective separation of vanadium and impurity iron, obtains the vanadium-contained leaching liquid with low iron content, and reduces the influence of iron on subsequent process.

Owner:WUHAN UNIV OF SCI & TECH

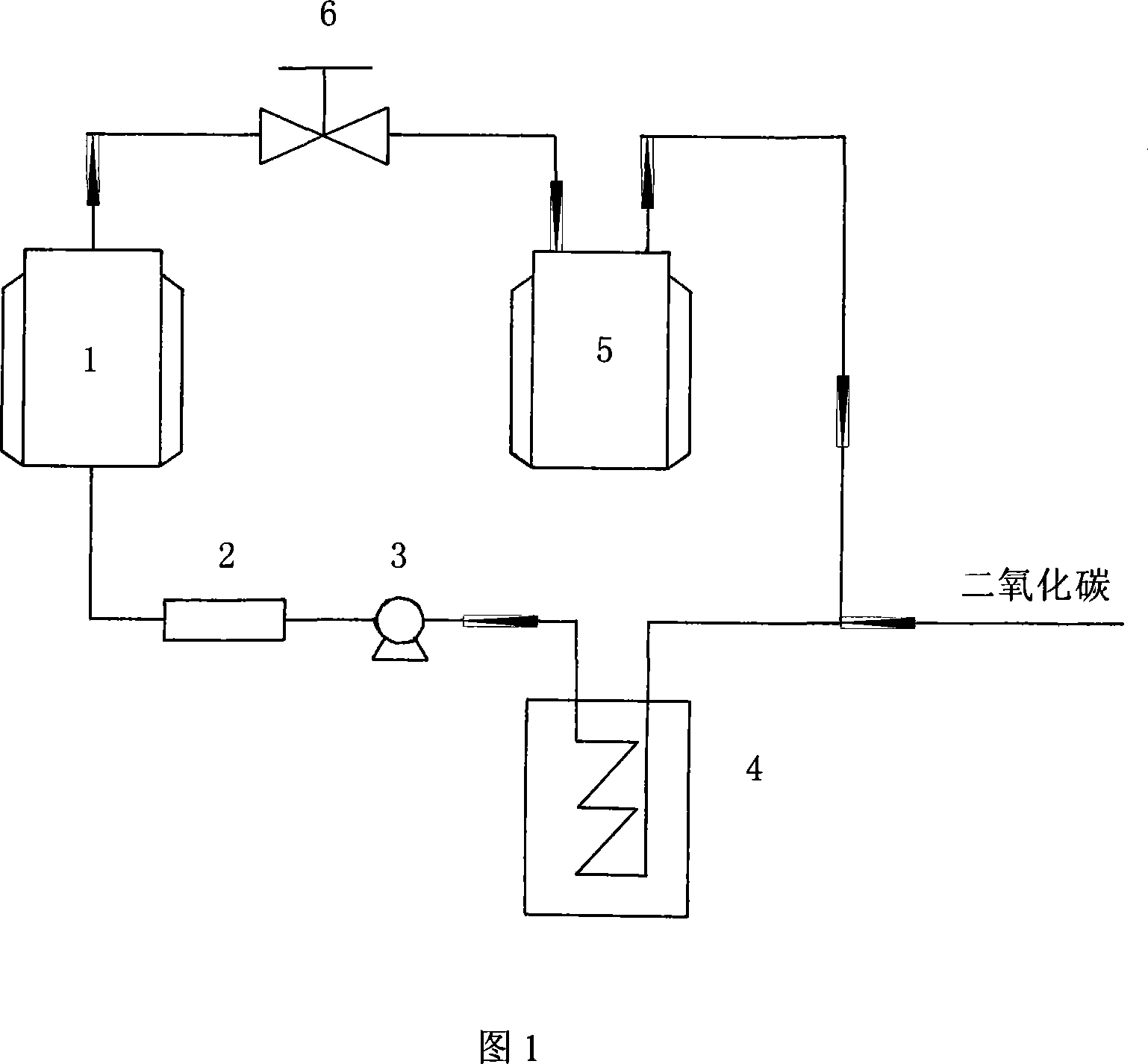

Method for extracting cholesterine in lanosterol by supercritical CO2

InactiveCN101074257APurity effectIncrease contentSteroids preparationBulk chemical productionLanosterolCholesterol

A method for extracting cholesterol from lanosterol by supercritical CO2 is carried out by putting lanosterol and laminating agent into extractor, delivering CO2 into extractor by compressing pump, adjusting CO2 extractor pressure and temperature, controlling CO2 flow speed, extracting to obtain CO2 with solute, decompressing CO2 with solute, separating to obtain cholesterol and lanosterol, dissolving for cholesterol by solvent, lowering temperature and crystallizing to obtain high-content final product. It's simple and inodorous, has better purity and light color.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

Oil-water separator and separation system

PendingCN110215741AAchieve separationAutomatic separationNon-miscible liquid separationChemical industryVolumetric Mass Density

The invention discloses an oil-water separator for chemical industry and an oil-water separation system. The oil-water separator is of a tank-type hollow structure and is internally provided with a separation channel coated with a hydrophobic membrane, a physical partition plate and a novel liquid level floating plate; and an oil phase discharging hole and a water phase discharging hole are respectively formed in a tank bottom. Due to the arrangement of a hydrophobic membrane layer, the rapid separation of oil and water is realized in the separation channel, and the oil-water separation time is shortened; the density-adjustable oil-water separation liquid level floating plate is designed by adopting a novel air sac floating plate, so that the separation of an oil phase and a water phase isefficiently accelerated; and meanwhile, due to the adoption of a magnetic induction device at a liquid level floating plate end, phase interface positions of the two phases including the oil phase and the water phase can be monitored in real time, the yield of the water phase is directed to be controlled, an effective liquid level monitoring means is provided for a chemical oil-water separation process, and the oil-water separator is suitable for traditional chemical oil-water separation controlled a DCS.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

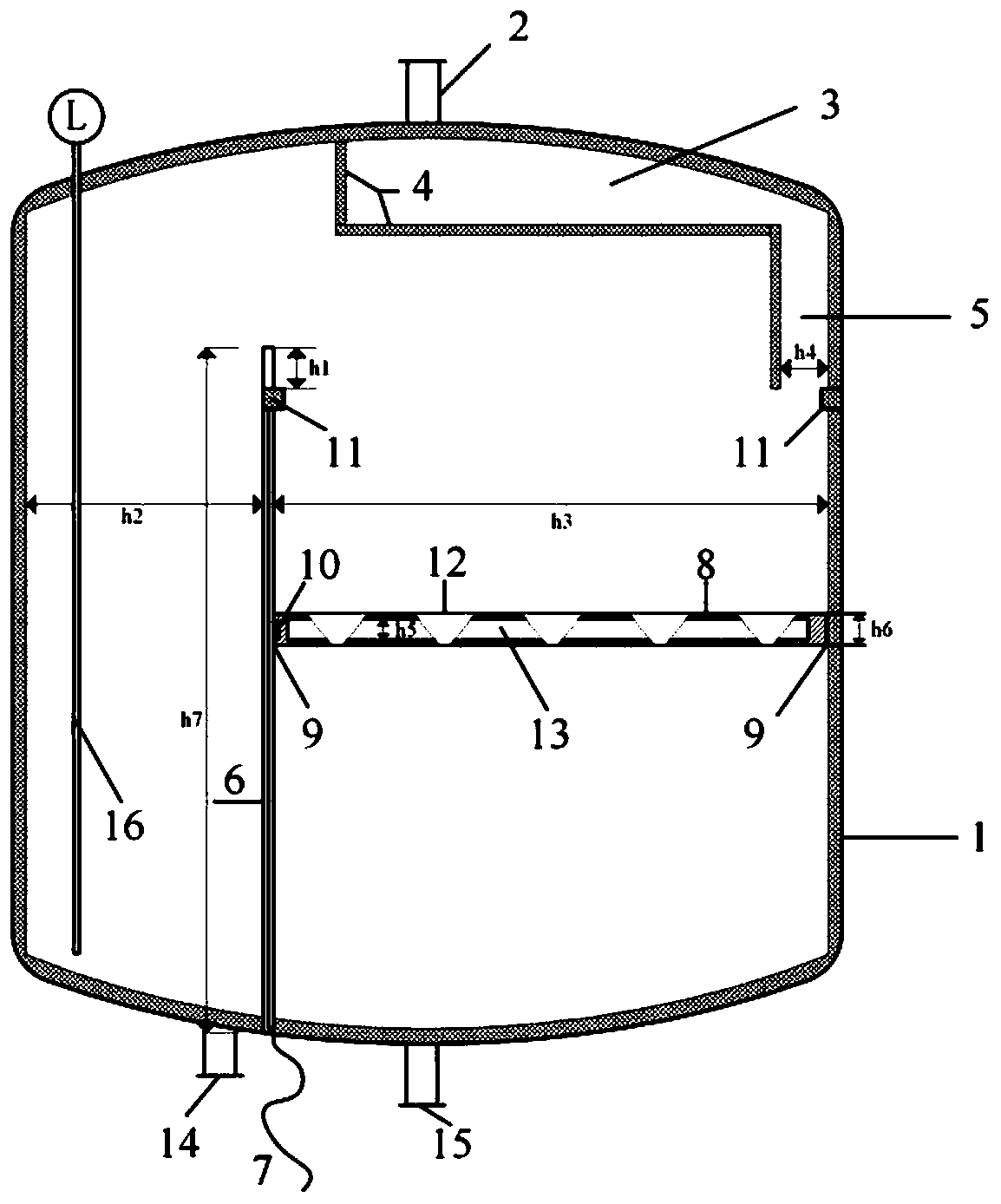

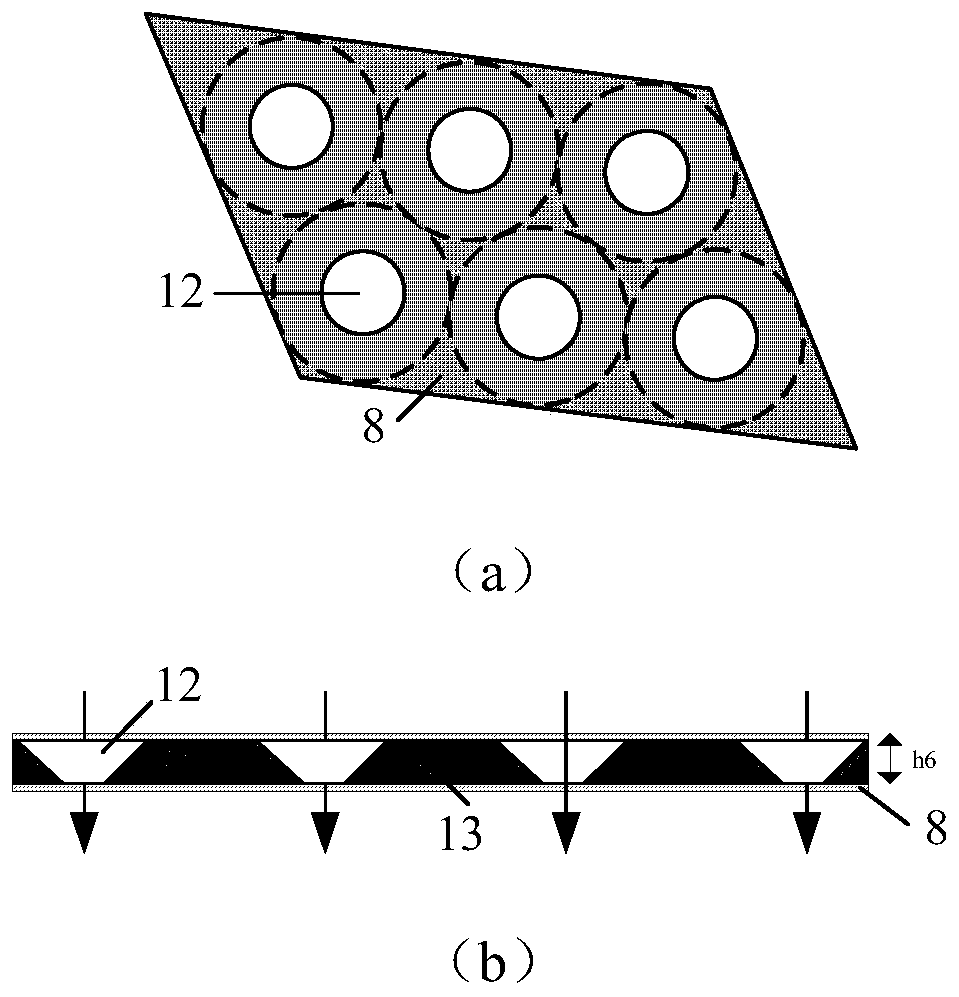

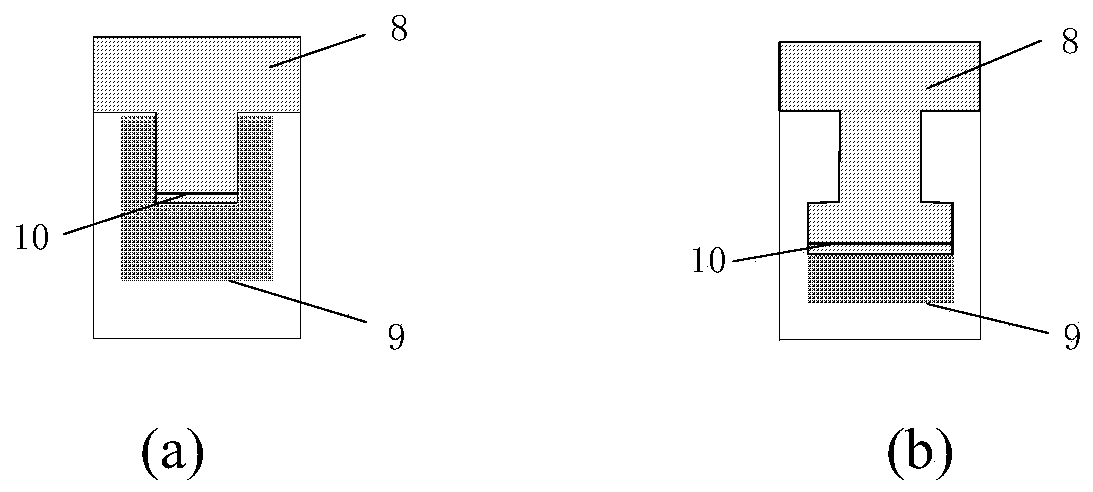

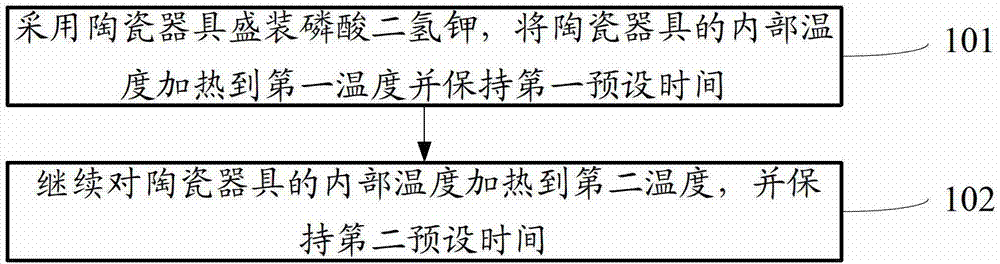

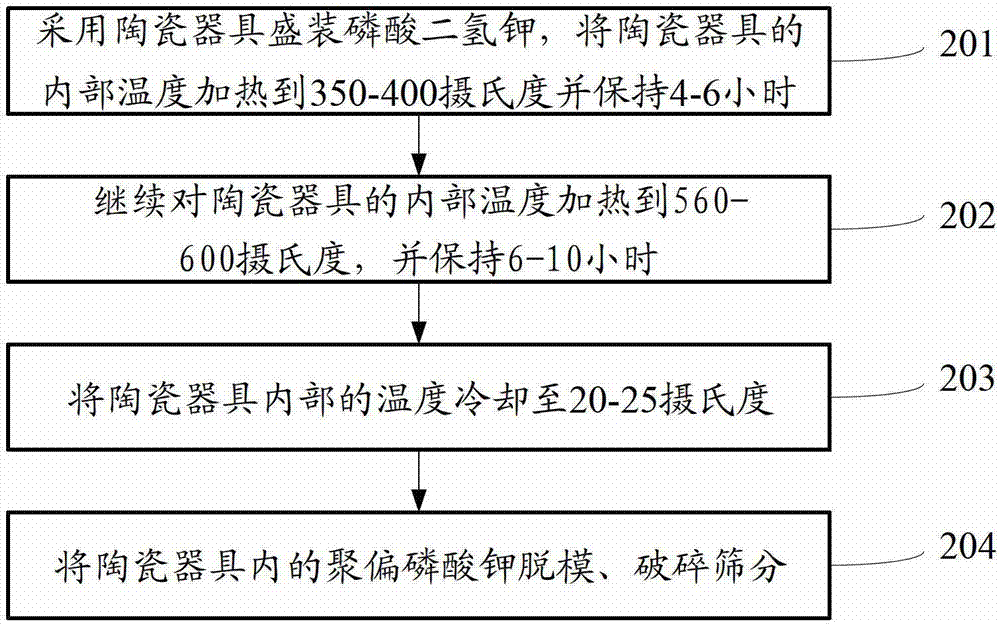

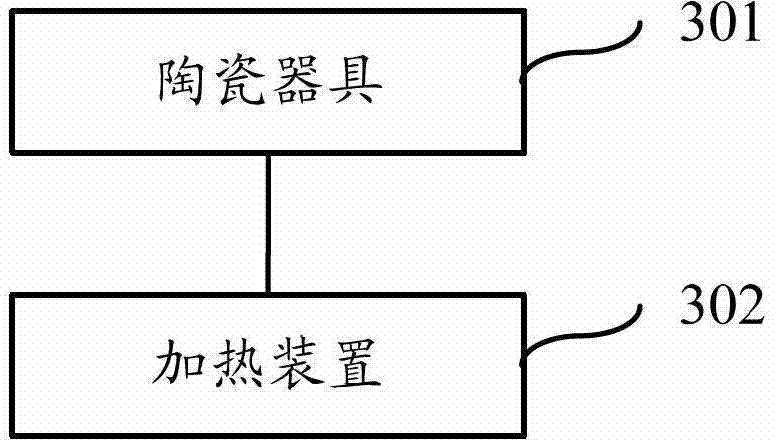

Production method and production equipment of potassium polymetaphosphate

ActiveCN102897740APurity effectReduce the impact of purityPhosphorus compoundsChemical productsMonopotassium phosphate

The invention relates to a chemical product production technology, and in particular relates to a production method and production equiopment of potassium polymetaphosphate. The production method of the potassium polymetaphosphate comprises the following steps: holding monopotassium phosphate with a ceramic container; and heating the inner part of the ceramic container to a first temperature, and maintaining the first temperature for a first preset time. The production equipment of the potassium polymetaphosphate comprises a ceramic container and a heating device, wherein the ceramic container is used for holding monopotassium phosphate; the heating device is used for heating the inner part of the ceramic container which is used for holding the monopotassium phosphate to the first temperature and also for maintaining the first temperature for the first preset time; and the inner part of the ceramic container is heated to a second temperature and maintained for a second preset time. According to the production method and production equiopment of potassium polymetaphosphate, the influence of metal ions on the purity of potassium polymetaphosphate can be reduced.

Owner:YUNNAN ADDIPHOS TECH CO LTD

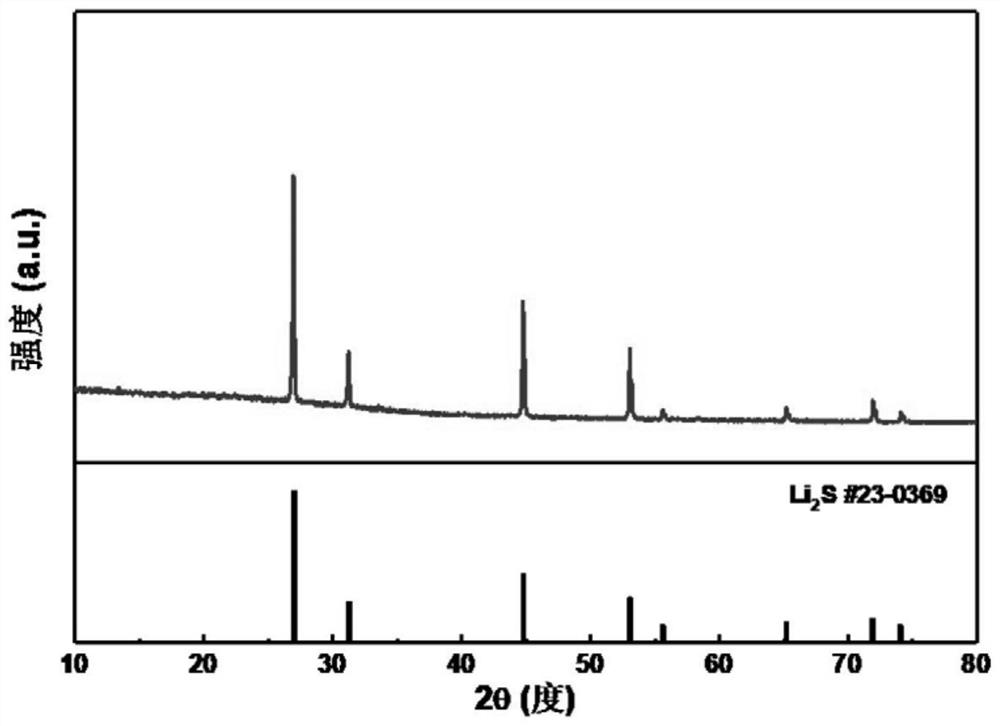

Green preparation method of lithium sulfide

ActiveCN112520703ALow costSimplify the operation processSecondary cellsAlkali metal sulfides/polysulfidesLithium sulfideMaterial synthesis

The invention belongs to the field of material synthesis, and particularly relates to a green preparation method of lithium sulfide. Aiming at the problems that high-purity lithium sulfide is high inprice inAladdin and Alpha reagent websites, the research burden in the field of lithium sulfide research is increased and the like, the invention discloses the green preparation method of lithium sulfide, and lithium sulfide powder can be obtained through simple processes such as solid-solid mixing, heating, heat preservation and the like. The method has the advantages of simple preparation method, easy realization of industrial production, low preparation cost, high product purity, realization of large-batch continuous preparation, and meeting of the requirements of the current research fieldon lithium sulfide.

Owner:ZHEJIANG UNIV OF TECH

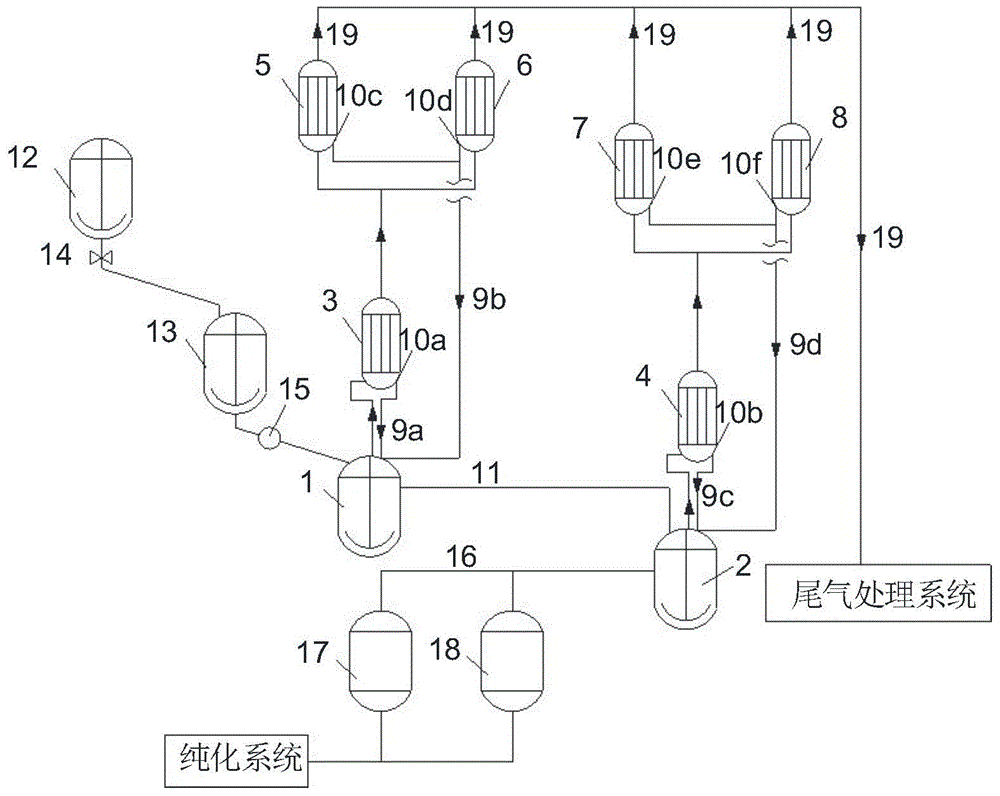

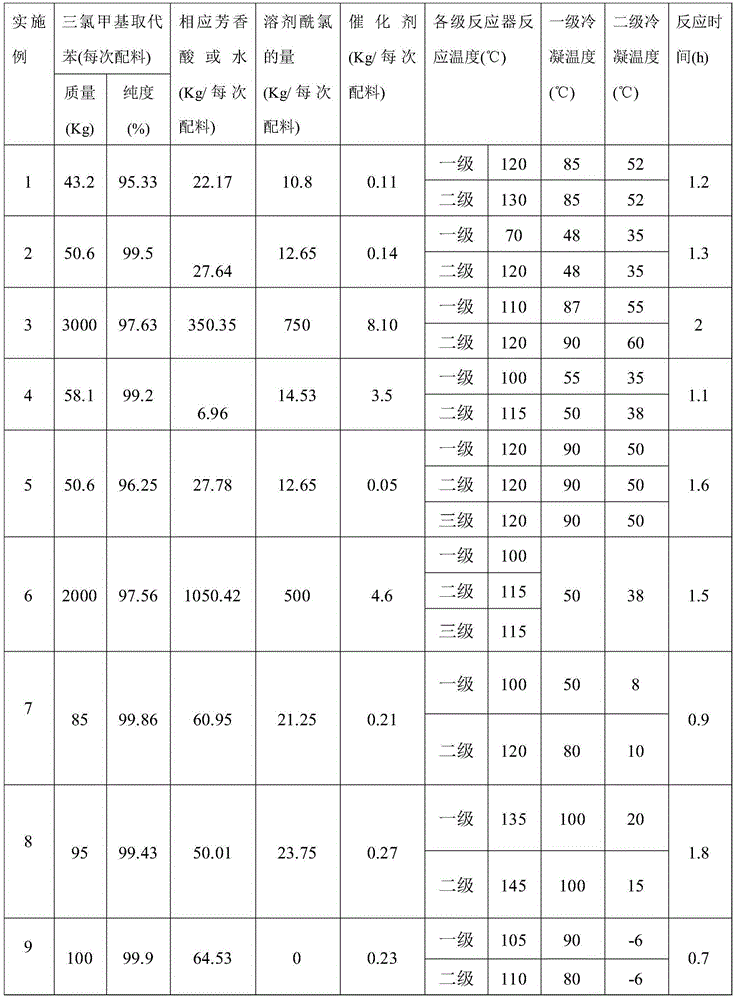

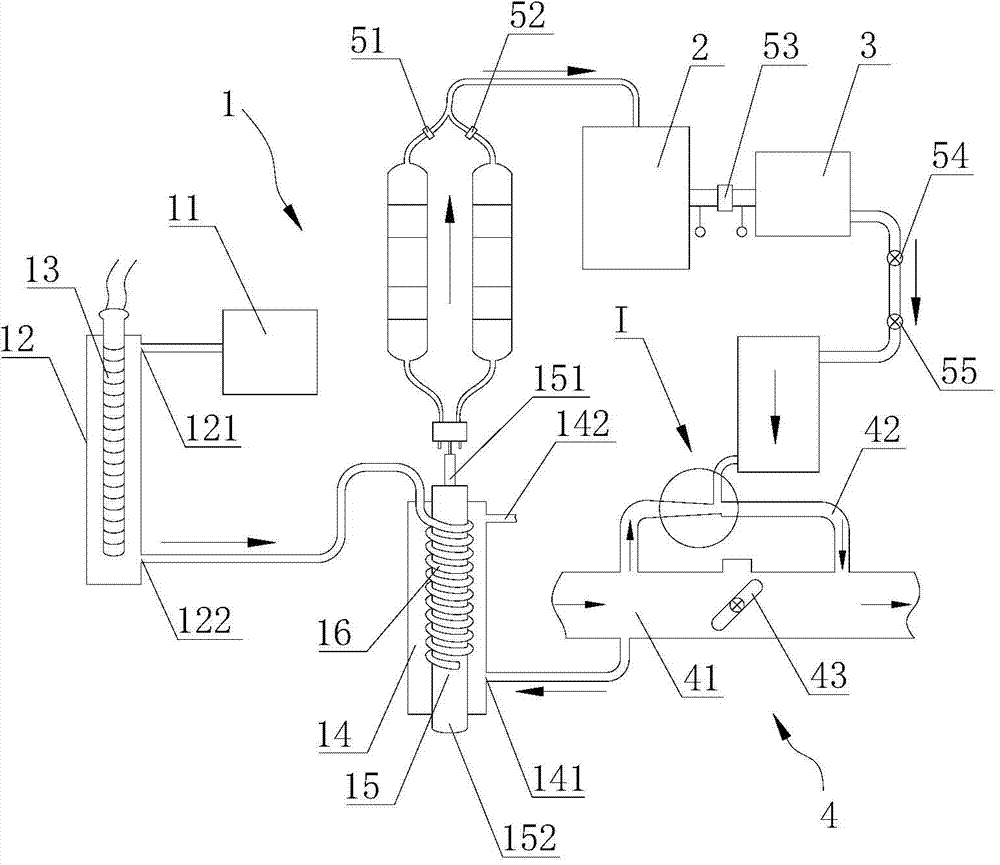

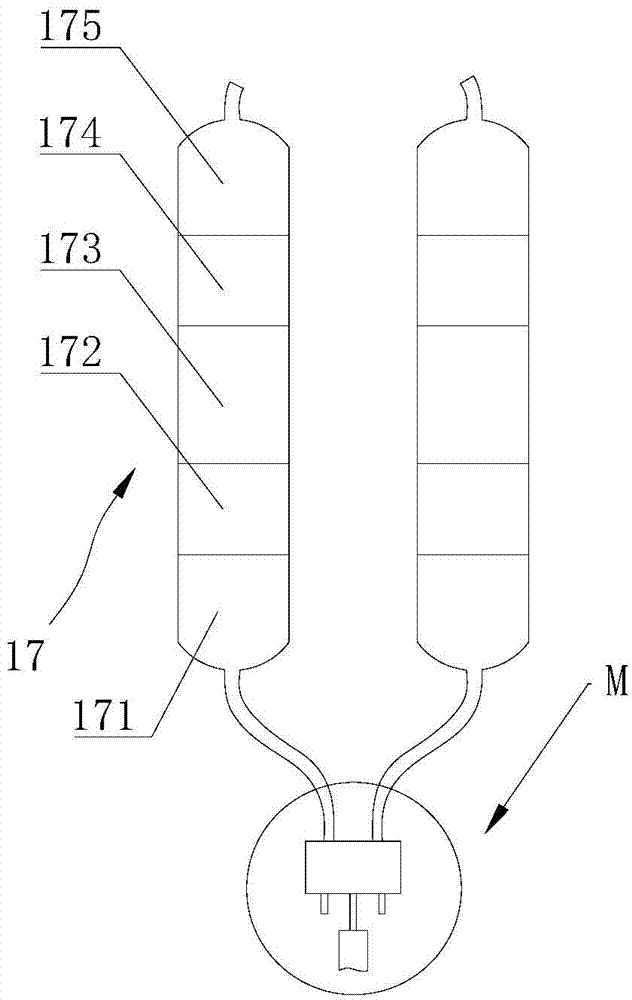

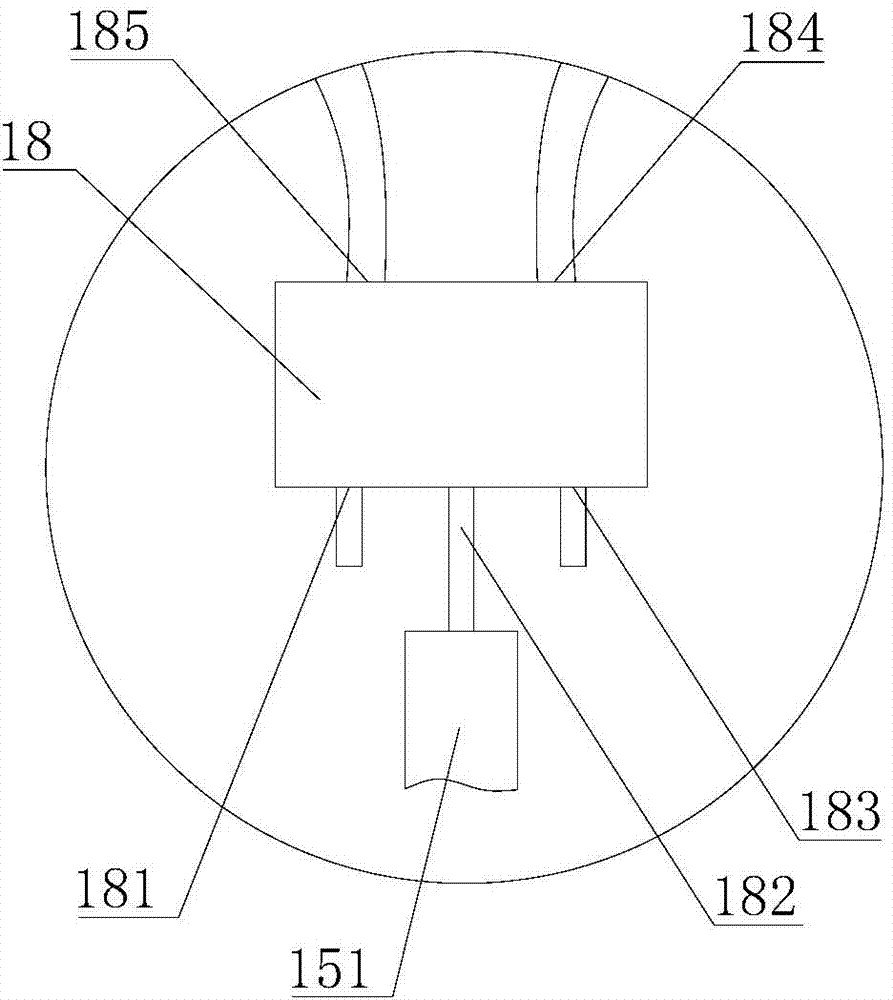

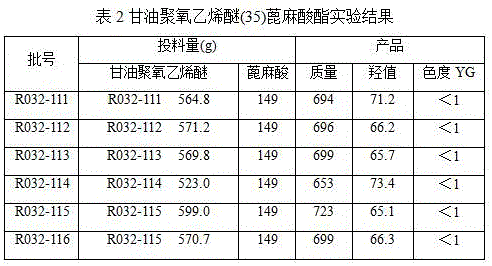

Continuous production method and device for chloroformyl substituted benzenes

InactiveCN104592012ARealize continuous productionImprove qualityOrganic compound preparationVapor condensationBenzeneReaction system

The invention discloses a continuous production method for chloroformyl substituted benzenes. According to the method, uniformly mixed reaction materials are continuously added in a reaction system composed of multiple stages of reactors which are connected in series, and the reaction materials have reaction under certain temperature conditions, and after the materials continuously flow out of the reactors, a chloroformyl substituted benzene crude product is obtained; and gas produced in the reaction is subjected to condensation treatment, a chloroformyl substituted benzene condensed fluid flows back to the reaction system, and non-condensable gas is optionally further subjected to tail gas treatment. The invention also discloses a continuous production device for chloroformyl substituted benzenes; the device comprises a proportioning system, a reaction system and a condensing system, wherein the reaction system comprises more than two stages of reactors which are connected in series, and the device also can further comprise a purification system and a tail gas treatment system. According to the invention, the continuous production of chloroformyl substituted benzenes is realized by using the continuous production of trichloromethyl substituted benzenes, the quality of prepared products is good, the yield is high, and tail gas is easily treated.

Owner:SHANGHAI FANGLUN NEW MATERIAL TECH

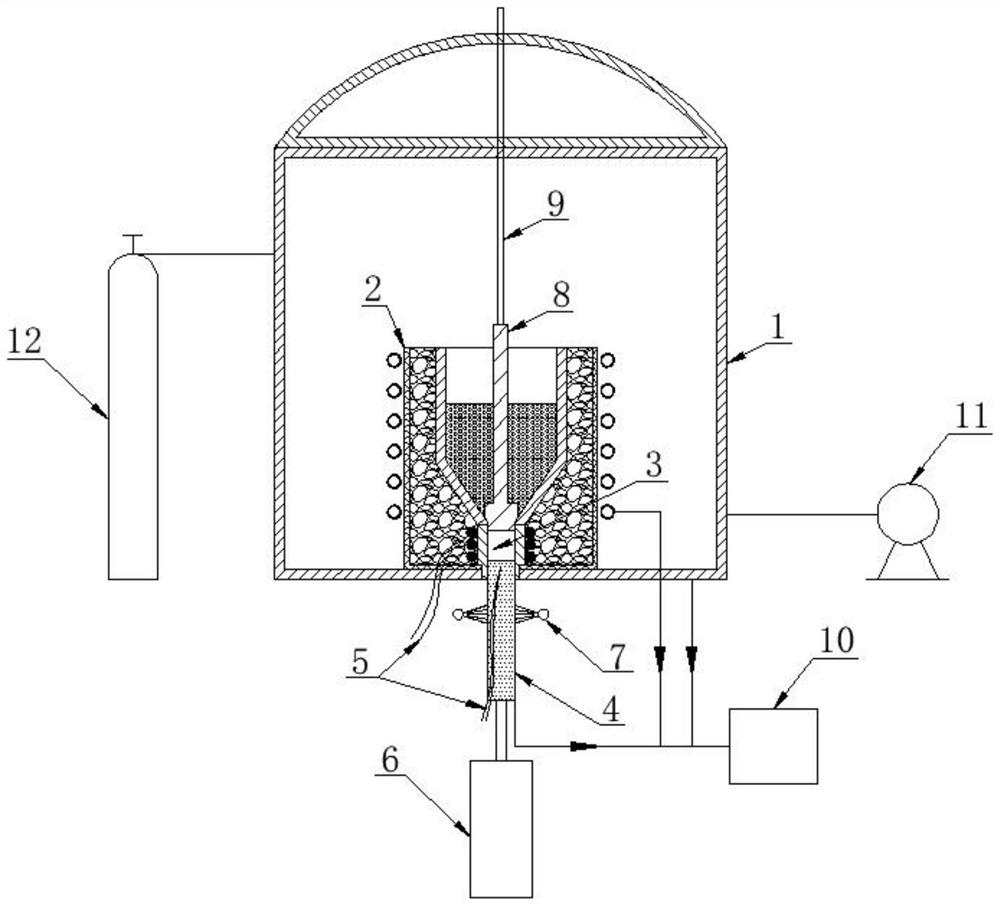

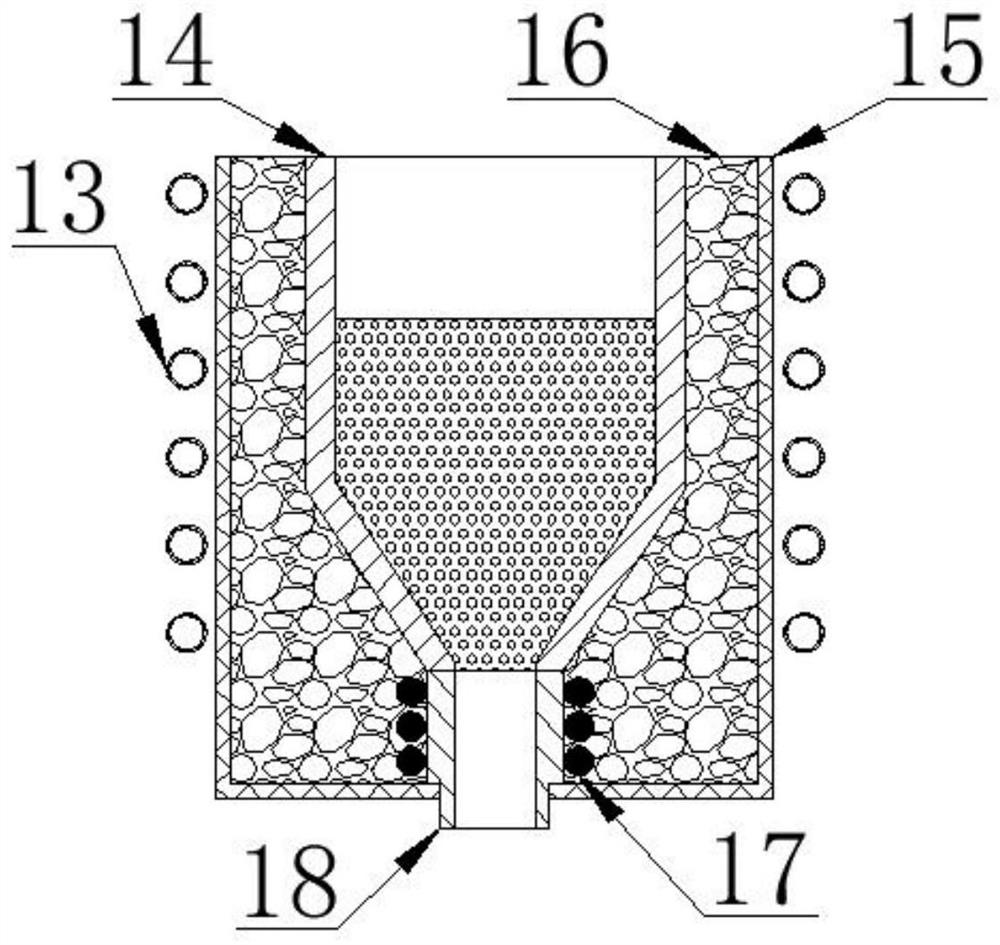

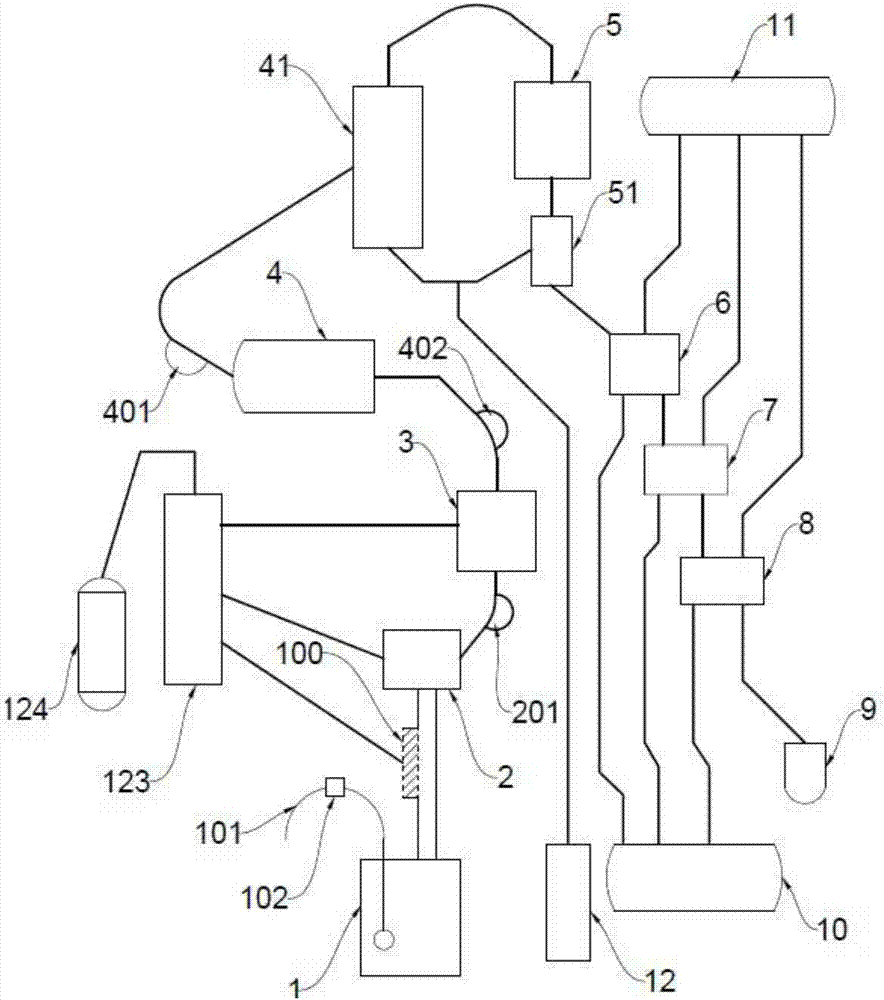

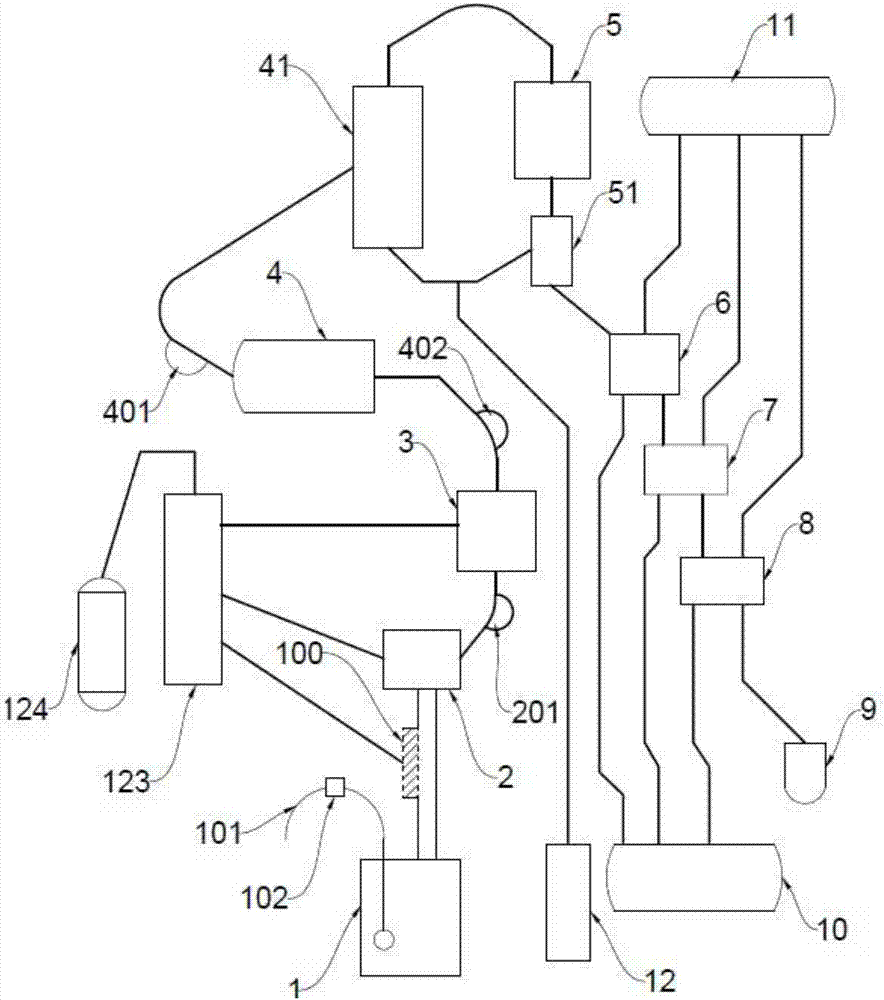

Ozone water and soil infectious insect pest prevention and control machine

ActiveCN103891700ASolve the problem of not being able to separate relatively pure oxygen from airGuaranteed purityOzone preparationChemicalsInsect pestAir compressor

The invention provides an ozone water and soil infectious insect pest prevention and control machine. The ozone water and soil infectious insect pest prevention and control machine comprises an oxygen extraction device, an oxygen storage tank, a high-voltage discharge chamber and an ozone water mixing device, all of which are connected in sequence. The oxygen extraction device comprises an air compressor, an air heating pipe, an air cooling pipe, a water removing pipe, a guide pipe and a nitrogen removing pipe. An electric heating bar is arranged in the air heating pipe, one end of the air heating pipe is provided with an air inlet communicated with the air compressor, and the other end of the air heating pipe is provided with an air outlet. The lower end of the air cooling pipe is provided with a cooling water inlet, and the upper end of the air cooling pipe is provided with a cooling water outlet. The water removing pipe is located in the air cooling pipe, and the upper end and the lower end of the water removing pipe penetrate through an upper seal and a lower seal of the air cooling pipe respectively. The guide pipe winds the outer wall of the water removing pipe, and the lower end of the guide pipe stretches into the lower end of the water removing pipe. One end of the nitrogen removing pipe is communicated with the water removing pipe, and the other end of the nitrogen removing pipe is communicated with the oxygen storage tank. The prevention and control device can effectively extract oxygen from air and can guarantee the purity of oxygen, the oxygen is converted into the ozone lastly to be irrigated into the farmland, and therefore the sterilization effect is achieved.

Owner:北京田缘农业科技发展有限公司

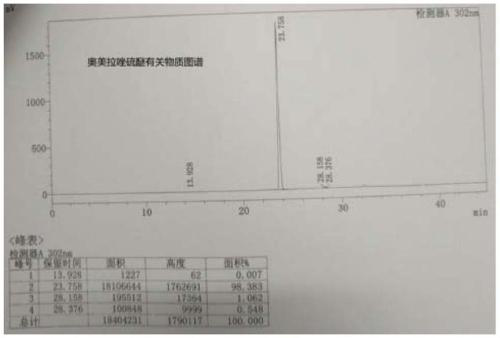

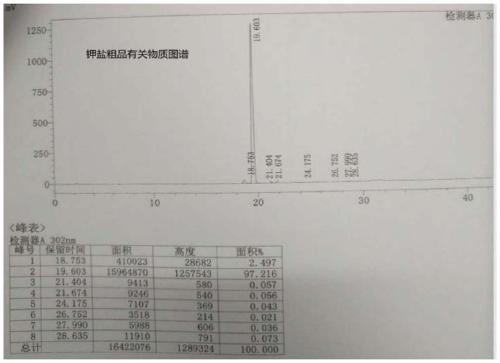

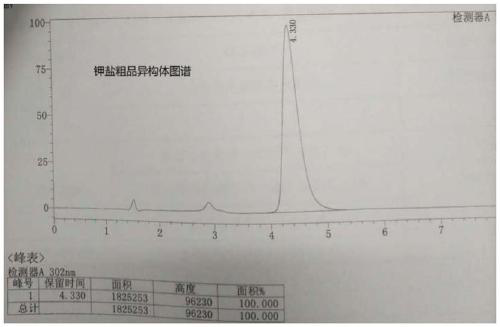

Novel preparation method of esprazole magnesium trihydrate and intermediate thereof

The invention relates to a novel preparation method of esprazole magnesium trihydrate and an intermediate thereof, and belongs to a pharmaceutical technology. The preparation method comprises the following steps: (1) performing condensation reaction to prepare omeprazole sulfide; and (2) performing chiral oxidation reaction to prepare esprazole, performing potassium salt forming reaction to prepare esprazole potassium, and performing ion exchange reaction to obtain the esprazole magnesium trihydrate. The method is high in product yield, high in product purity, mild and safe in reaction condition, low in energy consumption, easy to control and suitable for industrial mass production.

Owner:浙江康德药业集团股份有限公司 +1

Preparation method of carbonyl diimidazole

The invention discloses a preparation method of carbonyl diimidazole in the technical field of carbonyl diimidazole synthesis. The preparation method comprises the steps of taking imidazole and hexamethyl disilazane as starting materials, obtaining N-trimethylsilyl imidazole through condensation, absorbing a single byproduct, namely ammonia through a sodium hydroxide solution, allowing N-trimethylsilyl imidazole to react with triphosgene to prepare carbonyl diimidazole, and filtering the principal product, namely carbonyl diimidazole, from liquid trimethylchlorosilane for vacuum drying. A removal step is simpler; the byproduct is gaseous and does not influence purity of the product, namely N-trimethylsilyl imidazole; a reactor with higher purity is provided for a subsequent reaction; in areaction process of N-trimethylsilyl imidazole and triphosgene, no catalyst is required to be added; the method is simple to operate; a byproduct of the reaction of N-trimethylsilyl imidazole and triphosgene is liquid trimethylchlorosilane; and carbonyl diimidazole prepared by the method is higher in purity and good in quality.

Owner:浙江胡涂硅科技有限公司

Direct-seeding seed production method for two-line system hybrid rice

InactiveCN105746333AImprove lodging resistanceIncrease productionPlant genotype modificationRice cultivationHybrid seedEcology

The invention discloses a direct-seeding seed production method for two-line system hybrid rice. The method comprises the steps of seeding, field management, purity assurance and harvesting storage, wherein the seeding step comprises the following sub-steps: selecting Huanghuazhan as a male parent, examining and approving a sterile line in promotion mix as a female parent; taking a large-area Huanghuazhan planting area as a seed production field before use; fixing the sowing time according to the sowing date of the male and female parents, and ensuring flower synchronization of the male and female parent; ensuring that the sowing plot width of the male parent is equal to the harvesting width of a harvester, the sowing plot width of the female parent is 1-2 times that of the harvesting width of the harvester, and the spacing between the male parent and the female parent is 40-60cm, so that the male and female parents are conveniently and respectively harvested with machine; and manually transplanting a line of male parents at the seedling age of 22-25 days of the male parent, wherein 2-3 rice seedlings are planted in each stump, the row spacing is 25-40cm, and the spacing between the male parent transplanting line and the direct seeding male parent is 20-30cm. According to the method disclosed by the invention, the problems that the female parent is susceptible to lodging, the seed production yield is low, the weeding difficulty is high, the purity of hybrid seeds is low, the production efficiency is low and the cost is high are solved.

Owner:HUNAN RICE RES INST

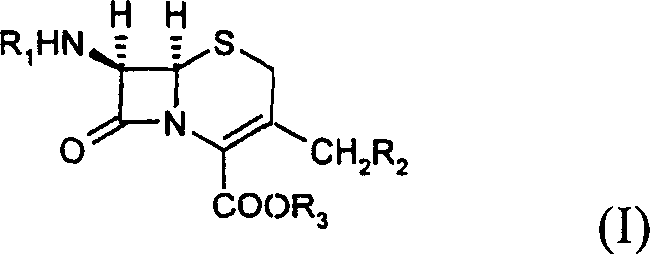

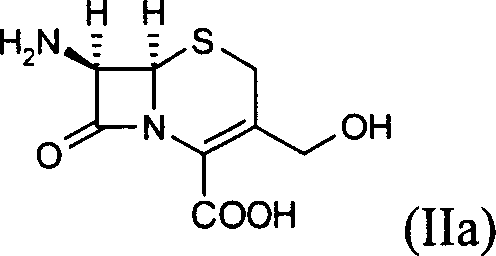

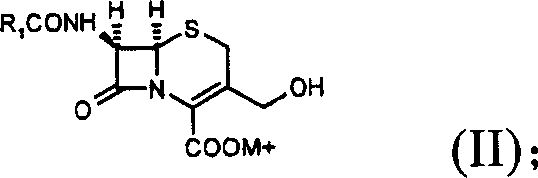

Cephalosporin analog antibiotic preparation method

InactiveCN100361996CHigh purityPurity effectOrganic chemistryNitro compound active ingredientsCarboxyl radicalAntibiotic Y

The present invention relates to new method of preparing cephalo antibiotic. The new preparation process includes first acidylating the C7 place of initial material 7-amino-3-methylol cephaloalkanoic acid, the subsequent esterifying the C2 place carboxyl radical with corresponding ester radical, and final functionating the C3 place of the product. The process of the present invention has less reaction steps, raised total synthesis efficiency, low cost and reduced environmental pollution.

Owner:ZHEJIANG ZHENYUAN PHARMA CO LTD +1

Filtering and washing device for KNO3

PendingCN110935226ADrain fastEasy to separateStationary filtering element filtersControl engineeringMachine

The invention relates to the technical field of KNO3 production equipment and discloses a filtering and washing device for KNO3, which includes: a machine frame, a tipping bucket mechanism, a spiral conveyor and a suction filter pump, wherein the tipping bucket mechanism and the spiral conveyor are respectively mounted on the machine frame. A control main machine is arranged outside the machine frame. The material inlet on the upper part of the spiral conveyor is corresponding to the pouring side of a feeding hopper of the tipping bucket mechanism. A liquid filtering tube and a suction filtertank are disposed below the feeding hopper. The suction filter pump is installed on the bottom of the suction filter tank and is communicated with the suction filter tank. A vacuumizing pipe is arranged on the top of the suction filter tank. The control main machine is respectively connected electrically to the tipping bucket mechanism, the spiral conveyor and the suction filter pump. The device has reasonable and compact structure. By arranging the suction filter pump on the suction filter tank and the vacuumizing pipe connected with a vacuumizing system, liquid in the hopper can be exhaustedcompletely quickly. By arranging the tipping bucket mechanism and spiral conveyor, during working, auto-transport of materials is achieved in the device without manual operation, so that the device saves time and manpower and is high in efficiency.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

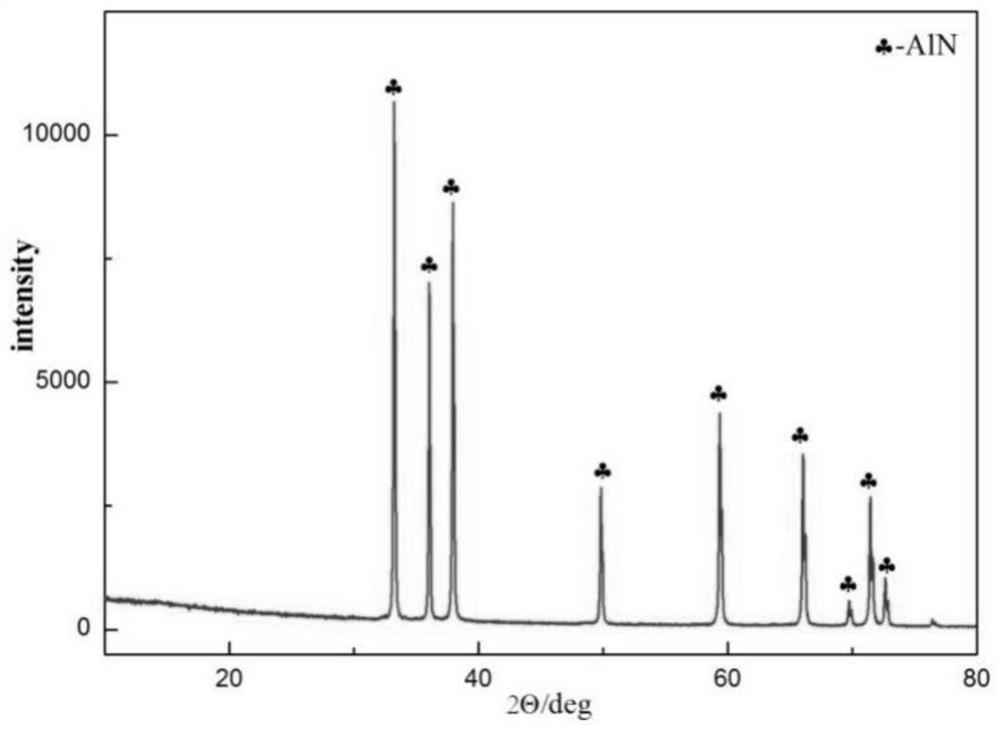

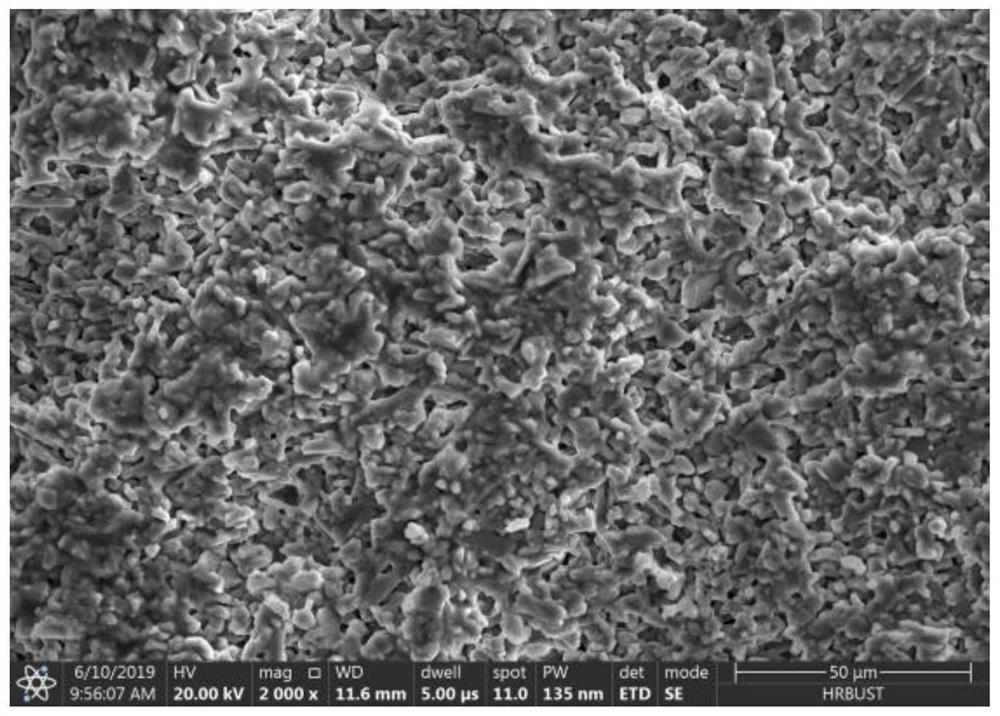

Preparation method of porous raw material for aluminum nitride crystal growth

InactiveCN112195512AHave mechanical strengthPlay a coupling rolePolycrystalline material growthFrom condensed vaporsFreeze-dryingAluminium powder

The invention relates to a preparation method of a porous raw material for aluminum nitride crystal growth, and belongs to the technical field of aluminum nitride crystal raw material preparation. Inorder to solve the problems that the existing aluminum nitride raw material is relatively compact and is not beneficial to raw material volatilization and crystal growth, the invention provides a preparation method of a porous raw material for aluminum nitride crystal growth. The method comprises the following steps: adding aluminum nitride powder subjected to hydrolysis-resistant pretreatment into a sodium alginate solution, carrying out stirring and ball milling to obtain mixed slurry; and pouring the obtained mixed slurry into a mold, uniformly spraying a calcium chloride solution onto thesurface of the slurry, freeze-drying the slurry, sintering in a protective gas atmosphere, pickling, washing with water, and drying to obtain the porous aluminum nitride raw material. The method is simple to operate and low in cost, the porous raw material with the porosity of 42-50% can be prepared, volatilization of aluminum nitride is facilitated, the utilization rate of the aluminum nitride raw material is high, and the method has positive influence on growth of aluminum nitride crystals.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

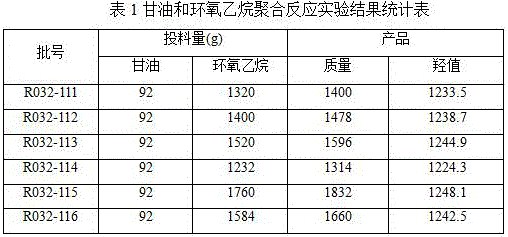

Preparation method for high-purity glycerin polyethenoxy ether ricinoleate

The invention provides a method for preparing high-purity glycerin polyethenoxy ether ricinoleate by etherifying an initiator raw material and ricinoleic acid-esterifying. The method comprises the following steps: using the glycerin as the raw material, executing the etherification reaction with ethylene oxide, and preparing the glycerin polyethenoxy ether, wherein the adding mole number of the ethylene oxide is 30-36 optimally; and according to the mass ratio of 3.79-3.83:1 of the glycerin polyethenoxy ether and the high-purity ricinoleic acid, executing the esterification reaction under the function of a specific catalyst, wherein the acid value, the hydroxyl value, the saponification value and so on of an esterification product satisfy the standard requirements. The glycerin polyethenoxy ether ricinoleate prepared by the method has the narrower chain distribution and lower esterification reaction temperature, the prepared product has light color, the product quality is easily controlled, and the stability is high.

Owner:NANJING WELL CHEM

2-acetylpyrazine continuous recrystallization device and method and application thereof

The invention relates to the field of chemical component purification, and in particular, relates to a 2-acetylpyrazine continuous recrystallization device and method and an application of the device. For solving the problems of low yield caused by low utilization rate of 2-acetylpyrazine and low production efficiency and safety and environmental protection risks caused by intermittent operation in a 2-acetylpyrazine recrystallization method in the prior art, the invention provides the 2-acetylpyrazine continuous recrystallization device and method and the application of the device. A crystallizer is provided with three feed ports, an inlet of a mixed solution containing 2-acetylpyrazine is located above a solvent, 2-acetylpyrazine is crystallized and falls back to the bottom of the crystallizer, and the situation that 2-acetylpyrazine crystals are doped with uncrystallized components, and the purity of 2-acetylpyrazine crystallized products is affected is avoided. Two discharge holes are formed in the upper part and the bottom of the crystallizer, so that solutions with different components can be obtained and are reused after being subjected to different treatments, and continuous recrystallization of 2-acetylpyrazine is realized.

Owner:JINAN ENLIGHTEN BIOTECH CO LTD

Device and method for preparing high-performance platinum and platinum-rhodium thermocouple wire

PendingCN114178500AGood plasticity at room temperatureGood high temperature plasticityPlatinumThermocouple Wire

The invention relates to a device and a method for preparing high-performance platinum and platinum-rhodium thermocouple wires. A smelting device is used for smelting a platinum-rhodium alloy material; the crystallizer is used for controlling the solid-liquid interface position; the dummy bar is used for pulling the cast ingot and pulling the cast ingot out of the crystallizer at a preset speed through the drawing device; and the cooling device rapidly cools the cast ingot by spraying cooling water. One-dimensional gradient heat transfer is realized in a mode of combining crystallizer heating and cooling water chilling, a dummy bar and a drawing device are ingeniously combined, directional solidification of platinum-rhodium alloy is realized, and the prepared platinum and platinum-rhodium thermocouple wire has good room-temperature plasticity, good high-temperature plasticity and relatively high high-temperature strength at the same time, and has no influence on the purity of the thermocouple wire; the cast ingot manufactured through the device is in a round rod shape, the surface is smooth, machining such as forging and strip rolling is not needed, direct die passing and drawing can be achieved, the machining procedure is simplified, and machining loss is reduced.

Owner:英特派铂业股份有限公司

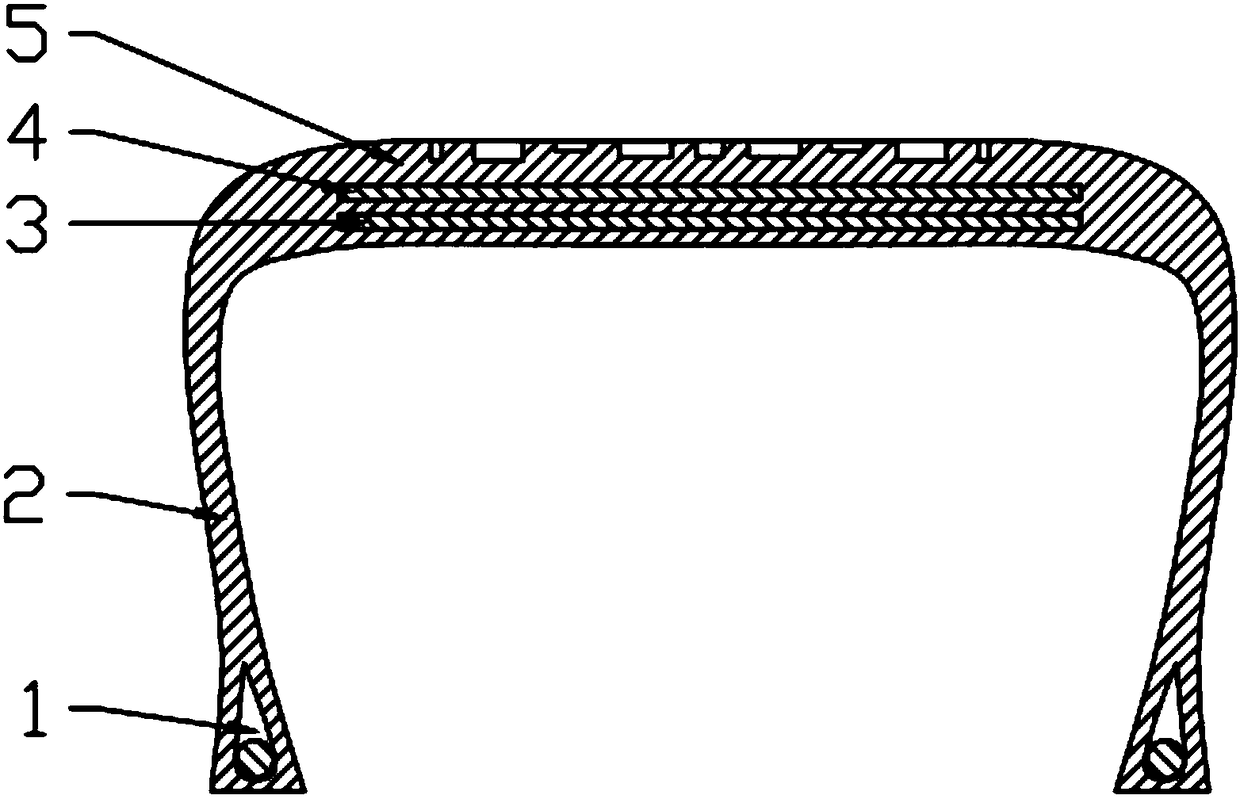

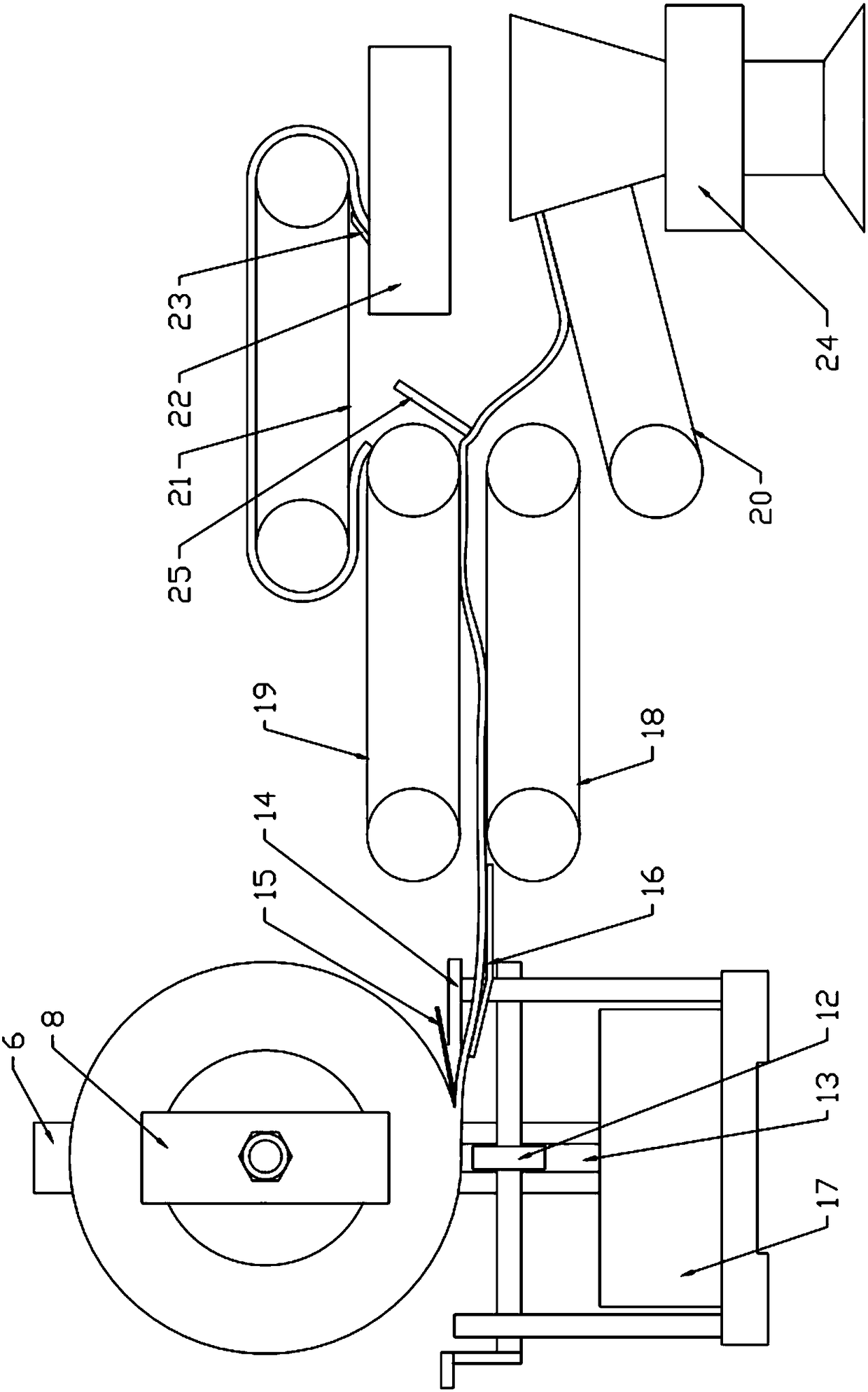

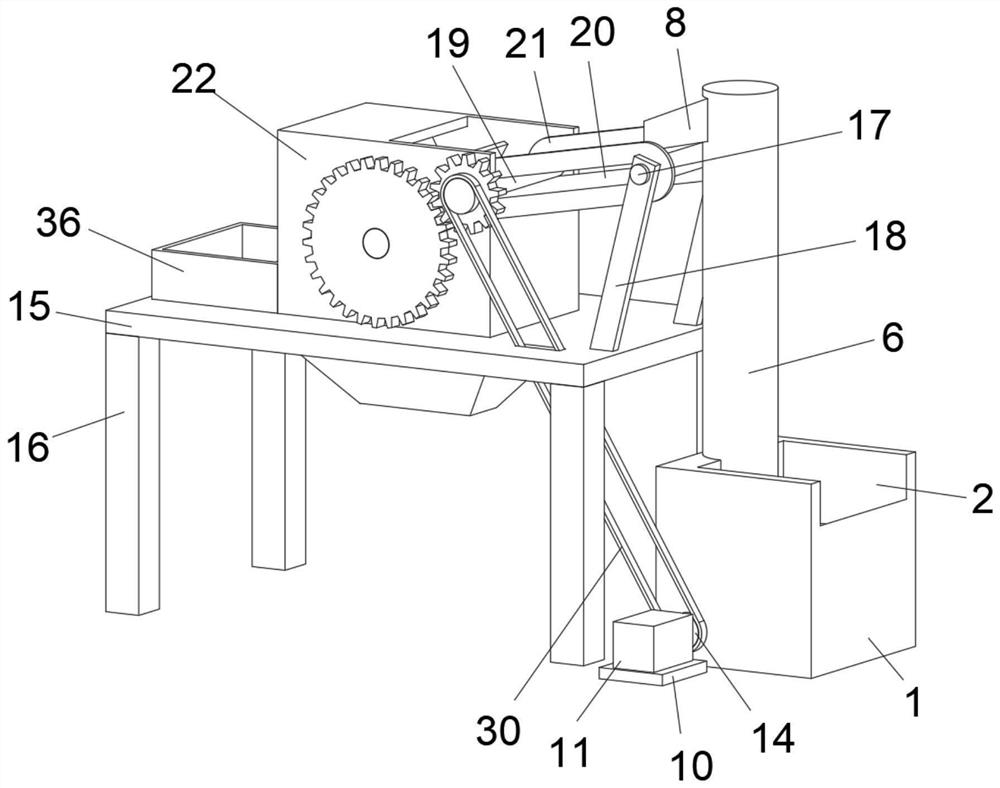

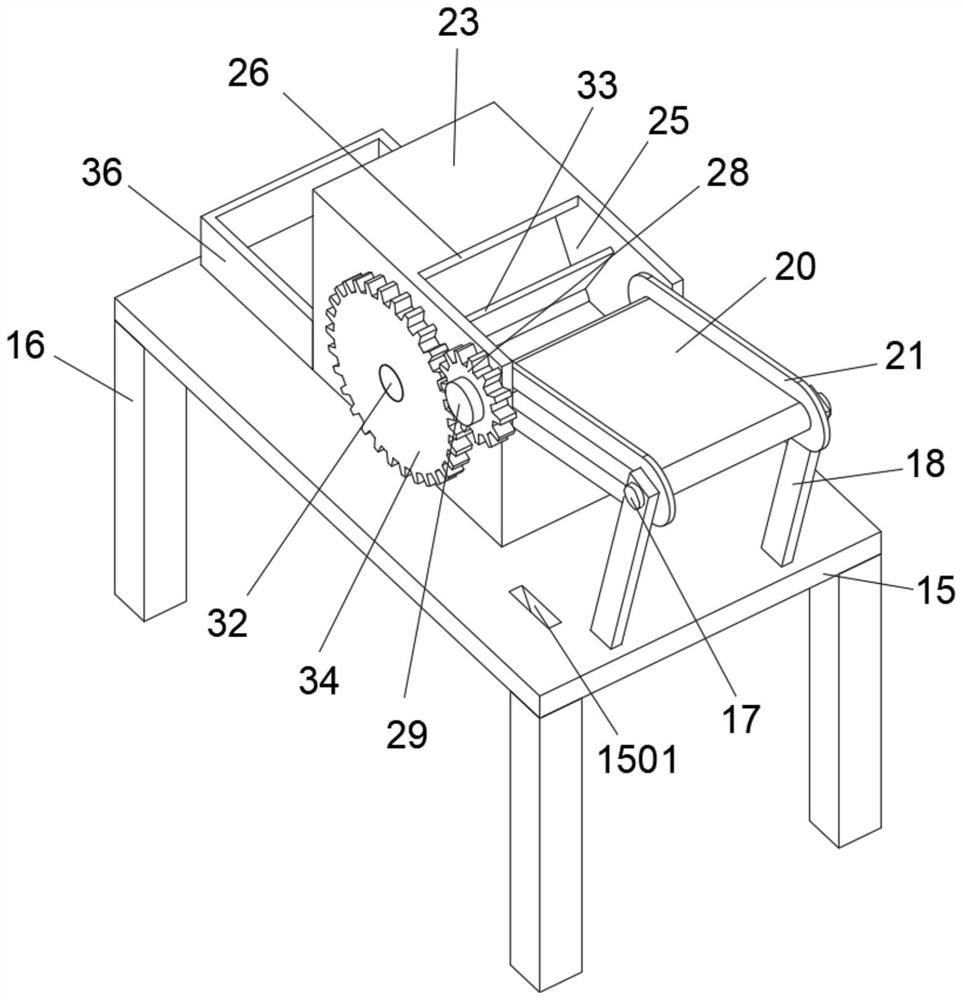

Production system for multi-grade crushing and processing of reclaimed rubber

InactiveCN108214995APurity effectPlastic recyclingMechanical material recoveryEngineeringConveyor belt

The invention relates to the field of rubber recycling and discloses a production system for multi-grade crushing and processing of reclaimed rubber. The production system comprises a layer peeling device, a magnetic separation device, a raw material conveying device and a crushing device, wherein the layer peeling device comprises a rack, a clamping mechanism and a motor; the clamping mechanism is in sliding connection with the rack; the rack is provided with a telescoping mechanism; a layer peeling cutter is fixed below the clamping mechanism; a guide plate and a material receiving frame arearranged below the layer peeling cutter; the magnetic separation device comprises a first conveyor belt and a second conveyor belt; the first conveyor belt and the second conveyor belt are parallel to each other; the second conveyor belt has permanent magnetism; a gap is formed between the first conveyor belt and the second conveyor belt; a cutting saw is arranged beside the gap; the raw materialconveying device comprises a feeding end and a discharging end; the feeding end is located below the first conveyor belt; the discharging end of the raw material conveying device is connected with afeeding opening of the crushing device. The invention aims at providing the production system which prevents the purity of the reclaimed rubber from being influenced by a bead wire when a bead wire isused for producing the reclaimed rubber.

Owner:重庆九橡化大橡胶科技有限责任公司

Preparation method of porous aluminum nitride material

The invention discloses a preparation method of a porous aluminum nitride material, and belongs to the technical field of aluminum nitride material preparation. The technical problem to be solved by the invention is the porous characteristic of the aluminum nitride material. The preparation method comprises the following steps: adding an Al (H2PO4) 3 solution into aluminum nitride, then adding themixture into a ball mill for ball milling and vacuum drying, then adding ovalbumin into deionized water, uniformly stirring, then weighing pretreated aluminum nitride powder, an ovalbumin solution, adispersing agent and a stabilizing agent, adding the aluminum nitride powder into the ovalbumin solution under a stirring condition, after stirring, adding a dispersing agent and a stabilizing agentto obtain a premix, putting the premix into a ball mill for ball milling, injecting slurry obtained after ball milling into a mold, standing and foaming for a certain time, putting the mold into a drying oven for drying, putting the mold into a furnace body, introducing a protective gas, sintering, cooling, taking out of the furnace, pickling, washing with water, and drying to obtain the porous aluminum nitride material. The method is simple to operate, simple in used equipment and low in cost.

Owner:哈尔滨化兴软控科技有限公司

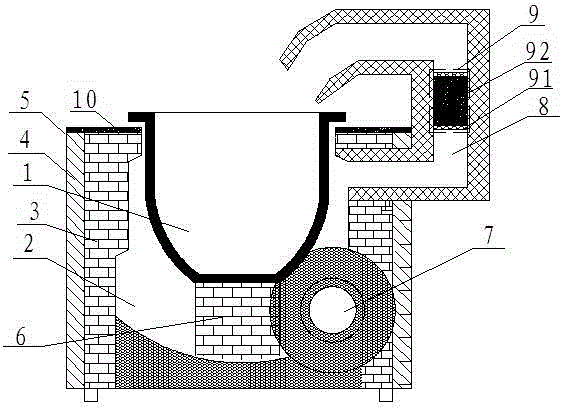

Novel biomass crucible furnace

InactiveCN102914153ANot easy to burn throughExtended service lifeCrucible furnacesWaste heat treatmentCrucibleHearth

The invention discloses a novel biomass crucible furnace which comprises a crucible, a high temperature resisting thermal insulating layer, a heat conversation thermal insulating layer surrounding outside the high temperature resisting thermal insulating layer, a furnace body arranged at the outermost, a base, a burner and a flue, wherein a hearth is formed between the high temperature resisting thermal insulating layer and the crucible; the crucible is embedded inside the hearth through a steel plate; the base is arranged inside the hearth to support the crucible; and the burner is arranged at a position parallel to the upper end surface of the base or lower than the height of the upper end surface of the base. With the adoption of the crucible furnace in such a mode, the problems that the existing crucible furnace is low in equipment utilization rate, the production efficiency is reduced, the service life of the crucible furnace is shortened, the repairing cost is increased, the purity and the quality of a metal solution are influenced are solved; and the crucible furnace has the advantages of prolonging the service life of the crucible and preventing the influence of dust grains in the fume to the purity of the metal solution.

Owner:郭丰亮

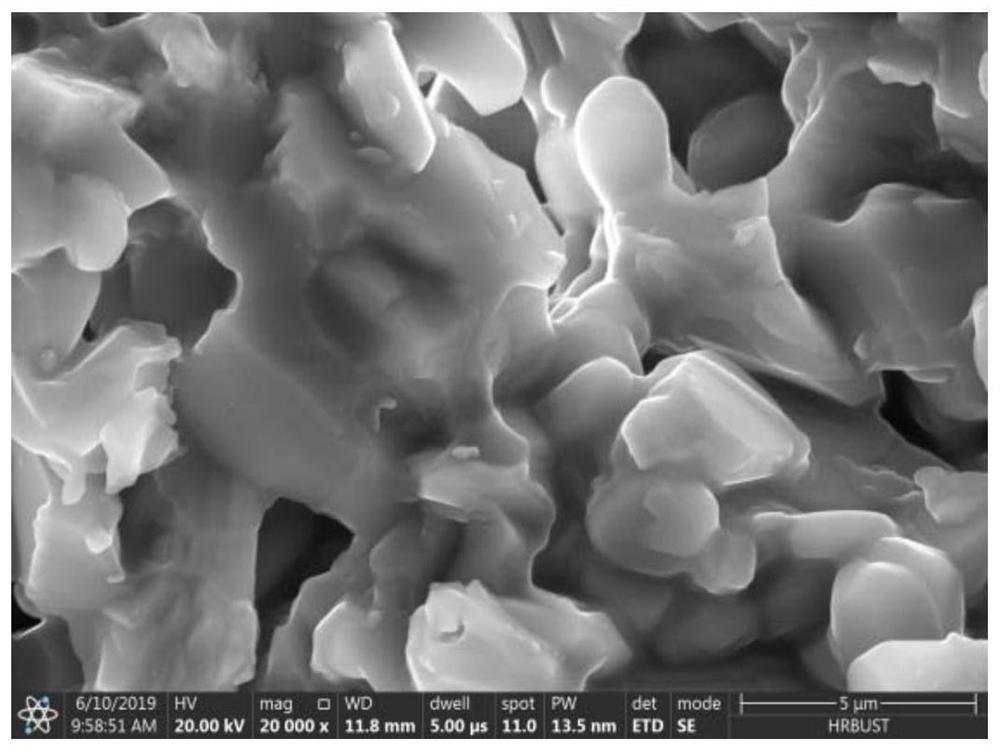

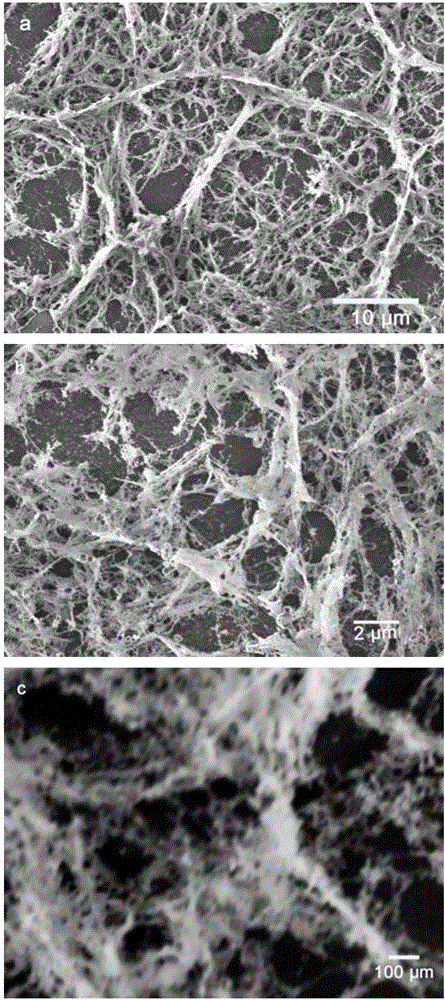

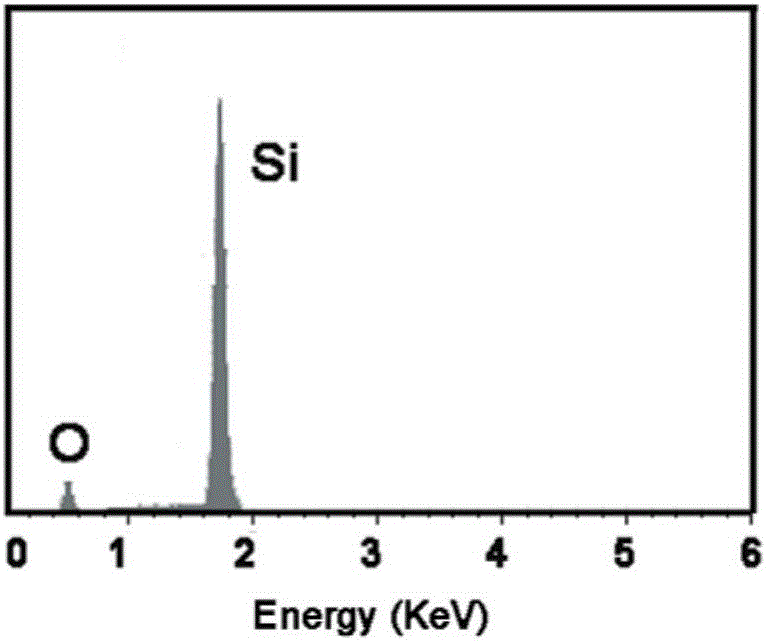

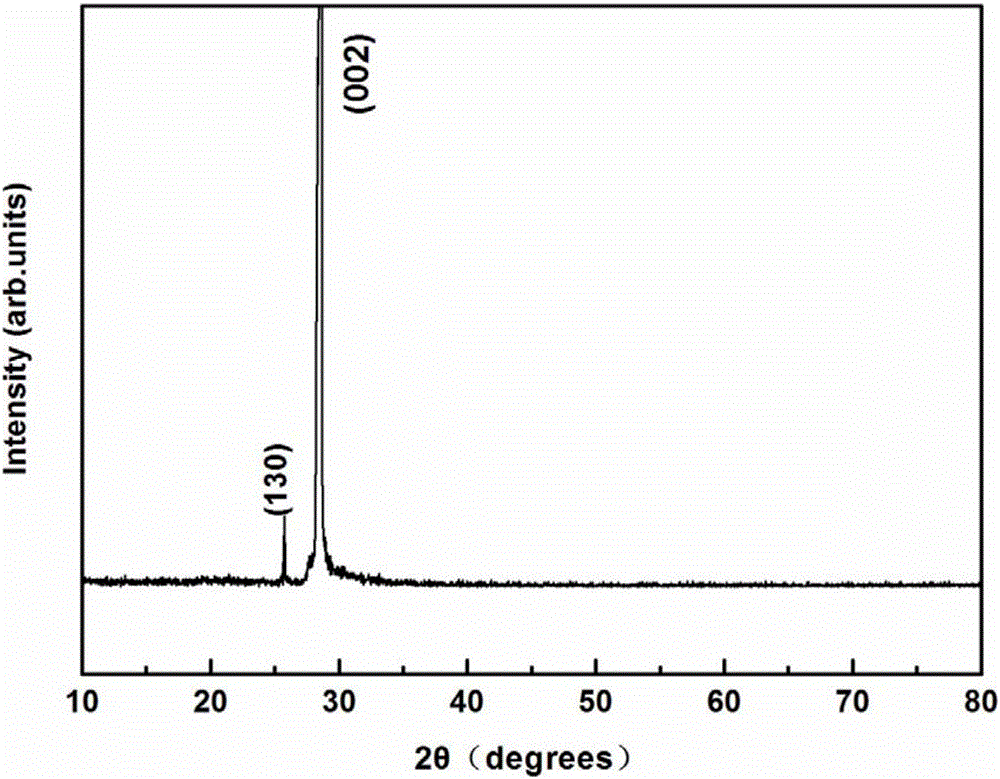

SiO2 irregular nanocrystal network structure and preparation method thereof

The invention belongs to the field of nanometer materials, and discloses a SiO2 irregular nanocrystal network structure and a preparation method thereof. The method comprises the following steps: with SiO2 powder and S powder as reaction sources, carrying out a reaction in a high-temperature area of a high-temperature tube furnace of a low vacuum system, and carrying out depositing with carrier gas onto the low-temperature area of a silicon-chip substrate. The method provided by the invention has the advantages of simple operation, high yield, low cost, safety, environmental protection and no need of any catalyst, and can be completed through a chemical reaction under the condition of high temperature. The SiO2 irregular crystal nanometer network prepared by utilizing the method provided by the invention has a mesoporous structure and facilitates to transfer and transportation of substances; meanwhile, due to a special structure of the SiO2 irregular crystal nanometer network, important academic significance and application in a novel field of development of material properties are obtained.

Owner:BOHAI UNIV

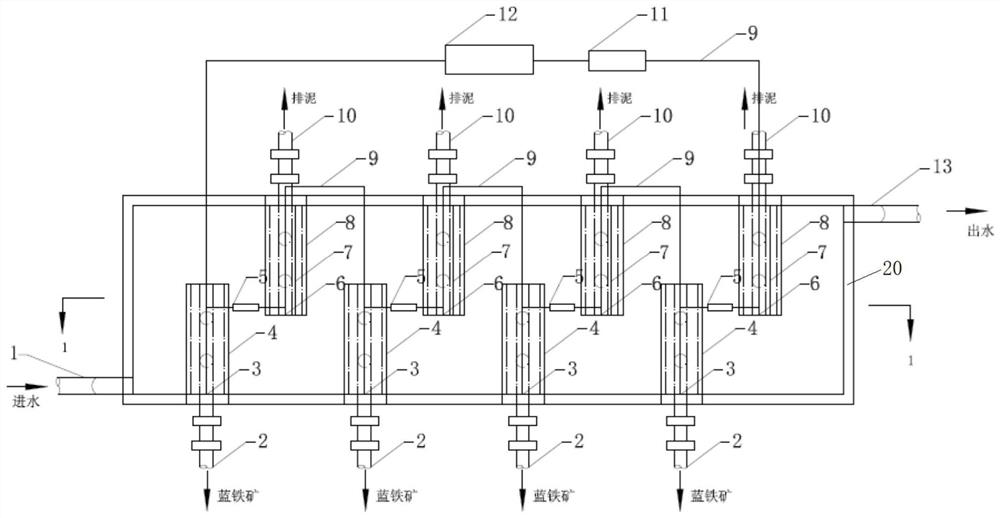

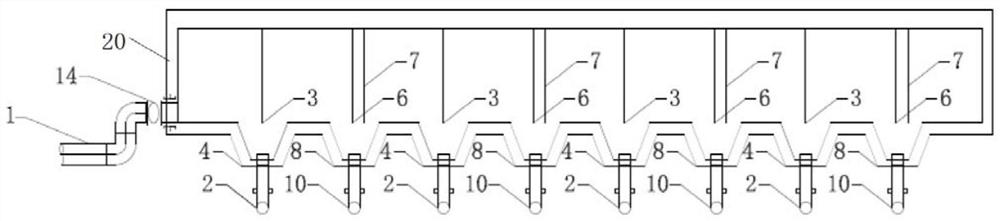

Microbial fuel cell for nitrogen and phosphorus removal of sewage treatment plant and sewage treatment method

InactiveCN112820924AReduce the difficulty of separation and purificationHigh purityWater contaminantsTreatment with anaerobic digestion processesMicrobial fuel cellBiofilm

The invention discloses a microbial fuel cell for nitrogen and phosphorus removal of a sewage treatment plant and a sewage treatment method. The microbial fuel cell comprises a nitrogen and phosphorus removal pool, the nitrogen and phosphorus removal pool is provided with a water inlet and a water outlet, and a nitrogen and phosphorus removal unit is arranged in the nitrogen and phosphorus removal pool; the nitrogen and phosphorus removal unit comprises an iron pole plate and a carbon felt which are sequentially arranged along the water flow direction in the nitrogen and phosphorus removal tank, a denitrification biological membrane is attached to the carbon felt, a collecting hopper and a sludge hopper are respectively arranged below the iron pole plate and the carbon felt in the nitrogen and phosphorus removal tank, and the iron pole plate is electrically connected with the carbon felt through a wire; and a resistor is connected in series on a lead connected between the iron polar plate and the carbon felt. According to the invention, nitrogen and phosphorus in the wastewater can be removed, the blue iron ore can be recycled, and the treatment target of combining wastewater treatment and resource recycling is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing La2O3 doped aluminium oxide base metal ceramic inert anode

The invention provides a La2O3 doped aluminum oxide base metal ceramic inert anode preparing method, characterized in adopting the following steps of: (1) proportioning raw materials: on the basis of a mixture of Fe-Ni metal powder in 50wt%-80wt% and aluminum oxide powder in 20wt%-50wt%, adding in La2O3 powder in 1%-3% of total weight of the mixture; (2) mixing Fe-Ni metal powder, aluminum oxide powder and La2O3 powder and placing them in a grinding jar for grinding into particles able to pass through 250-mesh sieve, then adopting powder metallurgy to make cold press molding to prepare metal ceramic inert anode material and dry it; (3) burying aluminum oxide and sintering in a Si-Mo furnace charged with Ar gas at 1450-1550 deg.C for 1-3 h; (4) lowering the temperature in the Si-Mo furnace under the protection of Ar gas at a rate <=5deg.C / min to the room temperature and obtaining La2O3 doped aluminum oxide base metal ceramic inert anode material where La enters Al site to form spinel solid solution. And the anode material has features of high compactness, good conductivity and corrosion resistance, and being good for aluminum electrolysis.

Owner:SHANDONG UNIV OF TECH

Super fine corn flour processing device and processing method

ActiveCN107996976AImprove processing efficiencyQuality improvementGrain treatmentsFood scienceSlagCorn flour

The invention relates to a super fine corn flour processing device. The super fine corn flour processing device comprises sequentially connected a corn storage bin, a primary slag-removing machine, asecondary slag-removing machine, a primary germ-selecting machine, a secondary germ-selecting machine, a primary breaking machine, a secondary breaking machine, a vibrating screen classifier and a toothed rail type corn clipper; and multi-layer screen meshes are integrated in the toothed rail type corn clipper. The super fine corn flour processing device is helpful to thoroughly eliminate corn skin and corn germs, eliminate residual aflatoxin on corn, improve the quality of obtained corn flour and ensure use safety of the corn flour.

Owner:成都昌盛鸿笙食品有限公司

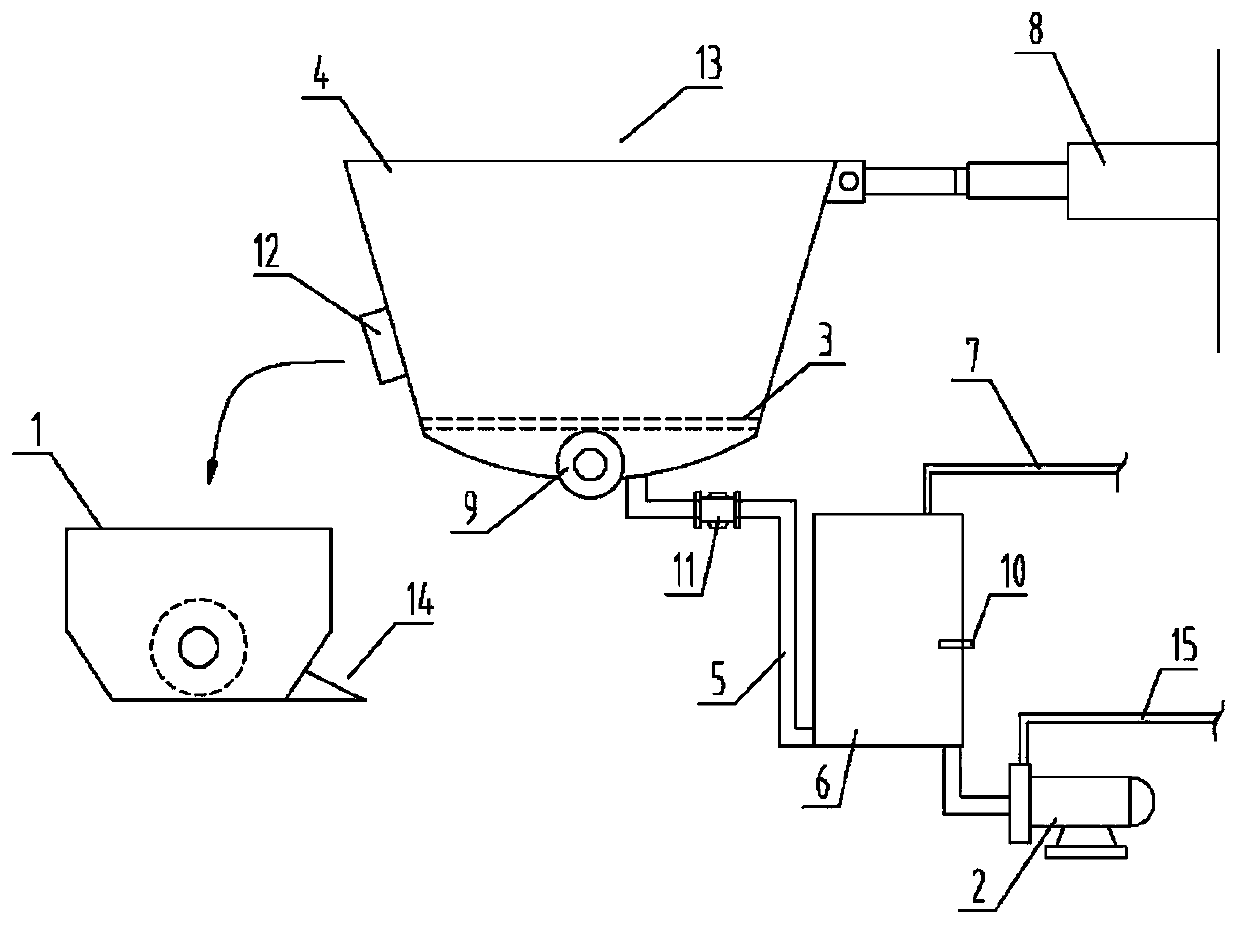

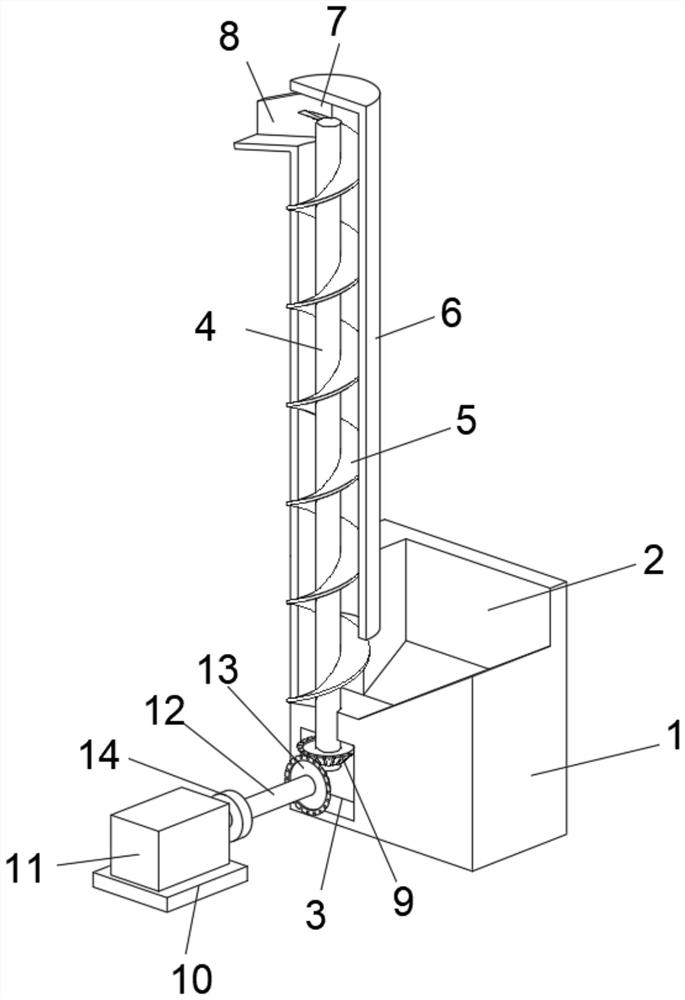

Powder feeding device for concrete mixing plant

ActiveCN112405875ASave energyImprove work efficiencyMixing operation control apparatusCleaningElectric machineryAgricultural engineering

The invention discloses a powder feeding device for a concrete mixing plant, and belongs to the technical field of concrete processing. The powder feeding device for the concrete mixing plant comprises a base, a feeding groove is formed in the middle of the top face of the base, an inner cavity is formed in the position, opposite to the lower portion of the feeding groove, in the base, a middle shaft is arranged on the left side of the bottom face of the feeding groove in a penetrating mode, and the upper portion of the middle shaft is sleeved with an auger blade which is sleeved with a sleeve. An output opening is formed in the left wall of the sleeve, a guide plate is fixedly arranged at the left end of the output opening, and the lower end of the middle shaft penetrates through the bottom face of the feeding groove, extends into the inner cavity and is coaxially and fixedly connected with a bevel gear A. A motor base is arranged on the front side of the base, and a motor is fixedlyarranged in the middle of the top face of the motor base. A fixing plate is arranged above the left side of the base. A discharging assembly is arranged in the middle of the top face of the fixing plate. By means of the powder feeding device, workers are prevented from being hard to lift and convey powder, impurities in the powder can be effectively removed, and practicability is high.

Owner:泉州坚石混凝土建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com